Patents

Literature

182results about How to "Alleviate the volume expansion effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

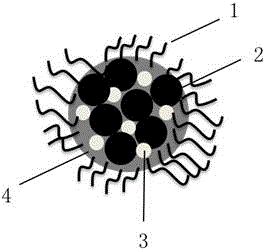

SiOx-based composite material, preparation method and lithium ion battery

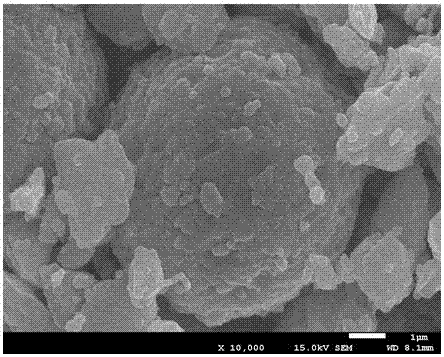

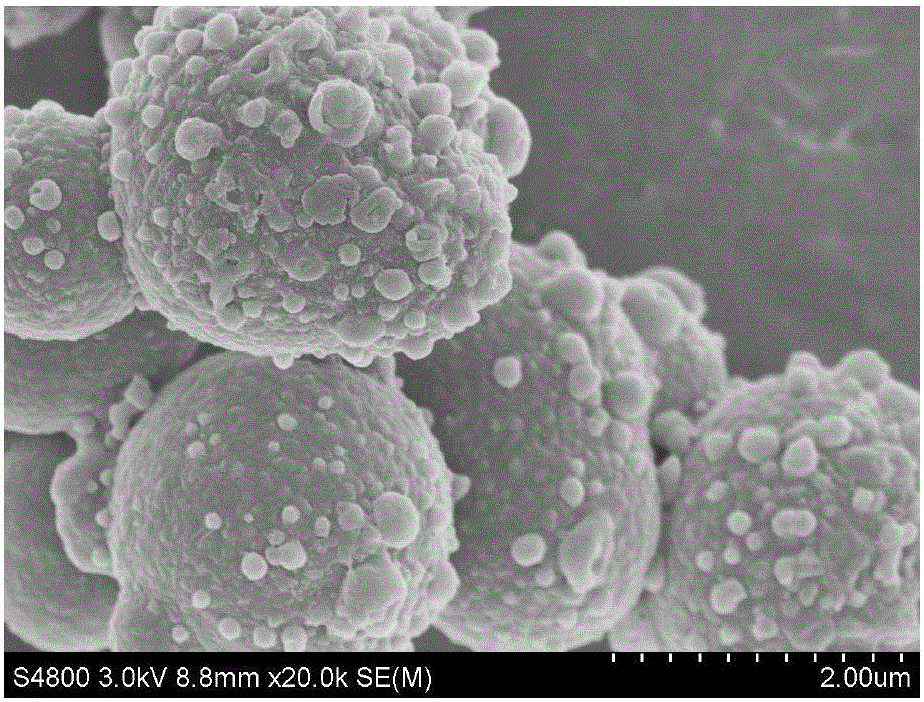

ActiveCN103855364AStable structureImprove electronic conductivityMaterial nanotechnologyCell electrodesCarbon layerSpherical shaped

