Patents

Literature

626 results about "Magnet device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In most cases, magnetic storage devices refer to hard drives, either internally mounted or external and portable. Inside are a series of magnetic platters, and a read-write head alters the magnetic field to create a one or a zero in binary language. Continue Reading.

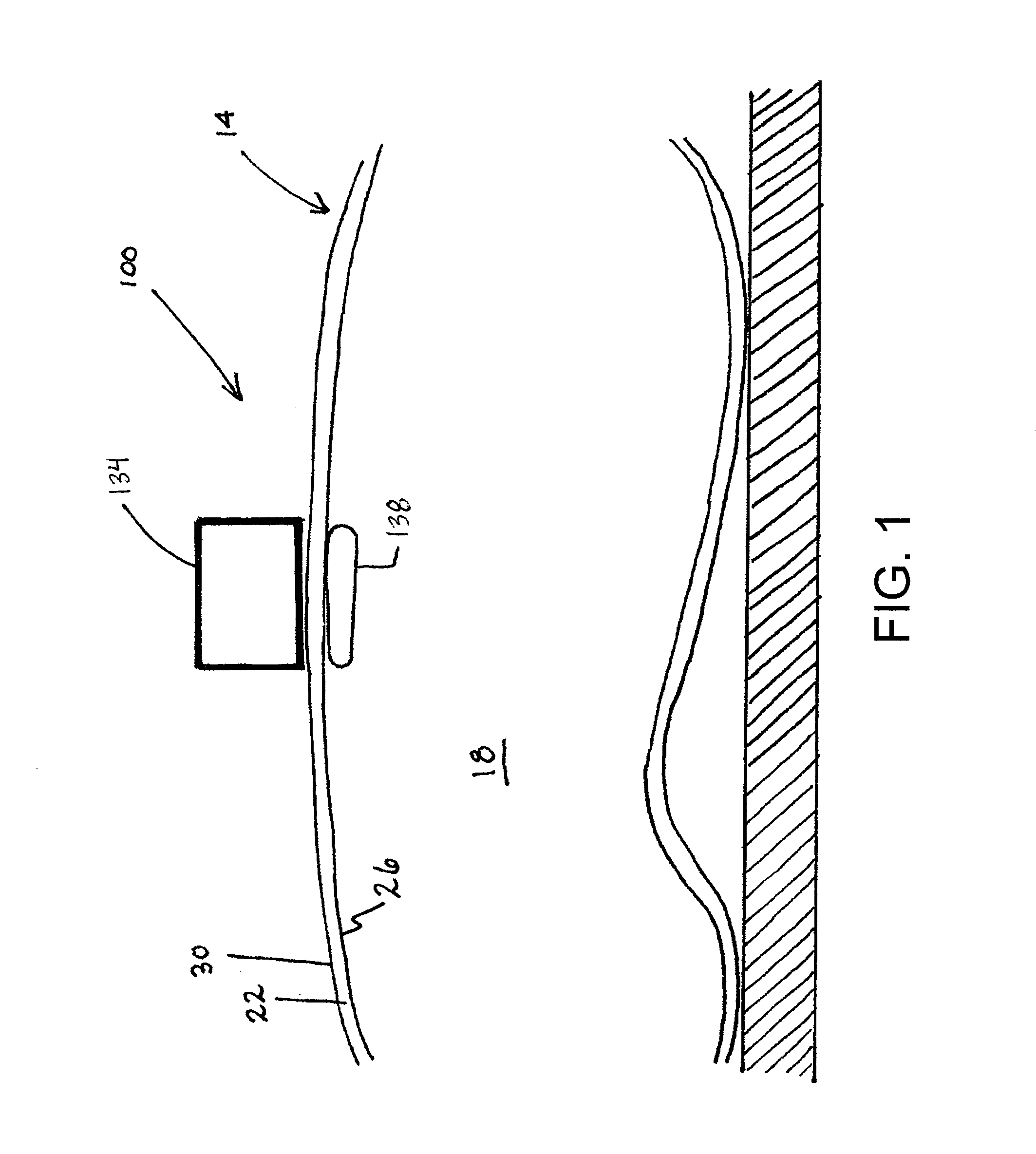

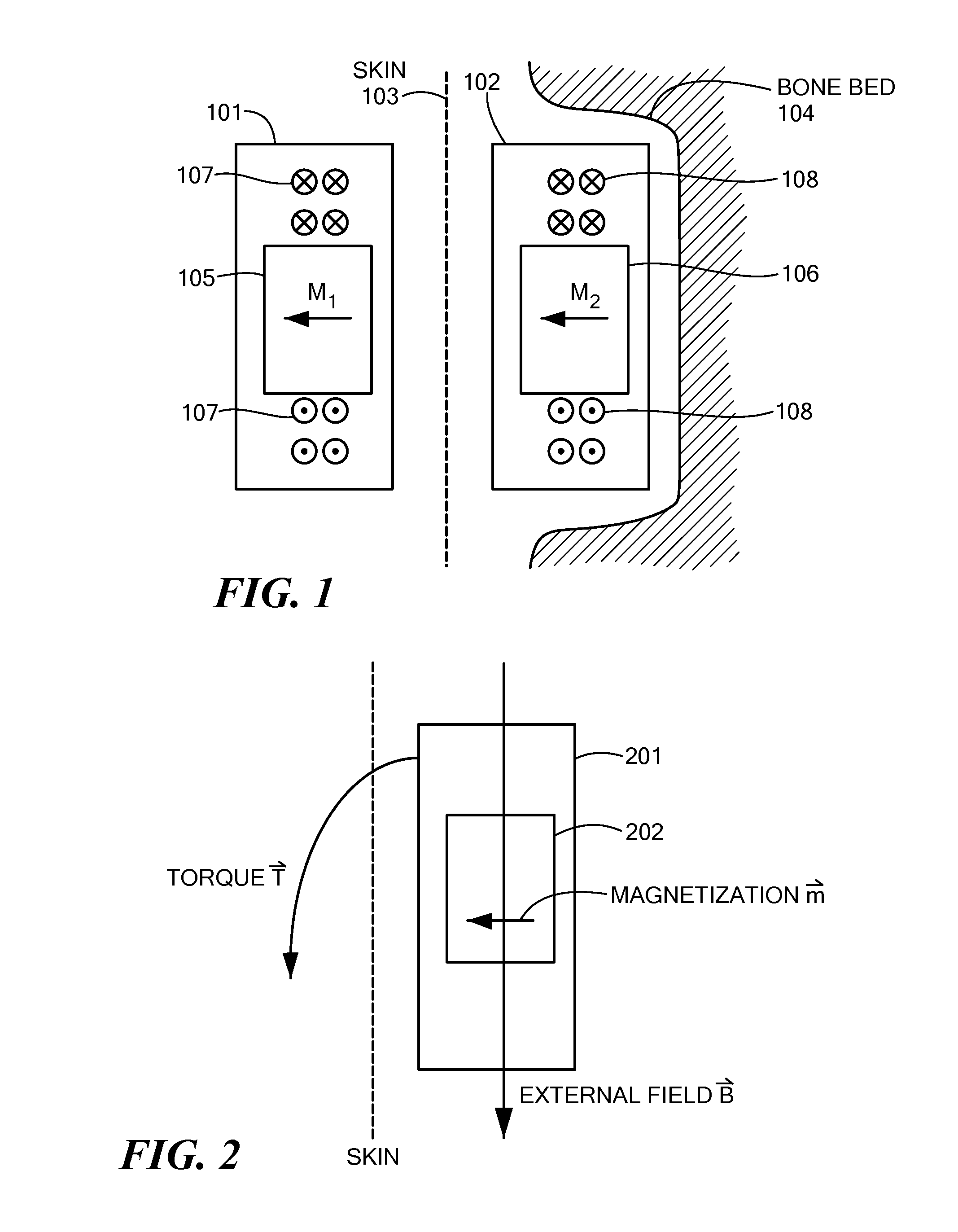

Medical Devices That Include Removable Magnet Units and Related Methods

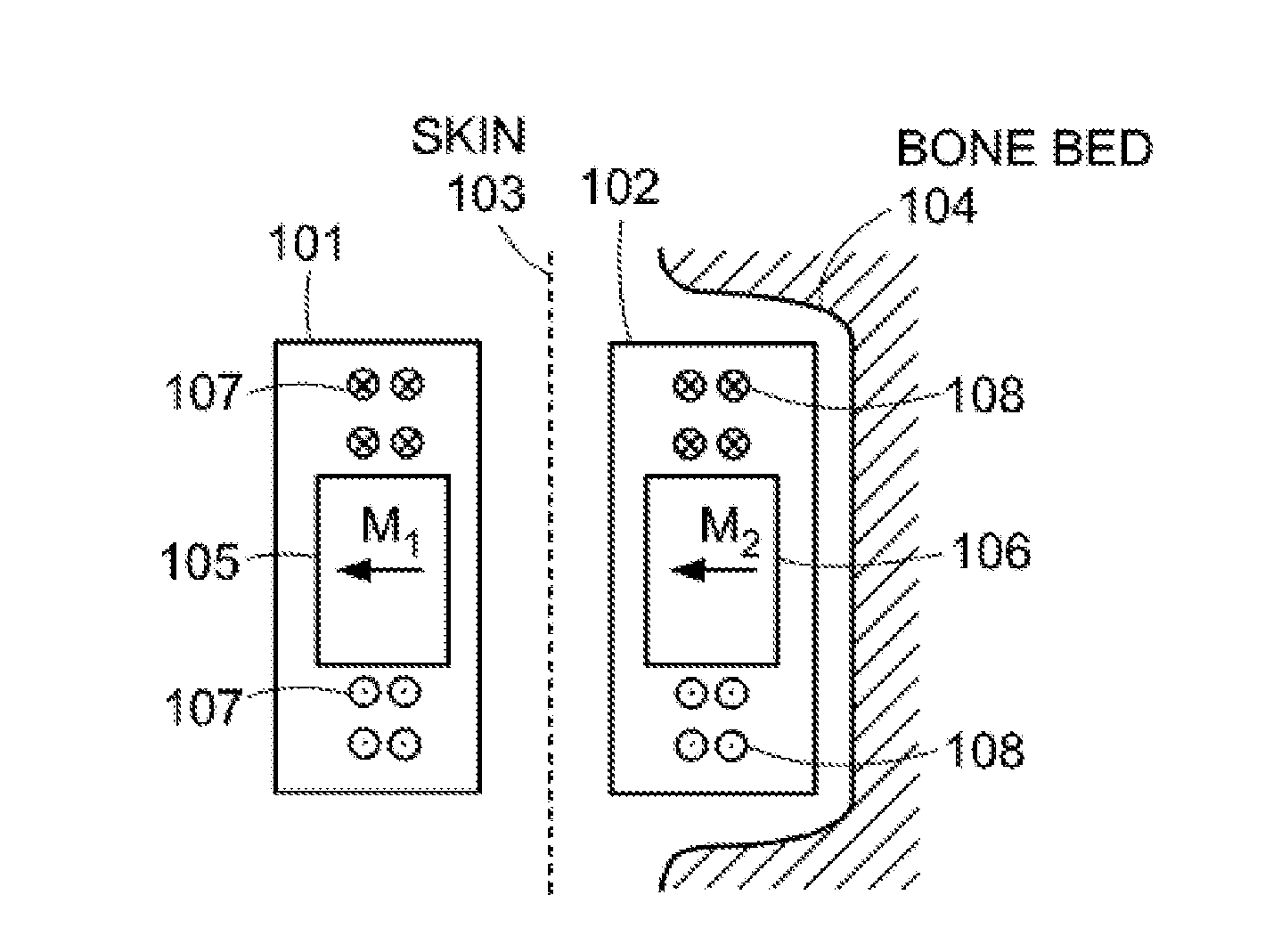

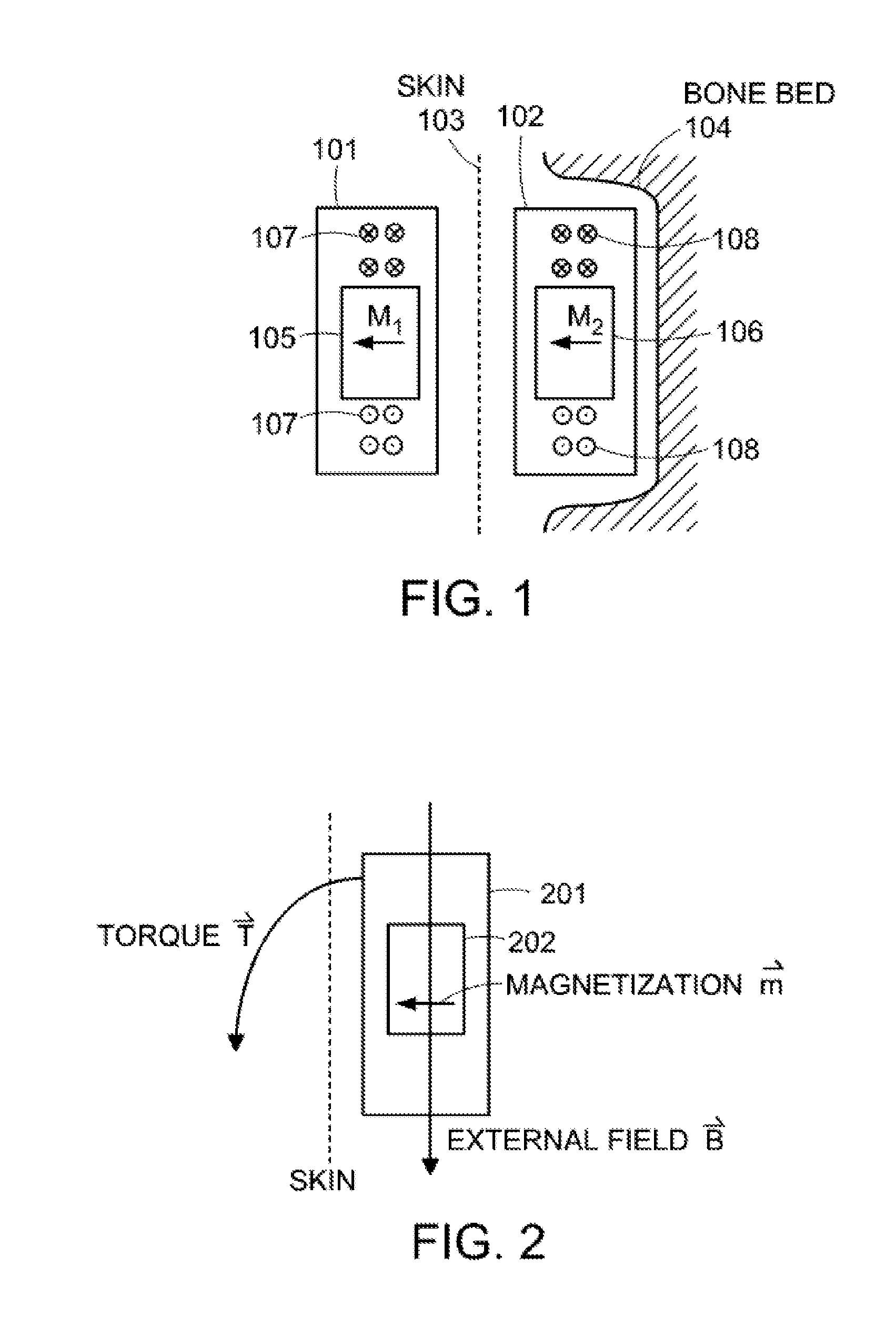

Medical devices and methods for magnetically positioning a device within a body cavity of a patient, including a removable magnet unit that can be reused across procedures.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

