Patents

Literature

48results about How to "Disperse fully and evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

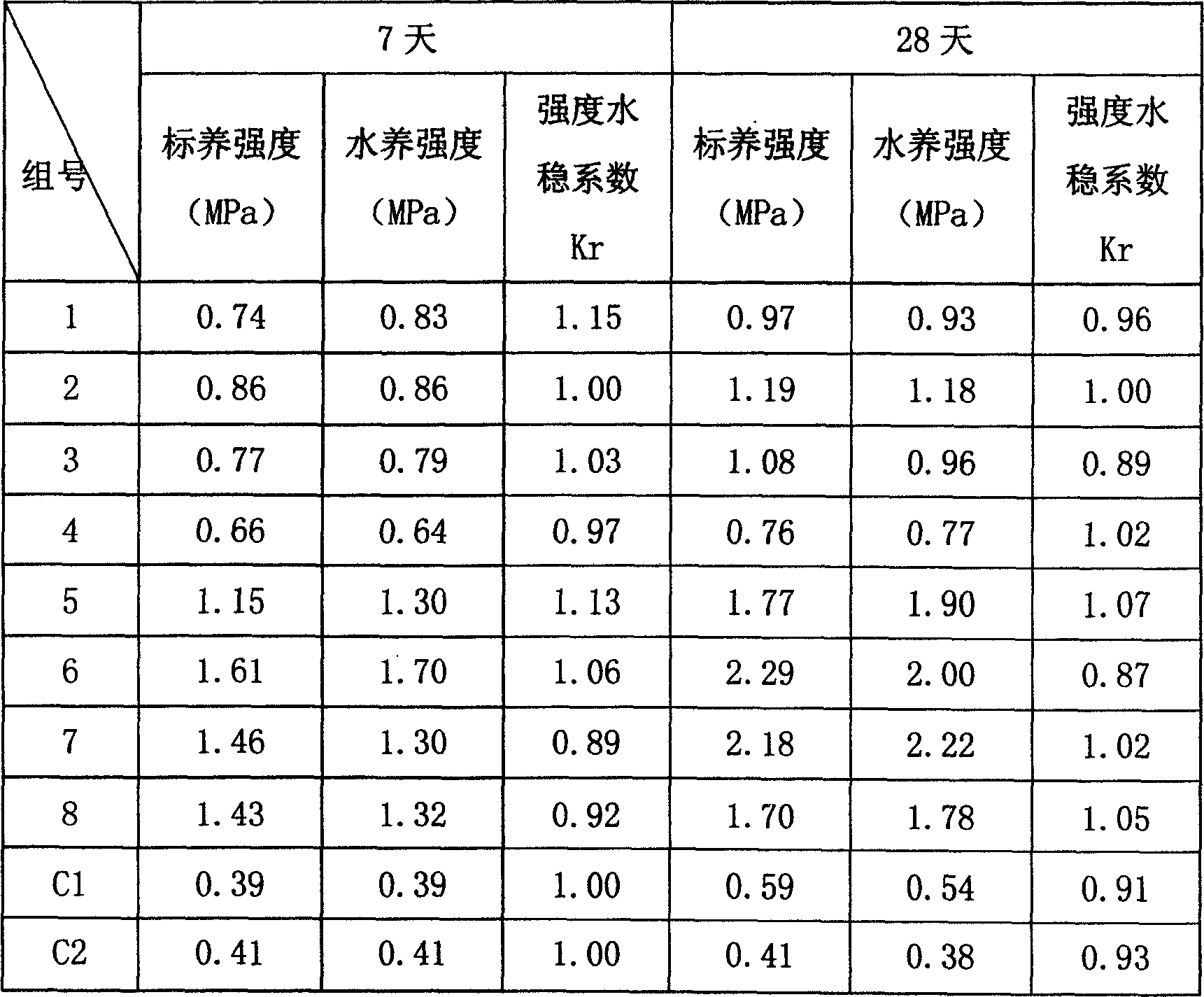

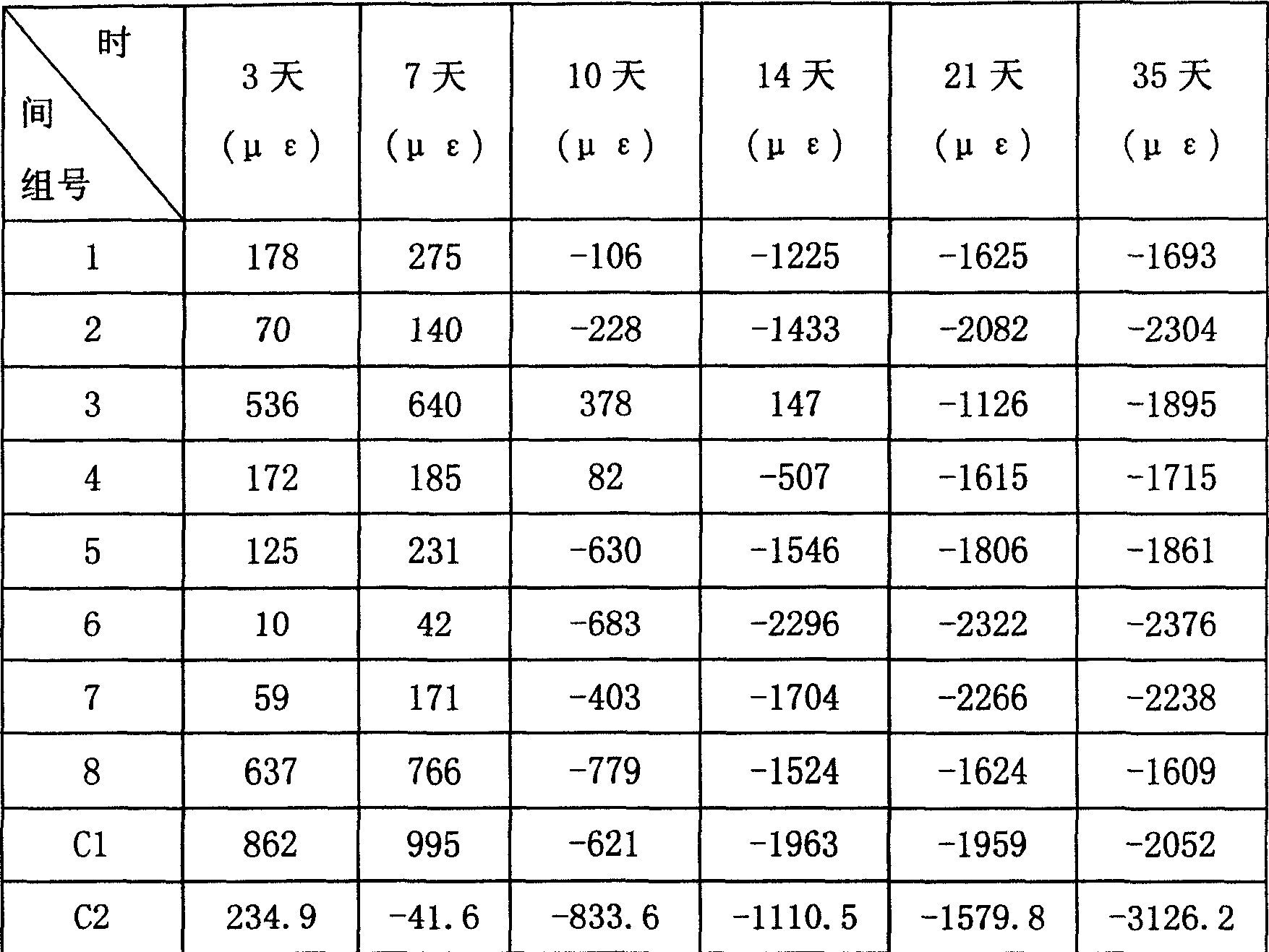

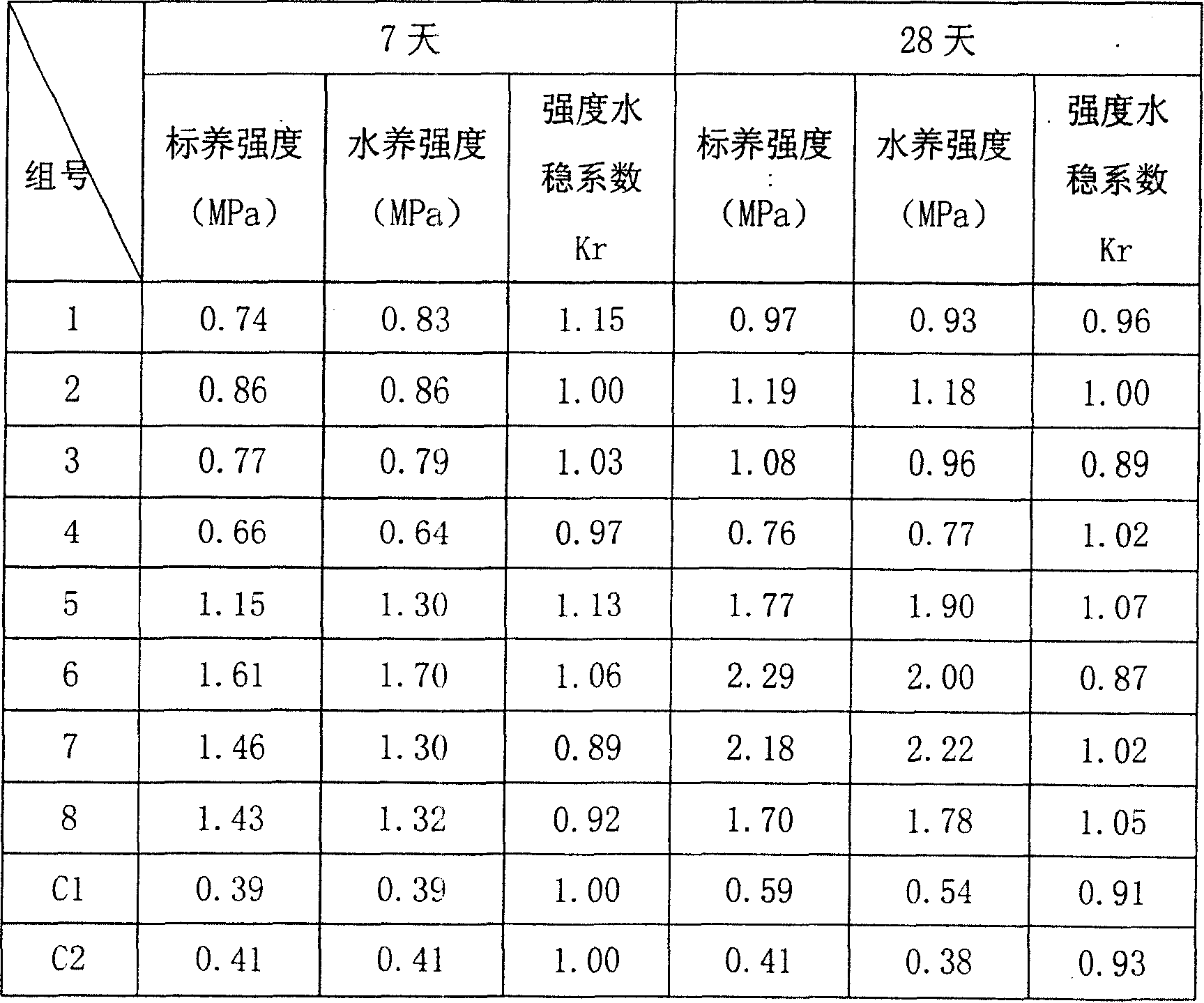

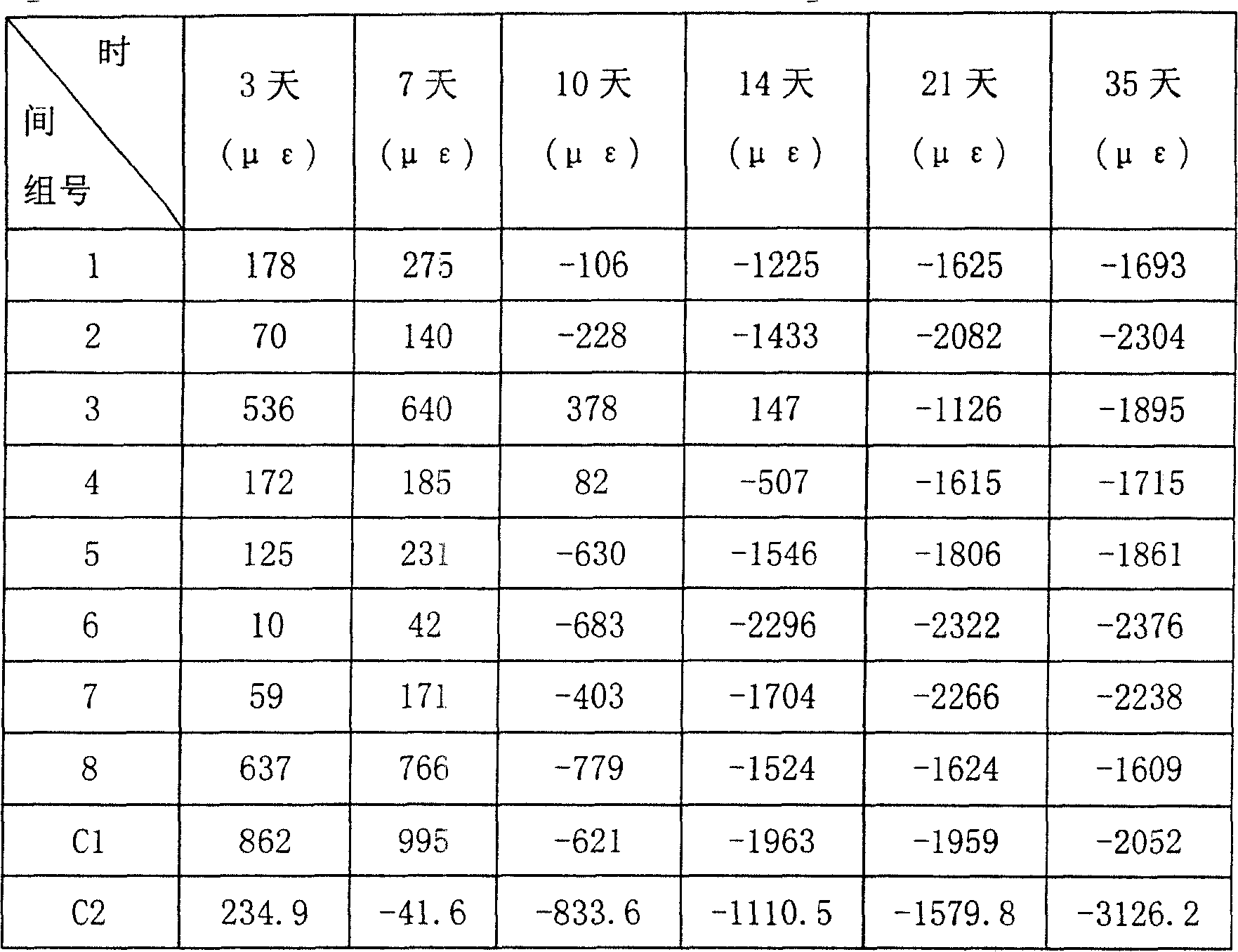

Soil solidifying agent

The soil curing agent as one kind of engineering material for curing and stabilizing various kinds of soil is especially suitable for curing silt and other kinds of low viscosity soil. The soil curing agent has main cement material comprising ore powder, flyash and water, as well as proper amount of alkali exciting component, expanding component and surfactant, and is prepared through mixing the materials and grinding to Blaine fineness of 3000-5000 sq m / kg. Specifically, it consists of mineral admixture 40-60 wt%, cement 15-25 wt%, alkali exciting component 5-15 wt%, expanding component 15-25 wt% and surfactant 0.01-0.1 wt%.

