Patents

Literature

420results about How to "Reduce fatigue strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

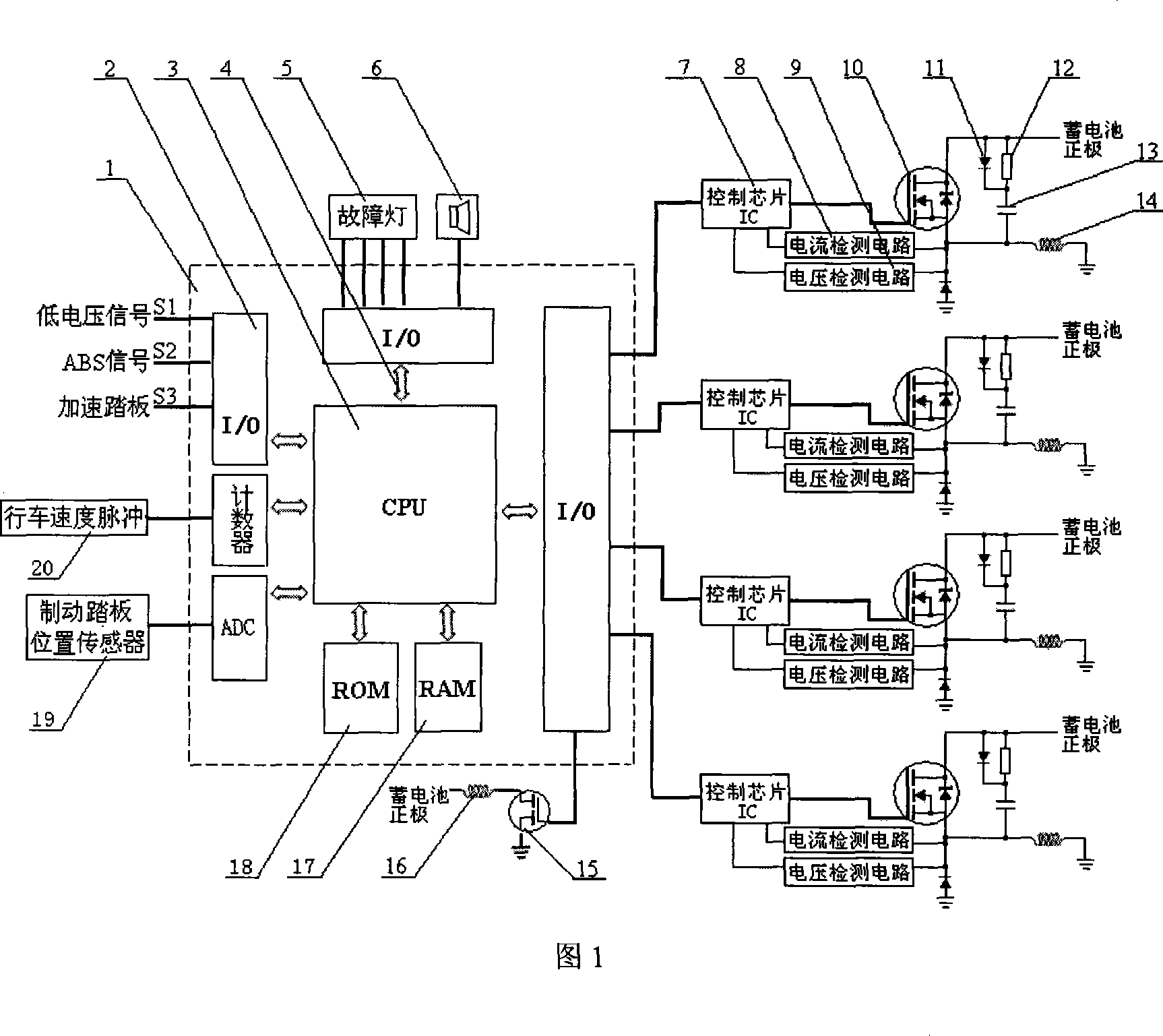

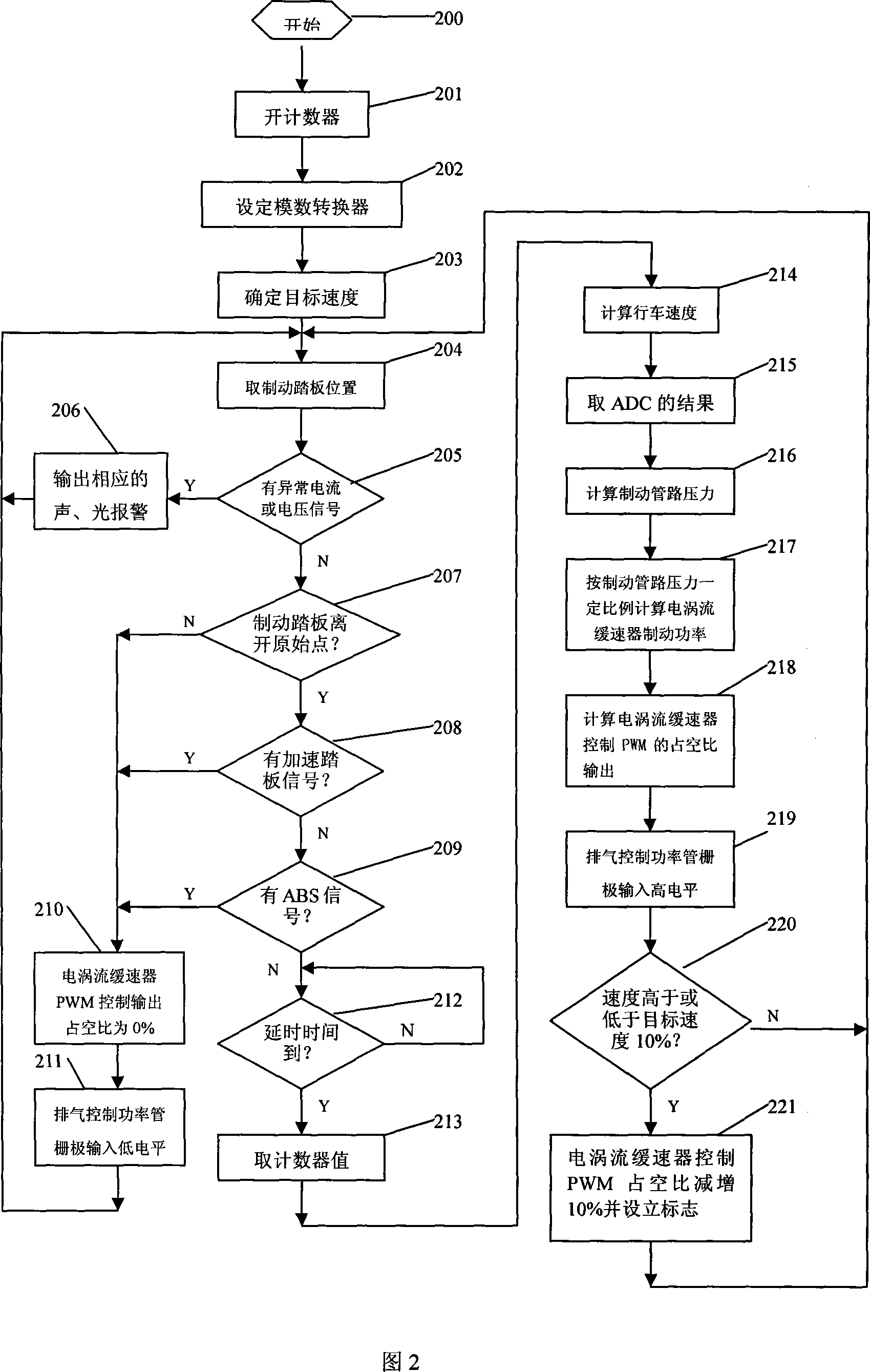

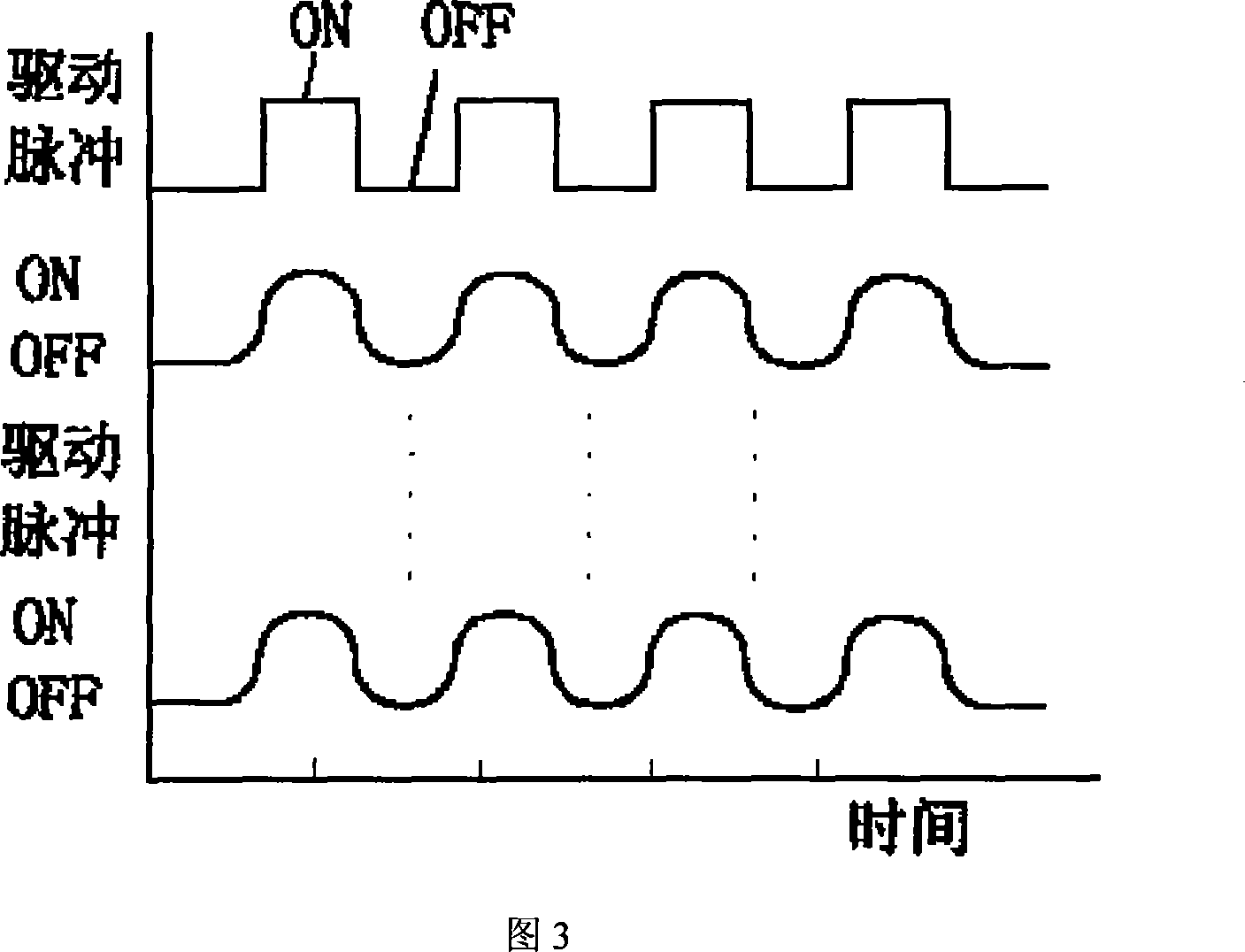

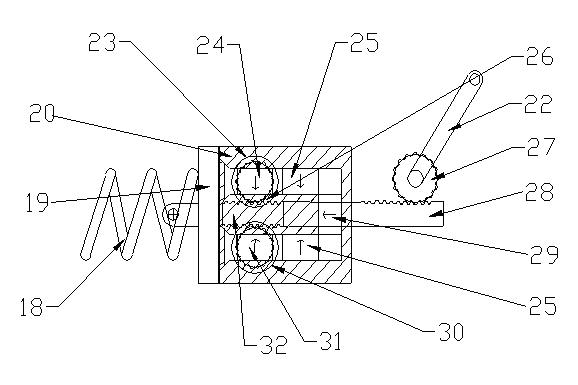

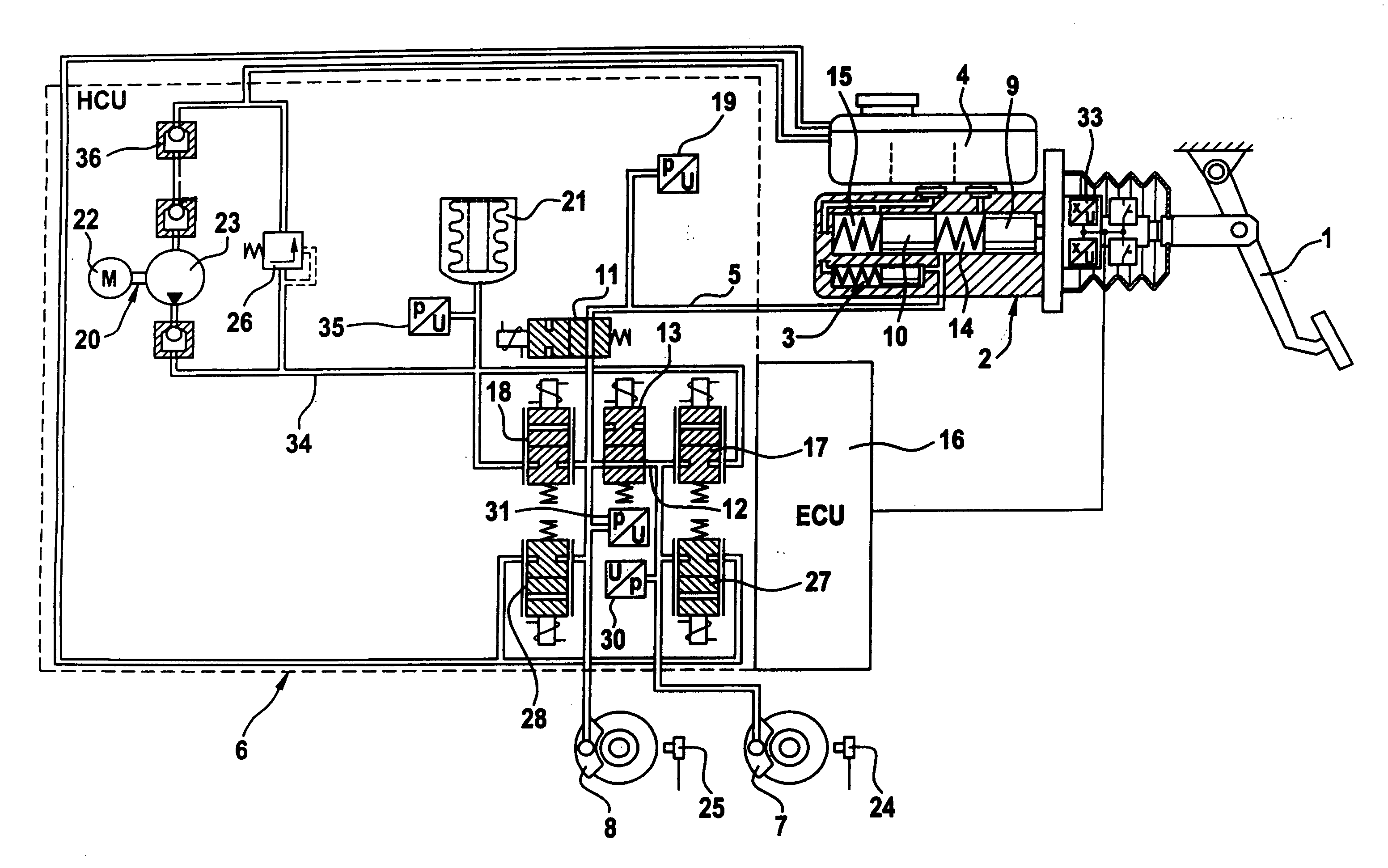

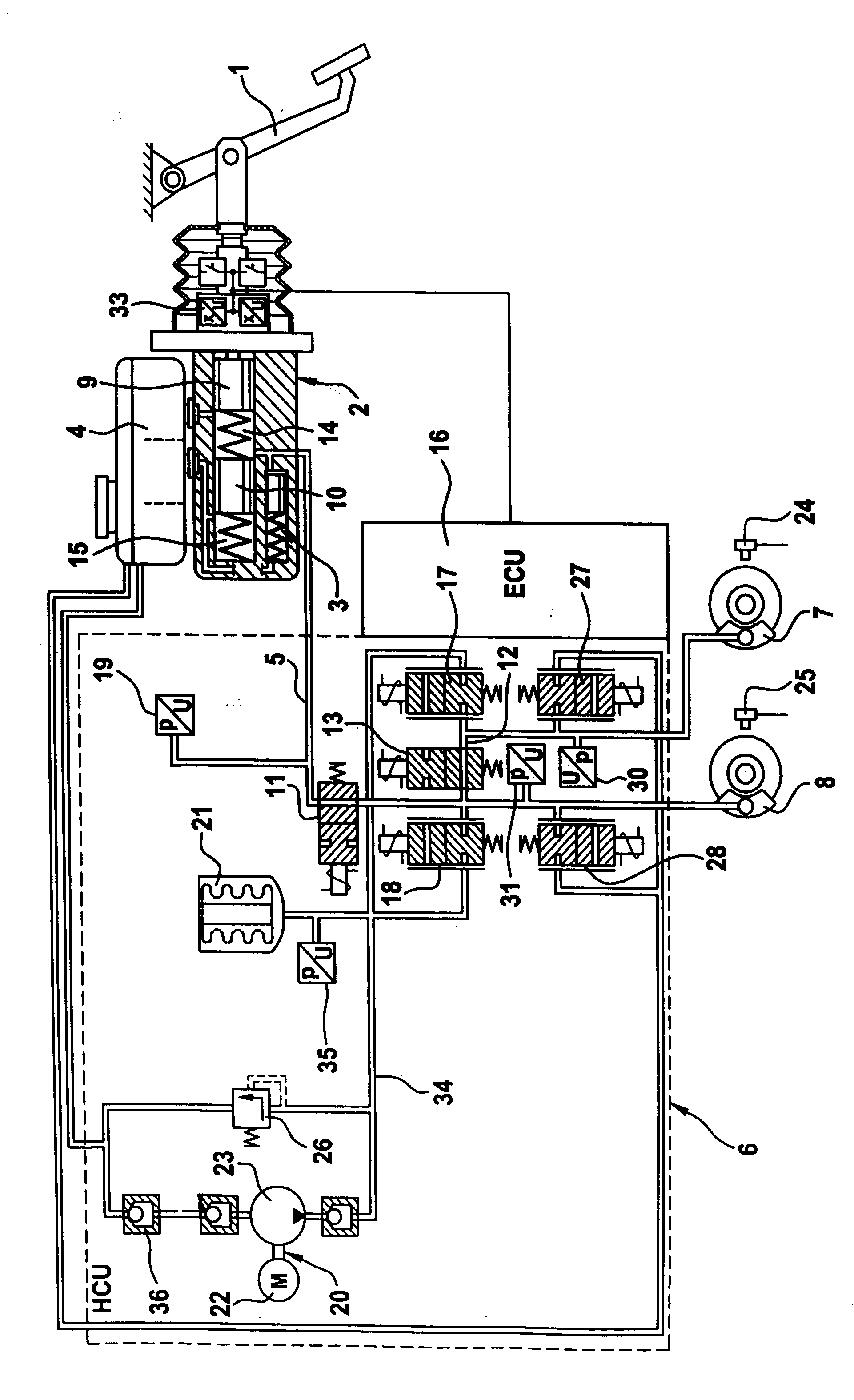

Joint controller of service brake of auto car and relaxed speed device, and controlling method

InactiveCN101049804AReduce fatigue strengthImprove driving safetyElectrodynamic brake systemsMicrocomputerDriver/operator

A controller for the master brake of car and the decelerator including electric eddy one and engine exhaust one is composed of microcomputer, the driver unit for the electric eddy decelerator, the driver for the electromagnetic valve of engine exhaust decelerator, power switching module, feedback detecting circuit, and sound-light alarm circuit. Its control method is also disclosed.

