Patents

Literature

147results about How to "Improve photosensitivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

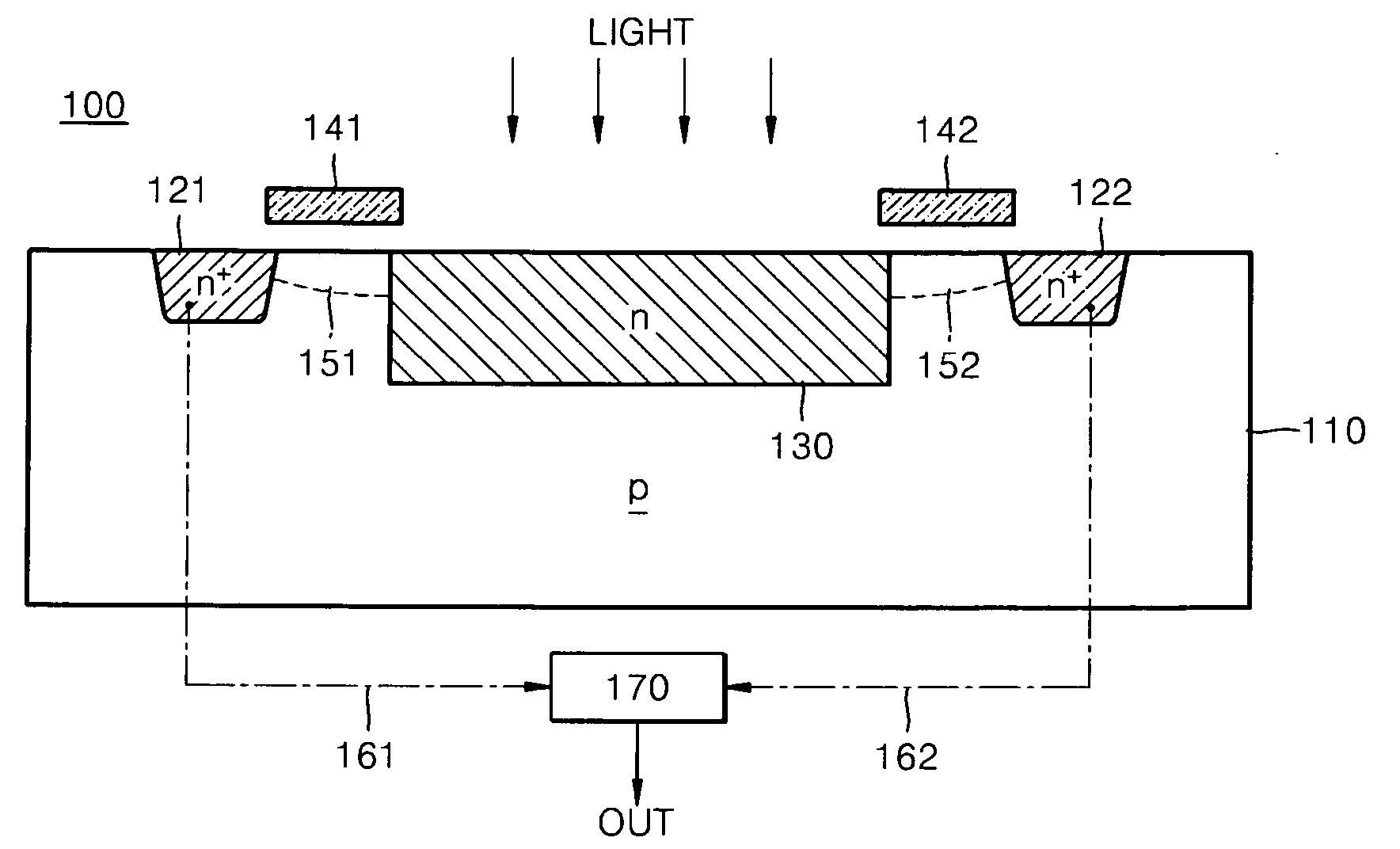

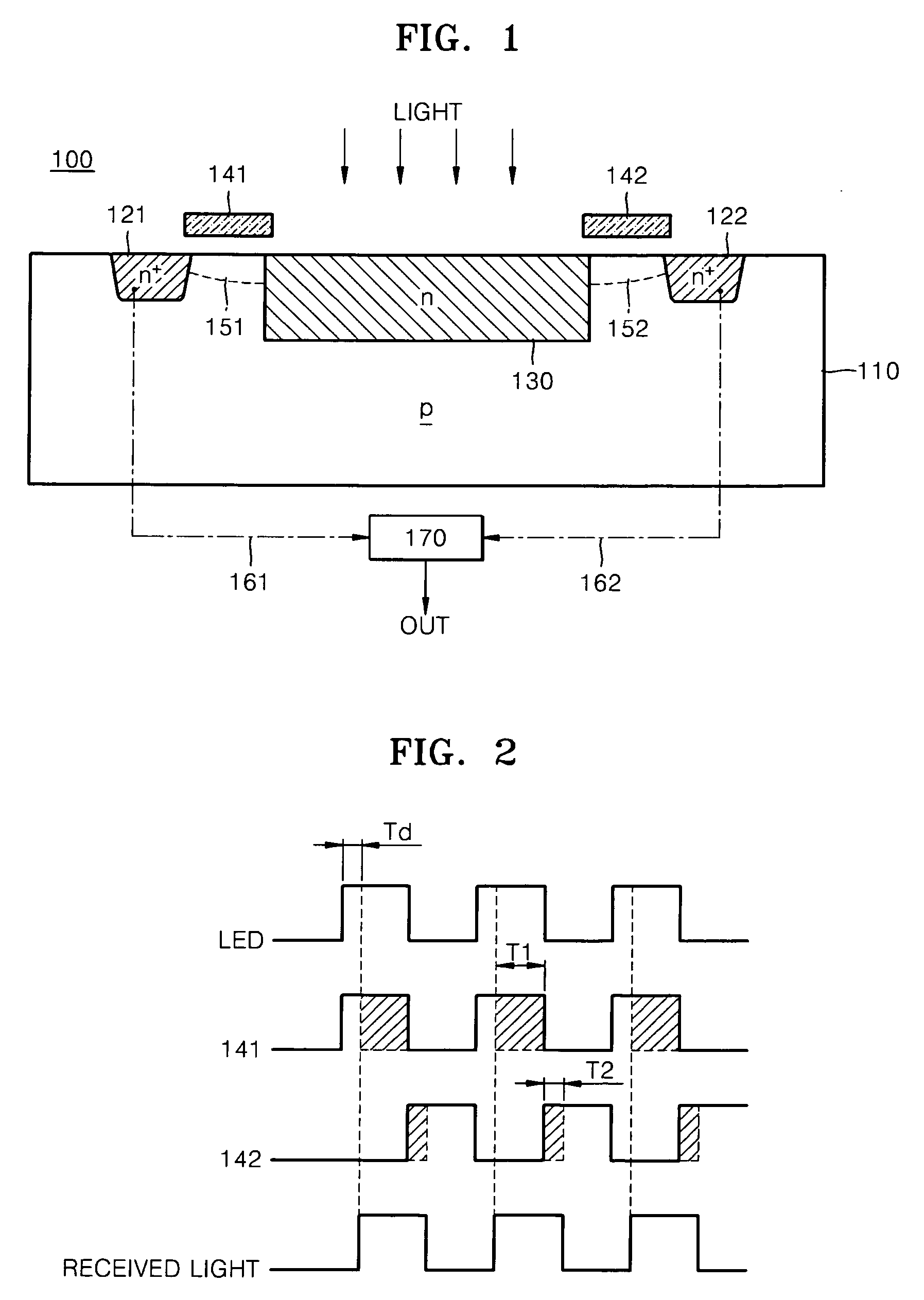

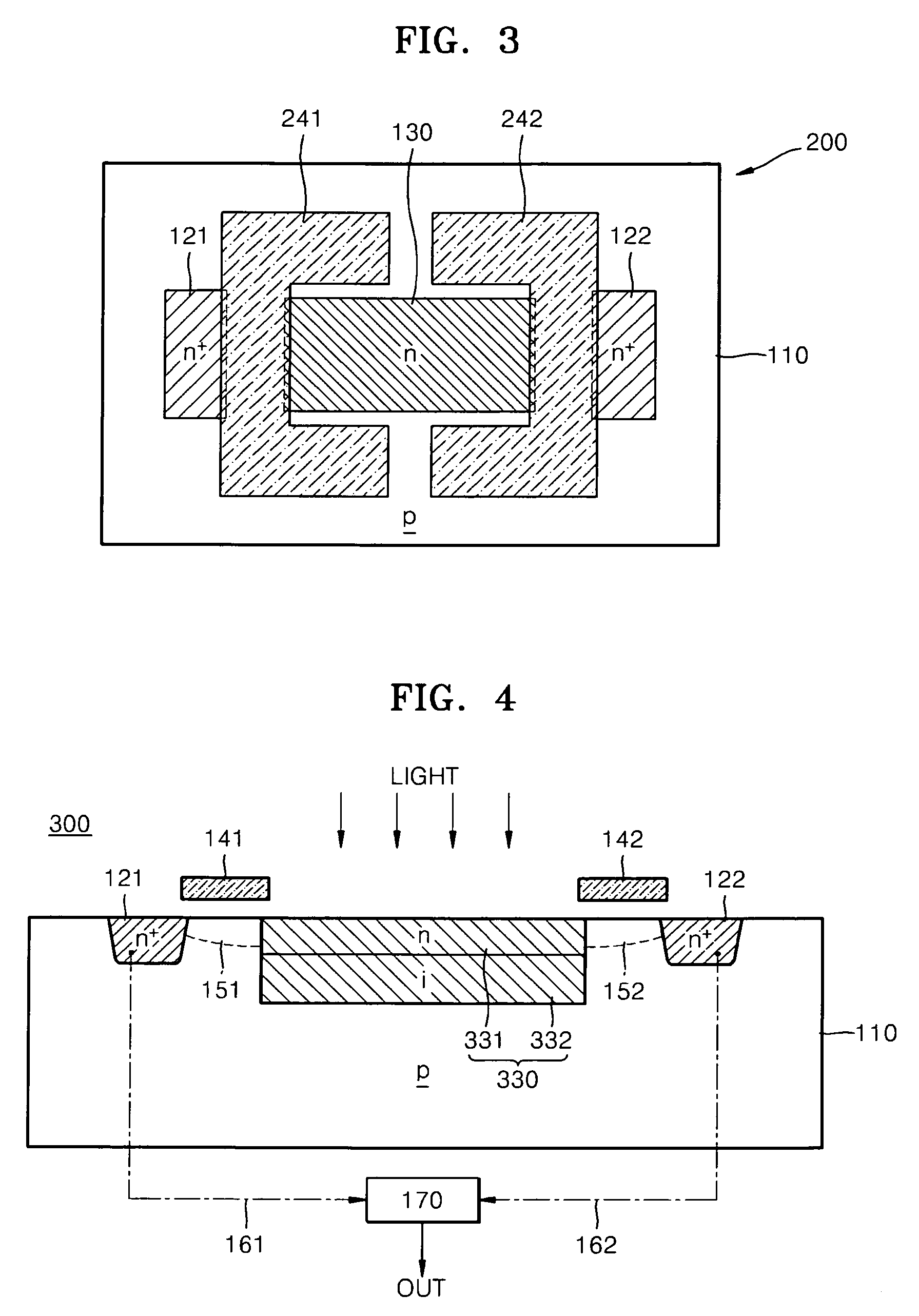

Distance measuring sensor including double transfer gate and three dimensional color image sensor including the distance measuring sensor

ActiveUS20090284731A1Improve photosensitivityImprove sensor sensitivityOptical rangefindersSolid-state devicesColor imagePhotoelectric conversion

Provided are a distance measuring sensor including a double transfer gate, and a three dimensional color image sensor including the distance measuring sensor. The distance measuring sensor may include first and second charge storage regions which are spaced apart from each other on a substrate doped with a first impurity, the first and second charge storage regions being doped with a second impurity; a photoelectric conversion region between the first and second charge storage regions on the substrate, being doped with the second impurity, and generating photo-charges by receiving light; and first and second transfer gates which are formed between the photoelectric conversion region and the first and second charge storage regions above the substrate to selectively transfer the photo-charges in the photoelectric conversion region to the first and second charge storage regions.

Owner:SAMSUNG ELECTRONICS CO LTD

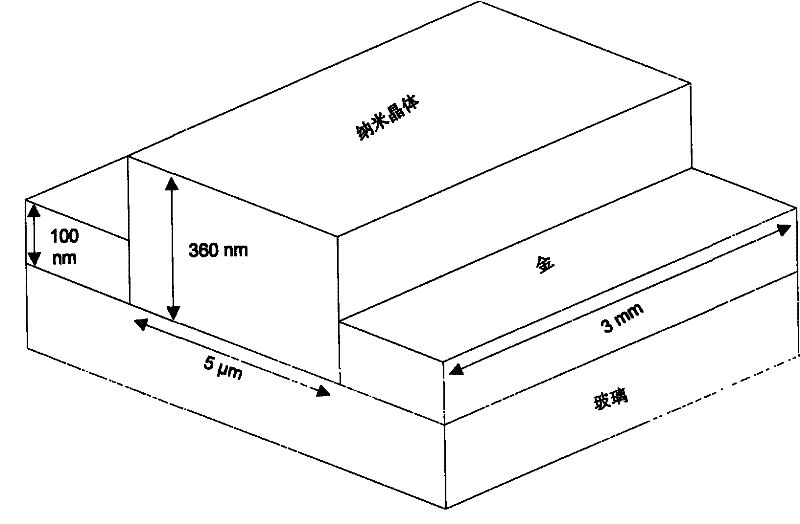

Photosensitive coating and preparation method thereof and photosensitive film made by utilizing same

InactiveCN101985531AHigh mechanical strengthIncreased refractive index modulationCoatingsPhotosensitive materials for photomechanical apparatusPhotosensitizerPolymer coatings

The invention provides a water nano compound photosensitive coating and a preparation method thereof and a photosensitive film formed by the coating. The water nano composite photosensitive coating is formed by the way that nano material with excellent properties is compounded with film forming agent, thus refractive index modulation degree of photosensitive coating is improved. The coating comprises the following components (by weight percent): 10-50% of film forming agent, 15-30% of monomer, 20-50% of photoinitiator, 0.05-1% of photosensitizer, 2-10% of crosslinking agent and 0.1-1% of nano material. The holographic photosensitive film of the invention comprises a base film, a photosensitive nano compound polymer coating and a surface protective film. The reflecting holographic photosensitive film has higher luminous sensitivity, reflection efficiency and refractive index modulation degree, storage life is long, and hologram is stable.

Owner:SHANGHAI HONGDUN ANTI COUNTERFEIT MATERIAL

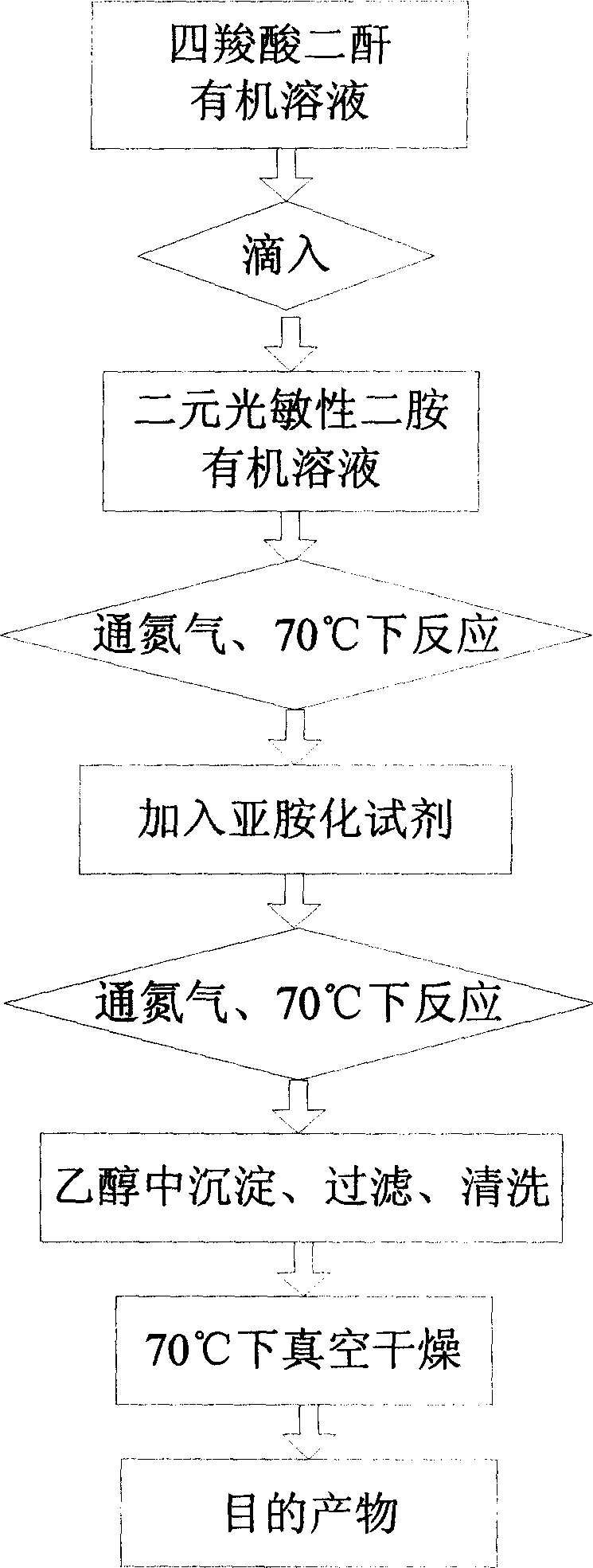

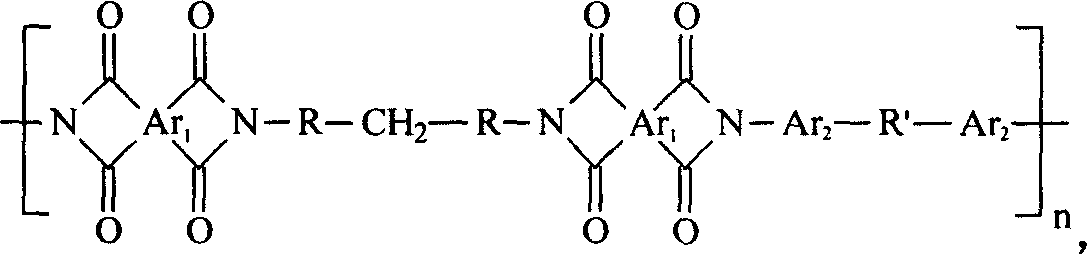

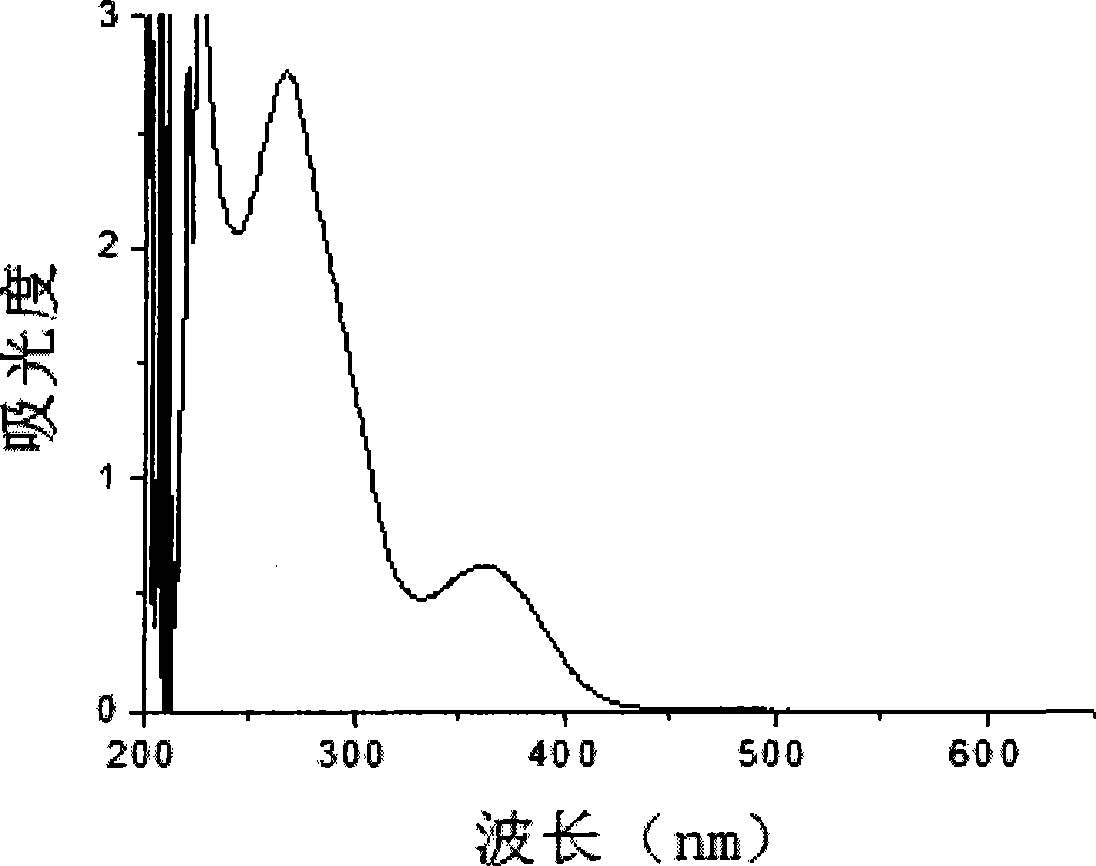

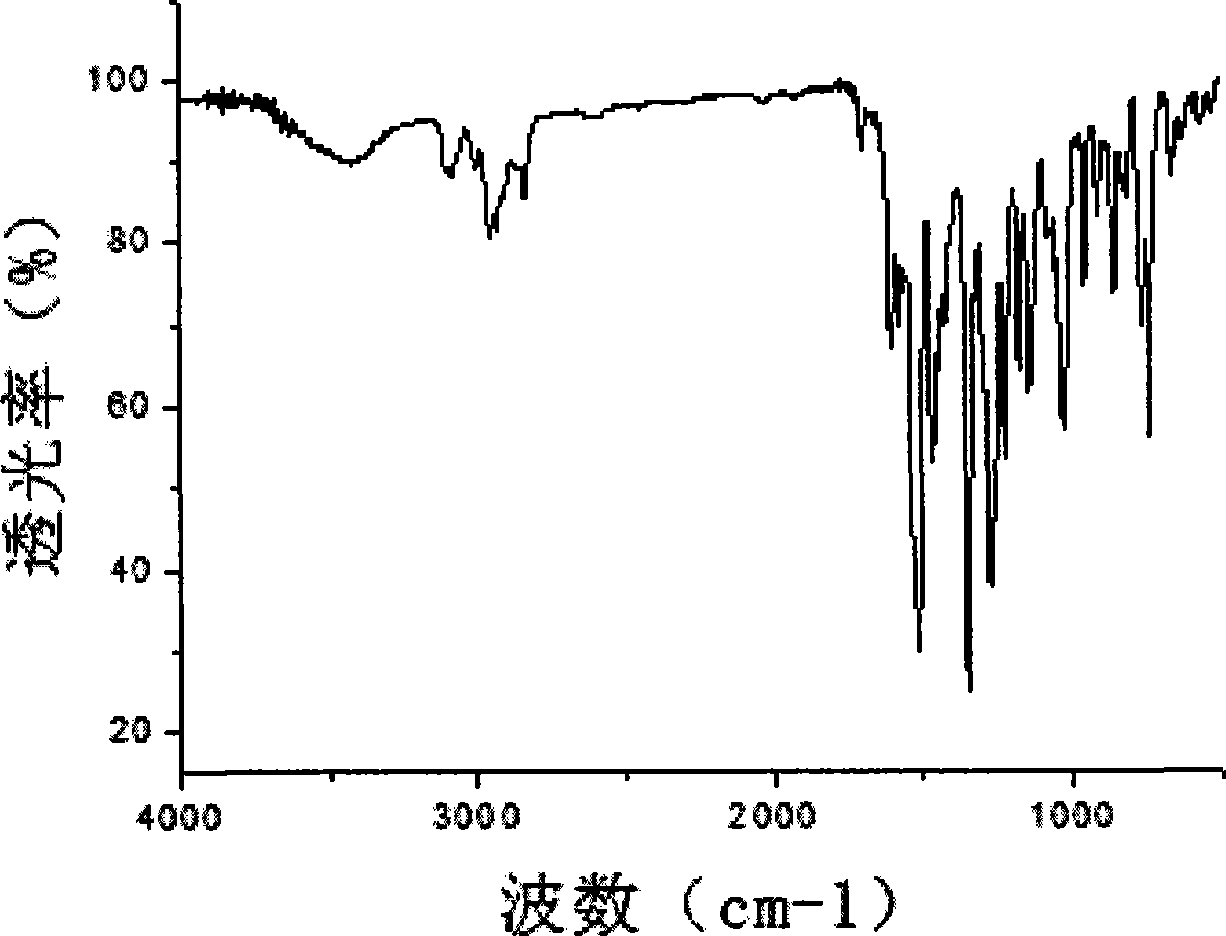

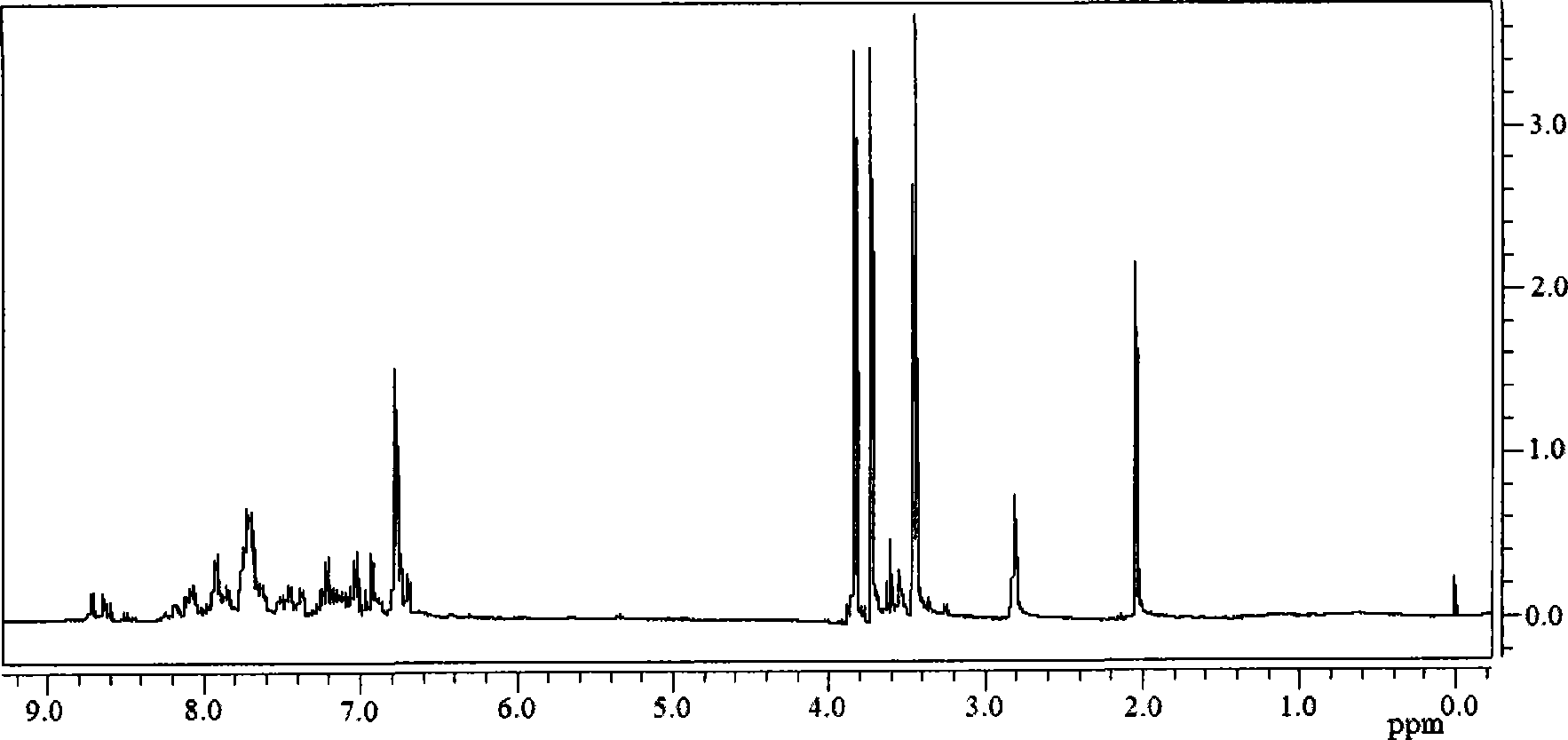

Method for preparing negative photosensitive polyimide based on 2,2-di[4-(2,4-diaminophenyloxy)phenyl]hexafluoropropane

InactiveCN101265328ASmall shrinkageGood dimensional stabilityPhotomechanical apparatusPolymer scienceEnd-group

The invention discloses a method for preparing negative photosensitive polyimide which is based on 2, 2-bis<4-(2, 4-diaminophenoxy) phenyl> hexafluoropropane. The method takes the 2,2-bis<4-(2,4-diaminophenoxy)phenyl> hexafluoropropane and dihydric acid anhydride as raw materials for carrying out the polymerization reaction, hyper-branched fluoride-containing polyamic acid which takes the macromolecular chain end group as the anhydride group is obtained, the hyper-branched fluoride-containing polyamic acid is further reacted with p-hydroxyaniline or m-hydroxyaniline, hyper-branched fluoride-containing polyimide which takes phenolic hydroxyl as the end group by chemical imidization reaction is obtained, phenolic hydroxyl end-blocked fluoride-containing hyper-branched polyimide powder is obtained by precipitation, washing and vacuum drying process, and the hyper-branched fluoride-containing polyimide photosensitive material with the negative photosensitive performance is obtained by undergoing the functionalization after the dissolution. The material has high photosensitive performance, high resolution and excellent process, and the cured product has low water absorption, excellent heat resistance, dielectric performance and mechanical performance, thus having great application prospect in the field of electronic micro-electronics.