Owner:SOUTHEAST UNIV

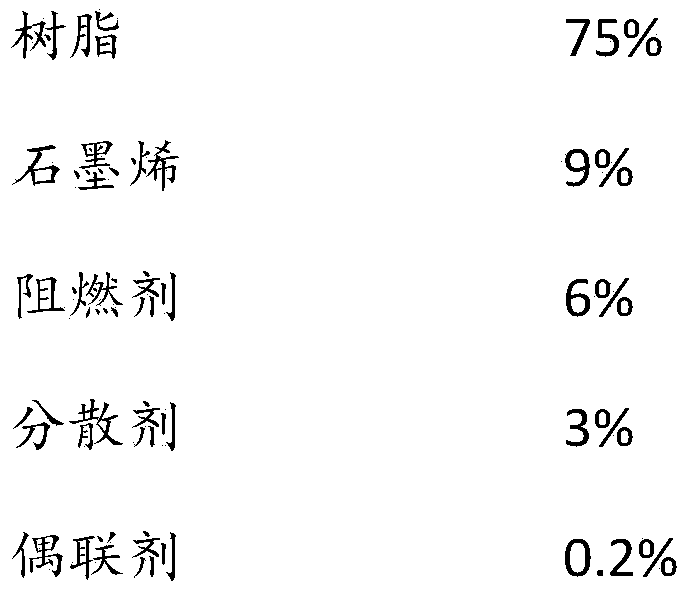

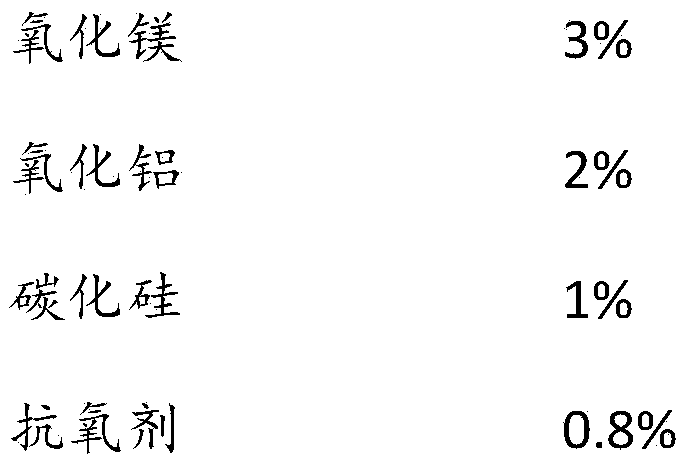

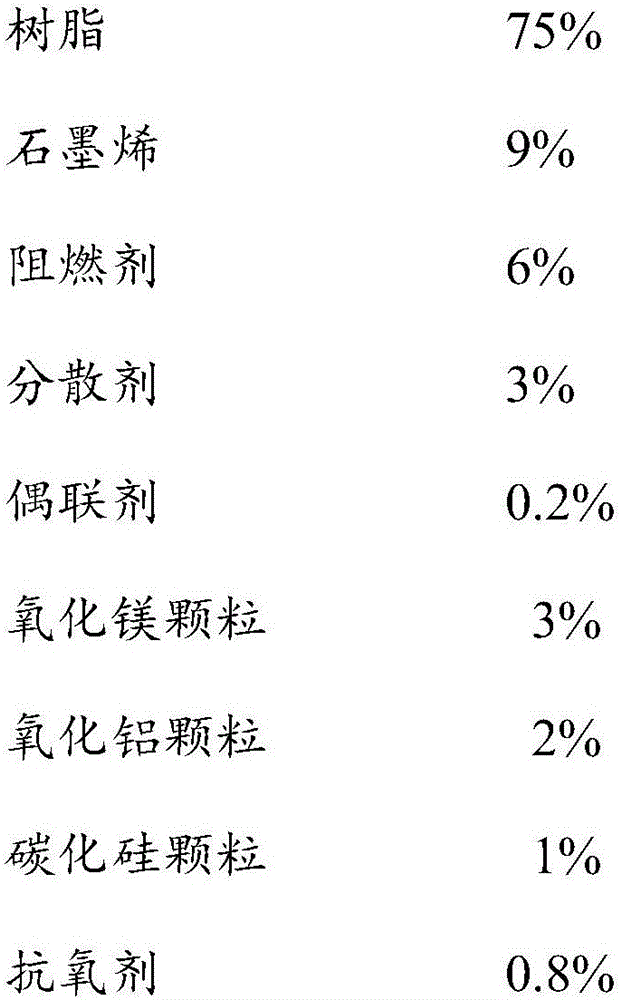

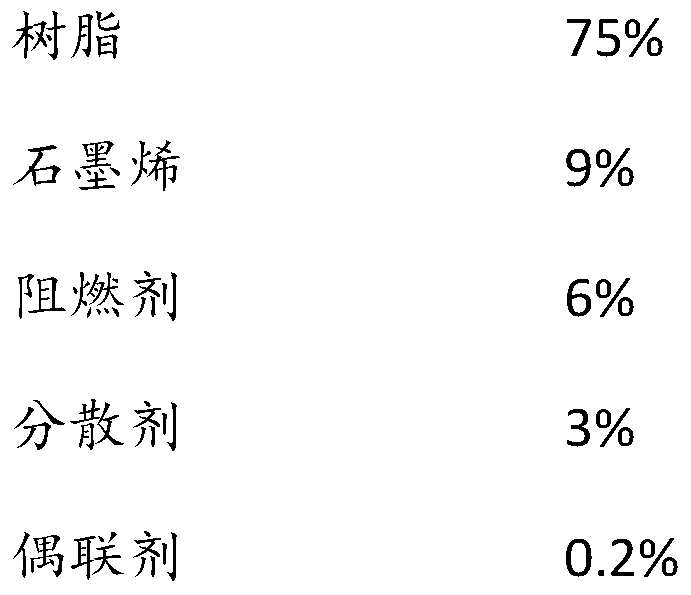

Graphene thermal conductive plastic, and preparation method thereof

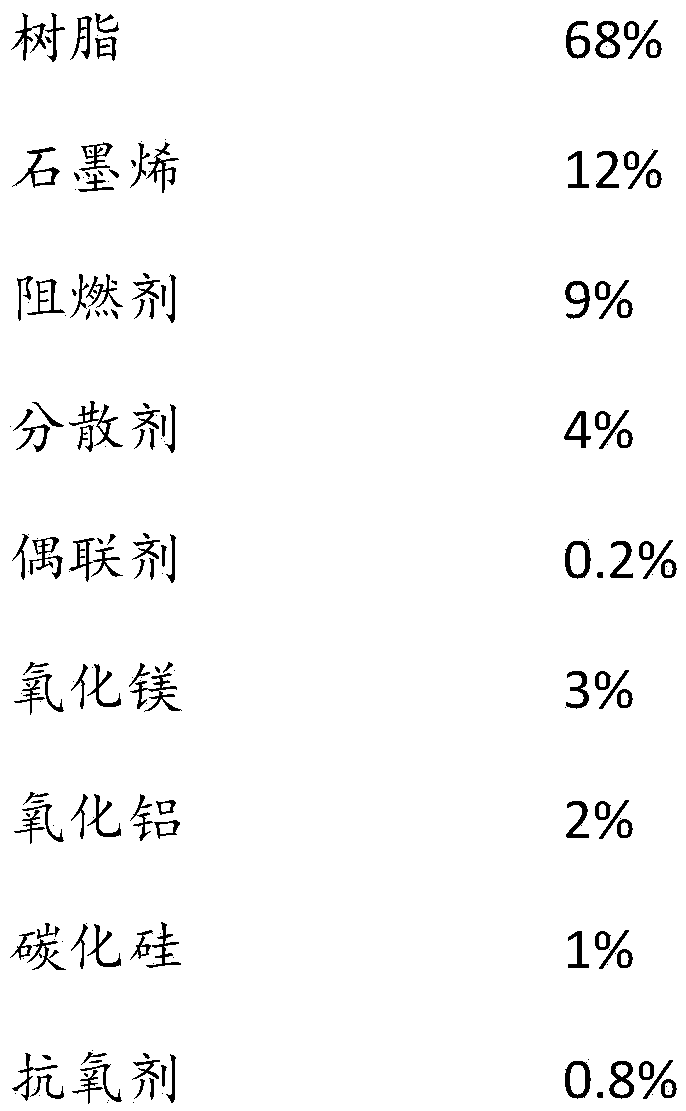

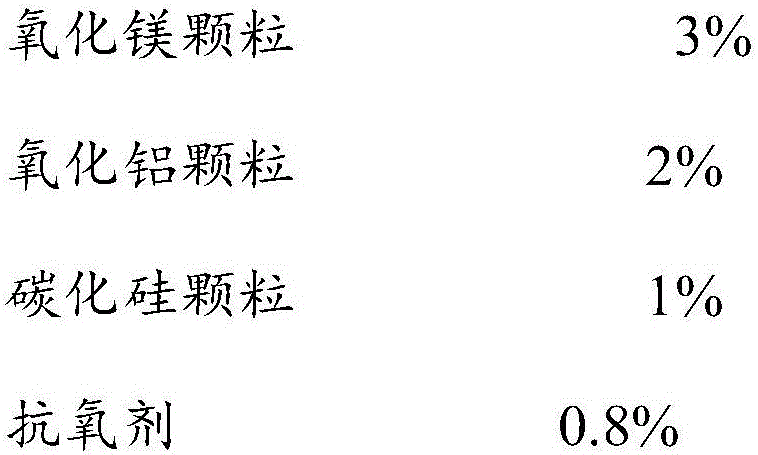

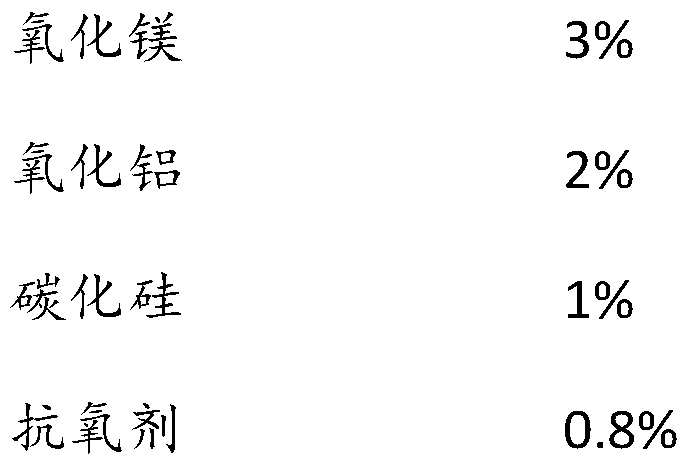

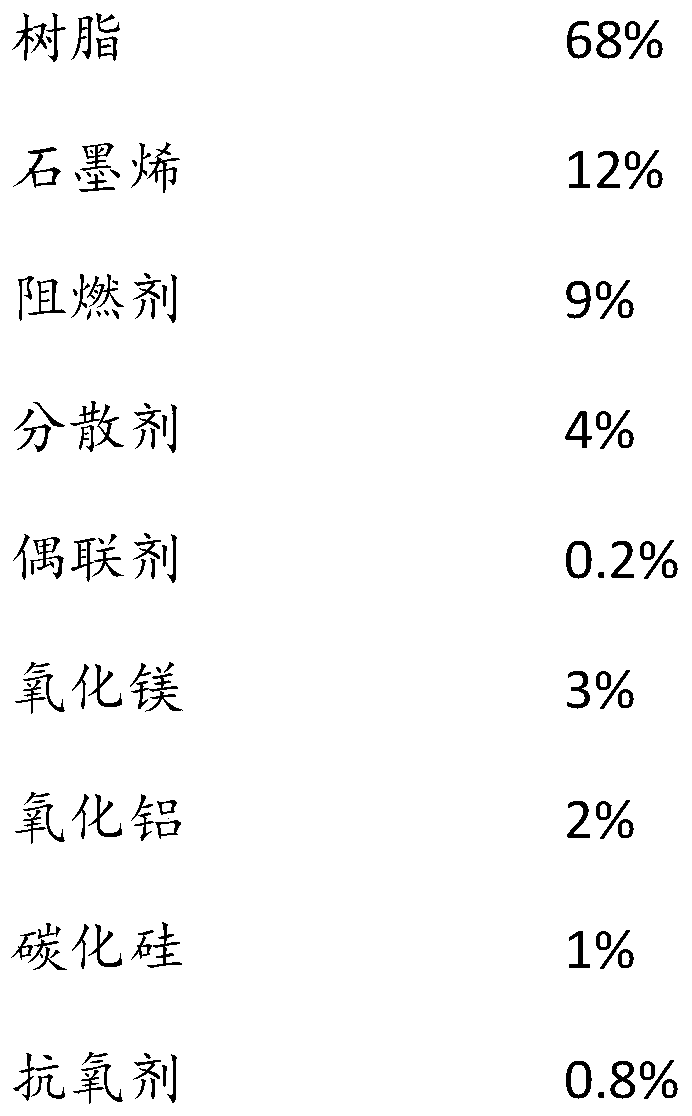

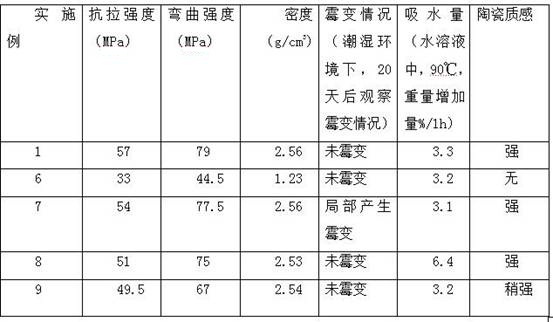

The invention relates to a graphene thermal conductive plastic. The graphene thermal conductive plastic comprises, by mass, 60 to 90% of a resin, 1 to 20% of graphene, 5 to 20% of a fire retardant, 1 to 10% of a dispersant, 0.5 to 5% of an antioxidant, 0.1 to 5% of a coupling agent, and 1 to 10% of an auxiliary agent. The invention also provides a preparation method of the graphene thermal conductive plastic. Adding of magnesium oxide, aluminum oxide, and silicon carbide is capable of achieving uniform distribution of grapheme, and increasing thermal conductivity of the graphene thermal conductive plastic.

Owner:NINGBO MORSH NEW MATERIALS

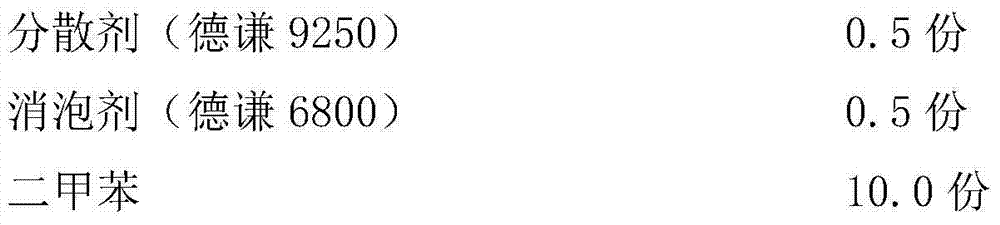

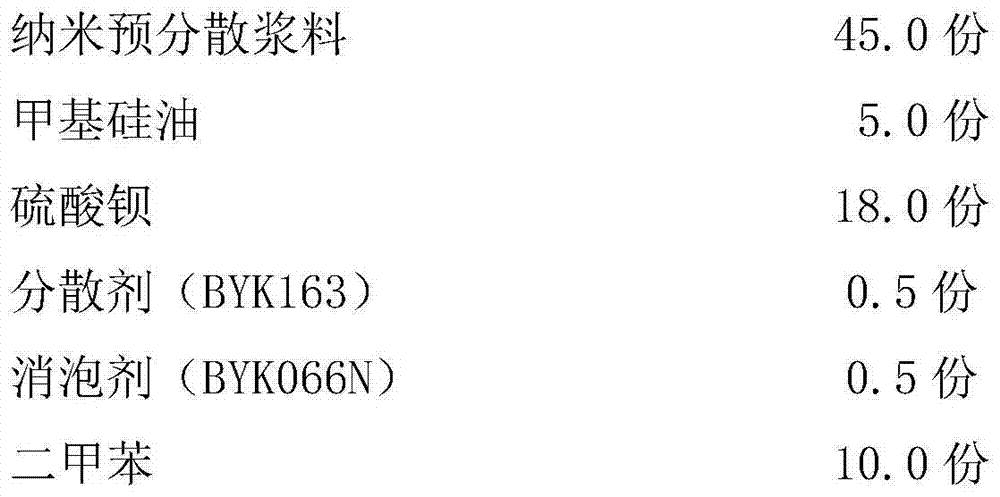

Nanometer reinforced, non-transition-layer, organosilicone and low-surface-energy type antifouling paint and preparation method thereof

ActiveCN104231919AEasy to buyEasy to synthesizeAntifouling/underwater paintsPaints with biocidesMaricultureSlurry

The invention discloses a novel nanometer reinforced, non-transition-layer, organosilicone and low-surface-energy type antifouling paint which can be directly coated to a base material and an epoxy primer without an intermediate transition layer. The antifouling paint comprises the following components in parts by weight: 10 to 20 parts of A, 2 to 10 parts of B, and 0.1 to 2 parts of C, wherein the component A comprises the following materials in parts by weight: 25.0 to 50.0 parts of nanometer pre-dispersed slurry, and 0.5 to 5.0 parts of silicone oil; the component B comprises the following materials in parts by weight: 3.0 to 50.0 parts of crosslinking curing agent, and 1.0 to 10.0 parts of silane coupling agent; the component C comprises the following materials in parts by weight: 0.1 to 3.0 parts of catalyst. The coating has the advantages of being high in intensity, high in attaching force, easy to be constructed, and high in recoatability, and can be applied to various ships, offshore oil platforms, ocean structures and facilities, and mariculture nets and the like.

Owner:DALIAN MARITIME UNIVERSITY

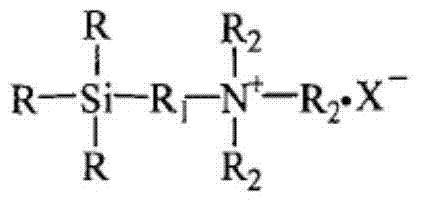

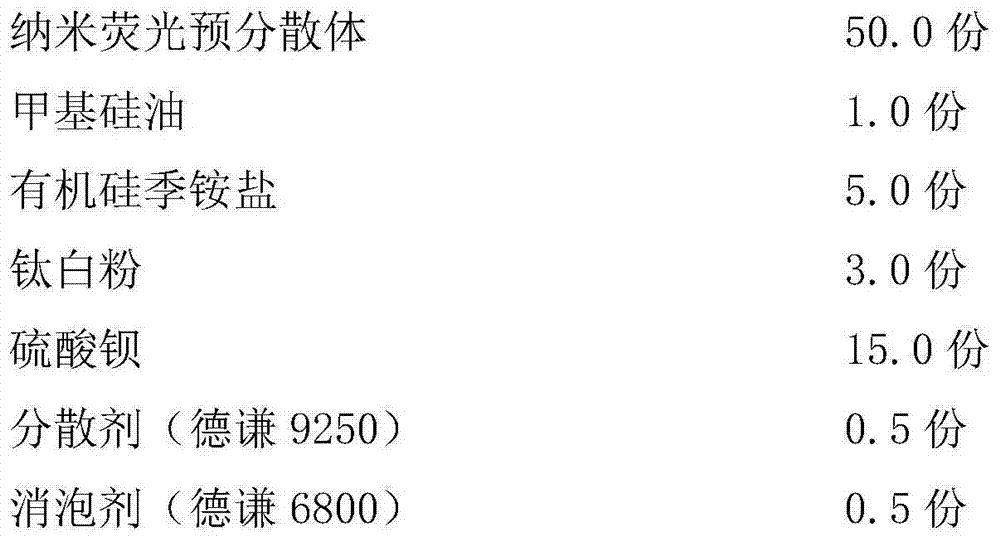

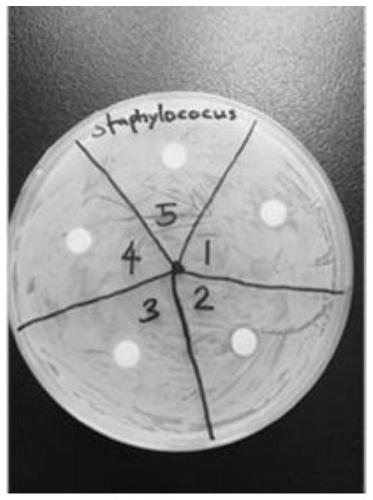

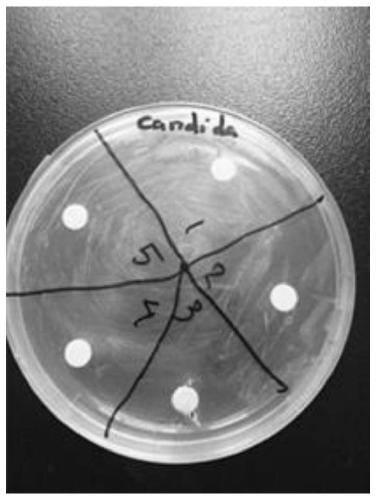

Nano-antibacterial low-surface energy organosilicon luminescence anti-fouling paint and preparation method thereof

ActiveCN104327721AEasy to buyEasy to synthesizeAntifouling/underwater paintsLuminescent paintsMarine aquacultureFluorescence

The invention discloses a nano-antibacterial low-surface energy organosilicon luminescence anti-fouling paint, which comprises the following components by weight: 25-35 parts of component A, 2-5 parts of component B and 1 part of component C; the component A comprises 25.0-50.0 parts of nano fluorescence pre-dispersion, 5-25.0 parts of organosilicon quaternary ammonium salt and 0.5-5.0 parts of silicone oil; the component B comprises 3.0-50.0 parts of crosslinking curing agent and 1.0-10.0 parts of silane coupling agent; The component C comprises 0.1-3.0 parts of catalyst; and the catalyst is at least one of stannous octoate, dibutyl tin diacetate and dibutyltin dilaurate. The paint has long persistence luminescent performance, has can prevent pollution by depending on fluorescence and enables contact sterilization, and has advantages of excellent antifouling performance, high strength and high adhesive force, can be used for various ships, sea petroleum platforms, marine structure and facility, marine aquaculture nets.

