CMOS (complementary metal oxide semiconductor) image sensor and manufacturing method thereof

A technology of an image sensor and a production method, which is applied in the directions of image communication, radiation control device, television, etc., can solve the problems of increasing production cost and achieve the effect of enhancing light sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

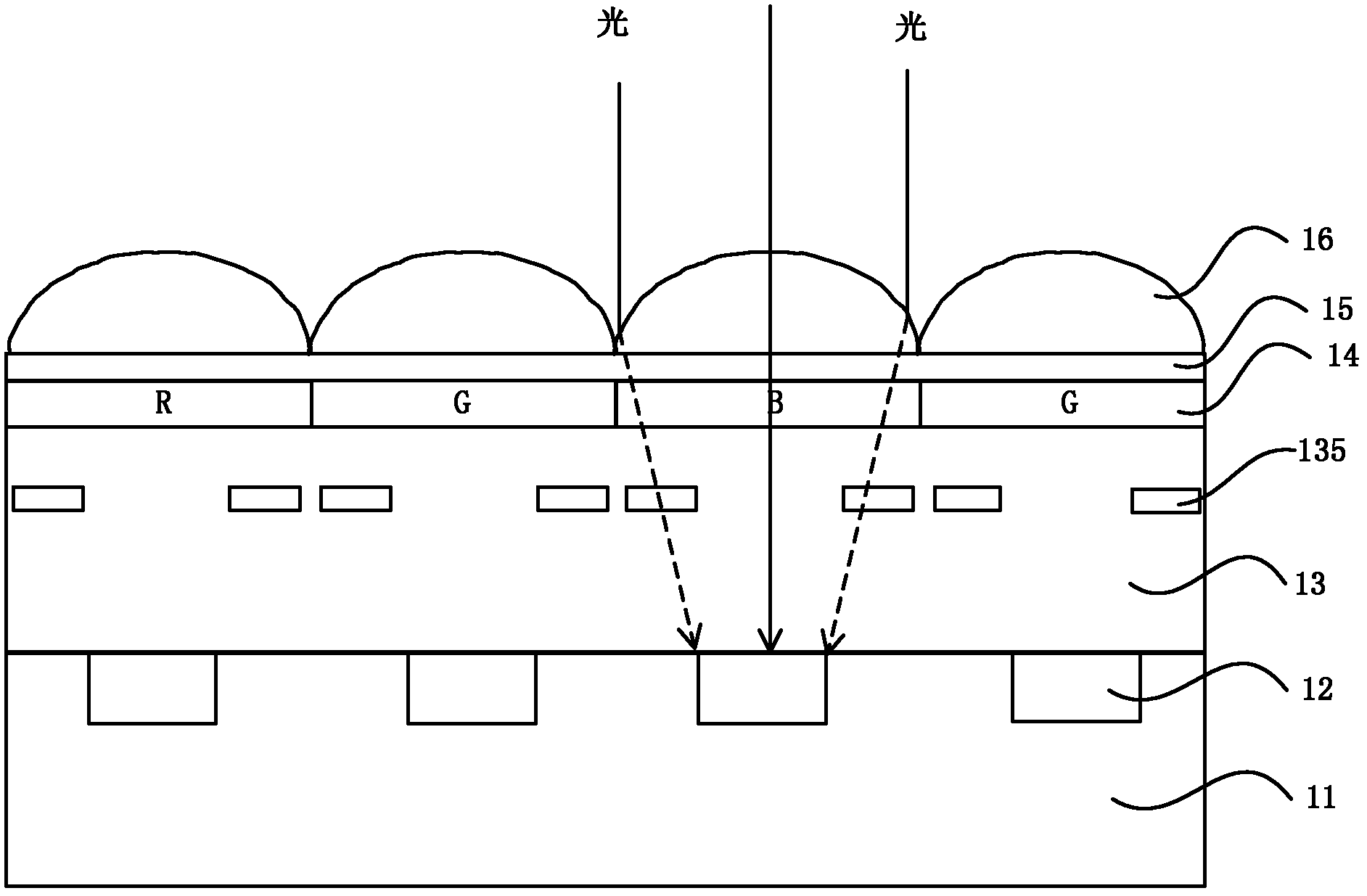

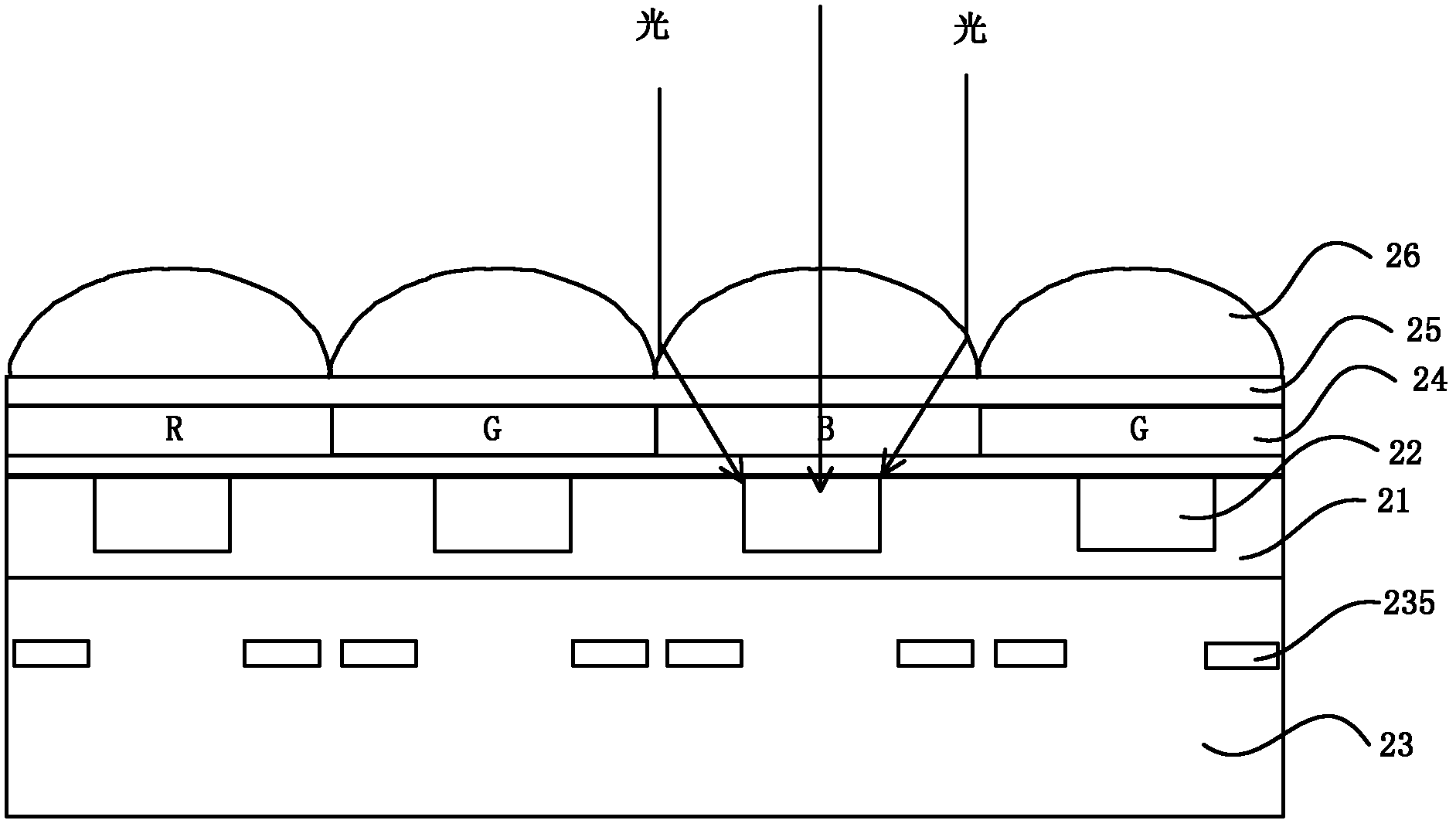

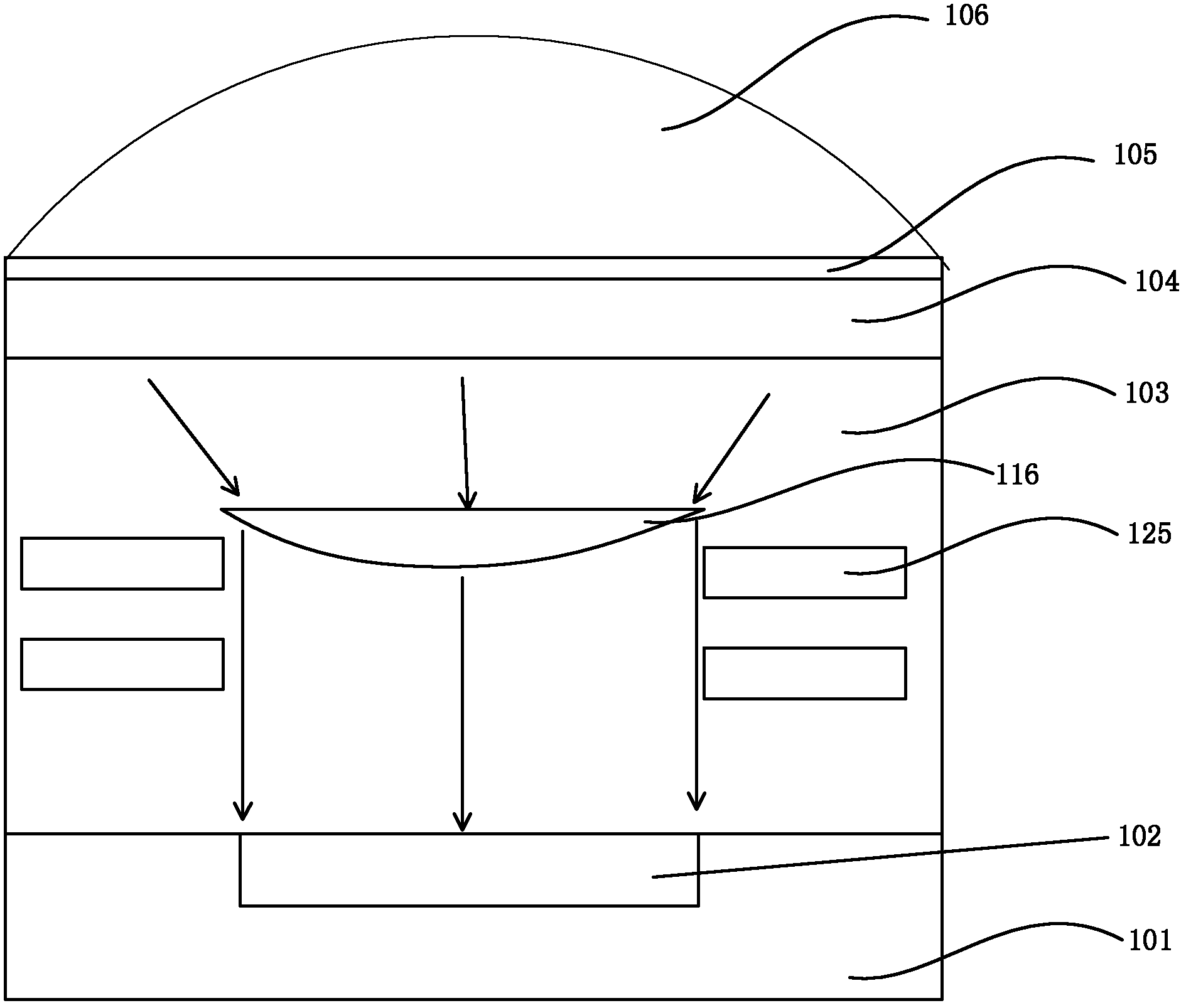

[0047] In order to avoid the situation mentioned in the background technology that the light collected by the microlens is blocked by the metal connection layer and cannot fully reach the photodiode, or other situations that affect the light sensitivity occur, the embodiments of the present invention are based on the original