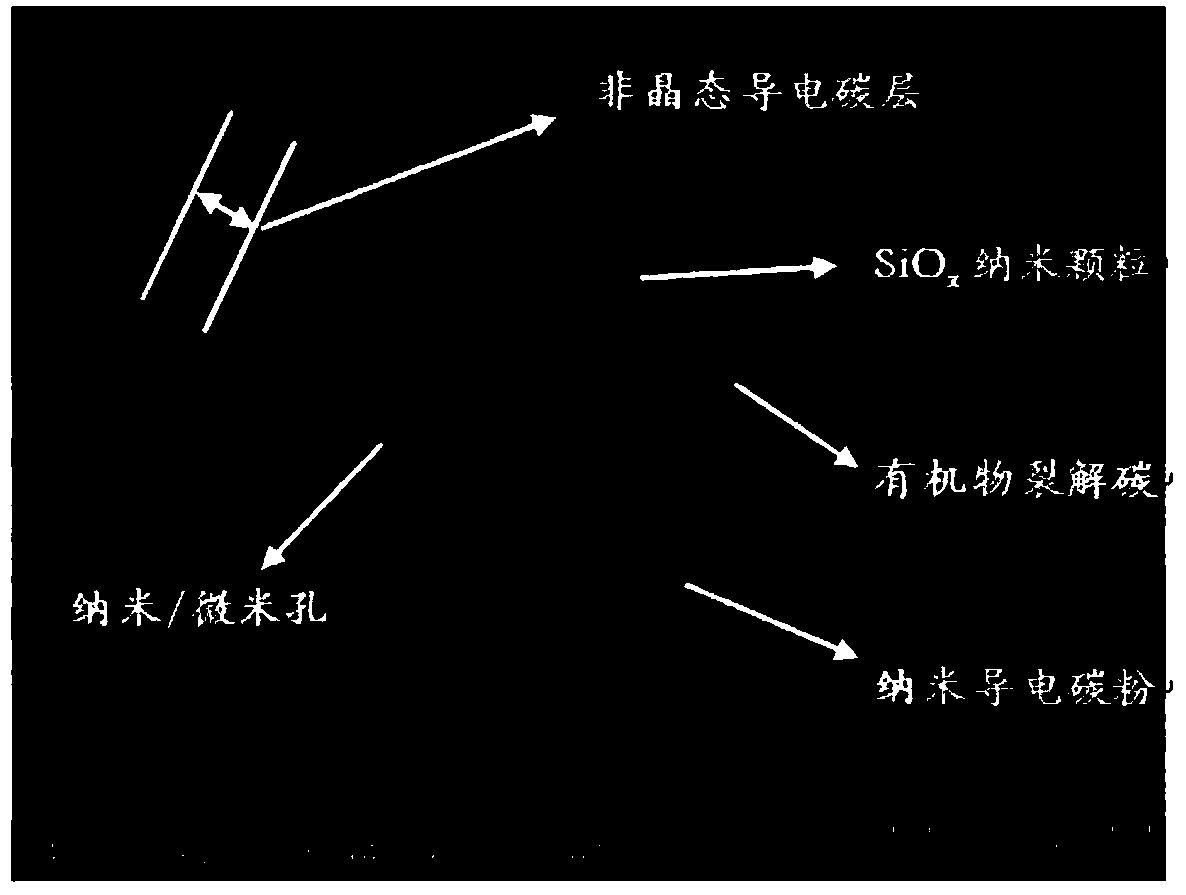

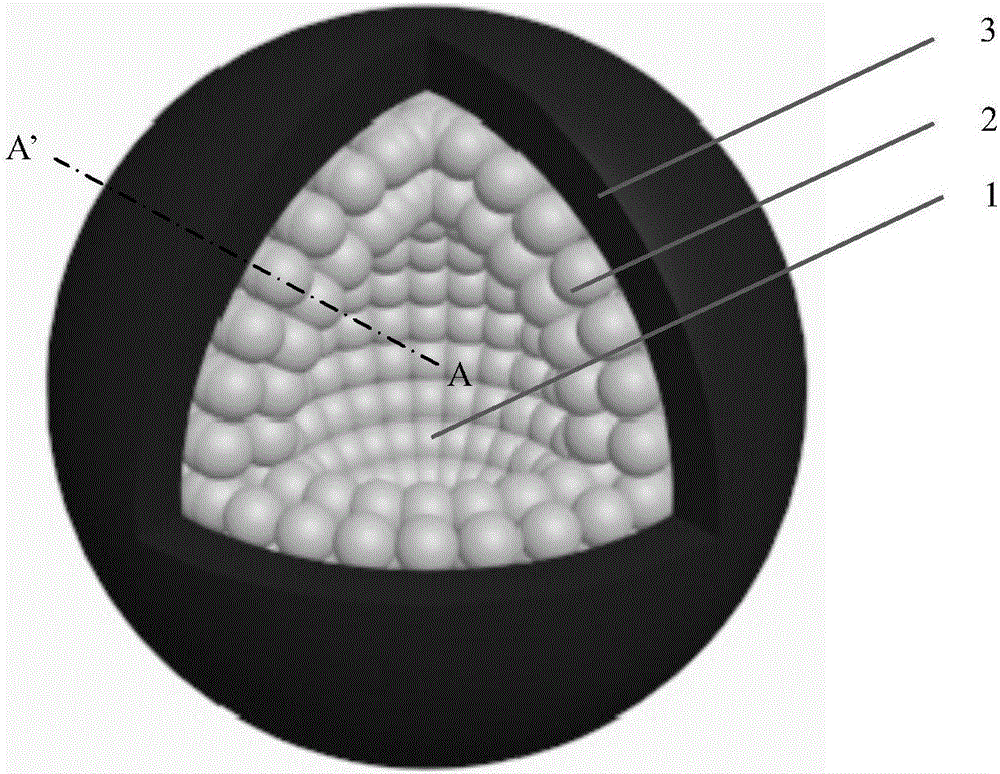

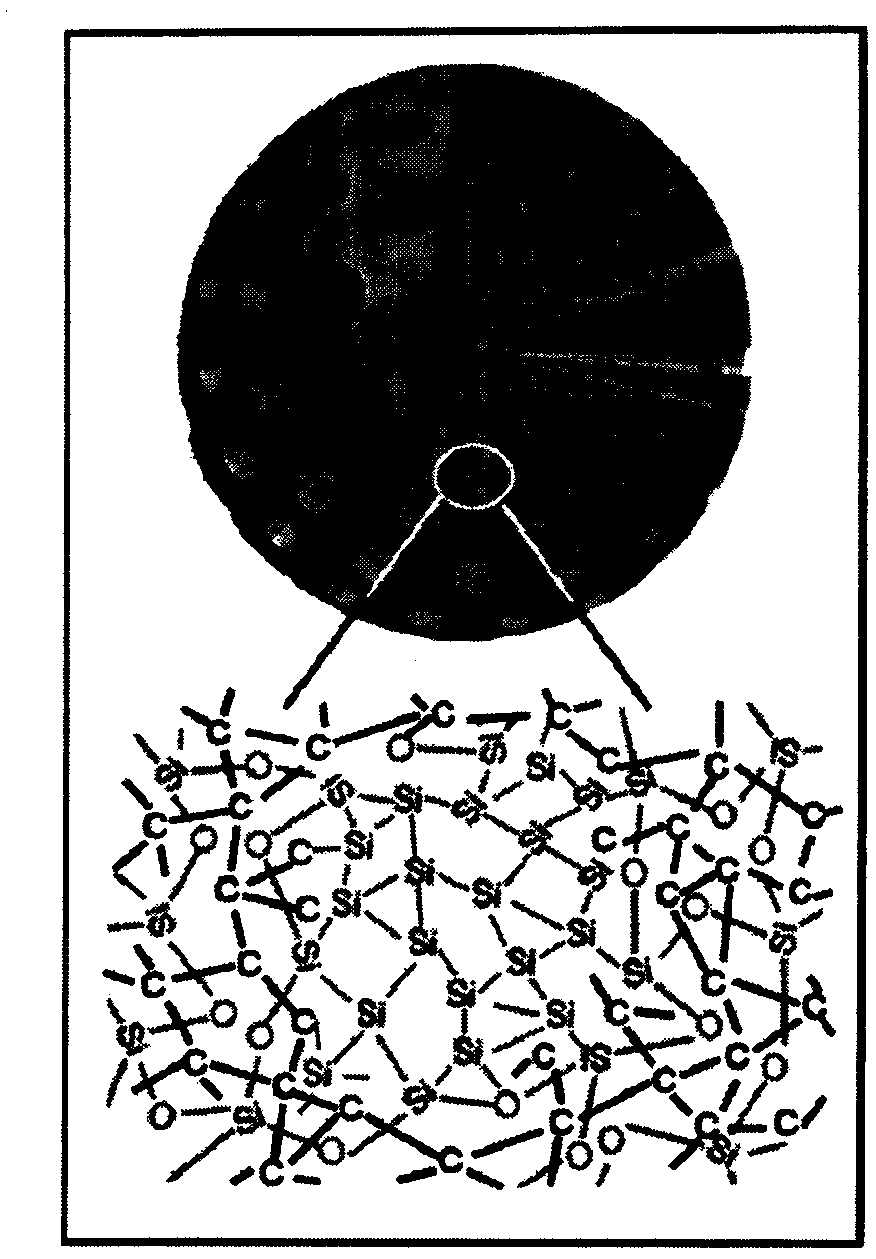

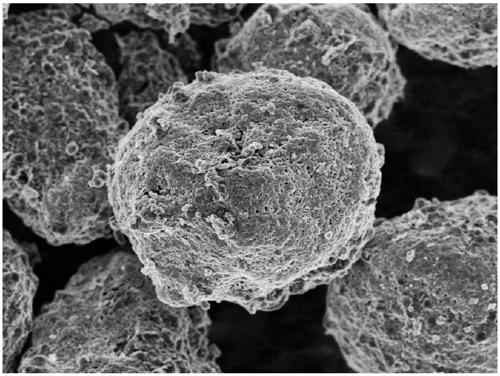

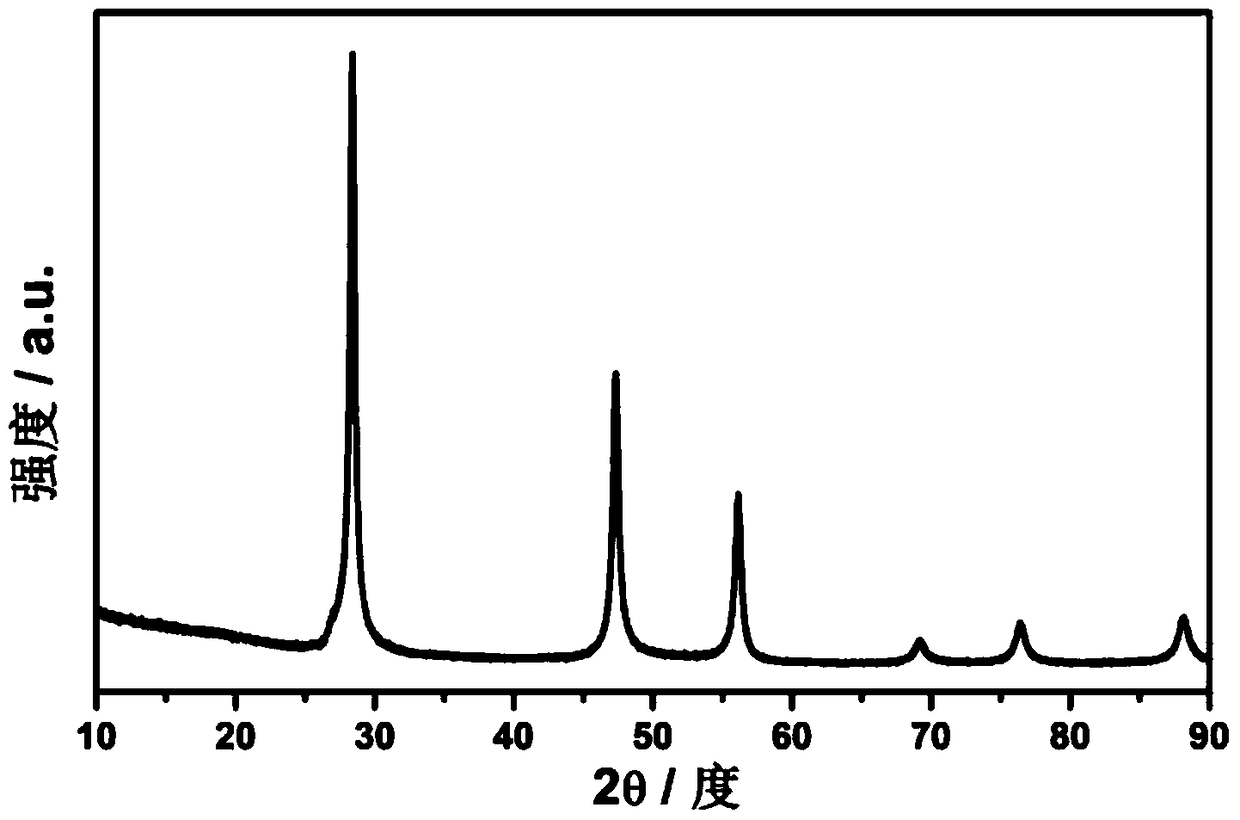

The invention relates to a SiOx-based composite material, a preparation method and a lithium ion battery. The SiOx-based composite material comprises a SiOx / C material, wherein the SiOx / C material comprises SiOx nano particles, organism cracked carbon, nano conductive particles and amorphous conductive carbon layers, the SiOx nano particles, the organism cracked carbon and the nano conductive particles are wrapped in the amorphous conductive carbon layers, the SiOx / C material is in a spherical shape and comprises a porous structure, and x is more than or equal to 0.5 and less than or equal to 1.3. The composite material is used as a negative electrode material of the lithium ion battery, excellent in cycling performance, excellent in rate performance and low in size expansion effect, applicable to the fields such as top-grade digital electrons, electric tools and next-generation vehicle-mounted devices and wide in market prospect.

Owner:BTR NEW MATERIAL GRP CO LTD

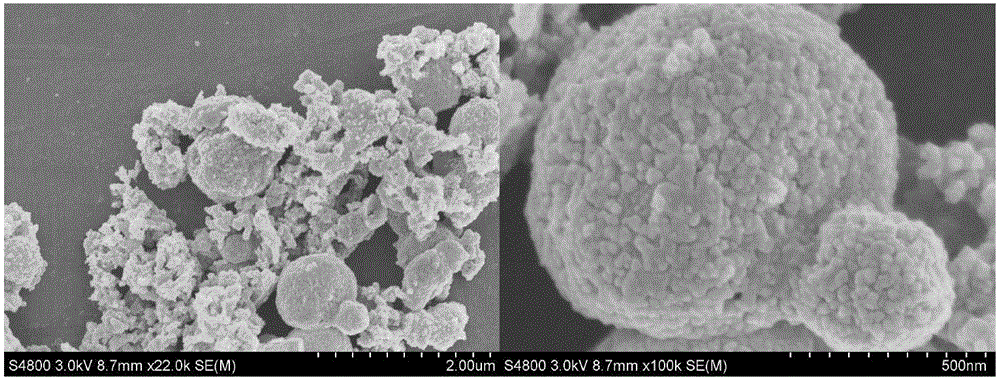

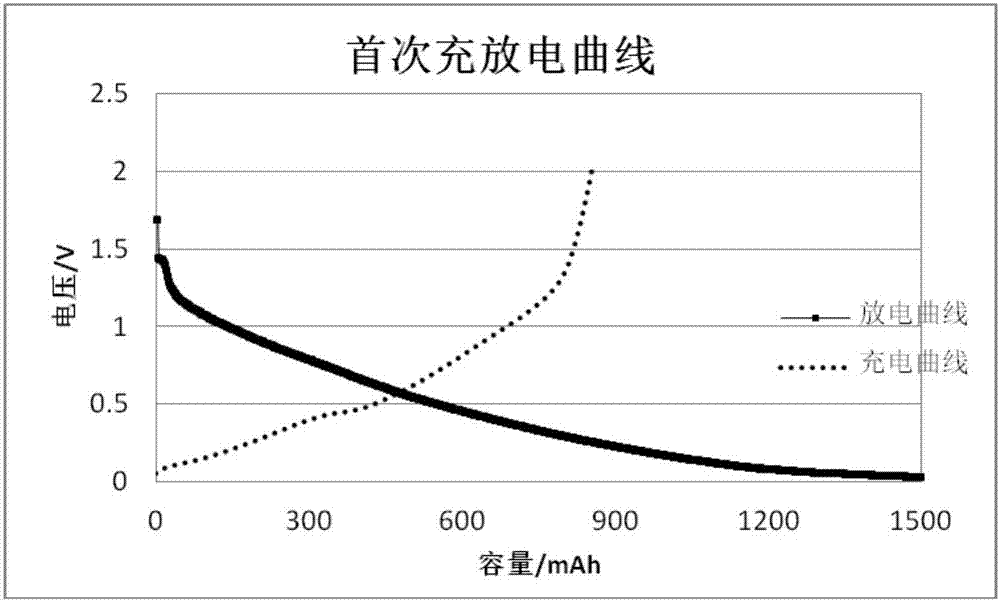

Hollow silicon-based composite material, preparation method and lithium ion battery comprising composite material