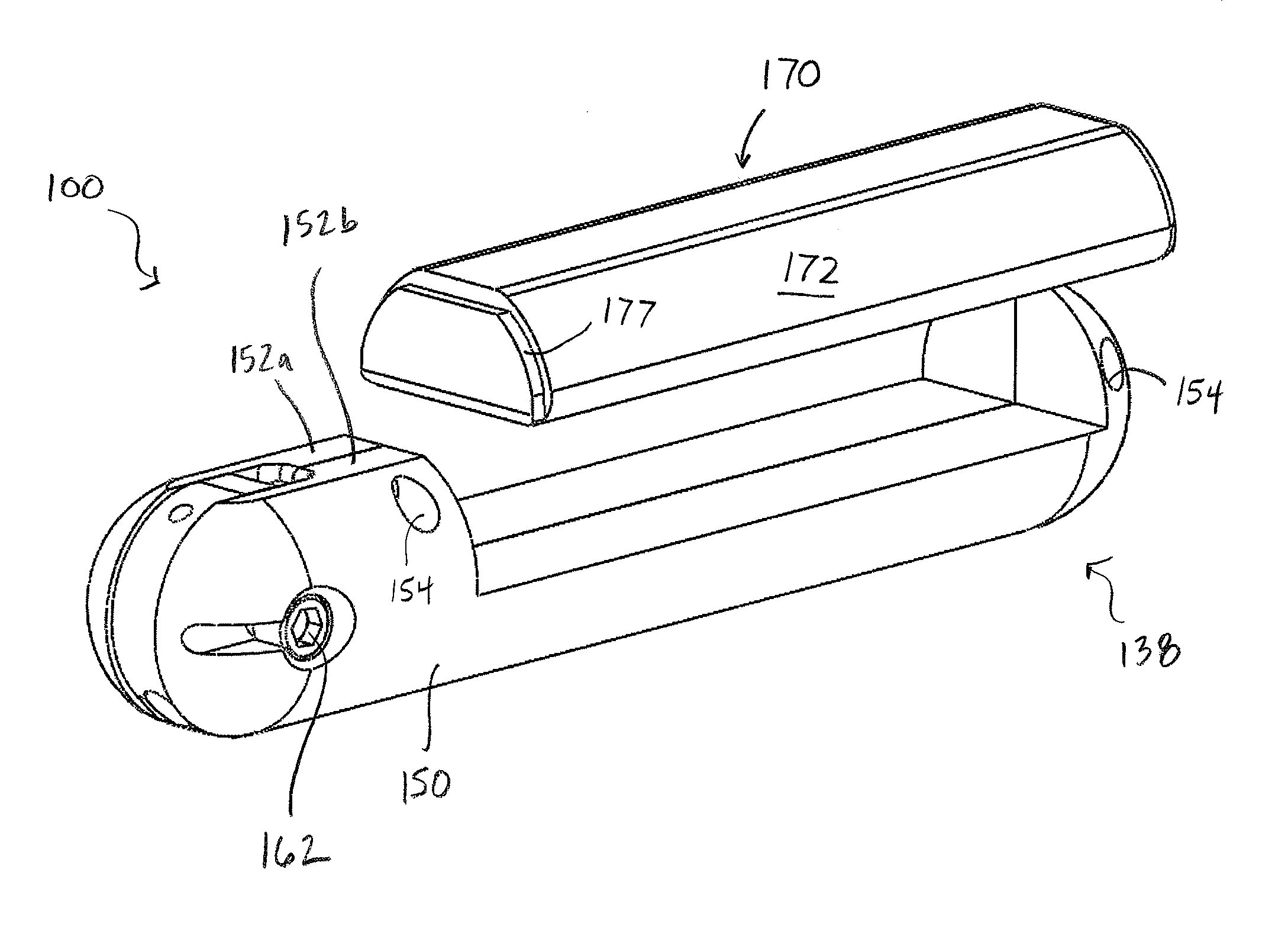

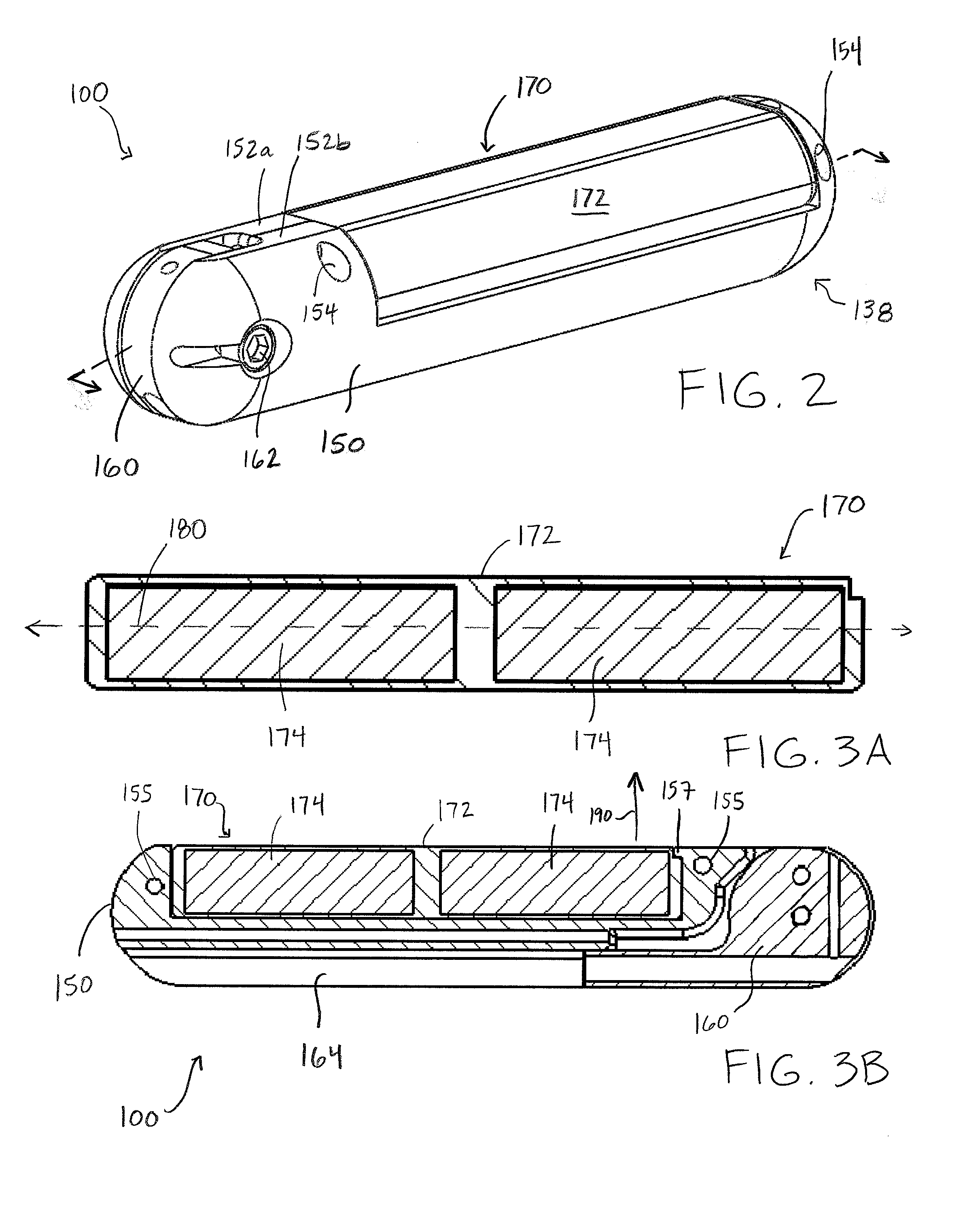

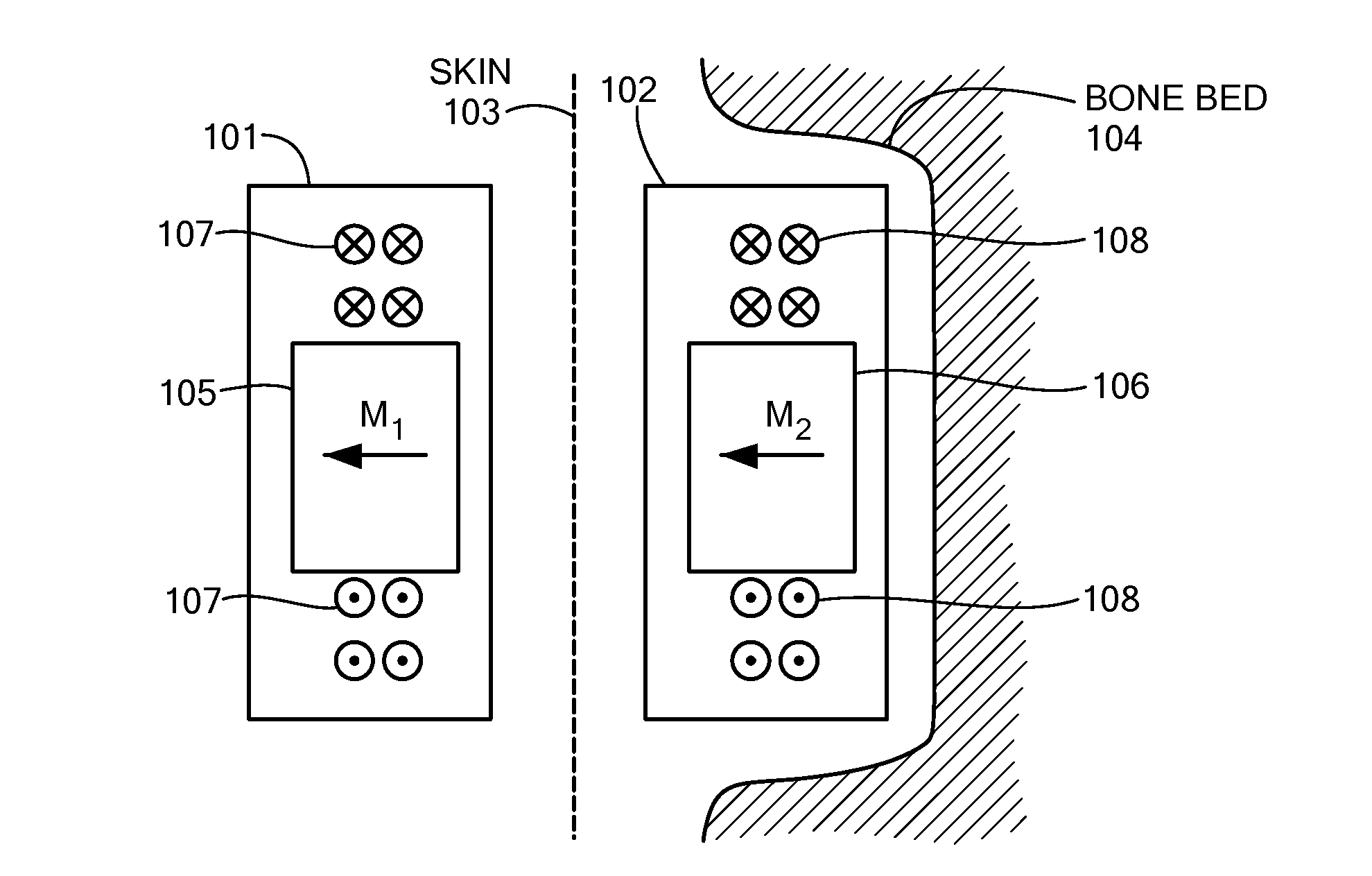

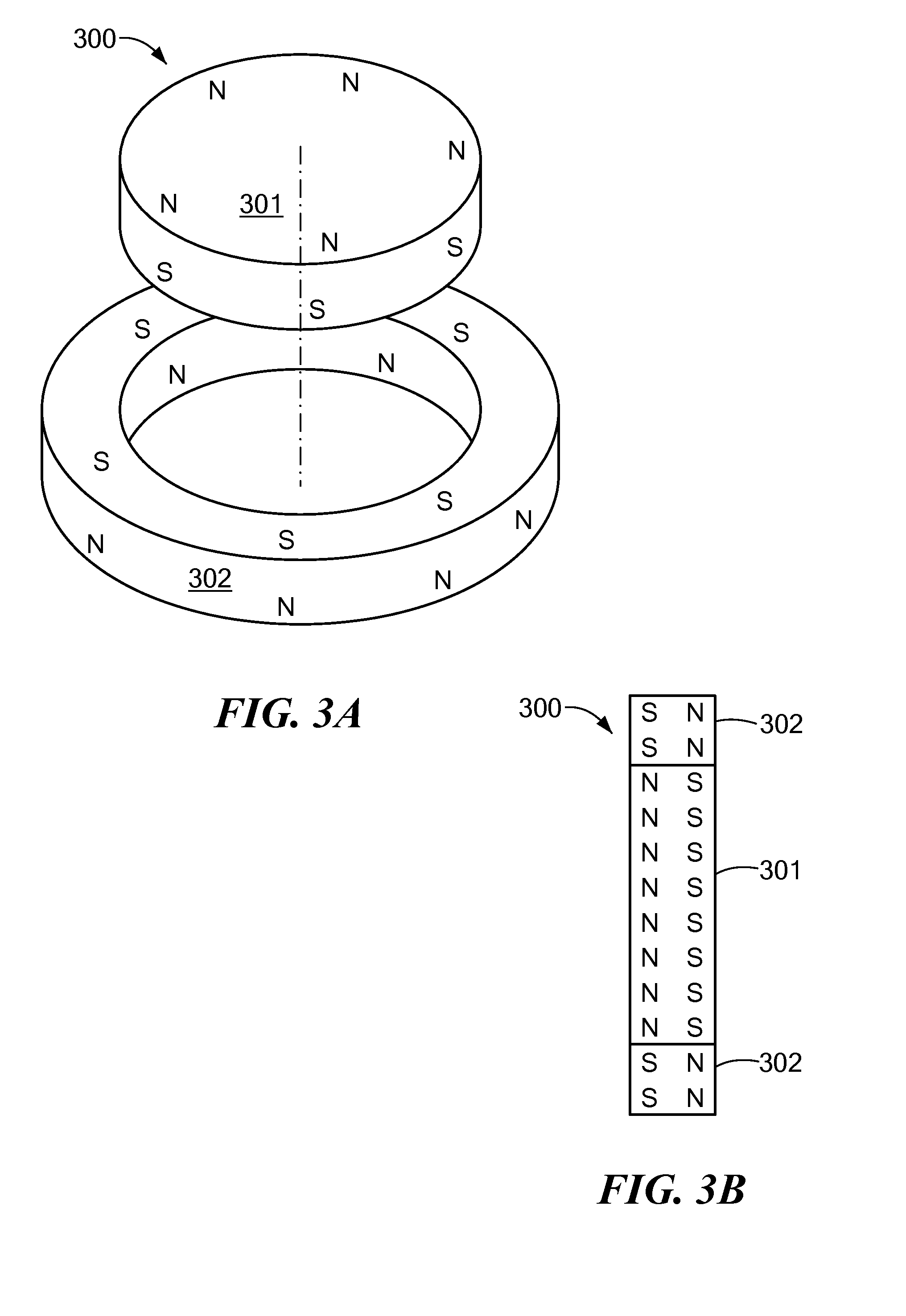

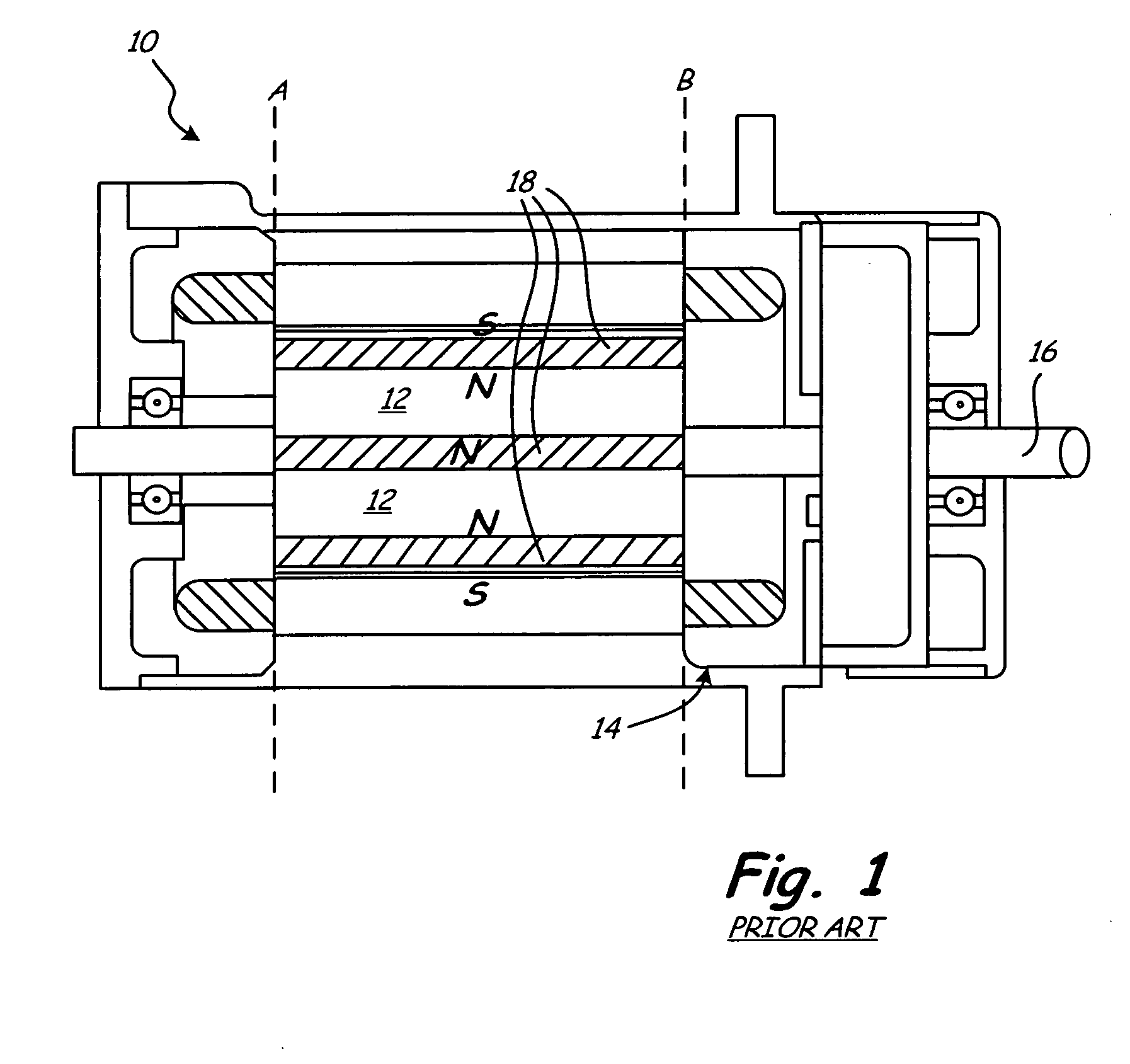

Magnetic Attachment Arrangement for Implantable Device

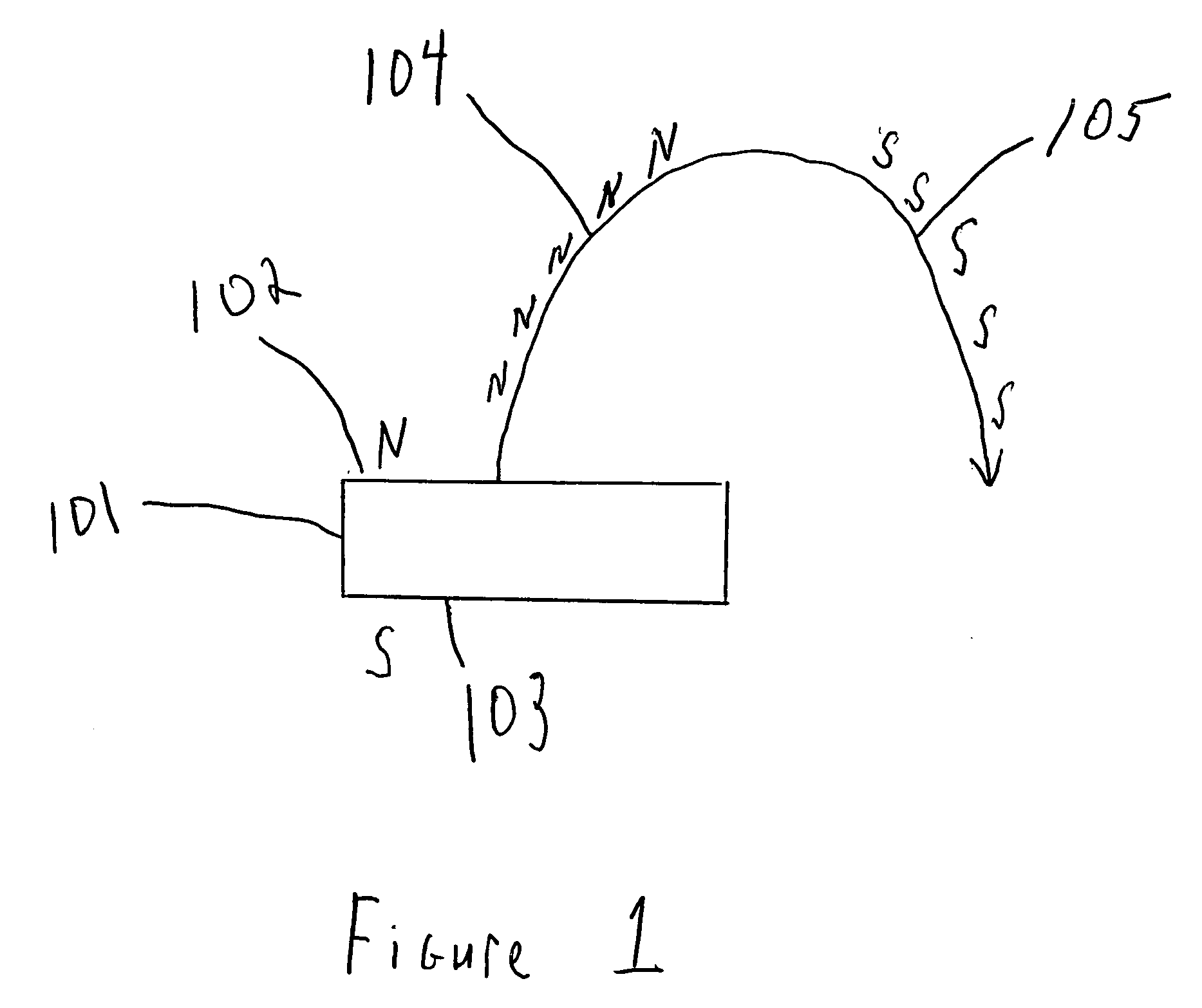

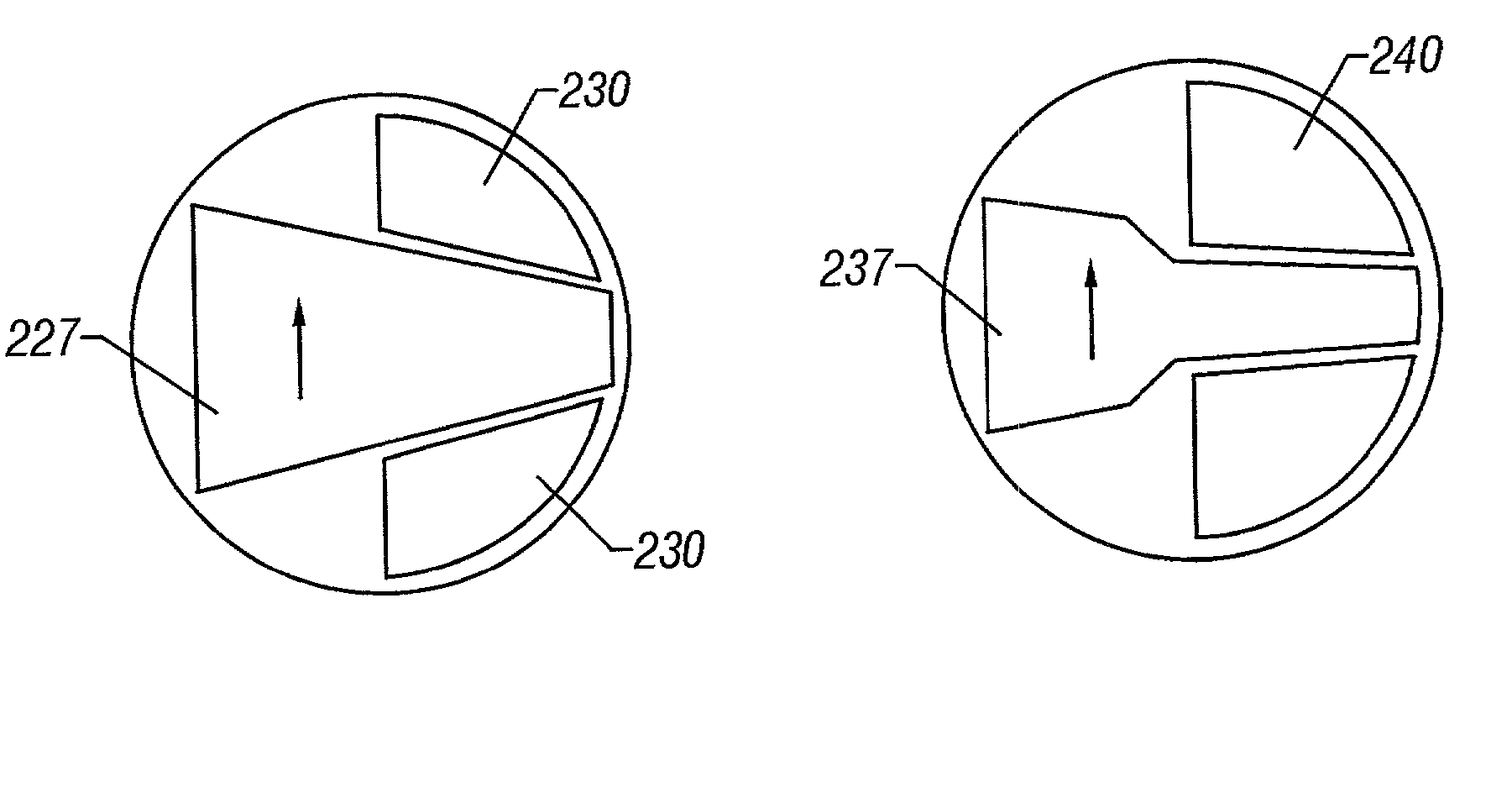

A magnet arrangement is described for use in implantable devices. An implantable housing contains a portion of an implantable electronic system. A cylindrical implant magnet arrangement within the housing includes multiple adjacent magnetic sections wherein at least two of the magnetic sections have opposing magnetic orientations in opposite magnetic directions. There may also be a similar external housing having a corresponding magnet arrangement.

Owner:VIBRANT MED EL HEARING TECH

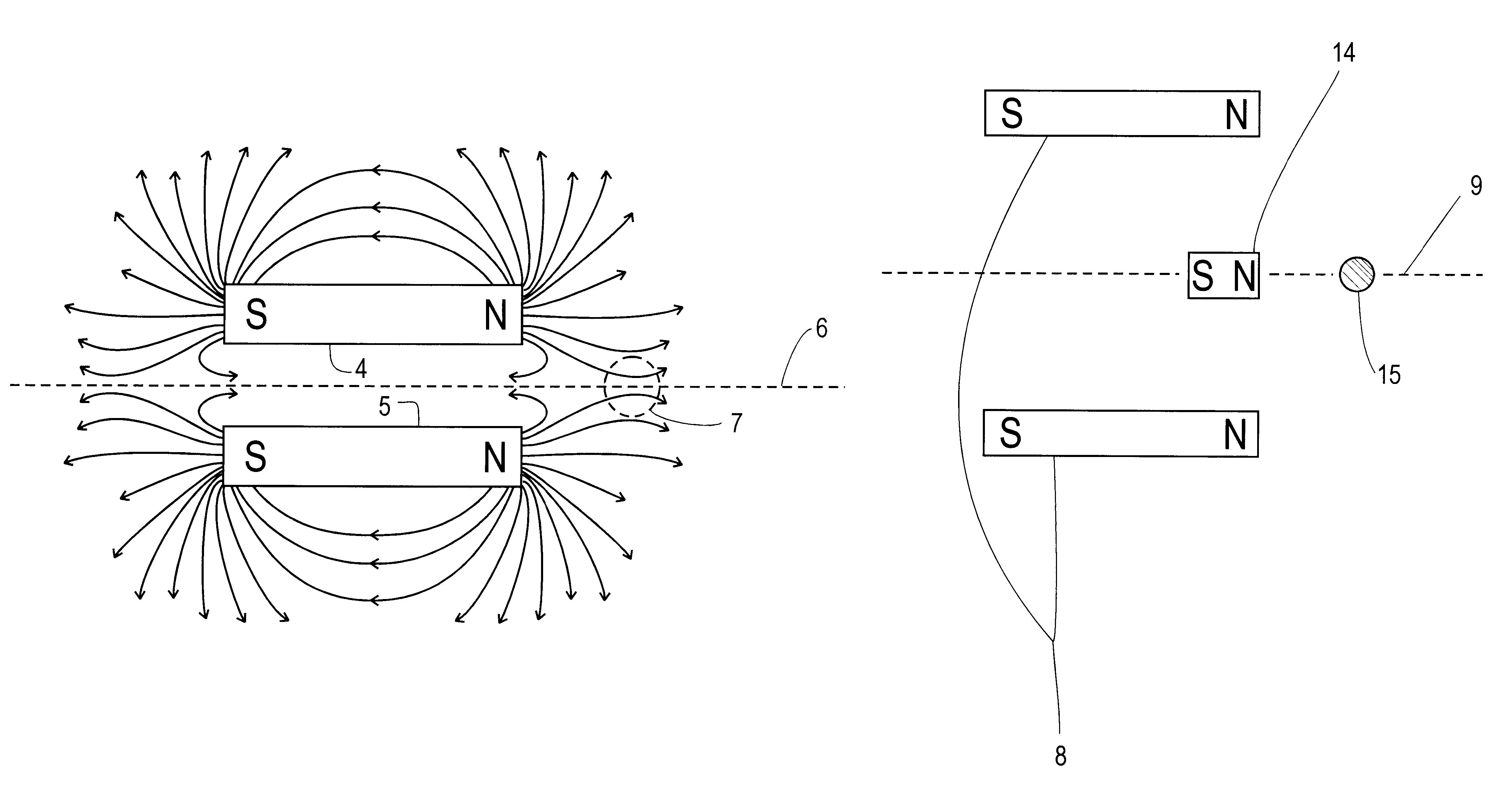

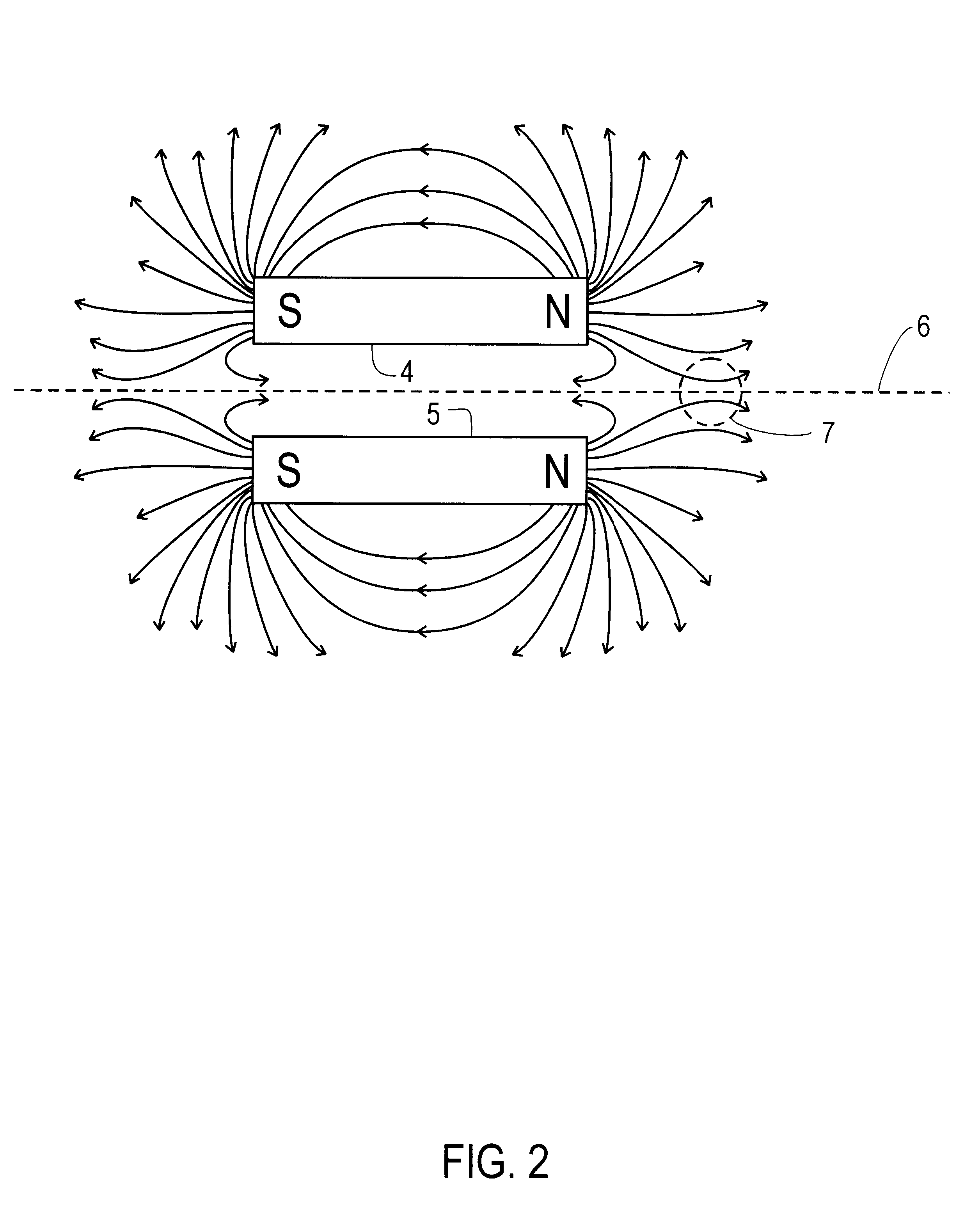

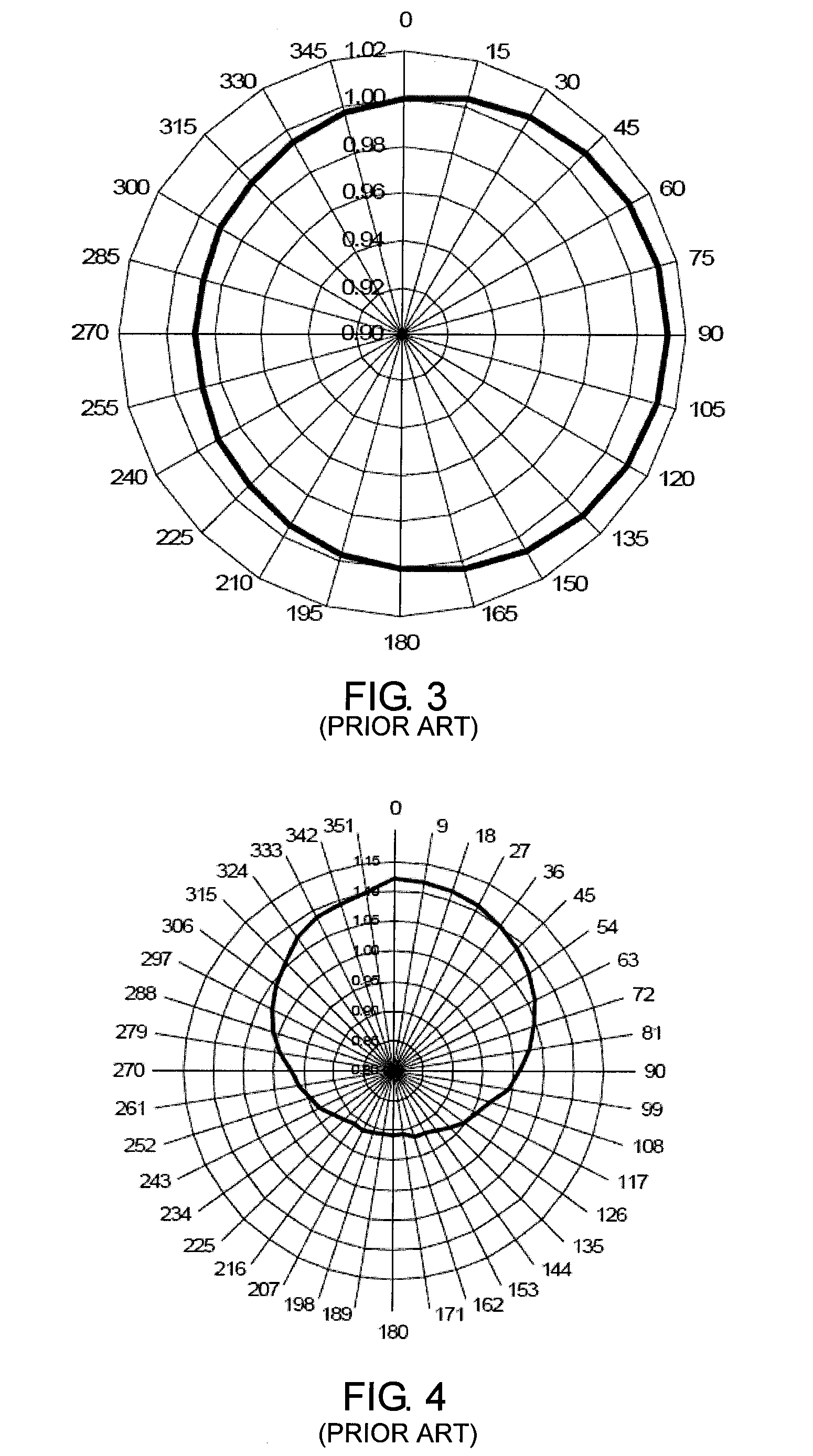

Unilateral magnet having a remote uniform field region for nuclear magnetic resonance

InactiveUS6489872B1Long distanceLarge aspect ratioElectromagnets without armaturesMagnetic materialsUniform fieldNMR - Nuclear magnetic resonance

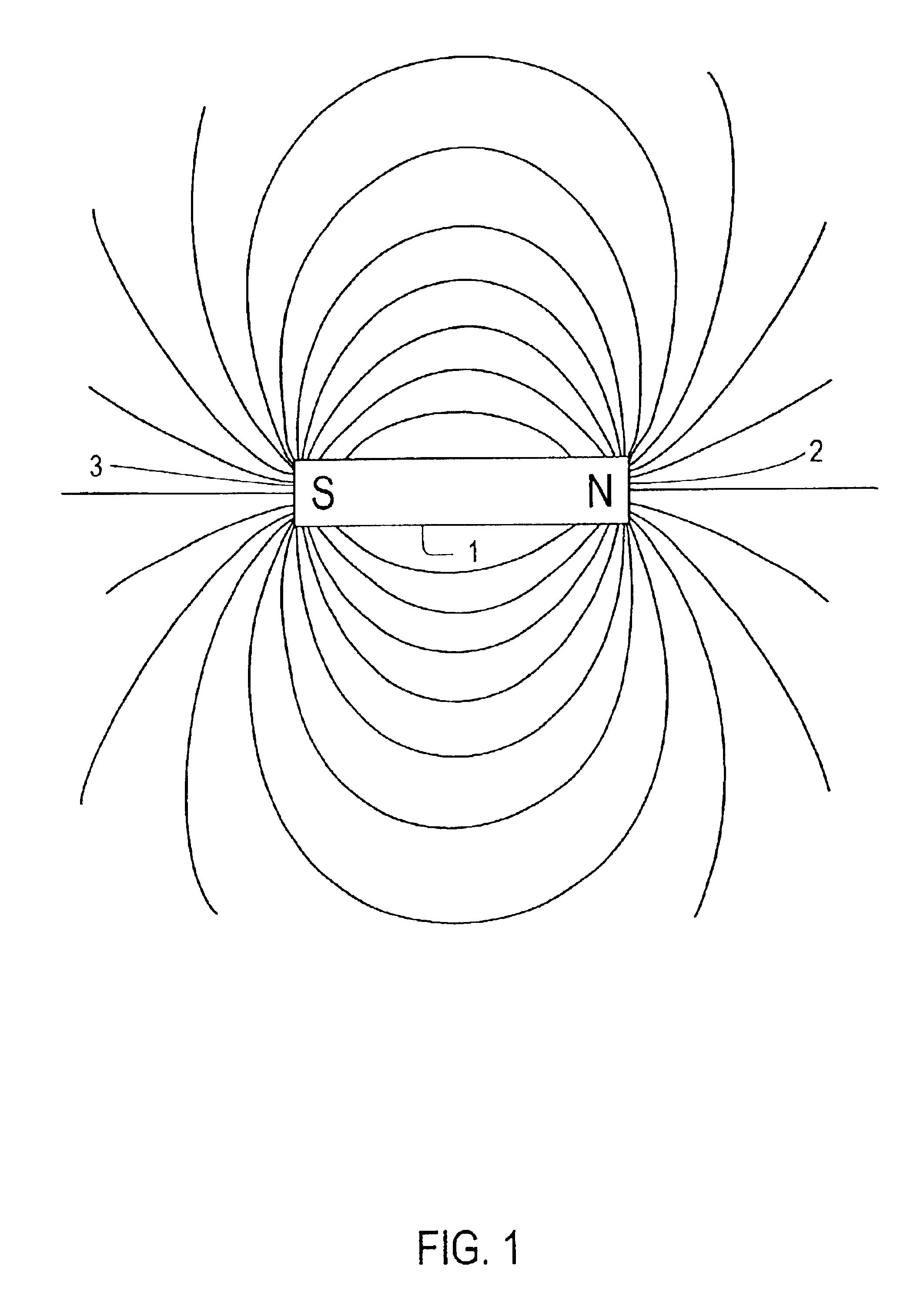

A unilateral magnet apparatus having a remote uniform field region. The apparatus' uniform remote field region is suitable for a variety of nuclear magnetic resonance applications.

Owner:NEW MEXICO RESONANCE

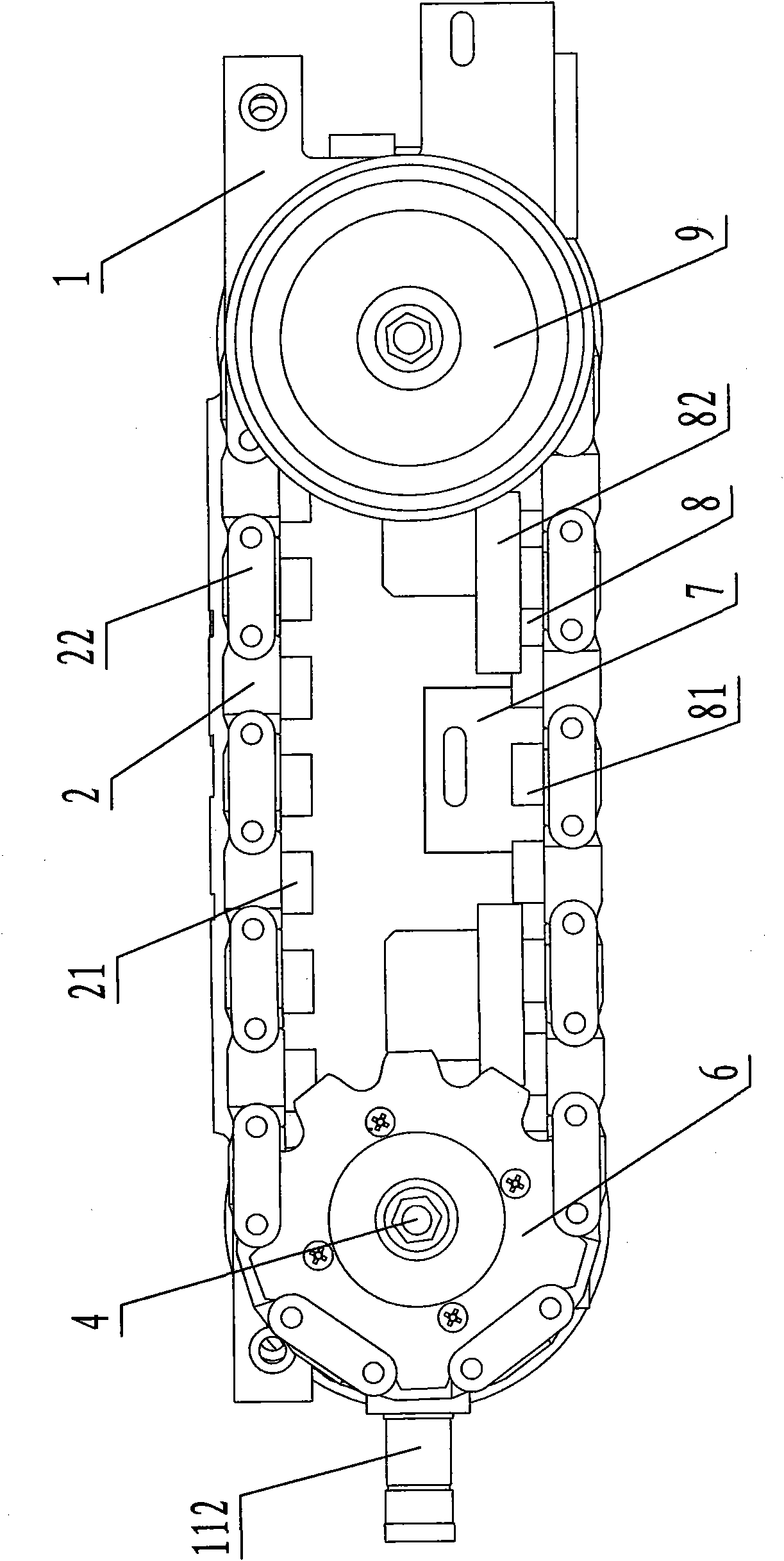

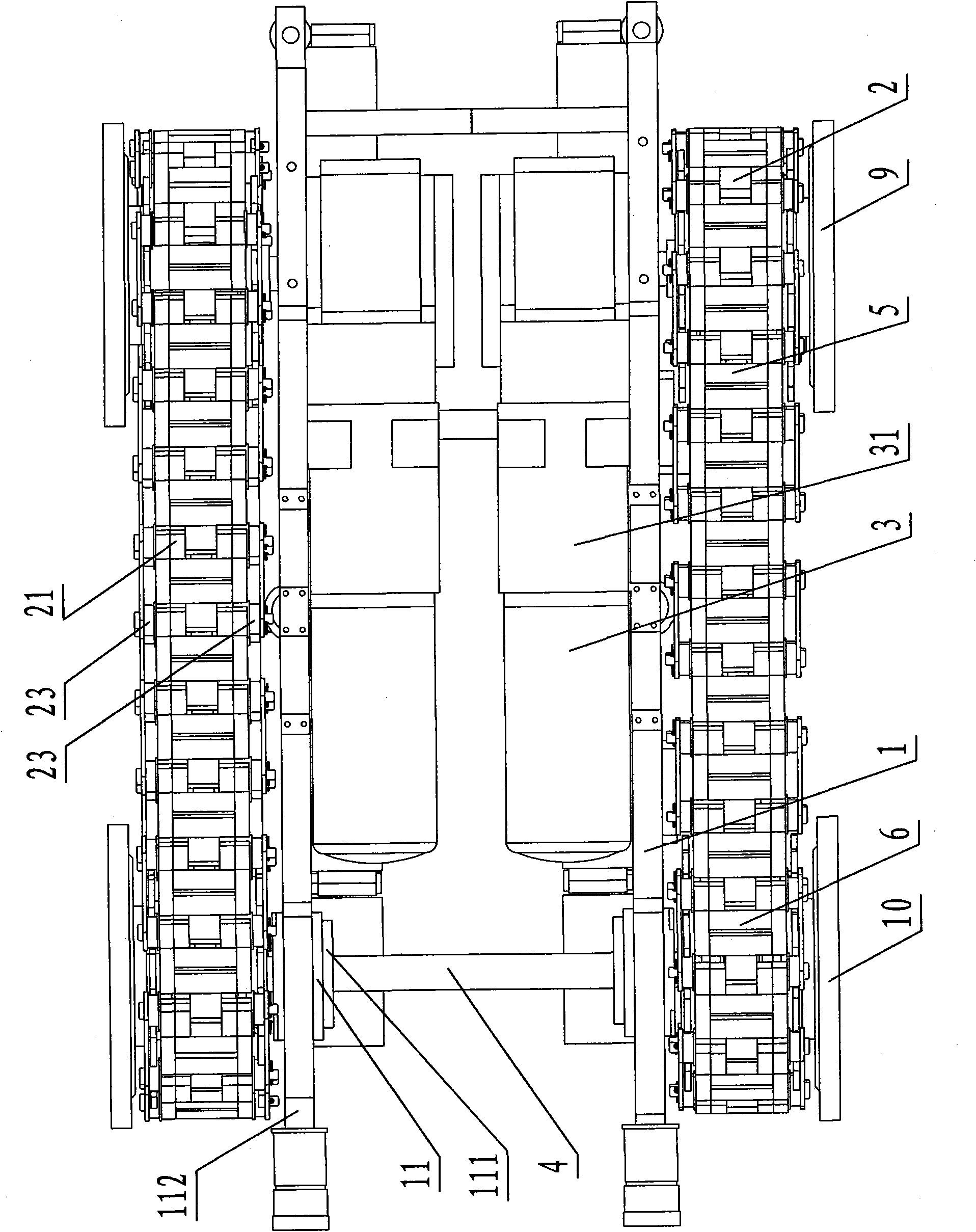

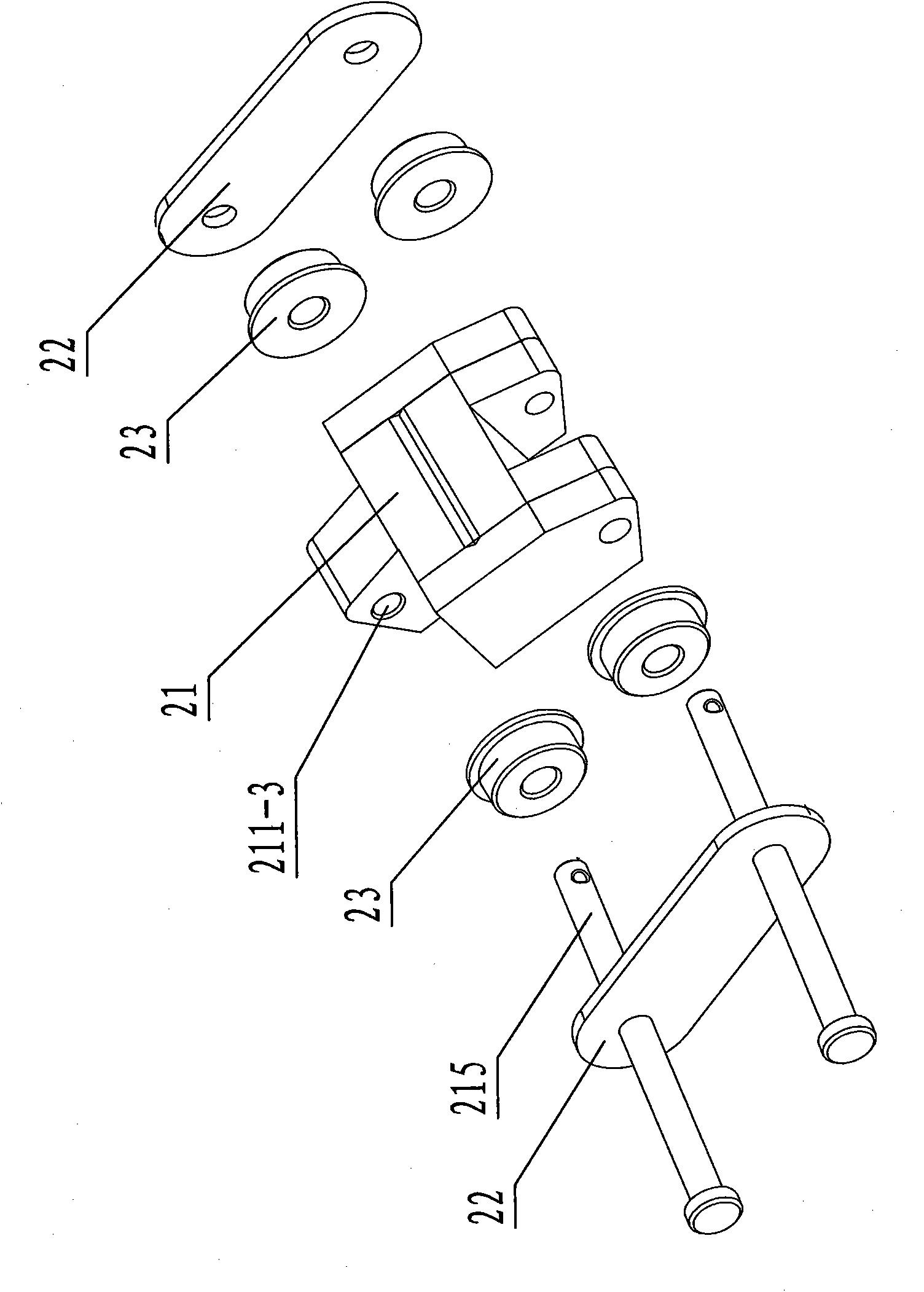

Crawler-type permanent magnet crawling vehicle

ActiveCN101863292AAvoid damageSolve the problem of lost stepsEndless track vehiclesClosed loopSprocket

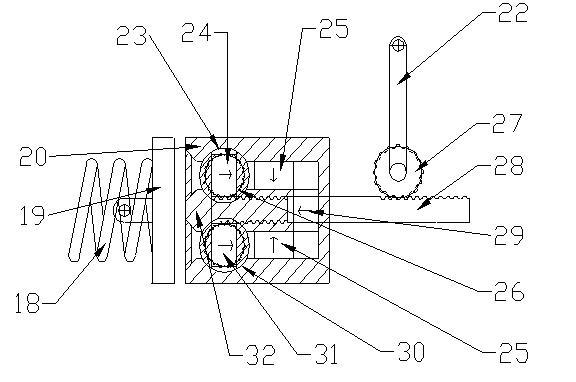

The invention discloses a crawler-type permanent magnet crawling vehicle which comprises a vehicle body, a crawler, a driving device and a connecting shaft. A drive sprocket and a driven sprocket are arranged at the two sides of the vehicle body; the drive sprocket is driven by the driving device to rotate; the driven sprocket is rotatablely arranged on the connecting shaft; the drive sprocket is connected with the driven sprocket through the crawler in a transmission manner; and the lower end of the inner side plate of the vehicle body is assembled with a magnetic suspension component which can be adsorbed on a magnetic workpiece. The crawler comprises permanent magnet devices and connecting sheets, which are sequentially arranged; the permanent magnet devices are hinged together in an occlusion manner through the connecting sheets to form a closed loop shape; rotatable middle idler wheels are respectively arranged at the inner sides and the outer sides of the permanent magnet devices and the hinged positions of the permanent magnet devices and the connecting sheets; and the middle idler wheels can roll along the dentiform profile faces of the drive sprocket and the driven sprocket in the crawler transmission process. The crawler-type permanent magnet crawling vehicle solves the problems of the existing crawling vehicle such as difficulty in accurately climbing weld joints, inflexible steering and damage on the permanent magnet devices due to easy dropping off.

