Patents

Literature

101 results about "Sn element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

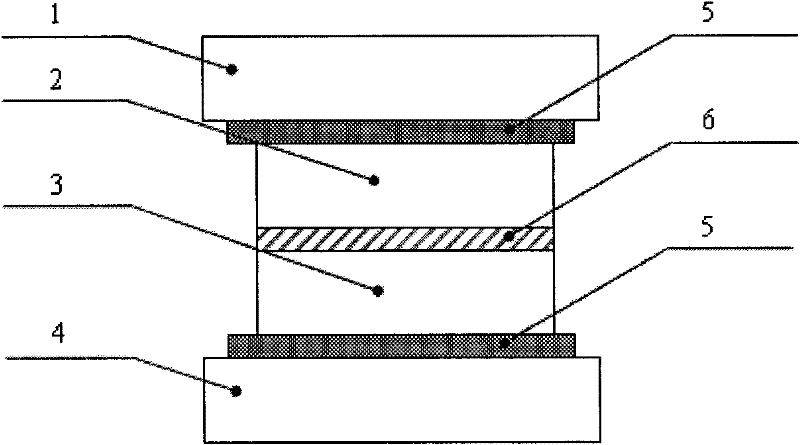

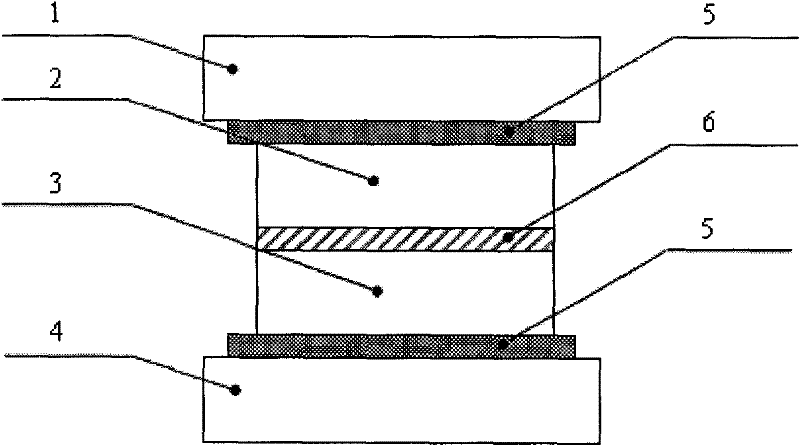

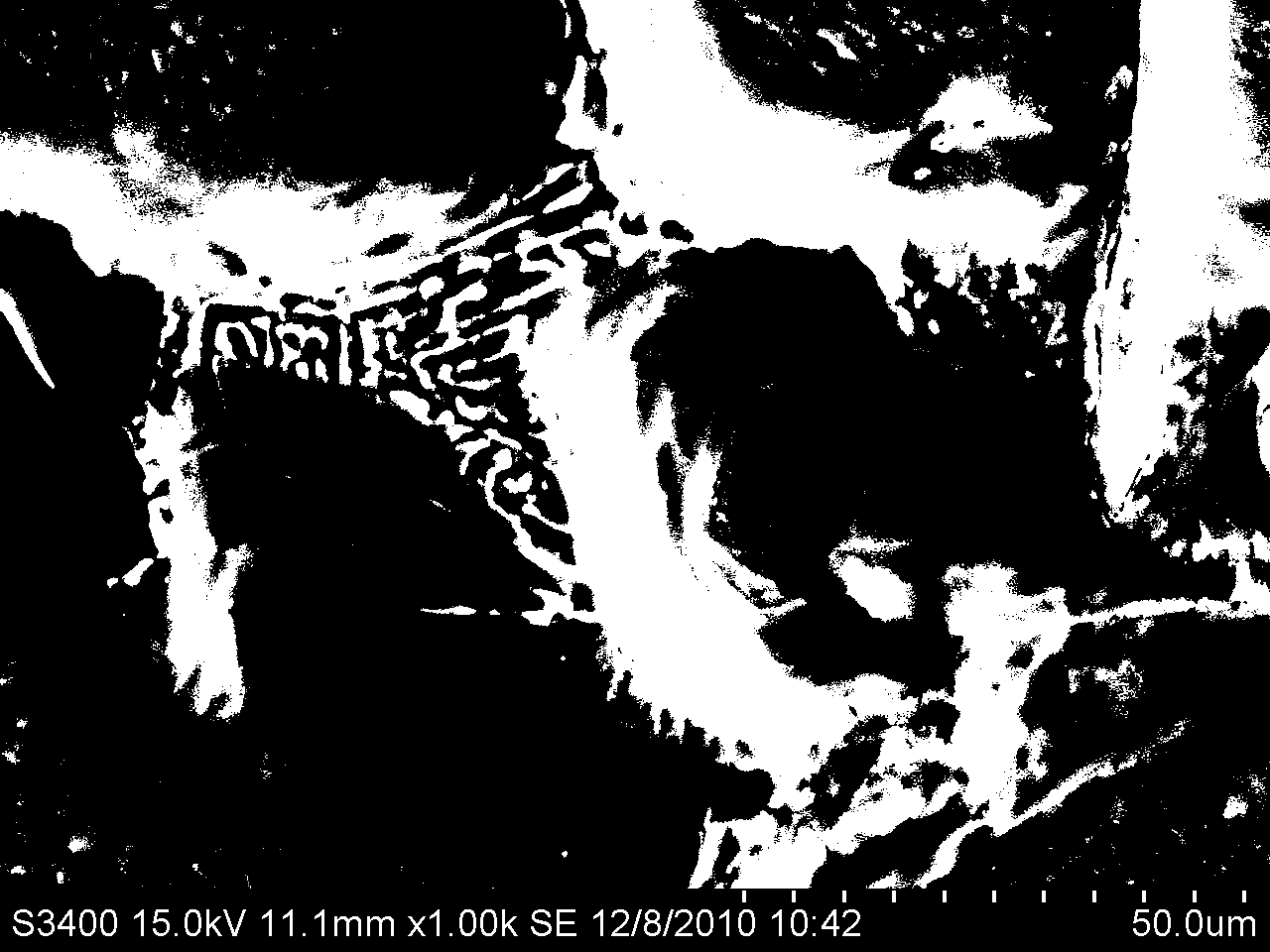

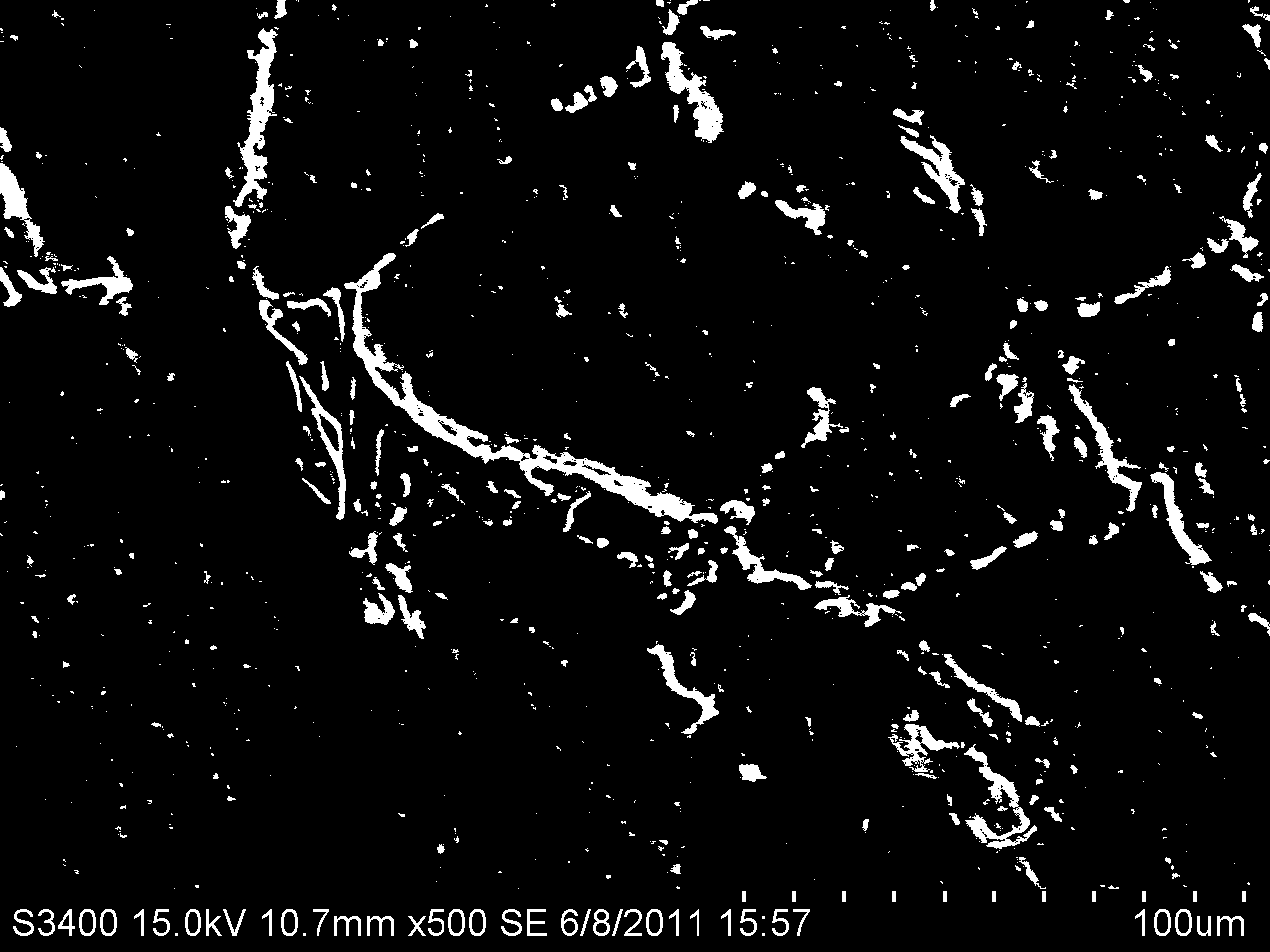

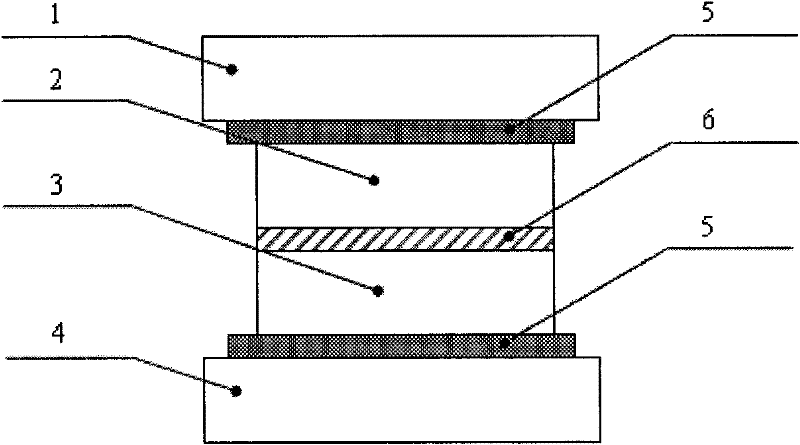

Diffusion welding method of copper alloy and stainless steel

InactiveCN101745736AHigh tensile strengthIncrease the effective welding areaNon-electric welding apparatusCorrosionSn element

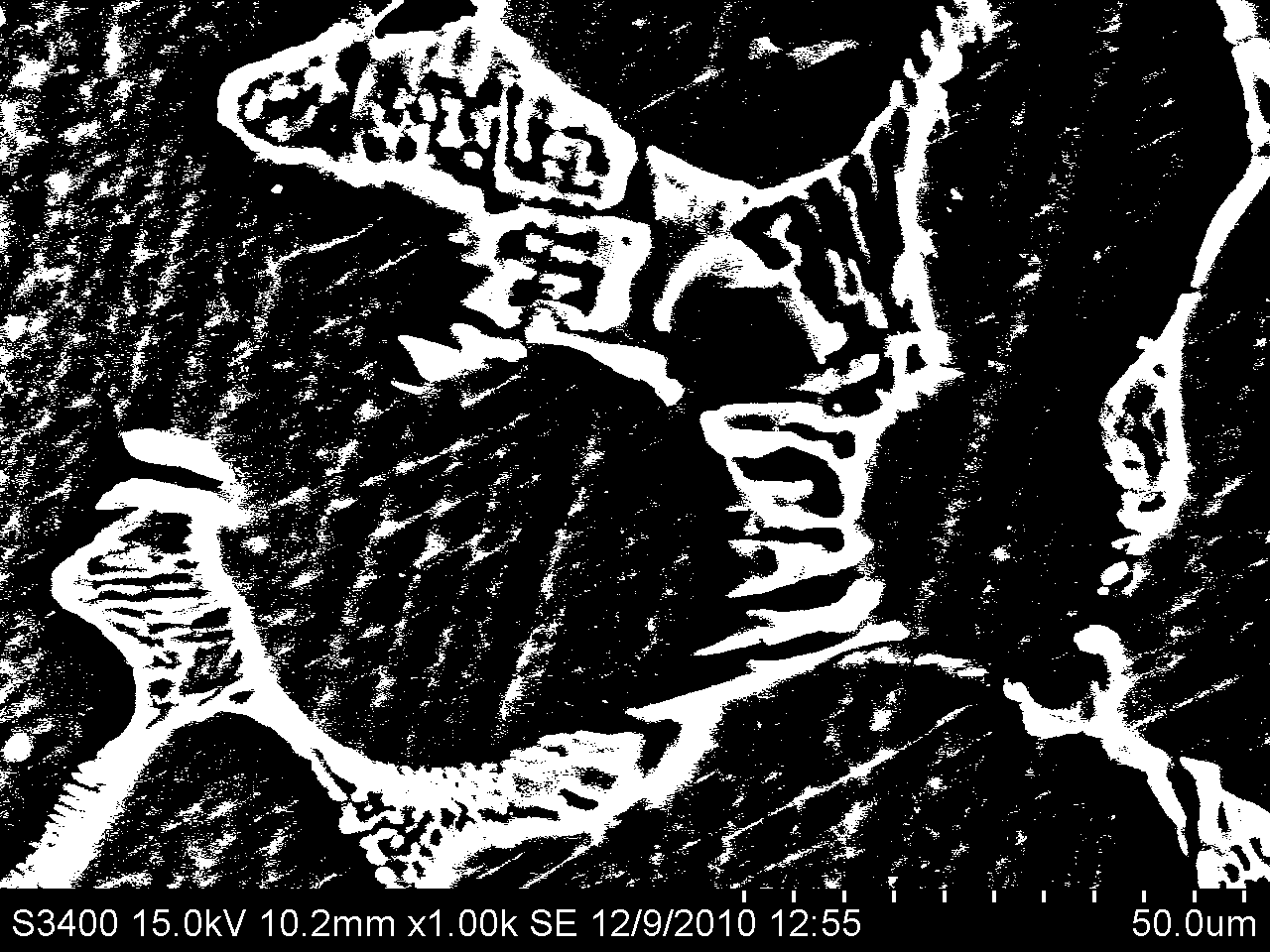

The invention discloses a diffusion welding method of copper alloy and stainless steel, which is used for increasing the strength of a welded joint of the copper alloy and the stainless steel. The method thereof comprises the following steps that: a processed tin bronze foil is placed between the copper alloy to be welded and the stainless steel; then the whole tin bronze foil is placed into a vacuum diffusion welding furnace; the temperature is raised from room temperature to 880 to 920 DEG C, the pressure is applied by 4 to 8MPa, and the temperature is preserved for 30 to 60min; and cooling is carried out with the furnace after the temperature preservation is finished. Since the tin bronze is adopted for carrying out diffusion welding on a middle layer, a zigzag welding interface is formed by using the characteristic that a Cu-Sn liquid phase is formed by clustering of Sn element in the tin bronze toward the welding interface as well as the corrosion effect of the liquid phase to the stainless steel crystal boundary, thus improving the effective welding area and leading the tensile strength of the joint to be improved to be more than 93 percent from 80 percent to 88 percent of the strength of the copper alloy base material of the prior art.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Non-oriented electrical steel and production method thereof

ActiveCN103882293AHigh magnetic inductionImprove magnetic induction and reduce iron lossElectrical steelChemical composition

The invention discloses non-oriented electrical steel. The non-oriented electrical steel comprises the following chemical components in percent by weight: not greater than 0.005% of C, 0.1%-1.0% of Si, 0.30%-1.2% of Mn, 0.2%-0.4% of Al, 0.02%-0.1% of P, not greater than 0.01% of S, not greater than 0.008% of N, not greater than 0.015% of O, not greater than 0.002% of B, 0.04%-0.12% of Sn, not greater than 0.003% of Sb, not greater than 0.003% of Nb, not greater than 0.003% of Ti, 0.005%-0.016% of Ce, and the balance of Fe and other trace elements. The invention further discloses a method of producing the non-oriented electrical steel. According to the invention, Ce and Sn elements are compounded and added in components of the conventional non-oriented electrical steel with Si less than 1%, so that respective effect of the two elements is brought into play, and therefore, contradiction between magnetic induction improving and iron loss lowering is effectively solved; hot rolled plate normalizing treatment is not carried out under the same (Si+Al) content through processes such as continuous casting, hot rolling, acid pickling, cold rolling back, and the like, so that iron loss is lowered by 0.4w / kg-0.8w / kg, and magnetic induction is improved by 0.01T-0.02T at the same time.

