Patents

Literature

1215results about How to "Suitable for industrialization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of producing a sustained-release preparation

InactiveUS6197350B1Reduce the number of stepsSuitable for industrializationPowder deliveryPeptide/protein ingredientsBlood concentrationOrganic solvent

A method of producing sustained-release microcapsules which comprises dispersing a physiologically active polypeptide into a solution of a biodegradable polymer and zinc oxide in an organic solvent, followed by removing the organic solvent; which provides a sustained-release preparation showing a high entrapment ratio of the physiologically active polypeptide and its constant high blood concentration levels over a long period of time.

Owner:TAKEDA PHARMA CO LTD

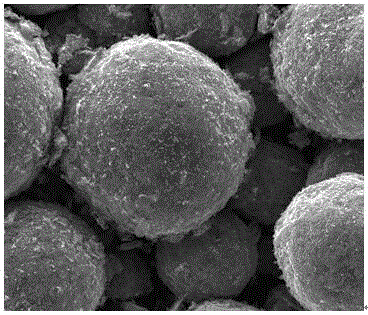

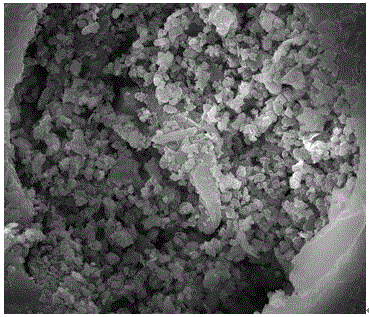

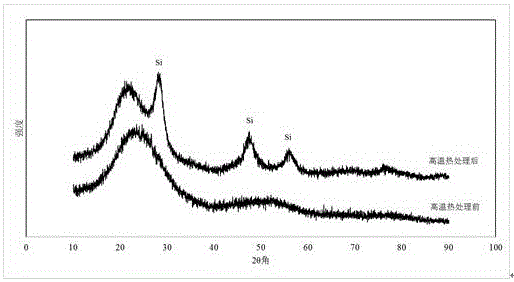

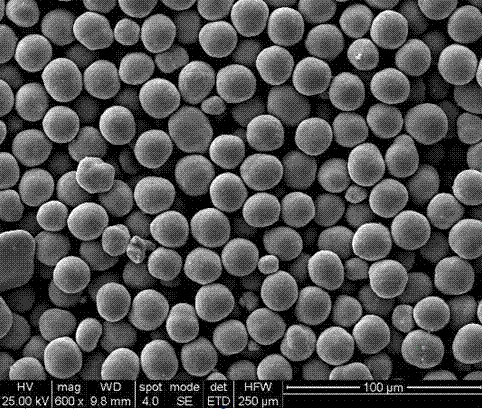

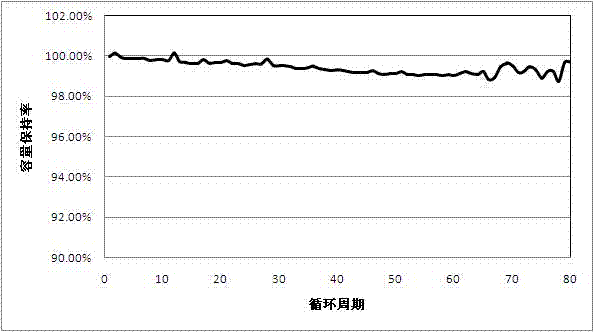

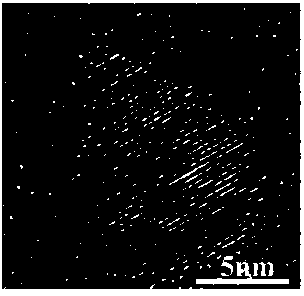

Spherical porous silicon/carbon composite material as well as preparation method and application thereof

InactiveCN106711461AHigh specific capacityPromote circulationCell electrodesCarbon compositesAdhesive

The invention discloses a spherical porous silicon / carbon composite material as well as a preparation method and application thereof. The spherical porous silicon / carbon composite material is structurally characterized in that a SiOx / C matrix, graphite with small particle size and a conductive agent are dispersed in porous amorphous carbon, wherein the average particle diameter is 12-25mu m; the method comprises the following steps of carrying out first coating on a SiOx raw material with powder pitch, and performing heat treatment so as to obtain a SiOx / C material; then performing ball milling by use of a wet method so as to reduce the particle diameter of powder, adding a carbon source adhesive, the graphite with the small particle diameter and the conductive agent, and performing high-speed dispersion, thereby obtaining pulp; and finally performing spray granulation and sintering on the pulp, thereby obtaining the final spherical porous silicon / carbon composite material. According to the invention, SiOx is dispersed in cracking carbon, the graphite and the conductive agent, so that SiOx volume expansion during a charge / discharge process is buffered, and the conductibility is enhanced; by virtue of the porous structure, the imbibition rate and cycle performance of the material can be effectively improved; by virtue of bitumencarb coating and high-heat treatment performed in advance, SiOx is prevented from being directly contacted with an electrolyte, and furthermore, the stability and first efficiency of the silicon / carbon material are improved.