Owner:哈焊所华通(常州)焊业股份有限公司

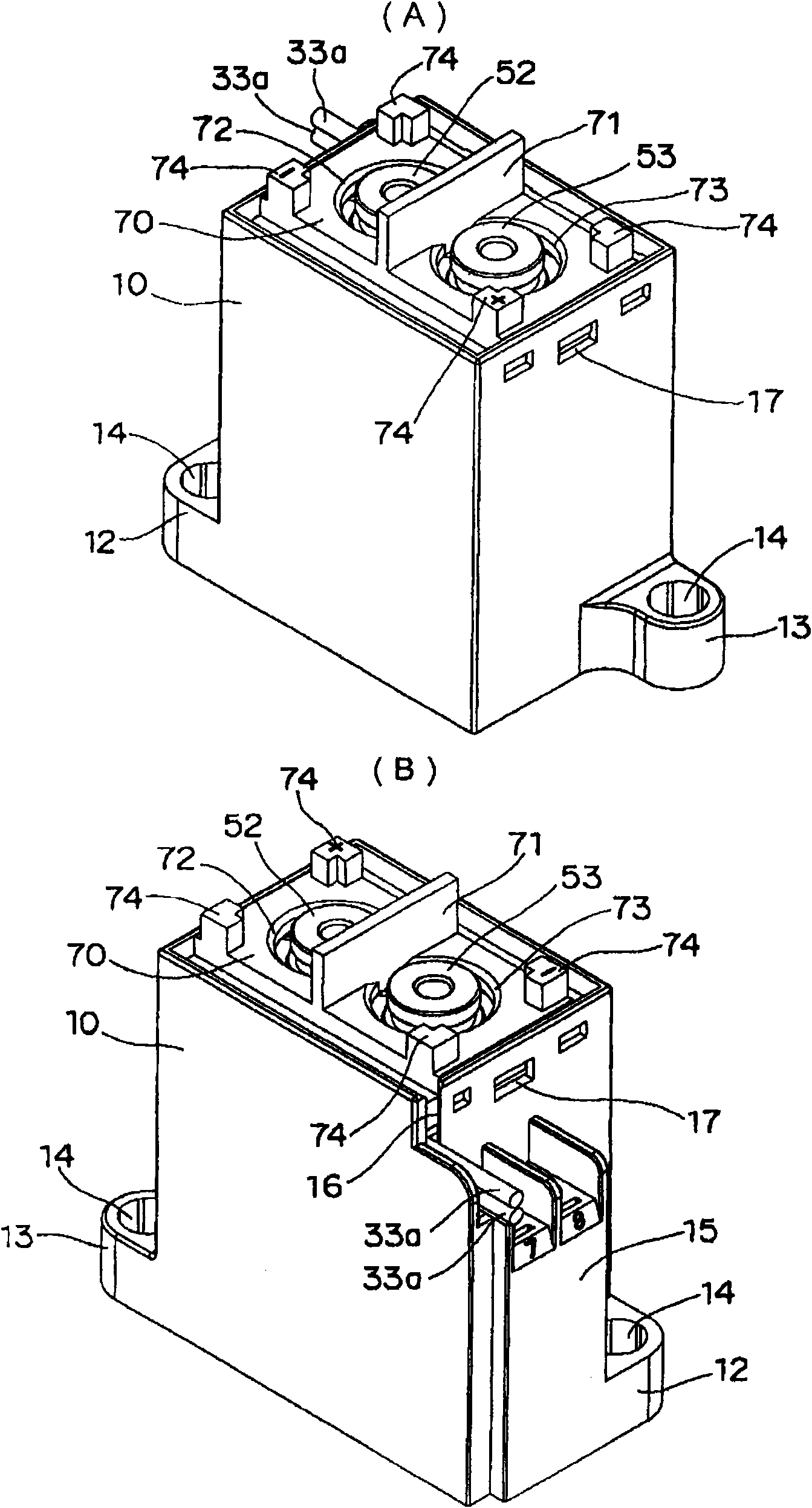

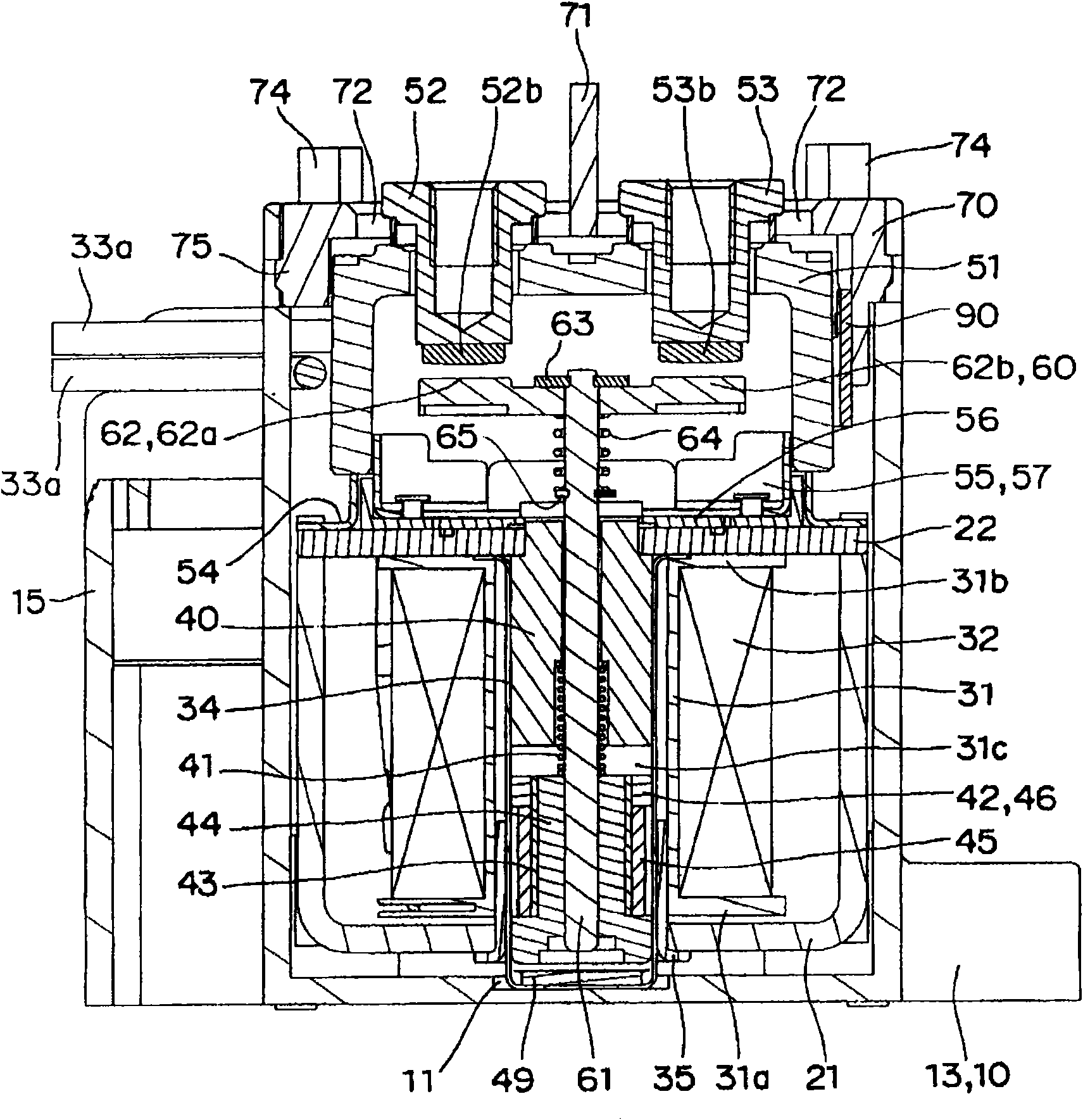

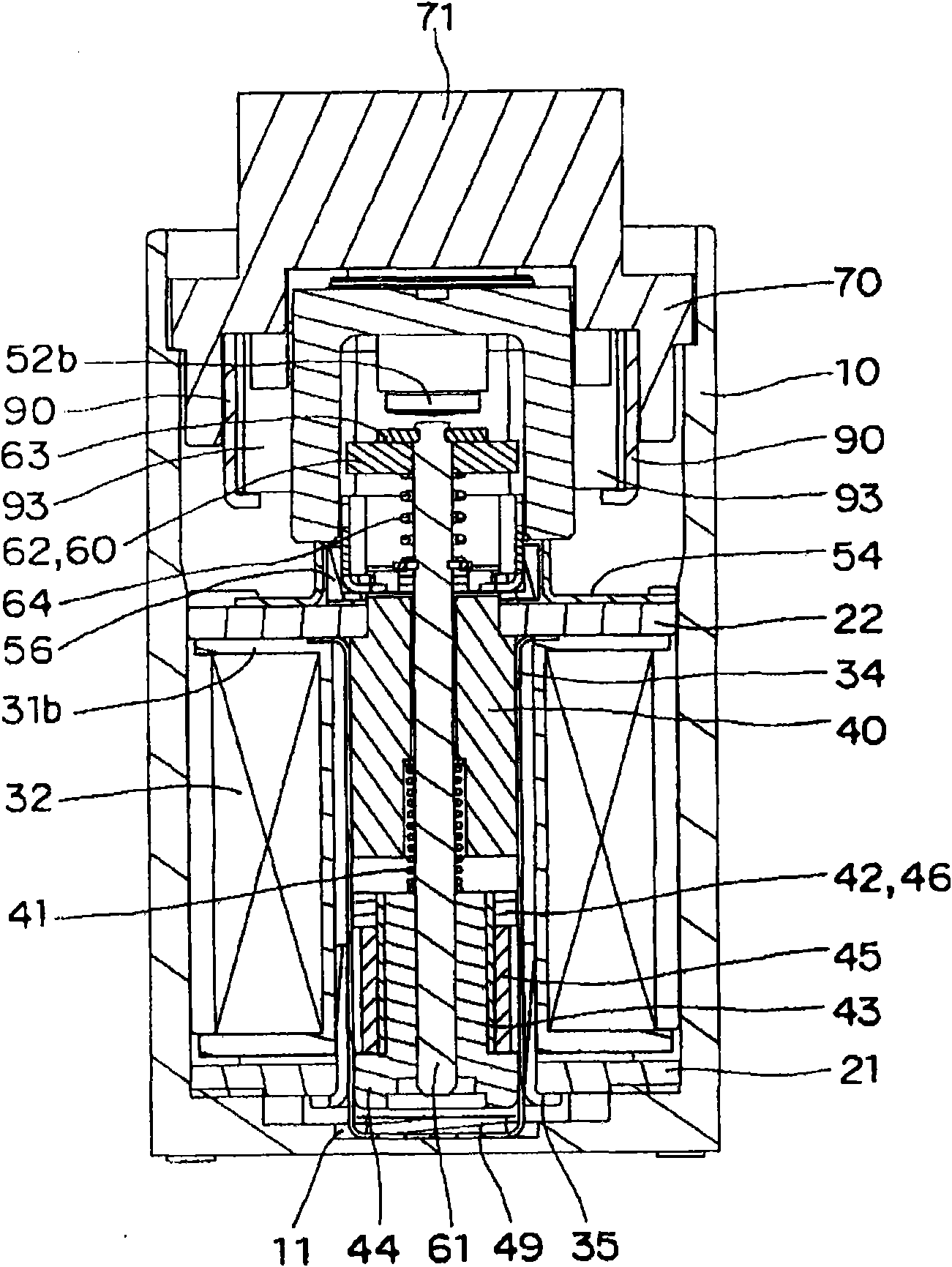

Electromagnet device

ActiveCN101630567ALow operating voltageLess power consumptionElectric switchesElectromagnetic relay detailsDrive shaftEngineering

This invention provides a small polar electromagnet device of small power consumption. Provided is a polar electromagnet device in which a drive shaft (61) is supported so as to reciprocate in an axis center direction at a center hole (31c) of a spool (31) wound with a coil (32), a movable iron core (42) is attached to a lower end of the drive shaft (61) on the same axis center, and the drive shaft (61) is reciprocated with the movable iron core (42) which reciprocates based on excitation and demagnetization of the coil. A permanent magnet (45) is integrally arranged at the movable iron core (42) on the same axis center.

Owner:ORMON CORP

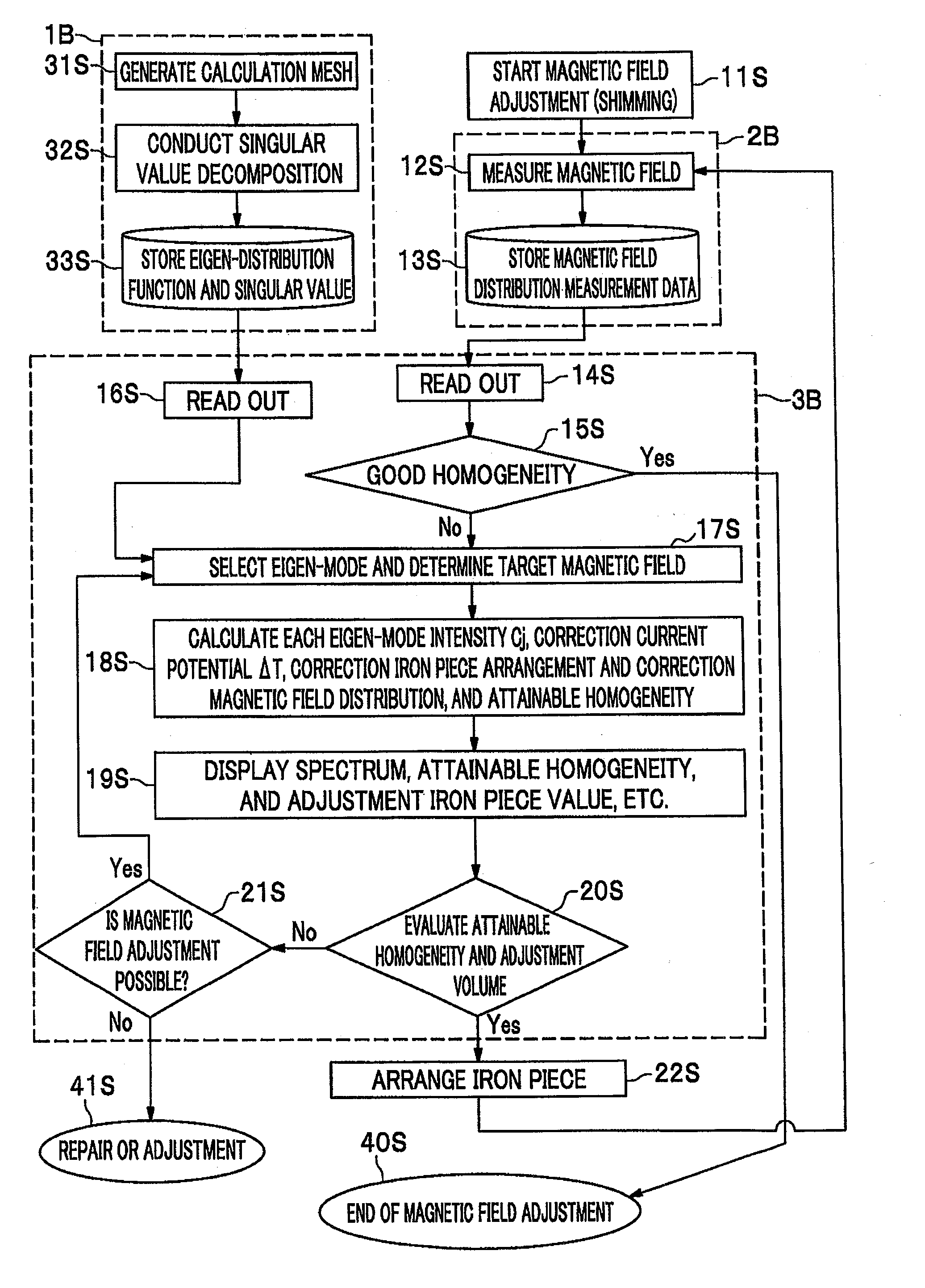

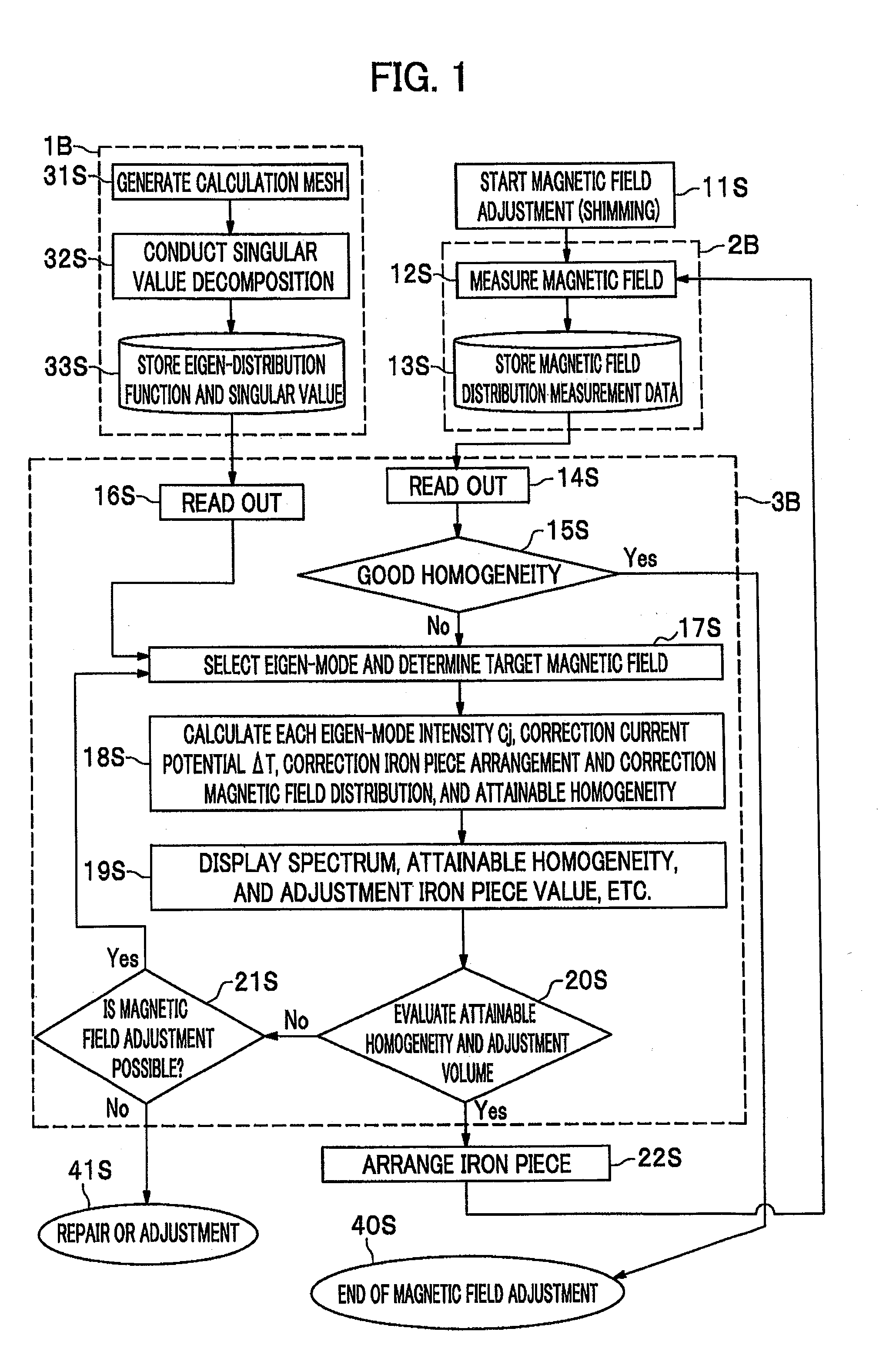

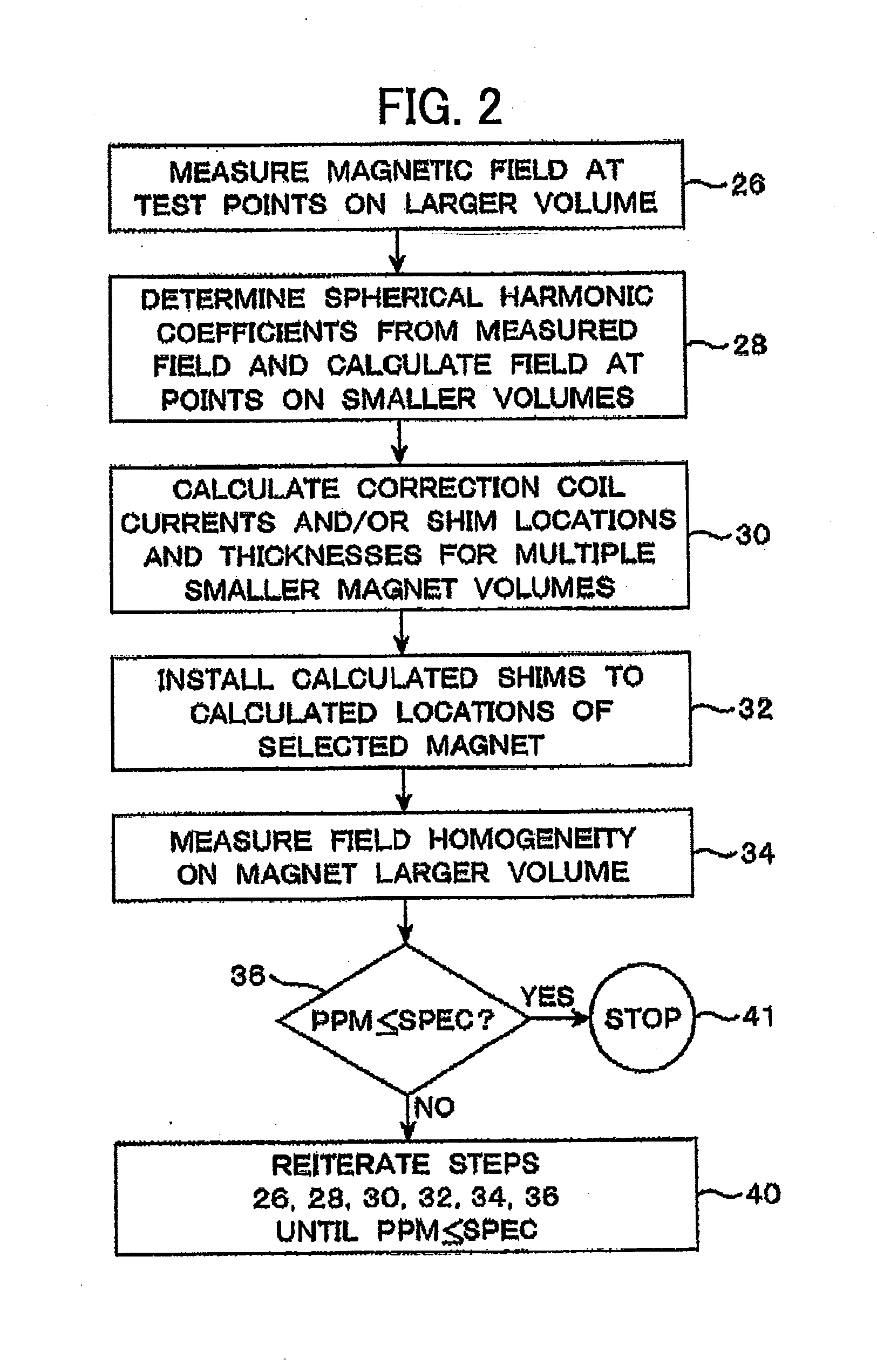

Magnetic field adjustment method for MRI device

InactiveUS20120268119A1Low costImprove accuracyElectric/magnetic detectionMeasurements using NMRPerpendicular magnetic fieldMagnet device

An eigen-mode to be corrected is selected in accordance with an attainable magnetic field accuracy (homogeneity) and appropriateness of arranged volume of the iron pieces. Because the adjustment can be made with the attainable magnetic field accuracy (homogeneity) being grasped, an erroneous adjustment can be grasped, and the adjustment is automatically done during repeated adjustment. When the magnetic field adjustment is carried out with support by the method of the present invention according to the first and second embodiments or an apparatus including this method therein, the magnetic field adjustment can be surely completed. As a result, the apparatus with a high accuracy can be provided. In addition, there is an advantageous effect of earlier detection of a poor magnet by checking the attainable homogeneity. They are applicable to magnet devices for the horizontal magnetic field type, being an open type MRI, and vertical magnetic field type MRI.

Owner:HITACHI LTD

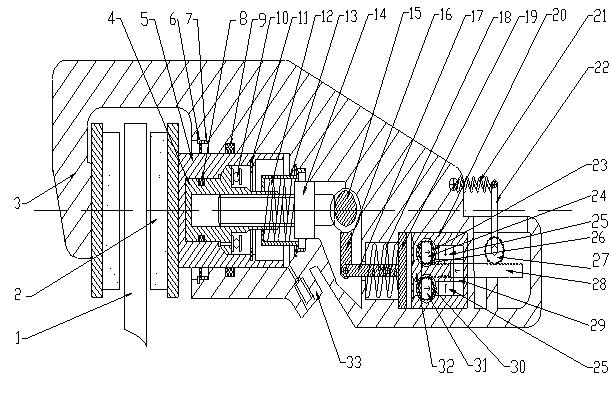

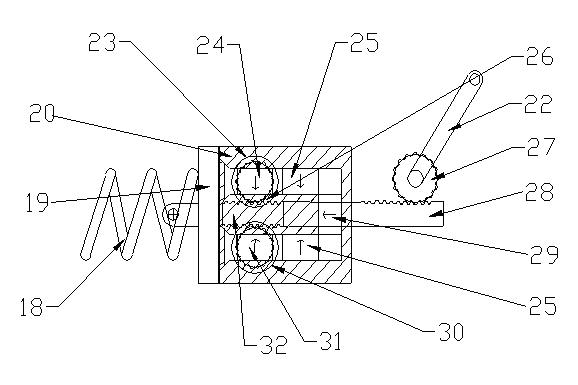

Disc brake with permanent magnet parking brake mechanism and braking method

ActiveCN102011814AReduce fatigue strengthImprove securityAxially engaging brakesBrake actuating mechanismsDriver/operatorElectrical conductor

The invention discloses a disc brake with a permanent magnet parking brake mechanism and braking method for highway transportation vehicles. A main piston and a permanent magnet driving device are arranged in a cylinder body; when a manual brake is pulled, a magnetic circuit in a permanent magnet device is open; a magnetic field is generated nearby a conductor, and the conductor contacts with the shell of the permanent magnet device towards right, so that two pull rods are driven to generate displacement and driving a round wheel to rotate so as to push the main piston to move towards left to drive a brake block assembly to move towards left, thereby braking a brake disc to generate braking; and when the manual brake is released, the magnetic circuit in the permanent magnet device is closed, and the two pull rods and the round wheel return, so that the main piston moves towards right to return. In the invention, as the disc brake consists of the permanent magnet driving device and a mechanical mechanism, the braking security is enhanced, the fatigue strength of a driver is reduced, and no electric energy needs to be consumed.

Owner:YANCHENG BUGAO AUTO PARTS MFG CO LTD

Unilateral magnet having a remote uniform field region for nuclear magnetic resonance

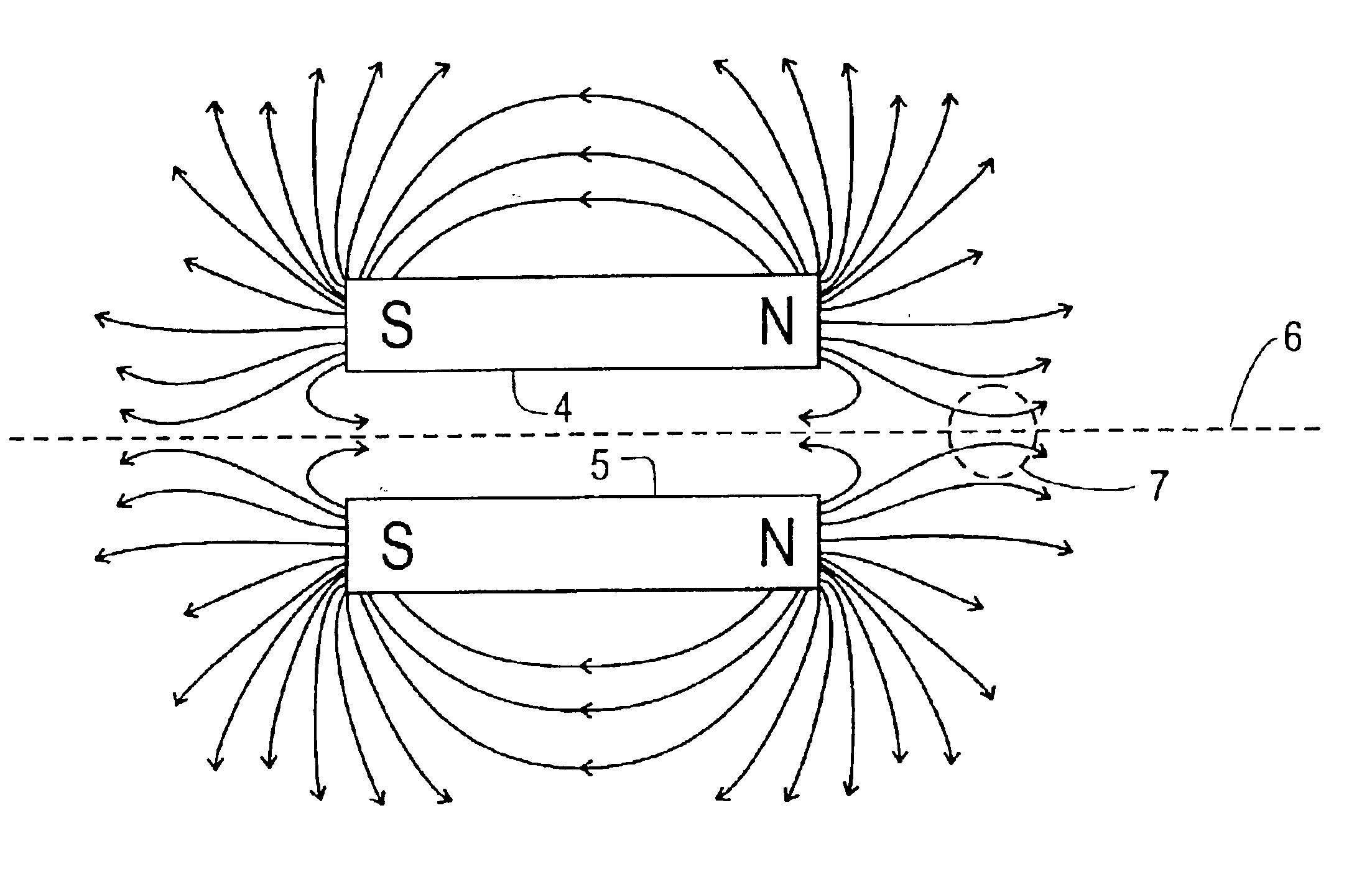

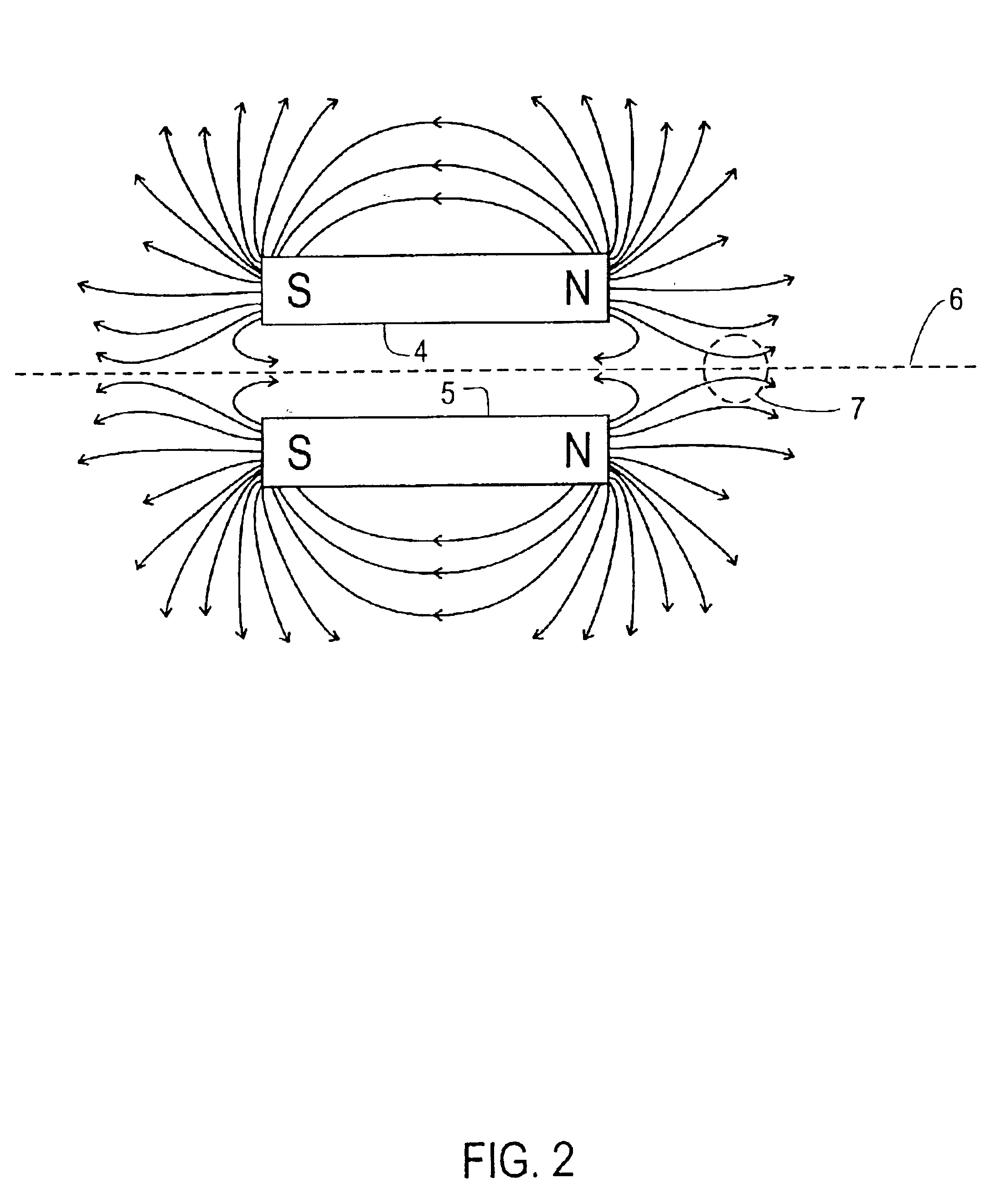

InactiveUS6828892B1Large aspect ratioLarge horizontal sizeElectromagnets without armaturesMagnetic materialsUniform fieldNMR - Nuclear magnetic resonance

A unilateral magnet apparatus having a remote uniform field region. The apparatus' uniform remote field region is suitable for a variety of nuclear magnetic resonance applications.