Owner:JIANGSU UNIV

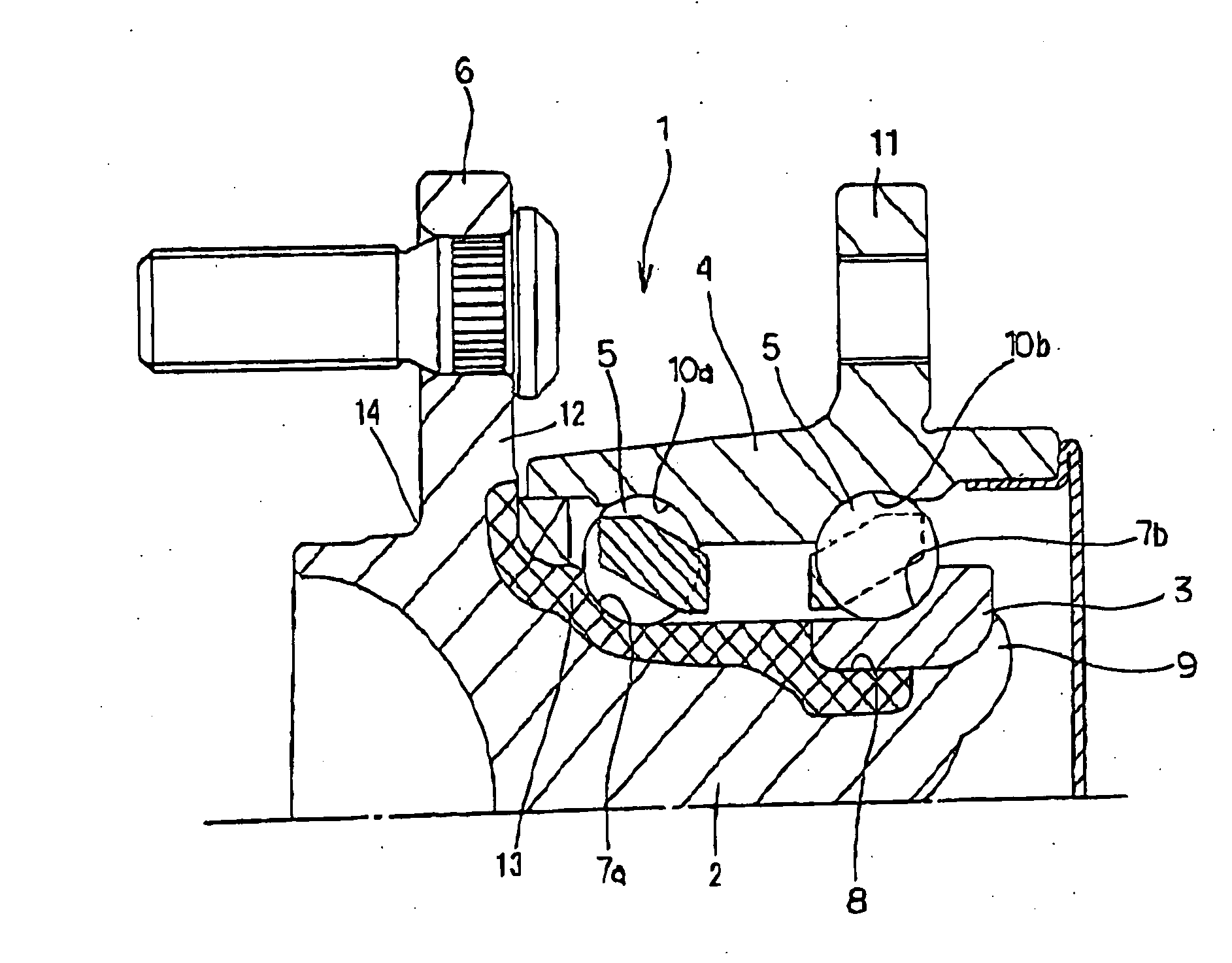

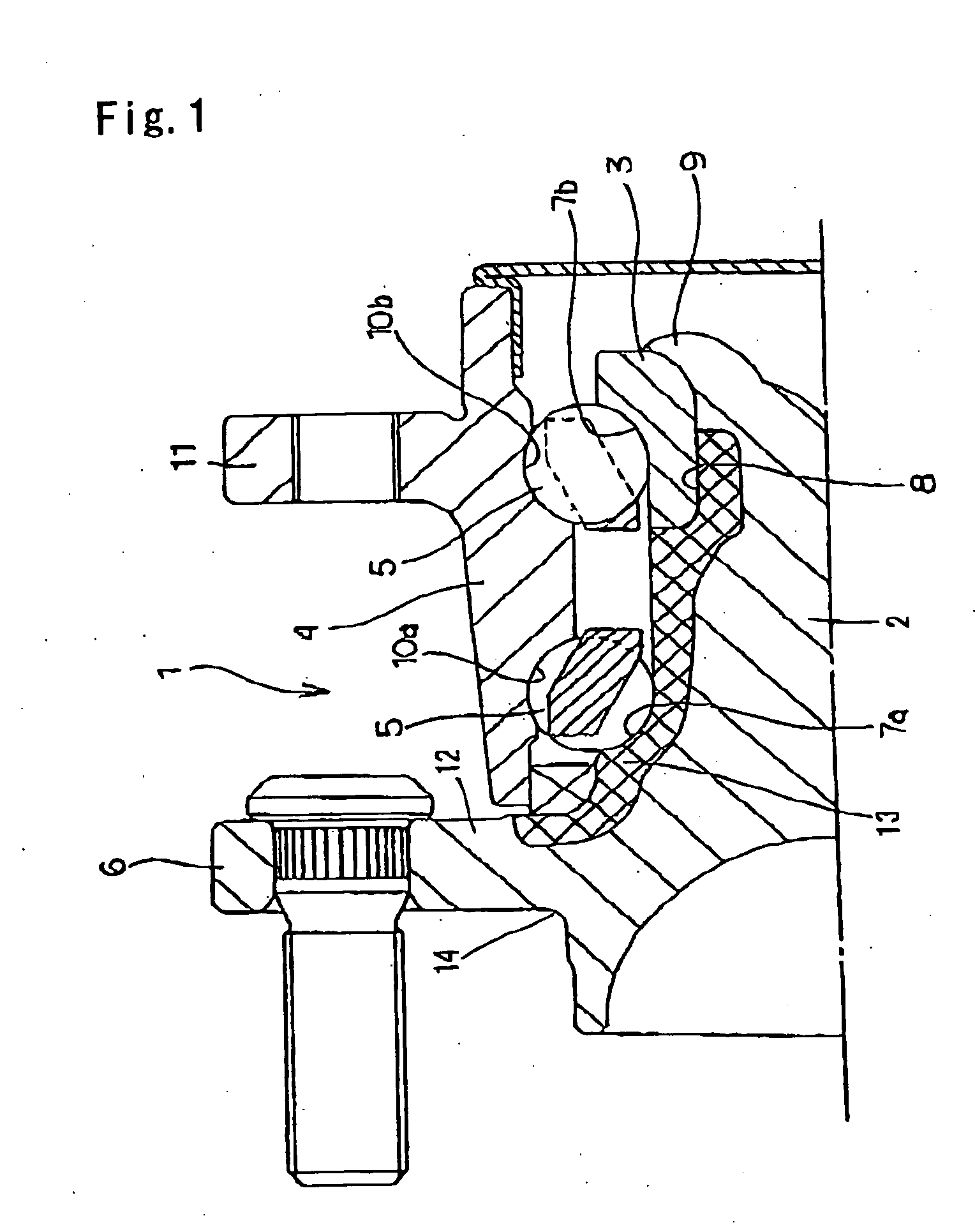

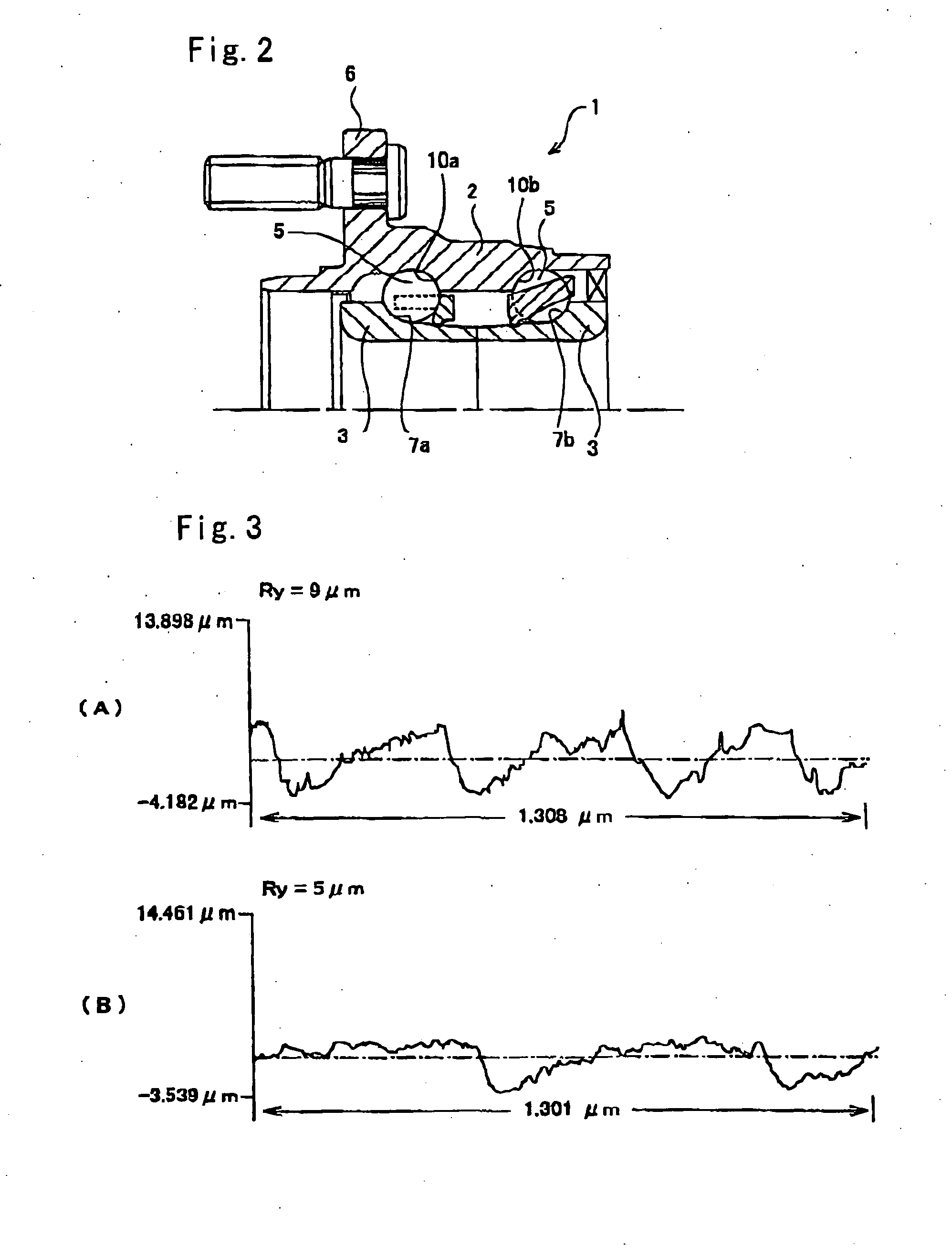

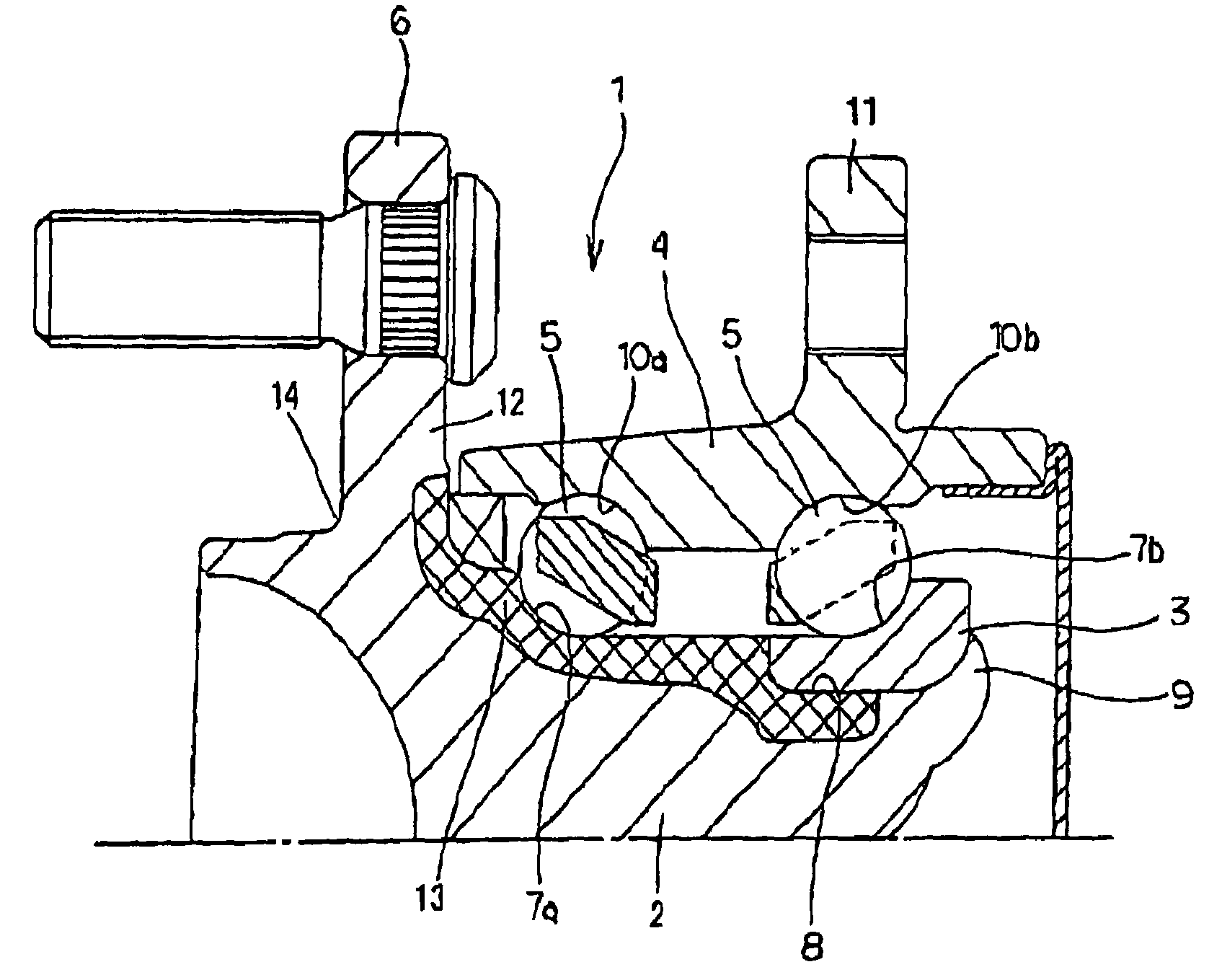

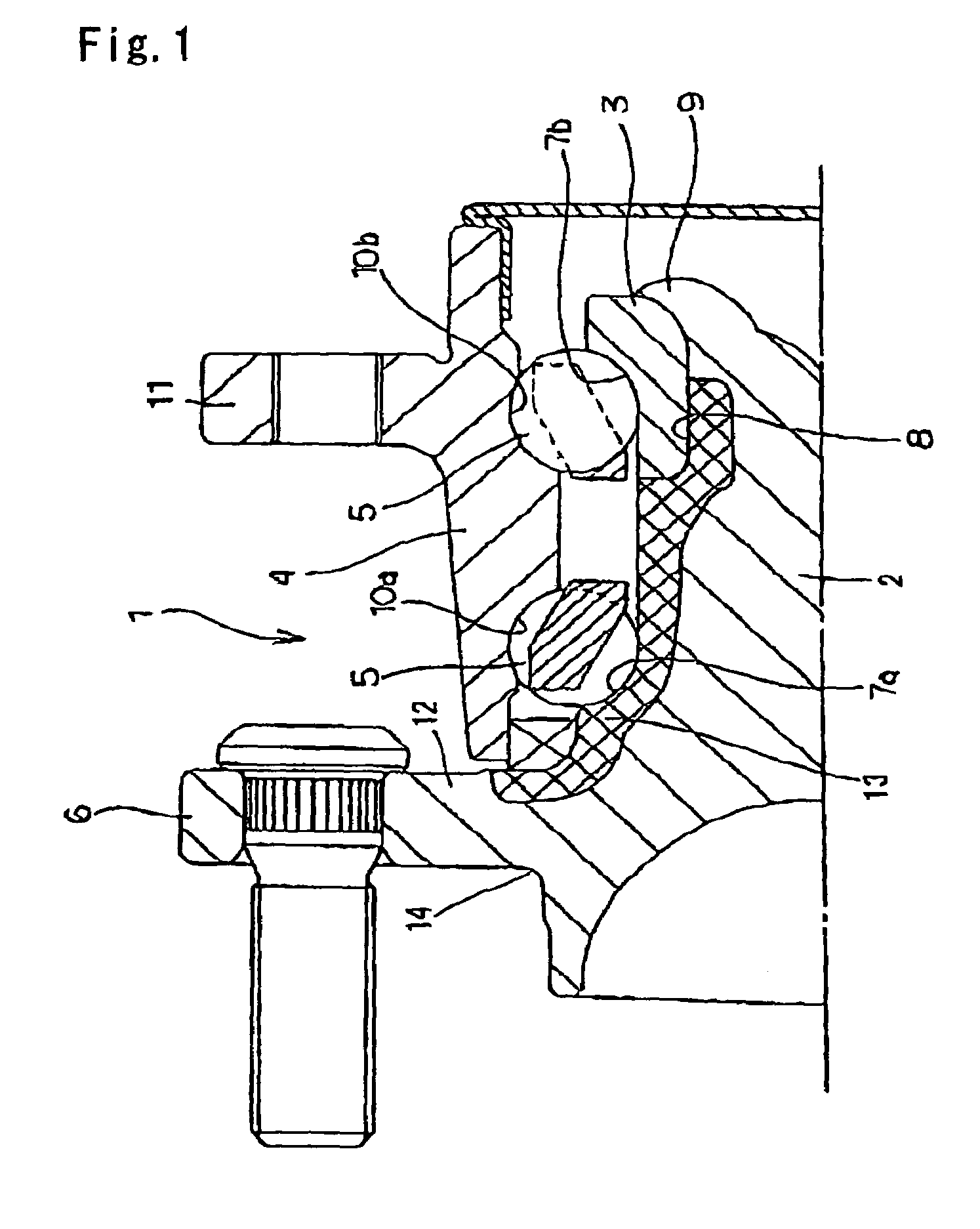

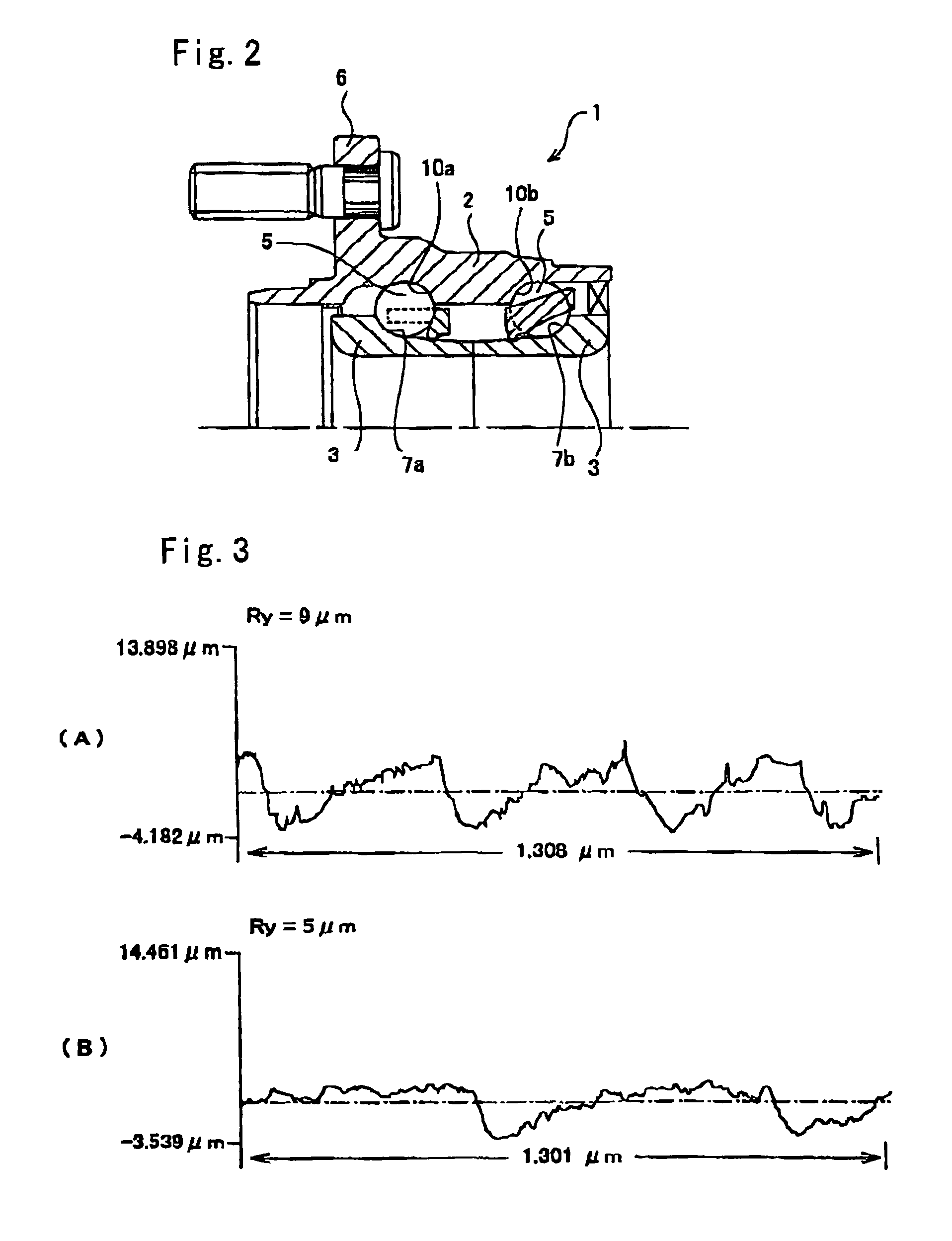

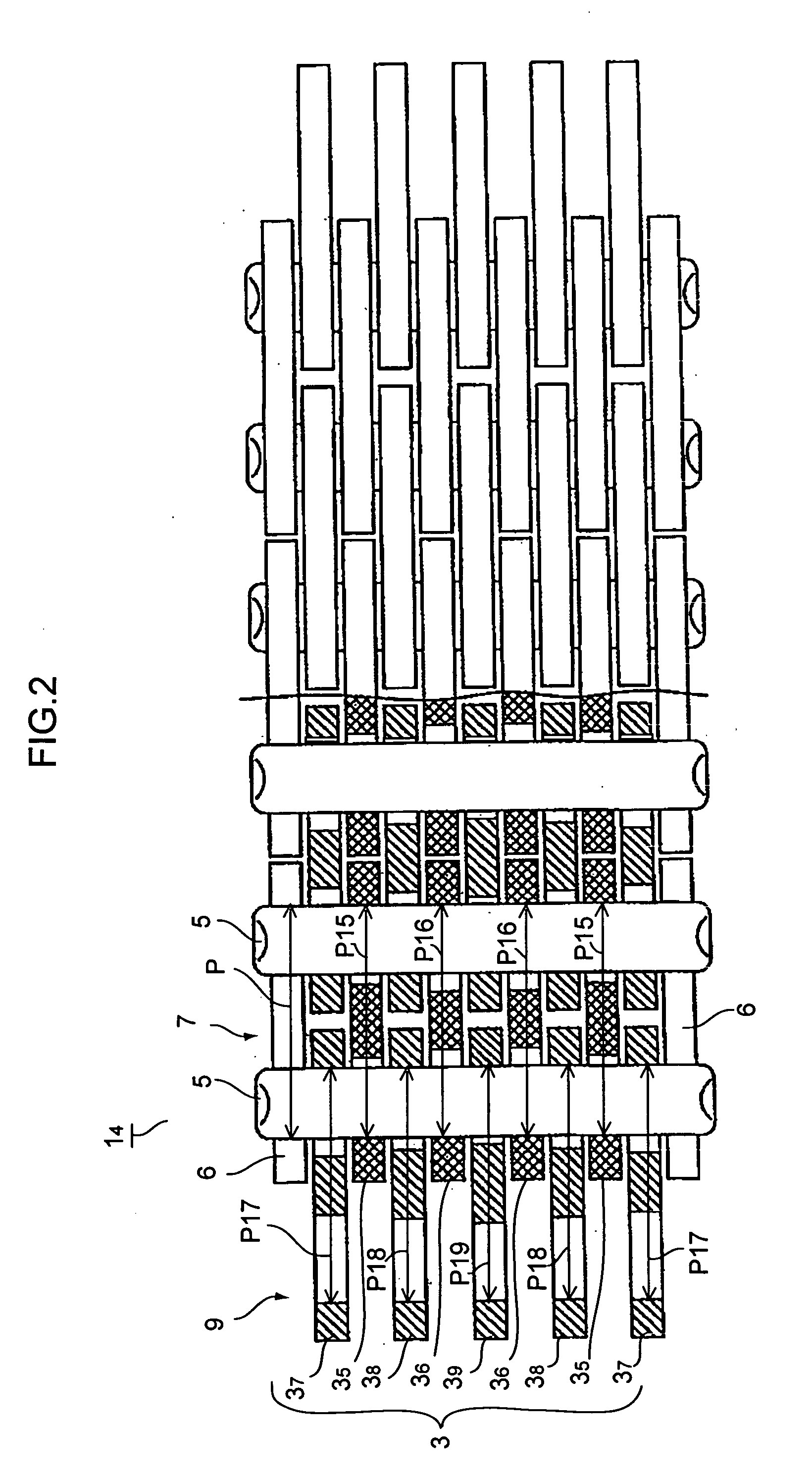

Wheel-support rolling bearing unit

InactiveUS20050141799A1Reduced deformabilityEasy to crackRolling contact bearingsBearing assemblySurface roughnessHardness

In a wheel-support rolling bearing unit, in order to made a flange 6 thinner and thus lighten the bearing unit without impairing fatigue strength, machinability, and workability after forging, the composition of the alloy steel constituting the flange attached member (hub ring 2), the surface hardness of the root portion 14 on the axial outside surface side of the flange 6, and the surface roughness, are stipulated to thereby improve the durability ratio (fatigue limit strength / tensile strength) of the flange 6. In one aspect, the member is made from an alloy steel containing C: 0.5 to 0.65 weight %, Mn: 0.3 to 1.5 weight %, Si: 0.1 to 1.0 weight %, Cr: 0.01 to 0.5 weight %, S: 0.35 weight % or less, and any one type or more selected from 0.01 to 0.2 weight % of V, 0.01 to 0.15 weight % of Nb, and 0.01 to 0.15 weight % of Ti, with the rest being Fe and inevitable impurities, and the oxygen contents is 15 ppm or less. Moreover, the surface hardness of the inner raceway 7a formed with the hardened layer, is between Hv 650 and 780, and the surface hardness of a portion not formed with the hardened layer is between Hv 230 and 300.

Owner:NSK LTD

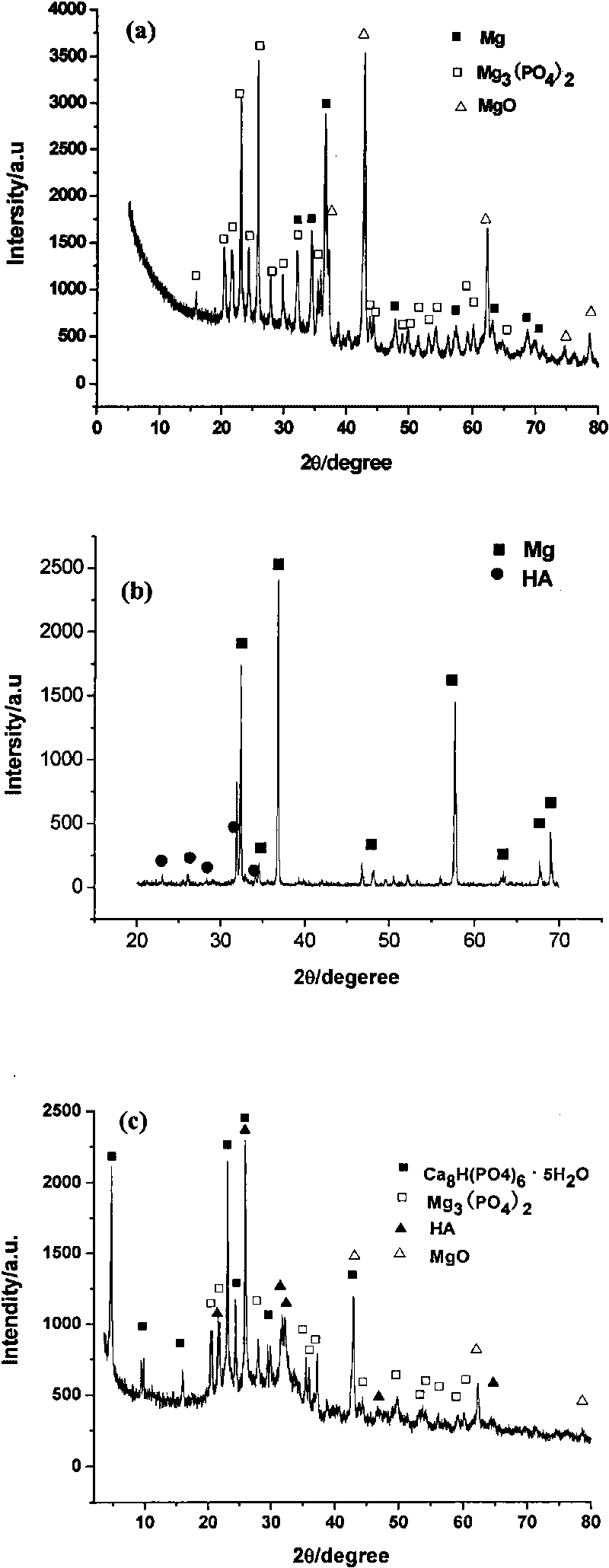

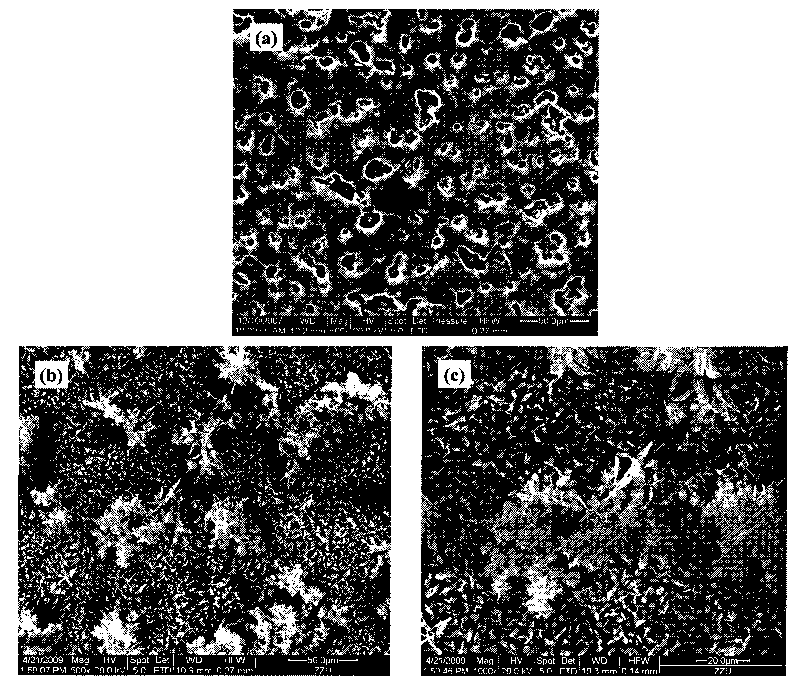

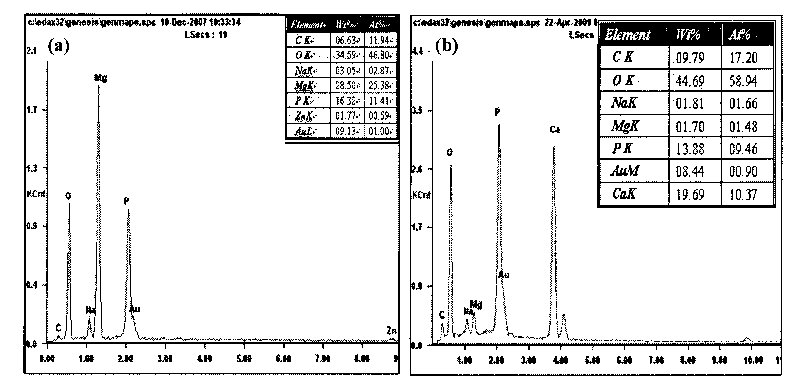

Micro-arc oxidation-electrodeposition preparation method of magnesium-based bioactive coating

InactiveCN101709496AMatch mechanical propertiesAvoid degradation difficultiesAnodisationElectrolytic inorganic material coatingMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a micro-arc oxidation-electrodeposition preparation method of a magnesium-based bioactive coating. The preparation method comprises the following steps: putting a magnesium-based base material in micro-arc oxidation electrolyte after pretreatment to perform micro-arc oxidation reaction to obtain a micro-arc oxidation coating sample; then, putting the micro-arc oxidation coating sample in electrodeposition electrolyte to perform electrodeposition reaction; and after electrodeposition, taking the sample out, and washing and drying the sample. The micro-arc oxidation-electrodeposition preparation method has the advantages that a biologic coating prepared by the method has high binding property with a base material; and the entire biologic coating has excellent corrosion resistance, bioactivity and compatibility; moreover, the formed bioactive coating is a composite coating (comprising HA, OCP, Mg3(PO3)2 and MgO); and because the composite coating comprises OCP, problems that the degradation of pure HA is difficult are avoided and only an HA crust is left after the degradation of formed magnesium alloy can be avoided.

Owner:ZHENGZHOU UNIV

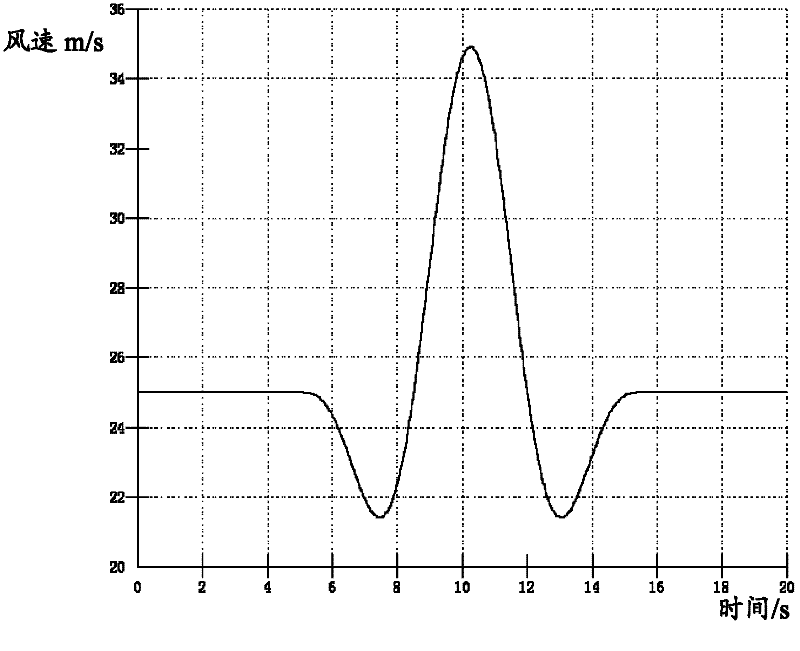

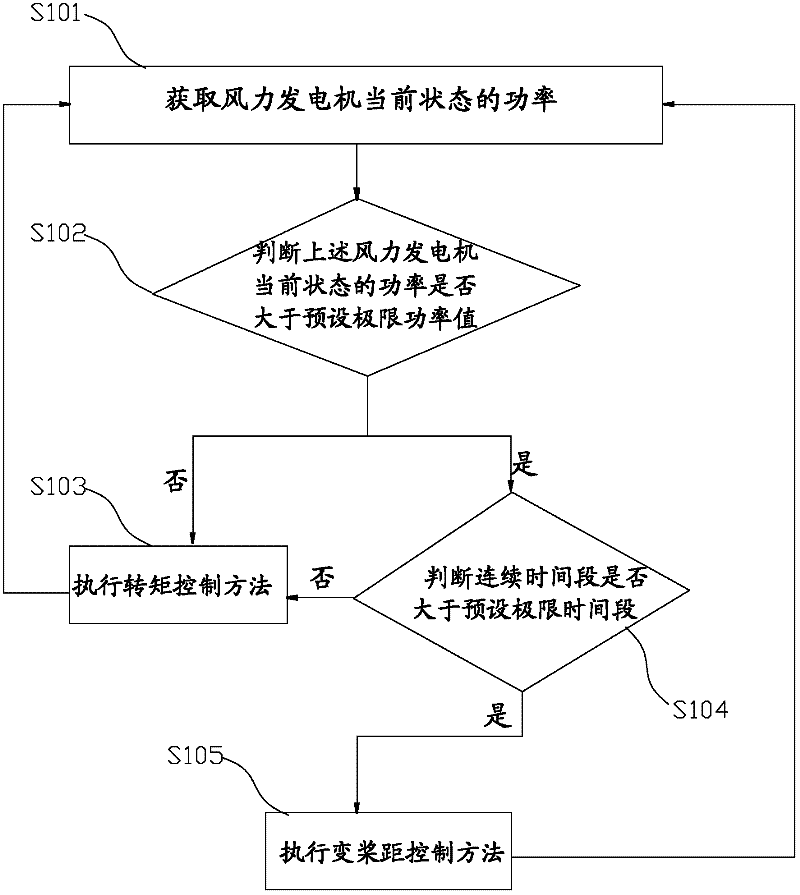

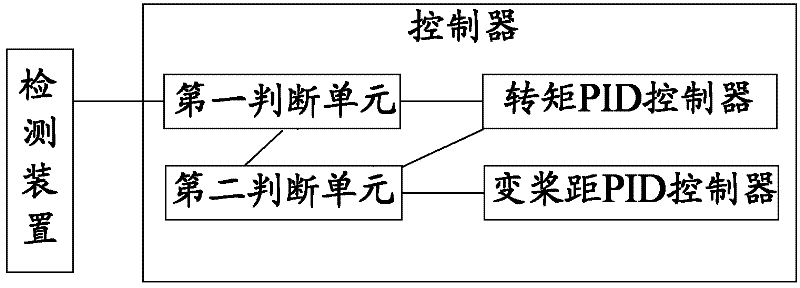

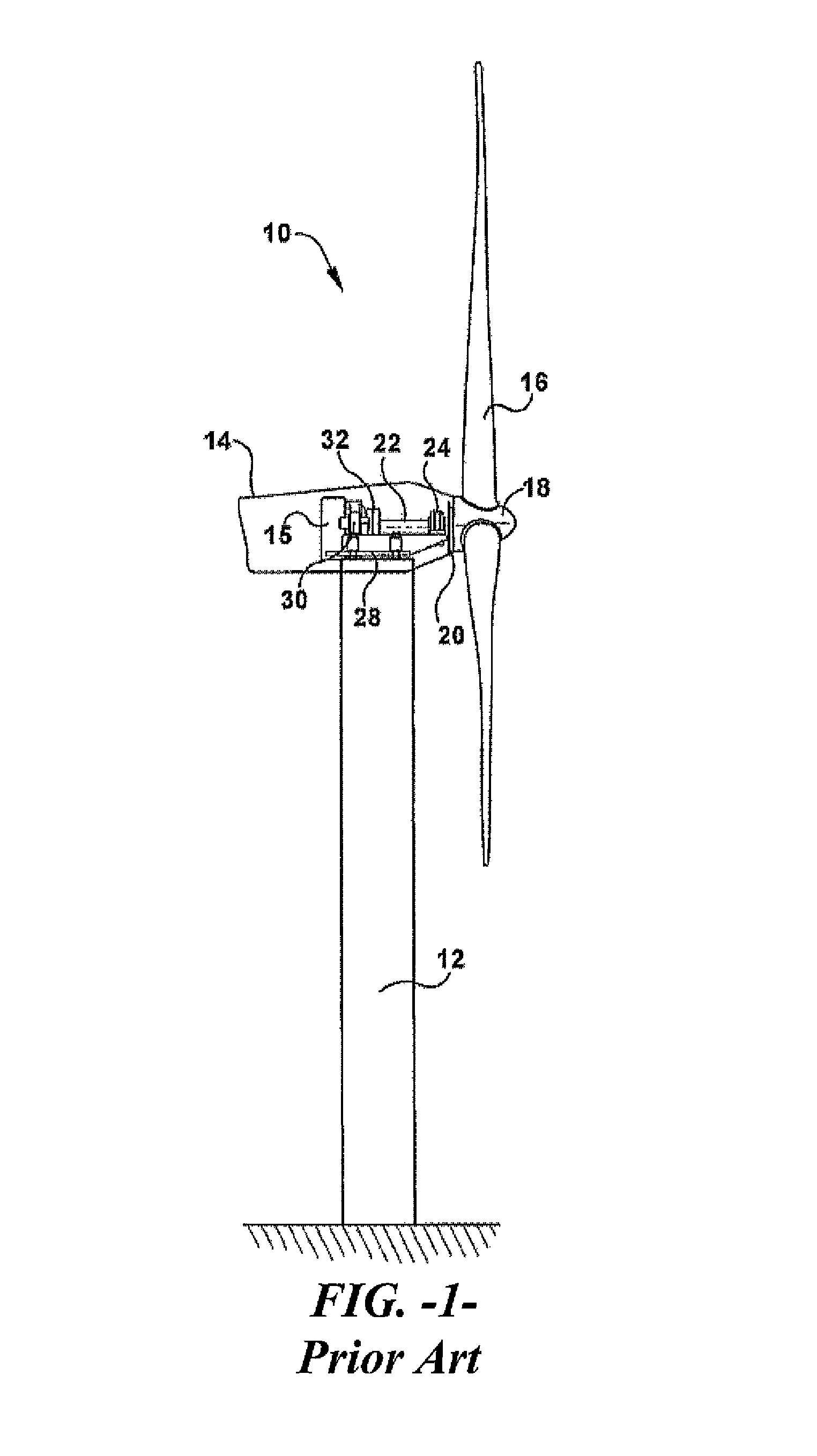

Megawatt wind driven generator set as well as control method and control system thereof

ActiveCN102518555ASolve the phenomenon of frequent conversionReduce fatigue strengthWind motor controlMachines/enginesWind drivenWind force

The invention discloses a control method and a control system of a megawatt wind driven generator as well as the megawatt wind driven generator set. In the control method, the power of the current status of a wind driven generator is firstly detected; only when the controller judges that the power of the current status of the wind driven generator is more than a preset limit power value and the continuous working time of the wind driven generator under the status that the power of the current status of the wind driven generator is more than the preset limit power value is more than preset time, the control method of the wind driven generator is transformed into a variable-pitch control method from a torque control method. In addition, the torque control method with quicker response is always adopted for controlling. With the method, the control requirement of the wind driven generator under the certain working condition can be satisfied, the phenomenon that two control methods are frequently transformed under the working conditions that the wind speed is fluctuated at the rated wind speed and the fluctuation is small can be effectively solved, the fatigue strength of a variable-pitch system is reduced, the service life of each component of the wind driven generator set is prolonged, and the problems of wind wheel overspeed and large limit load can be solved for the working condition of extreme lifting gust.

