Patents

Literature

80results about How to "Good conductive network" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

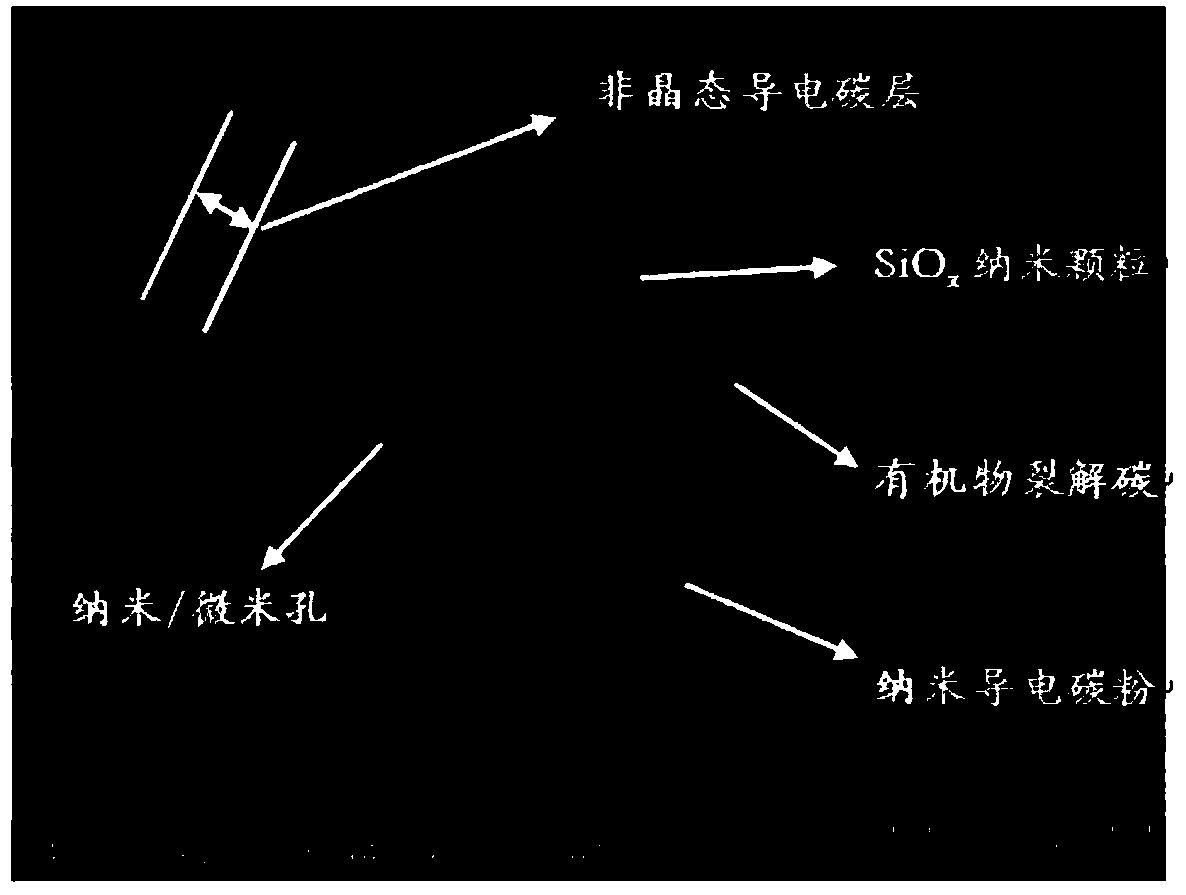

SiOx-based composite material, preparation method and lithium ion battery

ActiveCN103855364AStable structureImprove electronic conductivityMaterial nanotechnologyCell electrodesCarbon layerSpherical shaped

The invention relates to a SiOx-based composite material, a preparation method and a lithium ion battery. The SiOx-based composite material comprises a SiOx / C material, wherein the SiOx / C material comprises SiOx nano particles, organism cracked carbon, nano conductive particles and amorphous conductive carbon layers, the SiOx nano particles, the organism cracked carbon and the nano conductive particles are wrapped in the amorphous conductive carbon layers, the SiOx / C material is in a spherical shape and comprises a porous structure, and x is more than or equal to 0.5 and less than or equal to 1.3. The composite material is used as a negative electrode material of the lithium ion battery, excellent in cycling performance, excellent in rate performance and low in size expansion effect, applicable to the fields such as top-grade digital electrons, electric tools and next-generation vehicle-mounted devices and wide in market prospect.

Owner:BTR NEW MATERIAL GRP CO LTD

Nano-NiS/graphene composite anode material and preparation method thereof

ActiveCN104134783ABuffer volume expansionImprove cycle stabilityCell electrodesSecondary cellsActive agentDissolution

The invention provides a preparation method of a NiS / graphene composite anode material. The method includes: firstly preparing NiS nanoparticles by a solvothermal method, performing surface modification on the NiS particles by a surfactant, then compounding the modified NiS particles with graphene oxide under electrostatic attraction; and reducing graphene oxide by hydrazine hydrate so as to finally form graphene packaged nano-NiS / graphene composite anode material. The dispersion and packaging effects of graphene on NiS can effectively buffer NiS's volume expansion generated during charging and discharging, and inhibit dissolution of the product in an electrolyte solution in an electrode reaction process, thus improving the cyclic stability of the composite material. At the same time, graphene provides a good conductive network, which is conducive to rapid transmission of electrons, thereby reducing electrode polarization and greatly improving the rate performance of the composite material. The NiS / graphene composite material prepared by the method provided by the invention has excellent electrochemical performance, and the preparation process is simple, the conditions are mild, so that the method is suitable for large-scale industrialized production.

Owner:UNIV OF SCI & TECH BEIJING

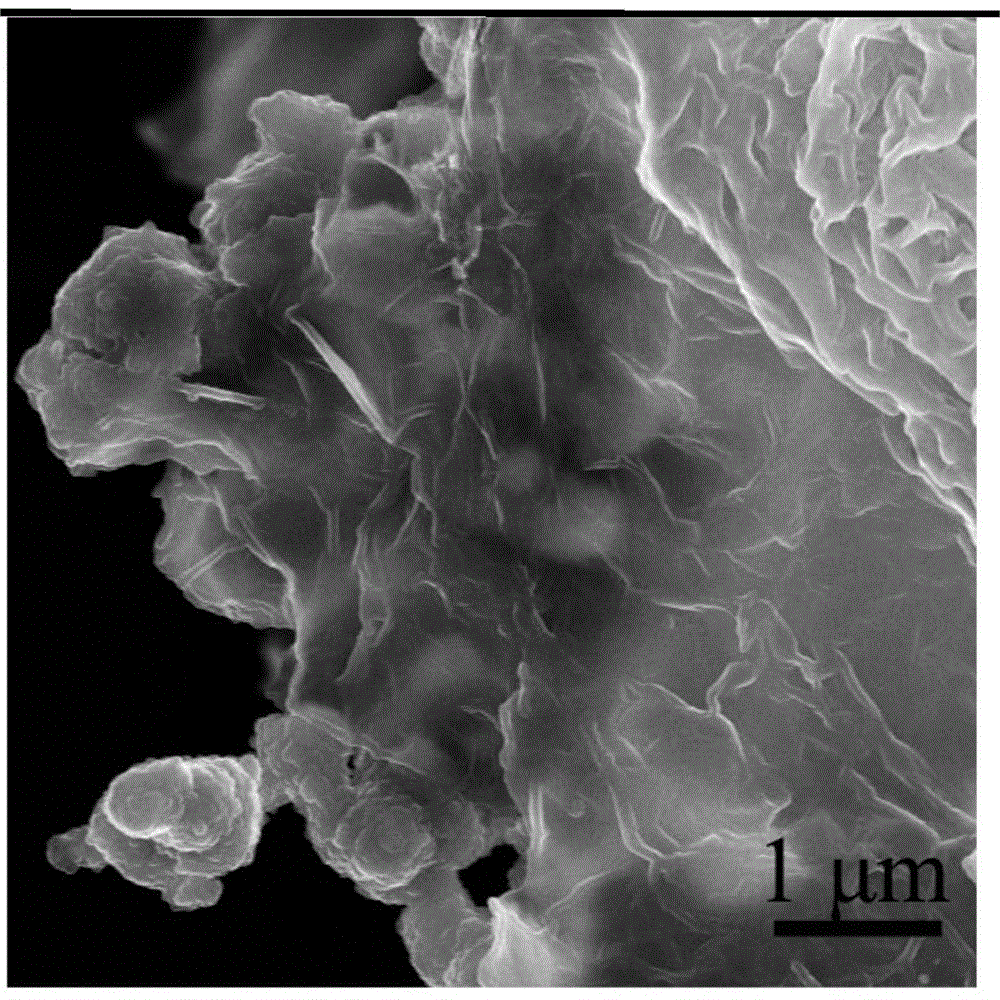

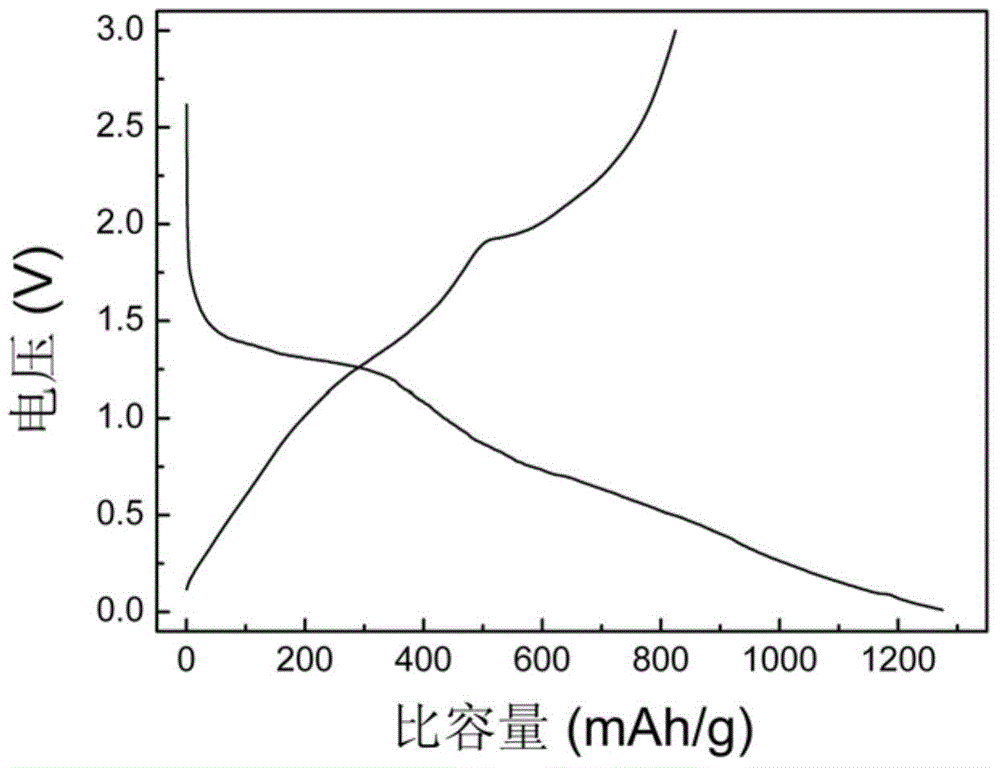

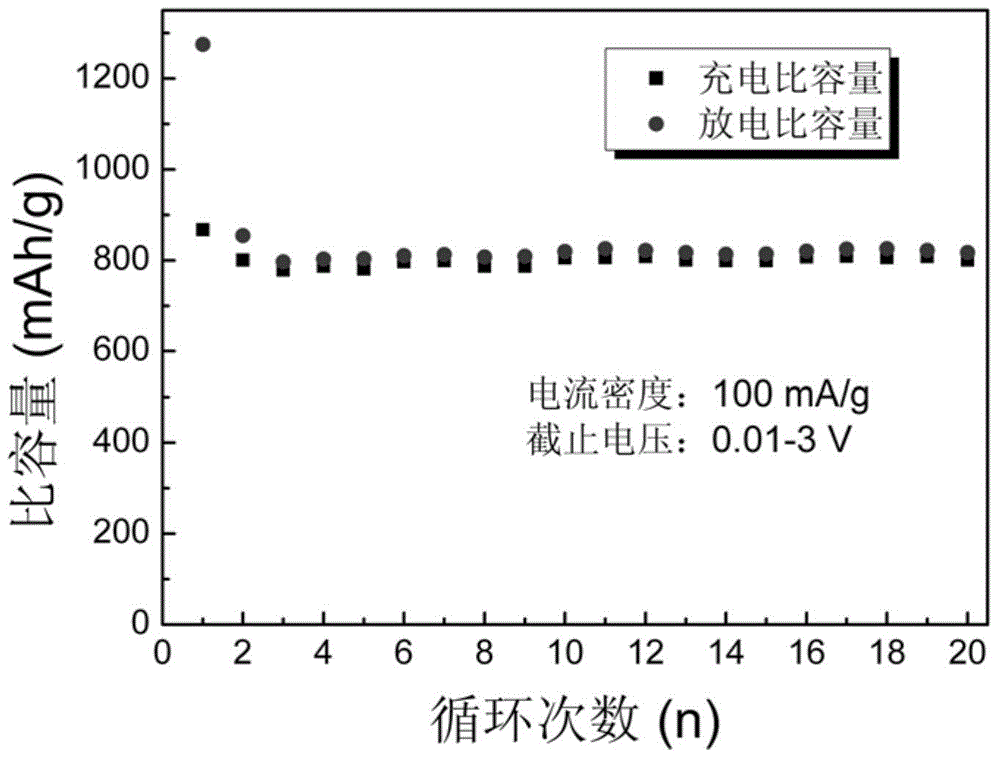

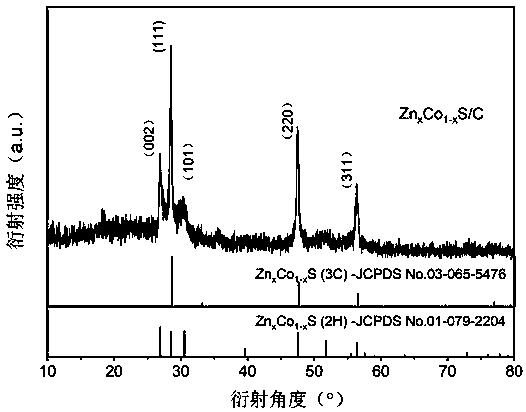

Zinc-cobalt sulfide/carbon nano negative electrode material and preparation method thereof

ActiveCN111293300AGood dispersionImprove conductivityCell electrodesSecondary cellsActive agentSurface-active agents

The invention discloses a zinc-cobalt sulfide / carbon nano negative electrode material and a preparation method thereof. The negative electrode material is of a hollow irregular spherical shell structure formed by distributing zinc-cobalt sulfide nano particles in a carbon matrix and on the surface of the carbon matrix, wherein the mass ratio of the zinc-cobalt sulfide to the carbon is (0.5 to 4.0): 1. The method comprises the steps of (1) adding a surfactant and 2-methylimidazole into an alcoholic solution, stirring, adding a zinc source alcoholic solution, stirring, standing and centrifuging;(2) dissolving in an alcoholic solution, adding a surfactant and 2-methylimidazole, stirring, adding a cobalt source alcoholic solution, stirring, carrying out solvothermal reaction, cooling, centrifuging, washing and drying; (3) adding trihydroxymethyl aminomethane into an alcoholic solution, stirring, adding dopamine hydrochloride, stirring, carrying out suction filtration, washing and drying;and (4) pre-roasting, cooling, mixing with sulfur powder, roasting and cooling. The material provided by the invention is excellent in electrochemical performance. The method provided by the inventionis mild, low in cost, environmentally friendly and suitable for industrial production.

Owner:CENT SOUTH UNIV

Vanadium manganese sodium phosphate @ 3D porous graphene composite material, preparation method thereof, and applications of vanadium manganese sodium phosphate @ 3D porous graphene composite material in sodium-ion batteries

InactiveCN106992298ALarge specific surface areaIncrease the active siteCell electrodesSecondary cellsPorous grapheneFreeze-drying

The invention discloses a vanadium manganese sodium phosphate @ 3D porous graphene composite material, a preparation method thereof, and applications of the vanadium manganese sodium phosphate @ 3D porous graphene composite material in sodium-ion batteries. The vanadium manganese sodium phosphate @ 3D porous graphene composite material is formed via in-suit growth of flaky vanadium manganese sodium phosphate on a 3D porous graphene skeleton. The preparation method comprises following steps: oxidized graphene is added into an aqueous solution containing a phosphorus source, a sodium source, a manganese source, and a vanadium source; ultrasonic dispersion is adopted, stirring reaction is carried out at room temperature, an obtained product is delivered into a reaction kettle for hydro-thermal reaction so as to obtain a hydrogel precursor; the hydrogel precursor is subjected to freeze drying so as to obtain an aerogel; and the aerogel is subjected to calcining so as to obtain a finished product. The vanadium manganese sodium phosphate @ 3D porous graphene composite material possesses excellent electrochemical performance as a sodium-ion battery cathode material. Operation of the preparation method is simple; cost is low; and commercial application prospect is promising.

Owner:CENT SOUTH UNIV

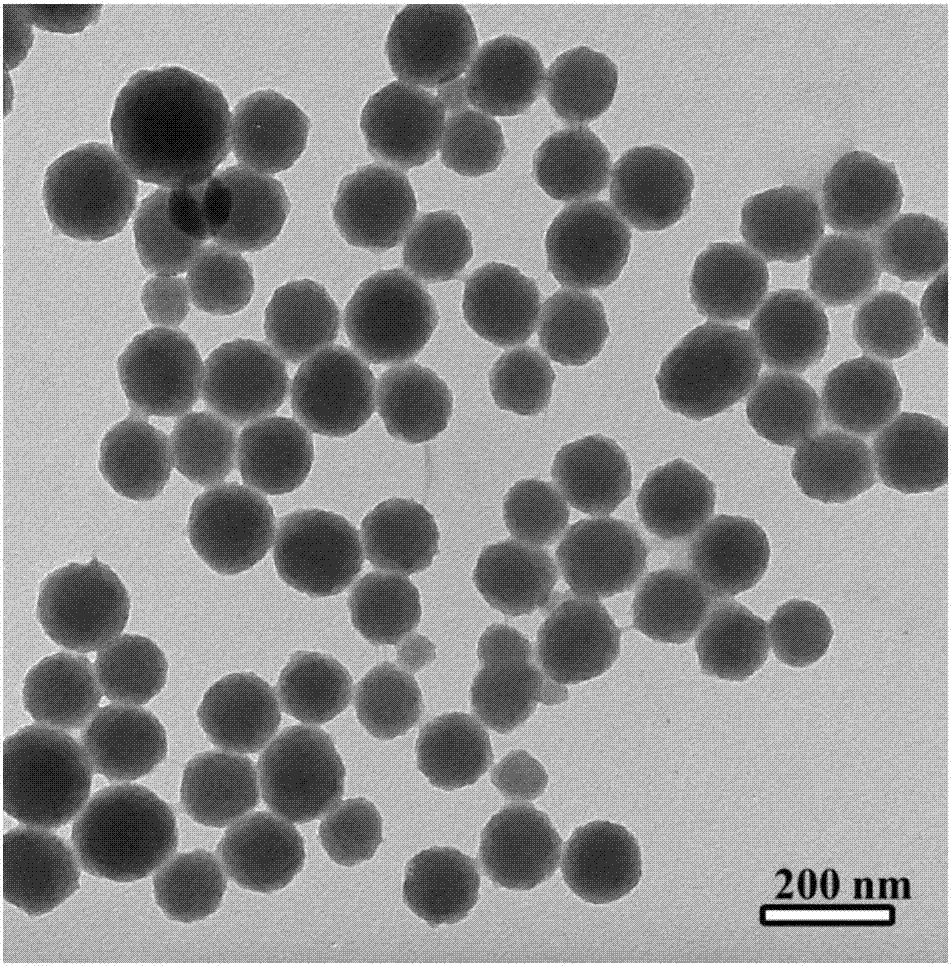

Nitrogen doped carbon nanosphere/molybdenum disulfide sodium-ion battery cathode plate

InactiveCN106981647AImprove cycle stabilityImprove stabilityCell electrodesSecondary cellsElectrical batterySodium-ion battery

The invention belongs to the technical field of battery production, relates to a sodium-ion battery cathode plate, and particularly relates to a nitrogen doped carbon nanosphere / molybdenum disulfide sodium-ion battery cathode plate. Natural-melanin nanospheres are wrapped with a layer of graphene-like transition metal molybdenum disulfide to prepare a nitrogen doped carbon sphere / molybdenum disulfide material, and the nitrogen doped carbon sphere / molybdenum disulfide material is used to prepare a battery. The nitrogen doped carbon nanosphere / molybdenum disulfide sodium-ion battery cathode plate has the advantages that melanin is extracted from natural squid ink, the melanin is wrapped with the molybdenum disulfide through a hydrothermal method, the melanin becomes nitrogen doped carbon spheres during the hydrothermal process due to the fact that the main component of the melanin is polydopamine, molybdenum disulfide nanosheets evenly wrap the carbon nanospheres, and a good conductive load network is formed among the nanosheets; the prepared CS / MoS2 material is used as the cathode material of a sodium-ion battery, cathode structure and interface stability are increased, cathode circulation stability is improved, and commercial production and application are benefited.