Owner:ABQMR

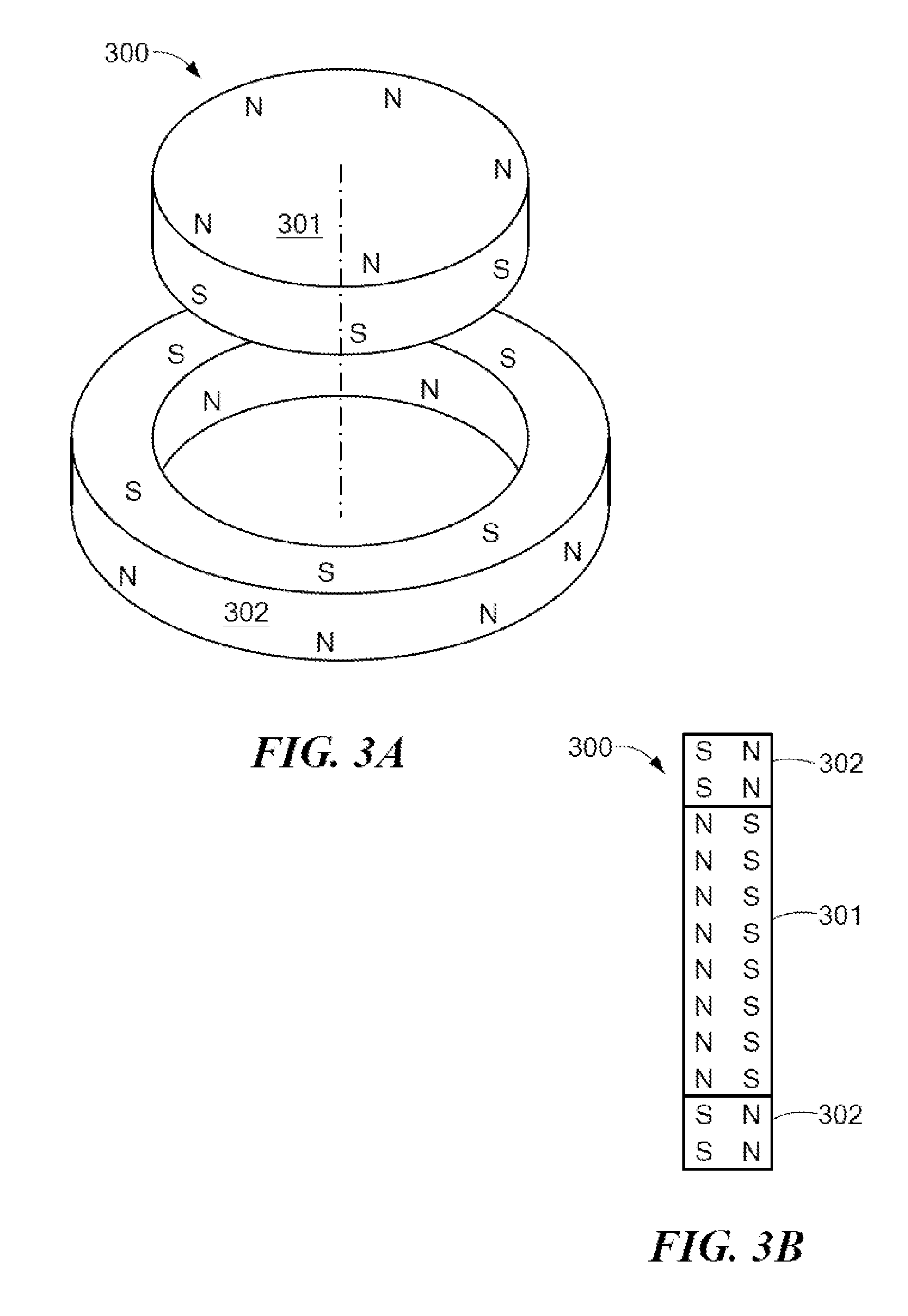

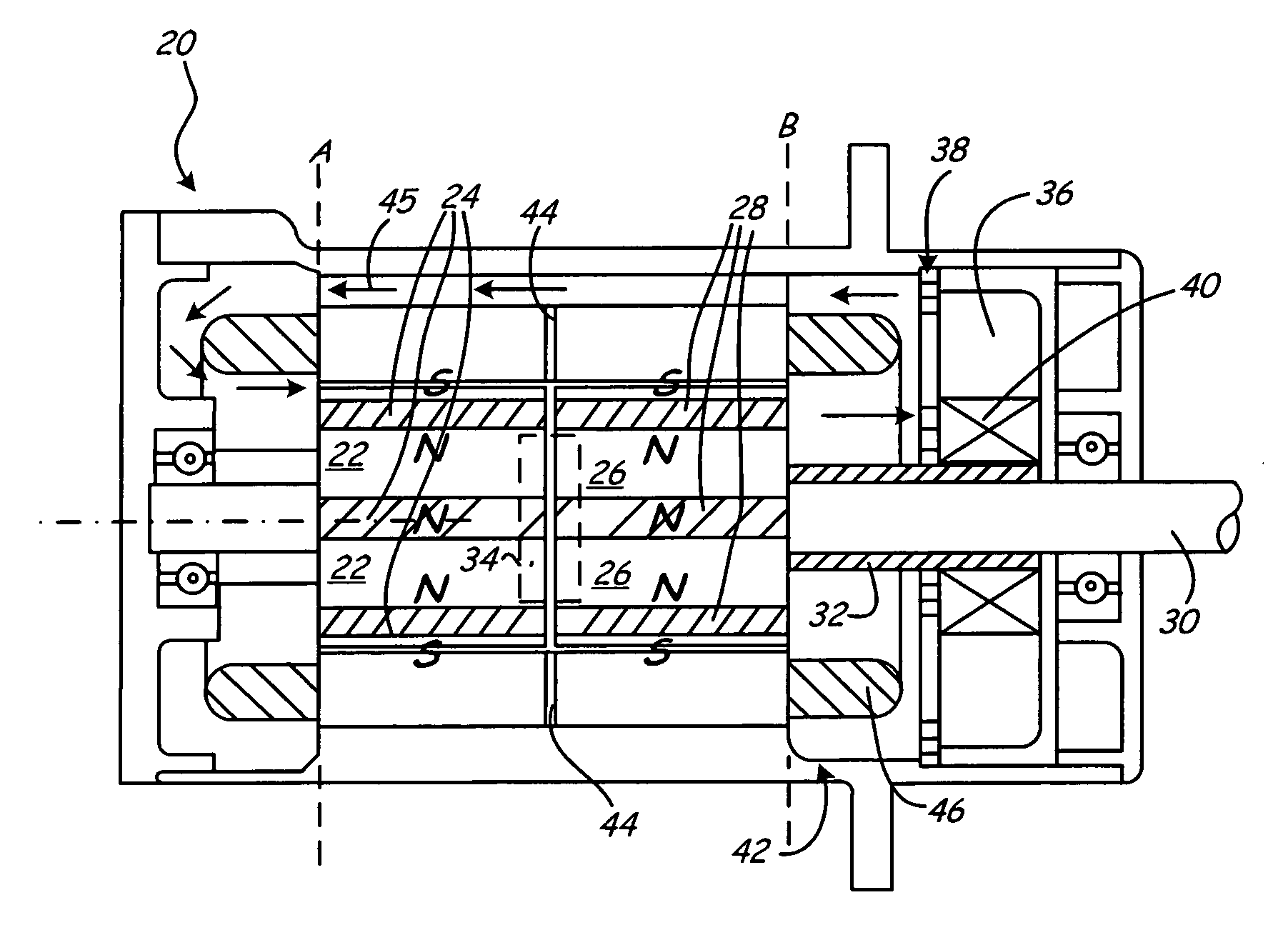

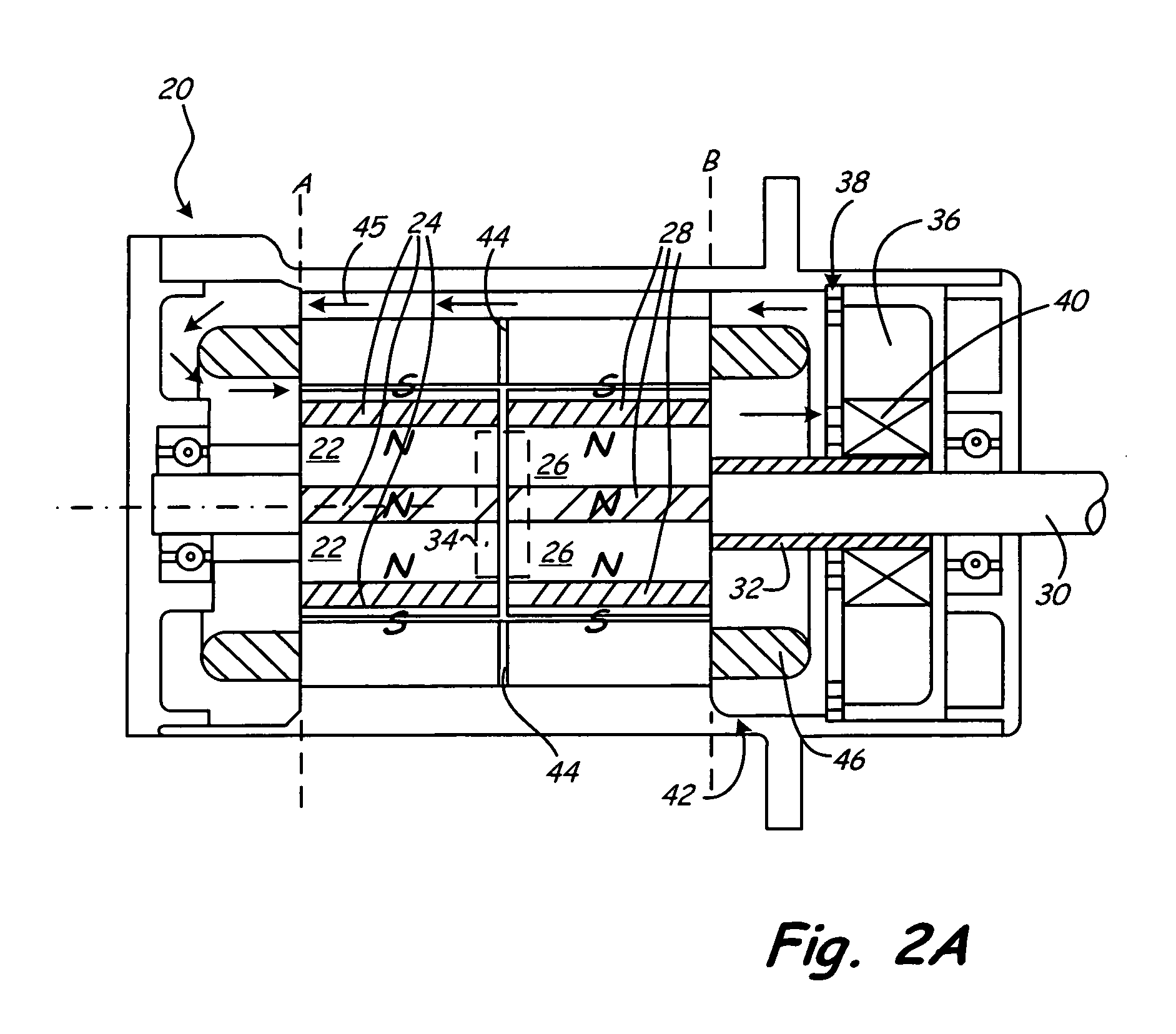

Magnetic Attachment System for Implantable Device

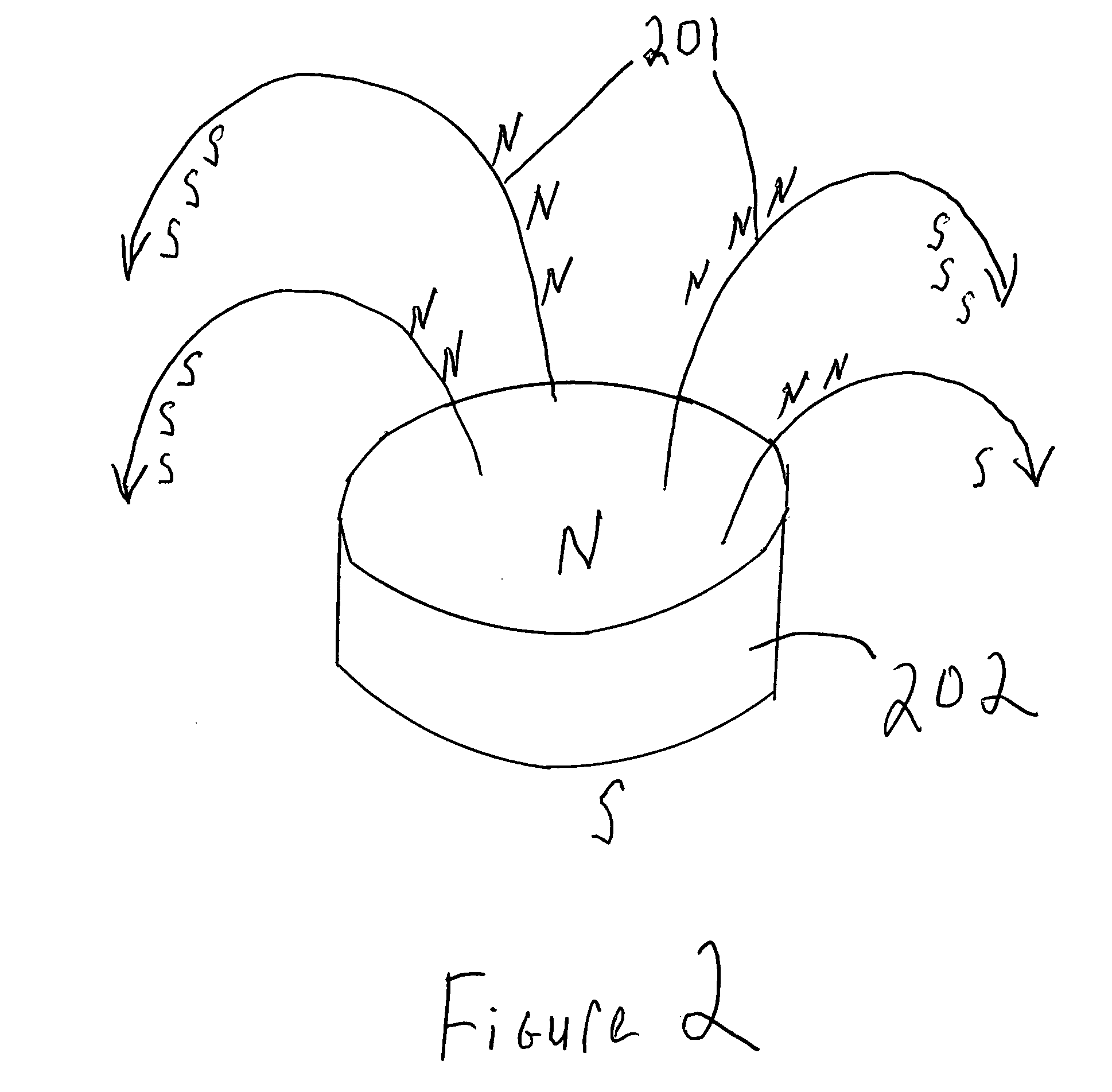

A magnet arrangement is described for use with hearing implant systems. An external device for use with an implant system has an external device housing that contains external elements of a hearing implant system. A cylindrical external magnet arrangement within the housing has multiple magnetic sections lying in a common plane, including an inner center disc having an inner magnetic orientation in an inner magnetic direction, and an outer radial ring having an outer magnetic orientation in an outer magnetic direction opposite to the inner magnetic direction.

Owner:MED EL ELEKTROMEDIZINISCHE GERAETE GMBH

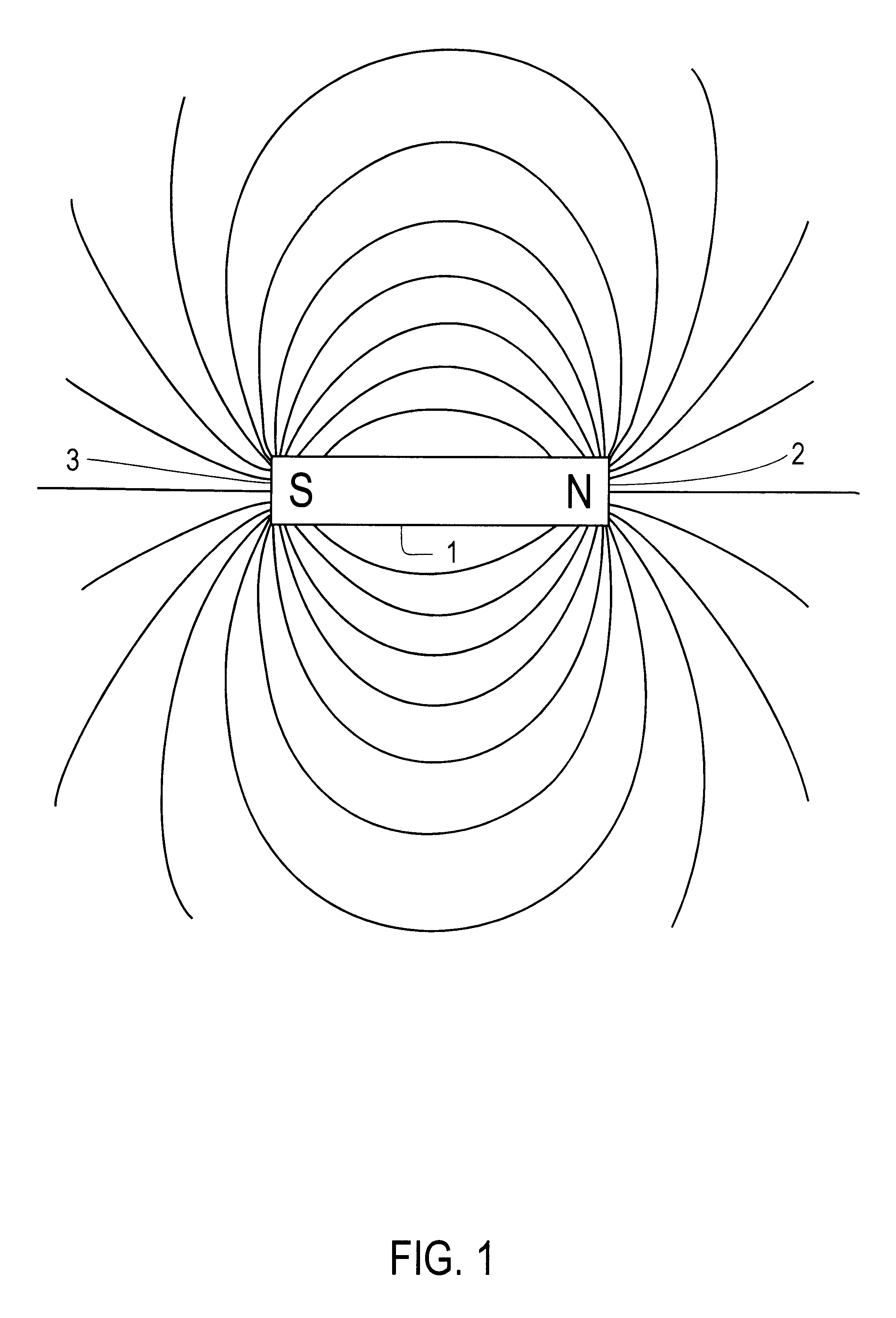

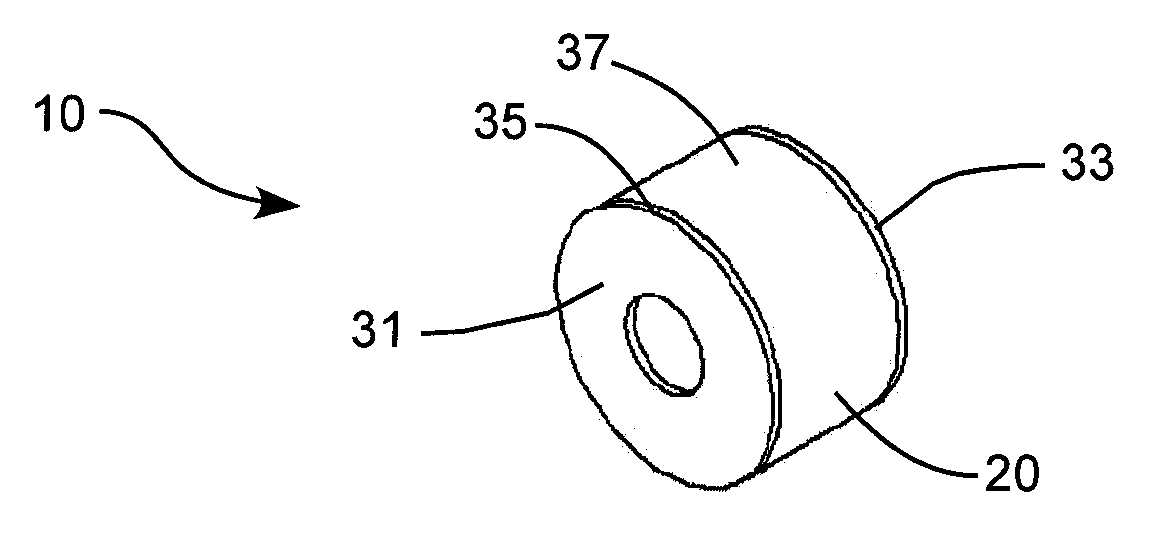

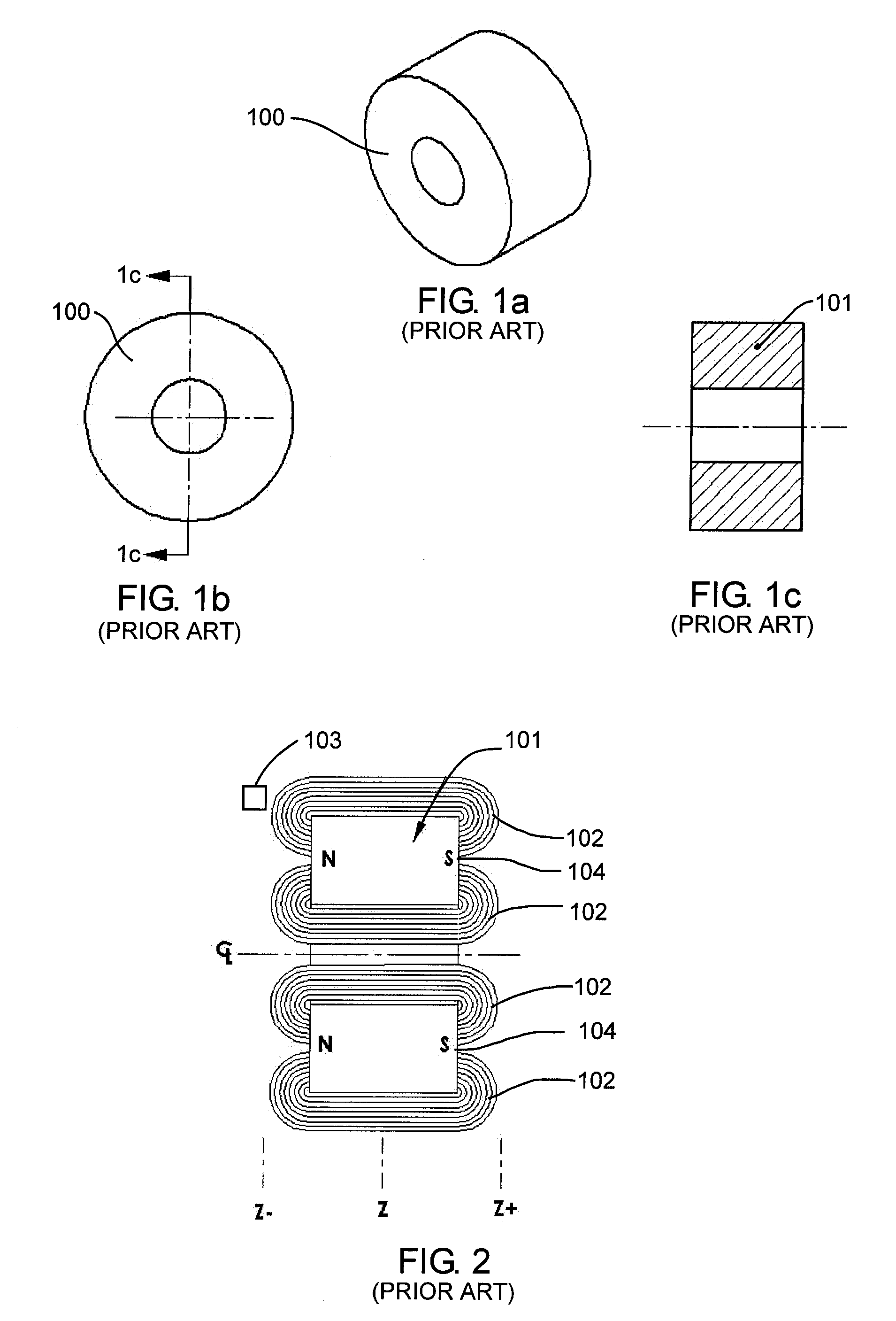

Permanent Magnet or Permanent Magnet Array having Uniform Flux Density

InactiveUS20090039995A1High magnetic flux densityHigh densityMagnetic circuitPermanent magnetsFlux linesMagnet device

A permanent magnet device includes a polarized permanent annular magnet having two oppositely charged poles faces. A magnetically conductive faceplate is disposed on each of the opposite pole faces of the permanent magnet. Each faceplate is sized, shaped and oriented to equally distribute the flux lines emanating from the permanent magnet, and to increase or concentrate the density of the magnetic flux field of a permanent magnet or permanent magnet device.

Owner:KIPP RONALD +2

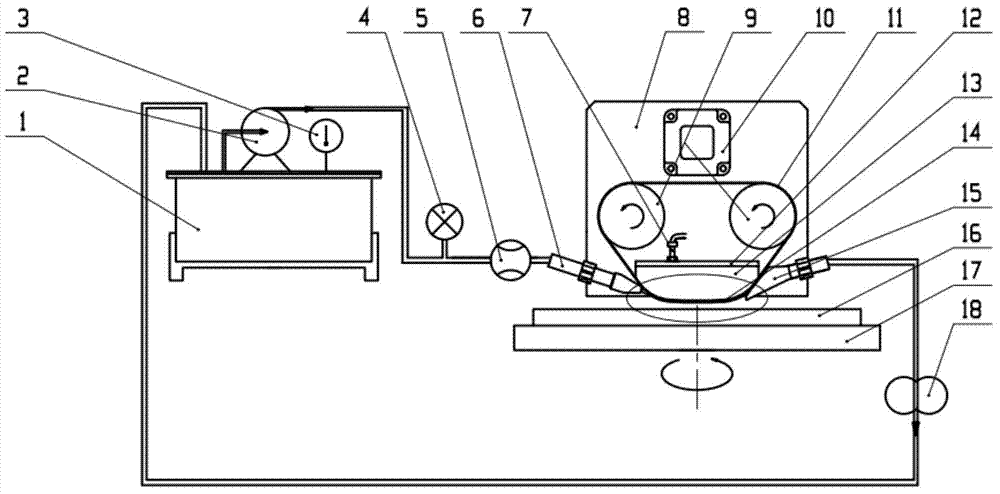

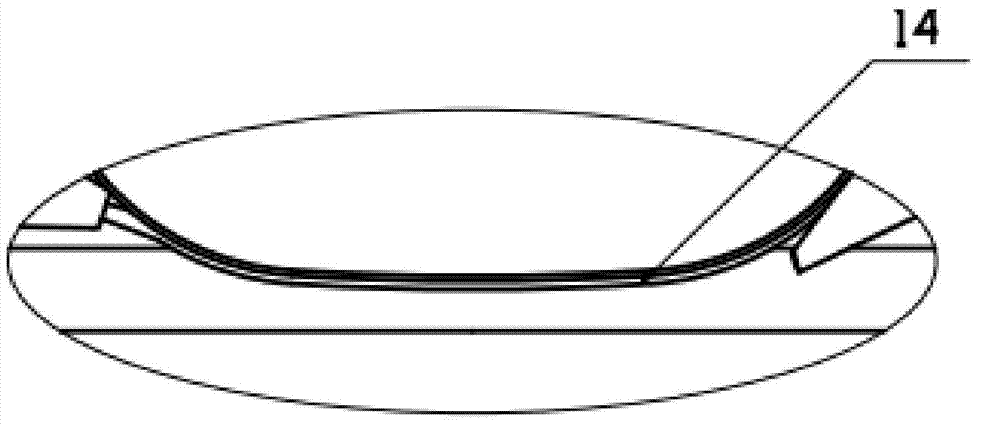

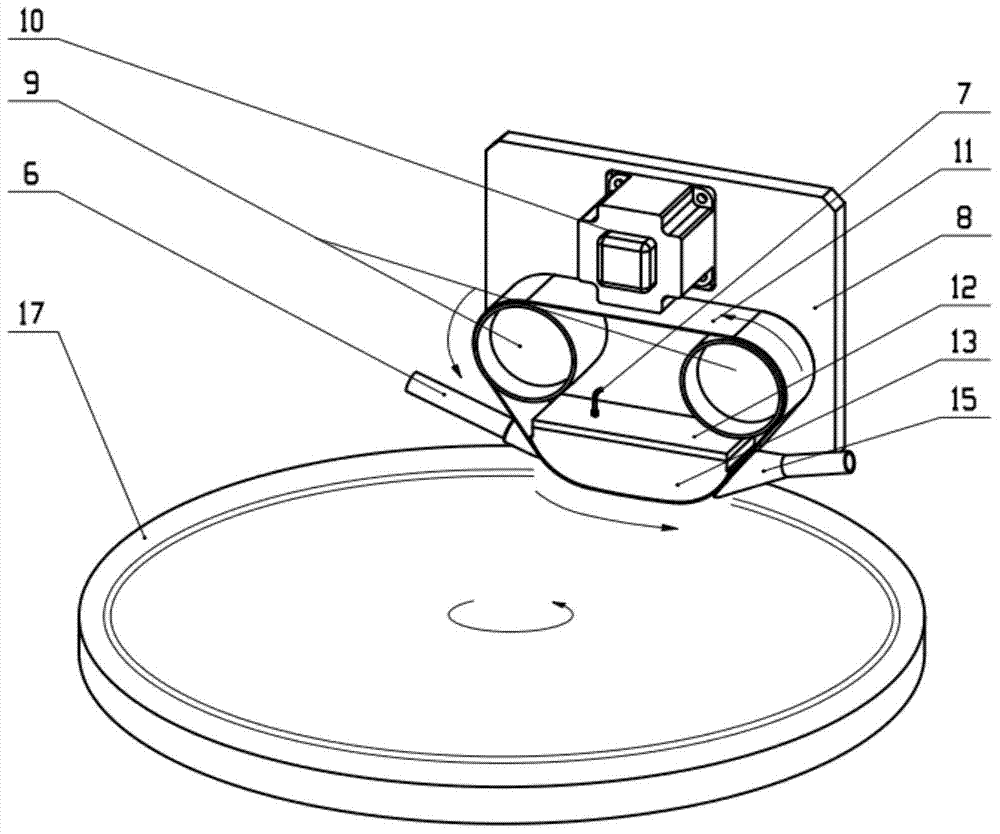

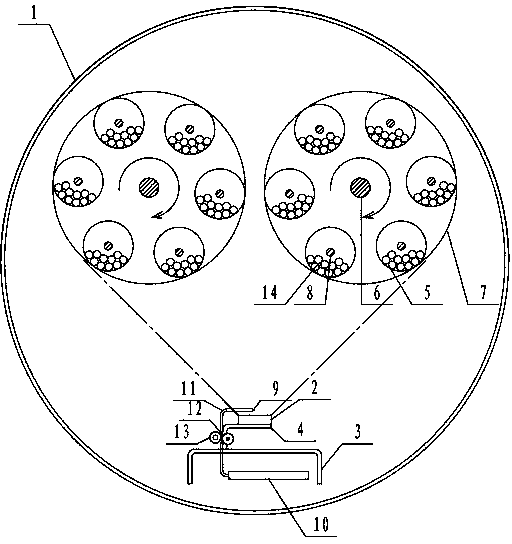

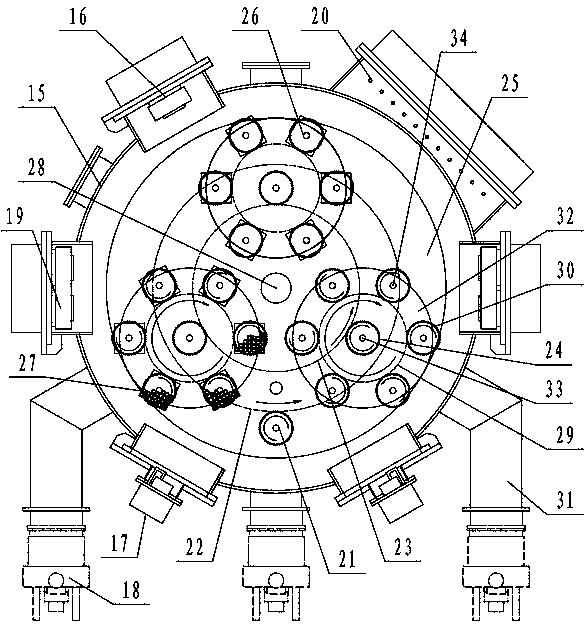

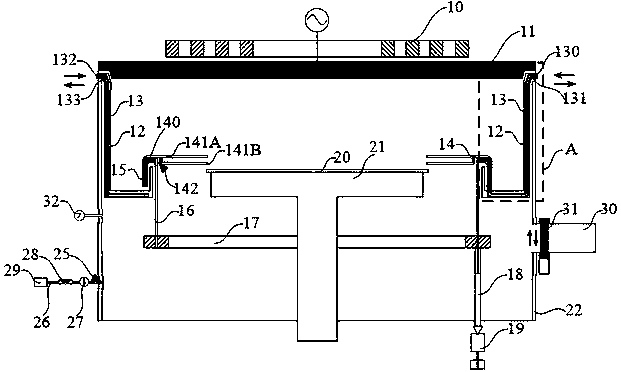

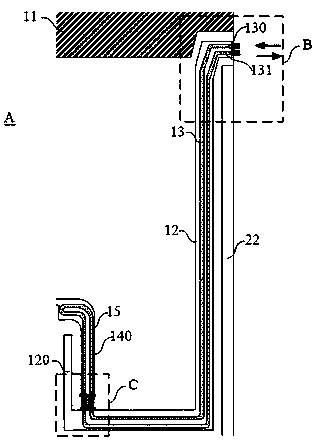

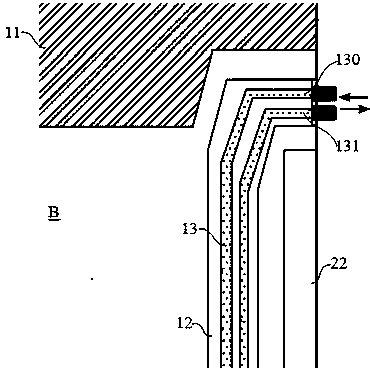

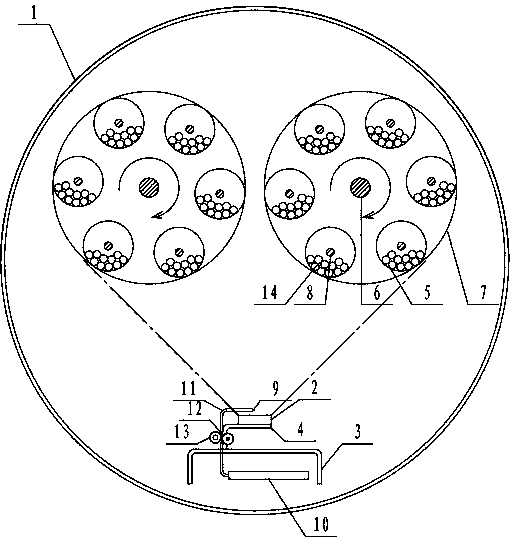

Magnetorheological finishing device applicable to ultra-large-diameter optical processing