Owner:SHOUGANG CORPORATION

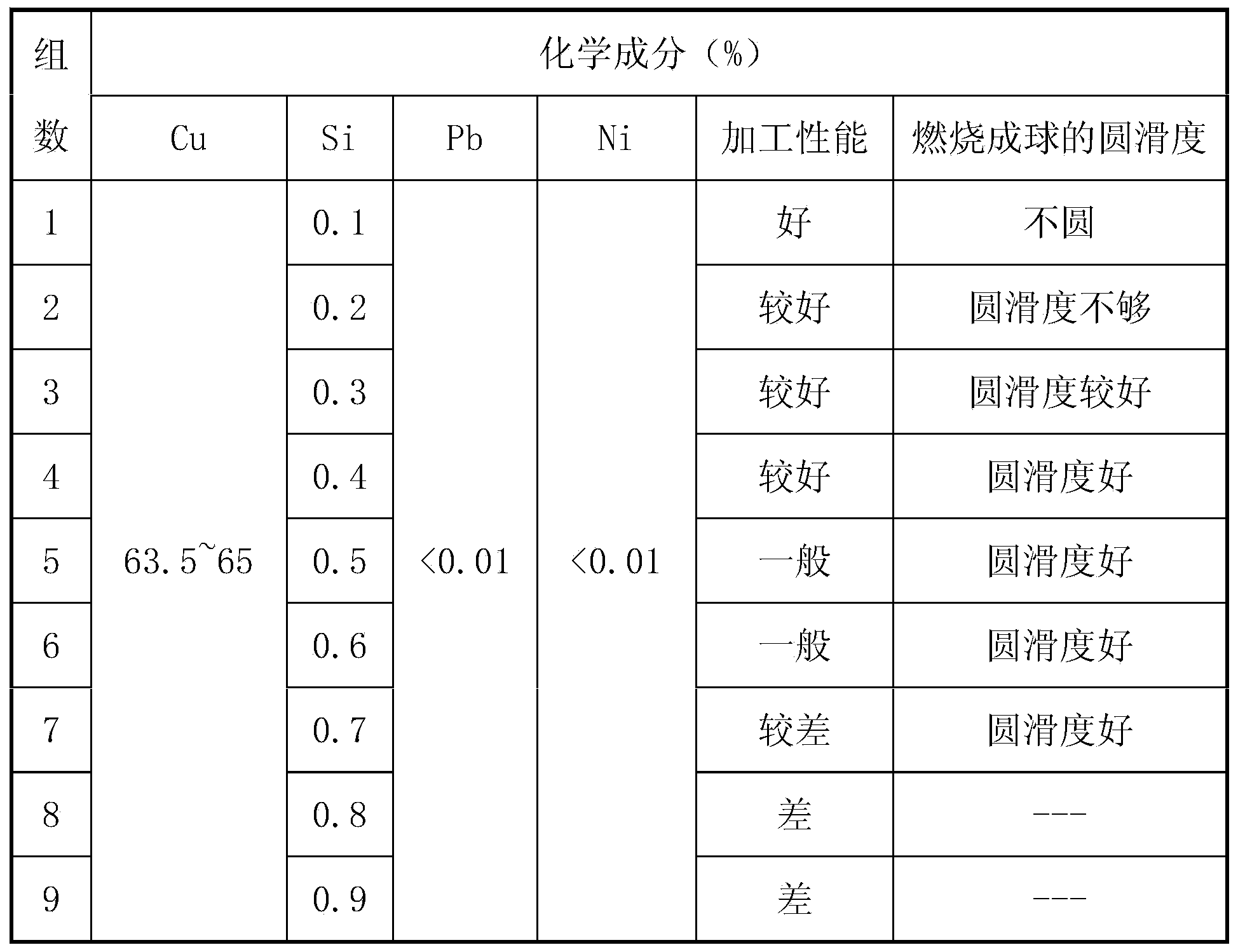

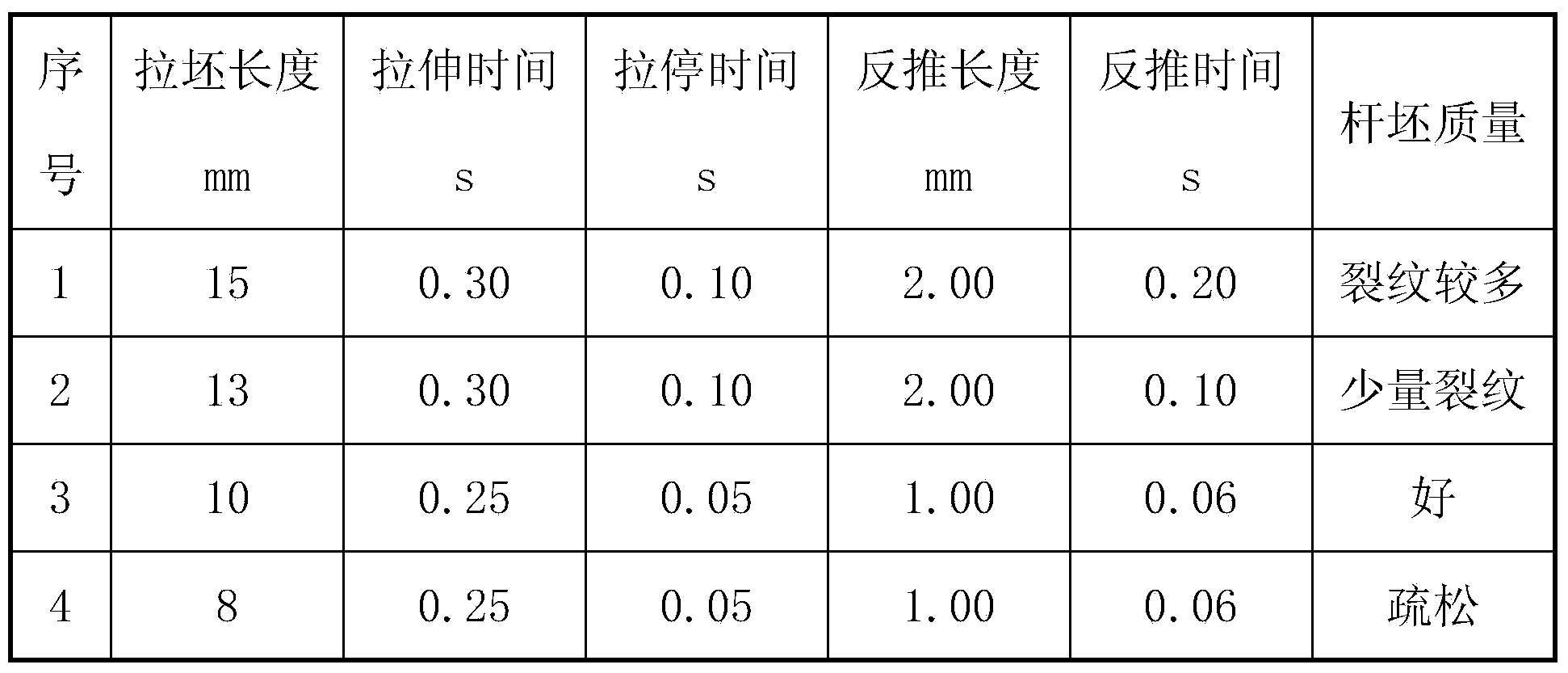

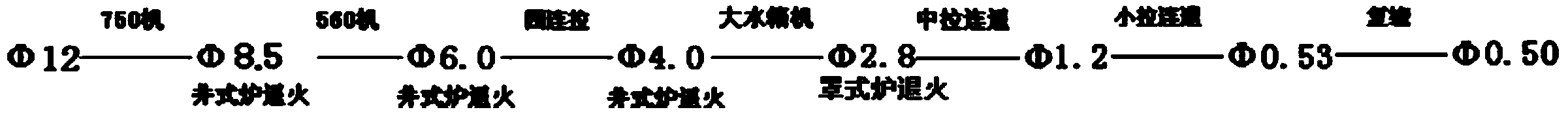

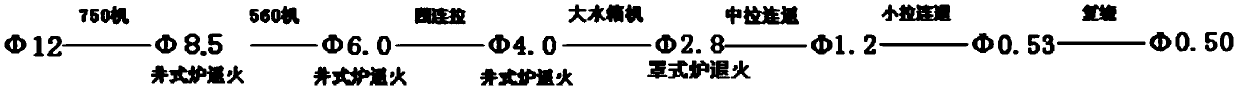

Brass wire and processing method of brass wire

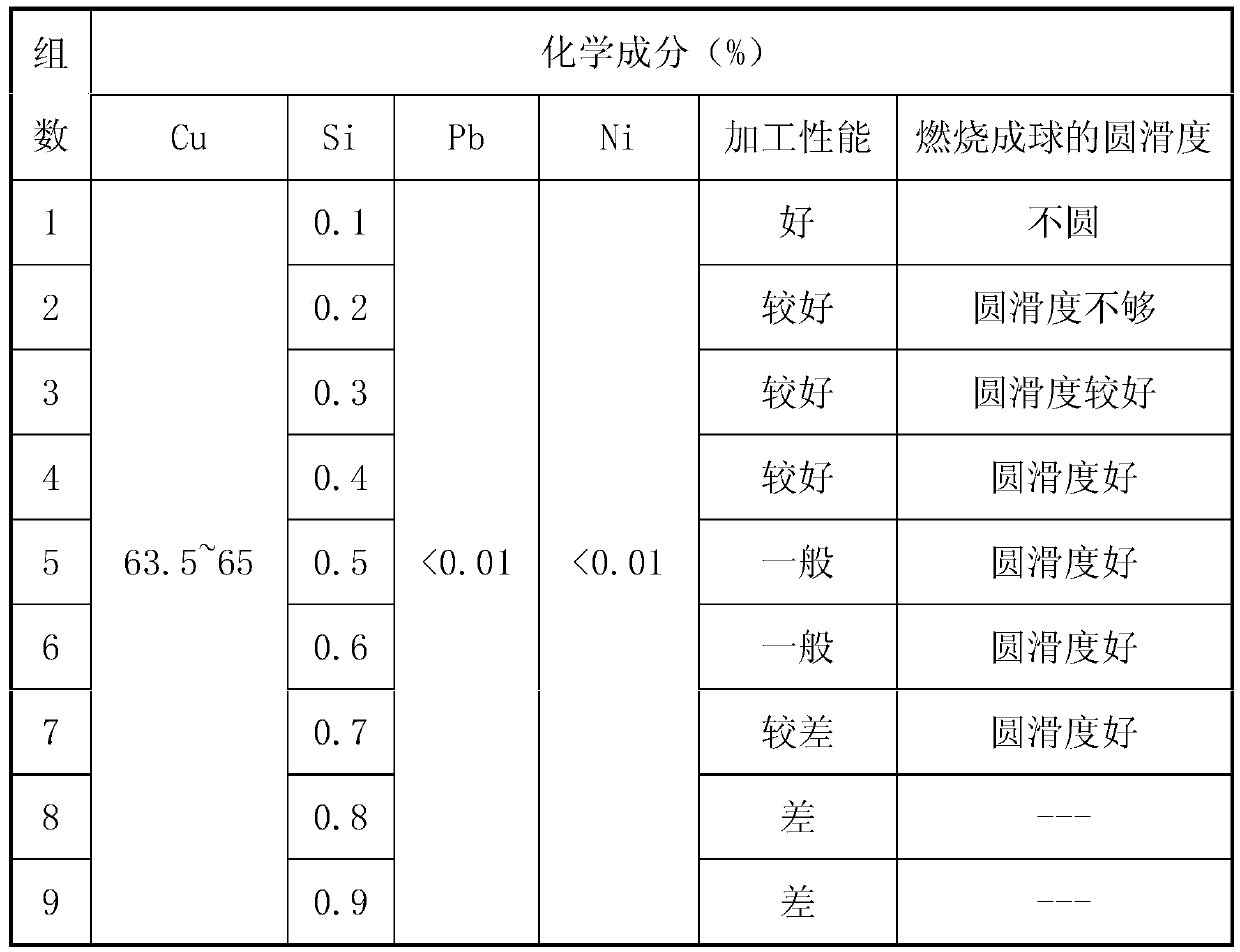

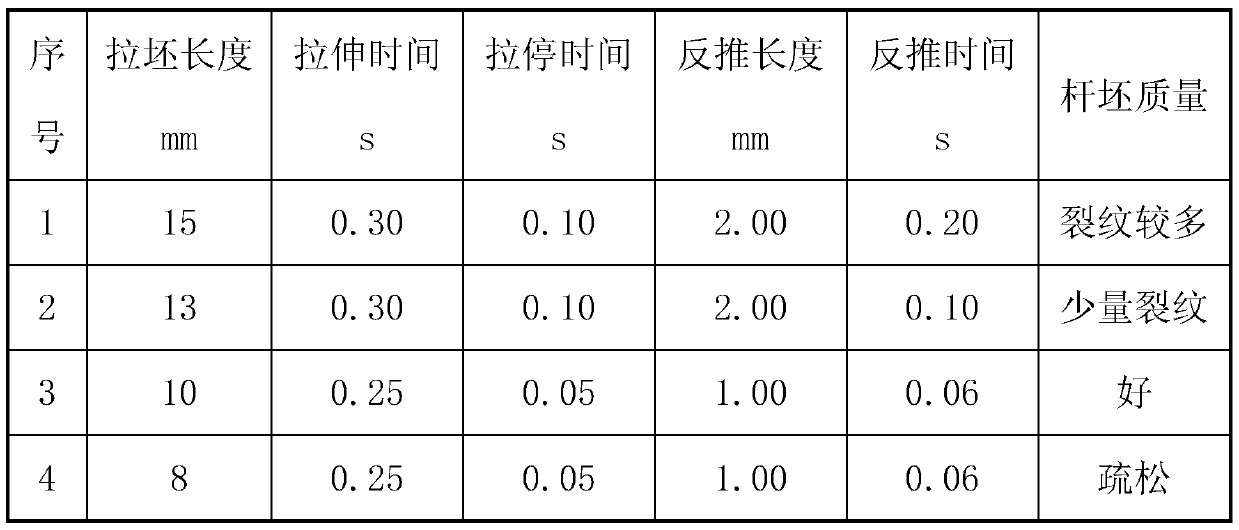

The invention provides a brass wire applied to the technical field of production and processing of wires. The invention simultaneously relates to a processing method of the brass wire. The brass wire comprises the following components: Cu, Sn, Si and Zn, wherein the Cu element accounts for 63.5%-65% by weight, the Sn element accounts for 0.8-1.2% by weight, the Si element accounts for 0.10-0.50% by weight, and the balance is the Zn. In the brass wire and the processing method, provided by the invention, the mechanical performance value of the brass wire is controlled at 650-750MPa, a sphere formed by combustion is smooth and full, the problem of brittle failure caused by over-hard performance can be avoided, and the brass wire can not be processed into a ball needle due to the influence of relatively soft performance. When the brass wire is formed, a rewinding machine is adopted for taking up, and the diameter degree is good; and when the brass wire is machined by a customer, the paying-off is smooth, the wire wrapping phenomenon can be avoided, and the brass wire can completely meet the requirements of jewelry processed from the brass wires in jewelry industry.

Owner:安徽鑫科铜业有限公司

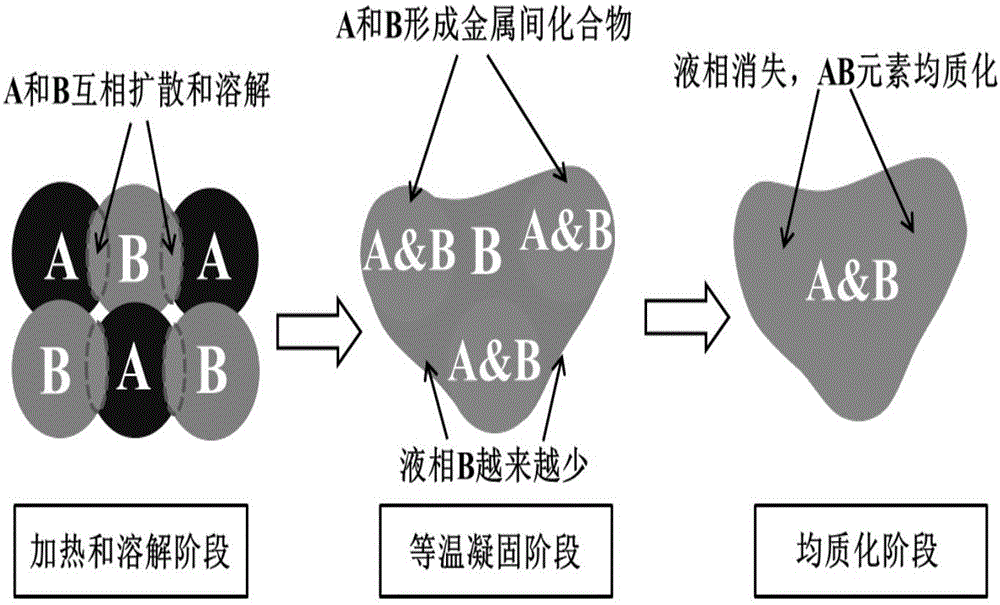

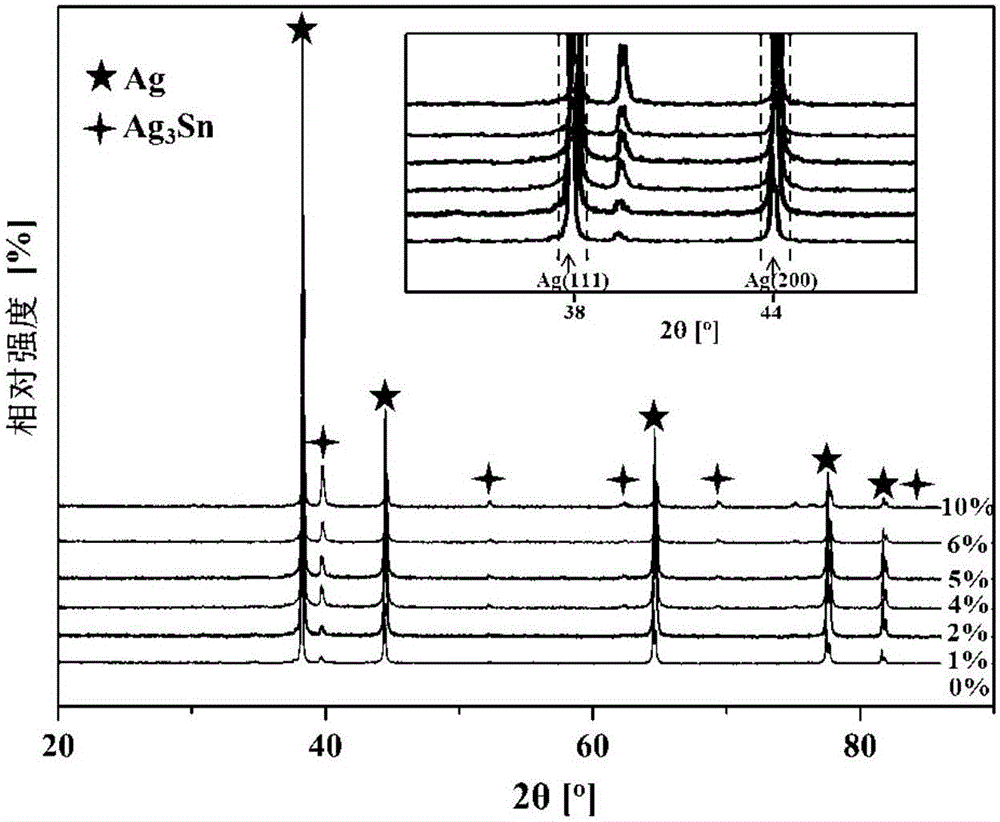

Preparation method for low-temperature sintered tin-doped nano-silver soldering paste

InactiveCN107175433ARigorous processRigorous implementationWelding/cutting media/materialsSoldering mediaRosinUltimate tensile strength

The invention relates to a preparation method for low-temperature sintered tin-doped nano-silver soldering paste. According to the mass ratio of tin powder to a soldering flux, 90% of powder and 10% of the rosin soldering flux are prepared, wherein raw material of the powder is Sn element. A micron solder paste is prepared through stirring, the silver mass fraction is 90-99%, and the tin mass fraction is 1-10%; a nano-silver soldering paste and the micron solder paste are weighed and added with terpilenol to be dissolved, firstly mechanical oscillation is conducted by using a spiral oscillator, then ultrasonic oscillation is conducted by using an ultrasonic cleaner, and a mixture is obtained; and constant temperature bath and volatilization are conducted on the mixture at the temperature of 70 DEG C till the mixture is in a paste shape. Pressure is not added in the sintering process of the tin-doped nano-silver soldering paste, protection of inert gases is not needed, and the maximum sintering temperature is 235 DEG C. According to the preparation method for the low-temperature sintered tin-doped nano-silver soldering paste, the process procedure is well-conceived, and implementation is strict; and the sintering temperature of the low-temperature sintered tin-doped nano-silver soldering paste is lower than the sintering temperature of a traditional silver soldering paste, and compared with a pure nano-silver soldering paste, under the same sintering process, the connection strength of the low-temperature sintered tin-doped nano-silver soldering paste after being sintered is double of the connection strength of the pure nano-silver soldering paste.

Owner:TIANJIN UNIV

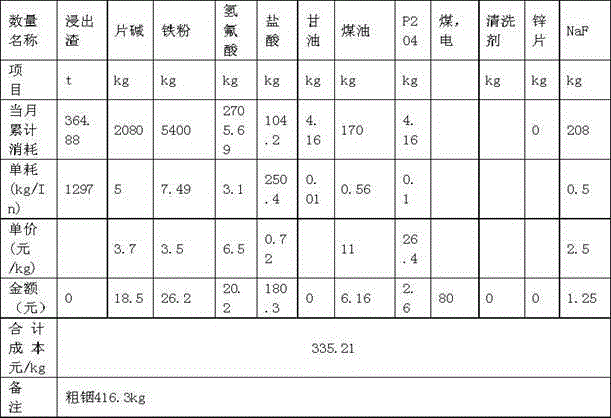

Method for extracting and separating indium and tin from indium-containing leaching residues

InactiveCN104831077AHigh purityHigh concentration of indiumProcess efficiency improvementEnvironmental resistanceIndium

The invention relates to a method for extracting and separating indium and tin from indium-containing leaching residues. The method comprises the following steps: leaching a complex middle-low grade zinc oxide material containing Cu, Pb, Zn and Ag by using a concentrated NH4Cl solution as a leaching agent to make zinc form a zinc ammonia complex solution; allowing all Fe, As, In and Sn elements in ores to enter residues; adding iron powder to the above obtained leached solution to remove bismuth, lead and iron; filtering to obtain a hydrochloric acid system solution containing indium and tin; and simultaneously extracting indium and tin by adopting P2O4, carrying out complexing stripping on tin by adopting fluoride, and stripping indium by adopting hydrochloric acid. The method has the advantages of one-time thorough separation of indium and tin, short flow, low cost, wide raw material source, high recovery rate of various metals, and no environmental protection problem, and allows the zinc recovery rate in the whole flow to reach above 95%.

Owner:郴州雄风环保科技有限公司

Casting process of nodular cast iron planet carrier

The invention relates to a casting process of a nodular cast iron planet carrier, which comprises the following procedures of modeling, iron melt melting, spheroidizing, modifying, casting and stress relieving and annealing. The design of a casting system adopts a step casting method which takes consideration of both bottom casting and top casting to improve the finished product rate of castings, and also adopts technical schemes of placing chill iron at the position of thick walls, adding Sn element in the iron melt, optimizing, spheroidizing, modifying, casting and the like, so that the produced planet carrier not only meets the high demands on property, but also achieves great improvement in production cost and efficiency.

Owner:JIANGSU HONGDE SPECIAL PARTS CO LTD

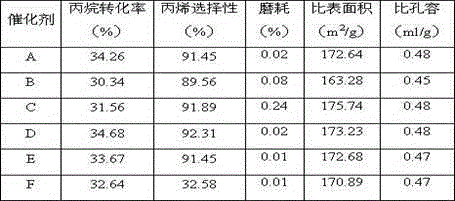

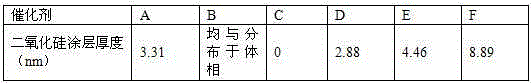

Light-alkane dehydrogenation-to-olefins catalyst and preparation method thereof

ActiveCN106669666AGood alkane conversionEasy to prepareHeterogenous catalyst chemical elementsCatalystsAlkaneWear resistant

The invention discloses a light-alkane dehydrogenation-to-olefins catalyst and a preparation method thereof. The catalyst contains, by weight, 0.1-0.5% of a SiO2 coating, 0.05-0.8% of Pt element, 0.1-5.0% of Sn element, 0.1-5.5% of an auxiliary agent, and the rest of active Al2O3. The thickness of the SiO2 coating is 0.01-10 nm. The preparation method comprises the following steps: (1) loading an active ingredient Pt onto an active Al2O3 carrier, drying and roasting; (2) carrying out saturated impregnation-calcination by the use of an impregnation liquid containing promoter metal, and carrying out semi-dry dehydration; (3) impregnating a catalyst precursor obtained in the step (2) by the use of an organic solvent solution containing estersil; and (4) drying the catalyst precursor obtained in the step (3), and roasting so as to obtain the catalyst. The surface of the catalyst is smooth and wear-resistant and has low abrasion. The catalyst is more suitable for moving-bed dehydrogenation process and has good conversion rate of alkanes and good olefin selectivity in the light-alkane dehydrogenation reaction.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

High-hardness heat-resistant magnesium alloy

The invention discloses a high-hardness heat-resistant magnesium alloy. The alloy is characterized by comprising the following components in percent by mass: 5% of Al, 2% of Sn, 1-5% of Ca, not greater than 0.005% of impurity Fe, not greater than 0.015% of impurity Cu, not greater than 0.002% of impurity Ni, and the balance of Mg. According to the alloy disclosed by the invention, the high-temperature strengthening phases of Mg2Sn, Mg2Ca, Al2Ca and CaMgSn are generated by adding Al element, Sn element and Ca element together, so that the alloy has the characteristics of being high in hardness, good in heat resistance, and the like. Compared with the existing heat-resistant magnesium alloy, the alloy disclosed by the invention is good in room-temperature performance and high-temperature performance, low in production cost, high in efficiency, and capable of being widely applied to commercial components comprising automobile parts, electronic product components and aerospace components.

