Novel n type semi-insulating GaAs ohmic contact electrode material and method for preparing novel n type semi-insulating GaAs ohmic contact electrode material

An ohmic contact electrode, semi-insulating technology, applied in the direction of final product manufacturing, circuits, electrical components, etc., to achieve the effect of low cost, good economic benefits, and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] According to technical solution of the present invention, enumerate embodiment as follows:

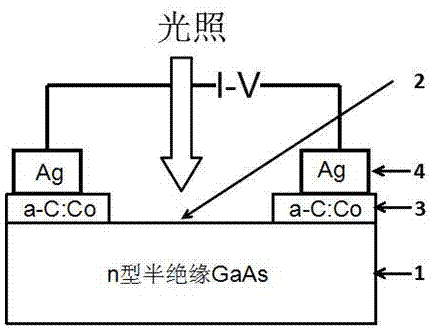

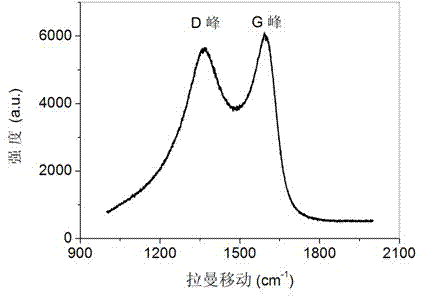

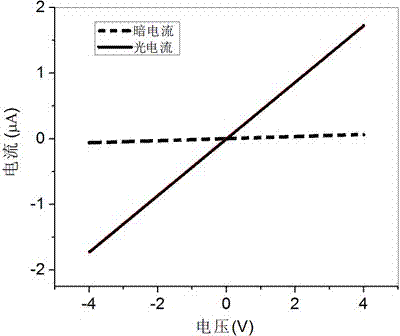

[0022] First, a Co-doped non-carbon crystal film was plated on the substrate by pulsed laser deposition. The resistivity of the substrate is about 5×10 8 Ω.cm undoped n-type semi-insulating GaAs material. Graphite with a purity of 99.99% and metal Co with a purity of 99.9% are used as the target source, and the metal Co sheet is attached to the graphite target, and the pulse laser deposition coating is performed on the two electrode areas set on the n-type semi-insulating GaAs substrate. During the coating process, uniform doping is achieved by the rotation of the target and the substrate, and the Co doping amount is about 10 at% (atomic percentage). Laser energy 450 mJ / pulse, cavity vacuum 5×10 -5 Pa, the substrate temperature is controlled at about 450°C, and the distance between the target and the substrate is 5.5cm. The non-carbon crystal film is plated with a thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| lattice constant | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com