Owner:DALIAN MARITIME UNIVERSITY

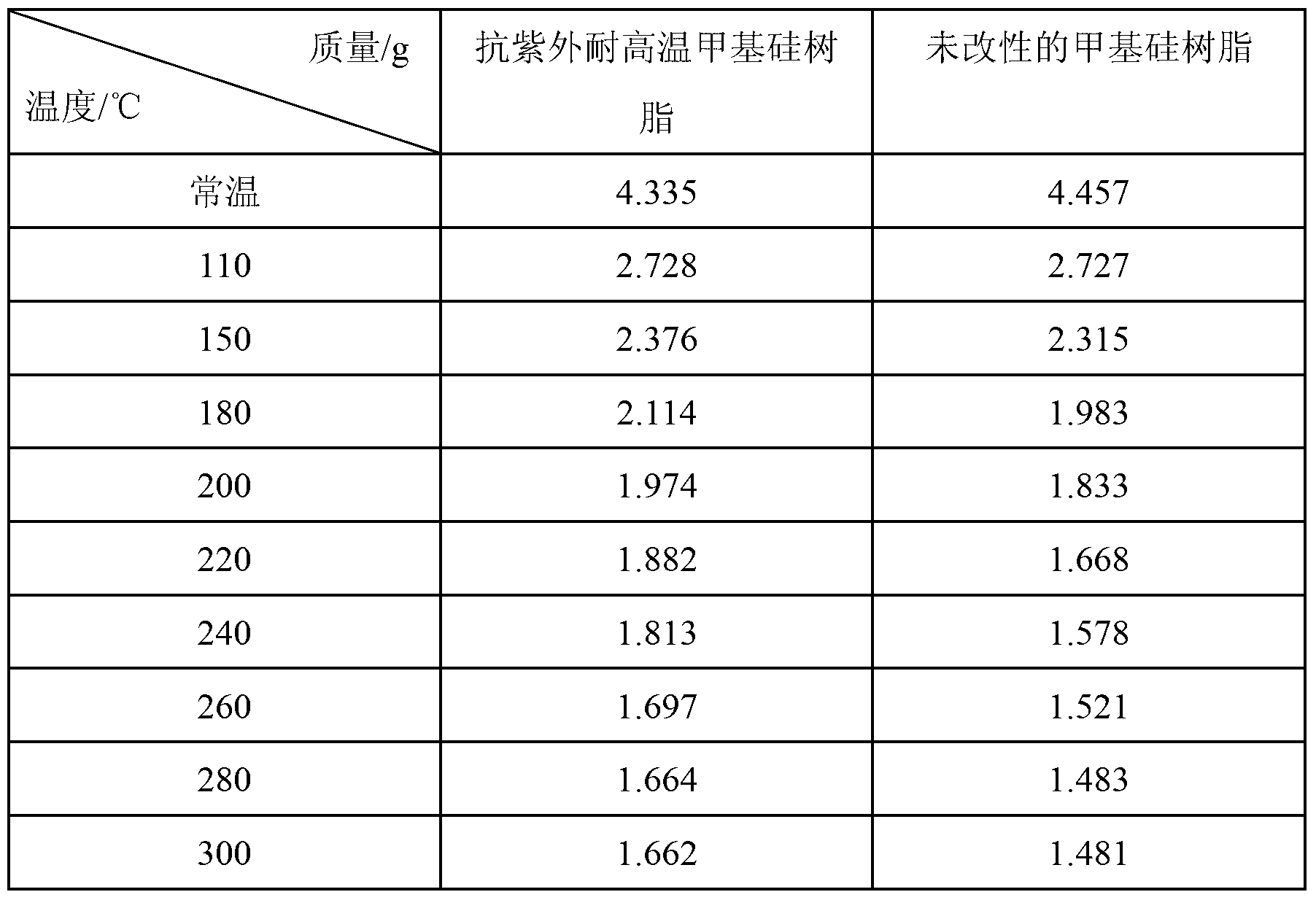

Preparation method of ultraviolet-resistant and high-temperature-resistant methyl silicone resin

The invention relates to a preparation method of ultraviolet-resistant and high-temperature-resistant methyl silicone resin, relates to the preparation method of modified methyl silicone resin, and is used for solving the problems that the existing methyl silicone resin is poor in high temperature and ultraviolet resistance, complicated in preparation method and high in cost. The preparation method comprises the following steps of:1, dispersing ethyl orthosilicate in anhydrous ethanol and then adding a mixing solution of deionized water, the anhydrous ethanol and ammonia, thereby obtaining a silica ethanol solution; 2, dispersing tetrabutyl titanate in the anhydrous ethanol and then adding the mixing solution of the deionized water, the anhydrous ethanol and hydrochloric acid, thereby obtaining a titania ethanol solution; 3, dispersing methyl triethoxysilane and diethoxydimethylsilane in the anhydrous ethanol, thereby preparing a methyl silicone resin prepolymer; and 4, regulating the pH values of the solutions obtained in the steps 1 and 2 to be 7 and performing a refluxing operation after adding the prepolymer, thereby obtaining the methyl silicone resin. The method is conventional in raw material preparation as well as simple and easy to implement. The thermal weight loss rate of the modified methyl silicone resin at the temperature of 300 DEG C is 0.6, so that the modified methyl silicone resin is good in ultraviolet resistance.

Owner:HARBIN INST OF TECH

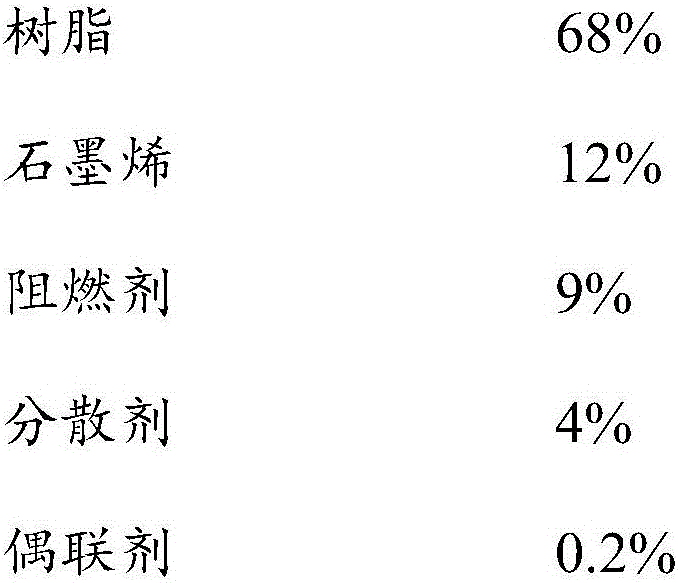

Graphene antistatic plastic and preparation method thereof

The invention relates to graphene antistatic plastic, which comprises the following components in percentage by mass: 60-90% of resin, 1-20% of graphene, 5-20% of fire retardant, 1-10% of a dispersing agent, 0.5-5% of an antioxidant, 0.1-5% of a coupling agent and 1-10% of an assistant, wherein the graphene is evenly dispersed into the graphene antistatic plastic; and the assistant is a mixture prepared from magnesium oxide, aluminum oxide and silicon carbide. The invention further provides a preparation method of the graphene antistatic plastic. Through addition of magnesium oxide, aluminum oxide and silicon carbide, the graphene can be evenly distributed, so that the conductivity of the graphene antistatic plastic is improved.

Owner:NINGBO MORSH TECH

Preparation method for graphene/epoxy resin composite material

The invention provides a preparation method for a graphene / epoxy resin composite material. The preparation method comprises the following steps that after graphene microsheets and an organic solvent are mixed, dispersion liquid is obtained; then, the dispersion liquid obtained in the first step is mixed with epoxy resin again, and mixed liquid is obtained; the mixed liquid obtained in the second step is subjected to vacuum rotary steaming, and a mixture is obtained; finally, a curing agent is added into the mixture obtained in the third step to be blended, and after resolidification, the graphene / epoxy resin composite material is obtained. For the problem that the mechanical performance of a graphene modified epoxy resin composition material is poor, a large number of experiments and a large deal of creative exploration are carried out on a plurality of steps and parameters in the preparation process; from the perspective of the addition proportion, the evaporation mode and the like, the vacuum rotary steaming mode is adopted, the removal efficiency of the solvent is improved, residues are reduced to the maximum extent, and the performance of the graphene modified epoxy resin is further improved through optimization of the whole operation steps.

