Patents

Literature

31results about How to "High first reversible capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hard carbon/graphite composite negative electrode material and lithium ion battery as well as preparation method and application thereof

ActiveCN111244407AHigh electron mobilityImprove conductivityCell electrodesSecondary cellsElectrolytic agentCarbon graphite

The invention discloses a preparation method of a hard carbon / graphite composite negative electrode material. The preparation method comprises: S1, carrying out a cross-linking reaction on a hard carbon source to obtain a hard carbon precursor, the hard carbon source being a thermoplastic polymer compound or a non-thermoplastic polymer compound; S2, mixing graphite, a hard carbon precursor and anadditive liquid phase, and drying; S3, carrying out pre-carbonization treatment and carbonization treatment; and S4, performing surface coating treatment. The hard carbon / graphite composite negative electrode material prepared by the preparation method is good in adaptability to electrolyte and other additives, the lithium ion battery prepared from the hard carbon / graphite composite negative electrode material is high in capacity and good in rate capability and cycle performance, and the preparation method is simple and feasible in process, wide in raw material source and low in cost and has awide application prospect.

Owner:SHANGHAI SHANSHAN TECH CO LTD

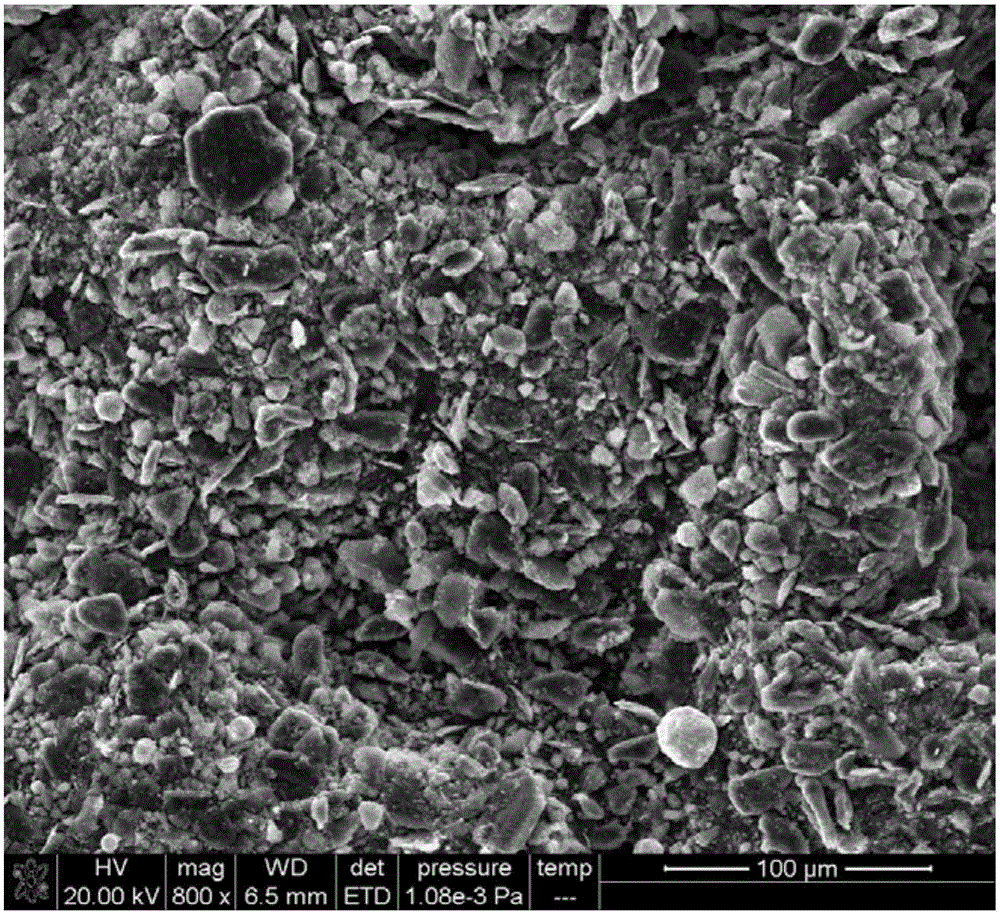

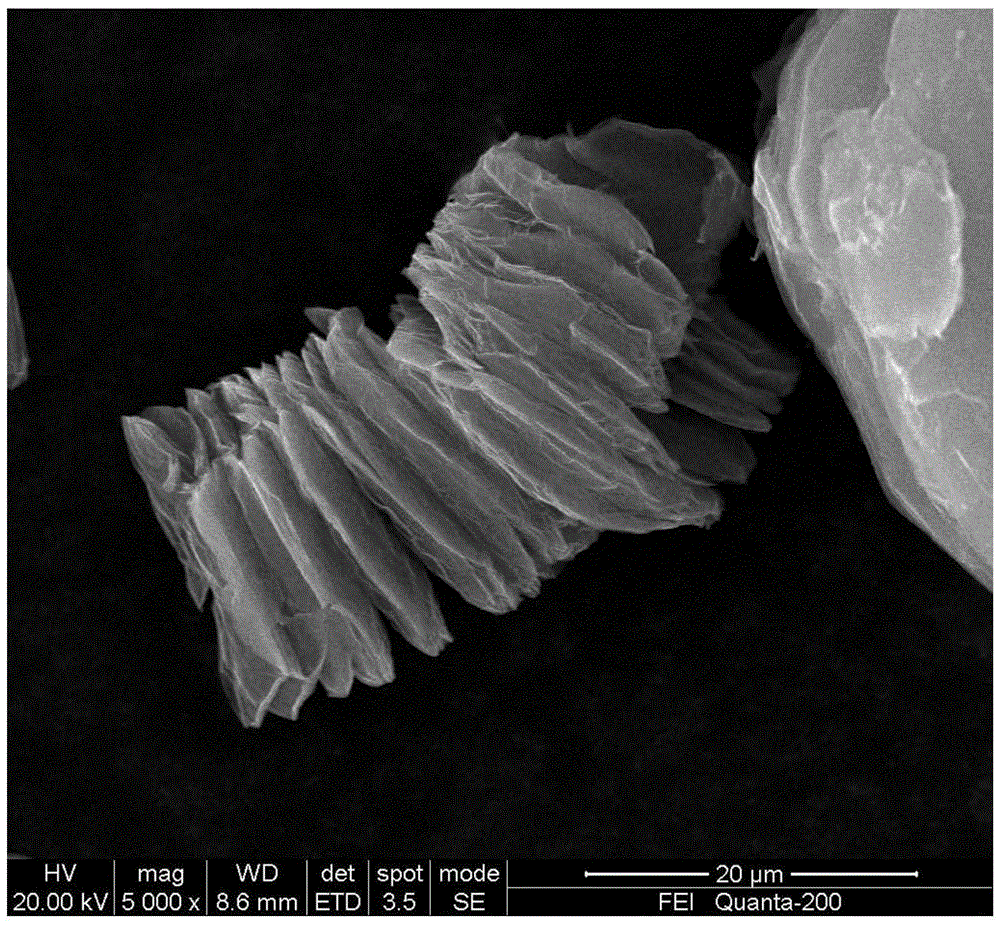

Carbon-carbon multi-component negative electrode material and preparation method thereof

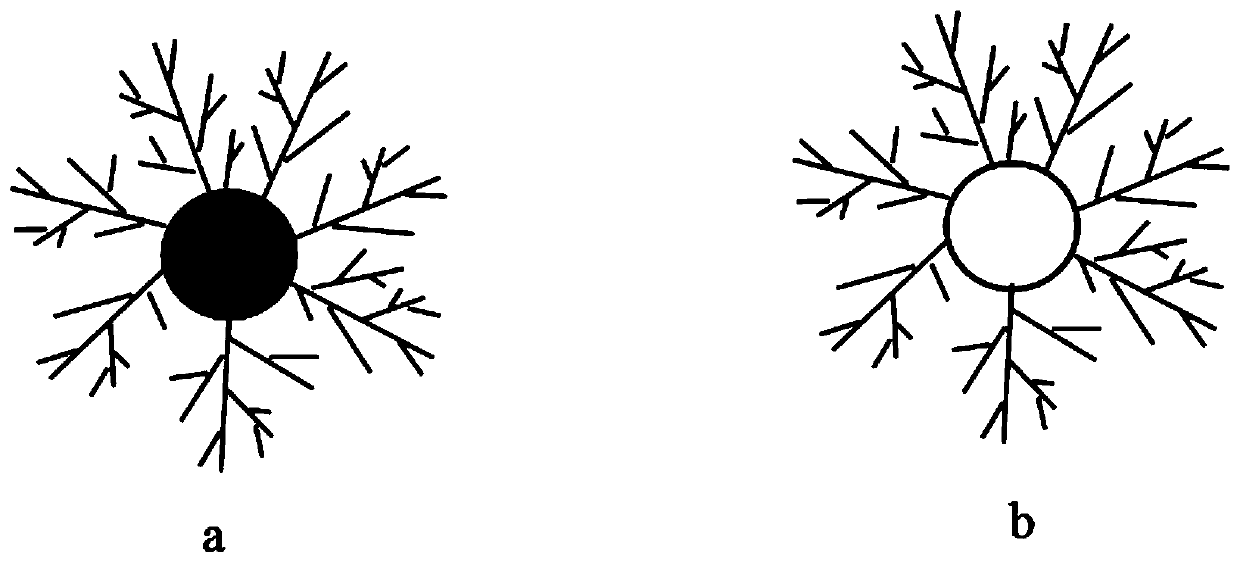

ActiveCN104037396AIncrease the attachment areaIncrease energy densityCell electrodesSecondary cellsCarbon compositesGraphite

The invention relates to a carbon-carbon multi-component negative electrode material. The carbon-carbon multi-component negative electrode material is mainly composed of flexible graphite, nanometer silicon and amorphous carbon which respectively account for 30-60%, 30-50% and 10-30% based on mass percent, the amorphous carbon is obtained through high-temperature pyrolyzation of an organic carbon source, and the flexible graphite is obtained by applying pressure to expanded graphite. A preparation method of the product comprises the steps of: firstly, preparing an expanded graphite / silicon-silicon dioxide / carbon composite negative electrode material through high-temperature pyrolyzation; secondly, pouring the expanded graphite / silicon-silicon dioxide / carbon composite negative electrode material into a mould and applying pressure to obtain a flexible graphite / silicon-silicon dioxide / carbon composite negative electrode material; thirdly, processing silicon dioxide to obtain a flexible graphite / silicon / carbon composite negative electrode material through etching by a corrosive liquid; and finally, using asphalt to permeate a gap inside the flexible graphite / silicon / carbon composite negative electrode material in a protective atmosphere, and obtaining the product after high-temperature heat treatment and repetition. The carbon-carbon multi-component negative electrode material has the advantages of high capacity, high coulombic efficiency, good cycle performance, structure stability, high reversible capacity and the like.

Owner:CENT SOUTH UNIV

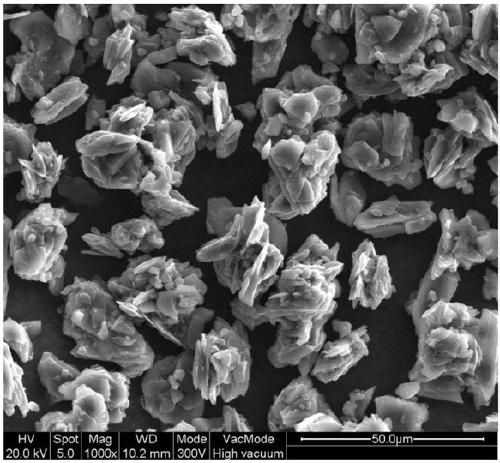

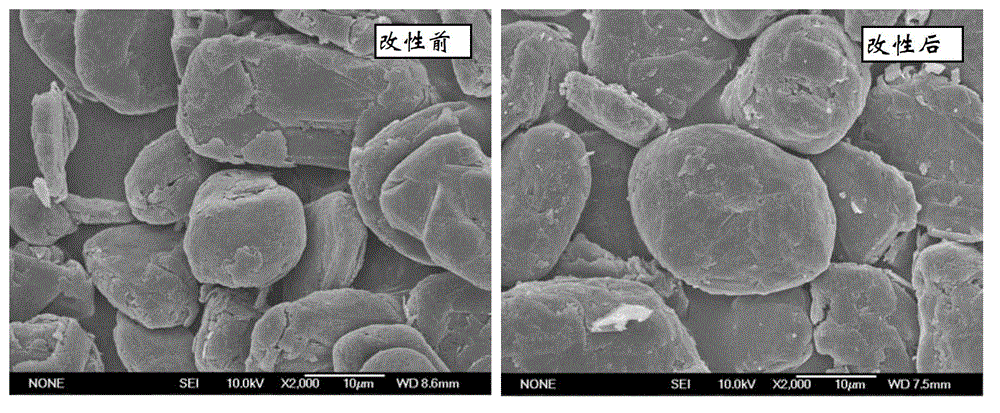

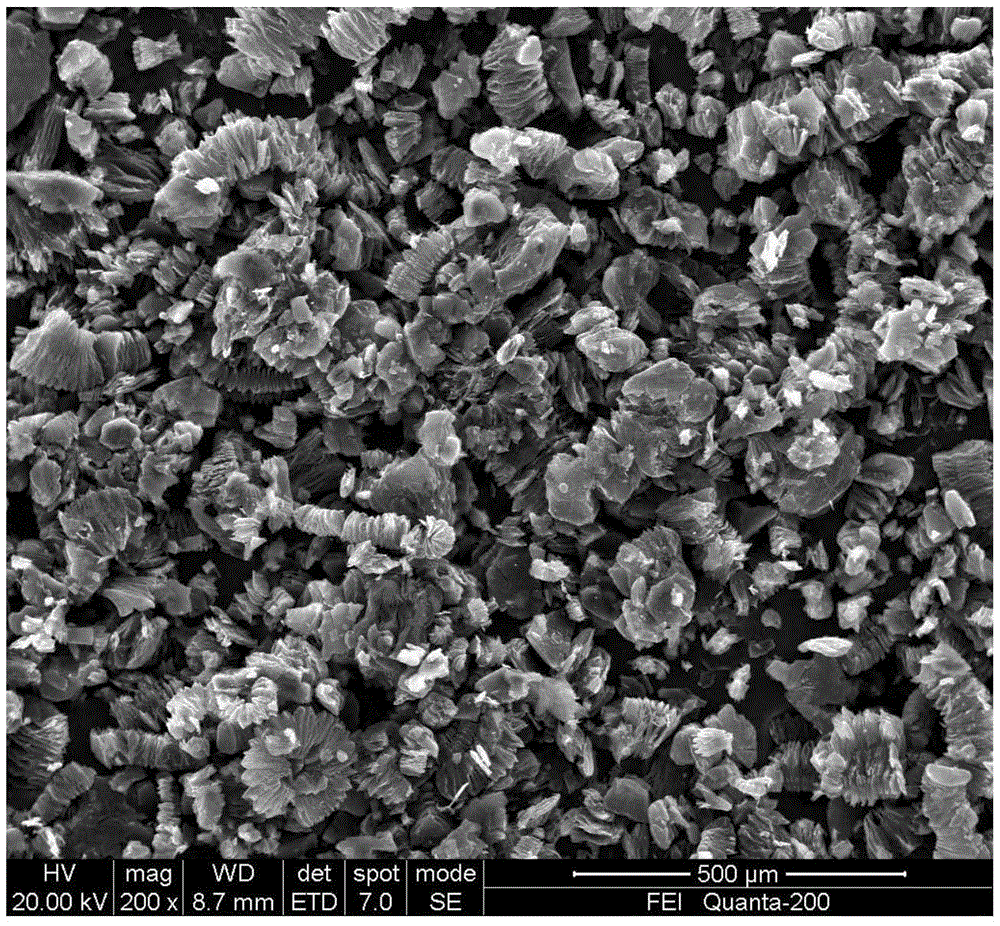

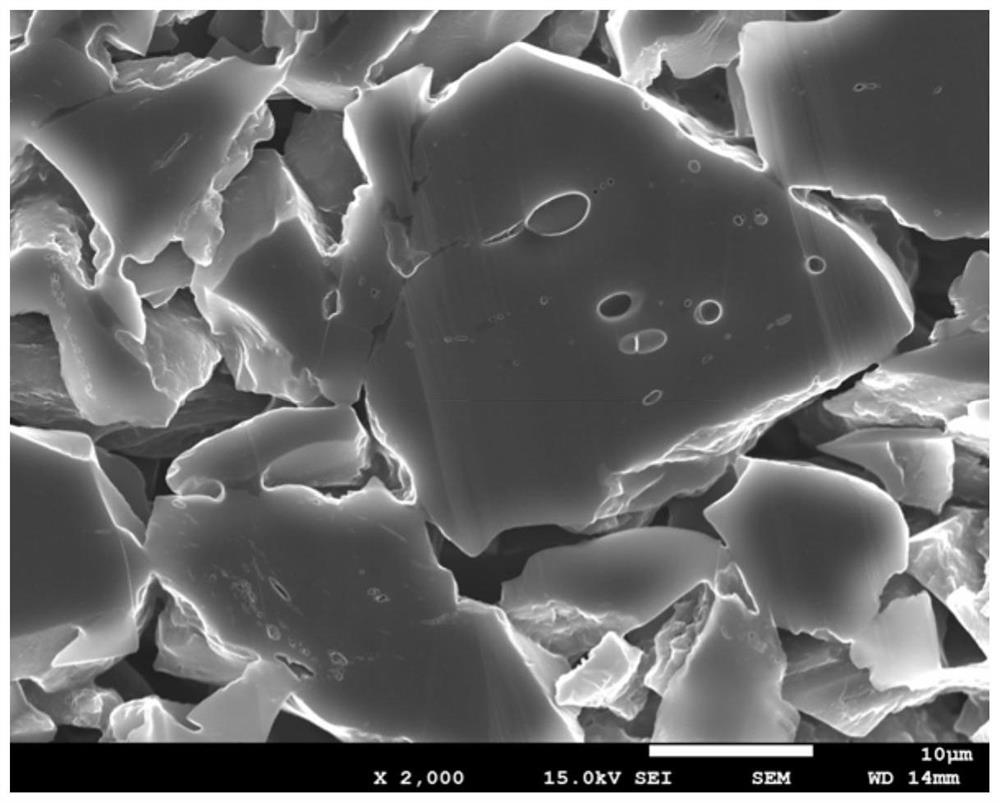

Spherical graphite with median diameter of 11 to 16 mu m and preparation method thereof