Owner:QINGDAO HAICHENG INTPROP SERVICES CO LTD

Carbon sulfur composite material for lithium-sulfur battery and preparation method and application for carbon sulfur composite material

InactiveCN105449175AInhibited DiffusionEfficient use ofCell electrodesSecondary cellsSulfurLithium–sulfur battery

The invention provides a carbon sulfur composite material for a lithium-sulfur battery and a preparation method and an application for the carbon sulfur composite material. The carbon sulfur composite material is positioned between a positive electrode and a diaphragm of the lithium-sulfur battery. For solving the problems of severe circulation capacity degradation, low active substance conductivity and the like of the lithium-sulfur battery, the carbon sulfur composite material positioned between the positive electrode and the diaphragm is designed and prepared and is used for improving the electrochemical performance of the lithium-sulfur battery; the capability of the material for absorbing and holding polysulfide ions can be adjusted by controlling the content of sulfur in the carbon sulfur composite material to improve the utilization rate of sulfur so as to improve the charge-discharge capacity and the cycling performance of the lithium-sulfur battery; and in addition, the carbon sulfur composite material provided by the invention is simple and easy to implement the preparation process, and good for later industrial production and quite high in potential in actual applications.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Ultraviolet-cured polyurethane-based conductive silver paste and preparation method thereof

InactiveCN104575671AImprove shrinkageGood mechanical propertiesNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pastePolyethylene glycol

The invention discloses an ultraviolet-cured polyurethane-based conductive silver paste and a preparation method thereof. The preparation method comprises the following steps: heating an active monomer to 40-60 DEG C, dissolving a photoinitiator in the active monomer, cooling to 20-35 DEG C, mixing the active monomer with superfine spherical silver, after ultrasonic dispersion, sequentially adding a polyurethane prepolymer and flake-like silver powder, stirring and grinding to obtain conductive silver paste, wherein the conductivity of the ultraviolet-cured silver paste is 7.59*10<5>S / m to 1.32*10<6>S / m, and the conductivity of the ultraviolet-cured silver paste is still 7.82*10<4>S / m to 3.38*10<5>S / m after a bending test is performed for ten times. The ultraviolet-cured polyurethane-based conductive silver paste prepared by adopting the preparation method is high in conductivity, excellent in flexibility, strong in adhesive force to a polyethylene glycol terephthalate base material, and less in dosage of the photoinitiator, and can be widely applied to flexible printed circuits such as a keyboard, a mobile phone, a flat computer and a digital camera.

Owner:SOUTH CHINA UNIV OF TECH +1

Silicon-carbon composite material, preparation method and application as well as lithium ion battery negative electrode material

ActiveCN107394176AAlleviate the problem of easy and current collector falling offBuffer volumeCell electrodesSecondary cellsCarbon compositesSilicon thin film

The invention provides a silicon-carbon composite material, a preparation method and application as well as a lithium ion battery negative electrode material, which relate to the technical field of negative materials for lithium ion batteries. The silicon-carbon composite material comprises a three-dimensional carbon material, wherein the surface of the three-dimensional carbon material is coated with a silicon thin film. The silicon-carbon composite material is used as a negative electrode of the lithium ion battery, so that the technical problem in the prior art that the decreasing of the battery performance is caused by the separation of a silicon material and a current collector due to the volume change of silicon when the silicon is used as a negative electrode material can be solved, and the service life of the lithium ion battery utilizing the silicon as the negative electrode material is prolonged.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

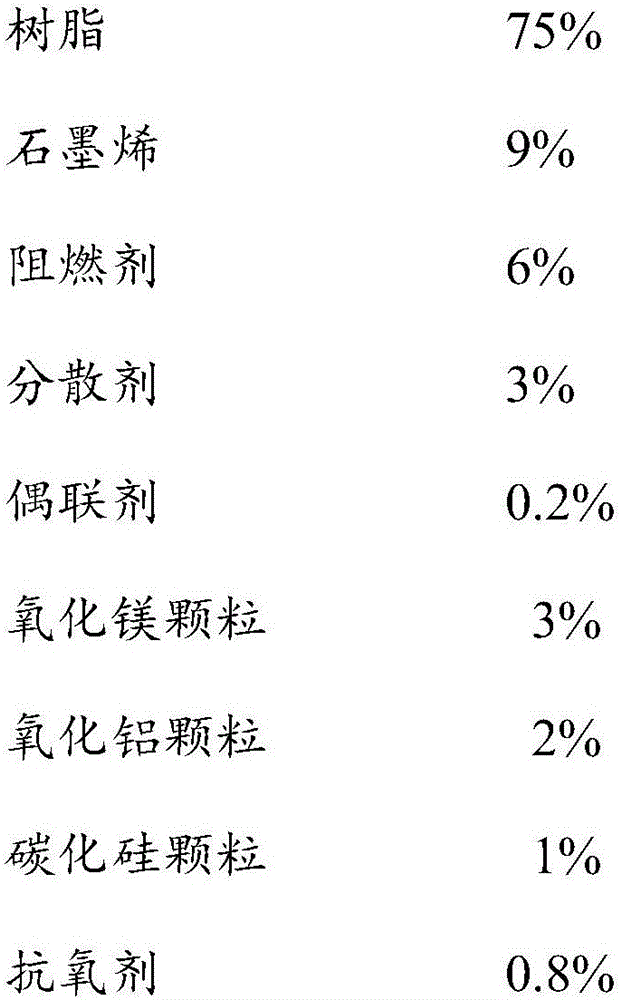

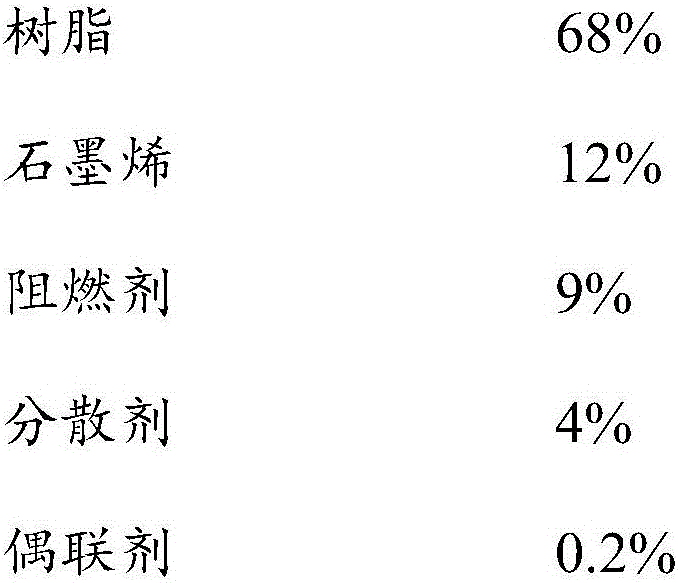

Graphene antistatic plastic and preparation method thereof

The invention relates to graphene antistatic plastic, which comprises the following components in percentage by mass: 60-90% of resin, 1-20% of graphene, 5-20% of fire retardant, 1-10% of a dispersing agent, 0.5-5% of an antioxidant, 0.1-5% of a coupling agent and 1-10% of an assistant, wherein the graphene is evenly dispersed into the graphene antistatic plastic; and the assistant is a mixture prepared from magnesium oxide, aluminum oxide and silicon carbide. The invention further provides a preparation method of the graphene antistatic plastic. Through addition of magnesium oxide, aluminum oxide and silicon carbide, the graphene can be evenly distributed, so that the conductivity of the graphene antistatic plastic is improved.