Owner:SHANDONG OBO NEW MATERIAL CO LTD

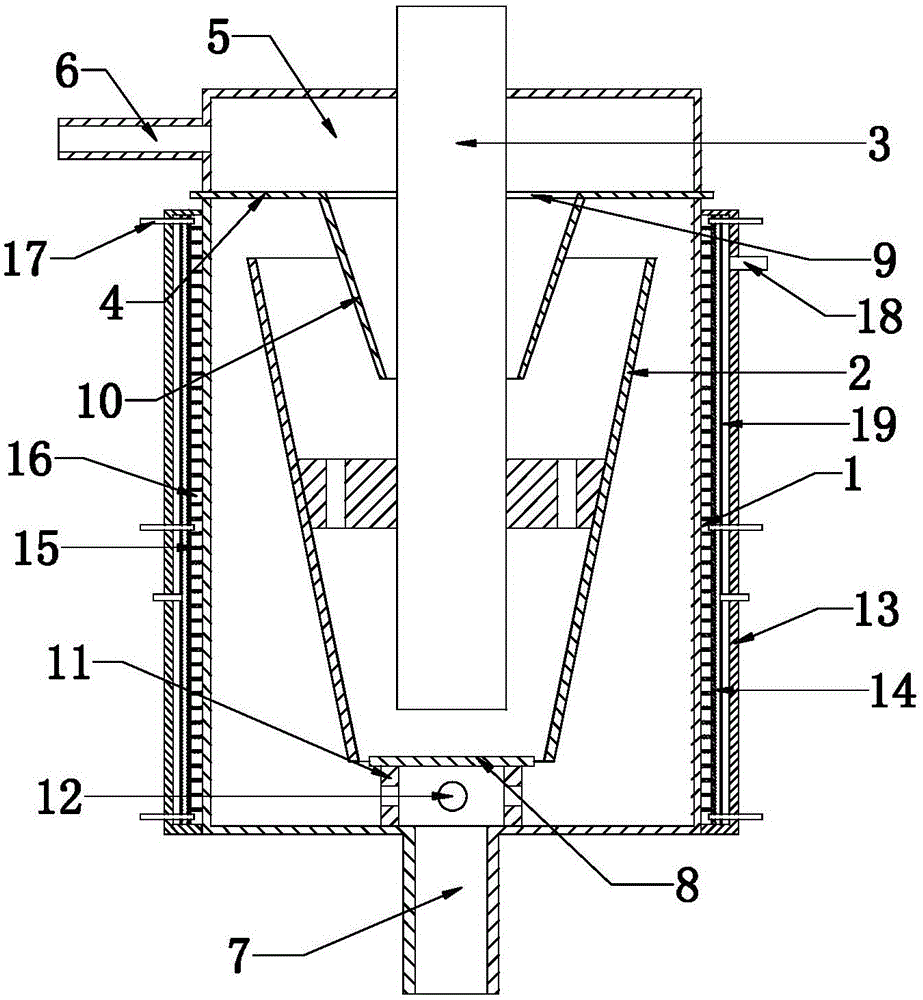

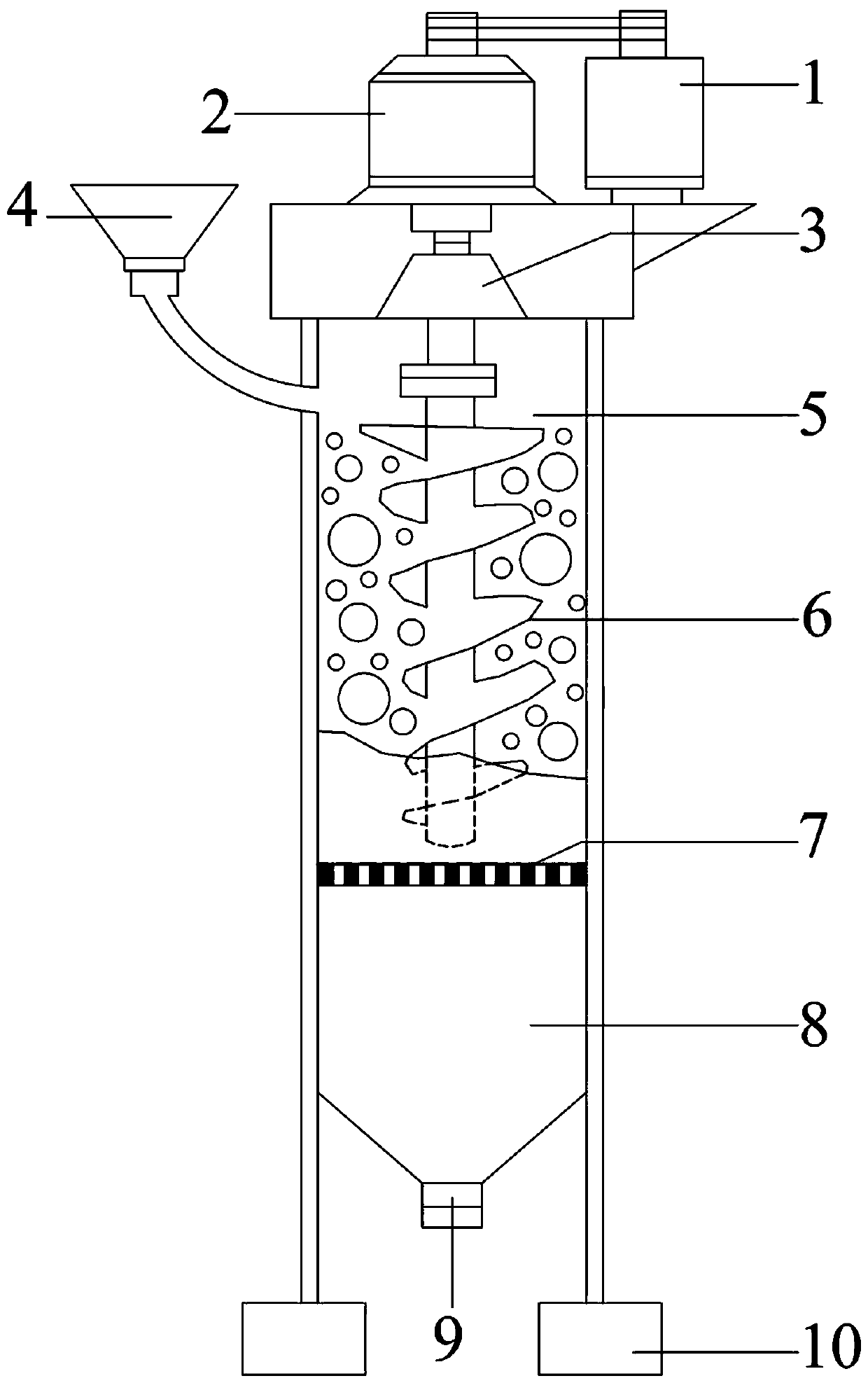

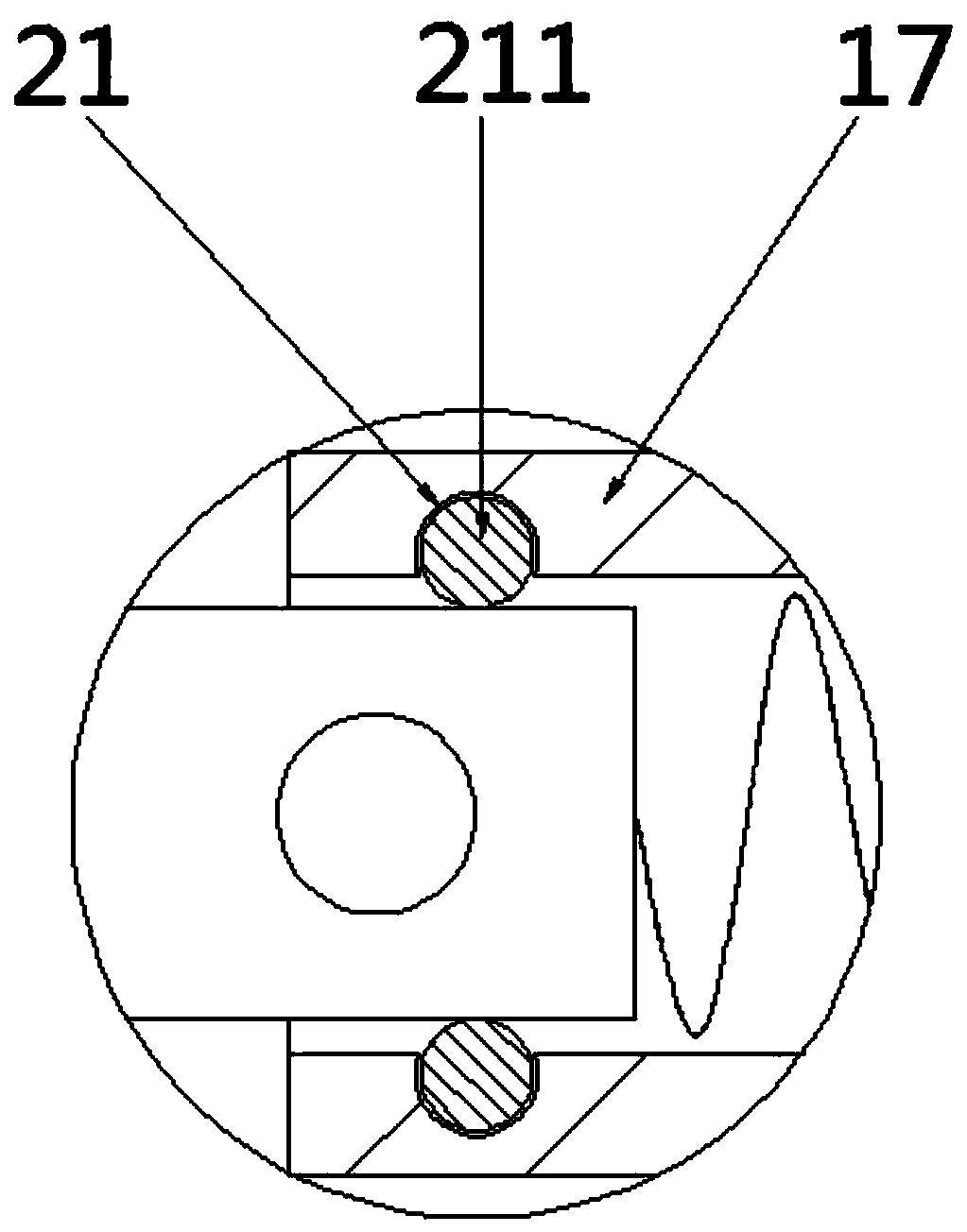

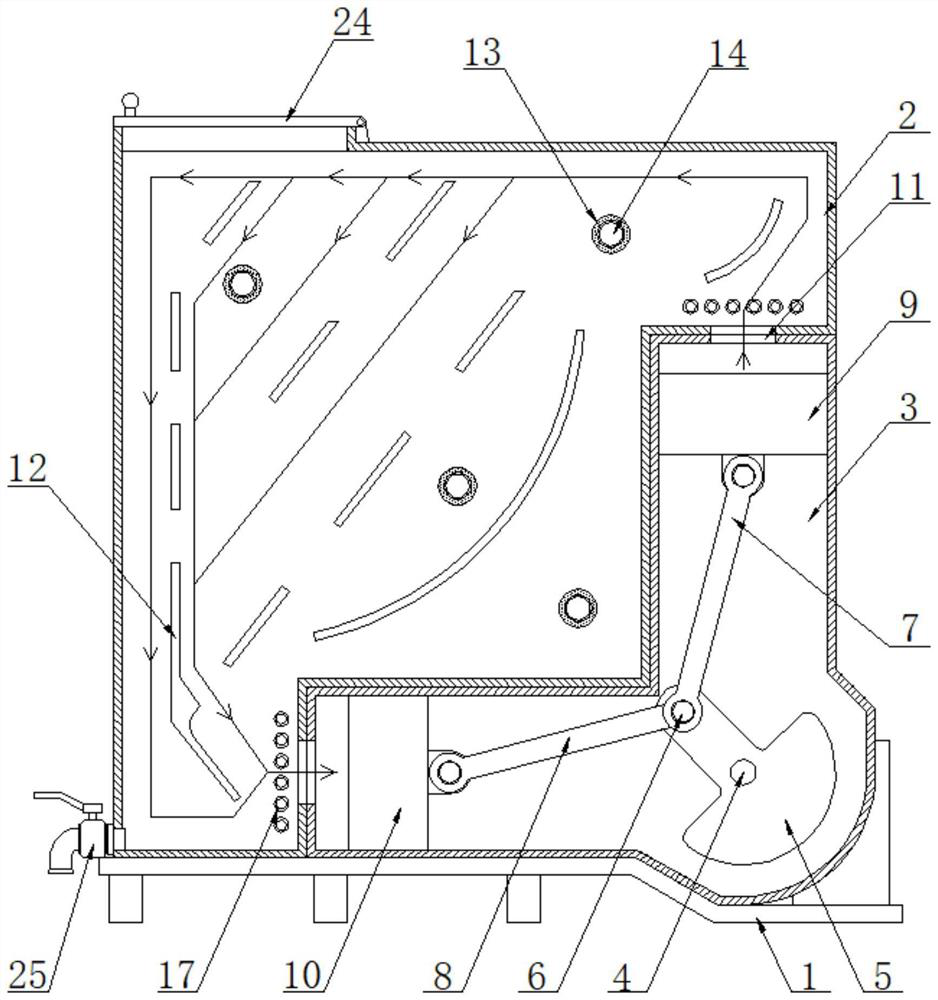

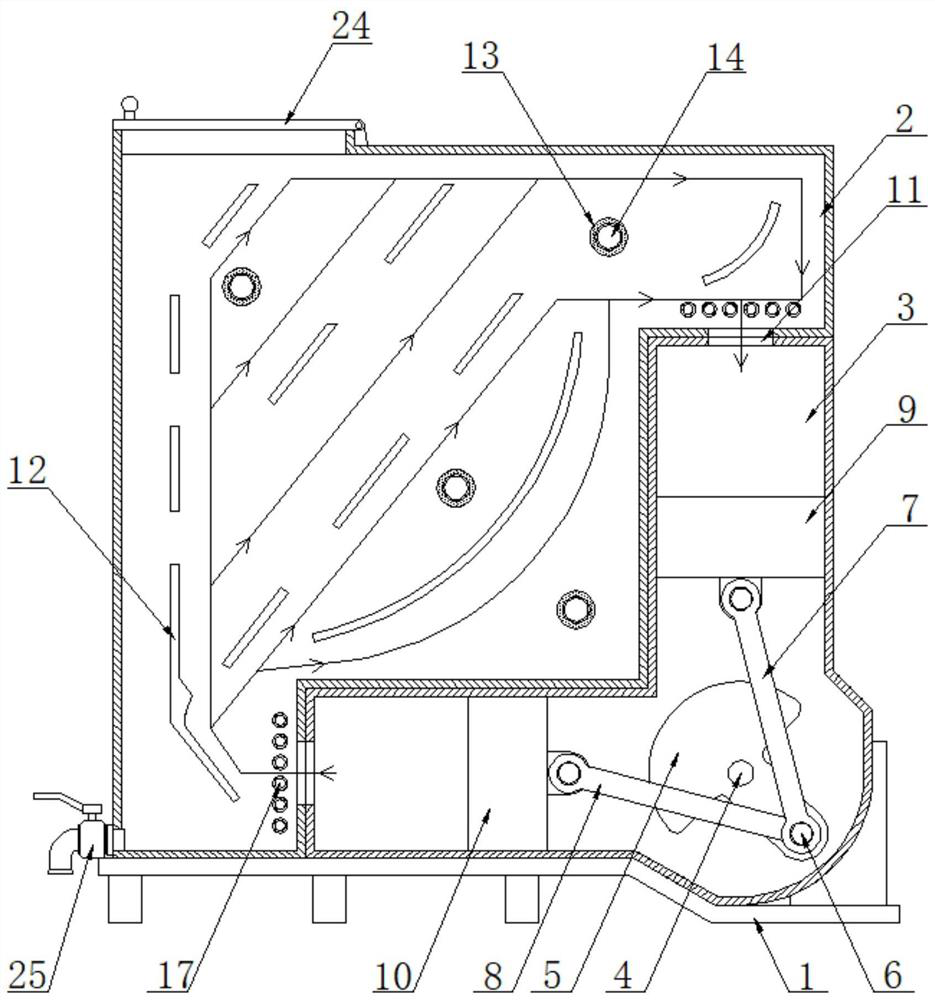

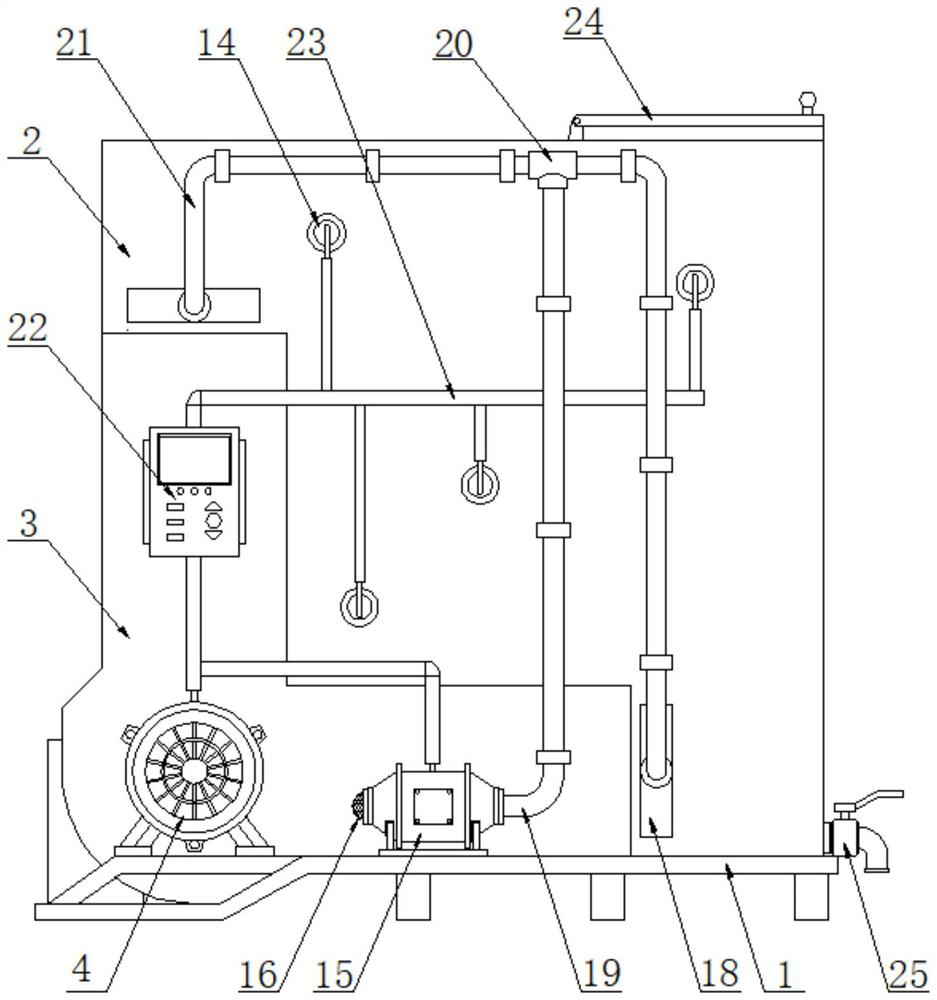

Stirring device of high-speed dispersion equipment

InactiveCN105664765ADisperse fully and evenlyEvenly dispersedTransportation and packagingRotary stirring mixersSlurryEngineering

The invention discloses a stirring device of high-speed dispersion equipment. The stirring device comprises a dispersion barrel, a dispersion wheel and a spindle. A barrier is arranged at the upper end of the dispersion barrel, a discharge cavity is formed on the upper side of the barrier, a through hole is formed in the center of the barrier, a dynamic screen cloth separator which is of a conical structure is arranged at the through hole in the barrier, a flow guide plate is arranged above a feed inlet, the section of the dispersion wheel is in the shape of a conical structure, the flow guide plate is arranged at the lower end of the dispersion wheel, supports are arranged between the dispersion wheel and the dispersion barrel, and a plurality of via holes are formed in the supports. The stirring device with the structure has the advantages that slurry is forced to be distributed peripherally and participates in dispersion procedures of the dispersion wheel, the consistency of the flow speeds of the slurry in a cavity can be guaranteed by the dispersion barrel which is of a conical structure, and the slurry can be sufficiently and uniformly dispersed; homogenized dispersion effects can be realized by the aid of the dynamic screen cloth separator which is of the conical structure, certain guide effects can be realized by the conical structure, good discharge and heat dissipation effects can be realized, and accordingly the quality of the slurry can be guaranteed.

Owner:江苏中兴派能电池有限公司

Preparation method of fiber-toughening calcium phosphate-based bone repairing material for 3D printing

PendingCN109999220ADisperse fully and evenlyEasy to cutAdditive manufacturing apparatusPharmaceutical delivery mechanismFiberPolymer science

The invention discloses a preparation method of a fiber-toughening calcium phosphate-based bone repairing material for 3D printing. The method comprises the steps of A, preparation of high-dispersionpolymer fibers, wherein a degradable polymer is dissolved in an organic solvent, diphosphonate is added, and even stirring is conducted for obtaining a polymer solution; the polymer solution is subjected to electrostatic spinning for obtaining the polymer fibers arrayed directionally; then deionized water is used for ultrasound-assisted soaking, folding and freezing in the direction vertical to the directional direction are conducted, cutting is conducted through a slicer at intervals of 5-100 microns, ethyl alcohol ultrasonic fiber dispersion, centrifugation collection and vacuum drying are conducted, and the high-dispersion polymer fibers are obtained; B, preparation of a fiber dispersion solution, wherein the high-dispersion polymer fibers are added to a calcium phosphate bone cement liquid phase with the pH of 7.4, and the fiber dispersion solution with the mass concentration of 1-5% is obtained; C, preparation of the bone repairing material, wherein the fiber dispersion solution is evenly mixed with calcium phosphate bone cement solid phase powder according to the mass ratio of (0.7-1.3):1, and the bone repairing material is obtained. The calcium phosphate-based bone repairingmaterial prepared through the method is good in printability and high in mechanical property.

Owner:SOUTHWEST JIAOTONG UNIV

Preparation method of fruit tree pollen solution and pollination method

InactiveCN102106253AIncrease nutritionDisperse fully and evenlyPlant genotype modificationFruit treeFruit set

The invention discloses a preparation method of a fruit tree pollen solution and a pollination method. The preparation method of the pollen solution comprises the steps of: adding food grade glucose powder into cleaning water with the PH value of 6.5-8.2, preparing glucose water solution with the percentage concentration by weight of 4-7% for later use according to the weight, adding the acquired pollen into the glucose water solution according to the proportion that 2-5g of pollen is added into each 100g of the glucose water solution, and evenly stirring to lead the pollen to be suspended in the glucose water solution, so that the obtained pollen glucose suspended mother solution is the fruit tree pollen solution of the invention. The use method of the fruit tree pollen solution comprises the steps of diluting by the glucose water solution and adding the Solubor according to 0.1-0.3% weight to atomize and pollinate. Compared with the prior art, due to the use of the fruit tree pollen suspension, the artificial pollinating efficiency and the fruit-bearing rate are improved, and the planting quantity of the pollinating tree in an orchard garden can be greatly reduced, so that the economic benefit of the orchard garden is further increased, and the invention has the advantages of being fast in applying speed, easy to control the use level of the pollination, good in pollination effect, and pollen use level-saving.

Owner:INST OF AGRI SCI DIV 2 OF XINJIANG PRODN & CONSTR CORPS

Soil solidifying agent

InactiveCN100371418CLow costGood value for moneyOrganic fertilisersSoil conditioning compositionsFirming agentSodium lignosulfonate

The soil curing agent as one kind of engineering material for curing and stabilizing various kinds of soil is especially suitable for curing silt and other kinds of low viscosity soil. The soil curing agent has main cement material comprising ore powder, flyash and water, as well as proper amount of alkali exciting component, expanding component and surfactant, and is prepared through mixing the materials and grinding to Blaine fineness of 3000-5000 sq m / kg. Specifically, it consists of mineral admixture 40-60 wt%, cement 15-25 wt%, alkali exciting component 5-15 wt%, expanding component 15-25 wt% and surfactant 0.01-0.1 wt%.