The invention relates to a magnetorheological finishing device applicable to ultra-large-diameter optical processing. The magnetorheological finishing device comprises a magnet device and a magnetorheological fluid circulating device. The magnet device is capable of providing a magnetic field, the lower end of the magnet device is provided with a horizontal protruding section, and the magnetorheological fluid circulating device enables magnetorheological fluid flowing through the horizontal protruding section to form a ribbon protrusion under the action of the magnetic field perpendicular to the flowing direction. The magnetorheological finishing device applicable to ultra-large-diameter optical processing can be modified on a finishing machine tool to replace a finishing head, such as a stress plate, a small grinding head and the like of the finishing machine tool without changing an original mechanical structure of the machine tool. The magnetorheological finishing device has the advantages that system size is reduced, mechanical structure is simplified, material removal efficiency is improved, and accordingly the current problems of long processing period and low removal efficiency of large-diameter aspherical processing are solved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

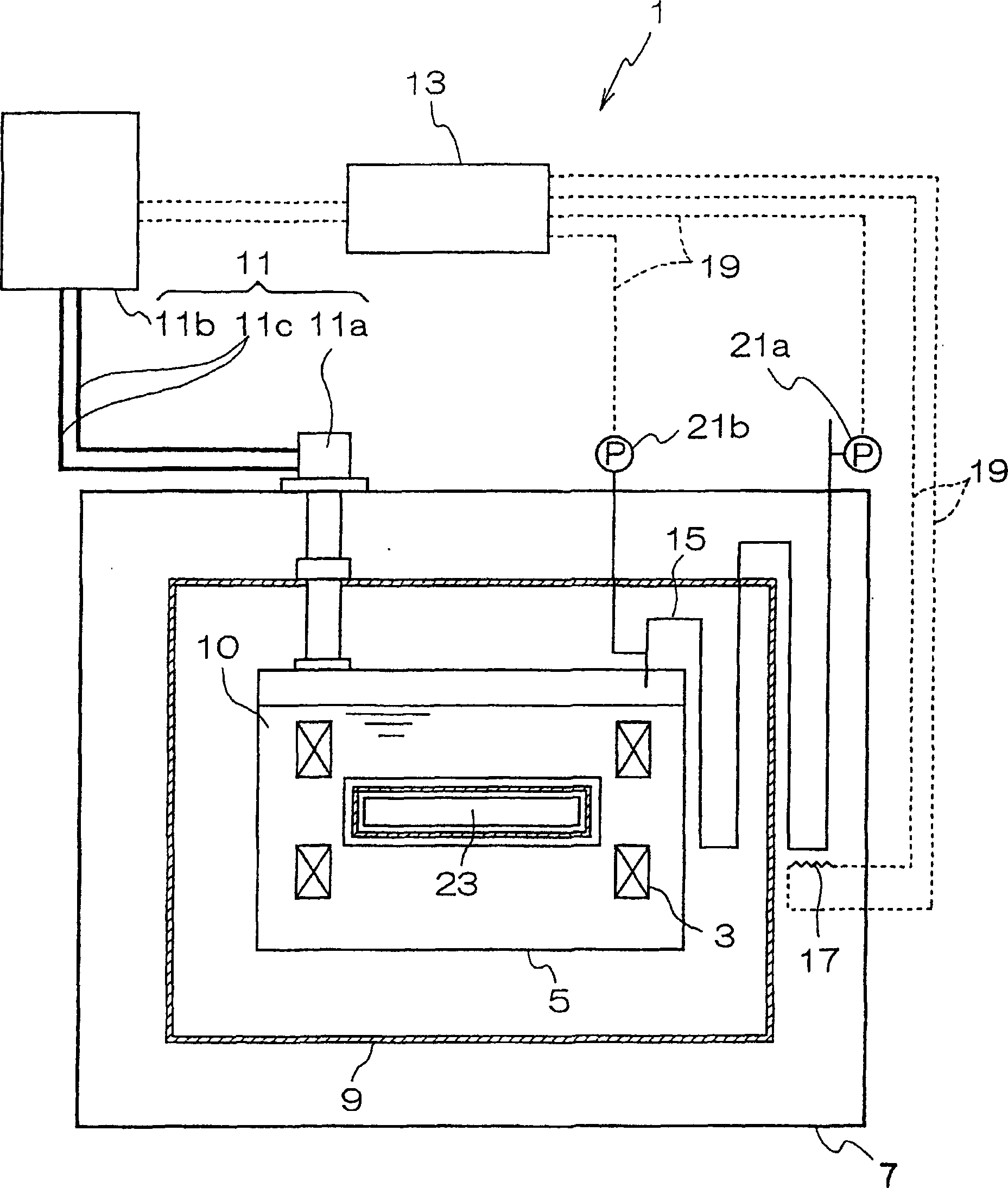

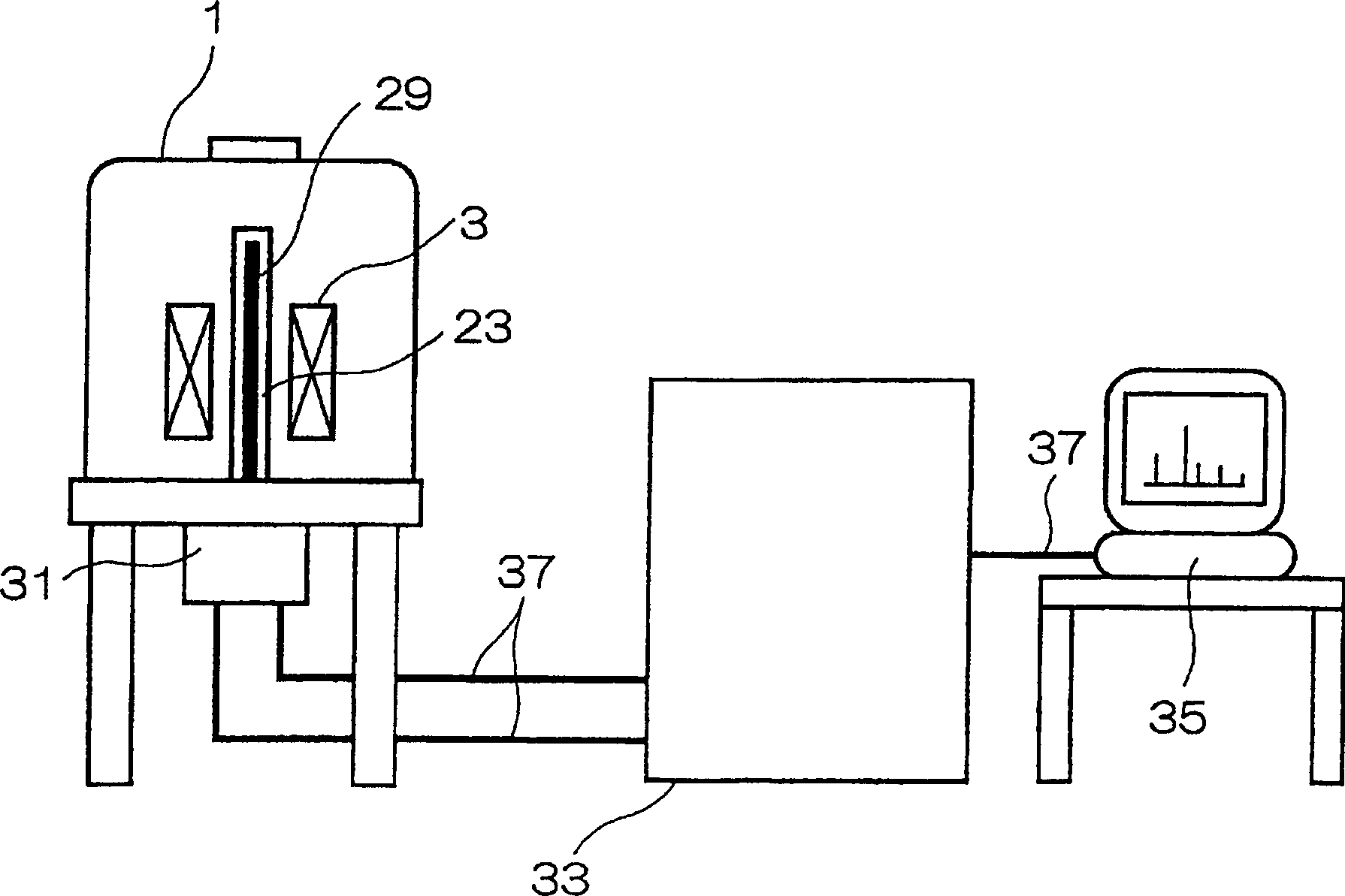

Superconductive magnet device

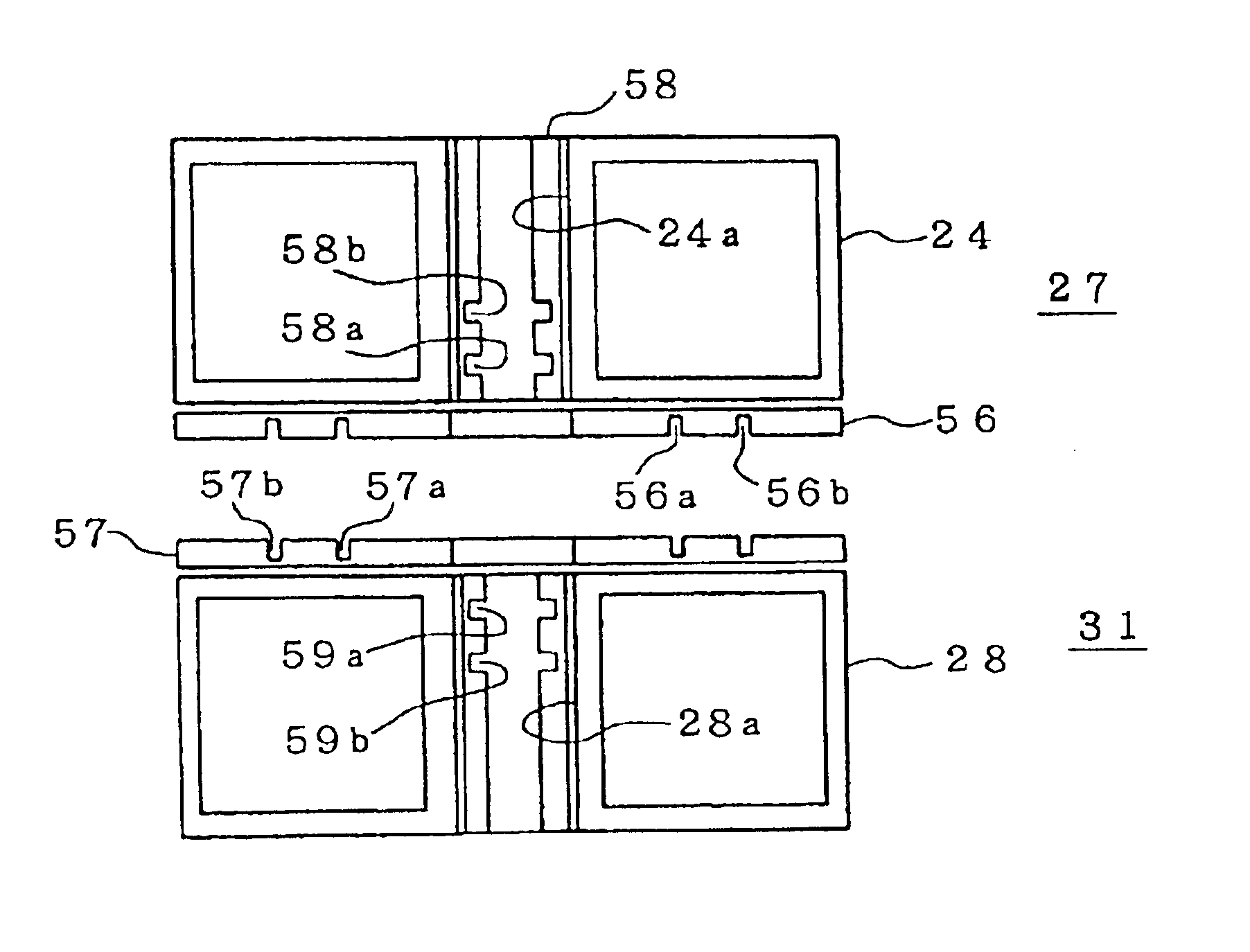

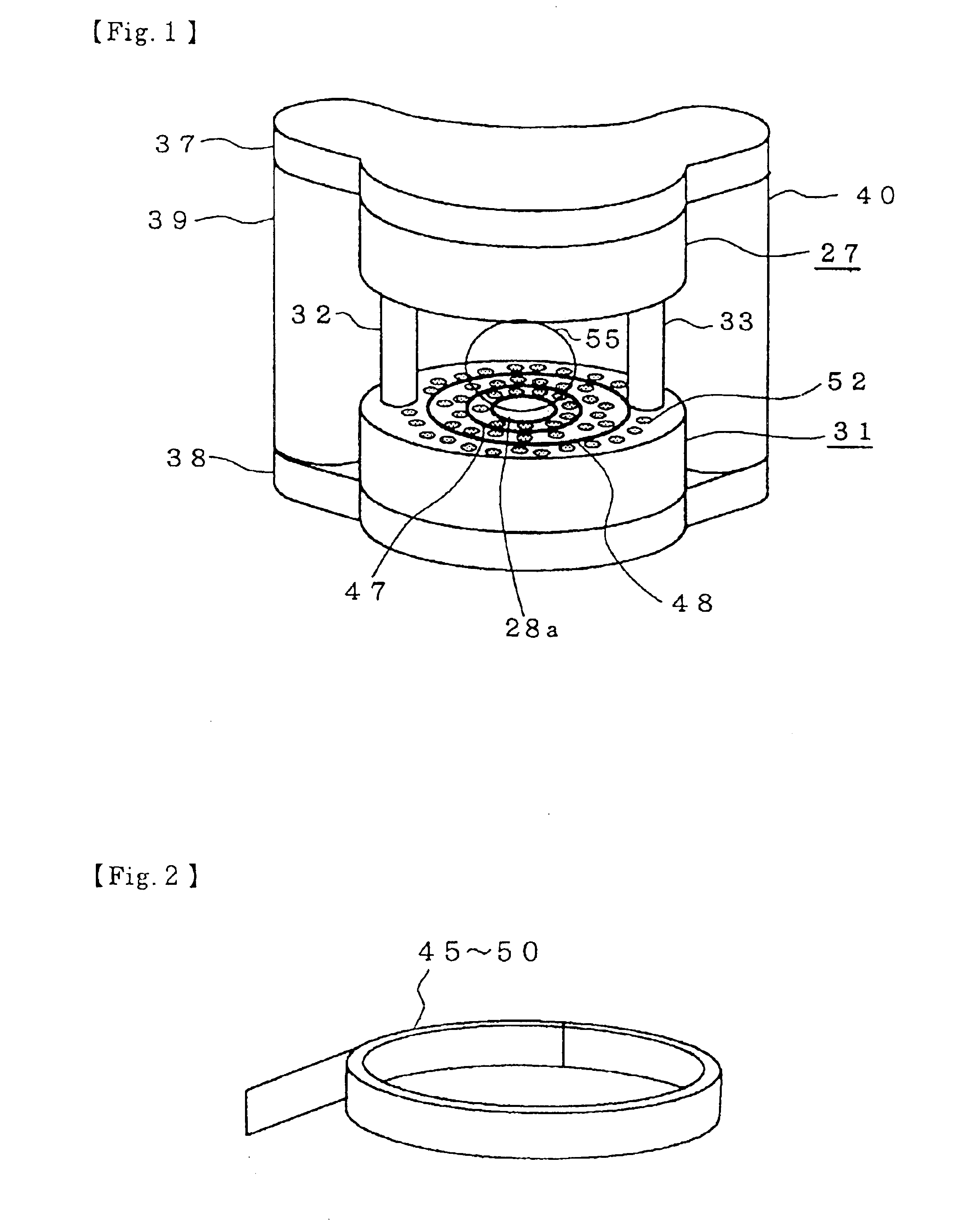

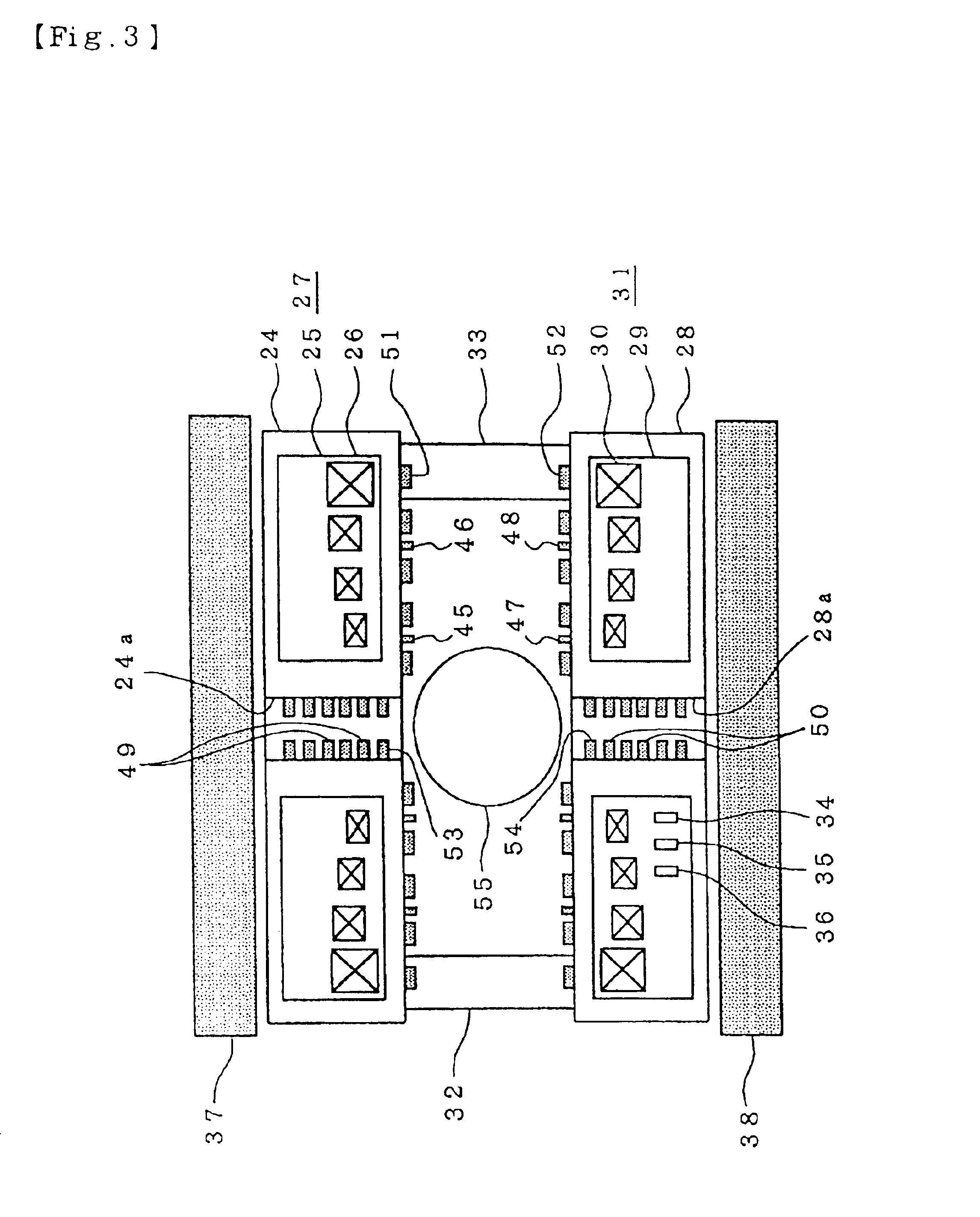

InactiveUS6861933B1Reduce consumptionImprove the uniformity of the magnetic fieldMagnetsElectric/magnetic detectionSuperconducting CoilsHomogeneous magnetic field

A superconductive magnet device comprises a pair of oppositely disposed superconductive bodies in which annular superconductive coils are accommodated, and fine chip-shaped ferromagnetic shims disposed on a surface of the pair of superconductive magnet bodies so as to improve uniformity of magnetic field in a uniform magnetic field in a uniform magnetic field space generated in the proximity of the center between the superconductive magnet bodies, wherein ring-shaped ferromagnetic shims are disposed concentrically with the center of annular superconductive coils on the surface of the superconductive magnet bodies.