Owner:NINGBO MORSH TECH

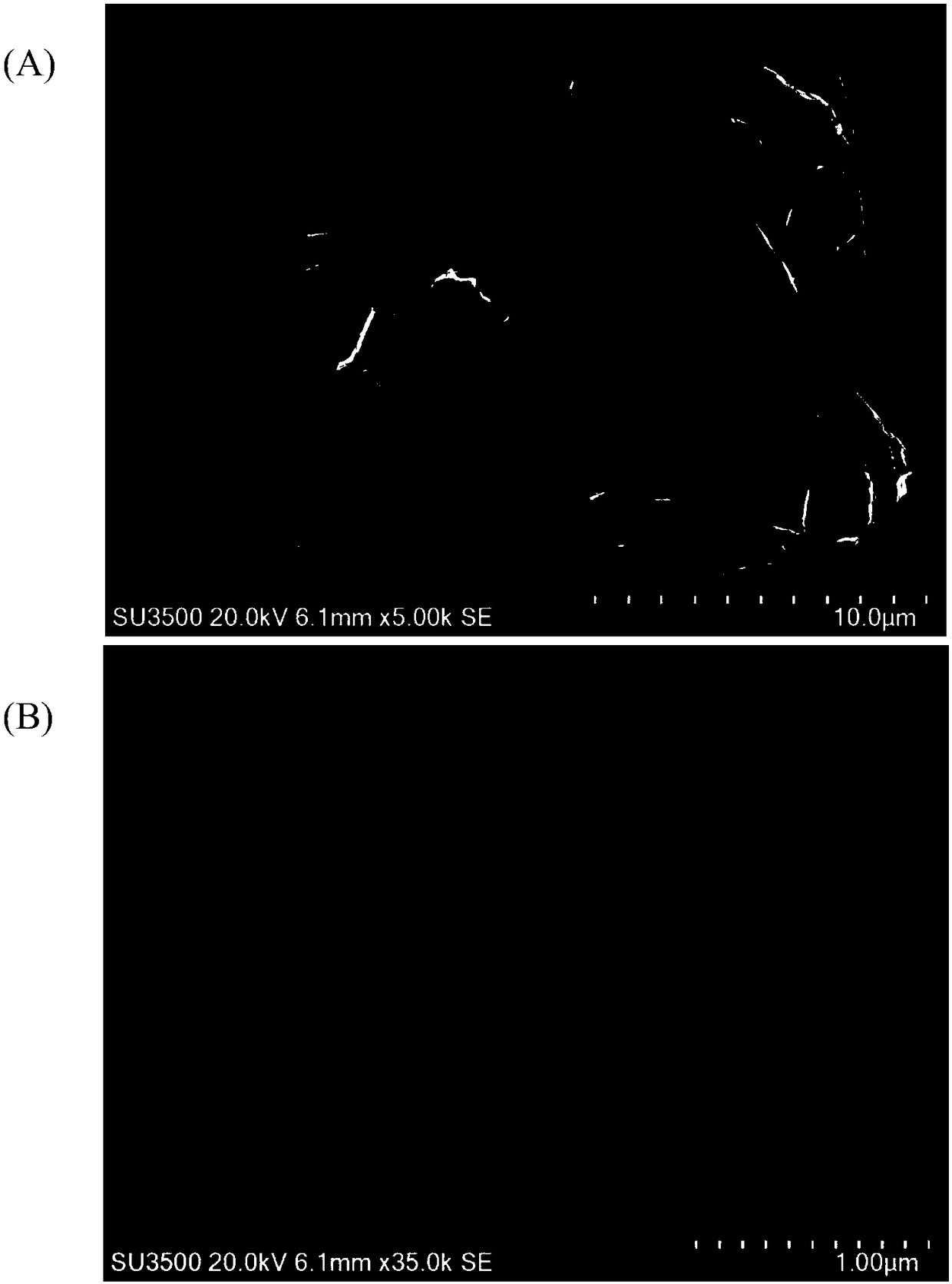

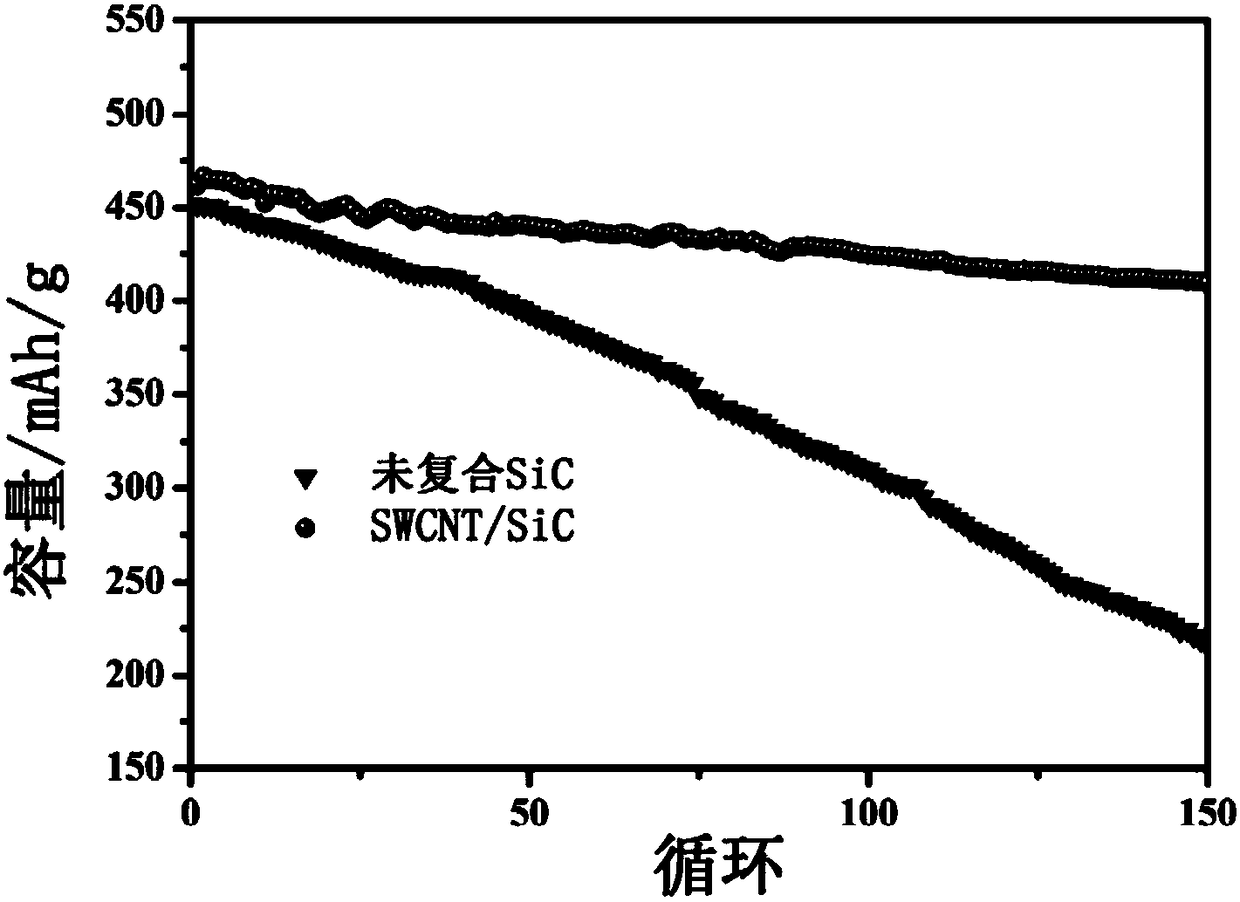

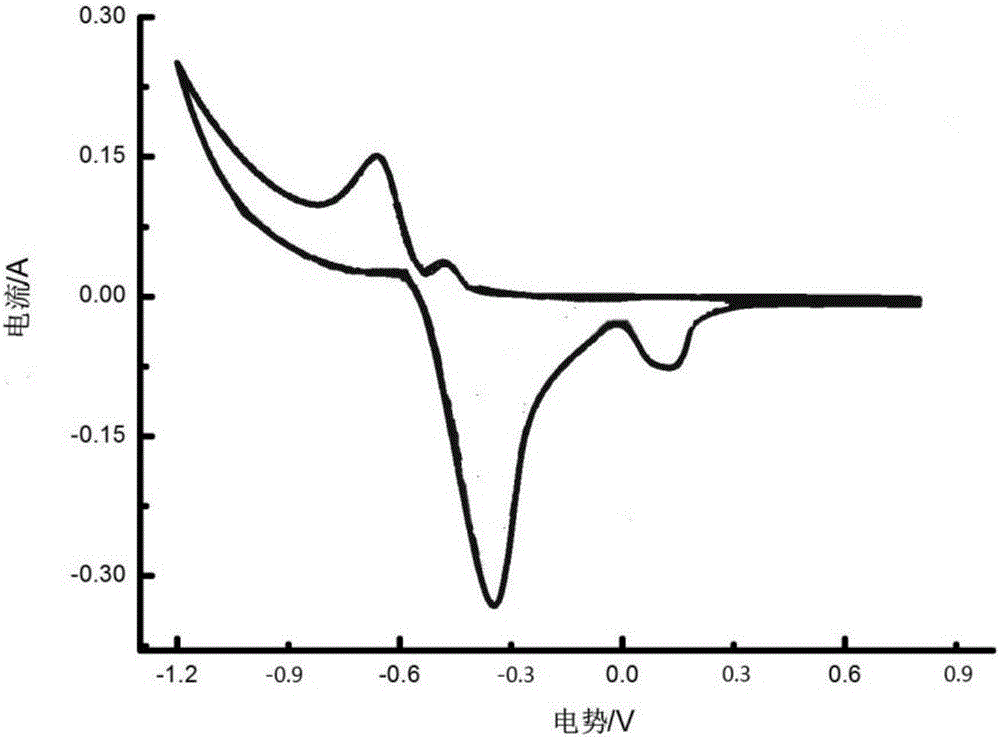

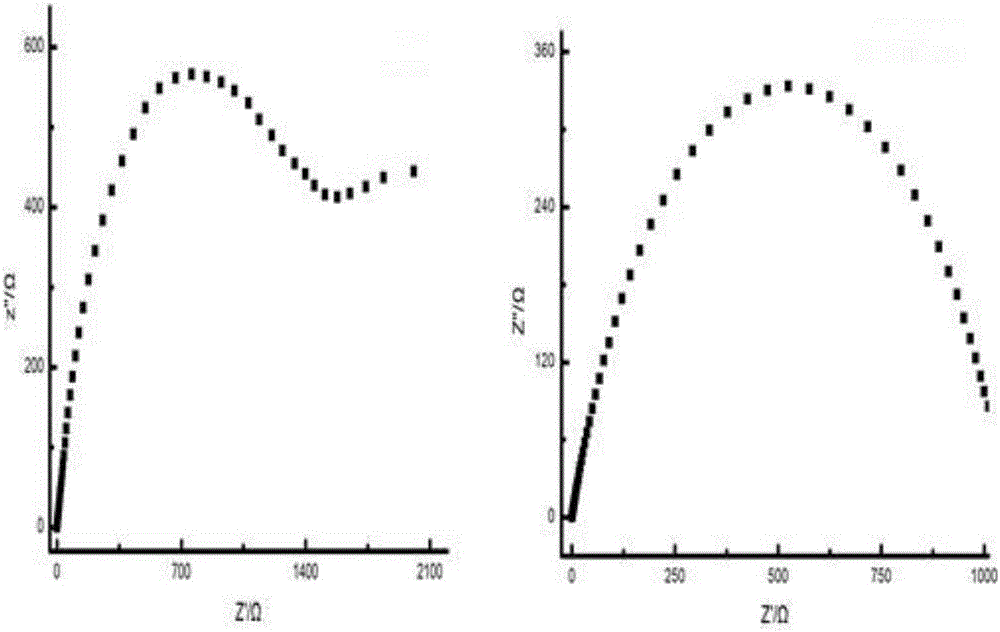

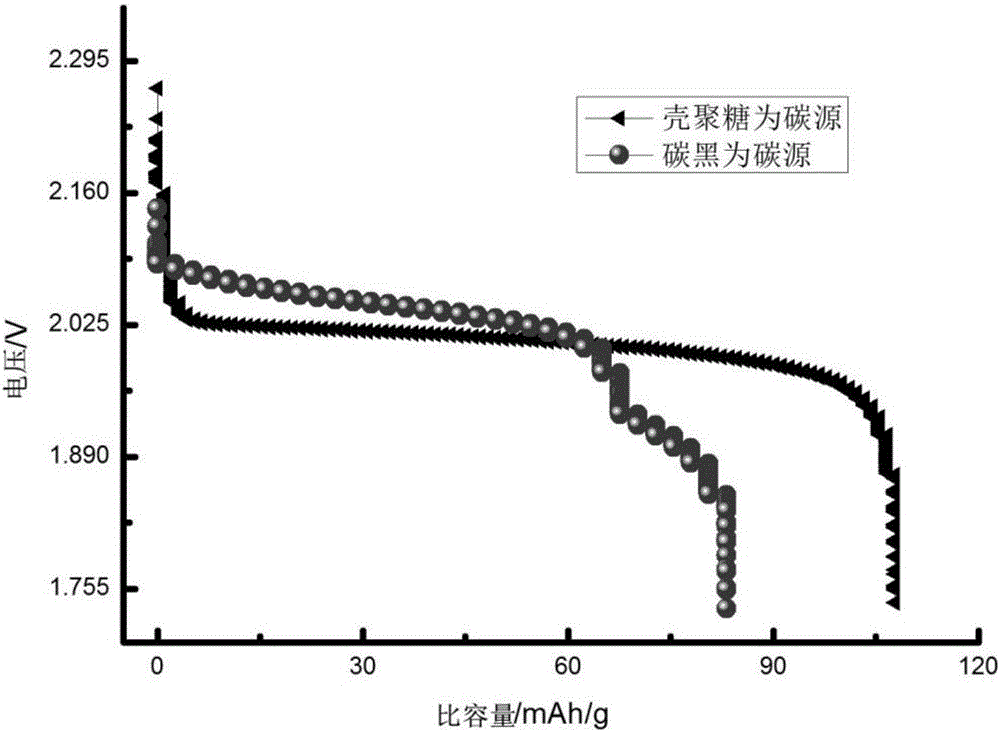

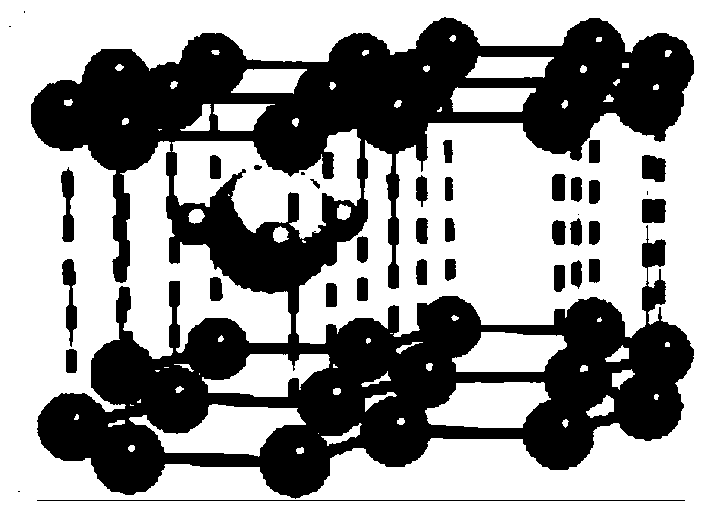

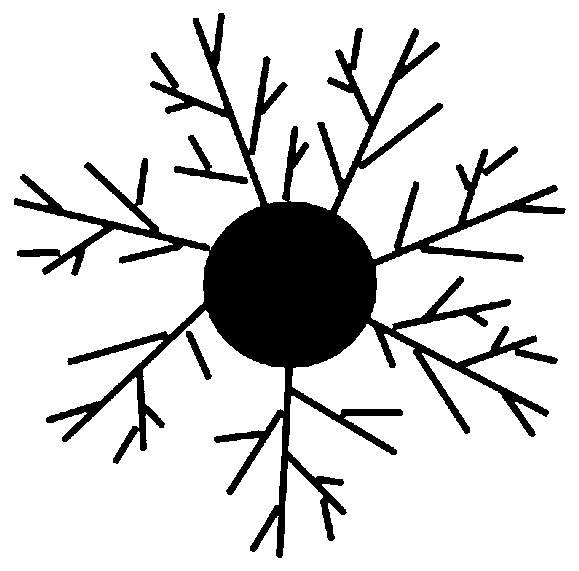

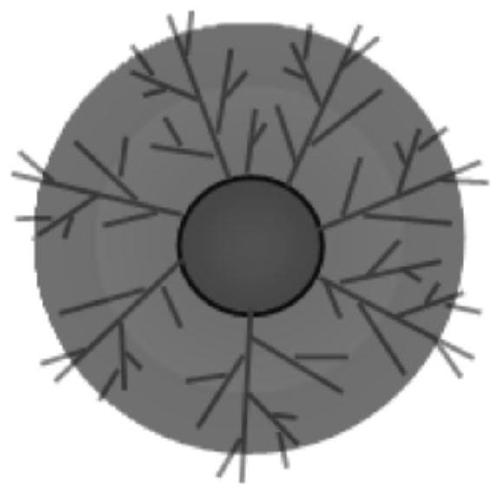

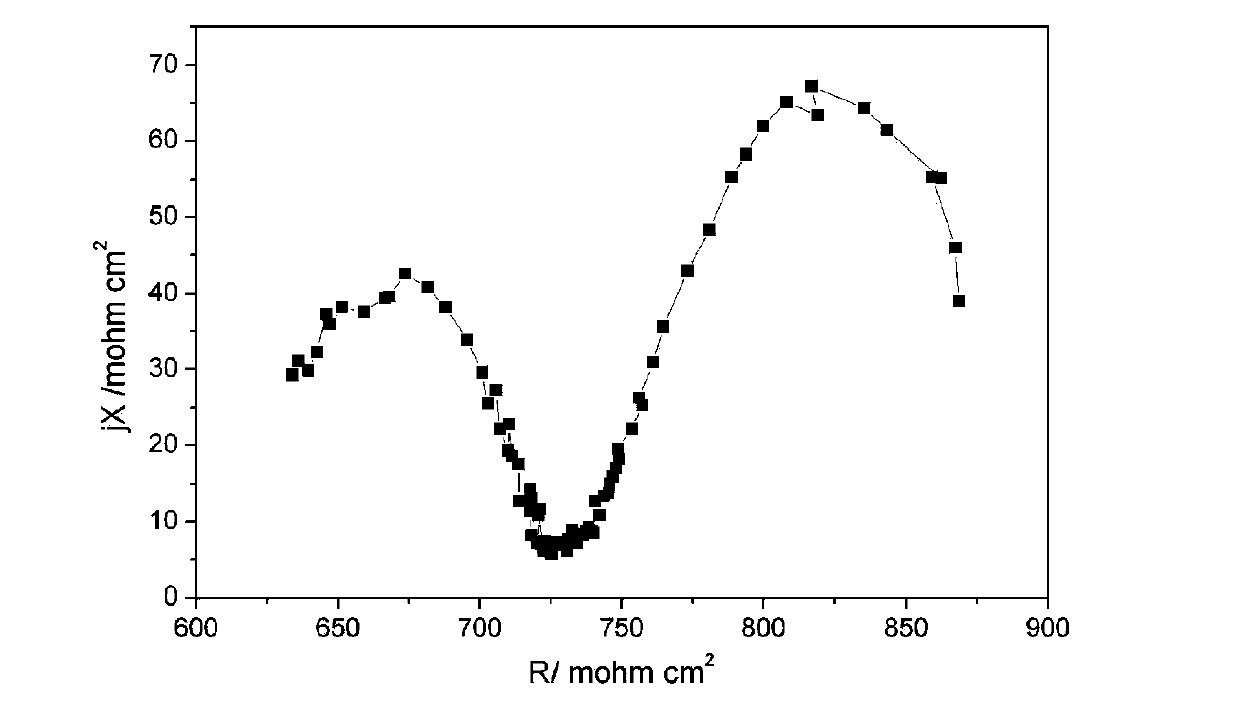

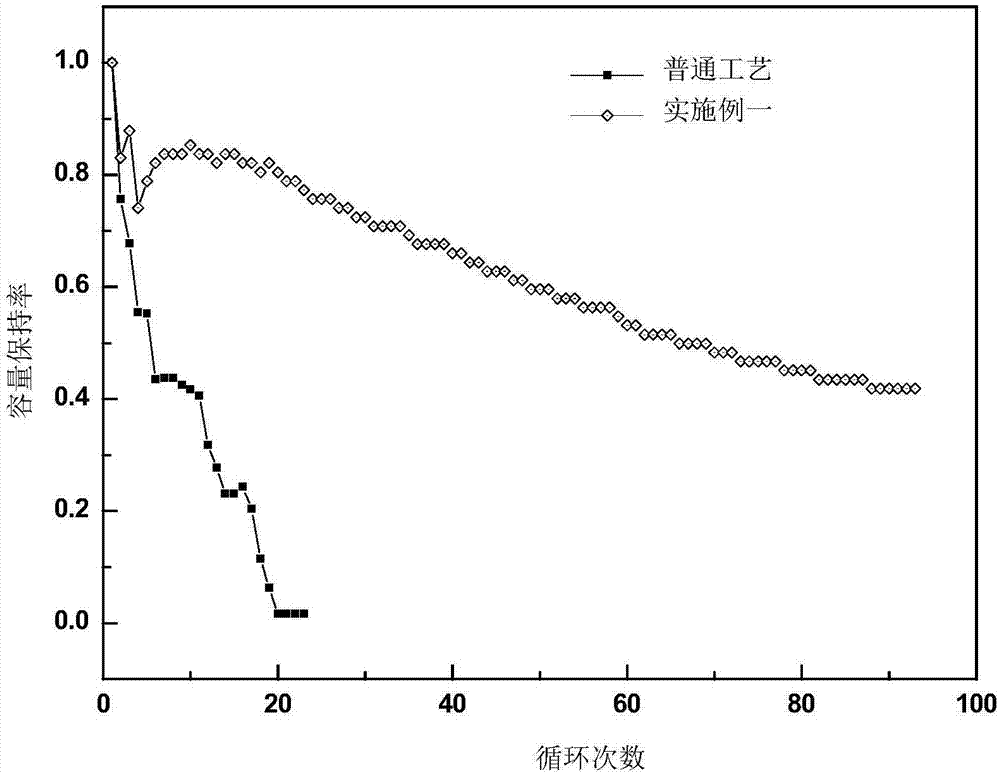

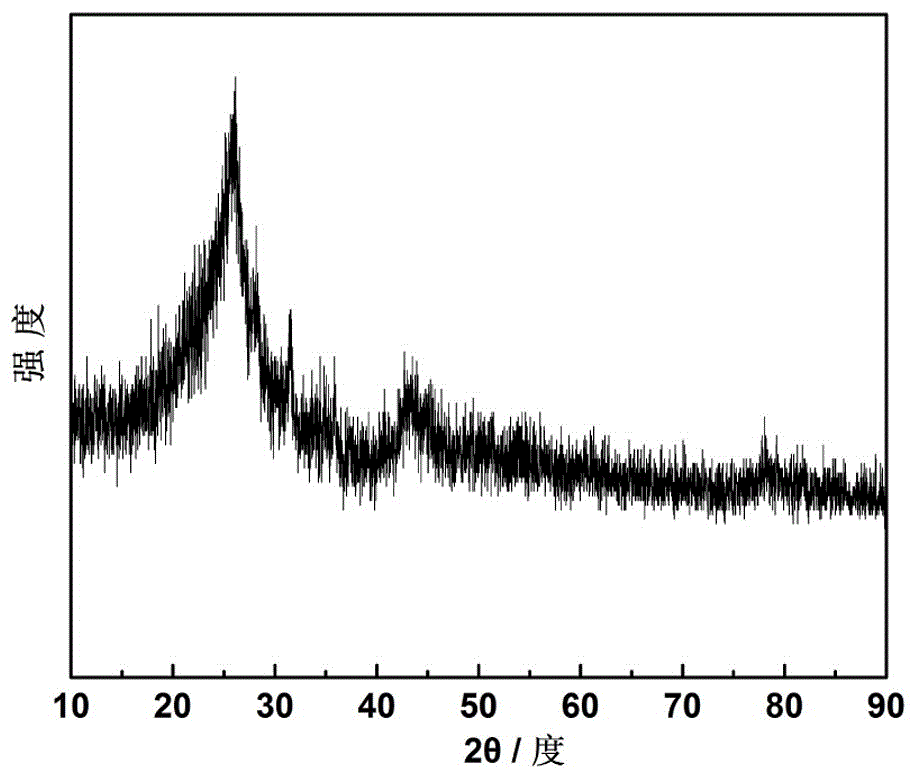

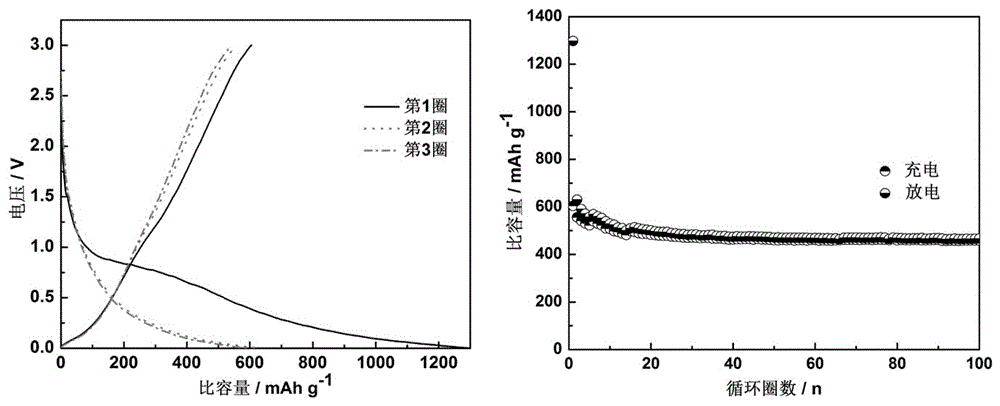

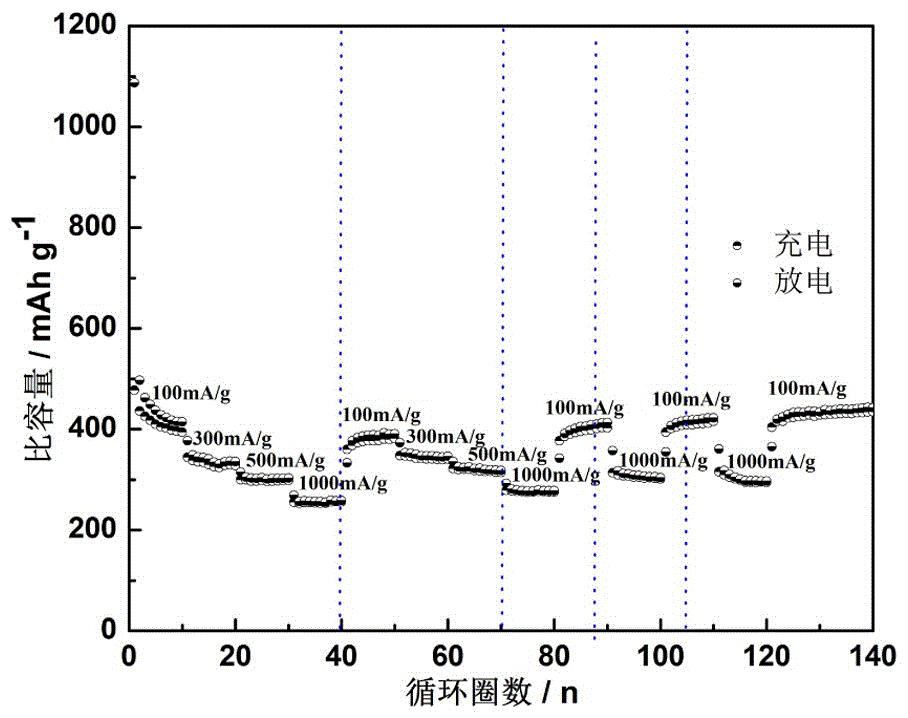

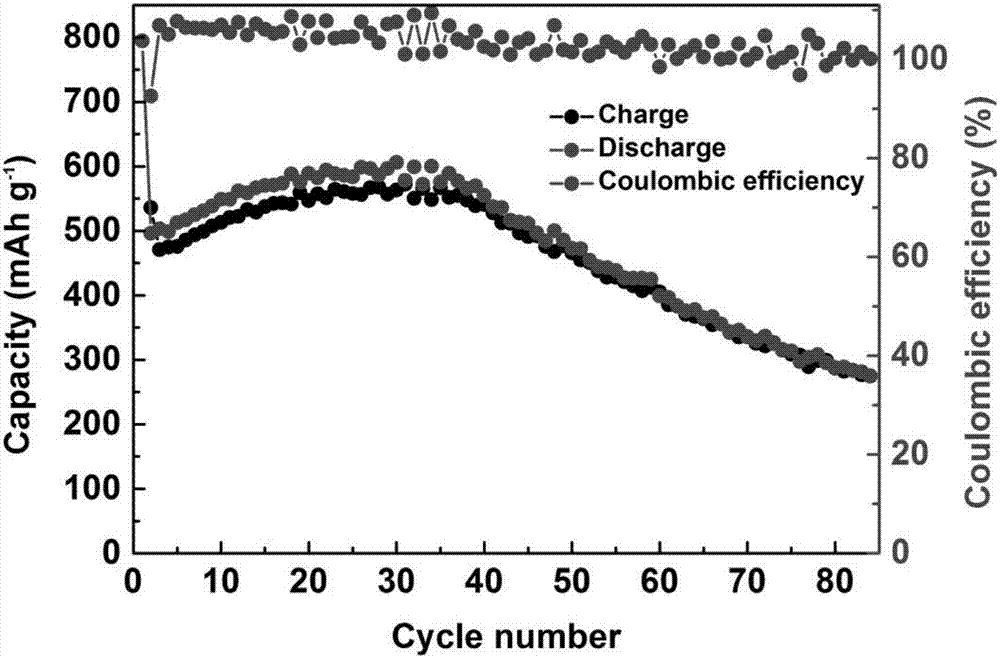

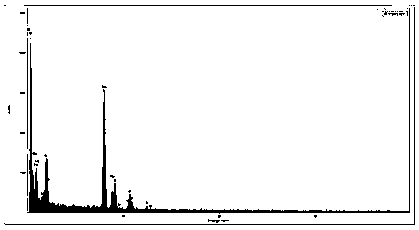

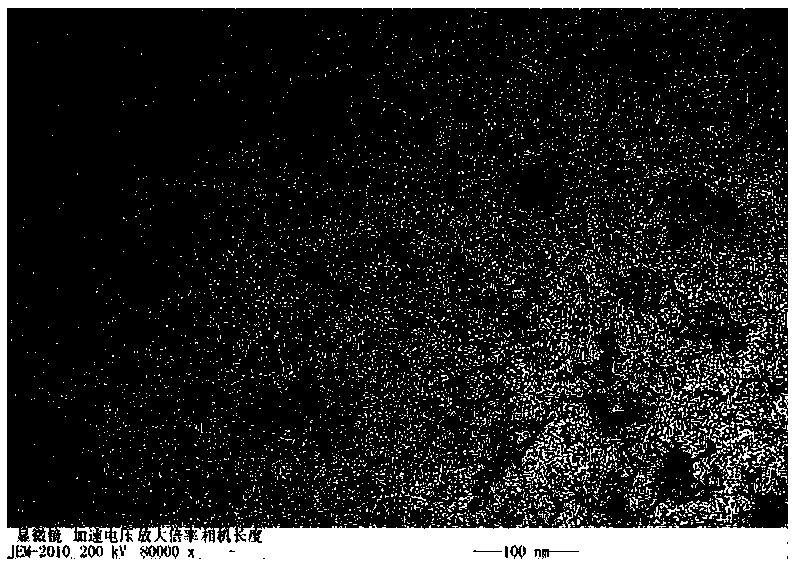

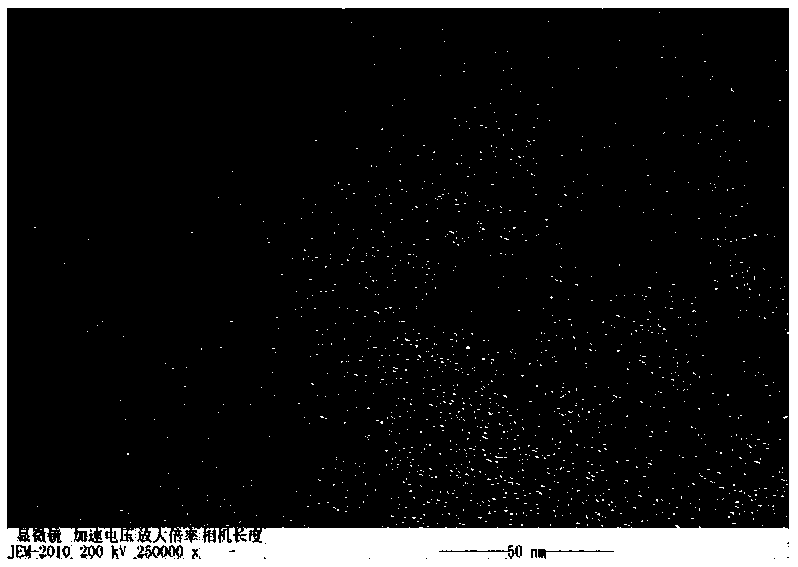

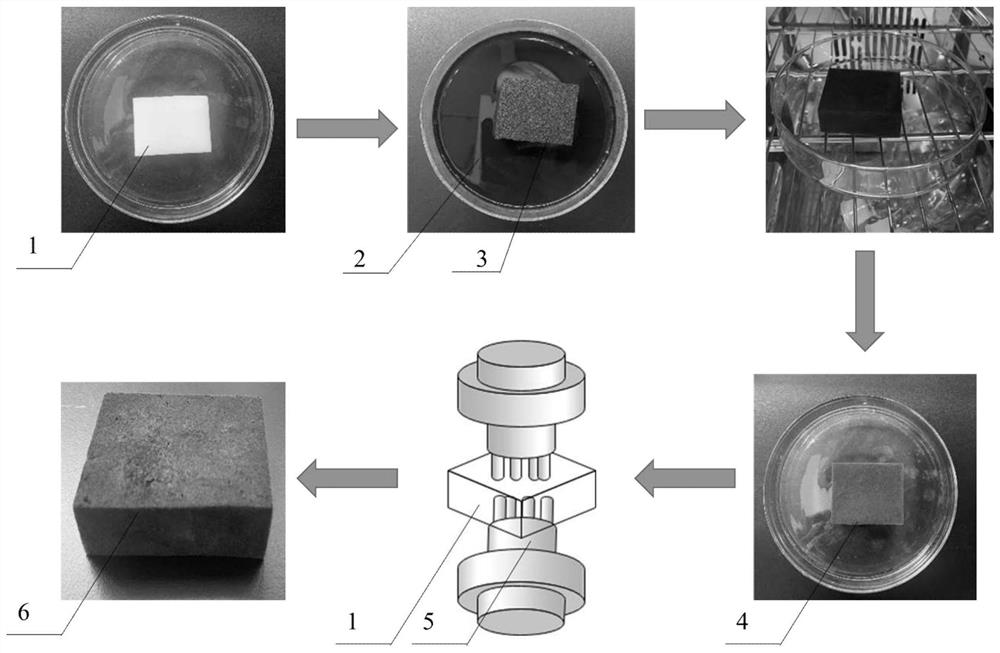

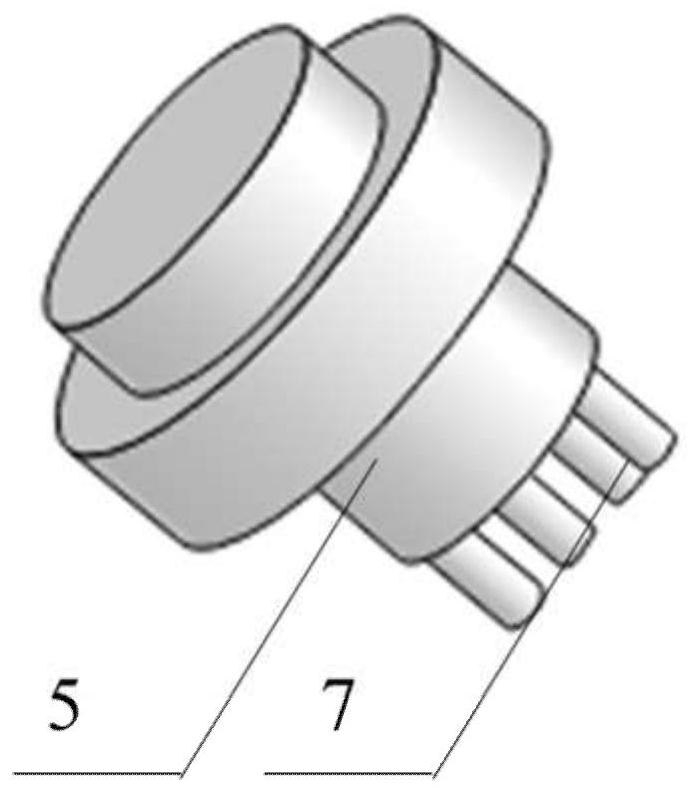

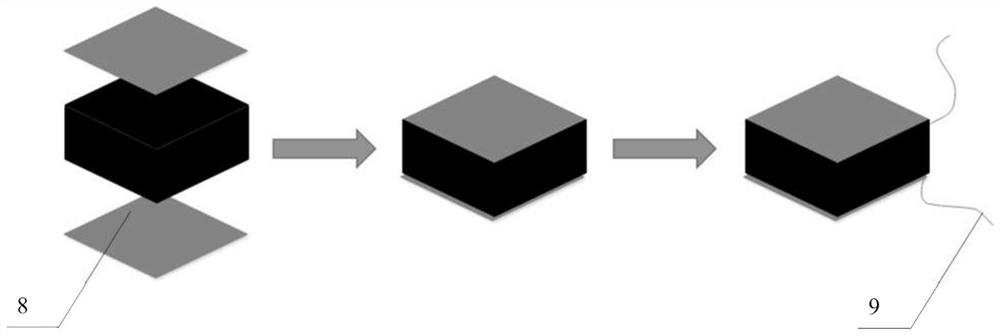

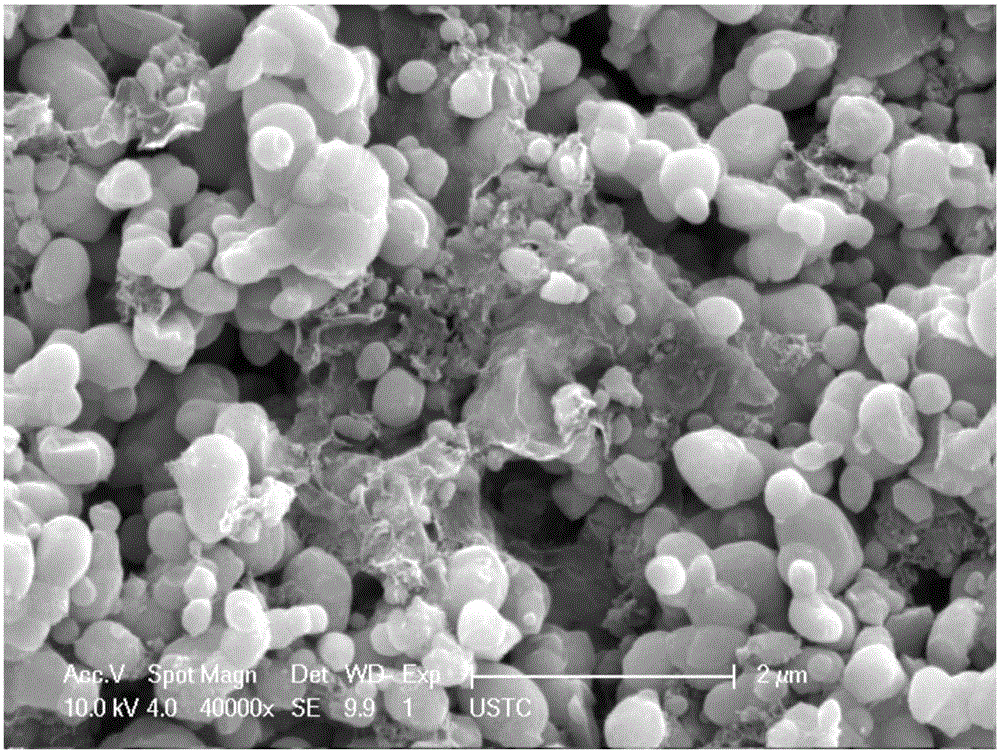

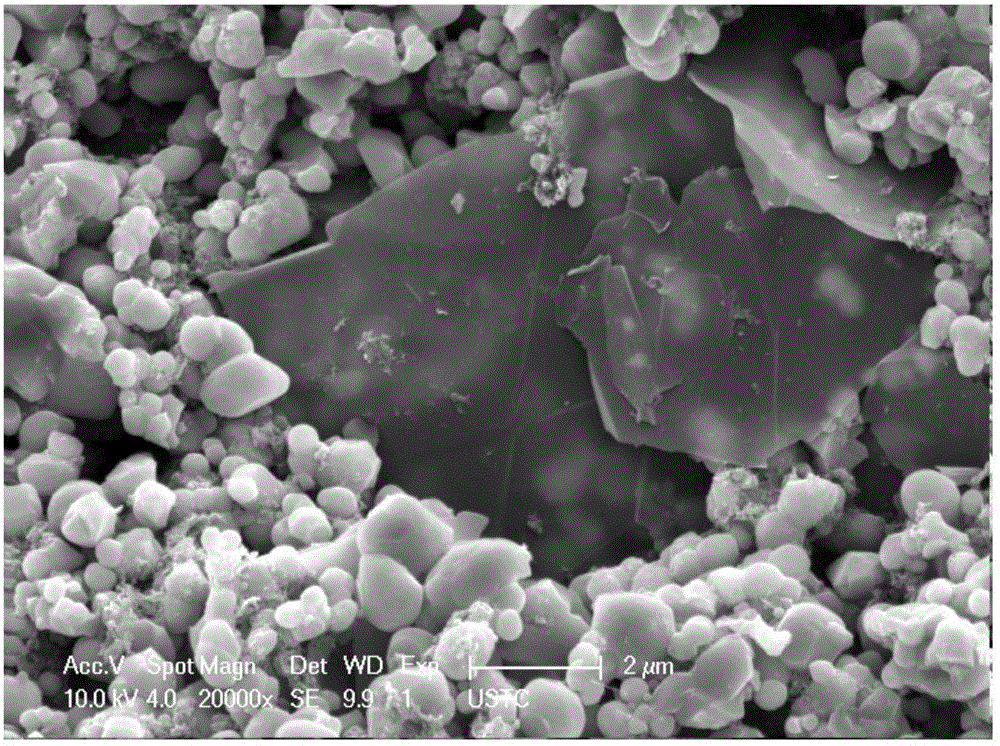

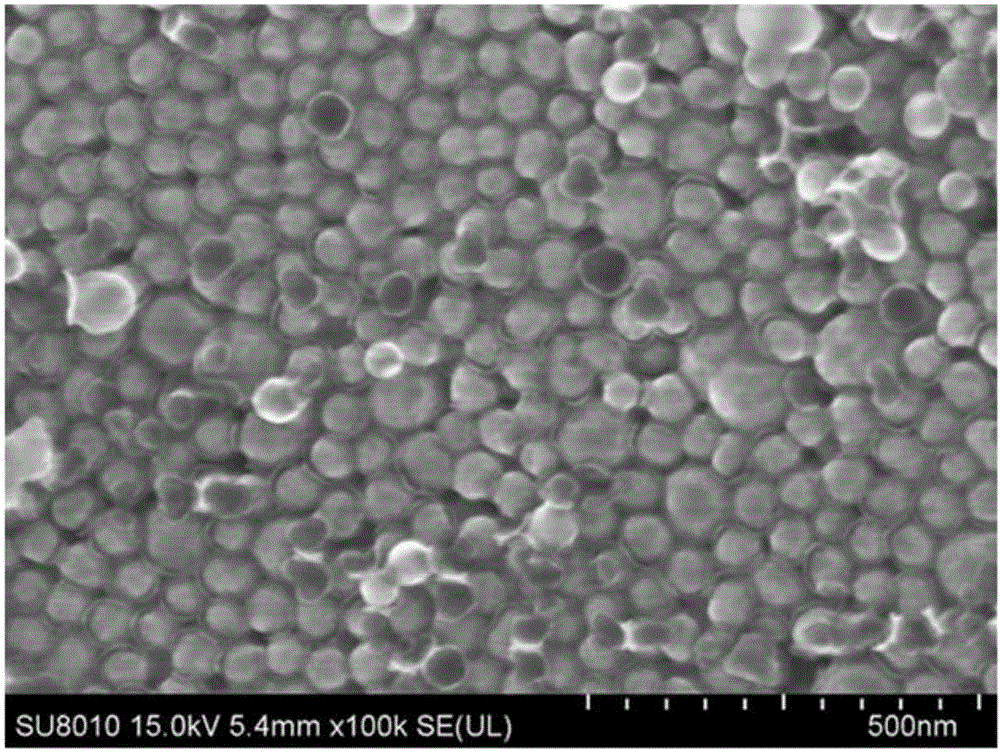

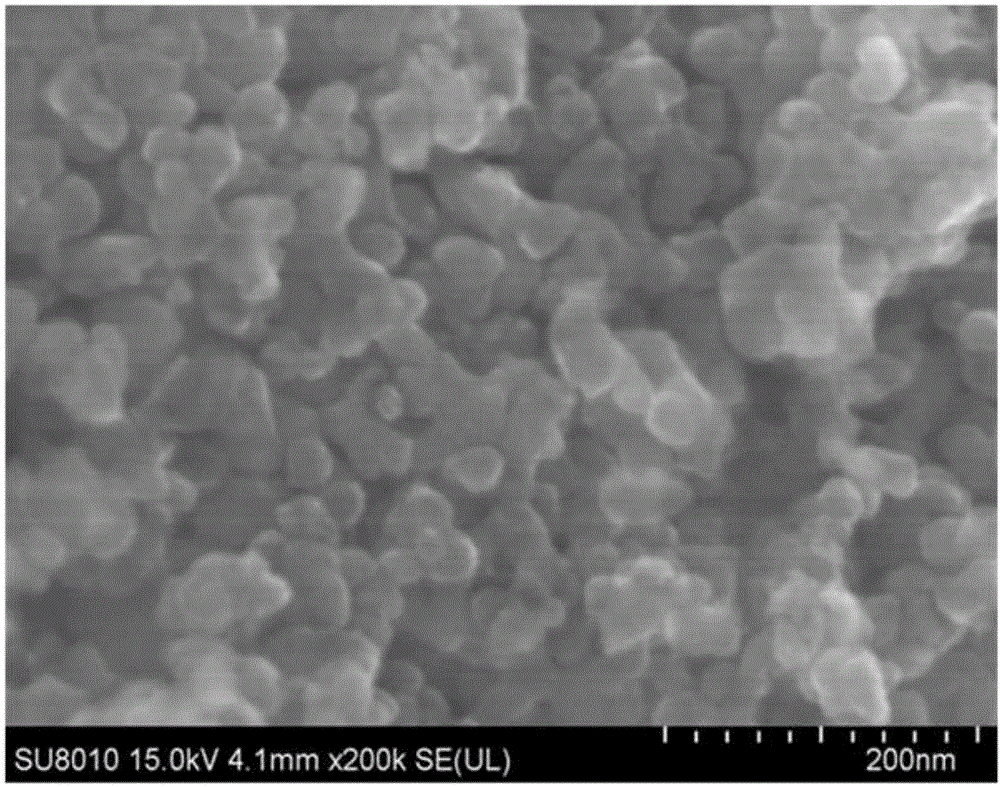

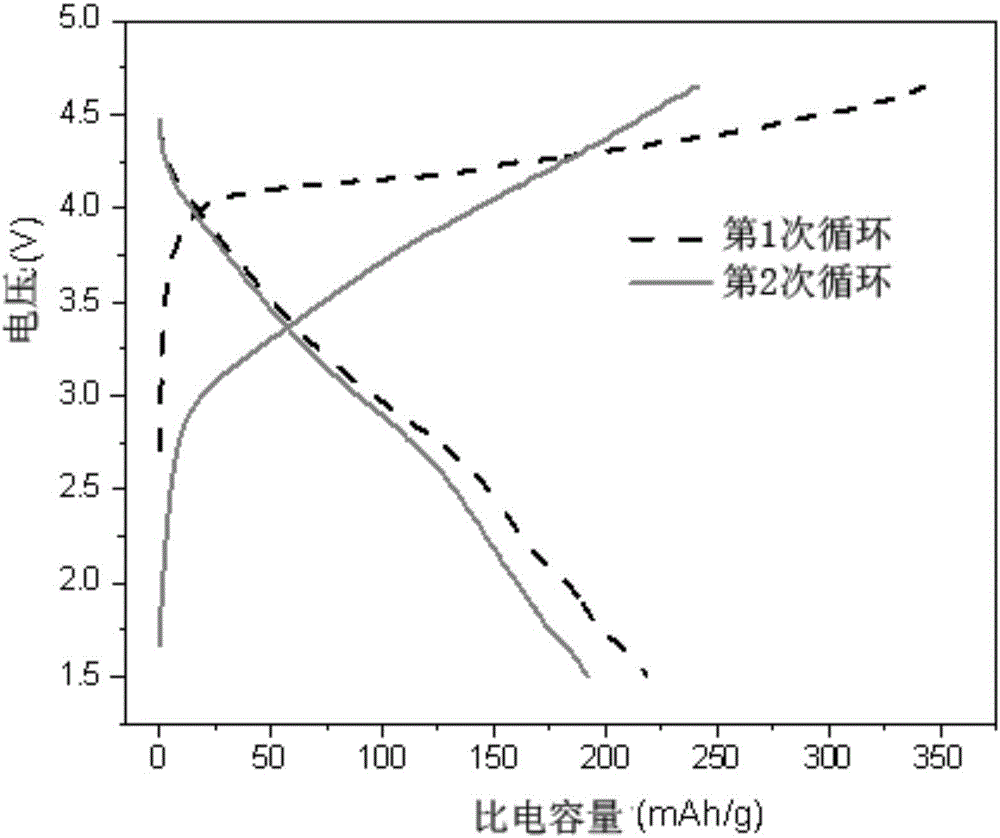

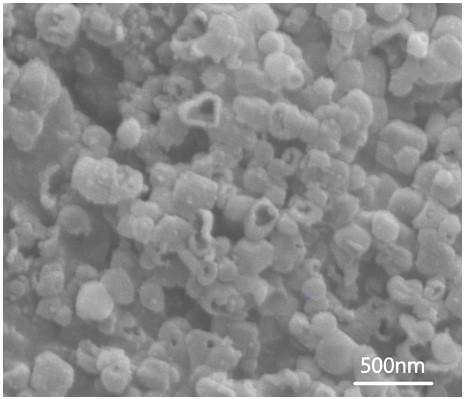

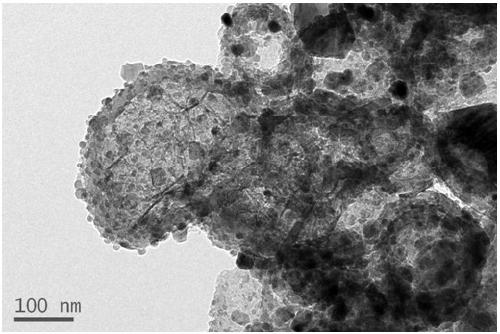

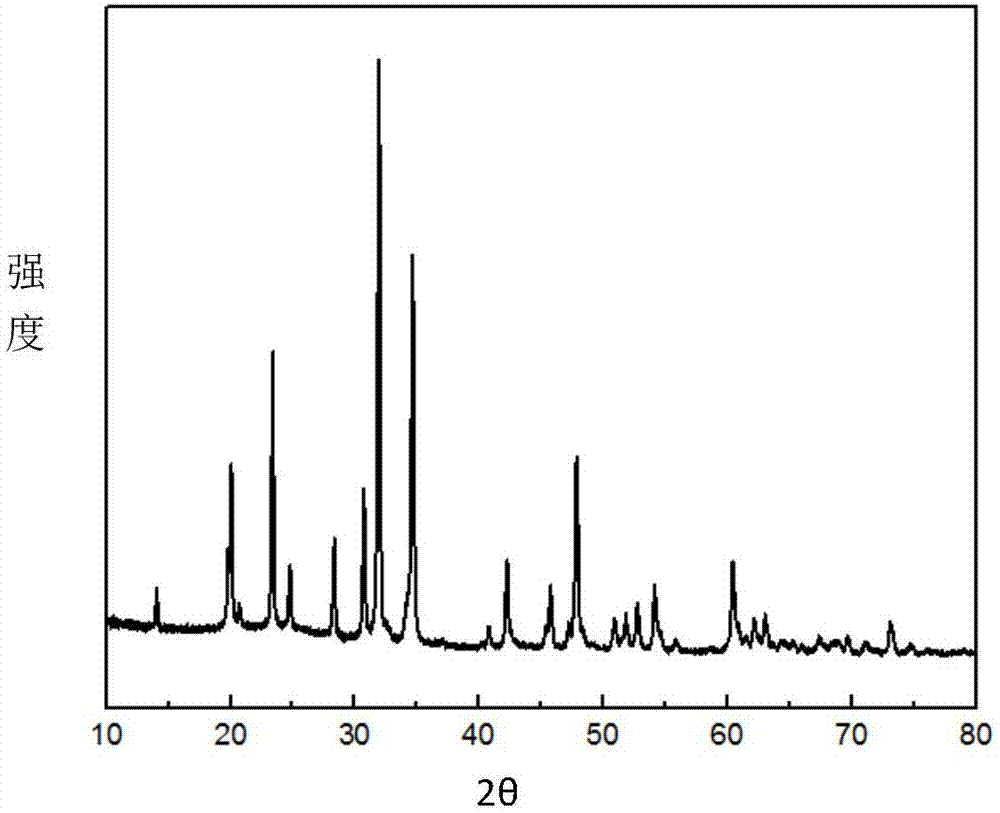

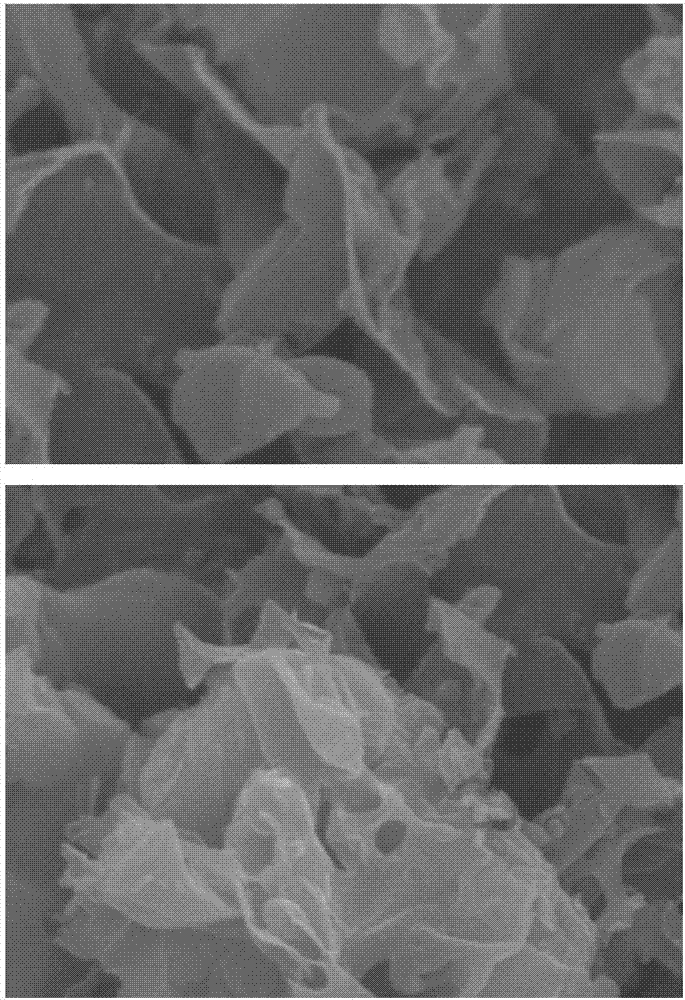

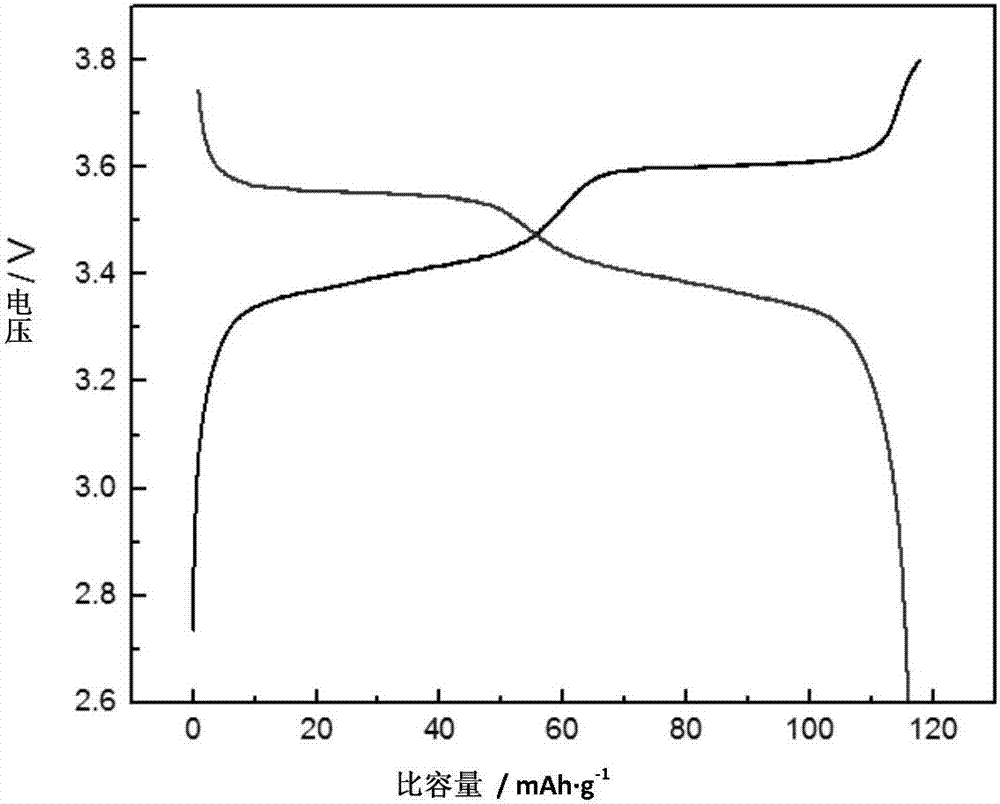

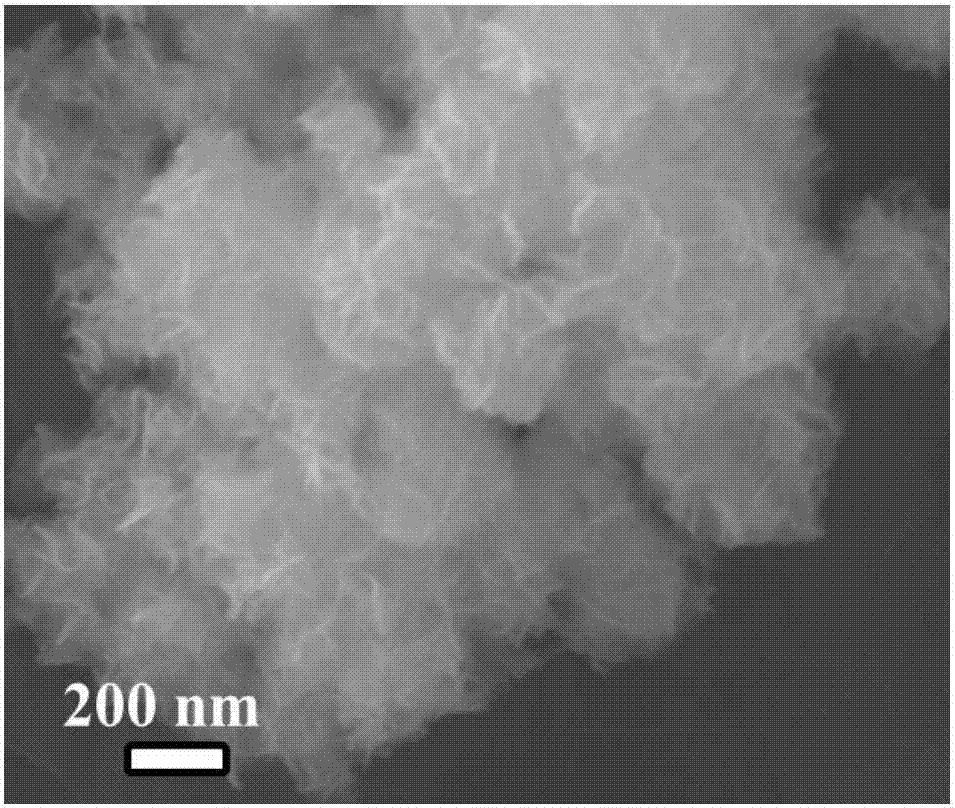

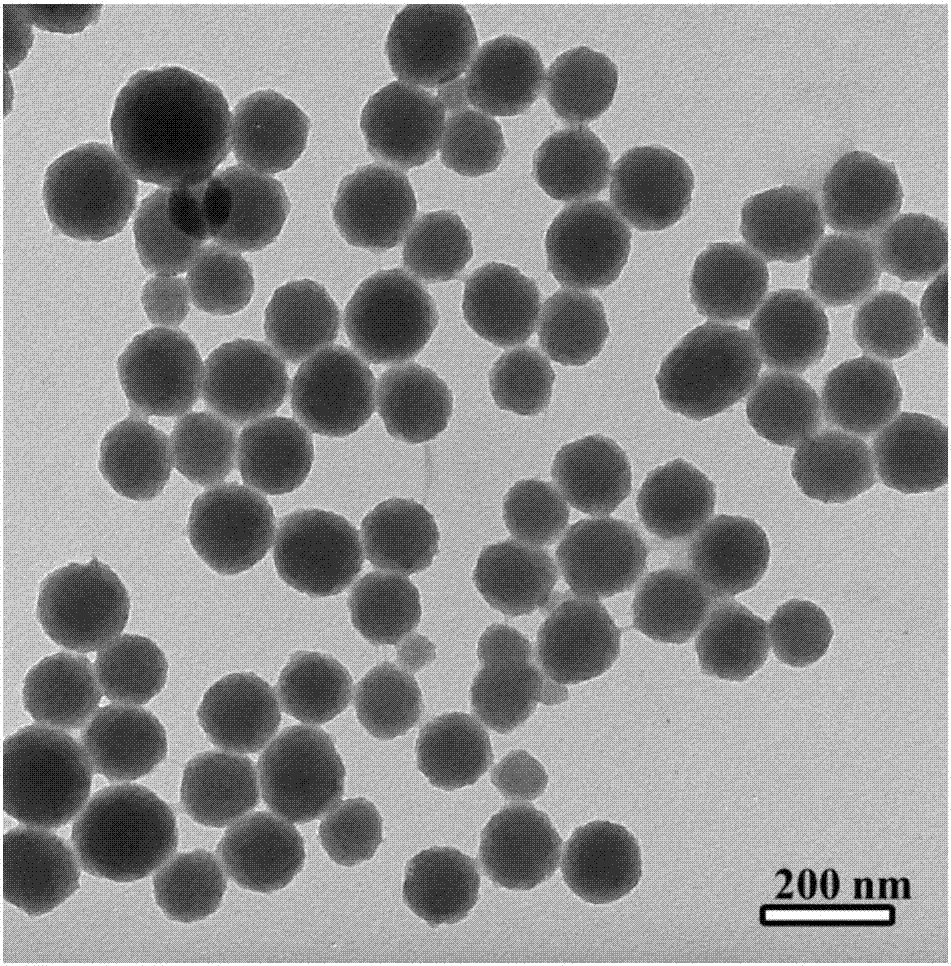

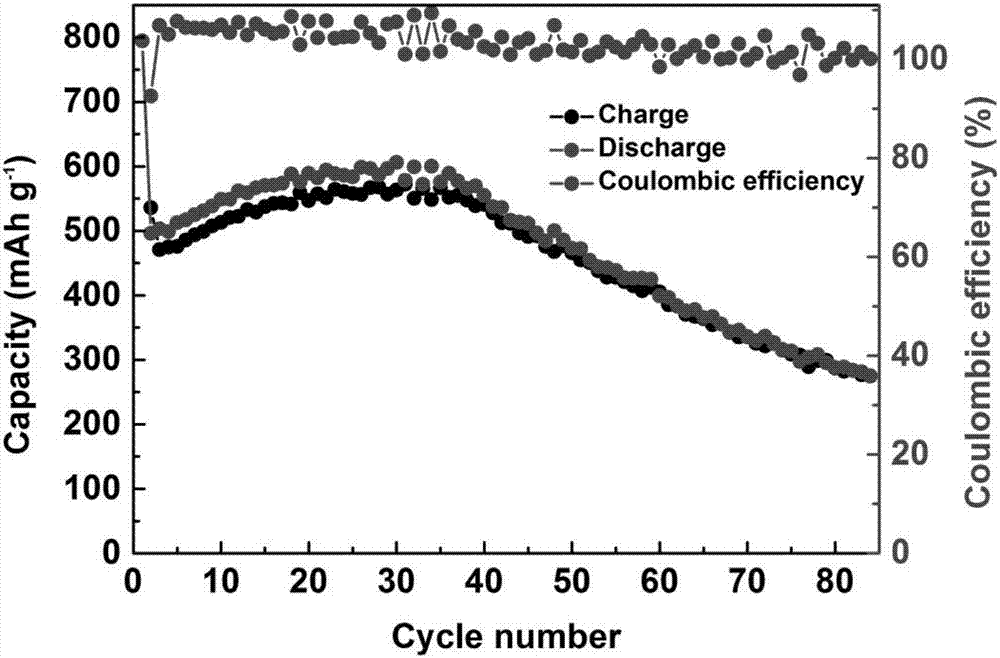

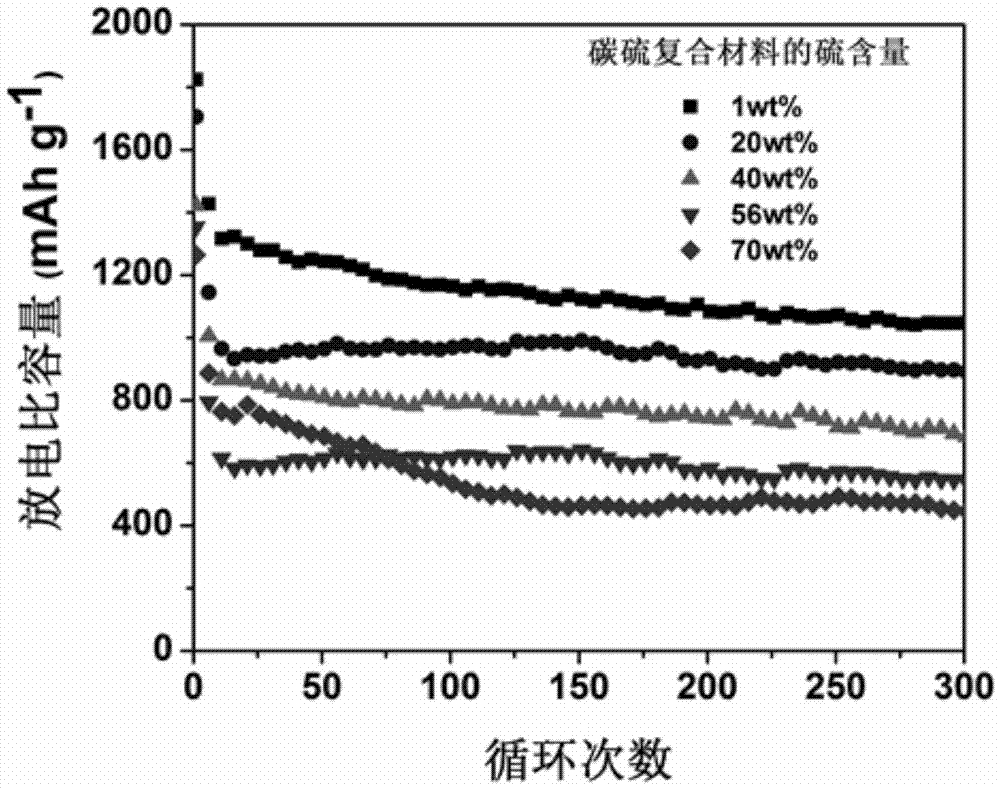

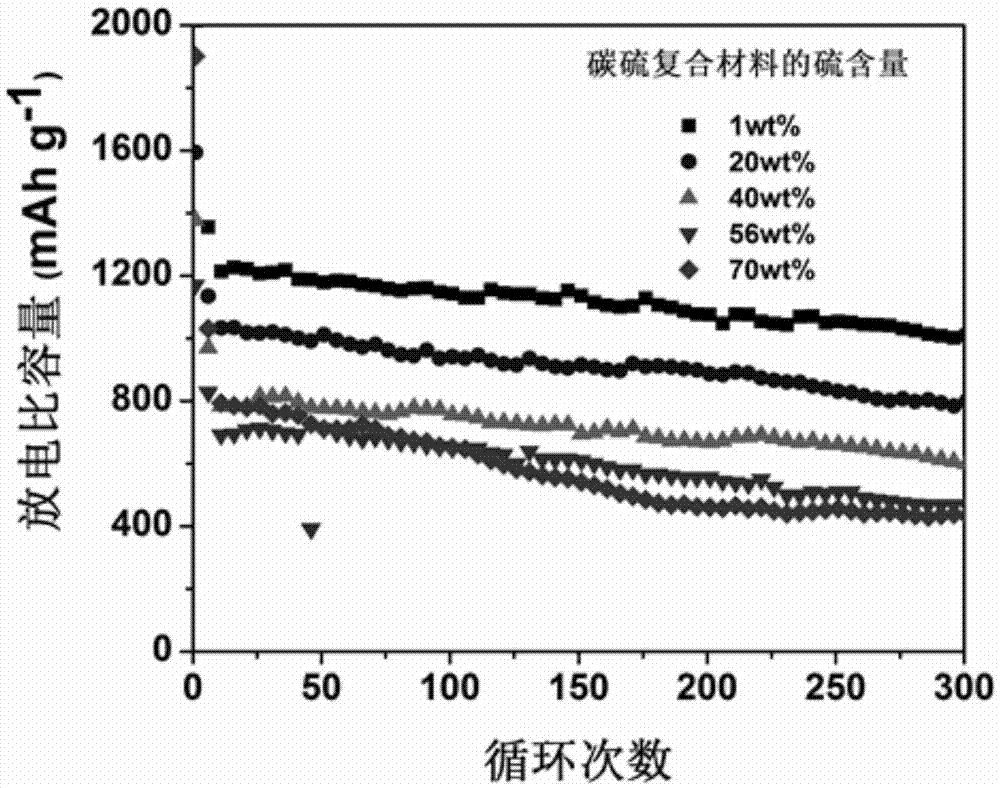

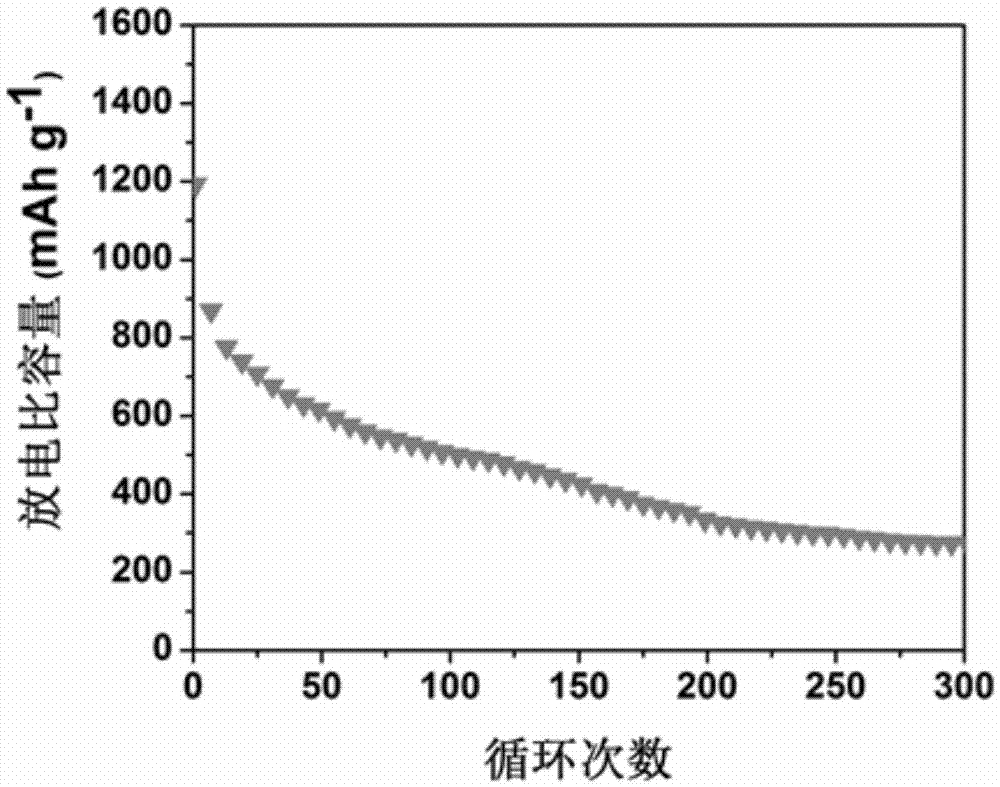

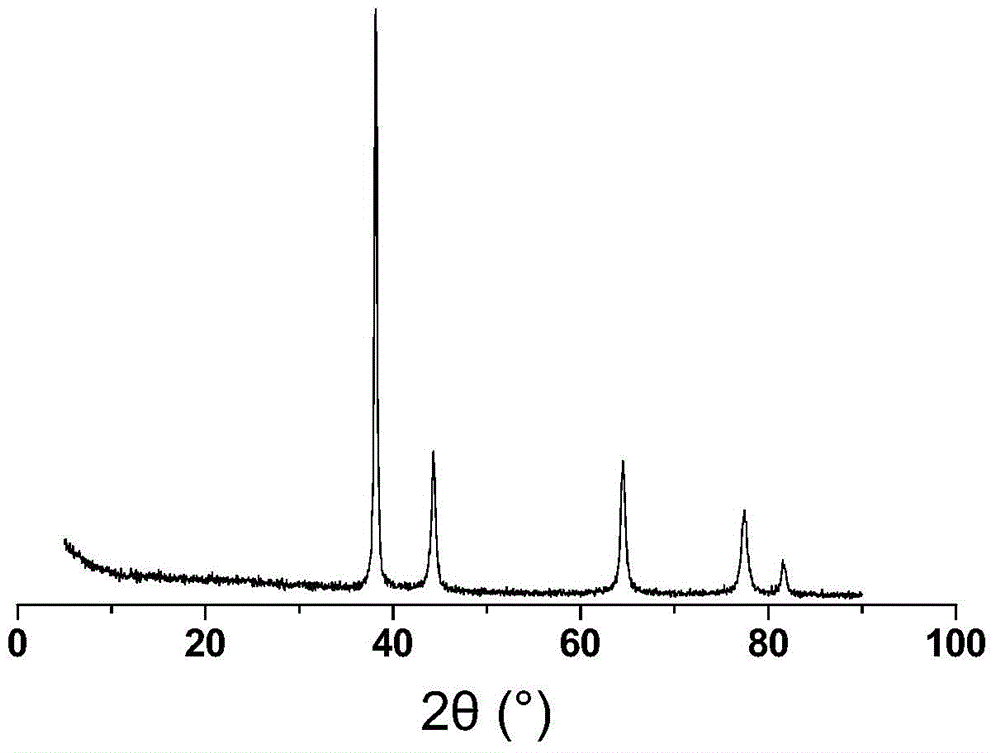

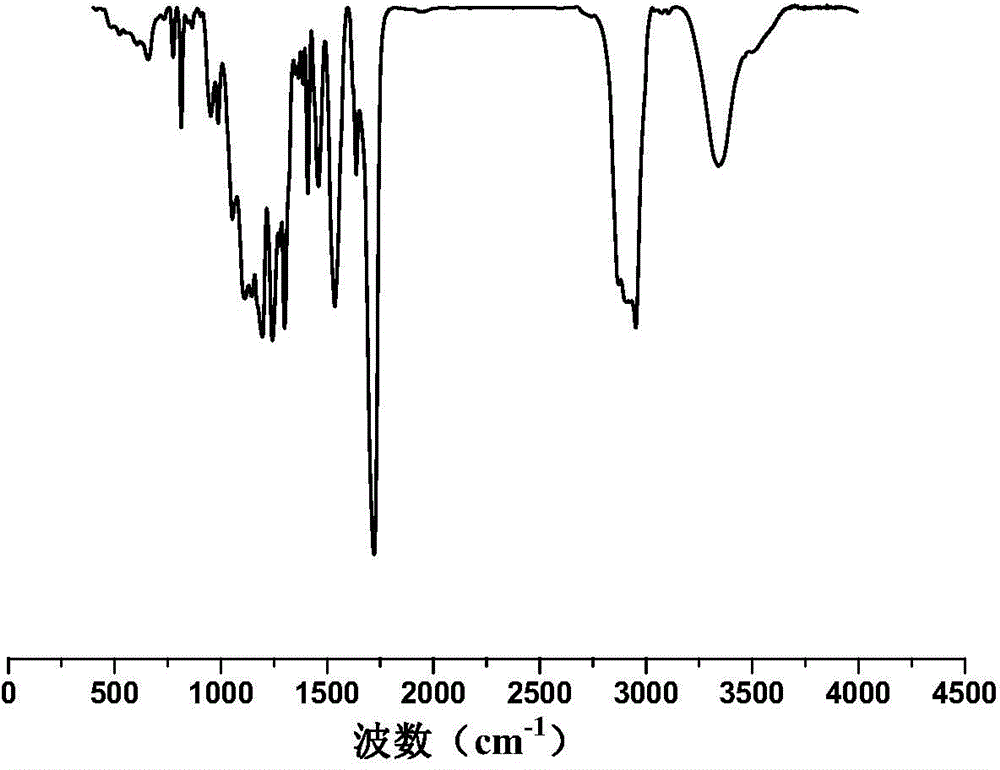

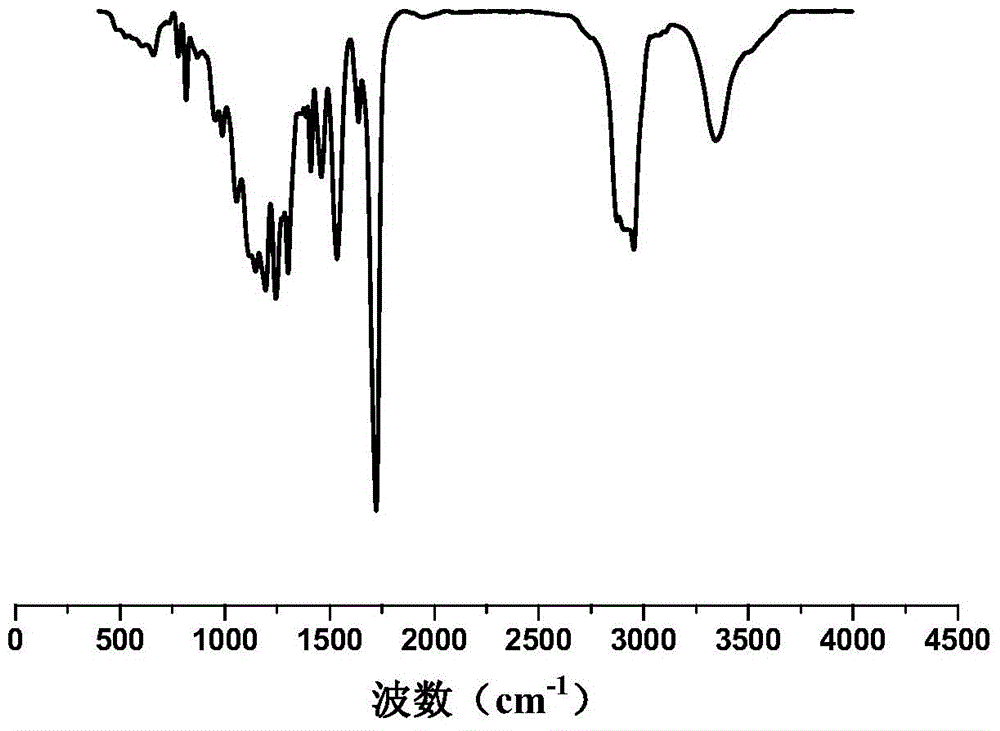

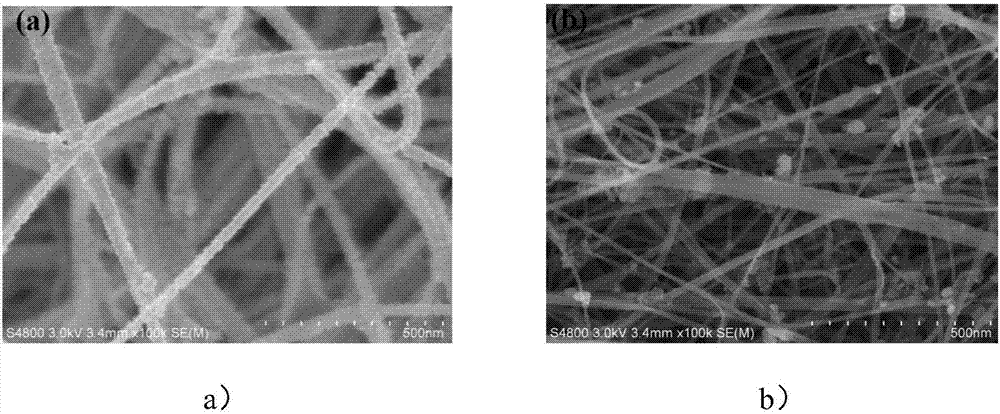

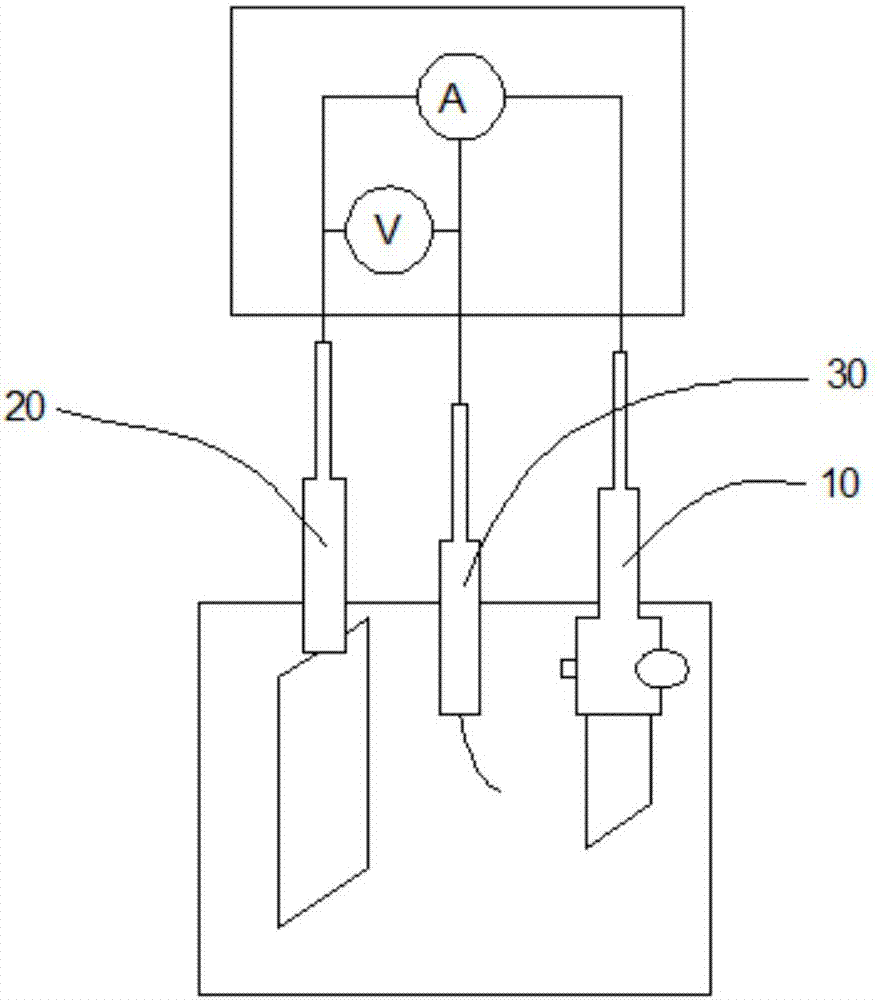

Preparation method and application of FeS[x]/C/CNT composite cathode materials

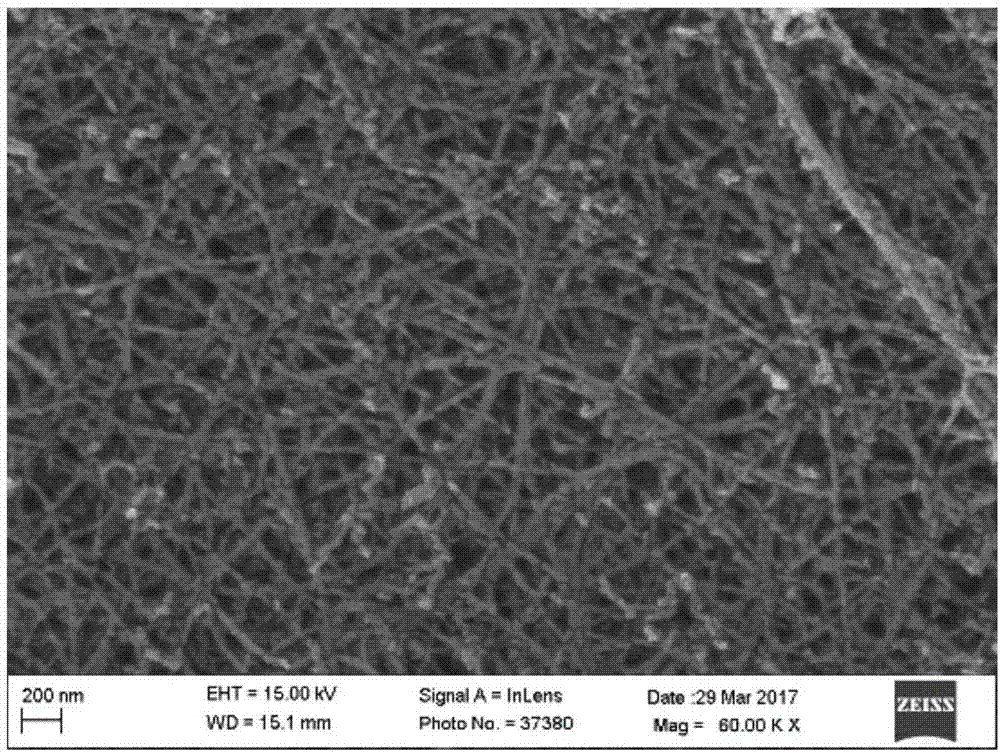

InactiveCN109585804AGood conductive networkImprove sulfur fixation effectCell electrodesSecondary cellsCarbon nanotubeVacuum drying

The invention discloses a preparation method and application of FeS[x] / C / CNT composite cathode materials, and belongs to the field of material synthesis and chemical power supplies. According to the invention , an iron source is dissolved into deionized water, and then a carbon source and carbon nanotubes are added in the deionized water and mixed uniformly; afterwards, a sulfur source is added and dissolved in the mixture and the mixture undergoes spray-drying to obtain a FeS[x] / C / CNT composite precursor; the FeS[x] / C / CNT