Owner:SOUTHEAST UNIV

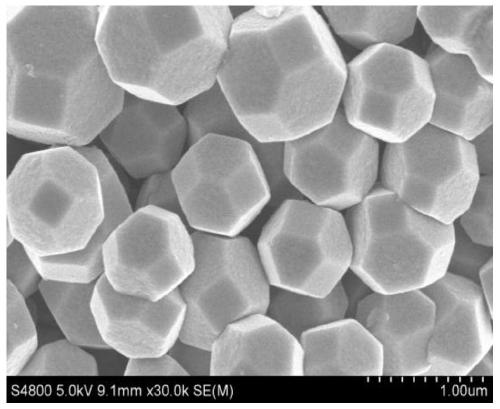

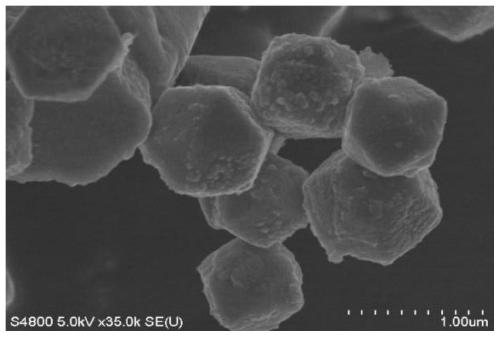

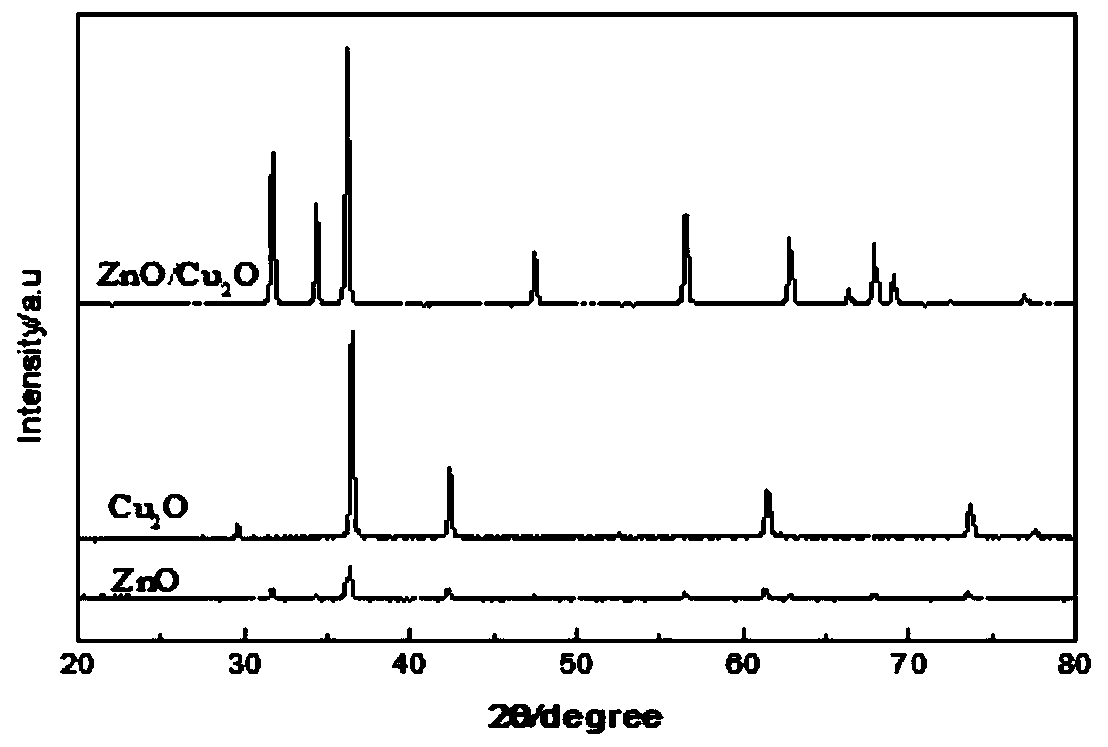

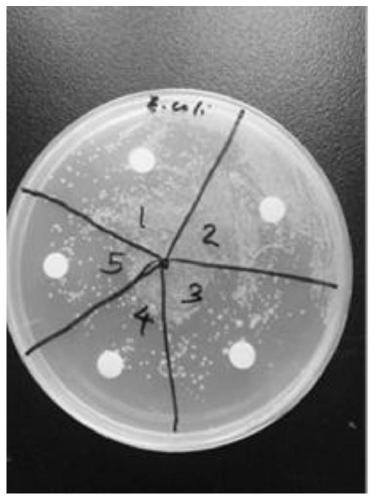

Composite nano cuprous oxide/zinc oxide material with photocatalytic performance as well as preparation method and application thereof

ActiveCN110479289AFast shippingEasy to separateMaterial nanotechnologyWater/sewage treatment by irradiationMaterials preparationZinc

The invention discloses a composite nano Cu2O / zinc oxide (ZnO) material with photocatalytic performance as well as a preparation method and application thereof, and belongs to the technical field of material preparation. A novel visible light catalyst is obtained. Nanometer zinc oxide particles are loaded on the surfaces of tetradecahedron cuprous oxide to form a heterostructure, rapid transportation and separation of photo-induced electrons and holes are effectively promoted, and the problems that a single cuprous oxide photocatalyst is high in cost, serious in photo-corrosion phenomenon, poor in stability and the like are solved. The preparation method of the composite material is simple, convenient to operate and beneficial to large-scale production.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of pH-responsive photonic crystal gel base for skin wound treatment

ActiveCN110420349ADisperse fully and evenlyImprove the bactericidal effectBandages(Hydroxyethyl)methacrylateTherapeutic effect

The invention discloses a preparation method of a pH-responsive photonic crystal gel base for skin wound treatment. The preparation method of the pH-responsive photonic crystal gel base for the skin wound treatment comprises the steps that chitosan, acrylic acid, N,N'-methylene bis acrylamide and Cu2WSe4 are used as raw materials, CS / PAA / nanoCu2WSe4 composite hydrogel is prepared by the photopolymerization method; a colloidal crystal template is prepared by the vertical deposition method; hydroxyethyl methacrylate and an acrylic acid monomer are mixed evenly with methanol, a photoinitiator canbe added, nitrogen is introduced to remove oxygen to obtain a precursor solution; the colloidal crystal template is immersed in the precursor solution, and the mixture reacts under ultraviolet lightirradiation to remove the template to obtain a membranous photonic crystal; the membranous photonic crystal is ultrasonically dispersed on the CS / PAA / nanoCu2WSe4 composite hydrogel, and the pH-responsive photonic crystal gel base is obtained. When preparation method of the pH-responsive photonic crystal gel base for the skin wound treatment is used for the treatment of skin wounds, the sterilization and treatment effects are good, and the infection and healing of the wound are easily observed and understood.

Owner:ZHEJIANG OCEAN UNIV

Biodegradable high-performance modified particle material and preparation method thereof

The invention relates to a biodegradable high-performance modified particle material and a preparation method thereof. The biodegradable high-performance modified particle material is prepared from polylactic acid PLA, a natural organic plant fiber material, oxidized modified high-amylose starch, a composite plasticizer, a combined modifier, a functional aid, a modifier, modified carbon nanofibers and an inorganic filler. By carrying out melting reaction extrusion at 55-185 DEG C through a double-stage serial screw granulating unit, and carrying out mixing, reaction, extrusion, cooling, cutting, drying, sterilization and packaging, the particle material is obtained. Various household and industrial products, toys, stationery and electronic product shells are produced by adopting universal equipment such as extrusion molding, plastic uptake or injection molding units. The adopted raw materials are rich in source, the raw material cost is low, the process is simple, the production cost is low, and the prepared particle material has high strength and good antibacterial performance, anti-aging performance and hydrophobic performance and can meet the requirements of various biodegradable hard material products.

Owner:广州绿徽新材料研究院有限公司

Fractional homogenate technology of cathode slurry of lithium ion battery

InactiveCN110085826ASimple processEasy to implementSecondary cellsPositive electrodesSlurryEngineering

The invention discloses a fractional homogenate technology of a cathode slurry of a lithium ion battery. The technology comprises the following steps that a PVDF glue solution is measured according toset components, a measured conductive agent and the PVDF glue solution are input to a mixer and mixed, 1 / 3-1 / 2 of a measured active substance is removed, and input to the mixer for mixing; the residual active substance is added to the mixer for mixing once or twice; and a solvent is added and mixed, and the cathode slurry after homogenate is deareated in the vacuum condition for at least 2 hoursafter homogenate. The homogenate technology in which active substance is added in a fractional manner and the speed is reduced gradually is used, friction between the active substance and the inner wall of the mixer is obviously reduced, and it is ensured the temperature of the cathode slurry does not exceed 50 DEG C during homogenate.

Owner:SHUANGDENG GRP

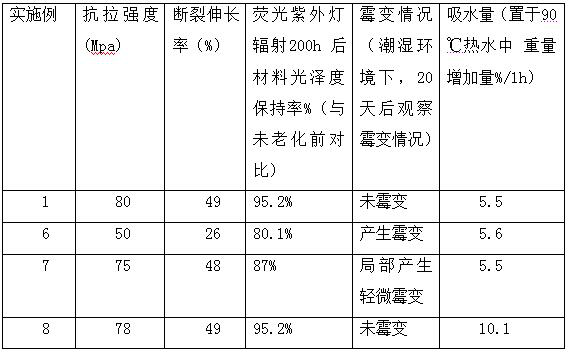

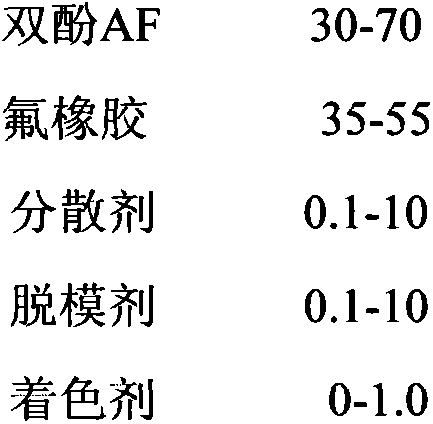

Fluorubber use bisphenol AF pre-dispersion mother colloidal particle formula

The invention discloses a fluorubber use bisphenol AF pre-dispersion mother colloidal particle formula prepared from the following raw materials by mass: 30-70 parts of bisphenol AF; 35-55 parts of fluorubber; 0.1-10 parts of a dispersant; 0.1-10 parts of a release agent; and 0-1 parts of a colorant. The fluorubber as a carrier is cooperated with the dispersant and the release agent, the bisphenol AF curing agent is mixed into the fluorubber on an open blending machine, so that the bisphenol AF is fully dispersed uniformly in the fluorubber, the bisphenol AF curing agent has excellent curing properties in the fluorubber, and can meet the use requirements. The fluorubber use bisphenol AF pre-dispersion mother colloidal particle formula can improve the dispersion of the fluorubber curing agent bisphenol AF (2, 2-bis-(4-hydroxy phenyl) hexafluoropropane) and BPP (tri phenyl phosphorus chloride) in the fluorubber, and overcomes the problems of the poor dispersion and mutual smelting of a traditional curing agent in the fluorubber.

Owner:SHANGHAI PINKE RUBBER & PLASTIC MATERIAL

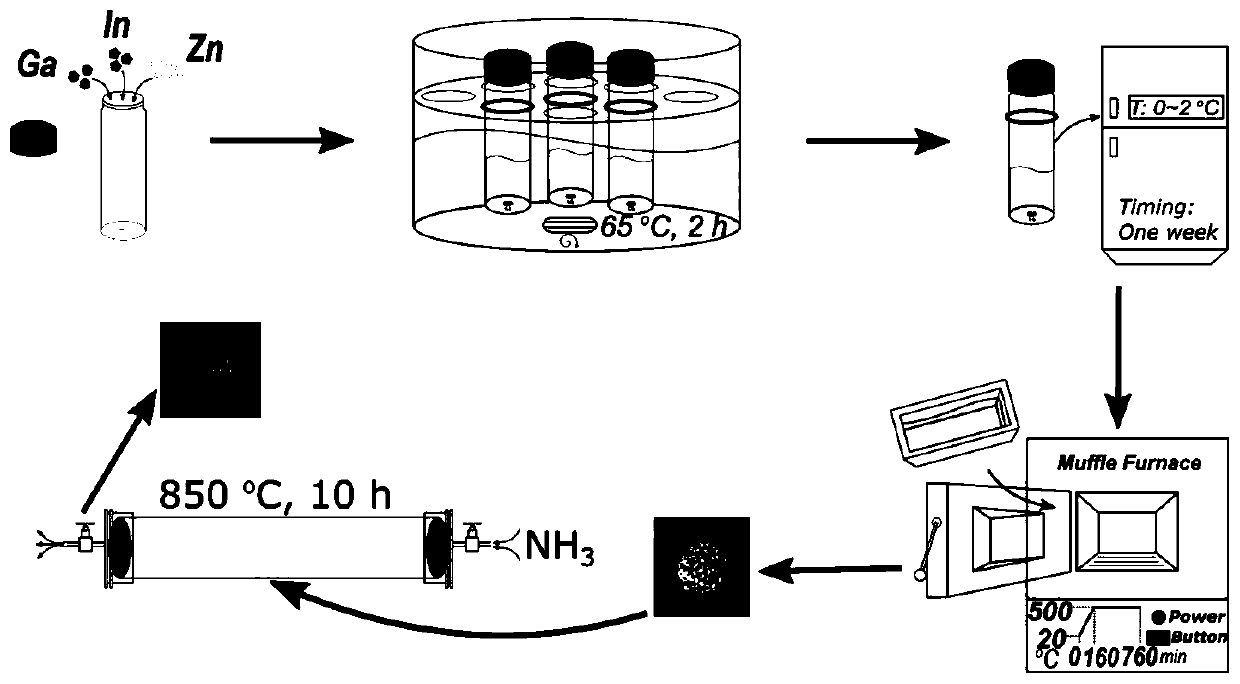

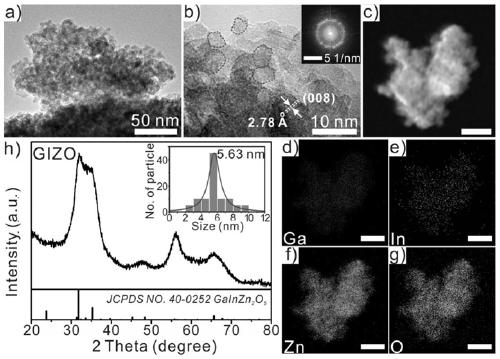

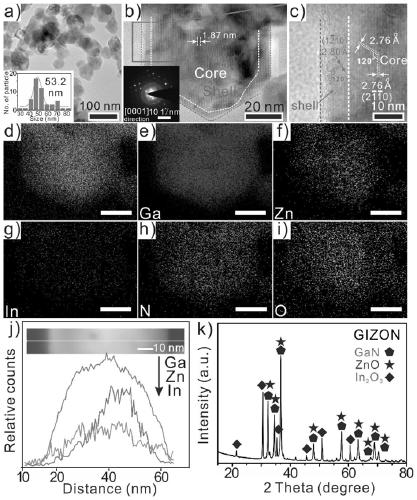

Preparation method and application of gallium-indium-zinc ternary nitrogen oxide

ActiveCN109746019AGuaranteed uniformityGood crystallinityMaterial nanotechnologyPhysical/chemical process catalystsChemistryVisible spectrum

The invention discloses a preparation method of gallium-indium-zinc ternary nitrogen oxide. Ga(NO3)3*xH2O, Zn(Ac)2*2H2O, In(NO3)3*XH2O serve as a gallium source, a zinc source and an indium source, ethanol amine and a small amount of acetic acid serve as solvents, uniform precursor mixed solution is acquired by a solvent thermal method, a precursor is placed in a low-temperature environment for along time and is gel-like, the precursor is roasted at high temperature to obtain faint yellow gallium-indium-zinc oxide (GIZO), and finally, high-temperature nitridation is performed in ammonia atmosphere to prepare a grayish-green GIZNO nano-material. The prepared GIZNO has an obvious core-shell structure, density functional theory (DFT) calculation proves that the core-shell structure can effectively promote separation of photon-generated carriers in the photocatalytic water splitting process, and photocatalytic water splitting can be efficiently performed. 1wt% of rhodium (Rh) is loaded toserve as a co-catalyst, under the irradiation condition of visible light (lambda>=420nm), photocatalytic water splitting hydrogen production rate is 603 micromoles h<-1> g<-1>, oxygen production rateis 274 micromoles h<-1> g<-1>, the apparent quantum efficiency of a 430nm position reaches 3.5%, and a good application prospect is shown.

Owner:XI AN JIAOTONG UNIV

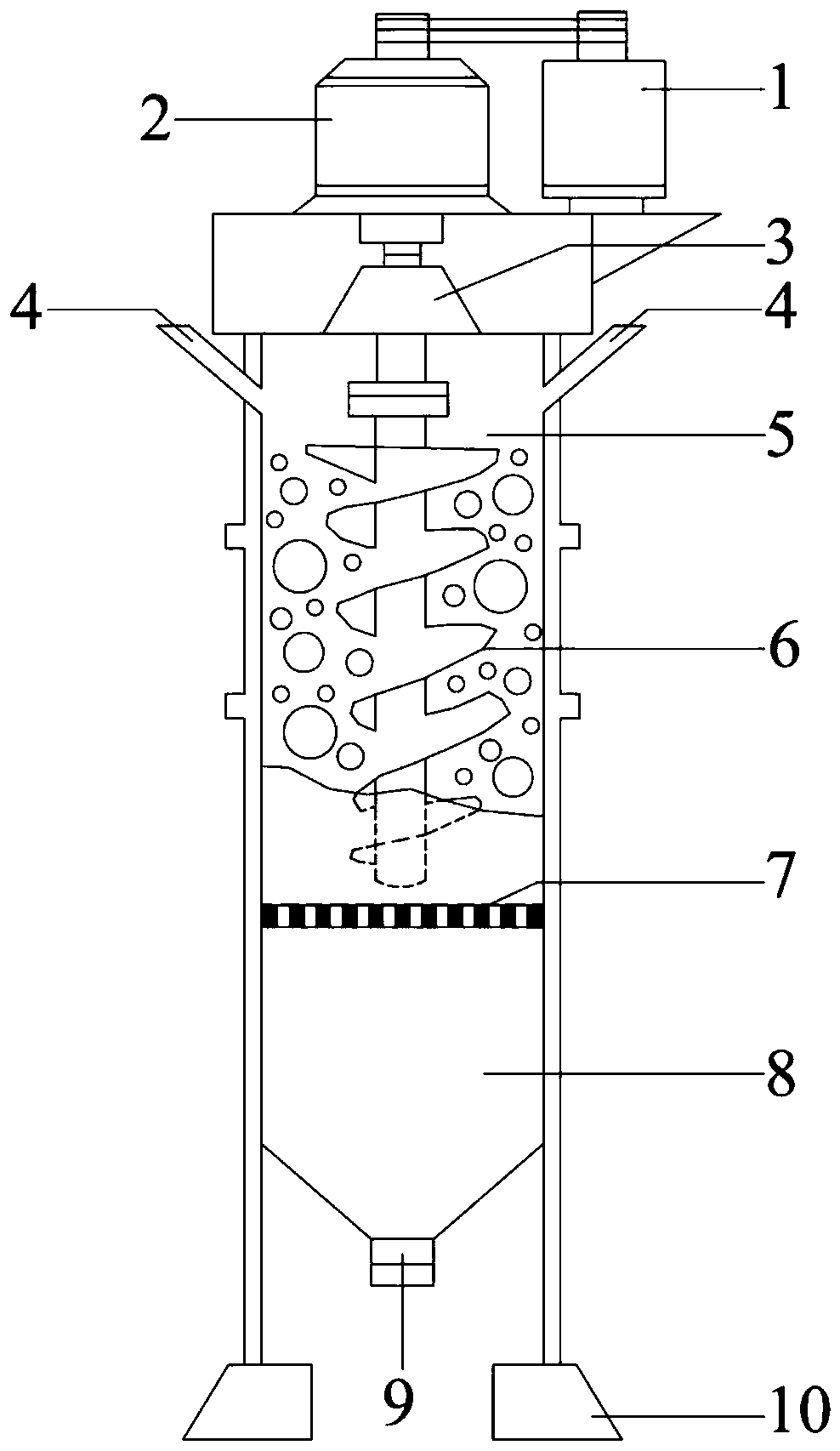

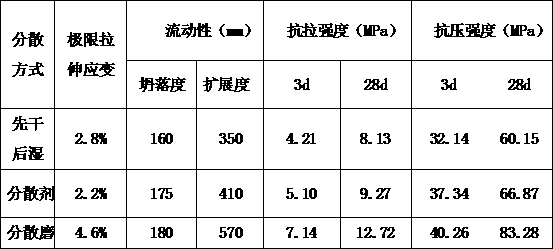

Dispersion mill for preparing nanometer material modified cement

ActiveCN108514928ADisperse fully and evenlyGet over reunion seriousGrain treatmentsMachining processMixing ratio

The invention discloses a dispersion mill for preparing nanometer material modified cement. A cabin body is separated into a mixing and grinding cabin and a material collecting cabin by a grid plate;the lateral upper part of the mixing and grinding cabin is provided with two feeding openings; a stirrer is arranged in the mixing and grinding cabin; a plurality of metal blocks are arranged in the mixing and grinding cabin; the lower half part of the material collecting cabin is a funnel; the bottom of the funnel is provided with a discharging opening. The mixing and grinding cabin can effectively realize the simultaneous mixing and grinding of nanometer materials and cement; the nanometer ore powder agglomeration is broken; the sufficient and uniform mixing of nanometer particles and otherpowder can be realized. In the use process, a discharging opening at the lower part of the material collecting cabin is connected with a concrete stirring machine; a certain mass of composite materials are regularly discharged according to the concrete mixing ratio and the stirring machine process parameters; meanwhile, through the feeding opening of the mixing and grinding cabin, nanometer materials and cement are respectively and regularly added according to the production requirement proportion, so that the continuous production operation with the concrete stirring machine can be realized.