Owner:MITSUBISHI ELECTRIC CORP

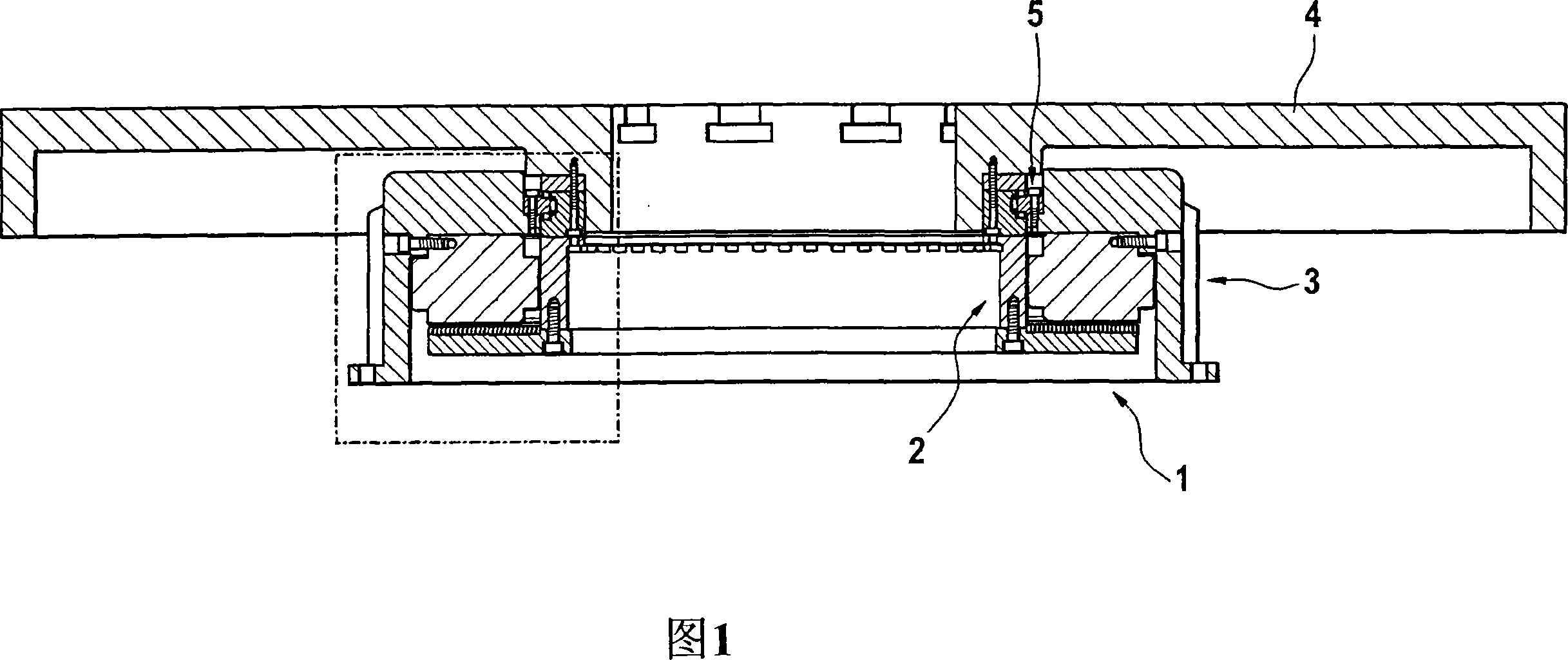

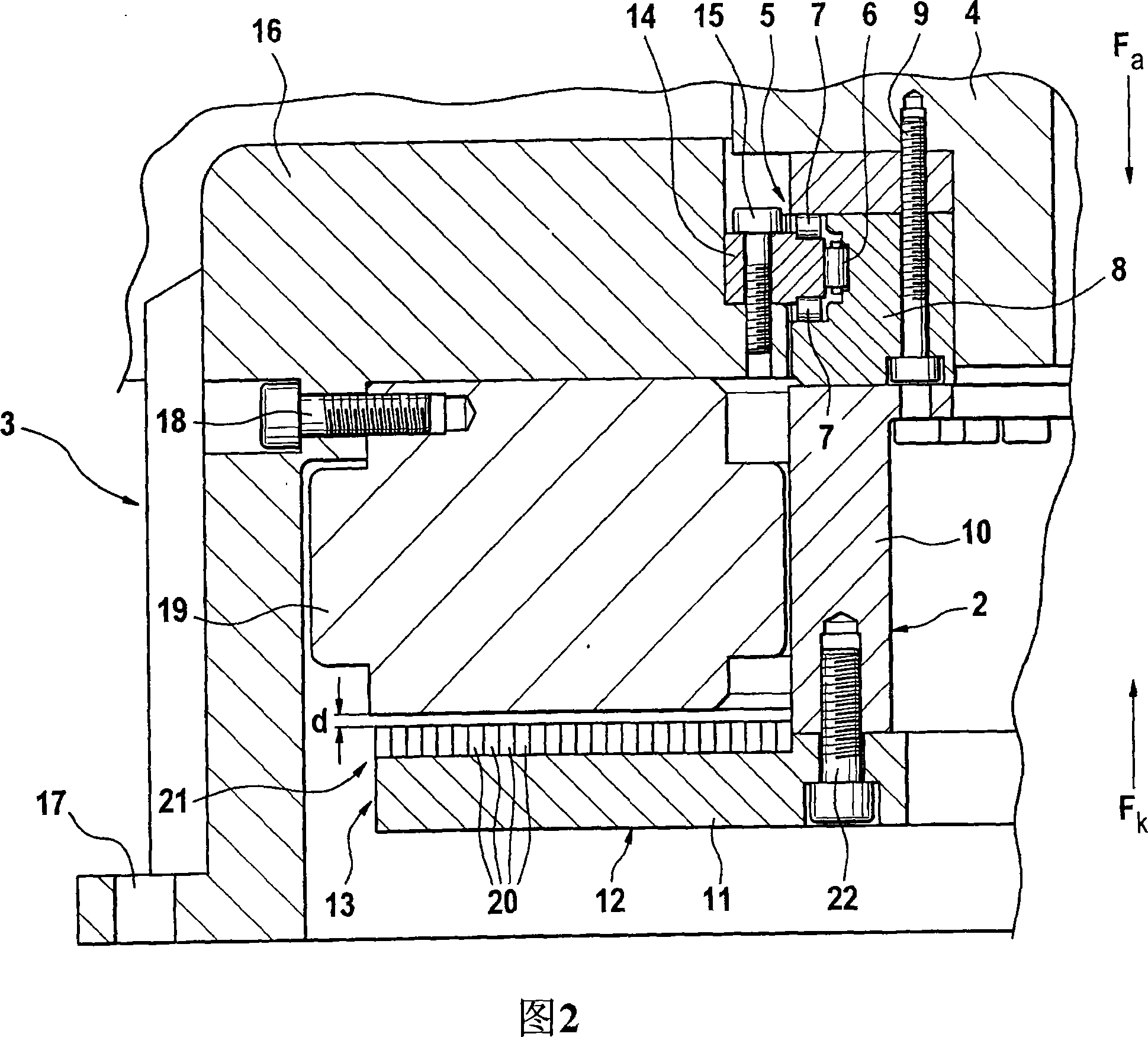

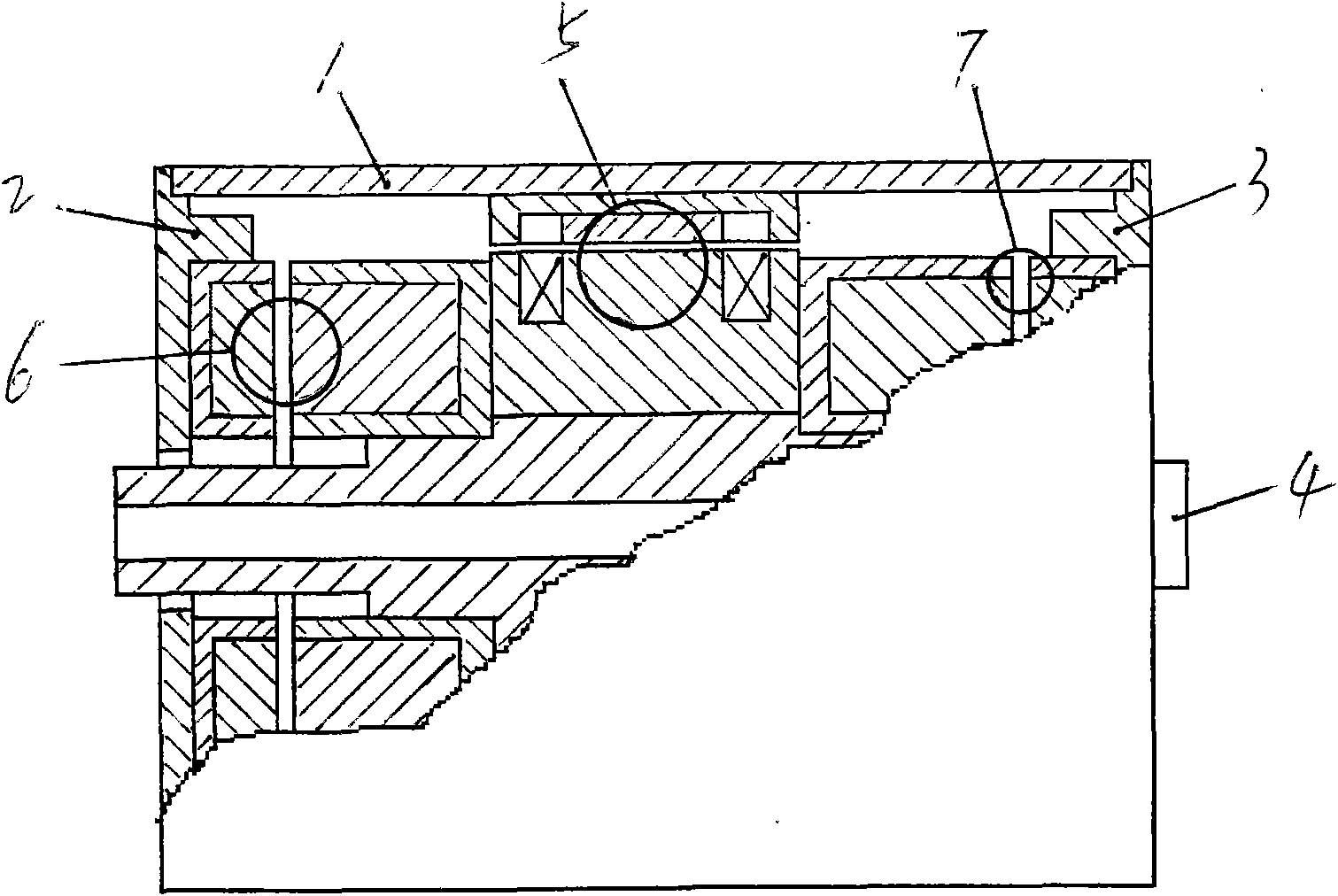

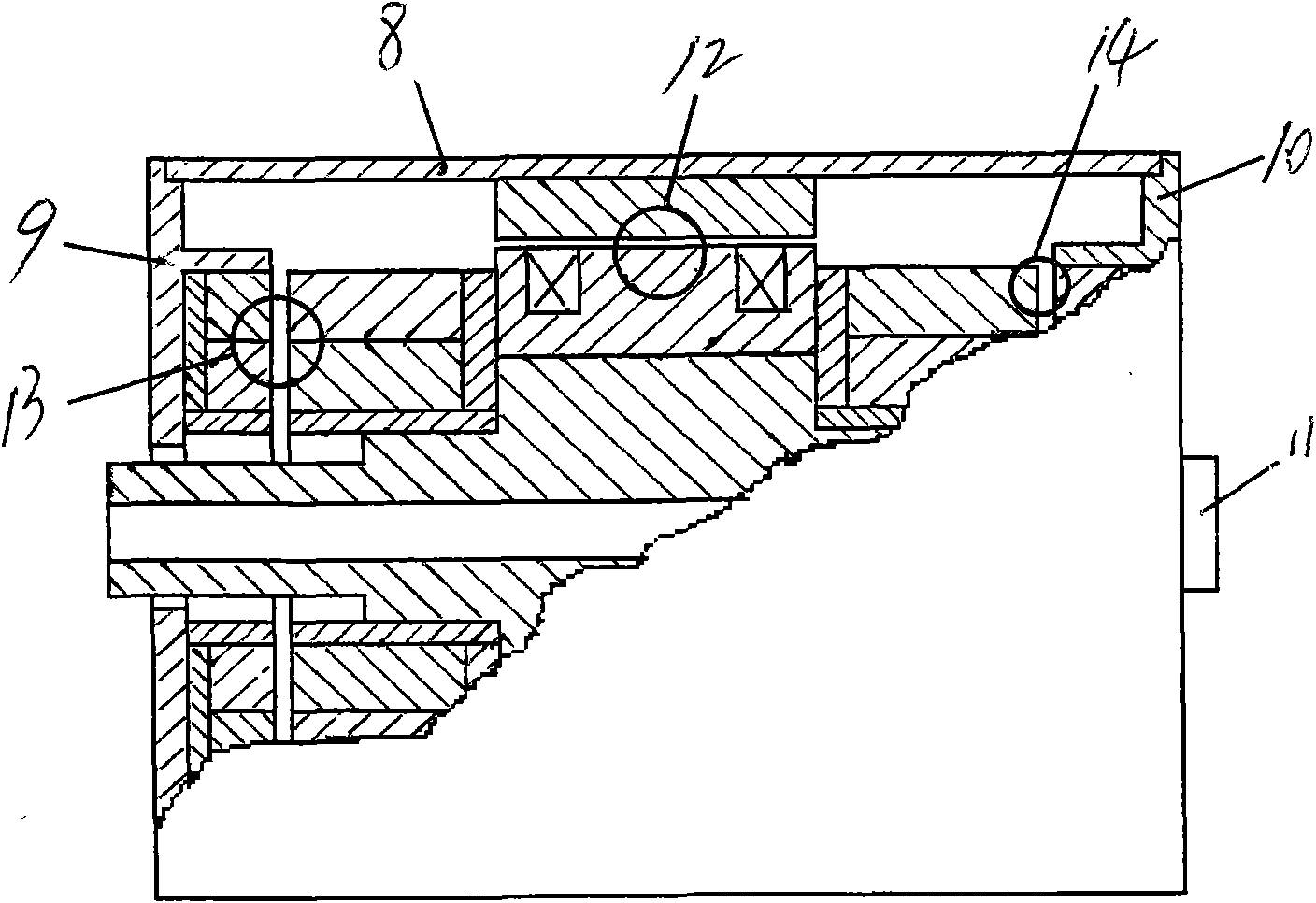

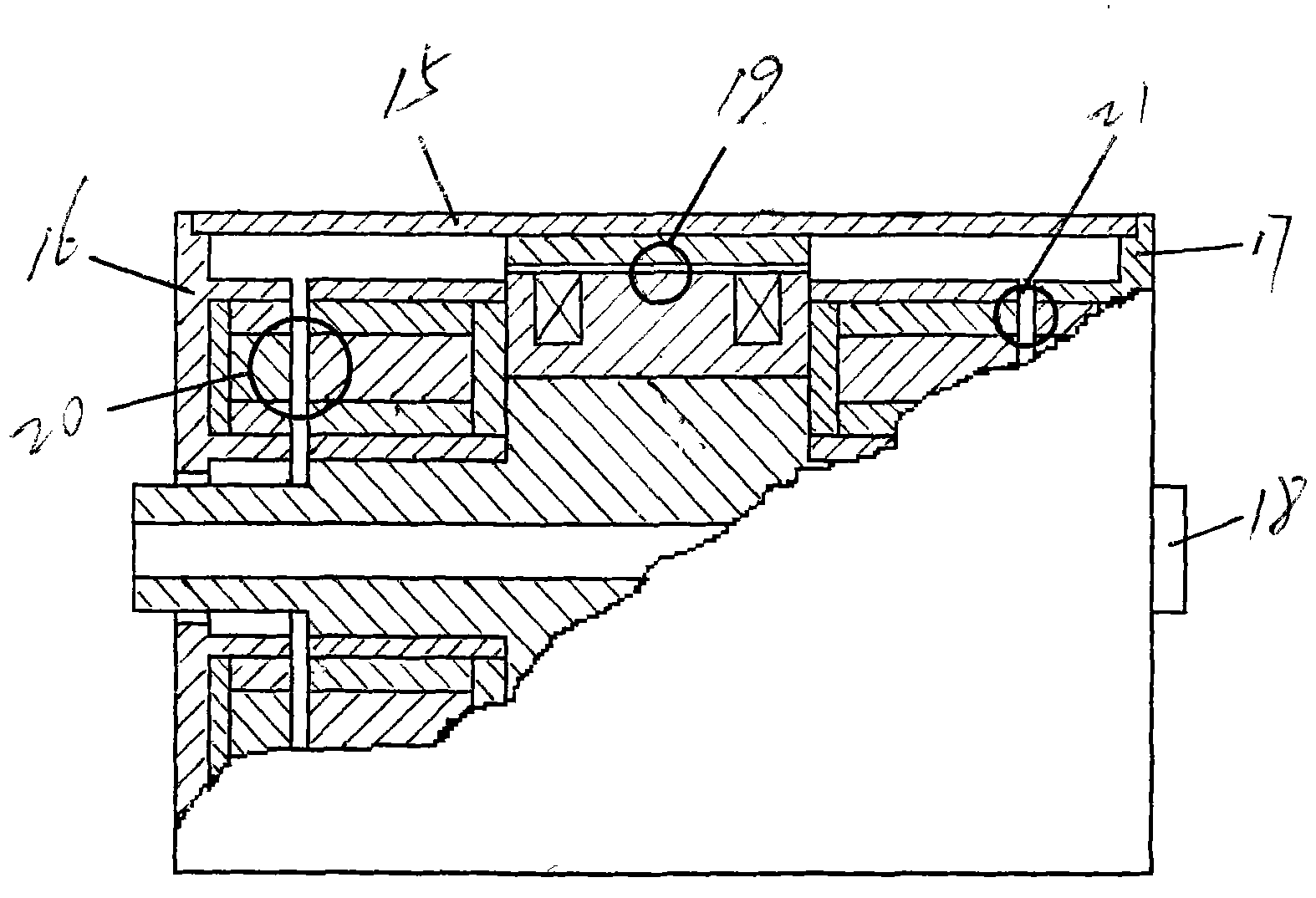

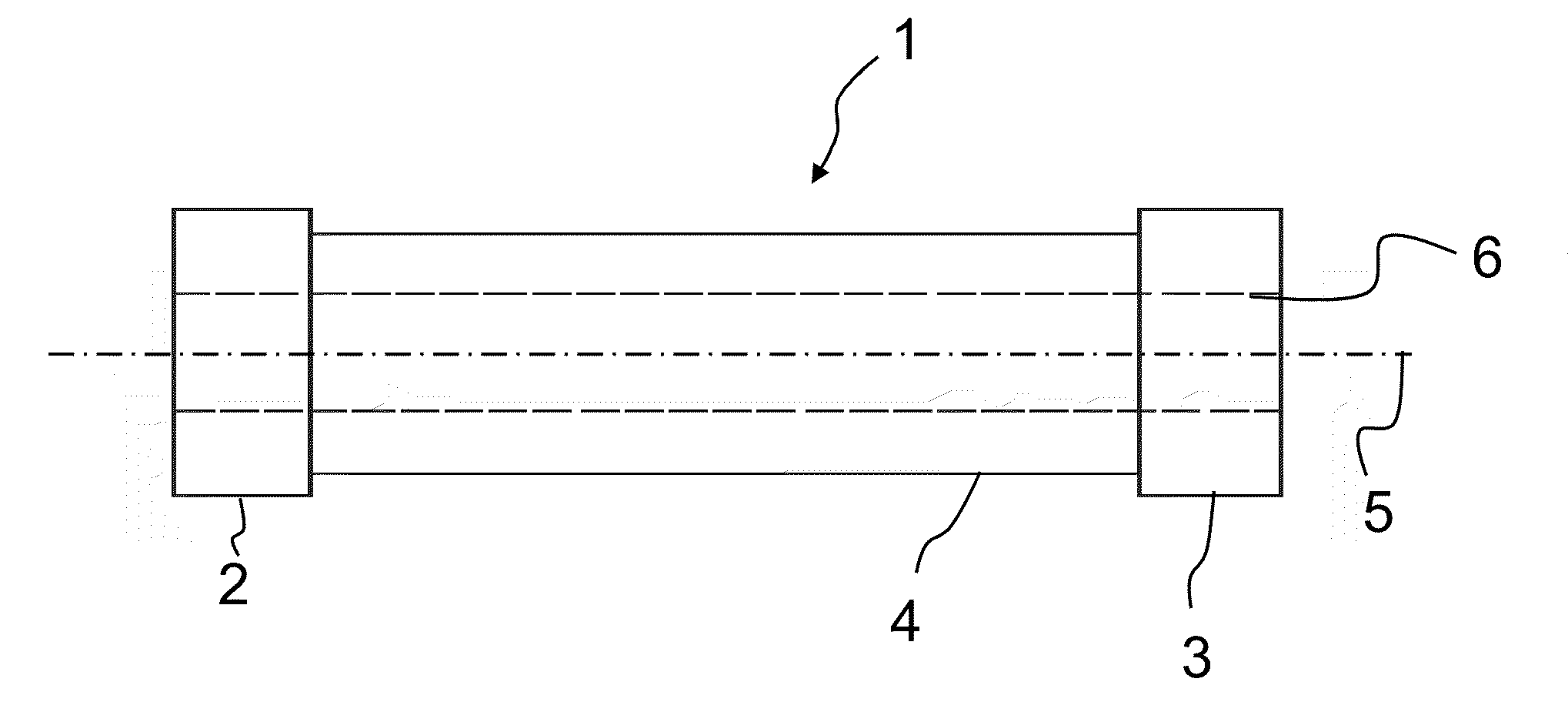

Pivot bearing device, particularly for a rotating circular table of a machine tool

InactiveCN101184579ASolution to short lifeLinear bearingsRolling contact bearingsRolling-element bearingAxial force

A pivot bearing device, particularly for a rotating circular table of a machine tool is provided, and includes a first device part, which is to be connected to an element that is to be rotatably mounted, particularly to the circular table, and a second fixed device part. The device parts are connected via at least one antifriction bearing upon which an axial force acts. A magnet device ( 21 ), which acts between the first and second device parts ( 2, 3 ), is provided for generating a compensating force (Fk) oriented in essentially the opposite direction to the axial force (Fa).

Owner:SCHAEFFLER TECH AG & CO KG

Single degree of freedom magnetic suspension rotor support system as well as magnetic bearing and weight losing method

InactiveCN101769334AHigh working reliabilityStable effective carrying capacityMechanical energy handlingBearingsMagnetic bearingMagnetic poles

The invention discloses a single degree of freedom magnetic suspension rotor support system as well as a magnetic bearing and weight losing method. The support system is composed of complete permanent magnetic radial magnetic suspension bearings, or driving / driven mixed type magnetic suspension bearings, or complete permanent magnetic pre-stress magnetic suspension bearings, as well as a weight losing bias magnet device and a radial / axial air gap limit protection device, wherein, the complete permanent magnetic radial magnetic suspension bearings, or driving / driven mixed type magnetic suspension bearings, or complete permanent magnetic pre-stress magnetic suspension bearings are arranged at the left and right of an electric motor (5) and maintain good proper alignment with the stator / rotor parts of the electric motor. By utilizing the synergic action of the axial stabilizing force of electric motor and the radial stabilizing force of magnetic bearings, the rotating part in the system is constrained in a single degree of freedom magnetic suspension state of only doing tangential dead axle rotation. The complete permanent magnetic radial magnetic suspension bearings (6, 7) are formed by respectively arranging two annular permanent magnets and maintaining the heights of interfaces at two sides to be symmetrical and the interfaces at two sides to attract each other via axial air gap, wherein the two annular permanent magnets are magnetized axially, have equivalent magnetic pole face, different volumes and magnetic attraction forces, and are respectively provided with an external magnetism conductive yoke.

Owner:张玉宝

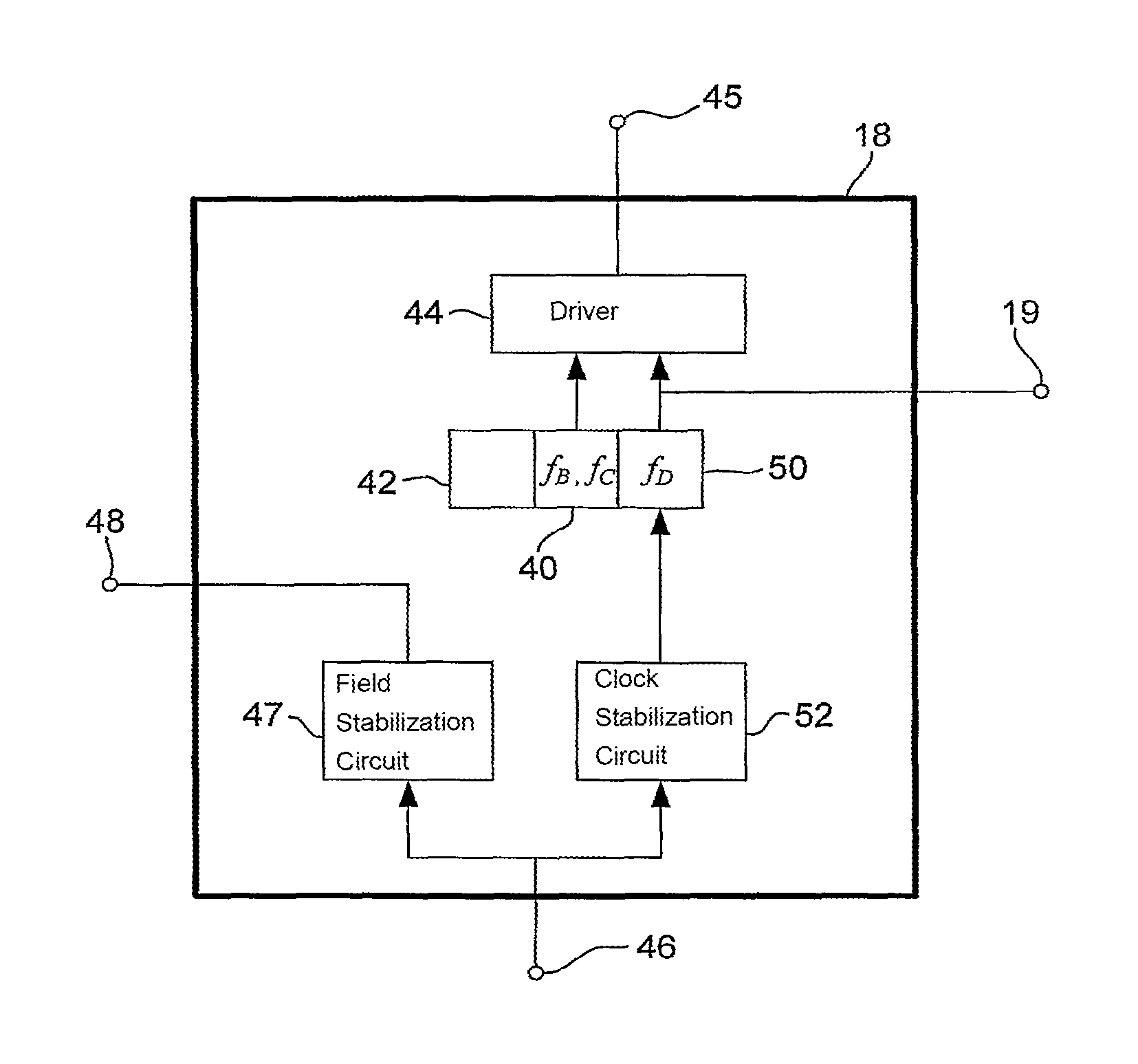

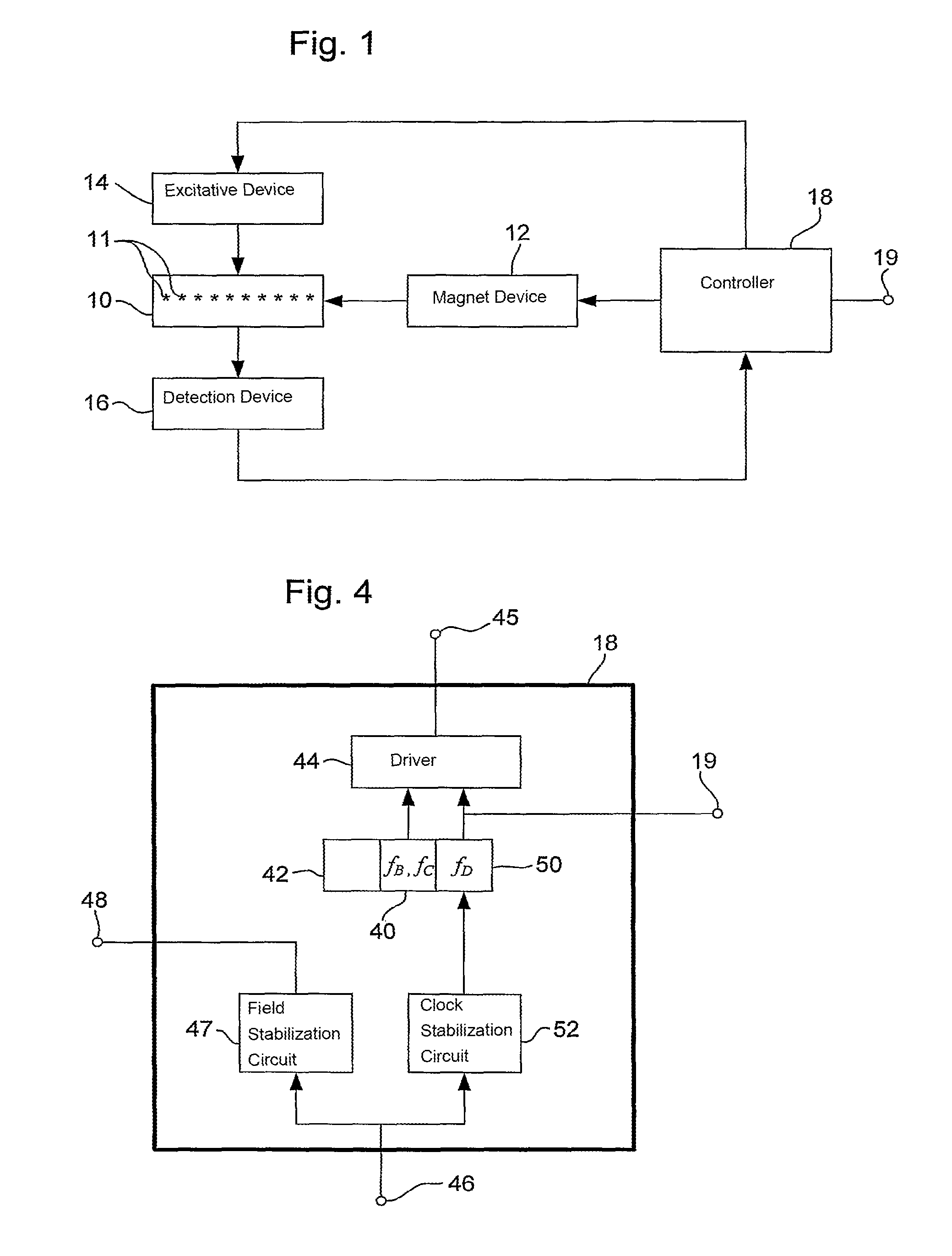

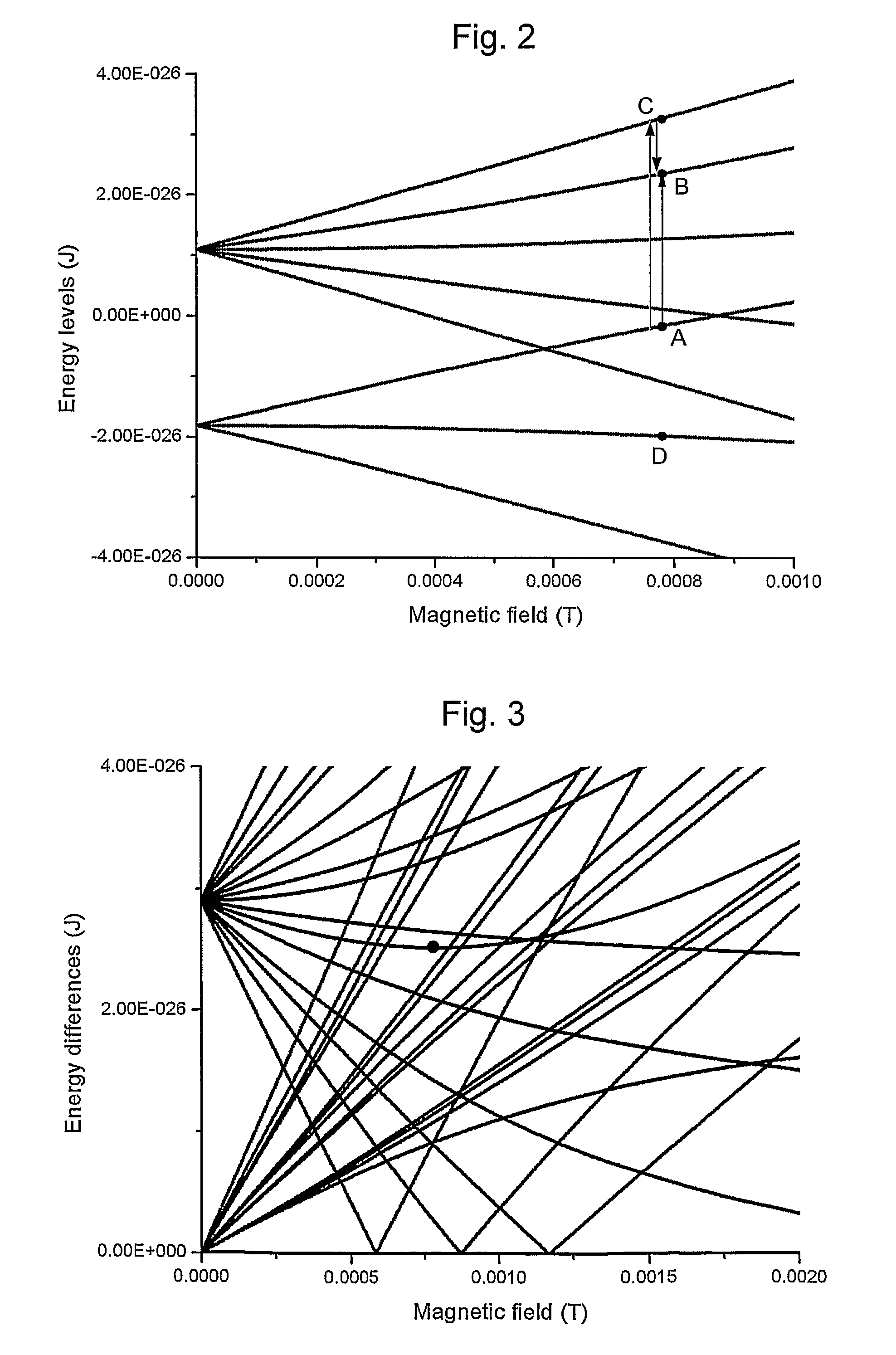

Atomic clock

An atomic clock comprises endohedral fullerene systems which provide the standard frequency oscillations. A magnet device applies a magnetic field to the endohedral fullerenes. The applied magnetic field is adjustable. An excitation device both excites each endohedral fullerene system to cause it to undergo transitions which generate the time-keeping oscillations, and also probes the systems such that the oscillations can be measured and the device controlled. A detection device senses the response of the systems induced by the excitation device. The output of the detection device is fed to a controller. The controller produces the atomic clock output, which is the clock signal or frequency standard, and also controls the magnet device and the excitation device. The controller controls the magnetic field applied by the magnet device such that the energy difference of the time-keeping transition is insensitive to variations in magnetic field, thereby stabilizing the frequency of the oscillations and avoiding the effects of changes in external magnetic field.

Owner:OXFORD UNIV INNOVATION LTD

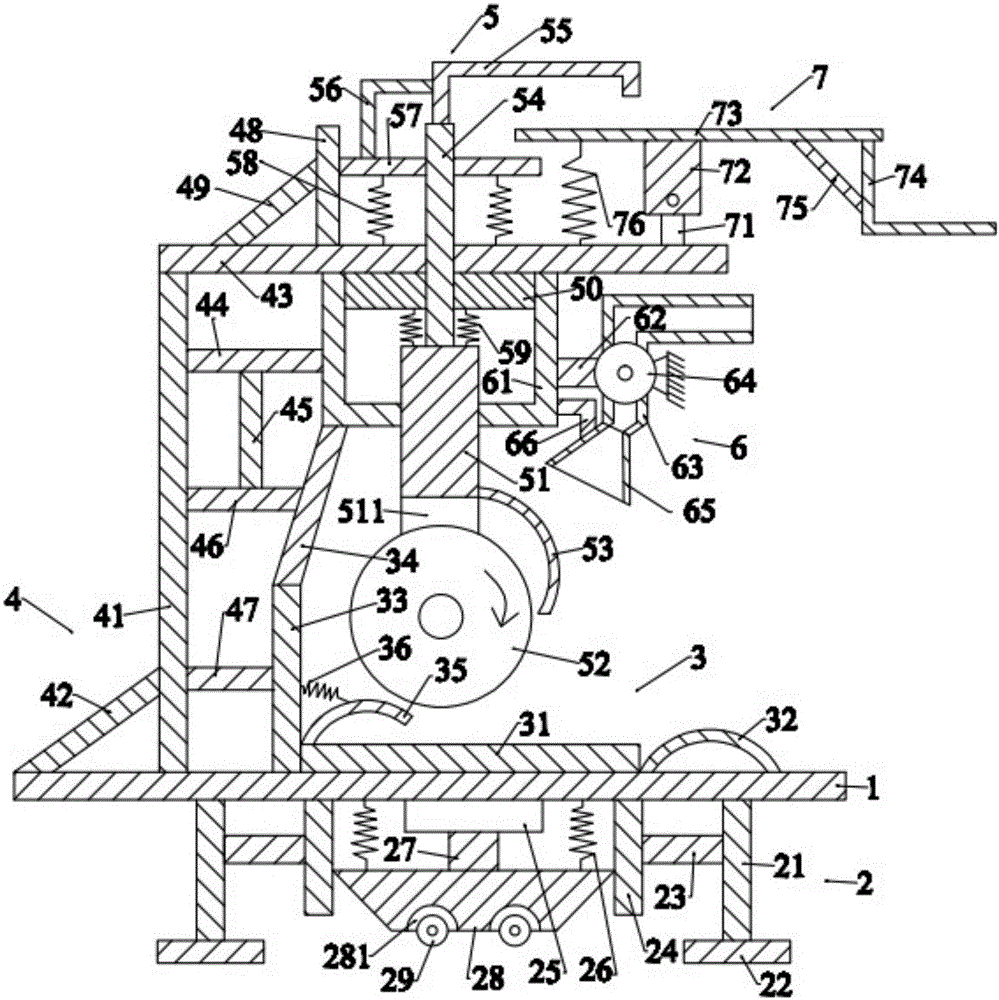

Polishing device for construction steel bar

ActiveCN106217206ASimple structureEasy to useGrinding carriagesGrinding machinesArchitectural engineeringRebar

The invention discloses a polishing device for a construction steel bar, comprising a bottom plate, a roller device, a magnet device, a support device, a polishing structure, a blowing device and a regulating device; the roller device comprises a first supporting rod, a first cushion block, a first cross rod, a first locating rod, an air cylinder, a first spring, a pushing rod, a supporting block and a first roller; the magnet device comprises a first magnet, a bent rod, a second magnet, a third magnet, a clamping rod and a second spring; the support device comprises a second supporting rod, a first inclined rod, a second cross rod, a third cross rod, a first vertical rod, a fourth cross rod, a fifth cross rod, a second vertical rod and a second inclined rod; the polishing structure comprises a moving rod, a polishing wheel, a baffle, a third vertical rod, a locating rack, a first support, a sixth cross rod, a third spring, a locating block and a fourth spring; and the blowing device comprises a fixed frame, a first connecting rod, a draught fan, a blow pipe and a blow hopper. The polishing device can be used for rapidly polishing the steel bar and is high in polishing efficiency.

Owner:广西华业建筑工程有限公司

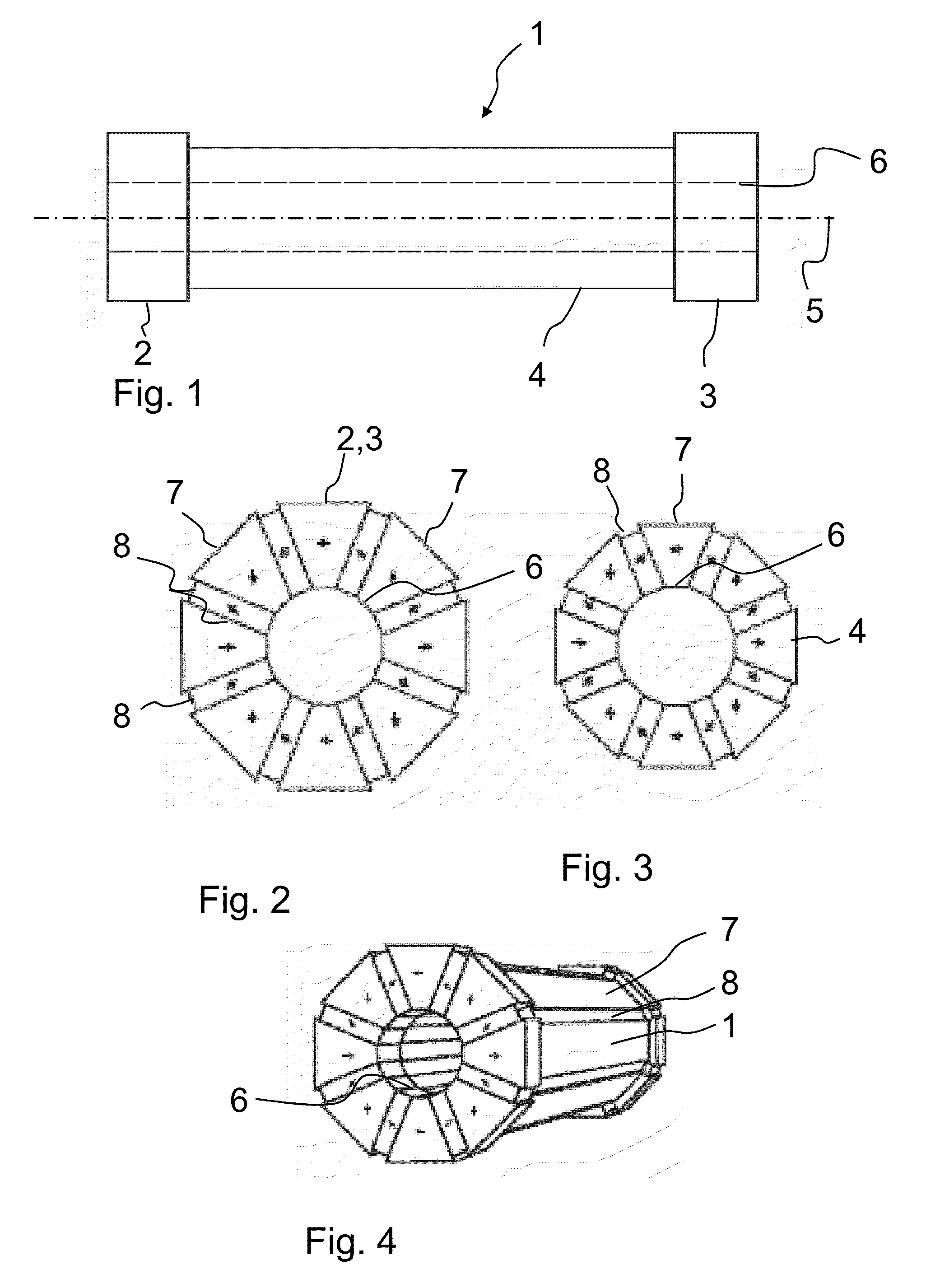

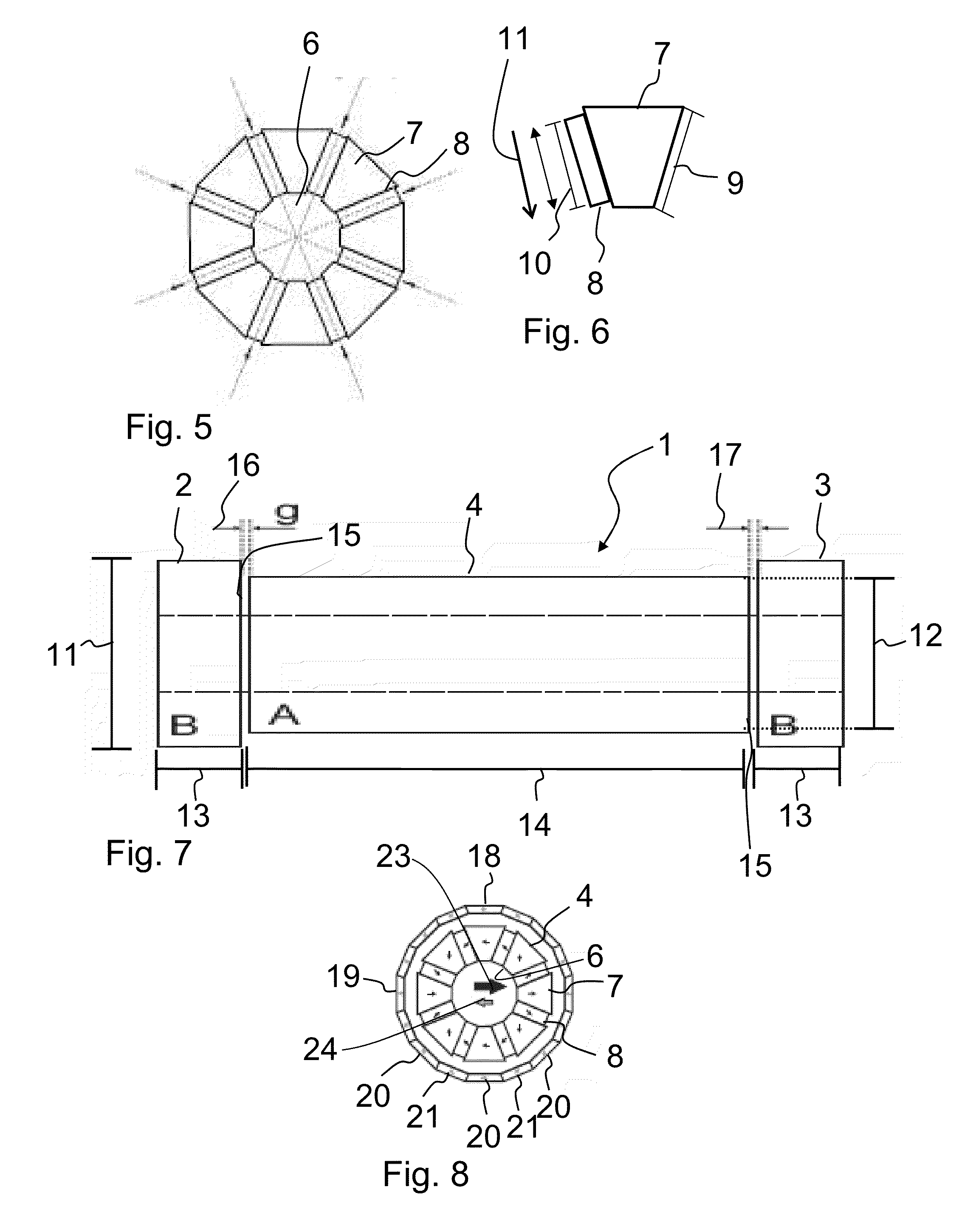

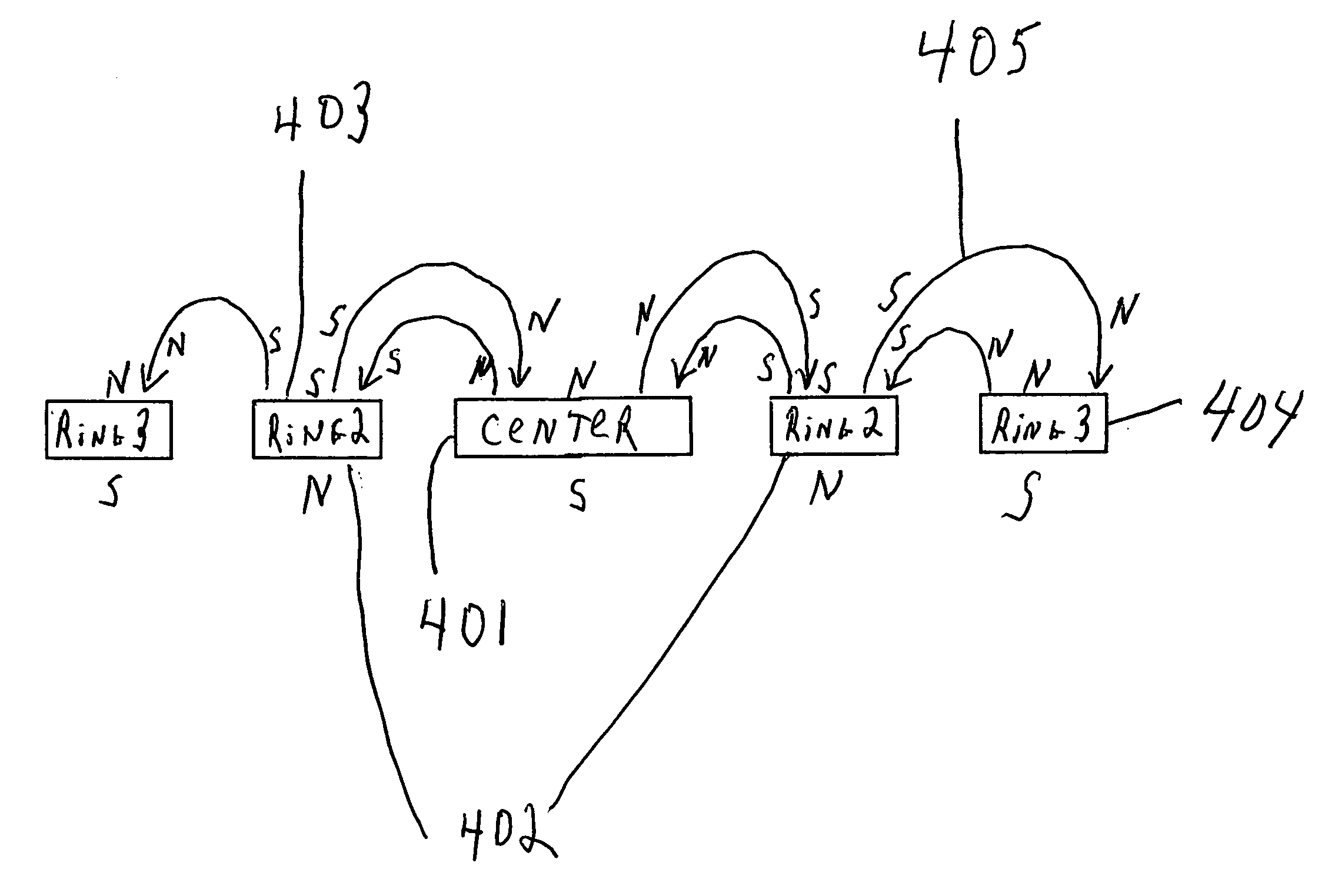

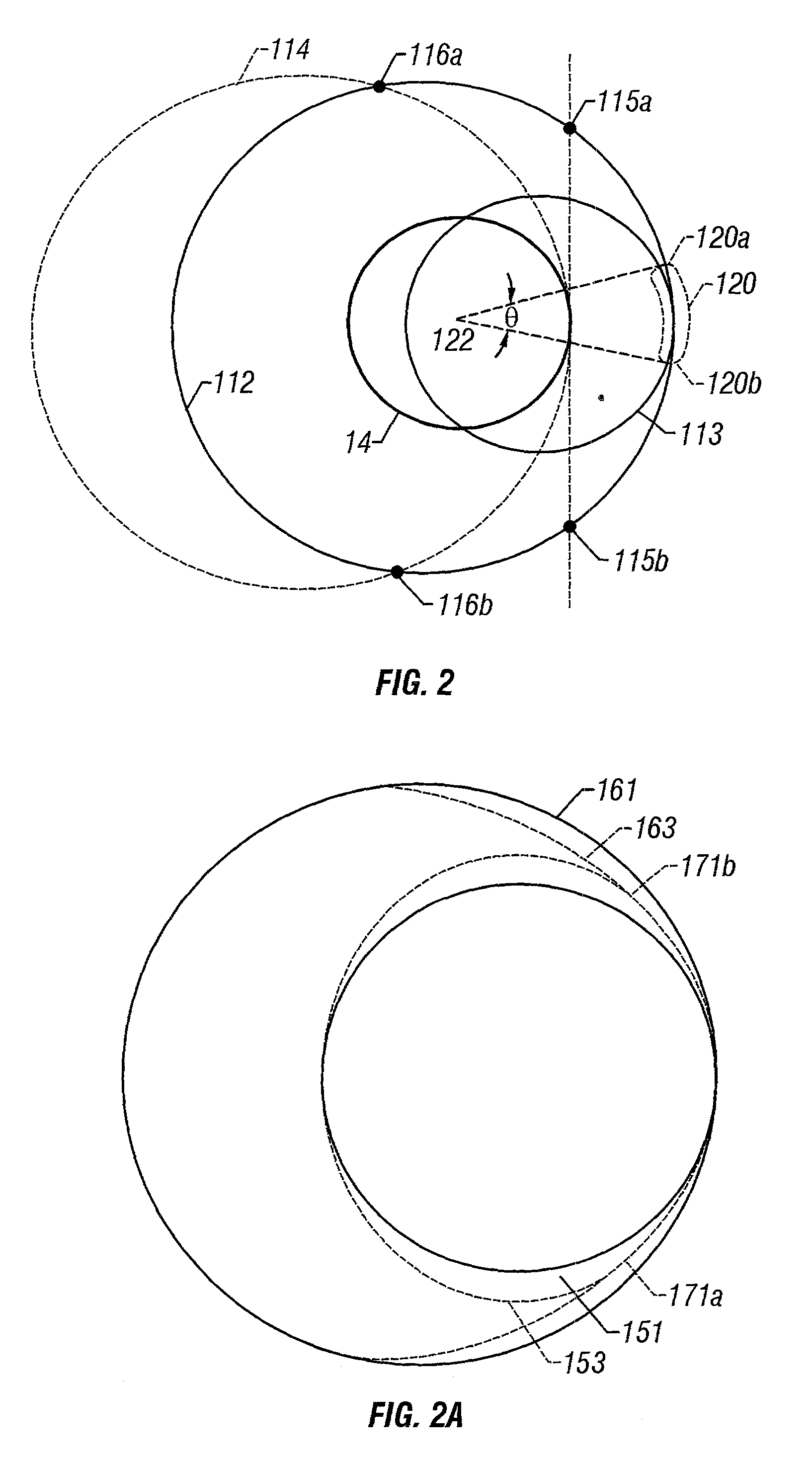

Magnet arrangement and method for providing a magnetic field in a sensitive volume