composite material precursor is calcined at a temperature of 500-600 DEG C under an inert gas atmosphere for 5-8 hours, cooled with a furnace, washed with the deionized water, and then undergoes vacuum drying to obtain FeS[x] / C / CNT composite cathode materials. The FeS[x] / C / CNT composite cathode materials of the invention can be used for a lithium battery cathodes, have high specific capacity and excellent cycle stability, and if the cathode materials are charged anddischarged repeatedly at a current density of 200 mA / g at room temperature, the cathode materials have a specific discharge capacity of 630 mAh / g and a Coulomb efficiency of 99% according to FeS[x] / C / CNT composite materials.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of graphene nanosilver composite material

InactiveCN105983708AImprove electrical conductivityGood conductive networkNanotechnologyIonCvd graphene

The invention discloses a preparation method of a graphene nanosilver composite material in the field of composite materials. The preparation method comprises the following steps: 1) mixing: oxide graphene and silver nitrate are mixed by a mass ratio of 1: 1.8-2.3, and are put in de-ionized water for ultrasonically dispersing by above 1 h; 2) reaction: the mixed liquid is put in a container to stir by above 18 h at room temperature; and hydrazine hydrate with a concentration of 80% and with a volume ratio of 2: 1 to the mixed liquid is added for standing by above 20 h at 95 DEG C; 3) cleaning: a reaction product is washed by the de-ionized water, and then, is washed by anhydrous ethanol; and 4) drying: the cleaned product is dried in vacuum at 30 DEG C to prepare graphene nanosilver. The prepared graphene / nanosilver composite material is excellent in electric conductivity, simple in production process and lower in cost, and saves the manpower and material resources.

Owner:颜秀珍

Silicon carbon composite material for lithium ion battery and preparation method thereof

ActiveCN108336317ALarge specific surface areaHigh aspect ratioCell electrodesSecondary cellsCarbon compositesCarbon nanotube

The invention discloses a silicon carbon composite material for a lithium ion battery and a preparation method thereof, belonging to the field of positive electrode materials of lithium ion batteries.The preparation method comprises the following steps: (1) adding carbon nanotubes and a surfactant into a solvent, and carrying out mixing and stirring to obtain dispersion liquid; (2) adding siliconmonooxide and graphite