Defibering, paving and screening device and method for recycled materials

A technology of recycling materials and screening devices, which is applied in the field of renewable resources recycling and processing equipment, can solve the problems of unwrapped materials, insufficient exposure and screening, and failure of screening, so as to improve the cleaning effect and efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

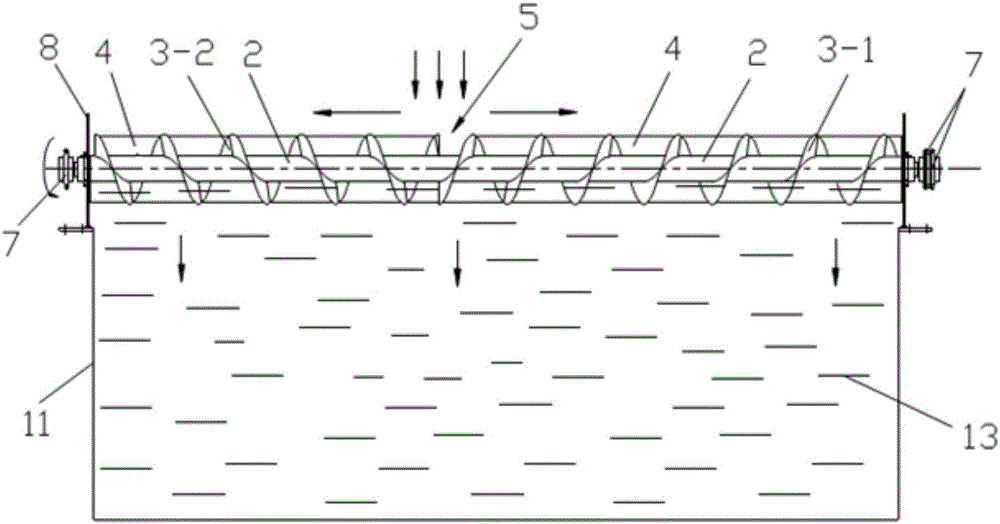

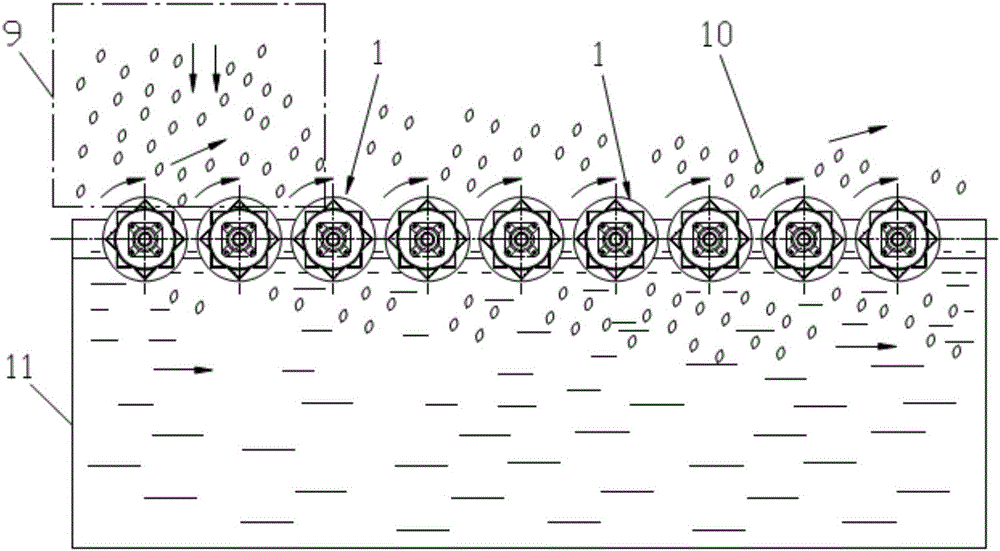

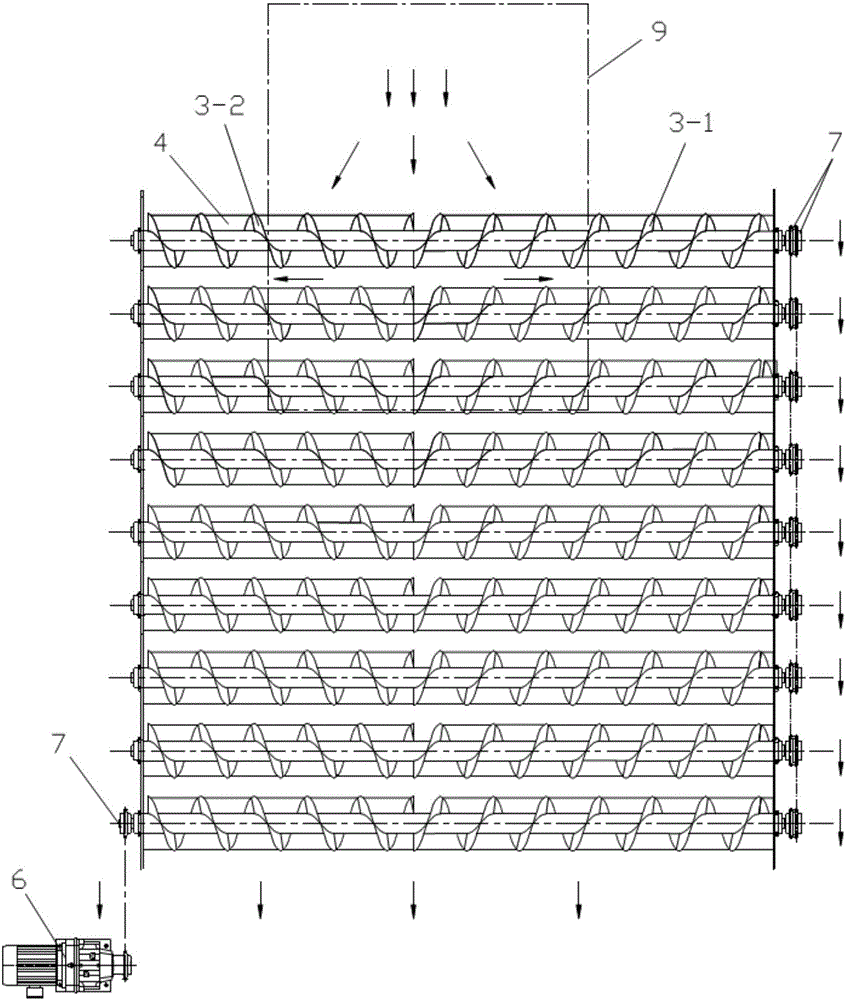

[0045] see Figure 1-Figure 5 , The device for dismantling, spreading and screening recycled recycled materials in this embodiment is composed of a plurality of scattered units 1 arranged together and a driving mechanism. Each breaking unit 1 includes a rotating shaft 2 , a helical blade 3 arranged on the rotating shaft 2 and a tearing member 4 arranged on the rotating shaft 2 , and the driving mechanism is used to drive the rotating shaft 2 to rotate. The spiral blade 3 is composed of a left-handed blade 3-1 and a right-handed blade 3-2, the left-handed blade 3-1 is arranged between the middle part of the rotating shaft 2 and one end thereof, and the right-handed blade 3-2 is arranged Between the middle part and the other end of the rotating shaft 2 , a boundary area 5 is formed at the junction of the left-handed blade 3 - 1 and the right-handed blade 3 - 2 .

[0046] see Figure 1-Figure 3 , the plurality of dispersing units 1 are arranged in parallel on the same level, and...

Embodiment 2

[0056] see Figure 6 The difference between the defibrating device of this embodiment and Embodiment 1 is that in this embodiment, the drive motor 6 is arranged in the middle of the cleaning tank 11 and connected to one of the rotating shafts 2 at the middle.

Embodiment 3

[0058] see Figure 7 The difference between the disintegrating device of this embodiment and that of Embodiment 1 is that, in this embodiment, the disintegrating unit 1 is suspended in the air, and a material conveying device for conveying the disintegrated material 10 is arranged below it, Examples include rinse tanks, conveyor belts, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com