Owner:SHENYANG POLYTECHNIC UNIV

Low-cost high-compression-strength wrought magnesium alloy and preparation method thereof

InactiveCN108118225ANo significant increase in preparation costsRich varietyElemental compositionCu element

The invention relates to a low-cost high-compression-strength wrought magnesium alloy and a preparation method thereof. The magnesium alloy material is composed of six elements, namely Mg, Zn, Mn, Sn,Ca and Cu, wherein the content of the Zn element is 4.0%-8.5%, the content of the Mn element is 0.1%-0.4%, the content of the Sn element is 0.1%-0.4%, the content of the Ca element is 0.1%-0.4%, thecontent of the Cu element is 0.1%-0.4%, the content of inevitable impurities is less than or equal to 0.15%, and the balance is the Mg; and compared with a traditional commercial grade magnesium alloymaterial, high compressive yield strength can be obtained after the magnesium alloy material is subjected to a conventional extrusion treatment, and the compressive yield strength of the alloy is obviously higher than tensile yield strength. The magnesium alloy material does not contain precious alloy elements, and is simple in preparation process and low in cost, has very important practical value for manufacturing a pressed magnesium alloy component.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

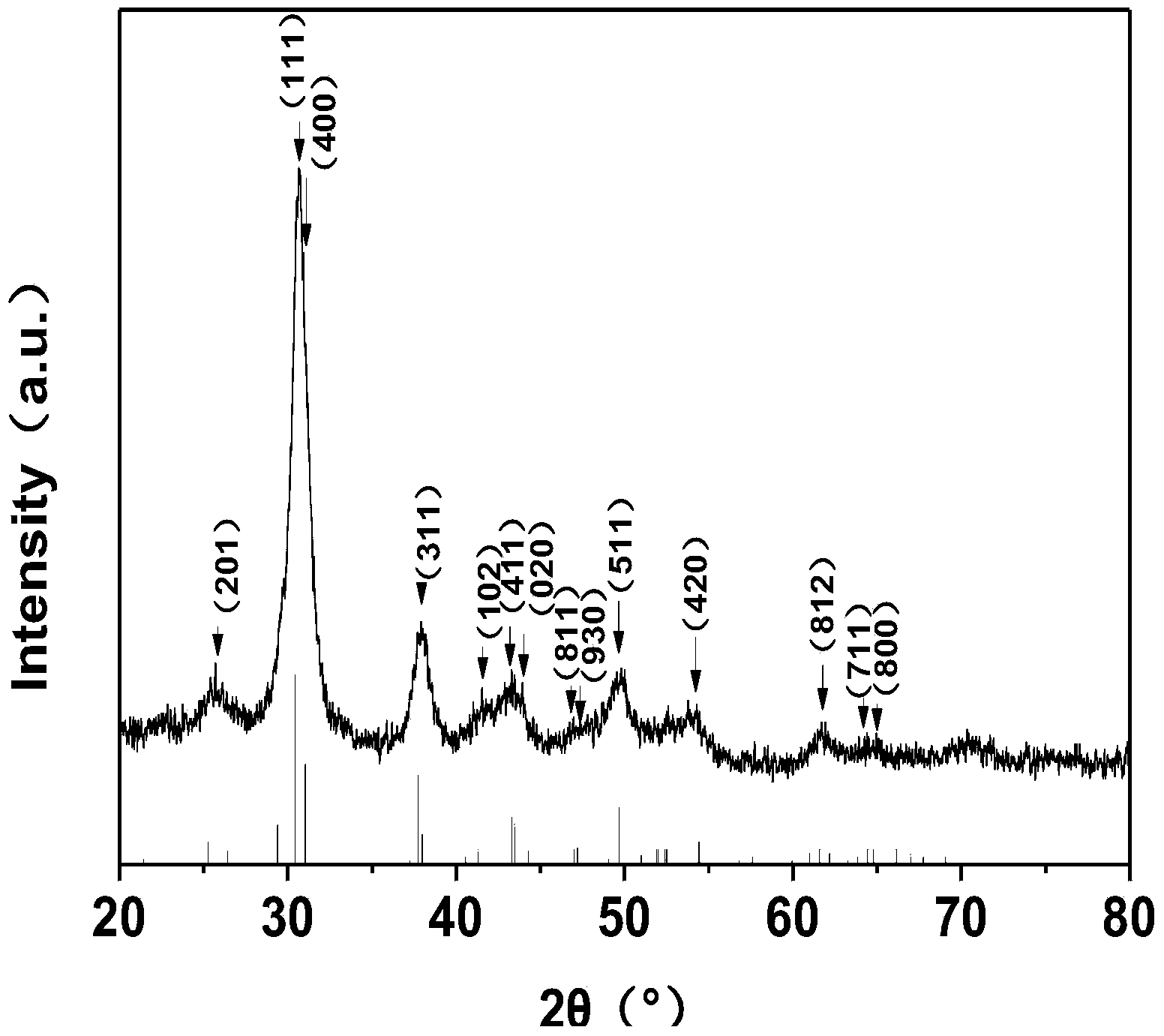

Preparation method of crystalline state Li-Sn-S series inorganic lithium ion solid electrolyte

The invention provides a preparation method of a crystalline state Li-Sn-S series inorganic lithium ion solid electrolyte. The method comprises the following steps: introducing H2S gas or adding a water-soluble sulfide into a LiOH.H2O aqueous solution in an enclosed container, reacting for a certain time period, and adding an aqueous solution containing a metal Sn element; introducing protective gas for reacting continually, adding an organic reagent, putting the mixture into a low-temperature environment, drying a crystal which is separated out, and removing crystalized water by means of thermal treatment to obtain a product. An all-solid electrolyte is prepared by adopting a novel wet process. Compared with the conventional solid-phase synthesis, the method has the remarkable advantages of short reaction time and controllability of the product morphology.

Owner:湖南国拓机械有限责任公司

Braze solder for air conditioner and brazing flux

InactiveCN103639615AQuality improvementEasy to clean and removeWelding/cutting media/materialsSoldering mediaUltimate tensile strengthToughness

The invention relates to braze solder and brazing flux, in particular to braze solder for an air conditioner and brazing flux. Brazing filler metal is an alloy with Zn as a substrate and contains Al and Sn elements. The brazing flux matched with the brazing filler metal in use is a saturated solution of ZnC12, NH4Cl and KCl. The melting temperature of the brazing filler metal is 370-375 DEG C. The braze solder and the brazing flux are low in price, firm in brazing line, free of cold joint, high in strength, good in toughness, low in cost and high in quality. Residues are easy to wash and remove after brazing.

Owner:SHINAN BRANCH OF QINGDAO BLUEPRINT CULTURE COMM

Preparation method of SnS3 nano powder

InactiveCN104291279AShort synthesis timeSimple processMaterial nanotechnologyBinary selenium/tellurium compoundsHigh volume manufacturingAlcohol

The invention discloses a preparation method of SnSe nano powder and belongs to the technical field of nano materials. The preparation method of the SnSe nano powder comprises the following steps: preparing high-purity substances of Sn element and Se element according to a stoichiometric ratio of a final product, putting the substances into a planet type high energy ball-milling machine for mechanical alloying under the protection of inert gas, carrying out dry grinding at a certain rotating speed, directly synthesizing a compound, then adding a certain amount of absolute ethyl alcohol, carrying out wet grinding, and finally drying, so that SnSe superfine powder is obtained. The preparation method of the SnSe nano powder has the advantages of available raw materials, short time and controllable particle size, and is easy to operate, so that the preparation method of the SnSe nano powder is applicable to mass production.

Owner:BEIHANG UNIV

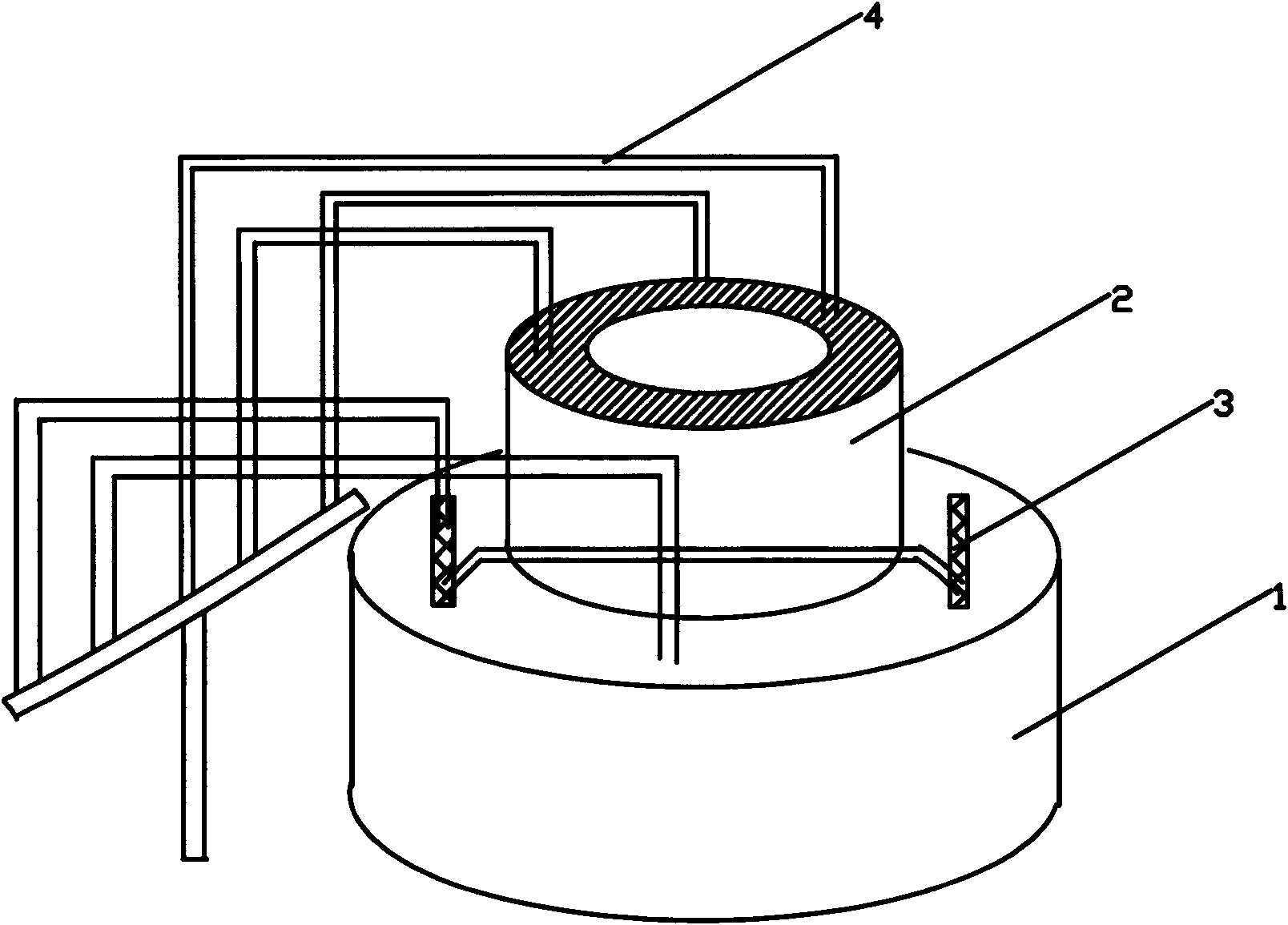

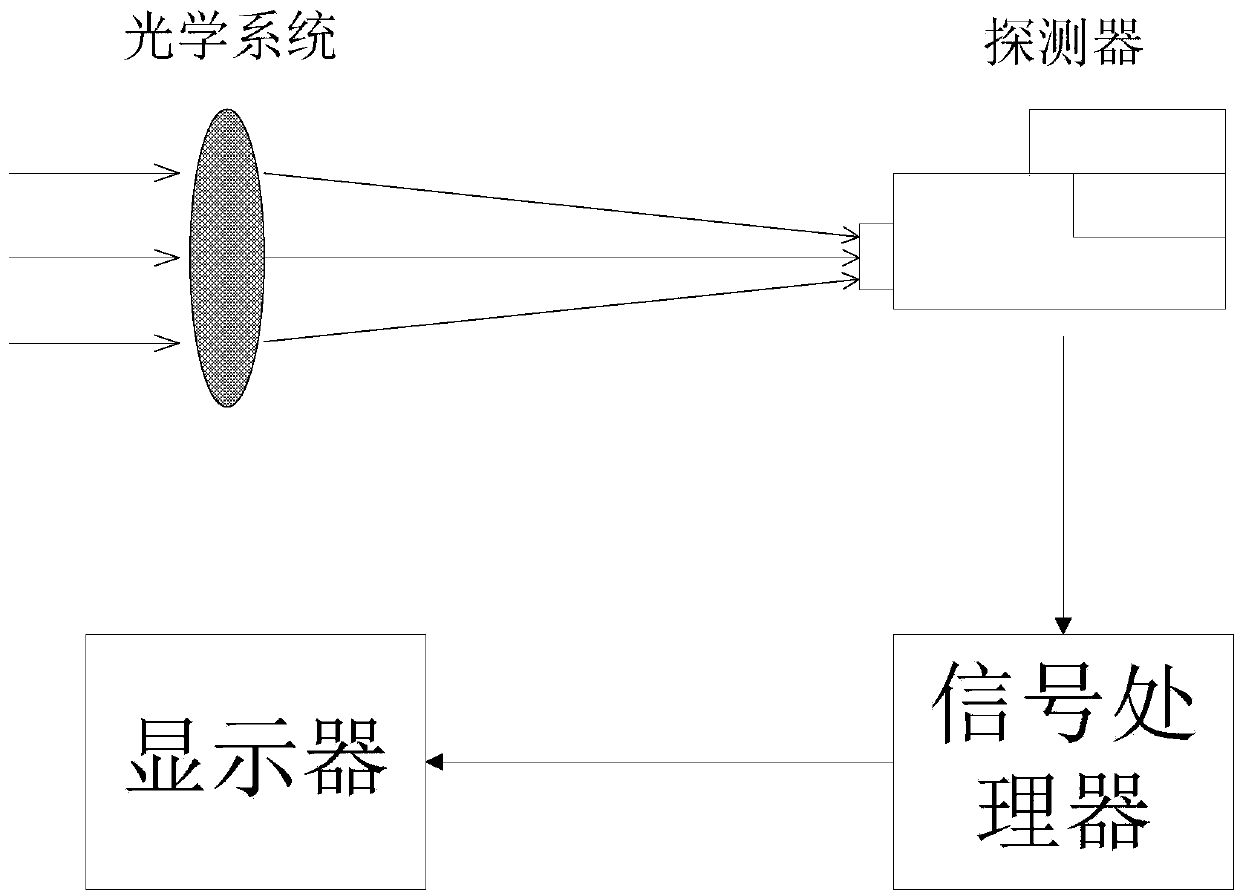

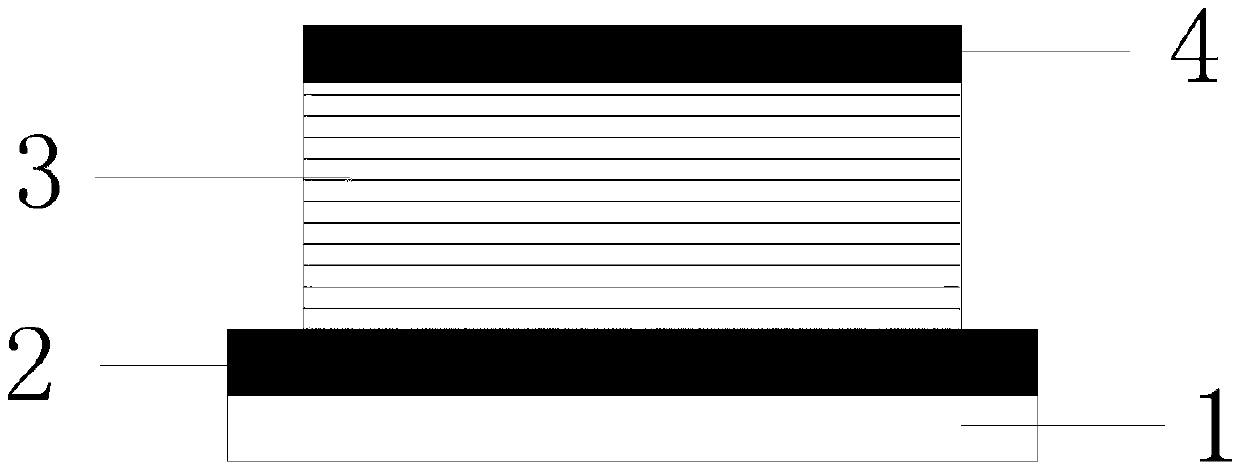

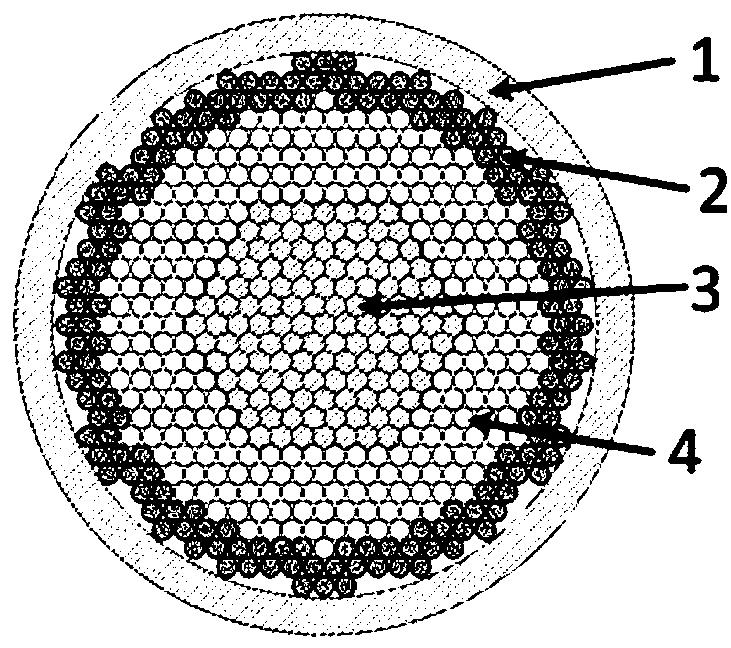

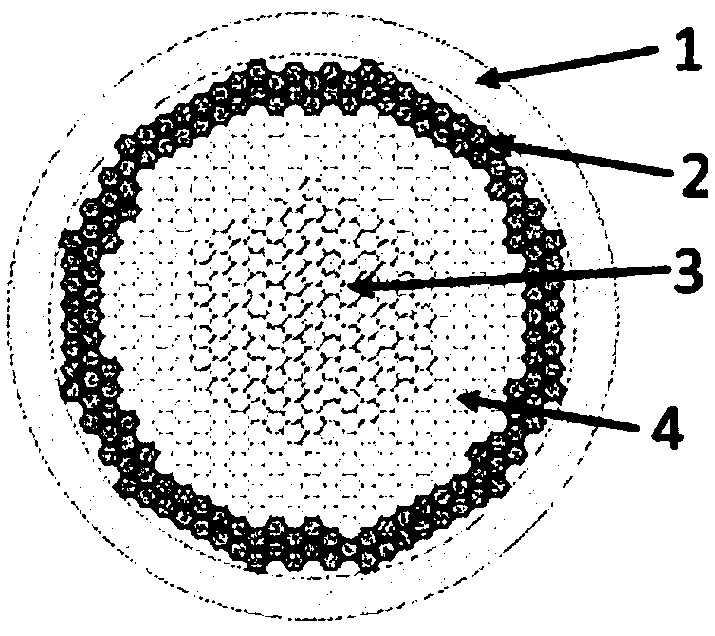

Infrared night-vision goggle based on GeSn infrared detector

InactiveCN105514209AImprove photosensitivityRedshift adjustableTelescopesSemiconductor devicesDisplay deviceGe element

The invention discloses an infrared night-vision goggle based on a GeSn infrared detector, and mainly aims to solve the problem that the existing infrared night-vision goggle is of low light sensing efficiency. The infrared night-vision goggle comprises an optical system, a detector, a signal processor and a display. The detector is a GeSn infrared detector, and comprises a substrate (1), a lower electrode (2), an absorption area (3) and an upper electrode (4), wherein the absorption area (3) is made of a GeSn material of which the general formula is Ge1-xSnx, x is a component of Sn, and 0<=x<=0.25. As the Sn element is added to the Ge element to form a relaxation intrinsic GeSn single crystal, the energy band structure of GeSn is changed from direct band gap to direct band gap while the forbidden bandwidth is decreased. Therefore, the light sensing frequency is increased, the red shift of the absorption edge is adjustable, and the light sensing efficiency and absorption wavelength range of the infrared night-vision goggle are improved.