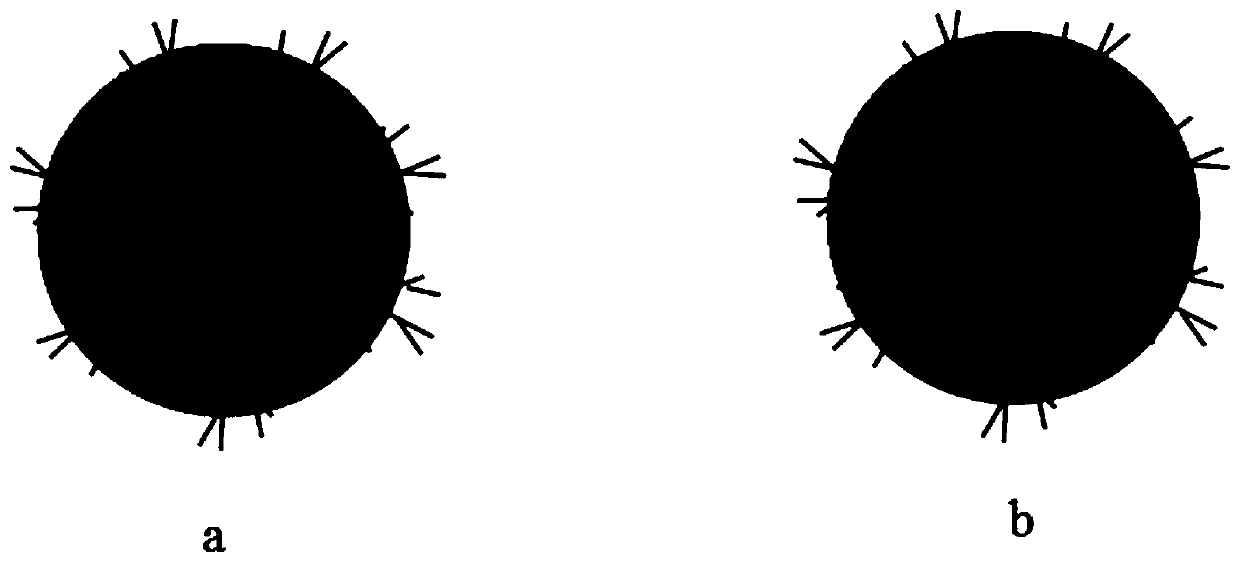

InactiveCN101850965AHigh first reversible capacityImprove Coulombic efficiencyVortex flow apparatusGrain treatmentsAirflowPhencyclone

The invention discloses a preparation method of spherical graphite with a median diameter of 11 to 16 mu m. A five-level powder refining machine set consisting of an air-flow vortex powder refining machine and a cyclone separator is sequentially connected with a fourteen-level nodulizing machine set consisting of an air-flow vortex nodulizing machine and a nodulizing classifier in series; the graphite material enters from the first powder refining machine set and then flows through the five powder refining machine sets and the fourteen nodulizing machine sets in turn and finally out of the last nodulizing machine set; and by refining and nodulizing the powder, the spherical graphite product is obtained. The tap density of the obtained spherical graphite is 1.07-1.10 g / ml, and the number of openings on the surface of the graphite powder is 9-80 per mu m. The sphericity of the product is high, the electrochemical performance is obviously improved, the battery capacity, the standby time and the service life are effectively increased, and no overheat happens; moreover, the preparation method can improve the yield by over 75 percent, lower the cost by 38 percent, save the power consumption by 42 percent and realize the dust recovery rate up to 100%.

Owner:LUOYANG GUANQI INDAL & TRADE

Preparation method for graphite negative electrode of lithium ion battery

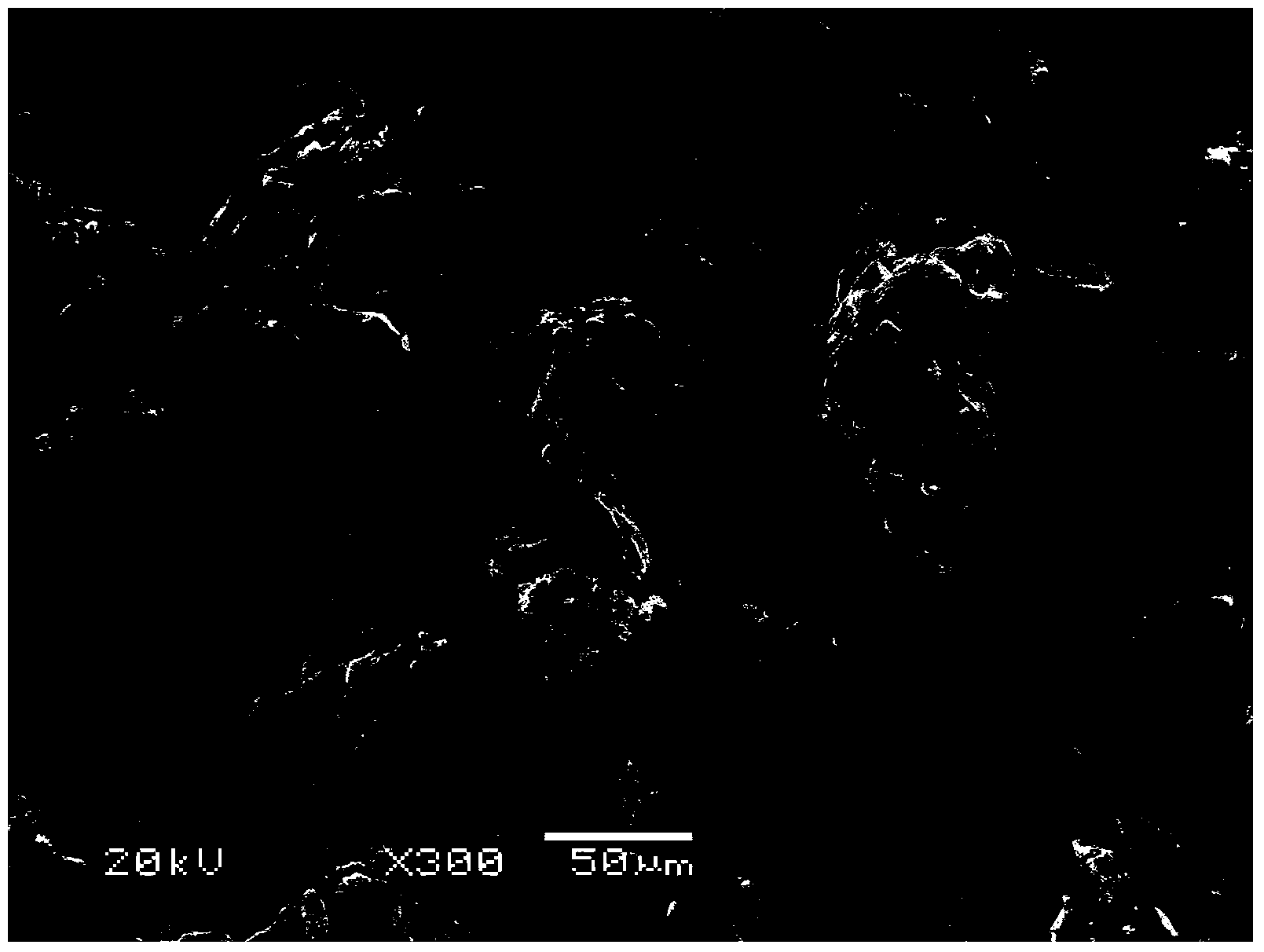

InactiveCN102983307ALow cost of preparationStrong industrial operabilityCell electrodesWater solubleLithium electrode

The invention discloses a preparation method for a high-performance modified graphite negative electrode, and in particular discloses a preparation method for a graphite negative electrode of a lithium ion battery. The preparation method mainly comprises the following steps of: conducting procedures of liquid-phase even mixing, drying, roasting, screening and the like to water-soluble phenol-formaldehyde resin, an aluminum source and graphite negative electrode material to be modified to prepare a graphite negative electrode which is modified jointly by pyrolytic carbon and aluminum oxide, wherein the surfaces of the pyrolytic carbon are coated with phenolic resin. The modified graphite negative electrode material has the characteristics of being high in reversibility specific capacity, high in first-time charging and discharging efficiency, long in recycling life and good in safety property. The modified technique is simple to operate, low in cost, and obvious in modification effect.

Owner:TIANJIN B&M SCI & TECH

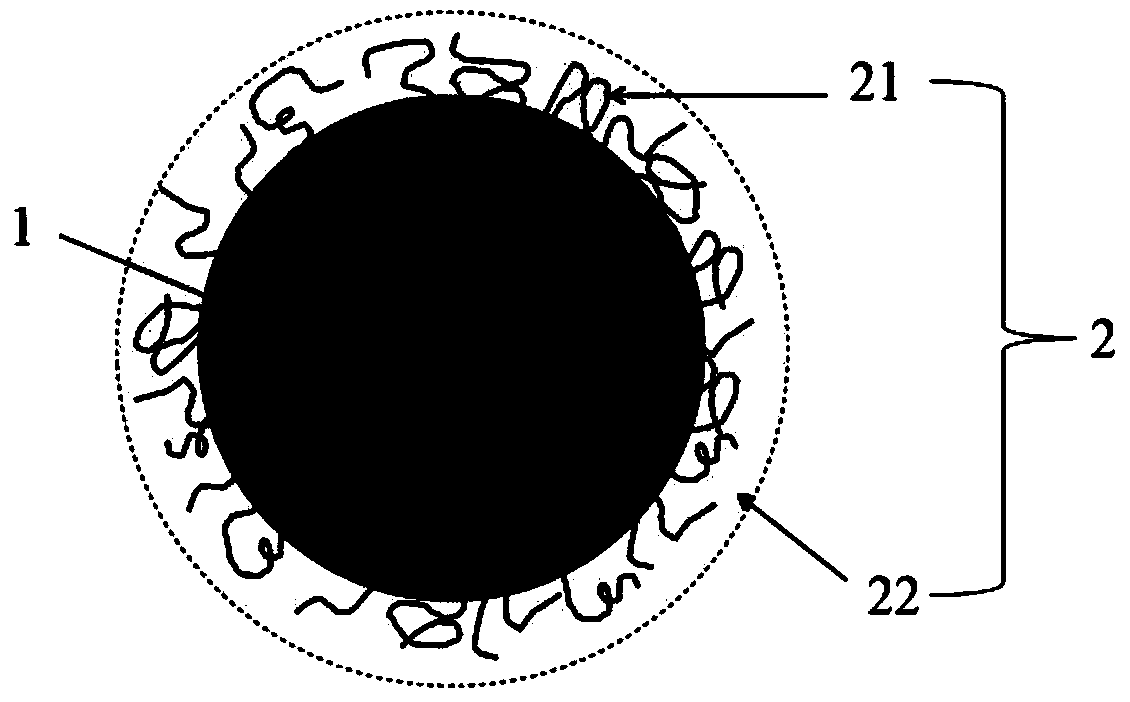

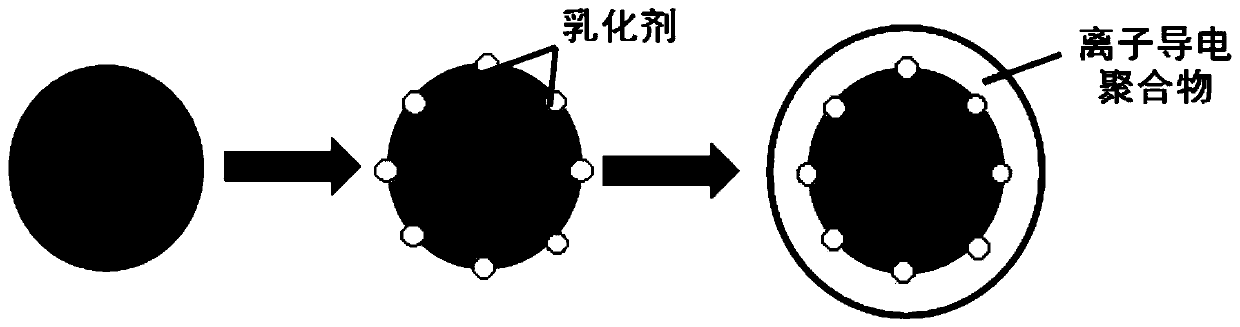

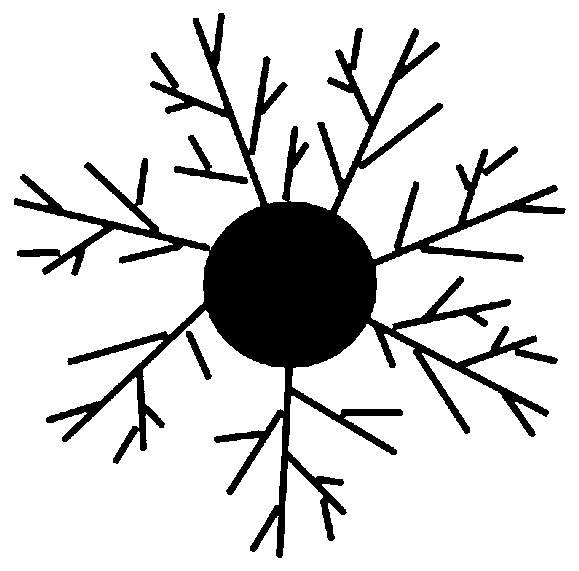

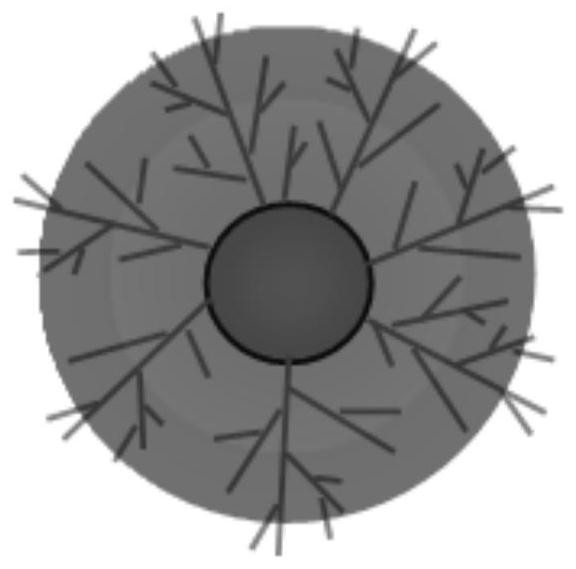

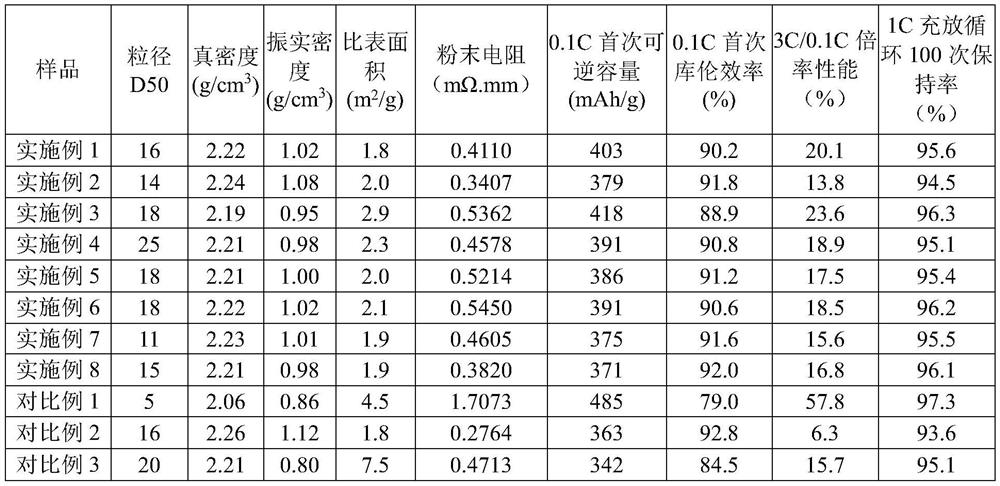

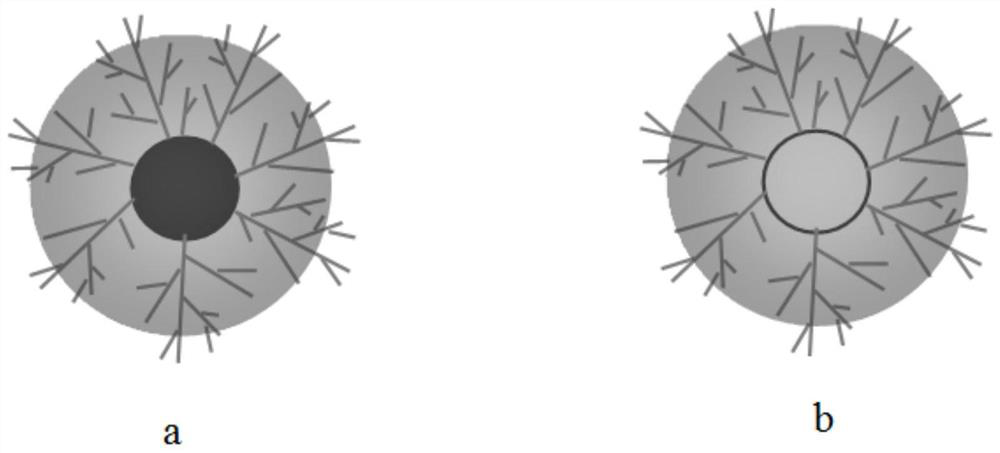

Core-shell structure multi-component composite material, preparation method thereof and a lithium ion battery comprising the multi-component composite material