Owner:ZHONGTIAN ENERGY STORAGE TECH

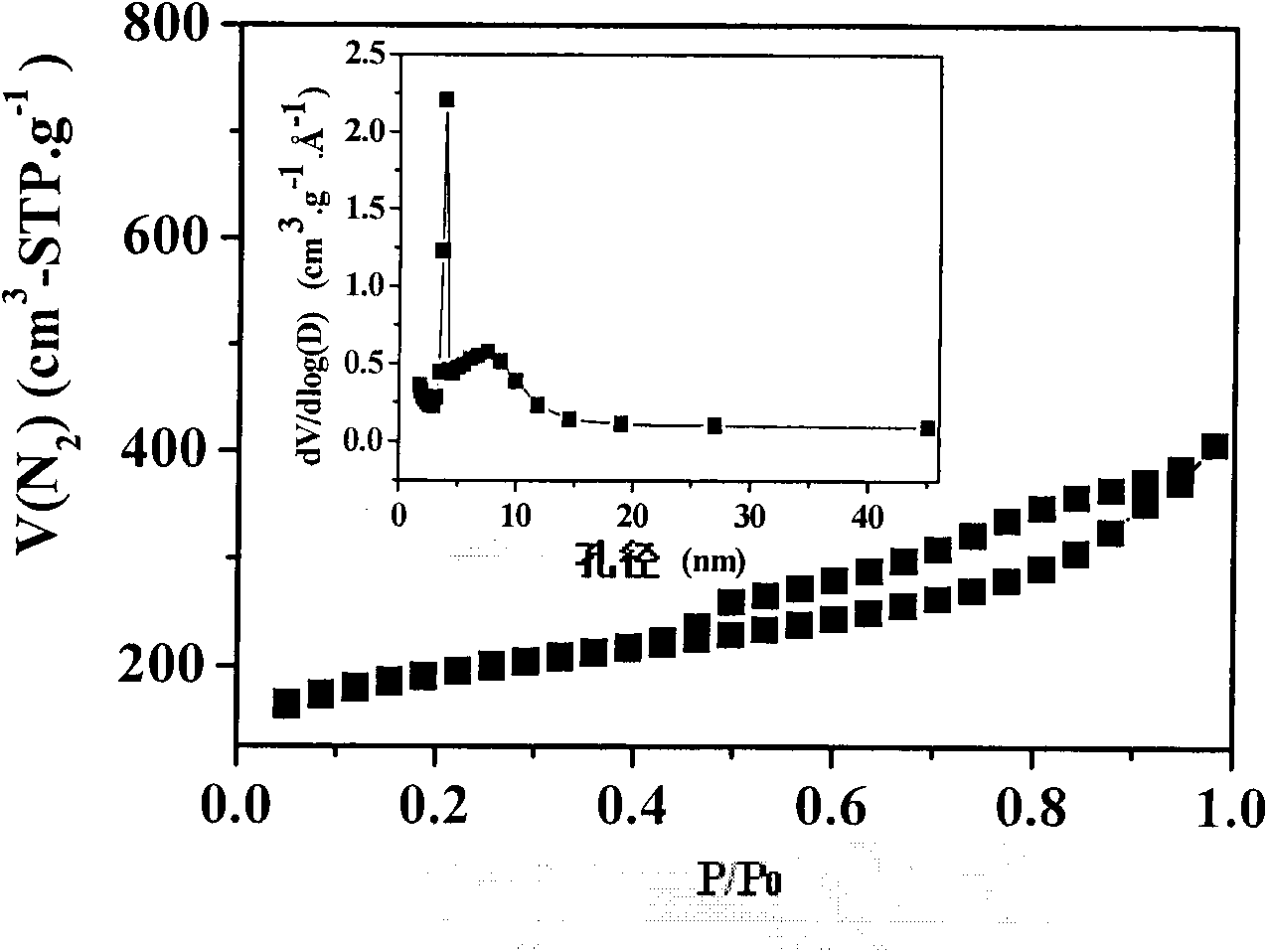

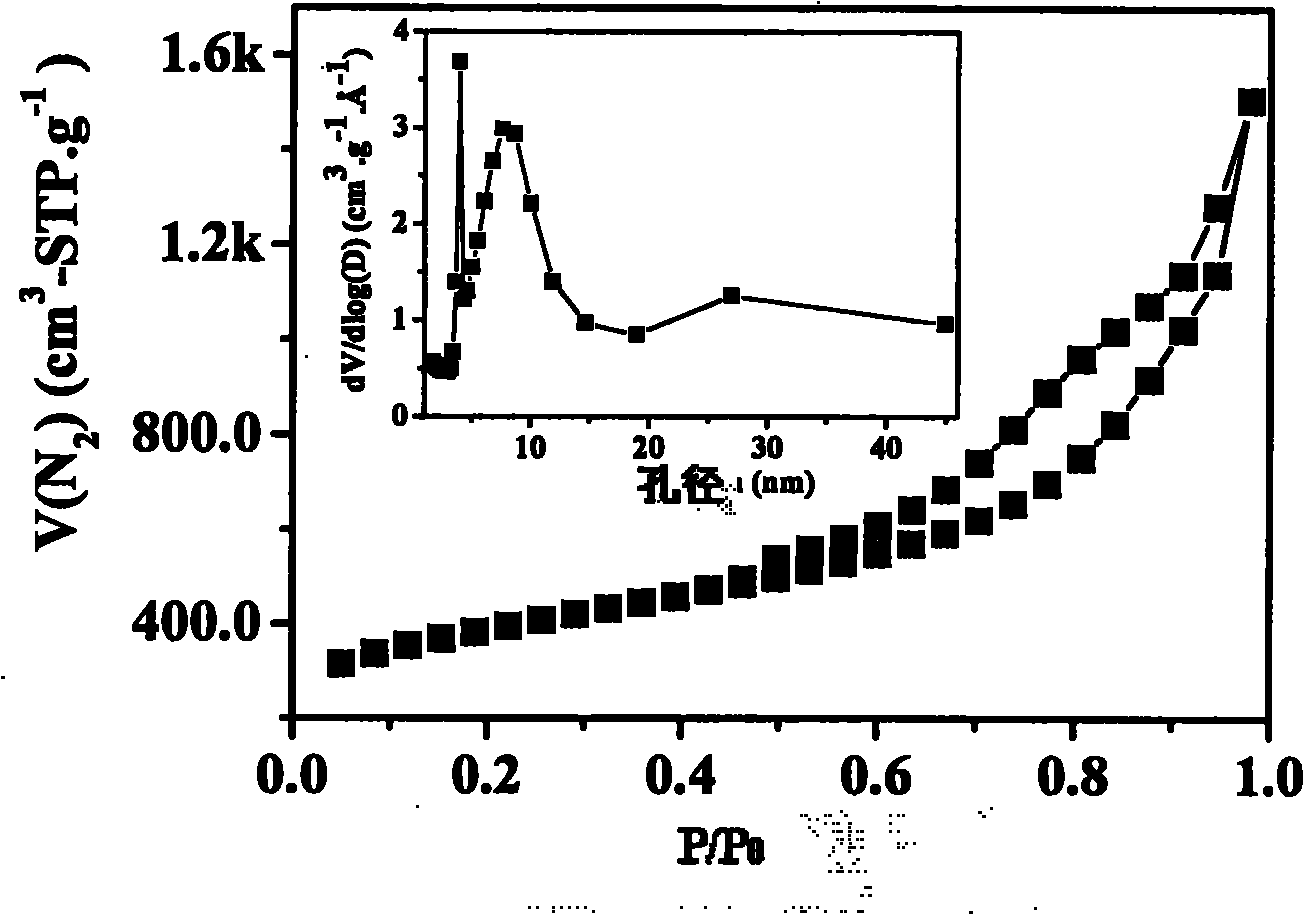

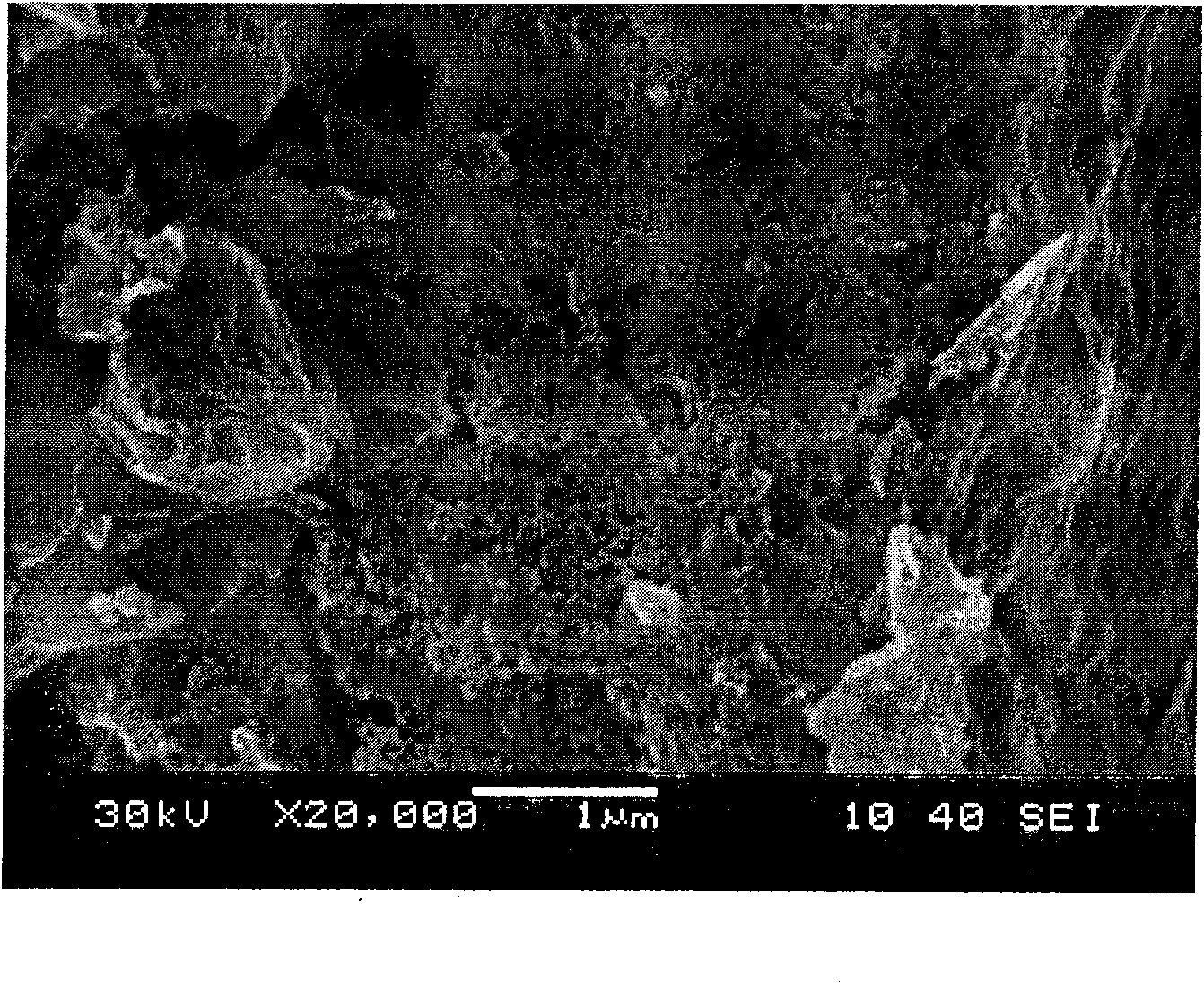

Method for preparing high-surface-area nitrogenous mesoporous carbon material

The invention discloses a method for preparing a high-surface-area nitrogenous mesoporous carbon material. The method prepares the nitrogenous mesoporous carbon material by using melamine, urea and formaldehyde as raw materials, using metal chloride as a template agent and an active agent, and performing the steps of dissolution, polymerization, solidification, carbonization, washing, drying and the like. The raw materials are rich in sources and have low prices; the metal chloride used as the template agent and the active agent has a low price and can be recycled; the whole preparation method is simple and feasible; and the prepared nitrogenous mesoporous carbon material has a specific area of 500 to 1,500 m<2> / g, a total pore volume of 1.0 to 3.0 cm<3> / g, a mesoporous ratio of 80 to 92 percent, an adjustable pore diameter of between 2.5 nm to a plurality of microns and the nitrogen content (atomic percent) of 5 to 28 percent at, and is expected to be widely applied in the fields of adsorbents, catalyst carriers, electrode materials and the like.

Owner:NANJING UNIV

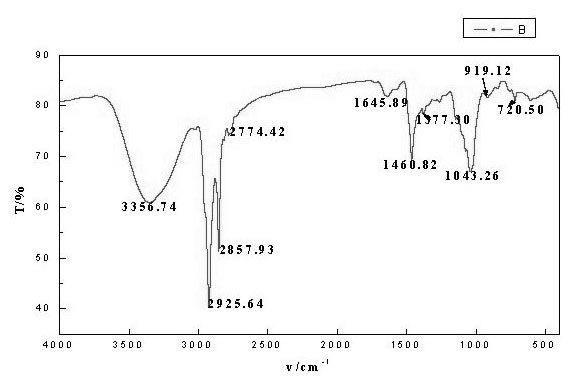

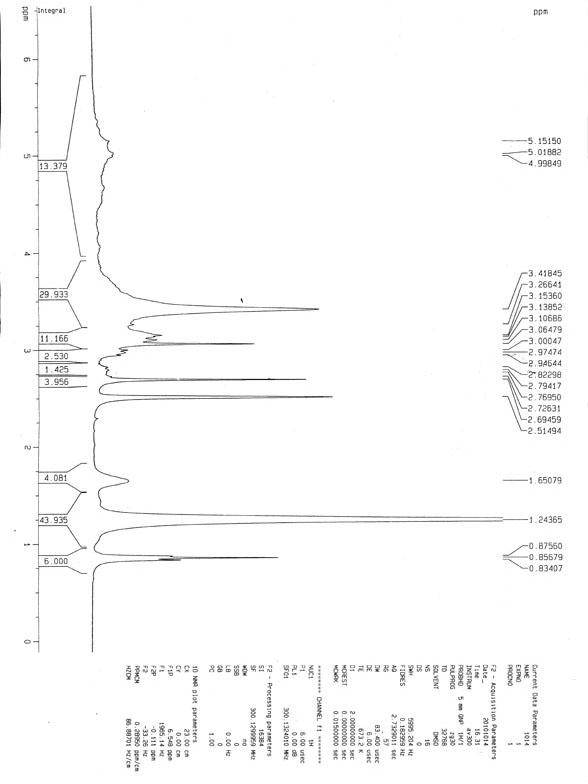

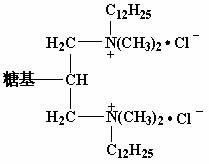

Sugar-based quaternary ammonium salt gemini surfactant and synthesis method thereof

InactiveCN101972612AThe synthesis method is simpleThe synthesis process is simpleTransportation and packagingMixingBromineHard water

The invention discloses a sugar-based quaternary ammonium salt gemini surfactant, which has a general structural formula, wherein a sugar base is a glucose base; R is the long-chain alkyl of C8 to C18; X is chlorine, bromine or iodine; m is equal to 1 to 2; and n is equal to 1 to 2. A synthesis method for the surfactant is simple, comprises the steps of directly synthesizing dihalogenated glycoside and performing quaternization reaction, ensures simple synthesis process and low requirements on equipment and is suitable for industrialization. A sugar-based quaternary ammonium salt structurally has nonionic glucose hydrophilic groups and cationic bisquaternary ammonium salt hydrophilic groups. The product has the bactericidal property, antistatic behavior and hard water resistance of a cationic surfactant, relatively lower irritation, and the high performance of a gemini surfactant as the gemini surfactant, can be compounded with an anionic surfactant to realize synergism, is a multifunctional surfactant, can be widely applied to the industries of textile, papermaking, cosmetics, mining and the like, and has potential application prospect.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

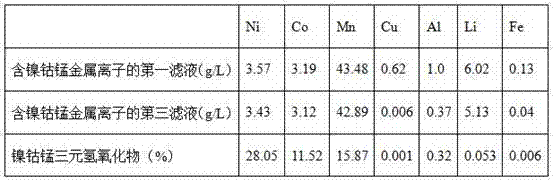

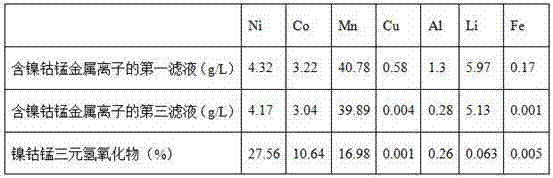

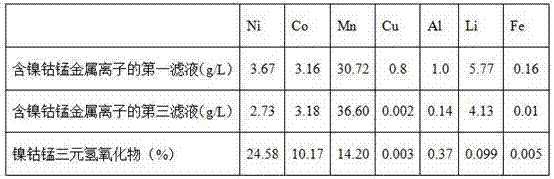

Method for preparing ternary hydroxide from nickel cobalt manganese recycled from waste lithium ion batteries through liquid phase method

ActiveCN107117661ALabor savingEasy to industrializeWaste accumulators reclaimingNickel oxides/hydroxidesManganeseSlurry

The invention discloses a method for preparing ternary hydroxide from nickel, cobalt and manganese in waste lithium ion batteries recovered by a liquid phase method, belonging to the technical field of metallurgical recovery of valuable metals, and solves the increasingly prominent problem of recycling waste lithium ion batteries. question. The invention uses waste lithium ion batteries as raw materials, and the main production steps include: dismantling and crushing, pulping, leaching, copper removal by extraction, iron and aluminum removal by precipitation, and preparation of nickel-cobalt-manganese ternary hydroxide. In the invention, the whole battery is crushed and then processed, no harmful gas is generated in the whole process of recovery and preparation, and green recovery is realized from the root. Raw material requirements, the entire production process is more convenient to operate, and the product is more pure, suitable for industrialization.

Owner:JINCHUAN GROUP LIMITED

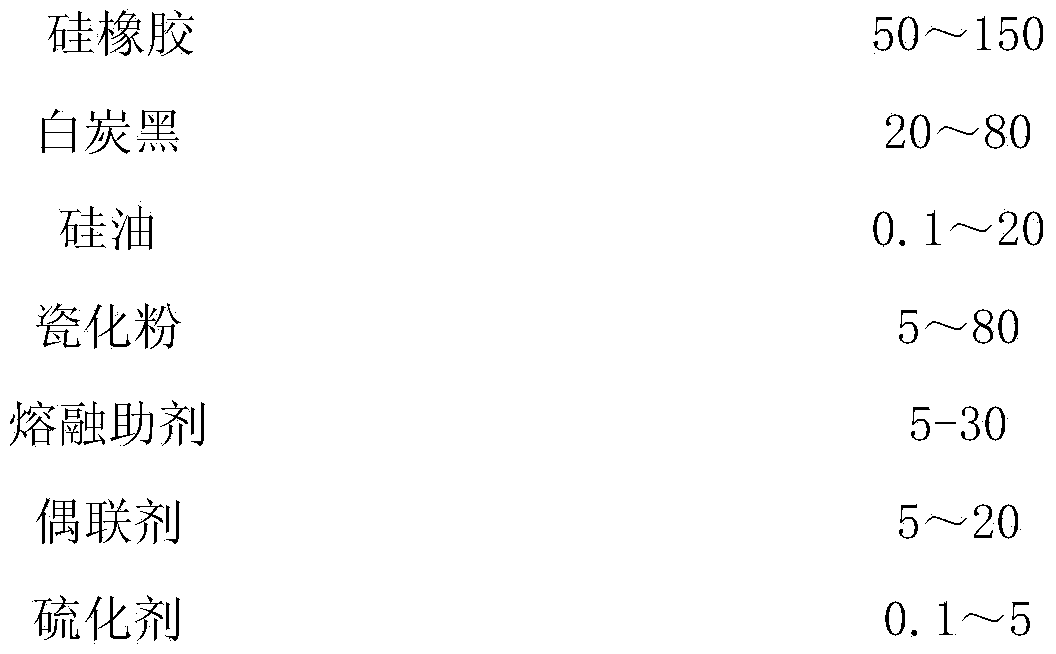

Environment-friendly ablation-resistant ceramic silicone rubber composite material and preparation method thereof

ActiveCN103923465AEnhanced ceramic performanceImprove mechanical propertiesVulcanizationPolymer science

The invention relates to an environment-friendly ablation-resistant ceramic silicone rubber composite material and a preparation method thereof. The composite material consists of silicone rubber, white carbon black, vitrified powder, a fusion aid, silicone oil and a coupling agent. The composite material is prepared by the following steps: first, mixing 50-150 parts of silicone rubber, 5-80 parts of white carbon black, 5-20 parts of coupling agent, 2-80 parts of vitrified powder, 2-30 parts of fusion aid and 0.1-20 parts of silicone oil; then, adding 2-10 parts of vulcanizing agent, uniformly mixing to obtain a sheet; and finally, carrying out hot press molding on the obtained sizing material under the pressure of 10-15MPa and at 100-200 DEG C, and carrying out two-sectional vulcanization by virtue of hot air with temperature of 150-220 DEG C to obtain the ceramic silicone rubber composite material. According to the composite provided by the invention, the ceramic performance of the material is greatly improved while the mechanical property of the composite material is ensured, and therefore the composite material has a wide application range.