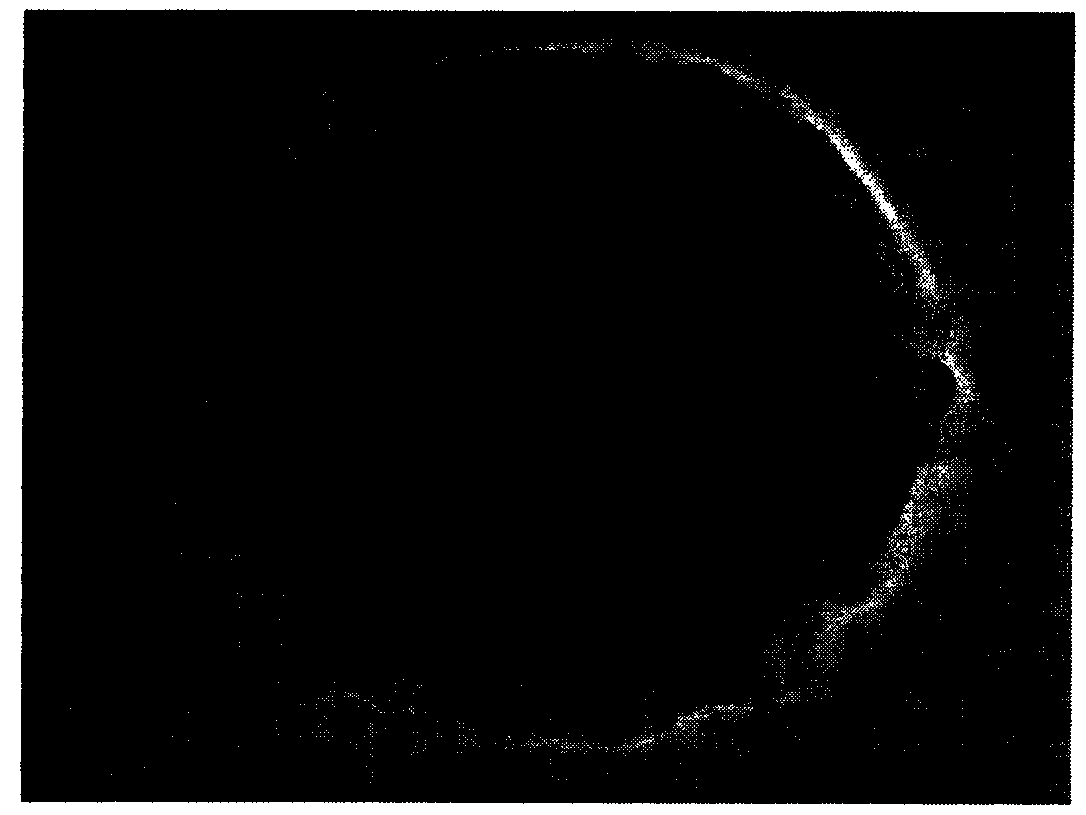

ActiveCN106129411AHigh strengthSmall volume expansionCell electrodesSecondary cellsLithium electrodeThermal treatment

The invention relates to a hollow silicon-based composite material, a preparation method and a lithium ion battery. The hollow silicon-based composite material disclosed by the invention comprises hollow cavities, a carbon-silicon composite layer and a cladding carbon layer in sequence from inside to outside, wherein the carbon-silicon composite layer comprises a secondary particle silicon layer and a deposited carbon layer. The preparation method comprises the following steps: firstly bonding silicon oxide and / or silicon on the surface of graphite uniformly, then removing the graphite through oxidizing heat treatment to obtain a hollow structure, then obtaining nanometer silicon through reduction by using a reducing agent, obtaining hollow particles consisting of the hollow cavities and the secondary particle silicon layer, then carrying out in-situ cladding on the surface of the secondary particle silicon layer, and then finally carrying out cladding of the cladding carbon layer to obtain the hollow silicon-based composite material. The battery prepared by using the composite material as an anode material has high cycle performance and rate capability, the first-time reversible capacity is more than 1453.2 mAh / g, the first-time coulomb efficiency is more than 87.8%, and the hundred-time cycle capacity retention ratio is more than 95.2%.

Owner:BTR NEW MATERIAL GRP CO LTD

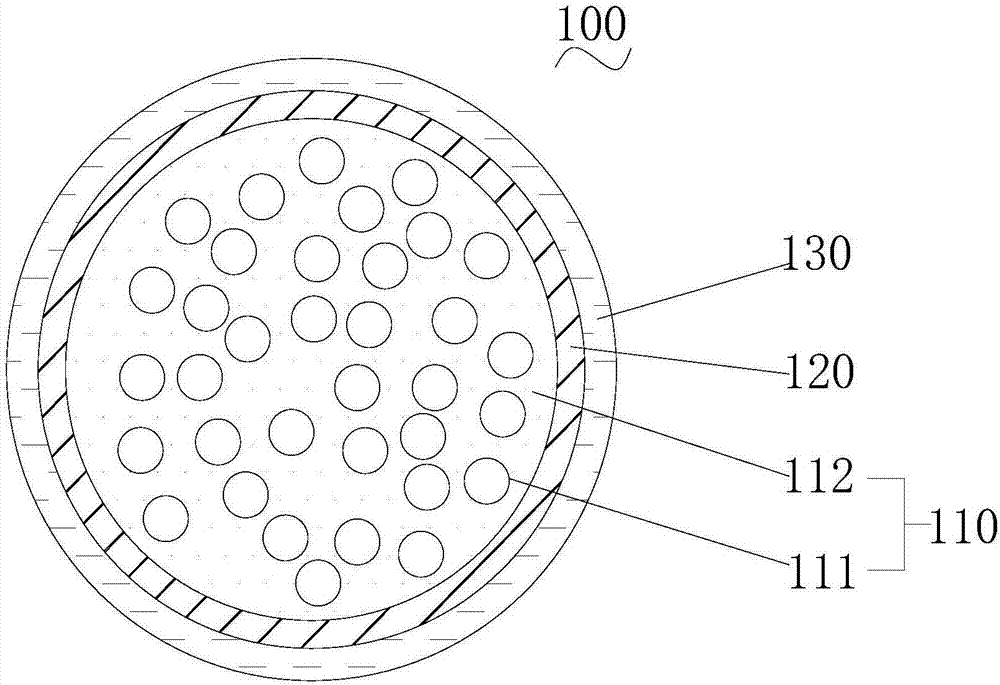

Spherical silicon-oxygen-carbon negative electrode composite material and preparation method and application thereof

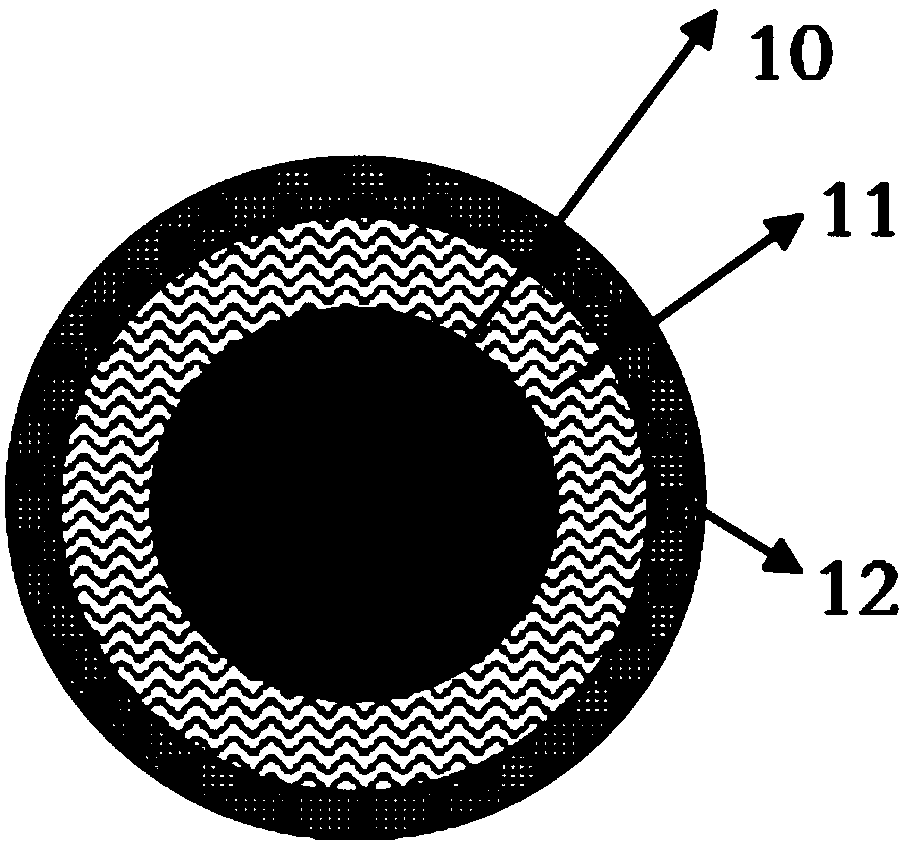

InactiveCN106025219AHigh specific capacityImprove conductivityCell electrodesSecondary cellsSilicon oxygenCarbon nanotube

The invention discloses a spherical silicon-oxygen-carbon negative electrode composite material, which is of a three-layer structure comprising an inner layer, an intermediate layer and an outer layer, wherein the inner layer is an SiOx / graphite substrate; the intermediate layer is an amorphous carbon coating layer; the outer layer is a carbon nanotube coating layer; the mass of the inner layer SiOx / graphite substrate accounts for 80%-90% of total mass of the spherical silicon-oxygen-carbon negative electrode composite material; the mass of the intermediate layer amorphous carbon accounts for 5%-10% of total mass of the spherical silicon-oxygen-carbon negative electrode composite material; and the outer layer carbon nanotube accounts for 5%-10% of total mass of the spherical silicon-oxygen-carbon negative electrode composite material. The grain diameter of the adopted SiOx substrate is smaller than 5 microns; the grain diameter is relatively small; intercalation and deintercalation of active substances are facilitated; higher specific capacity can be obtained; meanwhile, a dispersing agent is added when an SiOx sample is ground; and condition that the SiOx with a relatively small grain diameter is agglomerated in quantity to affect the performance is prevented.