Owner:CHINA UNIV OF MINING & TECH

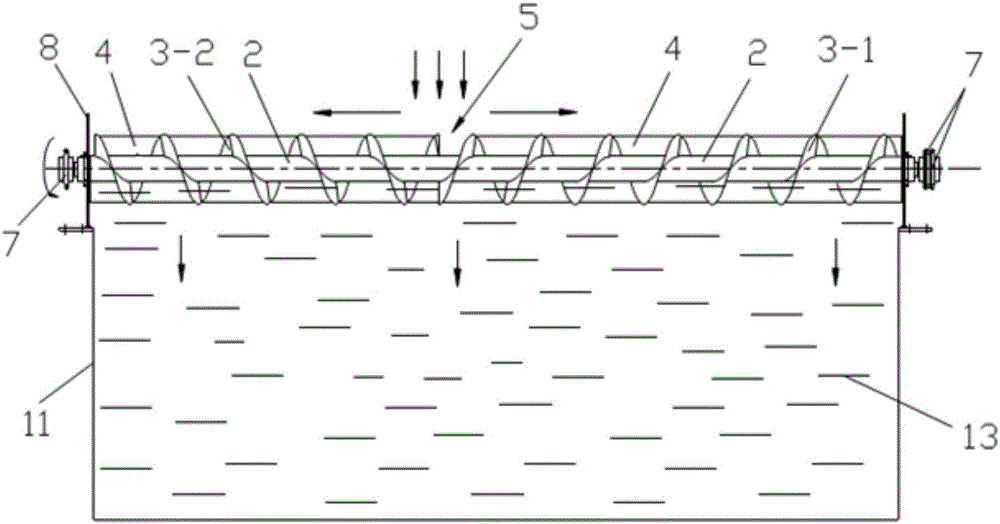

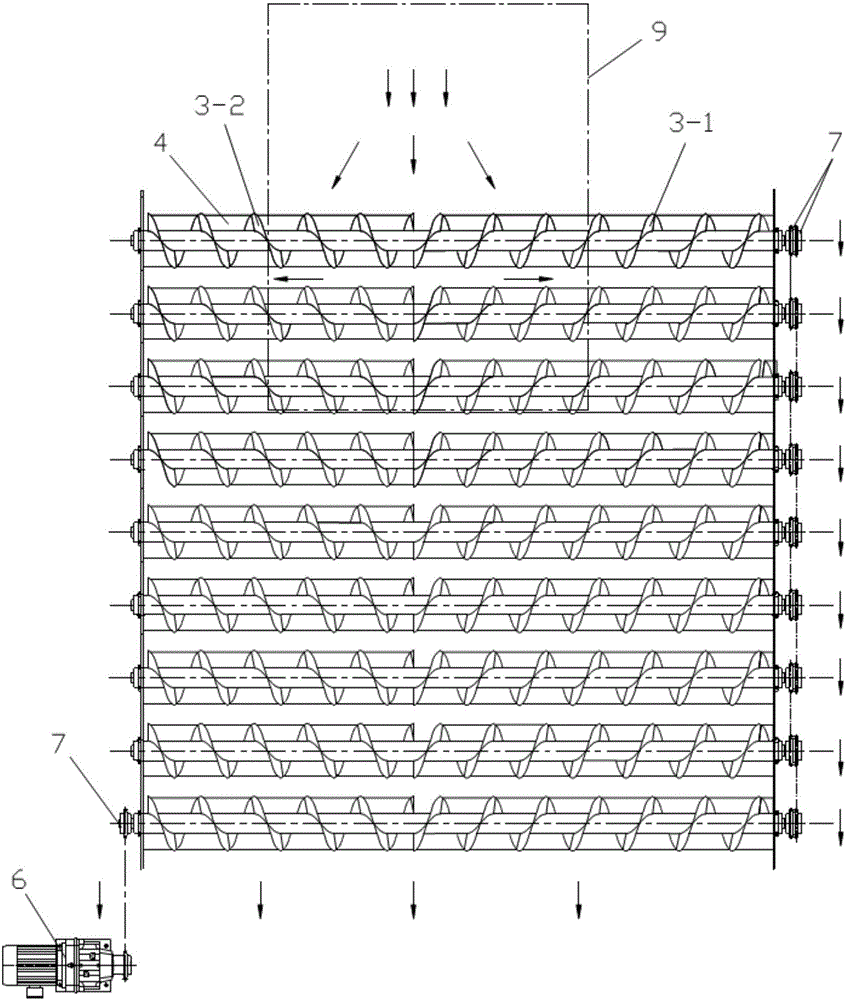

Defibering, paving and screening device and method for recycled materials

ActiveCN105945037AEvenly distributedDisperse fully and evenlySolid waste disposalHelical bladeScreening method

The invention discloses a defibering, paving and screening device and a defibering, paving and screening method for recycled materials. The device comprises a plurality of scattering units arranged together; each scattering unit comprises a rotating shaft, a helical blade arranged on the rotating shaft and a tearing unit arranged on the rotating shaft; the device further comprises a driving mechanism used for driving the rotating shaft to rotate; the helical blade is formed by a levorotation blade and a dextrorotation blade; the levorotation blade is arranged between the middle of the rotating shaft and one end part of the rotating shaft; the dextrorotation blade is arranged between the middle of the rotating shaft and the other end part of the rotating shaft; and a boundary zone is formed at the junction part of the levorotation blade and the dextrorotation blade. The device not only can scatter materials, but also can pave the material in the axial direction, so that the material can be sufficiently scattered and the scattered material can be uniformed paved, thus being favorable for screening of different materials and sufficient exposure and removal of impurities; and meanwhile, materials with different sizes and shapes can be screened during scattering, thus playing a role of screening materials.

Owner:广东致顺化工环保设备有限公司

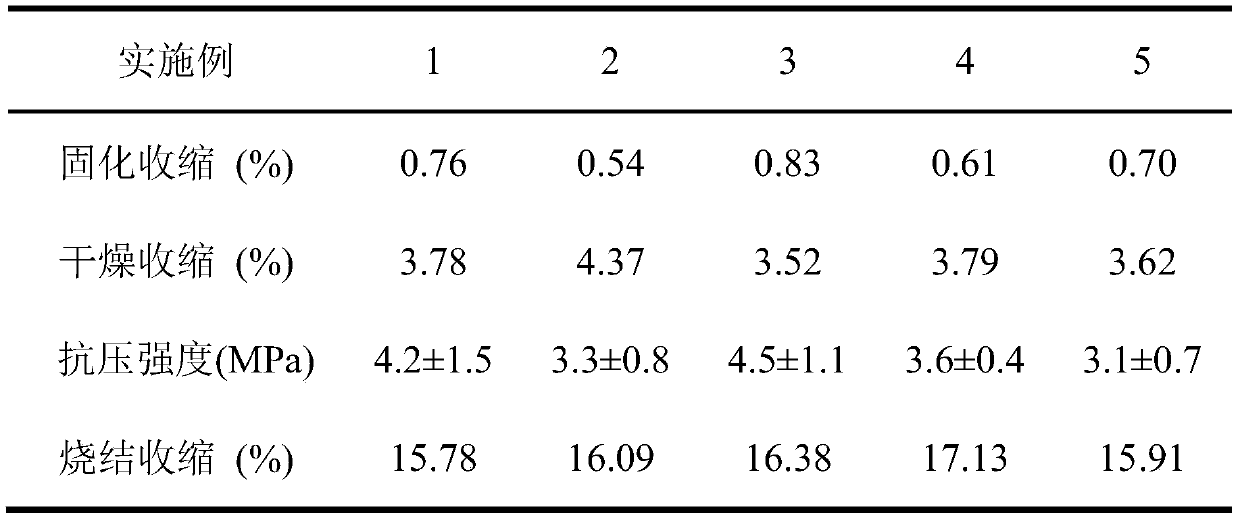

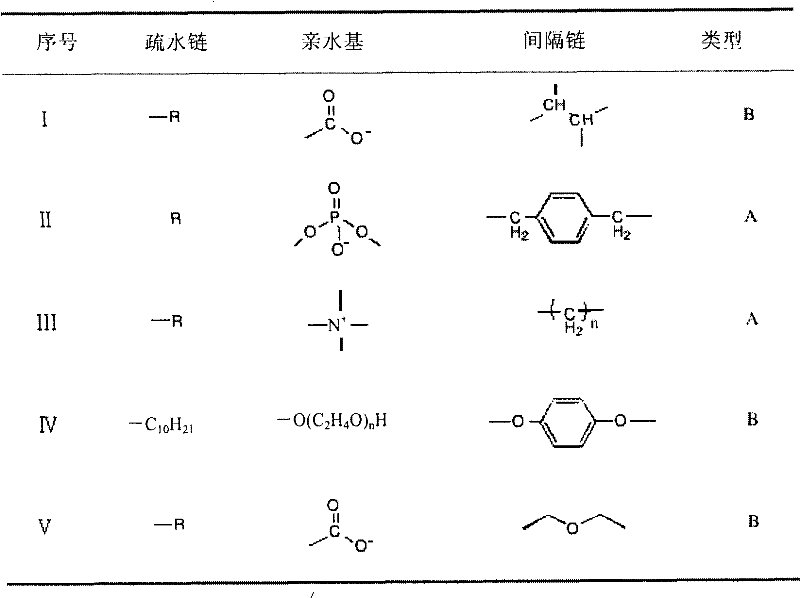

Preparation method of carbon nanotube/ceramic matrix composite material

The invention provides a preparation method of a carbon nanotube / ceramic matrix composite material, which comprises the following steps: S1, mixing a carbon nanotube, water, a dispersant and a pH regulator, and ultrasonic stirring to obtain a carbon nanotube suspension; S2, mixing and ball milling that carbon nanotube suspension, a ceramic powder, the water, the dispersant and the pH regulator toobtain a mixed suspension; S3, vacuum degassing that mixed suspension, injecting the mixture suspension body into a mold, water bath treatment and demoulding to obtain a wet blank of the composite ceramic material; S4, drying that wet blank of the composite ceramic material to obtain a dry blank of the composite ceramic material; S5, sintering that dry blank of the composite ceramic material to obtain the composite ceramic material; wherein the dispersant is a basic water-soluble polymer of isobutylene and maleic anhydride. By adopting the dispersant, the carbon nanotubes and the ceramic powder can be dispersed under the same conditions, and the carbon nanotubes are uniformly distributed in the ceramic blank, thereby preparing a composite material with excellent performance.

Owner:TSINGHUA UNIV

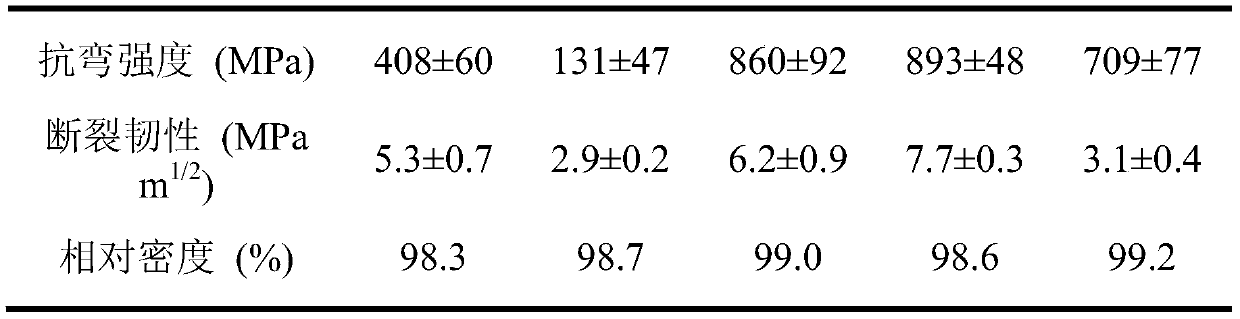

Fiber dispersion mill of organic fiber enhanced composite material and fiber dispersion method

InactiveCN108501210AGood dispersionRealize mixed grindingDischarging apparatusMixing operation control apparatusDispersityFiber-reinforced composite

The invention discloses a fiber dispersion mill of an organic fiber enhanced composite material and a fiber dispersion method. The fiber dispersion mill comprises a barrel body, a stirrer, a speed reducer and a motor. The fiber dispersion mill adopts a double-bin design; the upper part of the fiber dispersion mill is a mixing and milling bin and the lower part of the fiber dispersion mill is an aggregate bin. The stirrer and a steel ball in the mixing and milling bin can be used for effectively realizing joint mixing and milling of fibers and cement, surface properties of the fibers are changed and the dispersity of the fibers is improved; the aggregate bin can be used for temporarily storing a mixed and milled composite material; a lower discharging opening of the aggregate bin is connected with a concrete stirring machine and the composite material with a certain mass is discharged at fixed time according to the mixing proportion of the concrete and technological parameters of the stirring machine; meanwhile, the cement and the fibers are added at fixed time respectively through a feeding opening of the mixing and milling bin according to the ratio required by production, so thatcontinuous production work of the concrete stirring machine is realized.

Owner:CHINA UNIV OF MINING & TECH

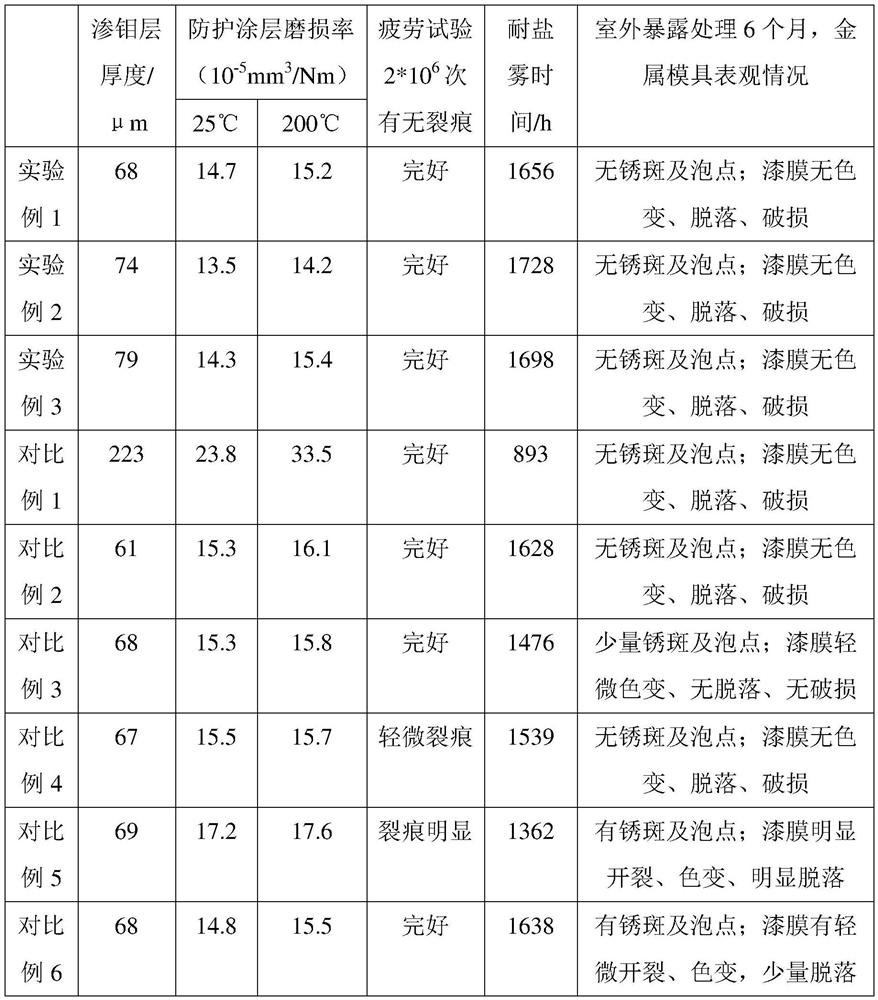

Metal mold surface treatment process

PendingCN114807833AImprove wear resistanceAdd depthVacuum evaporation coatingSputtering coatingTitanium nitrideSulfidation

The invention relates to the technical field of metal surface strengthening modification, in particular to a metal mold surface treatment process. The method comprises the following steps: placing a cleaned metal mold in an ion chemical heat treatment furnace, and carrying out molybdenum infiltration treatment on the surface of the metal mold by adopting a glow discharge process; in the molybdenum infiltration process, bombarded particles are accelerated under the action of electric field force when passing through an accelerating electric field, so that the particles can impact the surface of the metal mold with larger impact force, and the molybdenum infiltration depth is increased; the mixed gas permeates into the surface layer of the metal mold under a high-temperature condition, and a thicker and more compact molybdenum sulfide coating is formed on the surface of the mold, so that the wear resistance of the mold is effectively improved; under the synergistic cooperation of the molybdenum sulfide coating, the chromium nitride coating, the titanium nitride coating and the protective coating, the wear resistance, corrosion resistance and fatigue resistance of the treated metal mold are greatly improved, the service life of the mold is prolonged, and the grade of the metal mold is effectively guaranteed.