ActiveUS20100013473A1Easy to transportImprove the uniformity of the magnetic fieldMagnetsMagnetic property measurementsMagnet devicePhysics

A magnet arrangement includes (a) a first and a second head ring magnet each having a substantially circular geometry with respect to a centre axis and (b) a central ring magnet having a substantially circular geometry with respect to a centre axis. The central ring magnet is disposed between the first and second head ring magnet in direction of the centre axis. At least one of the magnets includes a first number of first magnets having at least one trapezoidal cross section and a second number of second magnets having at least one rectangular cross section. The second magnets are disposed in between the first magnets in circumferential direction. With this geometrical arrangement, magnets having a trapezoidal cross section include a guidance for a magnet having a rectangular cross section allowing the movements in radial direction of these last magnets.

Owner:RWTH AACHEN UNIVERSITY

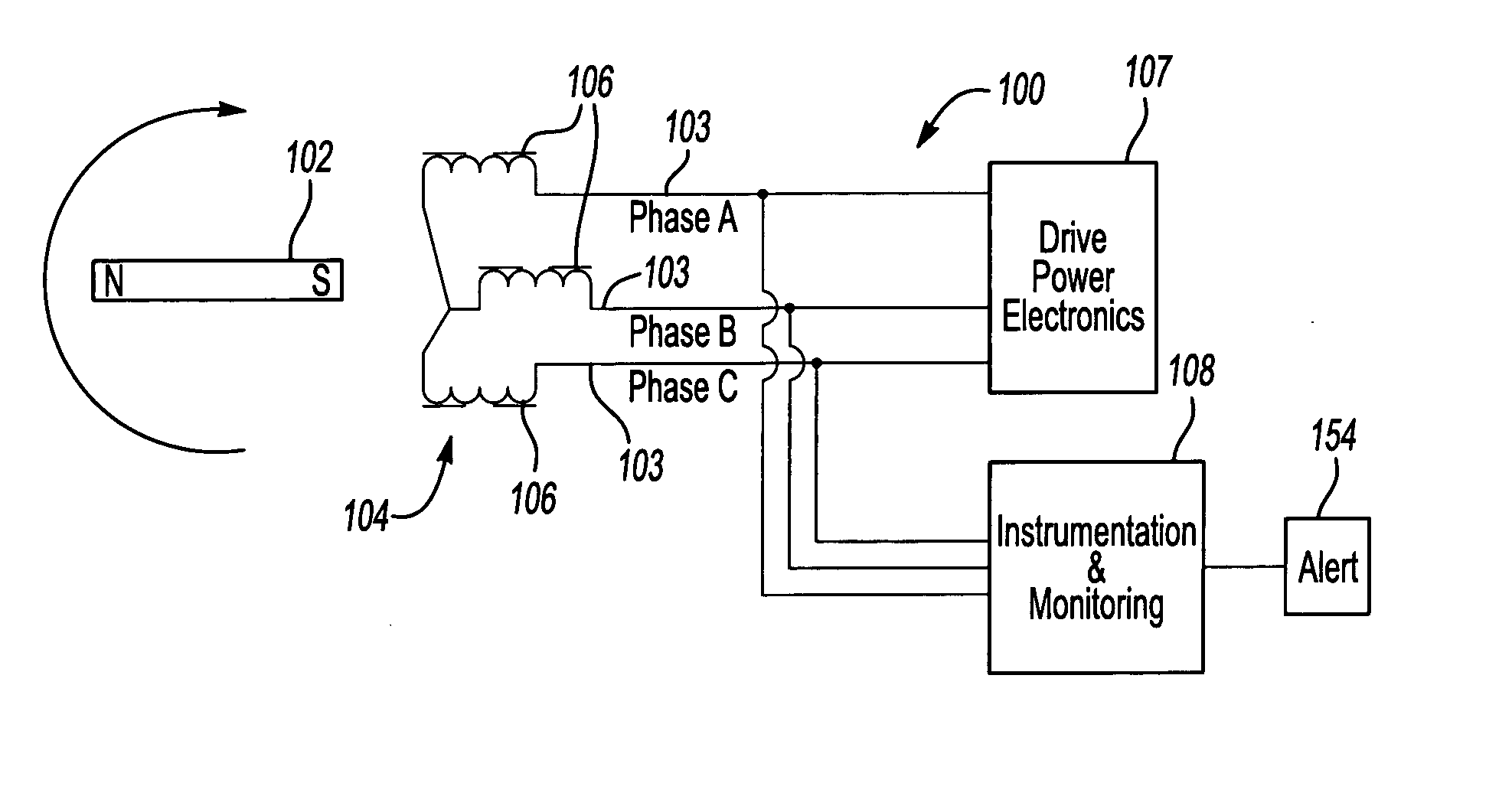

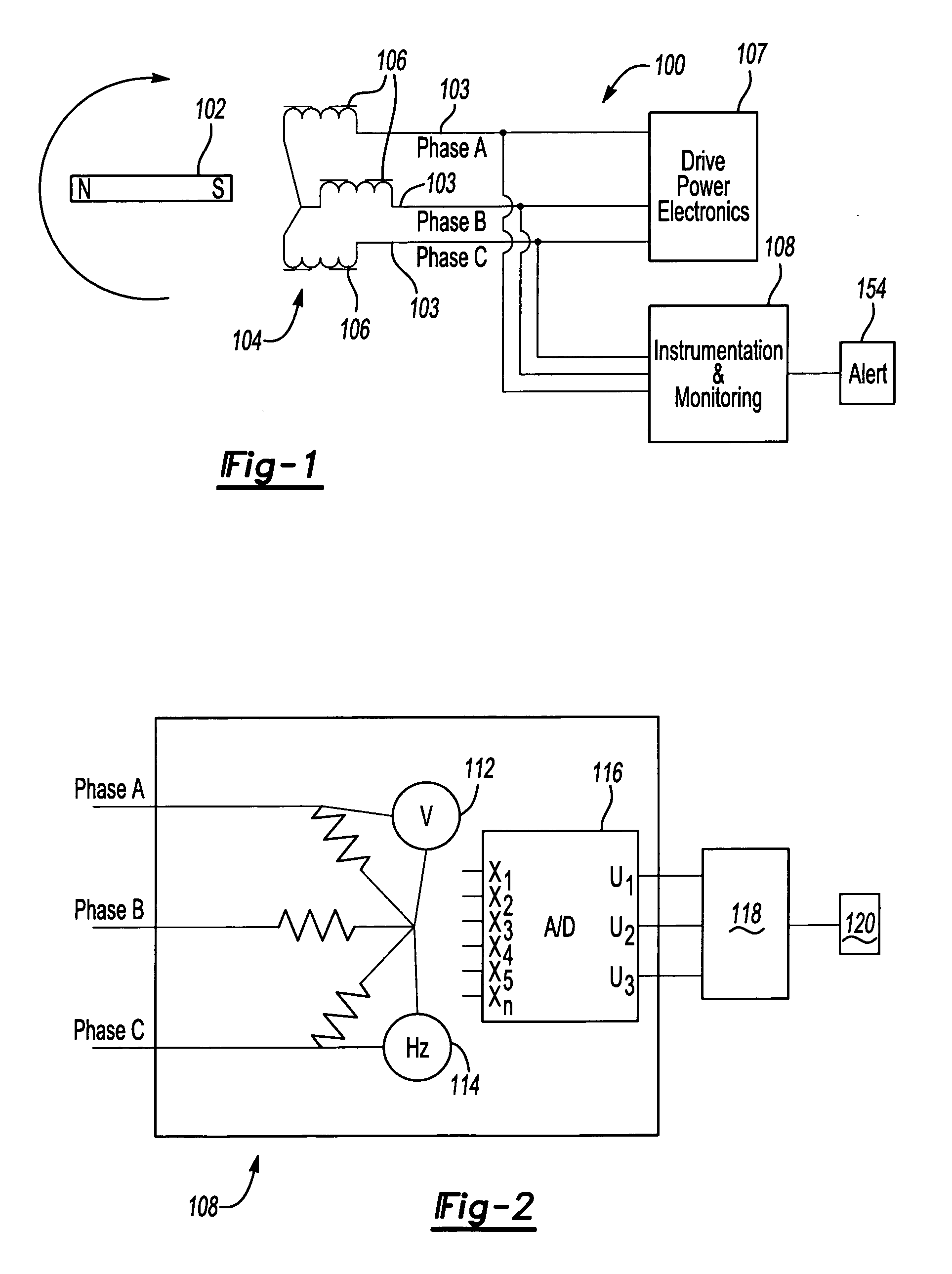

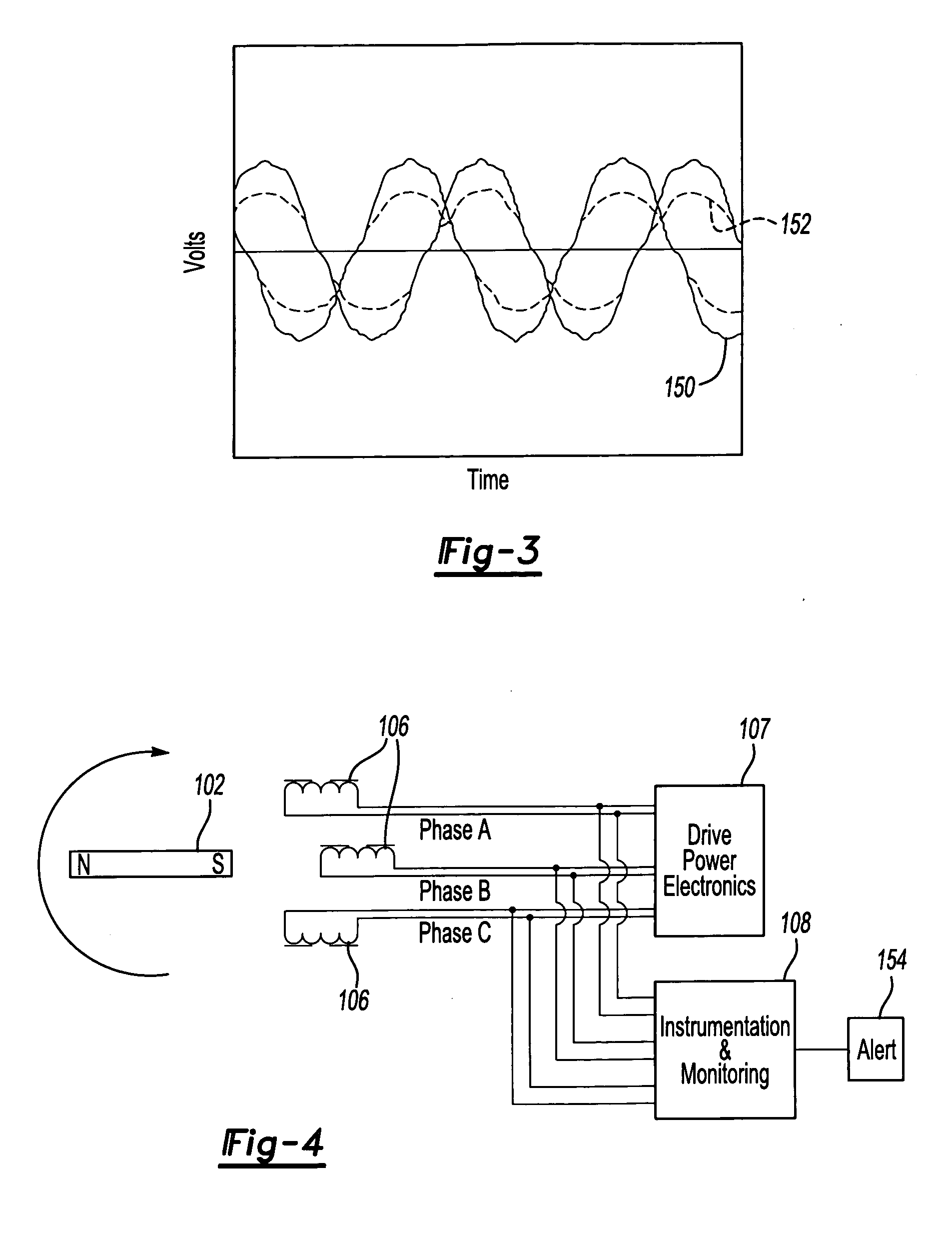

Health monitoring method and system for a permanent magnet device

ActiveUS20050237212A1DC motor speed/torque controlElectric testing/monitoringElectromotive forceCounter-electromotive force

A method and system for monitoring the performance of a permanent magnet device, such as a motor or generator, and providing early detection of motor performance deterioration. The back electromotive force (EMF) of the motor is measured at selected conditions when the motor is in a normal healthy condition to obtain a reference signature response. A measured signature is then obtained periodically during the life of the motor at the same conditions as the reference signature to check the current back EMF characteristic of the motor. If the measured signature deviates from the reference signature by a predetermined threshold, it indicates that the motor performance has degraded to a condition requiring attention.

Owner:HAMILTON SUNDSTRAND CORP

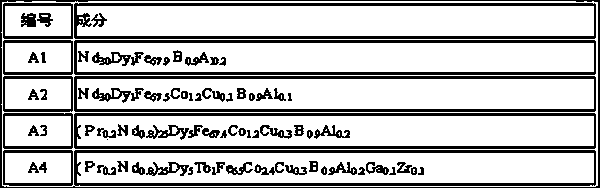

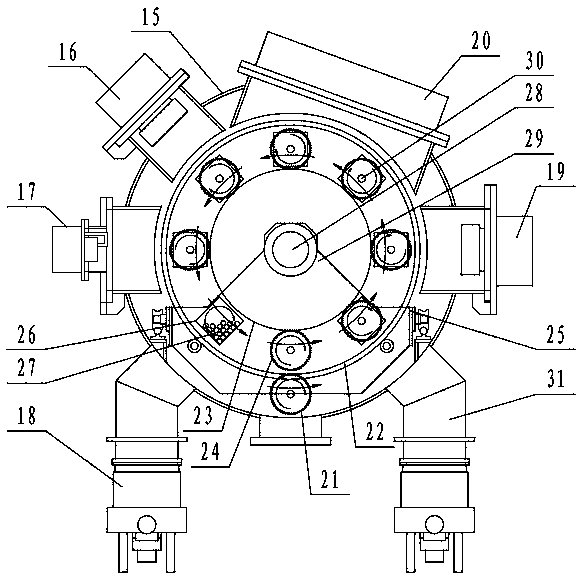

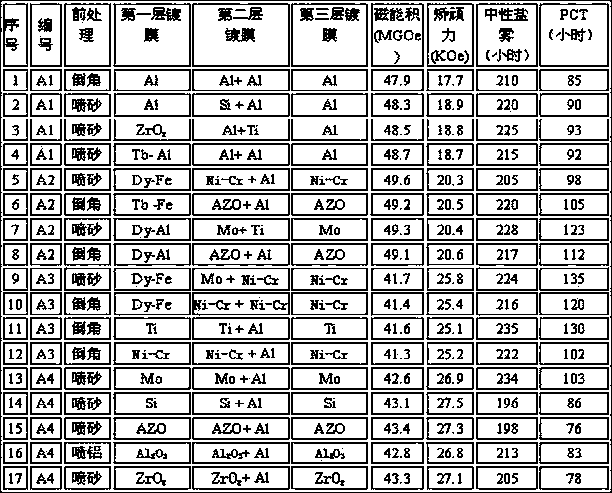

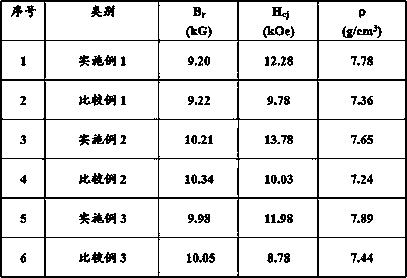

Hybrid film coating method of neodymium iron boron rare earth permanent magnet device

ActiveCN103854819AIncrease useImprove corrosion resistanceVacuum evaporation coatingSputtering coatingMolten stateRare earth

The invention discloses a hybrid film coating method of a neodymium iron boron rare earth permanent magnet device. According to the method, firstly, alloy smelting is carried out, alloy in a molten state is cast onto a rotary copper roller with a water cooling effect for being cooled to be manufactured into an alloy sheet, then, the alloy sheet is subjected to hydrogen decrepitation, material mixing and airflow powder grinding, next, materials are mixed by a material mixing machine and are then sent to a nitrogen gas protection magnetic field orientation pressing machine to be formed, the mixed materials are subjected to isostatic pressing after being encapsulated in a protection box, then, the sintering and the aging are carried out, a neodymium iron boron rare earth permanent magnet blank is prepared, the blank is subjected to machining, a neodymium iron boron rare earth permanent magnet is prepared, next, the neodymium iron boron rare earth permanent magnet is subjected to film coating, the neodymium iron boron rare earth permanent magnet device is formed, the film coating comprises three layers, the first layer and the second layer are magnetron sputtering coatings, and the second layer is a magnetron sputtering and multi-arc ion plating hybrid coating. The hybrid film coating is adopted as a surface treatment work procedure of the rare earth permanent magnet device, the anti-corrosion capability of the rare earth permanent magnet device is improved, and meanwhile, the magnetic performance of the rare earth permanent magnet device is also improved.

Owner:SHENYANG GENERAL MAGNETIC

Superconducting magnet apparatus

InactiveCN1684207AAvoid breakingTransformers/inductances coolingMagnetic measurementsSuperconducting CoilsEngineering

Owner:HITACHI LTD

Physical vapor deposition equipment used for thick film deposition

ActiveCN110670042AHeight adjustablePrevent platingVacuum evaporation coatingSputtering coatingTemperature controlWafer

The invention provides physical vapor deposition equipment used for thick film deposition. The physical vapor deposition equipment comprises a permanent magnet device, a target material, a wafer baseand a cavity wall, and further comprises a cavity wall baffle, a wafer shield ring and a shield ring supporting and adjusting device. One end of the cavity wall baffle is fixed between the target material and the cavity wall, the other end of the cavity wall baffle is a free end, and a first cooling pipe cavity used for containing a cooling pipe is arranged in the cavity wall baffle. The wafer shield ring comprises a vertical portion and a horizontal portion, the horizontal portion is annularly arranged on the upper edge of the wafer, the vertical portion is arranged on the periphery of the lower portion of the horizontal portion, a second cooling pipe cavity used for containing a cooling pipe is arranged in the vertical portion, and a groove is formed in the end, close to the vertical portion, of the horizontal portion. The shield ring supporting and adjusting device comprises an ejector pin, an ejector pin ring, a connecting rod and a transmission mechanism. One end of the ejector pin is inserted into the groove, the other end of the ejector pin is fixedly connected with the ejector pin ring, the ejector pin ring is connected with the transmission mechanism arranged on the outerportion through the connecting rod, and the ejector pin ring surrounds the periphery of the wafer base. According to the equipment, cooling and temperature control to the wafer, a deposition cavity and a process set can be effectively achieved in the deposition process.

Owner:BETONE TECH SHANGHAI

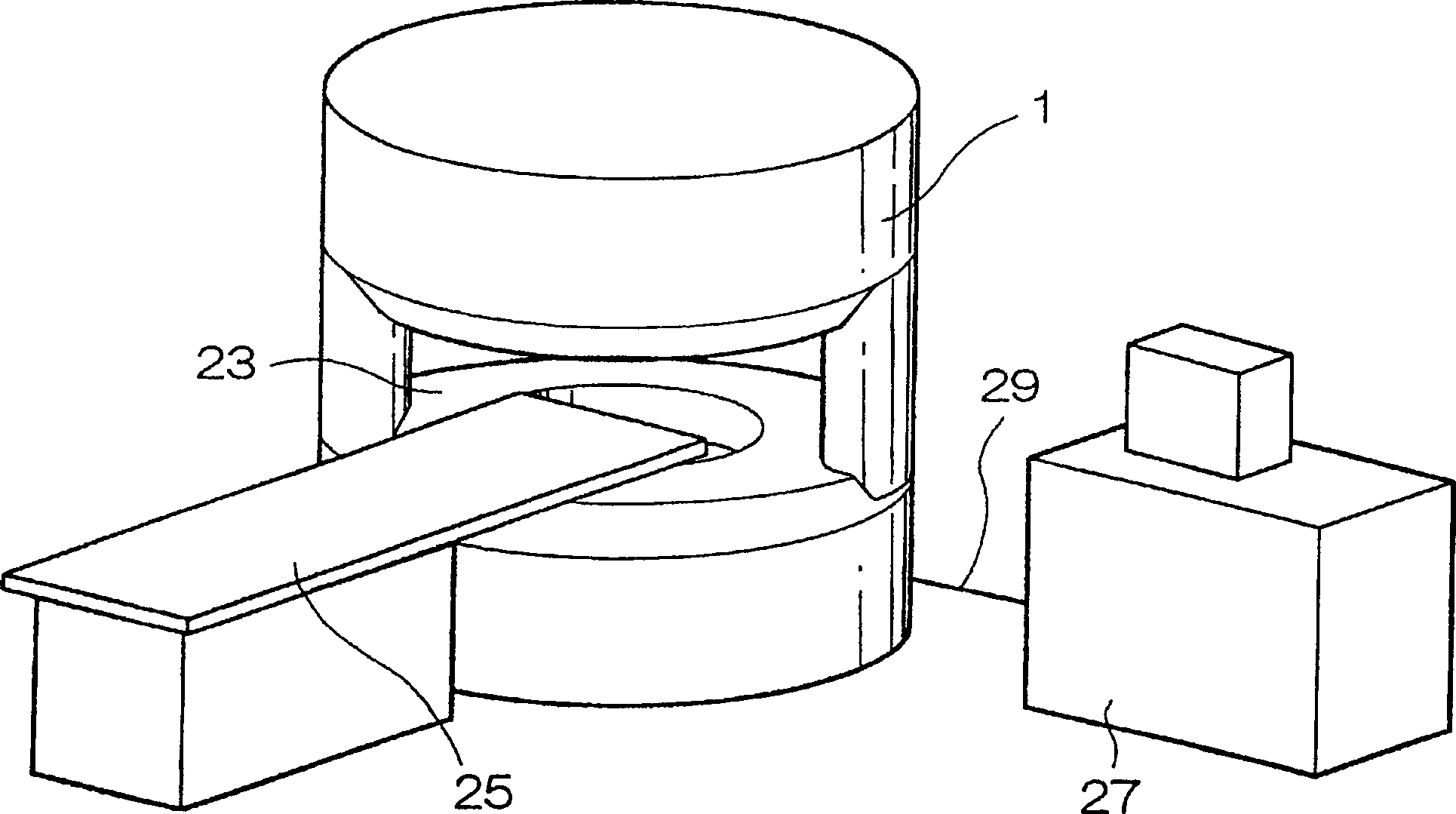

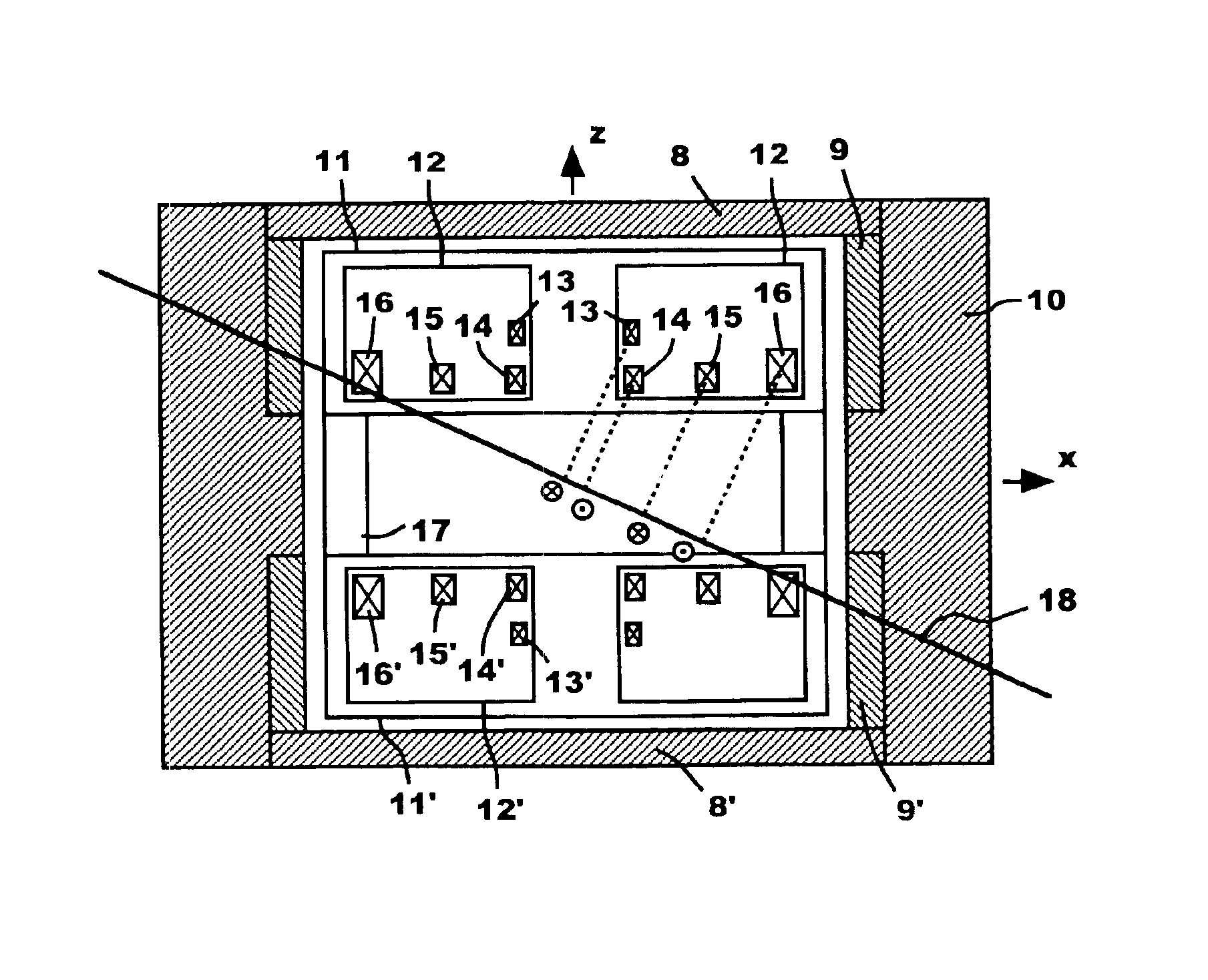

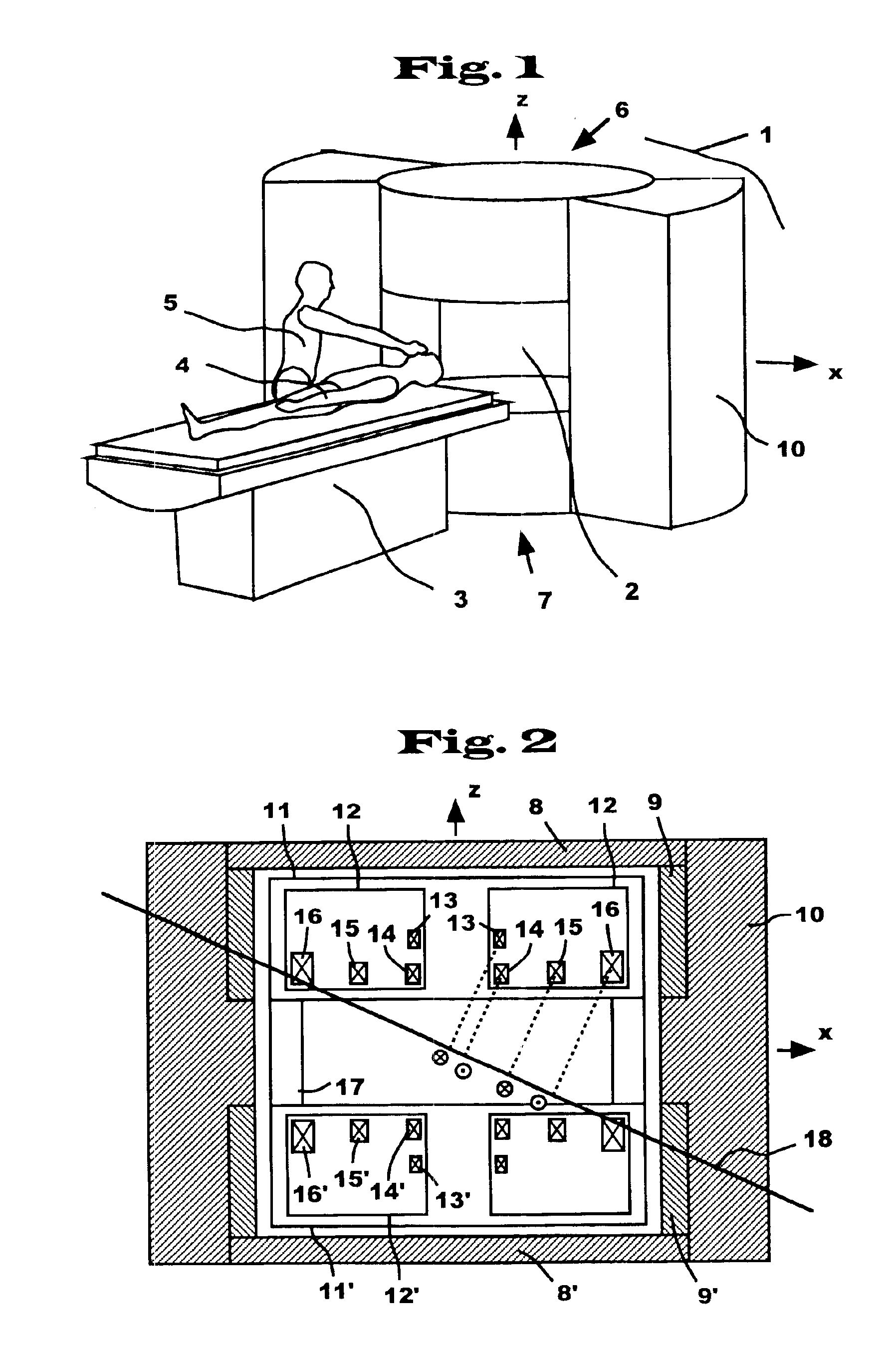

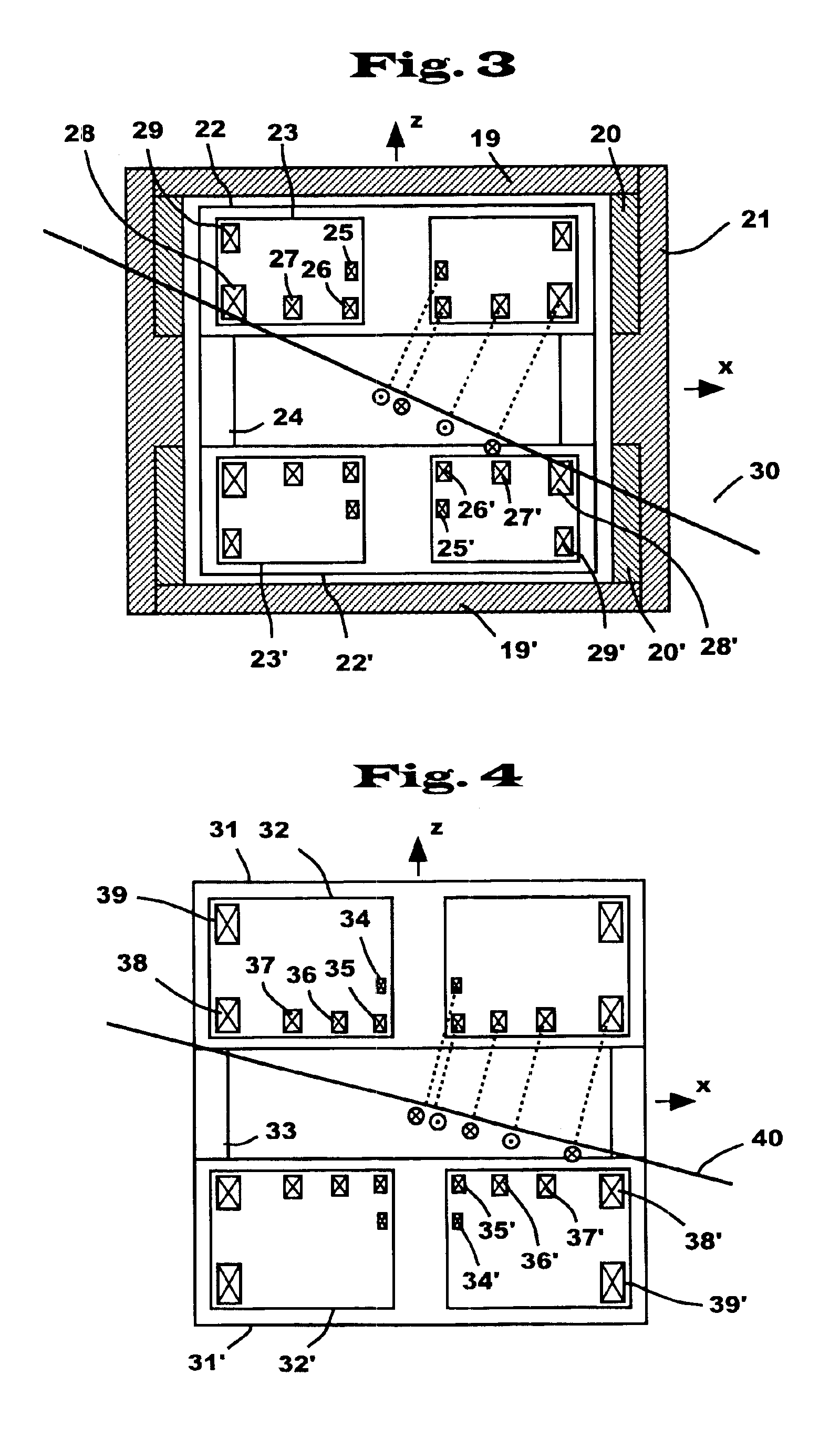

Magnet apparatus and mri apparatus

InactiveUS6853281B1Increase production costSignificant valueMagnetsMagnetic materialsPhysicsMagnet device

A magnet device includes two sets of static magnetic field generation sources spaced from each other in the vertical direction such that the uniform magnetic field region (patient space) is between then. Each set has concentric current carrying coils to generate a uniform magnetic field in a first direction (the vertical direction). Several such coils are used in each set, disposed such that when a first axis which is parallel to the first (vertical) direction and passes substantially through the centers of the current carrying coils crosses, at a first point, a second axis which is orthogonal to the first axis and is at substantially equal distance from the respective static magnetic field generation sources, the current carrying coils are disposed in such a manner that when geometrical centers of cross sections of the current carrying coils are projected on a first straight line that is in a first plane containing the first axis, the second axis and the first point and passing through the first point, the directions of the currents of the carrying coils at the respective corresponding projections align alternatively in positive and negative directions on the first straight line.