powder into the dispersion liquid, and successively carrying out uniform mixing and drying to obtain a silicon carbon composite precursor; and (3) calcining the silicon carboncomposite precursor in a non-oxygen atmosphere and then carrying out cooling to room temperature to obtain the silicon carbon composite material for the lithium ion battery. According to the invention, the characteristic of a high length-to-diameter ratio of the carbon nanotubes are utilized, and the carbon nanotubes are enwound with an active material to form a conductive network in the compositematerial, so the problem of the destruction of a conductive channel caused by shrinkage and expansion during the process of lithium intercalation and deintercalation are overcome; in addition, the silicon carbon composite material provided by the invention alleviates the volume expansion of silicon carbon to a certain extent, thereby improving the capacity retention rate and the cycle stability of the battery.

Owner:TIANNENG SAFT ENERGY JOINT CO

Method for preparing lead-carbon battery cathode composite material

InactiveCN106450212AGood compatibilityIncrease profitLead-acid accumulator electrodesIndiumRaw material

The invention discloses a method of an in-situ-synthesized carbon material which can be used as a lead-carbon battery cathode composite material. The raw materials comprise chitosan, conductive agent acetylene black, binder PTFR emulsion, expanding agent barium sulfate, hydrogen evolution inhibitor indium oxide and gallium oxide, anode active material lead oxide, lead powder and the like. Through the method of in-situ synthesis, the lead-carbon battery cathode composite material is prepared. The adoption of the in-situ-synthesized carbon material effectively improves compatibility of the carbon material and an active material interface, constructs an ideal conductive network, improves use ratio of the an active material and high dispersibility of the biomass carbon material, and inhibits generation of irreversible PbSO4.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

CNT/three-dimensional grapheme composite material, preparation method and application thereof

ActiveCN107808779AImprove conductivityLarge specific surface areaHybrid capacitor electrodesHybrid/EDL manufactureCarbon nanotubeElectroactive materials