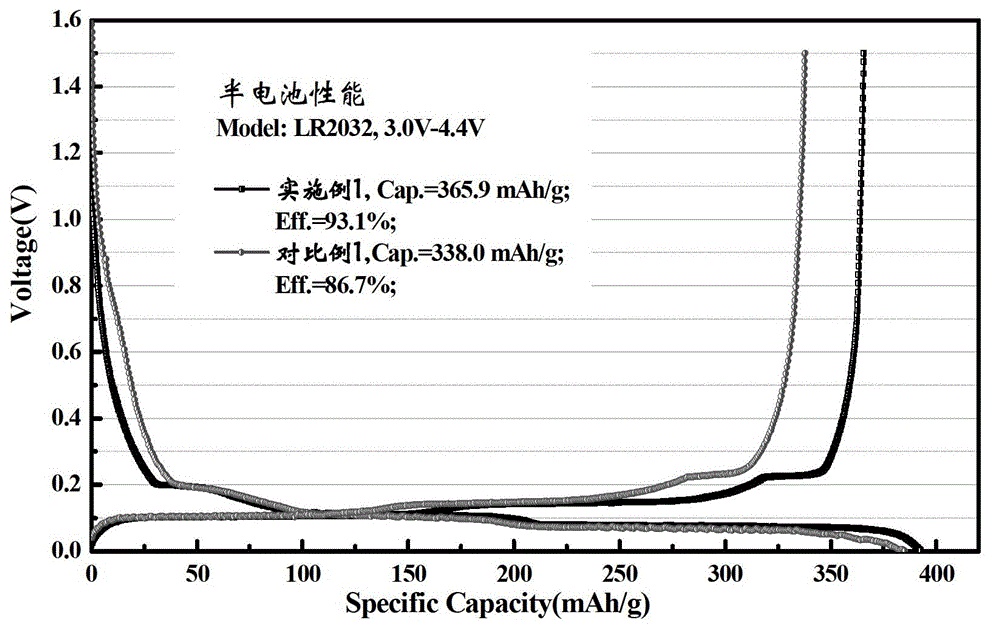

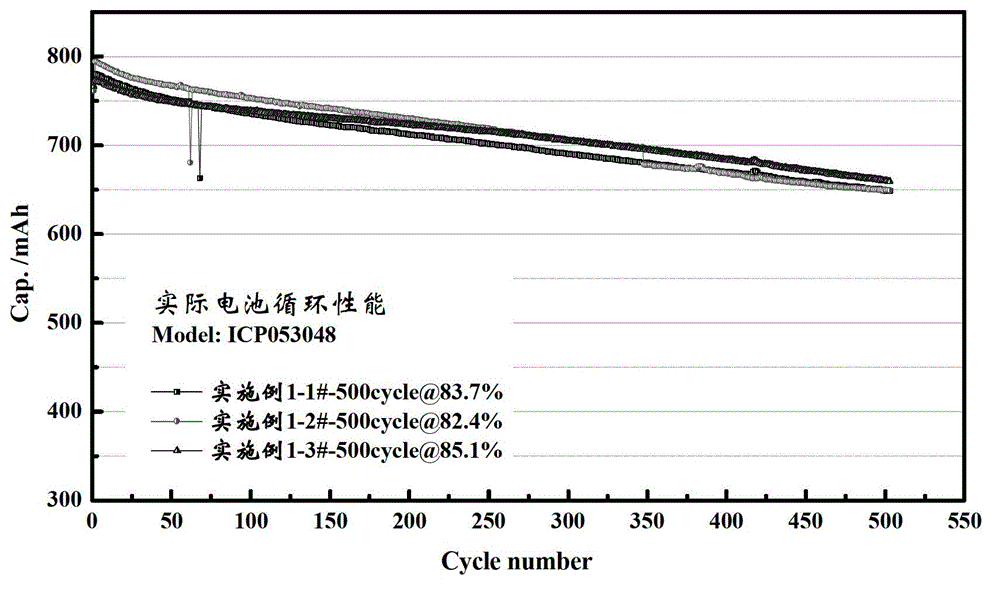

InactiveCN108832092AImprove low temperature charge and discharge performanceImprove high temperature storage performanceCell electrodesSecondary cellsCarbon layerCarbonization

The invention discloses a core-shell structure multi-component composite material, a preparation method thereof and a lithium ion battery comprising the multi-component composite material. The multi-component composite material comprises a graphite core and an outer shell coating the surface of the core, and the outer shell comprises a chain-shaped hard carbon layer and a soft carbon layer from the inside to the outside. The method comprises the following steps: 1) mixing an amorphous carbon precursor, a solvent and a surfactant to obtain a liquid phase first precursor; 2) mixing the core material graphite and the chain polymer material, and carrying out surface modification treatment to obtain a second precursor; 3) adopting a second precursor and the first precursor of the liquid phase to prepare a composite third precursor through coating treatment, and carry out carbonization to obtain a core-shell structure multi-component composite material. The method of the invention is simple,the process is short, the cost is low, the environment is friendly and pollution-free, and the obtained multi-component composite material has the characteristics of high compaction density, high first reversible capacity and first coulomb efficiency, and excellent processing performance and low temperature performance.

Owner:BTR NEW MATERIAL GRP CO LTD

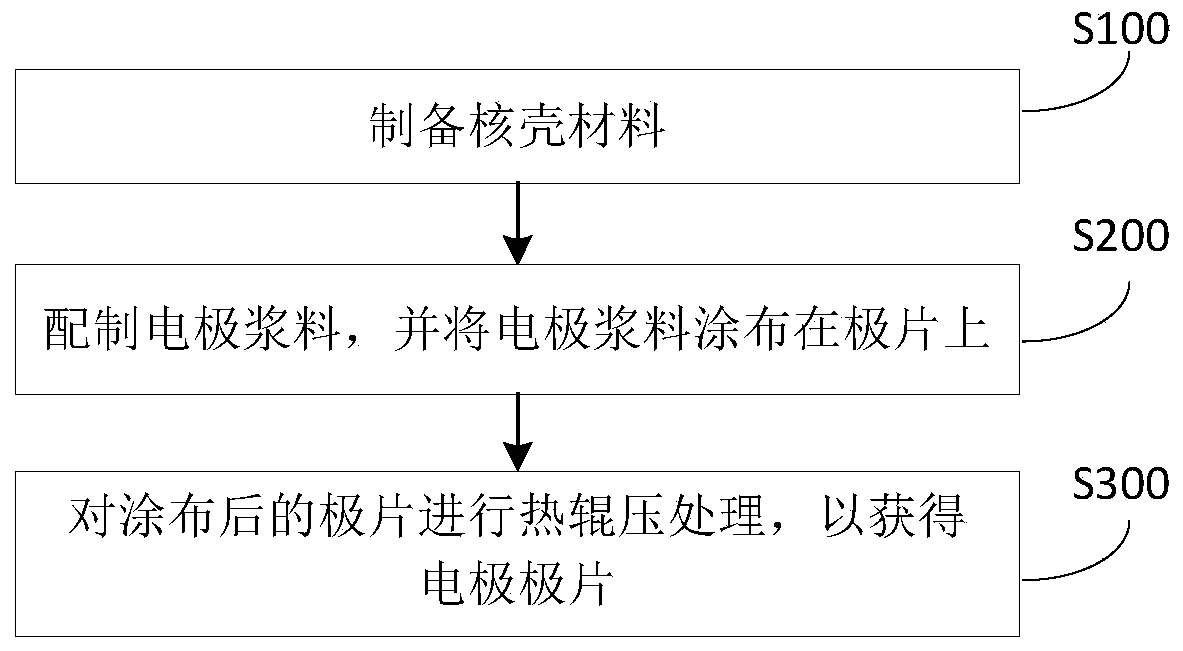

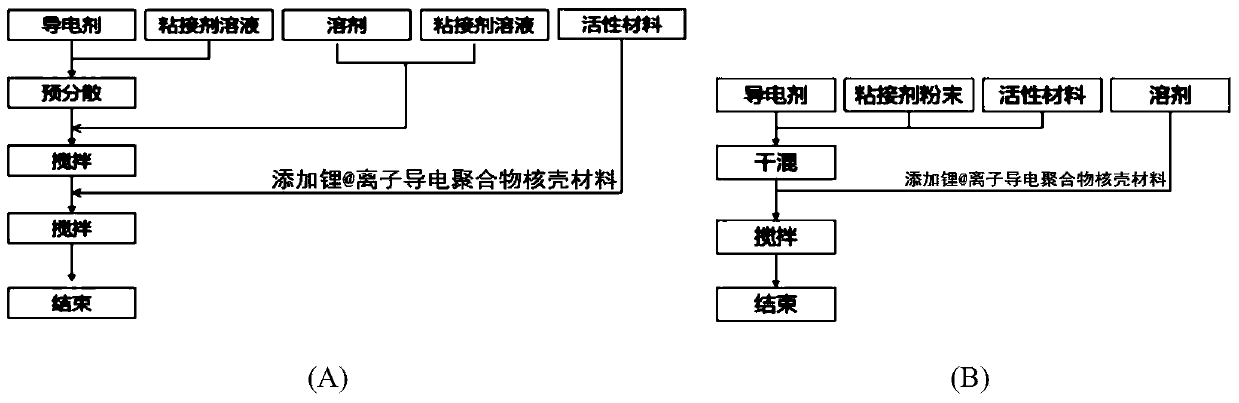

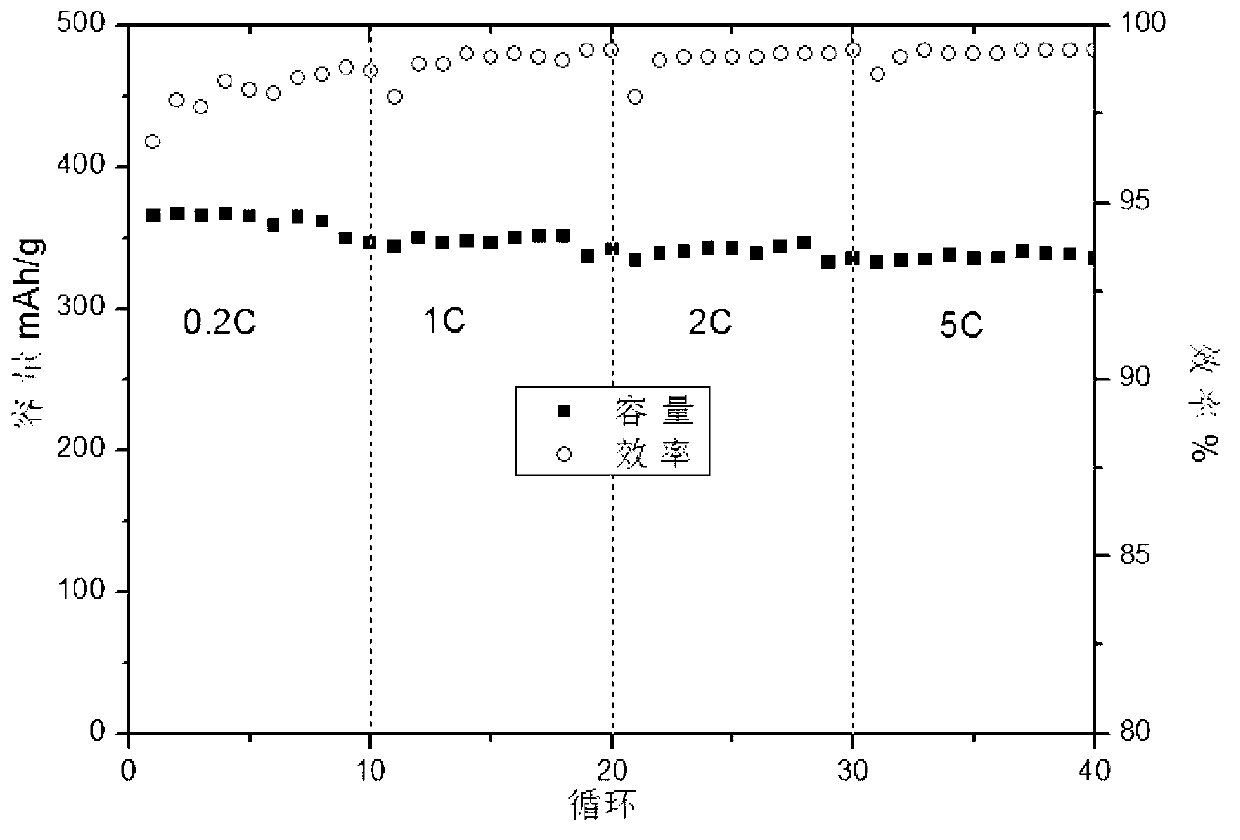

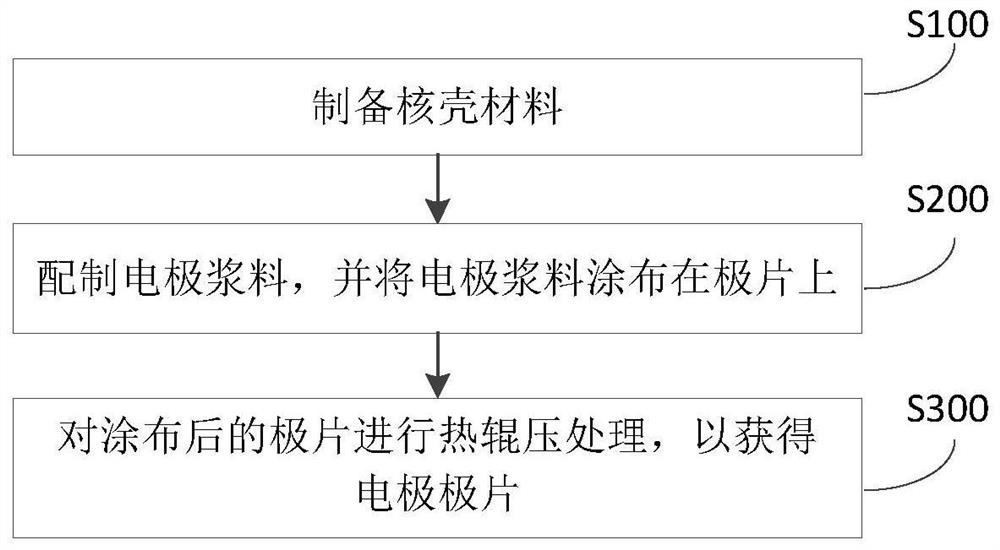

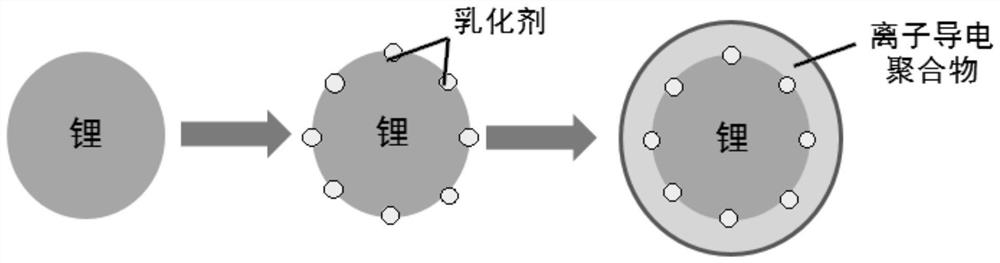

Electrode pole piece, manufacturing method thereof and semi-solid battery

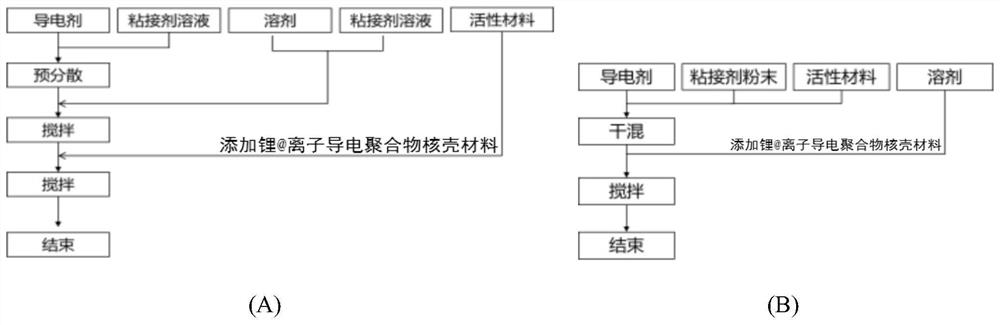

ActiveCN111430674AEvenly dispersedGuaranteed normal migrationElectrode rolling/calenderingElectrode thermal treatmentPolymer electrolytesConductive polymer

The invention provides an electrode pole piece, a manufacturing method thereof and a semi-solid battery. The manufacturing method of the electrode pole piece comprises the following steps of (1) preparing a core-shell material of which the inner core is formed by lithium and the outer shell is formed by an ionic conductive polymer; (2) preparing an electrode slurry, and coating the electrode slurry on a pole piece, the electrode slurry comprising the core-shell material; and (3) carrying out hot rolling treatment on the coated pole piece to obtain the electrode pole piece. According to the manufacturing method of the present invention, firstly, the surfaces of lithium metal particles are coated with the ionic conductive polymer material to form the core-shell material, the core-shell material is added into the electrode pole piece, and is heated and rolled to form the electrode pole piece, so that during the heating and rolling process, the ionic conductive polymer is molten to form alithium ion conductive network, and the polymer electrolyte is more uniformly distributed in the electrode pole piece, and a lithium ion channel is improved, and accordingly the first reversible capacity of the semi-solid battery is improved by supplementing the lithium ions.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

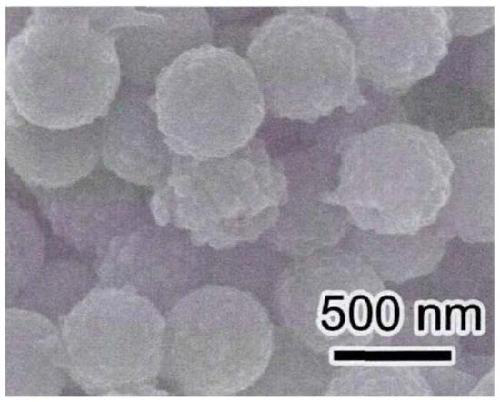

Lithium ion battery cathode material carbon microsphere and preparation method thereof

ActiveCN103274385AClever useControl shapeCell electrodesCarbon preparation/purificationMaterials preparationMicrosphere

The invention discloses a lithium ion battery cathode material carbon microsphere and a preparation method thereof. The preparation method comprises that in the presence of a catalyst, through optimization of condition factors such as a temperature in a reaction vessel system, time and carbon source kinds, a carbon microsphere intermediate having controllable morphology is obtained, and the carbon microsphere intermediate is sintered into a carbon microsphere sample in an inert atmosphere in a tubular furnace. The preparation method ingeniously and efficiently utilizes raw materials, fills the gap of development of a nano-material in lithium ion battery cathode material preparation, enriches a material preparation method, and effectively solves the problem that the existing carbon cathode material of a lithium ion battery has a high first irreversible capacity and poor rate discharge performances.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

Spherical graphite with median diameter of 3 to 10 mu m and preparation method thereof

ActiveCN101850963AImprove securityImprove practicalityVortex flow apparatusGrain treatmentsGraphiteBattery capacity

The invention discloses a preparation method of spherical graphite with a median diameter of 3 to 10 mu m. A five-level powder refining machine set consisting of an air-flow vortex powder refining machine and a cyclone separator is sequentially connected with a fourteen-level nodulizing machine set consisting of an air-flow vortex nodulizing machine and a nodulizing classifier in series; the graphite material enters from the first powder refining machine set and then flows through the five powder refining machine sets and the fourteen nodulizing machine sets in turn and finally out of the last nodulizing machine set; and by refining and nodulizing the powder, the spherical graphite product is obtained. The spherical graphite product has a surface closed end part structure, is spherical, and has the specific surface area of 8.0 to 12 m<2> / g. The number of openings on the surface of the graphite powder is 6-65 per mu m. The sphericity of the product is high; the electrochemical performance is obviously improved; the battery capacity, the standby time and the service life are effectively increased; moreover, the preparation method can improve the yield by over 90 percent, lower the cost by 50 percent, save the power consumption by 60 percent and realize the dust recovery rate up to 100%.

