Method of manufacturing touch control display device

A manufacturing method and touch display technology, applied in semiconductor/solid-state device manufacturing, data processing input/output process, optics, etc., can solve problems such as product yield and manufacturing cost increase, and achieve good sensing performance, good Carrier mobility, effects of good photosensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

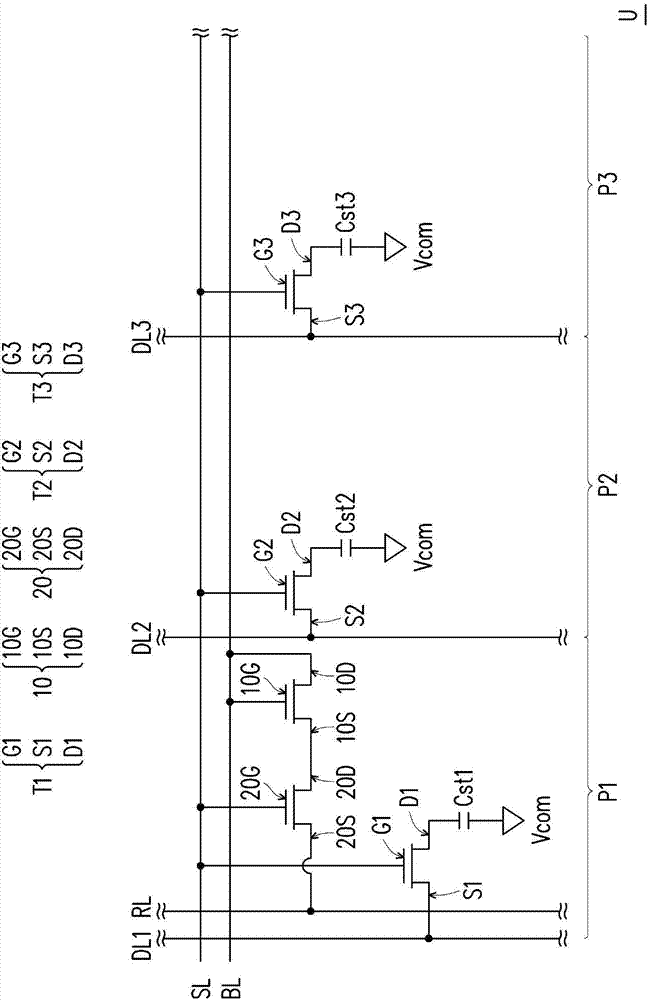

[0076] The touch display device of the present invention can be, for example, a touch liquid crystal display device. Anyone skilled in the art should understand that a touch liquid crystal display device generally includes a pixel array formed by a plurality of identical or similar pixel unit arrays. For clarity, figure 1 Only one pixel unit U is shown in .

[0077] figure 1It is a partial equivalent circuit diagram of a touch display device according to an embodiment of the present invention. Please refer to figure 1 The pixel unit U of the touch display device includes scan lines SL, data lines DL1˜DL3, sensing signal lines BL, readout lines RL, sub-pixel units P1, sub-pixel units P2, and sub-pixel units P3.

[0078] In this embodiment, the sub-pixel unit P1 includes the active element T1, the sensing element 10, the switching element 20, and the capacitor Cst1; the sub-pixel unit P2 includes the active element T2 and the capacitor Cst2; the sub-pixel unit P3 includes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com