A core-shell structure porous silicon negative electrode material for lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, nanotechnology for materials and surface science, structural parts, etc., can solve problems such as loss of active materials, sharp drop in battery capacity, and collapse of material structures, achieving the first High efficiency, improved conductivity, and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

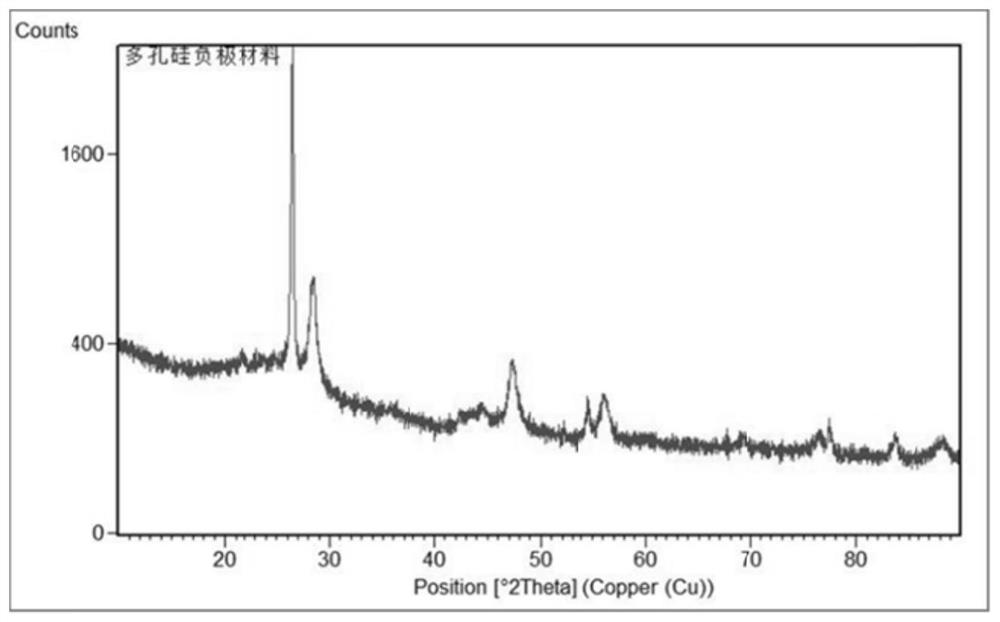

[0036] A preparation method of a core-shell structure porous silicon negative electrode material for a lithium ion battery, comprising the steps of:

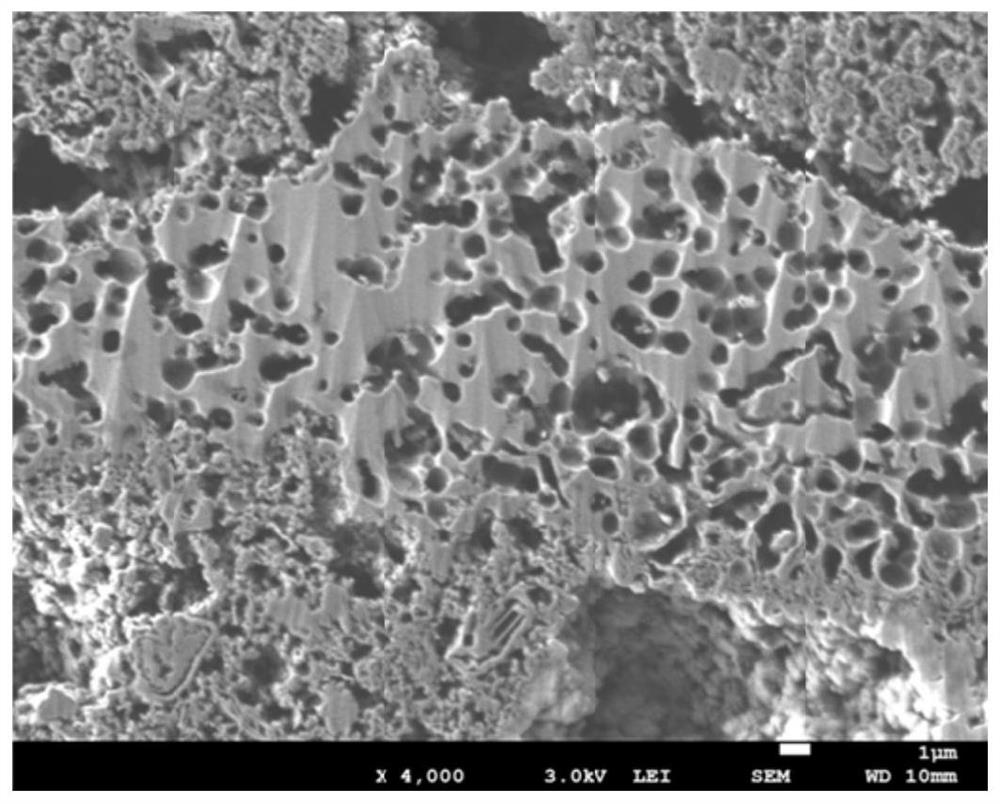

[0037] (1) Preparation of nanoporous silicon: Add 1000 g of porous silicon powder with a median particle size of 1 μm and a purity of 99.99% and ethanol into the dispersion tank of the sand mill, control the solid content of the mixed solution to 10%, and start stirring for 30 minutes; The material of the grinding beads is hard alloy, and the mass ratio of grinding beads to silicon powder is 30:1; the mixed solution in the mixing tank is introduced into the sand mill, the linear speed of the sand mill is 16m / s, and the grinding time is 70h , to obtain a porous silicon slurry; the mass content of oxygen in the nanoporous silicon obtained by testing is 32%, and the median particle size of the nanoporous silicon is 77nm;

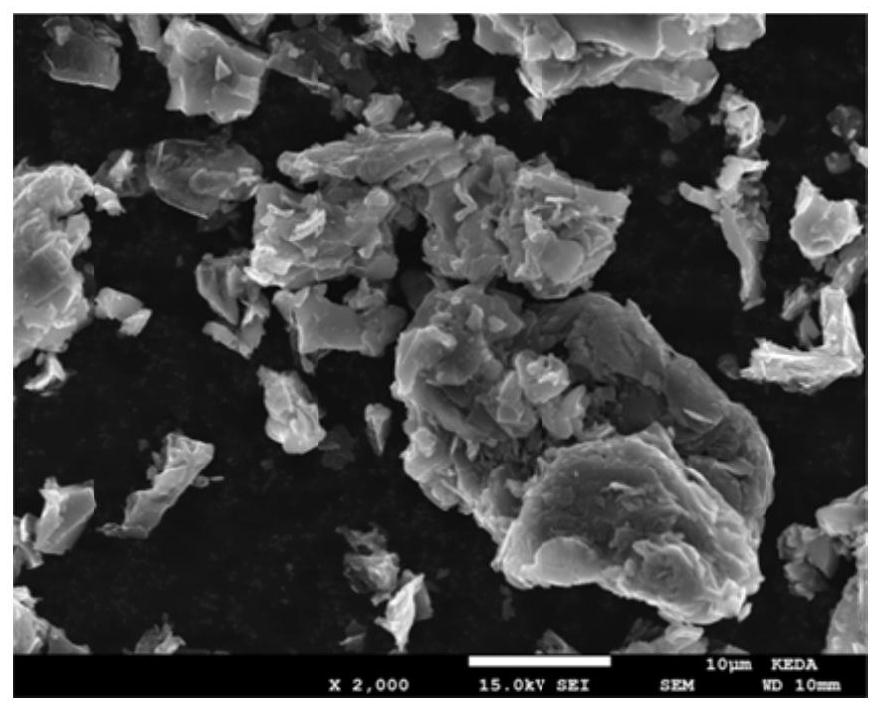

[0038] (2) Atomization granulation: adding nano-graphite and carbon source material-glucose with a median partic...

Embodiment 2

[0042] (1) Preparation of nanoporous silicon: Add 1000 g of porous silicon powder with a median particle size of 70 μm and a purity of 99.9% and ethanol into the dispersion tank of the sand mill, control the solid content of the mixed solution to 15%, and start stirring for 30 minutes; The material of the grinding beads is hard alloy, and the mass ratio of grinding beads to silicon powder is 30:1; the mixed solution in the mixing tank is introduced into the sand mill, the linear speed of the sand mill is 16m / s, and the grinding time is 55h , to obtain a porous silicon slurry; the mass content of oxygen in the nanoporous silicon obtained by testing is 27%, and the median particle size of the nanoporous silicon is 82nm;

[0043] (2) Atomization granulation: adding natural graphite and carbon source material-epoxy resin with a median particle size of 2 μm to the porous silicon slurry in step (1), adjusting the solid content of the mixed slurry to 20%, measured The viscosity of th...

Embodiment 3

[0047] (1) Preparation of nanoporous silicon: Add 1000 g of porous silicon powder with a median particle size of 130 μm and a purity of 99.2% and ethanol into the dispersion tank of the sand mill, control the solid content of the mixed solution to 20%, and start stirring for 30 minutes; The material of the grinding beads is hard alloy, and the mass ratio of grinding beads to silicon powder is 30:1; the mixed solution in the stirring tank is introduced into the sand mill, the linear speed of the sand mill is 16m / s, and the grinding time is 40h , to obtain a porous silicon slurry; the mass content of oxygen in the nanoporous silicon is 21%, and the median particle size of the nanoporous silicon is 88nm;

[0048] (2) Atomization granulation: adding artificial graphite and carbon source material-acrylic resin with a median particle size of 12 μm to the porous silicon slurry in step (1), adjusting the solid content of the mixed slurry to 30%, the mixed The viscosity of the slurry i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com