Owner:LUOYANG GUANQI INDAL & TRADE

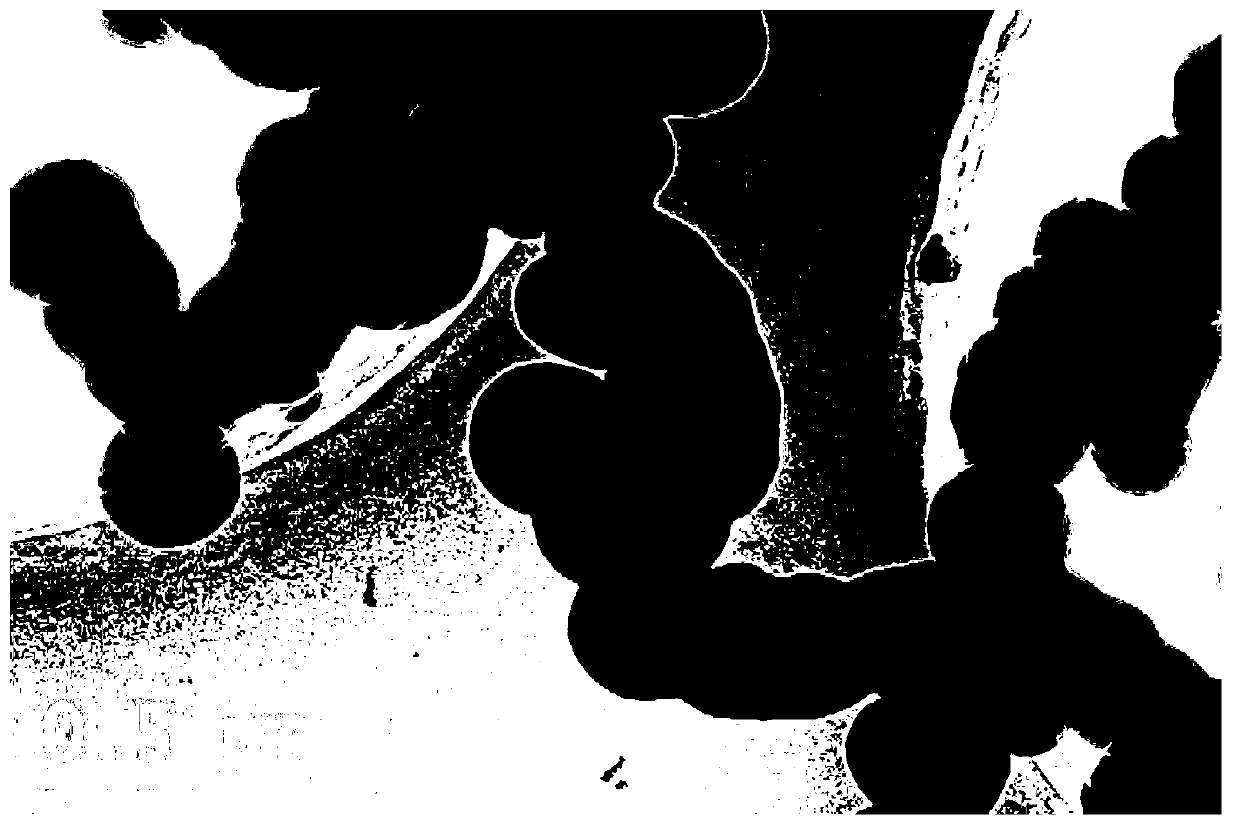

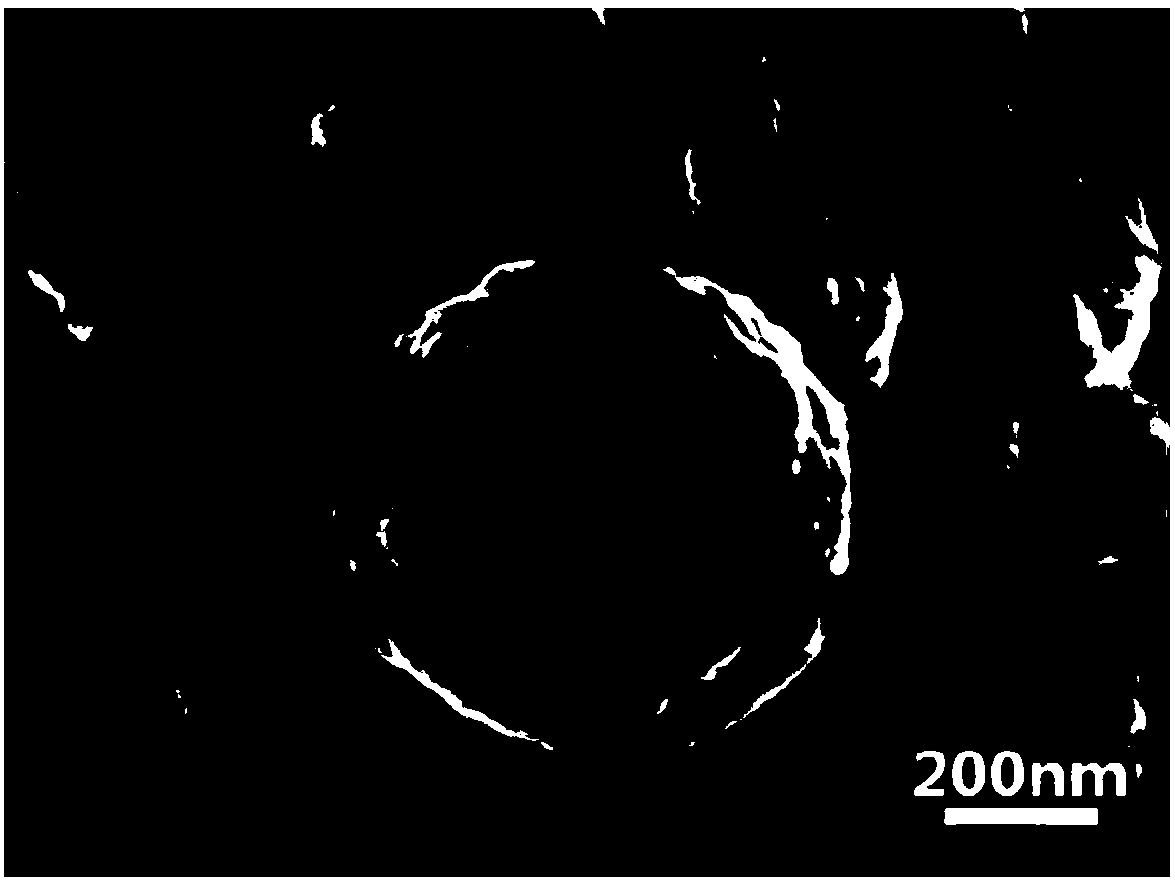

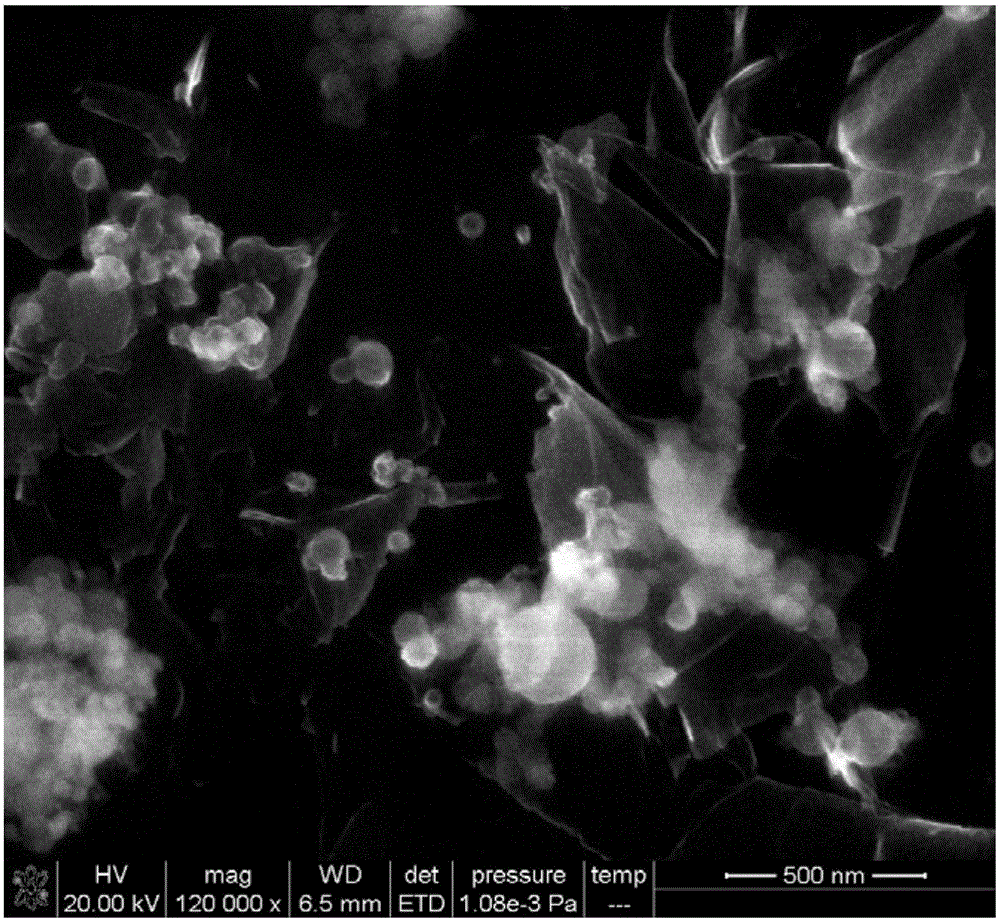

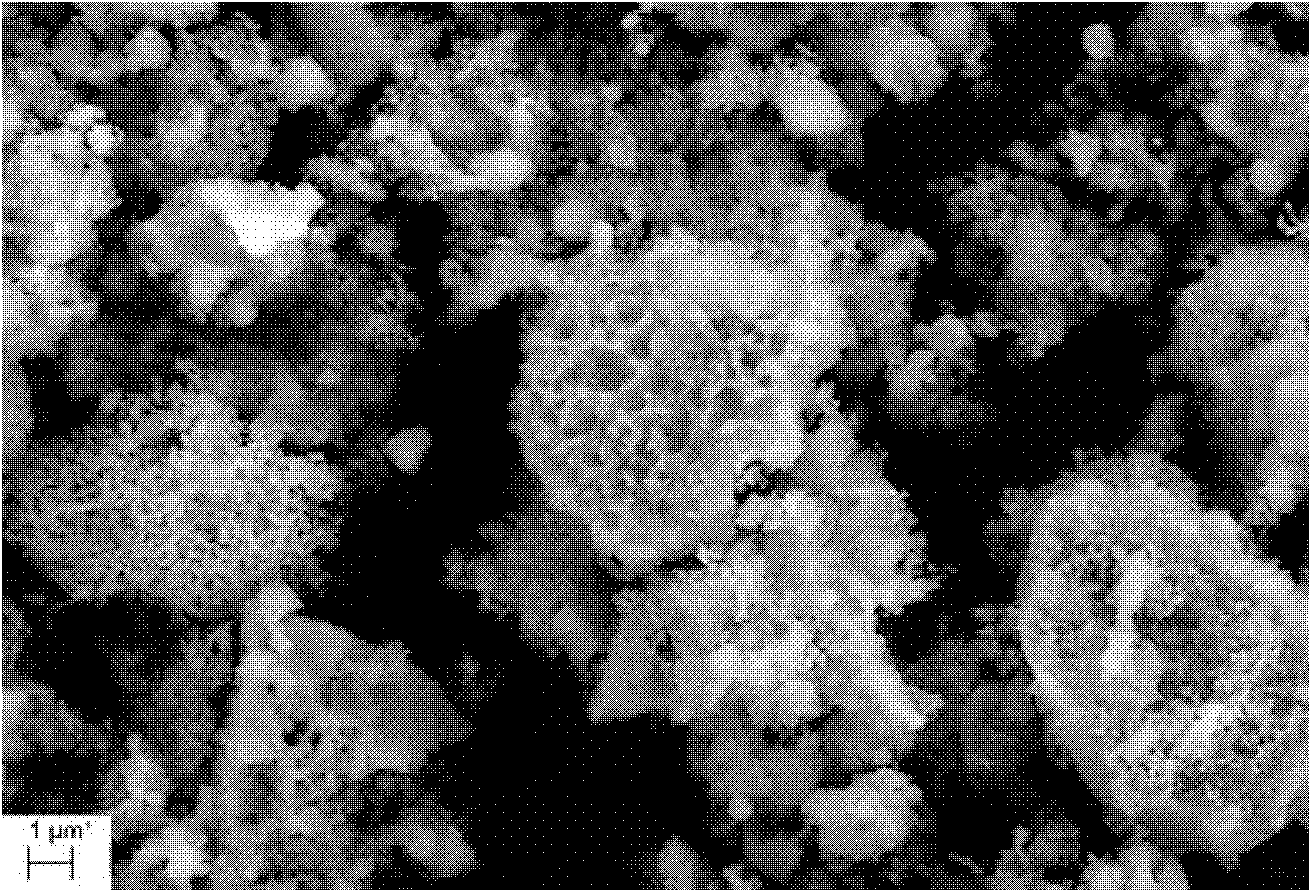

Nano silicon/carbon composite material, preparation method and lithium ion battery containing nano silicon/carbon composite material as negative electrode material

InactiveCN108470899AImprove stabilityGood dispersionCell electrodesSecondary cellsCyclic processCarbon layer

The invention discloses a nano silicon / carbon composite material, a preparation method and a lithium ion battery comprising the same as a negative electrode material. The method comprises: 1) mixing nano silicon, a coupling agent, a conjugated diene, and an olefin monomer; 2) mixing the resulting mixture with water, an emulsifier, an initiator, and a co-surfactant, using a microemulsification method to prepare microemulsion, and using a microemulsion polymerization method to form a crosslinked polymer wrapping material on the surface of the nano silicon; and 3) performing demulsification and carbonization to obtain the nano silicon / carbon composite material. In the nano silicon / carbon composite material, a nano-silicon core and an amorphous conductive carbon layer are very tight and stableto combine, the disadvantages that a general carbon layer and a silicon material are not uniformly wrapped and not tightly combined are solved, the volume expansion of the silicon material during thecycle is suppressed, and the battery prepared from the composite material has excellent cycle performance, and has excellent rate performance and low volume expansion effect.