The invention discloses a CNT(Carbon Nano Tube) / three-dimensional grapheme composite material, preparation method and application thereof. The preparation method includes disposing three-dimensional grapheme aerogel in a chemical vapor phase growth device, growing CNT on the surface and in the three-dimensional grapheme aerogel through a chemical chemical vapor deposition method by taking non-ionic high-molecular compound as a carbon source and acquiring a target project. According to the invention, the electrical conductivity of a conducting network of the CNT / three-dimensional grapheme composite material is good, the specific area is large, the electroactive material loading capacity is high and the electro-chemical performance is stable. The invention also discloses an electrode material, electrode and energy storage device based on the composite material, such as flexible full solid state asymmetric supercapacitors having very high stability.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

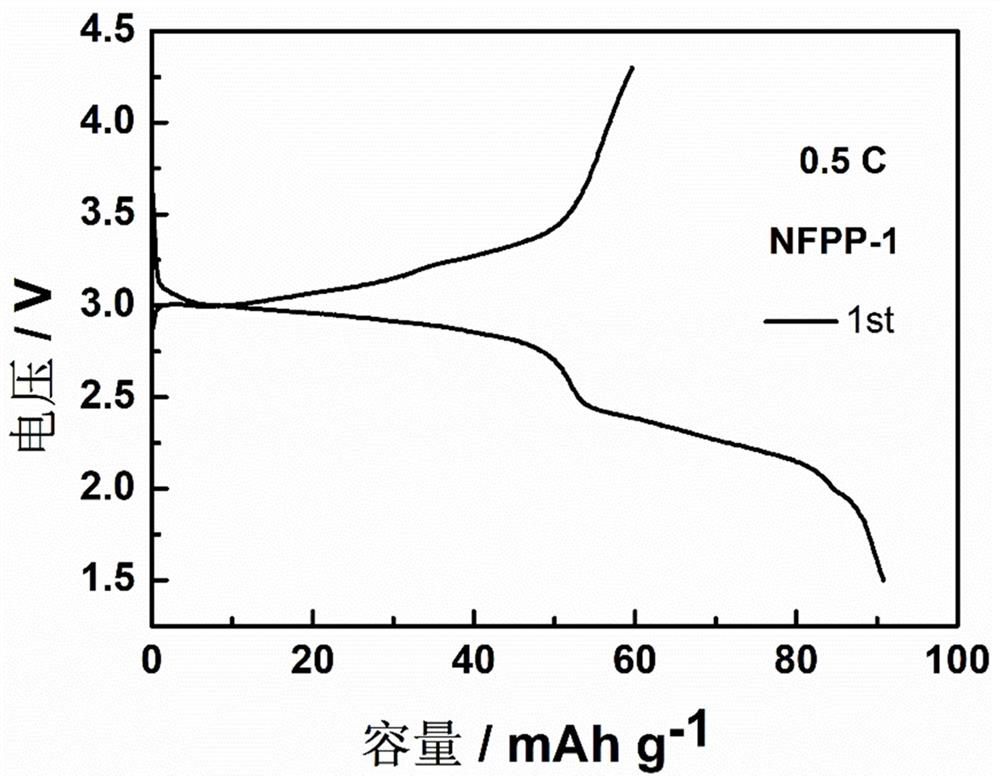

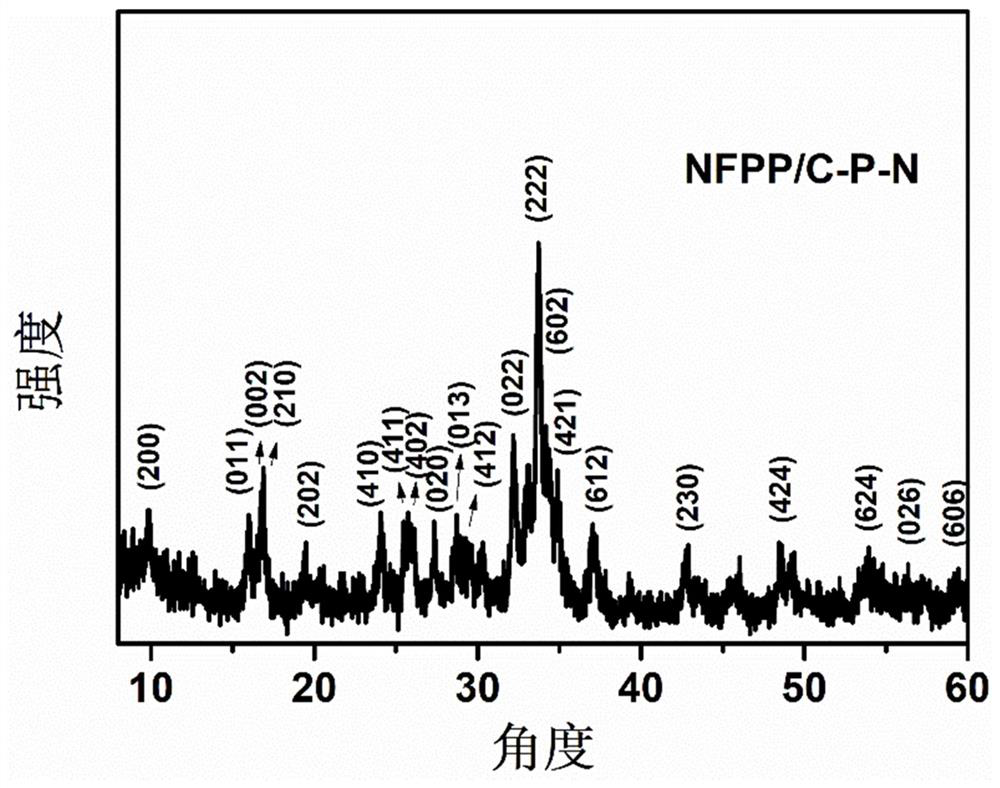

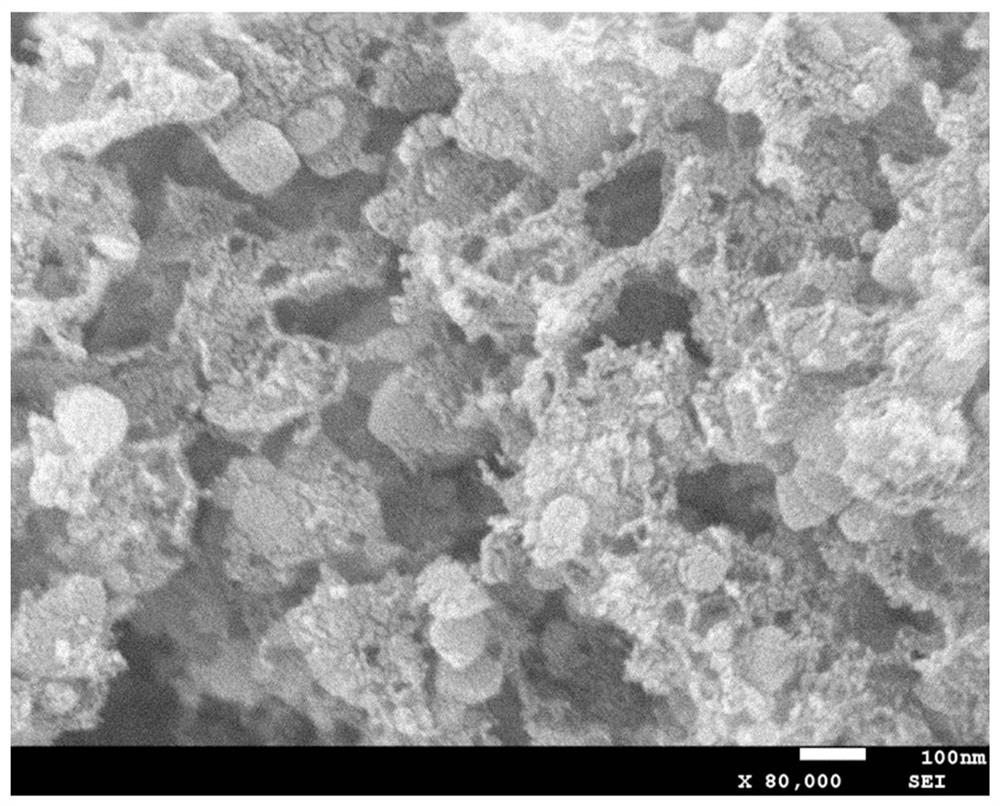

Preparation method for porous carbon modified ferric sodium pyrophosphate/carbon positive electrode material of sodium ion battery

ActiveCN113104828AImproved magnification performanceImprove cycle stabilityCell electrodesSecondary cellsPorous carbonSodium phosphates

The invention relates to a preparation method for a porous carbon modified ferric sodium pyrophosphate / carbon positive electrode material of a sodium ion battery. The preparation method comprises the following steps: dissolving ferric nitrate nonahydrate and citric acid in deionized water to form a solution A, dissolving ammonium dihydrogen phosphate and sodium pyrophosphate in deionized water to form a solution B, and dissolving polyvinylpyrrolidone and sodium chloride in deionized water to form a solution C; adding the solution A into the solution B at a constant speed, and conducting stirring while dropwise adding the solution A until the mixed solution becomes a yellow green suspension after dropwise adding is completed, thereby obtaining a solution D; adding the solution D into the solution C at a constant speed, continuing stirring for 7 hours, performing freezing for 24 hours, and conducting drying for 36 hours by using a freeze dryer to obtain a precursor; and finally, putting the precursor into a tubular furnace, conducting pre-burning for 6 hours at 300 DEG C in an Ar-H2 mixed atmosphere, then finally burning the precursor at 500 DEG C, and finally, carrying out cleaning with deionized water multiple times to obtain the porous carbon modified Na4Fe3(PO4)2P2O7 / C composite positive electrode material.