Owner:XIDIAN UNIV

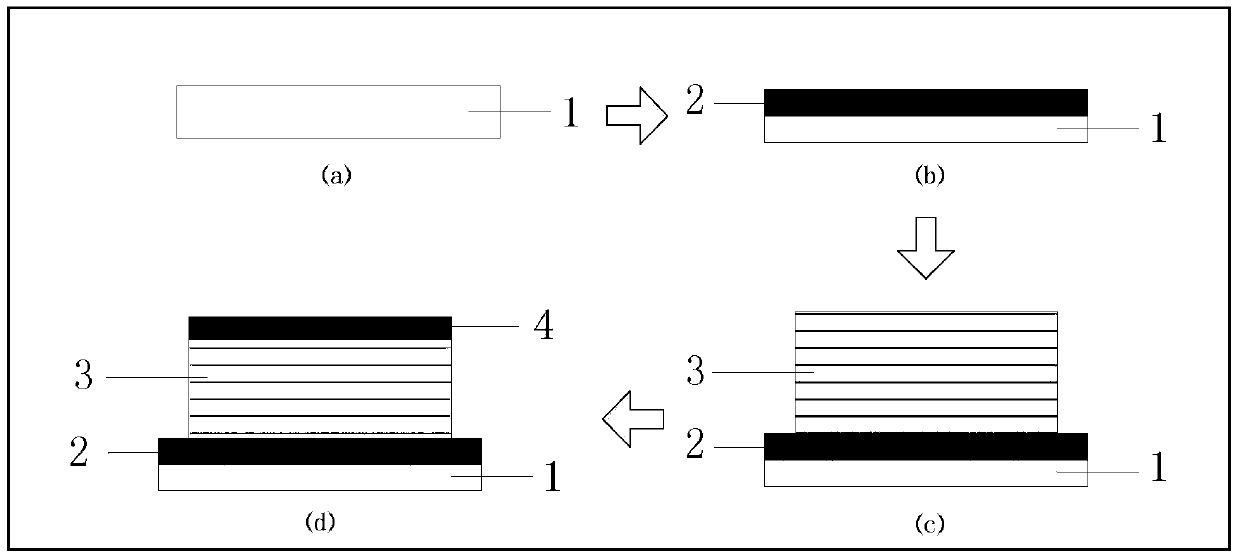

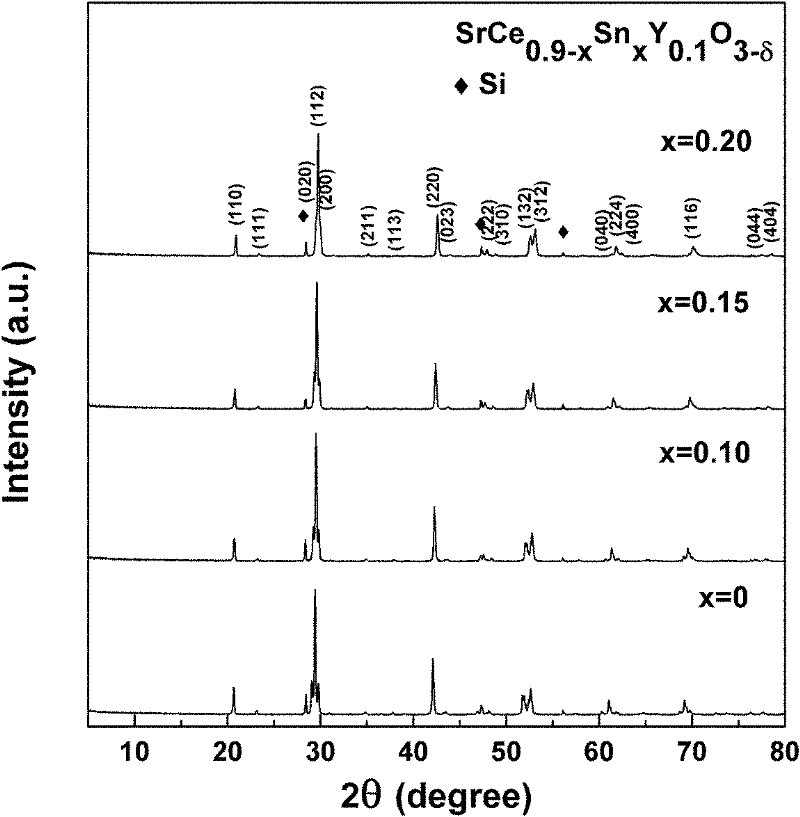

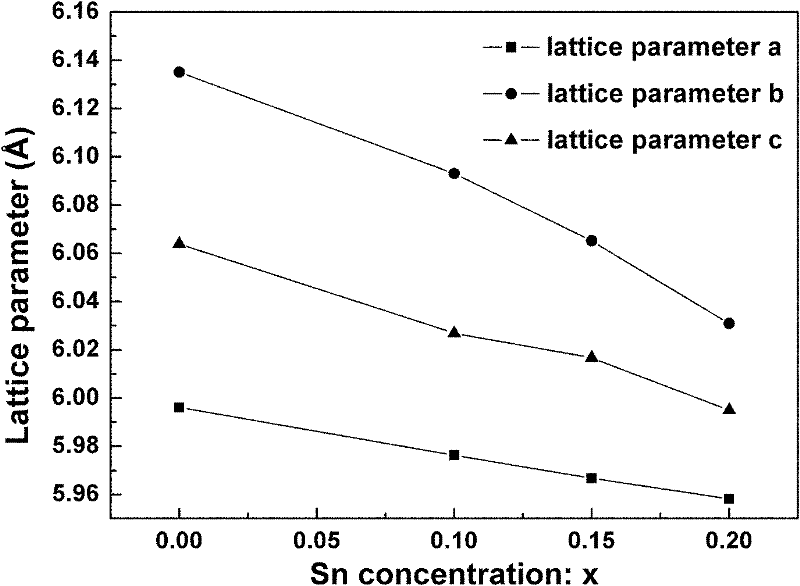

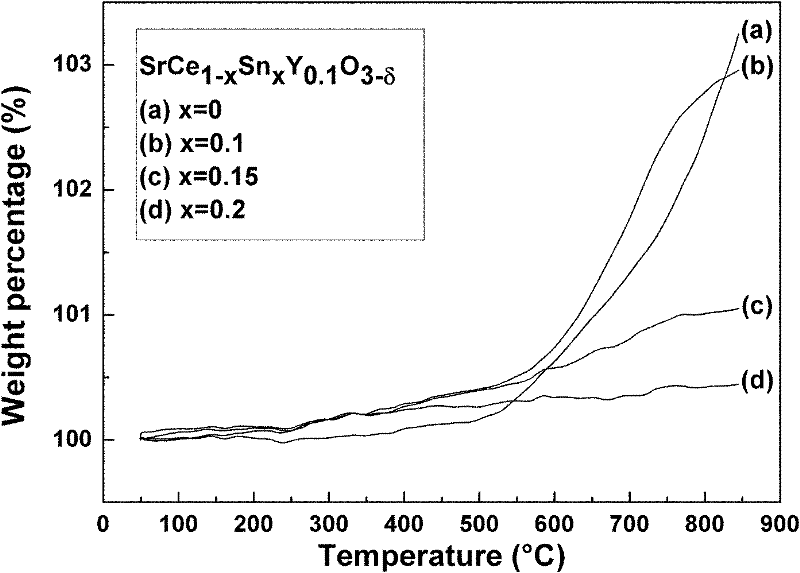

Strontium cerate-based high-temperature proton conductor material and preparation method and application thereof

The invention provides a Sn<4+>-doped and modified SrCeO3-based high-temperature proton conductor material and a preparation method and application thereof. The material has a chemical general formula, i.e., SrCe1-x-zSnxMzO3-6, wherein M is Y or Yb; x is more than 0 and less than or equal to 0.25; and y is more than or equal to 0.05 and less than or equal to 0.2. The chemical stability of the SrCeO3-based high-temperature proton conductor material to H2O and CO2 is enhanced by performing Sn<4+> doping and modifying, i.e., the SrCeO3-based high-temperature proton conductor material with higher chemical stability is prepared by adding an appropriate amount of oxide raw material powder containing an Sn element in the raw material powder synthesizing process of a ceramic system with a solid-phase reaction method. According to the invention, foundations are laid for application of the SrCeO3-based high-temperature proton conductor material on the aspects of hydrogen pumps, gas sensors, vapor electrolytic cells, fuel cells, gas separation membranes, membrane reactors for organic synthesis catalytic dehydrogenation and hydrogenation, and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

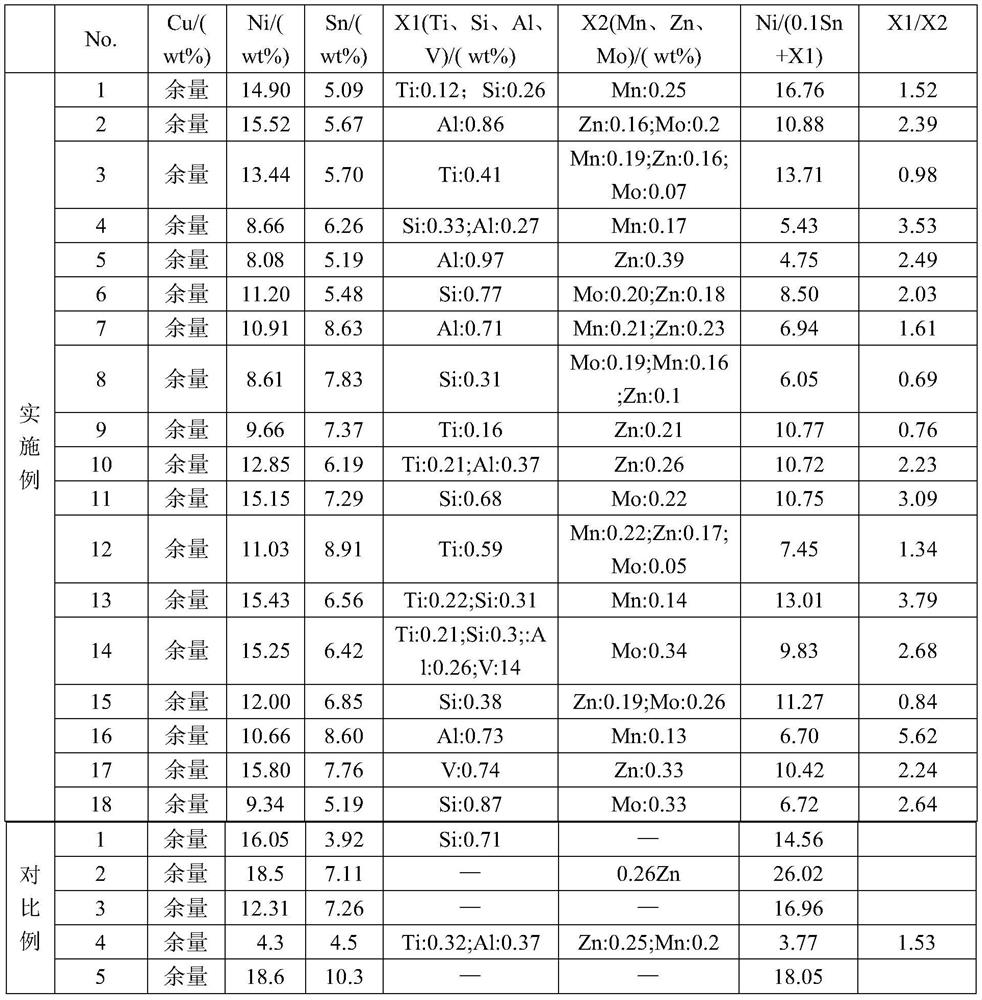

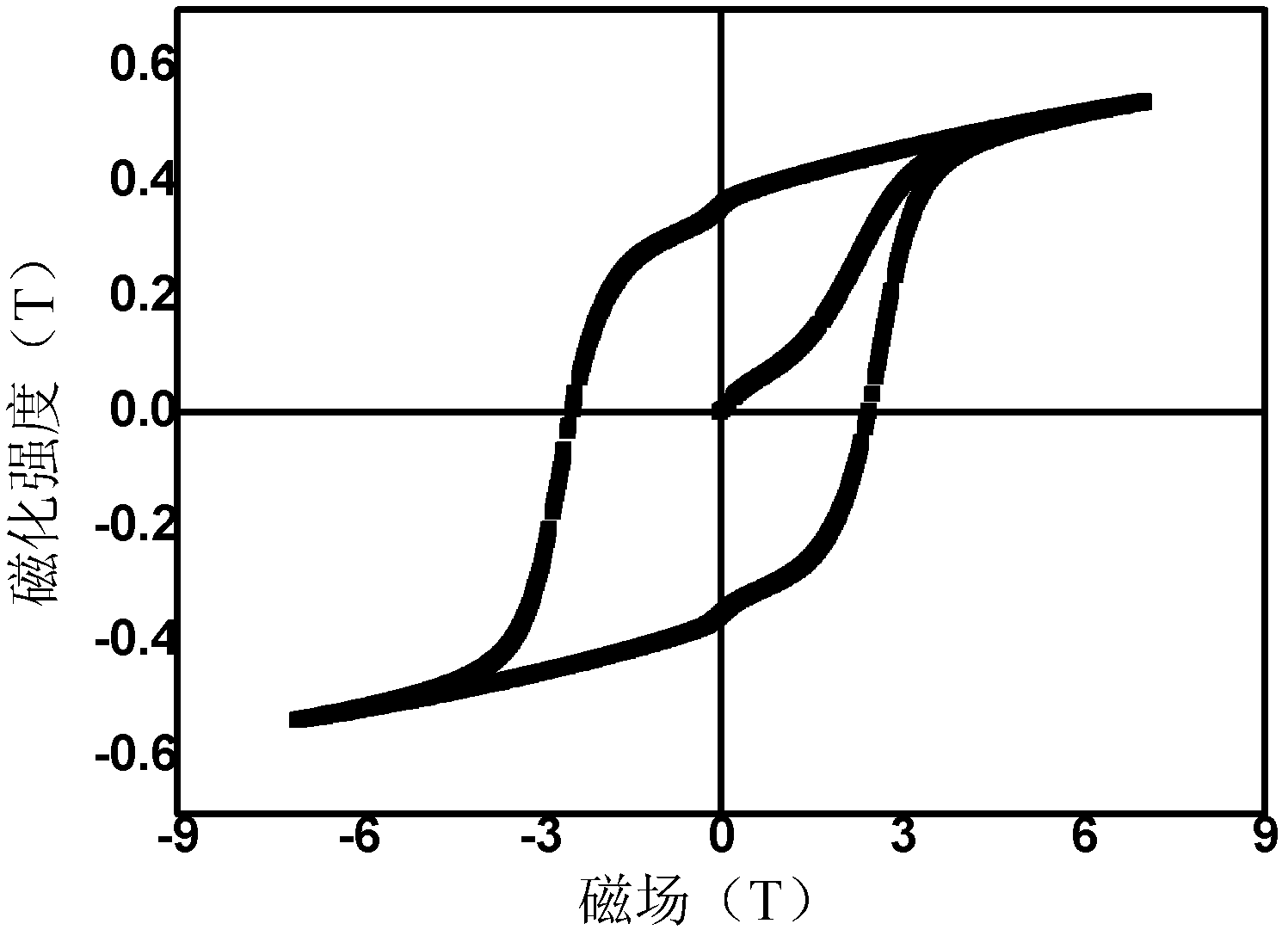

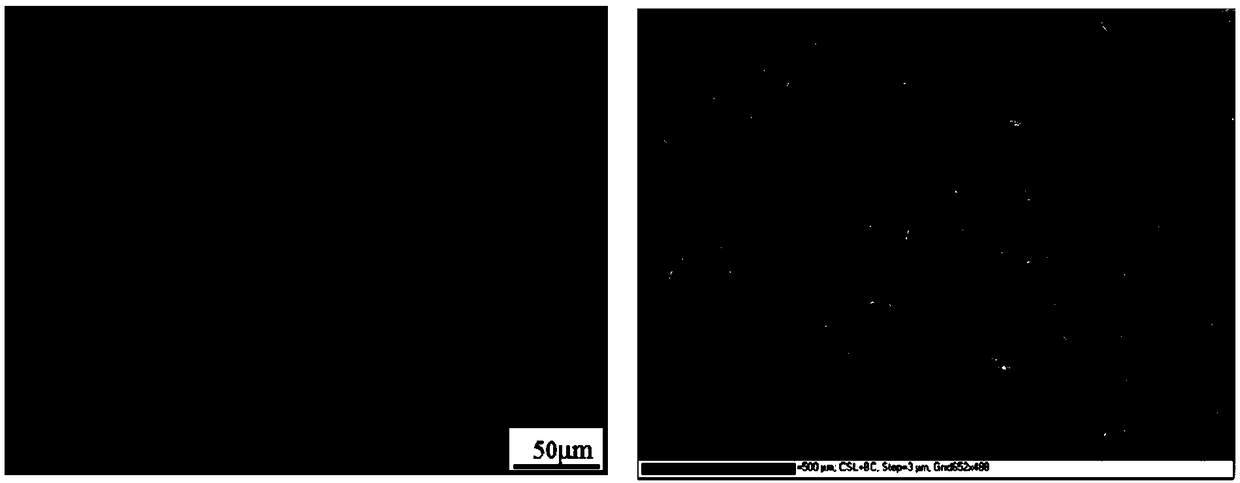

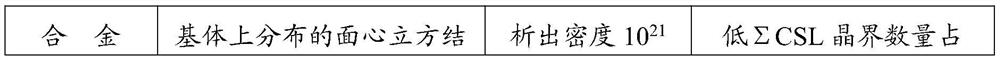

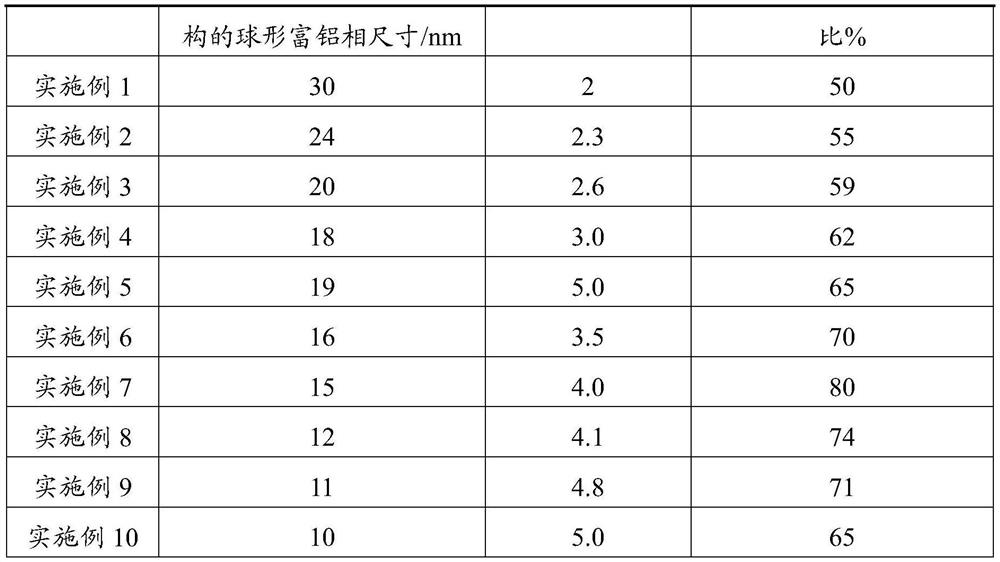

Copper-nickel-tin alloy and preparation method and application thereof

The invention discloses a copper-nickel-tin alloy and a preparation method and application thereof. The alloy comprises the following components in percentage by weight: 8-16% of Ni, 5-9% of Sn, 0.1-1.0% of X1 element, 0.1-0.5% of X2 element, X1 is selected from at least one of Ti, Si, Al and V, X2 is selected from at least one of Mn, Zn and Mo, and the balance is Cu and inevitable impurities. According to the copper-nickel-tin alloy and the preparation method and application thereof, segregation of the Sn element is restrained in the mode that precipitation strengthening, microalloying and semi-continuous casting electromagnetic stirring are combined, the Sn element concentration difference from the core to the surface layer of a copper alloy cast ingot is controlled to be within 2%, the hardness difference value is controlled to be within 10 HV, and the hardness deviation in different directions is controlled to be within 5%. The alloy cast ingot can be processed into bars, wires, plates, belts, pipes and other forms, the tensile strength is larger than or equal to 1100 MPa, the yield strength is larger than or equal to 1050 MPa, the ductility is larger than or equal to 5%, and the alloy cast ingot can be applied to the fields of aerospace, energy exploitation, intelligent forming and the like.