Owner:BTR NEW MATERIAL GRP CO LTD

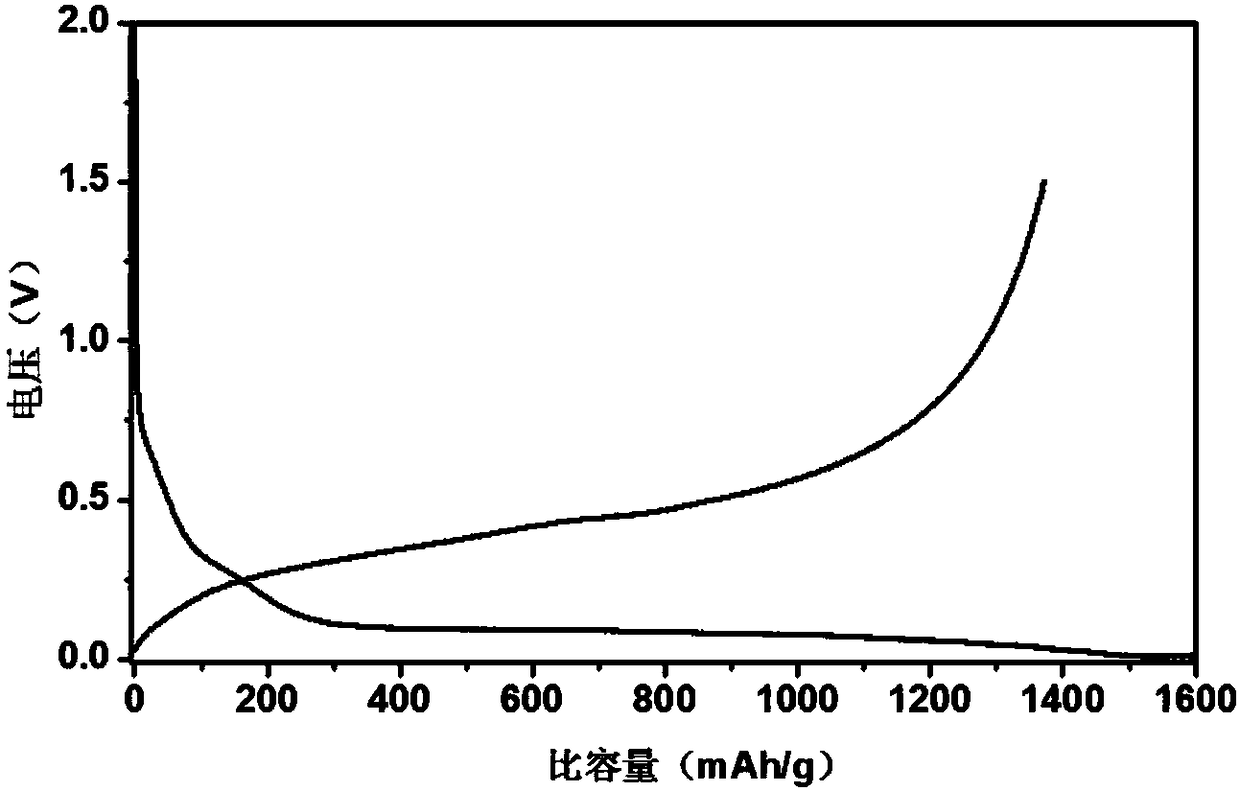

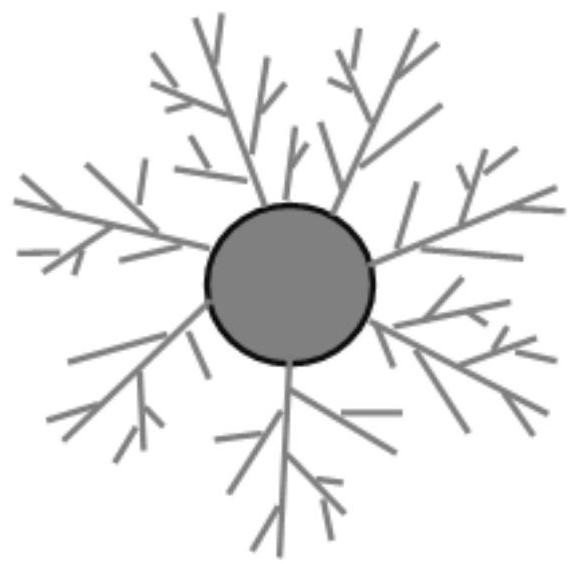

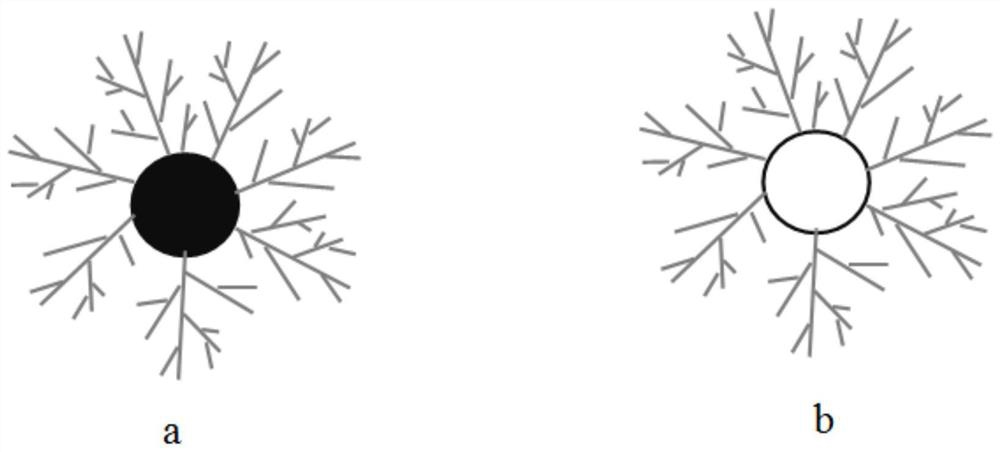

Silicon-carbon composite negative electrode material, negative electrode plate, preparation method thereof and lithium-ion battery

ActiveCN111509212AReduce concentrationIncrease deposition rateElectrode thermal treatmentNegative electrodesCarbon compositesAl powder

The invention belongs to the field of new energy materials, and relates to a silicon-carbon composite negative electrode material, a negative electrode plate, a preparation method thereof and a lithium-ion battery. The preparation method of the silicon-carbon composite negative electrode material comprises the following steps: S1, dispersing phenol and / or aminophenol, formaldehyde and a silicon precursor material into an alcohol-amine mixed aqueous solution, violently stirring and reacting at 20-90 DEG C for at least 20 minutes, carrying out solid-liquid separation, and drying to obtain a silicon dioxide / phenolic aldehyde compound with a fractal structure; and S2, roasting the silicon dioxide / phenolic aldehyde compound in the presence of magnesium powder and / or aluminum powder to obtain the silicon-carbon composite material with the fractal structure. When the silicon-carbon composite material is used as a lithium-ion battery negative electrode material, the failure caused by volume change in the charging and discharging process can be well overcome, a good conductive network is maintained, the volume expansion is reduced, the first reversible capacity and the first coulombic efficiency are improved, the first cycle capacity loss is reduced, and the cycle stability is improved.

Owner:厦门高容纳米新材料科技有限公司

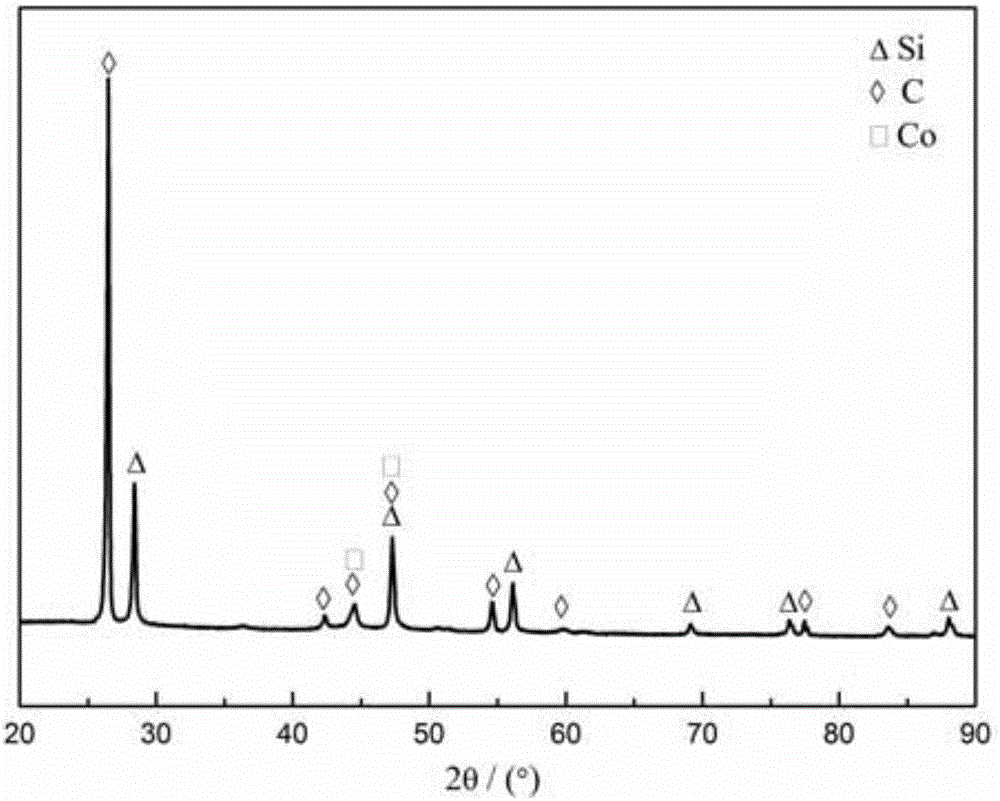

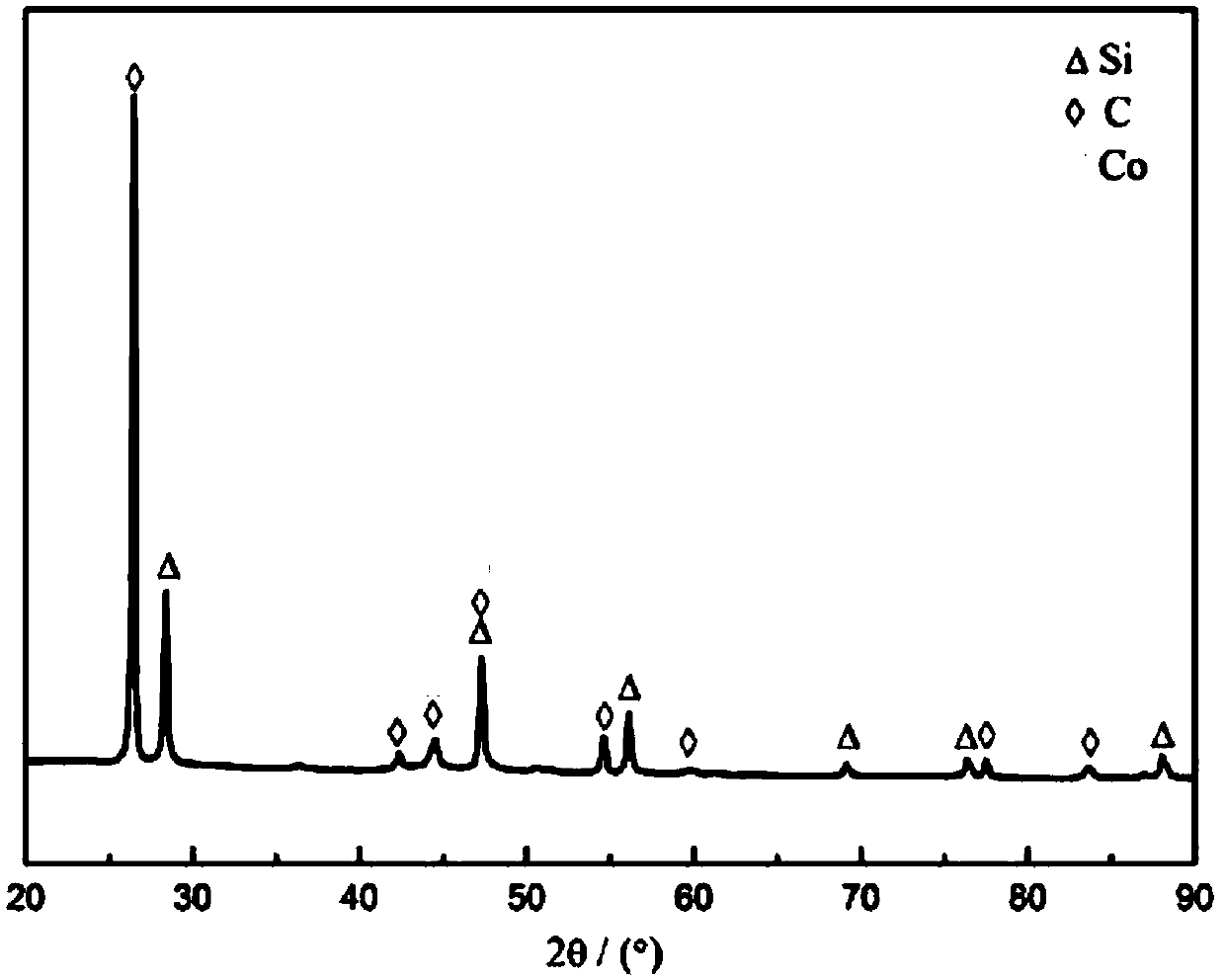

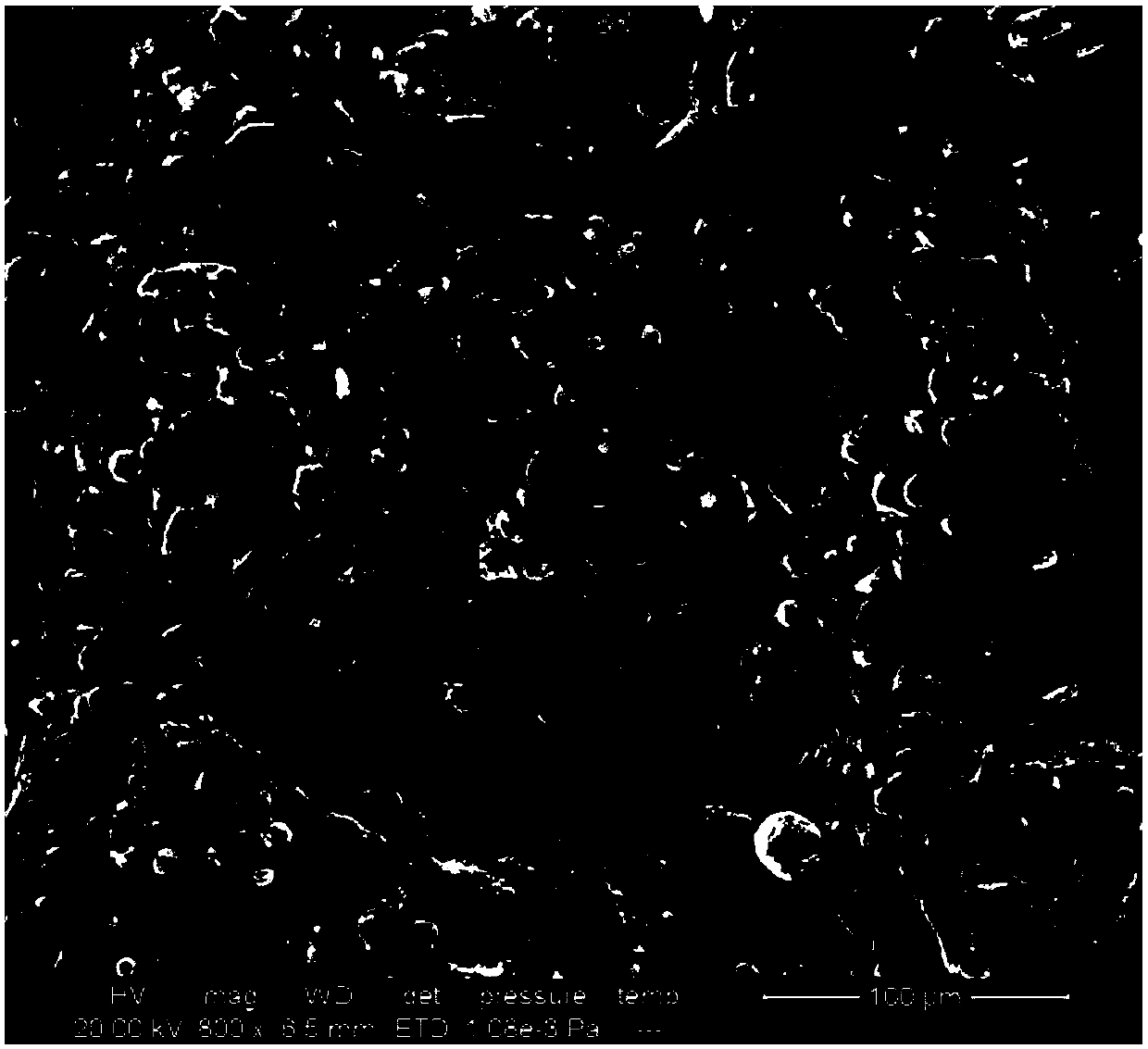

Silicon-cobalt-carbon composite material for negative electrode of lithium ion battery and preparation method of silicon-cobalt-carbon composite material

ActiveCN105742589ASolve the peeling problemIncrease capacityMaterial nanotechnologyCell electrodesCarbon compositesCitrinin hydrate

The invention discloses a silicon-cobalt-carbon composite material for a negative electrode of a lithium ion battery and a preparation method of the silicon-cobalt-carbon composite material. The preparation method comprises the following steps of uniformly dispersing nanometer silicon powder in water to obtain a nanometer silicon powder dispersing solution; adding a cobalt source into the nanometer silicon powder dispersing solution, dissolving the cobalt source, adding citric acid monohydrate, dissolving the citric acid monohydrate, adding graphite, and uniformly mixing the graphite to obtain a mixed solution; adjusting pH of the obtained mixed solution to be 2-5, precipitating a metal cobalt complex wrapping nanometer silicon powder particles from the surface of graphite powder particles to obtain a colloidal solution; carrying out drying and thermal processing on the obtained colloidal solution to obtain the silicon-cobalt-carbon composite material, wherein the mass ratio of the nanometer silicon powder to the cobalt source is (1:1) to (1:2), the mass ratio of the citric acid monohydrate to the cobalt source is (1:1) to (1:2), and the mass ratio of the nanometer silicon powder to graphite is (1:3) to (1:10). The silicon-cobalt-carbon composite material is environmental-friendly and is low in cost, the initial reversible capacity of the battery also can be effectively improved, and the cycle lifetime of the battery can be effectively prolonged.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

Silicon-carbon composite negative electrode material and preparation method thereof, negative electrode sheet and preparation method thereof, and lithium ion battery

ActiveCN111564614AIncrease deposition rateReduce concentrationCell electrodesSecondary cellsCarbon compositesMicrosphere

The invention belongs to the field of new energy materials, and relates to a silicon-carbon composite negative electrode material and a preparation method thereof, a negative electrode sheet and a preparation method thereof, and a lithium ion battery. The preparation method of the silicon-carbon composite negative electrode material comprises the following steps: S1, dispersing hollow silicon dioxide microspheres or a carbon particle material coated with a silicon dioxide layer on the surface, phenol and / or aminophenol, formaldehyde and a silicon precursor material into an alcohol-amine mixedaqueous solution; carrying out a violent stirring reaction at 20-90 DEG C for at least 20 minutes, carrying out solid-liquid separation, and drying to obtain a silicon dioxide / phenolic aldehyde composite material with a fractal structure on the surface; and S2, roasting the silicon dioxide / phenolic aldehyde composite material in the presence of magnesium powder and / or aluminum powder. When the silicon-carbon composite material is used as a lithium ion battery negative electrode material, the failure caused by volume change in the charging and discharging process can be well overcome, a good conductive network is maintained, the volume expansion is reduced, the first reversible capacity and the first coulombic efficiency are improved, the first cycle capacity loss is reduced, and the cyclestability is improved.