Owner:SANY ELECTRIC CO LTD

Wheel-support rolling bearing unit

InactiveUS7004637B1Improve fatigue strengthReduce fatigue strengthRolling contact bearingsHubsSurface roughnessHardness

In a wheel-support rolling bearing unit, in order to made a flange 6 thinner and thus lighten the bearing unit without impairing fatigue strength, machinability, and workability after forging, the composition of the alloy steel constituting the flange attached member (hub ring 2), the surface hardness of the root portion 14 on the axial outside surface side of the flange 6, and the surface roughness, are stipulated to thereby improve the durability ratio (fatigue limit strength / tensile strength) of the flange 6. In one aspect, the member is made from an alloy steel containing C: 0.5 to 0.65 weight %, Mn: 0.3 to 1.5 weight %, Si: 0.1 to 1.0 weight %, Cr: 0.01 to 0.5 weight %, S: 0.35 weight % or less, and any one type or more selected from 0.01 to 0.2 weight % of V, 0.01 to 0.15 weight % of Nb, and 0.01 to 0.15 weight % of Ti, with the rest being Fe and inevitable impurities, and the oxygen contents is 15 ppm or less. Moreover, the surface hardness of the inner raceway 7a formed with the hardened layer, is between Hv 650 and 780, and the surface hardness of a portion not formed with the hardened layer is between Hv 230 and 300.

Owner:NSK LTD

Disc brake with permanent magnet parking brake mechanism and braking method

ActiveCN102011814AReduce fatigue strengthImprove securityAxially engaging brakesBrake actuating mechanismsDriver/operatorElectrical conductor

The invention discloses a disc brake with a permanent magnet parking brake mechanism and braking method for highway transportation vehicles. A main piston and a permanent magnet driving device are arranged in a cylinder body; when a manual brake is pulled, a magnetic circuit in a permanent magnet device is open; a magnetic field is generated nearby a conductor, and the conductor contacts with the shell of the permanent magnet device towards right, so that two pull rods are driven to generate displacement and driving a round wheel to rotate so as to push the main piston to move towards left to drive a brake block assembly to move towards left, thereby braking a brake disc to generate braking; and when the manual brake is released, the magnetic circuit in the permanent magnet device is closed, and the two pull rods and the round wheel return, so that the main piston moves towards right to return. In the invention, as the disc brake consists of the permanent magnet driving device and a mechanical mechanism, the braking security is enhanced, the fatigue strength of a driver is reduced, and no electric energy needs to be consumed.

Owner:YANCHENG BUGAO AUTO PARTS MFG CO LTD

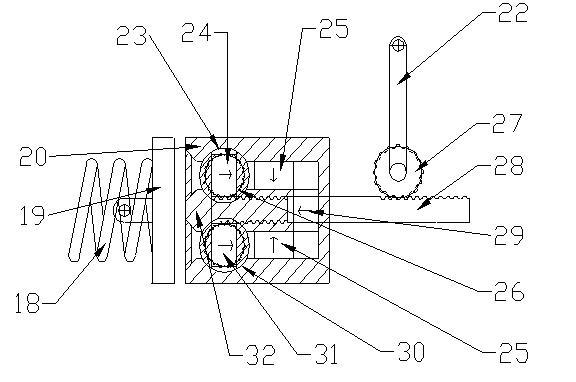

Method for manufacturing large-curvature aluminum alloy integral wall board component

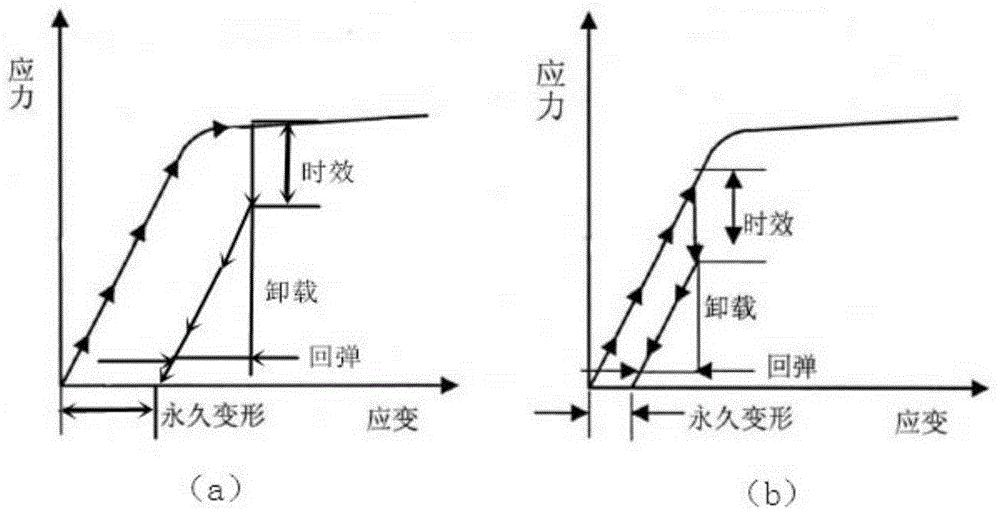

The invention provides a method for manufacturing a large-curvature aluminum alloy integral wall board component. The method includes the steps that A, solution hardening is conducted on a wall board; B, the wall board obtained in the step A is arranged in a sealed environment formed by a thin film covering layer and a forming die jointly, the wall board is elastically deformed and plastically deformed in sequence under the vacuumized condition, and then the deformed wall board is obtained, wherein the temperature in the sealed environment where the wall board is located ranges from 15 DEG C to 35 DEG C, the vacuum degree ranges from -0.1 MPa to -0.05 MPa, and the treatment time ranges from 5 min to 60 min; C, in-situ creep stress relaxation aging is conducted on the deformed wall board obtained in the step B, wherein creep stress relaxation aging time is more than 2 h; D, unloading operation is conducted, and then the large-curvature aluminum alloy integral wall board component is obtained. When the method is used for manufacturing the large-curvature aluminum alloy integral wall board component, the residual stress of the product is greatly reduced, the strength of the product is improved, and the product with high forming accuracy and good performance is obtained.

Owner:CENT SOUTH UNIV

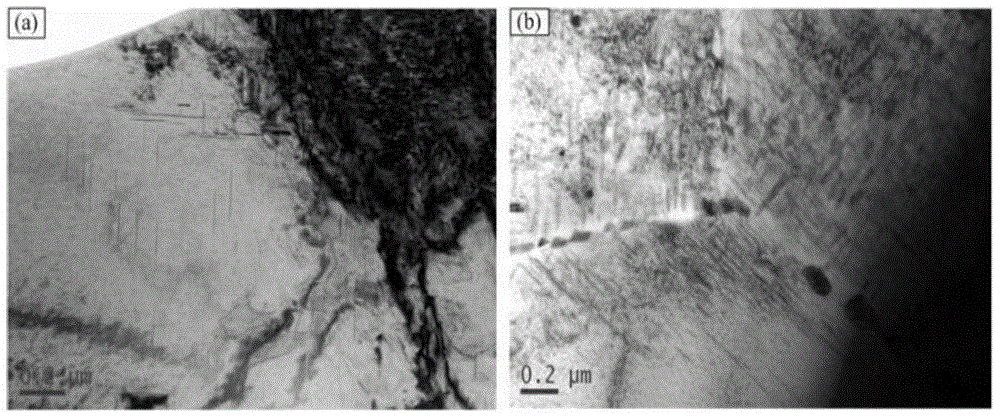

Austenitic stainless steel and manufacturing method thereof

ActiveUS6939415B2Reliably obtainedImprove high temperature strengthLavatory sanitoryFurnace typesMetallurgyUltimate tensile strength

An austenitic stainless steel excellect in high temperature strength and creep rupture ducitility which comprises, on the percent by mass basis, C: 0.03-0.12%, Si: 0.2-2%, Mn: 0.1-3%, P: 0.03% or less, S: 0.01% or less, Ni: more than 18% and less than 25%, Cr: more than 22% and less than 30%, Co: 0.04-0.8%, Ti: 0.002% or more and less than 0.01%, Nb: 0.1-1%, V: 0.01-1%, B: more than 0.0005% and 0.2% or less, sol. Al: 0.0005% or more and less than 0.03%, N: 0.1-0.35% and O (Oxygen): 0.001-0.008%, with the balance being Fe and impurities. The austenitic stainless steel may contain a specified amount of one or more element(s) of Mo and W, and / or a specified amount of one or more element(s) of Mg, Zr, Ca, REM, Pd and Hf.

Owner:NIPPON STEEL CORP

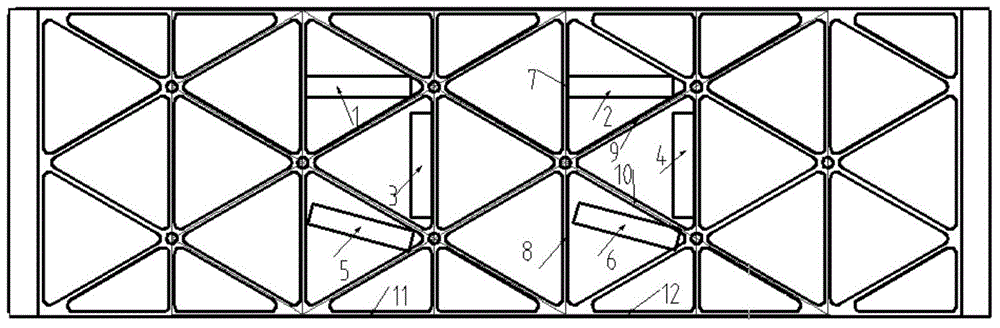

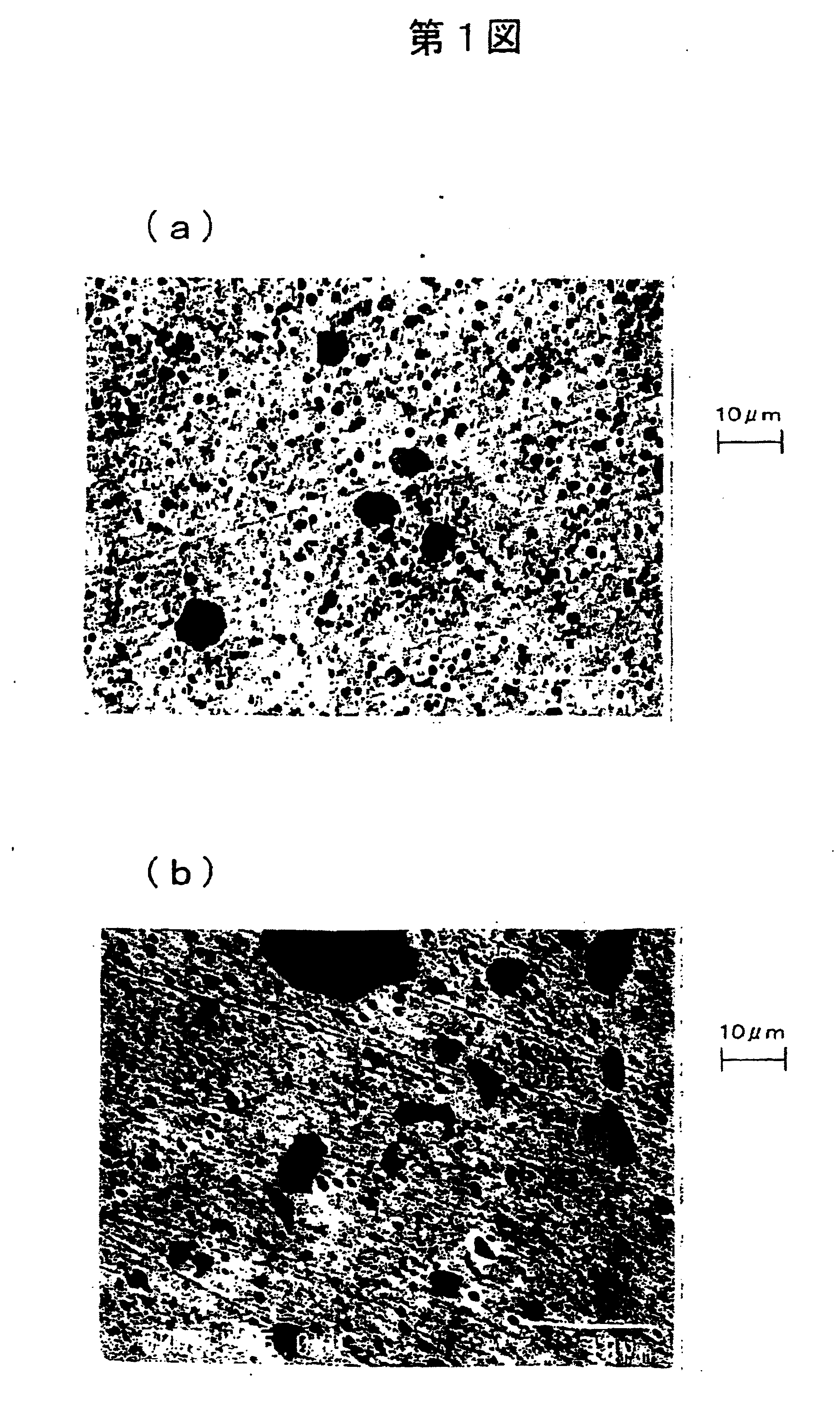

Piston ring excellent in resistance to scuffing, cracking and fatigue and method for producing the same, and combination of piston ring and cylinder block

InactiveUS20040040631A1Easy to wearEnhances scuffing resistancePiston ringsSolid state diffusion coatingCrack resistanceLongest Diameter

A piston ring having improved scuffing resistance, cracking resistance and fatigue resistance, consists of a high-chromium martensitic stainless steel and a sliding nitriding layer formed on the surface of said steel. The stainless steel consists of C: 0.3 to 1.0%; Cr: 14.0 to 21.0%, N: 0.05 to 0.50%, at least one of Mo, V, W and Nb: 0.03 to 3.0% in total, Si: 0.1 to 1.0%, Mn 0.1 to 1.0%, P: 0.05% or less, S: 0.05% or less, the balance being Fe and unavoidable impurities. The sliding nitriding layer comprises on its surface hard particles mainly consisting of nitrides in a range of from 0.2 to 2.0 mum of average particle size, 7 mum or less of the longest diameter, and from 5 to 30% in area ratio.

Owner:RIKEN CO LTD +1

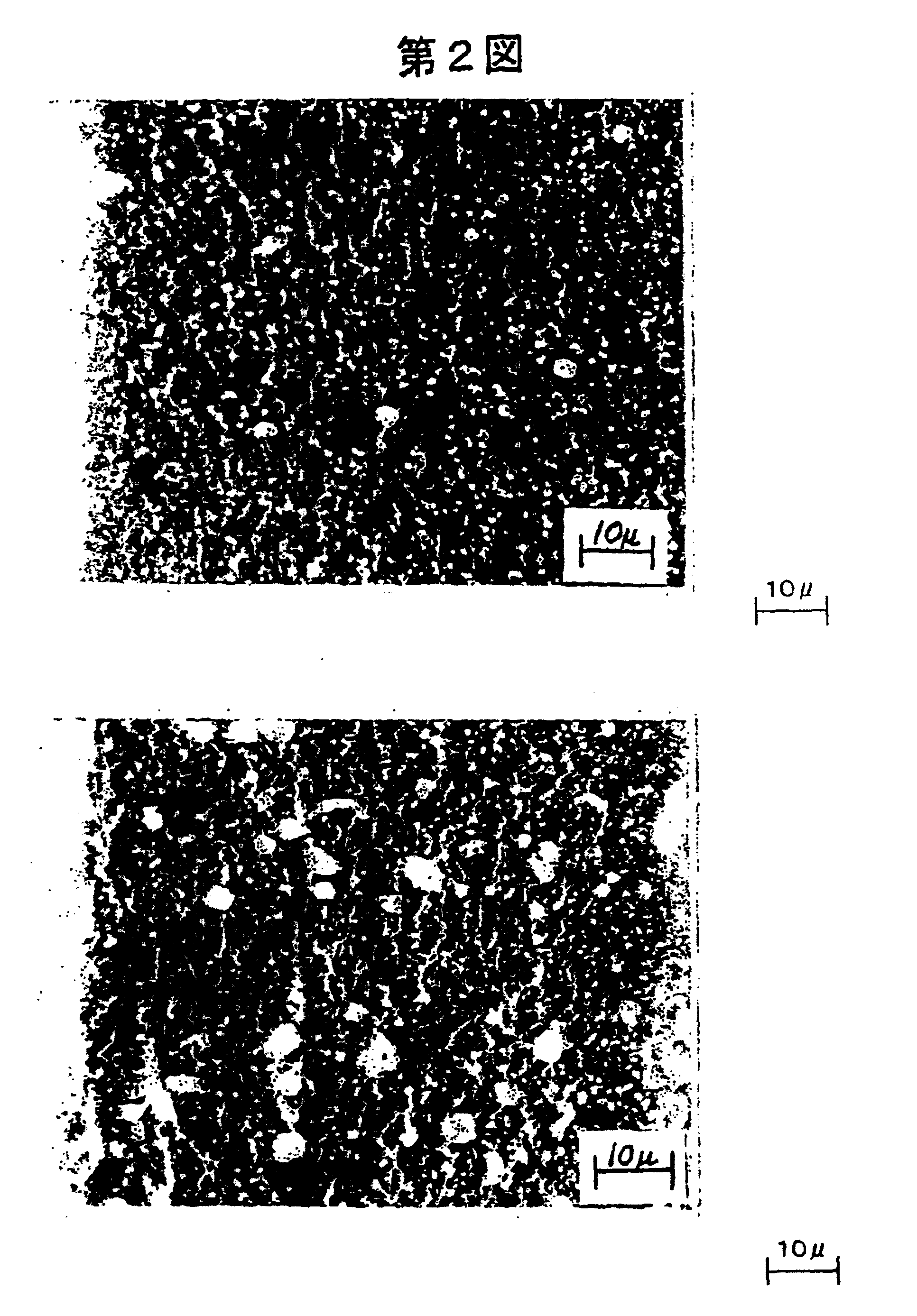

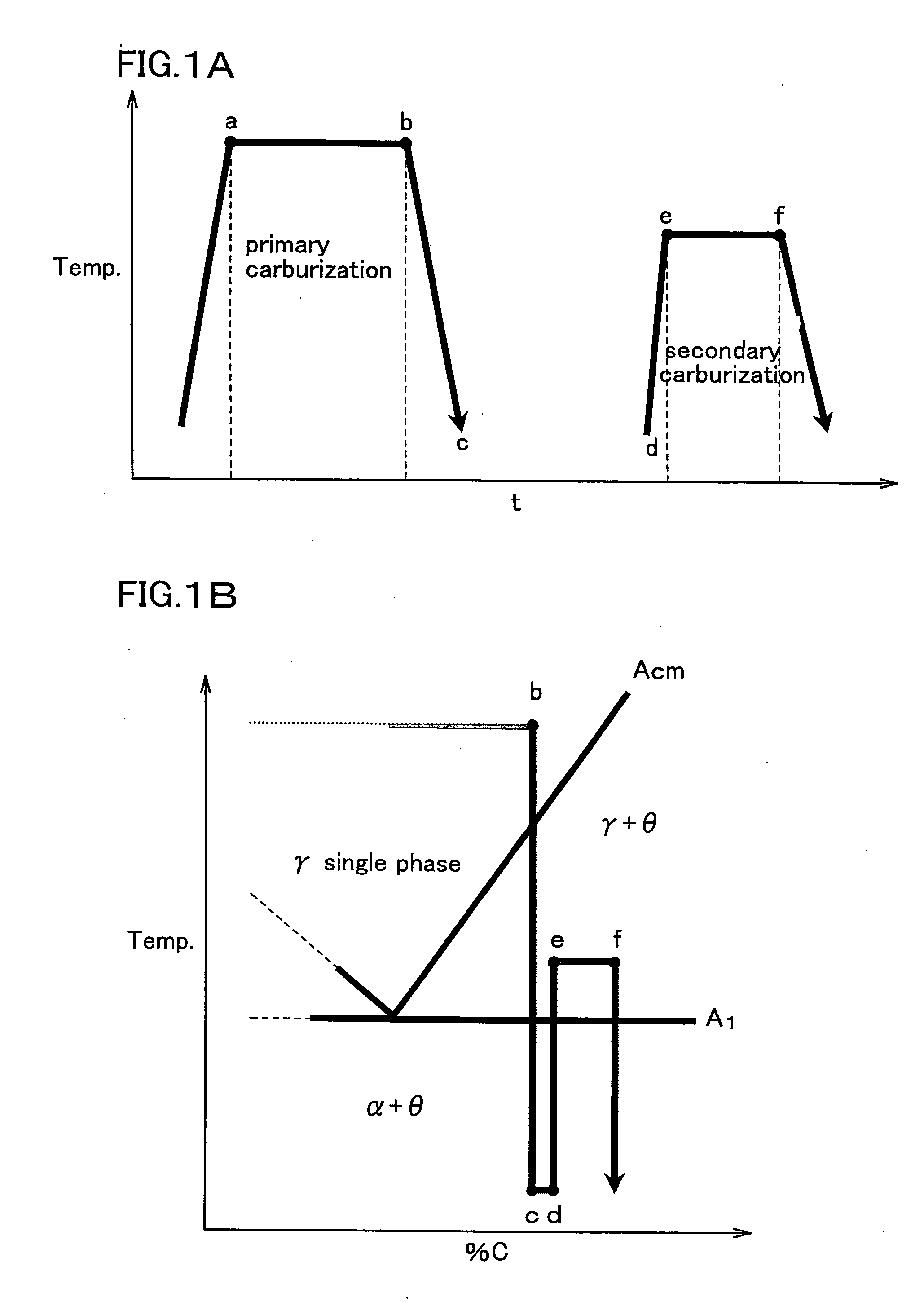

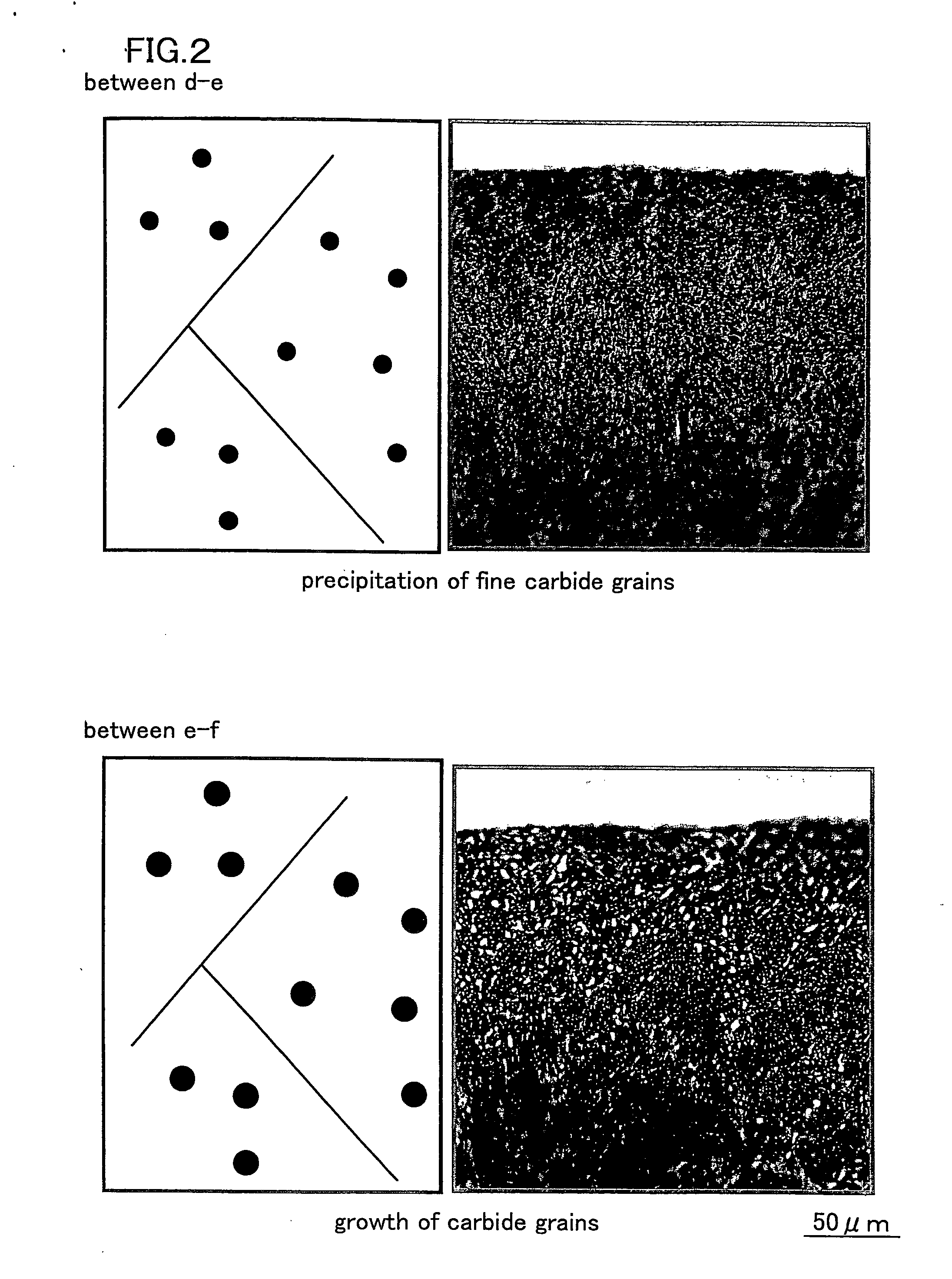

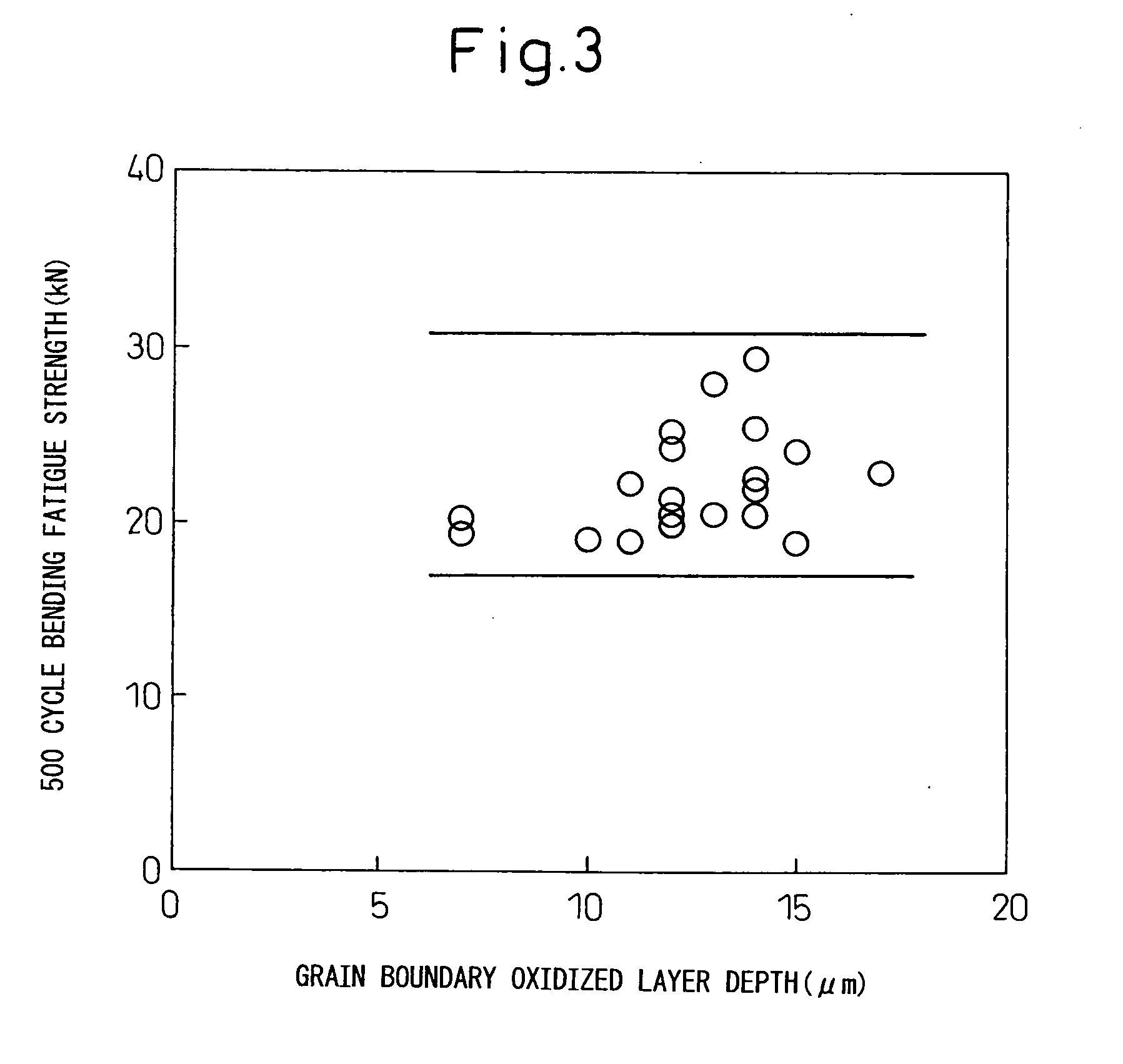

Carburized component and method of manufacturing the same

InactiveUS20060130935A1Reduce the overall heightHigh strengthSolid state diffusion coatingCarbideImpurity

This invention aims to provide a carburized component realizing a larger strength for power transmission components such as gears, and a method of manufacturing the same. The carburized component of this invention, aimed at realizing the object, consists essentially of, in % by mass and both ends inclusive, C: 0.1-0.30%, Si: 0.80-1.50%, Mn: 0.30-1.20%, Cr: 2.0-5.5%, and the balance of Fe and inevitable impurities; has a mean C concentration over the range from the surface of the steel to a depth of 0.2 mm after vacuum carburization of 1.2% or more and 3.0% or less, and has a ratio of a carbide area over the range from the surface to a depth of 50 μm of 15% or more and 60% or less, has the carbide precipitated in a finely dispersed manner so that the carbide having a grain size of 10 μm or less accounts for 90% or more of the entire portion, and has a depth of a grain boundary oxide layer below the surface of 1 μm or less.