Owner:NINGBO POWERWAY ALLOY MATERIAL +1

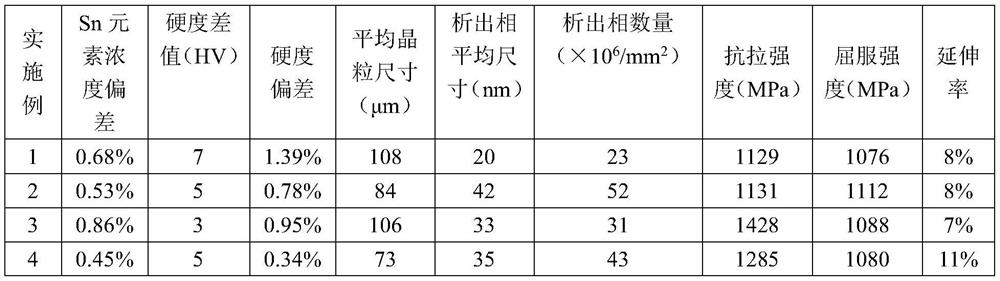

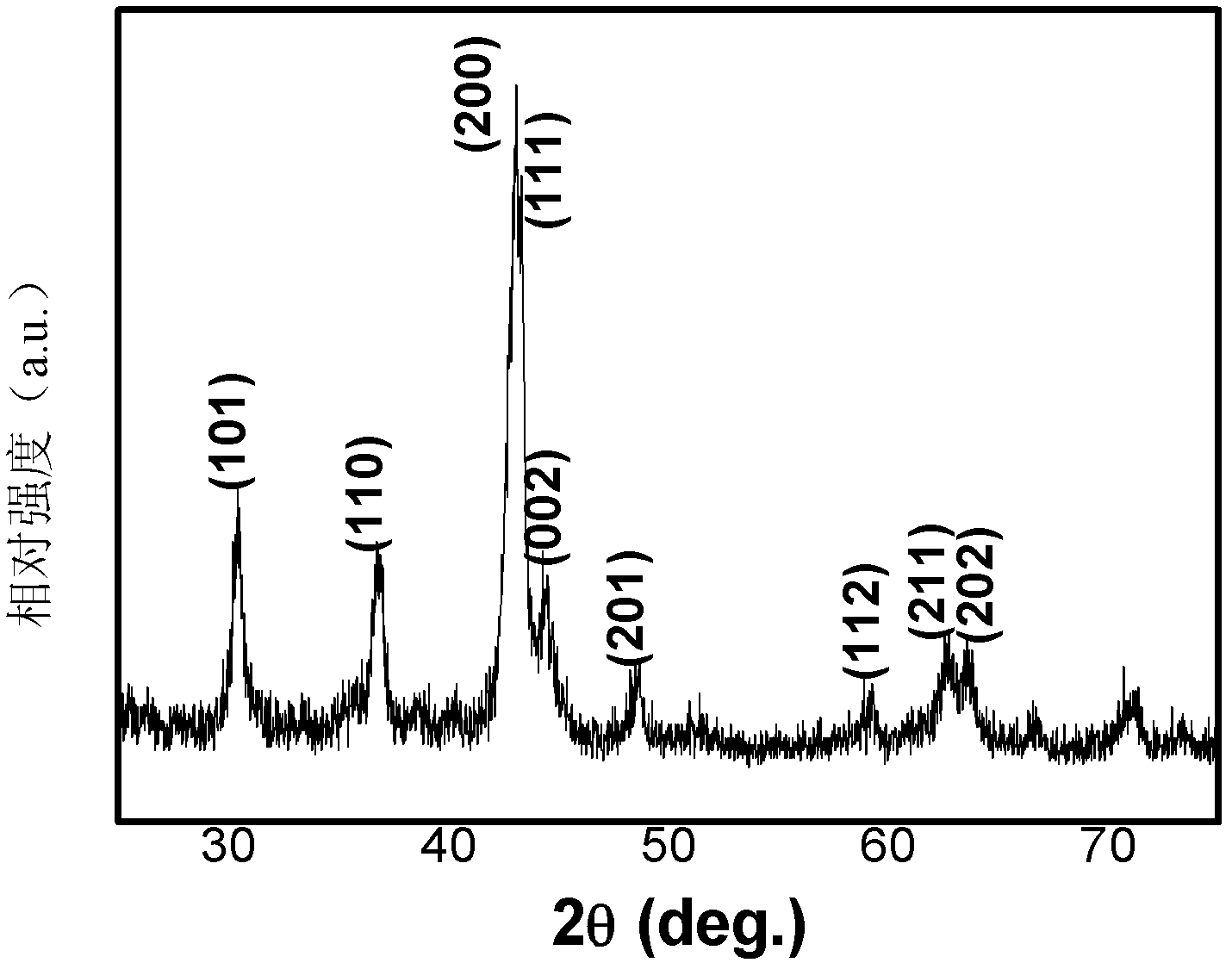

Oxidation-resistant SmCoX-Y(SiaGebSnc)Y high-temperature permanent-magnet material for aeroengine and preparation method thereof

ActiveCN102304646AImprove high temperature oxidation resistanceStable structureMagnetic materialsGe elementOxidation resistant

The invention discloses an oxidation-resistant SmCoX-Y(SiaGebSnc)Y high-temperature permanent-magnet material for an aeroengine and a preparation method thereof. The expression formula of the permanent-magnet material is SmCoX-Y(SiaGebSnc)Y, wherein the atom number of X is 5.0-8.5 and the atom number of Y is 0.01-1.90; and a+b+c=1, the atom number of a is 0.20-0.98, the atom number of b is 0.01-0.70 and the atom number of c is 0.01-0.10. In the invention, Si, Ge and Si elements are doped in SmCo7 alloy, and the ratio of three elements (Si, Ge and Sn) is properly adjusted to achieve the purposes of simultaneously stabilizing the structure of TbCu7 and improving the high-temperature oxidation resistant capacity of a magnet. The Si element is doped, so that the formation of a TbCu7 phase canbe promoted and the high-temperature oxidation resistance of the material can be improved; the Ge element is doped, so that the growth of crystal grains in the sintering process can be inhibited; andthe Sn element is doped, so that the sintering temperature can be reduced, the sintering efficiency can be improved and the mechanical performance of the material can be enhanced at the same time.

Owner:BEIHANG UNIV

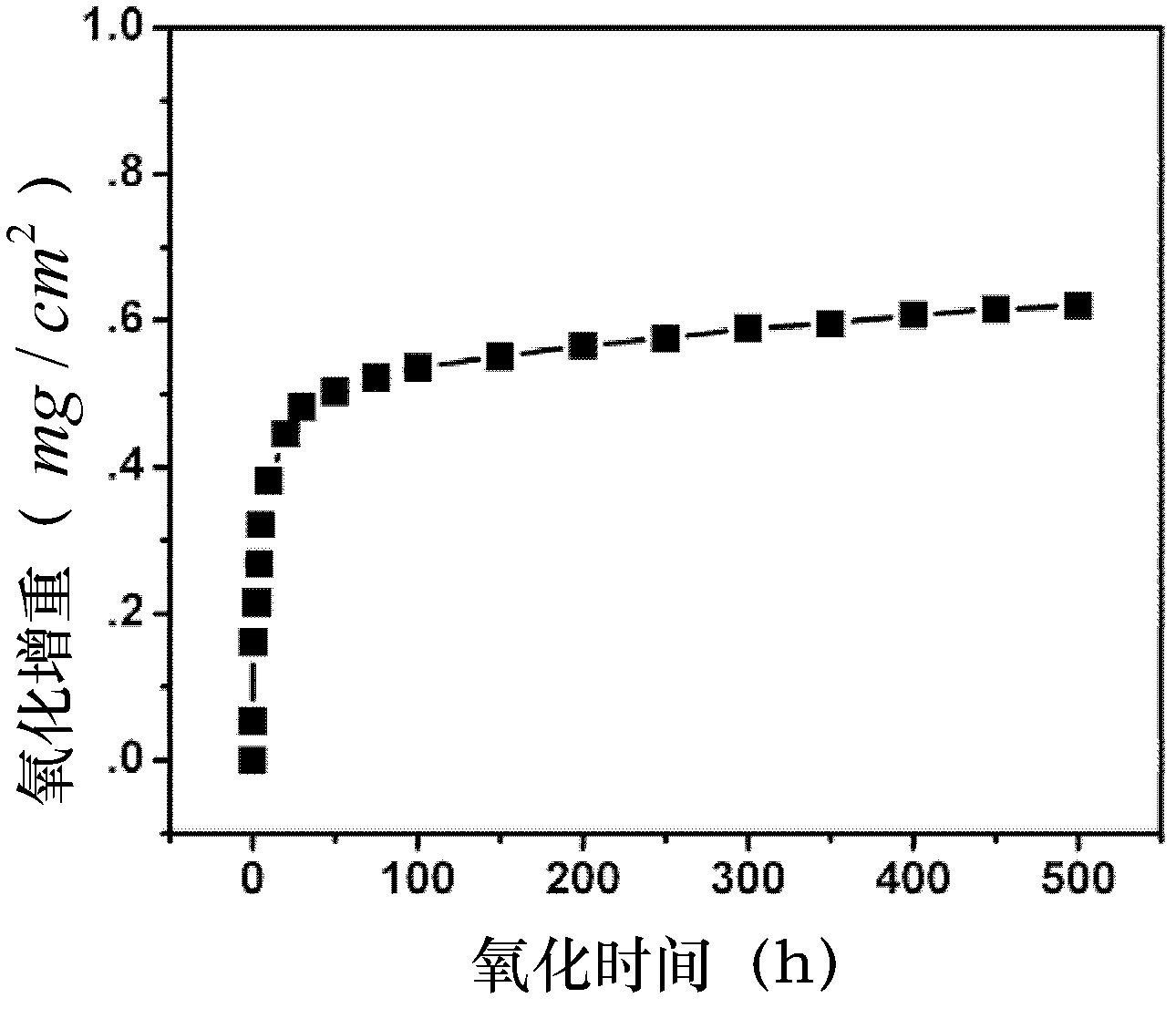

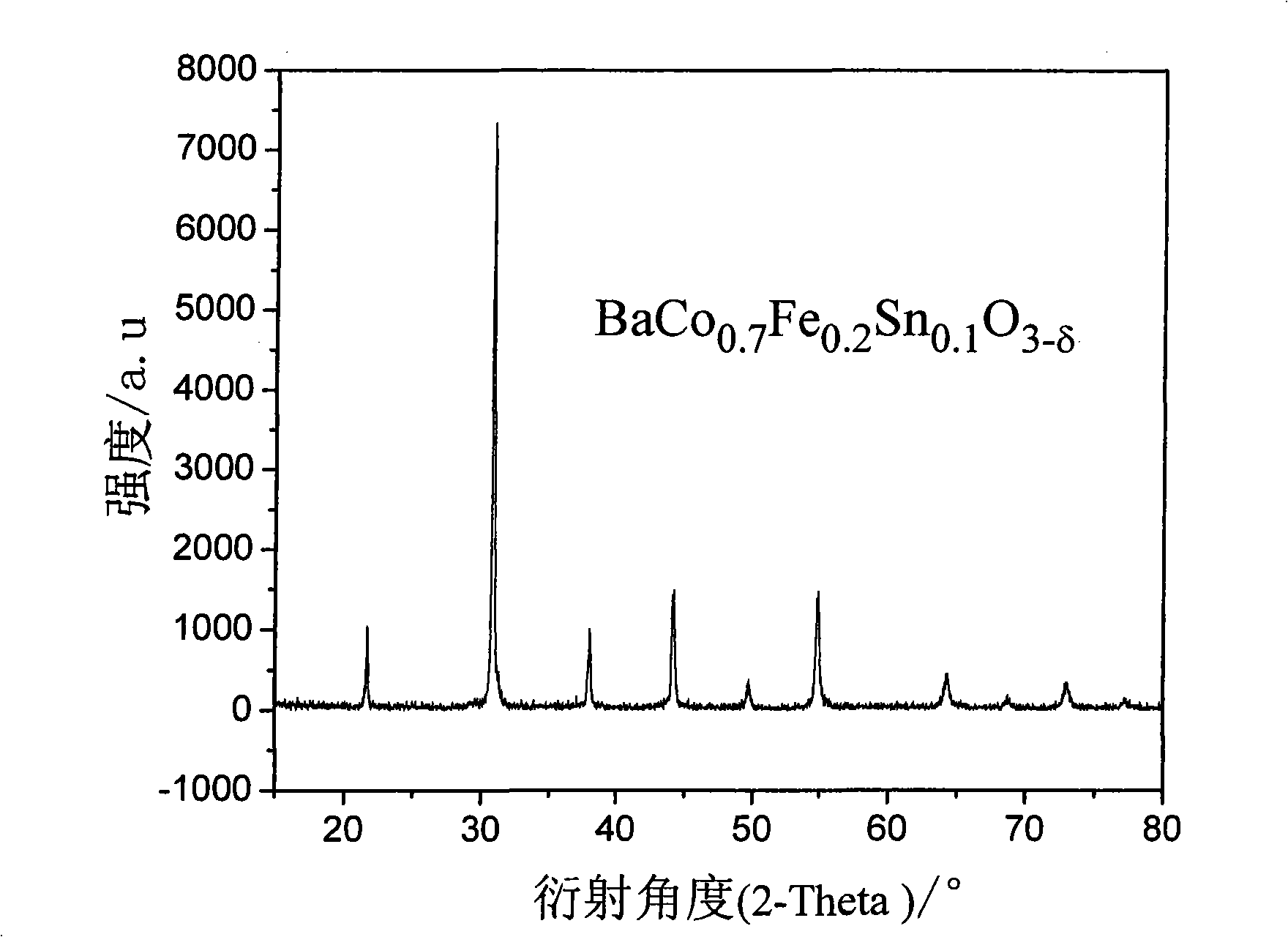

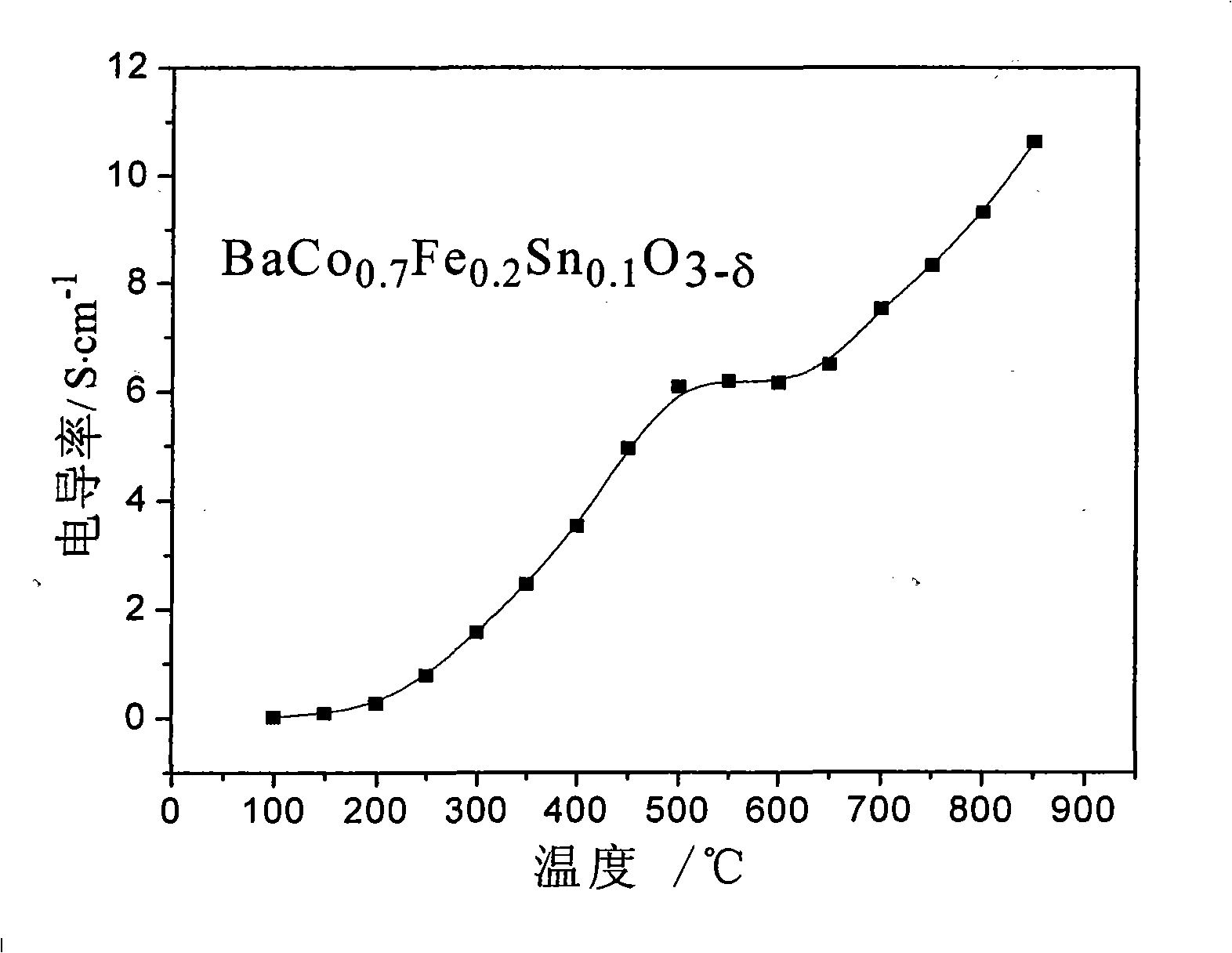

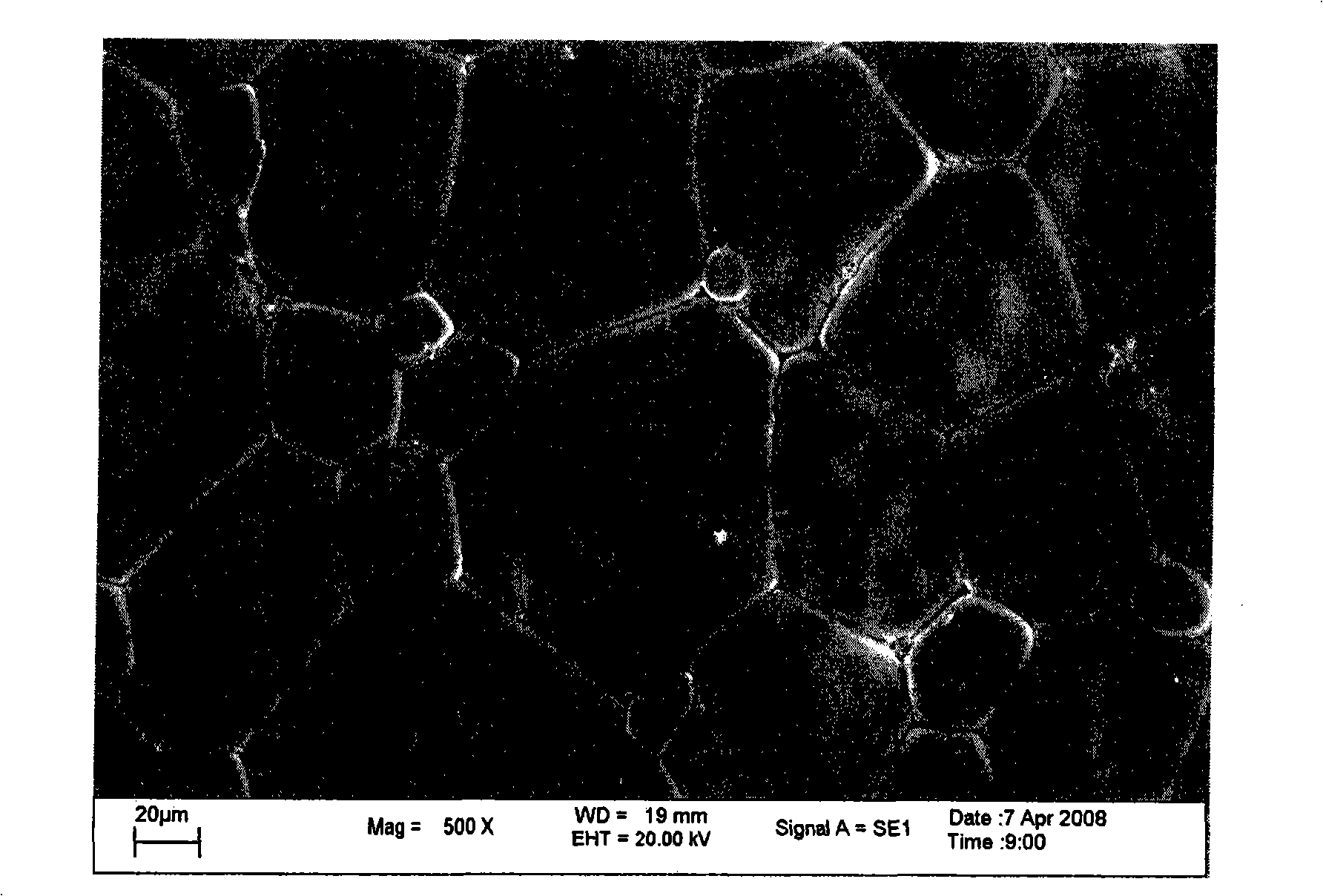

BaCoO3 based perovskite type ceramic oxygen-permeable membrane material with Sn, Fe doped at B position

InactiveCN101269954AGood phase structure stabilityImprove performanceSemi-permeable membranesOxygen preparationForeign matterPartial oxidation

The present invention relates to Sn-Fe-substitution-on-B-site BaCoO3-base calcium-titanium mineral ceramic oxygen-transmitting film material, and relates to inorganic oxygen-transmitting film material. The present invention is characterized in that B site of BaCo0.7Fe0.3O3-Delta is doped with Sn element; the chemical formula of the material is BaCo0.7Fe0.3-xSnxO3-Delta, wherein, x is equal to 0.06 to 0.30. The structure of the oxygen-transmitting film material with B site being doped with Sn element is compact; moreover, the crystal interface width is narrow, the crystal interface is clean and free from the foreign matter; the oxygen transmittance is high; the stability is good, thus being the oxygen-transmitting film material with excellent performance, so that the oxygen-transmitting film material can be used for the consecutive oxygen supply for partial oxidation reaction of the methane, and for the oxygen separation and purification in other gases containing the oxygen.