Owner:厦门高容纳米新材料科技有限公司

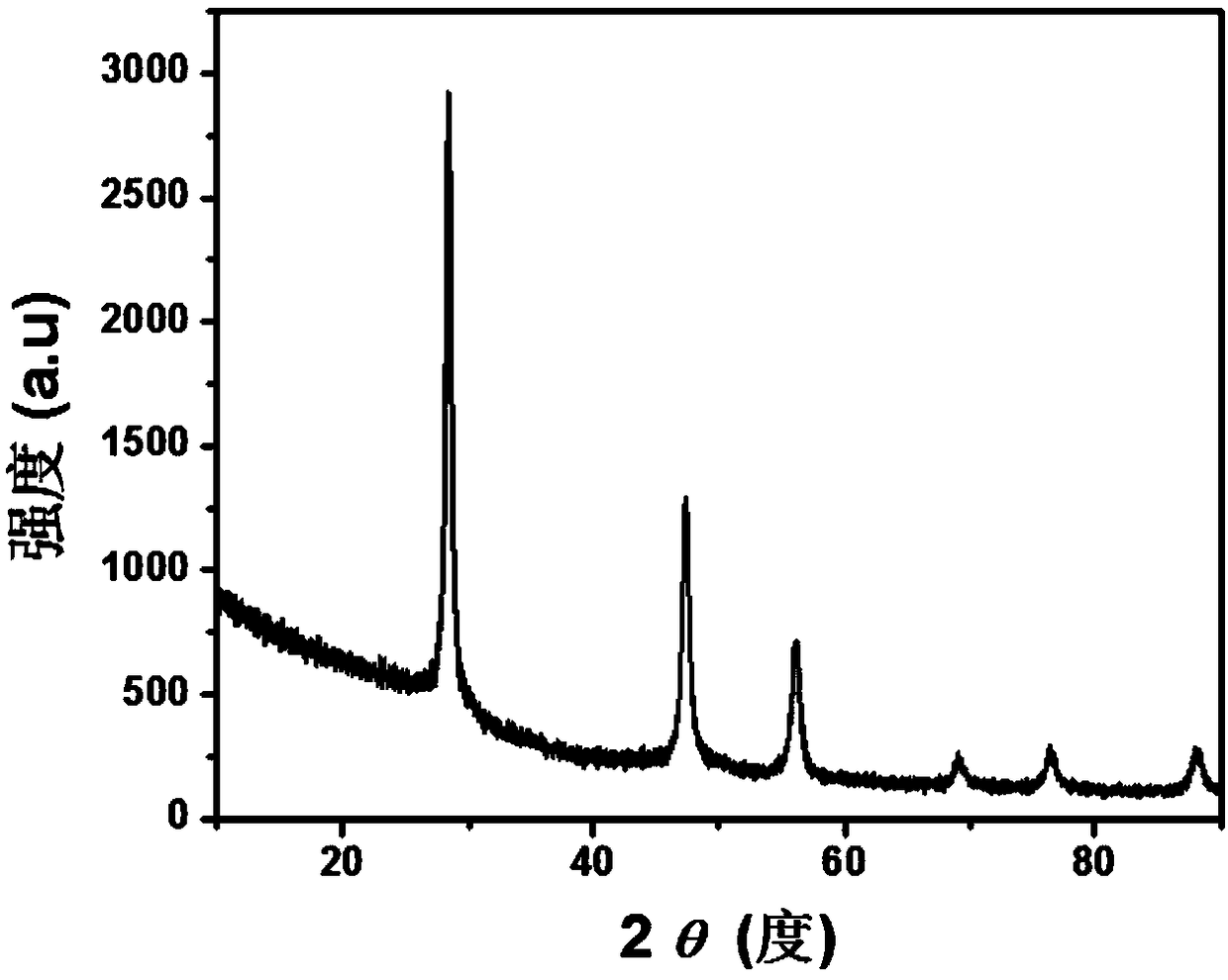

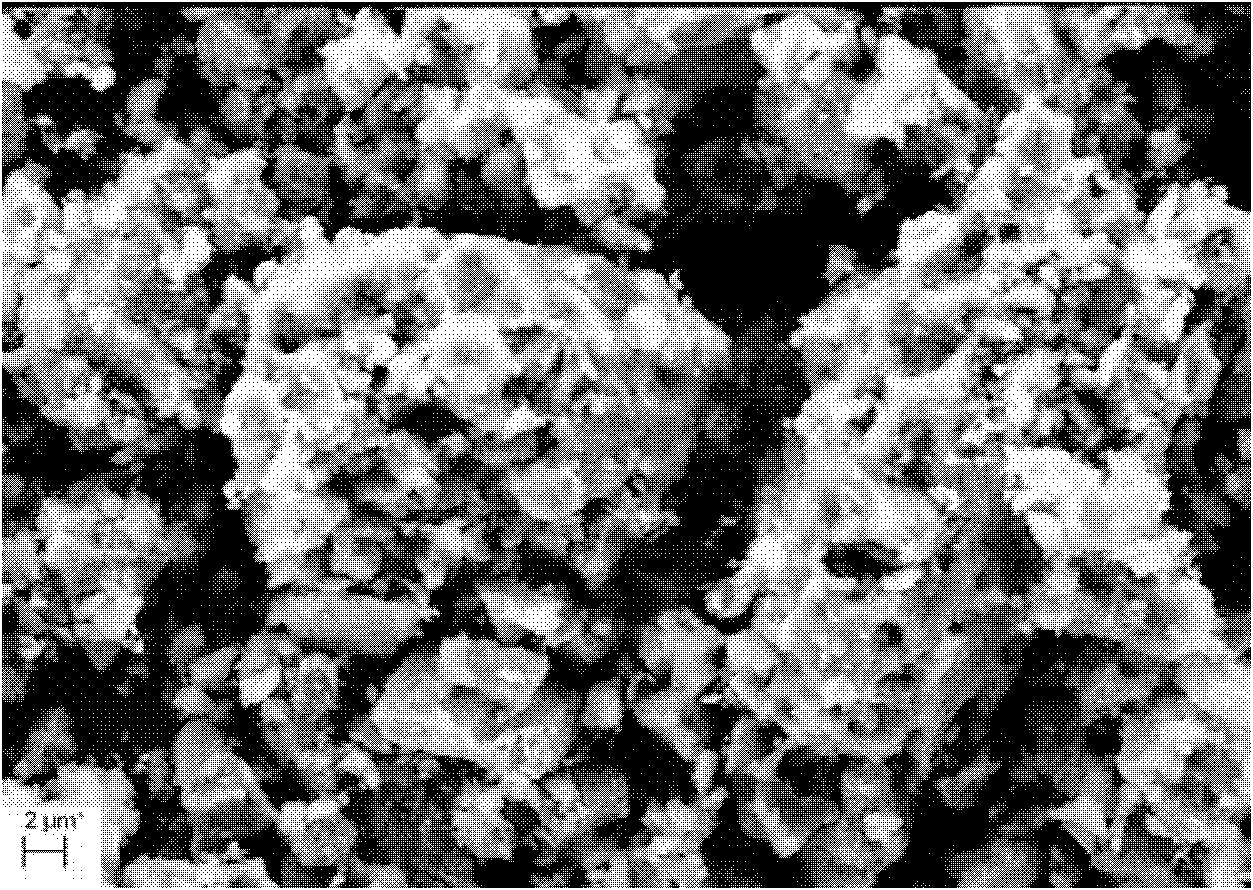

Method for preparing porous silicon/carbon composite material by using diatomite as raw material and application

InactiveCN102208636BUnique pore structureHigh first reversible capacityCell electrodesCarbon compositesChemical vapor deposition

The invention provides a method for preparing a porous silicon / carbon composite material by using diatomite as a raw material. It is characterized by using diatomite as raw material, through simple purification and purification treatment, and then adopting the method of metal thermal reduction to obtain silicon with a porous structure, and then through mechanical ball milling with carbon materials and / or carbon precursors, hydrothermal carbonization, Pyrolytic carbonization, or chemical vapor deposition methods have produced porous silicon / carbon composites. The composite material can be directly used for the negative electrode of the lithium ion battery, and can also be mixed with other negative electrode materials and used as the negative electrode material of the lithium ion battery. Compared with pure silicon material as the anode material of lithium-ion batteries, the material has greatly improved the reversible capacity and cycle stability for the first time. The invention uses cheap and easy-to-obtain natural minerals as raw materials, and has low cost and simple preparation method.

Owner:UNIV OF SCI & TECH BEIJING

Spherical graphite with median diameter of 6 to 14 mu m and preparation method thereof

ActiveCN101850966AIncrease true densityHigh first reversible capacityCell electrodesGraphiteVolumetric Mass Density

The invention discloses a preparation method of spherical graphite with a median diameter of 6 to 14 mu m. A five-level powder refining machine set consisting of an air-flow vortex powder refining machine and a cyclone separator is sequentially connected with a fourteen-level nodulizing machine set consisting of an air-flow vortex nodulizing machine and a nodulizing classifier in series; the graphite material enters from the first powder refining machine set and then flows through the five powder refining machine sets and the fourteen nodulizing machine sets in turn and finally out of the last nodulizing machine set; and by refining and nodulizing the powder, the spherical graphite product is obtained. The spherical graphite product has a surface closed end part structure, is spherical, and has the actual density of 2.28 to 2.3g / cm<3>. The number of openings on the surface of the graphite powder is 9-80 per mu m. The sphericity of the product is high, the electrochemical performance is obviously improved, and the battery capacity, the standby time and the service life are effectively increased; moreover, the preparation method can improve the yield by over 85 percent, lower the cost by 45 percent, save the power consumption by 40 percent and realize the dust recovery rate up to 100%.

Owner:LUOYANG GUANQI INDAL & TRADE

Spherical graphite with median diameter of 17 to 30 mu m and preparation method thereof

ActiveCN101850964AHigh first reversible capacityImprove Coulombic efficiencyCell electrodesBattery capacityFlake graphite

The invention discloses a preparation method of spherical graphite by natural crystalline flake graphite with a median diameter of 3 to 10 mu m. A five-level powder refining machine set consisting of an air-flow vortex powder refining machine and a cyclone separator is sequentially connected with a fourteen-level nodulizing machine set consisting of an air-flow vortex nodulizing machine and a nodulizing classifier in series; the graphite material enters from the first powder refining machine set and then flows through the five powder refining machine sets and the fourteen nodulizing machine sets in turn and finally out of the last nodulizing machine set; and by refining and nodulizing the powder, the spherical graphite product is obtained. The spherical graphite product has a surface closed end part structure, is spherical, and has the specific surface area of 8.0 to 12m2 / g. The number of openings on the surface of the graphite powder is 9-80 per mu m. The sphericity of the product is high; the battery capacity, the standby time and the service life are effectively increased; moreover, the preparation method can improve the yield by over 80 percent, lower the cost by 40 to 50 percent, save the power consumption by 55 percent and realize the dust recovery rate up to 100%.

Owner:LUOYANG GUANQI INDAL & TRADE

Composite nano material and preparation method thereof

ActiveCN110233256AImprove thermal stabilityImprove electronic conductivityMaterial nanotechnologyNegative electrodesElectrical batteryCarbon graphite

The invention provides a composite nano material and a preparation method thereof. The method comprises the following steps of: firstly, obtaining a SnO2 / carbon material and a V2O5 / graphene compositematerial by adopting a hydrothermal synthesis method, and then obtaining the SnO2 / carbon / V2O5 / graphene composite nano material by adopting a ball milling method. The preparation method is simple and easy to operate, and can provide a new way to the controllable synthesis of the multi-component nano composite. The quaternary composite nano material is used as a whole, so that the electronic conductivity of the electrode material is improved, particularly the first reversible capacity and the rate capability are remarkably improved, the charge and discharge performance of the electrode materialunder high rate is enhanced, the discharge capacity of the electrode material is increased, the attenuation of the battery capacity is reduced, the overcharge resistance of the battery is improved, the cycle life of the electrode material is prolonged, and the electrode material has high electrochemical lithium storage capacity, the good stable cycle performance and the less energy loss, and has avery wide application prospect.

Owner:YANGZHOUSRKLE INDAL

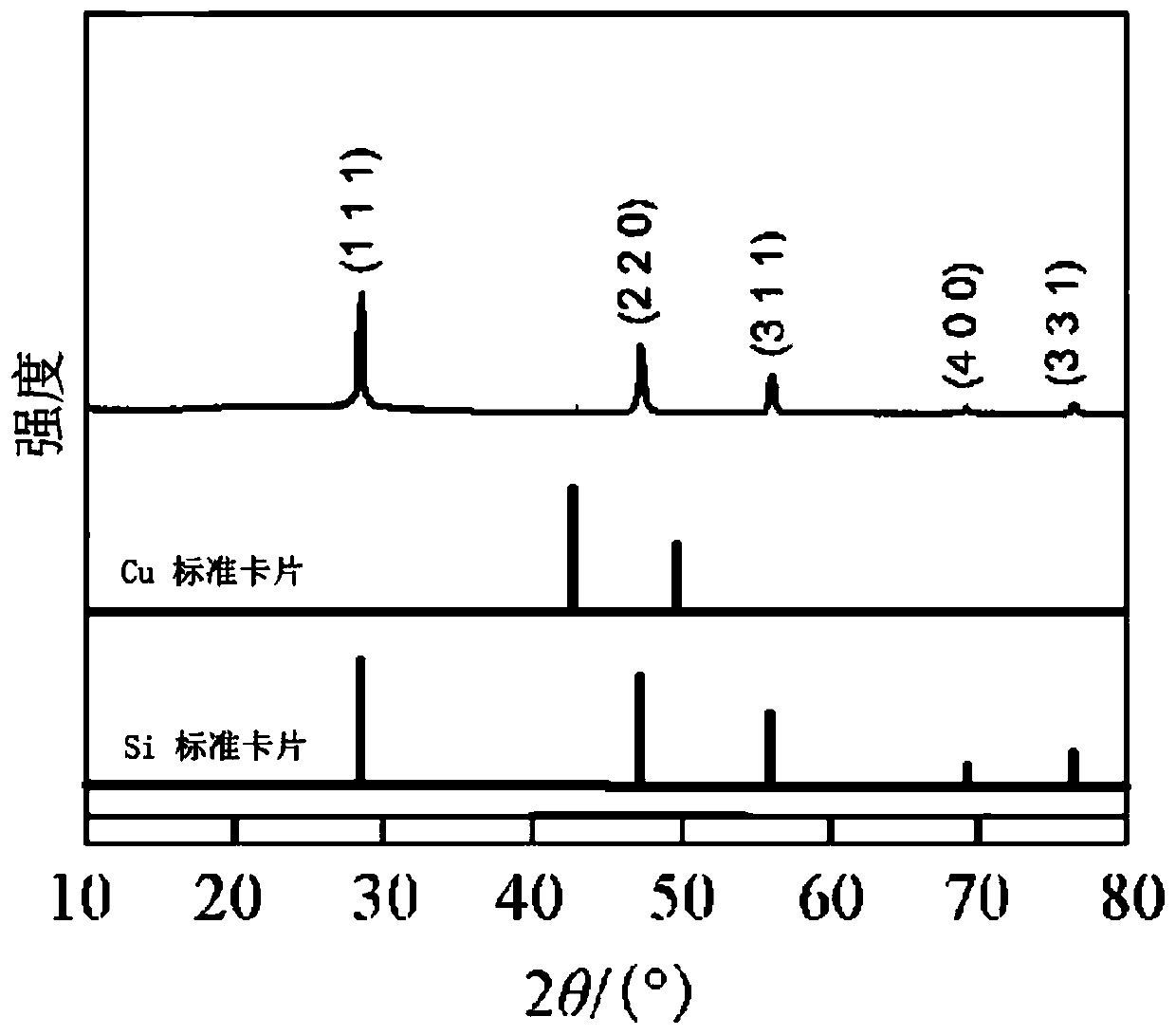

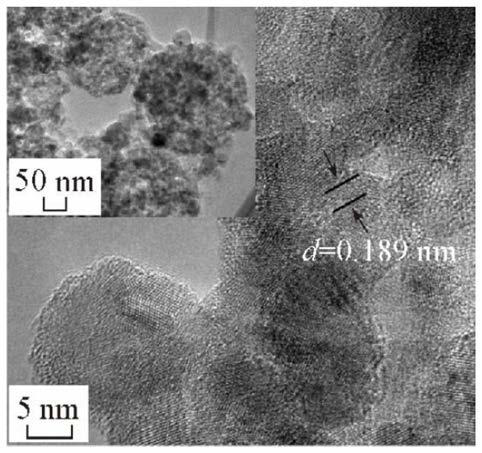

Preparation method of copper-coated porous silicon composite material and composite electrode for lithium ion battery

PendingCN111162259AInhibition of SEI film formationImprove conductivityCell electrodesSecondary cellsLithium electrodeCopper oxide

The invention provides a preparation method of a copper-coated porous silicon composite material and a composite electrode for a lithium ion battery. The preparation method comprises the following steps of S1, preparing a precursor containing silicon dioxide and copper oxide; and S2, treating the precursor by adopting a magnesiothermic reduction method so as to reduce silicon dioxide and copper oxide to form a porous silicon and copper coating layer. By coating copper on the surface of porous silicon, the generation of an SEI film can be effectively inhibited, and meanwhile, the conductivity of the above composite material can be improved, so that the higher first reversible capacity and the coulombic efficiency can be obtained by taking the composite material as an electrode material. Moreover, the porous structure of silicon buffers the volume expansion, and the coating of a proper amount of copper can effectively improve the conductivity of the material and form a proper amount of silicon-copper alloy supported porous skeleton structure, so that the composite material can keep higher reversible capacity and capacity retention ratio after being used as the electrode material.

Owner:NORTHERN ALTAIR NANOTECH CO LTD +1

Spherical graphite with median diameter of 17 to 30 mu m and preparation method thereof

ActiveCN101850964BHigh first reversible capacityImprove Coulombic efficiencyCell electrodesBattery capacityFlake graphite

The invention discloses a preparation method of spherical graphite by natural crystalline flake graphite with a median diameter of 3 to 10 mu m. A five-level powder refining machine set consisting of an air-flow vortex powder refining machine and a cyclone separator is sequentially connected with a fourteen-level nodulizing machine set consisting of an air-flow vortex nodulizing machine and a nodulizing classifier in series; the graphite material enters from the first powder refining machine set and then flows through the five powder refining machine sets and the fourteen nodulizing machine sets in turn and finally out of the last nodulizing machine set; and by refining and nodulizing the powder, the spherical graphite product is obtained. The spherical graphite product has a surface closed end part structure, is spherical, and has the specific surface area of 8.0 to 12m2 / g. The number of openings on the surface of the graphite powder is 9-80 per mu m. The sphericity of the product is high; the battery capacity, the standby time and the service life are effectively increased; moreover, the preparation method can improve the yield by over 80 percent, lower the cost by 40 to 50 percent, save the power consumption by 55 percent and realize the dust recovery rate up to 100%.