Owner:DAIDO STEEL CO LTD +1

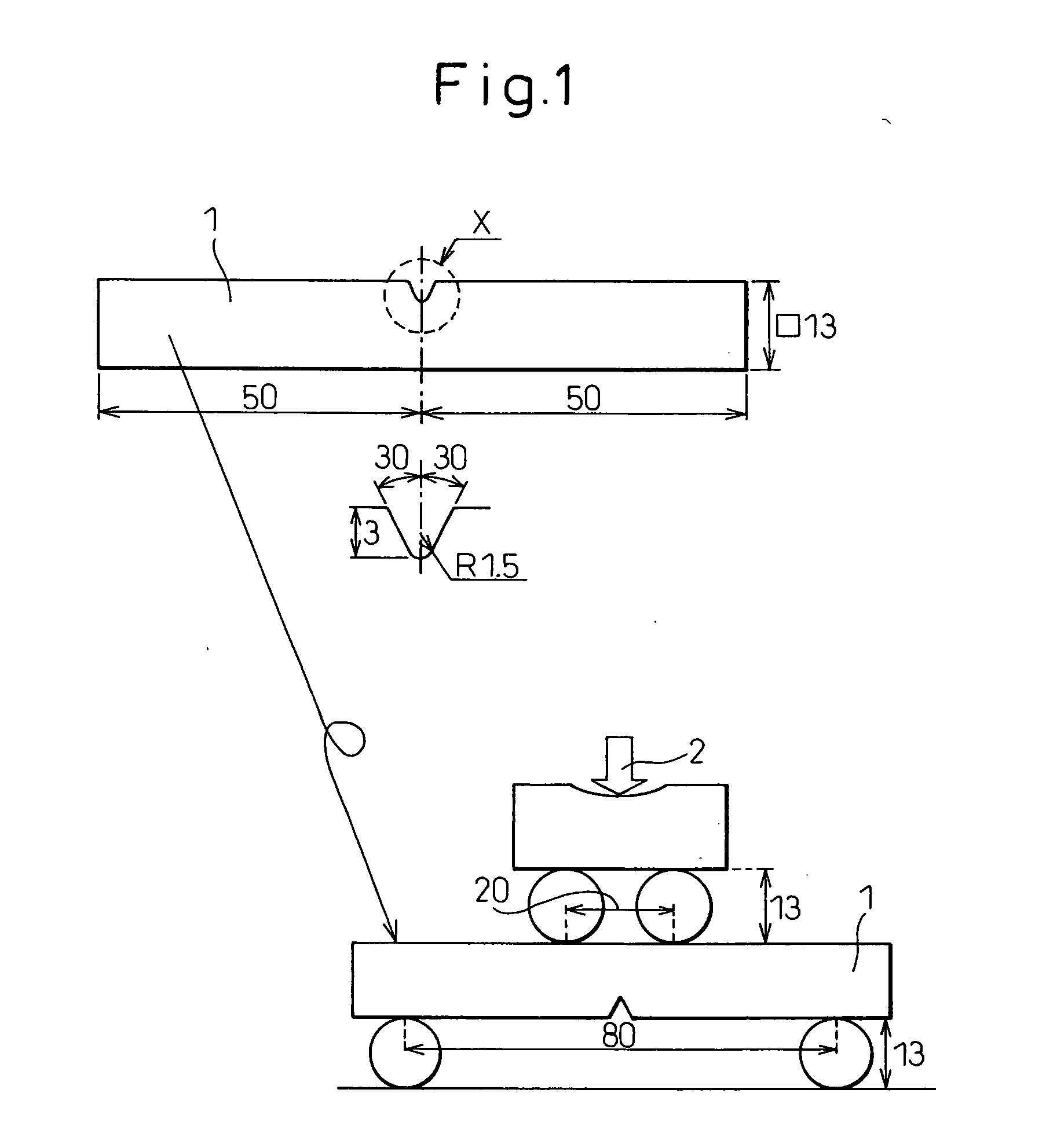

Method for mfg of double-metal saw blade

InactiveCN1449882AImprove solderabilityEasy to weldMetal sawing tool makingLaser cuttingMaterials science

The production method of bimetal saw blade for cutting metal includes the following three procedures: 1. heat treatment of saw-tooth material; 2. welding the azotized saw-tooth material on the saw band, adopting instantaneous electric welding process, and the energization time of the weld is not greater 1 second; 3. cutting saw-tooth material on the saw band, adopting laser cutting process and cutting the saw-tooth material into the saw-tooth form. Said invention is characterized by that said invented bimetal saw blade is made up by equidistantly welding several saw-tooth materials on the saw band and cutting them, and after the heat treatment of the saw-tooth material a coating process is added, so that the saw-tooth material can be easily welded on the saw band.

Owner:浙江汇达精密机械有限公司

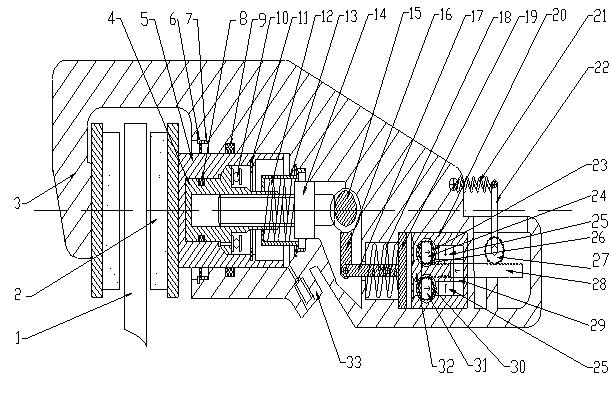

Casting process of nodular cast iron planet carrier

The invention relates to a casting process of a nodular cast iron planet carrier, which comprises the following procedures of modeling, iron melt melting, spheroidizing, modifying, casting and stress relieving and annealing. The design of a casting system adopts a step casting method which takes consideration of both bottom casting and top casting to improve the finished product rate of castings, and also adopts technical schemes of placing chill iron at the position of thick walls, adding Sn element in the iron melt, optimizing, spheroidizing, modifying, casting and the like, so that the produced planet carrier not only meets the high demands on property, but also achieves great improvement in production cost and efficiency.

Owner:JIANGSU HONGDE SPECIAL PARTS CO LTD

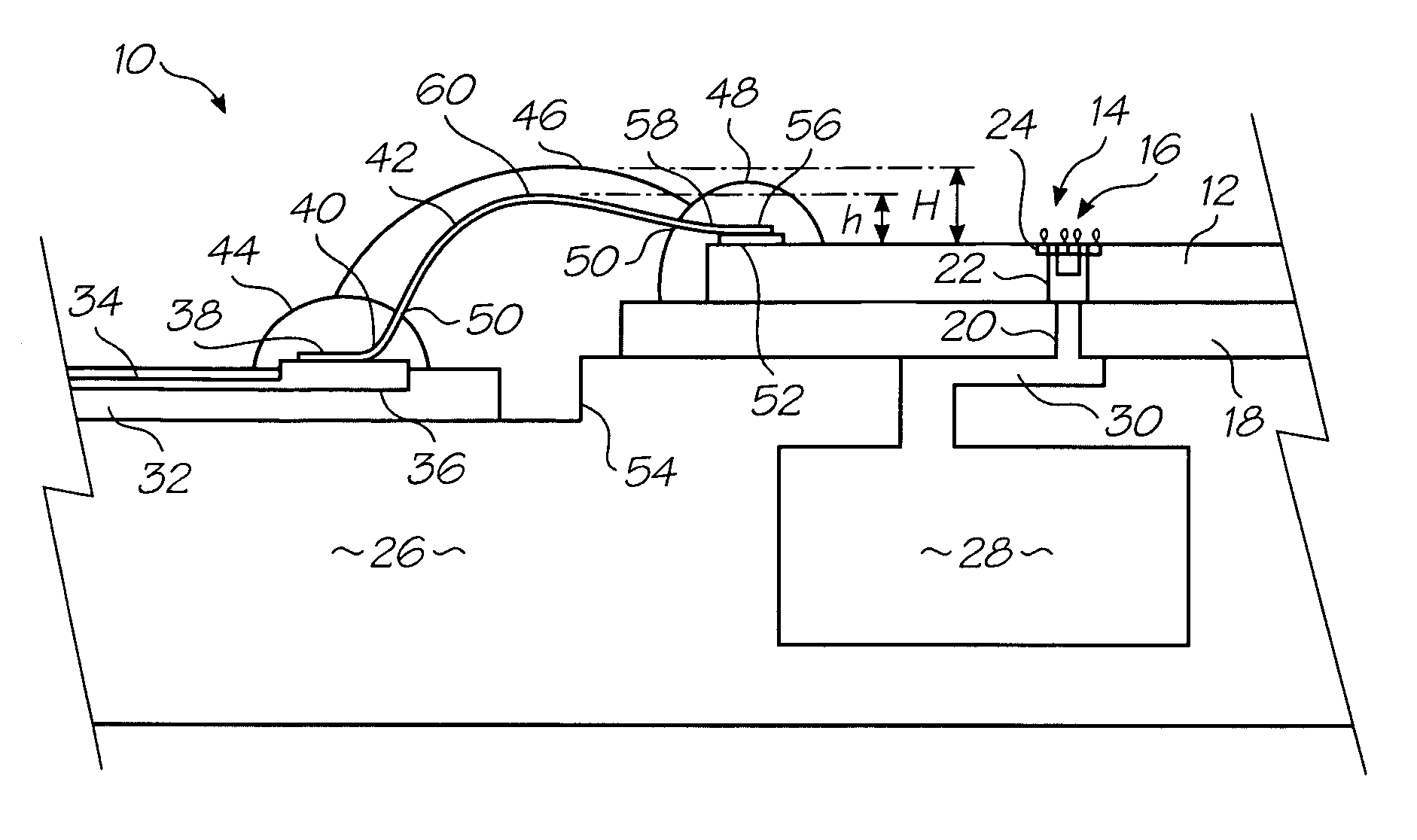

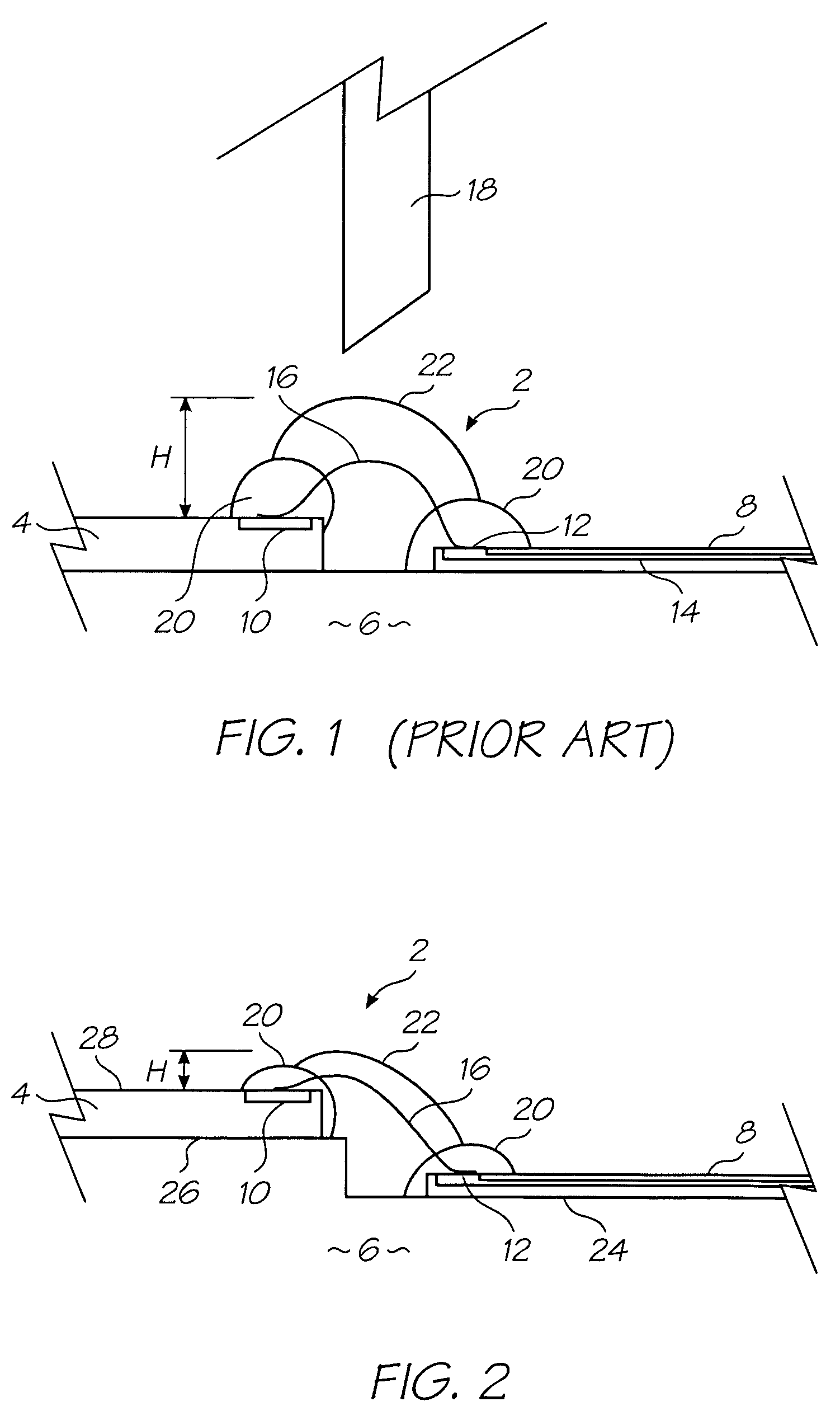

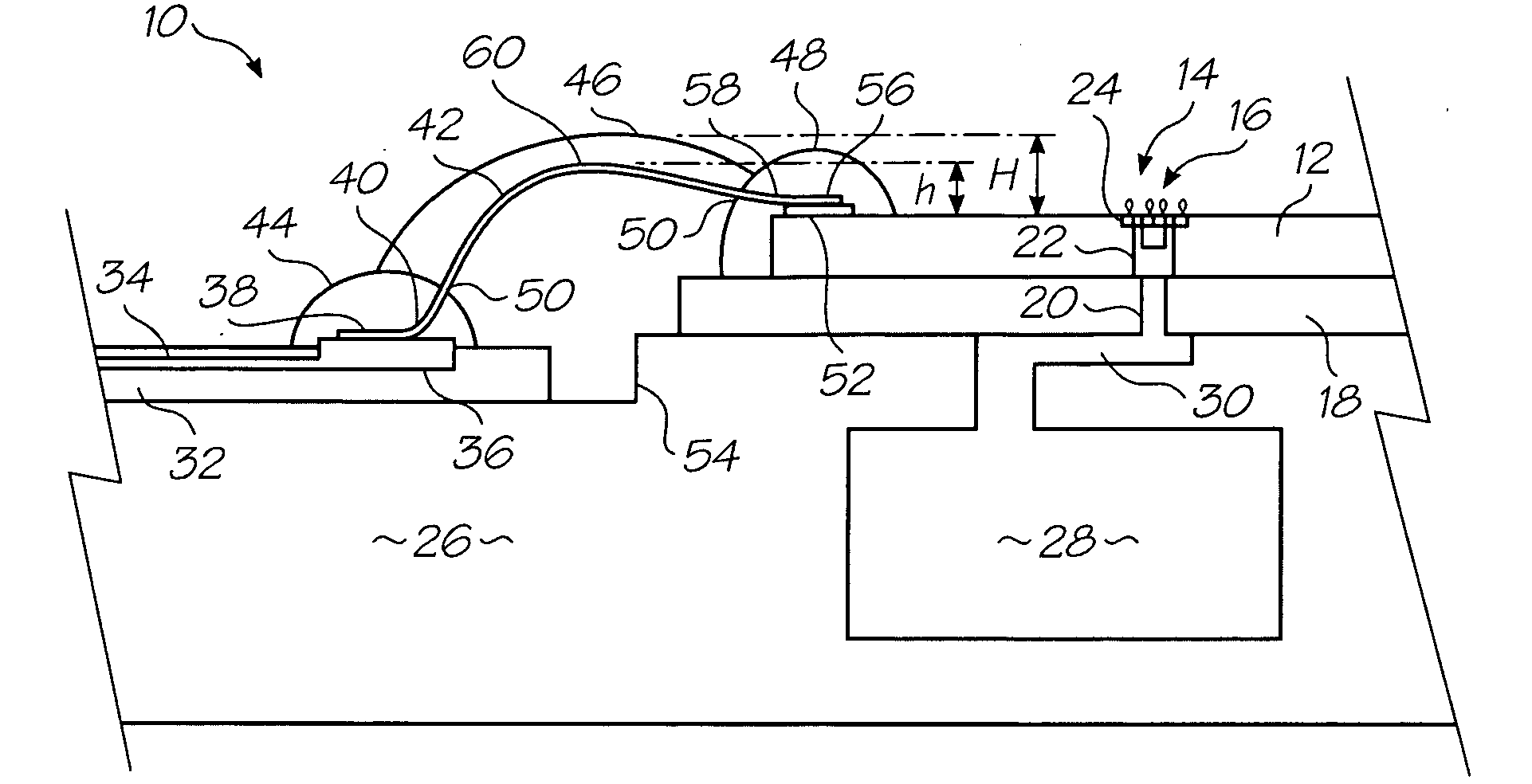

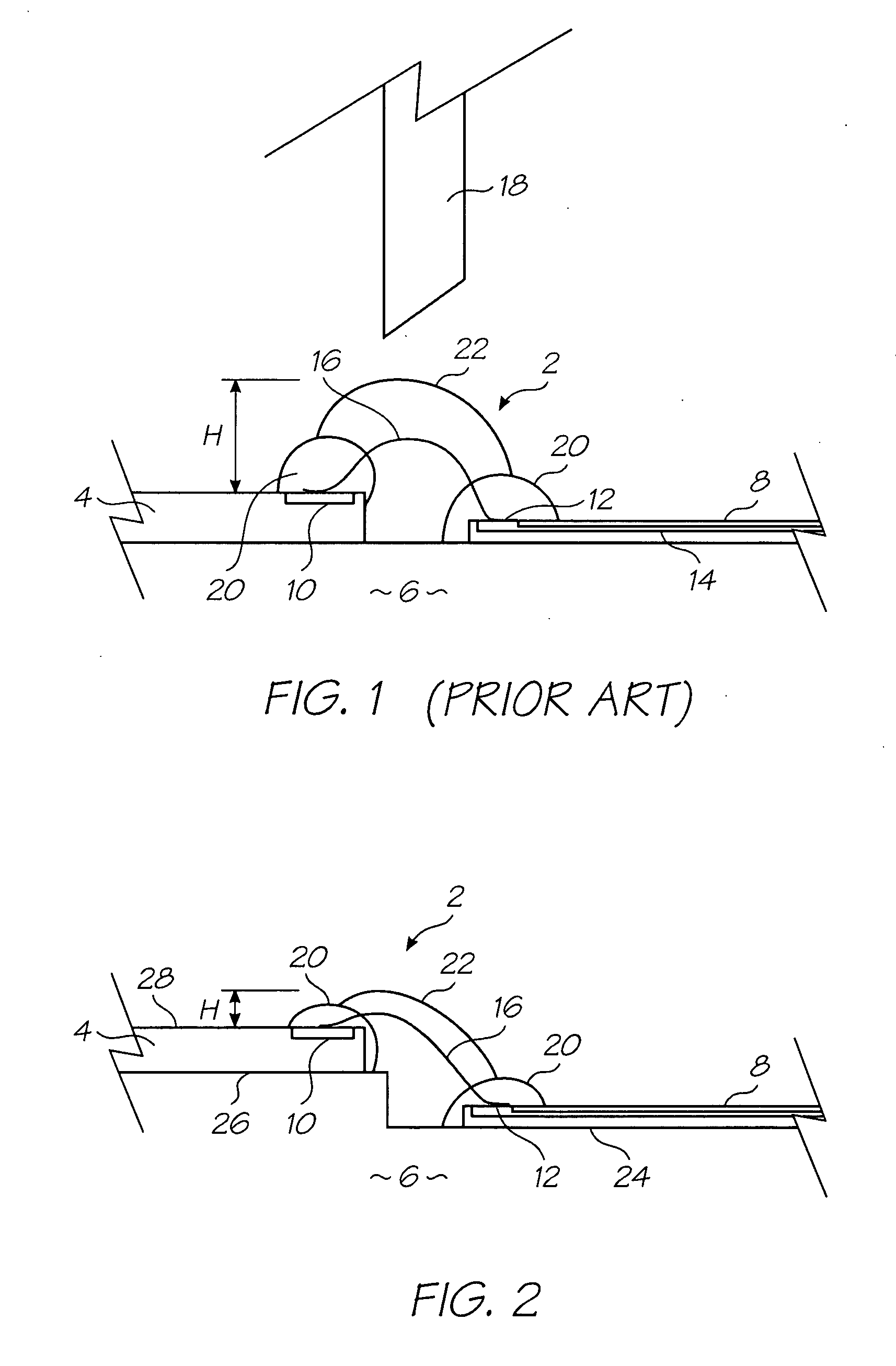

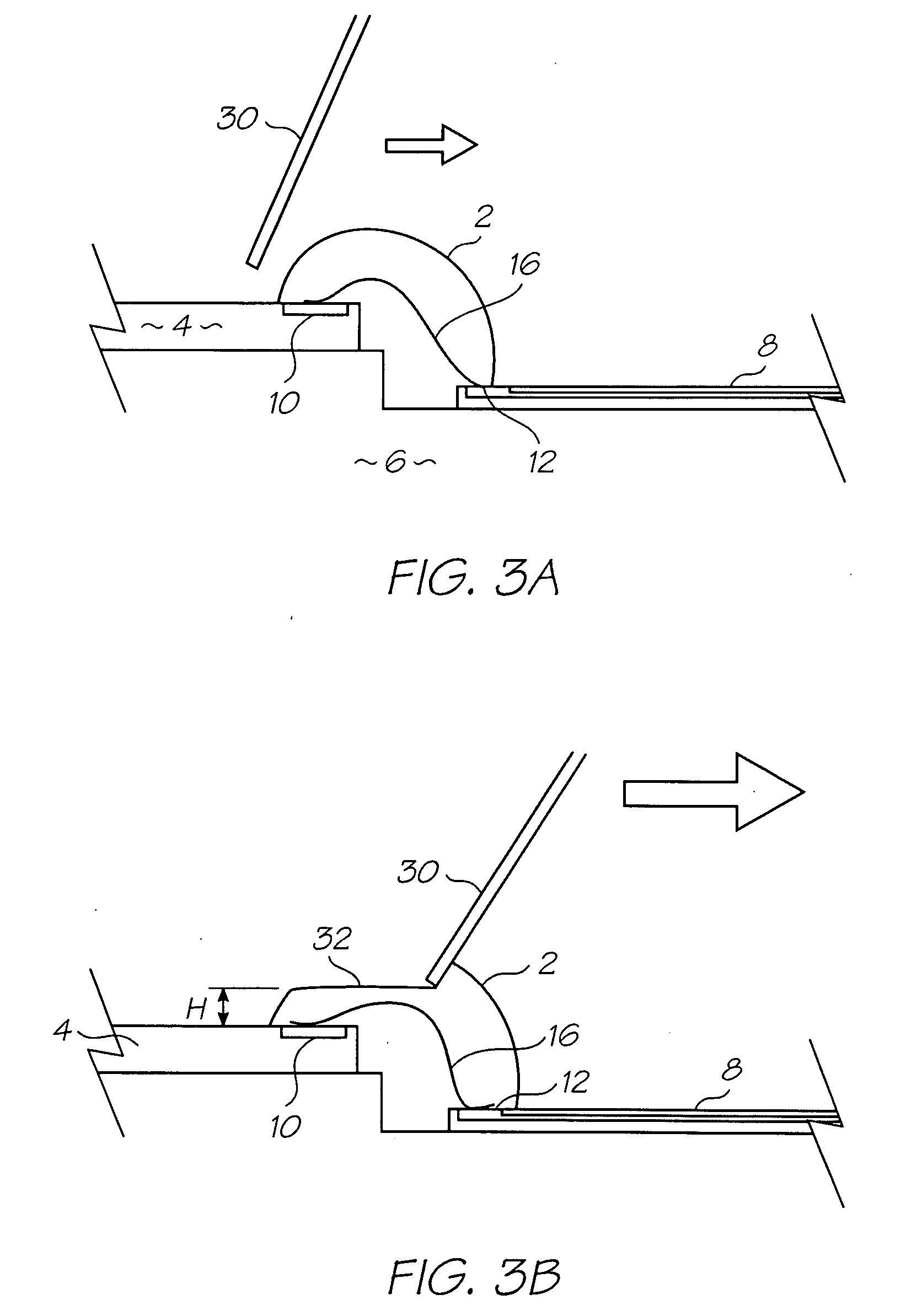

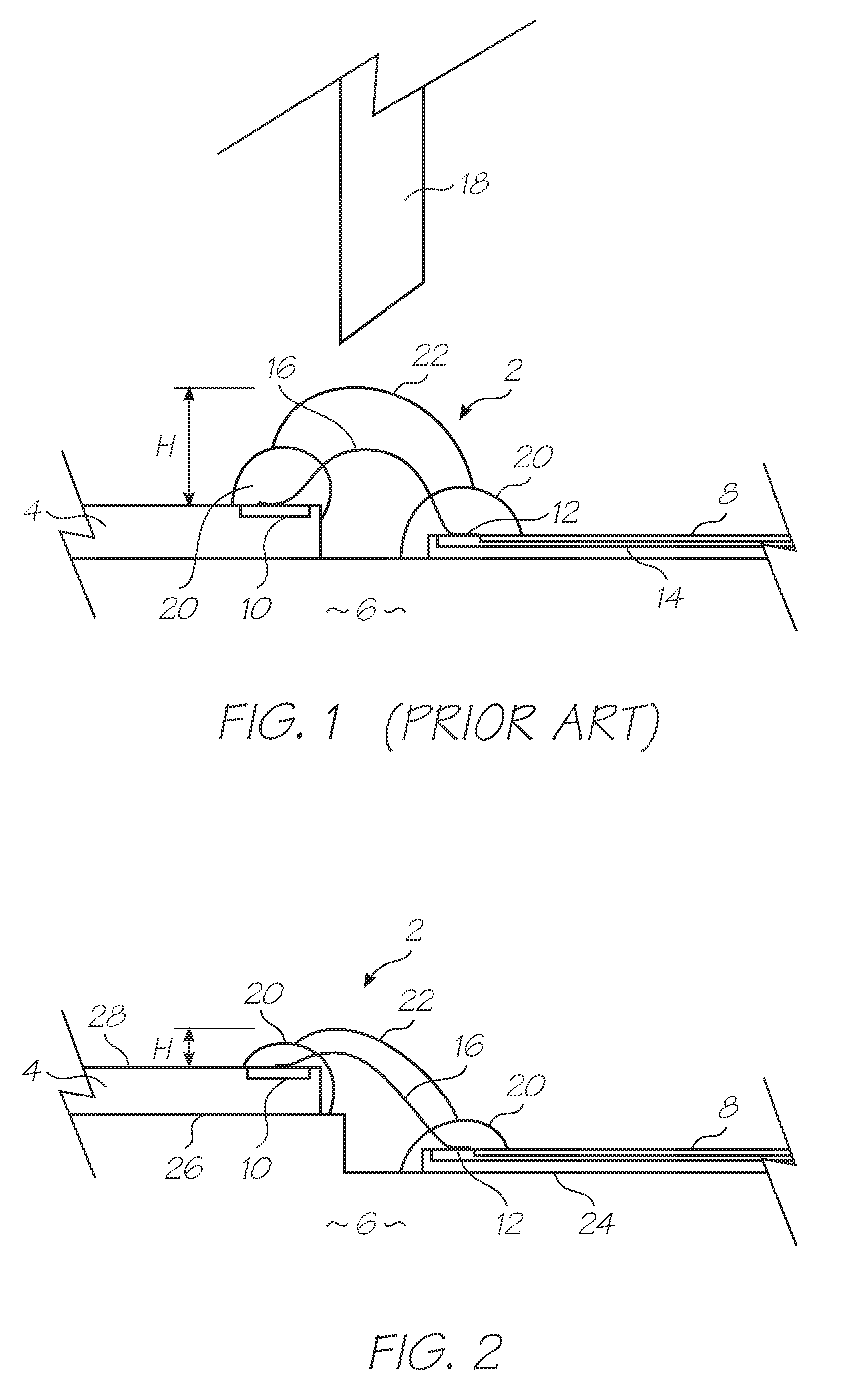

Electronic component with wire bonds in low modulus fill encapsulant

ActiveUS8063318B2High elastic modulusReduce fatigue strengthElectrically conductive connectionsSemiconductor/solid-state device detailsElectrical conductorEngineering

An electronic component that has a support structure with a plurality of electrical conductors, a series of wire bonds, each of the wire bonds extending from one of the electrical conductors respectively, each of the wire bonds having an end section contacting the electrical conductor and an intermediate section contiguous with the end section, a bead of dam encapsulant encapsulating the electrical conductors and the end section of each of the wire bonds, and a bead of fill encapsulant contacting the bead of dam encapsulant and encapsulating the intermediate portion of each of the wire bonds. The dam encapsulant has a higher modulus of elasticity than the fill encapsulant.

