Electrode pole piece and method of making the same, semi-solid battery

A semi-solid, negative pole piece technology, used in electrode manufacturing, electrode rolling/calendering, negative electrodes, etc., can solve the problems of reduced first reversible capacity, low first reversible capacity, serious volume, etc., and achieves high first reversible capacity, Ensure normal migration and high compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention are described in detail below, and those skilled in the art will understand that the following embodiments are intended to explain the present invention and should not be regarded as a limitation of the present invention. Unless otherwise specified, specific techniques or conditions are not explicitly described in the following examples, and those skilled in the art can follow common techniques or conditions in the art or follow product specifications.

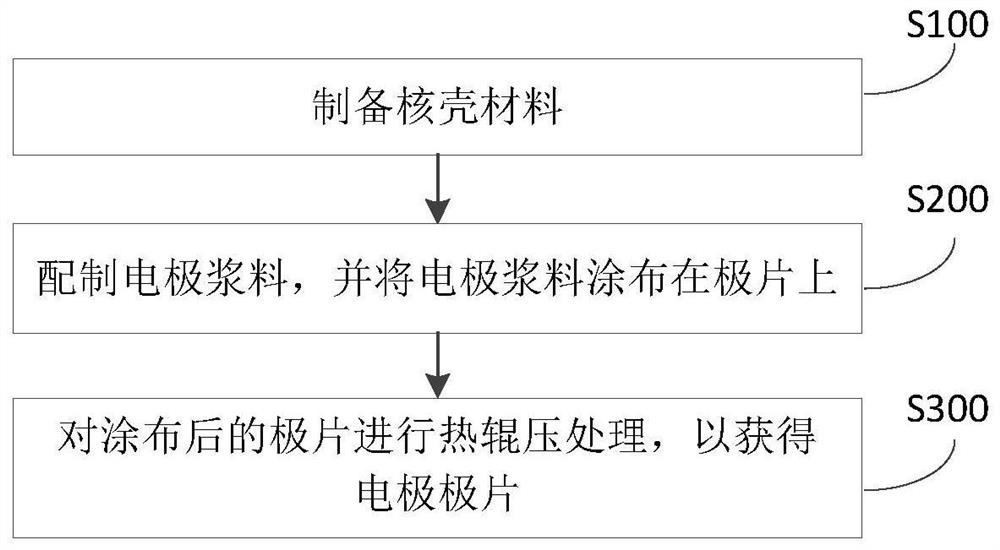

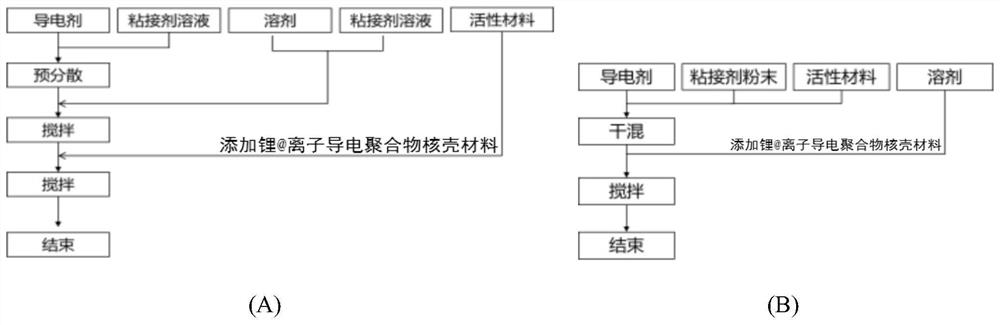

[0034] In one aspect of the present invention, the present invention provides a method for manufacturing an electrode pole piece. According to an embodiment of the present invention, refer to figure 1 , the production method includes:

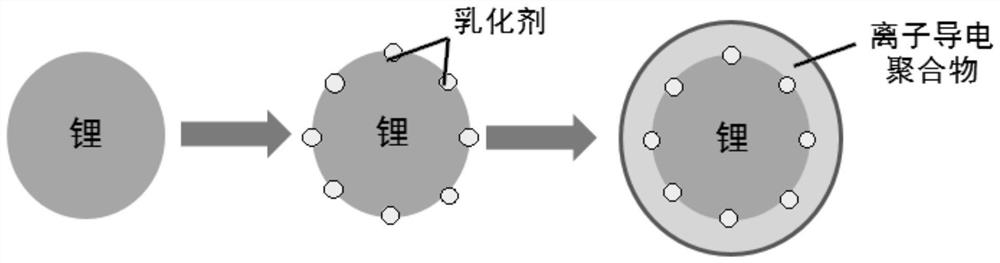

[0035] S100: Preparation of core-shell material.

[0036] In this step, a core-shell material is prepared, wherein the core of the core-shell material is formed of lithium and the outer shell is formed of an ion-conducting polymer. The inventor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com