Owner:DONGHUA UNIV +1

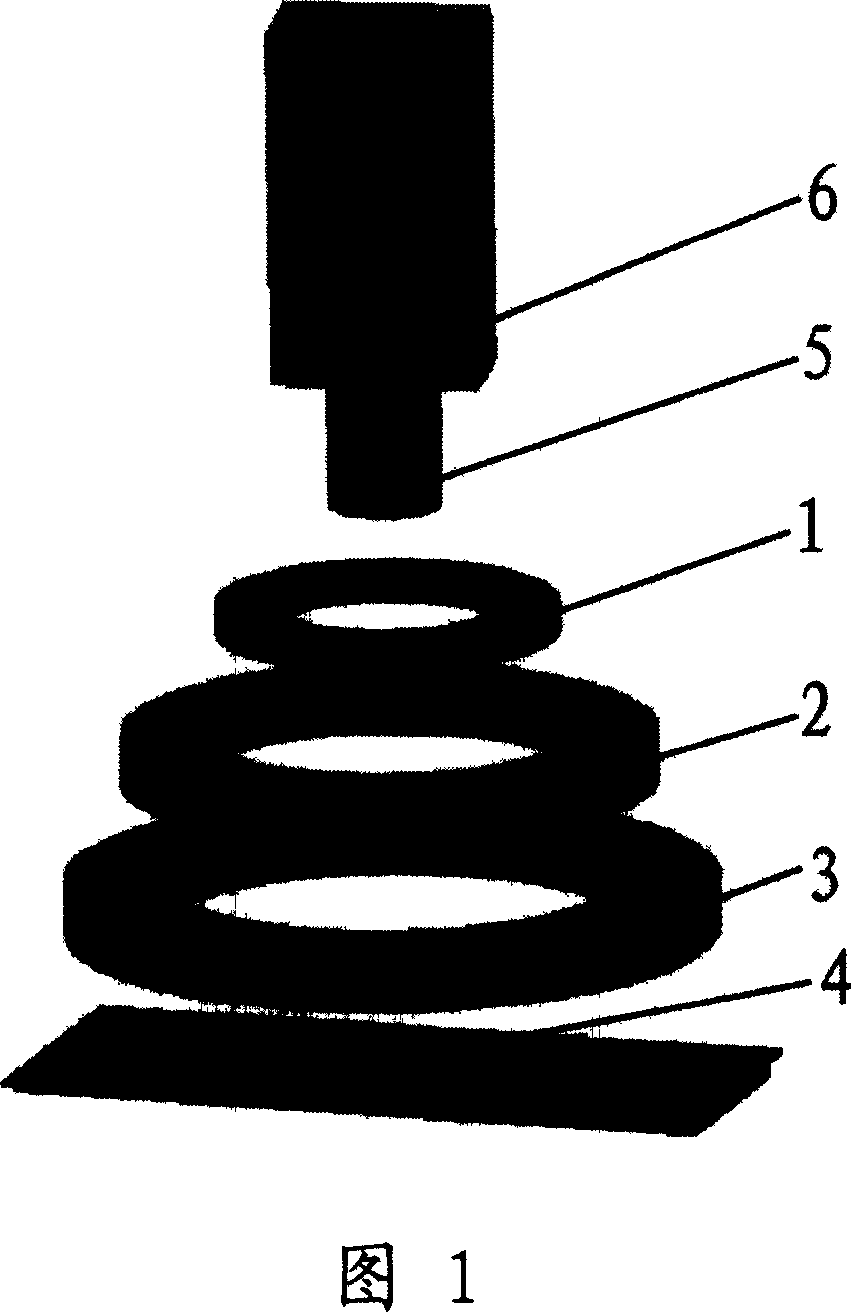

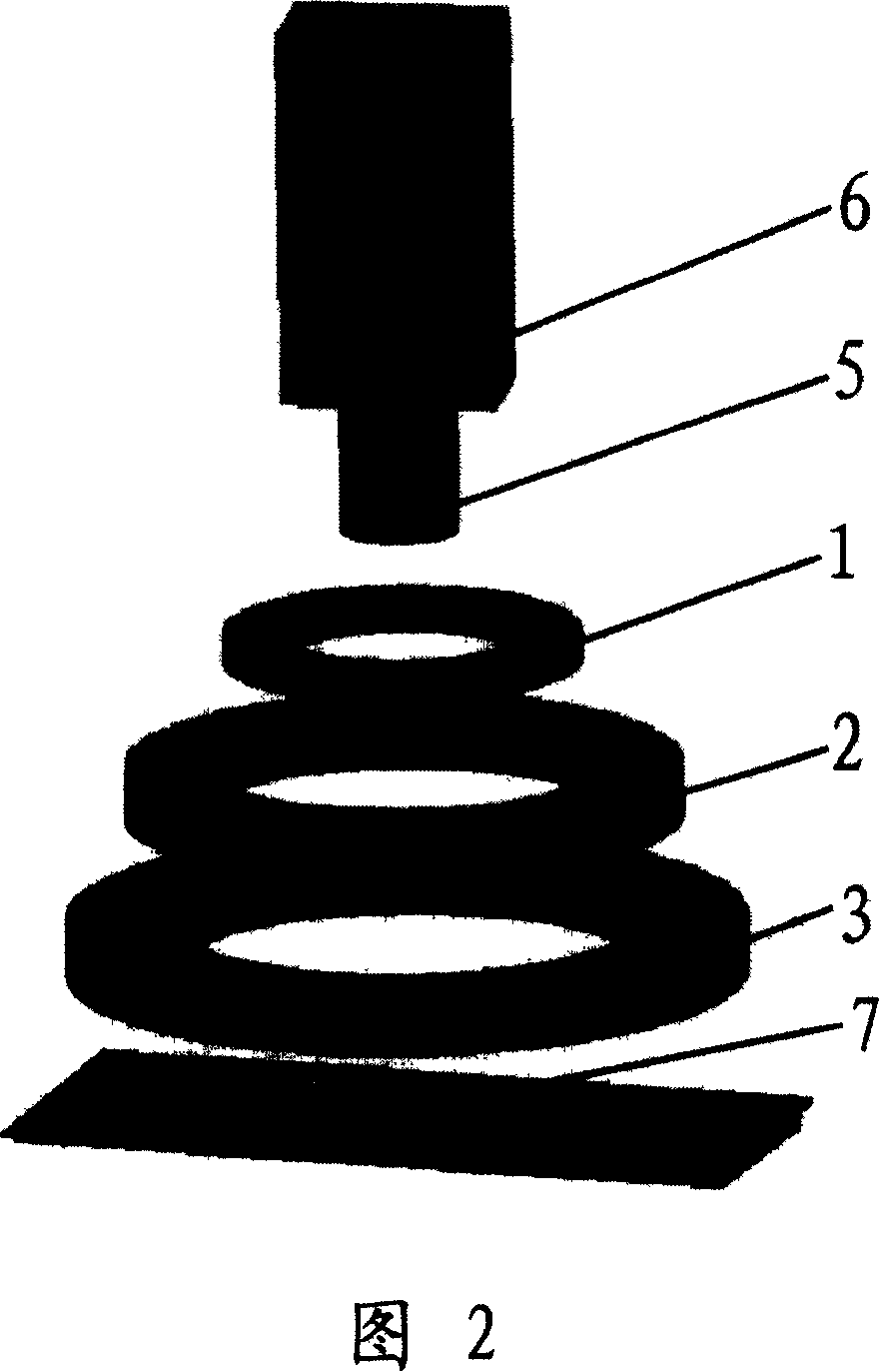

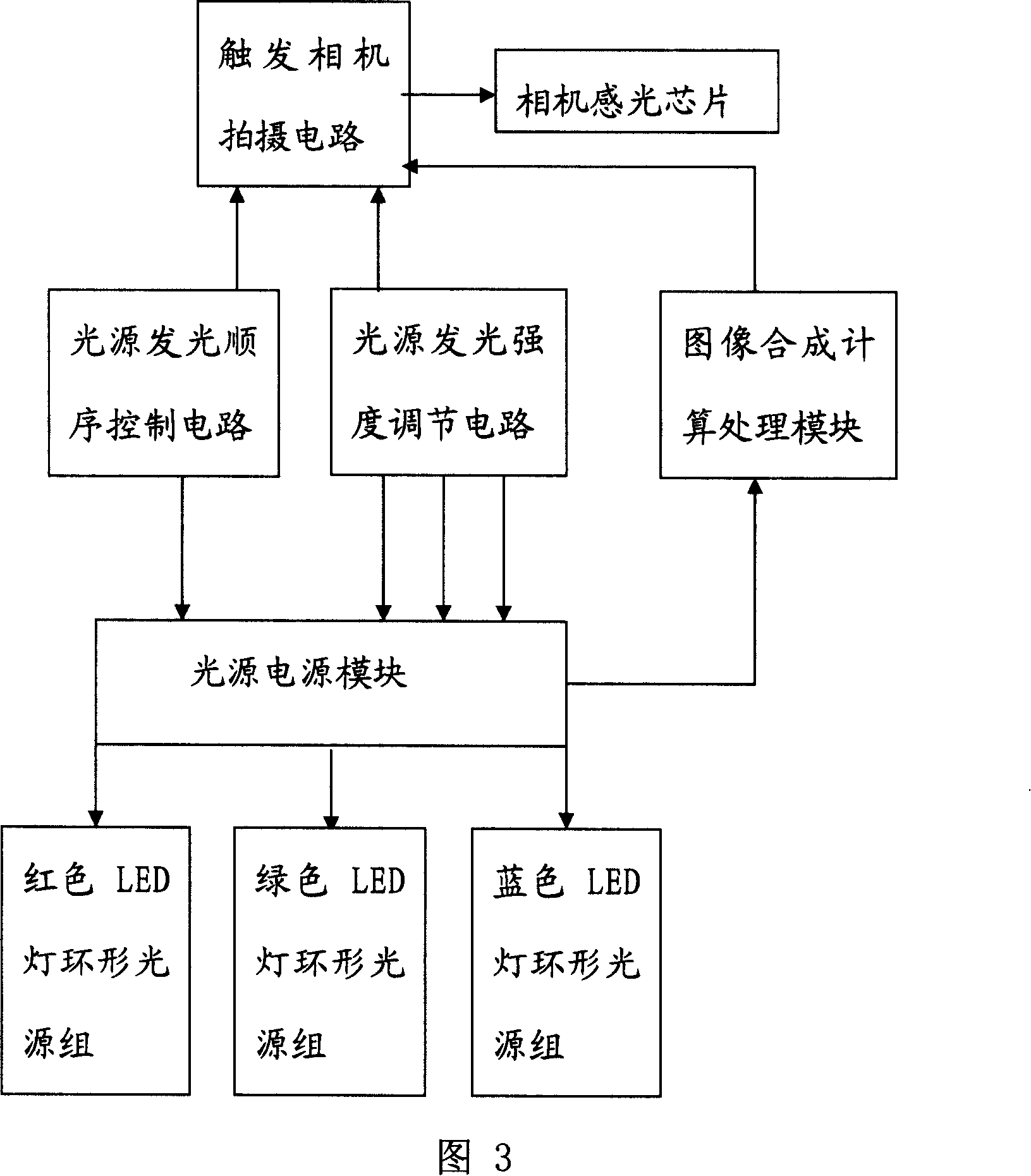

Imaging method and device for color image shot by black and white camera

ActiveCN101150732AThere is no overflow problemRemove color distortionTelevision system detailsColor photographyColor imageLuminous intensity

The invention relates to an imaging method which uses a black white camera to shoot color images and a device, the saturation regulatory factor value range is: 0.5-3; the luminance gain value range is: 0.5-3, under the condition is still relative to a camera in the environment without influence of external light or with influence of external light and during the shooting object is in a shot course of synthesizing color images, through a light source luminous intensity adjusting circuit, the luminance of a red LED lamp annular light source group, a green LED lamp annular light source group, a blue LED lamp annular light source group can be adjusted independently to adjust white balance; during shooting, each group of light source can be opened or closed independently through a light source luminescence sequencing circuit; when the light source is prepared, the camera is triggered to shoot images through a control circuit. By adopting the method and the structure, an imaging method and a device which use a black white camera to shoot color images with real color, without light filter, high lminous sensitivity for satisfying tip application are provided.

Owner:ALEADER VISION TECH

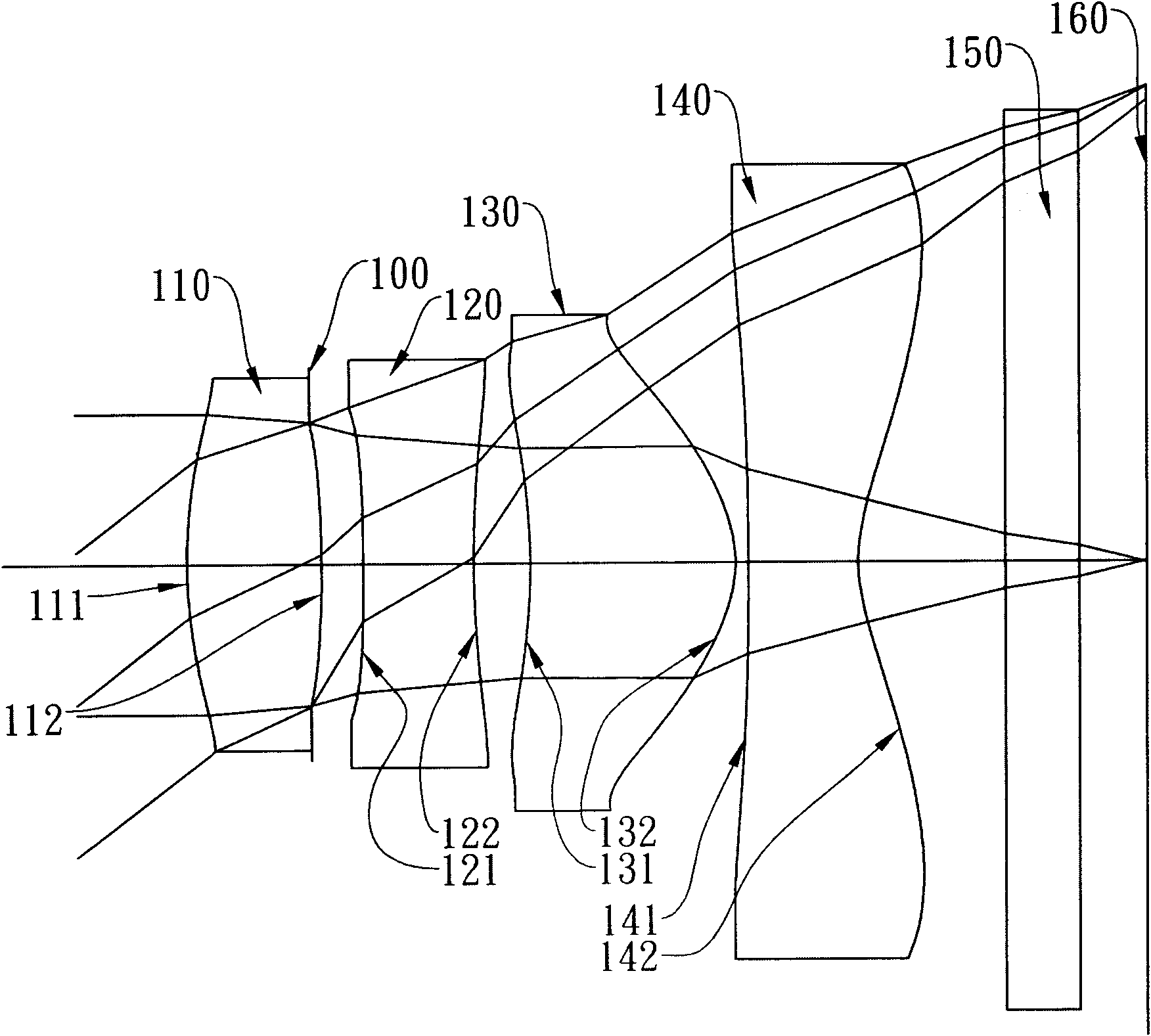

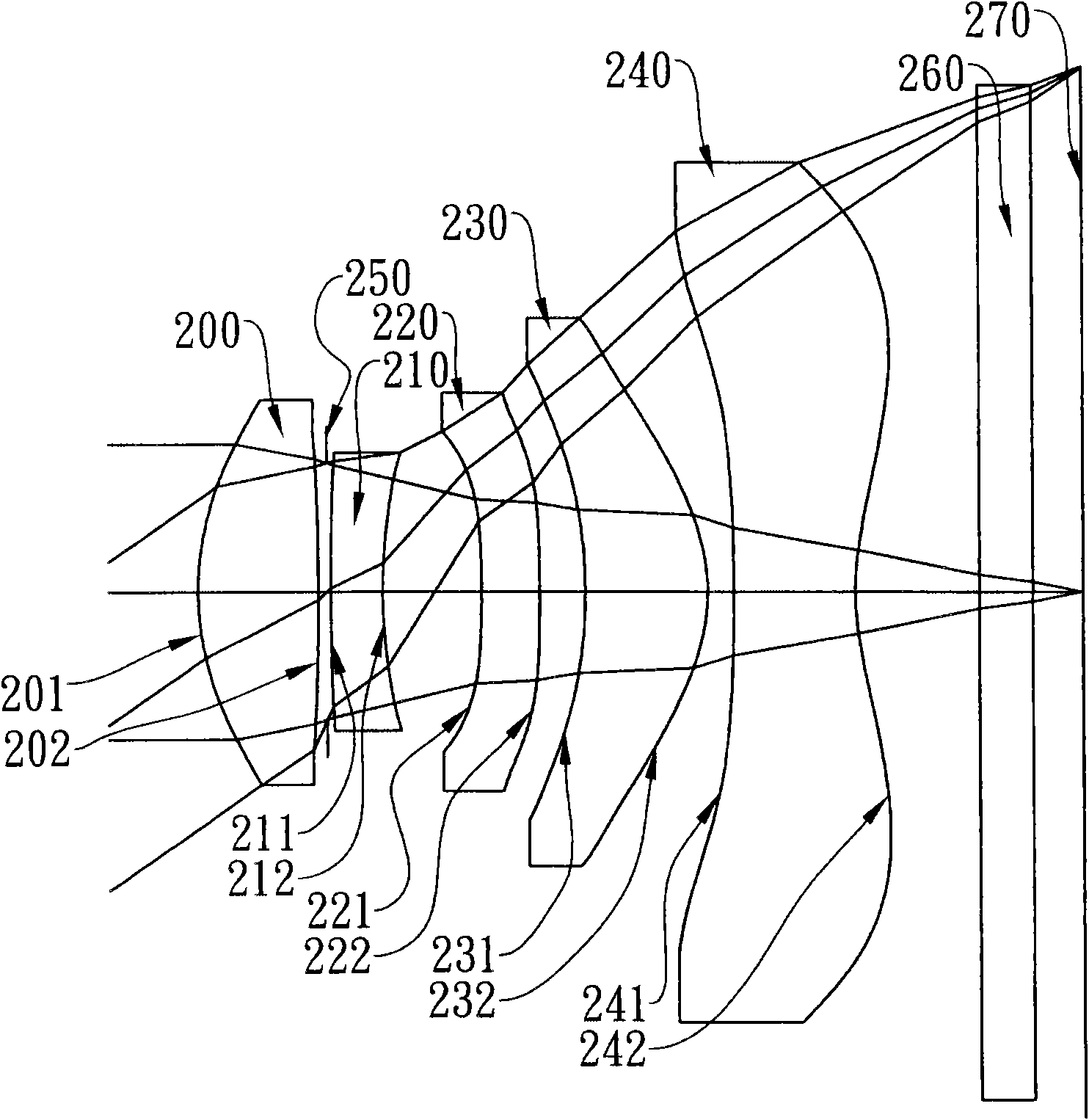

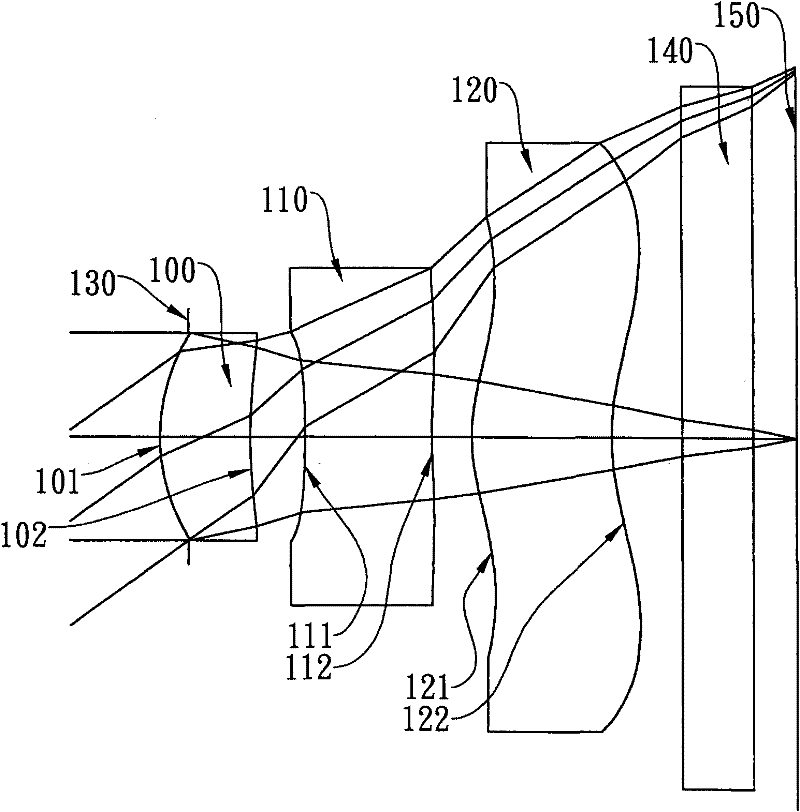

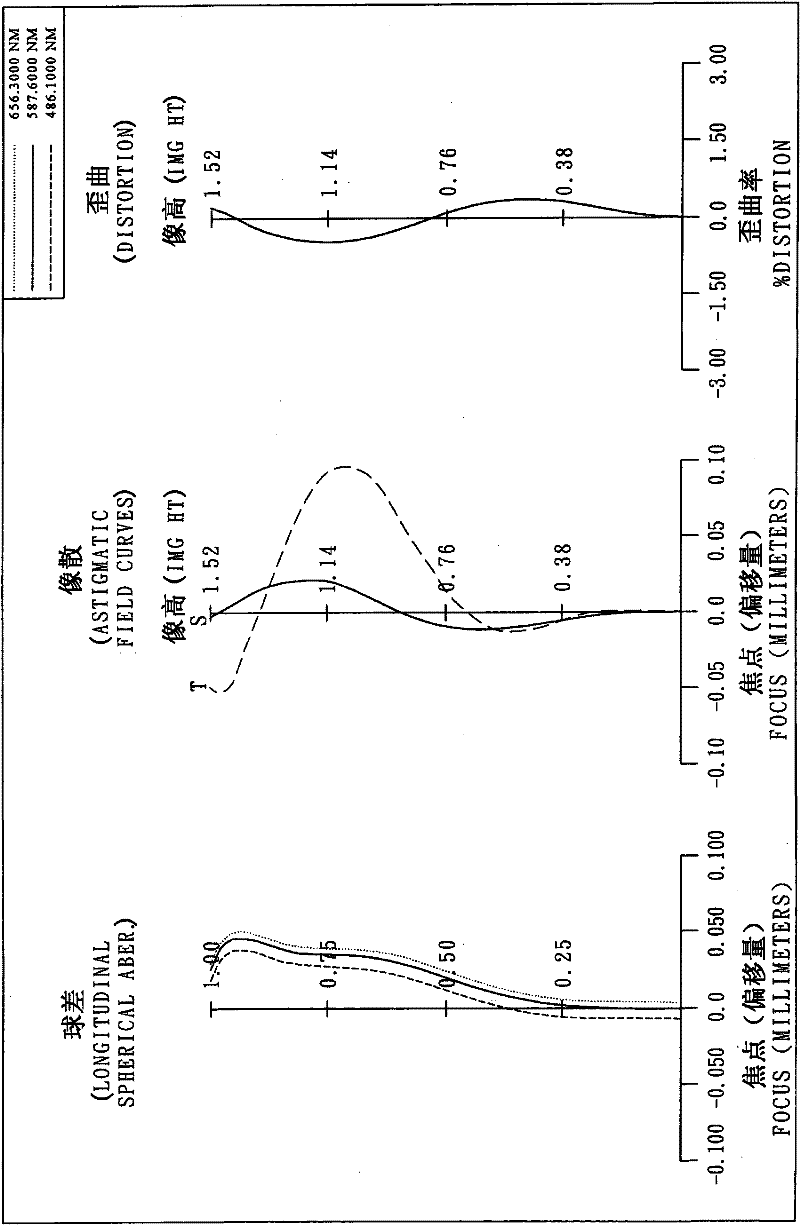

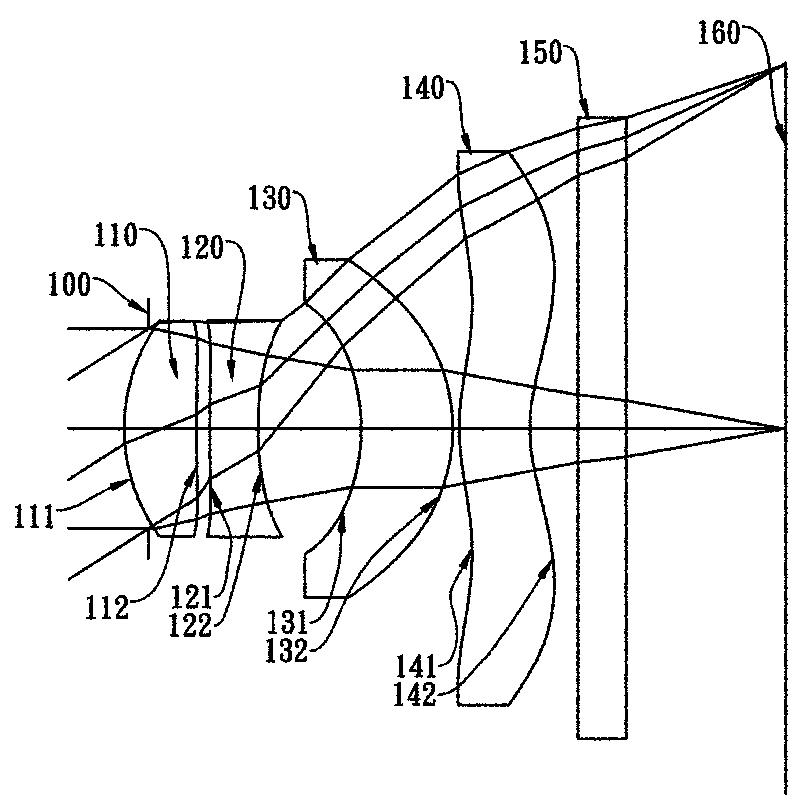

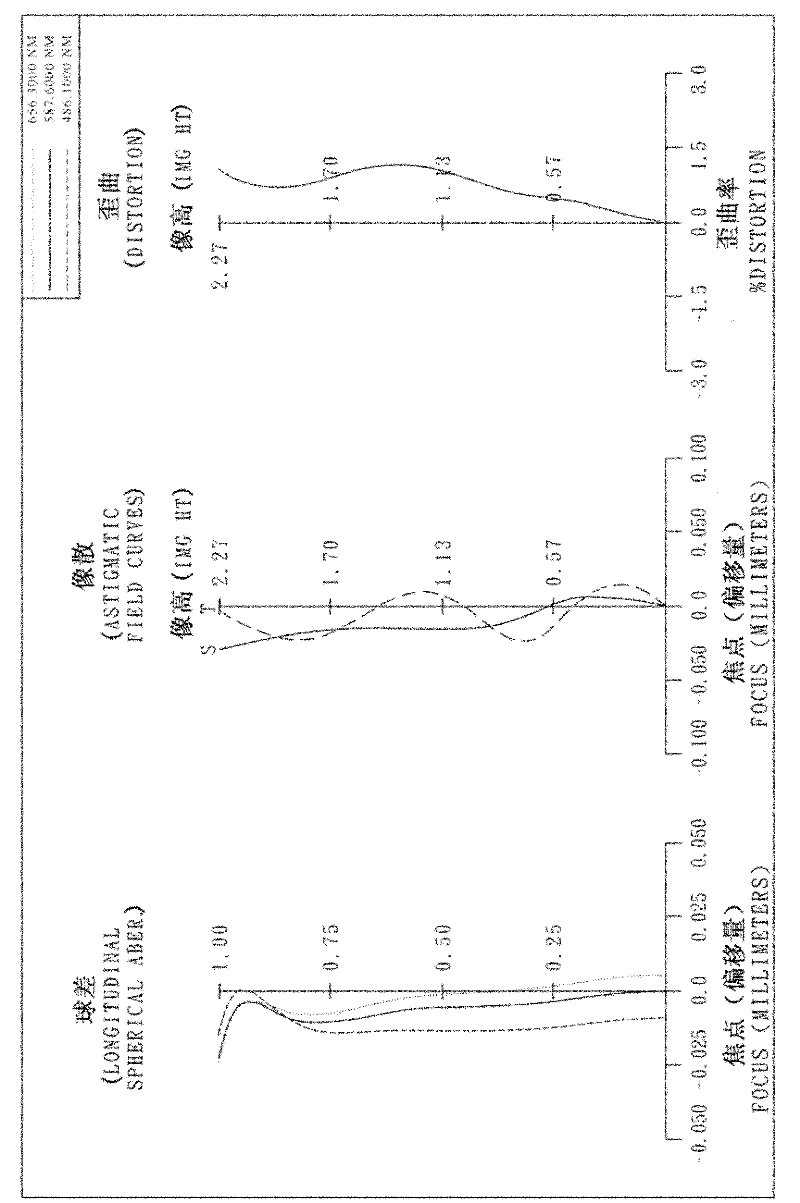

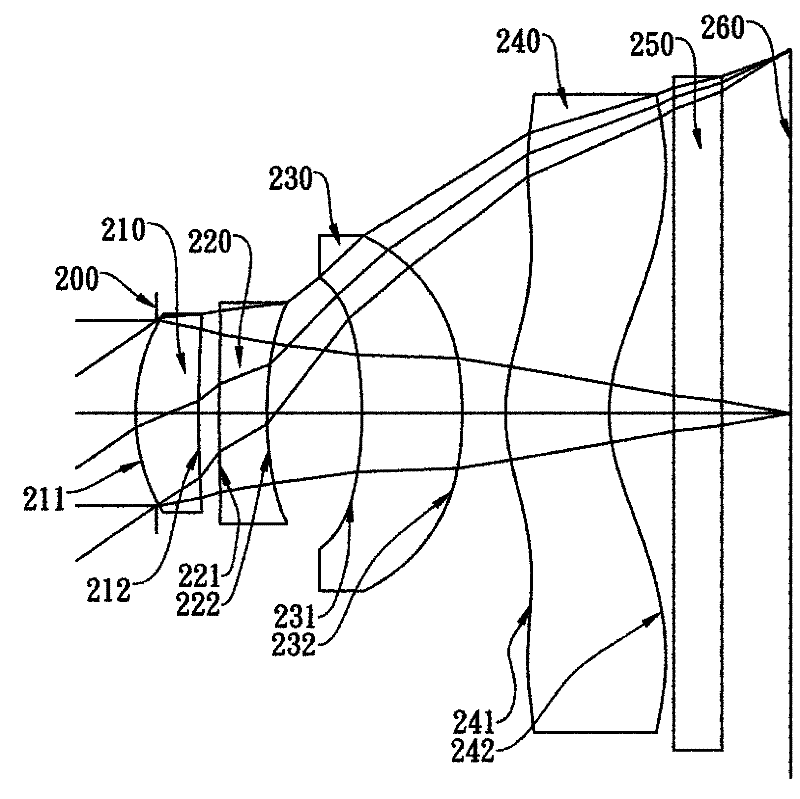

Optical image capturing lens

The invention provides an optical image capturing lens, which from an object side to an image side in turn comprises a first lens with positive flexion force, a second lens with negative flexion force, a third lens which has an object side surface and an image side surface that are both non spherical surfaces, and a fourth lens which has an image side surface that is a concave surface, has an object side surface and the image side surface that are both non spherical surfaces, and has at least one inflection point disposed on at least one of the object side surface and the image side surface. The optical image capturing lens is additionally provided with an aperture and an electronic light sensing element for imaging of captured object; the aperture is disposed between the captured object and the second lens; and the electronic light sensing element is disposed on the imaging surface.