Owner:西安致远航空科技有限公司

A kind of graphene thermally conductive plastic and preparation method thereof

The invention relates to a graphene thermal conductive plastic. The graphene thermal conductive plastic comprises, by mass, 60 to 90% of a resin, 1 to 20% of graphene, 5 to 20% of a fire retardant, 1 to 10% of a dispersant, 0.5 to 5% of an antioxidant, 0.1 to 5% of a coupling agent, and 1 to 10% of an auxiliary agent. The invention also provides a preparation method of the graphene thermal conductive plastic. Adding of magnesium oxide, aluminum oxide, and silicon carbide is capable of achieving uniform distribution of grapheme, and increasing thermal conductivity of the graphene thermal conductive plastic.

Owner:NINGBO MORSH NEW MATERIALS

Biodegradable high-performance particle material with ceramic texture and preparation method thereof

The invention relates to a biodegradable high-performance particle material with ceramic texture and a preparation method thereof. The biodegradable high-performance particle material is prepared from biologically fermented PBS, a modified natural organic plant fiber material, oxidized modified high amylose, a composite plasticizer, a functional aid, a modifier and modified high-density minerals. Melting reaction and extrusion are performed at 55-160 DEG C by virtue of a double-stage serial screw granulating unit, and mixing, reacting, extruding, cooling, cutting, drying, sterilizing and packaging are carried out to obtain the particle material. Various daily supplies are produced by adopting universal equipment such as extrusion molding, plastic uptake or injection molding units and the like. The adopted raw materials are rich in source, the raw material cost is low, the process is simple, the production cost is low, and the prepared high-performance particle material has high strength and good antibacterial property and hydrophobic property, achieves the ceramic texture and can meet the increasing requirements of people for consumption upgrading of daily supplies.

Owner:广州绿徽新材料研究院有限公司

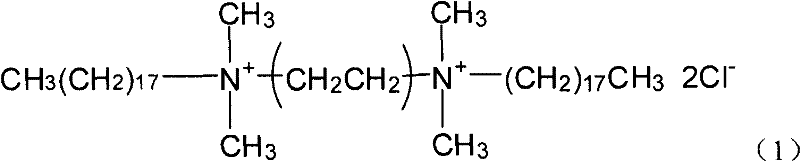

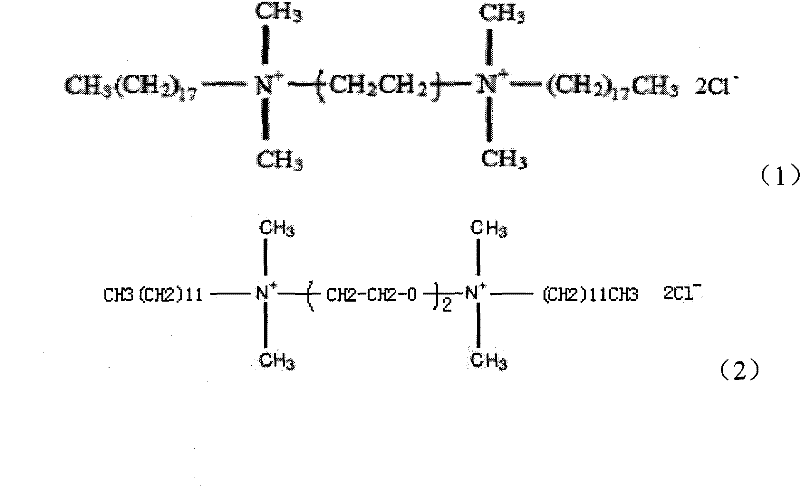

Anode slurry of lithium secondary battery, anode and battery including the same

ActiveCN101431155BImprove surface activityIncrease capacityActive material electrodesSecondary cellsInternal resistanceSlurry

The invention provides positive electrode slurry of a lithium-ion secondary battery. The positive electrode slurry contains a positive electrode active material, a conductive agent, a binding agent, a surfactant and a solvent, wherein, the surfactant is the gemini surfactant. The invention also provides a positive electrode which is prepared by adopting the positive electrode slurry and the lithium-ion secondary battery containing the positive electrode. The positive electrode slurry of the lithium-ion secondary battery can greatly improve the performance of the battery, compared with the lithium-ion secondary battery which is obtained by adopting the traditional surfactant to carry out the pre-dispersion to the conductive agent, the performance of the invention is much higher, such as, the internal resistance of the battery is much lower, the capacity and the discharge rate of the battery are much higher.

Owner:BYD CO LTD

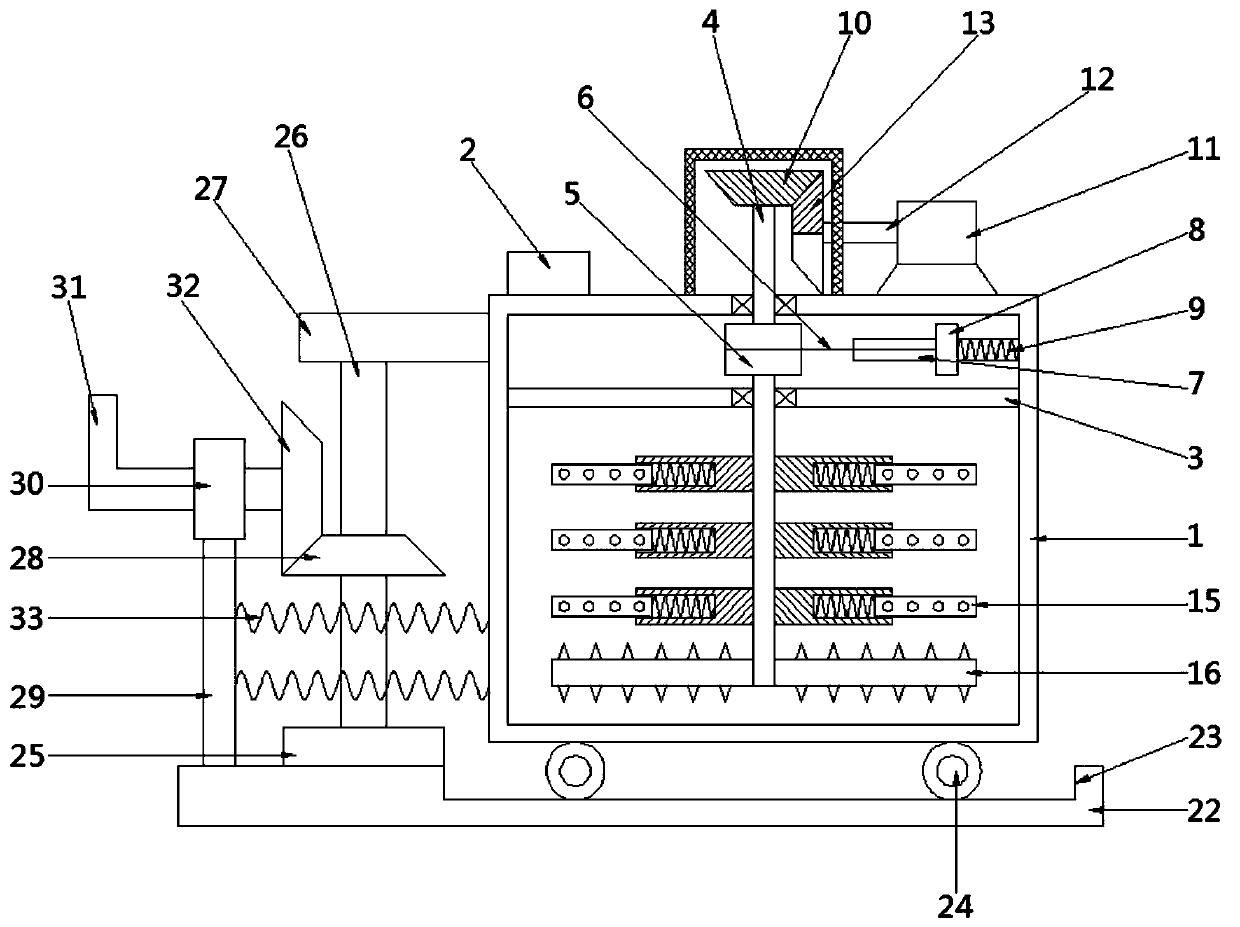

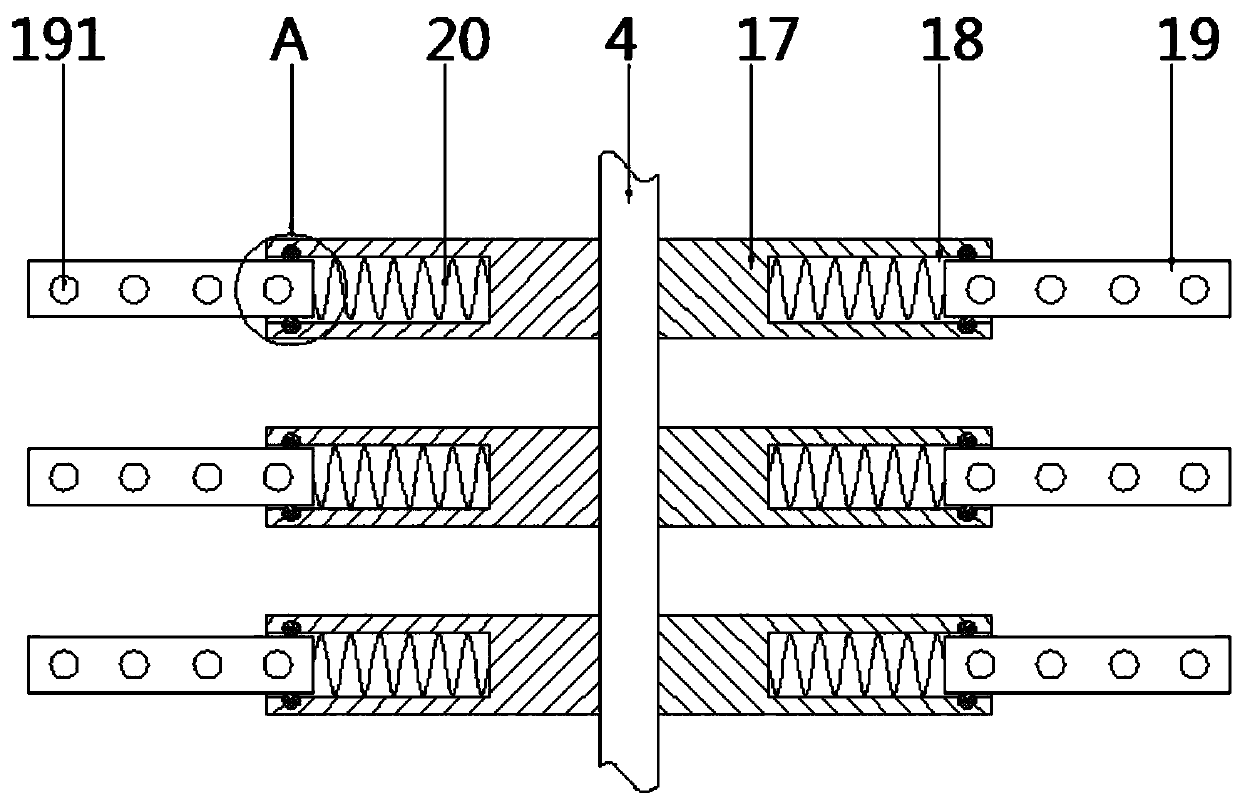

Rapid dye anti-condensation dispersing device for yarn space dyeing

InactiveCN111389271ADecentralized process shortenedFully dispersedShaking/oscillating/vibrating mixersTransportation and packagingDisperse dyeYarn

The invention discloses a rapid anti-condensation dispersing device for dye for yarn space dyeing. The invention belongs to the technical field of space dyeing equipment. The rapid anti-condensation dispersing device comprises a machine body; a feeding hole is formed in the left end of the upper side of the machine body; a partition plate is horizontally arranged on the upper side in the machine body. The partition plate is fixed on the inner wall of the machine body; a dispersing rotating shaft is arranged in the center in the machine body; the top end of the dispersing rotating shaft sequentially penetrates through the partition plate and the upper side wall of the machine body; a helical gear is connected to the top end of the dispersing rotating shaft; a driving motor is fixed on the upper surface of the machine body; a dispersing mechanism can be driven to rotate clockwise and anticlockwise to fully disperse and disperse dye components in the machine body; the phenomenon that materials cannot be fully dispersed is avoided, the dye dispersion process is effectively shortened, the water consumption is reduced, the machine body is driven to continuously shake leftwards and rightwards in the dispersion process, the formation of bubbles is reduced, the agglomeration phenomenon of the dye components can be avoided, and the dispersion efficiency is further improved.