Owner:EAST CHINA UNIV OF SCI & TECH

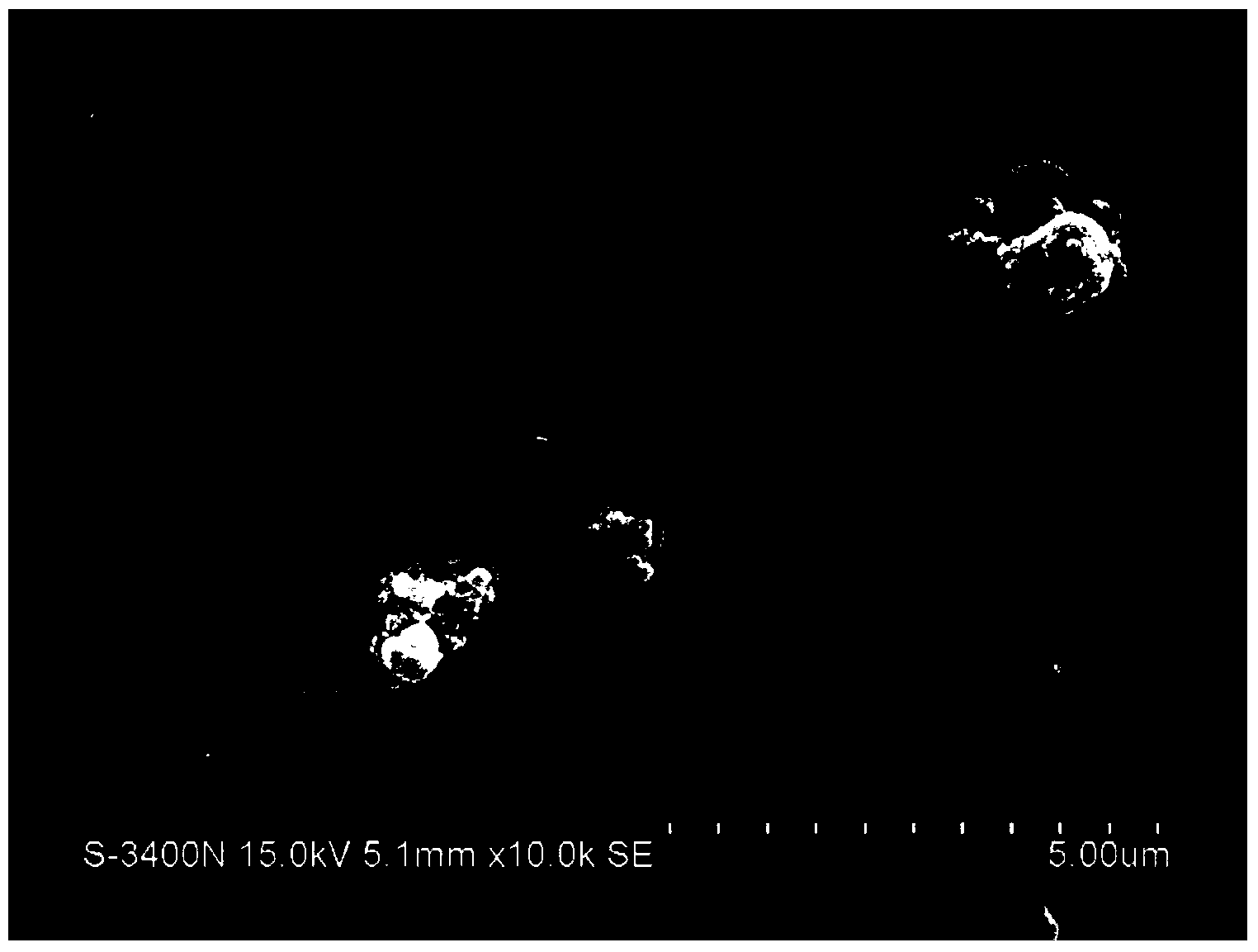

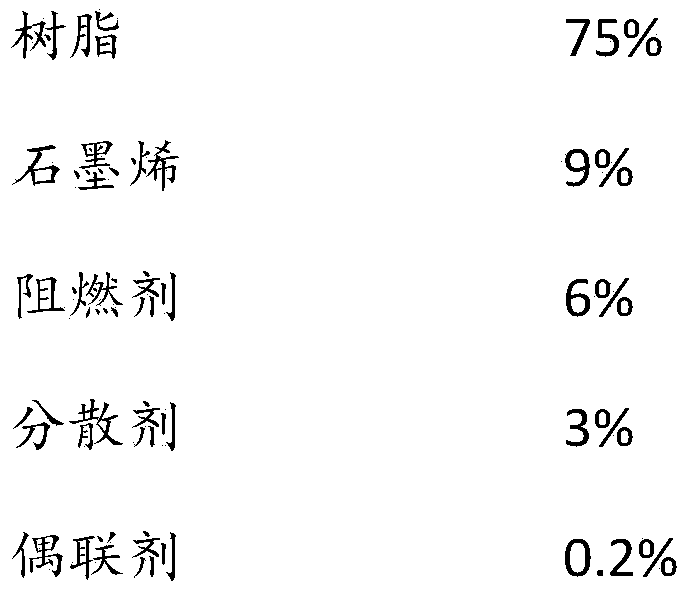

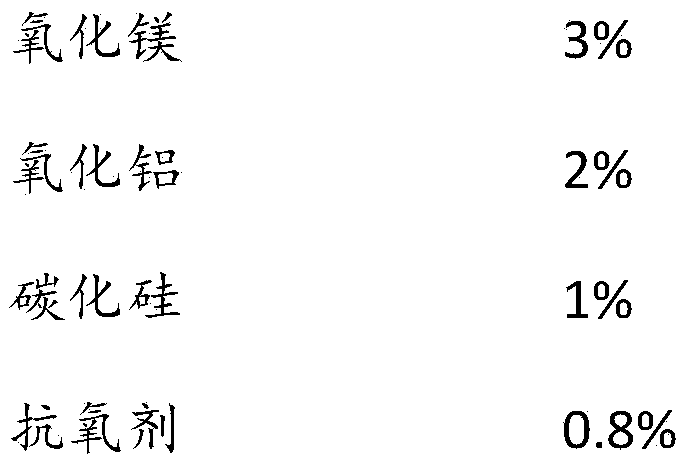

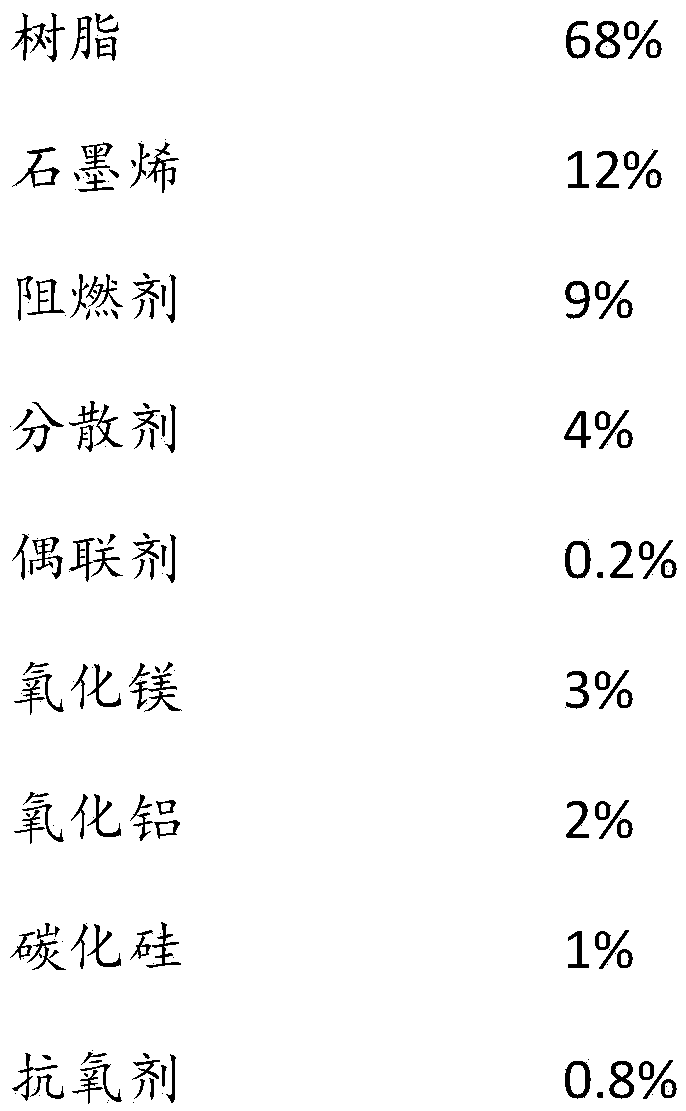

Graphene thermal conductive plastic, and preparation method thereof

The invention relates to a graphene thermal conductive plastic. The graphene thermal conductive plastic comprises, by mass, 60 to 90% of a resin, 1 to 20% of graphene, 5 to 20% of a fire retardant, 1 to 10% of a dispersant, 0.5 to 5% of an antioxidant, 0.1 to 5% of a coupling agent, and 1 to 10% of an auxiliary agent. The invention also provides a preparation method of the graphene thermal conductive plastic. Adding of magnesium oxide, aluminum oxide, and silicon carbide is capable of achieving uniform distribution of grapheme, and increasing thermal conductivity of the graphene thermal conductive plastic.

Owner:NINGBO MORSH NEW MATERIALS

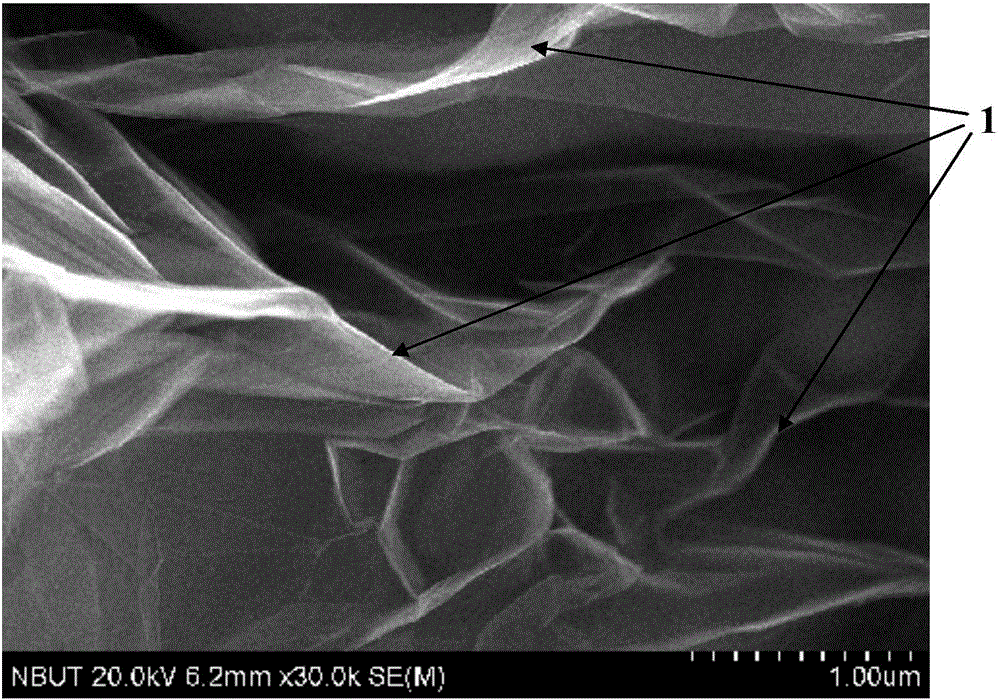

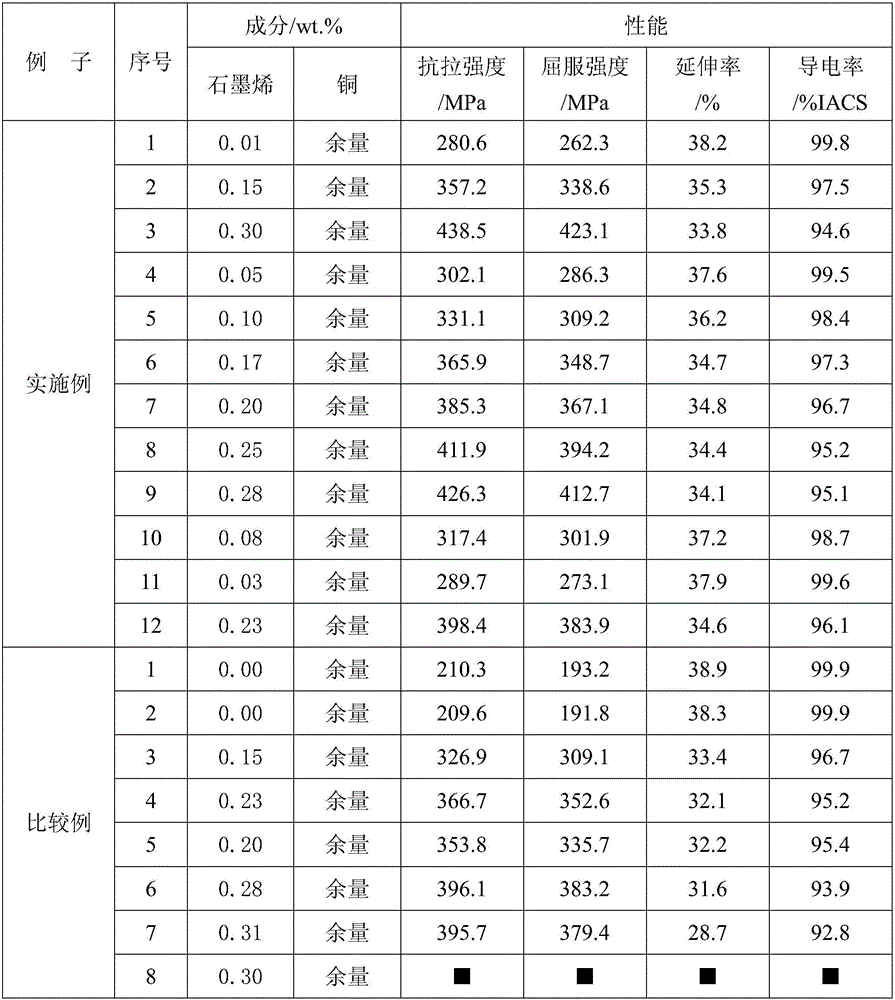

Copper-graphene composite material and preparation method thereof

ActiveCN105714139APrevent oxidationControllable distribution densityLead frameUltimate tensile strength