Owner:SILVERBROOK RES PTY LTD

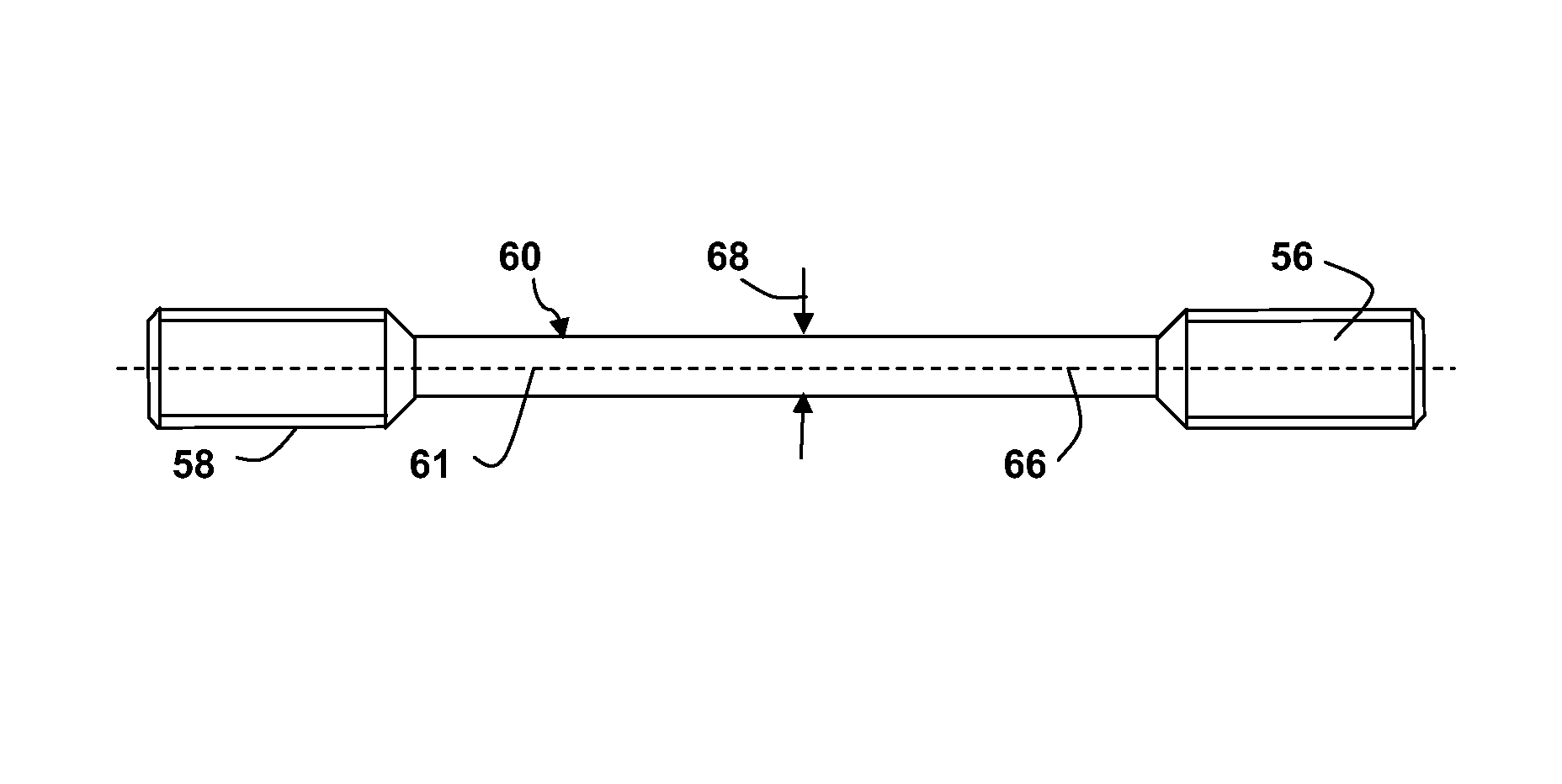

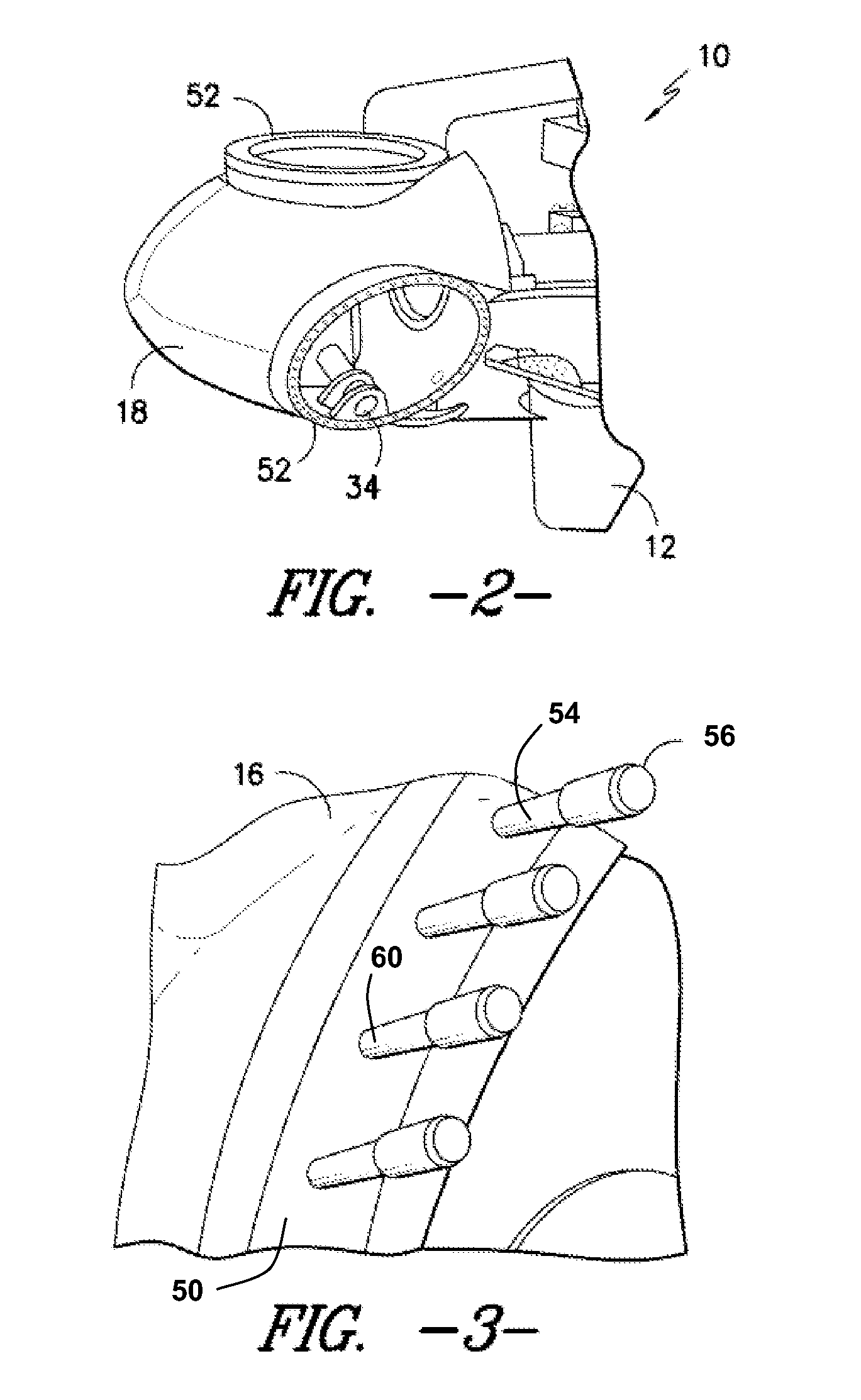

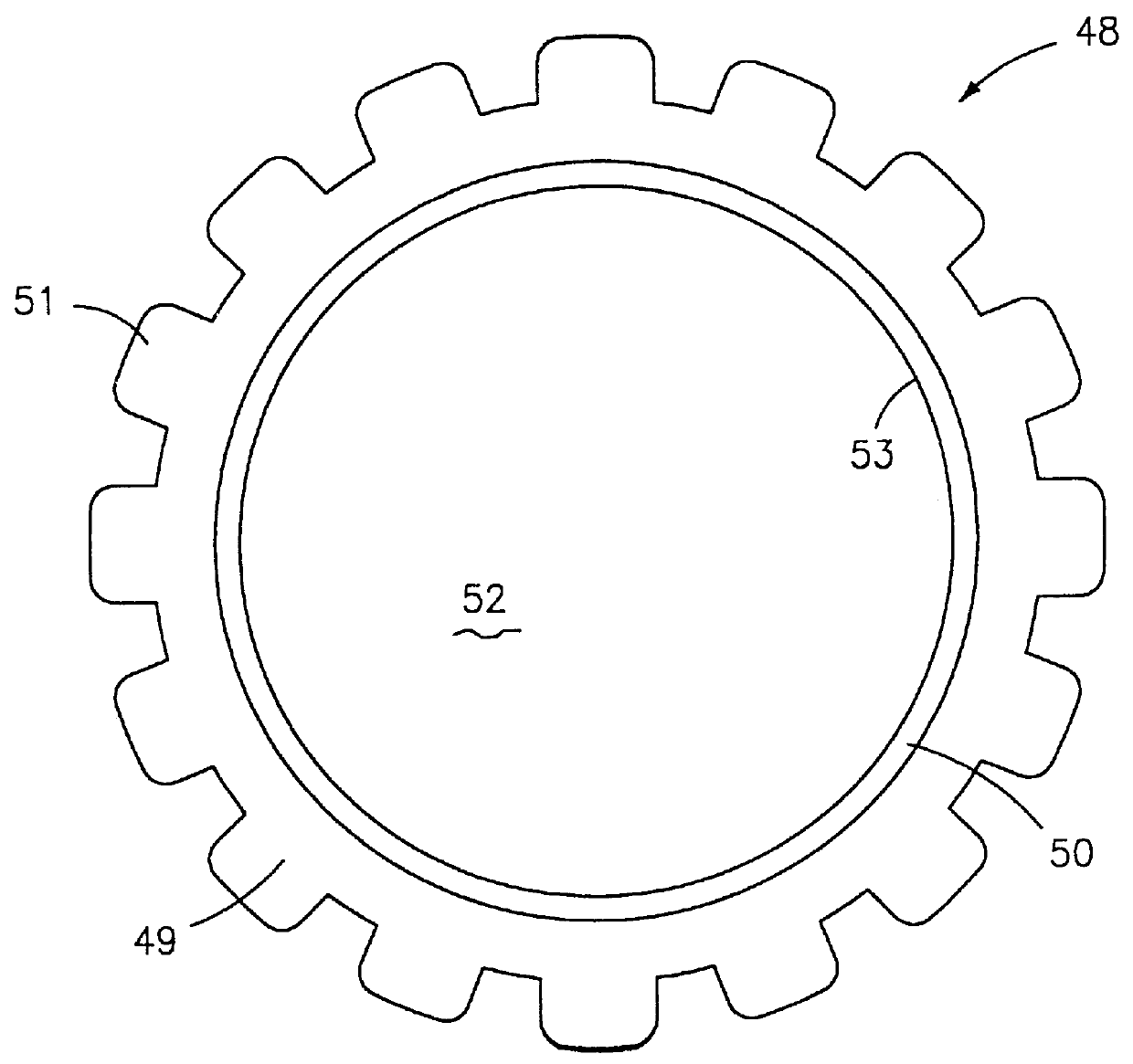

Wind turbine blade attachment configuration with flattened bolts

ActiveUS8025485B2Maximize fatigue strengthReduce load intensityPump componentsEngine fuctionsTurbine bladeEngineering

A wind turbine includes a plurality of turbine blades, with each of the blades having a root flange that attaches to a flange of a rotor hub by a plurality of circumferentially spaced blade bolts. The blade bolts have opposite cylindrical end sections engaged within the rotor hub flange and blade root flange, respectively, and a non-cylindrical shank extending between the cylindrical end sections. At least one flattened side is defined in the shank along a longitudinal axis of the bolt.

Owner:LM WIND POWER US TECH APS

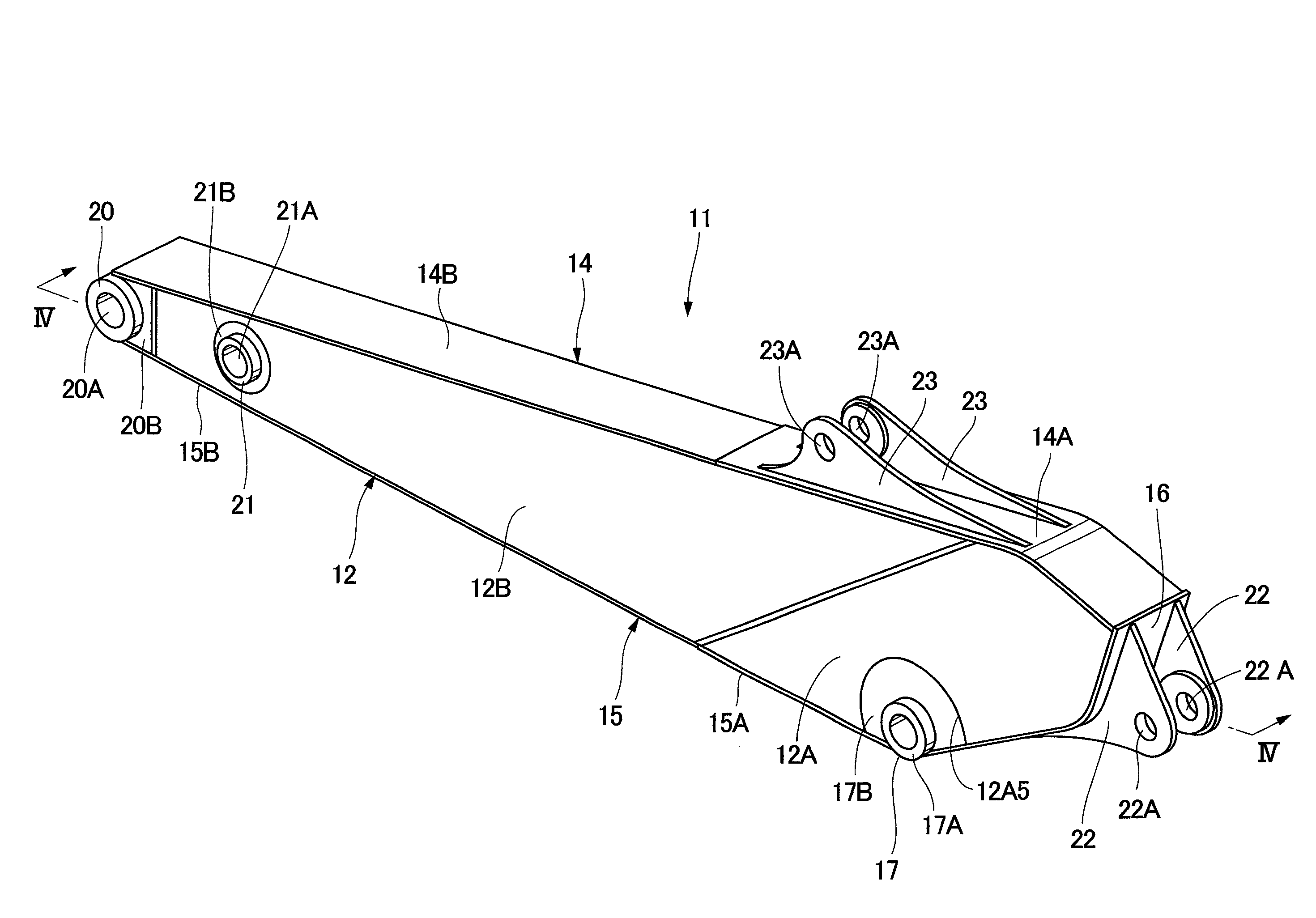

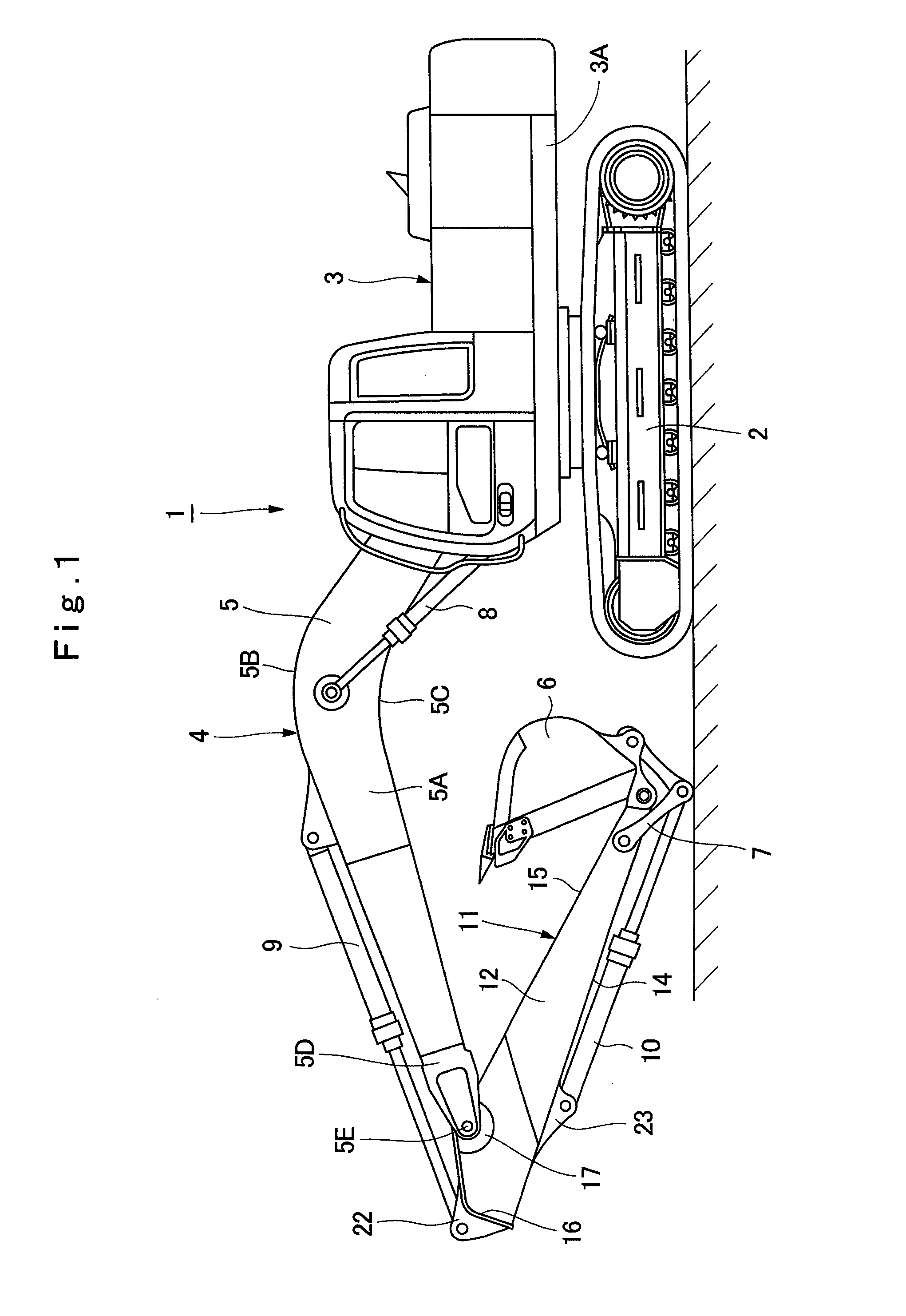

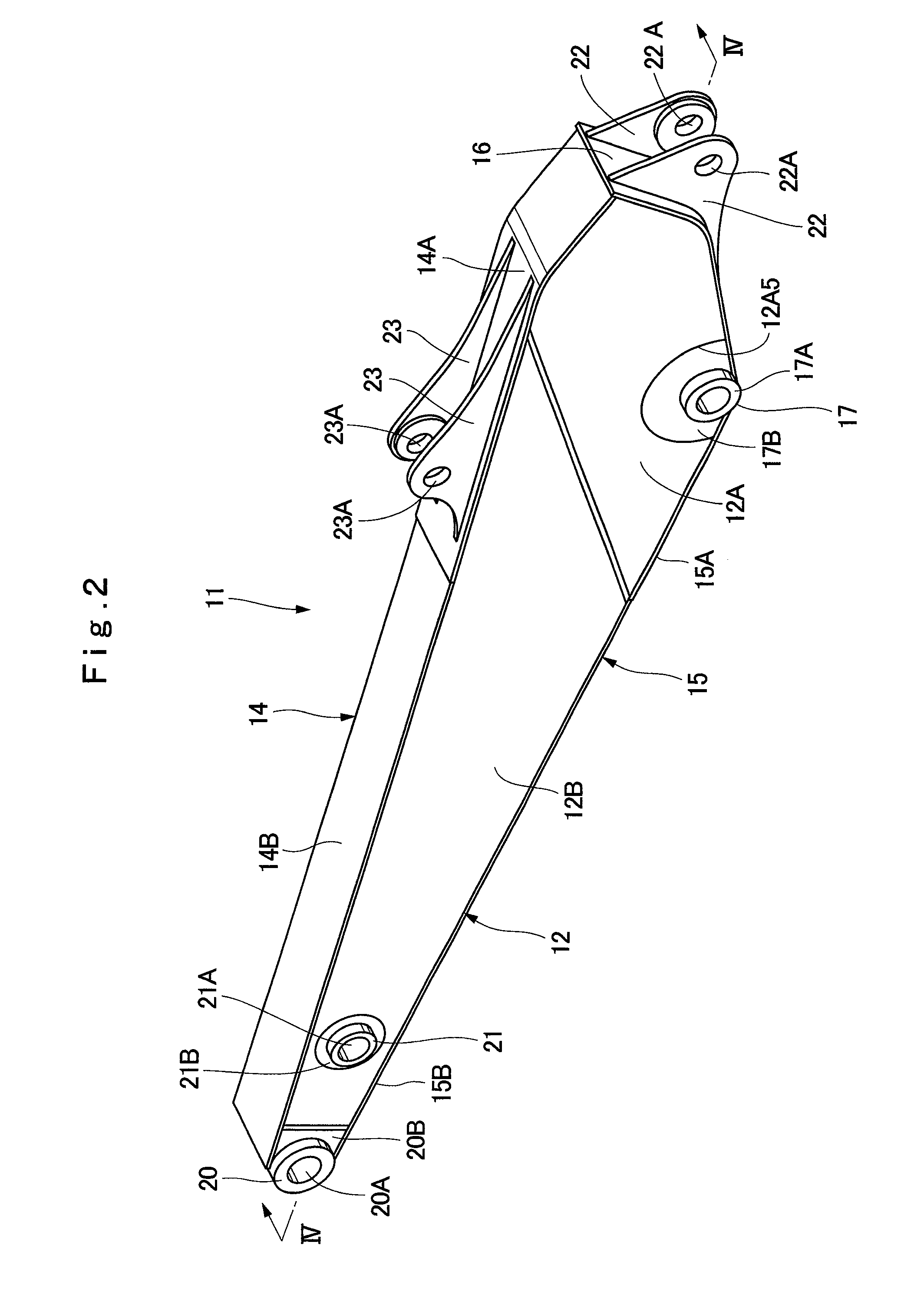

Arm for construction machine

ActiveUS20140334906A1Prone to fatigue crackingReduce fatigue strengthMechanical machines/dredgersLifting devicesArchitectural engineeringEntire arm

In an arm for a construction machine formed as a box-shaped structural body by left and right side plates, an upper plate, a lower plate, and a rear plate, a left rear thick side plate constituting the left side plate, a right rear thick side plate constituting the right side plate, a rear thick upper plate constituting the upper plate, and a rear thick lower plate constituting the lower plate are formed by using a soft steel material having a large plate thickness. A left front thin side plate constituting the left side plate, a right front thin side plate constituting the right side plate, a front thin upper plate constituting the upper plate, and a front thin lower plate constituting the lower plate are formed by using a high tensile steel material having a small plate thickness. As a result, the weight of the entire arm can be reduced.

