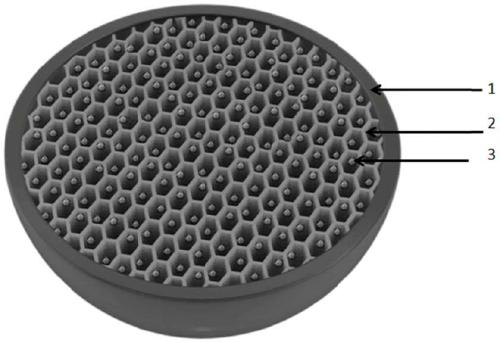

Porous core-shell structure silicon-carbon negative electrode material for lithium ion battery and preparation method thereof

A technology of lithium-ion batteries and negative electrode materials, applied in the direction of nanotechnology for materials and surface science, battery electrodes, negative electrodes, etc., can solve the problems of silicon electrode powdering and falling off, poor cycle performance, and current collector loss, etc., to achieve The effect of reducing absolute volume expansion, improving electrical conductivity, and increasing migration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

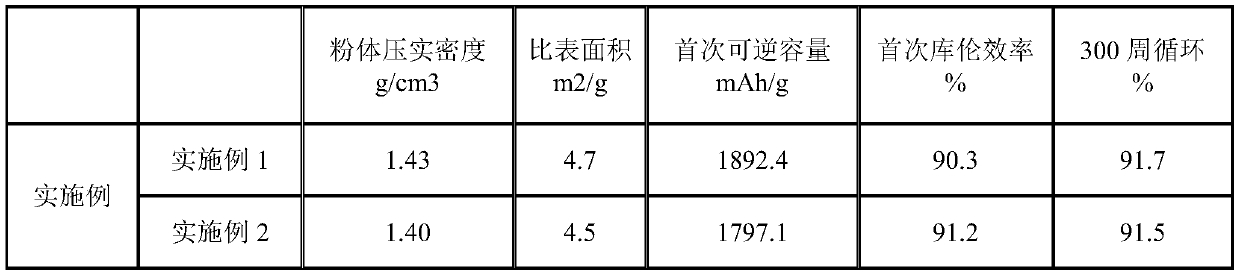

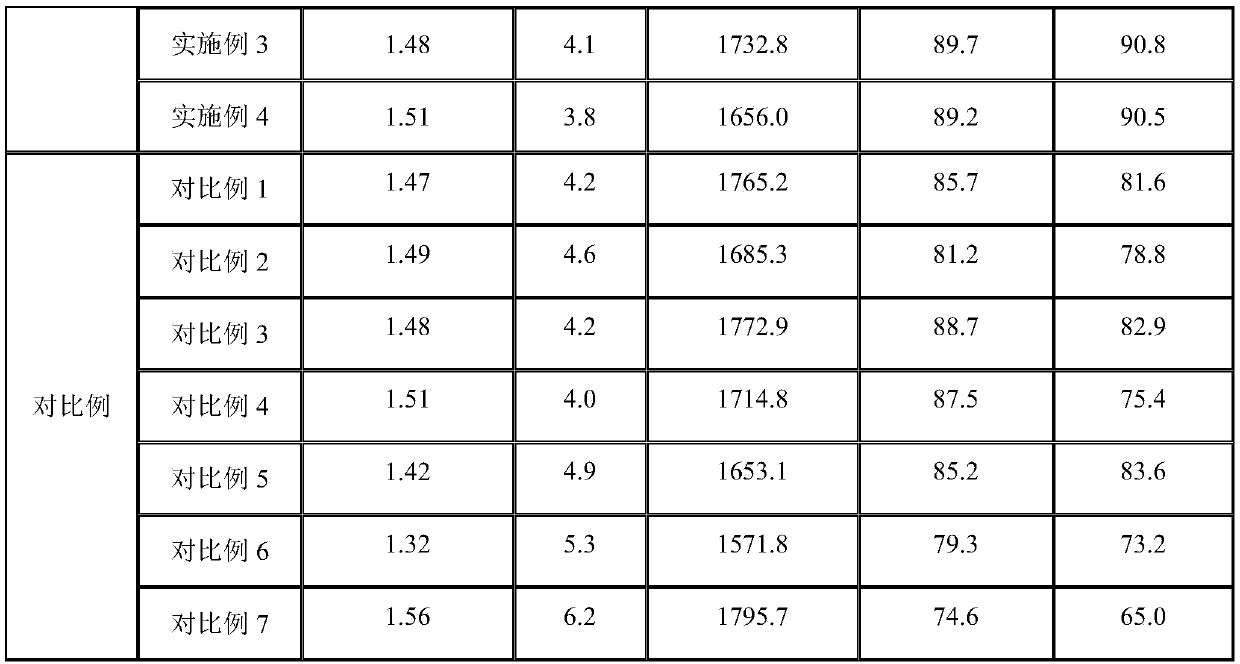

Examples

Embodiment 1

[0039] A method for preparing a porous core-shell structure silicon-carbon negative electrode material for a lithium ion battery, comprising the steps of:

[0040] (1) Preparation of nano-silicon slurry: 500 g of polycrystalline silicon powder with a median particle size of 10 μm and 5 g of polyvinylpyrrolidone, according to the mass ratio of silicon powder: polyvinylpyrrolidone = 100:1, are added to absolute ethanol, and the mixed solution solidifies The content is 10%, and the mixed slurry is introduced into a sand mill, and ground for 100 hours under the protection of nitrogen to obtain a nano-silicon slurry with a median particle size of 50nm, wherein the diameter of the ground zirconium ball is 0.1mm, and the zirconium ball and silicon powder The mass ratio of is 10:1;

[0041] (2) Preparation of porous carbon: put 900g of sucrose in a muffle furnace, feed nitrogen and oxygen mixed gas, in which the volume ratio of oxygen is 80%, heat up to 700°C, control the degree of co...

Embodiment 2

[0046] A method for preparing a porous core-shell structure silicon-carbon negative electrode material for a lithium ion battery, comprising the steps of:

[0047] (1) Preparation of nano-silicon slurry: the median particle size is 30 μm polycrystalline silicon powder 400g and sodium lauryl sulfate 2g, according to the mass ratio of silicon powder: sodium lauryl sulfate=100:0.5, join propanol , the solid content of the mixed solution is 20%, the mixed slurry is introduced into a sand mill, and ground for 80 hours under nitrogen protection to obtain a nano-silicon slurry with a median particle size of 100nm, wherein the diameter of the zirconium ball is 0.2mm, The mass ratio of zirconium balls to silicon powder is 10:1;

[0048] (2) Preparation of porous carbon: put 1000g of starch in a muffle furnace, feed nitrogen and oxygen mixed gas, in which the volume ratio of oxygen is 70%, heat up to 800°C, control the degree of combustion of starch, and obtain a porosity of 65 % porou...

Embodiment 3

[0053] A method for preparing a porous core-shell structure silicon-carbon negative electrode material for a lithium ion battery, comprising the steps of:

[0054] (1) Preparation of nano-silicon slurry: the median particle size is 50 μm polycrystalline silicon powder 300g and Gur gum 15g, according to the mass ratio of silicon powder: Gur gum=100:5, join in acetone, the solid content of the mixed solution is 30%, the mixed slurry is introduced into a star-type ball mill, and ground for 50 hours under the protection of nitrogen to obtain a nano-silicon slurry with a median particle size of 100nm, wherein the diameter of the ground zirconium ball is 0.3mm, and the mass of the zirconium ball and silicon powder The ratio is 10:1;

[0055] (2) Preparation of porous carbon: put 675g of glucose in a muffle furnace, feed nitrogen and oxygen mixed gas, in which the volume ratio of oxygen is 50%, heat up to 900°C, control the degree of combustion of glucose, and obtain a porosity of 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com