The invention relates to a copper-graphene composite material and a preparation method thereof. The copper-graphene composite material comprises graphene and copper, and is characterized in that the graphene is evenly distributed in a copper matrix in a sheet structure; distribution density of the graphene is 100 sheets per square centimeter to 3000 sheets per square centimeter; and preferably, the content of the graphene is 0.01 wt% to 0.30 wt%, and the balance is Cu. The copper-graphene composite material disclosed by the invention is prepared by adding the graphene into the copper; the copper matrix can be served as an electrical conduction main body to enable electrical conductivity of the composite material to be close to pure copper, and the graphene is served as a reinforcement phase, so that tensile strength performance and yield strength performance are both increased; therefore the copper-graphene composite material can be widely applied to the fields of consumer electronics, electrics, aeronautics and astronautics, high-speed rails, lead frames, electronic connector preparation; and the preparation method provided by the invention is suitable for industrial and scale production.

Owner:NINGBO POWERWAY ALLOY MATERIAL

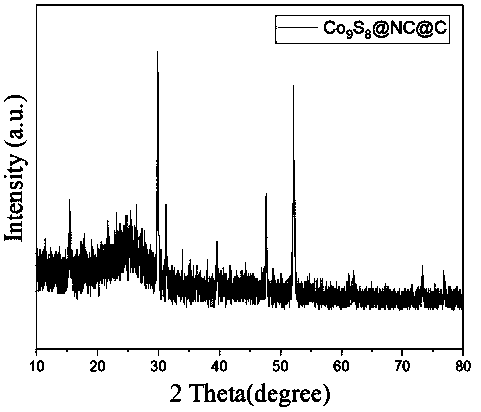

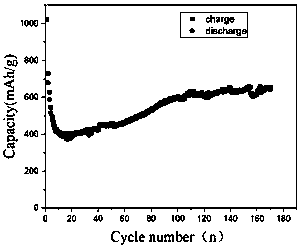

Preparation method for double-layer carbon coated metal sulfide composite electrode material with core-shell structure

The invention discloses a preparation method for a double-layer carbon coated metal sulfide composite electrode material with a core-shell structure. An amorphous carbon material is arranged on an outer layer of the composite electrode material and a nitrogen-doped carbon coated metal sulfide is arranged on an inner layer. The preparation method disclosed by the invention is simple and feasible. The double-layer carbon coated metal sulfide composite electrode material with the core-shell structure is acquired according to the following steps: adopting a room temperature aggregation method foracquiring a polypyrrole coated Co9S8 precursor, and then taking a shielding gas as a carrier gas for uniformly filling ethyl alcohol into a tube furnace, and performing thermal treatment. When the composite material prepared according to the method is used as a cathode material of a lithium ion secondary battery, the outer layer carbon is capable of effectively inhibiting the direct contact between active material metal sulfide and electrolyte, so that the initial coulombic efficiency and cycle performance of the composite material are promoted. Meanwhile, the nitrogen-doped carbon material isintroduced, so that the conductivity of the material is further promoted, the huge volume expansion of the metal sulfide in charging and discharging processes is relieved and the structural stabilityand rate capability of the composite material are greatly improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

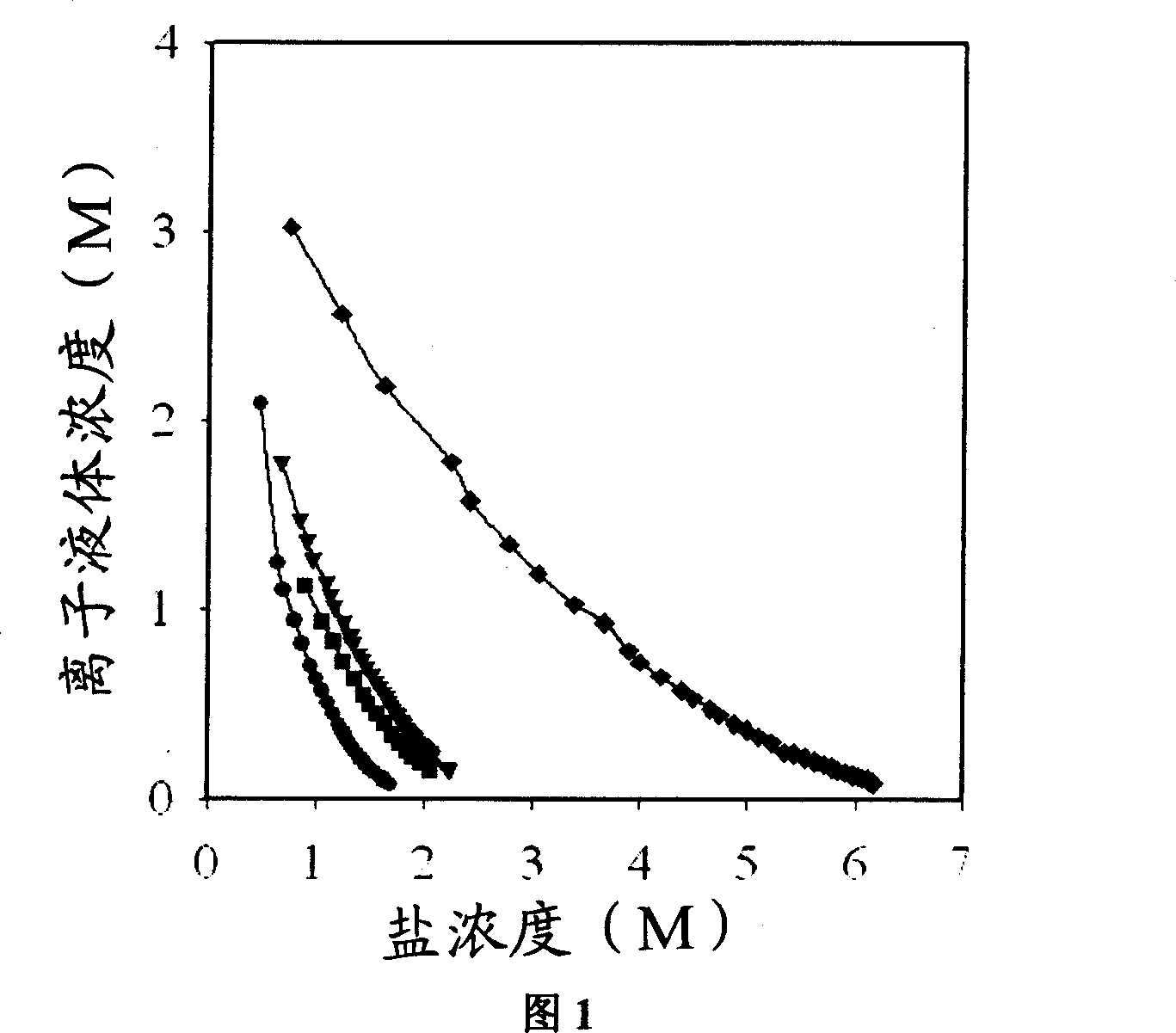

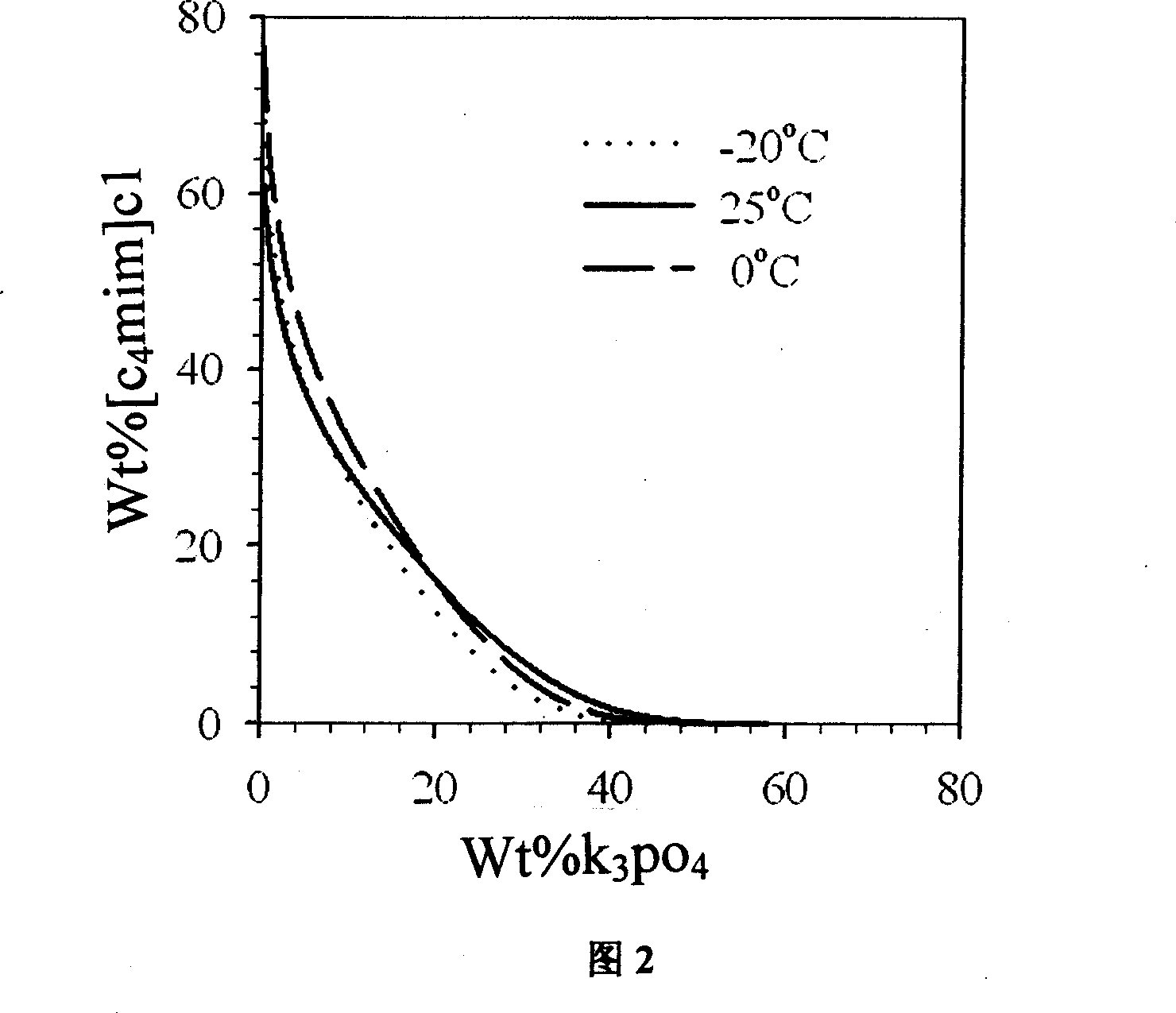

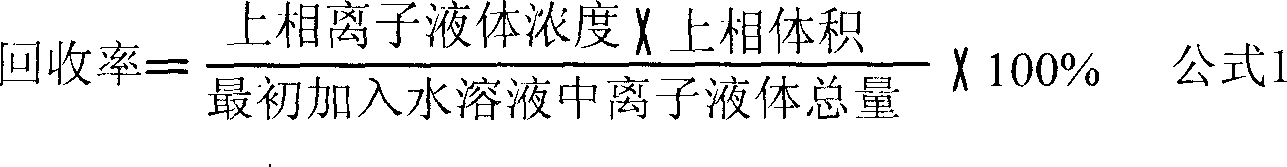

Process of enriching ionic liquid from water solution

InactiveCN1973943AEasy to adjustAchieve multi-level enrichmentLiquid solutions solvent extractionNon-miscible liquid separationEconomic benefitsAqueous solution

The present invention relates to process of enriching ionic liquid from water solution. Ionic liquid and salt in water solution may form a double water phase system, including the upper rich ionic liquid phase capable of enriching ionic liquid in water solution. By means of lowering the temperature of lower rich salt phase to 0 deg.c to -20 deg.c, a new double water phase system may be formed for further enriching ionic liquid. The present invention can reach total ionic liquid recovering rate up to 95-99 % and required water evaporating quantity only about 10 % of conventional process. The present invention can recover and reuse ionic liquid and salt, and has the advantages of great treating amount, simple apparatus, easy operation, low cost, easy combination of several stages, high economic benefit and environment friendship.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

