Copper iridium nanowire and synthetic method thereof

A synthesis method and nanowire technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of high price and immature iridium copper alloy nanowire synthesis method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

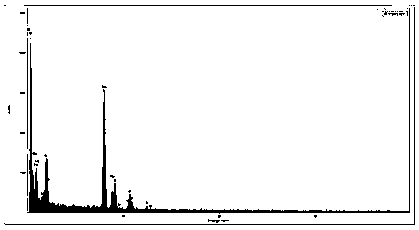

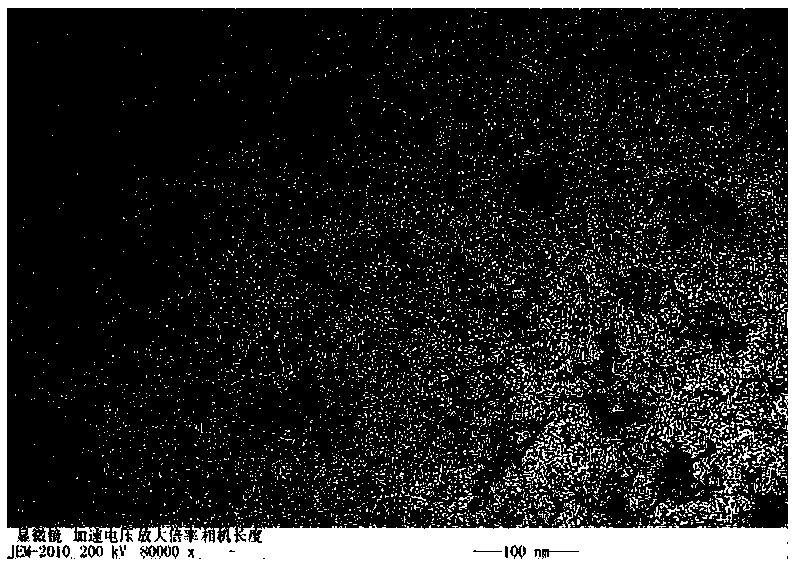

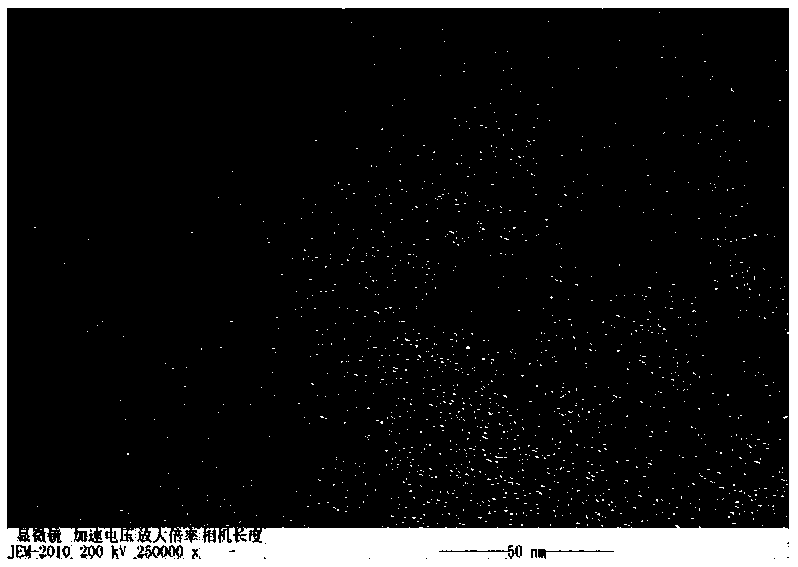

Image

Examples

Embodiment 1

[0032] A copper-iridium nanowire, the particle structure is a wire-like structure copper-iridium alloy with a diameter of 2-5nm.

[0033] The synthetic method of above-mentioned copper iridium nanowire, comprises the following steps:

[0034] (1) Weigh 5 g of oleylamine, 10 mg of carbonyl tris(triphenylphosphine) iridium (I), 10 mg of copper acetylacetonate, and 10 mg of hexadecyltrimethylammonium chloride into the same reactor, stir and mix well ;

[0035] (2) Raise the temperature of the reaction system to 85°C, keep the temperature constant, evacuate and degas, keep it in a vacuum state for 25 minutes, then pass in argon, then continue to heat up the system to 245°C, keep the temperature constant, and react for 55 minutes , to obtain a black powdery product. After the system was cooled, the product was separated, centrifuged at 6000r / min for 15min, washed three times with a mixture of absolute ethanol and toluene, and dried at 80°C for 12h.

Embodiment 2

[0037] A copper-iridium nanowire, the particle structure is a wire-like structure copper-iridium alloy with a diameter of 2-5nm.

[0038] The synthetic method of above-mentioned copper iridium nanowire, comprises the following steps:

[0039] (1) Weigh 50g of oleylamine, 100mg of carbonyl tris(triphenylphosphine)iridium(I) hydride, 100mg of copper acetylacetonate, and 400mg of cetyltrimethylammonium chloride into the same reactor, stir and mix well ;

[0040] (2) Raise the temperature of the reaction system to 95°C, keep the temperature constant, vacuumize and degas, keep it in a vacuum state for 35 minutes, then pass in argon, then continue to heat up the system to 255°C, keep the temperature constant, and react for 65 minutes , to obtain a black powdery product. After cooling the system, the product was separated, centrifuged at 12000r / min for 6min, washed 10 times with a mixture of absolute ethanol and toluene, and dried at 120°C for 2h.

Embodiment 3

[0042] A copper-iridium nanowire, the particle structure is a wire-like structure copper-iridium alloy with a diameter of 2-5nm.

[0043] The synthetic method of above-mentioned copper iridium nanowire, comprises the following steps:

[0044] (1) Weigh 15g of oleylamine, 50mg of carbonyltris(triphenylphosphine)iridium(I) hydride, 18mg of copper acetylacetonate, and 100mg of cetyltrimethylammonium chloride into the same reactor, stir and mix well ;

[0045] (2) Raise the temperature of the reaction system to 90°C, keep the temperature constant, vacuumize and degas, keep it in a vacuum state for 30 minutes, then pass in argon, then continue to heat up the system to 250°C, keep the temperature constant, and react for 60 minutes , to obtain a black powdery product. After the system was cooled, the product was separated, centrifuged at 7000r / min for 10min, washed 5 times with a mixture of absolute ethanol and toluene, and dried at 100°C for 10h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com