microlens and the photoelectric A second microlens is added between the diodes. The second microlens further adjusts the light collected by the original microlens. On the one hand, it prevents the light from being blocked by the metal connection layer and cannot reach the photodiode. On the other hand, it can also prevent the light from being blocked by the original microlens The situation where the lens is over-converged so that some areas of the photodiode receive excessive light, and some areas have no light incident.

[0048] The structure of a CMOS image sensor (CIS) and its fabrication method according to a first embodiment of the present invention w...

Embodiment 2

[0062] The structure of the product provided by this embodiment is the same as that of Embodiment 1, and the only difference lies in the manufacturing method of the microlens. The manufacturing method and advantages of the microlens used in this embodiment will be mainly introduced below.

[0063] Figure 4 to Figure 7 is a cross-sectional view showing a method of manufacturing a microlens or a microlens array (MLA). refer to Figure 4 , depositing a dielectric layer 303 , where the dielectric layer may be part of the interlayer insulating layer 103 in Embodiment 1. Next, a barrier layer 305 is formed over the entire surface of the top of the layer 303 . The barrier layer can be made of silicon nitride film (Si 3 N 4 )form.

[0064] Then, a PR pattern 307 for forming a microlens pattern is formed. PR (photoresist) is coated over the entire surface of the top of the barrier layer 305 . Portions of the top PR are selectively removed by performing an exposure process usin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com