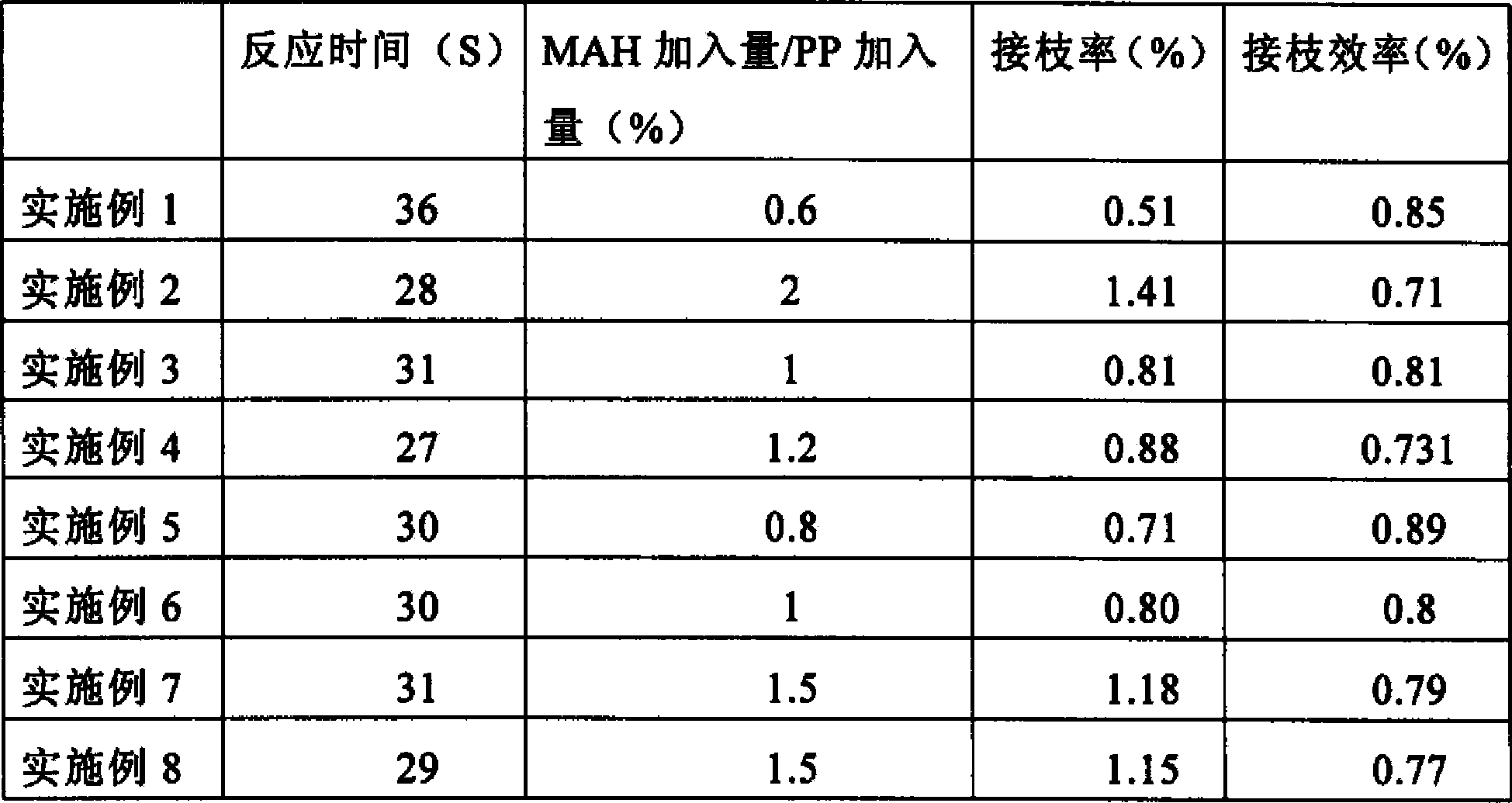

Preparation method for maleic anhydride-grafted polypropylene

The invention relates to a preparation method for maleic anhydride-grafted polypropylene. The preparation method comprises the following steps: (1) uniformly mixing 0.4 to 2 parts of an initiator and 0.6 to 2 parts of styrene by weight; (2) adding 110 parts of polypropylene and 0.6 to 2 parts of maleic anhydride by weight into a high-speed mixing machine and mixing for 1 to 3 minutes, and meanwhile dropwise adding the product obtained by the step (1); (3) adding the product obtained by the step (2) into a double-screw extruder, blending, extruding, melting and grafting to prepare the maleic anhydride-grafted polypropylene. Compared with the prior art, the preparation method has short reaction time, simple preparation and low production cost, and is suitable for industrialization; an anti-oxidant is not required to be added; the effective reaction time can be prolonged by controlling the factors, such as the rotating speed of a main machine, the feeding rotating speed, the temperature and the like; meanwhile, the maleic anhydride-grafted polypropylene with high grafting rate can be obtained by adding the styrene, so that the grafting efficiency of maleic anhydride is improved; the preparation method does not have special requirements on the double-screw extruder, a liquid feeding device is not required, and the length-diameter selection range is large.

Owner:HEFEI GENIUS NEW MATERIALS

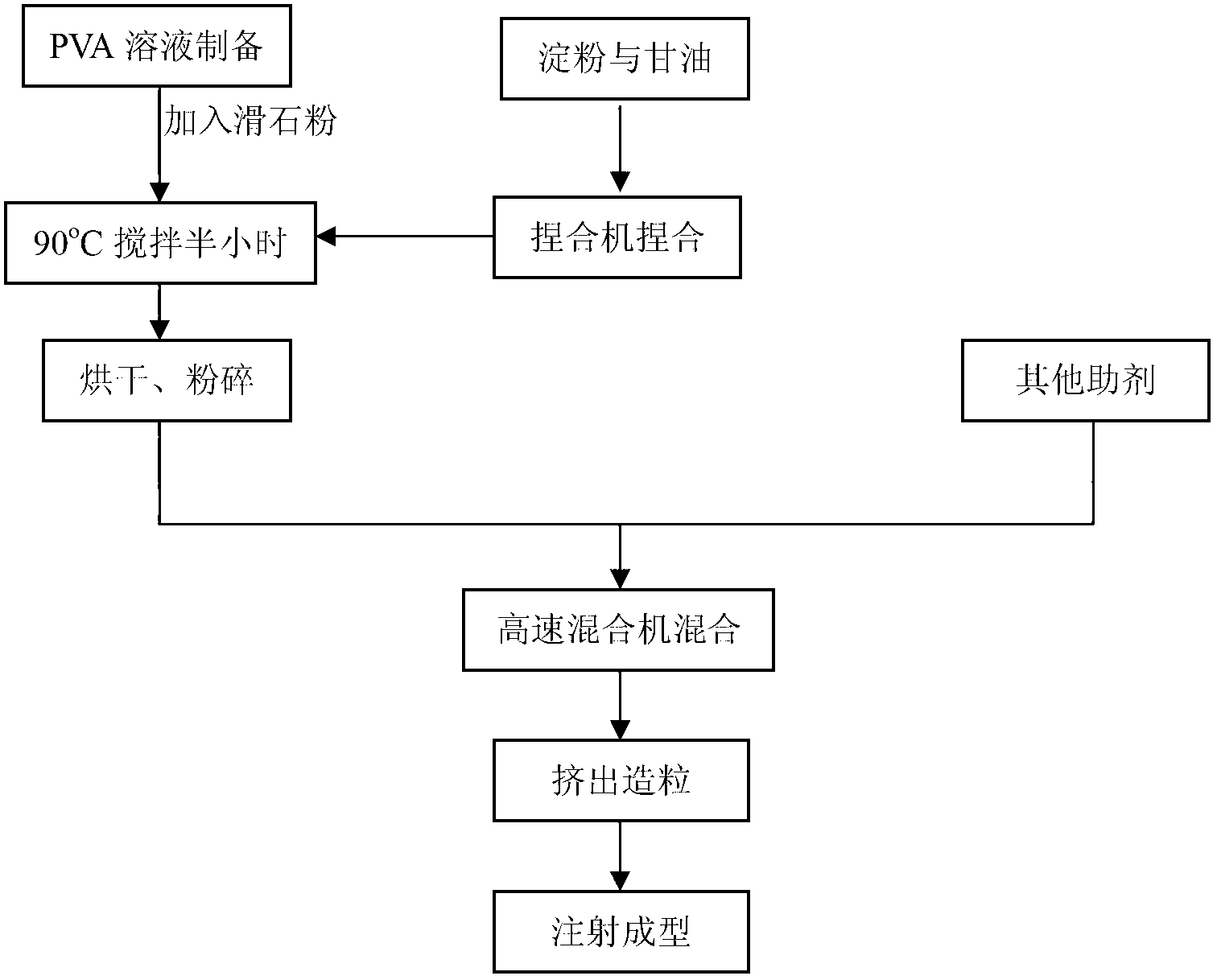

All-degradable thermoplastic starch/polylactic acid blend material and preparation method thereof

The invention relates to a thermoplastic starch / polylactic acid blend material and a preparation method thereof. The thermoplastic starch / polylactic acid blend material is prepared from 40-84% of starch, 8-51% of polylactic acid, 0.2-8% of polyvinyl alcohol, 1-10% of toughener, 0.1-2% of lubricant, 5-30% of plasticizer, 0.1-5% of preservative and 1-10% of inorganic filler. The starch is modified to prepare the thermoplastic starch with excellent properties, the polyvinyl alcohol solution is utilized to pretreat the inorganic filler and thermoplastic starch, and the mixture is subjected to extrusion and granulation by a double screw extruder, and subjected to injection molding to obtain the thermoplastic starch / polylactic acid blend material. The thermoplastic starch / polylactic acid blend material has the advantages of low cost and pollution-free production process, and is all-degradable. The cantilever notch impact strength of the prepared material is 3.5-6.4 KJ / m<2>, the tensile strength is 19-60 MPa, the bending strength is 63-110 MPa, the heat-deformation temperature is 75.5-88.3 DEG C, and the weight loss rate after three-month degradation reaches higher than 90%.

Owner:EAST CHINA UNIV OF SCI & TECH

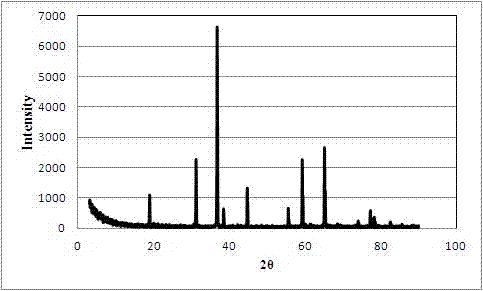

Preparation method for spherical cobaltosic oxide

InactiveCN103715418AUniform distribution of doping elementsHigh densityCell electrodesSecondary cellsCobalt(II,III) oxideParticle-size distribution

The invention discloses a preparation method for spherical cobaltosic oxide. The preparation method comprises the steps of mixing a cobalt salt with other trace metal elements; adding a precipitator and an oxidant in a flowing manner to obtain a synthetic product; and subjecting the synthetic product to solid-liquid separation, washing and sintering to obtain the spherical cobaltosic oxide material. The method disclosed by the invention is simple in process and convenient for operation; and the obtained product is uniform in distribution of doping elements, narrow in particle size distribution, good in degree of sphericity, and high in density.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

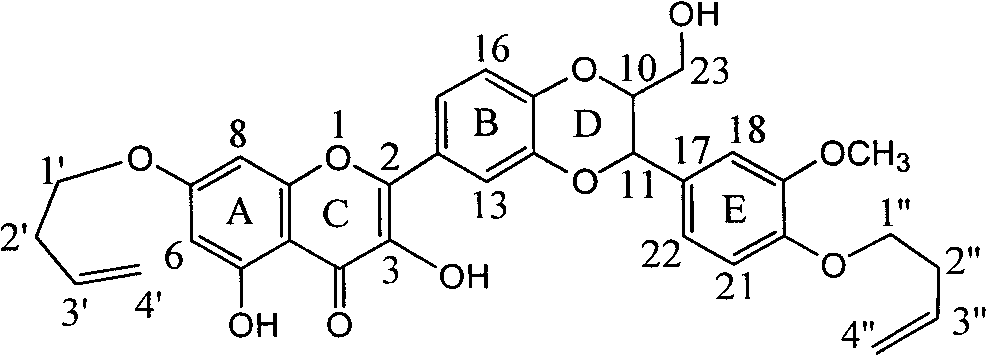

Application of dehydrogenated silibinin diether in preparation of medicaments for preventing and treating leukemia

InactiveCN101785767ASimple methodShort stepsOrganic active ingredientsAntineoplastic agentsMyeloid leukemiaLeukemia

The invention provides application of dehydrogenated silibinin diether in the preparation of medicaments for preventing and treating leukemia and relates to medical application of lignin flavone silibinin to the prevention and treatment of chronic myeloid leukemia. Particularly, the invention relates to application of dehydrogenated silibinin diether, of which the seventh bit and the twentieth bit are substituted by 1-butylene, or pharmaceutically acceptable salts thereof in the preparation of medicaments for preventing and treating chronic myeloid leukemia. Natural products of the silibinin are treated by simple steps to synthesize the compound. The pharmacological tests prove that the compound can potently inhibit the in-vitro proliferation of human chronic myeloid leukemia cell strains(K562) and adriamycin drug-resistant strains (K562 / ADR), and the IC50 values are 11.9+ / -1.6 micromoles and 15.9+ / -1.2 micromoles respectively.

