Sulfonated graphene metal salt and its preparation method and application

A technology of sulfonated graphene and metal salt, which is applied in the field of sulfonated graphene metal salt and its preparation, can solve the problems of poor graphene dispersion, poor cycle stability, aggregation of metal nanoparticles, etc., and achieve good dispersion , mild reaction conditions and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

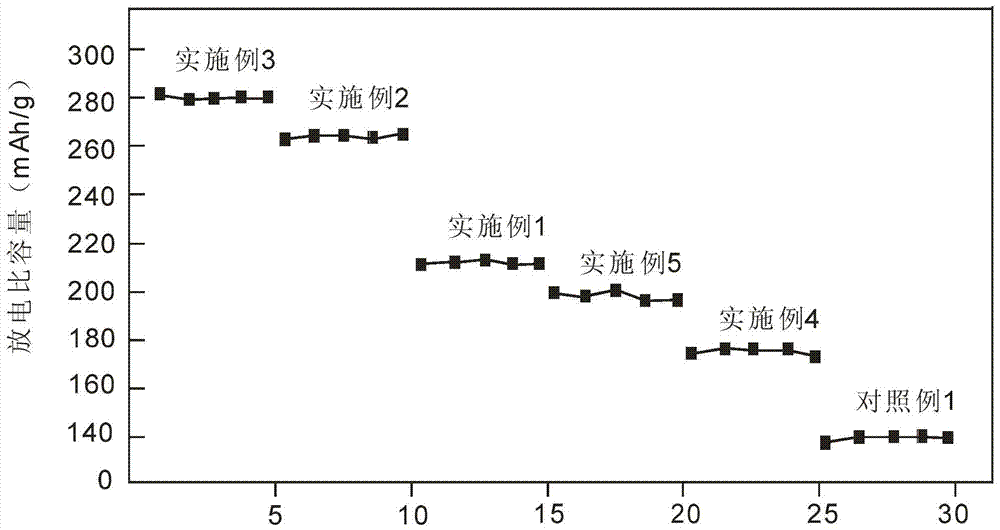

Examples

Embodiment 1

[0033] Example 1 A sulfonated graphene metal salt related to this example includes sulfonated graphene and a metal compound bound to the surface of the sulfonated graphene through ionic bonding.

[0034] A kind of method preparing this sulfonated graphene metal salt comprises the steps:

[0035] S1, uniformly dispersing the sulfonated graphene in DMSO to form a sulfonated graphene solution with a concentration of 0.1500g / L;

[0036] S2. Add lithium oxide or lithium hydroxide to the sulfonated graphene solution in an inert atmosphere, so that the amount of lithium oxide added to the sulfonated graphene solution is 0.3 g / L, and stir and react at room temperature for 6 h, Obtain sulfonated graphene lithium salt solution;

[0037] S3. Drying the sulfonated graphene metal solution at 85° C. to 100° C. to obtain the sulfonated graphene metal salt.

Embodiment 2

[0038] Example 2 A sulfonated graphene metal salt involved in this example includes sulfonated graphene and a metal compound ionically bound to the surface of the sulfonated graphene.

[0039] A kind of method preparing this sulfonated graphene metal salt comprises the steps:

[0040] S1, will be uniformly dispersed in DMF with reference to the prepared sulfonated graphene of CN103539105A method, form the sulfonated graphene solution that concentration is 500g / L;

[0041] S2. Add lithium hydroxide to the sulfonated graphene solution in an inert atmosphere, so that the amount of lithium hydroxide added to the sulfonated graphene solution is 30g / L, and stir and react at room temperature for 1h to obtain sulfonated graphene Graphene lithium salt solution;

[0042] S3. Drying the sulfonated graphene metal solution at 100° C. to 120° C. to obtain the sulfonated graphene metal salt.

Embodiment 3

[0043] Example 3 A sulfonated graphene metal salt involved in this example includes sulfonated graphene and a metal compound ionically bound to the surface of the sulfonated graphene.

[0044] A kind of method preparing this sulfonated graphene metal salt comprises the steps:

[0045] S1, uniformly dispersing the sulfonated graphene in DMAC to form a sulfonated graphene solution with a concentration of 100g / L;

[0046] S2. Add lithium oxide to the sulfonated graphene solution in an inert atmosphere, so that the amount of lithium oxide added to the sulfonated graphene solution is 10 g / L, and stir and react at room temperature for 4 hours to obtain sulfonated graphene Lithium salt solution;

[0047] S3. Drying the sulfonated graphene metal solution at 180° C. to 200° C. to obtain the sulfonated graphene metal salt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com