Owner:ZHONGTIAN ENERGY STORAGE TECH

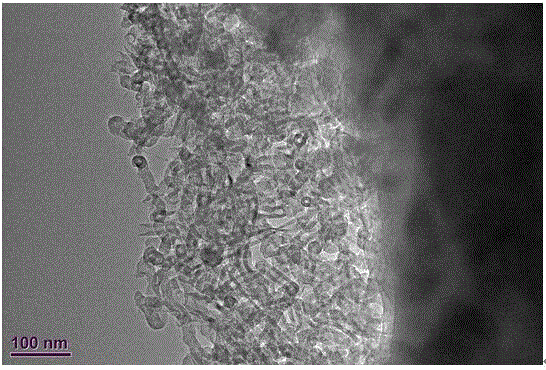

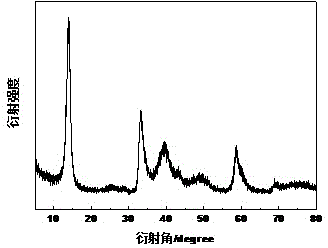

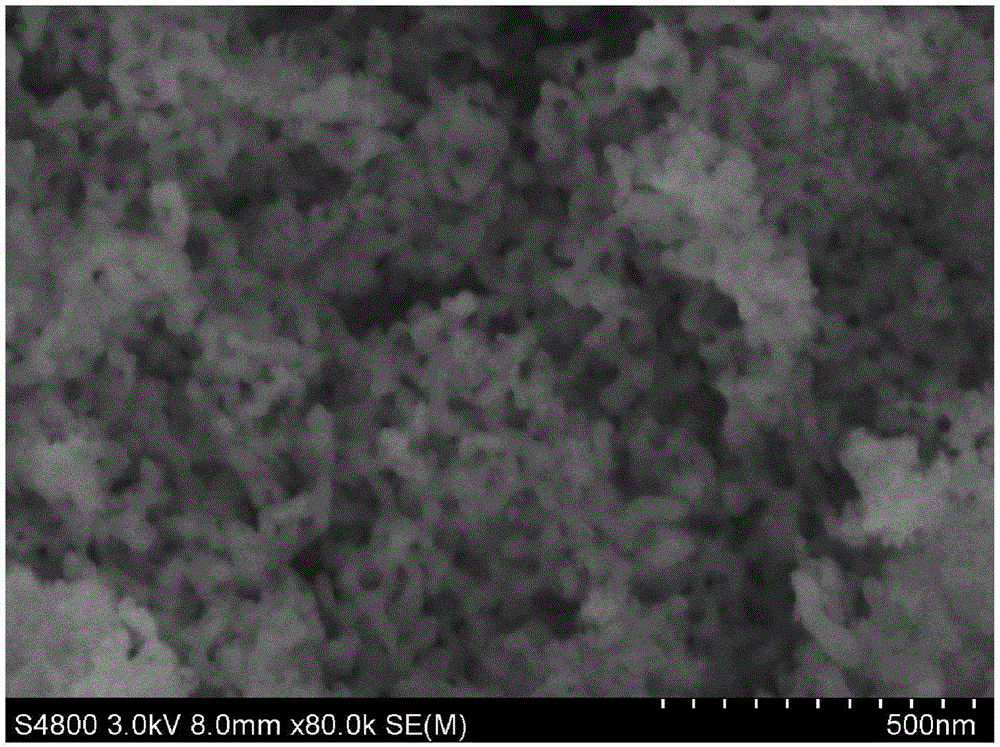

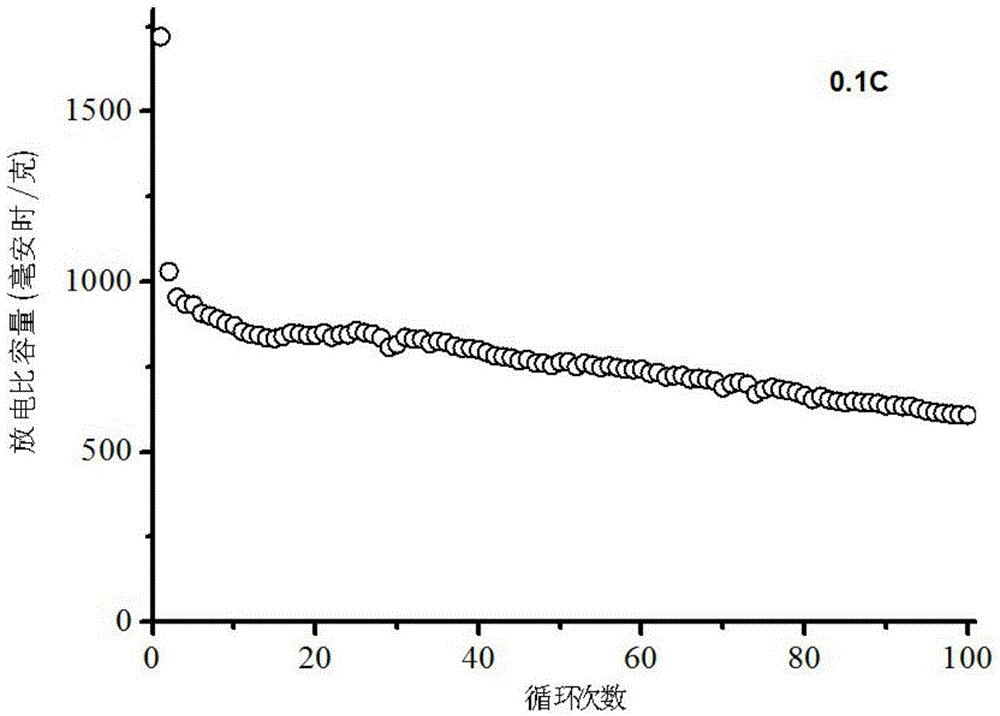

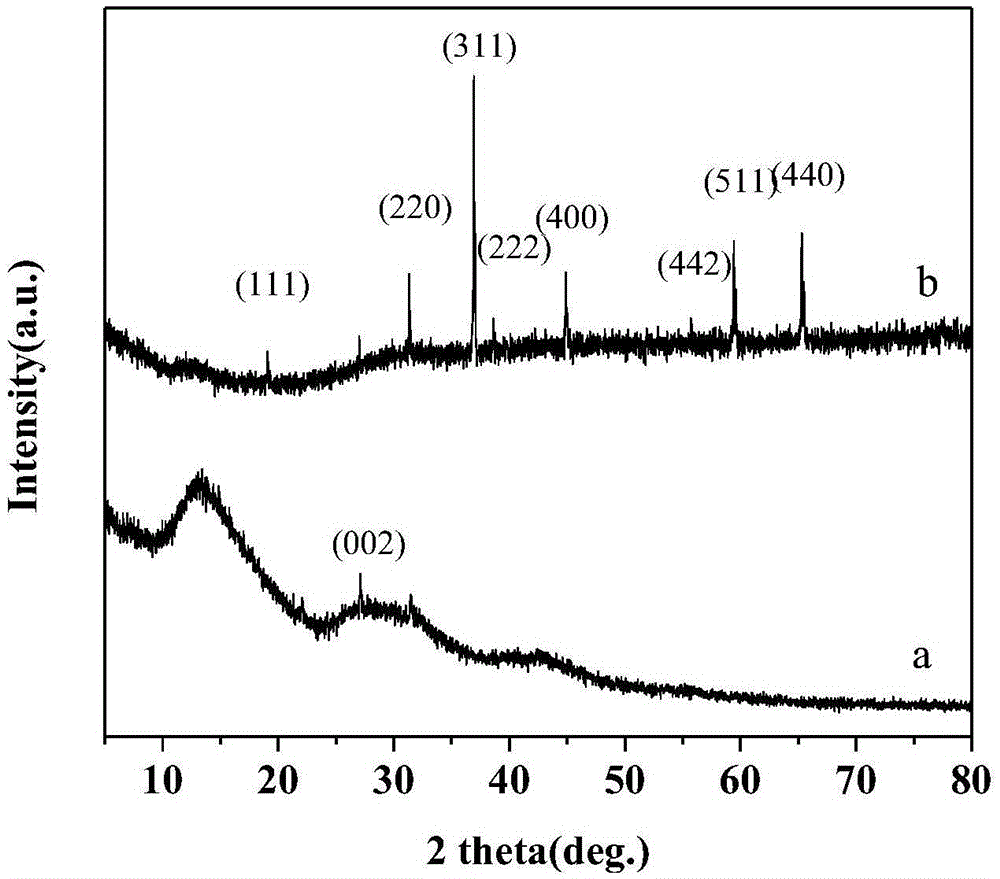

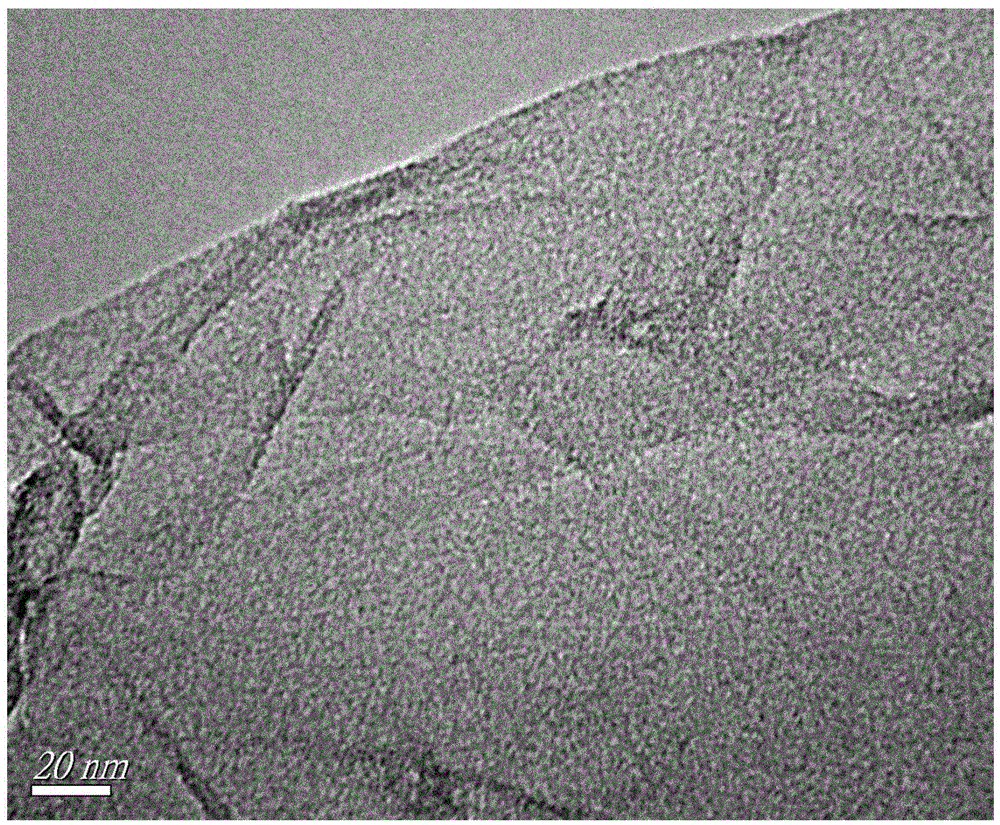

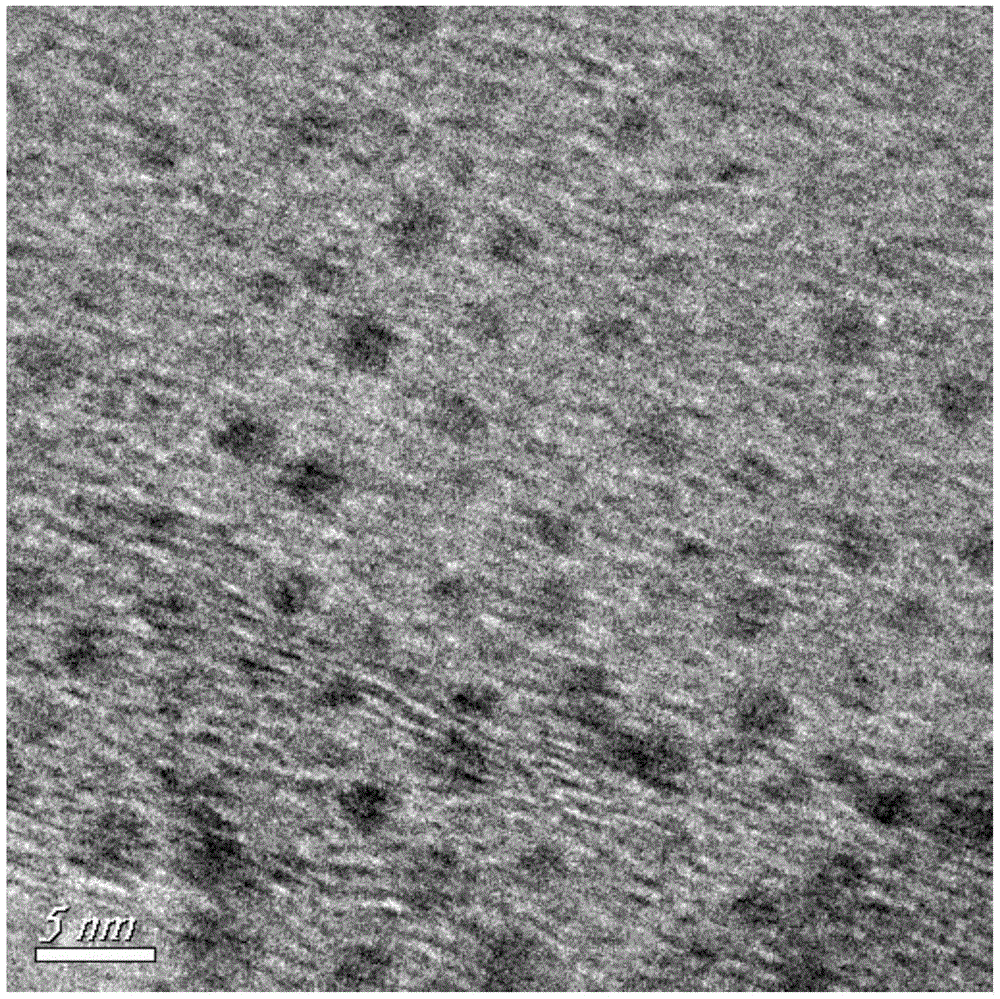

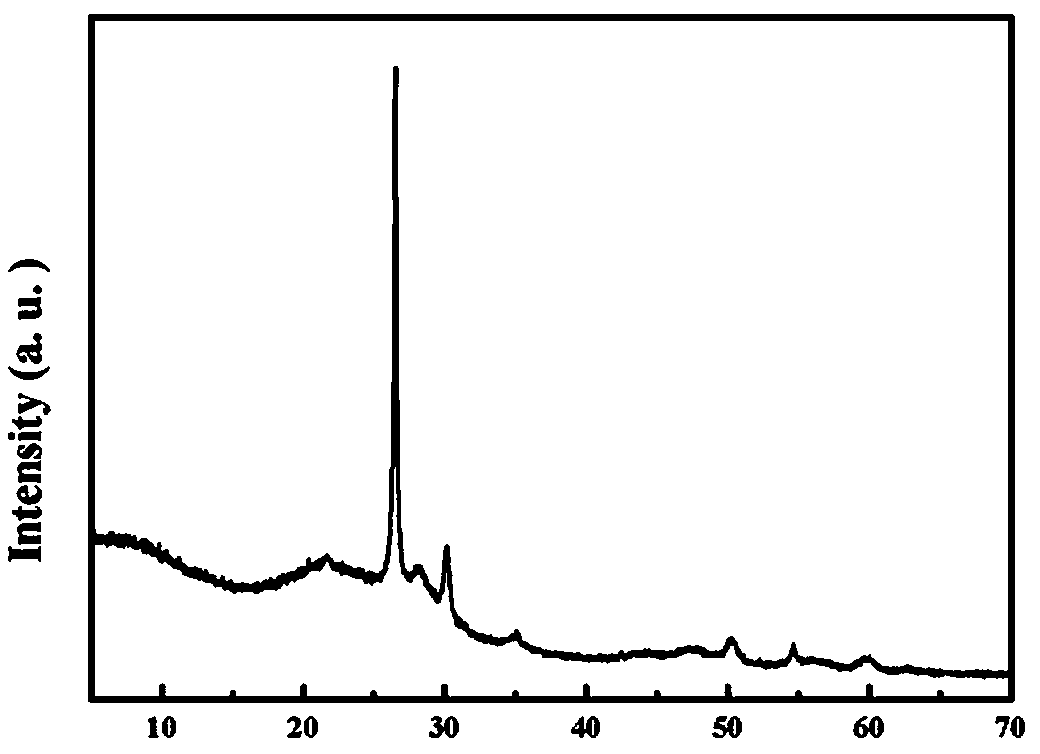

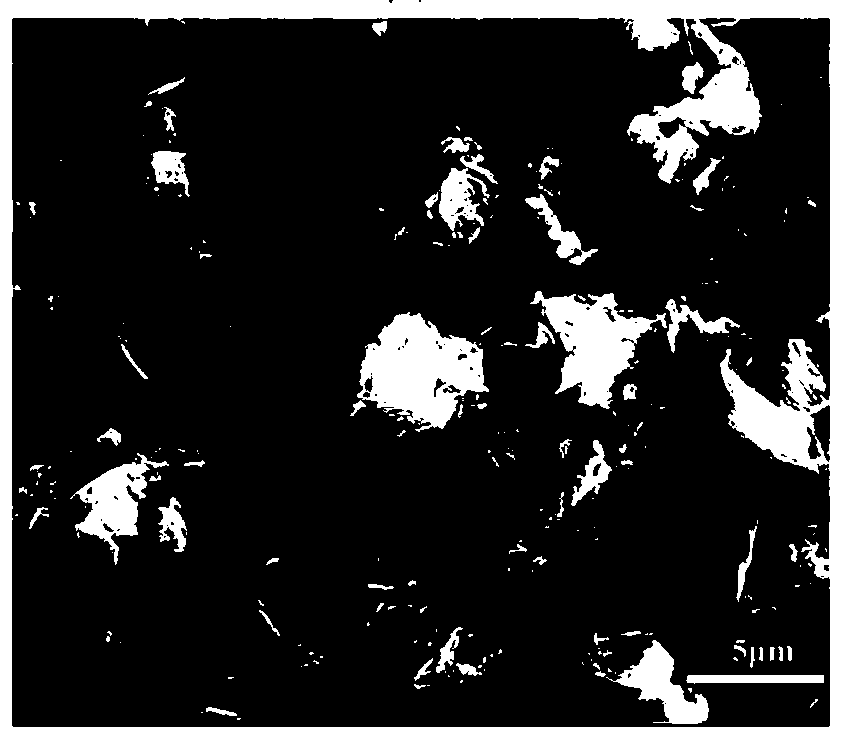

Flake MoS2/graphene composite aerogel and preparation method thereof

InactiveCN104600315AHigh electrical conductivityDeformation stableCell electrodesThioureaFreeze-drying

The invention relates to a flake MoS2 / graphene composite aerogel and a preparation method thereof and belongs to the technical field of anode materials of lithium ion batteries. The preparation method comprises the following steps: ultrasonically dispersing a certain quantity of graphene oxide solution into deionized water, adding a certain quantity of water-soluble molybdate and thiourea, then adding 0.1-3mL organic amine solution, taking out a cylindrical product after hydrothermal reaction at the temperature of 160-240 DEG C, freeze-drying, and then carrying out thermal treatment for 2h in the mixed atmosphere of argon and hydrogen at the temperature of 800 DEG C to obtain the flake MoS2 / graphene composite aerogel. According to the flake MoS2 / graphene composite aerogel and the preparation method thereof disclosed by the invention, thin layers of graphene are connected with one another in a staggering mode to form a three-dimensional ordered conductive network and form micron pore canals, MoS2 is uniformly dispersed on the ultra-large superficial area, and thus, the problems of volume expansion and crushing materials are effectively solved; meanwhile, the structure stability and the cycle performance of the flake MoS2 / graphene composite aerogel, serving as the anode material, are improved.