Owner:LARGAN PRECISION

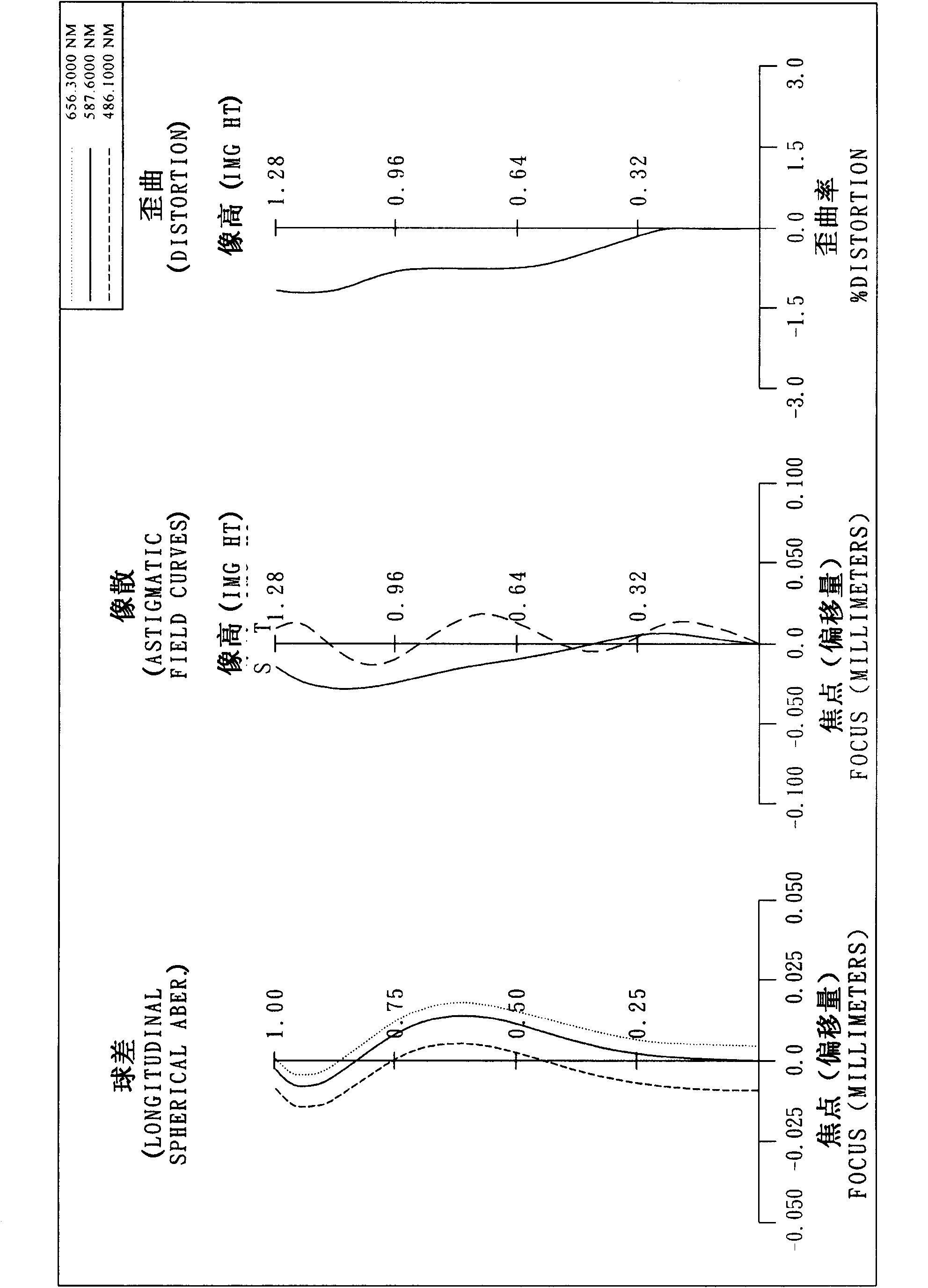

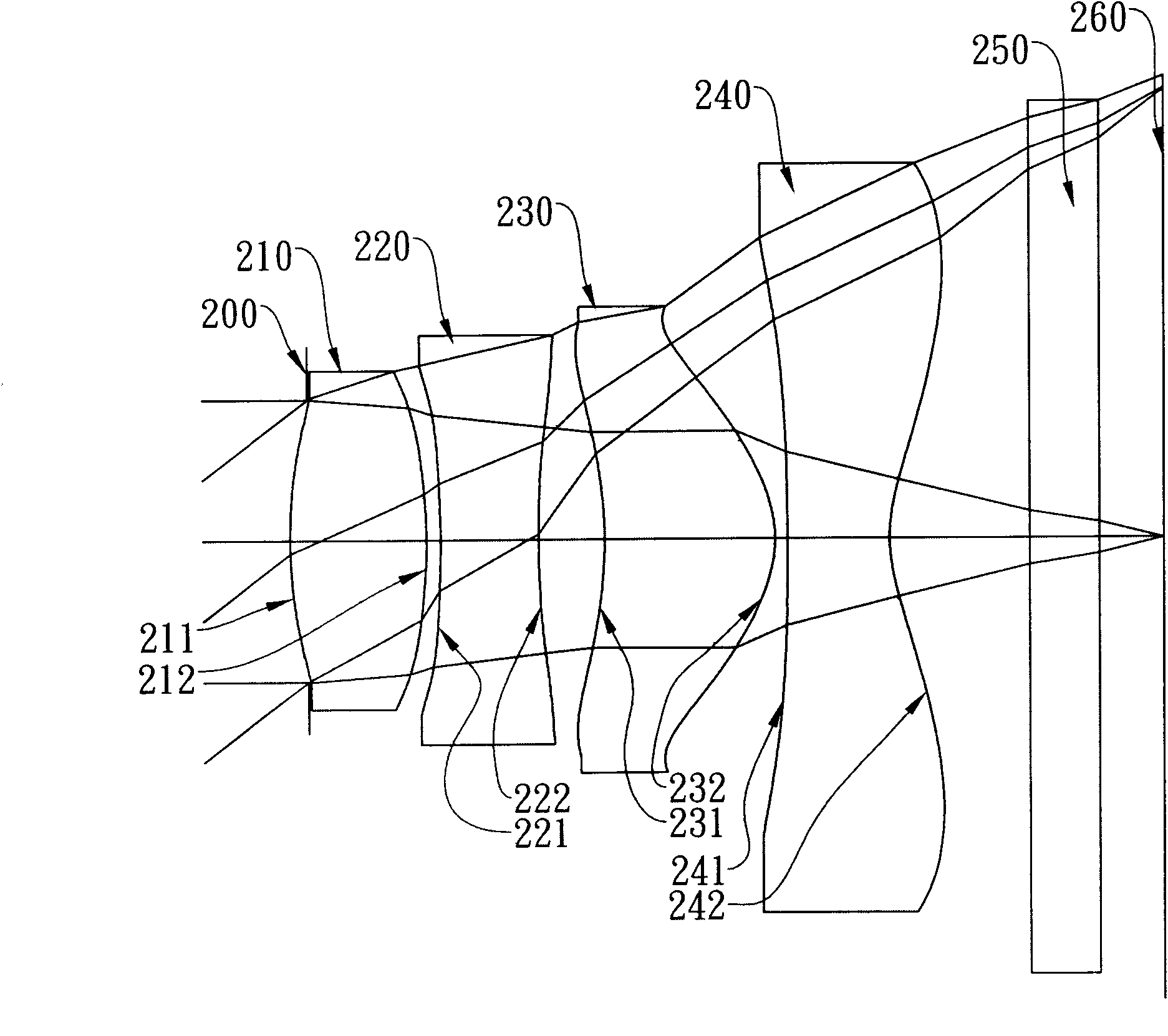

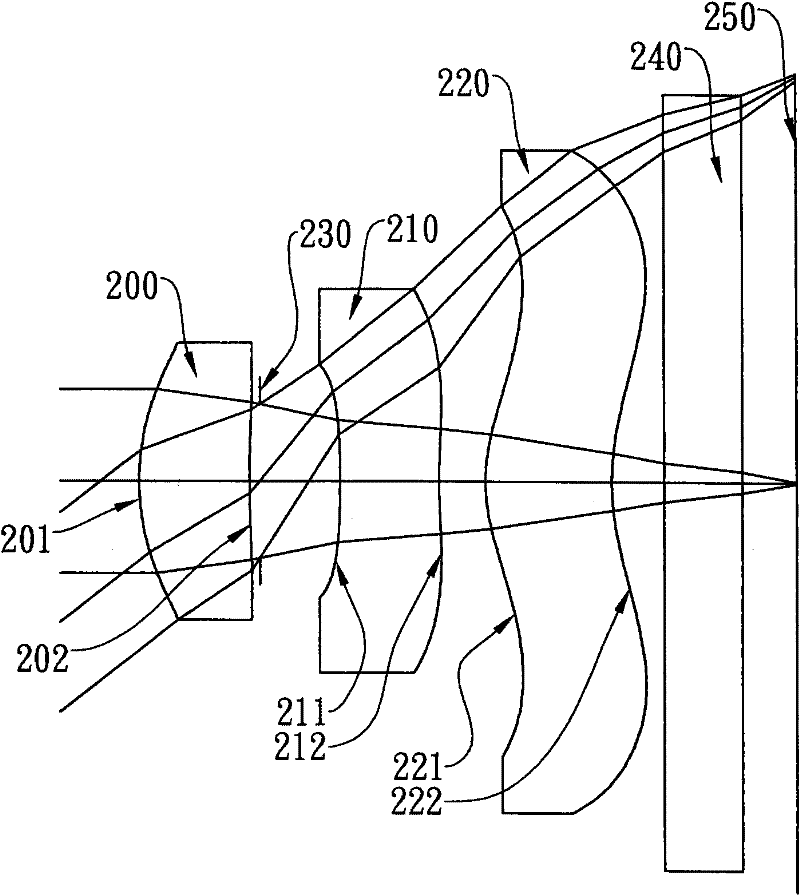

Optical shot for image capture

The invention discloses an optical shot for image capture. The optical shot comprises five lenses with refractive power, which, from an object side to an image side, are sequentially a first lens with positive refractive power, a second lens with negative refractive power, a third lens, a fourth lens with positive refractive power and a fifth lens with negative refractive power, wherein the object side surface of the first lens is a convex surface; the object side surface of the second lens is a concave surface; the object side surface of the fourth lens is a convex surface, and at least one surface of the object side surface and the image side surface of the fourth lens is an aspheric surface; and the object side surface of the fifth lens is a concave surface, and at least one inflectionpoint is formed on the image side surface of the fifth lens. The optical shot for image capture is also provided with an aperture and an electric photosensitive element for imaging a photographed object; and the aperture is arranged between the photographed object and the second lens. Through the mode of configuring the lens group, the shot volume can be effectively reduced, the sensitivity of anoptical system can be reduced, and higher resolution power can be acquired.

Owner:LARGAN PRECISION

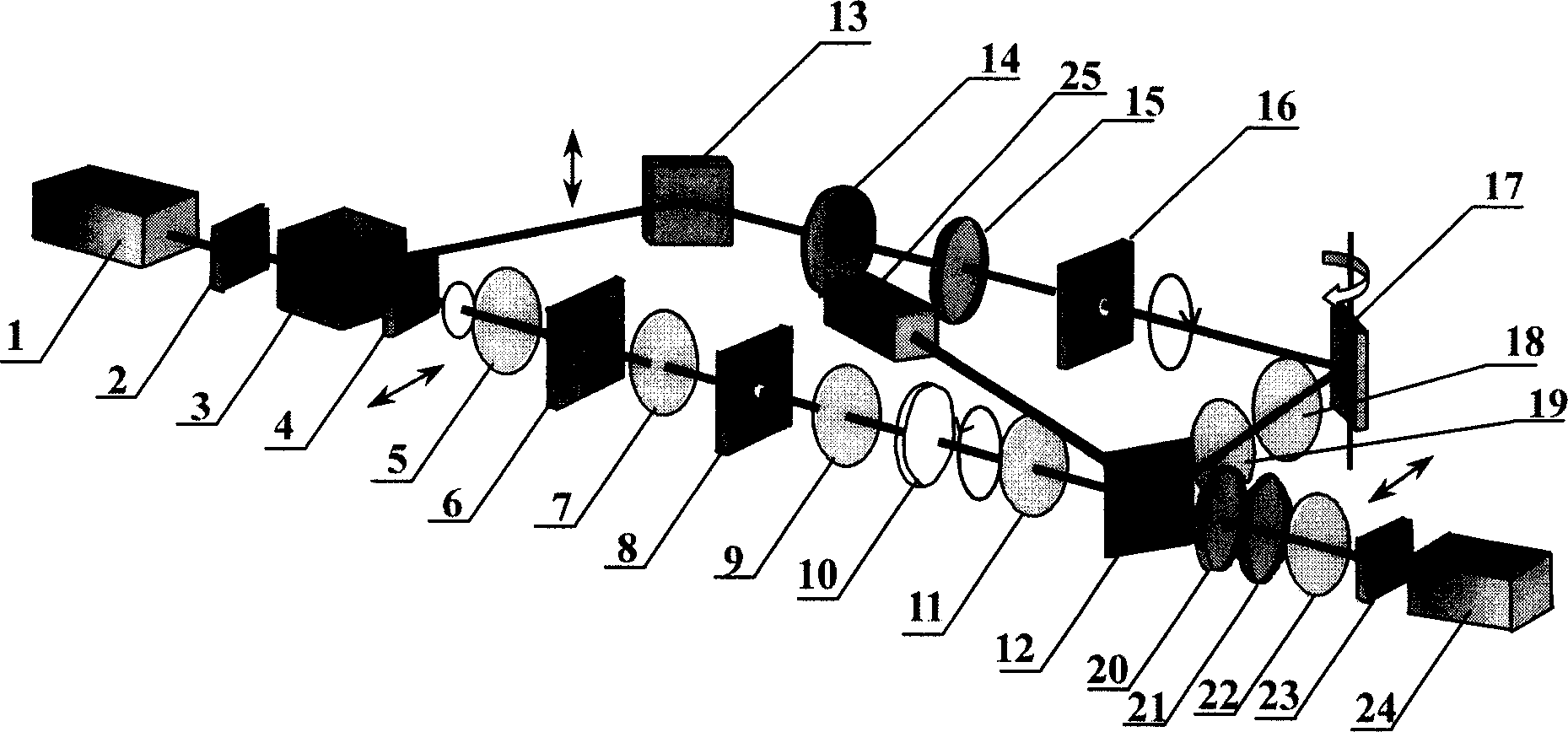

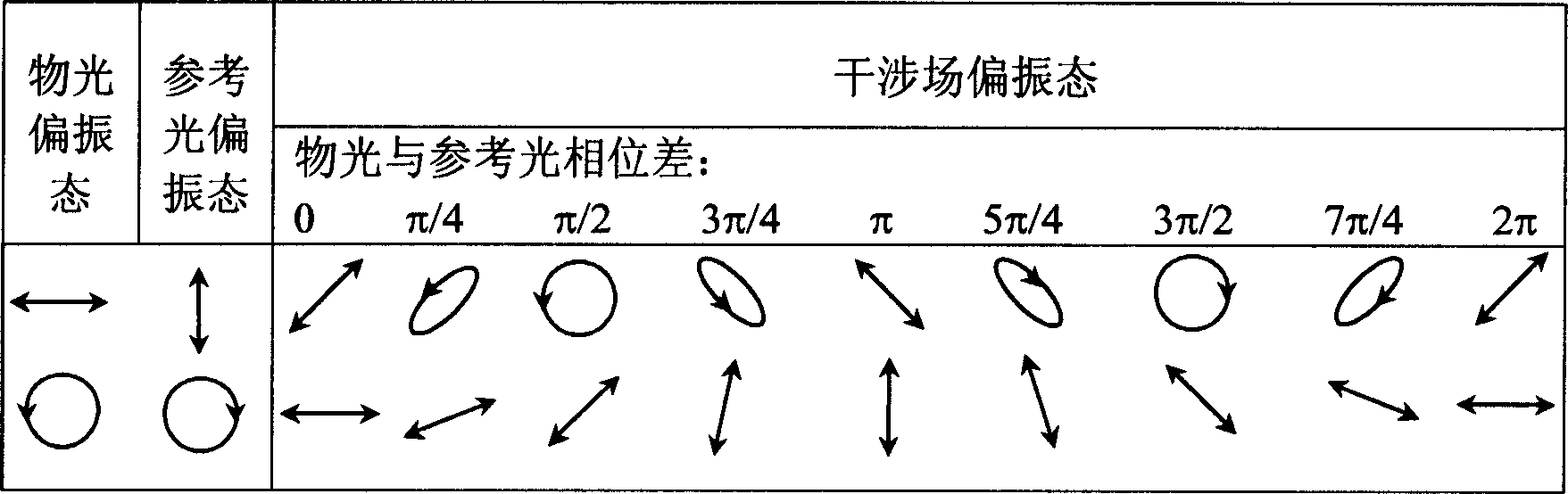

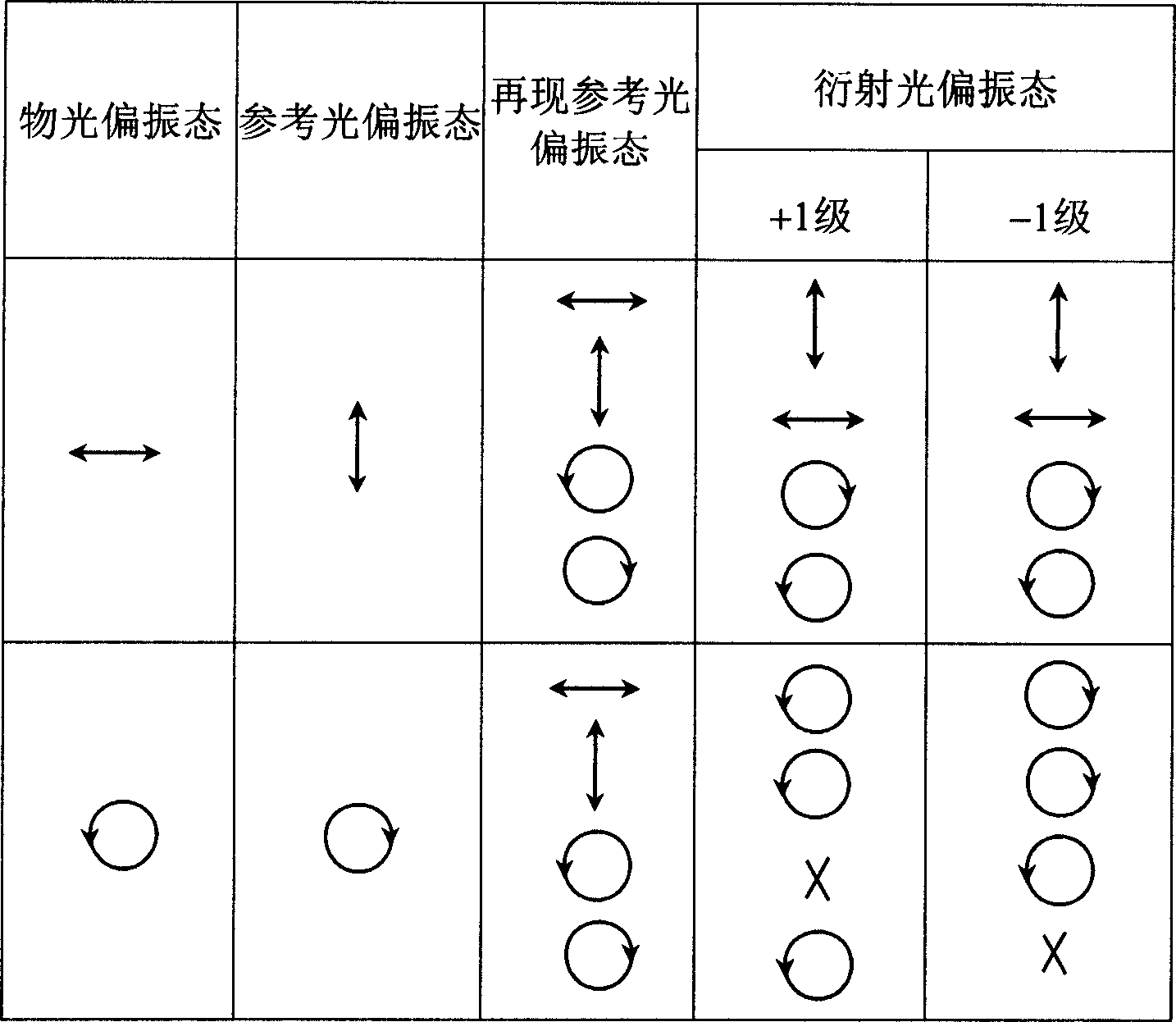

Polarized holographic optical memory device of using film of photochromic material as recording medium

InactiveCN1728246AImprove photosensitivityImprove spatial resolutionRecording/reproducing/erasing using optical interference patternsOptical elementsHolographic storageSpatial light modulator

A polarization holographic storage device of using photochromic material film as recording media is prepared as using space light modulator as page information input element, using image collector as information reading out unit and using photochromicmaterial material film as recording material, using light of photochromic material to lead each anisotropy , using orthogonal polarization light as object light and reference light to record modulated holography for raising image S ¿C N ratio, using bacteria sclererythrin film or fulgide film as erasable holographic recording media.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

