Rapid dye anti-condensation dispersing device for yarn space dyeing

A technology of dispersing device and dye, applied in the directions of transportation and packaging, dissolving, mixer, etc., can solve the problems of bonding and cohesion, affecting the quality and efficiency of stage dyeing processing, etc., to reduce frictional resistance, smooth telescopic movement, and improve dispersion. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

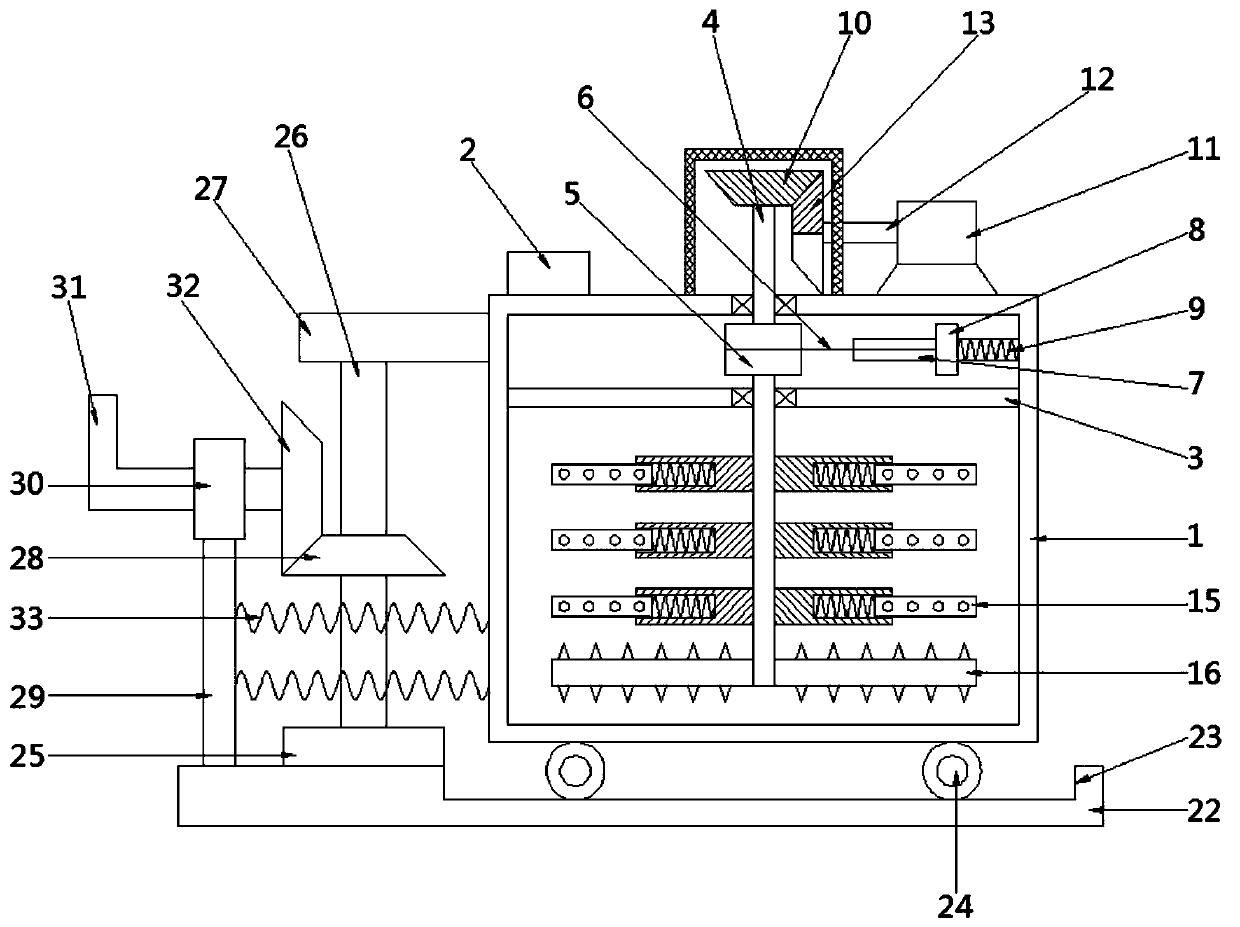

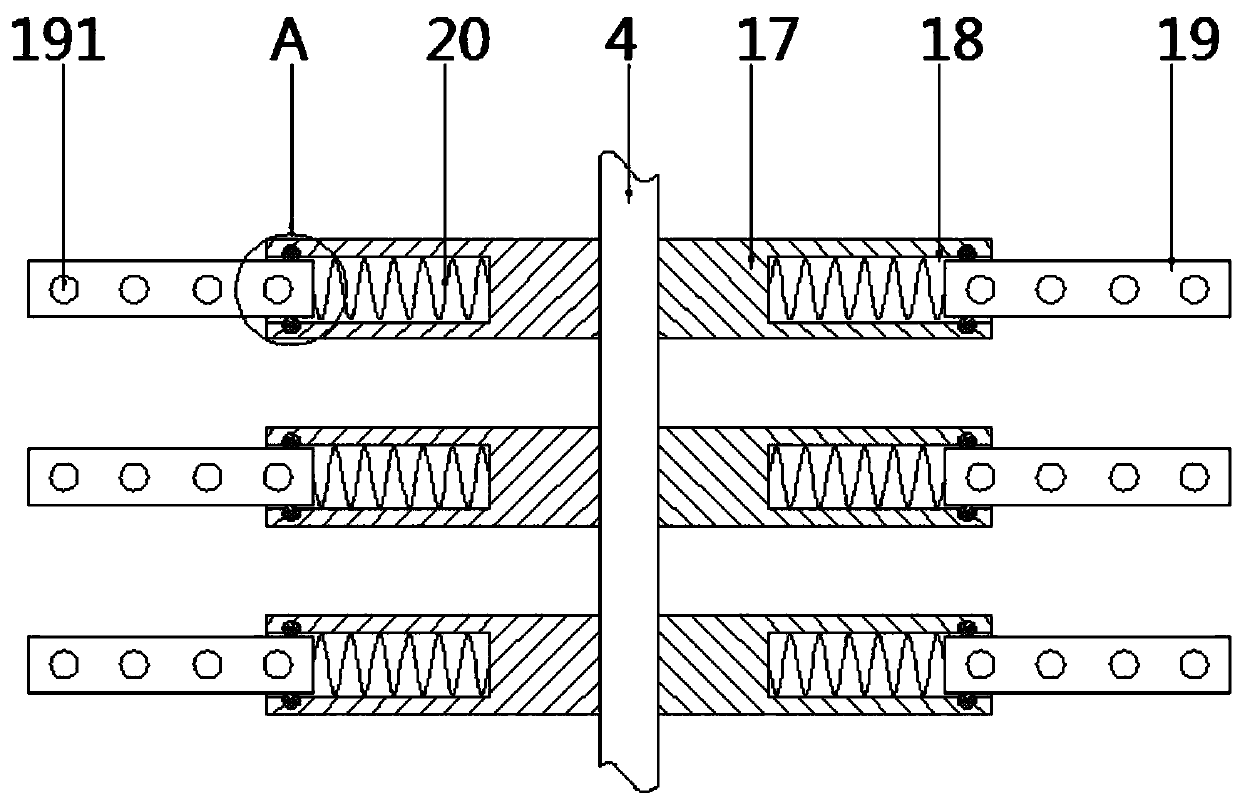

