A kind of silicon carbon negative electrode material for lithium ion battery and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc. The effect of reducing internal resistance, improving electrical conductivity and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

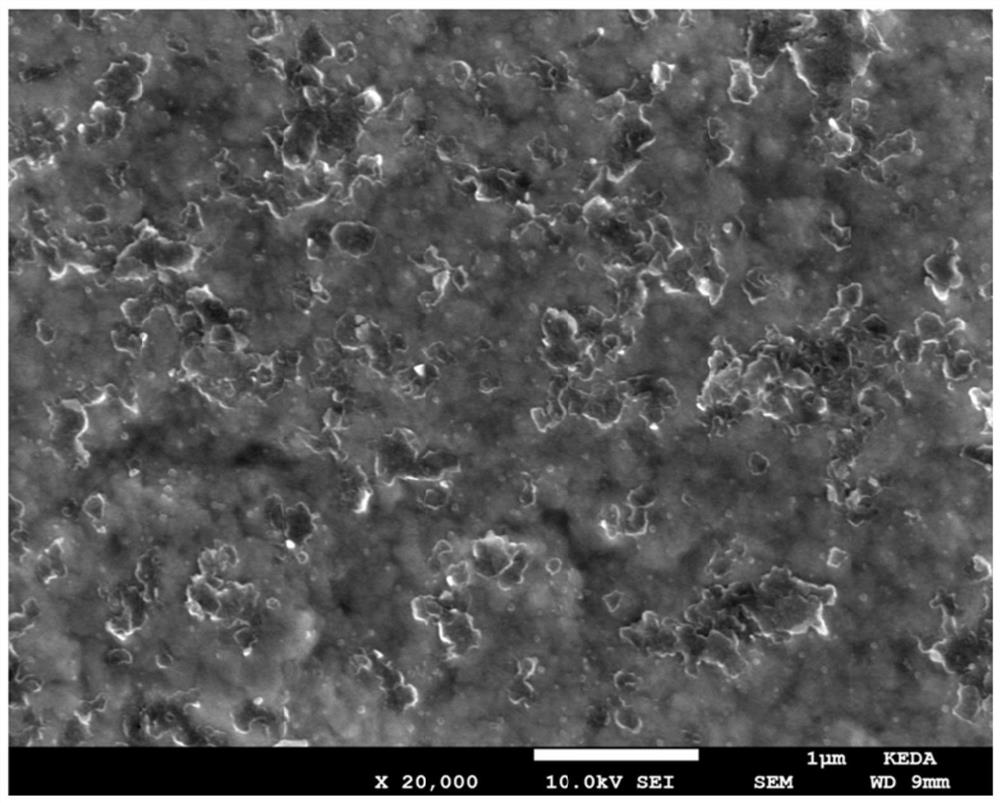

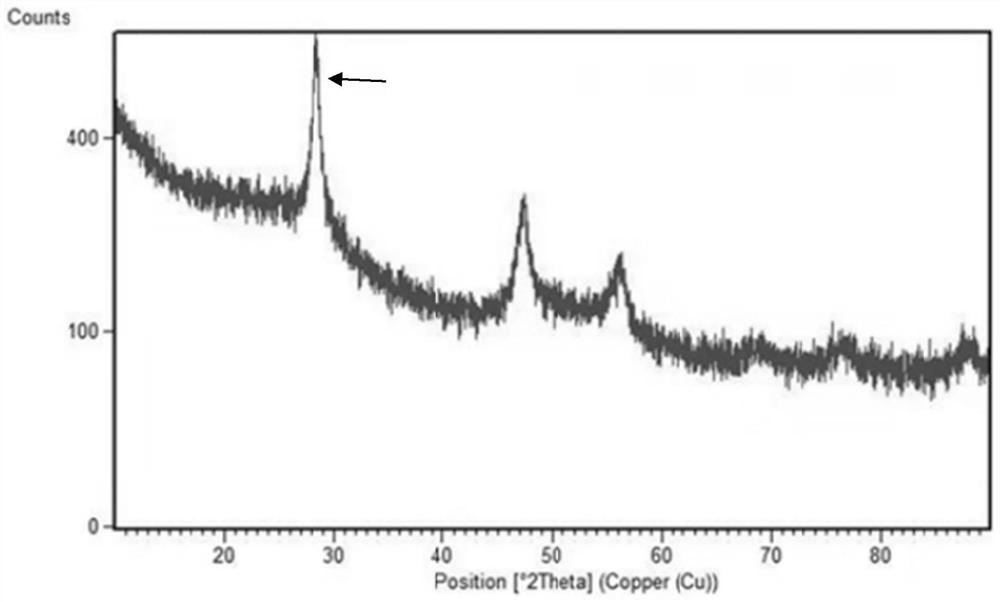

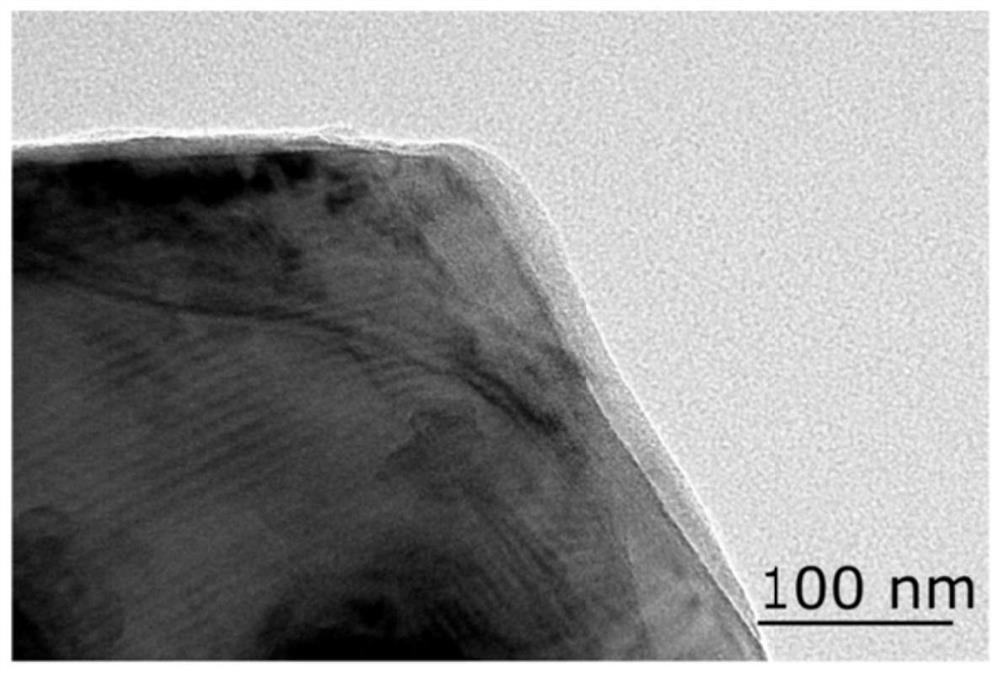

Image

Examples

Embodiment 1

[0042] A preparation method of silicon carbon negative electrode material for lithium ion battery, comprising the following steps:

[0043] (1) Preparation of nano-silicon slurry: 1000 g of polycrystalline silicon powder with a median particle size of 3 μm and 10 g of polyvinylpyrrolidone were added to methanol according to the mass ratio of silicon powder: polyvinylpyrrolidone=100:1, and the solid content of the mixed solution was 20%, introduce the mixed slurry into a sand mill, wherein the mass ratio of grinding beads zirconia balls and silicon powder is 10:1, and the grinding time is 50h to obtain the required nano-silicon slurry; the nano-silicon slurry passes through Mastersizer 3000 particle size analyzer detection, the median particle size of nano-silicon is 72nm;

[0044] (2) Atomization and drying: the nano-silicon slurry in step (1) is atomized and dried by a closed-type spray dryer, and the hot air inlet temperature of the spray dryer is 190° C., and the outlet tem...

Embodiment 2

[0048] (1) Preparation of nano-silicon slurry: 1000 g of polycrystalline silicon powder with a median particle size of 8 μm and 50 g of sodium dodecyl sulfate were added to propanol according to the mass ratio of silicon powder: sodium dodecyl sulfate = 100:5 , the solid content of the mixed solution is 