Field configurable magnetic array

a magnetic array and field technology, applied in the field of magnetic arrays, can solve the problems of power permanent, difficult to achieve monolithic composite high-power “hard” magnet concentric patterns, and high power required to magnetize a concentrically arranged high-power permanent magnet such as neodymium iron boron, so as to reduce the blending of opposite fields and increase the field projection of active magnet zones.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

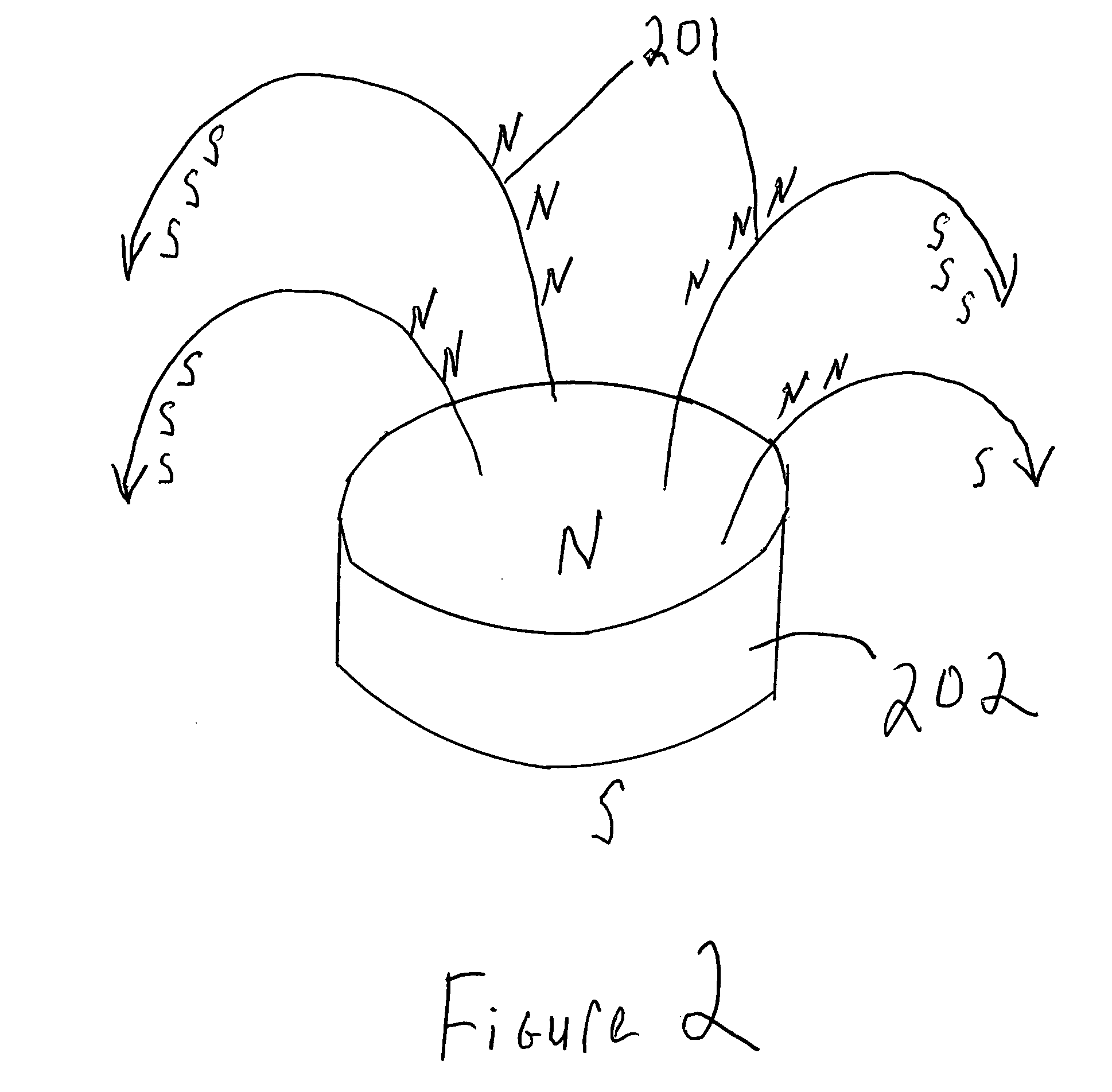

[0036]The apparatus according to present invention comprise adjacently or concentrically configuring a plurality of high power permanent magnets such that the array can deliver more flux per unit volume and can deliver optimum penetration characteristics.