Owner:SHANGHAI UNIV

High-performance silicon/carbon anode nanocomposite and preparation method thereof

ActiveCN108428876ARich varietyGuaranteed stabilityMaterial nanotechnologyCell electrodesLithiumCarbon nanosphere

The invention provides a high-performance silicon / carbon anode nanocomposite and a preparation method thereof. The high-performance silicon / carbon anode nanocomposite is characterized by containing carbon nano-spherical particles with mesoporous channels, and the spherical particles and / or the mesoporous channels are filled with elementary silicon particles. The prepared silicon / carbon anode nanocomposite is of a porous structure, the elementary silicon particles are dispersed in a carbon skeleton and the mesoporous channels, the volume expansion effect during lithium-ion charge and dischargeis low, and electrochemical cycle performance is stable.

Owner:DONGHUA UNIV

Silicon-carbon composite material and preparation method thereof

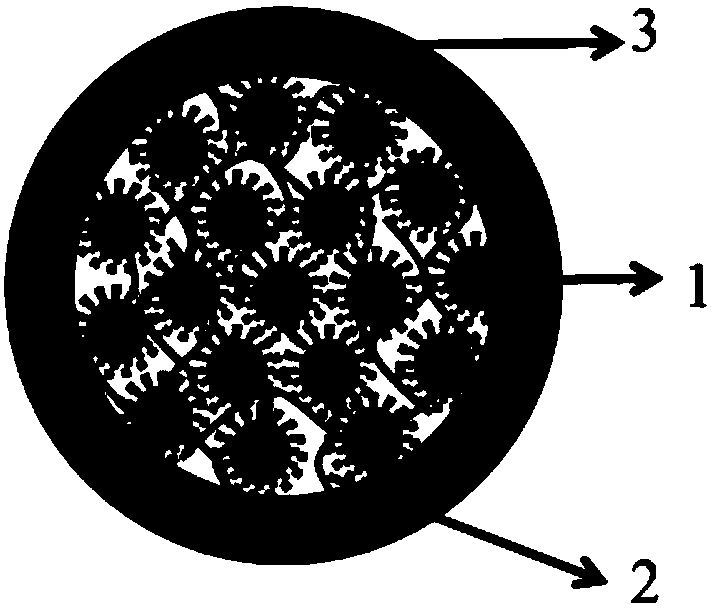

InactiveCN109802120AAvoid chalkingImprove cycle performanceMaterial nanotechnologyCell electrodesCyclic processCarbon coating

The invention discloses a silicon-carbon composite material which is a composite material similar to a dragon fruit structure. The silicon-carbon composite material comprises a base core, a silicon-carbon composite housing and a coating layer. The silicon-carbon composite housing is formed by uniformly dispersing a plurality of nano silicon particles in conductive carbon. The nano silicon particles are formed by pyrolysis of a silicon source. The conductive carbon is formed by pyrolysis of an organic carbon source. The coating layer is a carbon coating layer. At least one carbon coating layeris provided. The thickness of a single carbon coating layer is 0.2 to 3[mu]m. Compared with the prior art, a silicon-carbon composite material precursor is formed by using vapor phase synchronous deposition, and carbon coating is performed to form the silicon-carbon composite material similar to the dragon fruit structure. The silicon-carbon composite material has a high first effect, low expansion and long circulation, slows down the silicon material grain growth during the heat treatment process, avoids the powdering of the material during the cycle, alleviates the volume expansion effect ofthe silicon-based material, and is improved in the cycle performance, the electrical conductivity and the rate performance.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

Hollow/porous structure silicon-based composite material and preparation method thereof

InactiveCN109449423AAlleviate volume effectAvoid chalkingMaterial nanotechnologySiliconCarbon compositesCarbon coating

The invention discloses a hollow / porous structure silicon-based composite material. The composite material comprises a hollow / porous structure, a silicon-carbon composite layer and a coating layer, the silicon-carbon composite layer is formed by evenly dispersing nano silicon or silica in a conductive carbon network, the conductive carbon network in the silicon-carbon composite layer is formed with binder through pyrolysis, the coating layer is a carbon coating layer, and at least one carbon coating layer is provided. The composite material provided by the invention is prepared through a method of evenly mixing the nano silicon / silica, the binder and salt, then, performing spray granulation, high temperature sintering, water desalination and coating treatment. The composite material provided by the invention is a lithium ion battery silicon-carbon cathode material with the advantages, such as high first effect, low expansion and long cycle; grain growth of the silicon material in a thermal treatment process is slowed, powdering of the material in a cycle process is avoided effectively, volume expansion effect of the silicon-based material is remitted, cycle performance is promoted,and conductivity and rate capability of the material are improved.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

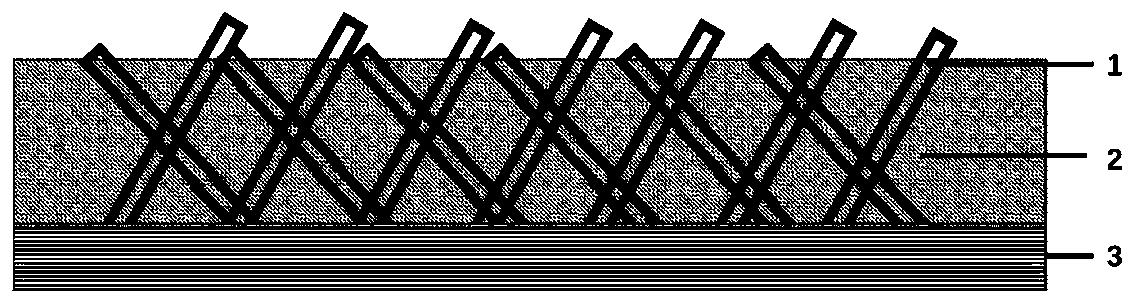

Electrochemical deposition preparation for lithium ionic cell tin-cobalt alloy film electrode