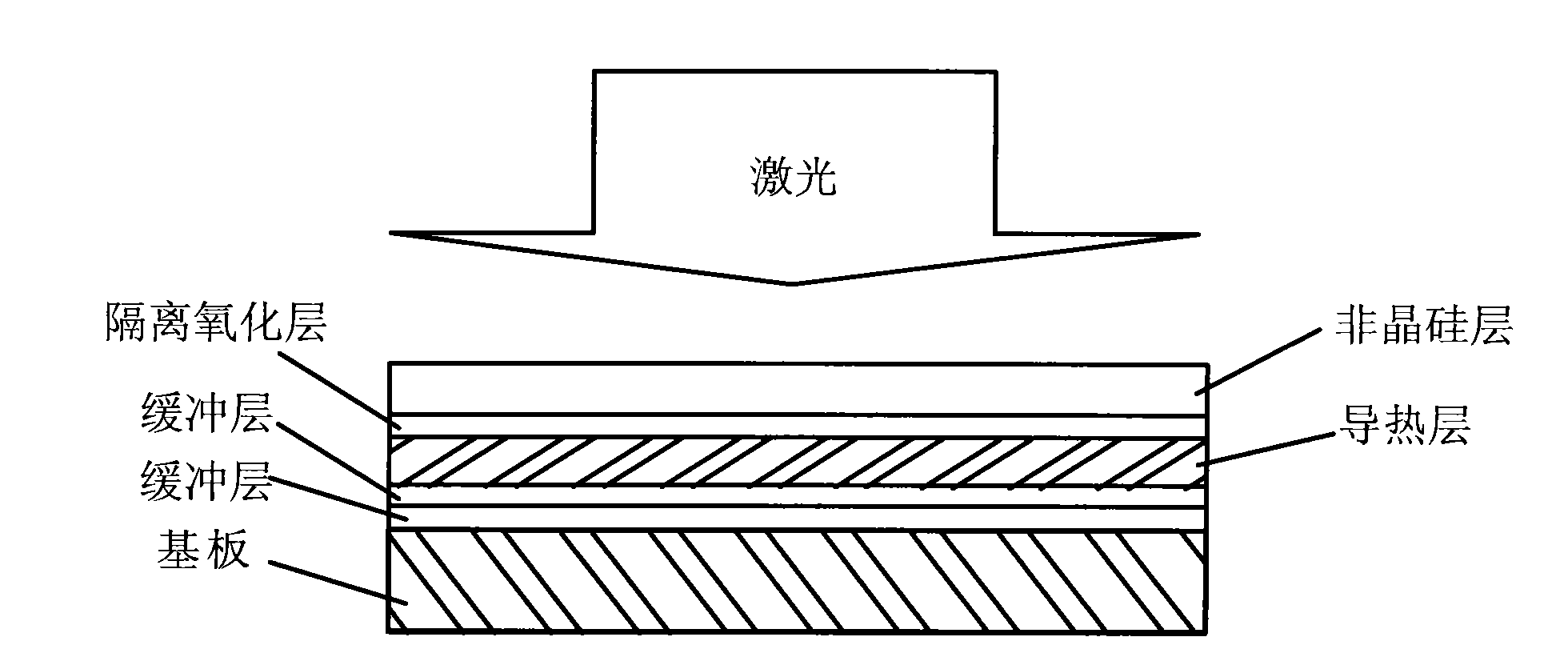

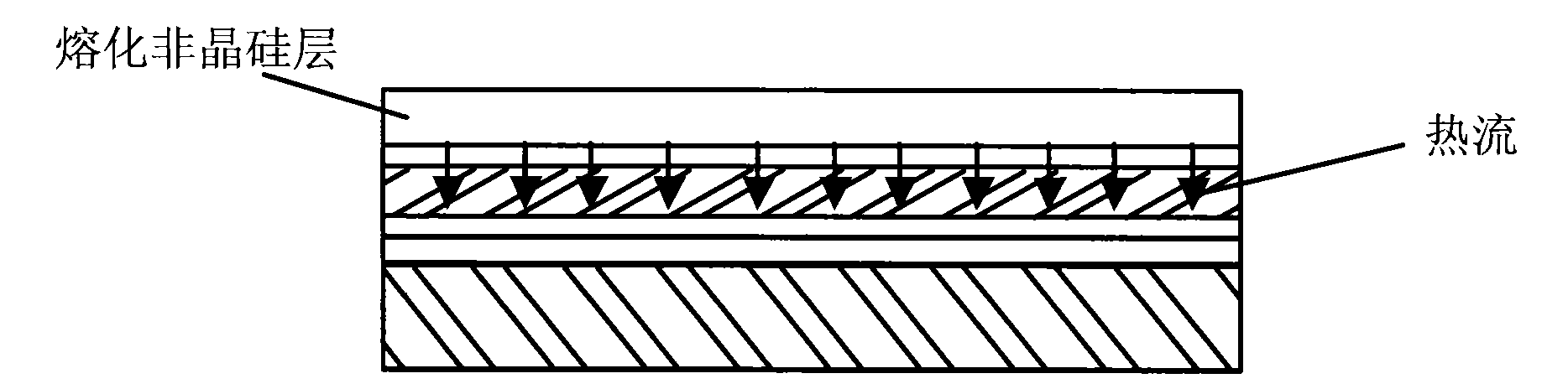

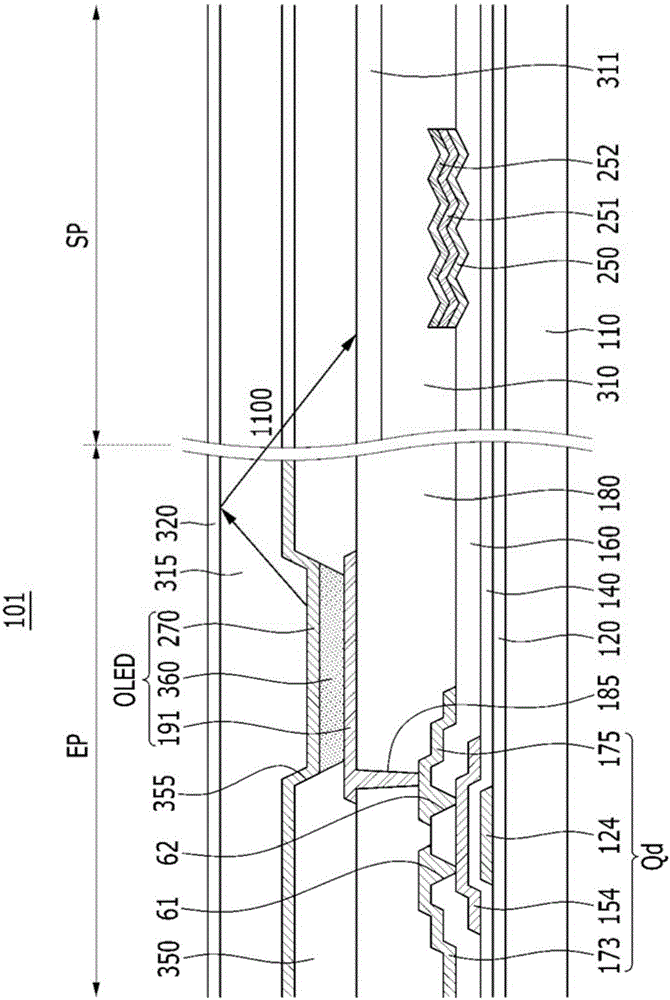

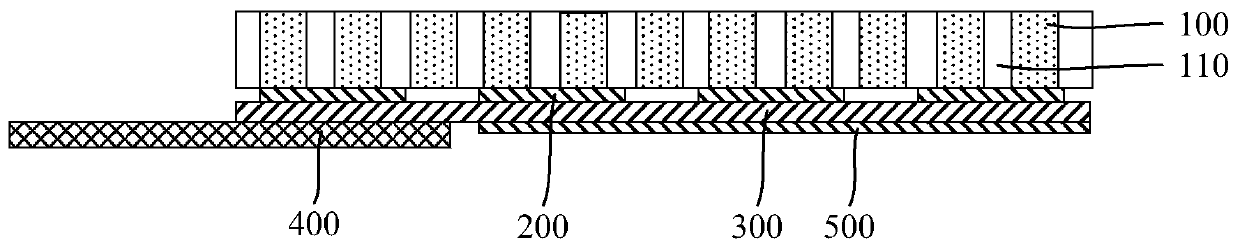

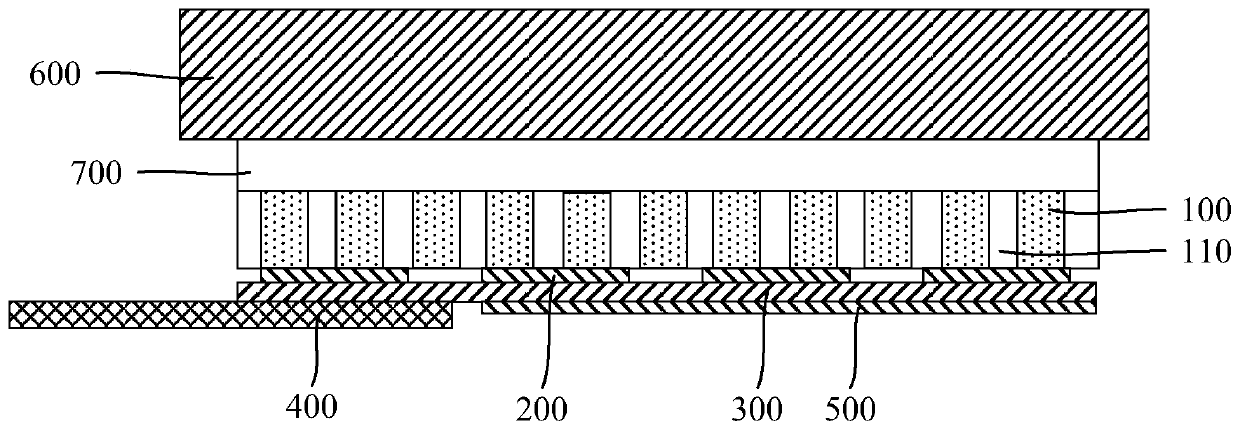

Image display system and manufacture method thereof

InactiveCN101593730AImprove photosensitivityIncrease opening ratioSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceLight sensing

The invention relates to an image display system and a manufacture method thereof. The image display system comprises a basal plate, a switch film transistor, a driving film transistor, a light-sensing component and a capacitor, wherein a baffle layer is formed on the basal plate; no conductive layer is formed in a first section predicted to form the switch film transistor so as to form a shielding layer; and a conductive layer is formed in a second section predicted to form the driving film transistor, the light-sensing component and the capacitor so as to form the shielding layer. Weather the conductive layer exists or not in the single crystallized processing procedure and the thermal conductive phenomenon of a quasimolecule laser annealing method are utilized to form polycrystalline silicon layers with different grain sizes in the first section and the second section so that the image display system has favorable uniformity of luminance.

Owner:INNOLUX CORP

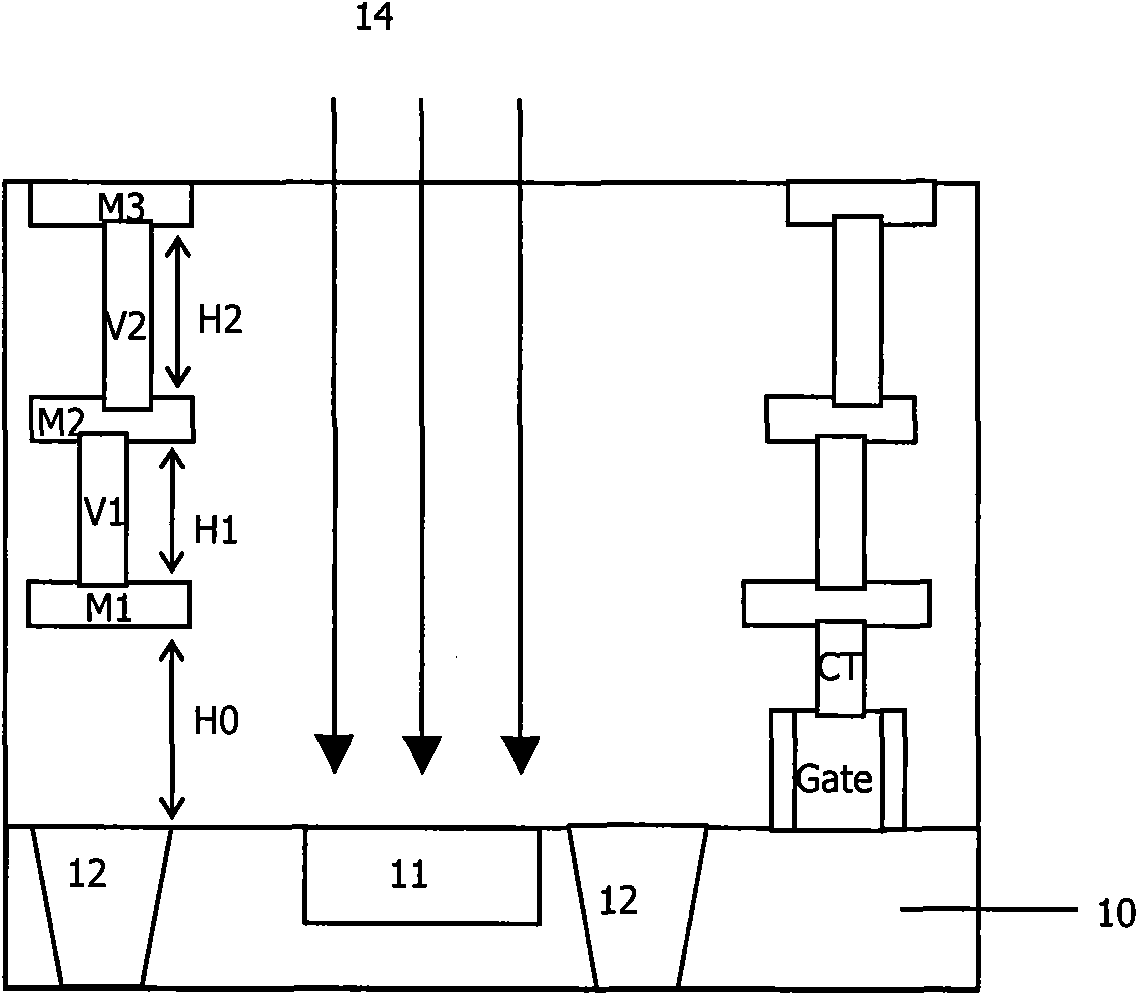

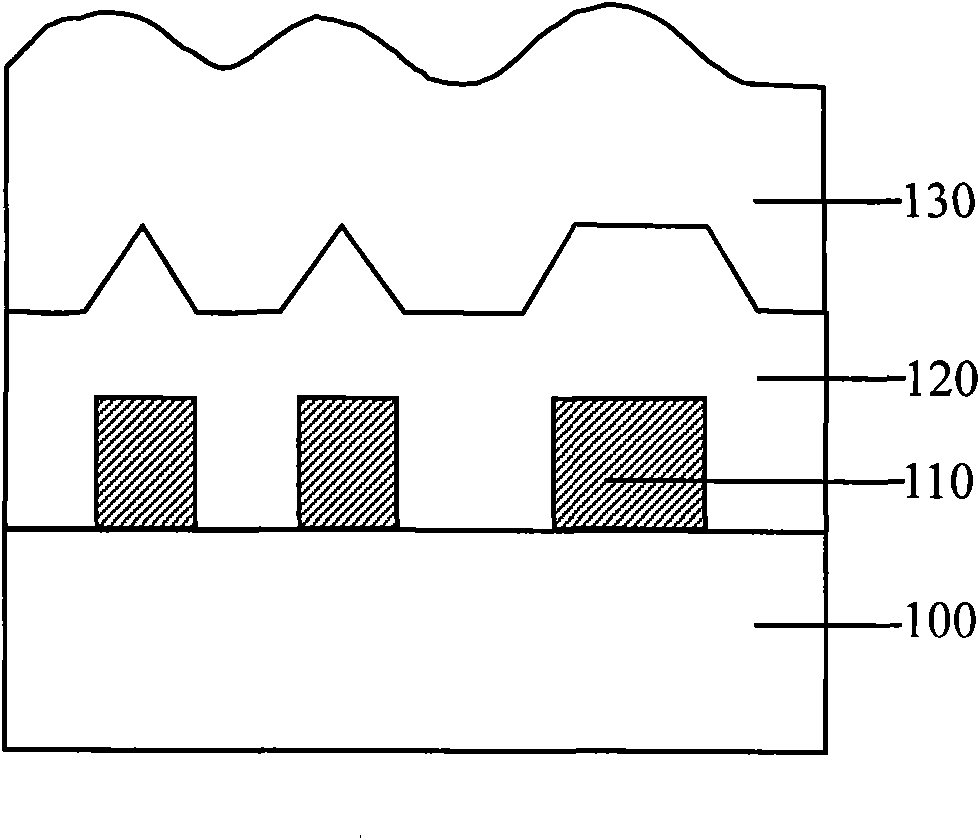

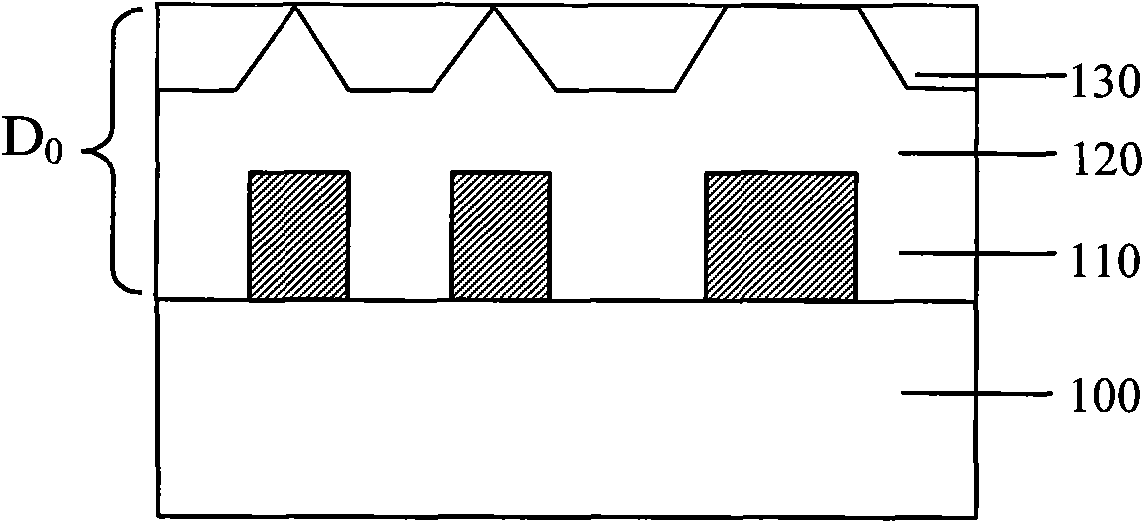

Method for manufacturing semiconductor device

InactiveCN102024754AThickness difference achievedThickness is easy to controlSemiconductor/solid-state device manufacturingRadiation controlled devicesDeposition processDielectric layer

The invention discloses a method for manufacturing a semiconductor device. The method comprises the following steps of: providing a semiconductor substrate, wherein a protrusion structure is arranged on the semiconductor substrate; depositing a first dielectric layer and an etching barrier layer on the semiconductor substrate in turn by adopting a deposition process, wherein upper surfaces of theetching barrier layer and the first dielectric layer at corresponding positions of the protrusion structure are higher than those at other positions; forming second dielectric layers with the same upper surface at different positions on the etching barrier layer by adopting a spin-coating process; etching the second dielectric layer to expose the highest point of the etching barrier layer by adopting a first etching process; and etching the second dielectric layer, the etching barrier layer and the first dielectric layer by adopting a second etching process until the etching barrier layer is completely removed. In the method, the thicknesses of the residual first dielectric layer at different positions on the whole wafer are the same, and the thickness of the first dielectric layer can bereduced. Therefore, the aim of improving the photosensitivity of the semiconductor device is fulfilled.

Owner:SEMICON MFG INT (SHANGHAI) CORP

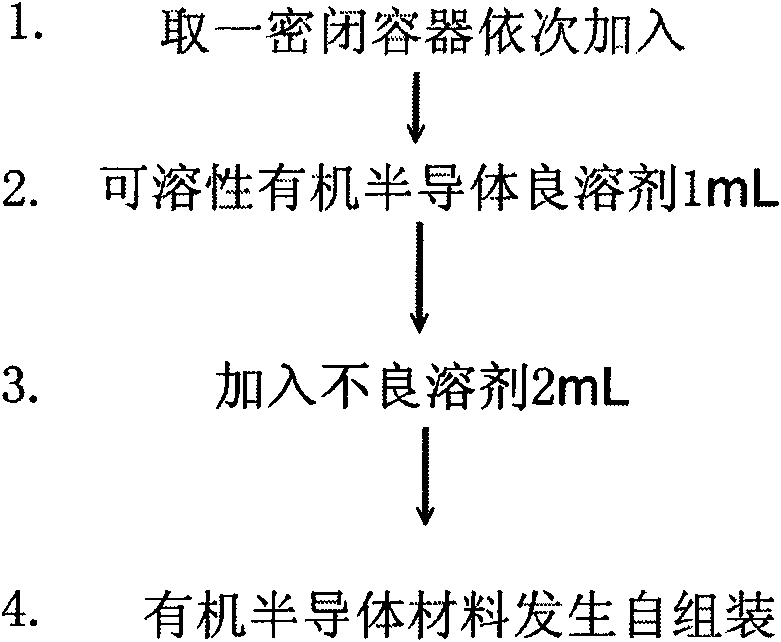

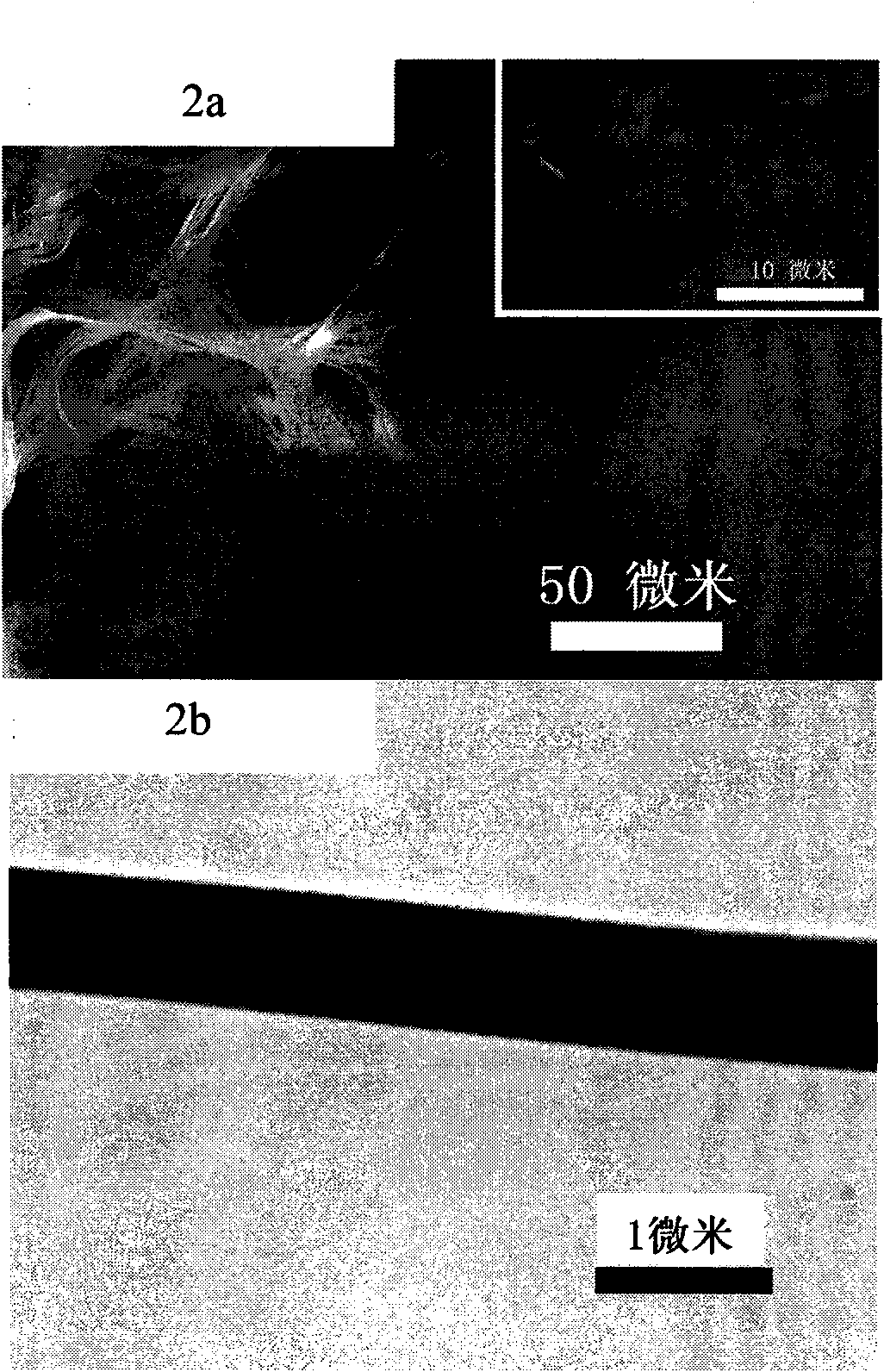

Light-sensing organic field-effect transistor and preparation method thereof

InactiveCN101645487ASimple preparation processLow costGroup 4/14 element organic compoundsFinal product manufactureOctadecyltrichlorosilaneOrganic field-effect transistor

The invention discloses a light-sensing organic field-effect transistor and a preparation method thereof. The transistor comprises a substrate, a grid electrode arranged on the substrate and an insulating layer arranged on the grid electrode; the transistor further comprises a self-assembled monomolecular-modified layer and a source electrode, a drain electrode and at least one organic semiconductor compound single crystal wire positioned on the self-assembled monomolecular layer. The self-assembled monomolecular layer comprises materials of octadecyltrichlorosilane, octacyltrichlorosilane, phenyltrichlorosilane and the like; and the preferential organic semiconductor compound is 6-methyl-anthracene [2,3-b] benzo-[d] thiophene. The length of the organic semiconductor compound single crystal is 80-300 microns, and the diameter is 1-10 microns. The preparation method provided by the invention has simple prepration process and low cost, and the prepared organic field-effect transistor has very high response on a low-energy light source with the energy of 10-90 microwatts per square centimeter, high mobility, high photosensitivity and high ratio of light current to dark current.