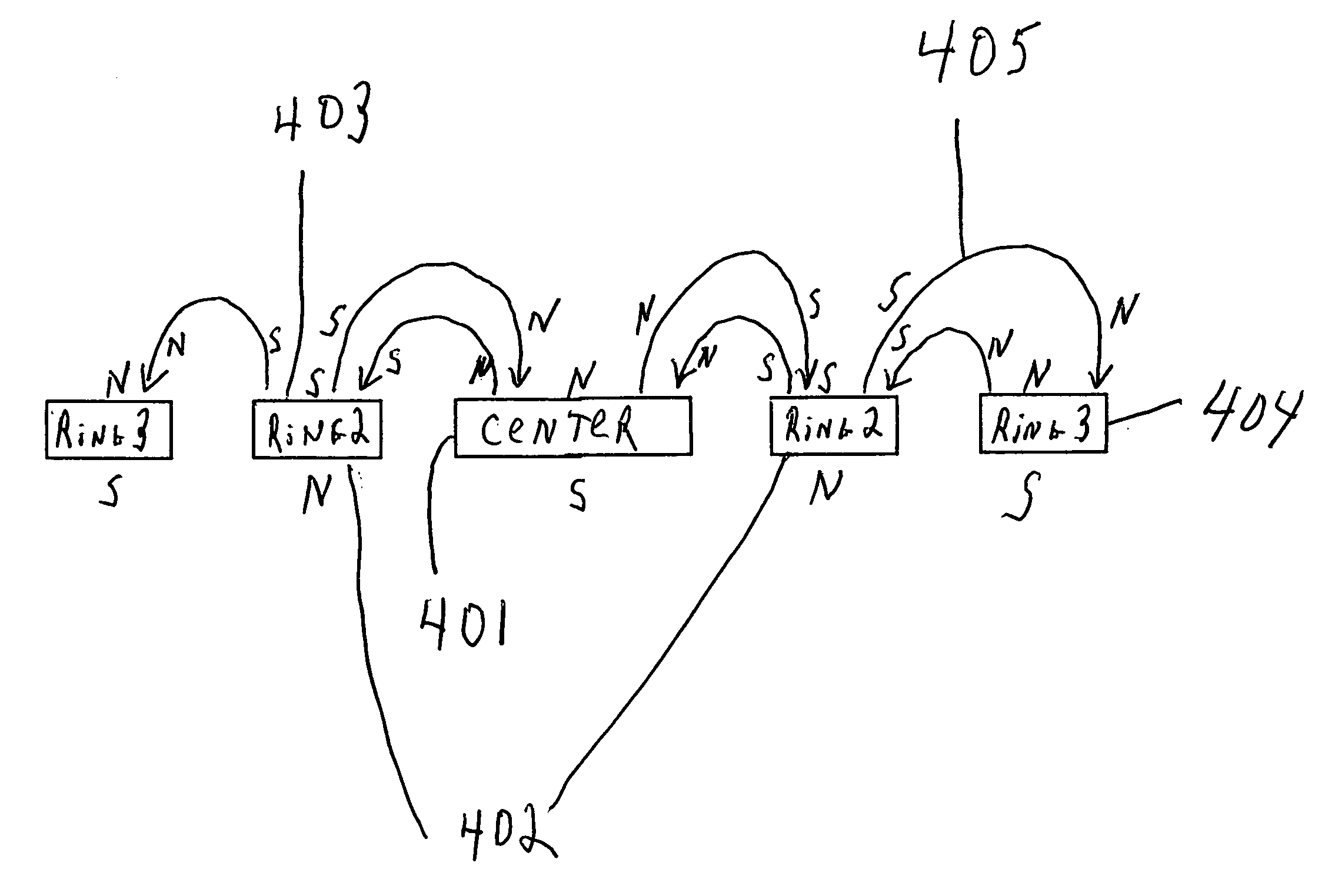

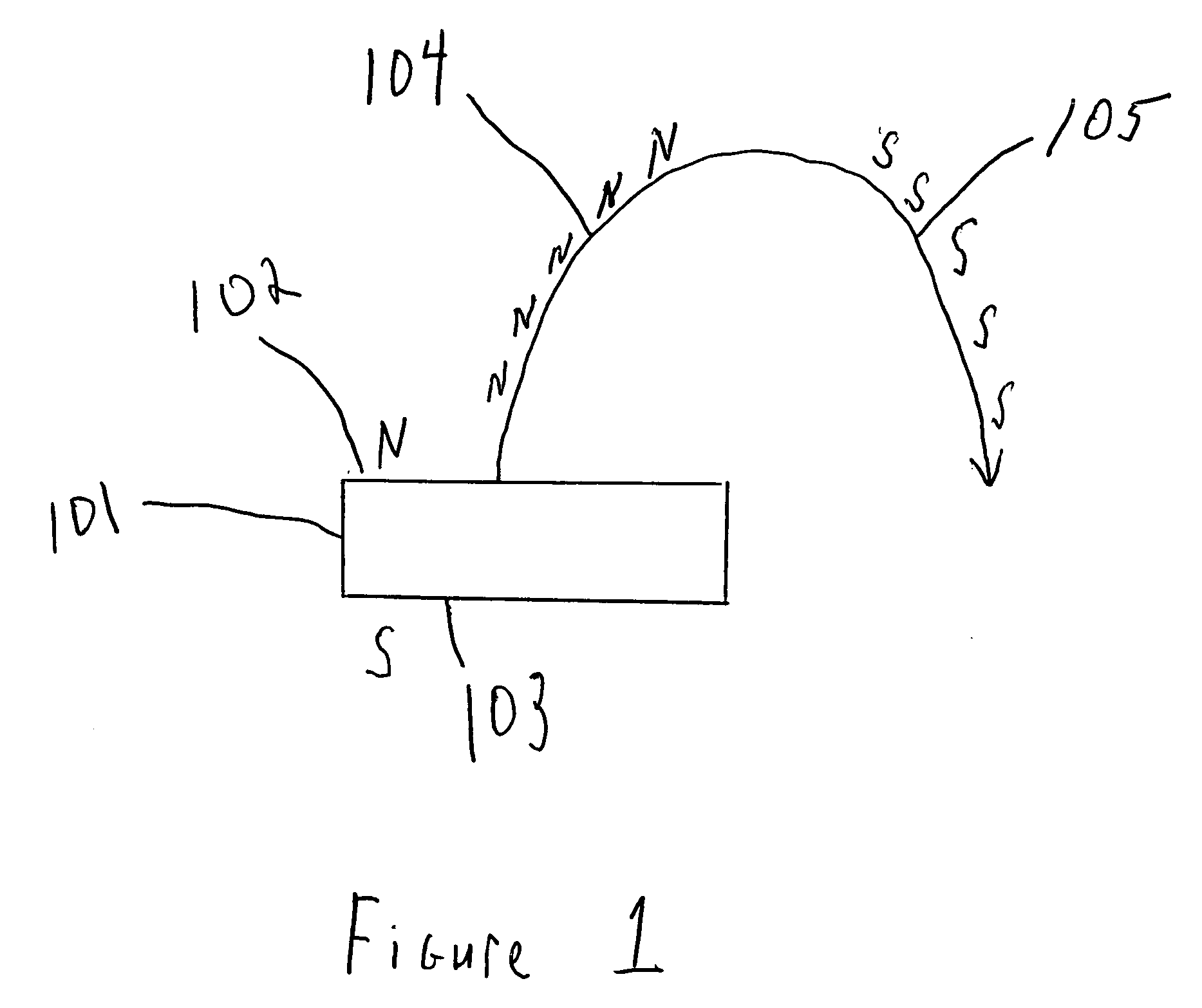

[0037]The benefits of concentric circle magnet arrays are believed by many practitioners to derive from blood vessels crossing over zones of opposite polarity. Additionally a concentric pattern is an ideal geometric pattern to permit a pole arrangement where the flux emanating from a central pole magnetic element or any given orbital ring can arc over on the arched trajectory of a flux line and descend on a magnetic element adjacent to it. After the flux reaches its apex it returns toward the plane from which it originated. When the flux returns to the plane from which it originated it is now going in the opposite direction. Thus a Gauss meter would ascribe the zone it travels through on the downward portion of the arc as having a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com