Owner:UNIV OF SCI & TECH BEIJING

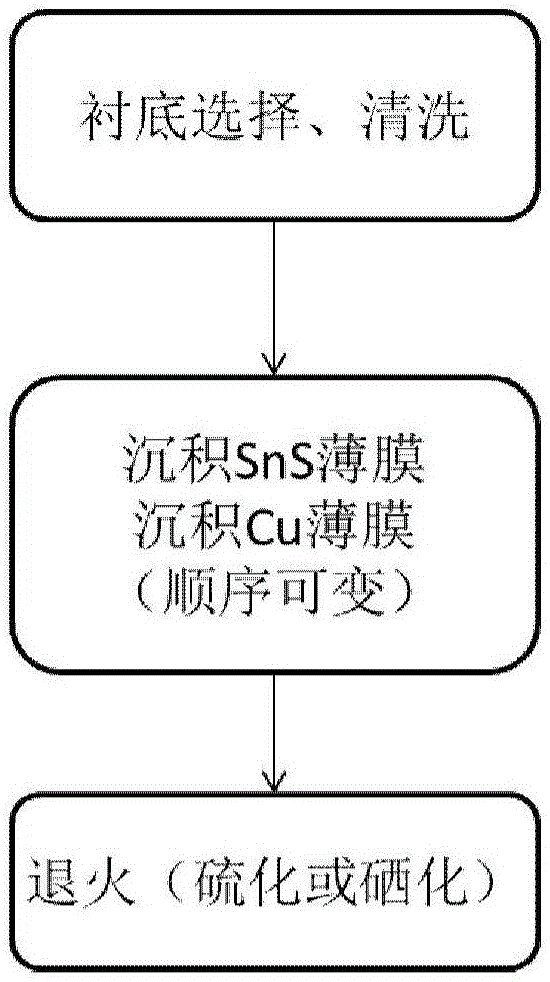

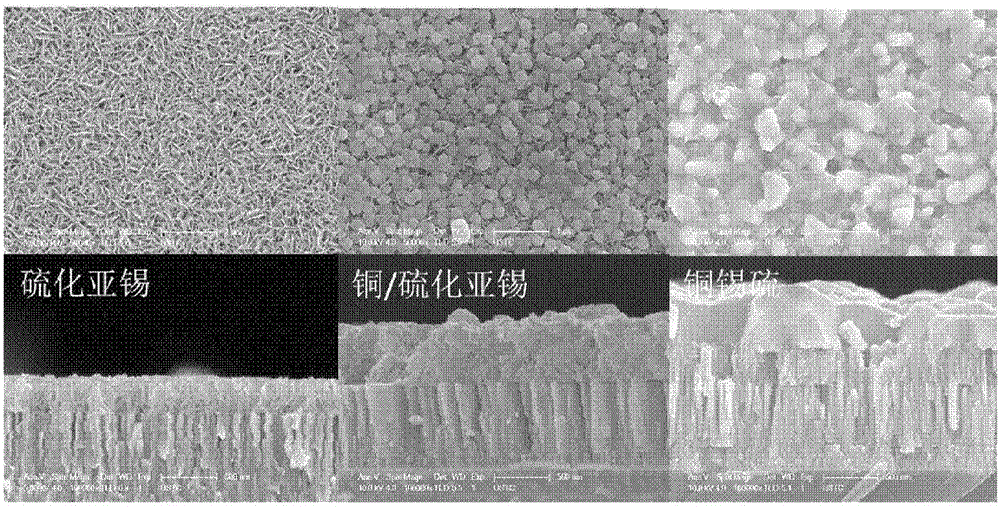

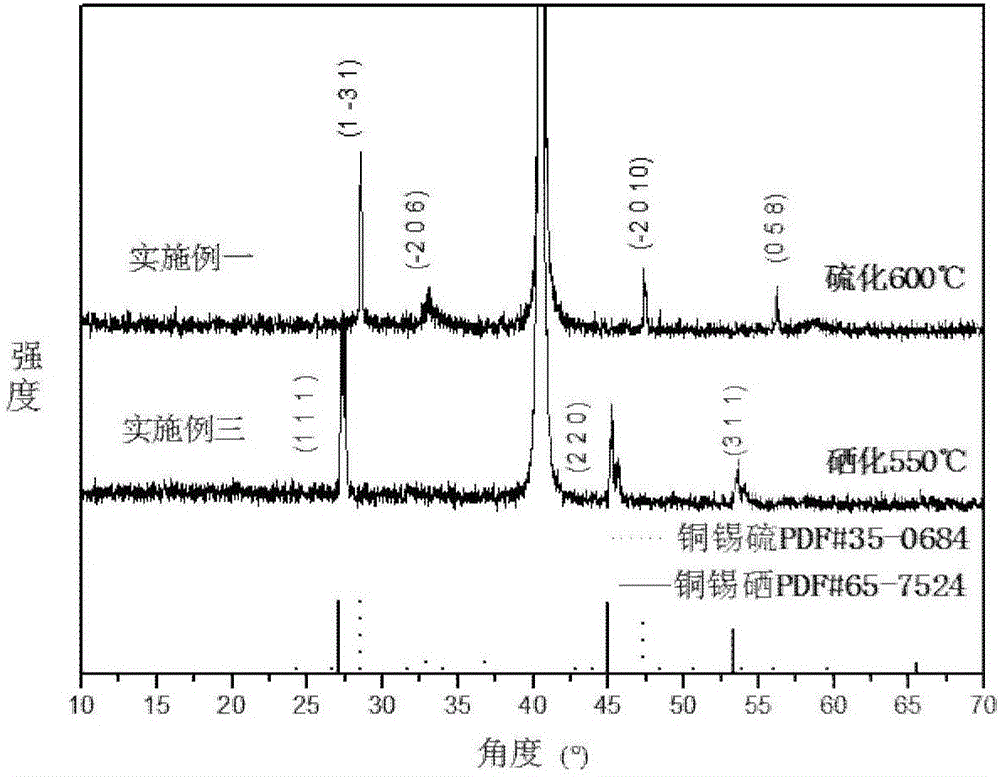

method for preparing CTS or CTSSe film

ActiveCN105047753AEasy to prepareFinal product manufactureSemiconductor/solid-state device manufacturingSulfurCu element

The invention provides a method for preparing a CTS or CTSSe film. The method comprises a step 1 of cleaning a substrate to obtain a clean substrate; a step 2 of continuously and alternately depositing a SnS film and a Cu film on the clean substrate in the step 1 in any sequence by using a solution deposition method; performing heat treatment on a laminate containing a Sn-element film and a Cu-element film acquired in the step 2 in sulfur or selenium atmosphere in order to obtain the copper-tin-sulfur or CTS or CTSSe film.

Owner:UNIV OF SCI & TECH OF CHINA

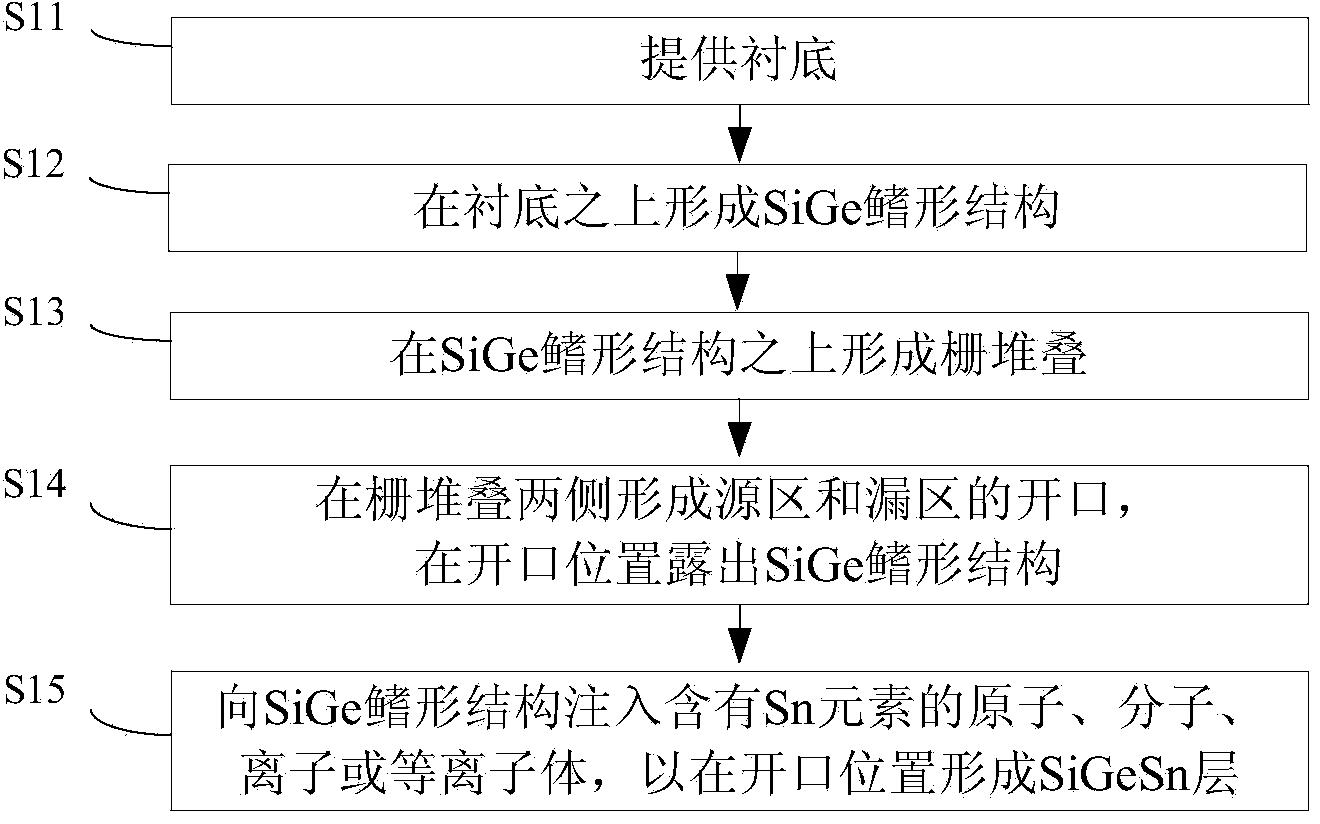

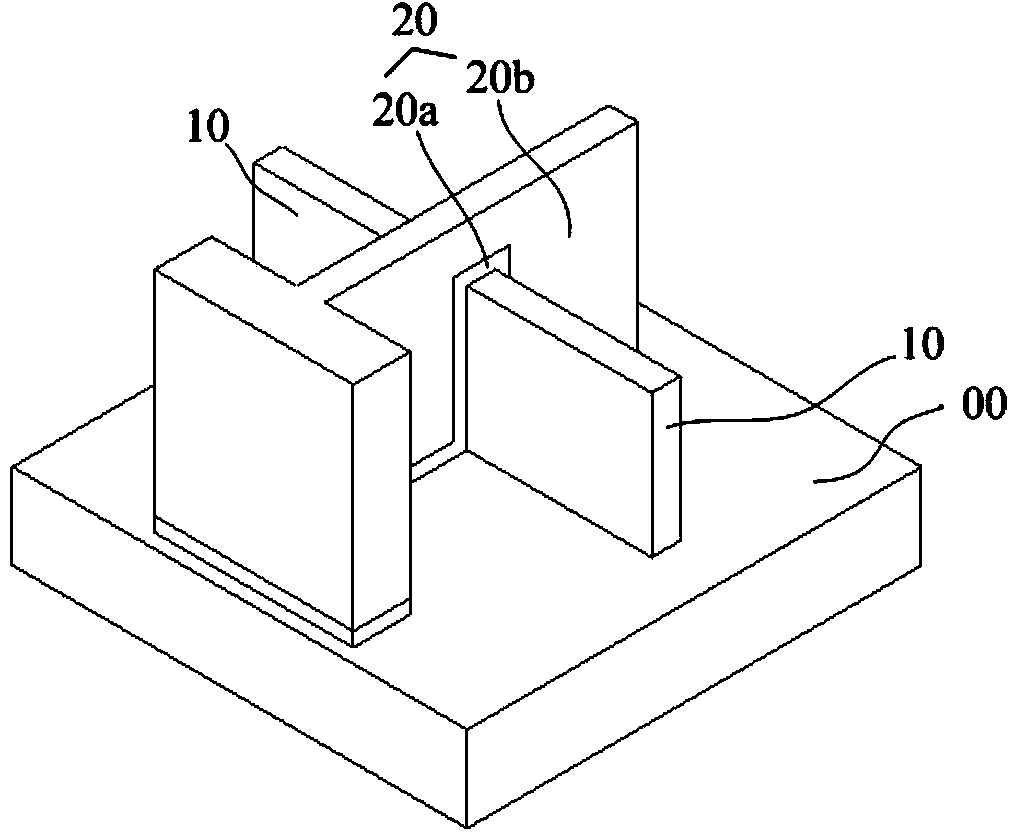

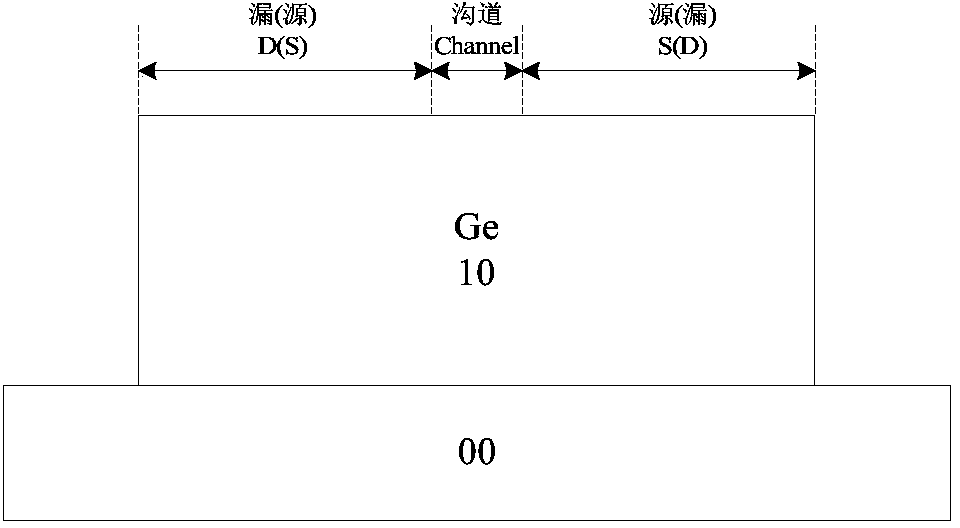

Fin type field effect transistor with SiGeSn source drain and forming method thereof

InactiveCN103840005AThe overall thickness is thinGood electrical propertiesSemiconductor/solid-state device manufacturingSemiconductor devicesGate stackSource area

Owner:TSINGHUA UNIV

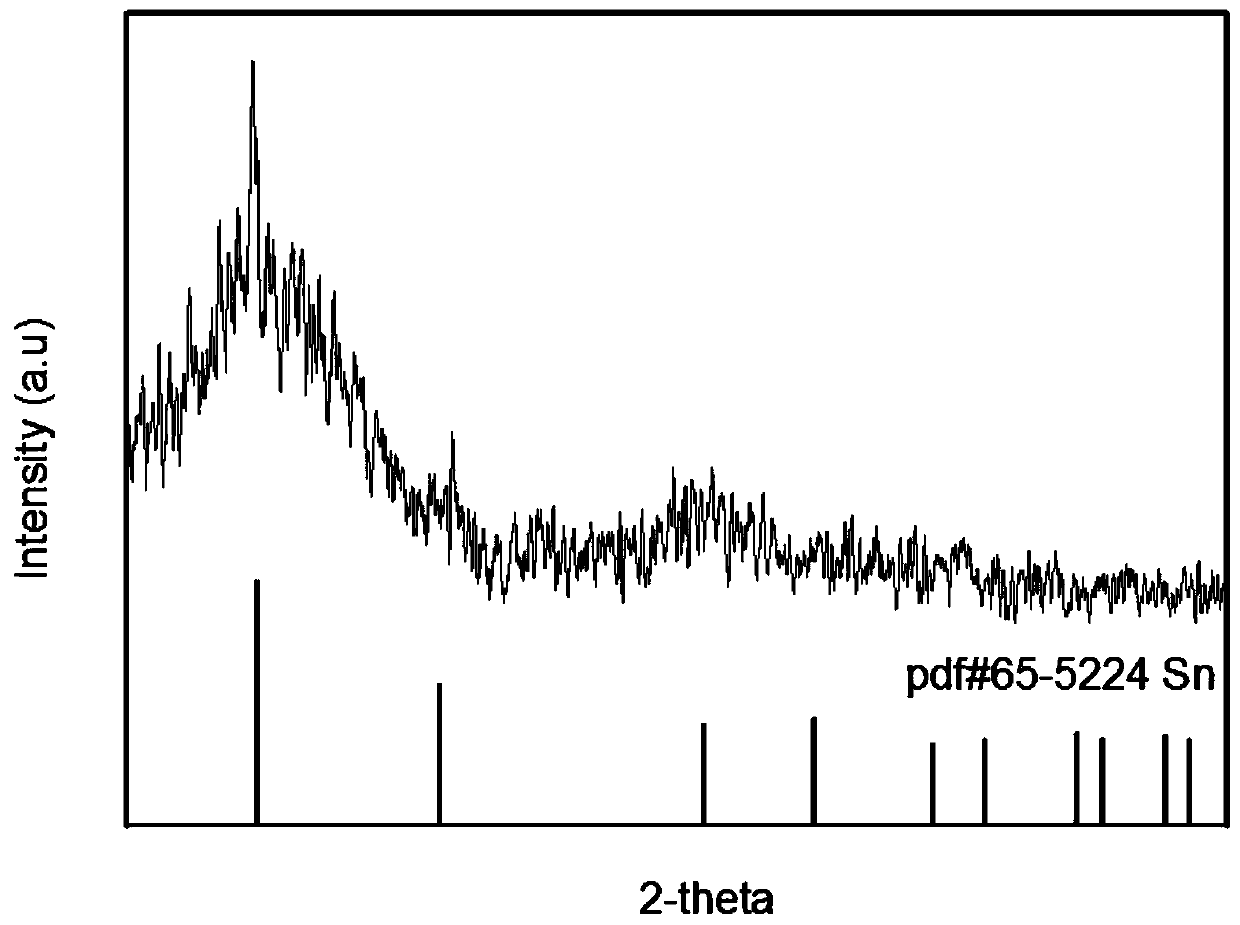

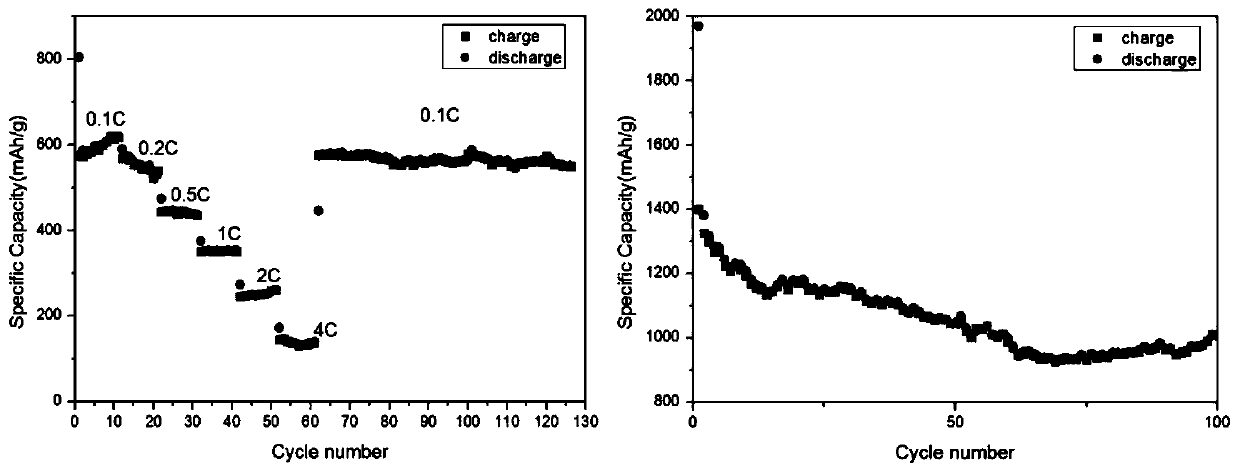

Method for preparing carbon cloth/tin flexible electrode material for negative electrode of sodium ion battery

InactiveCN109713291AIncrease energy densityImprove capacity fadeElectrode carriers/collectorsSecondary cellsSodium-ion batteryLithium-ion battery

The invention provides a method for preparing a carbon cloth / tin flexible electrode material for a negative electrode of a sodium ion battery. The method comprises the steps of (1) preprocessing carbon cloth, cutting the carbon cloth, and anodizing the carbon cloth in a hydrothermal electrophoresis device to increase an active functional group on the surface of the carbon cloth such that metal ions are more easily attached to grow, (2) dissolving polyvinylpyrrolidone in ethanol to obtain a solution A1, add SnCl2-2H2O to the solution A1, then ultrasonically processing to obtain a solution A2, adding the processed carbon cloth in step (1) into the solution A2, and stirring at a normal temperature, wherein the concentration of Sn2+ in solution A2 is 0.01-0.21 mol L-1, and (3) adding a solution of the reducing agent into the stirred solution A2, reducing Sn2+ on the carbon cloth to a Sn element by the reducing agent, and then performing vacuum drying on the obtained carbon cloth to obtainthe carbon cloth / tin flexible electrode material. The material has the advantages of bendable folding, simple assembly and no need for a current collector.