Owner:INST OF CHEM CHINESE ACAD OF SCI

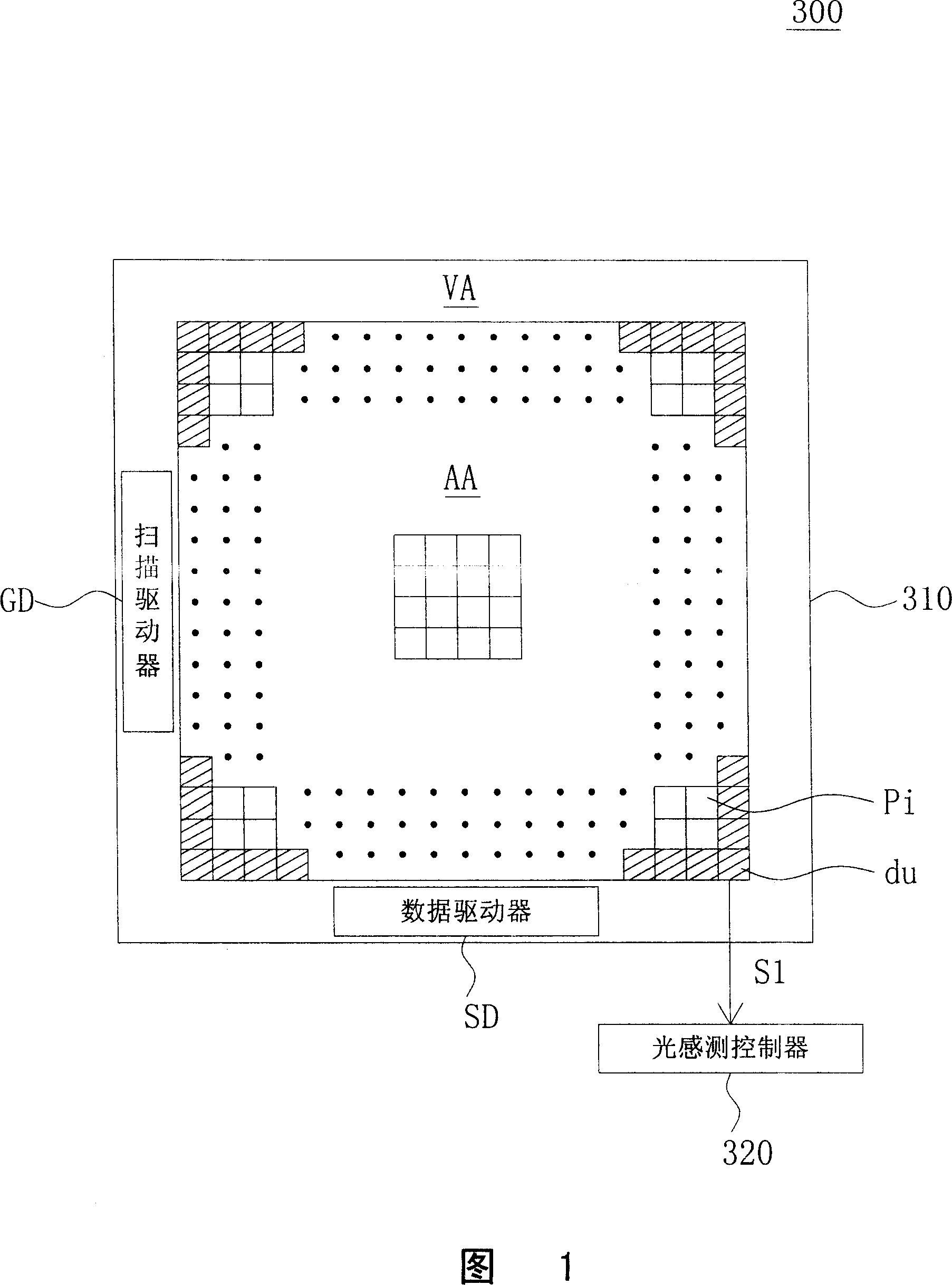

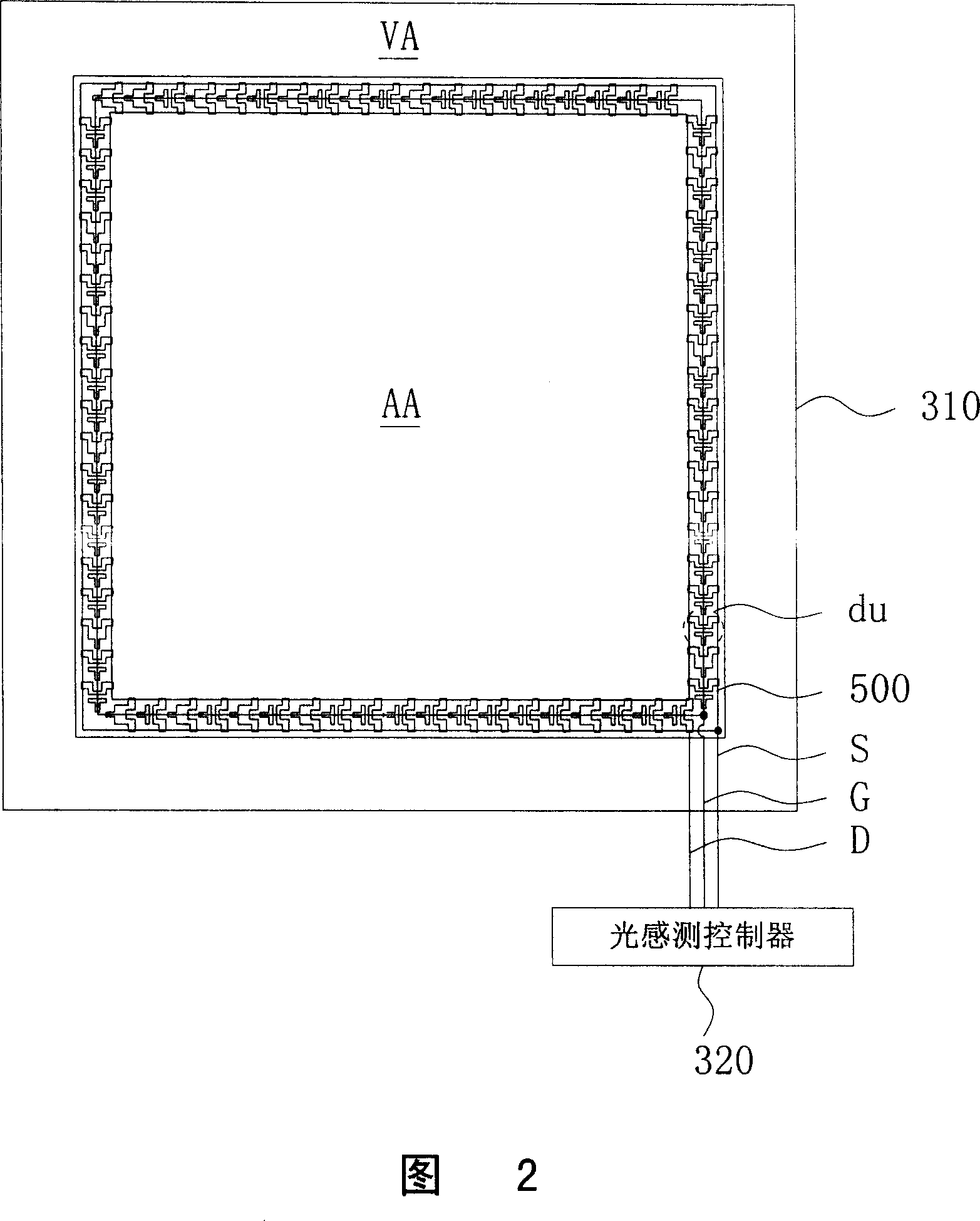

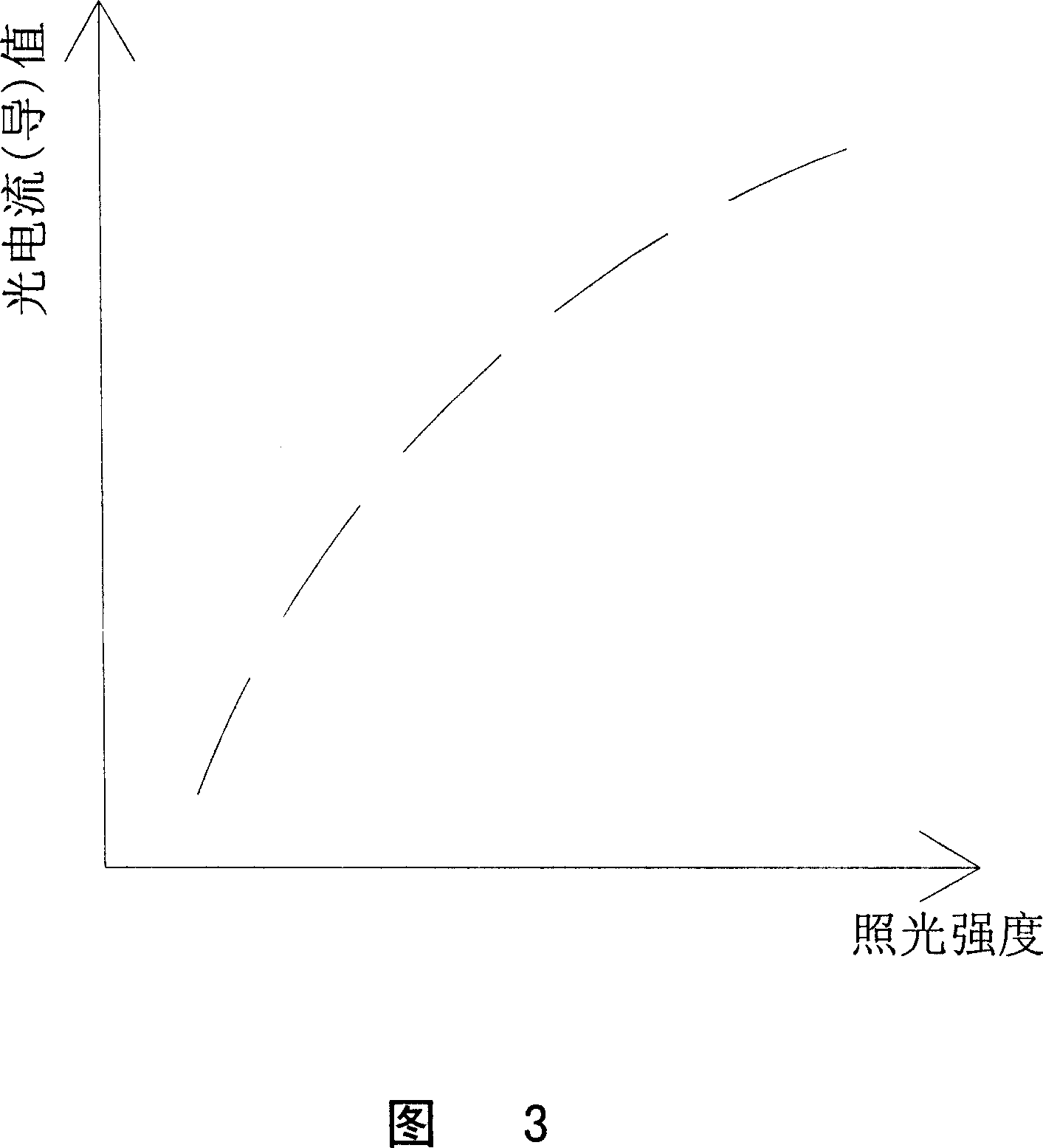

Light sensing display apparatus and display panel thereof

InactiveCN101097303AImprove aestheticsComprehensive photosensitive angleStatic indicating devicesLight sensingEngineering

A kind of optical sensing device includes a display panel and a optical sensing controller. The display panel includes a display area, a non-display area, and several sub-pixels and at least one void sub-pixel. The non-display area circles the display area. The sub-pixels are set in the display area to display the image. Besides, the void sub-pixel is also set in the display area and possesses an optical sensing subassembly. The optical sensing controller and optical subassembly are coupled.

Owner:WINTEK CORP

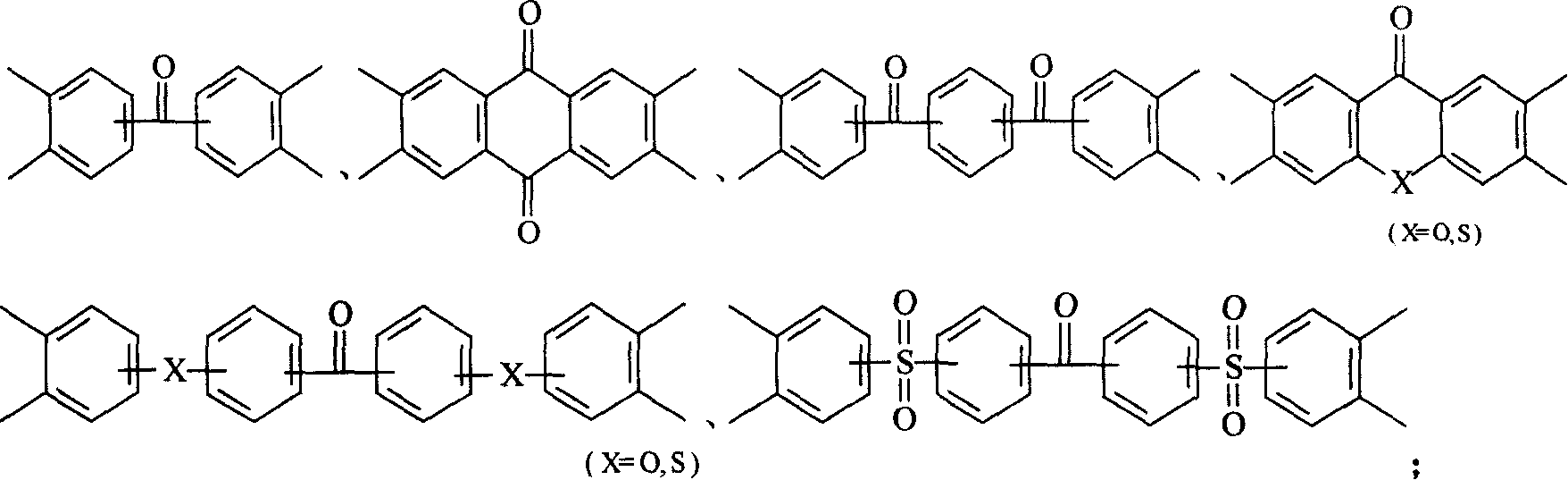

Photo-sensitive polyimide, and its preparing method

InactiveCN1850881AHigh densityImprove the shortcomings of poor sensitivityPhotosensitive materials for photomechanical apparatusSolubilityImage resolution

The invention relates to photosensitive polyimide (PSPI) and the manufacture method. It adopts photosensitivity diamine containing alkyl, alkoxyl or methylthio on consecutive position of benzene ring and photosensitivity diamine containing acryloyl, dropping tetracarboxylic acid bianhydride organic solution into photosensitivity diamine mixture solution to take polymerization, and taking chemical imine to gain PSPI. The polymer has high photosensitivity and high resolution, excellent thermal stability and dissolubility.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

High photosensitive real time polarization imaging minimal deviation array and imaging device thereof

ActiveCN105445952AImprove transmittanceImprove photosensitivityOptical elementsAngular degreesOptoelectronics

The invention discloses a high photosensitive real time polarization imaging minimal deviation array and an imaging device thereof. The deviation array comprises a plurality of minimum period units which are closely arranged successively, wherein each minimum period unit includes four polarization units with different polarization angles; the four polarization angles are respectively 0DEG, 45DEG, 90DEG or 135DEG; and the lens of each polarization unit includes a plurality of polarizing films and non-polarized lenses so that the problem that in the prior art insufficient photosensibility makes the obtained polarized image have great error when the light is low or the time of exposure is not sufficient can be solved. The invention also discloses an imaging device and a combination method of pixels based on a high photosensitive real time polarization imaging minimal deviation array, and can solve the saturation problem for different types of lenses.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

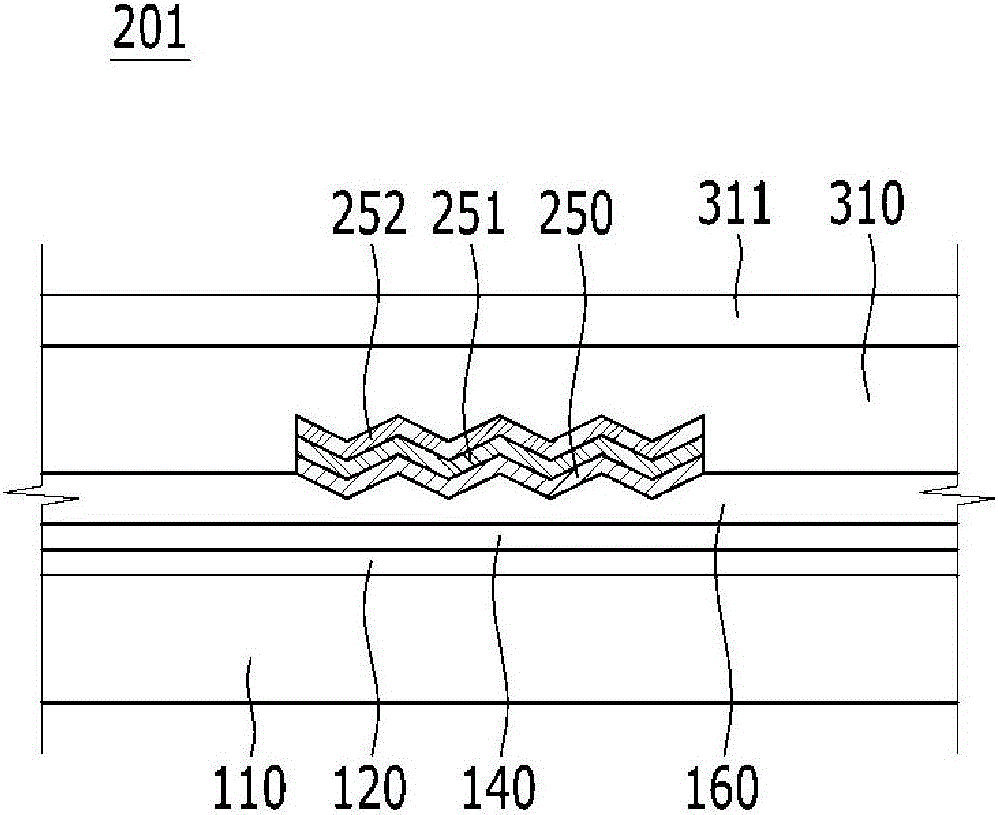

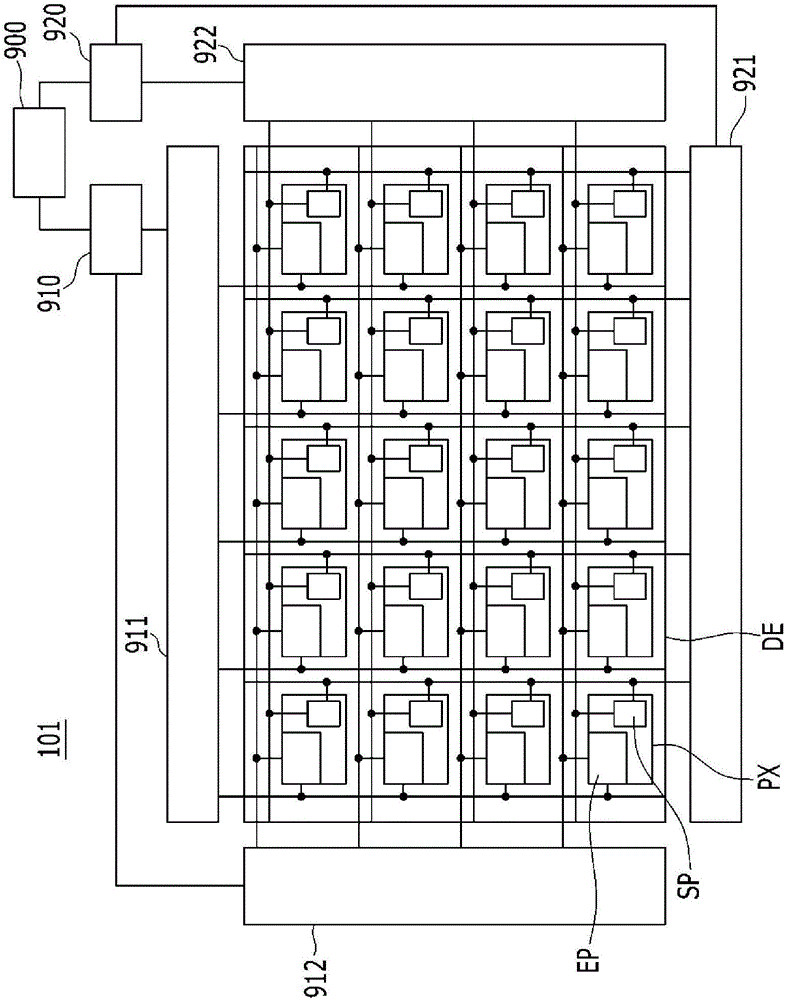

Photosensor and display device including the same

InactiveCN106549075AImprove photosensitivityGet Brightness UniformitySolid-state devicesSemiconductor devicesDisplay deviceDielectric layer

A disclosed photosensor includes: a first electrode layer including a reflection part having an inclination surface; a first semiconductor layer positioned on the first electrode layer; a second electrode layer positioned on the first semiconductor layer; and a first dielectric layer and a second dielectric layer sequentially positioned on the second electrode layer, wherein the first dielectric layer and the second dielectric layer have different dielectric constant values. Further, the disclosed display device includes a plurality of pixel areas positioned on a substrate, and a sensor unit formed in at least some pixel areas among the plurality of pixel areas.

Owner:SAMSUNG DISPLAY CO LTD

Hexaarylbisimidazoles compounds, preparation method and application thereof and composition containing thereof

InactiveCN101386599ALong absorption wavelengthImprove photosensitivityOrganic chemistryLong wavelengthPhotoinitiator

The invention disclosed a hexaarylbisimidazole like compound, a method for preparing the same, application thereof in the preparation of photooxidant or photoinitiator, as well as a composite containing the same. Compared with the prior hexaaryldiimidazole compound, the compound in the invention can absorb longer wavelength up to 410 nanometers, so the compound and the composite containing the same have higher photosensitivity.

Owner:王宝湖

Optical lens for camera

The invention discloses an optical lens for shooting, which comprises a first lens with positive refractive power, a second lens with negative refractive power and a third lens from an object side to an image side in turn, wherein an object side surface of the first lens is a convex surface; an object side surface of the second lens is a concave surface, and an image side surface of the second lens is a concave surface; the object side surface and the image side surface of the second lens are aspheric surfaces; an image side surface of the third lens is a concave surface; an object side surface and the image side surface of the third lens are aspheric surfaces; and at least one inflection point is arranged on the image side surface of the third lens. Three lenses with refractive power arearranged in the optical lens for shooting. Due to the configuration mode of the lens, the total length of the lens can be effectively shortened, the sensitivity of an optical system is reduced, and high imaging quality is achieved.

Owner:LARGAN PRECISION

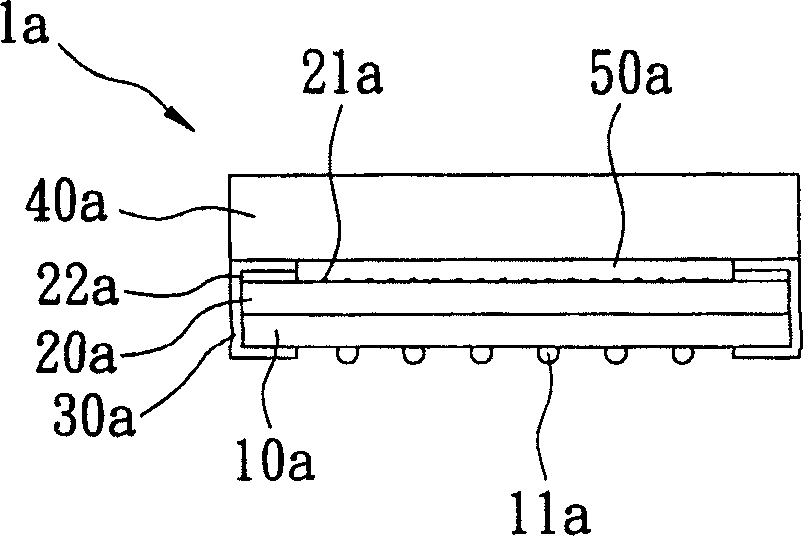

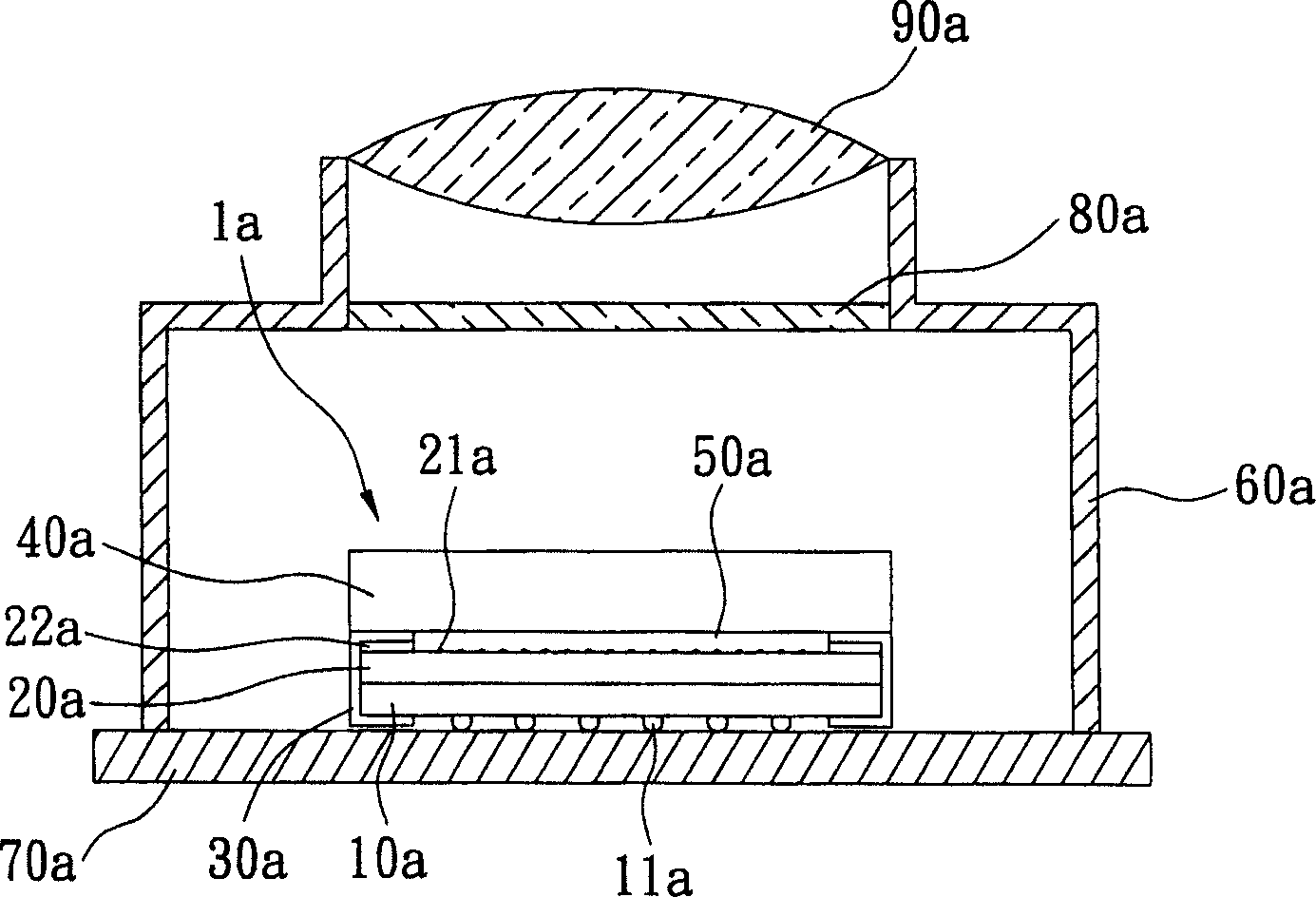

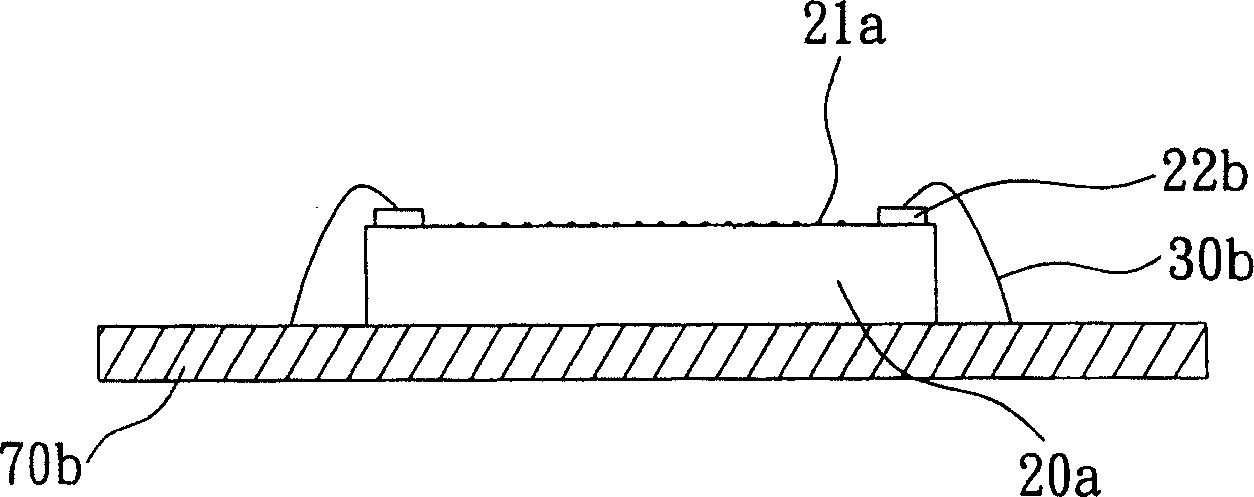

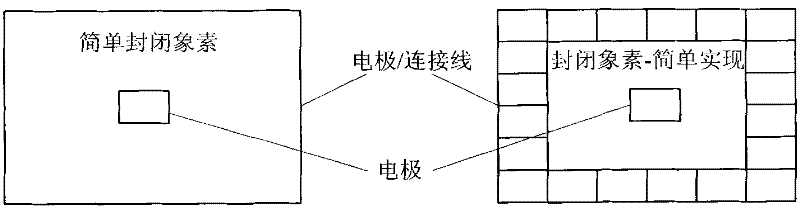

Method and equipment for fabricating structure of compound crystal

InactiveCN1761042ASimple processLow costSemiconductor/solid-state device detailsSolid-state devicesComputer moduleEngineering

The method improves capability of technique for packing tranditional photoelectric chip for example chip of optical sensor. Photoelectric chip is bonded on prearranged position of transparent base plate (such as glass base plate), where there is circuit layout. A joining pad connects the photoelectric chip to the transparent base plate at the prearranged place. After an existed sealed hollow interlayer is detected, then structure of each chip is cut to each simple piece, which is assembled to module according to specification. Being different to traditional encapsulation, the invention raises rate of good product, and saves material.