Owner:南通隆彩纺织科技有限公司

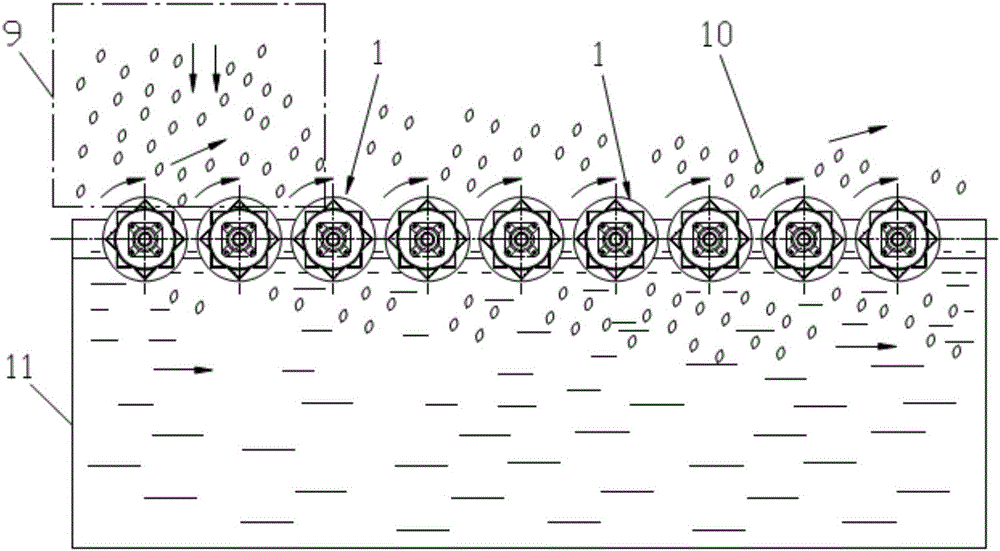

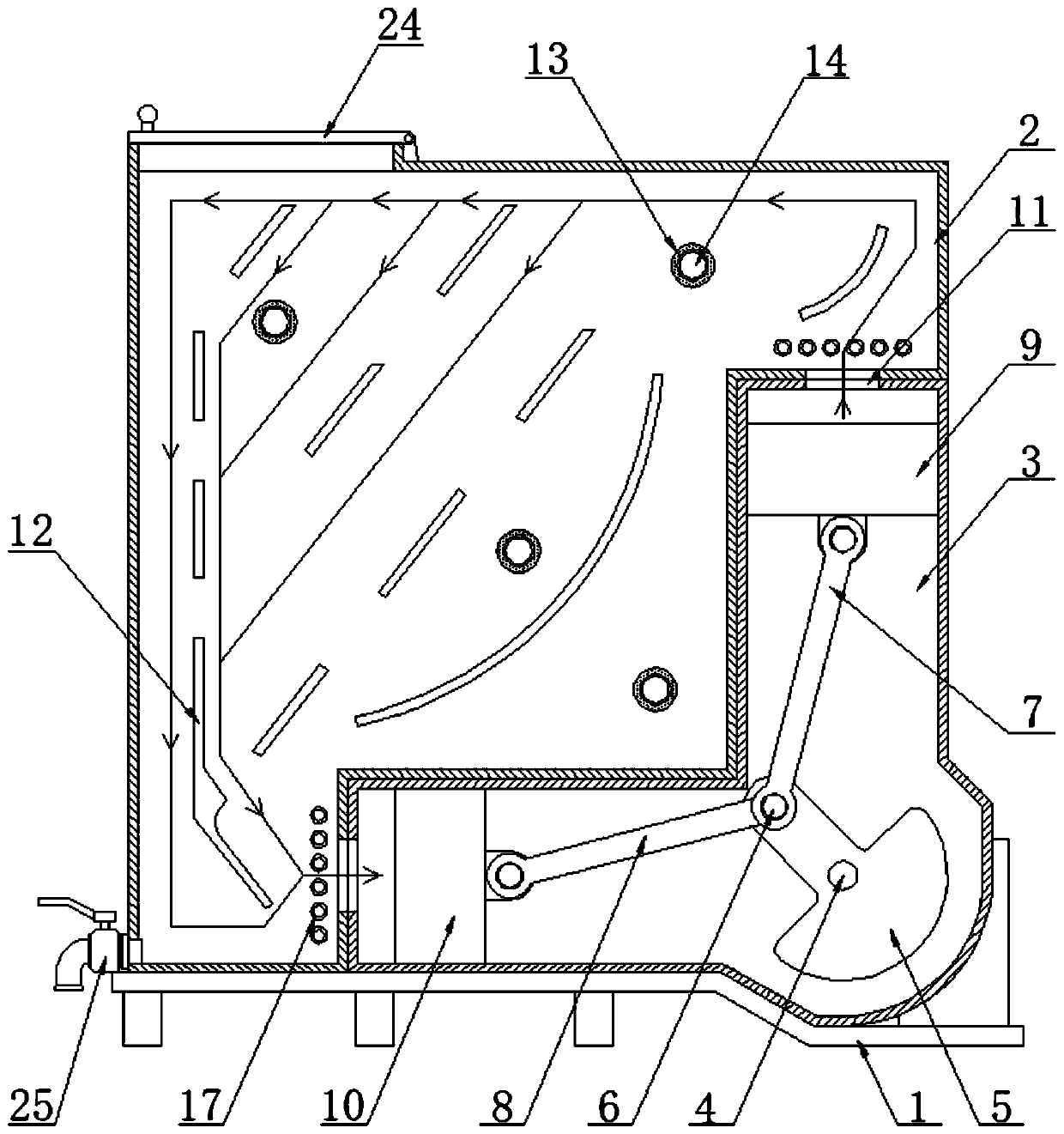

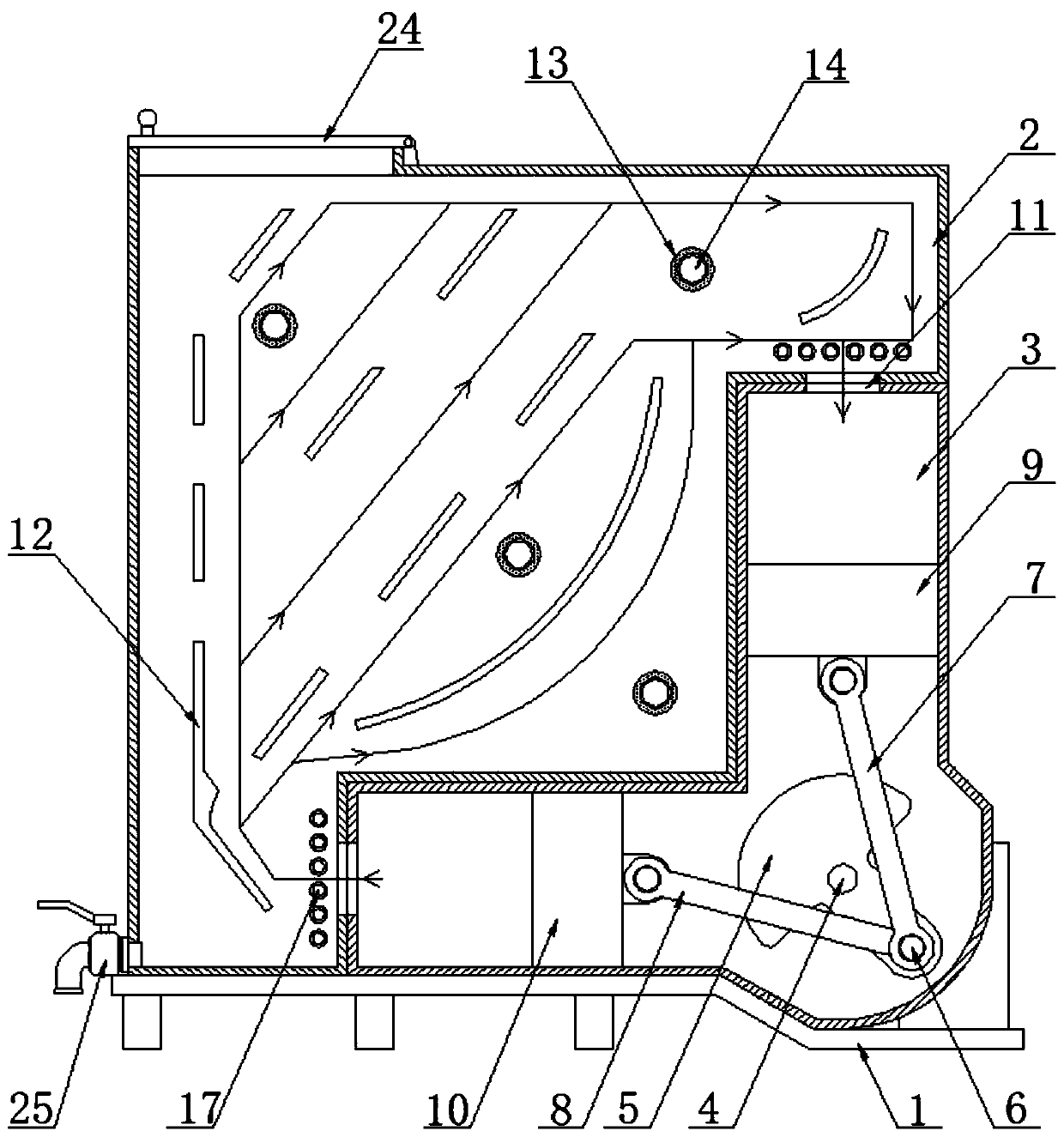

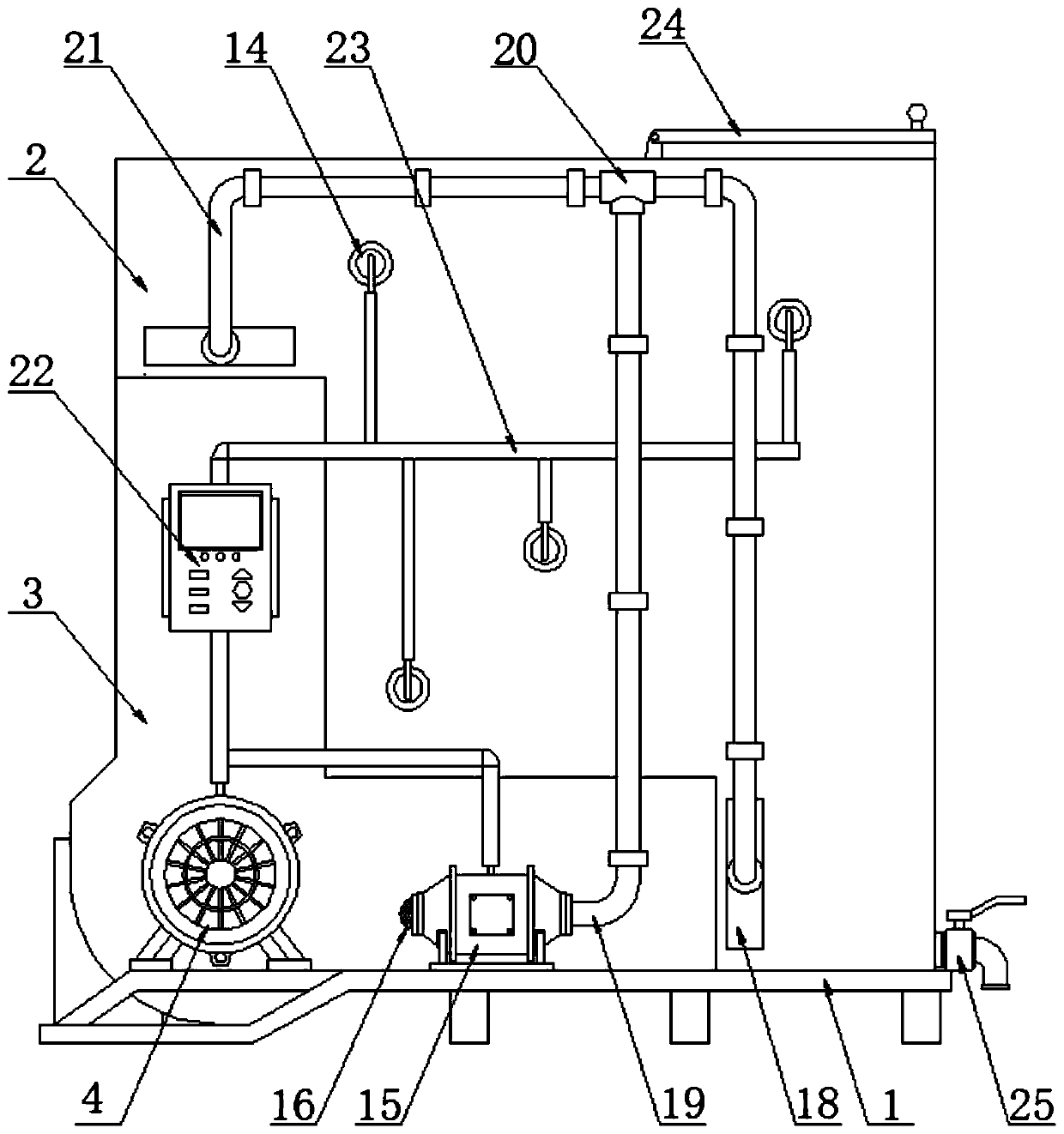

Algae cultivation device capable of uniform light illumination

ActiveCN110521581AEvenly illuminatedEasy to breedClimate change adaptationCultivating equipmentsPistonPhysics

The invention discloses an algae cultivation device capable of uniform light illumination and relates to the technical field of algae cultivation devices. The algae cultivation device capable of uniform light illumination includes a bottom plate, the top of the bottom plate is fixedly connected with a water tank and a power box successively from left to right, the water tank and the power box areglued together, a motor is fixedly connected with the portion, located on the rear side of the power box, of the right side of the top of the bottom plate, and the front end of an output shaft of themotor penetrates through the rear wall of the power box and extends to the inside of the power box. According to the algae cultivation device capable of uniform light illumination, a swing wheel is arranged to cooperate with two sleeve rods to pull two pistons to reciprocate, accordingly the water in the water tank can be pushed to flow back and forth, circulating flow can be formed, so that algaeis prevented from clustering, the water is always maintained in a flowing state, formation of dead water is avoided, cultivation of the algae is facilitated, and flowing water always keeps the algaein a moving state; lamp tubes are arranged inside the water body, accordingly the algae can be directly illuminated from the inside, and it can also be ensured that the overall algae is uniformly illuminated during the movement of the algae.

Owner:ZHEJIANG OCEAN UNIV

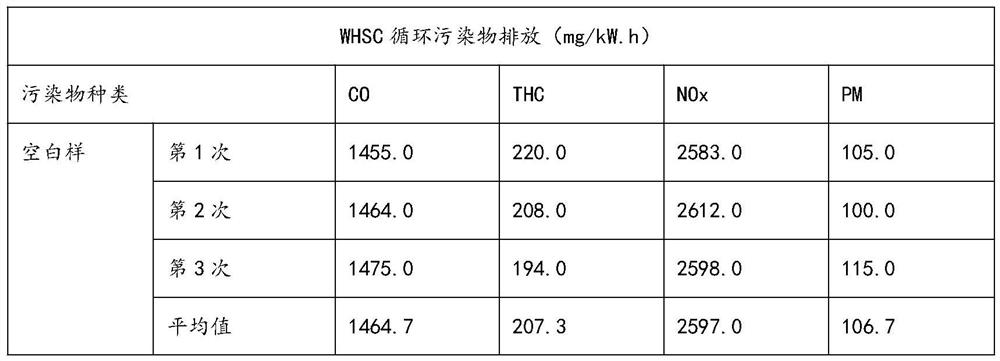

Clean environment-friendly diesel oil and preparation method thereof

PendingCN114164027AIncrease the degree of atomizationPrevent covalent coalescenceLiquid carbonaceous fuelsFuel additivesKetoneFuel oil

The invention provides clean and environment-friendly diesel oil. The clean and environment-friendly diesel oil comprises the following raw material components: 90-97 wt% of diesel oil; and 3 to 10 wt% of a liquid nanodetergent. According to the clean and environment-friendly diesel oil disclosed by the invention, a small amount of special bead liquid nano detergent is added into common diesel oil (generally used for national six-standard diesel oil in market gas stations) to improve the overall performance of a diesel oil product, and the diesel oil product does not contain harmful elements (the product does not contain forbidden components such as aldehyde and ketone, and does not contain heavy metals such as sulfur, nitrogen and the like); clean diesel oil is formed from a pure petroleum-based physical method product additive (a non-chemical method), and the effects of improving efficiency, saving oil, cleaning carbon and reducing emission are achieved by changing the physical performance of the fuel oil; the oil quality is greatly improved, and the cetane number of the oil is obviously increased; the oil sensitivity is good, the engine resonance phenomenon is eliminated, kinetic energy output is stable, and oil consumption is reduced; and sufficient combustion of oil in the engine is realized, so that emission of automobile exhaust pollutants is reduced.

Owner:SINOCHEM ENERGY SAVING ENVIRONMENTAL PROTECTION HLDG BEIJING +1

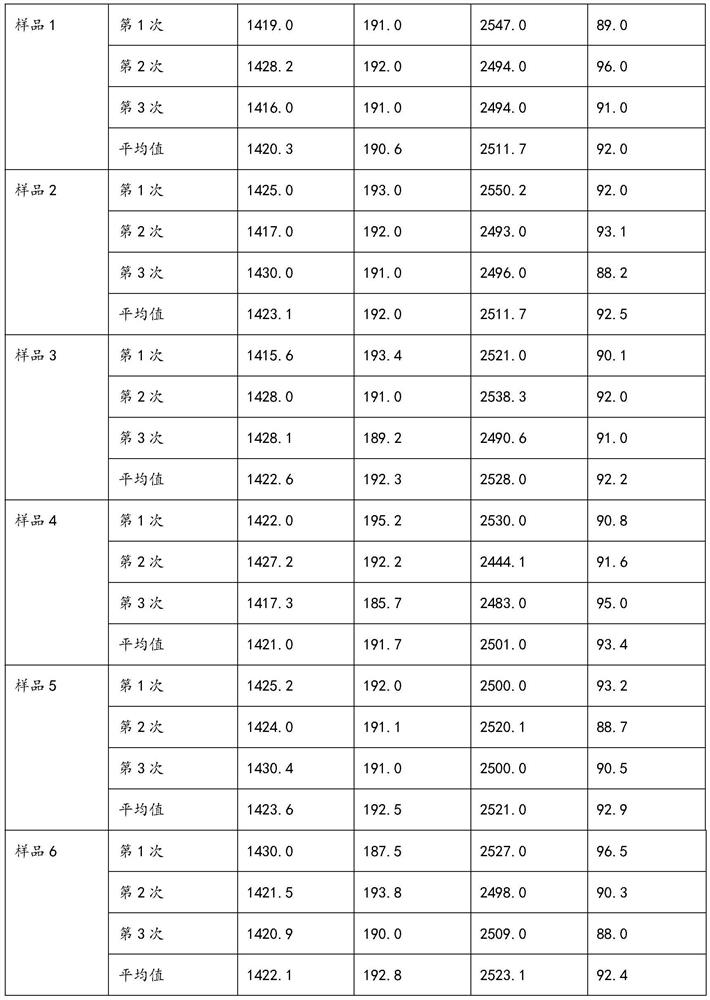

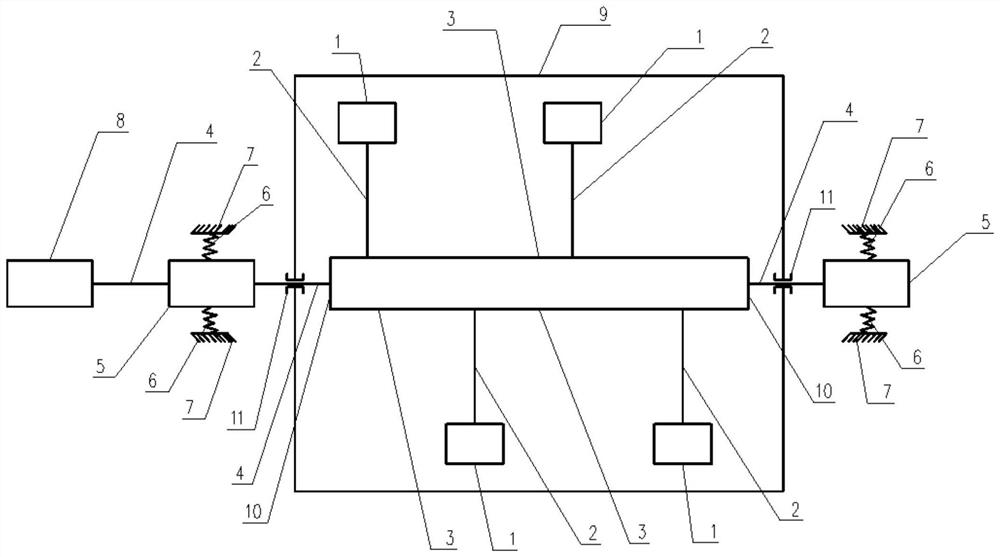

Preparation method of high-performance asphalt mixture

The invention discloses a preparation method of a high-performance asphalt mixture. The preparation method comprises the following steps: S1, setting the heating temperature of a stirring bin to be 180 DEG C; s2, putting a screened coarse and a fine aggregate in and stirring for 25-30 seconds, wherein the stirring rotating speed in the stirring process is 35 + / -0.5 r / min, and the vibration frequency is 40 + / -0.5 Hz; s3, adding asphalt, stirring for 25-30 seconds, wherein the stirring rotating speed in the stirring process is 35 + / -0.5 r / min, and the vibration frequency is 40 + / -0.5 Hz; s4, adding mineral powder, stirring for 25-30 seconds, wherein the stirring rotating speed in the stirring process is 35 + / -0.5 r / min, and the vibration frequency is 40 + / -0.5 Hz; and S5, discharging and preserving heat for later use. According to the preparation method disclosed by the invention, the asphalt can be fully utilized in the asphalt mixture, the loss of the asphalt mixture is reduced, and meanwhile, the pavement performance of the asphalt mixture can be improved.

Owner:ROAD & BRIDGE SOUTH CHINA EINGINEERING CO LTD +1

A light uniform algae cultivation device

ActiveCN110521581BEvenly illuminatedEasy to breedClimate change adaptationCultivating equipmentsFisheryElectric machinery

The invention discloses a lighting uniform algae cultivation device, which comprises a bottom plate, the top of the bottom plate is fixedly connected with a water tank and a power box in turn from left to right, and the water tank and the power box are glued together, the right side of the top of the bottom plate and A motor is fixedly connected to the rear side of the power box, and the front end of the output shaft of the motor passes through the rear wall of the power box and extends to the inside of the power box. The invention relates to the technical field of algae cultivation devices. The light uniform algae cultivation device is equipped with a balance wheel and two sleeve rods to pull two pistons to move back and forth, which can push the water in the water tank to flow back and forth, and can form a circulation, so that the algae cannot gather in groups, and keep the water flowing all the time state, no stagnant water will be formed, which is beneficial to the cultivation of algae. At the same time, the flowing water will always keep the position of the algae in a moving state. Installing a lamp tube inside the water body can directly irradiate the algae from the inside, and the algae can also be illuminated during the movement. Ensure that the whole algae are evenly illuminated.

Owner:ZHEJIANG OCEAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com