Owner:CHINA THREE GORGES UNIV

High-strength antistatic alloy and preparation method thereof

The invention discloses a high-strength antistatic alloy and a preparation method thereof. a PC (Polycarbonate) / PBT (Polybutylece Terephthalate) alloy is prepared from the following raw materials in parts by weight: 50 to 80 parts of PC, 20 to 40 parts of PBT, 8 to 18 parts of antistatic filler, 3 to 11 parts of compatibilizer, 0.05 to 0.3 part of ester exchange inhibitor, 0.2 to 0.6 part of antioxidant, 0.2 to 0.6 part of lubricating agent and 0.1 to 0.5 part of ultraviolet absorbent. According to the high-strength antistatic alloy disclosed by the invention, the PC / PBT alloy is subjected to blending modification by adopting assistants such as the compatibilizer, the ester exchange inhibitor and the antistatic filler, so that a prepared alloy system has the advantages of respective excellent properties of the PC and the PBT baste materials, excellent antistatic property, high strength, small warp, good dimensional stability, good processing fluidity and excellent chemical solvent resistance, and further the high-strength antistatic alloy can be widely applied to the fields of automobiles, household appliances, illumination, electronic communication and the like.

Owner:DONGGUAN HONOUR E P

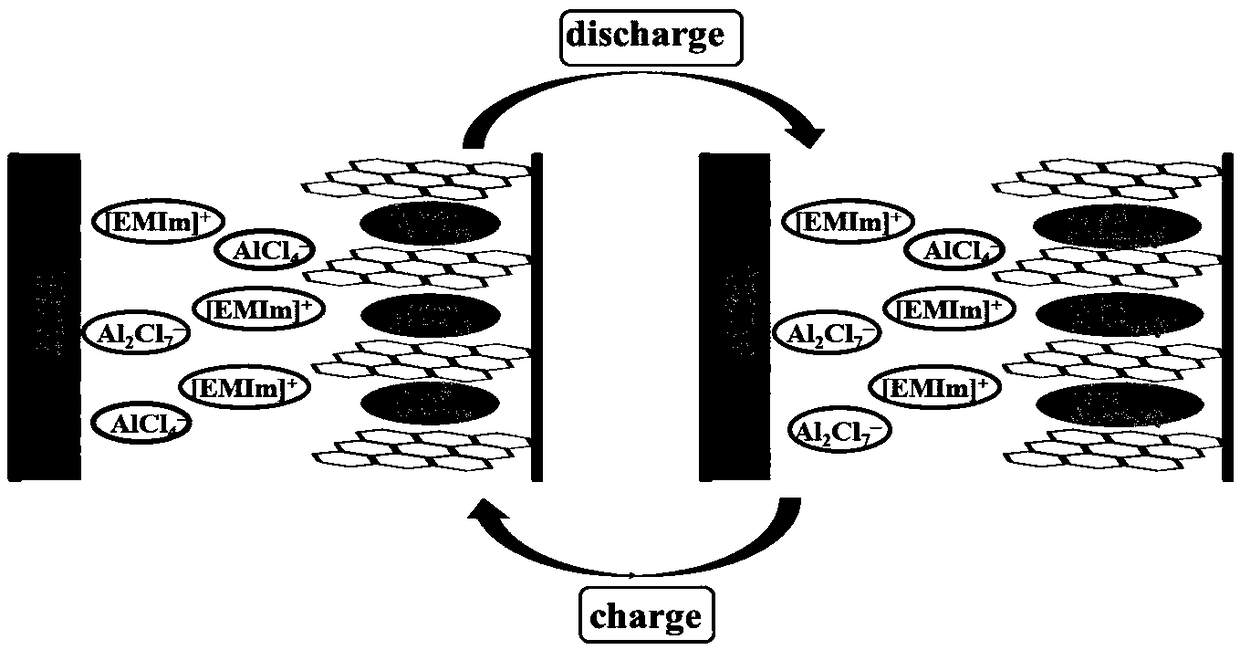

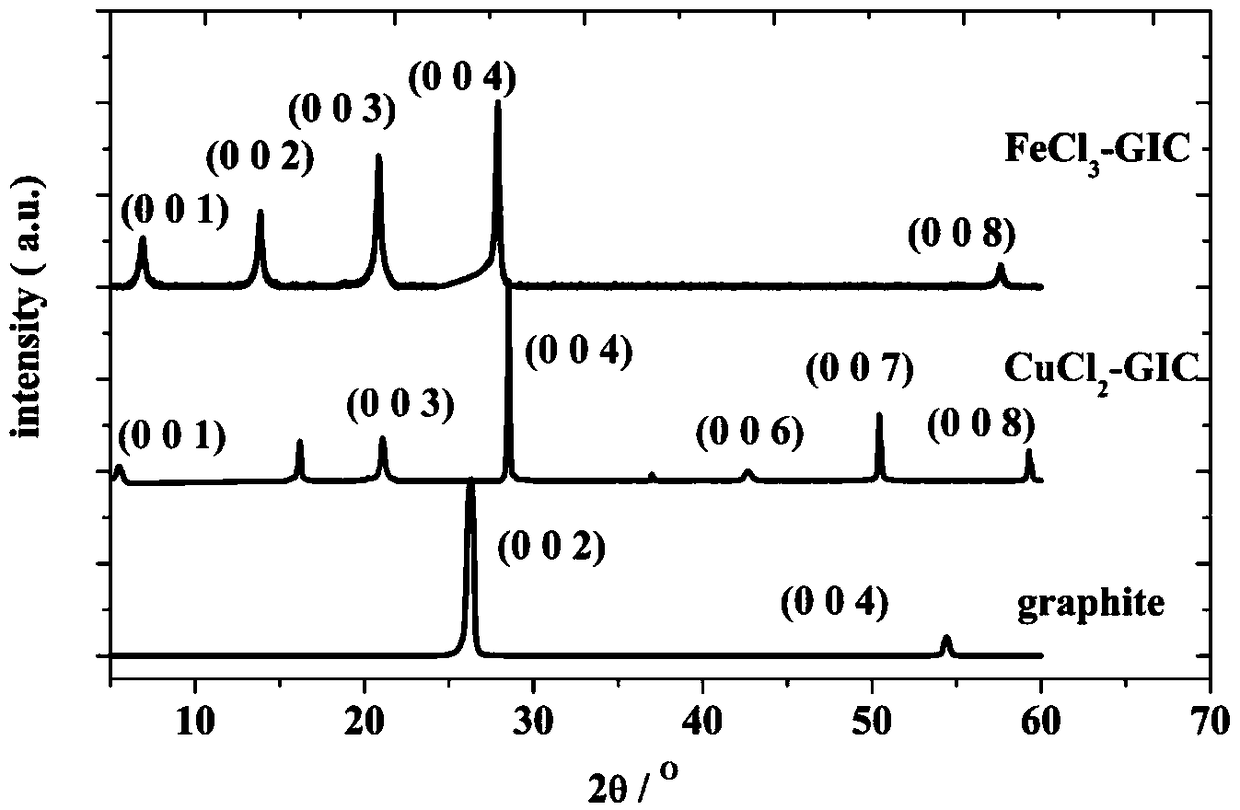

Novel aluminum-chlorine mixed ion battery

ActiveCN109411712AIncrease the active siteHigh specific capacityFinal product manufactureCell electrodesAluminium-ion batteryOrganic chloride compound

The invention provides a novel aluminum-chlorine mixed ion battery which includes a cathode, an anode, an electrolyte, and a diaphragm between the cathode and the anode, wherein the cathode is made from a chloride-graphite intercalation compound (MClX-GIC), the electrolyte is an ionic liquid composed of a metal chloride and an organic chloride. The innovation point of the invention is that the graphite intercalation compound is successfully applied to an ion battery; by means of the theory of mixing chemistry, an aluminum ion battery system and a chlorine ion battery system are combined to form the aluminum-chlorine mixed ion battery, of which the electric charge carrier is not simple, wherein the ion who is actually embedded in the cathode of the mixed ion battery is Cl<-> (may also include AlCl4<->); however, the ion who contributes a decisive effect to deposition and dissolution processes of the aluminum anode is Al2Cl7<->. The aluminum-chlorine mixed ion battery is a design on thebasis of a new idea for an aluminum battery.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

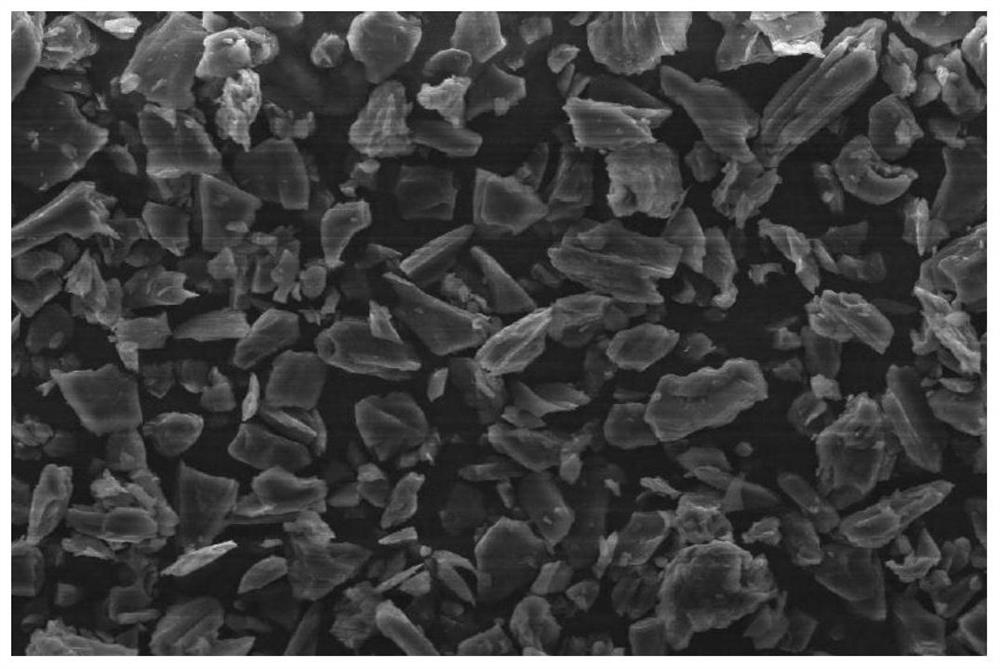

Preparation method of high-magnification quick-charging graphite negative electrode material

ActiveCN112289986AImprove defectsImprove the rate of fast charging performanceCell electrodesSecondary cellsGraphitePetroleum coke

The invention discloses a preparation method of a high-magnification quick-charging graphite negative electrode material. The method comprises the following steps: carrying out coarse crushing and fine grinding on one or more of needle coke, petroleum coke and pitch coke, carrying out spheroidizing shaping treatment, mixing with a first carbon source, heating to carry out surface coating, and carrying out high-temperature carbonization; then carrying out high-temperature graphitization treatment to obtain an artificial graphite powder; and mixing the obtained artificial graphite powder with asecond carbon source, heating for surface coating, and carbonizing at a high temperature to obtain the high-magnification quick-charging graphite negative electrode material. The graphite negative electrode material prepared by the invention has the advantages of a high charge-discharge rate, a large discharge gram capacity and good cycle performance, and a battery prepared from the graphite negative electrode material has excellent comprehensive performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Silicon-carbon composite negative electrode material, negative electrode plate, preparation method thereof and lithium-ion battery

ActiveCN111509212AReduce concentrationIncrease deposition rateElectrode thermal treatmentNegative electrodesCarbon compositesAl powder

The invention belongs to the field of new energy materials, and relates to a silicon-carbon composite negative electrode material, a negative electrode plate, a preparation method thereof and a lithium-ion battery. The preparation method of the silicon-carbon composite negative electrode material comprises the following steps: S1, dispersing phenol and / or aminophenol, formaldehyde and a silicon precursor material into an alcohol-amine mixed aqueous solution, violently stirring and reacting at 20-90 DEG C for at least 20 minutes, carrying out solid-liquid separation, and drying to obtain a silicon dioxide / phenolic aldehyde compound with a fractal structure; and S2, roasting the silicon dioxide / phenolic aldehyde compound in the presence of magnesium powder and / or aluminum powder to obtain the silicon-carbon composite material with the fractal structure. When the silicon-carbon composite material is used as a lithium-ion battery negative electrode material, the failure caused by volume change in the charging and discharging process can be well overcome, a good conductive network is maintained, the volume expansion is reduced, the first reversible capacity and the first coulombic efficiency are improved, the first cycle capacity loss is reduced, and the cycle stability is improved.

Owner:厦门高容纳米新材料科技有限公司

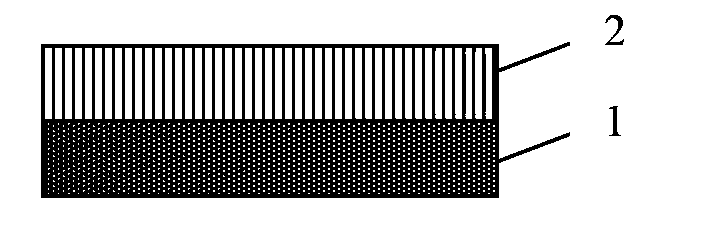

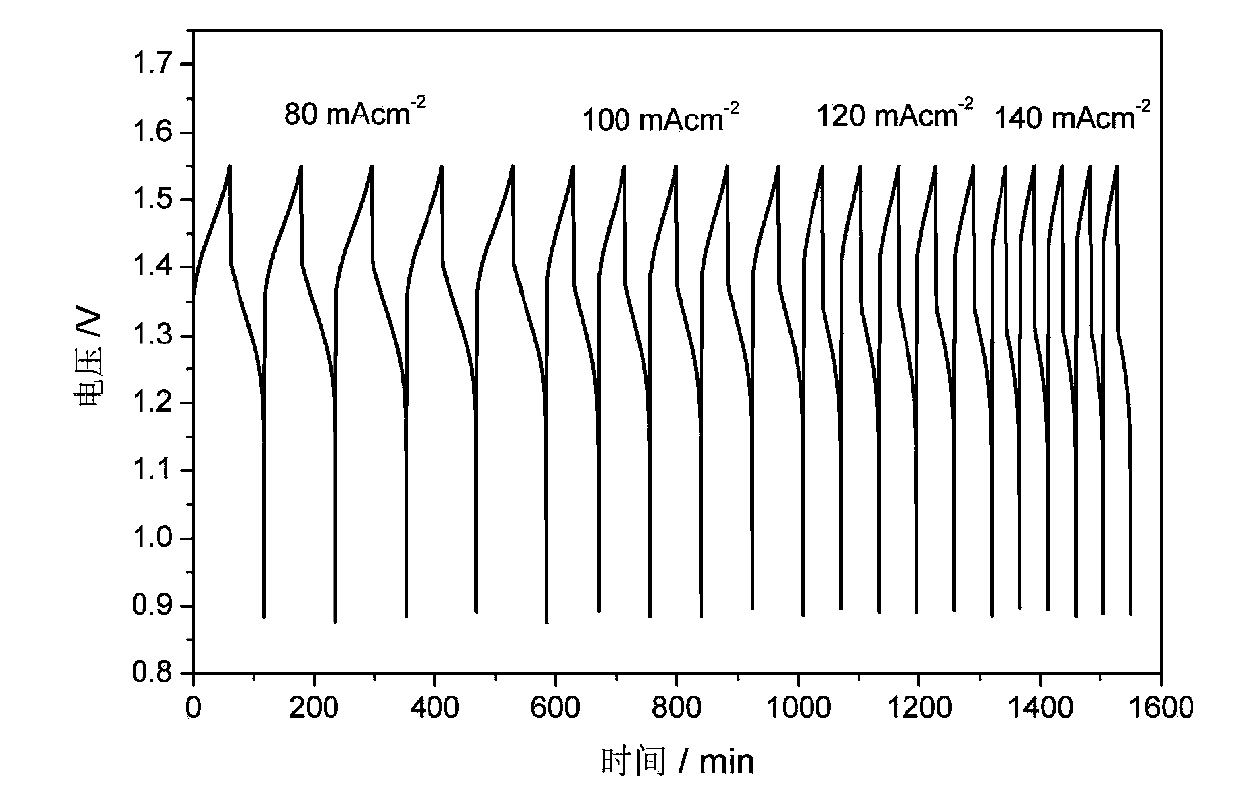

Combined electrode for flow battery and flow energy storage battery

ActiveCN103633330AGood conductive networkReduce contact resistanceCell electrodesRegenerative fuel cellsTotal thicknessOhm

The invention relates to a combined electrode for a flow energy storage battery and a flow energy storage battery containing the combined electrode. The combined electrode comprises a conducting layer and a catalyst layer which are superimposed mutually. The thickness of the conducting layer is 10-90% of the total thickness of the electrode. The conducting layer is made of carbon materials with good conductivity and low porosity. The catalyst layer is made of carbon materials with high electrocatalytic activity and high porosity. The self resistance of the electrode and the contact resistance between bipolar plates of the electrode are decreased, and finally the Ohm internal resistance of the flow energy storage battery is decreased. The energy efficiency and the voltage efficiency of the flow energy storage battery are raised, and therefore the working current density is raised, thus, the weight, the volume and the cost of the battery with the same output power are all decreased greatly.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Silicon anode electrode plate for lithium ion battery and preparation method of electrode plate

InactiveCN107170962AGood conductive networkImprove cycle lifeElectrode rolling/calenderingElectrode thermal treatmentElectrical batteryAdhesive

The invention discloses a silicon anode electrode plate for a lithium ion battery and a preparation method of the electrode plate. Silicon materials and organic matters are mixed and dissolved in solvents to obtain mixture, the mixture is spray-dried to obtain organic matter coated silicon composite materials, the materials are sequentially treated at three temperature sections in an inert gas environment: the materials are placed for 0.5-1 hour at normal temperature, heated to reach 150-250 DEG C and placed for 0.5-1 hour, heated again to reach 450-750 DEG C and placed for 2-4 hours, the coated organic matters are cracked into carbon to obtain carbon-coated silicon composite materials, the carbon-coated silicon composite materials are sufficiently mixed with conductive agents, adhesives, dispersing agents and the solvents to obtain electrode slurry, the surface of a current collector is uniformly coated with the electrode slurry, and the current collector is dried to obtain the electrode plate. The electrode plate comprises the current collector and a negative active layer, the surface of the current collector is coated with the negative active layer, the negative active layer comprises the carbon-coated silicon composite materials, the conductive agents, the adhesives and the dispersing agents, the carbon-coated silicon composite materials are silicon materials with surfaces coated with carbon and comprise, by weight, 0.1-99 parts of carbon, the thickness of the carbon-coated silicon composite materials ranges from 1 nanometer to 100 micrometers, and the internal silicon materials are metal-containing micro-nanostructure silicon or silicon micro-powder.