Owner:LUOYANG GUANQI INDAL & TRADE

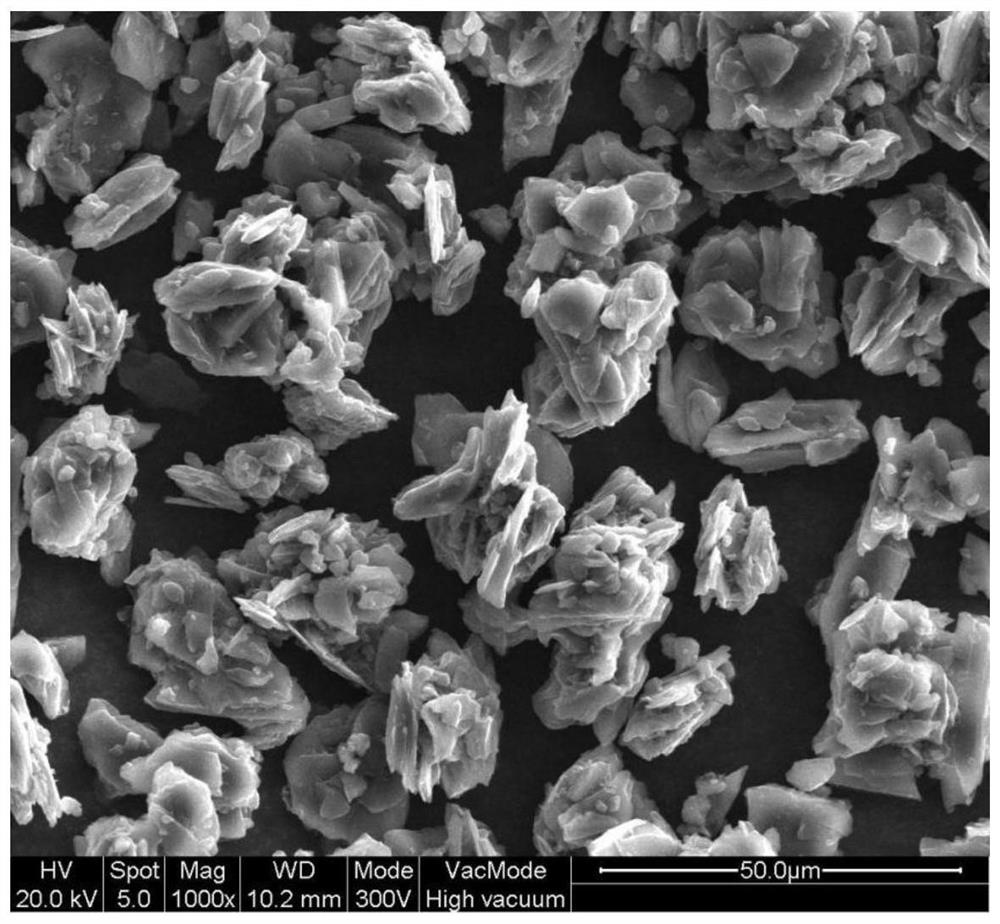

Silicon-carbon multi-component composite negative electrode material and preparation method thereof

ActiveCN104037396BIncrease the attachment areaIncrease energy densityCell electrodesSecondary cellsCarbon compositesGraphite

The invention relates to a carbon-carbon multi-component negative electrode material. The carbon-carbon multi-component negative electrode material is mainly composed of flexible graphite, nanometer silicon and amorphous carbon which respectively account for 30-60%, 30-50% and 10-30% based on mass percent, the amorphous carbon is obtained through high-temperature pyrolyzation of an organic carbon source, and the flexible graphite is obtained by applying pressure to expanded graphite. A preparation method of the product comprises the steps of: firstly, preparing an expanded graphite / silicon-silicon dioxide / carbon composite negative electrode material through high-temperature pyrolyzation; secondly, pouring the expanded graphite / silicon-silicon dioxide / carbon composite negative electrode material into a mould and applying pressure to obtain a flexible graphite / silicon-silicon dioxide / carbon composite negative electrode material; thirdly, processing silicon dioxide to obtain a flexible graphite / silicon / carbon composite negative electrode material through etching by a corrosive liquid; and finally, using asphalt to permeate a gap inside the flexible graphite / silicon / carbon composite negative electrode material in a protective atmosphere, and obtaining the product after high-temperature heat treatment and repetition. The carbon-carbon multi-component negative electrode material has the advantages of high capacity, high coulombic efficiency, good cycle performance, structure stability, high reversible capacity and the like.

Owner:CENT SOUTH UNIV

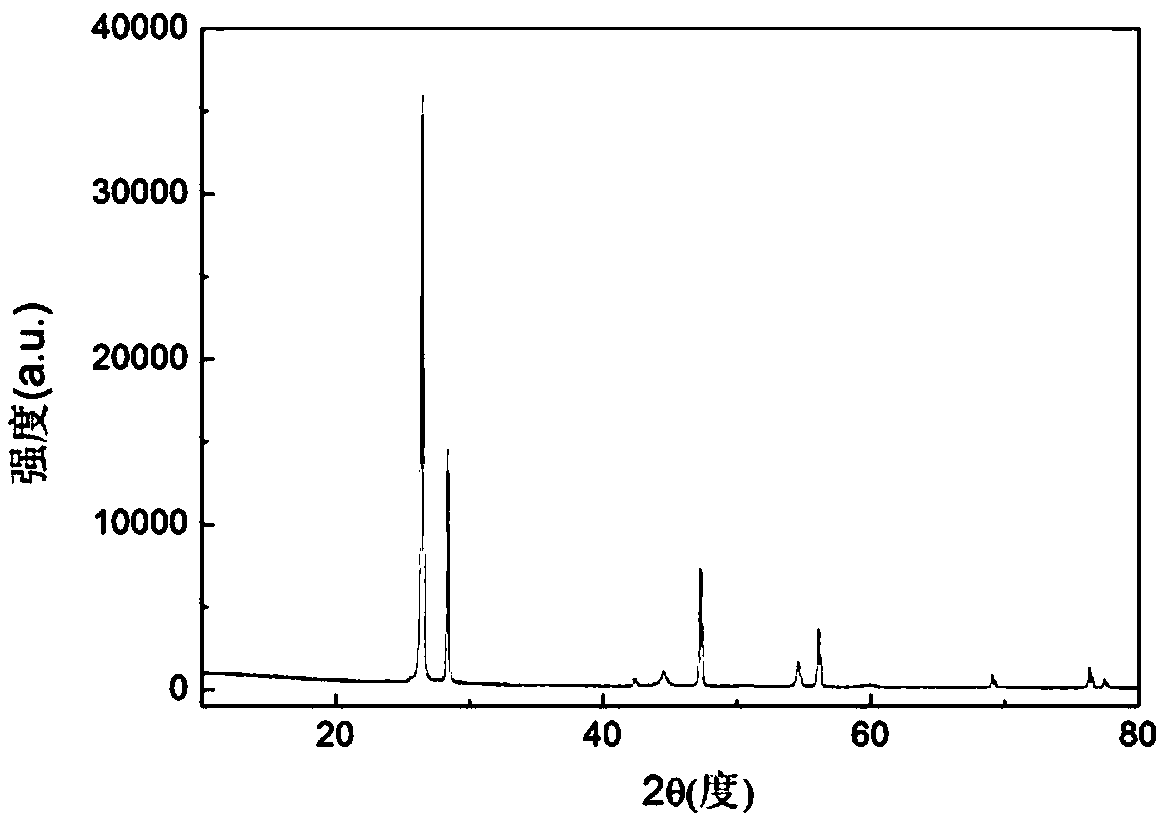

TiO2 (B) negative electrode material as well as preparation method and application thereof

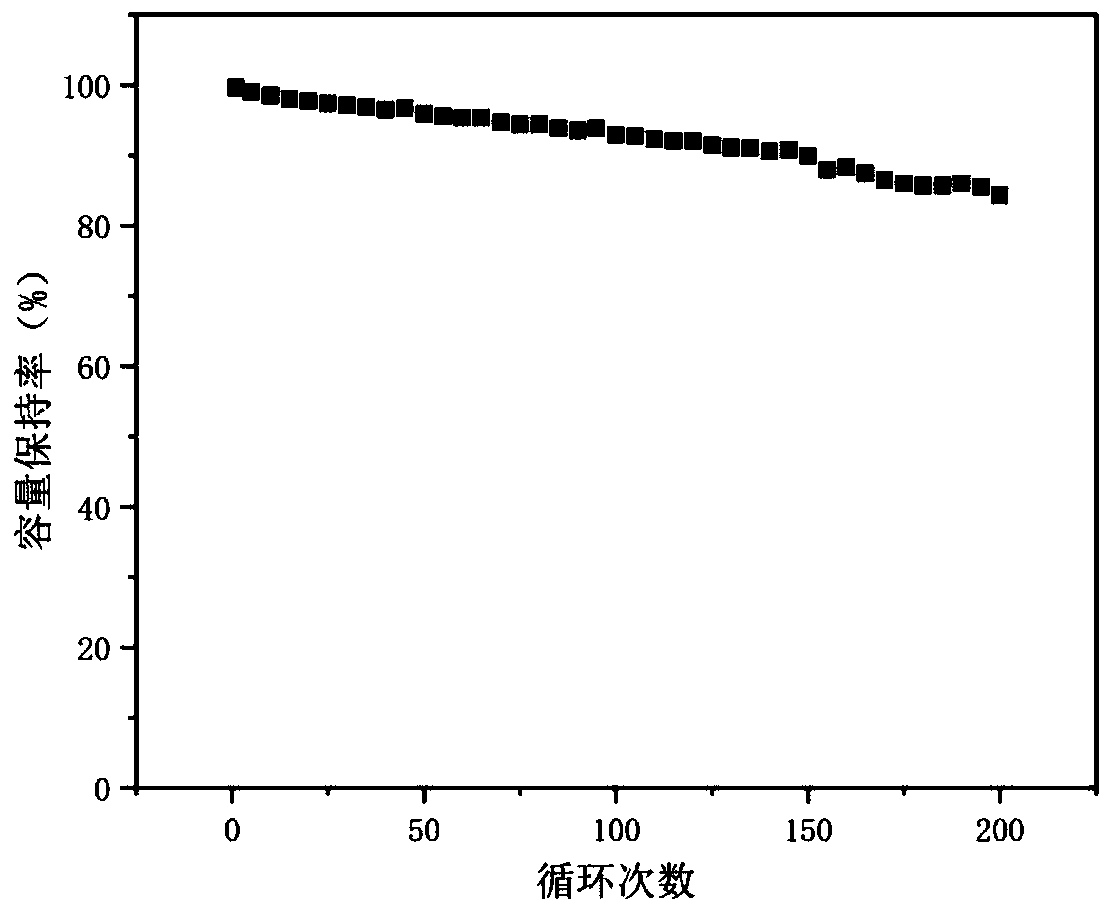

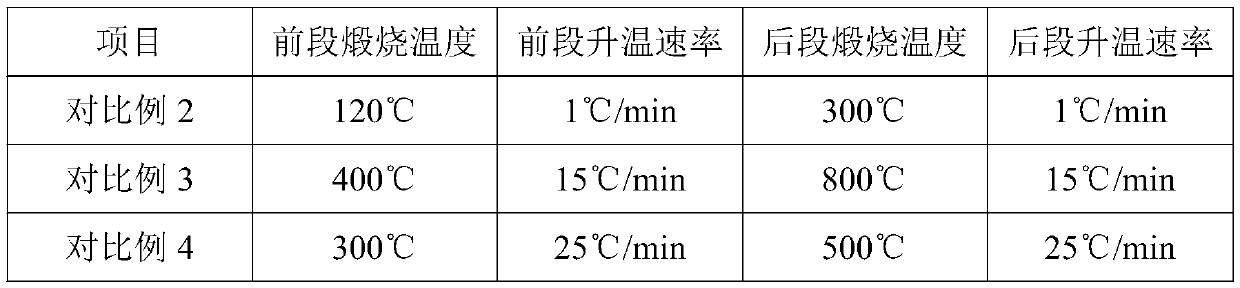

InactiveCN110444755AHigh first reversible capacityHigh specific capacityCell electrodesSecondary cellsAlcoholSolvent

The invention discloses a TiO2 (B) negative electrode material as well as a preparation method and an application thereof; the preparation method of the TiO2 (B) negative electrode material comprisesthe following steps of S1, mixing a solvent with a titanium source, carrying out heating and refluxing, adding water, cooling, and dropwise adding acetone to obtain a white precipitate; and S2, carrying out alcohol washing and / or water washing on the white precipitate in the step S1 and then performing vacuum drying and calcining to obtain the negative electrode material, wherein the calcining adopts segmented calcining. The first reversible capacity of the prepared negative electrode material is as high as 190 mAh / g or above, the first coulombic efficiency is higher than 82%, the capacity retention rate after being circulated for 200 cycles is 82-94%, and the negative electrode material has the advantages of high cycle performance and high specific capacity. The TiO2 (B) negative electrode material prepared by adopting a solvothermal method is high in purity, the preparation method is simple, the conditions are easy to control, the preparation period is short, the cost is low and theapplication value is high.

Owner:SHENZHEN HYUTEEN NEW ENERGY CO LTD

A kind of silicon-cobalt-carbon composite material for negative electrode of lithium ion battery and preparation method thereof

ActiveCN105742589BSolve the peeling problemIncrease capacityMaterial nanotechnologyCell electrodesCarbon compositesNano silicon

The invention discloses a silicon-cobalt-carbon composite material for a negative electrode of a lithium ion battery and a preparation method of the silicon-cobalt-carbon composite material. The preparation method comprises the following steps of uniformly dispersing nanometer silicon powder in water to obtain a nanometer silicon powder dispersing solution; adding a cobalt source into the nanometer silicon powder dispersing solution, dissolving the cobalt source, adding citric acid monohydrate, dissolving the citric acid monohydrate, adding graphite, and uniformly mixing the graphite to obtain a mixed solution; adjusting pH of the obtained mixed solution to be 2-5, precipitating a metal cobalt complex wrapping nanometer silicon powder particles from the surface of graphite powder particles to obtain a colloidal solution; carrying out drying and thermal processing on the obtained colloidal solution to obtain the silicon-cobalt-carbon composite material, wherein the mass ratio of the nanometer silicon powder to the cobalt source is (1:1) to (1:2), the mass ratio of the citric acid monohydrate to the cobalt source is (1:1) to (1:2), and the mass ratio of the nanometer silicon powder to graphite is (1:3) to (1:10). The silicon-cobalt-carbon composite material is environmental-friendly and is low in cost, the initial reversible capacity of the battery also can be effectively improved, and the cycle lifetime of the battery can be effectively prolonged.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

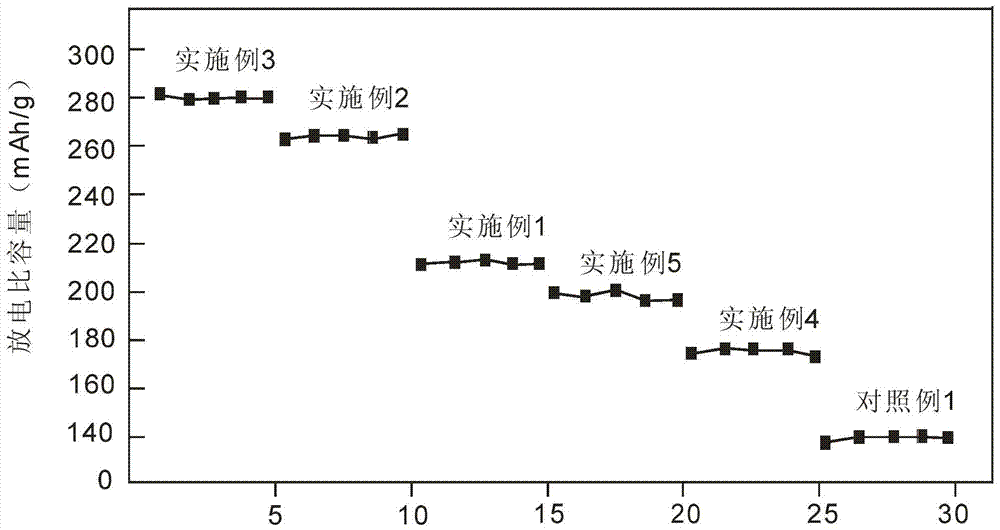

Sulfonated graphene metal salt and its preparation method and application

ActiveCN105366644BWide variety of sourcesHigh first reversible capacityOxide/hydroxide preparationMicrometerSulfur

The invention discloses sulfonated graphene metal salt and a preparation method and application thereof. The sulfonated graphene metal salt is mainly prepared from sulfonated graphene through a reaction of sulfonyl of the sulfonated graphene and a metal compound; the radial dimension of the sulfonated graphene is between 0.05 micrometer and 100 micrometers, the thickness is between 0.5 nanometer and 20 nanometers, the carbon-sulfur molar ratio of the sulfonyl content is between 3 to 1 and 12 to 1, and the molar ratio of sulfonate radicals in the sulfonated graphene to metal elements in the metal compound is between 1 to 1 and 5 to 1. The sulfonated graphene metal salt can be used as an electrode material in an energy storing device, the capacity of the sulfonated graphene metal salt can be between 173 mAh / g and 282 mAh / g, and therefore the sulfonated graphene metal salt has a wide application prospect in manufacture of electrochemical and / or physical energy storing devices; moreover, the preparation process is simple and easy to implement and control, reaction conditions are mild, raw material sources are wide, and large-scale production is facilitated.

