Carburized steel part having excellent low cycle bending fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

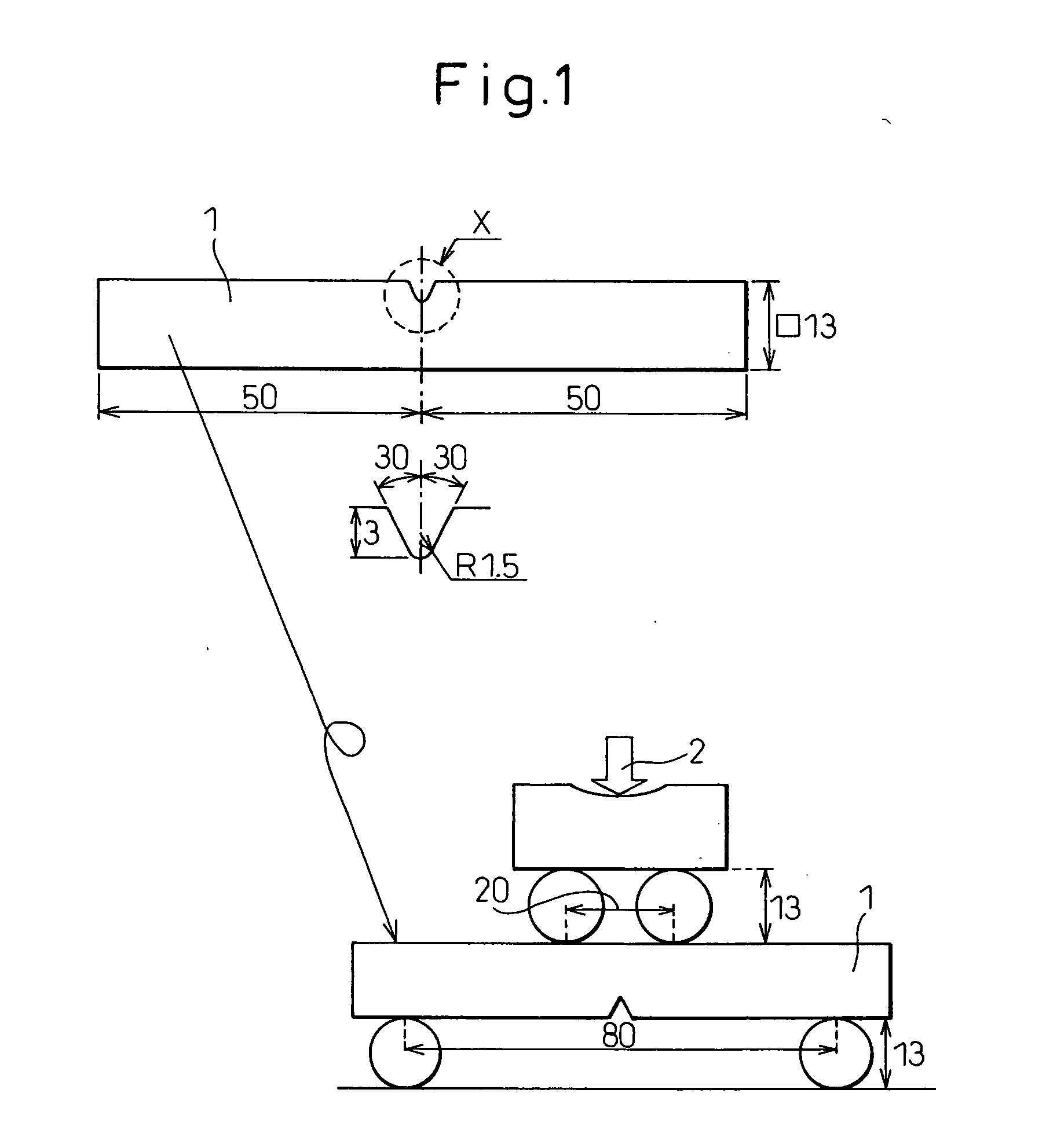

[0138]Steel materials of the compositions of ingredients which are shown in Table 1 and Table 2 were drawn, then soaked and normalized to prepare roughly worked test pieces for low cycle bending fatigue tests and roughly worked test pieces for wear tests.

TABLE 1TestComposition of ingredients (mass %)no.ClassCSiMnPSNAlOB1Inv. ex.0.350.260.800.0100.0150.0120.0300.0010—2Inv. ex.0.401.000.800.0090.0150.0060.0390.0009—3Inv. ex.0.310.900.810.0100.0150.0060.0370.00120.00154Inv. ex.0.600.240.730.0080.0300.0060.0210.0006—5Inv. ex.0.350.011.200.0090.0310.0040.0100.00100.00156Inv. ex.0.341.490.790.0090.0300.0120.0150.0011—7Inv. ex.0.331.020.300.0100.0160.0040.0220.00090.00208Inv. ex.0.360.602.000.0090.0290.0120.0280.0007—9Inv. ex.0.391.200.790.0200.0150.0050.0300.00110.001210Inv. ex.0.400.900.810.0080.1490.0120.0310.00090.001811Inv. ex.0.321.110.790.0100.0150.0010.0370.0010—12Inv. ex.0.380.790.800.0100.0280.0290.0100.0010—13Inv. ex.0.351.020.800.0100.0150.0110.0010.0010—14Inv. ex.0.400.990.790...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com