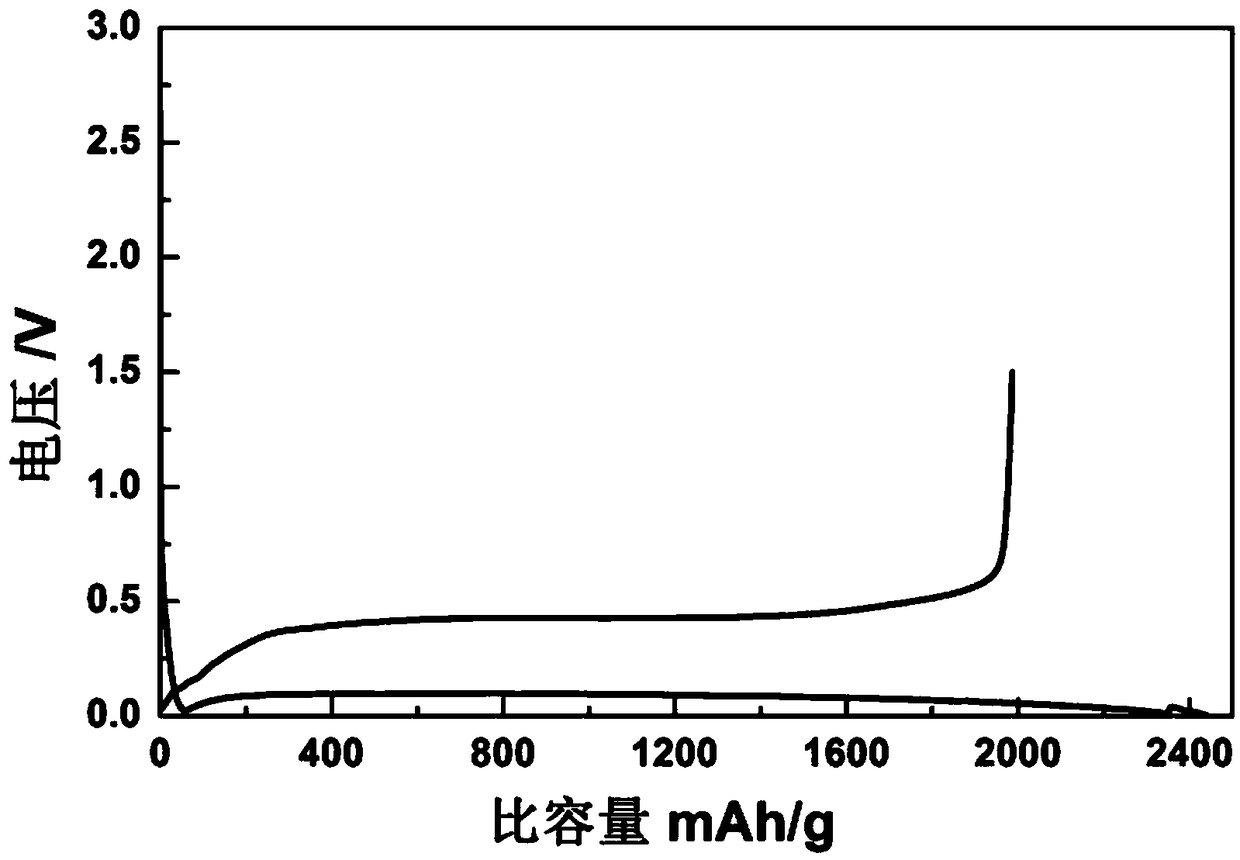

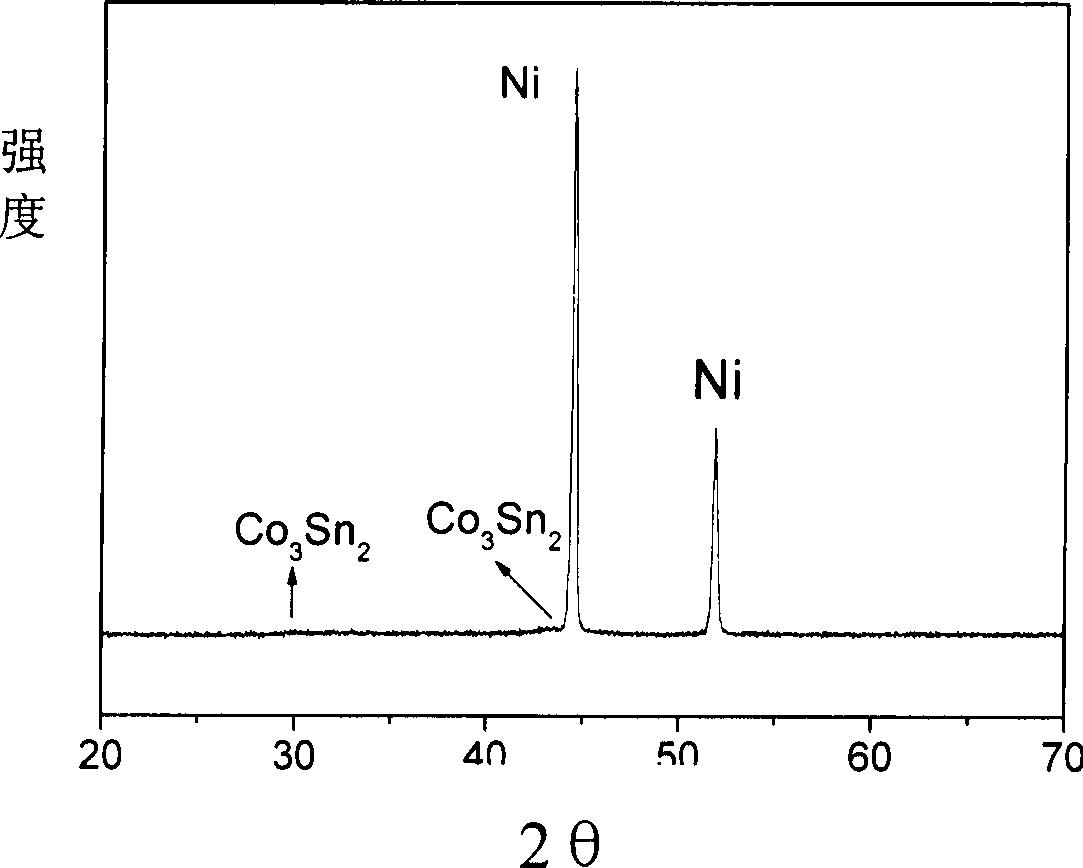

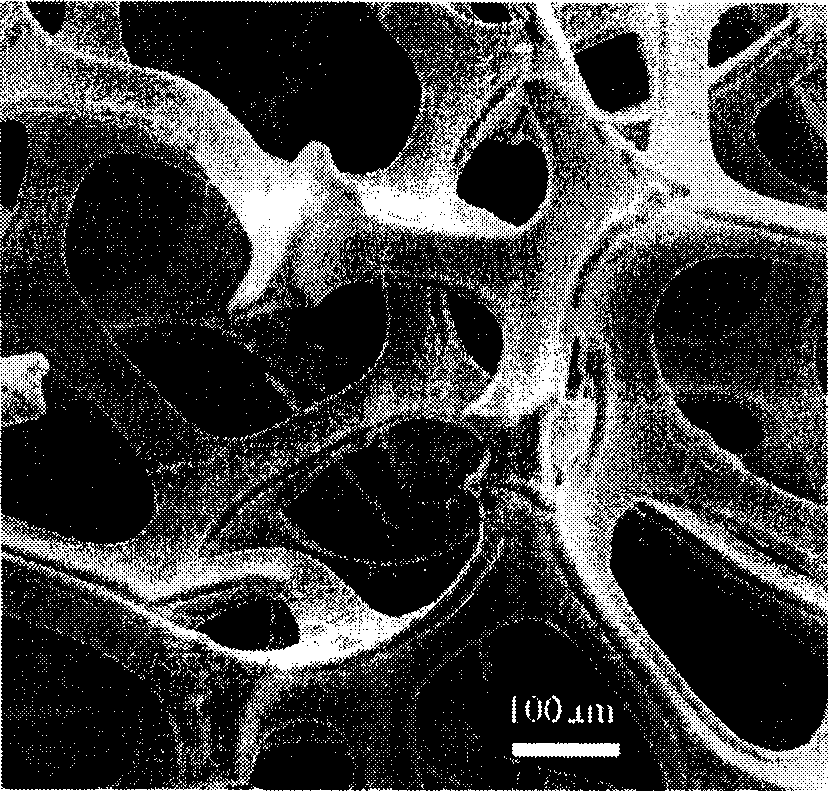

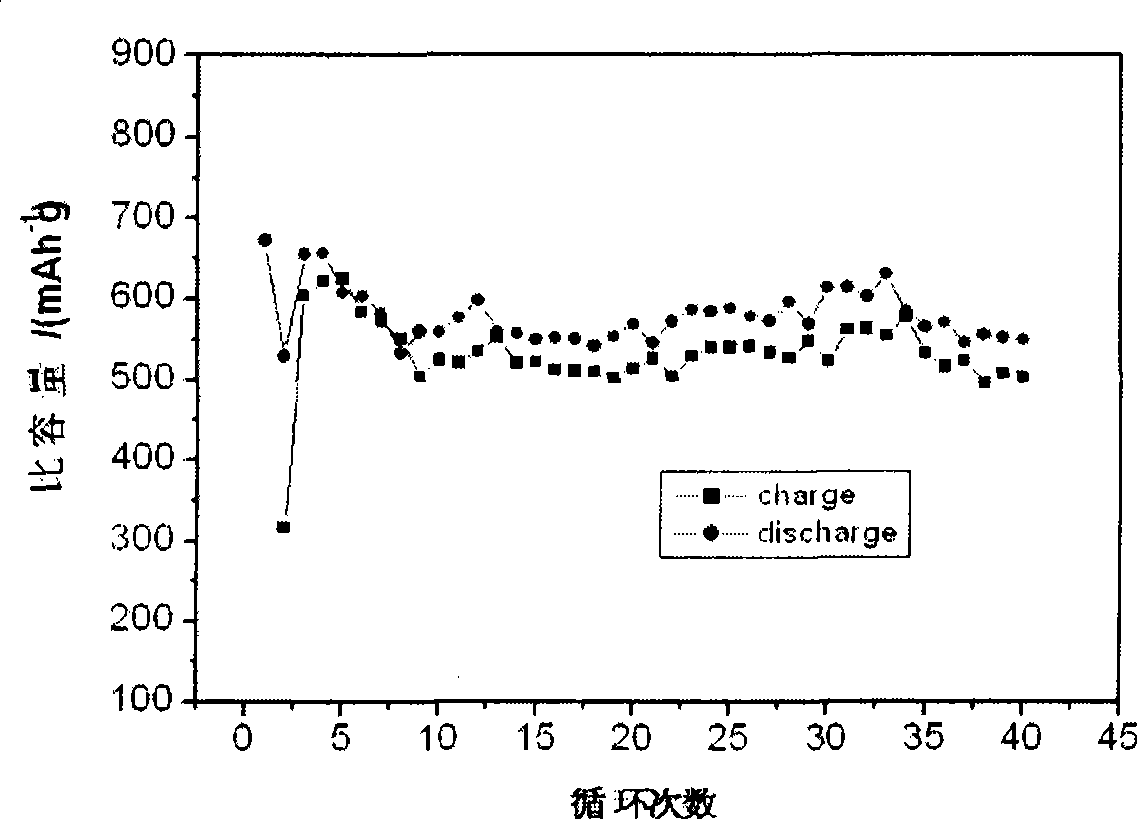

InactiveCN101476139AThe preparation process is easy to controlSimple processAlkaline accumulator electrodesThin film electrodeLyonium ion

The invention provides an electrical chemical depositing method for preparing lithium battery tin-cobalt alloy thin film electrode which has characteristics that foam nickel with a plurality of holes is used as basic body, the tin-cobalt alloy thin film is obtained by electrical chemical depositing on the foam nickel basic body for manufacturing lithium battery tin-cobalt alloy thin film electrode. The method has advantages of simple practical and low cost, and the tin-cobalt alloy thin film electrode is distributed on the foam nickel basic body that can ease electrode expansion in charge / discharge cycle process for improving cycle performance of battery. The method has latent application prospect in the lithium battery electrode material field.

Owner:HEFEI UNIV OF TECH

A silicon-based composite negative electrode material, a preparation method thereof and an energy storage device

ActiveCN109119617AAlleviate the volume expansion effectGood conductivity and ion conductivitySolid electrolytesHybrid capacitor electrodesQuinoneStructural stability

An embodiment of the present invention provides a silicon-based composite negative electrode material, which comprises a silicon-based material core and a cladding layer coated on the surface of the silicon-based material core, the cladding layer comprises a first cladding layer disposed on the core surface of the silicon-based material and a second cladding layer disposed on the surface of the first cladding layer, the first cladding layer comprising a two-dimensional quinone-aldehyde covalent organic skeleton material, and the second cladding layer comprising a fast conductive ion material.Wherein, the first cladding layer has superhigh toughness and ordered pore structure, can effectively absorb the stress generated by the expansion of the silicon-based material core and ensure the integrity of the cladding layer, simultaneously has high conductivity and ionic conductivity, and can effectively improve the electronic and ionic conductivity effect of the cladding layer; and the second cladding layer has high rigidity, the structure stability of the whole material can be maintained when the silicon expands and contracts, and the volume expansion can be effectively alleviated. Theembodiment of the invention also provides a preparation method of the silicon-based composite negative electrode material and an energy storage device comprising the silicon-based composite negative electrode material.

