Silicon-carbon composite negative electrode material, negative electrode plate, preparation method thereof and lithium-ion battery

A negative electrode material, silicon carbon composite technology, applied in batteries, negative electrodes, electrode manufacturing and other directions, can solve the problems of volume expansion, poor cycle performance of lithium ion batteries, electrochemical performance and cycle life to be improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing a negative electrode sheet. The method comprises uniformly mixing the negative electrode material with a conductive agent, a binder and a solvent to obtain an electrode slurry, and coating the electrode slurry on the surface of a current collector, and drying Dry, wherein, the negative electrode material is the above-mentioned silicon-carbon composite negative electrode material.

[0035] The main improvement of the preparation method of the negative electrode sheet provided by the present invention is to adopt a new negative electrode material, and the specific types of conductive agent, binder and solvent and their consumption with the negative electrode material and the like can be compared with the existing ones. The technique is the same. For example, specific examples of the conductive agent include, but are not limited to: at least one of super carbon black, graphene, carbon fiber and graphite. Specific ...

Embodiment 1

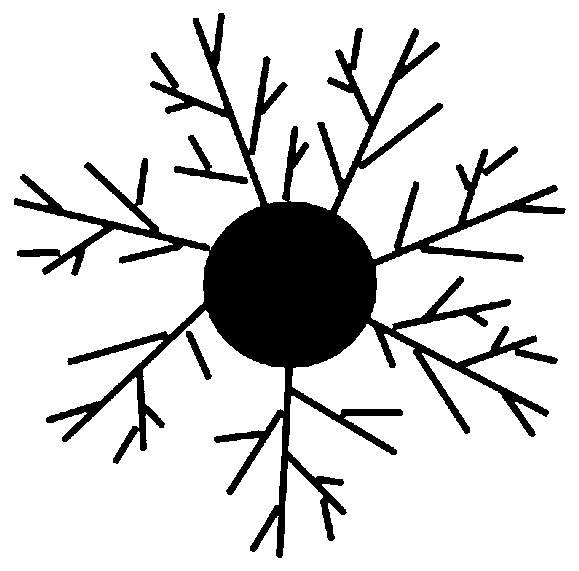

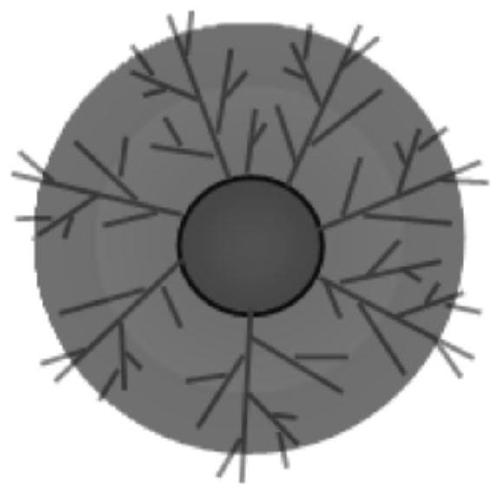

[0042] S1. Mix 100mL ethanol and 20mL water and heat to 60°C, add 2.5mL ammonia water (concentration: 5wt%, the same below) and 0.5mL ethylenediamine and mix evenly, then add 1g 3-aminophenol, 2mL formaldehyde and 4mL silicic acid Ethyl ester was vigorously stirred at 30rpm for 6 hours to form a precipitated product, which was centrifuged and dried at 60°C for 3 hours to obtain a silica / phenolic compound with a fractal structure.

[0043] S2. Take 2g of the above-mentioned silica / phenolic compound and 2g of magnesium powder, grind and mix them evenly, and put them into a tube furnace. The tube furnace is protected by argon gas containing 1% hydrogen, and the tube furnace is heated to 350°C. The heat preservation reaction is carried out for 10 hours, and the composite material powder of silicon and amorphous carbon having a fractal structure is obtained from the reaction. The composite material powder is taken out, treated with dilute hydrochloric acid to remove the remaining u...

Embodiment 2

[0046] S1. Mix 90mL of ethanol and 10mL of water and heat to 80°C, add 2mL of ammonia water and 0.3mL of ethylenediamine and mix well, then add 1.5g of 3-aminophenol, 3.2mL of formaldehyde and 6mL of ethyl silicate, and stir vigorously at 150rpm After 4 hours, the reaction produced a precipitate product, which was centrifuged, and the obtained solid product was dried at 90° C. for 1 hour to obtain a silica / phenolic compound with a fractal structure.

[0047] S2: Take 2 g of the above-mentioned silica / phenolic compound and put it into a tube furnace. The tube furnace is protected by argon gas containing 1% hydrogen, and the tube furnace is heated to 1000 ° C for 0.5 h. The roasted product is cooled to room temperature, crushed and ground and mixed with 3g of aluminum powder evenly, put into the tube furnace again, and the tube furnace is fed with argon gas protection containing 1% hydrogen, and the tube furnace is heated to 500°C for roasting for 6 Hours, the reaction yields a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com