Owner:欣相光电股份有限公司

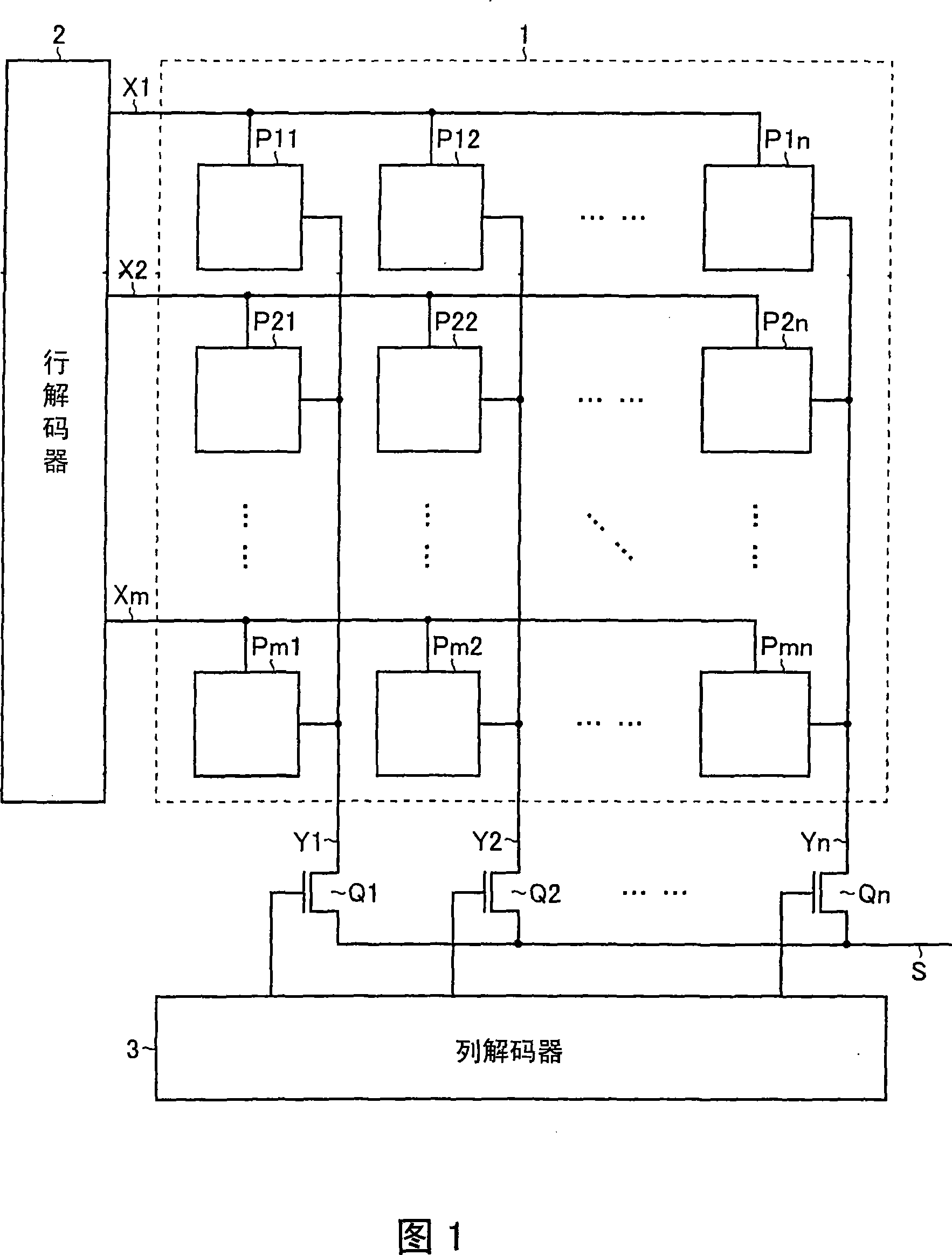

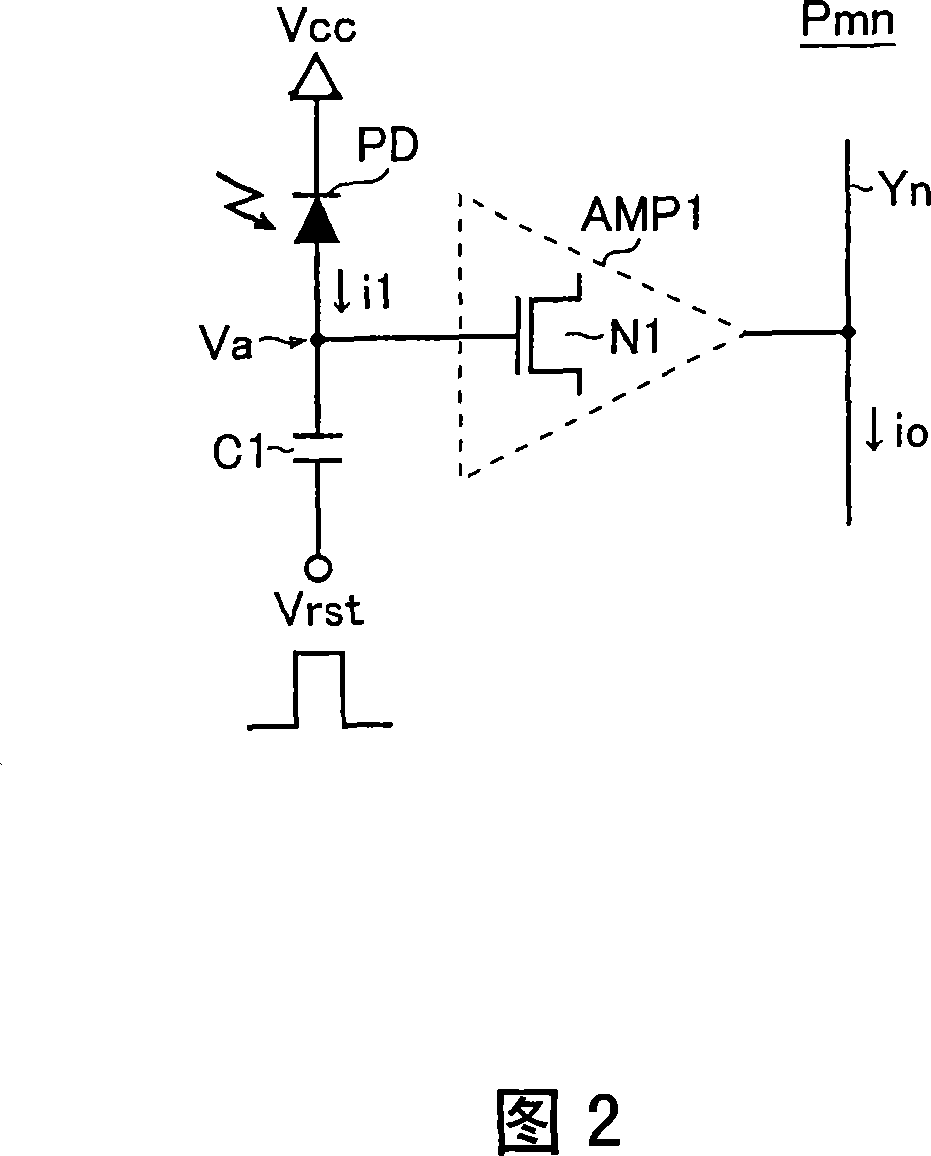

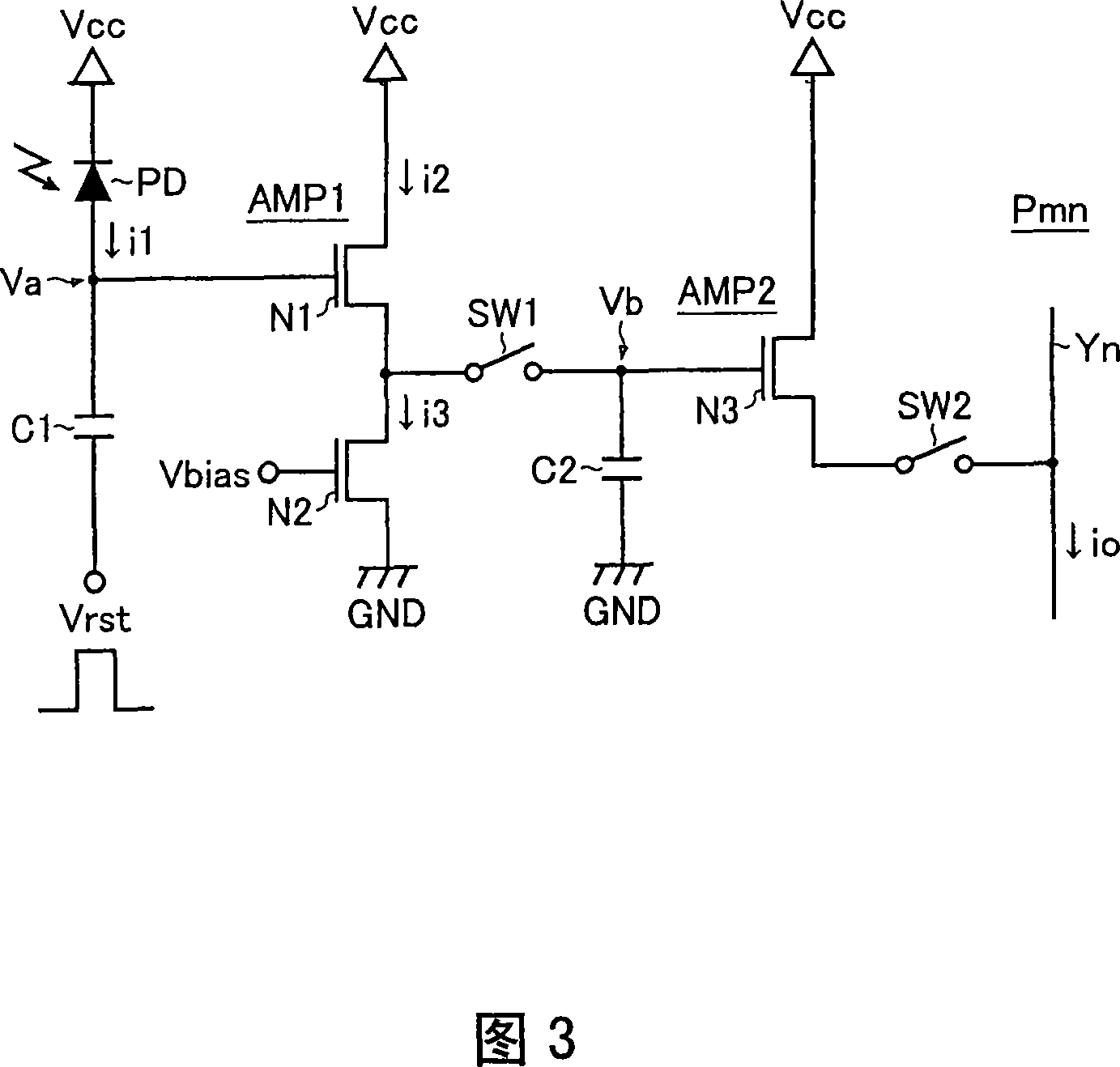

Photoelectric conversion circuit and solid-state image-sensing device using it

InactiveCN101102423AImprove S/N ratioImprove photosensitivityTelevision system detailsTelevision system scanning detailsAudio power amplifierTerminal voltage

A photoelectric conversion circuit has: a photoelectric conversion element that produces a detection current commensurate with the amount of light received thereby; a capacitor having one end connected to one end of the photoelectric conversion element, the one end of the capacitor from which a terminal voltage commensurate with the integral of the detection current is drawn; and an amplifier that receives the terminal voltage of the capacitor and produces an amplified signal commensurate with the terminal voltage thus received. The photoelectric conversion circuit outputs a final optical signal (an output current) by using the amplified signal of the amplifier. As a current path that can serve as a charging / discharging path of the capacitor, the photoelectric conversion circuit includes only a current path along which the photoelectric conversion element is located. With this configuration, it is possible to enhance responsivity to light and improve the S / N ratio of a received optical signal by making the most of electric power obtained from a photoelectric conversion element.

Owner:ROHM CO LTD

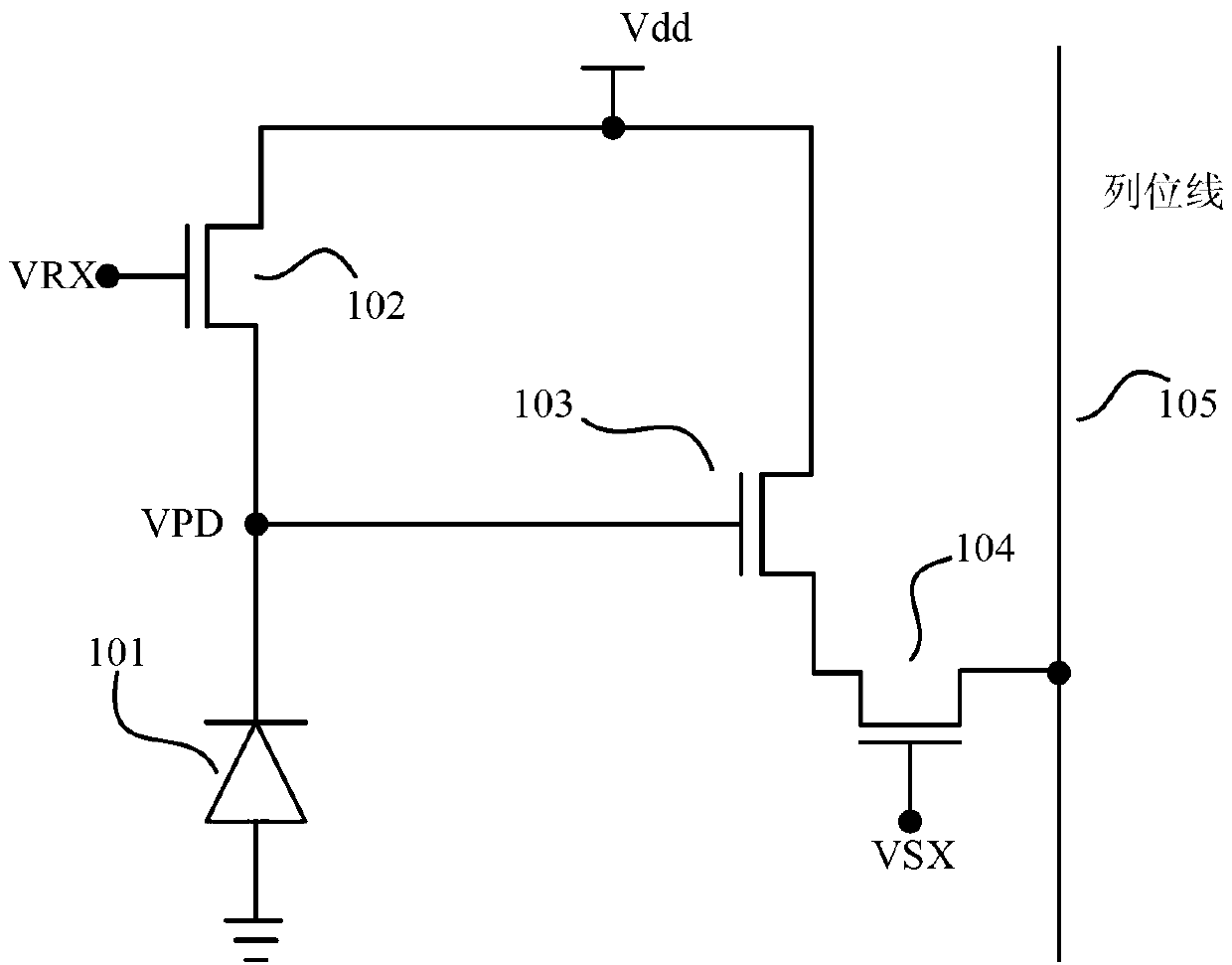

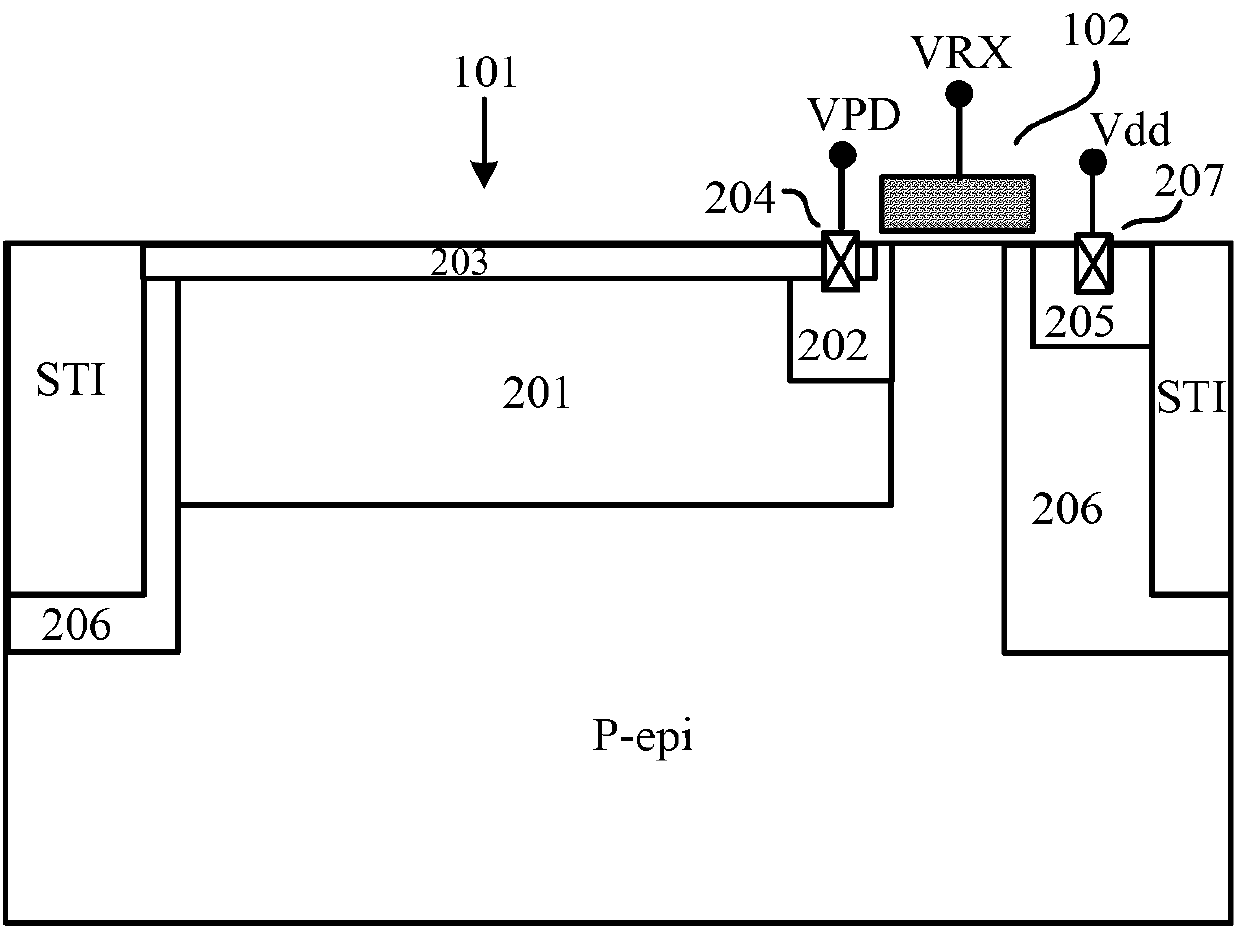

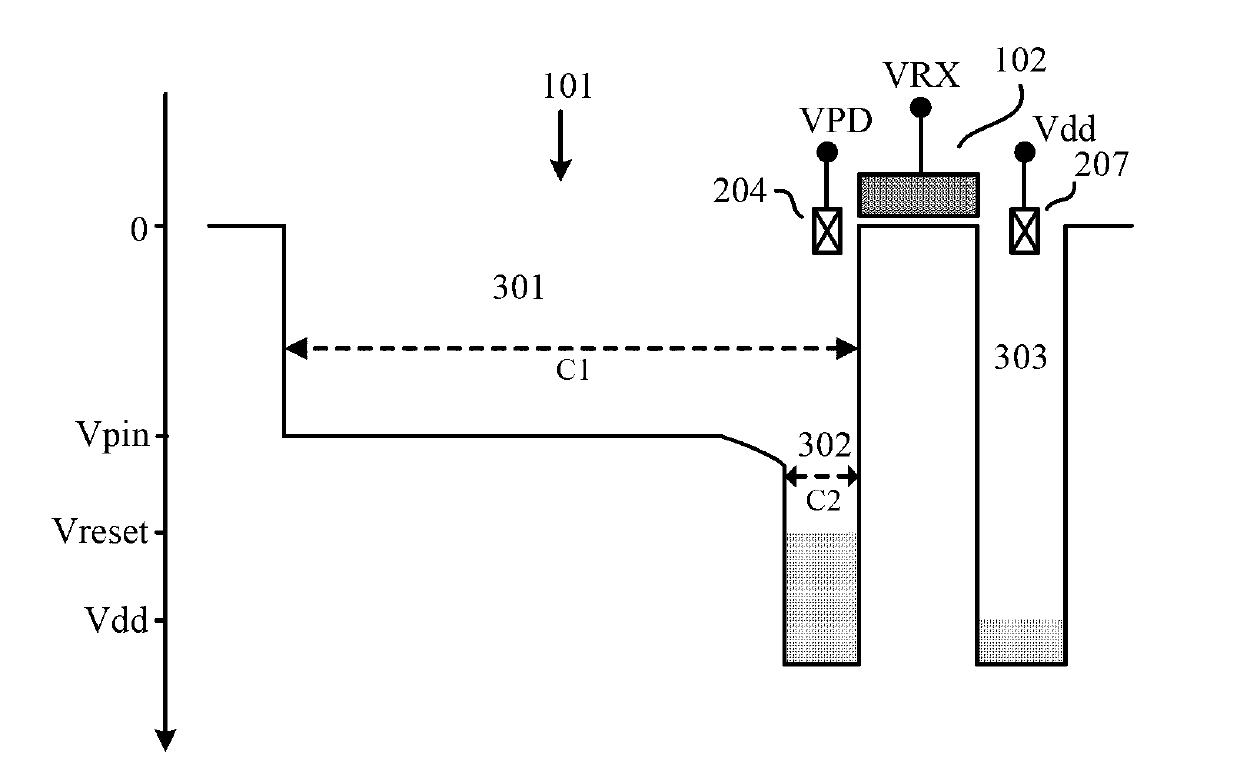

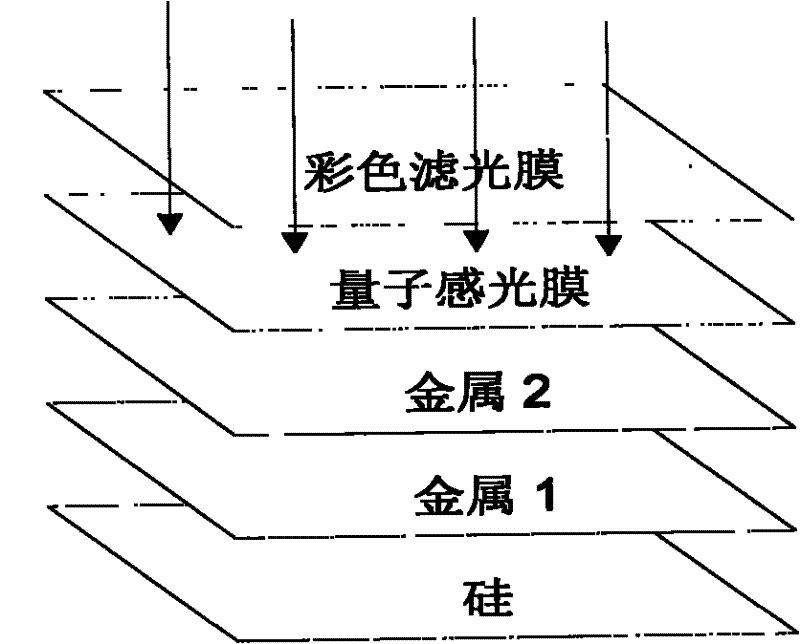

Active pixel of complementary metal oxide semiconductor (CMOS) image sensor and CMOS image sensor

ActiveCN103139497AHigh sensitivityImprove photosensitivityTelevision system detailsColor television detailsCMOSElectricity

The invention discloses an active pixel of a complementary metal oxide semiconductor (CMOS) image sensor. The active pixel at least comprises a photosensitive component which is placed inside a semi-conductor substrate, a reset transistor and a source following transistor which are connected with the photosensitive component, a switch transistor, and a row positioning line. The pixel photosensitive component of the image sensor comprises two photosensitive regions, namely a low dose foreign ion injection region, and a high dose foreign ion injection region near the reset transistor. When in low illumination, photo-electricity charge generated in the photosensitive component is only collected in the high dose foreign ion injection region, grain of photo-electricity transition is high, and sensitivity of the sensor is high. When in high illumination, photo-electricity charge generated in the photosensitive component is collected in the whole photosensitive component. Therefore, the active pixel can effectively improve the luminous sensitivity of the image sensor in the low illumination, and the sensor collects more real object detail information when in the low illumination.

Owner:BEIJING SUPERPIX MICRO TECHNOLOGY CO LTD

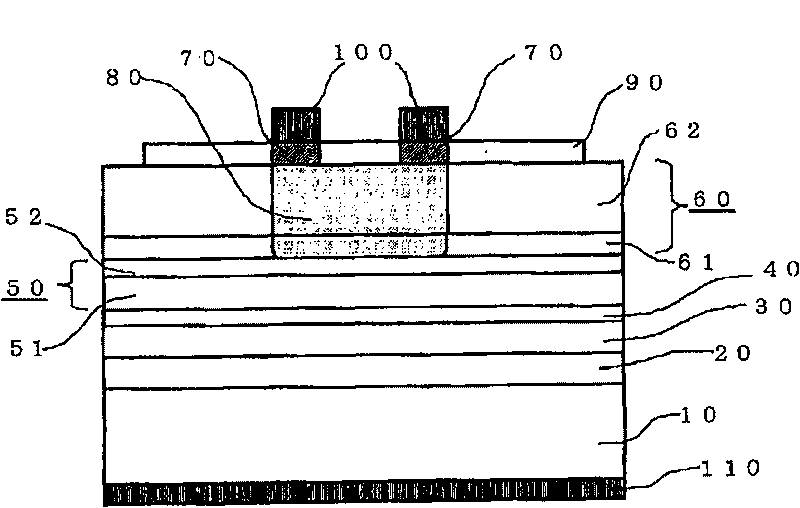

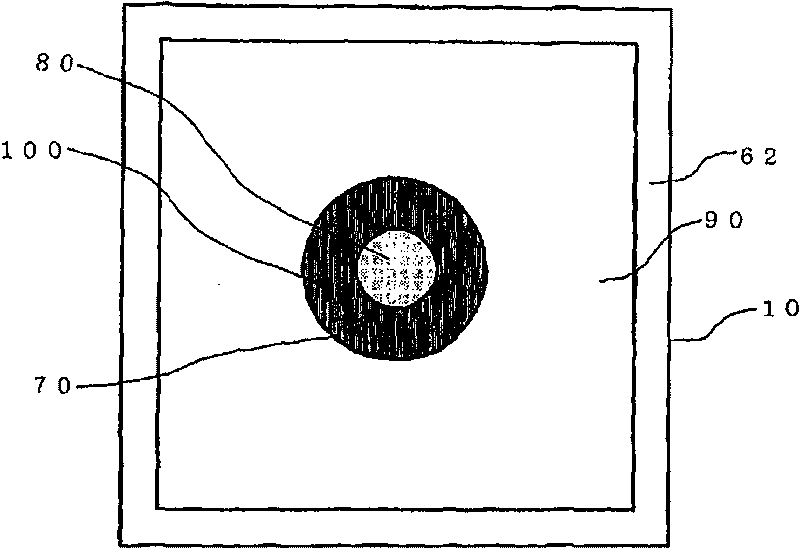

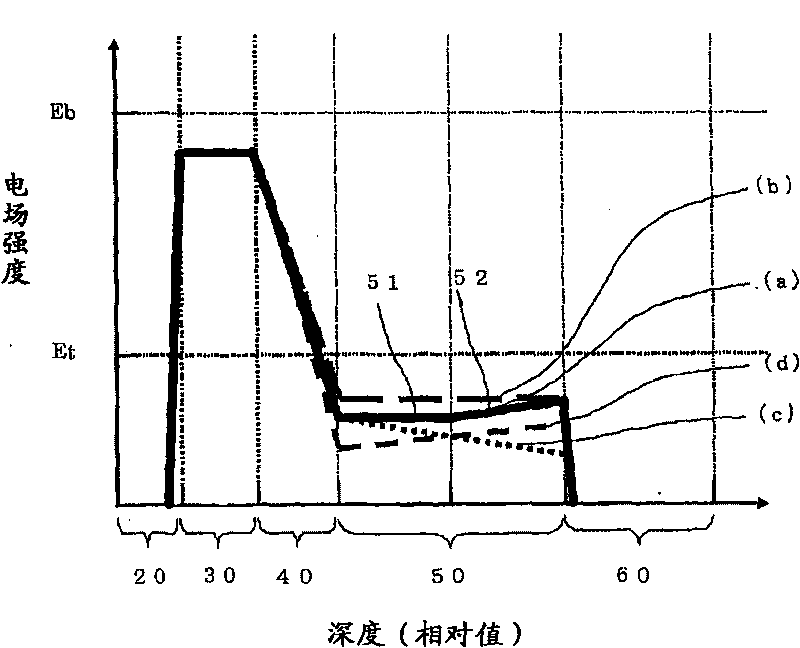

Avalanche photodiode

InactiveCN101752446ALess power consumptionImprove photosensitivitySemiconductor devicesOpto electronicElectron avalanche

The conventional avalanche photodiodes are not easy to be fabricated, because if the light absorption layer is in un-doped type, the bias voltage during operation is high, and if the light absorption layer is only slightly doped, the doping amount thereof is hard to be controlled. To this end, the invention provides an avalanche photodiode comprises: a substrate of a first conductivity type; and an avalanche multiplication layer, a light absorption layer, and a window layer which are sequentially laminated from the substrate, wherein a part of the window layer is a region of a second conductivity type, and the light absorption layer includes a first light absorption layer, and a second light absorption layer which has higher electric conductivity than electric conductivity of the first light absorption layer.

Owner:MITSUBISHI ELECTRIC CORP

Single layer organic photoelectric conductor containing fluoroperylene imide and its preparing method

InactiveCN1365120AIncreased electron affinityEnhanced electron transport capabilitiesNon-conductive material with dispersed conductive materialElectrography/magnetographyImideElectricity

The preparation process to single layer organic phhotoelectric conductor containing Fluoroperylene imide includes the steps of: mixing carrier generating material and carrier converying material in the weight ratio of 1 to 10-100 and dissolving in solvent to obtain organic photoconductive solution with solid content of 5-40 wt%; and dip coating the solution to conducting substrate and eliminating solvent to obtain single layer organic photoelectric conductor film of 5-40 micron thickness. The present invention uses Fluoroperylene imide as organic photoelectric conductor and prepares the photoelectric conductor through direct dissolving and coating process. The phoeoelctric conducting has high photosensitive sensitivity and small dark conductance and may be work in positive and negative voltage.