Owner:SHAANXI UNIV OF SCI & TECH

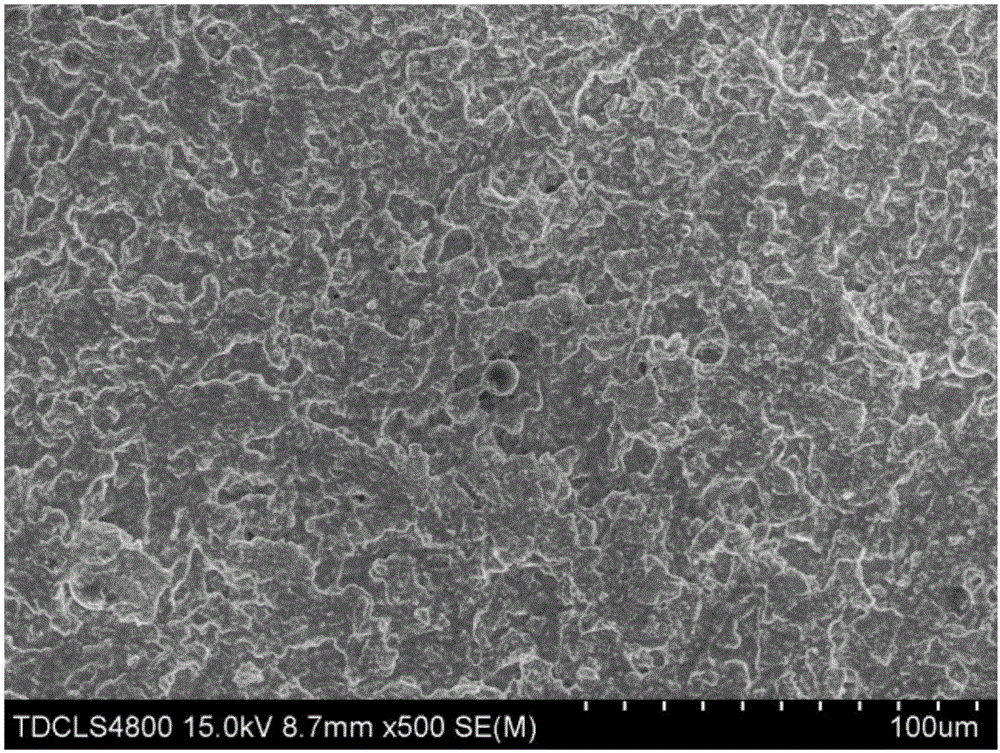

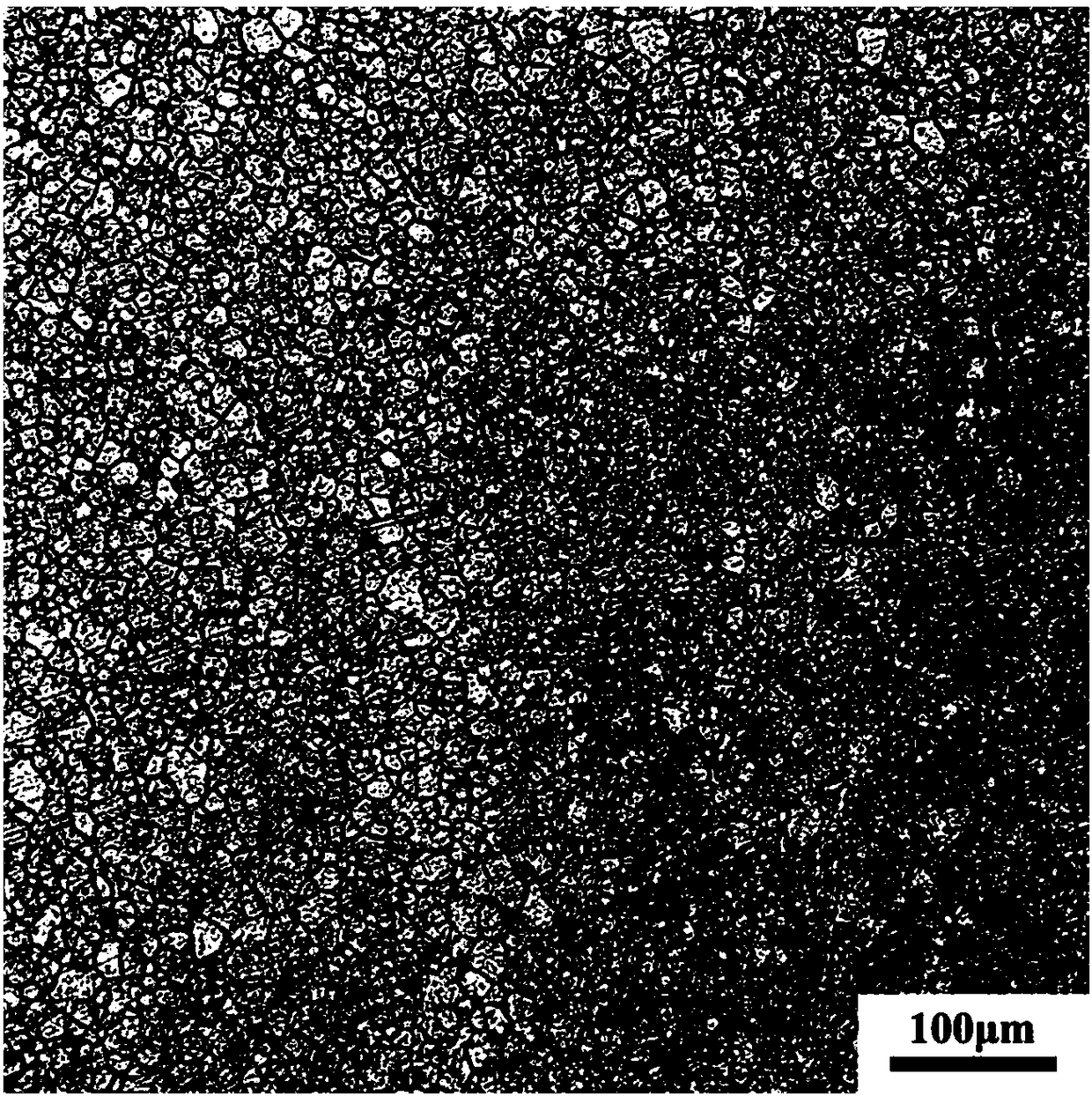

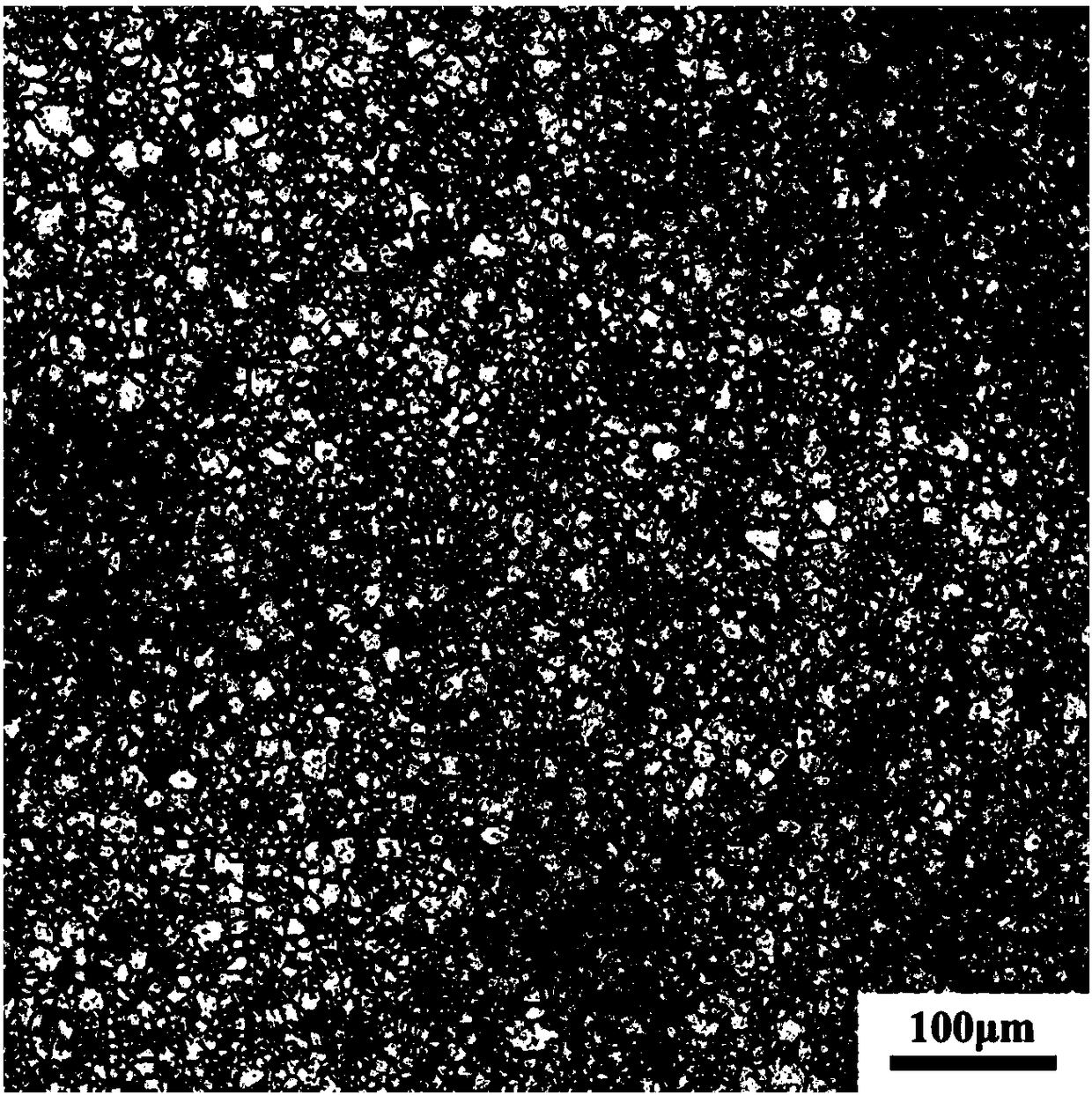

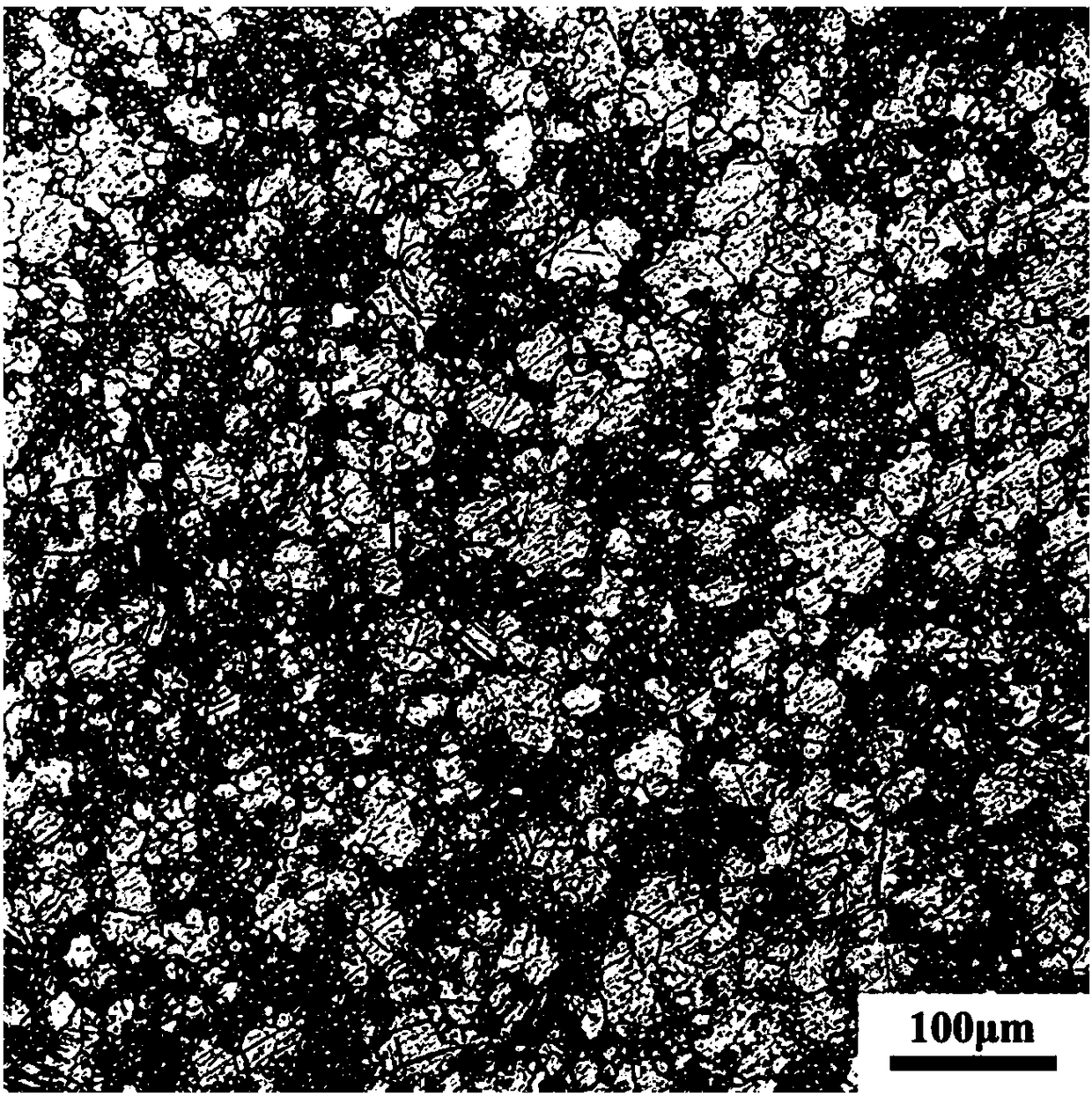

Reduction preparation method of copper-based elastic alloy thin strip

The invention relates to a reduction preparation method of a copper-based elastic alloy thin strip. The reduction preparation method of the copper-based elastic alloy thin strip is carried out according to the following steps of (1) smelting a copper alloy according to design compositions so as to obtain a copper alloy melt, wherein the compositions contain (in percentage by mass): 7.5 to 15 percent of Ni, 5 to 10 percent of Sn, less than or equal to 0.05 percent of impurities, and the balance Cu; (2) pouring into a tundish, controlling the degree of superheat to be 15 to 40 DEG C, then pouring into a twin roll strip continuous casting for continuously casting, discharging a casting strip out of a casting roller, then water cooling, controlling the cooling speed to be larger than or equalto 35 DEG C / s, and coiling at 250 to 400 DEG C; (3) cold rolling at a single stage, and obtaining a cold rolling strip; and (4) carrying out aging treatment on the cold rolling strip at 350 to 450 DEGC. According to the method provided by the invention, the segregation of the Sn element can be effectively inhibited, the processes such as homogenizing annealing, hot rolling and solution treatmentin a traditional process are omitted, the process is simplified, the cost is reduced, and the resources are saved.

Owner:NORTHEASTERN UNIV

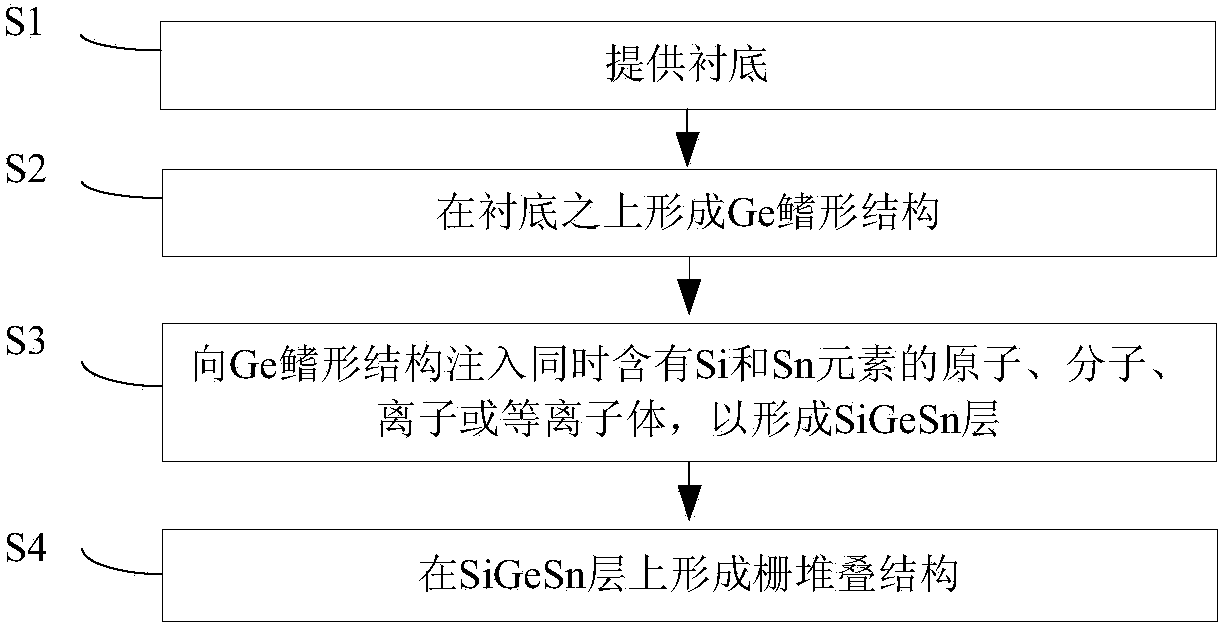

Fin type field effect transistor with SiGeSn channel and forming method thereof

InactiveCN103839829AThe overall thickness is thinQuality improvementSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringGate stack

The invention provides a fin type field effect transistor with a SiGeSn channel and a forming method thereof. The forming method comprises the following steps of providing a substrate, forming a fin-shaped Ge structure on the substrate, injecting atoms or molecules or ions or plasma containing a Si element and a Sn element into the fin-shaped Ge structure so that a SiGeSn layer can be formed, and forming a gate stack structure on the SiGeSn layer. According to the forming method, a FinFET with a SiGeSn channel area small in thickness and good in quality can be obtained; the method has the advantages of being simple and easy to implement and low in cost.

Owner:TSINGHUA UNIV

Preparation method of composite rod for improving performance of Nb3Sn superconducting composite wire

InactiveCN110556213AIncrease profitIncrease the RRR valueSuperconductors/hyperconductorsSuperconductor devicesSingle-coreMachining

The invention discloses a preparation method of a composite rod for improving performance of an Nb3Sn superconducting composite wire. The preparation method comprises steps that a Nb rod is wrapped with a copper layer to obtain a CuNb single-core rod, the CuNb single-core rod, a pure Nb rod and a hexagonal oxygen-free copper rod are bundled according to hexagonal arrangement and are put into an oxygen-free copper sheath, the oxygen-free copper sheath, the pure Nb rod, the CuNb single-core rod and the hexagonal oxygen-free copper rod are sequentially arranged from outside to inside to obtain aCuNb composite sheath, and then the composite rod is obtained through heating and extrusion. The preparation method is advantaged in that the CuNb single-core rod prepared by coating the copper layerand the pure Nb rod are assembled, diffusion of Sn elements to an external Cu region is effectively slowed down, the utilization rate of the Sn elements is improved, an RRR value of the wire is effectively improved, finally, the overall current-carrying capacity of the Nb3Sn superconducting wire is improved, the CuNb single-core rod is obtained through the copper layer wrapping method, the Nb content proportion in the Nb3Sn superconducting wire is increased, moreover, core wire reaction is more sufficient when the Nb3Sn superconducting wire is subjected to heat treatment, and the wire machining yield is increased.

Owner:西部超导材料科技股份有限公司

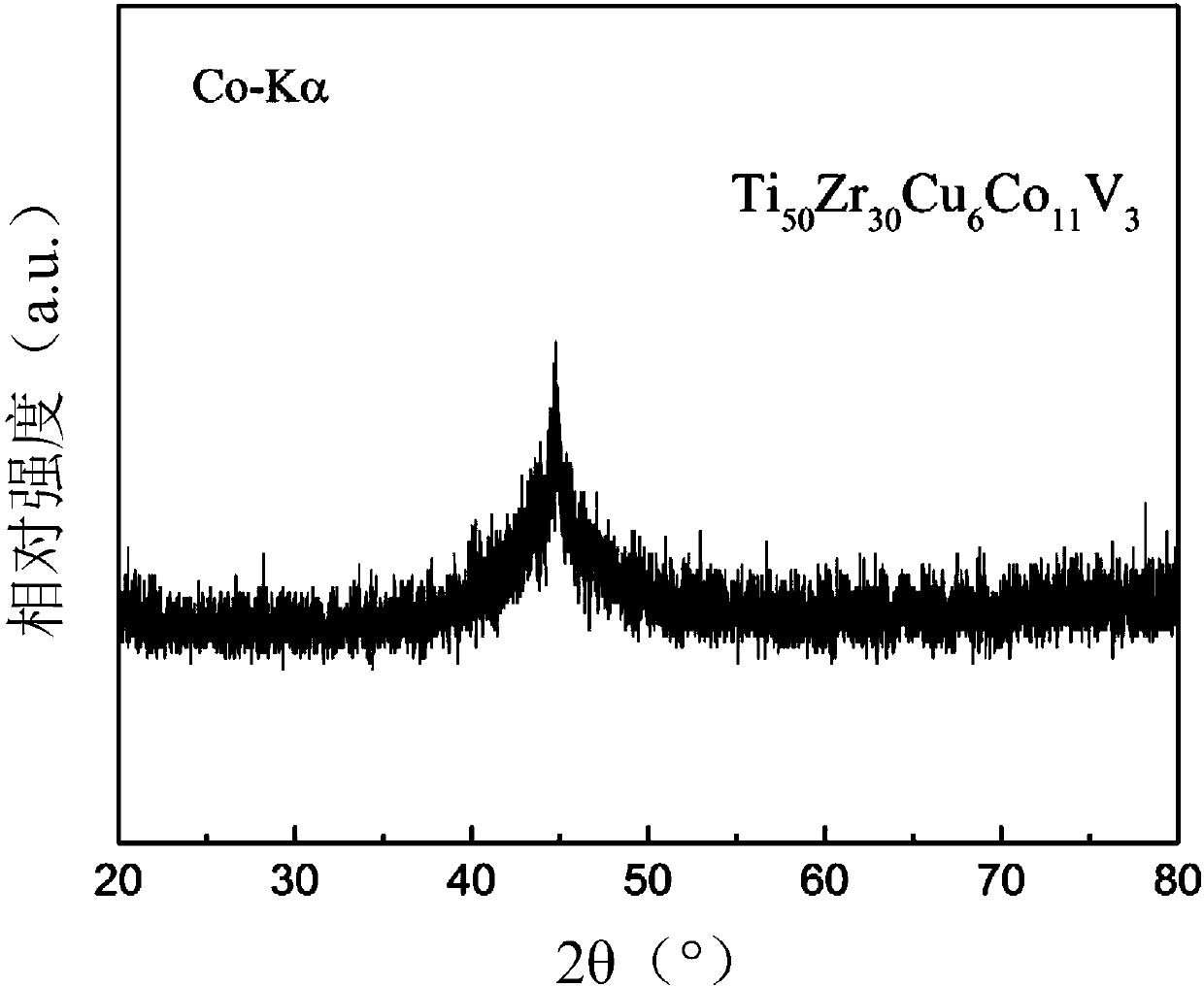

Ti-Zr-Cu-Co-M alloy brazing filler metal and preparing method thereof

InactiveCN107815619AGood compatibilityAvoid generatingWelding/cutting media/materialsSoldering mediaTitanium zirconiumTitanium

The invention discloses a Ti-Zr-Cu-Co-M alloy brazing filler metal and a preparing method thereof. Components of the brazing filler metal comprise 15-55 parts of Zr, 1-20 parts of Cu, 1-20 parts of Coand 0.01-15 parts of M and the balance of Ti. M is the main group or transition metal element, and preferably M is V, Al and / or Sn element. A continuous alloy brazing filler metal thin belt with better tenacity and the thickness being 20-60 mu m is prepared by a melt spin-quenching method. The brazing filler metal according to the invention is applied to soldering of titanium alloy, the shearingstrength of a soldered joint is 200-600MPa, wherein the shearing strength of the TC4 alloy soldered joint is as high as 547 MPa. Compared with the existing titanium base brazing filler metals and titanium-zirconium base brazing filler metals, the Ti-Zr-Cu-Co-M high-performance alloy brazing filler metal involved in the invention has the advantages of low melting point, good soldered joint performances, high reliability, wide applicable range and the like.

