Graphene antistatic plastic and preparation method thereof

An antistatic plastic and graphene technology, applied in the field of plastic materials, can solve problems such as poor antistatic properties of plastics, and achieve the effects of excellent antistatic properties, good antistatic properties, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The present invention also provides a kind of preparation method of graphene antistatic plastic, it comprises the following steps:

[0022] S1, adding resin to the barrel of the twin-screw extruder;

[0023] S2, mix graphene, dispersant, antioxidant, coupling agent and auxiliary agent uniformly to obtain a mixture, then add the mixture to the cylinder of the twin-screw extruder, so that the graphene is uniformly dispersed in the mixture In, wherein, the auxiliary agent is composed of magnesium oxide particles, aluminum oxide particles and silicon carbide particles; and

[0024] S3, adding the flame retardant to the twin-screw extruder;

[0025] S4, extruding and granulating through a twin-screw extruder to obtain graphene antistatic plastics.

[0026] In step S2, the graphene may be added in the form of powder or slurry. The graphene, dispersant, antioxidant, coupling agent and auxiliary agent are mixed at 80° C. to 100° C. for 5 minutes to 15 minutes by a high-speed...

Embodiment 1

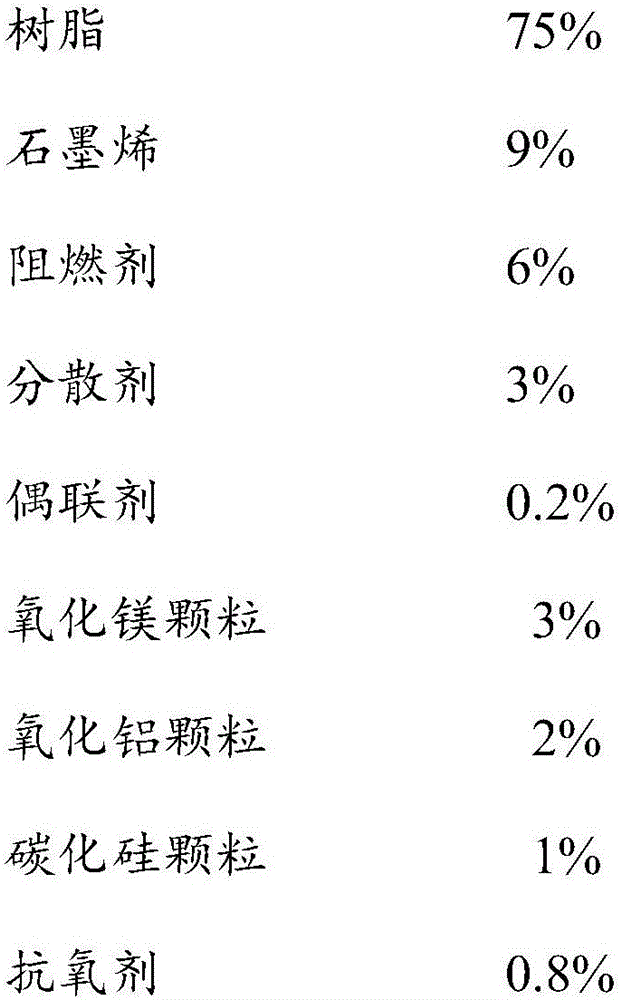

[0035]A graphene antistatic plastic, calculated by weight percentage, its composition and content are as follows:

[0036]

[0037] Wherein, the resin is polyamide nylon 66;

[0038] Described flame retardant is nitrogenous flame retardant MCA-12 (melamine uric acid ester);

[0039] Described coupling agent is silane coupling agent;

[0040] The dispersant is ethylene bis stearamide EBS;

[0041] Described antioxidant is antioxidant 1098;

[0042] The preparation method of above-mentioned antistatic plastics specifically comprises the following steps:

[0043] (1) Add the resin from the first barrel port of the twin-screw extruder;

[0044] (2) Put graphene, coupling agent, magnesium oxide particles, aluminum oxide particles, silicon carbide particles, antioxidant, and dispersant into a high-speed mixer and mix for 5 minutes. The temperature is controlled at 80°C, and then extruded by twin-screw The first barrel of the machine is added;

[0045] (3) The flame retardan...

Embodiment 2

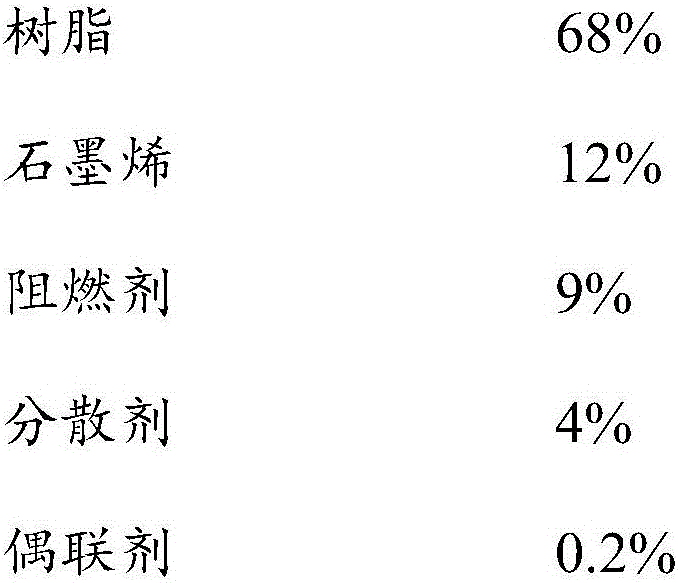

[0050] A graphene antistatic plastic, calculated by weight percentage, its composition and content are as follows:

[0051]

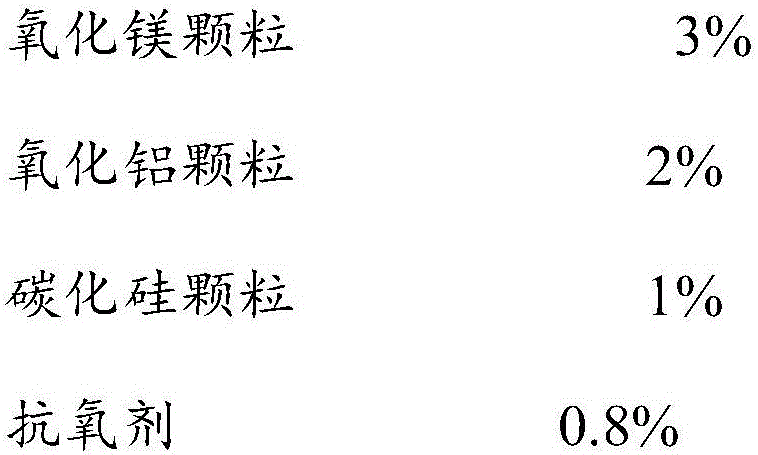

[0052]

[0053] Wherein, the resin is ABS;

[0054] The flame retardant is a mixture of antimony trioxide and decabromodiphenylethane in a mass ratio of 1:5;

[0055] Described coupling agent is silane coupling agent;

[0056] Described dispersant is liquid paraffin;

[0057] Described antioxidant is antioxidant 1098;

[0058] The preparation method of above-mentioned antistatic plastics specifically comprises the following steps:

[0059] (1) Add the resin from the first barrel port of the twin-screw extruder.

[0060] (2) Put graphene, coupling agent, magnesium oxide particles, aluminum oxide particles, silicon carbide particles, antioxidant, and dispersant into a high-speed mixer and mix for 10 minutes. The temperature is controlled at 85°C, and then extruded by twin-screw The first barrel of the machine is added;

[0061] (3) The flame r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com