Owner:DALI UNIV

Method for extracting glutathione from glutathione fermented broth

The invention relates to a method to distill glutathione from glutathione fermentation liquid. It uses glutathione fermentation liquid taking centrifuge to gain yeast cell, adjusting pH value, and boiling to distill glutathione in the cell and make the macromolecular substance denaturalization and depositing. Using the positive iron exchange technology to remove small molecule and coloring matter, the white power glutathione that has molecular weight of 307.33, protein content of 23%, and distilling yield 80.5% would be gained. The invention has simple process, high efficient, low cost, high purity, low pollution, etc.

Owner:JIANGNAN UNIV

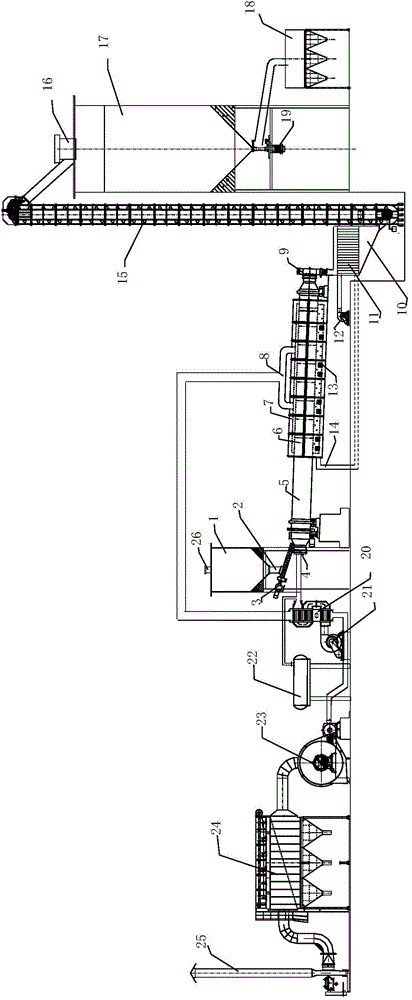

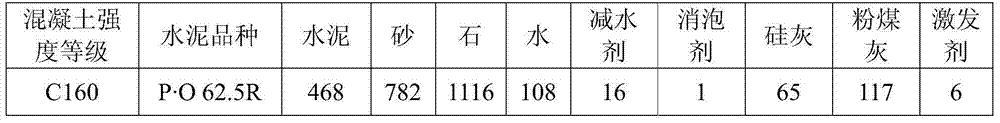

Two-section rotation oxygen-enrichment external heating oxidation technology and device for dry-method and semi-dry method desulfurized ash

ActiveCN104150520AStable oxidation timeEquilibrium oxidation temperatureCalcium/strontium/barium sulfatesEnergy inputAutomatic controlResource utilization

The invention relates to a two-section rotation oxygen-enrichment external heating oxidation technology and device for dry-method and semi-dry method desulfurized ash. A two-section type rotation oxidation kiln is adopted, oxygen is introduced into the kiln and heating is implemented by adopting an external heating furnace, so that the oxidizing process for converting CaSO3 in the desulfurized ash into CaSO4 is completed. Compared with the prior art, the technology and the device have the benefits as follows: (1), during the oxidation of the desulfurized ash in the oxidation kiln, stable oxidation time, balanced oxidation temperature, sufficient oxygen content and appropriate oxidation atmosphere are realized, the technical measures such as automatic control, surplus heat utilization, dust removal and environment protection are adopted, so that the low-cost oxidation and industrialized production are realized; (2), the provided systematic desulfurized ash oxidation production line is suitable for the industrialized and large-scale production requirements; (3), the processing parameters such as oxidation temperature, time and oxygen content are controlled through a PC (Personal Computer), so that the appropriate oxidation conditions are ensured; (4), the promotion of the development of a dry-method and semi-dry method desulfuration technology is facilitated; (5), the resource utilization of the desulfurized ash is realized, and the energy conservation, emission reduction and environment protection are facilitated.

Owner:孟昭全 +2

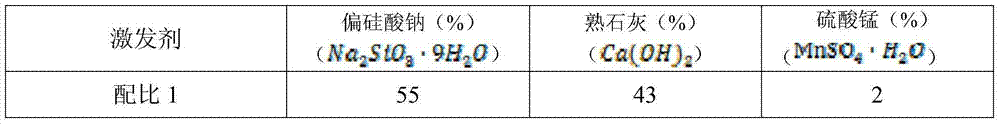

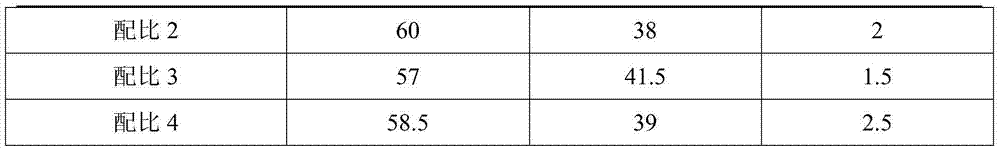

Concrete for steel reinforced concrete combined structure with C160 strength level

InactiveCN103539407AIncreased durabilityHigh strength and durabilityCarrying capacityReinforced concrete

The invention discloses concrete for a steel reinforced concrete combined structure with C160 strength level. The concrete is composed of cement, fine aggregate, coarse aggregate, water, a concrete super plasticizer, a defoaming agent, silica fume, fly ash and an activator according to a ratio of 468:782:1116:108:16:1:65:117:6. The preparation method is as follows: firstly, uniformly mixing the concrete super plasticizer and the activator in weighed water to obtain a mixture, sequentially adding 1 / 3 of total dosage of the fine aggregate and the mixture in a stirring machine according to a weight ratio, and stirring; adding 1 / 3 of total dosage of the coarse aggregate and the mixture and stirring; and adding the cement, the silica fume and the fly ash, and stirring; and adding the defoaming agent and the rest mixture, stirring and discharging. The concrete can greatly perfect the adhesive property between section steel and the concrete under a natural state, effectively play the respective mechanical properties and mutual cooperative working performance of the steel and the concrete and greatly improve the carrying capacity, application performance and durability of the structural member, thereby having good high-volume stability and economical efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Preparation method of conjugated linoleic acid

InactiveCN101565367AHigh yieldReduce manufacturing costFatty acid isomerisationOrganic compound preparationIsomerizationVegetable oil

The invention relates to a preparation method of conjugated linoleic acid, comprising the following steps: placing the vegetable oil containing linoleic acid glyceride or mixed fatty acid containing linoleic acid or extracted and separated linoleic acid product as raw material, low boiling point alcohols solvent and base catalyst into a reaction kettle and performing the isomerization reaction at a certain temperature. The reaction product is subjected to evaporating, acidifying, extracting and vacuum drying to obtain the conjugated linoleic acid. The conversion of the linoleic acid is above 97.5% and the total yield of the conjugated linoleic acid is above 85%, the proportions of the cis-9, trans-11 isomer and trans-10, cis-12 isomer in the total conjugated linoleic acid are above 96%. The preparation method has features of less reaction steps, easy recovery and repeated use of solvent, simple follow-up separation, low production cost, and easy industrialization.

Owner:ZHEJIANG UNIV

Method of producing a sustained-release preparation

InactiveUS6399103B1Reduce the number of stepsSuitable for industrializationCosmetic preparationsPowder deliveryBlood concentrationOrganic solvent

A method of producing sustained-release microcapsules which comprises dispersing a physiologically active polypeptide into a solution of a biodegradable polymer and zinc oxide in an organic solvent, followed by removing the organic solvent; which provides a sustained-release preparation showing a high entrapment ratio of the physiologically active polypeptide and its constant high blood concentration levels over a long period of time.