Owner:BEIHANG UNIV

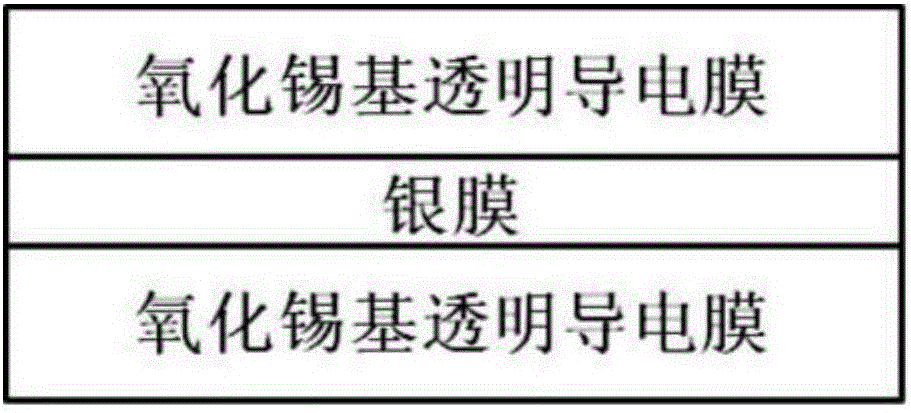

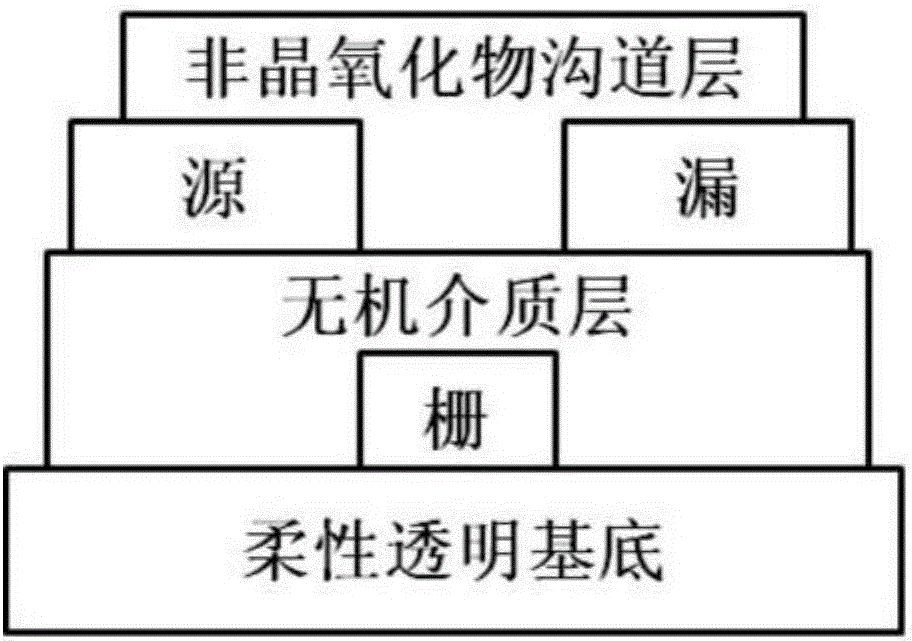

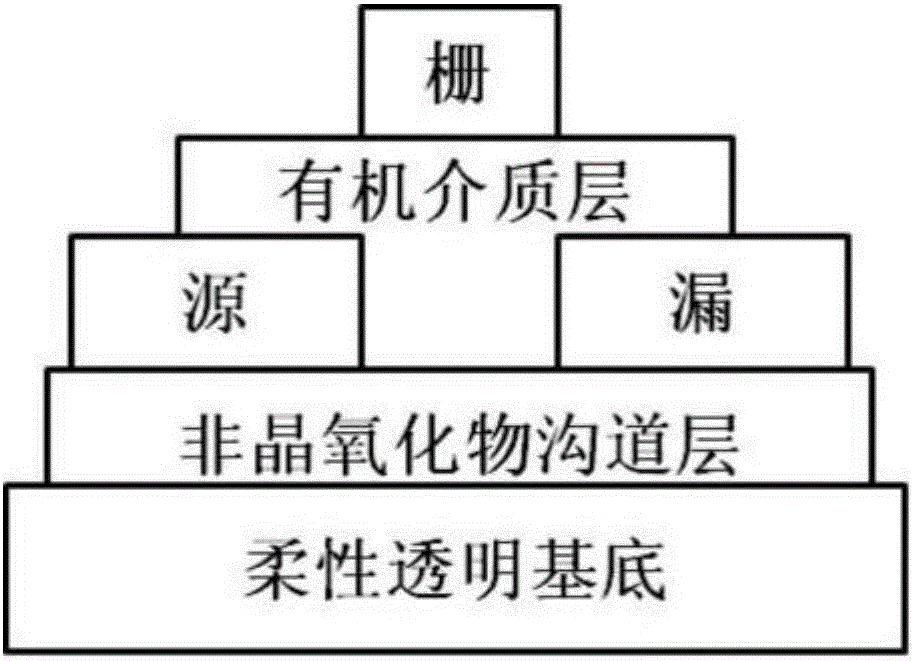

Flexible full-transparent amorphous oxide thin film transistor and preparation method thereof

ActiveCN105870173AAvoid adverse effects caused by electrical stabilityHigh visible light transmittanceTransistorSemiconductor/solid-state device manufacturingOxide thin-film transistorTransmittance

The invention relates to the field of a thin film transistor, and provides a flexible full-transparent amorphous oxide thin film transistor and a preparation method thereof. The flexible full-transparent amorphous oxide thin film transistor comprises a substrate, a channel layer, a dielectric layer, a gate (G) electrode layer and a source / drain electrode layer, wherein the source / drain electrode layer is a silver-based transparent conductive multi-layer film composed of two layers of transparent conductive oxide (TCO) films and a silver (Ag) film sandwiched between the two layers of transparent conductive oxide (TCO) films, a TCO is a high-valence doping tin oxide based oxide SnO2 containing Sn element and M element, in the oxide SnO2, the atomic weight of the M element in M is that M / (M+Sn) is equal to 0-0.01, and the M element is at least one of Cr, Mo and W. The amorphous oxide thin film transistor provided by the invention has the advantages of compatibility of a preparation process temperature with a flexible transparent substrate, high visible light transmittance and favorable electrical property.

Owner:GUIZHOU MINZU UNIV

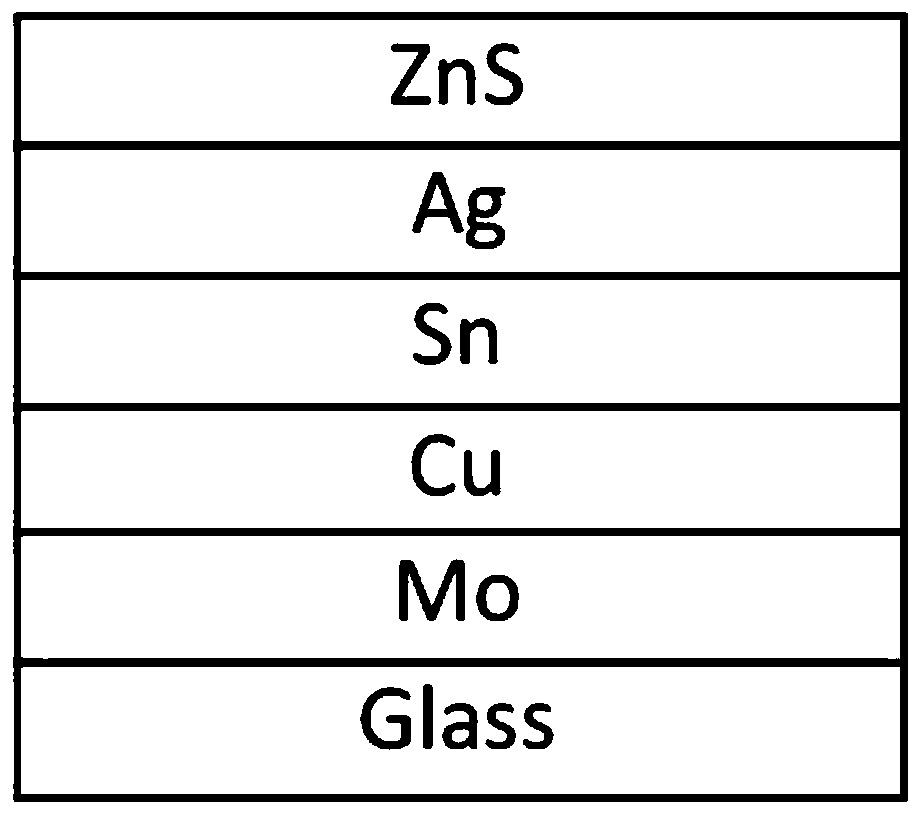

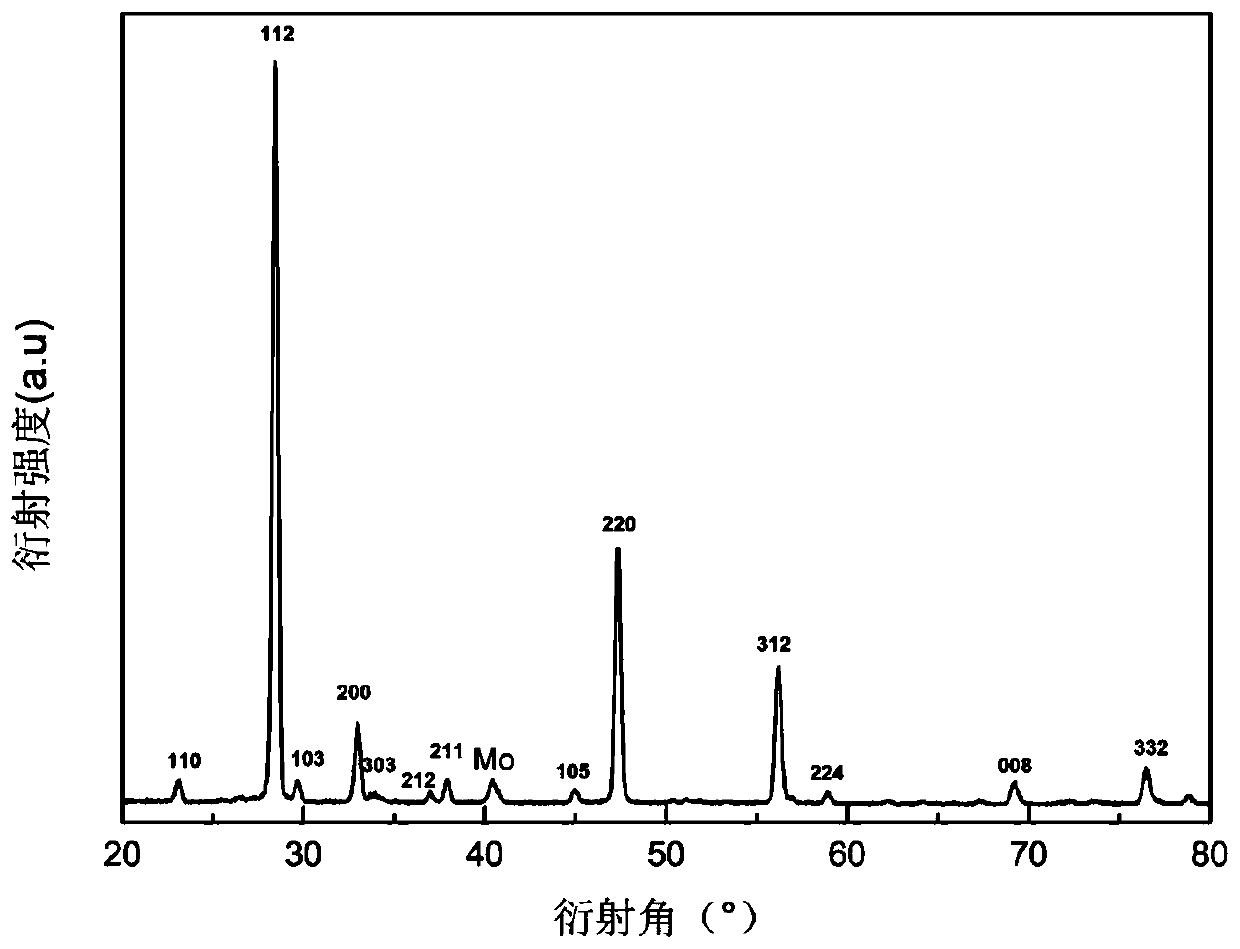

Structure-optimized silver-doped Cu-Zn-Sn sulfur thin film solar cell and preparation method thereof

ActiveCN110176517AInhibition lossTightly boundFinal product manufactureVacuum evaporation coatingSulfurCopper

The invention discloses a structure-optimized silver-doped Cu-Zn-Sn sulfur thin film solar cell and a preparation method thereof, and belongs to the field of solar cells. The solar cell comprises a glass substrate, an absorption layer, a buffer layer, a transparent conductive window layer and an upper electrode which are sequentially connected, wherein a pre-fabrication layer structure of the absorption layer is Cu / Sn / Ag / ZnS. The pre-fabrication layer structure of the absorption layer employs a Cu / Sn / Ag / ZnS structure, the loss of a Sn element is prevented by depositing Ag on a Sn layer, and holes among boundaries are reduced; meanwhile, the defect of a CuZn reverse structure is effectively reduced by employing Ag to Cu, and the collection efficiency of photoproduction carrier is improved;and moreover, silver doping has benefits to expansion of the grain size of the Cu-Zn-Sn sulfur thin film and improvement of attachment of a Mo back electrode.

Owner:YUNNAN NORMAL UNIV

Diffusion welding method of copper alloy and stainless steel

InactiveCN101745736BHigh tensile strengthIncrease the effective welding areaNon-electric welding apparatusRoom temperatureUltimate tensile strength

The invention discloses a diffusion welding method of copper alloy and stainless steel, which is used for increasing the strength of a welded joint of the copper alloy and the stainless steel. The method thereof comprises the following steps that: a processed tin bronze foil is placed between the copper alloy to be welded and the stainless steel; then the whole tin bronze foil is placed into a vacuum diffusion welding furnace; the temperature is raised from room temperature to 880 to 920 DEG C, the pressure is applied by 4 to 8MPa, and the temperature is preserved for 30 to 60min; and coolingis carried out with the furnace after the temperature preservation is finished. Since the tin bronze is adopted for carrying out diffusion welding on a middle layer, a zigzag welding interface is formed by using the characteristic that a Cu-Sn liquid phase is formed by clustering of Sn element in the tin bronze toward the welding interface as well as the corrosion effect of the liquid phase to the stainless steel crystal boundary, thus improving the effective welding area and leading the tensile strength of the joint to be improved to be more than 93 percent from 80 percent to 88 percent of the strength of the copper alloy base material of the prior art.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Copper alloy material and preparation method thereof

The invention provides a copper alloy material and a preparation method thereof, and belongs to the technical field of non-ferrous metals. The invention provides a copper alloy material. The copper alloy material comprises the following chemical components in percentage by mass: 8-21% of Ni, 5-10% of Sn, 0.5-2.0% of Al, 0.05-1.6% of trace elements and the balance of Cu, the trace element is at least one of P, Fe, Co and Si. The components are optimized and improved on the basis of the copper-nickel-tin alloy, and by adding Al and at least one element of P, Fe, Co and Si, the vacancy concentration of the solute element Sn at the grain boundary and the concentration of the Sn element are changed, the precipitation power of a discontinuous precipitated phase is reduced, precipitation of the discontinuous precipitated phase is inhibited, and the strength, corrosion resistance and wear resistance of the alloy are improved.

Owner:GRIMAT ENG INST CO LTD

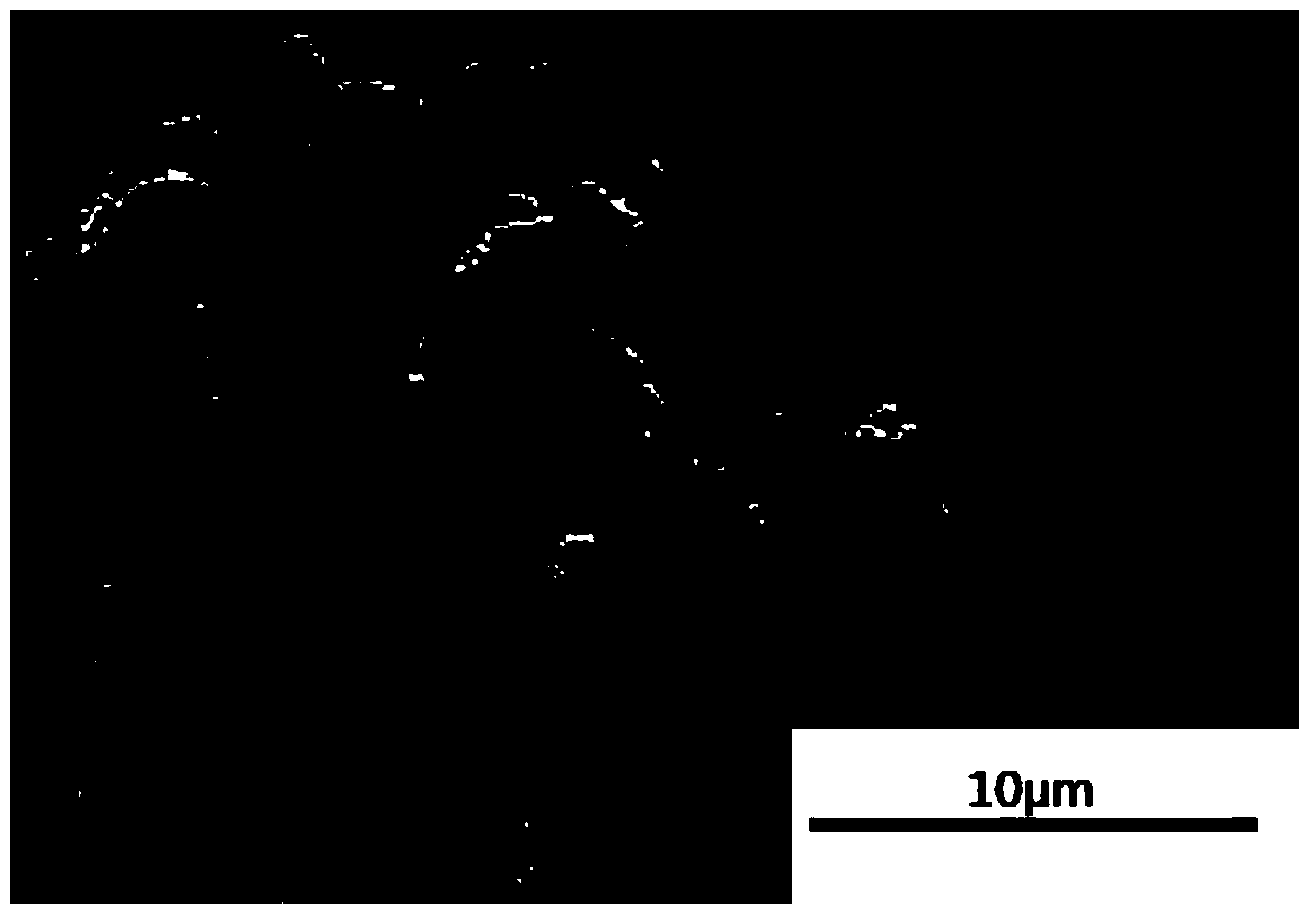

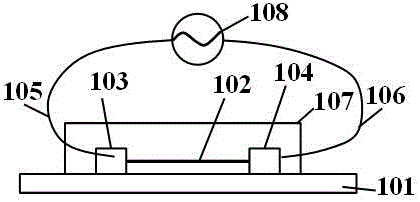

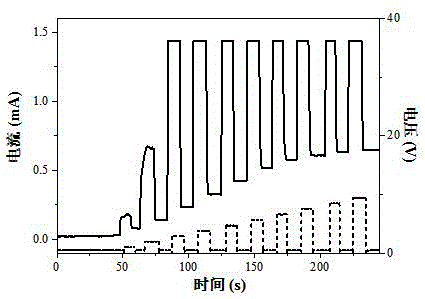

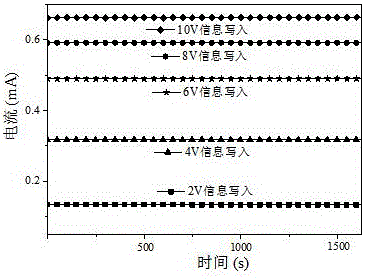

Trap state regulation and control based nonvolatile multi-bit micro/nanometer resistive random access memory and use method therefor

The invention discloses a trap state regulation and control based nonvolatile multi-bit micro / nanometer resistive random access memory and a use method therefor. The resistive random access memory comprises an insulating substrate, a single Sn-element-doped ZnO one-dimensional micro / nanowire, electrodes, a packaging material and the like; the single Sn-element-doped ZnO one-dimensional micro / nanowire is put on the insulating substrate, and electrodes are welded at the two ends of the nanowire respectively; and the single Sn-element-doped ZnO one-dimensional micro / nanowire and the electrodes are packaged on the insulating substrate by the packaging materials. In information write-in, a write-in voltage is applied between the electrodes at the two ends; in nonvolatile multi-bit storage, the write-in voltage is applied between the electrodes at the two ends, then the write-in voltage is removed and a read voltage is applied; in information erasure, the write-in voltage is applied between the electrodes at the two ends, then the write-in voltage is removed and the read voltage is applied; then the resistive random access memory is put in an environment at a temperature of 70 DEG C and then put in a room temperature. According to the resistive random access memory, response and storage to electric field information is realized; and meanwhile, the resistive random access memory is simple and convenient in process, small in volume, light and portable, high in compatibility and capable of realizing efficient utilization.

Owner:横峰县虹联铝业有限公司

A kind of brass wire rod and the processing method of described brass wire rod

The invention provides a brass wire applied to the technical field of production and processing of wires. The invention simultaneously relates to a processing method of the brass wire. The brass wire comprises the following components: Cu, Sn, Si and Zn, wherein the Cu element accounts for 63.5%-65% by weight, the Sn element accounts for 0.8-1.2% by weight, the Si element accounts for 0.10-0.50% by weight, and the balance is the Zn. In the brass wire and the processing method, provided by the invention, the mechanical performance value of the brass wire is controlled at 650-750MPa, a sphere formed by combustion is smooth and full, the problem of brittle failure caused by over-hard performance can be avoided, and the brass wire can not be processed into a ball needle due to the influence of relatively soft performance. When the brass wire is formed, a rewinding machine is adopted for taking up, and the diameter degree is good; and when the brass wire is machined by a customer, the paying-off is smooth, the wire wrapping phenomenon can be avoided, and the brass wire can completely meet the requirements of jewelry processed from the brass wires in jewelry industry.

Owner:安徽鑫科铜业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com