Owner:厦门高容新能源科技有限公司

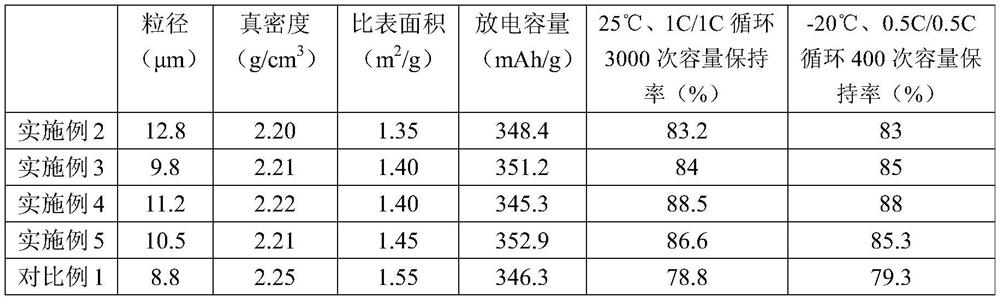

Anthracite/silicon monoxide/amorphous carbon negative electrode material and preparation method thereof

ActiveCN107180958AImprove conductivityHigh lithium storage capacityNegative electrodesSecondary cellsSilicon monoxideAnthracite

The invention provides an anthracite / silicon monoxide / amorphous carbon negative electrode material and a preparation method thereof. The prepared composite negative electrode material is a powdered lithium ion battery negative electrode material which is prepared by performing mechanical ball grinding and dispersion on amorphous SiO, anthracite and citric acid and then sintering the materials and has the particle size of about 13 to 15 microns. The preparation method of the anthracite / silicon monoxide / amorphous carbon negative electrode material comprises the following steps: performing smashing, impurity removal and high temperature treatment on anthracite mine, mixing the treated anthracite mine with SiO, then adding the citric acid for coating, performing mechanical ball grinding and compounding, thus obtaining a precursor, and performing high temperature treatment, thus obtaining the lithium ion battery negative electrode material with high specific capacity. By effective combination of high conductivity of a carbon material and high lithium storage capacity of SiO, the composite material has excellent electrochemical property; under a condition of 0.1 A / g, after the anthracite / silicon monoxide / amorphous carbon negative electrode material is cycled for 100 turns, the reversible capacity is up to 459.2 mAh / g, and certain feasibility selection is provided for functionization of the SiO negative electrode material.

Owner:OCELL NEW ENERGY TECH

Preparation method of high-performance silicon carbon-graphite composite negative electrode material for lithium ion batteries

ActiveCN110844908AImprove cycle lifeImprove the first effectMaterial nanotechnologySiliconCarbon compositesElectrolytic agent

The invention discloses a preparation method of a high-performance silicon carbon-graphite composite negative electrode material for lithium ion batteries. The preparation method comprises the following steps: dissolving an organic carbon source in a solvent, adding nano silicon particles, uniformly mixing, adding crystalline flake graphite into an obtained mixture, carrying out continuous vacuum-high pressure impregnation reaction, and carrying out vacuum drying to obtain a silicon carbon composite material precursor; and spheroidizing the silicon carbon composite material precursor, carryingout surface solid-phase coating, and finally, carrying out sintering and screening to obtain the target product. According to the invention, the contact between nano silicon and electrolyte is greatly reduced to form a stable solid electrolyte membrane, and the target product has the characteristics of high first effect, long cycle and the like, and the application prospect is promising.

Owner:HUNAN SHINZOOM TECH

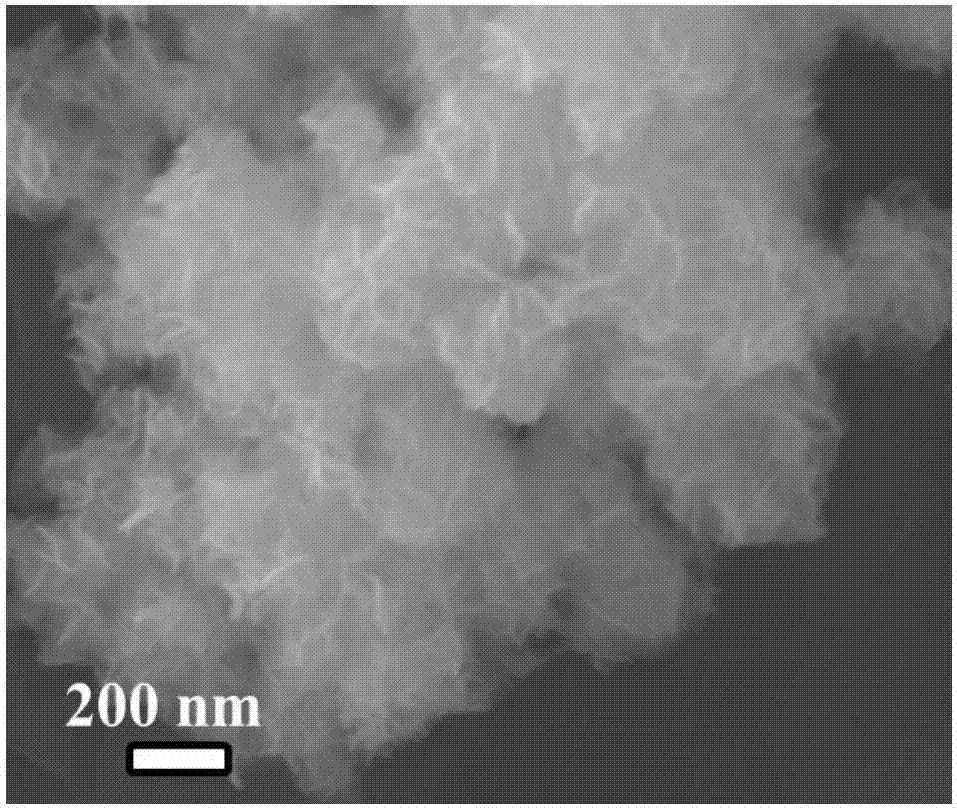

Preparation method of nitrogen-doped carbon nanosphere/molybdenum disulfide sodium ion battery negative electrode plate

InactiveCN107230782AEasy to prepareImprove stabilityCell electrodesSecondary cellsCvd grapheneChemistry

The invention belongs to the technical field of battery preparation, relates to a preparation method of a sodium ion battery negative electrode plate, and particularly relates to a preparation method of a nitrogen-doped carbon nanosphere / molybdenum disulfide sodium ion battery negative electrode plate. Natural melanin nanospheres are coated with a layer of graphene-like transitional metal molybdenum disulfide to prepare the nitrogen-doped carbon sphere / molybdenum disulfide material and to prepare a battery; the preparation method is simple and easy, green and environment-friendly, and effective; according to the preparation method, melanin is extracted from natural squid ink, and the melanin is coated with molybdenum disulfide through a hydrothermal method; the main component of the melanin is polydopamine, so that the nitrogen-doped carbon spheres are formed in the hydrothermal process; the carbon nanospheres are uniformly coated with the molybdenum disulfide nanosheets, and a load network is formed among the nanosheets, so that an effect of high conductive network is played; and when the prepared CS / MoS<2> material is used as the negative electrode material of the sodium ion battery, the negative electrode structure and interface stability are improved, and commercial production and application can be promoted.

Owner:QINGDAO HAICHENG INTPROP SERVICES CO LTD

Copper iridium nanowire and synthetic method thereof

ActiveCN108788125AFill in research gapsImprove conductivityMaterial nanotechnologyTransportation and packagingIridiumNanowire

The invention provides a copper iridium nanowire and a synthetic method thereof, and relates to the field of synthesis of nano-scale inorganic metal materials. The copper iridium nanowire is of a lineage structure with the diameter of 2-5 micron on a particle structure. The synthetic method comprises the following steps that oleylamine, carbonyl tris (triphenylphosphine) hydrogenated iridium (I),acetylacetone copper and cetyl trimethyl ammonium chloride are weighed to be put into the same reactor, and uniformly stirring and mixing are carried out; the reaction system is heated at a first time; vacuumizing and degassing are carried out, a primary reaction is carried out in a vacuum state, then argon is introduced, meanwhile, the system is rapidly heated for a second time, and a black powdery product is obtained after a secondary reaction is carried out for a period of time. The copper iridium nanowire and the synthetic method thereof has the beneficial effects that the atmosphere, thefactors of the temperature, the time and the like of the reaction system in the synthesis process are further controlled by selecting specific materials, the copper iridium nanowire which is the linear structure with the synthesis diameter between 2-5 micron is realized, so that the research blank in the direction of the copper iridium nanowires is filled up.

Owner:HUAIHAI INST OF TECH

Method for preparing high-sensitivity flexible piezoresistive sensor based on fractured microstructure

ActiveCN111982362AIncrease contact areaHigh sensitivityNanosensorsForce measurement using piezo-resistive materialsHigh volume manufacturingThin membrane

The invention discloses a method for preparing a high-sensitivity flexible piezoresistive sensor based on a fracture microstructure, relates to the field of preparation of flexible wearable equipment,and aims to solve the problems of low sensitivity, complex preparation process, unstable performance and high detection limit of a current wearable piezoresistive sensor. The preparation method comprises the following steps: adsorbing a large amount of carbon nanotube solution through polyurethane sponge to obtain conductive carbon nanotube foam, and forming a conductive network in the conductivecarbon nanotube foam after centrifugal drying; increasing the contact area of the carbon nanotubes by adopting a pre-pressing process, so that the electron transmission capacity in a deformation state is improved; and finally, assembling electrodes on the upper surface and the lower surface of the conductive carbon nanotube film to prepare the flexible piezoresistive sensor. The method has the advantages of simple process, low cost, capability of realizing large-batch production and the like, and meanwhile, has extremely high stability and sensitivity and extremely low detection limit. The method is applied to the field of flexible wearable equipment preparation.

Owner:工科思维技术(深圳)有限公司

Preparation method of graphene/lithium iron phosphate composite material

InactiveCN105932255ASolve floatingSolve reunionPhosphatesCell electrodesLithium iron phosphateReducing atmosphere

The invention discloses a preparation method of a graphene / lithium iron phosphate composite material. The method comprises the following steps: adding a graphene oxide suspension liquid to a lithium iron phosphate precursor or a pre-sintered material or a sintered body; adding a little of solvent for wet ball-milling; and carrying out dry grinding treatment after ball-milling, and sintering the product in a reducing atmosphere to prepare the graphene / lithium iron phosphate composite material. The adopted graphite oxide contains a lot of oxygen-containing hydrophilic groups and is easily dispersed into the solvents of water, ethyl alcohol and the like under ultrasonic action, so that the problems of floatation, agglomeration and uneven mixing due to direct addition of graphene in a traditional lithium iron phosphate preparation method are solved; and the graphene prepared by the method is evenly dispersed among lithium iron phosphate particles, is free of accumulation and agglomeration and can form a good conductive network. The method is simple to operate; and large-scale industrial production is easy to implement.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

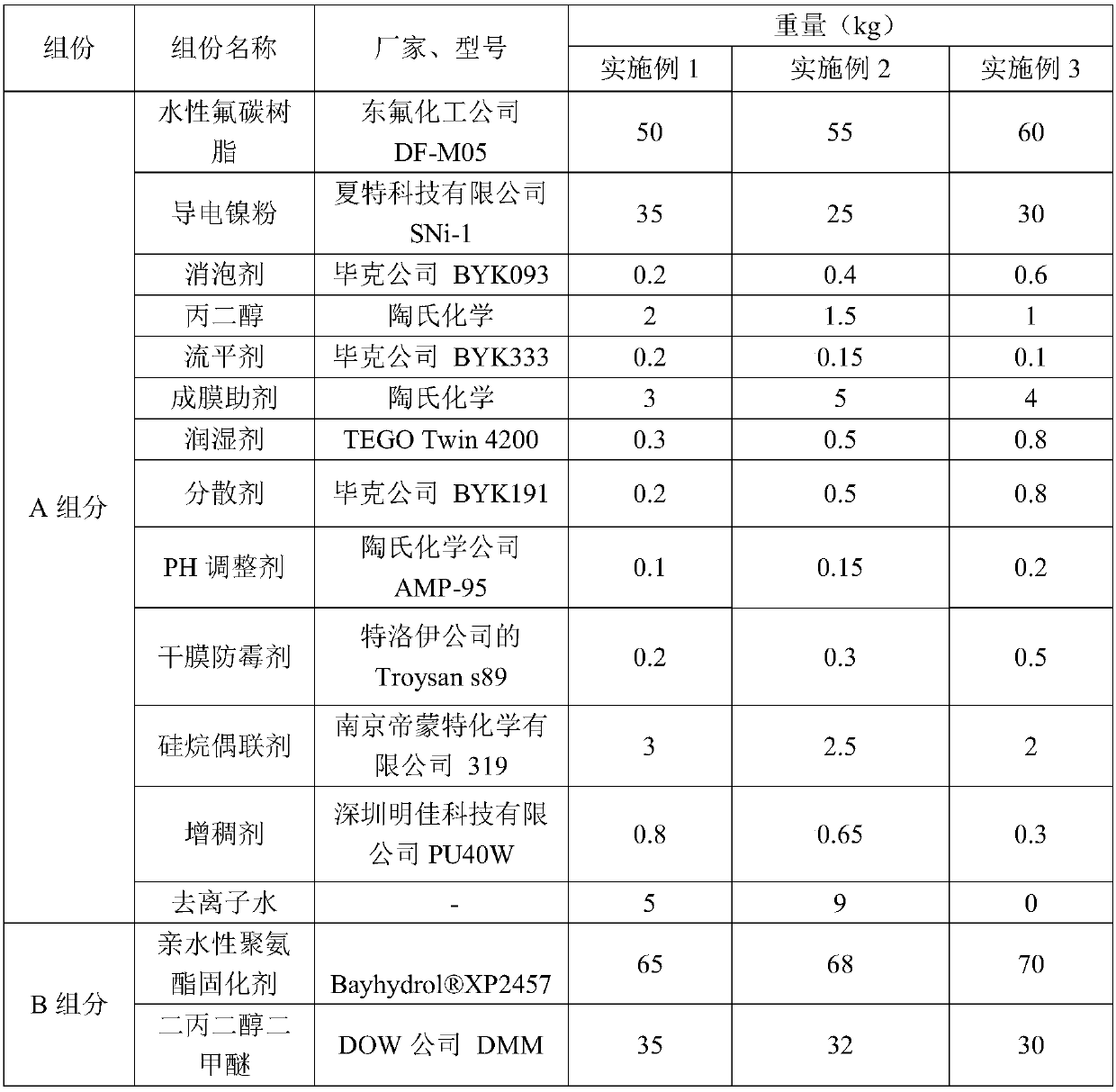

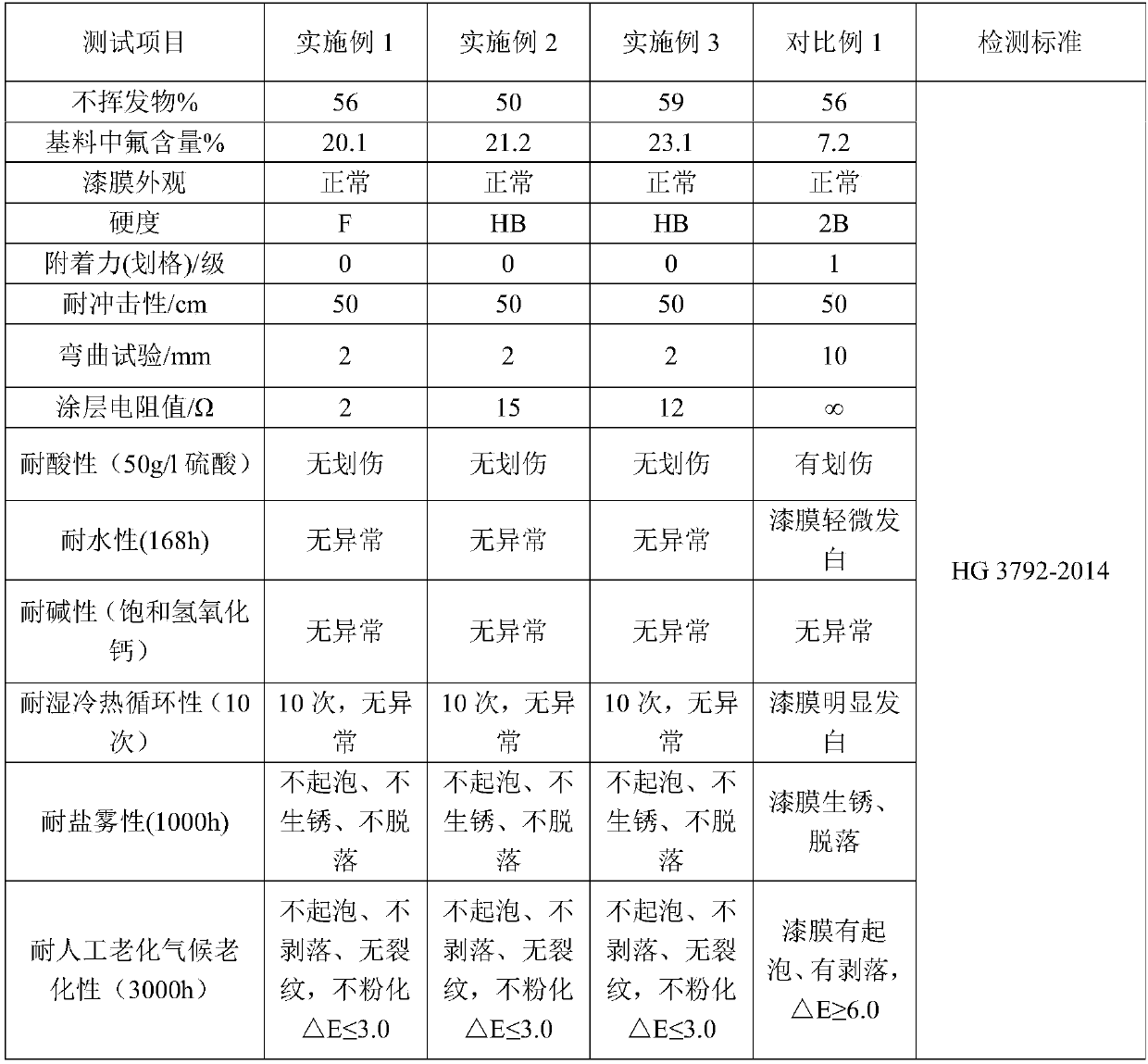

Waterborne bicomponent fluorocarbon conductive anticorrosion paint and preparation method and application method thereof

InactiveCN109575707AImprove crosslink strengthImprove functionalityLiquid surface applicatorsAnti-corrosive paintsDefoaming AgentsMaterials science

The invention provides a waterborne bicomponent fluorocarbon conductive anticorrosion paint, made by mixing component A and component B; the component A comprises, by weight, 50-60 parts of waterbornefluorocarbon resin, 25-35 parts of conductive nickel powder, 1-2 parts of propylene glycol, 0.2-0.6 part of a defoaming agent, 2-3 parts of silane coupling agent, 0.2-0.8 part of a dispersant, 0.1-0.2 part of a leveling agent, 0.1-0.2 part of a PH regulator, 0.3-0.8 part of a wetting agent, 0.2-0.5 part of a dry film mildew preventive, 3-5 parts of a film-forming aid, 0.3-0.8 part of a thickener,and 0-9 parts of deionized water; the component B comprises 65-70 parts of hydrophilic isocyanate curing agent, and 30-35 parts of dipropylene glycol dimethyl ether; the weight ratio of the componentA to the component B is 10:1. film of the waterborne bicomponent fluorocarbon conductive anticorrosion paint has excellent weatherability, water resistance, oil resistance, low temperature resistance, solution resistance, corrosion resistance, and conductivity; static electricity on the surface of a coating layer can be effectively eliminated.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Preparation method for lithium manganese silicate/carbon composite material used as positive electrode material of lithium ion battery, and positive electrode slurry and application

ActiveCN106450186ASmall sizeAvoid reunionCell electrodesSecondary cellsCarbon layerCarbon composites

The invention relates to a preparation method for a lithium manganese silicate / carbon composite material used as a positive electrode material of a lithium ion battery. The preparation method comprises the following steps: the surface of silicon dioxide is coated with an amorphous carbon layer; then a chemical etching reaction is performed to etch off a part of SiO<2> to generate a composite material with a yolk-egg shell structure, wherein by virtue of the SiO<2> composite material with the structure, the dimensions of lithium manganese silicate granules can be reduced while a lithium source and a manganese source can be dispersed into the SiO<2> main body through a carbon layer; the carbon layer on the surface of the SiO<2> can prevent the generated lithium manganese silicate from agglomerating; next, the SiO<2>@void@C composite material, the manganese salt and the lithium salt are added into a water solution based on certain proportion to be mixed uniformly; then the obtained solution is heated and volatilized to obtain a solid body, and high-temperature processing is performed under inert atmosphere protection to obtain the lithium manganese silicate / carbon composite material. The prepared lithium manganese silicate is uniform in granule dispersion without obvious agglomeration, and relatively small in granule sizes; and meanwhile, the surface is coated with the uniform amorphous carbon layer.

Owner:江苏载驰科技股份有限公司

Preparation method for graphite and silicon composite anode material

InactiveCN106025280AEvenly dispersedReduce dispersionCell electrodesSecondary cellsNano siliconGraphite

The invention provides a preparation method for a graphite and silicon composite anode material. The graphite and silicon composite anode material is obtained by taking expanded graphite as a raw material, adsorbing an organic dispersion liquid of nano silicon, then, performing heat treatment to obtain an expanded graphite silicon composite material, and flattening the expanded graphite silicon composite material. The graphite and silicon composite anode material has the characteristics of high effectiveness, long cycle life and high capacity; moreover, the method is simple in process; the raw materials are easily obtained; the used organic dispersion liquid can be recycled and is green and environment-friendly; industrial production is facilitated.

Owner:苏州微格纳米科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method and application of FeS[x]/C/CNT composite cathode materials Preparation method and application of FeS[x]/C/CNT composite cathode materials](https://images-eureka.patsnap.com/patent_img/4435b25b-a9a3-4b5e-b1e7-2a6f29a2a52f/1810240934361.png)

![Preparation method and application of FeS[x]/C/CNT composite cathode materials Preparation method and application of FeS[x]/C/CNT composite cathode materials](https://images-eureka.patsnap.com/patent_img/4435b25b-a9a3-4b5e-b1e7-2a6f29a2a52f/1810240934362.png)

![Preparation method and application of FeS[x]/C/CNT composite cathode materials Preparation method and application of FeS[x]/C/CNT composite cathode materials](https://images-eureka.patsnap.com/patent_img/4435b25b-a9a3-4b5e-b1e7-2a6f29a2a52f/1810240934363.png)