Owner:TAKEDA PHARMA CO LTD

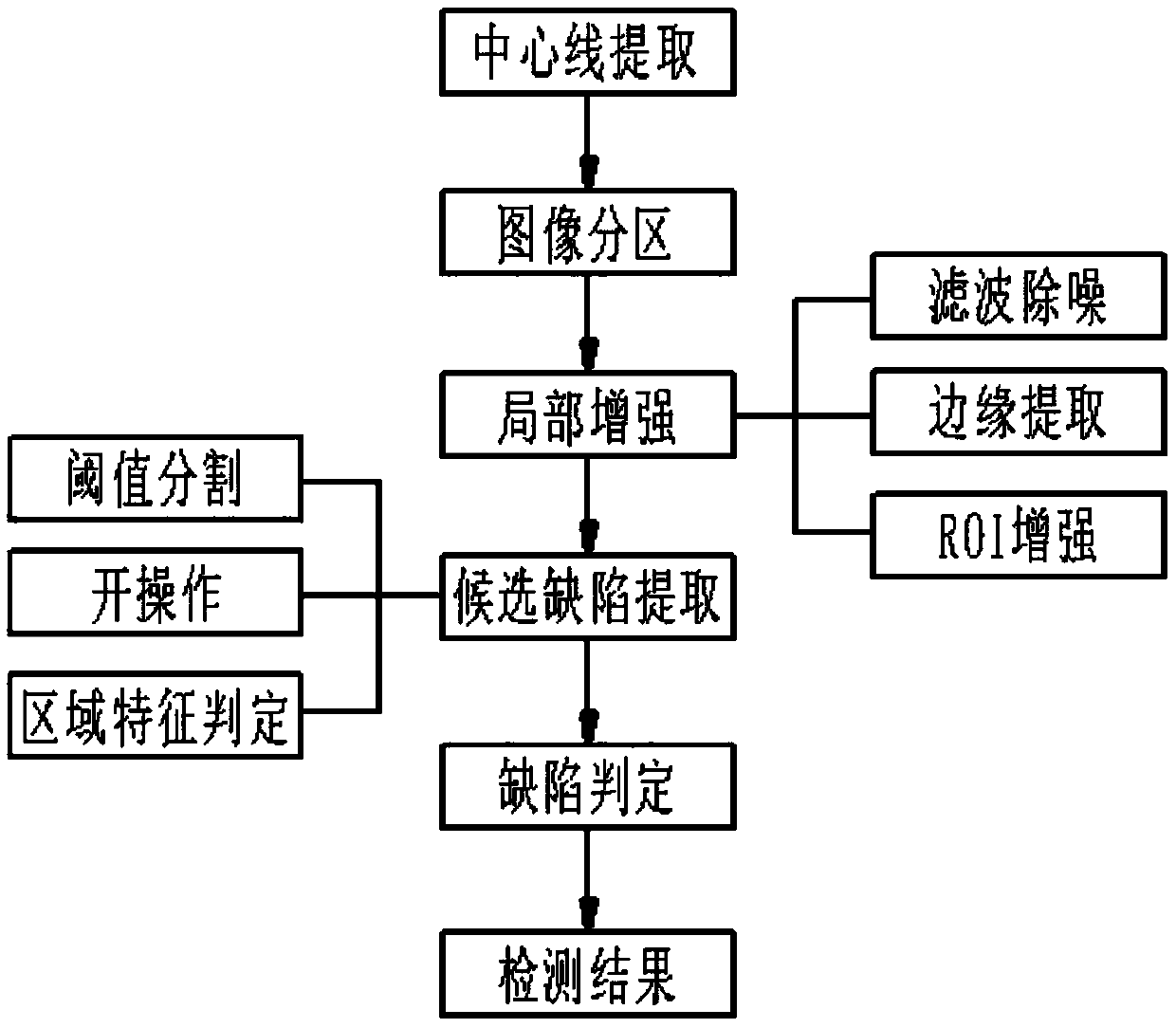

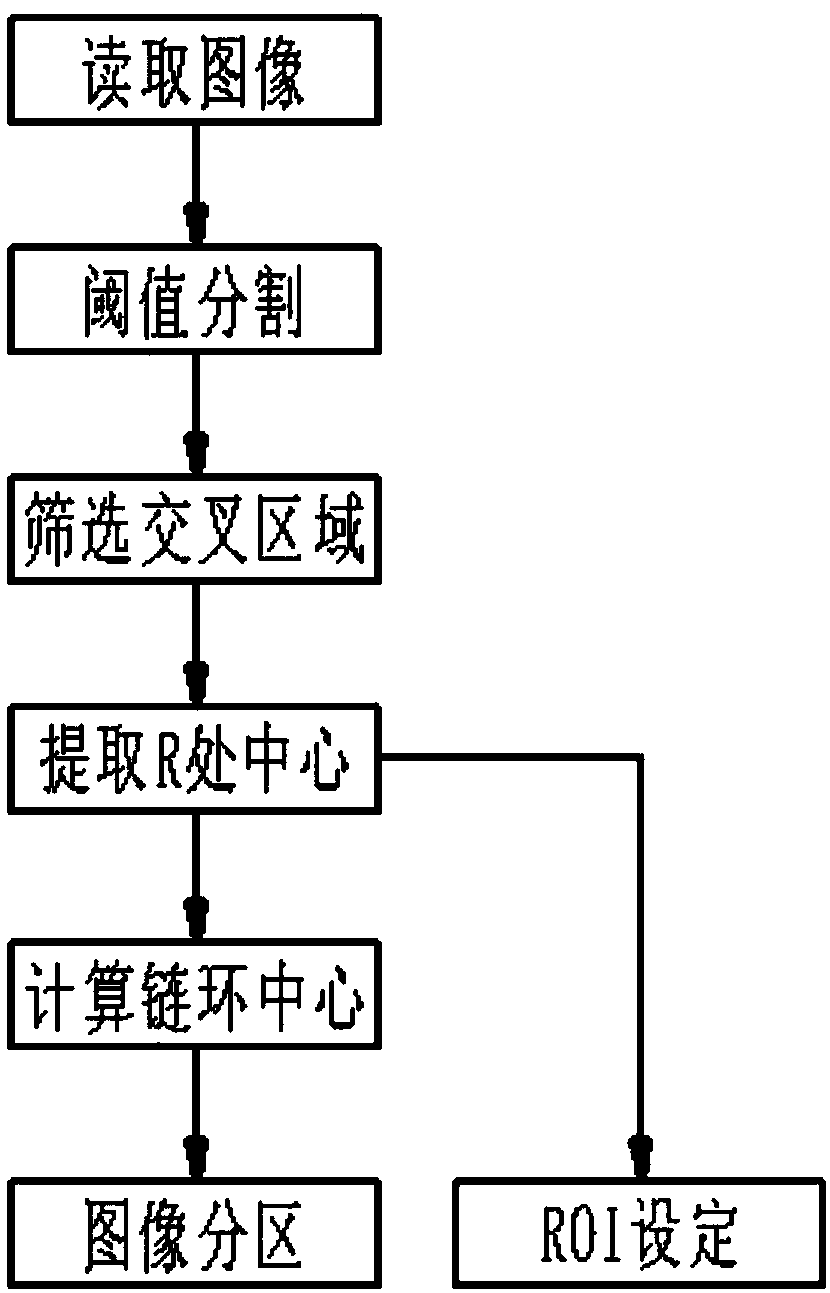

Machine vision-based elevator compensation chain place-R crack detection method

InactiveCN107610104AReduce complexityReduce detectionImage enhancementImage analysisMachine visionFeature extraction

The invention provides a machine vision-based elevator compensation chain place-R crack detection method. The method includes the following steps: (1) collecting an image which is a chain place-R crack image, and carrying out partitioning on the image, wherein image partitioning comprises threshold segmentation for extracting a centerline of an elevator compensation chain and a place-R area, whichcontains to-be-detected defects, to obtain a to-be-detected target area image of the place-R area; (2) carrying out corresponding local enhancement, filtering and noise removal and edge extraction onthe to-be-detected target area image, which is collected in the step (1), of a place R, and then carrying out area enhancement processing on the place R to obtain an ROI area image; (3) carrying outthreshold segmentation, open operation and morphological feature extraction on the ROI area image obtained in the step (2), primarily determining the defects thereof, and extracting candidate defect images; and (4) carrying out secondary determination on the candidate defect images, which are obtained in the step (3), according to location features to obtain a final defect image determination result. According to the method, an automation degree is higher, detection is accurate, and detection efficiency is high.

Owner:NANTONG XING HUA DA GAO IND CO LTD

Modified PET polyester as well as preparation method and application thereof

ActiveCN107312166AFree from destructionShorten the replacement periodFlame-proof filament manufactureSilicon compoundsPolyethylene terephthalateSlurry

The invention relates to modified PET (Polyethylene terephthalate) polyester as well as a preparation method and application thereof, and belongs to the field of modified polyester. The modified PET polyester comprises aerogel particles and polyethylene terephthalate; the aerogel particles are dispersed between the molecular chains of the polyethylene terephthalate uniformly; the particle size of the aerogel particles is 2 to 3 microns; the content of the aerogel particles in the modified PET polyester is 1 to 10 percent by weight. Modified PET is prepared by the steps of adding the aerogel powder into glycol, putting into a grinding machine, grinding to prepare mixed slurry, mixing the mixed slurry and terephthalic acid, and performing esterification reaction and polymerization reaction. Modified PET fiber is prepared by slicing the modified PET, metering, spinning, cooling, applying oil, stretching, performing heat setting and performing winding formation. The aerogel particles are introduced before polymerization of the PET polyester, so the prepared PET has high spinnability, can produce modified PET fibers with various thickness, has wide application range and can meet the production requirement of various fabrics.

Owner:天津朗华科技发展有限公司

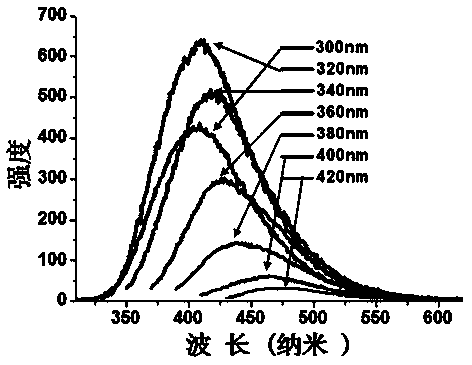

Preparation method of fluorescent carbon quantum dot probe for detecting beryllium in water

InactiveCN104003370AImprove solubilityCause secondary pollutionNano-carbonFluorescence/phosphorescenceRotary evaporatorVacuum drying

A preparation method of a fluorescent carbon quantum dot probe for detecting beryllium in water comprises the following steps: preparing a citric acid solution with a concentration of 0.04 g / ml; weighing urea, adding the urea into the above citric acid solution, uniformly stirring to obtain a mixed solution, wherein the urea concentration is 0.01-0.04 g / ml; transferring the above mixed solution into a hydro-thermal reaction vessel, reacting at 200-240 DEG C, naturally cooling the reaction vessel to room temperature to obtain a brown aqueous solution; performing centrifugation by a centrifuge and dialysis in order of the brown aqueous solution, then concentrating the brown aqueous solution by a rotary evaporator, and finally drying in a vacuum drying oven to obtain a solid viscous substance. The product of the invention makes use of the fluorescence characteristic of carbon quantum dots; detection of beryllium ion content is carried out by a fluorescence spectrophotometer, which is low in cost; the sample preparation and treatment steps are simple and easy to operate; the detection selectivity and sensitivity are high; the product of the invention is widely applicable to beryllium ion detection.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for producing solar energy stage polycrystalline silicon by using high-pure quartz sand as raw material

The invention provides a method for producing solar energy level polysilicon by taking quartz sands with high purity as materials. In the method, silica materials, in which the SiO2 content is more than 99 percent, are chosen to undergo water quenching, crushing, sieving, acid cleaning, magnetic separation and high voltage ionizing treatments, which makes the purity of silica particles reach more than 99.99 percent, and the quartz sands with high purity are obtained; carbonaceous reducing agents and graphite electrodes in a mine hot stove are chloridized at a high temperature in a chlorination furnace, making the purity of carbonaceous reducing agents reach more than 99.99 percent; in the mine hot stove, the carbonaceous reducing agents are used to reduce the quartz sands with high purity so as to produce silicon, and while producing, silicon liquids are periodically discharged from the mine hot stove; the obtained silicon liquids are injected in a holding furnace, and the products directly undergo the high-frequency plasma air refining for impurity removal under the non oxidizing atmosphere, and at the same time oxidizing gases are added in the melting silicon; the silicon liquids are injected in a directional solidification furnace for the directional solidification, and the silicon is further purified, so that the solar energy level polysilicon is obtained. The method of the invention has the advantages of low investment, short building period, low manufacturing cost, simple process and no pollution; moreover, the method is also suitable for industrialization.

Owner:JINZHOU NEW CENTURY QUARTZ GROUP CO LTD

Cold water dispersion type xanthophyll micro-capsule and its preparing method

InactiveCN101219125AUniform particlesUniform particle distributionHydroxy compound active ingredientsAntinoxious agentsSolubilityWater dispersible

The invention discloses a cool water dispersible lutein microcapsule. The lutein microcapsule comprises lutein powder used as core material, modified starch and natural colloid used as wall material, and appropriate amount of emulsifier added, which are mixed and added with proper amount of water, heated and stirred, and then filtered and spray dried to obtain the lutein microcapsule. The invention has easy material acquiring, can be applied to food or pharmaceutical industry, and has good safety without using organic solvents thus the nature of the lutein is well kept. In the invention, the core material and the wall material are mixed directly in one step, and emulsified by controlling the temperature; the lutein liquid is embedded into semi-permeable or hermetic solid microcapsule powder by adopting spay drying. The obtained microcapsule powder has good water-solubility, high stability and encapsulation rate.

Owner:云南博浩清亮生物科技有限公司

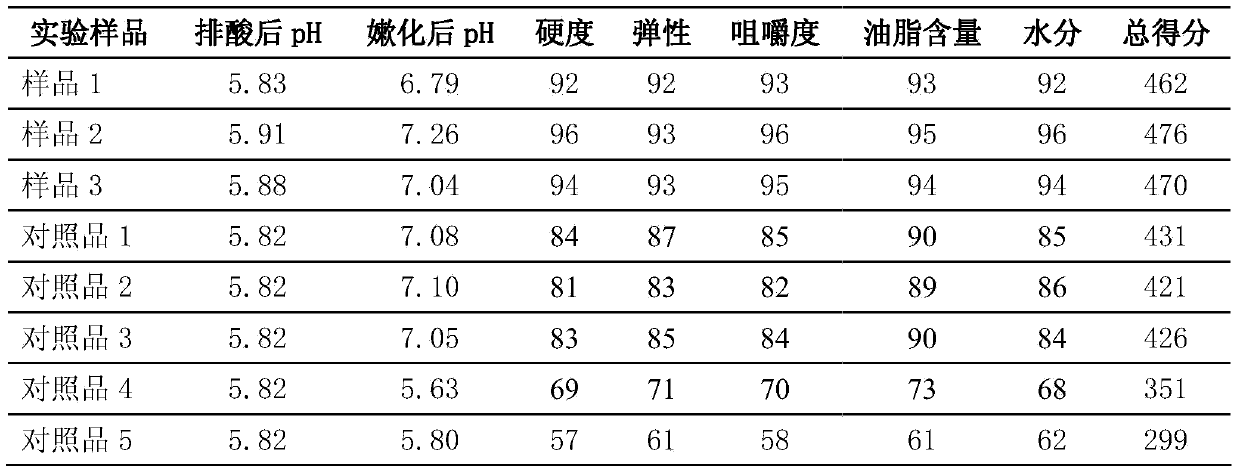

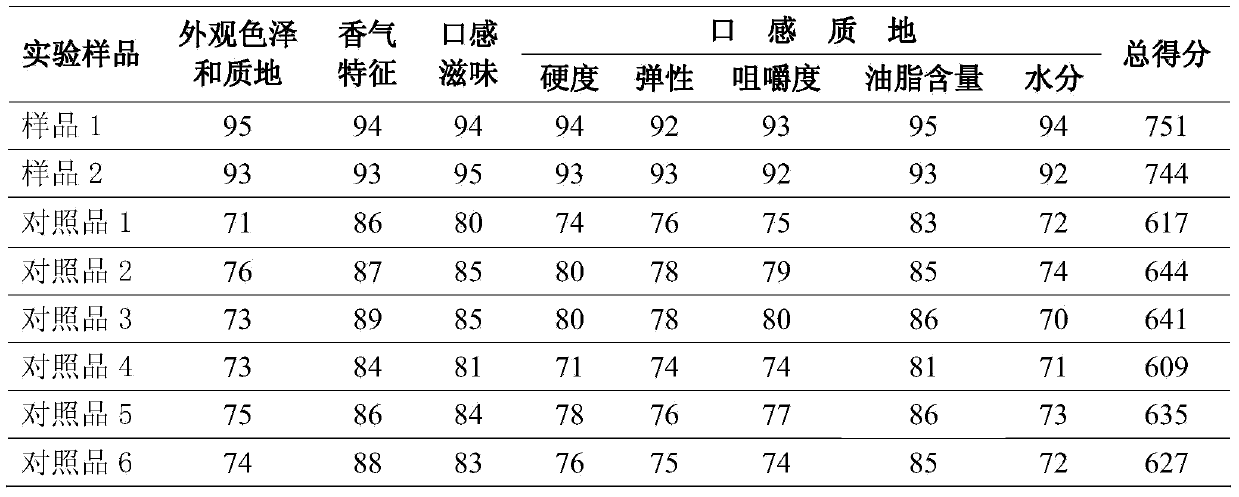

Steak processing method

InactiveCN104187772AExcellent tenderizing effectEnhanced tenderizing effectFood preparationGlucose powderVegetable Juices

The invention relates to a steak processing method. The steak processing method comprises the following steps: (1) cooling for removing lactic acid; (2) segmenting and cleaning; (3) adding a tenderizer until the pH value of the meat is 6.7-7.3, and then adding a curing agent and tumbling for curing; (4) shaping and packaging; (5) quick-freezing; (6) encasing and warehousing, wherein tenderizer is prepared from the following raw materials in parts by weight: 8-12 parts of mashed pawpaw, 3-5 parts of mashed pineapple, 2-4 parts of glucose powder and 2-4 parts of sodium bicarbonate powder; the curing agent is prepared from the following raw materials in parts by weight: 13-17 parts of salt, 8-12 parts of aginomoto, 8-12 parts of soybean sauce, 4-6 parts of beef powder, 11-15 parts of black pepper powder, 1-3 parts of white pepper powder, 10 parts of egg white and 15 parts of vegetable juice; the vegetable juice is obtained by juicing celery, onion, radish, garlic and tomato by equal weights; the steak processed by use of the method is rich in nutrition, and more fresh and tender in taste, and has a health care effect.