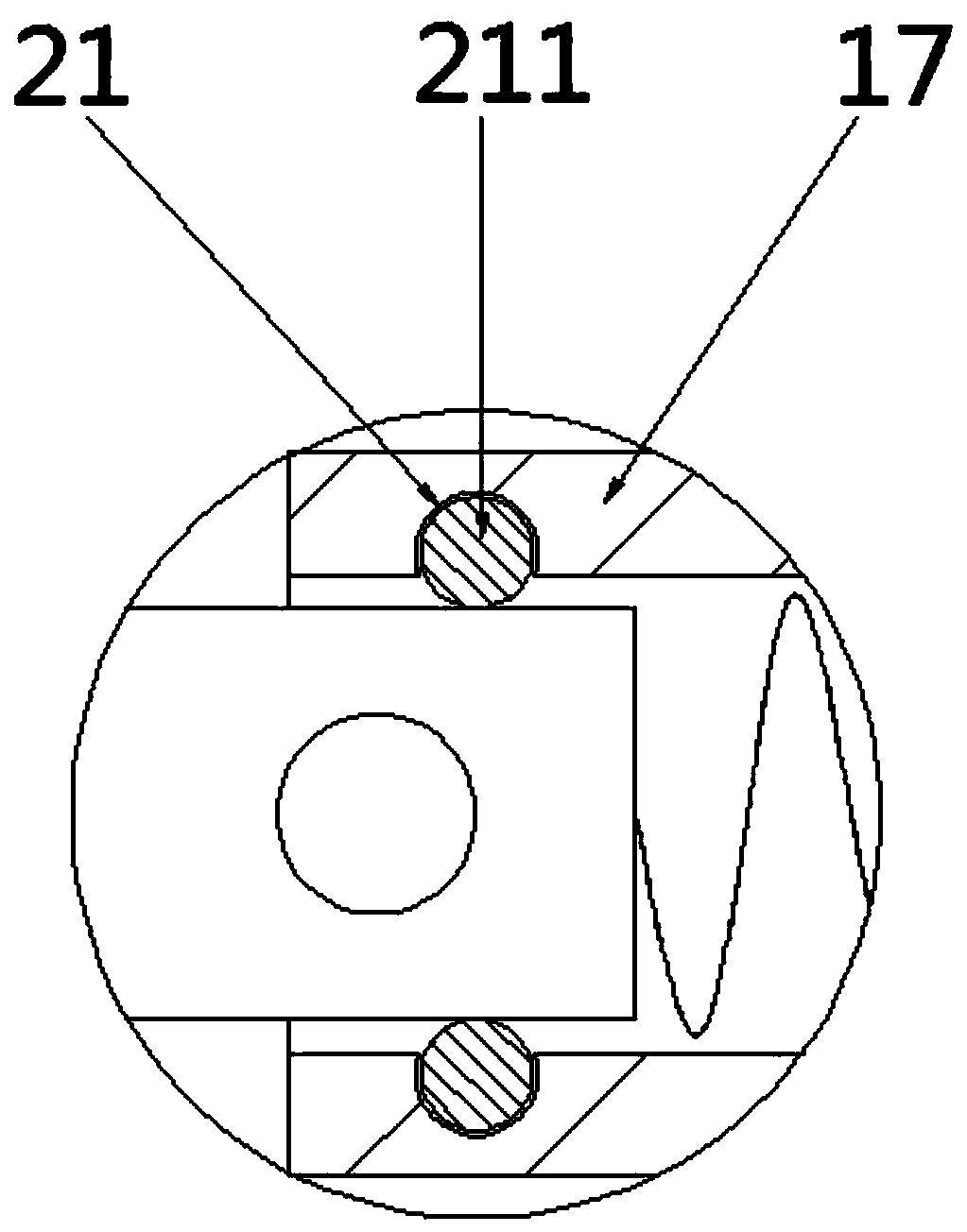

[0035] see Figure 1-3, a dye rapid anti-coagulation dispersion device for yarn segment dyeing, comprising a body 1, the upper left end of the body 1 is provided with a feed port 2, the upper side of the body 1 is horizontally provided with a partition 3, and the partition 3 is fixed on the body On the inner wall of the body 1, a dispersing shaft 4 is arranged at the center of the body 1, and the top of the dispersing shaft 4 runs through the upper side wall of the partition 3 and the body 1 in turn, and the contact between the dispersing shaft 4 and the partition 3 and the upper side wall of the body 1 is uniform. Bearings are socketed, the top of the dispersion shaft 4 is connected with a helical gear 10, the upper surface of the body 1 is fixed with a driving motor 11, the output shaft of the driving motor 11 is connected with a rotating rod 12, and the left end of the rotating rod 12 is connected with an incomplete helical gear 13, Gear teeth are provided on the half-circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com