Owner:ZHEJIANG UNIV

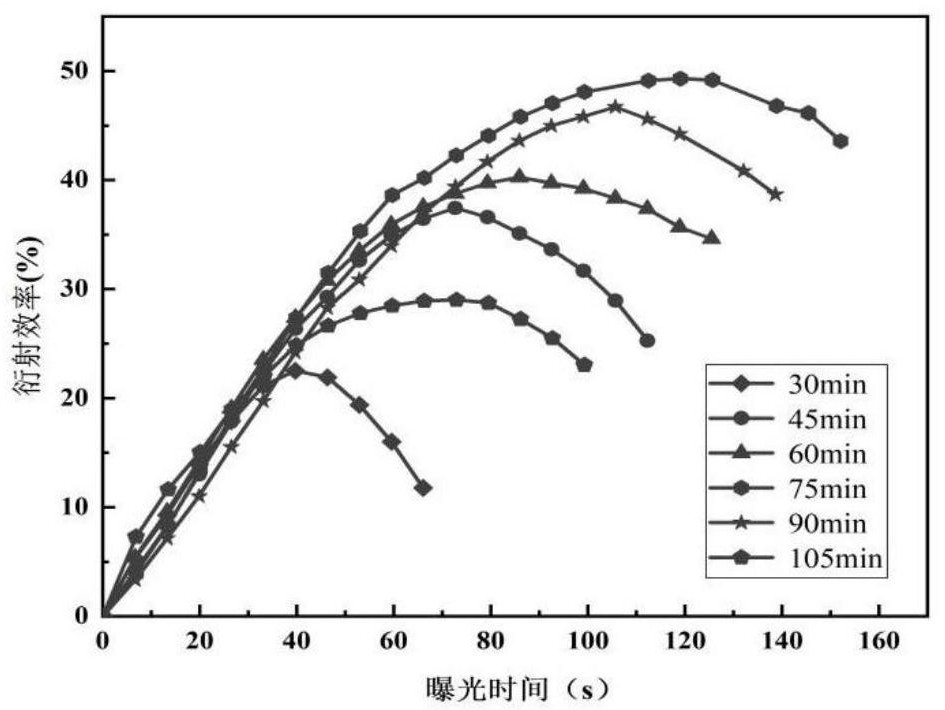

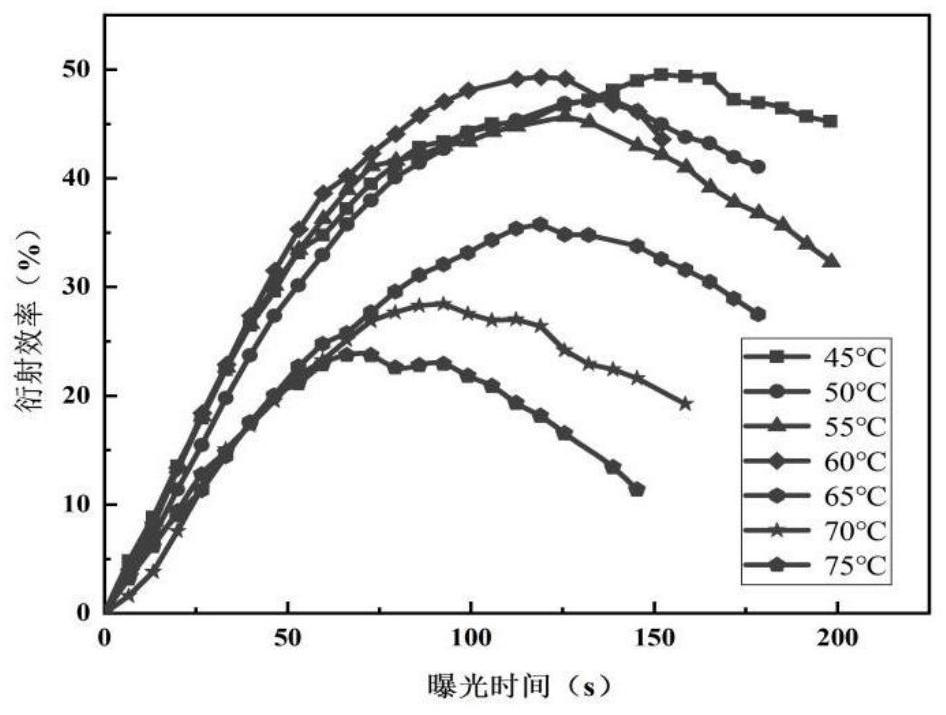

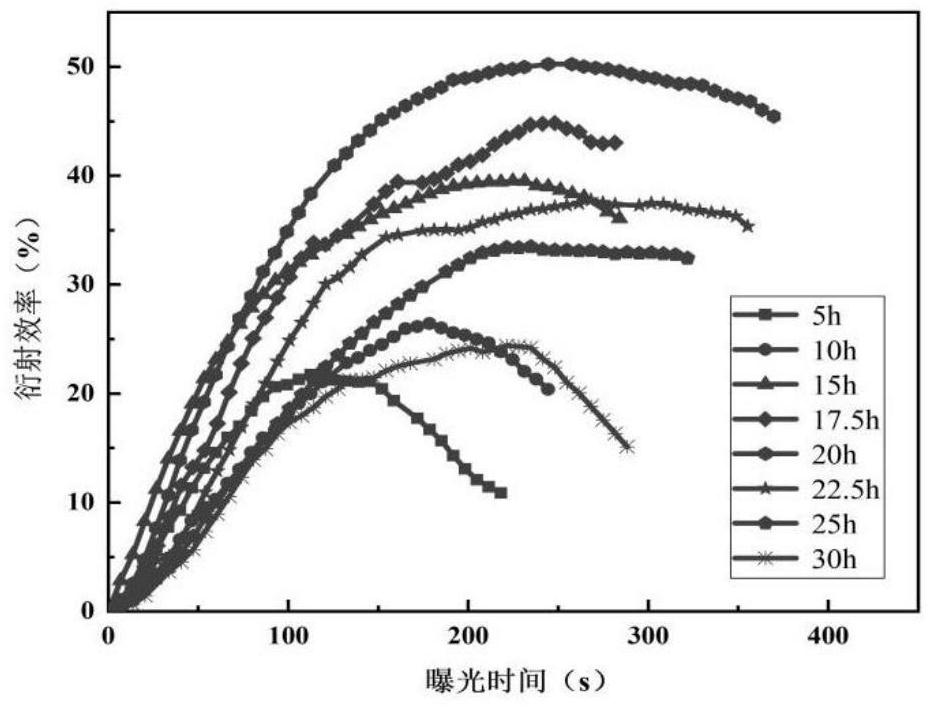

Thermal polymerization process of PQ/PMMA photopolymer material, PQ/PMMA photopolymer material and holographic optical disc thereof

InactiveCN112812210AGood optical performanceImprove material stabilityRecord carrier materialsHolographic storagePolymer science

The invention discloses a thermal polymerization process of a PQ / PMMA photopolymer material, the PQ / PMMA photopolymer material and a holographic optical disc thereof. The thermal polymerization process comprises the following steps: weighing and proportioning raw materials including MMA, AIBN and PQ according to a preset mass ratio, and oscillating and uniformly mixing the proportioned mixture to obtain a mixed solution of the raw materials; carrying out prepolymerization stirring on the uniformly mixed solution to obtain a viscous substance; and pouring the viscous substance into a mold, baking the viscous substance to change the viscous substance into a solidified PQ / PMMA photopolymer material, and then removing the mold. From the perspective of a material preparation thermal polymerization process, the optical properties, such as diffraction efficiency and photosensitive sensitivity, of the material are further improved, so that the material can be better applied to optical holographic storage.

Owner:FUJIAN NORMAL UNIV

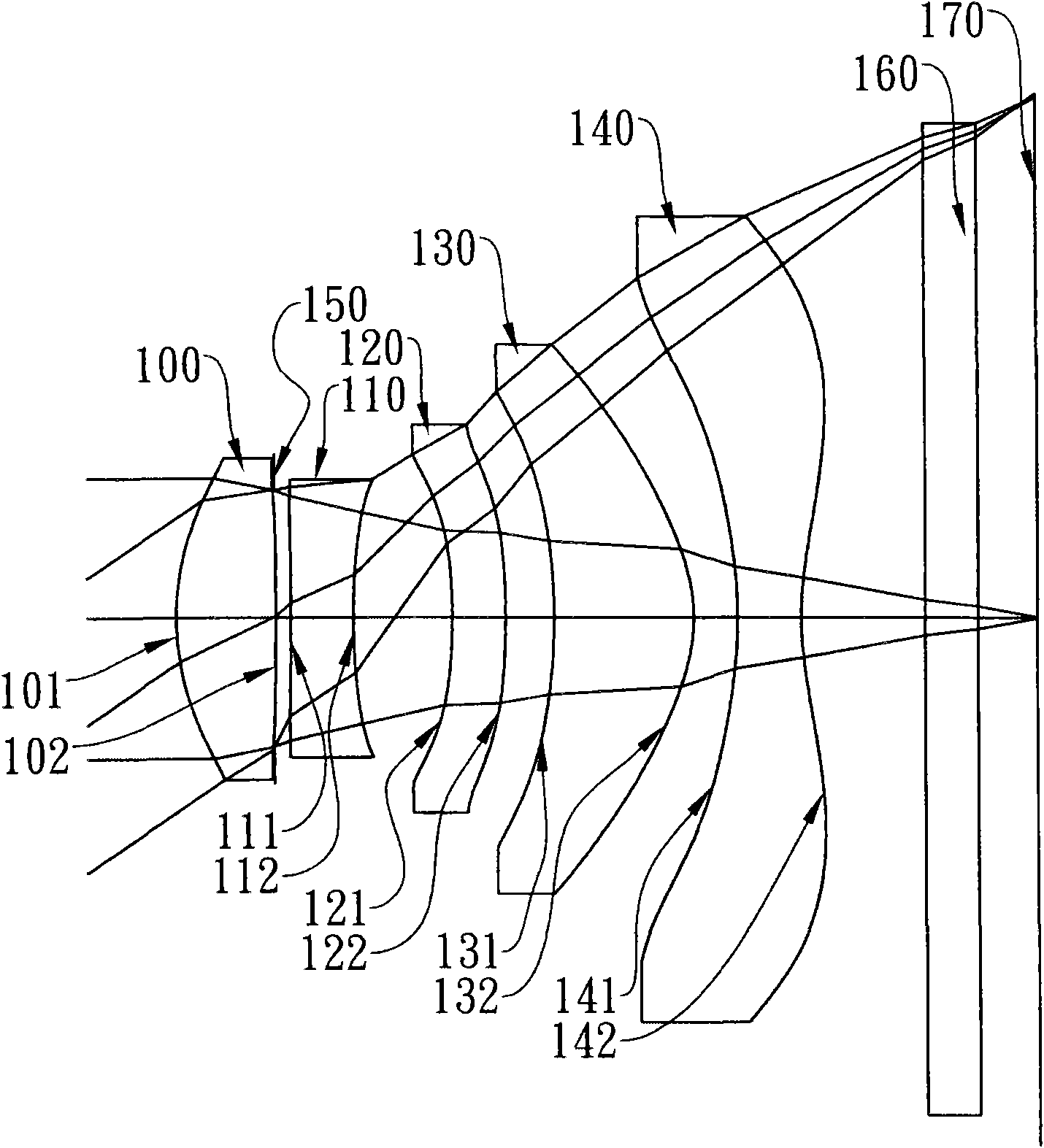

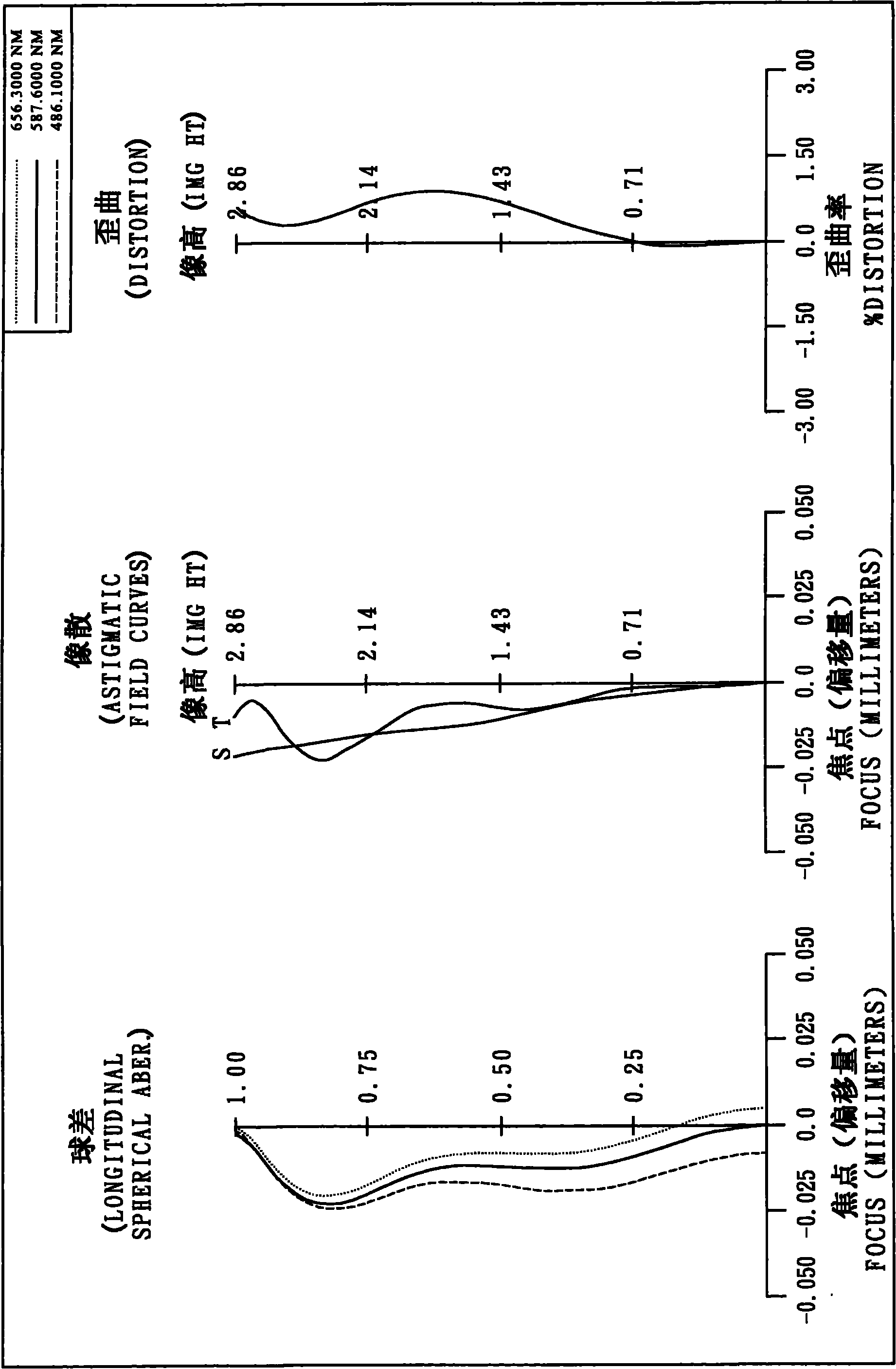

Optical imaging system

The invention provides an optical imaging system, which sequentially comprises a first lens with a positive refraction force, a second lens with a negative refraction force, a third lens with a positive refraction force and a fourth lens from an object side to an image side, wherein the object side surface of the first lens is a convex surface, and the image side surface of the first lens is a concave surface; the object side surface of the second lens is a convex surface, and the image side surface of the second lens is a concave surface; the image side surface of the fourth lens is a concave surface, and at least one of the object side surface and the image side surface of the fourth lens is an aspheric surface; wherein, the optical imaging system is also provided with an aperture and an electronic photographic element for imaging a shot object, wherein the aperture is arranged between the shot object and the first lens; and the optical imaging system has four lenses with refraction forces. By the configuration mode of the lens group, the lens volume can be effectively reduced, the sensitivity of the system is reduced, and high resolving power can be obtained.

Owner:LARGAN PRECISION

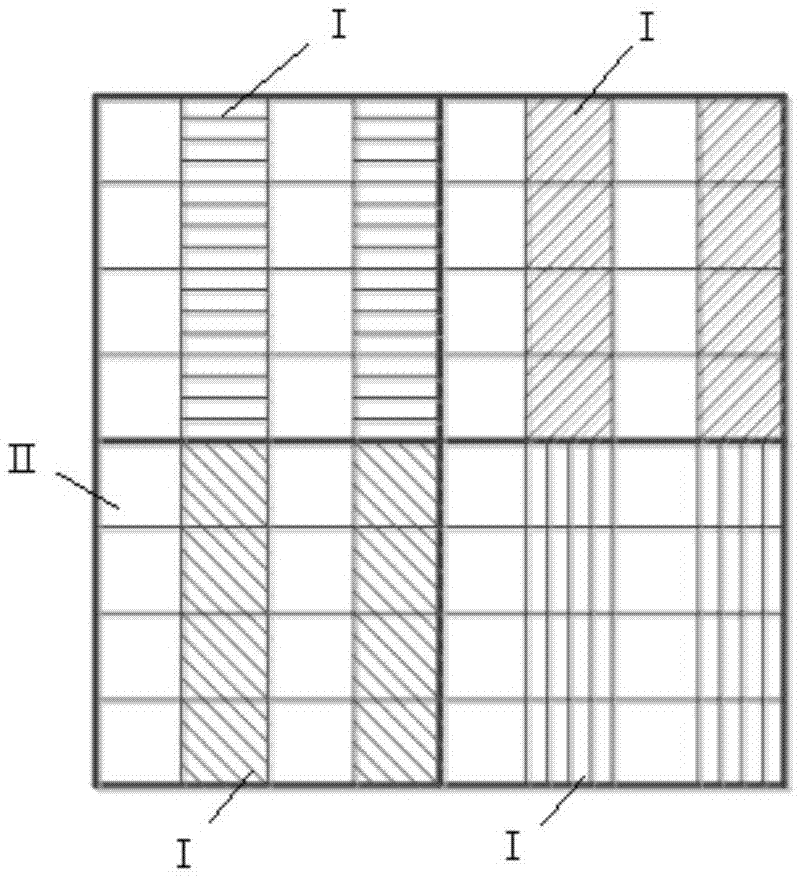

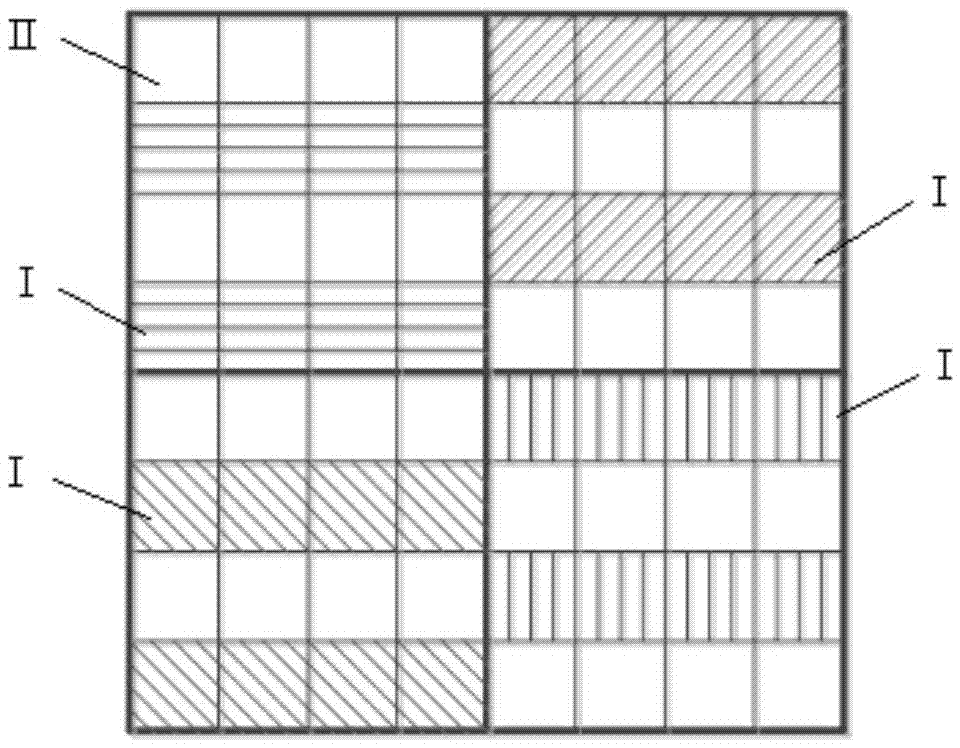

Mixed multispectral photosensitive pixel group, photosensitive device and photosensitive system

ActiveCN102244083AReduce manufacturing difficultyImprove photosensitivityTelevision system detailsColor television detailsUltravioletFar infrared

The invention relates to a mixed multispectral photosensitive pixel group, a photosensitive device and a photosensitive system. The mixed multispectral photosensitive pixel group comprises at least one photosensitive pixel of chemical coating and at least one photosensitive pixel of semiconductor. In the invention, the photosensitive pixel of chemical coating is combined with the photosensitive pixel of semiconductor to generate the mixed multispectral photosensitive pixel so that a plurality of color signals and other spectrum signals can be simultaneously obtained, incident photon energy can be maximally used and an upper bound of a photoelectric conversion efficiency theory can be or almost be reached. Images of other spectrums, such as an ultraviolet image, a near infrared image and a far-infrared image, can be acquired and simultaneously colors can be completely reconstructed.

Owner:BOLYMEDIA HLDG

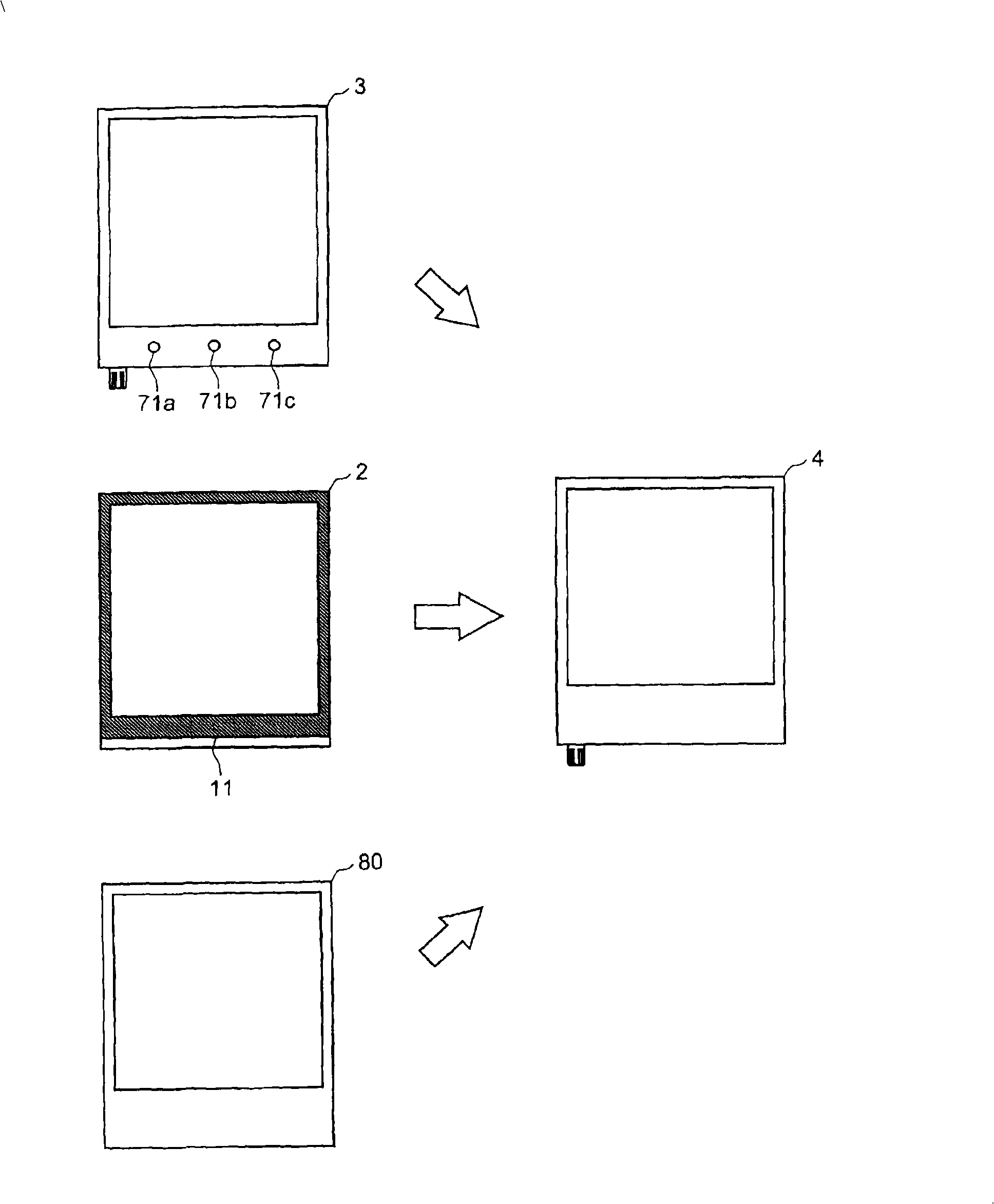

Method of manufacturing touch control display device

ActiveCN107272964AHigh carrier mobilityIncrease luminous fluxSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorDisplay device

A method of manufacturing a touch control display device includes the following steps: forming a sensing element on a substrate, and forming a sensing signal line electrically connected with the sensing element; the step of forming the sensing element includes: forming a semiconductor layer on the substrate, the semiconductor layer including a semiconductor pattern of the sensing element; forming a gate insulating layer on the semiconductor layer; forming a first conductor layer on the gate insulating layer; forming an interlaye insulating layer on the gate insulating layer; performing a tempering process; after the tempering process, removing the interlayer insulating layer in a gate predetermined region; removing the first conductor layer in the gate predetermined region; forming a gate in the gate predetermined region; and forming a second conductor layer, wherein the second conductor layer includes a source electrode and a drain electrode of the sensing element that are electrically connected with the semiconductor pattern of the sensing element.