Owner:安徽刘郎食品有限公司

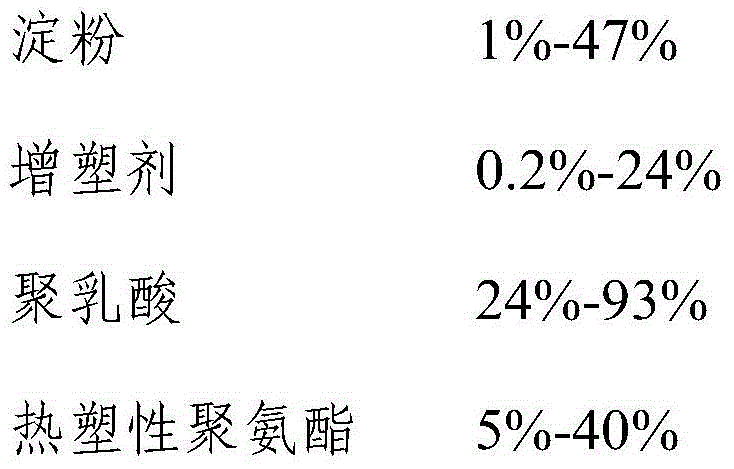

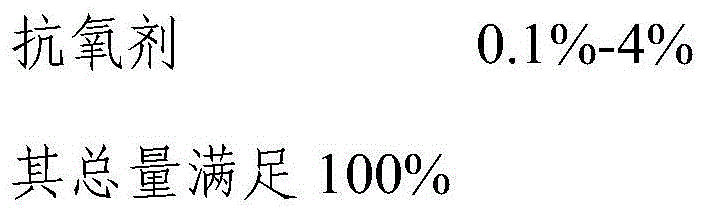

Toughening and waterproof starch plastic and preparation method thereof

The invention relates to a toughening and waterproof starch plastic and a preparation method thereof. A formula of the toughening and waterproof starch plastic comprises 1-47% of starch, 0.2-24% of plasticizer, 24-93% of polylactic acid, 5-40% of thermoplastic polyurethane and 0.1-4% of antioxidant. The toughening and waterproof starch plastic is prepared by the preparation method comprising the following steps: mixing starch and plasticizer according to a proportion, mixing for 3 minutes in a high-speed mixer, extruding with a double-screw extruder, cooling the product and pulverizing to obtain thermoplastic starch; and mixing the thermoplastic starch, polylactic acid, thermoplastic polyurethane and antioxidant according to a proportion, and kneading for 10-15 minutes in a kneading machine till the materials are mixed uniformly, thus obtaining the toughening and waterproof starch plastic. The toughening and waterproof starch plastic has the advantages of simple preparation process, good toughness, good water resistance, low cost, degradability, environmental friendliness in the production process and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing 4, 6 dichloropyridine

ActiveCN1687036ASimple and fast operationSuitable for industrializationOrganic chemistryChemistryDiphosgene

The present invention relates to a method capable of using diphosgene or triphyosgene to chlorinate 4,6-dihydroxypyrimidine to obtain 4,6-dichloropyrimidine in the presence of proper alkali and a certain solvent or mixed solvent.

Owner:JIANGSU INST OF ECOMONES

One-time glu-filling formation method for double-pole-plate sealing assembly

InactiveCN1815783AImprove work efficiencyImprove sealingCell electrodesFinal product manufactureMechanical engineering

Owner:南京博能燃料电池有限责任公司

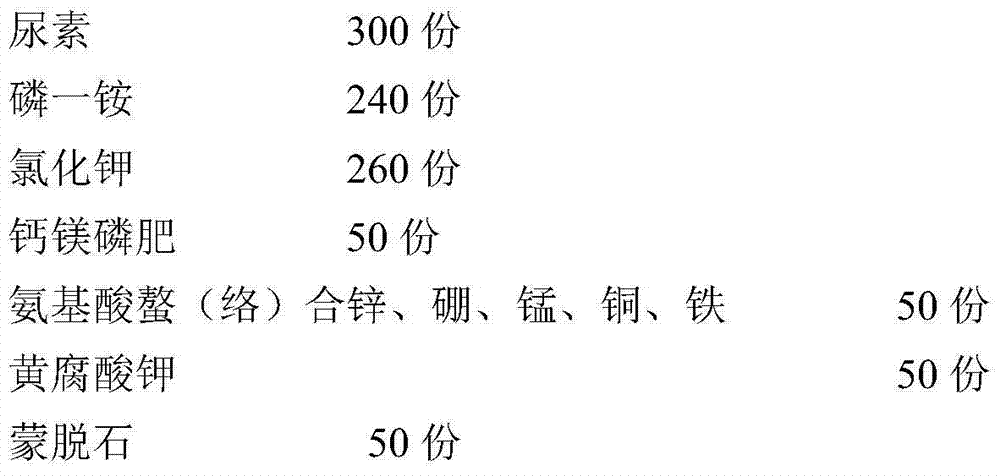

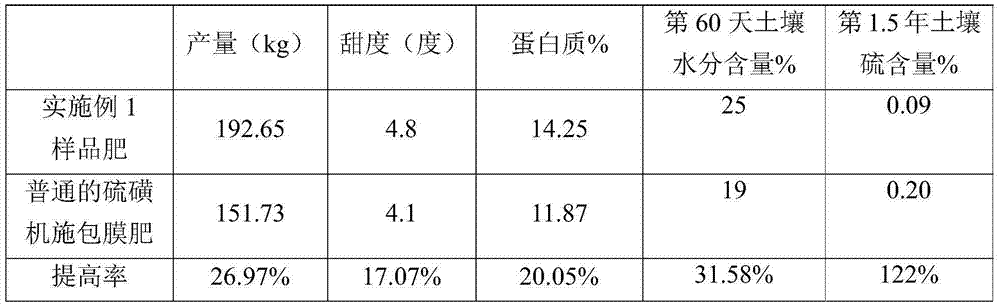

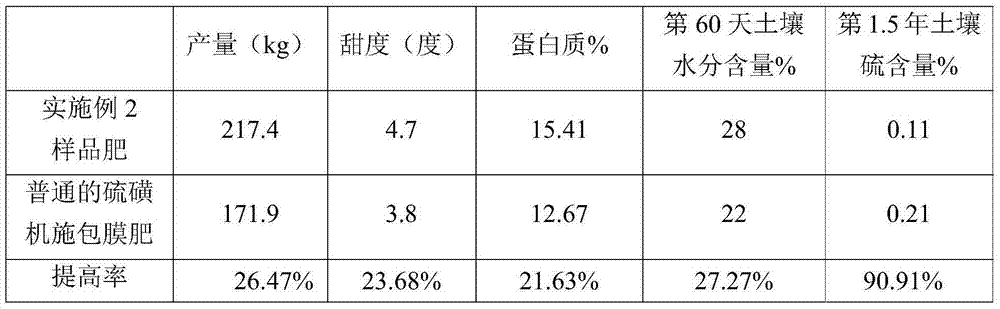

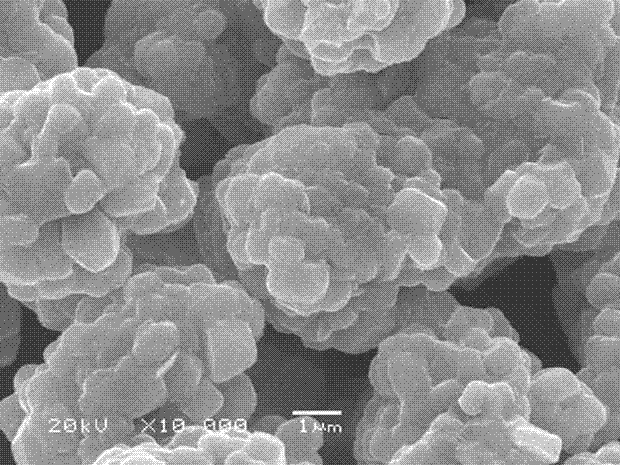

Total-nutrient water-retaining degradable mechanically-applied coated fertilizer

InactiveCN104496650ANutritional diversityImprove water retentionAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSulfurNutrient

The invention discloses a total-nutrient water-retaining degradable mechanically-applied coated fertilizer and a preparation method thereof, and belongs to the technical field of fertilizers. The preparation method comprises the following steps: (1) preparing a total-nutrient fertilizer core; (2) preparing a water-retaining degradable coating liquid, namely melting sulfur in a high-speed shearing mixer, heating after amino resin and a membrane modifying agent are added, mixing and adding a water retaining agent till the stable water-retaining degradable coating liquid is formed; (3) preheating the total-nutrient fertilizer core; and (4) coating, namely coating the prepared water-retaining degradable coating liquid on the surface of the preheated total-nutrient fertilizer core. The mechanically-applied coated fertilizer prepared according to the preparation method has global nutrition, is low in price and degradable, can be mechanically applied, has the functions of retaining water, improving soil and the like, and can be applied to field crops in northwest arid areas of China.

Owner:SHENZHEN BATIAN ECOTYPIC ENG

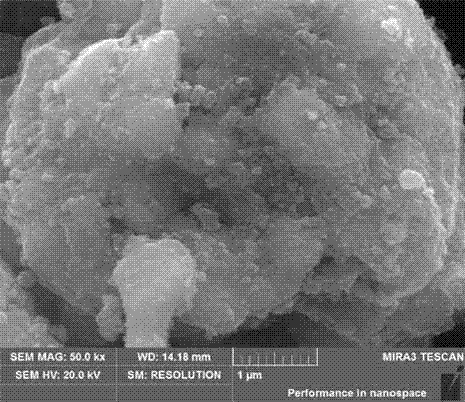

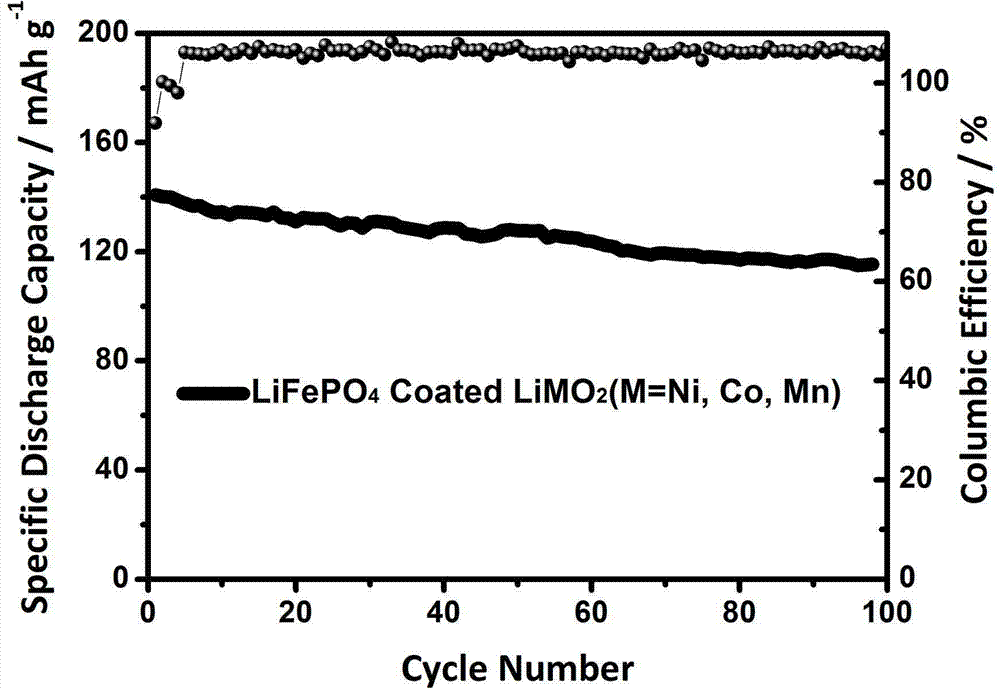

Preparation method of lithium nickel cobalt manganate composite material coated with lithium iron phosphate on surface

ActiveCN104733708AImprove cycle performanceImprove securityCell electrodesSecondary cellsLithium iron phosphateThermal stability

The invention relates to a preparation method of lithium nickel cobalt manganate composite material coated with lithium iron phosphate on the surface and the lithium nickel cobalt manganate composite material has good cycle property and high safety. According to the method, lithium nickel cobalt manganate is subjected to surface coating modification in a way that a hydrothermal method is adopted to grow lithium iron phosphate on the surfaces of the lithium nickel cobalt manganate particles. The lithium iron phosphate is an active cathode material for lithium ion batteries and has better thermal stability, chemical stability, cycle performance and safety performance than lithium cobaltate, lithium nickel cobalt manganate, lithium manganate and the like, so that the problem about safety of the lithium ion batteries made of lithium nickel cobalt manganate under the conditions of high temperature, over-charging and needling can be effectively solved. The composite material is high in energy density, good in cycle performance and safety performance and simple in preparation technology and can be put into industrialization easily.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com