Owner:HITACHI MEDICAL CORP +1

Field configurable magnetic array

InactiveUS20080246573A1Increased field projectionReduce mixPermanent magnetsMagnetotherapy using permanent magnetsMagnetic polesMagnet device

A magnet apparatus comprising a plurality of geometrically shaped nested magnetic elements each being of a different size relative to each other and each having a first side with a first magnetic pole orientation and a second side with a second magnetic pole orientation that is opposite to the first magnetic pole orientation, capable of being assembled concentrically to form a single planar magnet array having a treatment surface and an opposing backer surface, the treatment surface having either an all like magnetic pole orientation or a mixed magnetic pole orientation; and a backer plate having a first side and a second side constructed of ferromagnetic material such that when the plurality of geometrically shaped nested magnetic elements is assembled concentrically on the first side of the backer plate each of the geometrically shaped nested magnetic elements that comprise the single planar magnet array is secured to the first side of the backer plate by magnetic attraction whereby the treatment surface of the single planar magnet array is formed opposite to the backer surface of the single planar magnet array that is magnetically secured to the backer plate.

Owner:SOUDER JAMES J +1

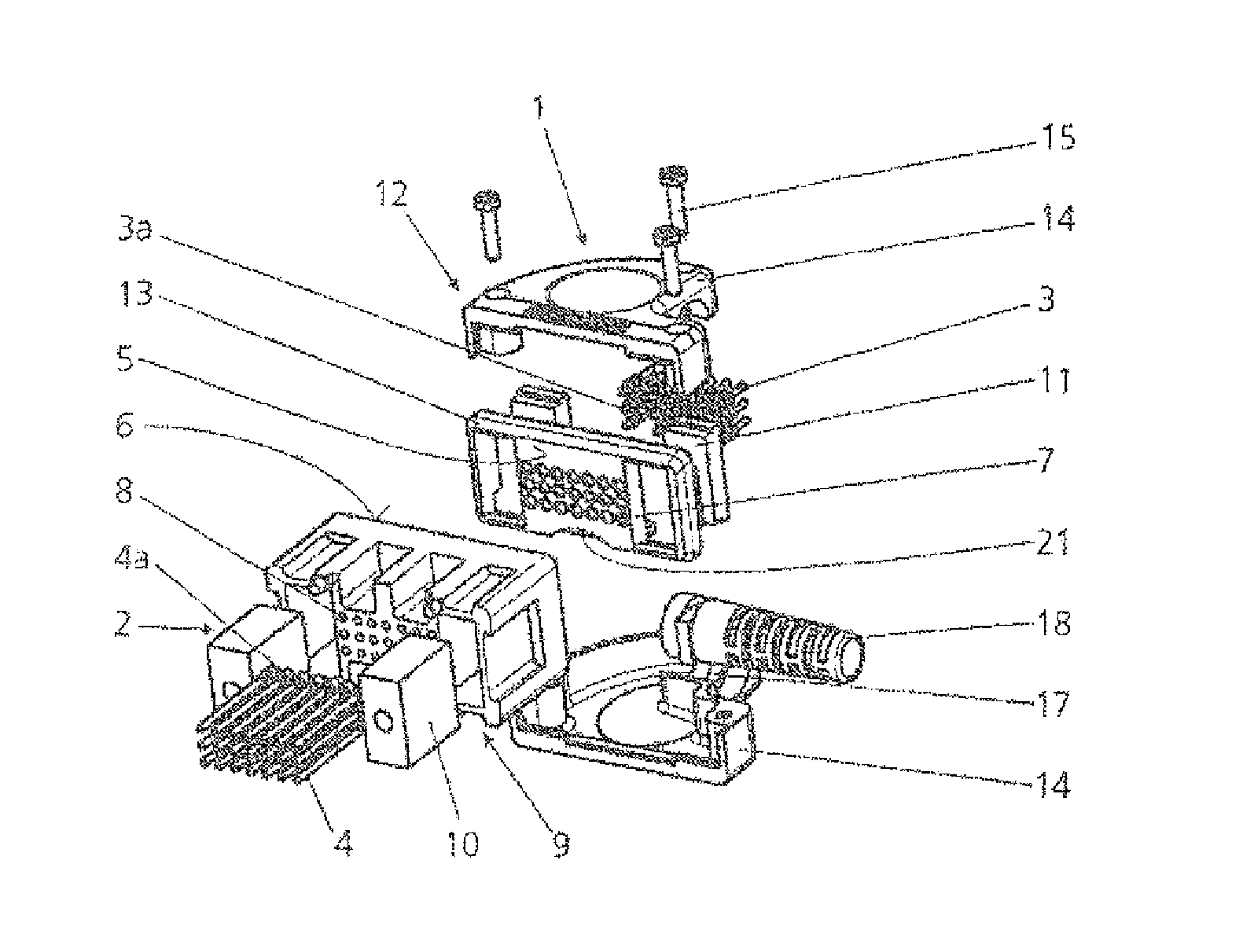

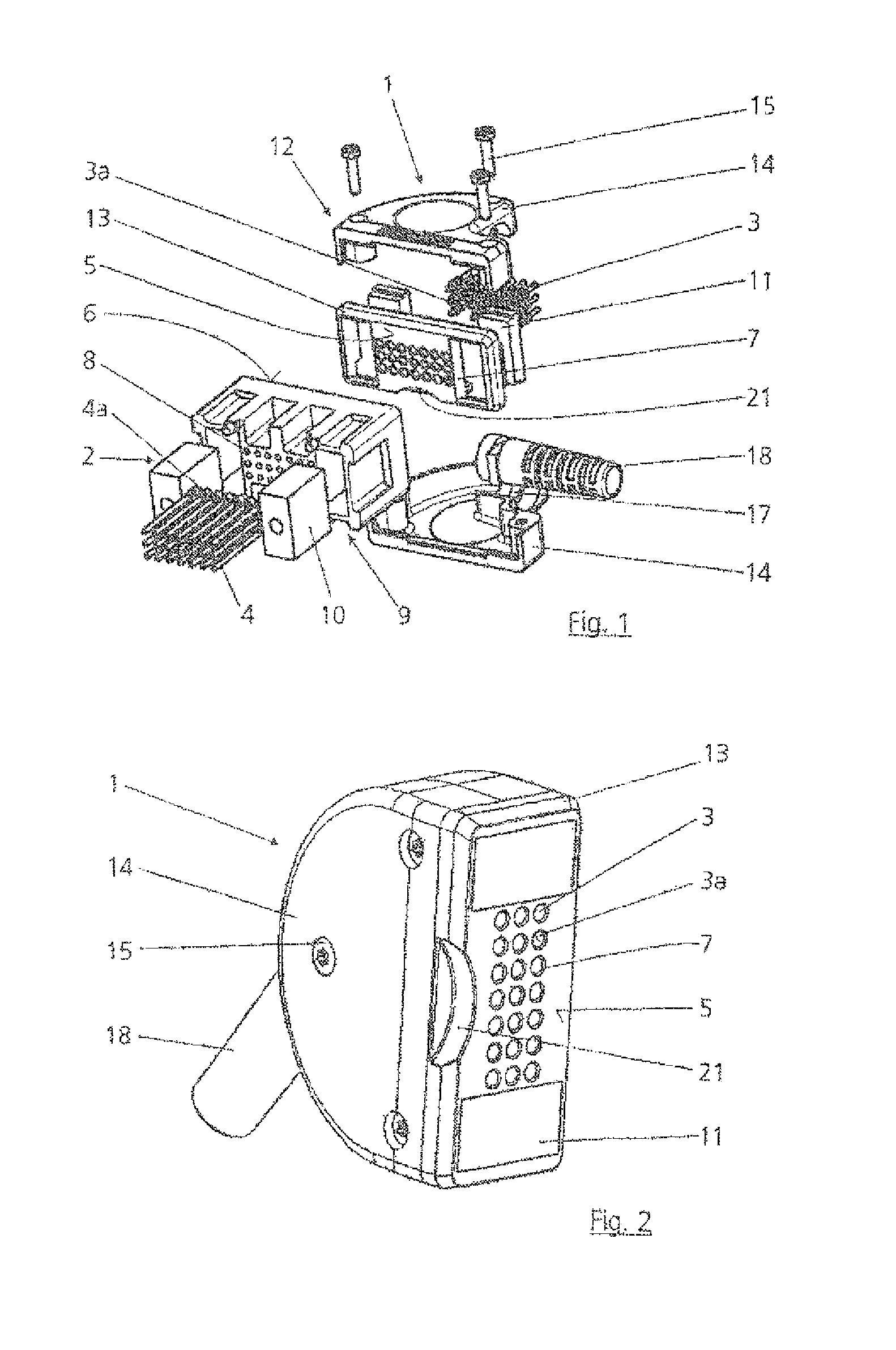

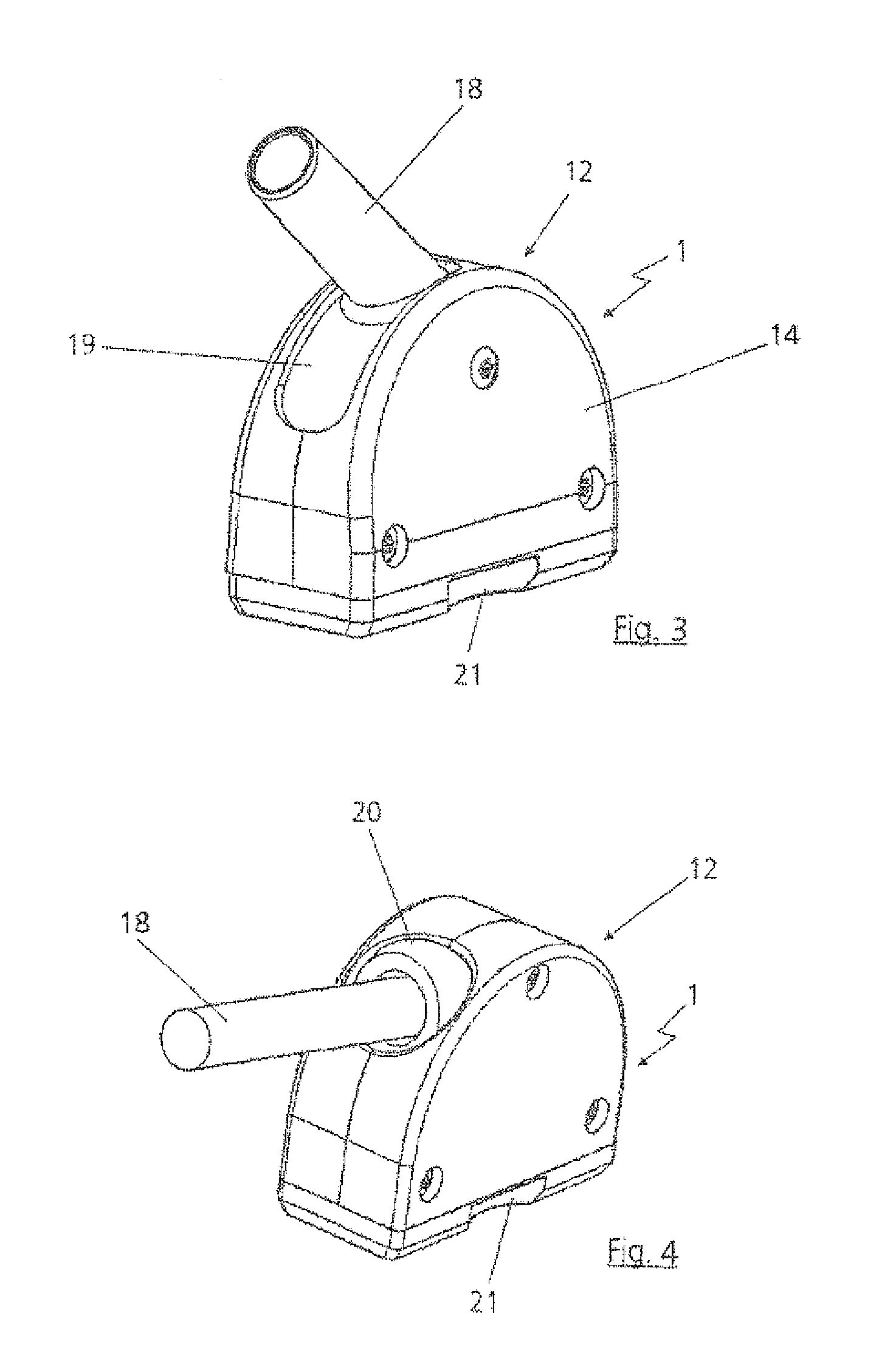

Electrical connection apparatus

ActiveUS8894420B2Reducing risk of inadvertent disconnectionReduce disconnectionEngagement/disengagement of coupling partsRelieving strain on wire connectionElectricityElectrical connection

An electrical connection system includes a plug having contact elements, and a socket having mating contact elements. The plug can be connected magnetically to the socket by means of a magnet device for transmitting signals or current. The magnet device has at least one connection pair, which comprises a magnet and a connecting element, which can be attracted by the magnet, but itself is not in the form of a permanent magnet, wherein respectively the magnet of a connection pair is arranged in the socket, and the connecting element which is not in the form of a permanent magnet is arranged in the plug.

Owner:ROSENBERGER HOCHFREQUENZTECHNIK GMBH & CO KG

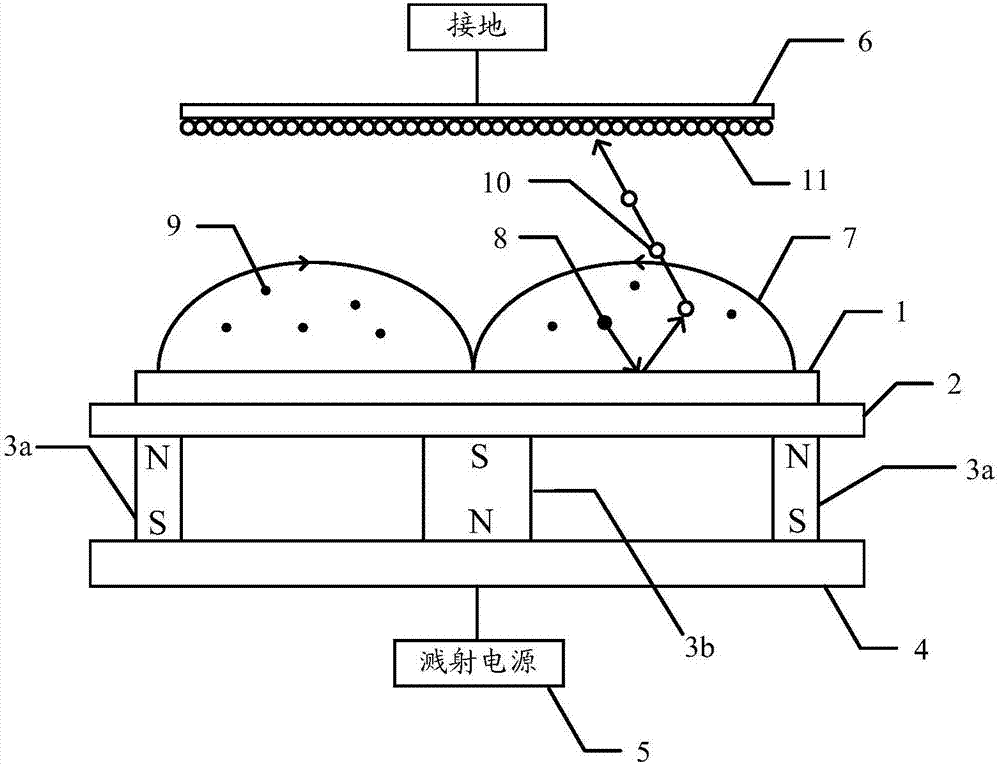

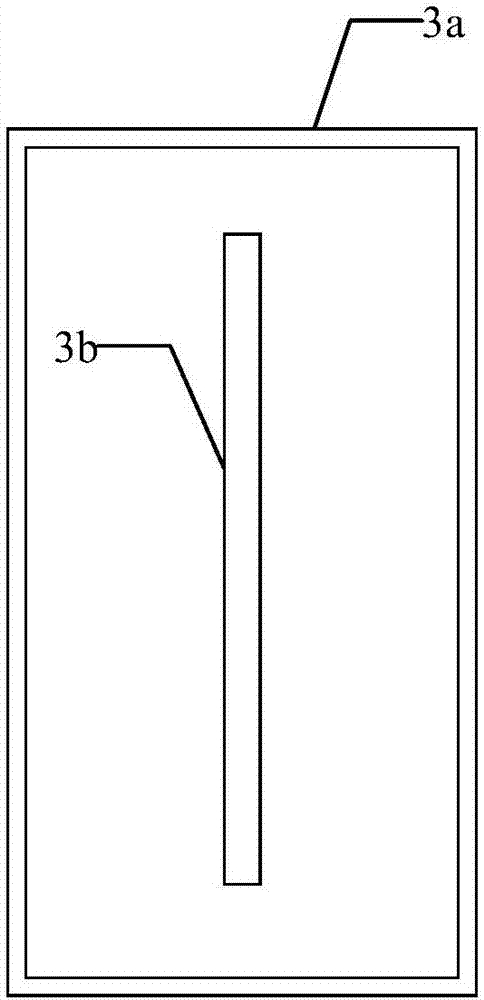

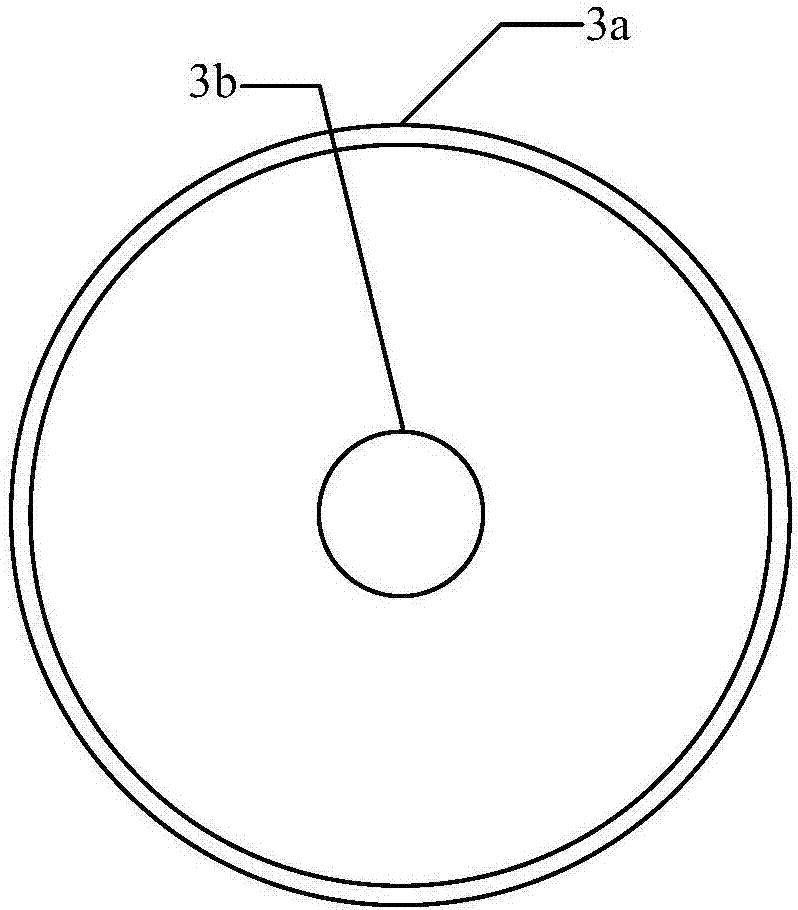

Novel plane magnetron sputtering cathode with high target material utilization rate

ActiveCN107083537AIncrease profitUniform sputteringVacuum evaporation coatingSputtering coatingPhysicsMagnet device

The invention provides a novel plane magnetron sputtering cathode. The plane magnetron sputtering cathode comprises a target material, a backboard, a magnet device and a magnetic conductive plate. The target material is arranged at one side of the backboard, and the magnetic conductive plate is arranged at the other side of the backboard. The magnet device is arranged between the backboard and the magnetic conductive plate. The magnet device comprises a middle magnet and an outer ring magnet surrounding the middle magnet. The middle magnet comprises at least two electromagnets. The polarities of magnetic poles, facing the target material, of the outer ring magnet and the middle magnet are opposite. The plane magnetron sputtering cathode further comprises an electromagnet power source. The electromagnet power source is connected with the at least two electromagnets and supplies power to the at least two electromagnets in sequence so that magnetic field distribution between the outer ring magnet and the middle magnet can be changed continuously. By implementing the novel plane magnetron sputtering cathode, the target material utilization rate can be effectively increased, pollution to the target material is prevented, and stability of the sputtering speed is improved. In addition, the plane magnetron sputtering cathode provided by the invention has the characteristics of being simple in structure, easy to control and high in reliability.

Owner:三河市衡岳真空设备有限公司

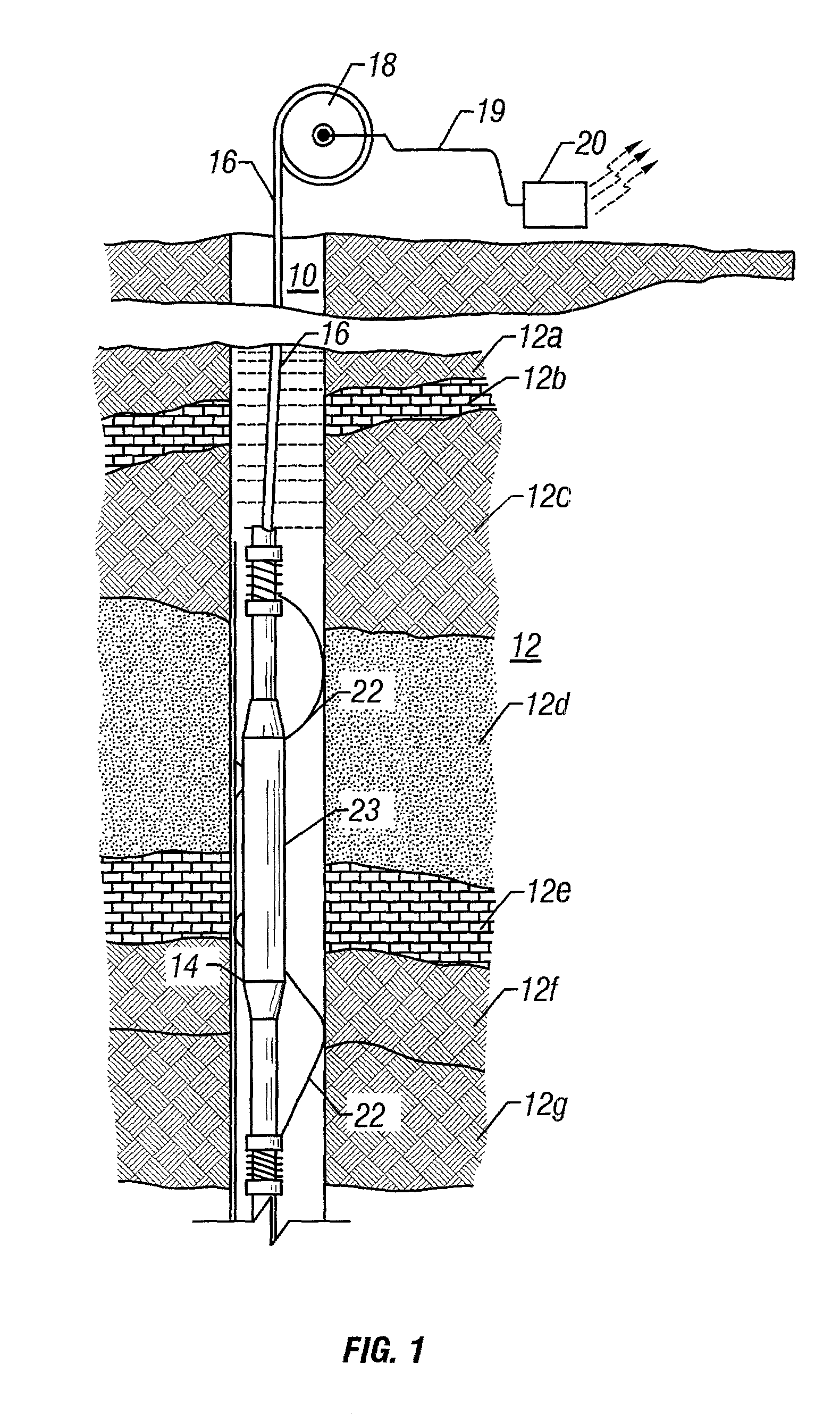

Side-looking NMR probe for oil well logging

InactiveUS20020125885A1Improve efficiencyIncrease effective radiusElectric/magnetic detection for well-loggingMaterial analysis by using resonanceRf fieldUniform field

A side-looking NMR logging tool incorporates a permanent magnet arrangement having a magnetization direction oriented towards a side of the tool and a dipole RE antenna displaced towards the front of the tool. The magnet arrangement produces a shaped region of investigation in front of the tool wherein the magnetic field has a uniform field strength and the RF field has a uniform field strength in a direction orthogonal to the static field. The shaping of the static field is accomplished by the magnet arrangement comprising a plurality of magnets having parallel magnetization or by a single shaped magnet. The antenna arrangement includes a gapped core made of non-ferritic soft material for increasing the antenna efficiency. The magnet arrangement also reduces ringing in the core and the antenna. An optional RF shield is used to reduce NMR signals from borehole fluids.

Owner:BAKER HUGHES INC

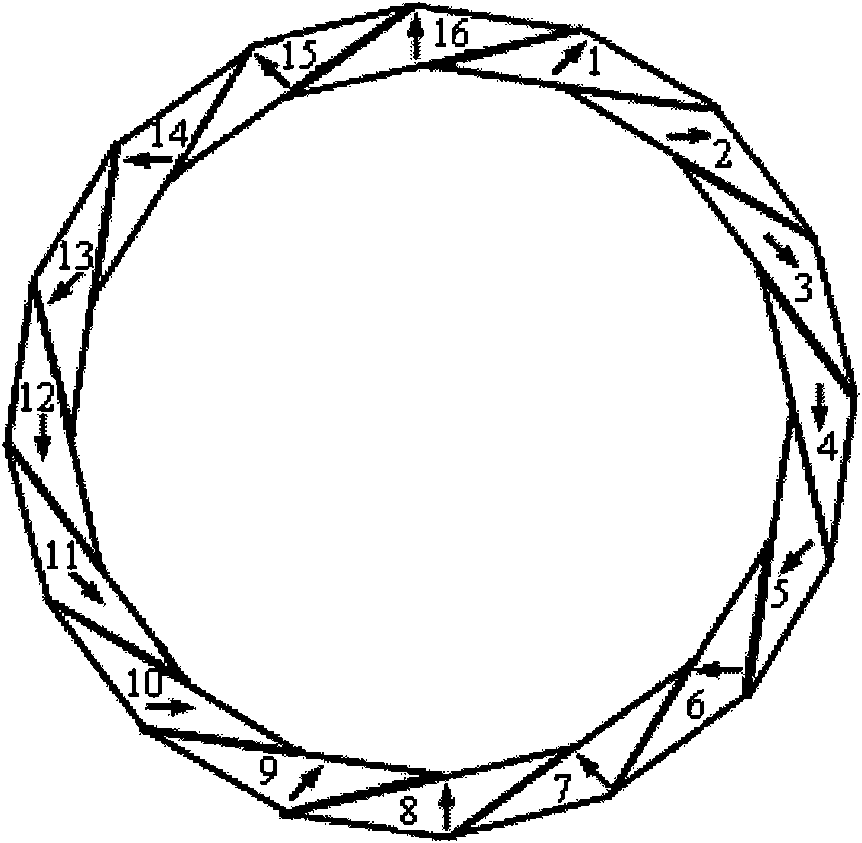

Improved Halbach array permanent magnet device

InactiveCN101908399AIncrease profitReduce processing costsPermanent magnetsInductances/transformers/magnets manufactureMagnetic polesMachining

The invention discloses an improved Halbach array permanent magnet device, which belongs to the field of permanent magnet mechanisms. Although the uniformity of the magnetic field of a Halbach array permanent magnet is improved, obvious repulsion between magnetic poles of same magnetic property exists during the installation of fan-shaped magnetic blocks, so the installation is complicated and difficult. The permanent magnet device is a hollow cylindrical permanent magnet, which is equally divided into N=2<M> blocks along the circumferential direction, wherein M is an integer more than 2; the axial cross section of each equally divided block of the permanent magnet device has a shape of isosceles triangle; the side of one of two adjacent isosceles triangles is overlapped with the base of the other isosceles triangle; an included angle between the side and the base of the triangle is 2pi / N; and the axial cross section of the permanent magnet device has a hollow regular N-sided shape, and the side of the hollow regular N-sided shape is that of the isosceles triangles. By improving the Halbach array permanent magnet, the device has the advantages of simple structure, high utilization ratio of the permanent magnet material, low machining cost, convenient installation, high utilization ratio of the magnetic field space, high uniformity of the magnetic field, less magnetic leakage and capability of easily increasing the field strength, greatly reducing the size of the magnet and reducing the manufacturing cost of the instrument.

Owner:BEIJING UNIV OF TECH

Manufacturing method for neodymium iron boron lanthanon permanent magnet device with composite plated film

ActiveCN103824693AIncrease useImprove corrosion resistanceVacuum evaporation coatingSputtering coatingMolten stateRare earth

Owner:SHENYANG GENERAL MAGNETIC

Self-regulating permanent magnet device

InactiveUS20080136294A1Maintain alignmentMagnetic circuit rotating partsEmergency protective circuit arrangementsStator coilSpring force

A self-regulating permanent magnet device has a first rotor segment and second rotor segment, each supporting a set of permanent magnets, wherein the position of the second rotor segment relative to the first rotor segment is modified based on the speed of the self-regulating permanent magnet device. By modifying the position of the second rotor segment relative to the first rotor segment, the alignment between their respective sets of permanent magnets, and therefore, the electromotive force (emf) generated in the stator coils is regulated. The position of the second rotor segment is defined by the connection of a torsion spring between the first rotor segment and second rotor segment and a reactionary torque device connected to the second rotor segment. The torsion spring creates a spring force that acts to maintain the alignment between the first rotor segment and the second rotor segment. The reactionary torque device provides reactionary torque that is proportional to the speed of the self-regulating permanent magnet device and opposes the spring force. As the speed of the self-regulating permanent magnet device increases, the reactionary torque causes the second rotor segment to rotate, thereby creating a misalignment between the first rotor segment and second rotor segment.

Owner:HAMILTON SUNDSTRAND CORP

Apreparation method of SmCu alloy doped samarium-cobalt based nano composite permanent magnet

ActiveCN108962523AImprove textureImprove coercive forceTransportation and packagingMetal-working apparatusMagnetic phaseAlloy

The invention discloses a preparation method of a SmCu alloy doped samarium-cobalt-based nano composite permanent magnet, belonging to the technical field of magnetic materials. The material takes 1:5-type SmCo nanometer magnet and nanocrystalline alpha-Fe composite magnet as the base body, employs the magnetron sputtering and spark plasma sintering technology to take the low melting point Sm_6Cu_4 alloy as interface phase to improve the grain boundary and diffuse into the hard magnetic phase, , thus improving the magnet coercivity, and the Sm-Co based nanocrystalline composite permanent magnet with good magnetic properties was obtained. At that same time, the invention has the advantage of simple process and low cost, and is favorable for the application of samarium-cobalt-based nano composite permanent magnet in more permanent magnet device.

Owner:ZHEJIANG ZHONGKE MAGNETIC IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com