20%, and the mixed slurry is introduced into the sand mill, wherein the mass ratio of grinding beads cemented carbide balls and silicon powder is 10:1, and the grinding time is 60h to obtain the desired nano-silica slurry. The nano-silicon slurry was tested by Mastersizer 3000 particle size analyzer, and the median particle size of nano-silicon was 78nm;

[0049] (2) Atomization and drying: the nano-silicon slurry in step (1) is atomized and dried by a closed-type spray dryer, and the hot air inlet temperature of the spray dryer is 280° C., and the outlet temperature is 130° C. to obtain nano-silicon dry powder;

[0050] (3) Mechanical shaping: the nano-silicon dry powder obta...

Embodiment 3

[0053] (1) Preparation of nano-silicon slurry: Add 1000 g of polysilicon powder with a median particle size of 15 μm and 100 g of gul gum, according to the mass ratio of silicon powder: gul gum = 100:10, into acetone, and the solid content of the mixed solution is 30%, introduce the mixed slurry into a sand mill, wherein the mass ratio of grinding beads stainless steel balls and silicon powder is 10:1, and the grinding time is 40h to obtain the required nano-silicon slurry; the nano-silicon slurry is passed through Mastersizer 3000 particle size analyzer detection, the median particle size of nano-silicon is 85nm;

[0054] (2) Atomization and drying: the nano-silicon slurry in step (1) is atomized and dried by a closed-type spray dryer, and the hot air inlet temperature of the spray dryer is 200°C, and the outlet temperature is 100°C to obtain nano-silicon dry powder;

[0055] (3) Mechanical shaping: the nano-silicon dry powder obtained in step (2) is processed by a pulverize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com