Thermal polymerization process of PQ/PMMA photopolymer material, PQ/PMMA photopolymer material and holographic optical disc thereof

A technology of photopolymerization and thermal polymerization, applied in the direction of record carrier materials, optical record carriers, etc., can solve problems such as internal structure instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] PQ / PMMA photopolymer material thermal polymerization process, including the following steps:

[0047]The raw material methyl methacrylate (MMA), azobisisobutyronitrile (AIBN), and phenanthrenequinone (PQ) that will be made into PQ / PMMA materials are weighed and proportioned according to a certain mass ratio, wherein MMA: 100wt%, AIBN: 0.7~1wt%, PQ: 0.7~1wt%, promptly take the mass percentage of MMA as 1 part, then the mass percentage of AIBN is 0.007~0.01 part, and the mass percentage of PQ is 0.007~0.01 part;

[0048] Put the prepared ingredients into a glass bottle and vibrate in an ultrasonic cleaner for 15-30 minutes to mix them evenly;

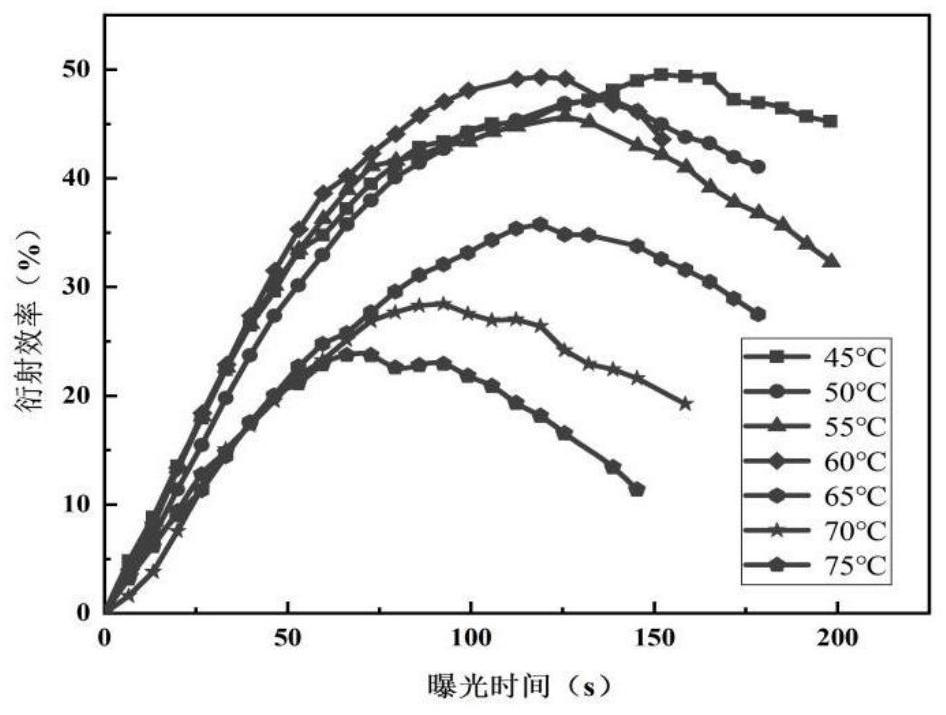

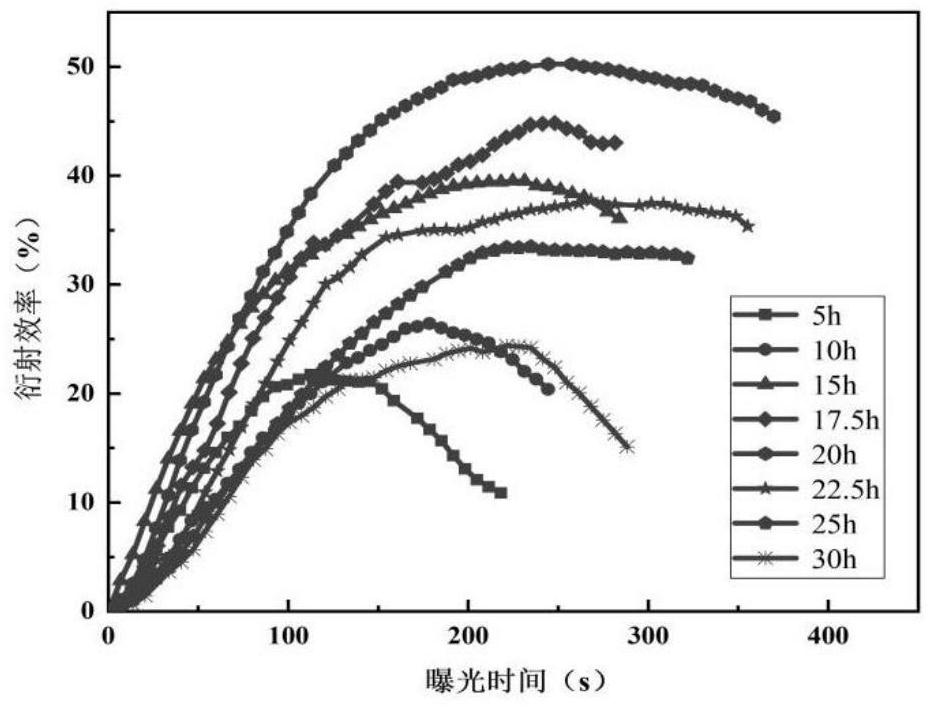

[0049] Put the mixed solution into a constant temperature water bath with magnetic stirring at 45-75°C for pre-polymerization and stirring. The stirring time is 30-105 minutes. At this time, the speed of the stirrer is 10-20r / s. Exhaust the nitrogen generated during the thermal decomposition of AIBN and the heat generated by the f...

Embodiment 2