Owner:AU OPTRONICS CORP

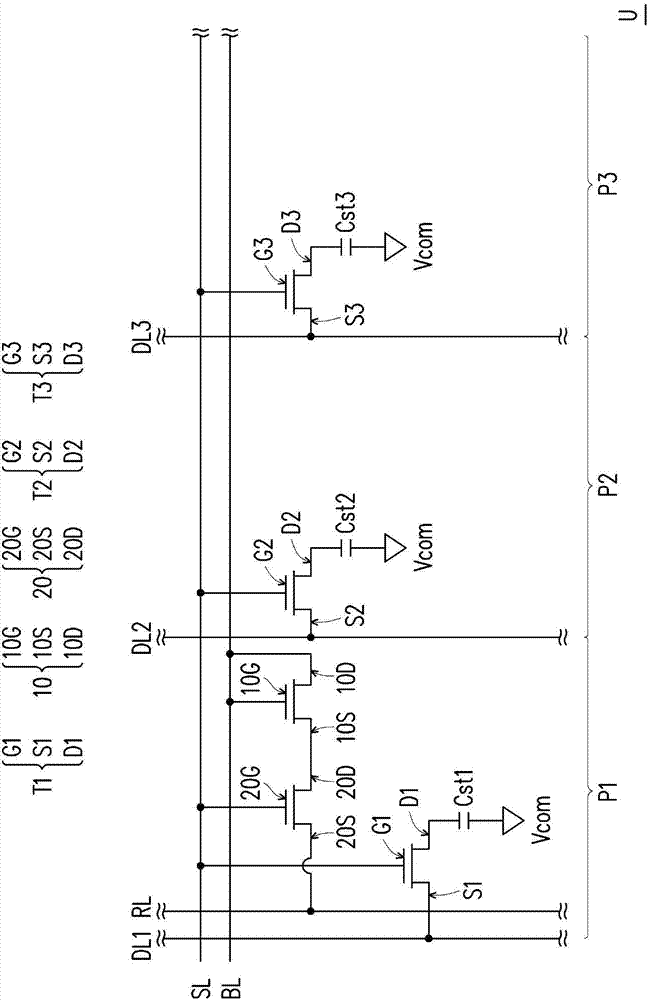

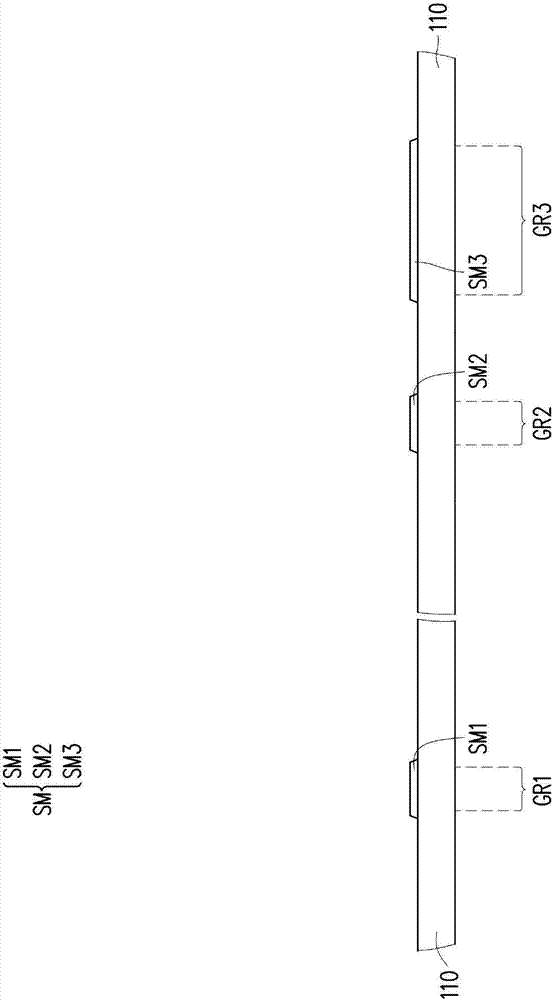

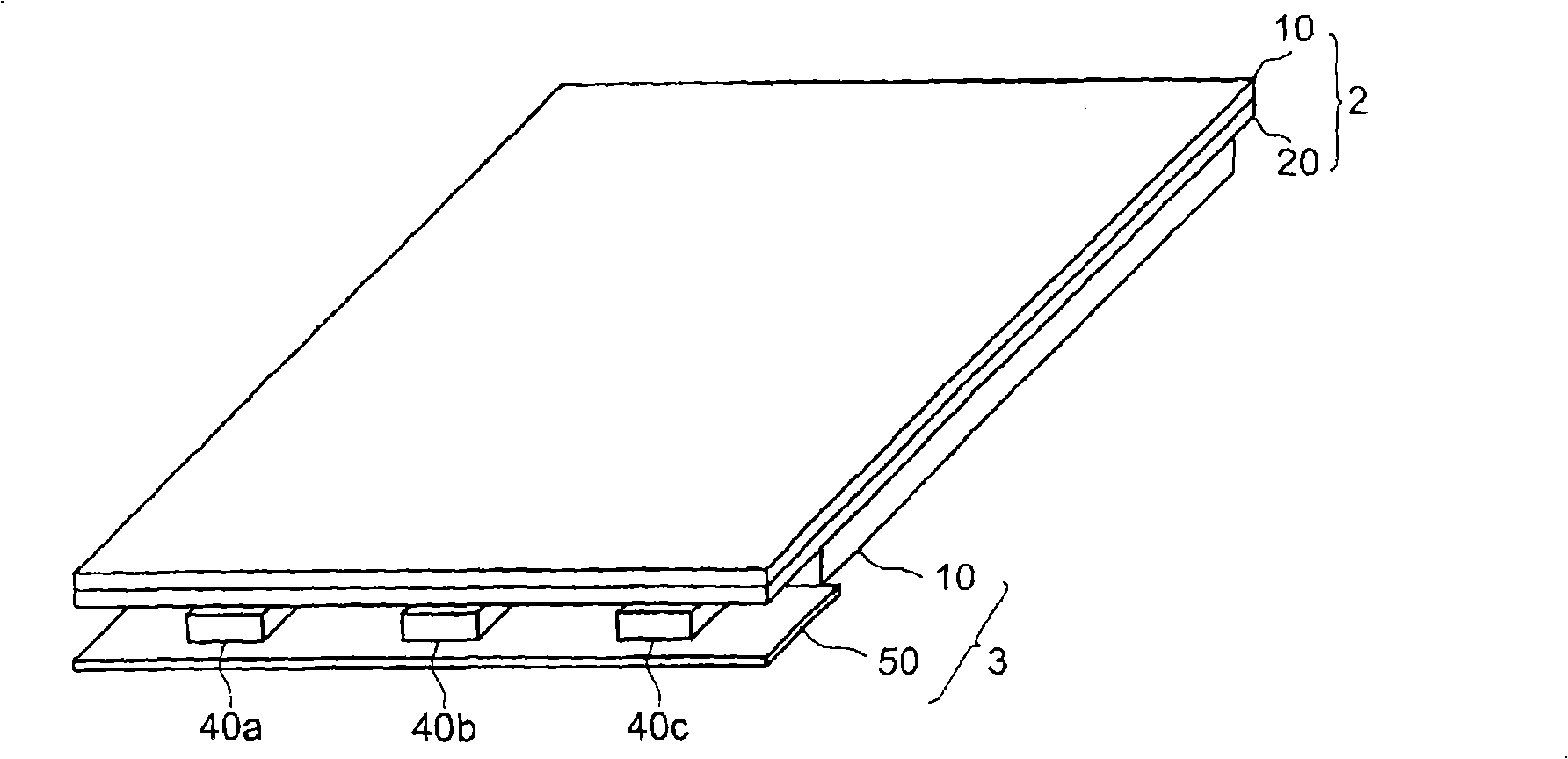

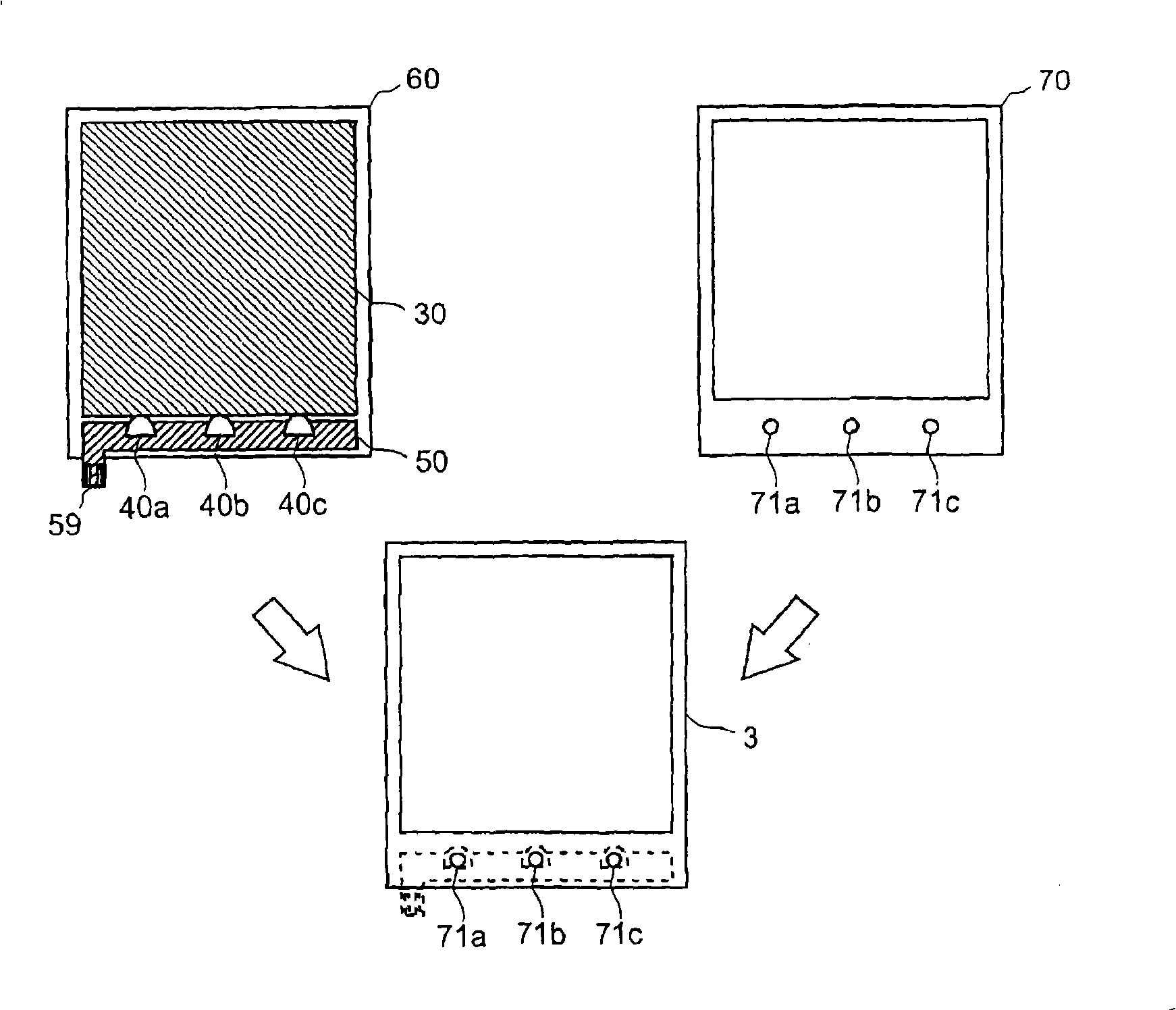

Display device

InactiveCN101313352ASimple compositionNot prone to flickerStatic indicating devicesNon-linear opticsDisplay deviceEngineering

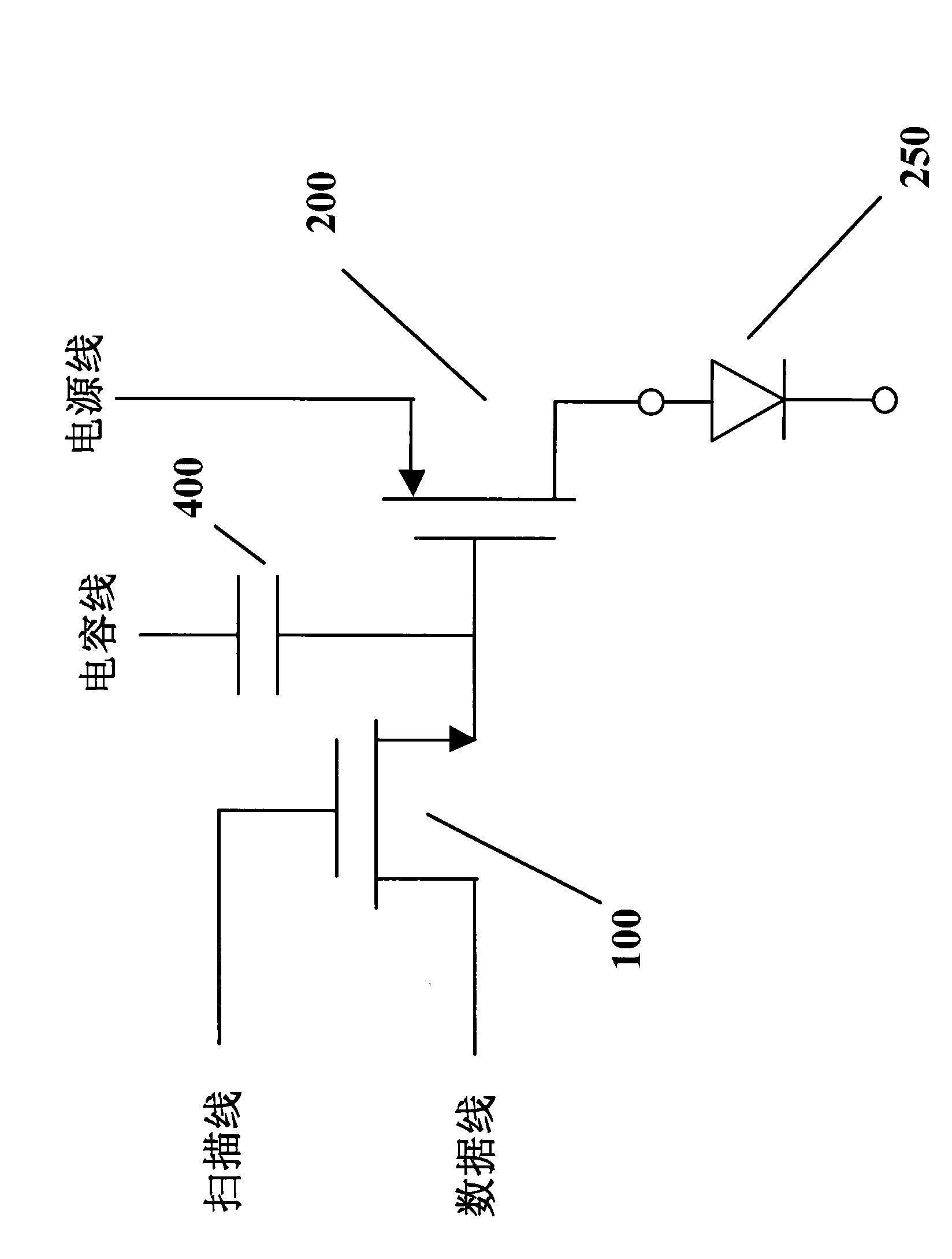

A display device provided with a signal transmitting mechanism, which has reduced number of pins of an FPC substrate to be connected with a TFT substrate or eliminates such pins and is easily applicable even to a small device. The display device is provided with a light receiving element (90) formed on the TFT substrate of a liquid crystal panel (2), a receiving circuit (100), a display control circuit (200), a video signal line drive circuit (300), a scanning signal line drive circuit (400), a display section (500), and white LEDs (40a-40c) and a LED drive circuit (51) included in a backlight section (3). The LED drive circuit (51) drives a white LED (40) which emits light by an optical (modulation) signal (LS) corresponding to a video signal (VS) given from the external of the device. The receiving circuit (100) generates (demodulates) the video signal (VS) from the signal received through the light receiving element (90).

Owner:SHARP KK

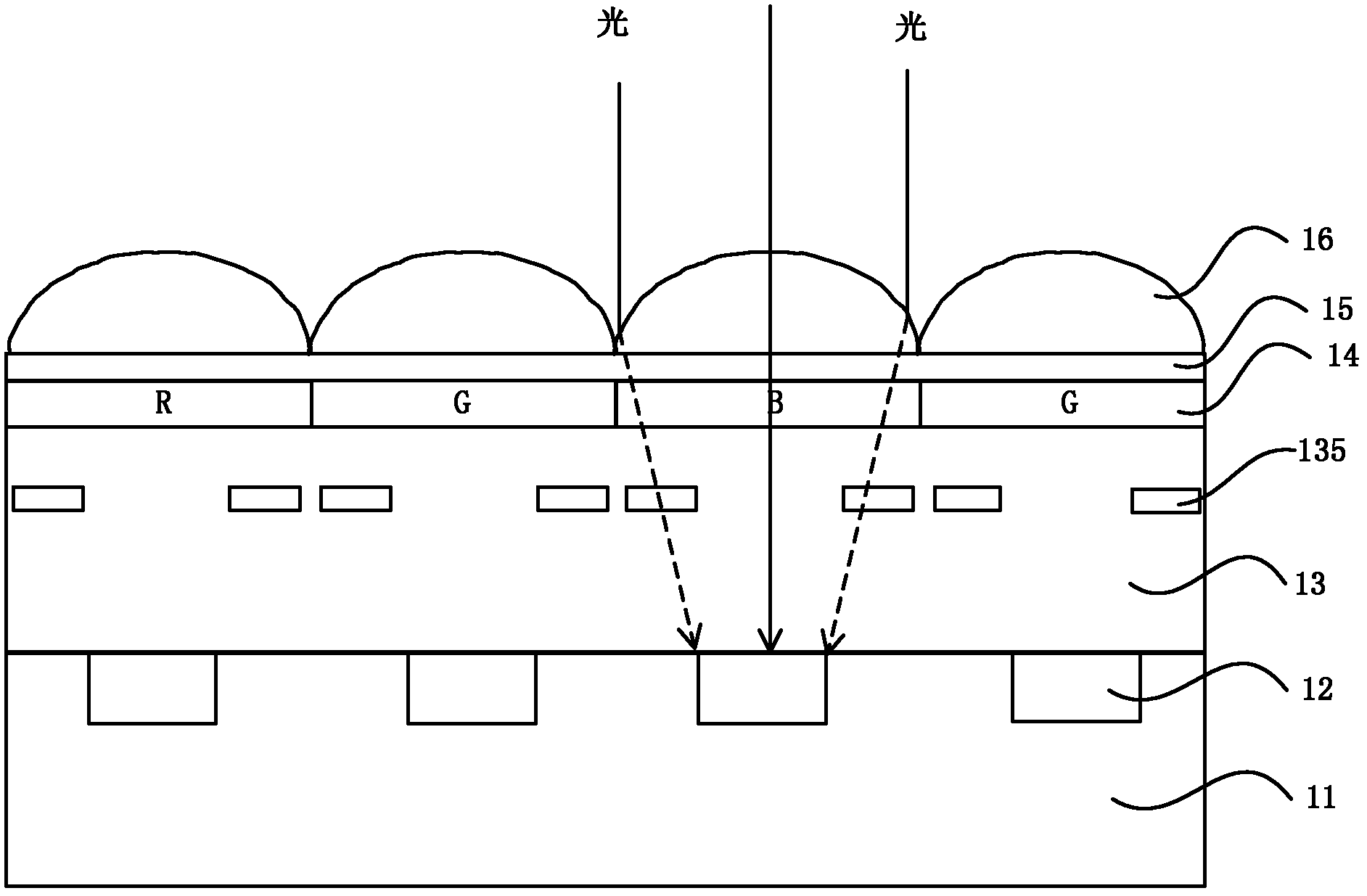

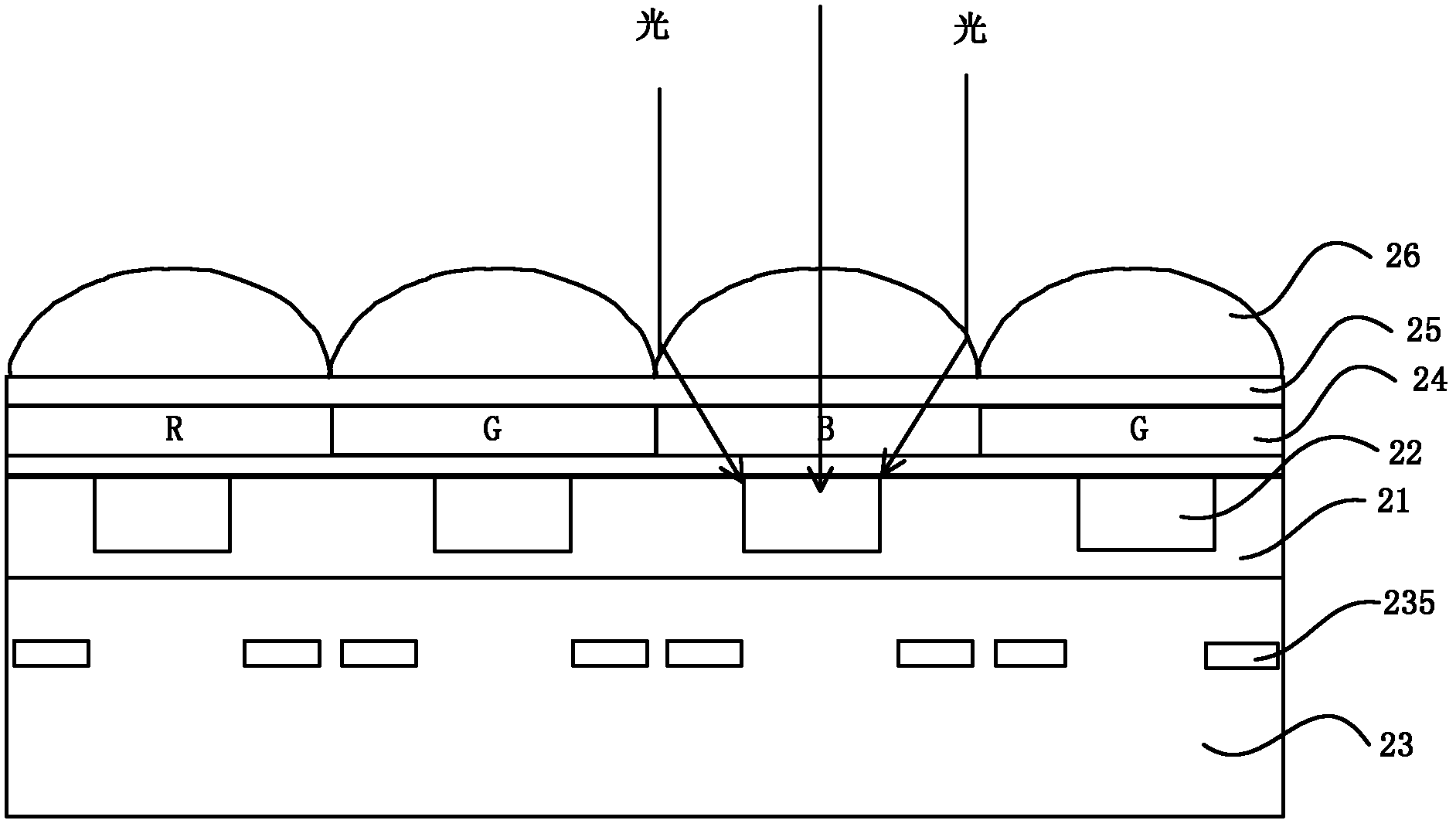

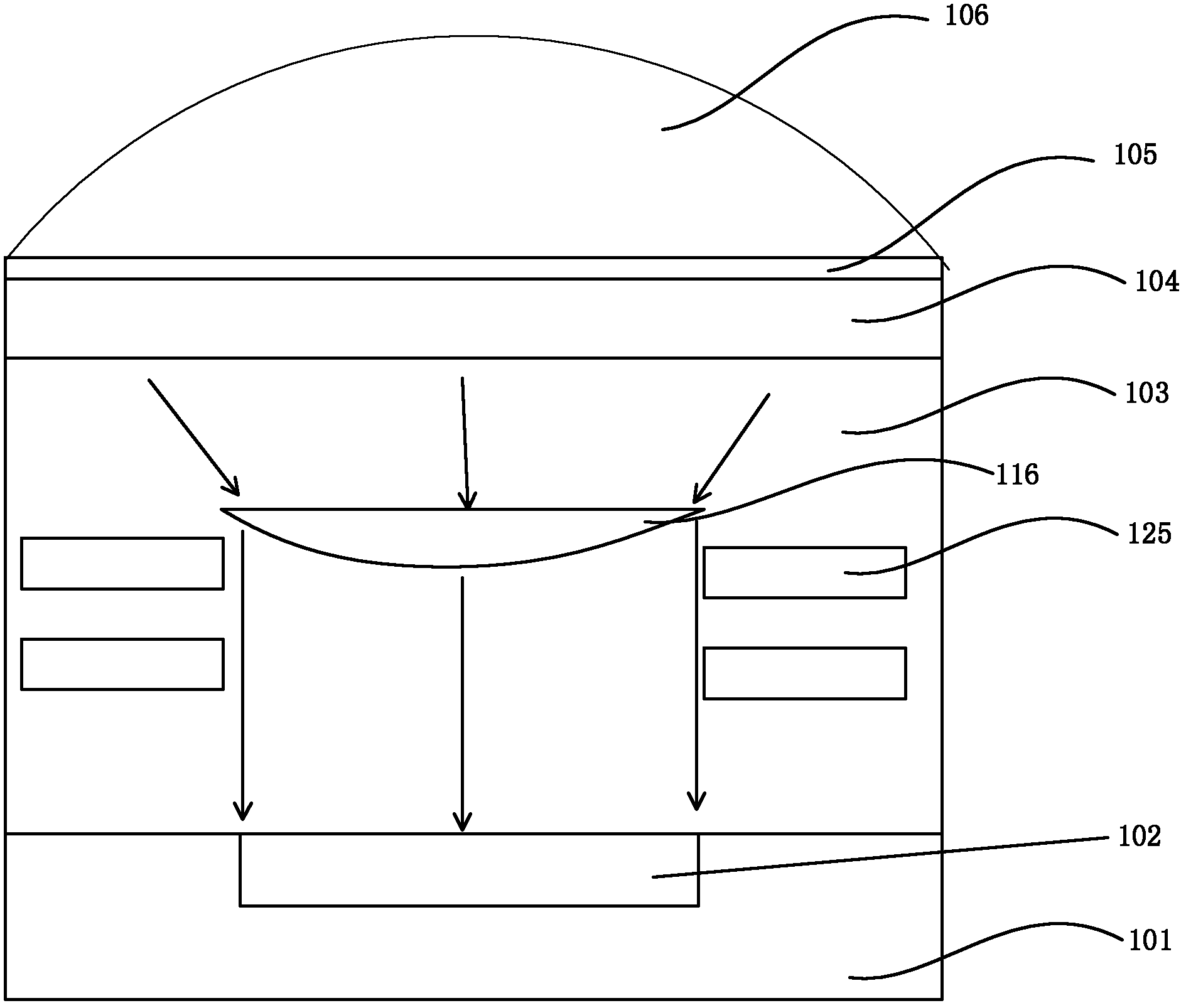

CMOS (complementary metal oxide semiconductor) image sensor and manufacturing method thereof

InactiveCN102522415AImprove photosensitivityNo need to increase production costTelevision system detailsColor television detailsCMOSPhotodiode

The invention provides a CMOS (complementary metal oxide semiconductor) image sensor and a manufacturing method thereof. The CMOS image sensor comprises a photodiode, a first micro lens and a metal connection layer, wherein the first micro lens is used for focusing the incident light to a position where the photodiode is arranged, and the metal connection layer is positioned between the photodiode and the first micro lens and exposes at least part of the photodiode. The CMOS image sensor further comprises a second micro lens which is arranged between the first micro lens and the photodiode and positioned outside the metal connection layer. Since the second micro lens is additionally arranged between the first micro lens and the photodiode, luminous sensitivity of the CMOS image sensor is improved with manufacturing cost barely increased.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Optical module and mobile terminal

ActiveCN110321832AReduce thicknessSmall footprintDigital data processing detailsSolid-state devicesOptical ModuleAdhesive

The invention discloses an optical module and a mobile terminal, the optical module comprises a collimator, a photosensitive unit and a wiring structure, the photosensitive unit is arranged on the surface of one side of the collimator, and the wiring structure is arranged on the surface of the side, deviating from the collimator, of the photosensitive unit. The photosensitive unit and the wiring structure are directly formed on the surface of one side of the collimator. Therefore, the photosensitive unit and the wiring structure do not need to be bonded with the collimator through an adhesive,and a bearing substrate does not need to be added for forming the photosensitive unit and the wiring structure, so that the thickness of the whole optical module is reduced, and the occupied space ofthe optical module is smaller. Meanwhile, after the adhesive between the photosensitive unit and the collimator and the adhesive between the wiring structure and the collimator are omitted, the distance between the photosensitive unit and the display screen of the mobile terminal and the distance between the wiring structure and the display screen of the mobile terminal are smaller, so that the signal strength is higher, and the photosensitive efficiency of the optical module is higher.

Owner:VIVO MOBILE COMM CO LTD

Production method for photoinitiator GR-FMT

Provided is a production method for a photoinitiator GR-FMT. The production method includes the following steps: adding dimethylbenzene and 2,5- dimethoxy tetrahydrofuran to a reaction kettle with inert atmosphere, cooling to -4 - 5 DEG C, then slowly dropwise adding 2,4-two fluoroaniline, heating to 50-60 DEG C, and maintaining the temperature for 5-10 hours; adding dimethylbenzene, heating to 140-145 DEG C for distillation; adding titanocene dichloride; cooling to -10- 40 DEG C, dropwise adding a catalyst of organic alkali amino lithium salt, reacting and synthesizing to obtain reaction liquid of the photoinitiator GR-FMT at -10 - 40 DEG C; heating to 15-30 DEG C, and chromatographing; maintaining the temperature and crystallizing; chromatographing, washing with dimethylbenzene, and draining to obtain wet product; and vacuum drying and obtaining the photoinitiator GR-FMT. The production method has the advantages of being fast in curing speed and not requiring heating.

Owner:HUBEI GURUN TECH CO LTD

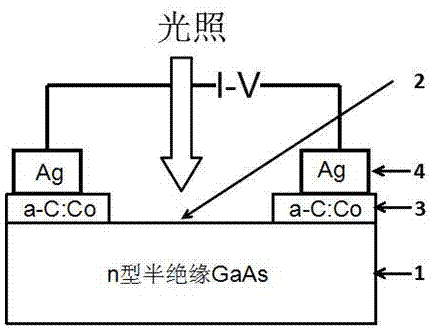

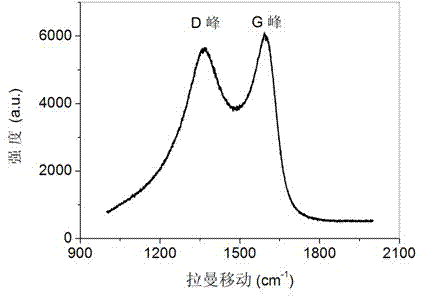

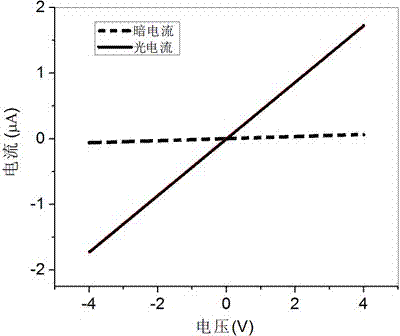

Novel n type semi-insulating GaAs ohmic contact electrode material and method for preparing novel n type semi-insulating GaAs ohmic contact electrode material

ActiveCN103794664AImprove linearityImprove photosensitivityFinal product manufactureSemiconductor devicesCarbon filmEvaporation (deposition)

The invention provides a novel n type semi-insulating GaAs ohmic contact electrode material and a method for preparing the novel n type semi-insulating GaAs ohmic contact electrode material. According to the method for preparing the novel n type semi-insulating GaAs ohmic contact electrode material, an undoped n type semi-insulating GaAs substrate is adopted to serve as an electrode bottom layer, two electrode areas on the substrate are plated with Co-doped amorphous carbon (a-C) films with the pulsed laser deposition method, the amorphous carbon films are plated with Ag with the vacuum heat evaporation method, and then the novel n type semi-insulating GaAs ohmic contact electrode material is obtained. According to various data detection results, the novel n type semi-insulating GaAs ohmic contact electrode material has the advantages that the I-V curve of an electrode has good linear relation and symmetric relation, all performance indexes meet requirements of stable contact electrodes, the luminous sensitivity is high, and the material can be successfully applied to devices relevant to n type semi-insulating GaAs; compared with a preparing technology in the prior art, the method for preparing the novel n type semi-insulating GaAs ohmic contact electrode material has the advantages that the processes are simple, cost is low, and the economic benefit is good.

Owner:HUAIYIN TEACHERS COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for preparing negative photosensitive polyimide based on 2,2-di[4-(2,4-diaminophenyloxy)phenyl]hexafluoropropane Method for preparing negative photosensitive polyimide based on 2,2-di[4-(2,4-diaminophenyloxy)phenyl]hexafluoropropane](https://images-eureka.patsnap.com/patent_img/fa404351-10dd-49df-9e89-119ad27fa20f/a20081003650500221.PNG)

![Method for preparing negative photosensitive polyimide based on 2,2-di[4-(2,4-diaminophenyloxy)phenyl]hexafluoropropane Method for preparing negative photosensitive polyimide based on 2,2-di[4-(2,4-diaminophenyloxy)phenyl]hexafluoropropane](https://images-eureka.patsnap.com/patent_img/fa404351-10dd-49df-9e89-119ad27fa20f/a20081003650500041.PNG)

![Method for preparing negative photosensitive polyimide based on 2,2-di[4-(2,4-diaminophenyloxy)phenyl]hexafluoropropane Method for preparing negative photosensitive polyimide based on 2,2-di[4-(2,4-diaminophenyloxy)phenyl]hexafluoropropane](https://images-eureka.patsnap.com/patent_img/fa404351-10dd-49df-9e89-119ad27fa20f/a20081003650500051.PNG)