Photo-sensitive polyimide, and its preparing method

A polyimide and photosensitive technology, applied in the field of photoresist preparation, can solve the problems of affecting graphic resolution, low photosensitivity, limiting applications, etc., and achieve the effects of increased photosensitivity, high sensitivity, and high film retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

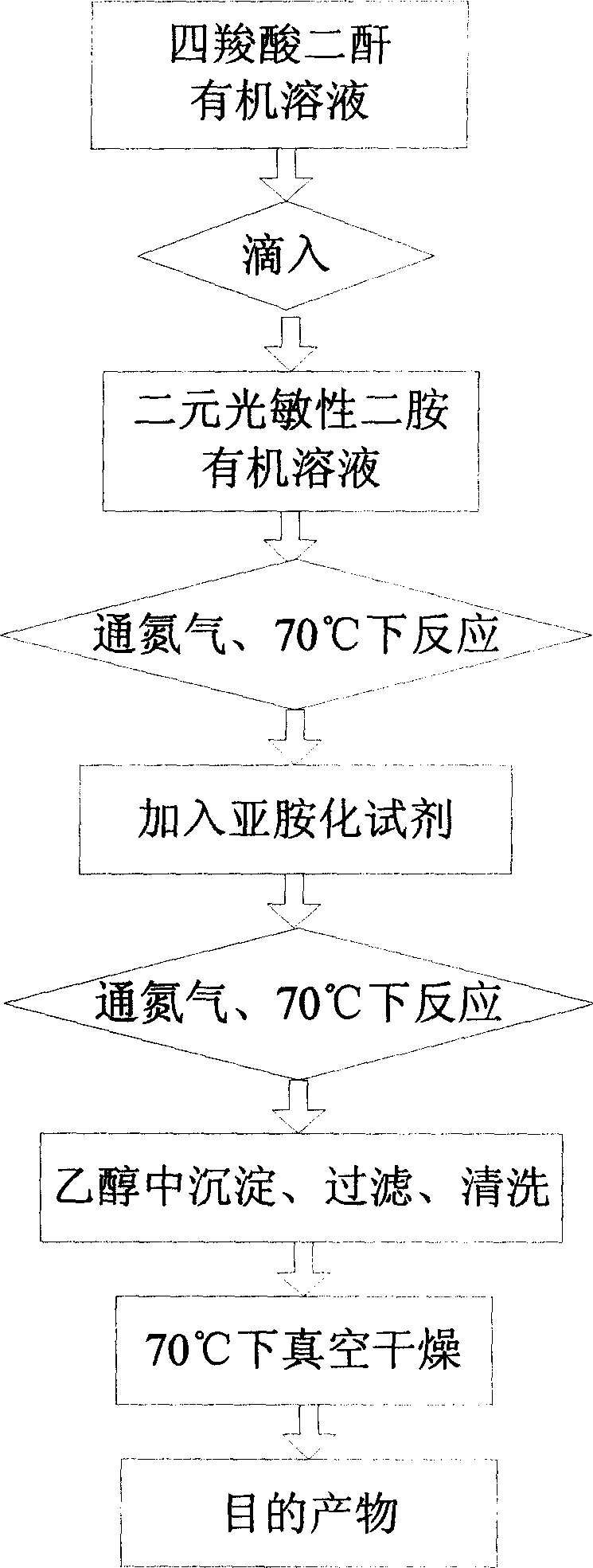

Method used

Image

Examples

Embodiment Construction

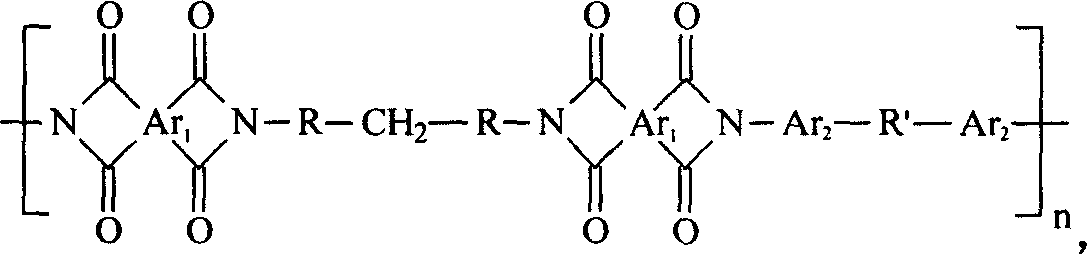

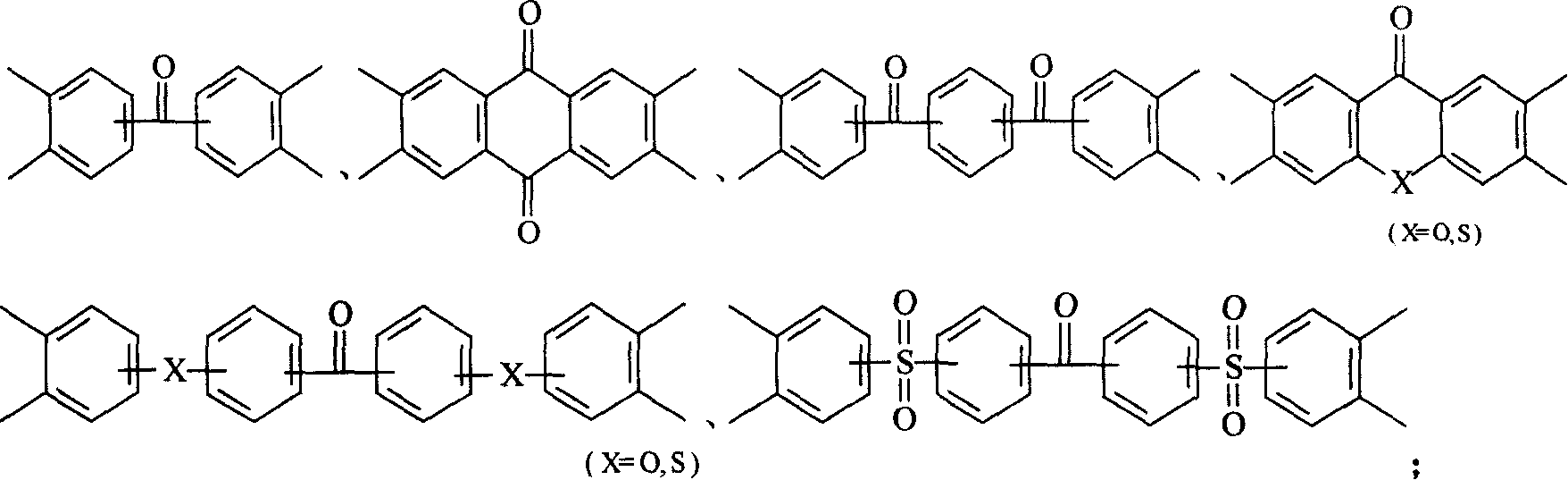

[0047] Add 6 mL of N,N-dimethylacetamide and 2.0 mmol of photosensitive diamine containing alkyl group and photosensitive acryloyl group in equimolar ratio to a 50 mL three-necked flask with nitrogen inlet. Diamine was made into a solution, and an equimolar amount of 3,3',4,4'-benzophenonetetracarboxylic dianhydride solution dissolved in 6mL of N,N-dimethylacetamide was slowly added dropwise, protected by nitrogen gas, The reaction was carried out at 70°C for 8 hours; then, 3 mL of a mixture of acetic anhydride and pyridine in an equimolar ratio was added, and the reaction was maintained at 70°C for 5 hours to obtain a viscous glue. Precipitate into 100 mL of ethanol, filter and wash with ethanol for 5 times, and vacuum-dry at 70° C. for 8 h to obtain 1.05 g of the target product.

[0048] For the photosensitive polyimide material prepared in the above embodiment, after testing: the sensitivity is 80-135mJ / cm 2 , The film retention rate is 80% to 90%, and the highest decompos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com