[0054] PQ / PMMA photopolymer material, the PQ / PMMA photopolymer material is made through the PQ / PMMA photopolymer material thermal polymerization process described in Example 1.

[0055] Further, the raw materials of the PQ / PMMA photopolymer material include: MMA, AIBN and PQ.

[0056] Further, the raw materials of the PQ / PMMA photopolymer material include: when MMA, AIBN and PQ are weighed and proportioned according to a preset mass ratio, the preset mass ratio is set to MMA:100wt%, AIBN: 0.7~1wt%, PQ: 0.7~1wt%.

Embodiment 3

[0058] A holographic disc, which is made of the PQ / PMMA photopolymer material described in Embodiment 2.

[0059] It should be noted that, the weight ratio of the raw materials of the PQ / PMMA photopolymer material can preferably be MMA: 100wt%, AIBN: 1wt%, PQ: 1wt%. The weight ratio of above-mentioned each component raw material is that the weight of MMA is 1, promptly 100wt%, other raw material components are relative to the weight percentage of MMA. Namely MMA: 100wt%, AIBN: 1wt%, PQ: 1wt%. For example, the weight ratio of each component raw material MMA:AIBN:PQ is 100:1:1.

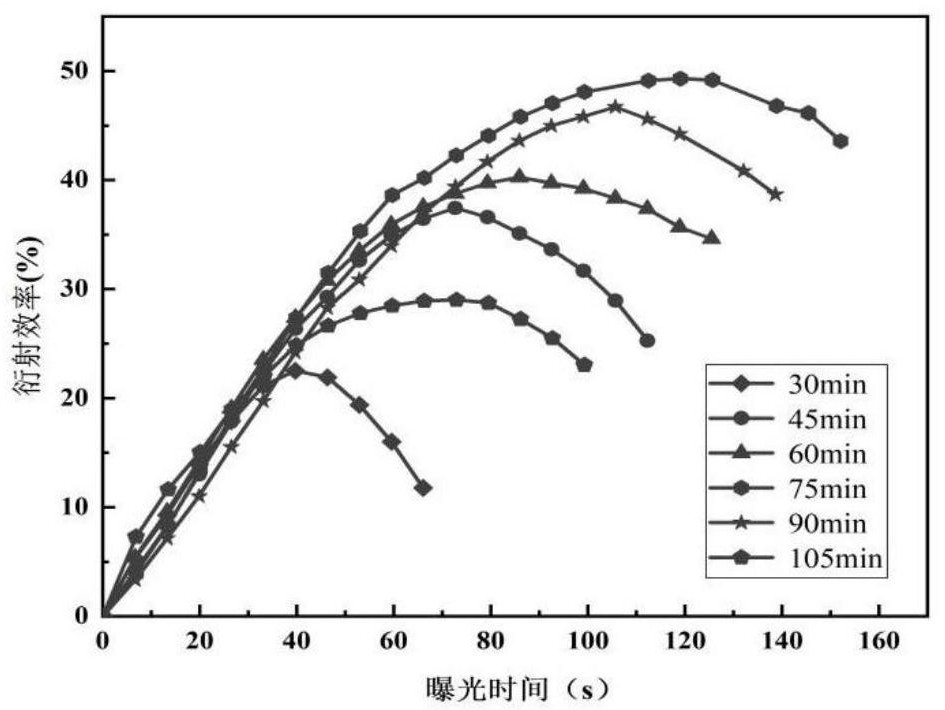

[0060] like figure 1 As shown, as the stirring time increases, the diffraction efficiency of the material will first increase and then decrease. When the stirring time is 75min, the maximum diffraction efficiency of the material is 49.3%. During this process, the stirring temperature and the baking temperature are set to be 60°C, the baking time is 20h; during the diffraction efficiency test, the inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com