Owner:NIHON KENKI CO LTD

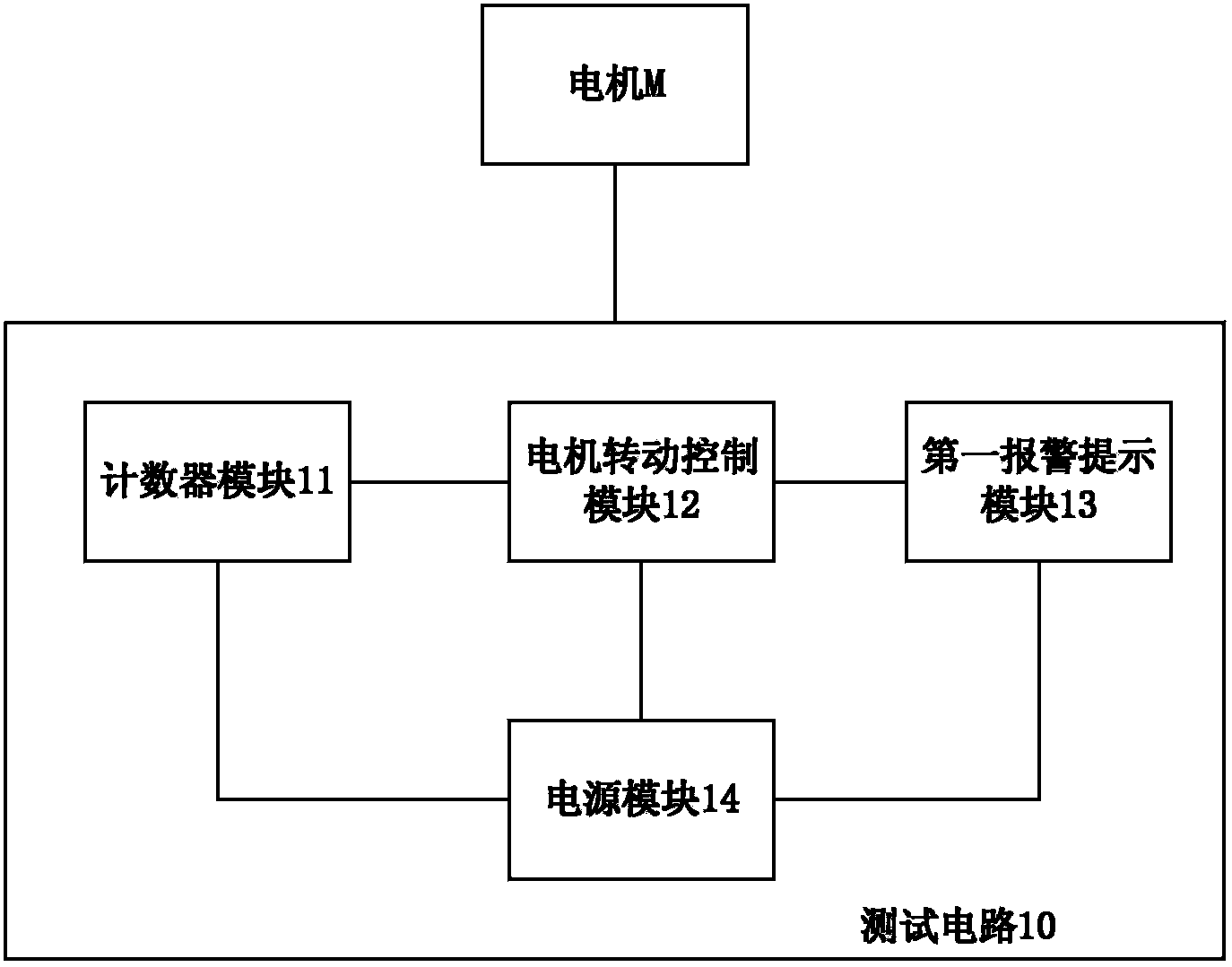

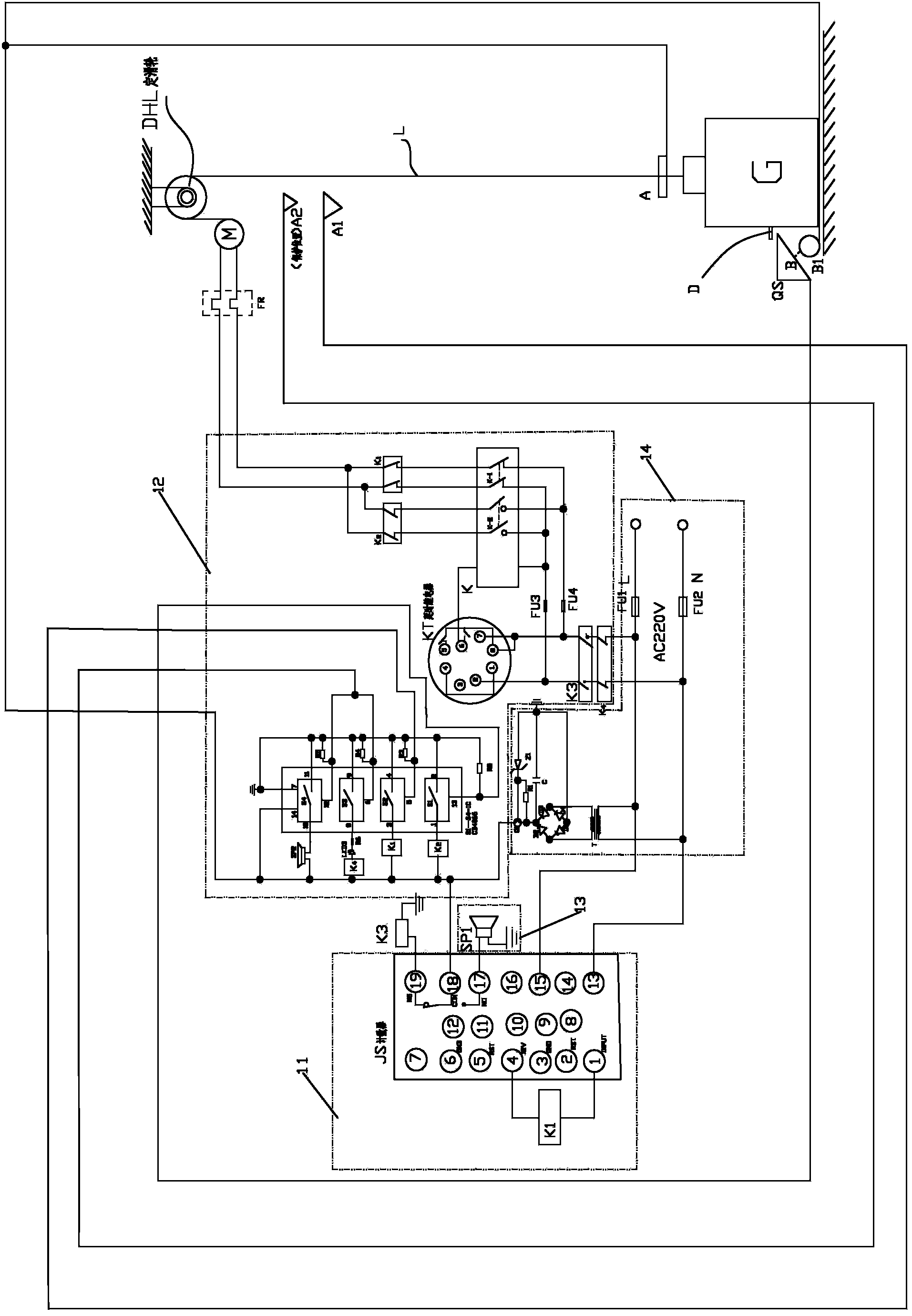

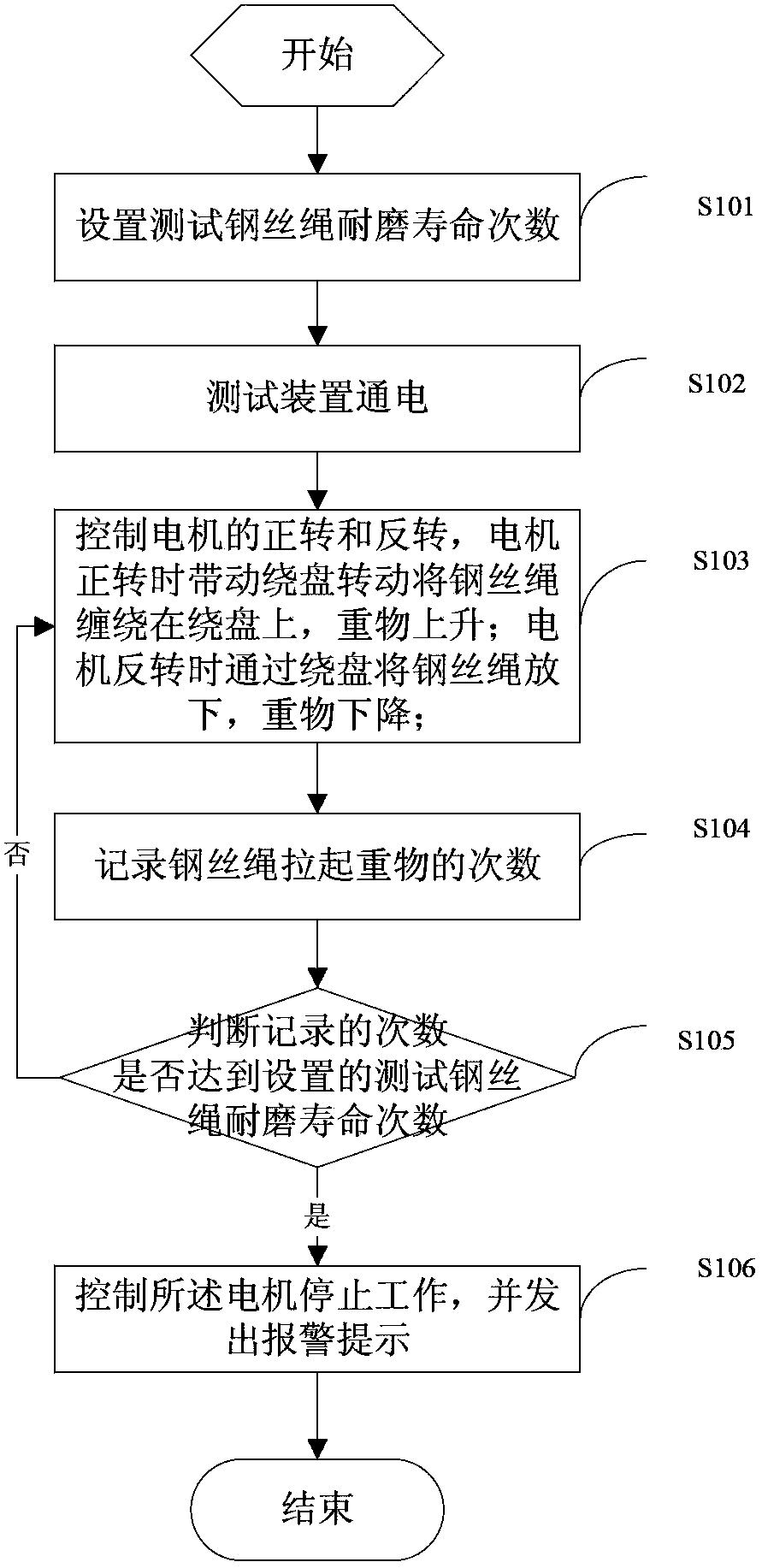

Device and method for testing wearing life of steel wire rope

ActiveCN103454171AReduce fatigue strengthImprove securityInvestigating abrasion/wear resistanceFatigue IntensityTest efficiency

The invention discloses a device and a method for testing the wearing life of a steel wire rope. The test device comprises a fixed pulley, a steel wire rope and a heavy object, and one end of the steel wire rope is suspendingly provided with the heavy object; the test device also comprises a motor, a winding disk and a test circuit, the winding disk is assembled on the motor, the other end of the steel wire rope passes through the fixed pulley and is fixed on the winding disk, and the test circuit is connected with the motor; the test circuit is used for controlling positive rotation and reverse rotation of the motor under a condition of a preset number of times for testing the wearing life of the steel wire rope, so as to driving the heavy object to rise and fall through the steel wire rope; when the preset number of times for testing the wearing life of the steel wire rope reaches, finishing of the test is reminded through the test circuit. The device and the method can allow testing personnel not to personally pull the steel wire rope to test and also not to always keep recording tensile times, and thereby reducing the fatigue intensity of the testing personnel; and the test device is simple, safe and reliable, and moreover, can improve the testing efficiency and safety.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

Composite binder grinding wheel and manufacturing method thereof

InactiveCN105538177AImprove qualityRich varietyAbrasion apparatusGrinding devicesCeramic metalGrinding wheel

The invention relates to the field of grinding tools and abrasives, in particular to a composite binder grinding wheel and a manufacturing method thereof. The composite binder grinding wheel is prepared from raw materials comprising the abrasive, metal powder, an organic binder and magnesia. The manufacturing method comprises the following steps: producing metal composite abrasive particles and ceramic metal composite abrasive particles, then compressing to form a grinding wheel billet, and finally solidifying to form the composite binder grinding wheel. A metal binder, a magnesia binder, a resin binder are sintered with the abrasive particles by stages, and finally the grinding wheel is formed by compression. The performance of the manufactured grinding wheel is significantly improved compared with a single-binder grinding wheel, the manufacture cost of special grinding wheels can be reduced, and the varieties of binders and the varieties of grinding wheels are expanded in grinding wheel manufacturing.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

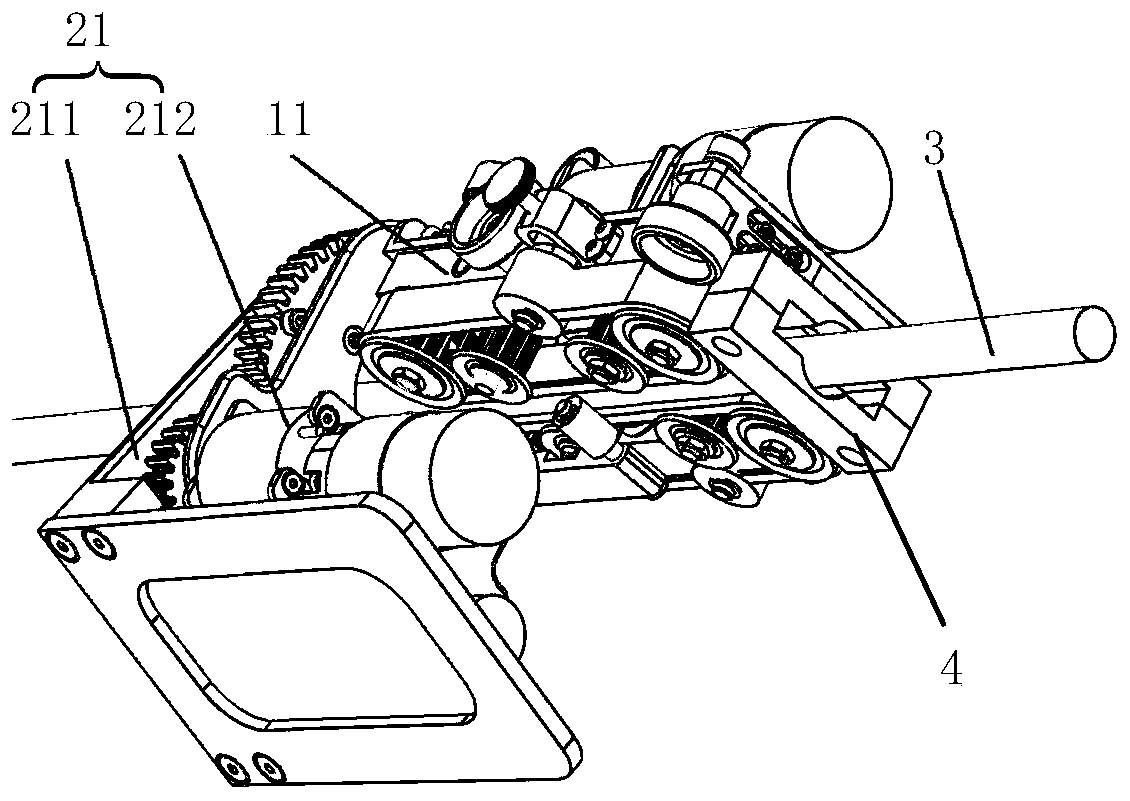

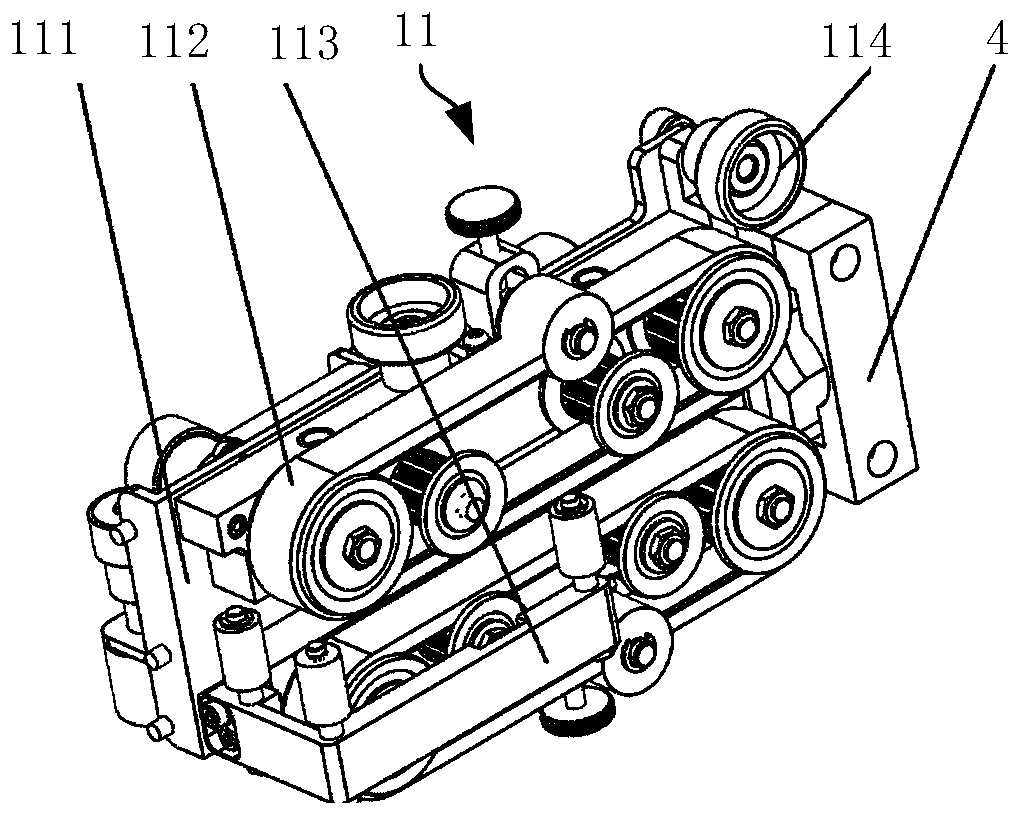

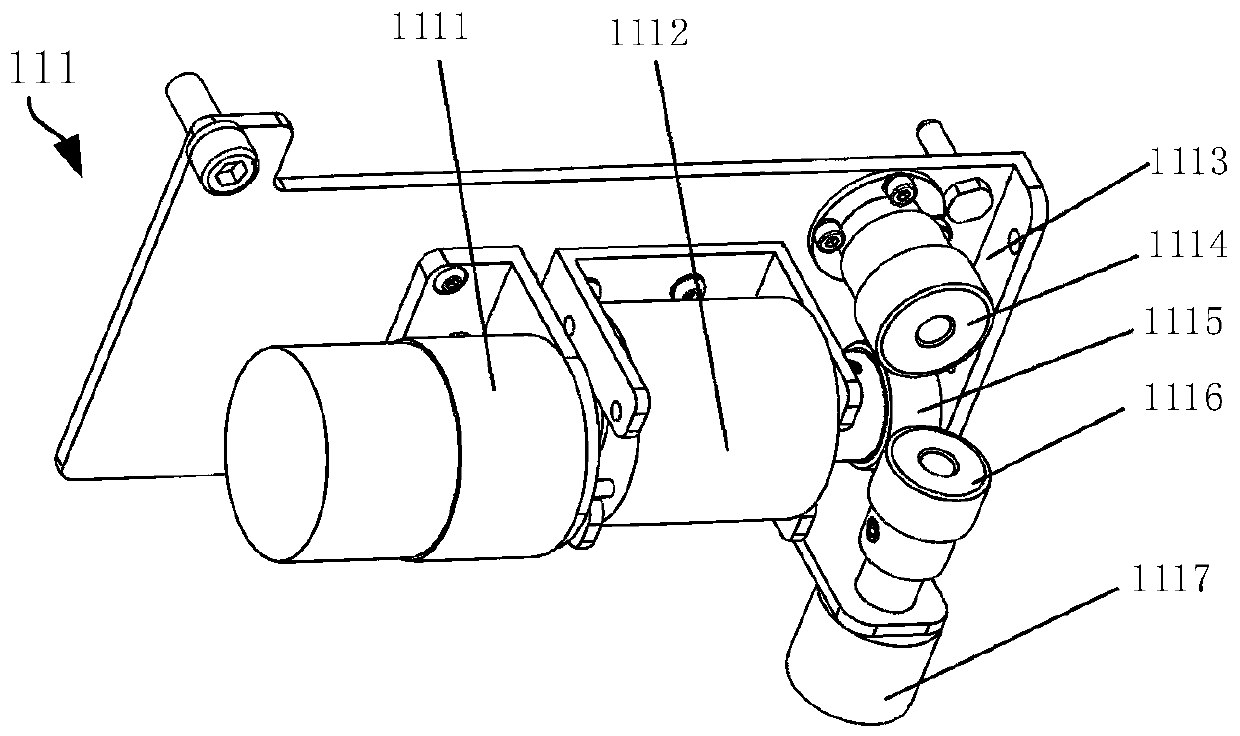

Clamping control device for endoscope

The invention relates to the technical field of auxiliary equipment for an endoscope, and discloses a clamping control device for an endoscope. The clamping control device is used for clamping an endoscope tube body and performing advancing, retreating and rotating operations on the endoscope tube body. The clamping control device comprises: a tube body advancing and retreating mechanism for driving the endoscope tube body to continuously advance or retreat, and a tube body rotating mechanism used for driving the endoscope tube body to rotate, wherein the tube body advancing and retreating mechanism and / or the tube body rotating mechanism abut / abuts against the endoscope tube body so as to clamp the endoscope tube body. The clamping control device for the endoscope is easy and convenient to maintain, flexible in action, safe and reliable to, convenient to disassemble and clean and good in operation comfort, can greatly shorten the time needed by an operation or examination, and allowsthe fatigue strength of a doctor in the operation to be reduced.

Owner:北京双翼麒电子有限公司 +1

Corrosion resistant metal coating for gear box inner surface

ActiveCN106498291AStable austenite phaseImprove hardenabilityNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveCorrosion resistantMetal coating

The invention discloses a corrosion resistant metal coating for a gear box inner surface. The corrosion resistant metal coating comprises the following components by mass percentage: 0.03-0.05% of C, 0.45-0.48% of Mn, 12.76-12.79% of Cr, 6.12-6.15% of Ni, 0.16-0.18% of Mg, 0.22-0.25% of Mo, 0.27-0.29% of Co, 0.26-0.28% of V, 0.22-0.24% of Ti, 0.21-0.23% of Na, 0.12-0.15% of Ga, 0.32-0.35% of Eu, 0.12-0.14% of Lu, 0.62-0.68% of La, and the balance Fe.

Owner:南京创贝高速传动机械有限公司

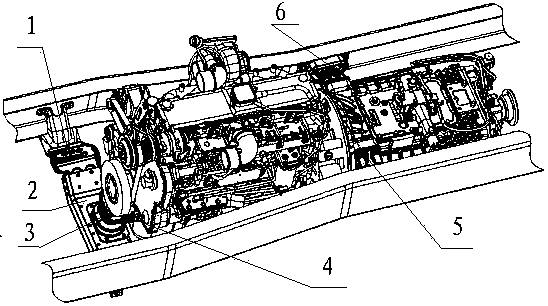

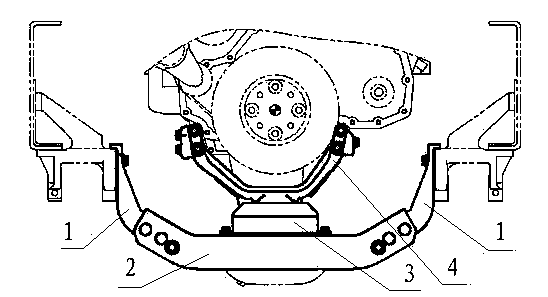

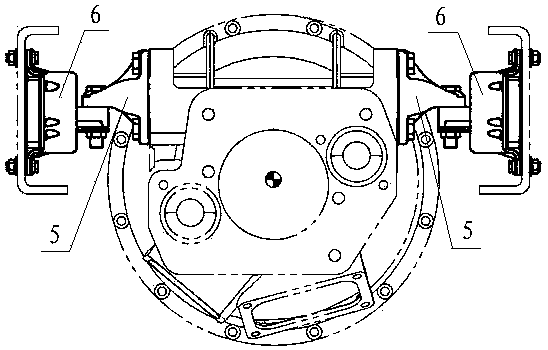

Automobile power assembly suspension device

InactiveCN104118307AStable structureImprove the vibration isolation effectJet propulsion mountingInternal combustion mountingManufacturing technologyVibration isolation

The invention discloses an automobile power assembly suspension device, and relates to the technical field of automobile making. The automobile power assembly suspension device comprises an engine suspension arranged on the front portion of an engine and two gearbox suspensions arranged on a rear gearbox of the engine. The engine suspension comprises a front suspension cylinder body support connected to the bottom of the engine, a front suspension transverse beam connected with two ends connected with a front suspension support is arranged below the front suspension cylinder body support, and the front suspension support is connected with an automobile beam. A front suspension soft cushion is arranged between the front suspension cylinder body support and the front suspension transverse beam. Each gearbox suspension comprises a rear suspension cylinder body support connected with the gearbox, wherein the rear suspension cylinder body support is connected with a rear suspension soft cushion fixed to the automobile beam. The automobile power assembly suspension device can solve the problems that a whole heavy truck is high in vibration and noise and poor in vibration isolation capacity, and consequently riding comfort of the truck is influenced.

Owner:DONGFENG LIUZHOU MOTOR

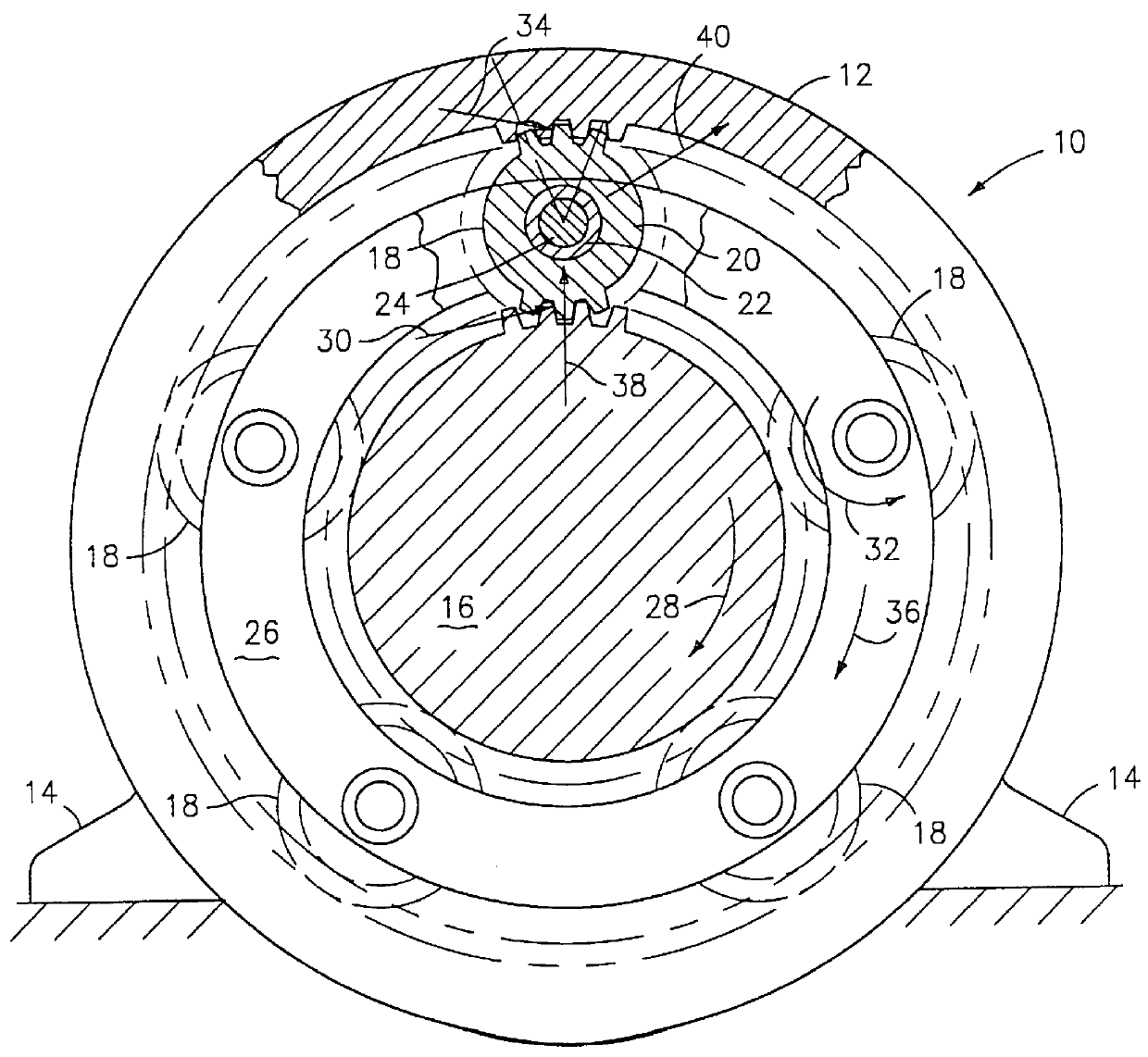

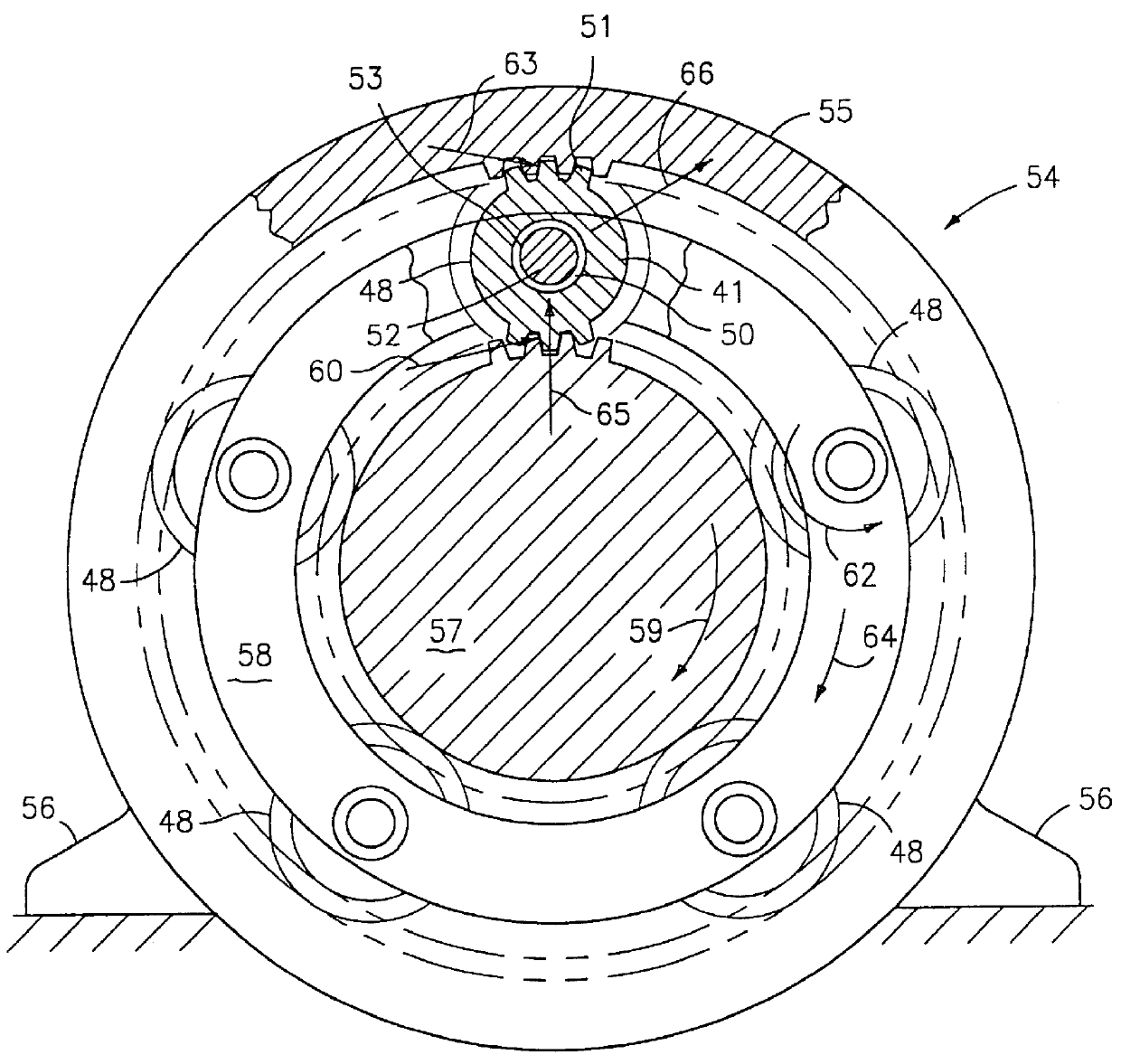

Method of making a coated planet gear journal bearing

InactiveUS6159348AReduce weightLow sommerfeld numberLiquid surface applicatorsVacuum evaporation coatingBearing surfaceLand based

The production of a bearing surface by coating a known bearing material directly on the surface of a gear bore. A process of coating bearing materials directly onto the surface of a gear and the product thereof. The surface is preferably the inner bore surface of a planet gear. The coating methods include sputtering and vapor deposition. The bearing material applied as a coating is preferably a copper-lead composition. The resultant gear having a bearing coating can be useful in any high density, high efficiency epicyclic gear train for aircraft, marine or land based power transmissions.