Owner:SUZHOU GRAPHENE NEW MATERIAL TECH

A silicon carbon composite negative electrode material and negative electrode sheet, its preparation method and lithium ion battery

ActiveCN111509212BReduce concentrationIncrease deposition rateElectrode thermal treatmentNegative electrodesCarbon compositesAl powder

The invention belongs to the field of new energy materials, and relates to a silicon-carbon composite negative electrode material and a negative electrode sheet, a preparation method thereof, and a lithium ion battery. The preparation method of the silicon-carbon composite negative electrode material includes: S1, dispersing phenol and / or aminophenol, formaldehyde and silicon precursor material in an alcohol-amine mixed aqueous solution, vigorously stirring the reaction at 20-90 ° C for at least 20 minutes, solid-liquid Separating and drying to obtain a silica / phenolic composite with a fractal structure; S2, calcining the silica / phenolic composite in the presence of magnesium powder and / or aluminum powder to obtain a silicon-carbon composite material with a fractal structure. When the silicon-carbon composite material is used as a negative electrode material for lithium-ion batteries, it can well overcome the failure caused by the volume change during charging and discharging, maintain a good conductive network, reduce volume expansion, improve the first reversible capacity and the first Coulomb efficiency, reduce the First cycle capacity loss and improved cycle stability.

Owner:厦门高容纳米新材料科技有限公司

Hard carbon/graphite composite negative electrode material, lithium ion battery, preparation method and application thereof

ActiveCN111244407BHigh electron mobilityImprove conductivityCell electrodesSecondary cellsElectrolytic agentElectrical battery

The invention discloses a preparation method of a hard carbon / graphite composite negative electrode material, which comprises the following steps: S1: performing a crosslinking reaction on a hard carbon carbon source to obtain a hard carbon precursor, wherein the hard carbon carbon source is a thermoplastic polymer compound Or non-thermoplastic polymer compound; S2: dry after mixing graphite, hard carbon precursor and additive in liquid phase; S3: pre-carbonization treatment, carbonization treatment; S4: surface coating treatment. The hard carbon / graphite composite negative electrode material prepared by the preparation method has good adaptability to electrolyte and other additives, and the lithium-ion battery prepared by using it has high capacity, good rate performance and cycle performance, and the preparation method is simple and easy to operate, and the raw materials It has wide sources and low cost, and has broad application prospects.

Owner:SHANGHAI SHANSHAN TECH CO LTD

Spherical graphite with median diameter of 6-14 μm and preparation method thereof

ActiveCN101850966BIncrease true densityHigh first reversible capacityCell electrodesGraphiteBattery capacity

The invention discloses a preparation method of spherical graphite with a median diameter of 6 to 14 mu m. A five-level powder refining machine set consisting of an air-flow vortex powder refining machine and a cyclone separator is sequentially connected with a fourteen-level nodulizing machine set consisting of an air-flow vortex nodulizing machine and a nodulizing classifier in series; the graphite material enters from the first powder refining machine set and then flows through the five powder refining machine sets and the fourteen nodulizing machine sets in turn and finally out of the last nodulizing machine set; and by refining and nodulizing the powder, the spherical graphite product is obtained. The spherical graphite product has a surface closed end part structure, is spherical, and has the actual density of 2.28 to 2.3g / cm<3>. The number of openings on the surface of the graphite powder is 9-80 per mu m. The sphericity of the product is high, the electrochemical performance is obviously improved, and the battery capacity, the standby time and the service life are effectively increased; moreover, the preparation method can improve the yield by over 85 percent, lower the cost by 45 percent, save the power consumption by 40 percent and realize the dust recovery rate up to 100%.

Owner:LUOYANG GUANQI INDAL & TRADE

Electrode pole piece and method of making the same, semi-solid battery

ActiveCN111430674BEvenly dispersedGuaranteed normal migrationElectrode rolling/calenderingElectrode thermal treatmentPolymer electrolytesConductive polymer

The invention proposes an electrode pole piece, a manufacturing method thereof, and a semi-solid battery. The method for making an electrode sheet includes: (1) preparing a core-shell material, wherein the inner core of the core-shell material is formed of lithium and the outer shell is formed of an ion-conducting polymer; (2) preparing an electrode slurry, and coating the electrode slurry with cloth on the pole piece, wherein the electrode slurry includes the core-shell material; (3) the coated pole piece is subjected to hot rolling treatment to obtain the electrode pole piece. In the production method proposed by the present invention, the surface of the lithium metal particles is firstly coated with an ion conductive polymer material to form a core-shell material, and the core-shell material is added to the electrode pole piece and heated and rolled to form the electrode pole piece. During the process, the ion-conducting polymer is melted to form a lithium-ion conductive network, and the polymer electrolyte is more uniformly distributed in the electrode plates, which improves the lithium-ion channel, thereby improving the first reversible capacity of the semi-solid battery by replenishing lithium ions.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

A silicon carbon composite negative electrode material and negative electrode sheet, preparation method thereof, and lithium ion battery

ActiveCN111564614BIncrease deposition rateReduce concentrationCell electrodesSecondary cellsCarbon compositesAl powder

Owner:厦门高容纳米新材料科技有限公司

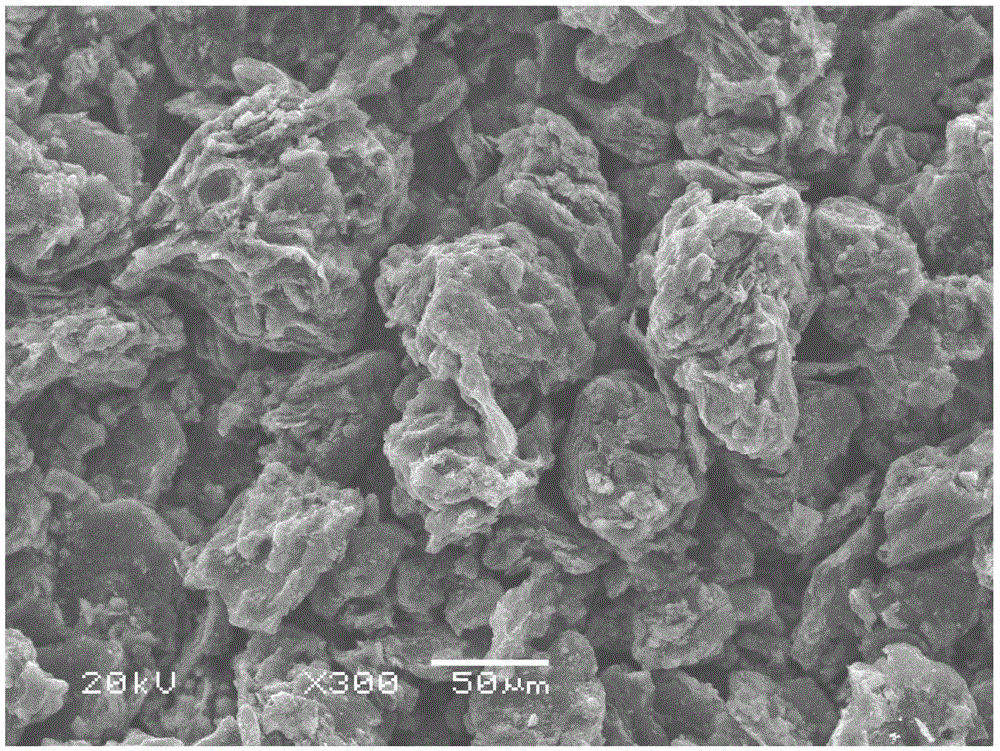

Composite negative electrode material for lithium ion battery, and preparation method thereof

InactiveCN112968169AHigh first reversible capacityImprove low temperature performanceGraphiteCell electrodesLithium electrodeCarbon particle

The invention relates to a composite negative electrode material for a lithium ion battery, and a preparation method thereof. The composite negative electrode material comprises hard carbon particles and graphite particles, the hard carbon particles and the graphite particles are uniformly dispersed, and the hard carbon particles are obtained by carrying out high temperature sintering operation, mechanical shaping operation and surface coating operation on a carbon raw material. The hard carbon particles and the graphite particles are compounded and have complementary performance advantages, so that the rate capability and the low-temperature performance of the composite material are improved, and meanwhile, the first efficiency, the high-temperature performance and the storage performance of the composite material can be ensured; and when the composite negative electrode material provided by the invention is used as a negative electrode active material of the lithium ion battery, the lithium ion battery has excellent rate capability, the raw materials are cheap, the preparation process and equipment are mature, and the composite negative electrode material is suitable for large-scale production.

Owner:赣州立探新能源科技有限公司

Spherical graphite with a median diameter of 3-10 μm and its preparation method

ActiveCN101850963BImprove securityImprove practicalityVortex flow apparatusGrain treatmentsGraphiteSphericity

Owner:LUOYANG GUANQI INDAL & TRADE

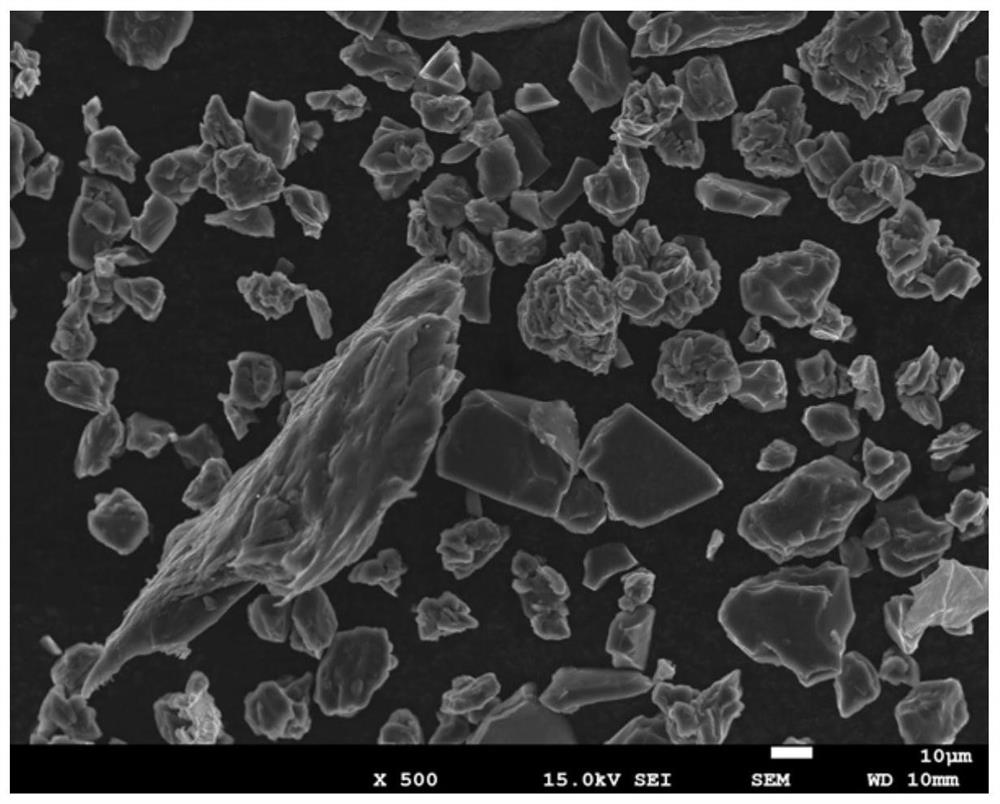

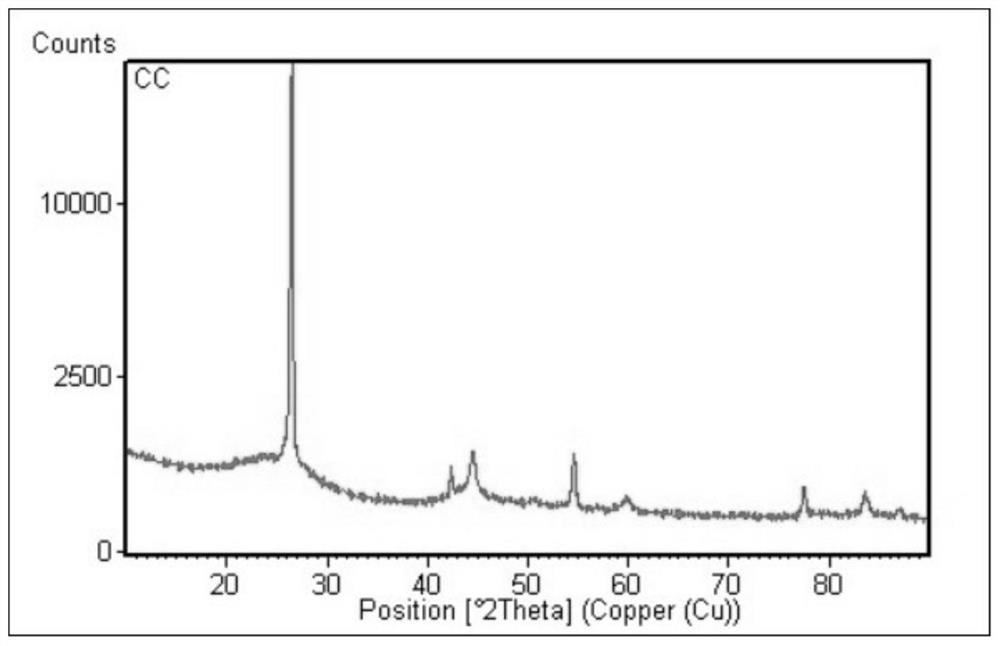

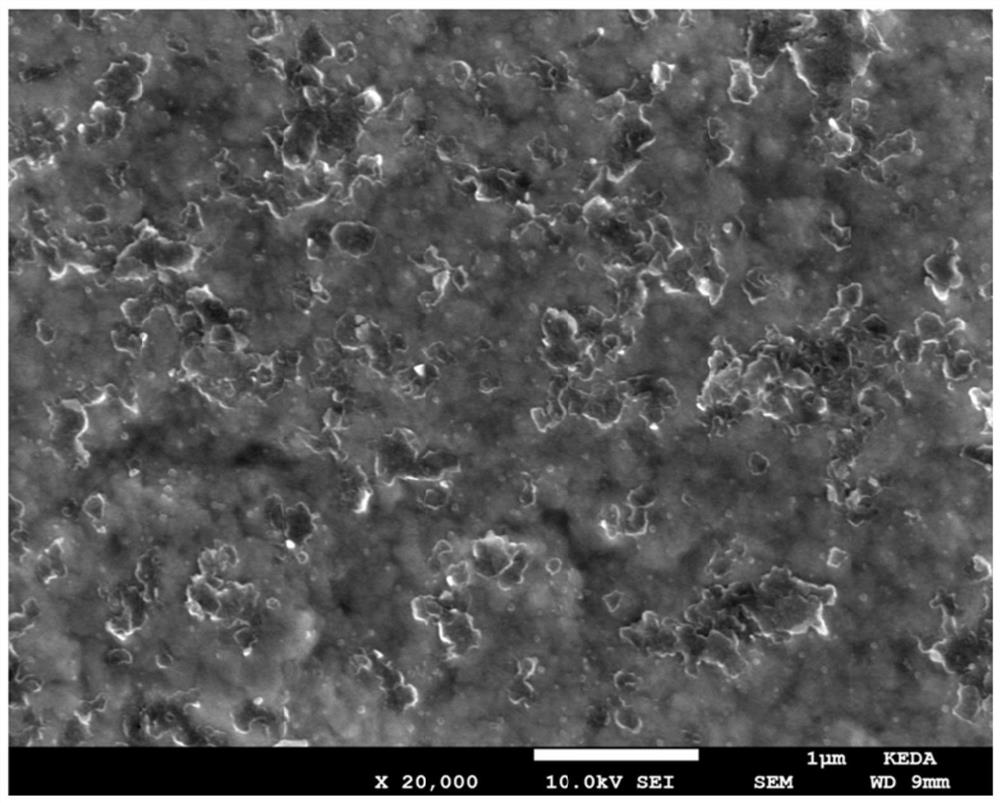

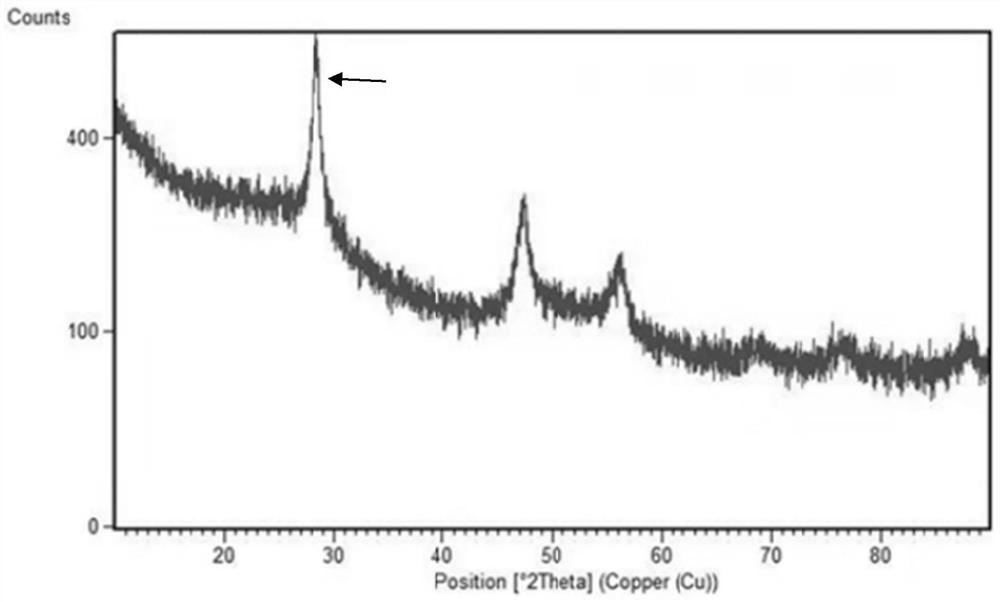

A kind of silicon carbon negative electrode material for lithium ion battery and preparation method thereof

ActiveCN111755684BReduce absolute volume expansionImprove dynamic performanceMaterial nanotechnologyNegative electrodesNano siliconChemical physics

The invention belongs to the technical field of lithium ion batteries, and in particular relates to a silicon-carbon negative electrode material for lithium ion batteries and a preparation method thereof. Part of the surface is covered by the carbon source of vapor deposition, the median particle size D50 of the nano-silicon is below 100nm; the crystal grains of the nano-silicon are below 10nm; the average thickness of the vapor-deposited carbon source is 10-200nm; in the nano-silicon Contains oxygen, the mass content of oxygen element is 5-30%, the negative electrode material contains 60%-90wt.% nano-silicon, 10%-40wt.% gas-phase carbon source; compared with the prior art, the present invention The prepared silicon-carbon anode material for lithium-ion batteries has excellent electrochemical performance.

Owner:MAANSHAN KEDA PURUI ENERGY TECH CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com