Owner:UNITED TECH CORP

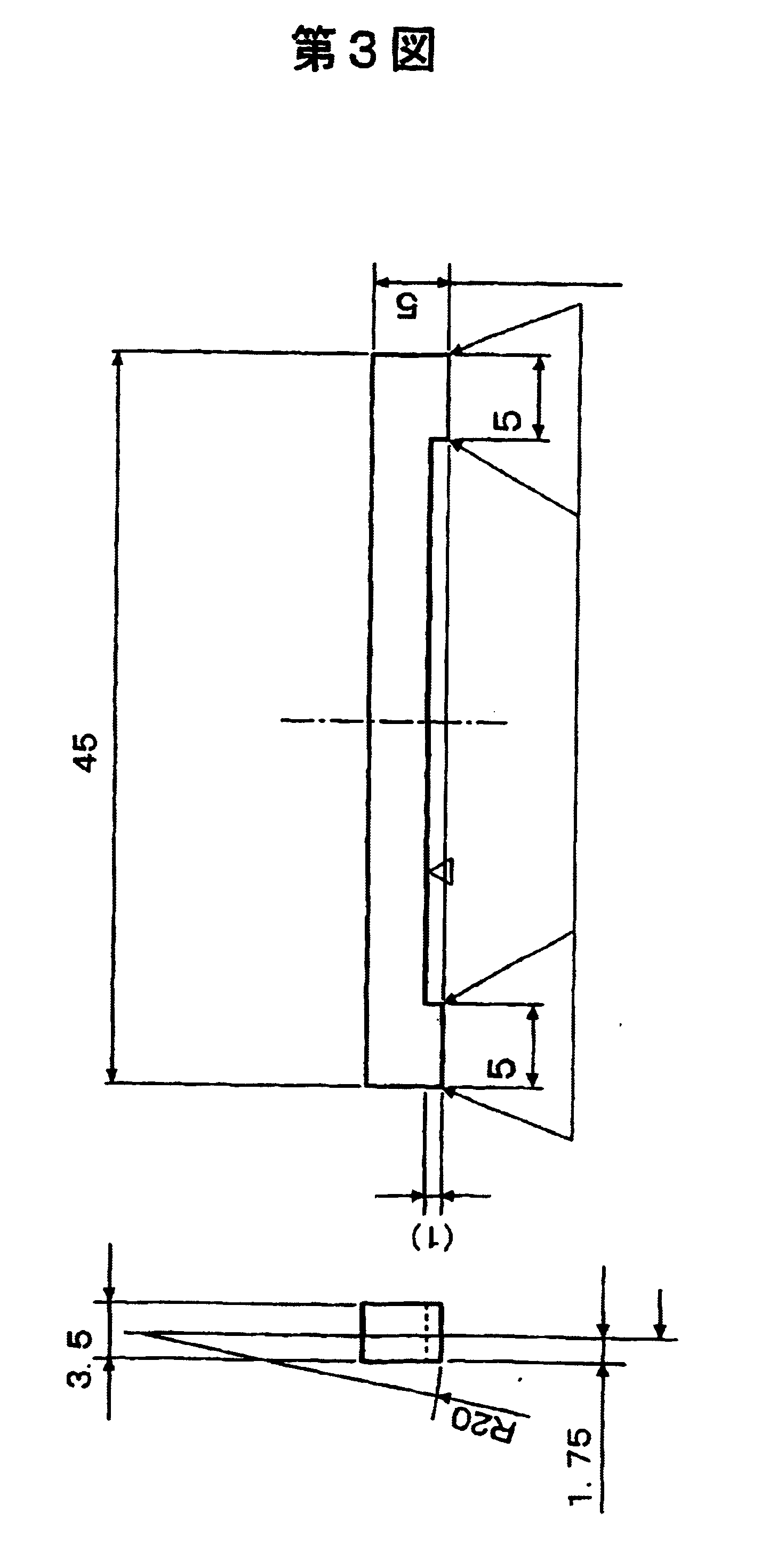

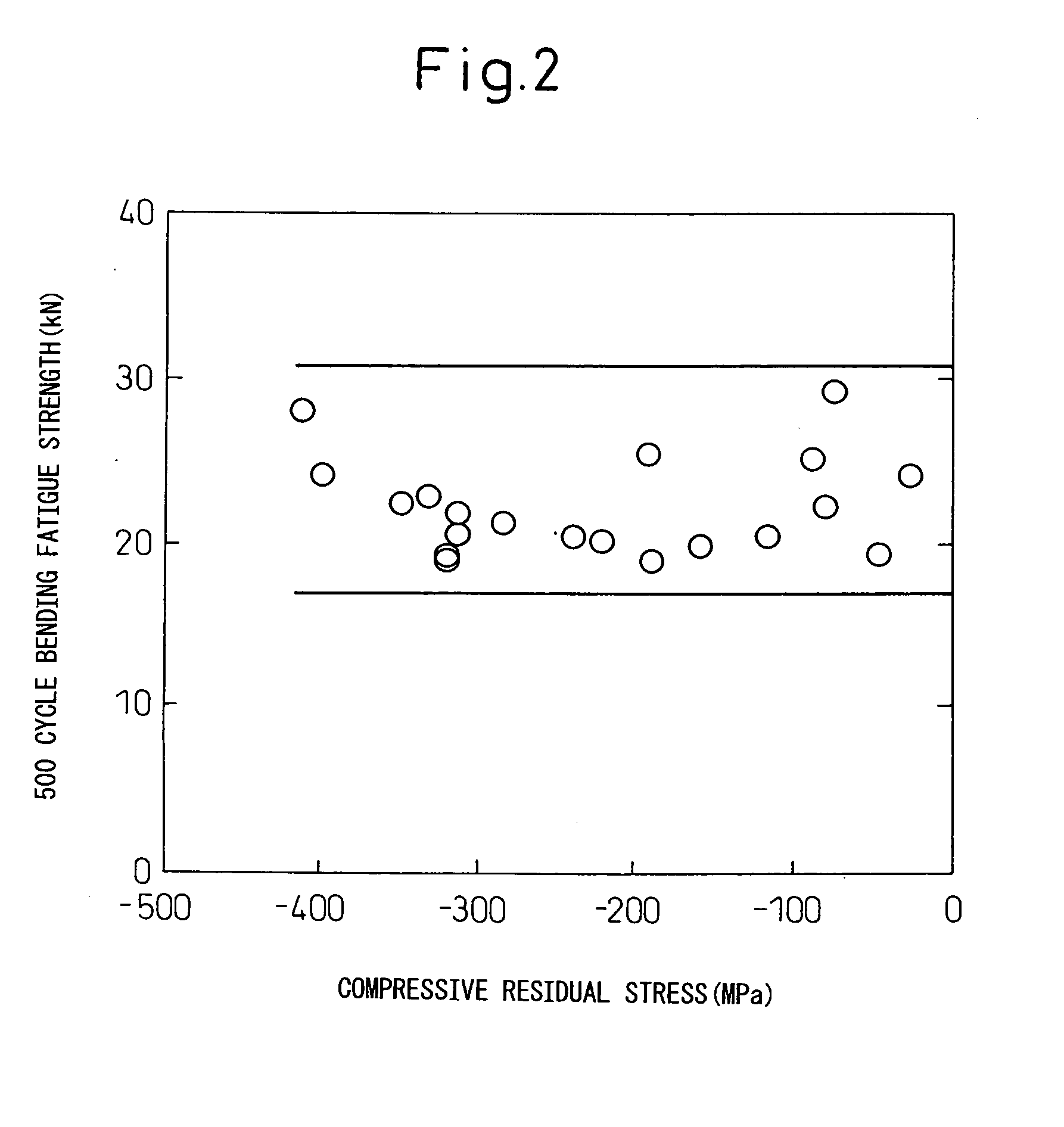

Carburized steel part having excellent low cycle bending fatigue strength

InactiveUS20120060979A1Reduce in sizeImprove fuel economySolid state diffusion coatingFurnace typesHardnessUltimate tensile strength

A carburized steel part having excellent low cycle bending fatigue strength which is comprised of a steel material which contains, by mass %, C: 0.1 to 0.6%, Si: 0.01 to 1.5%, Mn: 0.3 to 2.0, P: 0.02% or less, S: 0.001 to 0.15%, N: 0.001 to 0.03%, Al: 0.001 to 0.06%, and O: 0.005% or less and has a balance of substantially iron and unavoidable impurities and which is carburized and quenched, and then tempered, which steel part has a surface hardness of HV550 to HV800 and a core hardness of HV400 to HV500.

Owner:NIPPON STEEL & SUMITOMO METAL CORP +1

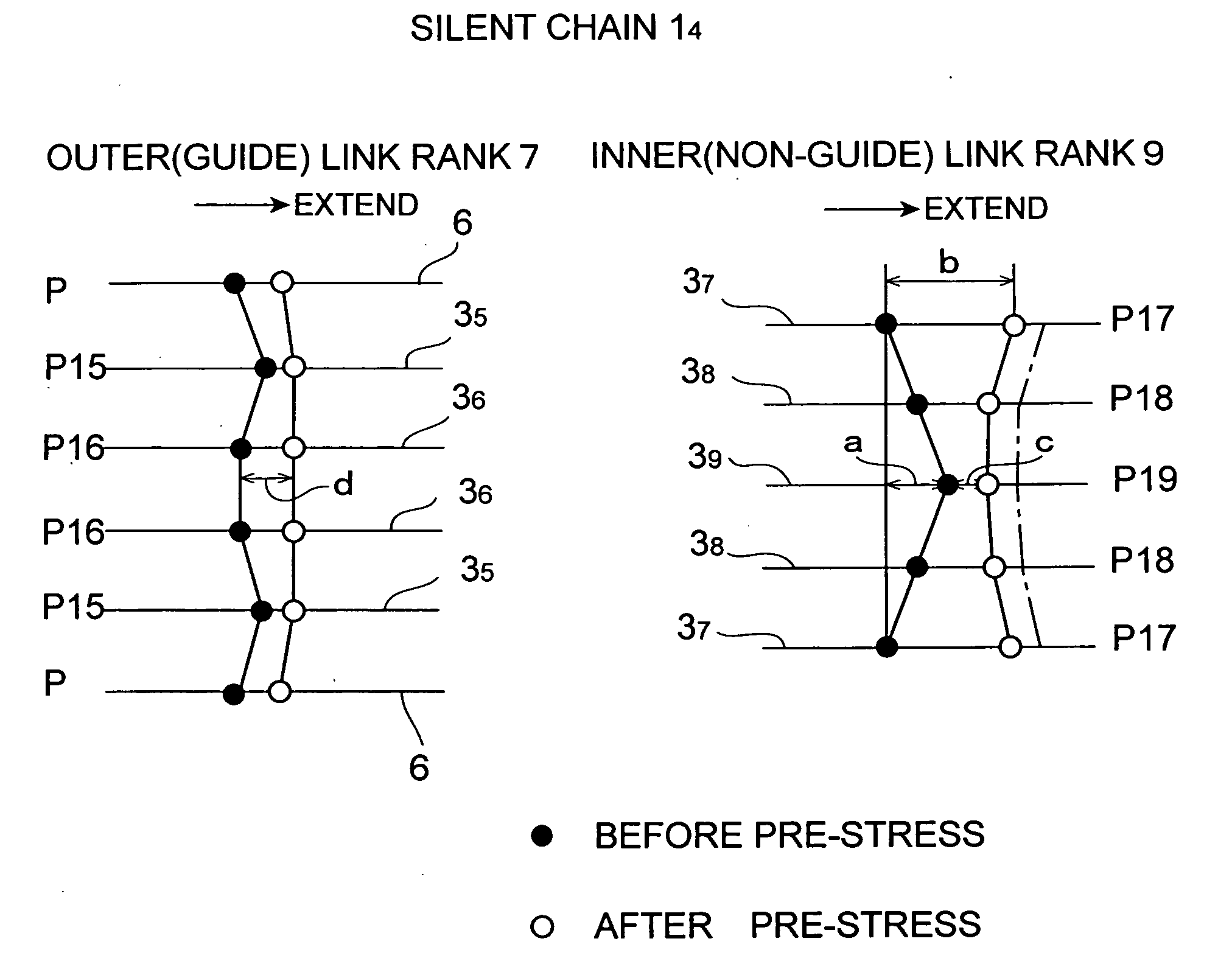

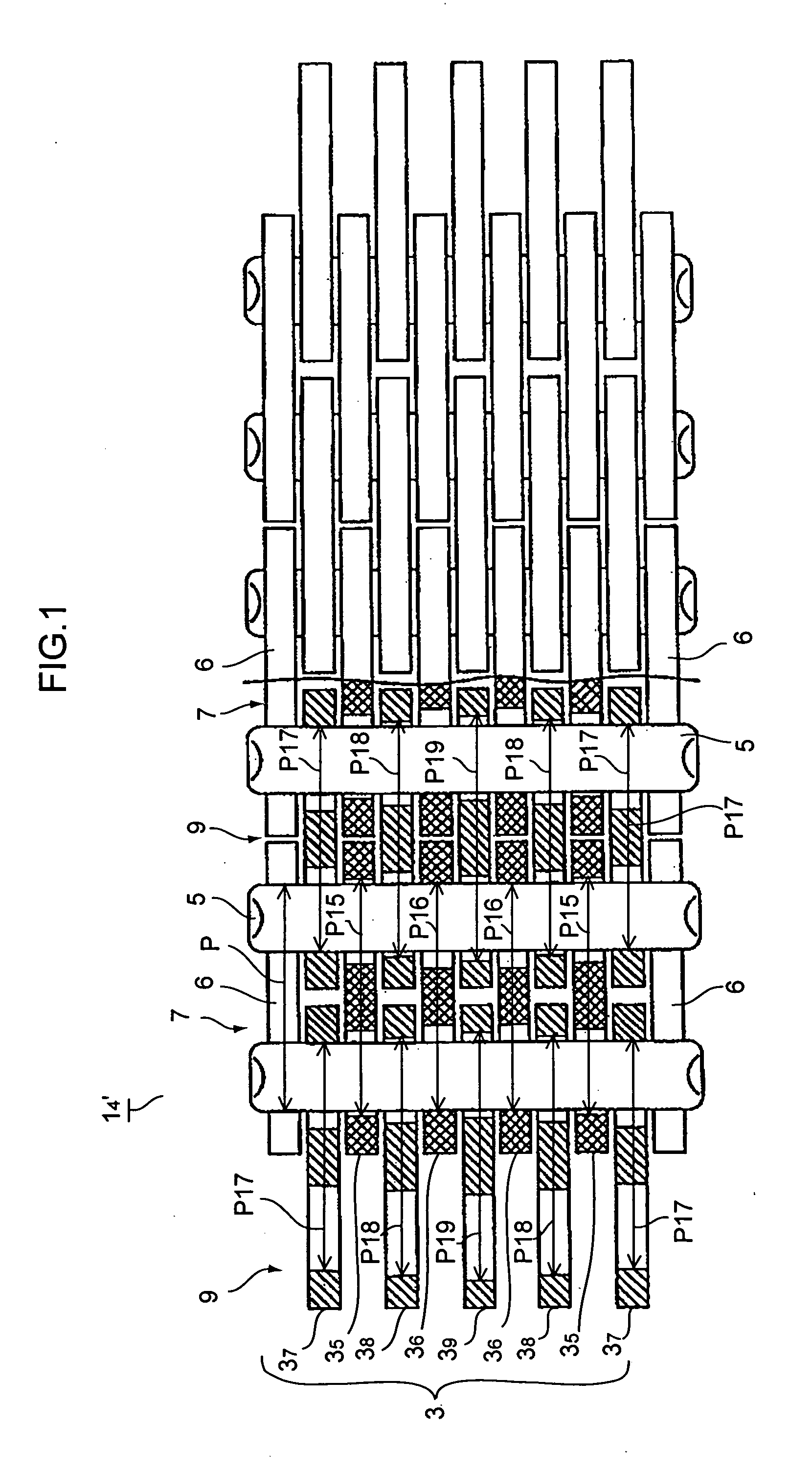

Silent Chain and Manufacturing Method of the Same

InactiveUS20090048047A1Burden of stressImprove fatigue strengthDriving chainsMetal chainsWear resistantPre stress

Owner:DAIDO KOGYO CO LTD

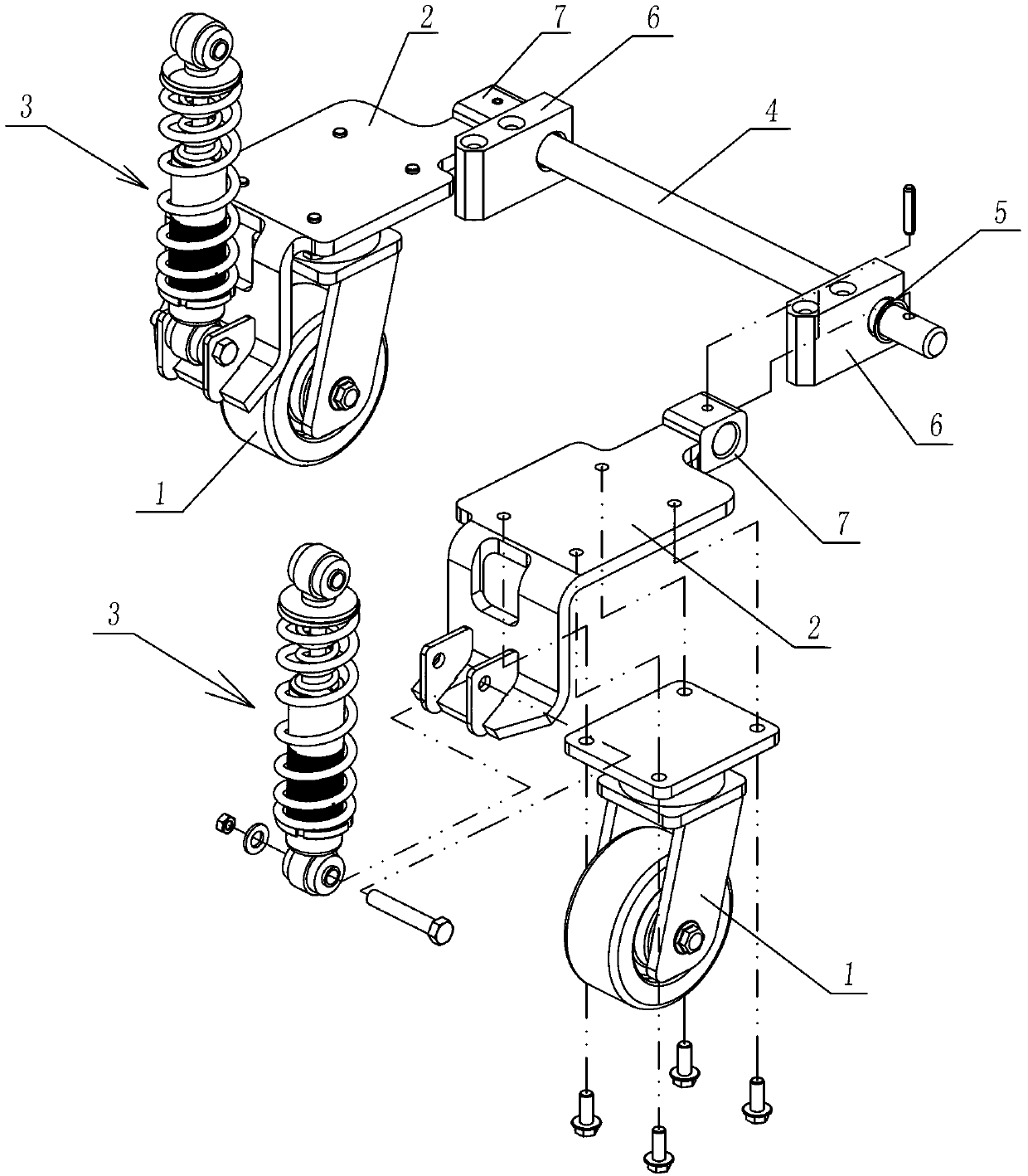

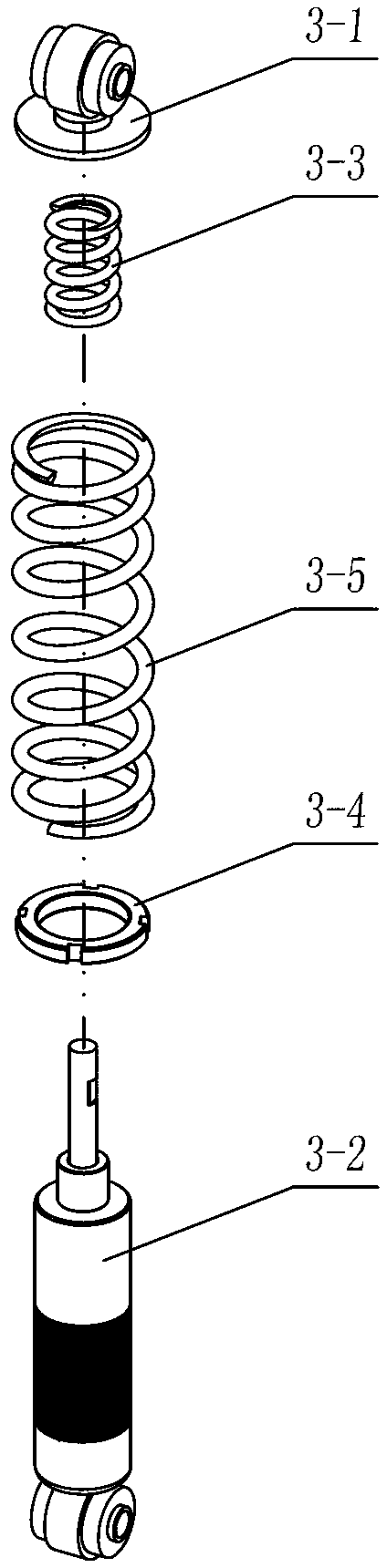

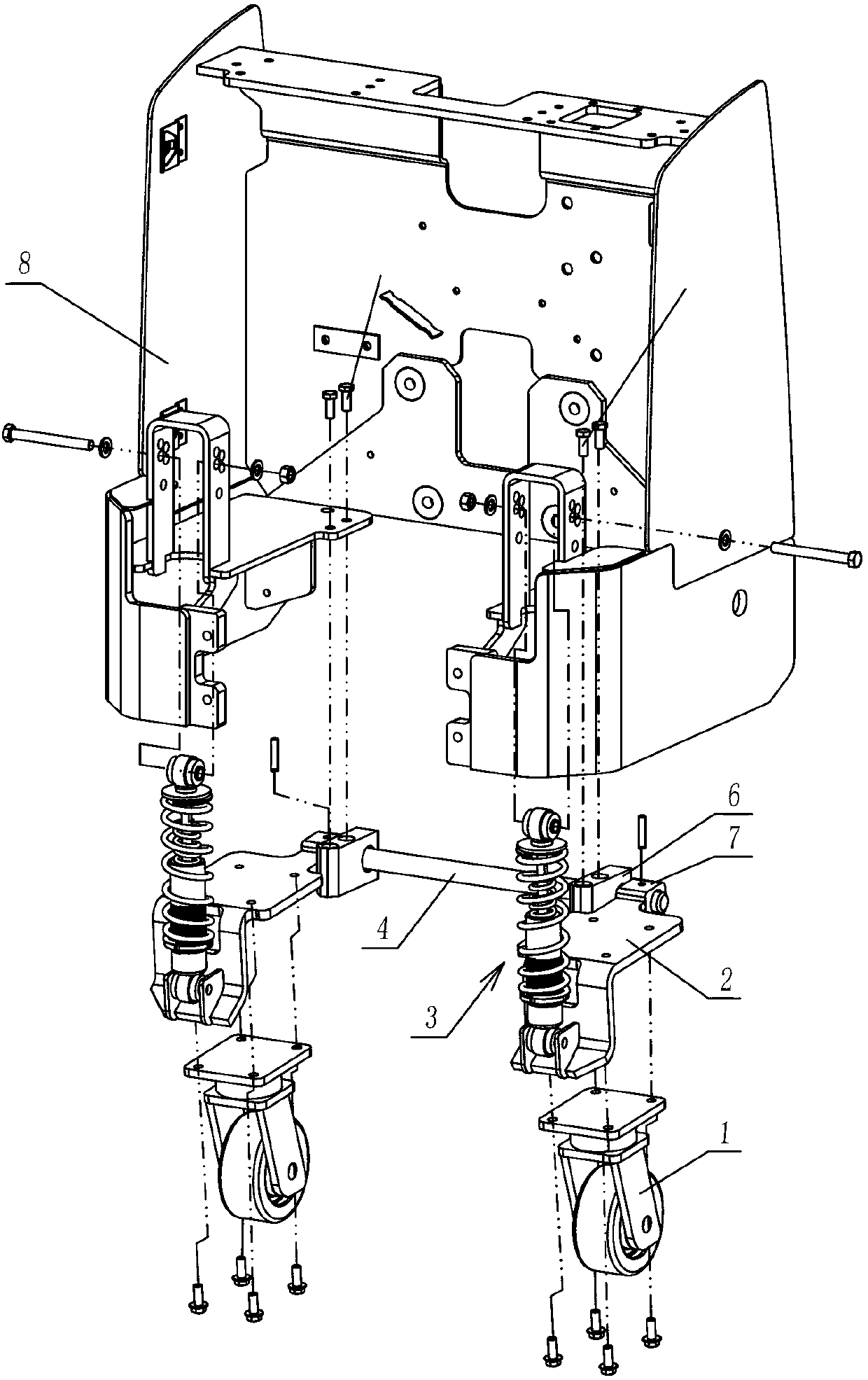

Electric truck connecting rod auxiliary wheel device

The invention relates to an electric truck connecting rod auxiliary wheel device and aims to provide an electric truck connecting rod auxiliary wheel device so as to reduce the vibrating amplitude in the traveling process. According to the technical scheme, the electric truck connecting rod auxiliary wheel device comprises an auxiliary wheel which can freely rotate within 360 degrees in a horizontal plane, and also comprises a supporting plate which is to be hinged with a frame and can freely rotate around an axis on which a hinge point is positioned, wherein a shock absorber assembly is hinged at one end, which is far away from the hinge point of the frame, of the supporting plate; the other end of the shock absorber assembly is hinged with the frame; the auxiliary wheel is arranged on the lower surface of the supporting plate; the shock absorber assembly comprises a support hinged with the frame, a shock absorber on the outer surface of which a thread is tapped, and an adjusting nut which is in threaded connection with the outer surface of the shock absorber; a spring II is coaxially sleeved outside the shock absorber; two ends of the spring are respectively pressed against the support and the adjusting nut; and one end of the shock absorber far away from the support is hinged with the supporting plate. The device is suitable for an electric tray carriage.

Owner:HANGCHA GRP

Corrosion-resistant metal coating used for outer surface of gear box

ActiveCN106498290AImprove corrosion resistanceImprove antistatic performanceNon-macromolecular adhesive additivesFilm/foil adhesivesMetal coatingCorrosion resistant

The invention discloses a corrosion-resistant metal coating used for the outer surface of a gear box. The corrosion-resistant metal coating comprises, by mass, 0.06%-0.08% of C, 0.15%-0.18% of Mn, 10.76%-10.79% of Cr, 2.12%-2.15% of Ni, 0.13%-0.15% of Mg, 0.21%-0.23% of Mo, 0.25%-0.27% of Co, 0.06%-0.08% of V, 0.42%-0.44% of Ti, 0.22%-0.25% of Na, 0.17%-0.19% of Ga, 0.22%-0.25% of Ce, 0.16%-0.18% of Nd, 0.32%-0.38% of La and the balance Fe.

Owner:南京创贝高速传动机械有限公司

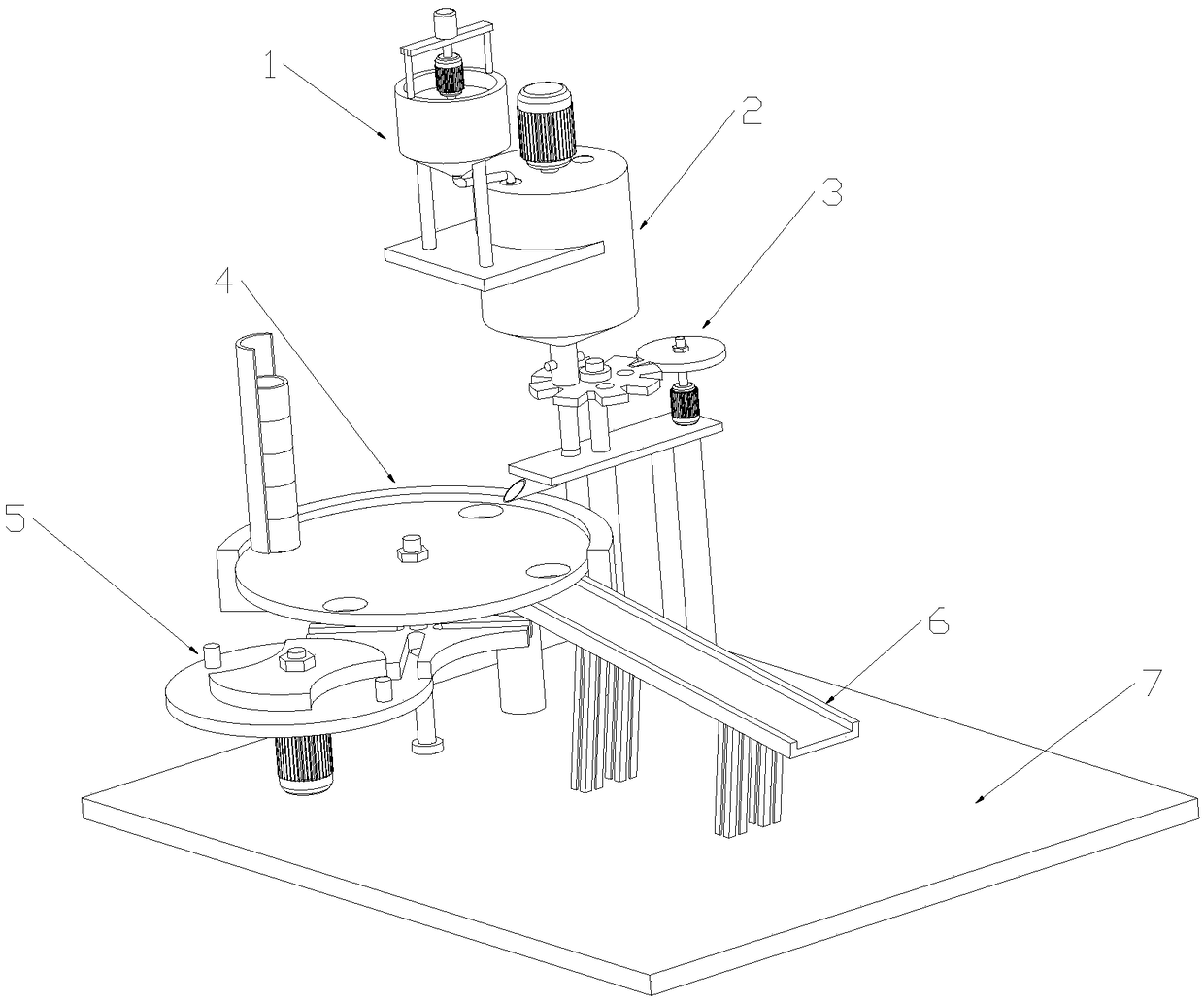

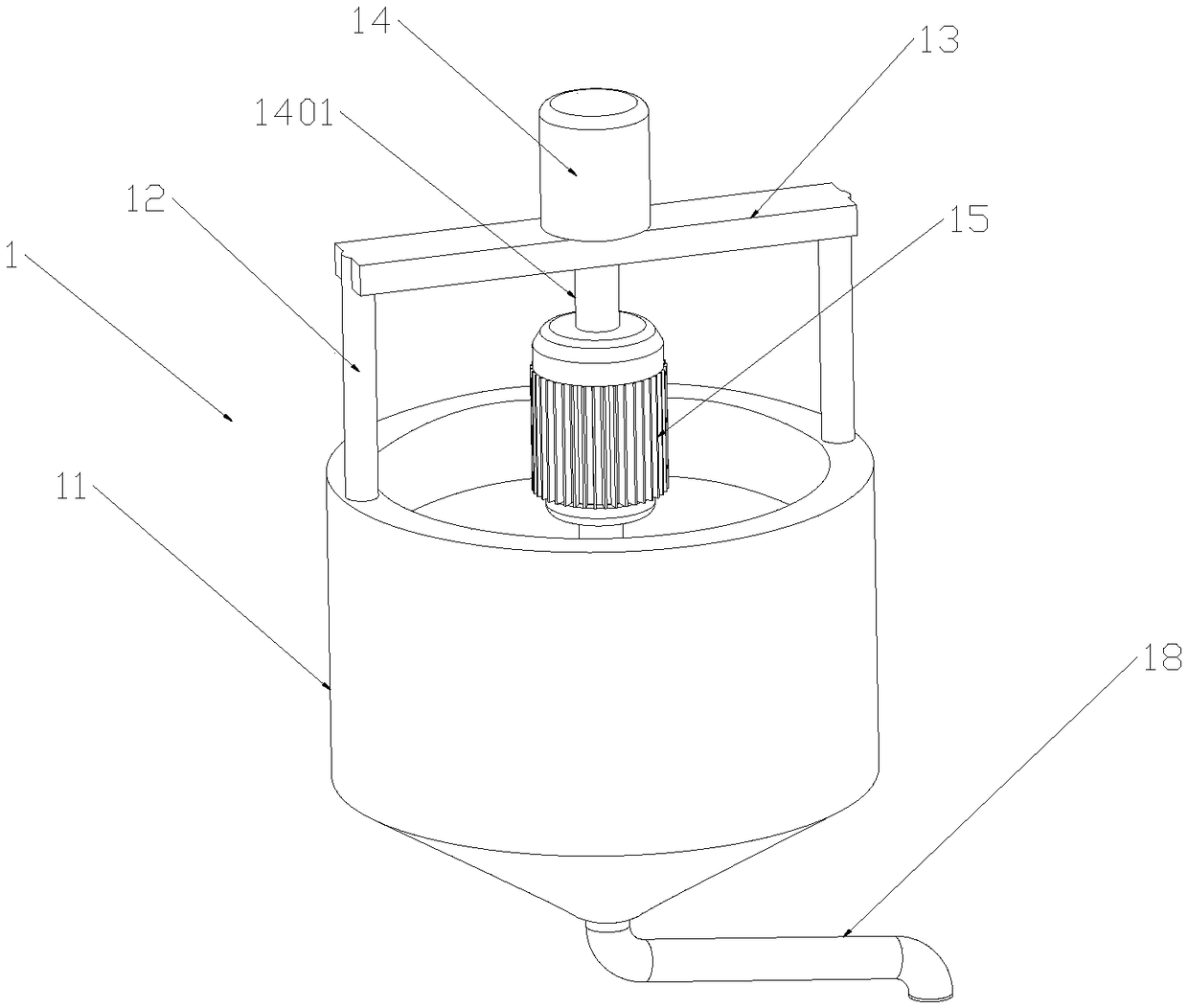

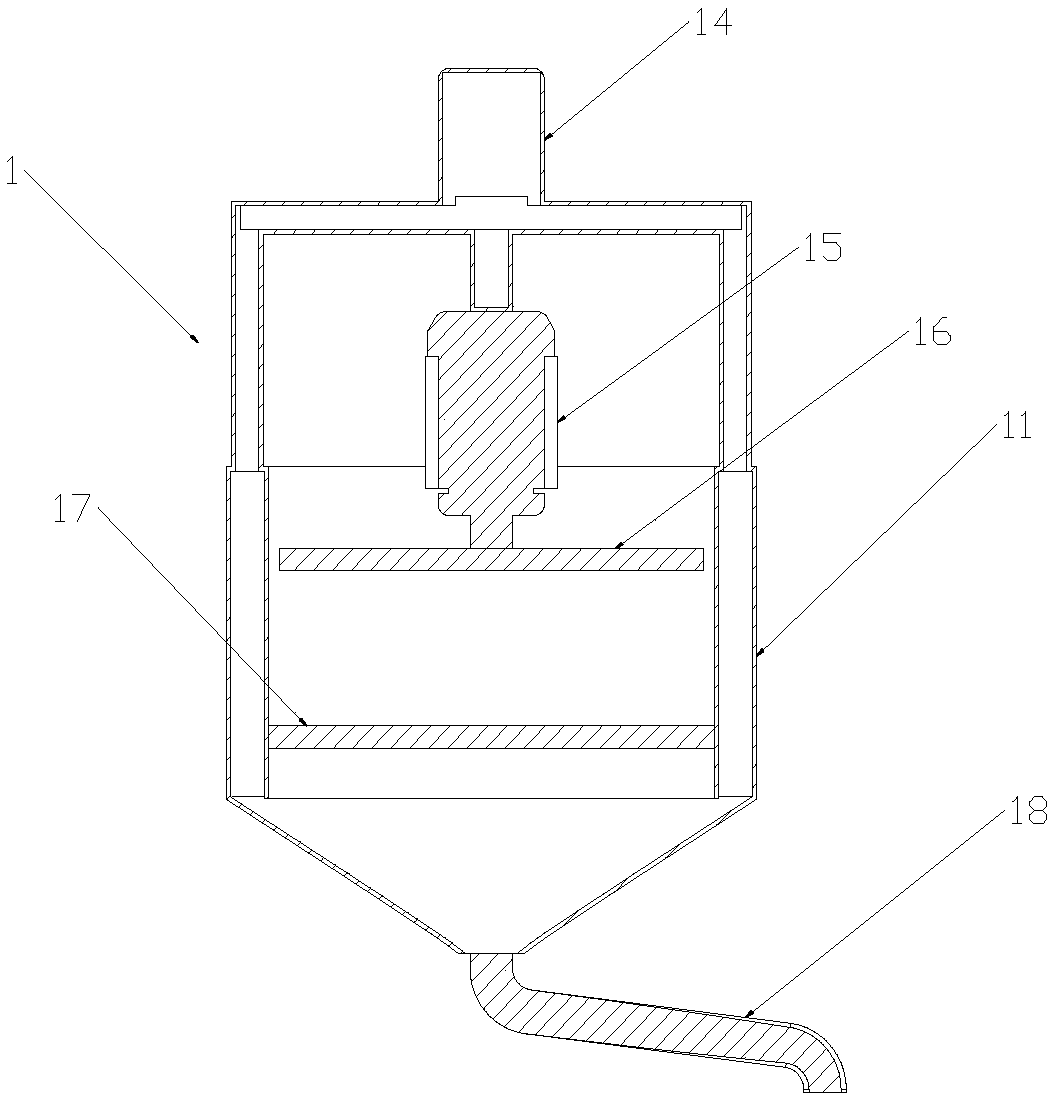

Solid beverage automatic shaping and conveying equipment

InactiveCN109480158AWon't spillGuaranteed intermittent feedingRotary stirring mixersTransportation and packagingDrive wheelEngineering

The invention discloses solid beverage automatic shaping and conveying equipment. The solid beverage automatic shaping and conveying equipment comprises a grinding device, a stirring device, a liquidblocking device, a rotating mechanism, a pushing device, a conveying frame and a base, wherein the grinding device comprises a cylinder, a first motor, a grinding disk and a mesh screen; the stirringdevice comprises a stirring barrel, a second motor and a stirring mechanism; a flow limiting mechanism is arranged at the bottom end of the stirring barrel; the liquid blocking device comprises a third motor, a driving wheel and a driven wheel; and the rotating mechanism comprises a semicircle bottom disk and a rotary disk; and the pushing device comprises a fourth motor and the like. According tothe solid beverage automatic shaping and conveying equipment disclosed by the invention, the rotating speed of the third motor and the rotating speed of the fourth motor are adjusted to appropriate rotating speeds, liquid which flows out from an L-shaped pipeline can just be completely injected into a rotating liquid box, so that intermittent feeding is guaranteed, and automated operation is realized; besides, the solid beverage automatic shaping and conveying equipment is provided with the flow limiting mechanism, and through twisting a threaded rod, enclosing and flow limiting can be realized; and in the stirring course of a solid beverage, liquid cannot spill, the magnitude of flow capacity can be controlled, and then the volume of liquid which flows in the liquid box is further controlled.

Owner:罗燕辉

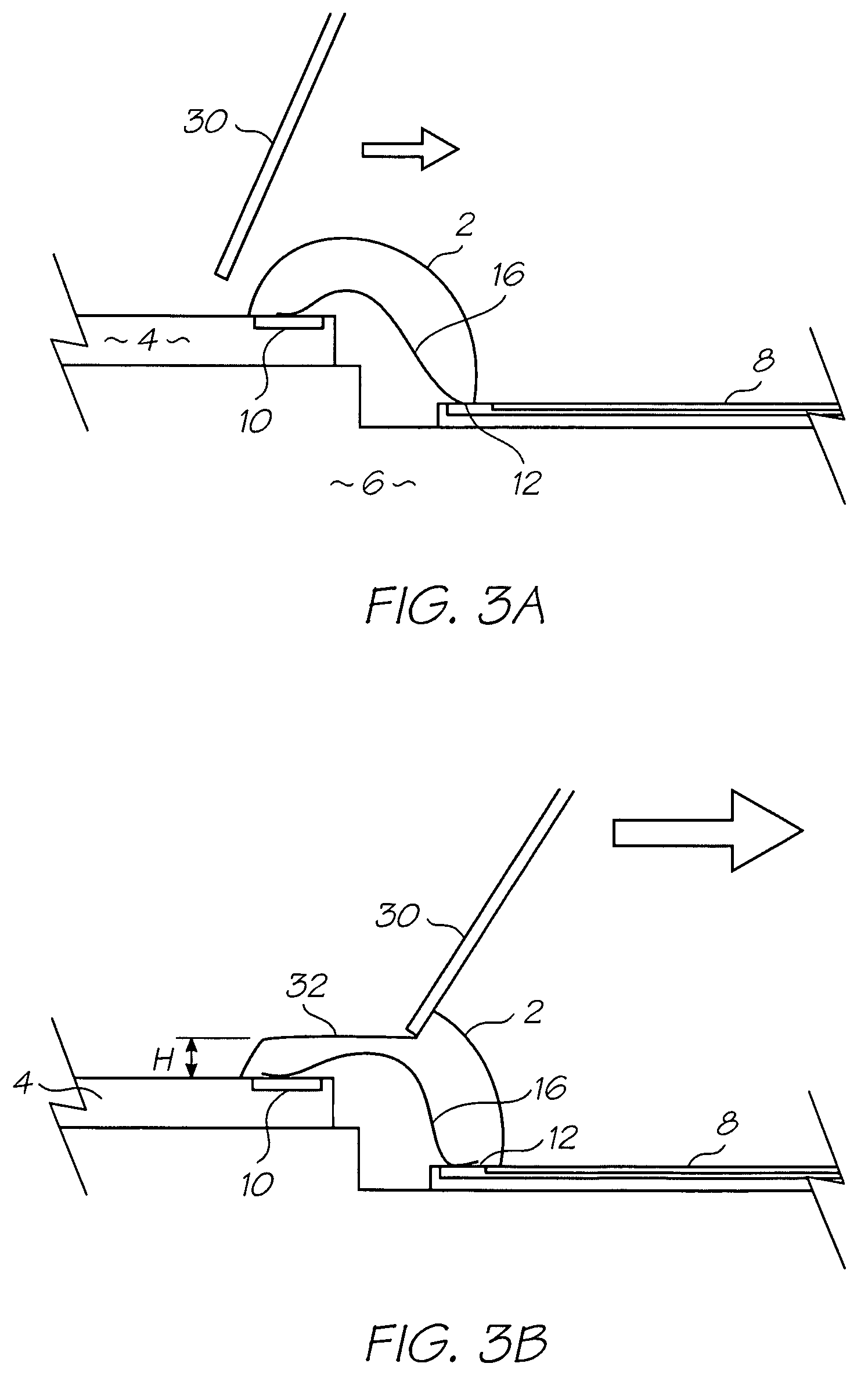

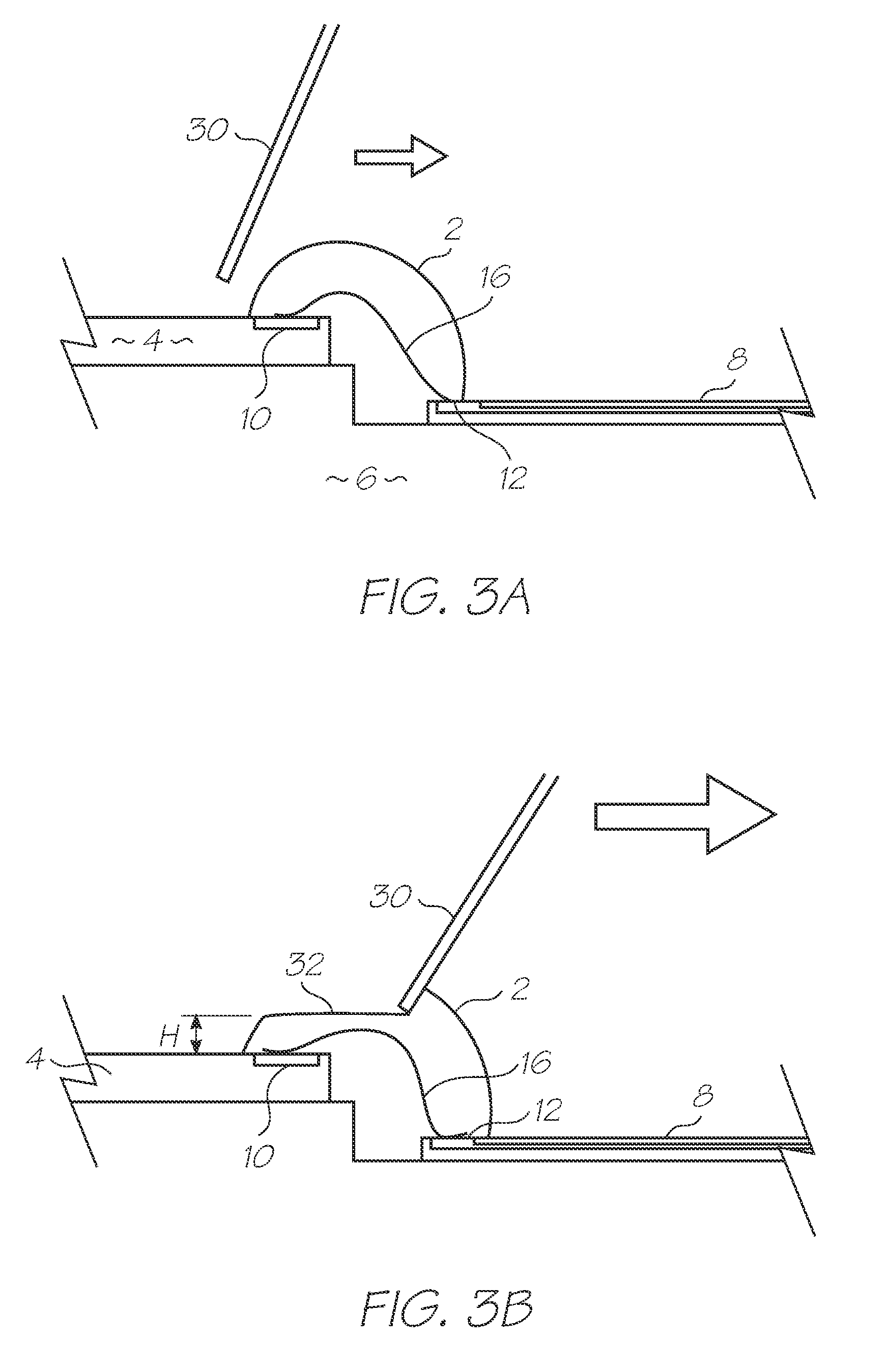

Method of forming assymetrical encapsulant bead

ActiveUS20100075466A1Negligible effectEfficient depositionSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsElectrical conductorLead bonding

A method of forming an asymmetrical encapsulant bead on a series of wire bonds electrically connecting a micro-electronic device to a series of conductors, the micro-electronic device having a planar active surface. The method has the steps of positioning the die and the wire bonds beneath an encapsulant jetter that jets drops of encapsulant on to the wire bonds, the drops of encapsulant following a vertical trajectory, tilting the die such that the active surface is inclined to the horizontal and, jetting the drops of encapsulant to form a bead of encapsulant material covering the series of wire bonds, the bead having a cross sectional profile that is asymmetrical about an axis parallel to a normal to the active surface.

Owner:MEMJET TECH LTD

Tack adhesion testing device

InactiveUS20100071456A1High elastic modulusReduce fatigue strengthSolid-state devicesUsing mechanical meansEngineeringContact force

A tack adhesion testing device for quantitatively measuring tack adhesion between a material and an object with a planar surface for contact with the material. The device has a material mount for mounting a quantity of the material such that the quantity of material presents an exposed flat face, an object mount for securely holding the object such that the planar surface is in flat contact with the exposed flat surface, the material mount and the object mount being movable relative to each other, a contact force applicator for applying a known force urging the exposed flat face and the planar surface into contact and, separation mechanism for applying a variable force to the material mount and the object mount to slide the flat face and the planar surface relative to each other such that the variable force can be increased until the flat face and the planar surface slide relative to each other.

Owner:SILVERBROOK RES PTY LTD

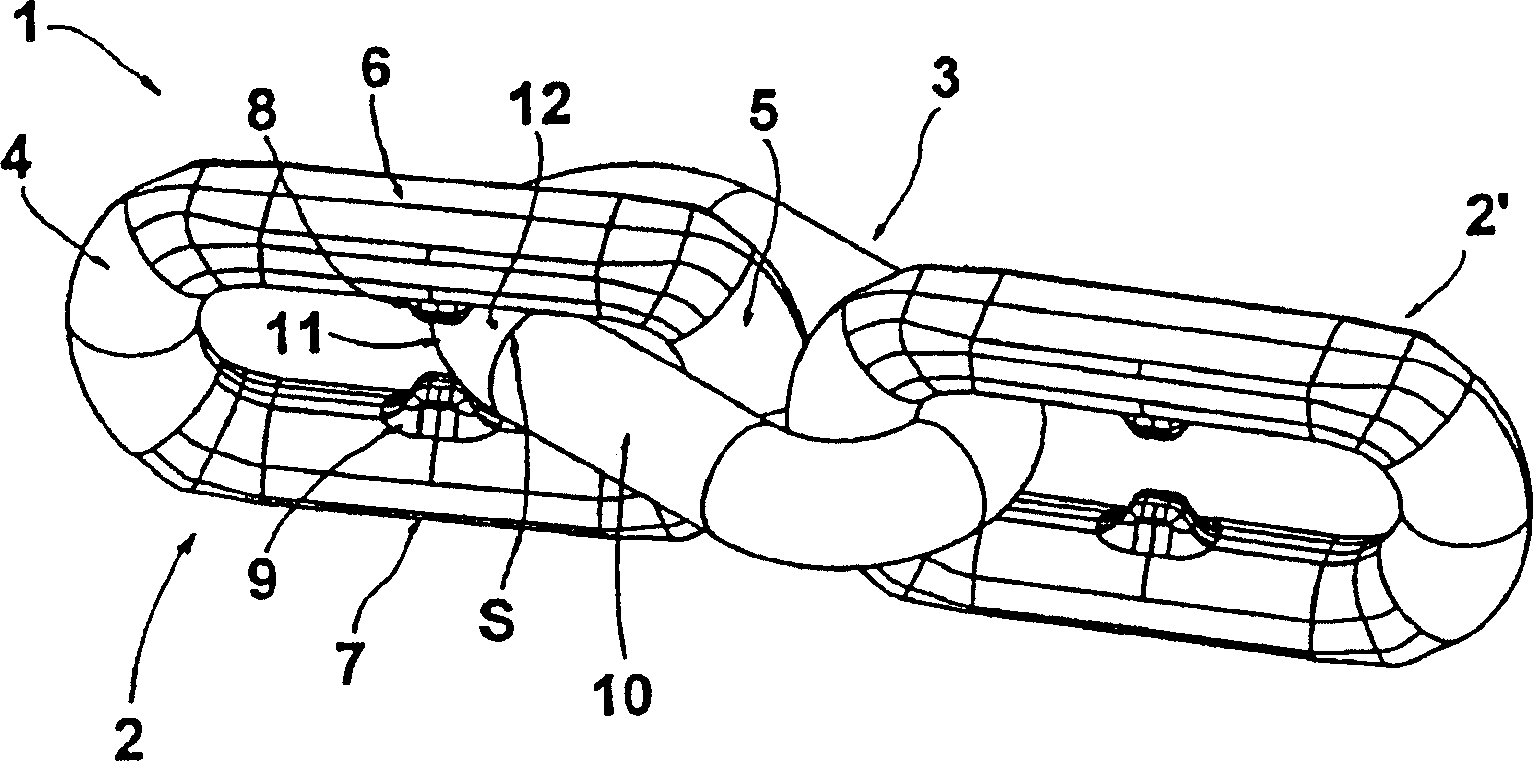

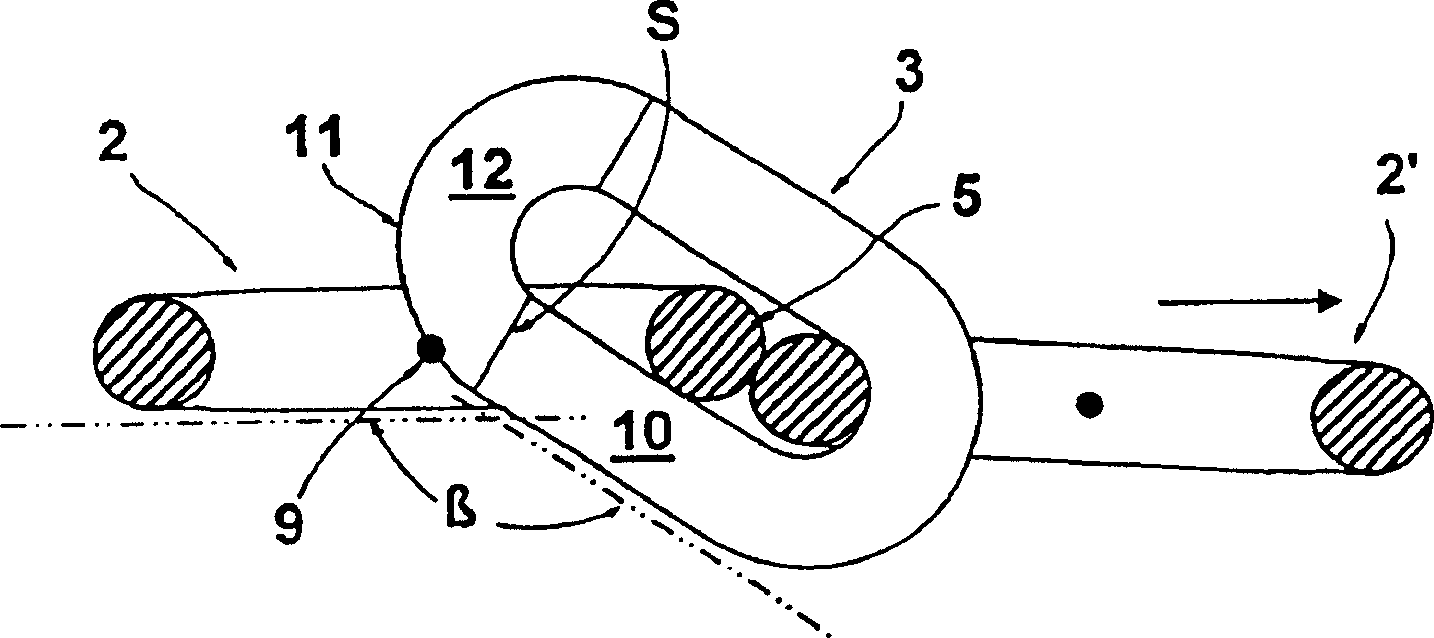

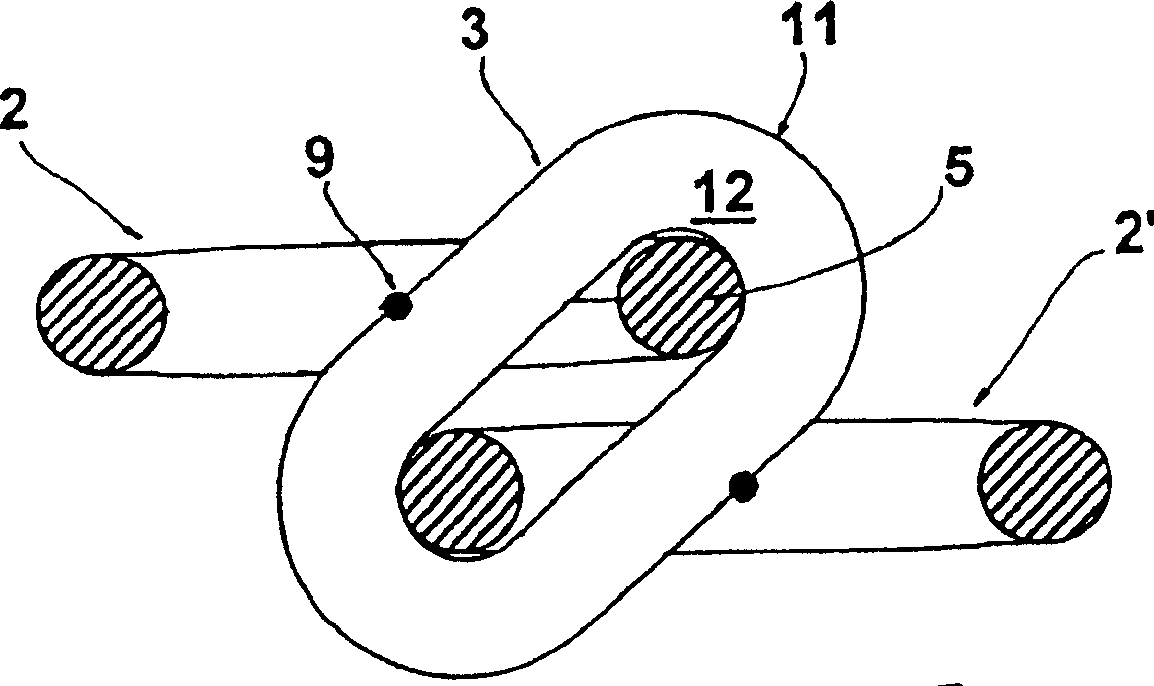

Open chain

ActiveCN1746528APrevent intrusionReduced net inner diameterConveyorsHauling chainsEngineeringChain link

The present invention relates to an opening chain having a series of chain loops clasping each other, the chain loop sequence is composed of repeating sub-sequence chain loop, in each sub-sequence, a first chain loop is separated provided having a dividing element projecting from side internal side to inside, reducing the inner radii in transverse direction and dividing the internal chamber of the chain loop into two active chambers at least on one of its two straight edge, when the chain is loose, the second chain loop in the first chain loop is hitched, restrained by effective width of at least a dividing element and external shape, diameter and / or other active chamber internal length of the second chain loop inserting the first chain loop, only the part intruding into the first chain loop active chamber is achieved, that is when a longitudinal axis of the second chain loop is moved from an intended, substantially aligned position by less than 90 degrees, an outside of an arc portions of the second chain loop that engages a movement space of the first chain loop contacts the dividing element, and an inside of a shank portion of the second chain loop contacts an arc portion of the first chain loop.

Owner:J D THEILE

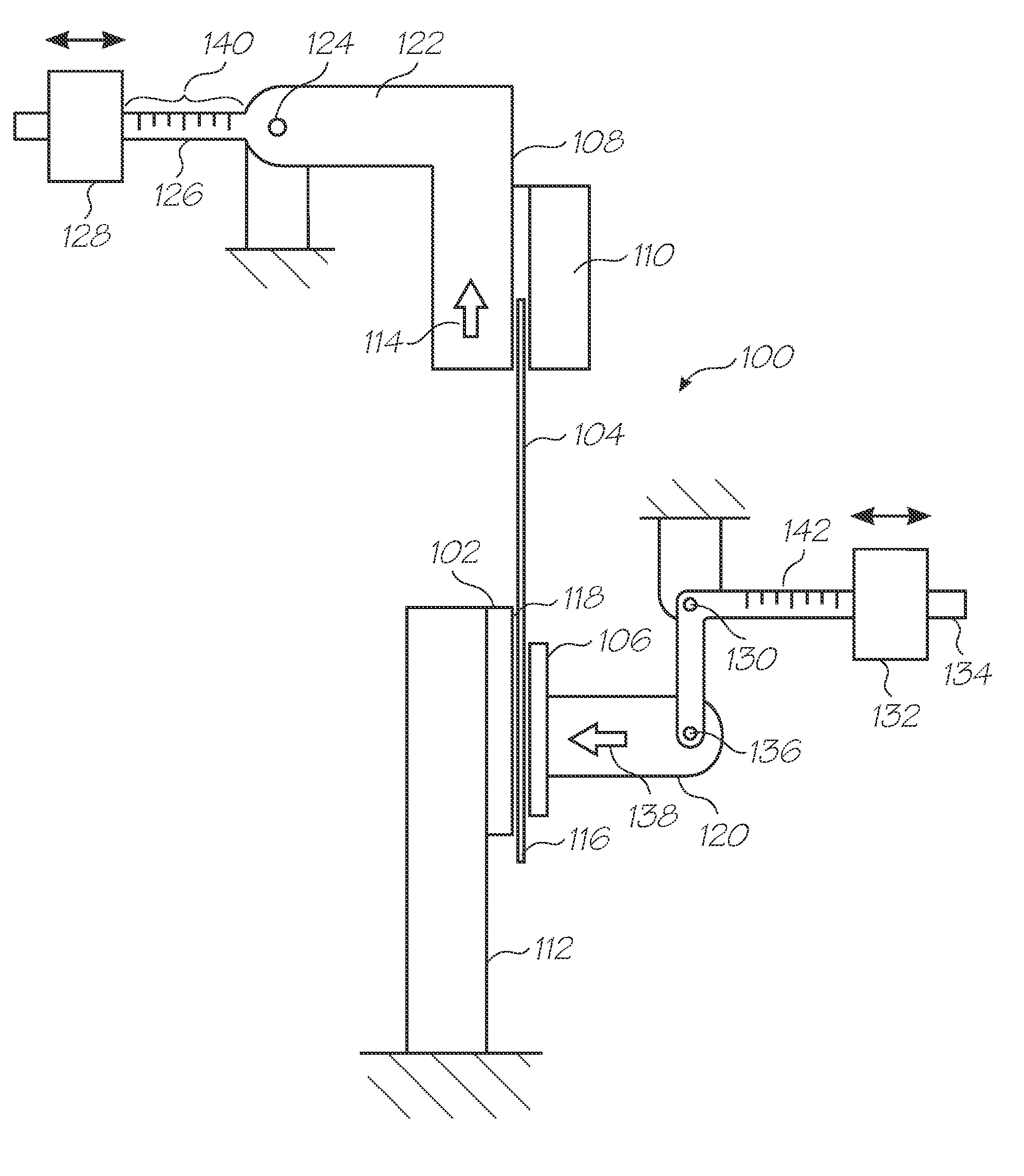

Method and device for monitoring a brake system

InactiveUS20050121974A1High material strengthReduce fatigue strengthFluid-pressure actuator testingActuator accumulatorsRisk strokeBraking system

The present invention relates to a method and a device for monitoring a brake system for motor vehicles equipped with an electronic controlling and regulating unit, as well as a hydraulic pressure accumulator that is used as an auxiliary pressure source and subdivided by a media-separating element into two chambers, the first chamber being filled with a gas and the second chamber being filled with a liquid pressure medium. To conduct a reliable monitoring of the pressure accumulator, the invention provides that the number of the partial strokes of the media-separating element is detected. To this end, brake actuations are weighted and counted according to their duration and intensity. When the sum of the weighting factors reaches a predetermined number, a warning indicates an imminent damage to the media-separating element. This renders it possible to use a less costly and less sensitive media-separating element, which obviates the need for extensive protective measures against mechanical loads.

Owner:CONTINENTAL TEVES AG & CO OHG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com