Owner:HUAWEI TECH CO LTD

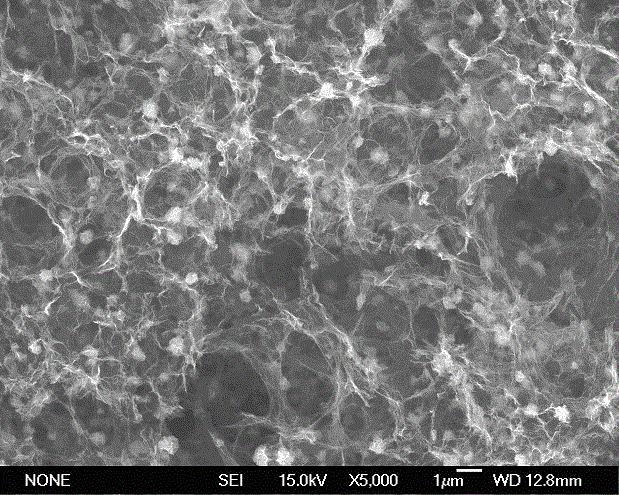

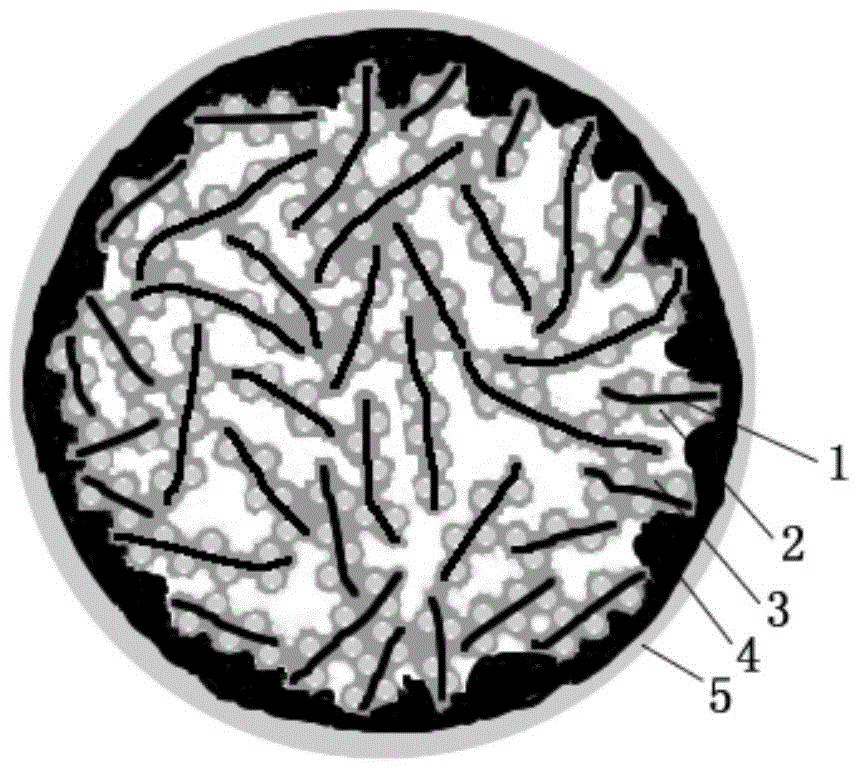

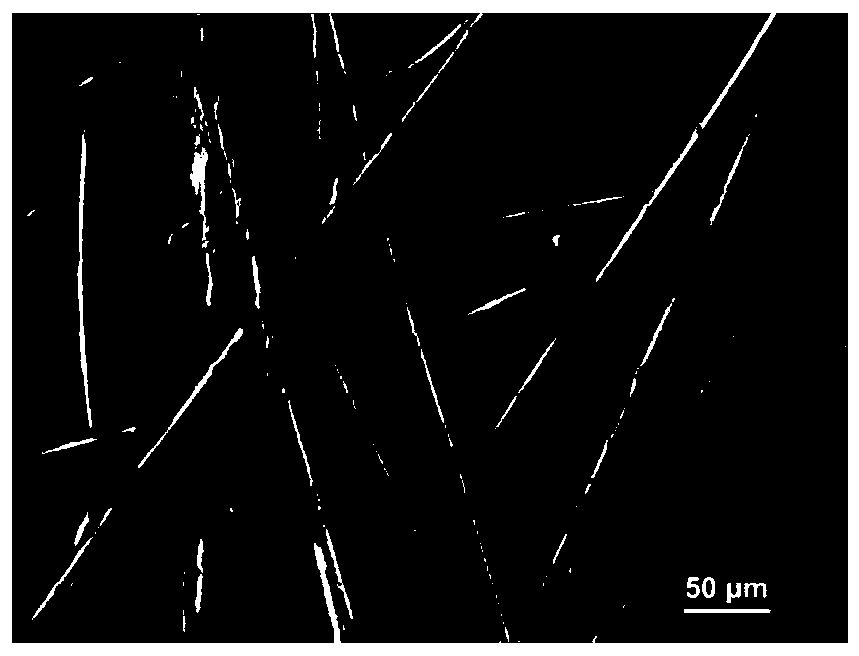

Lithium battery silicon-carbon nanotube composite cathode material as well as preparation method and application thereof

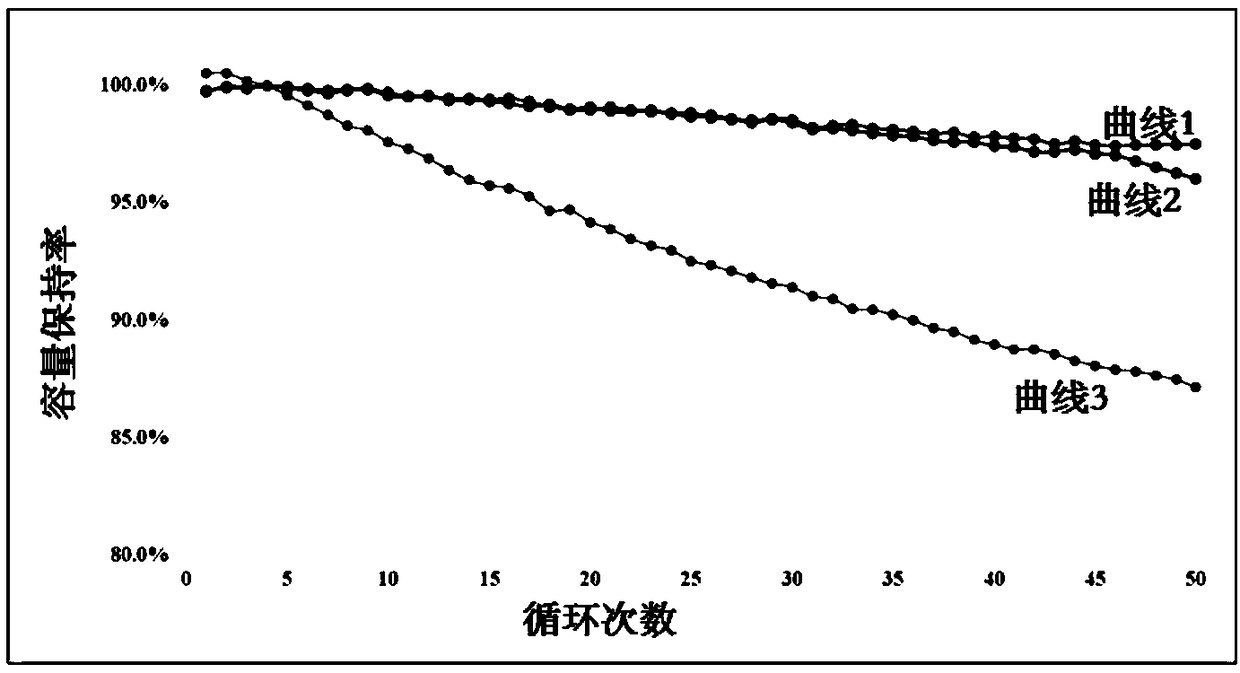

InactiveCN103346302ASolution volumeSolve efficiency problemsMaterial nanotechnologyCell electrodesCarbon nanotubeSlurry

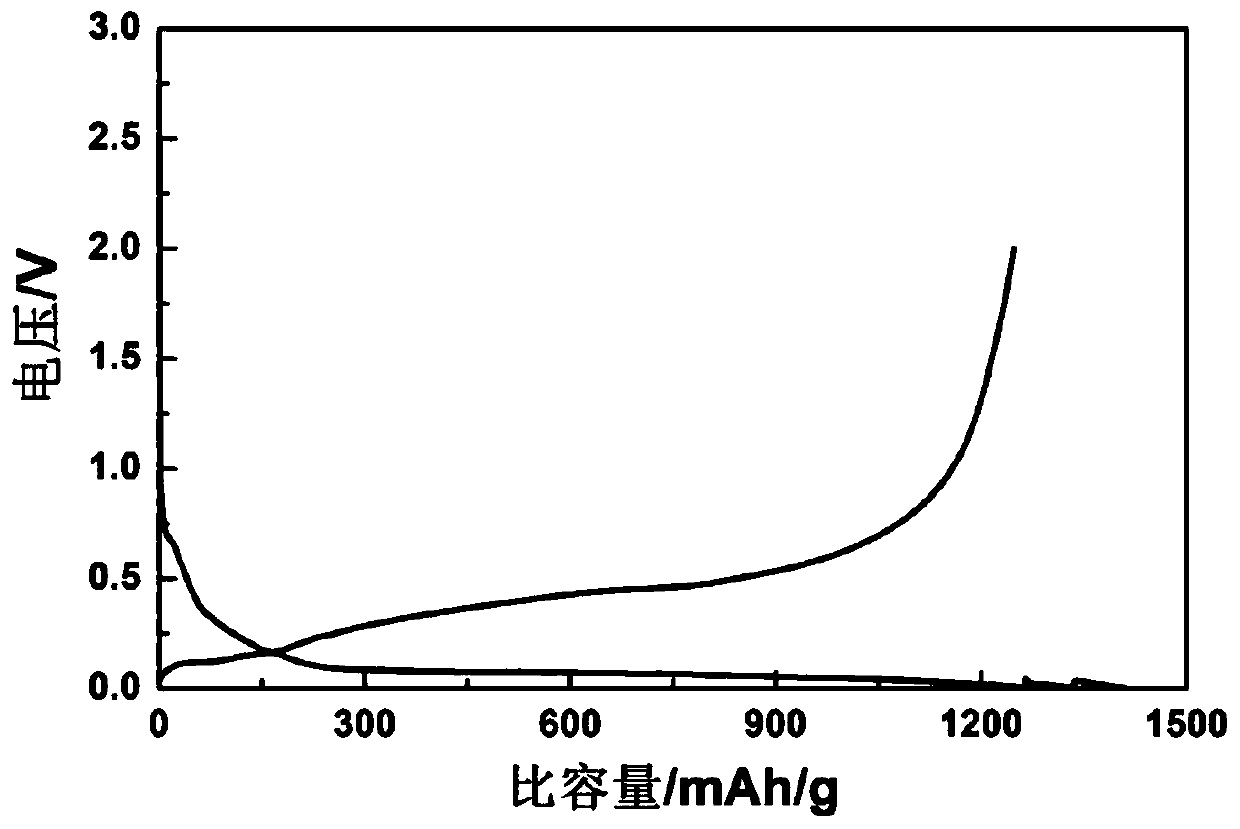

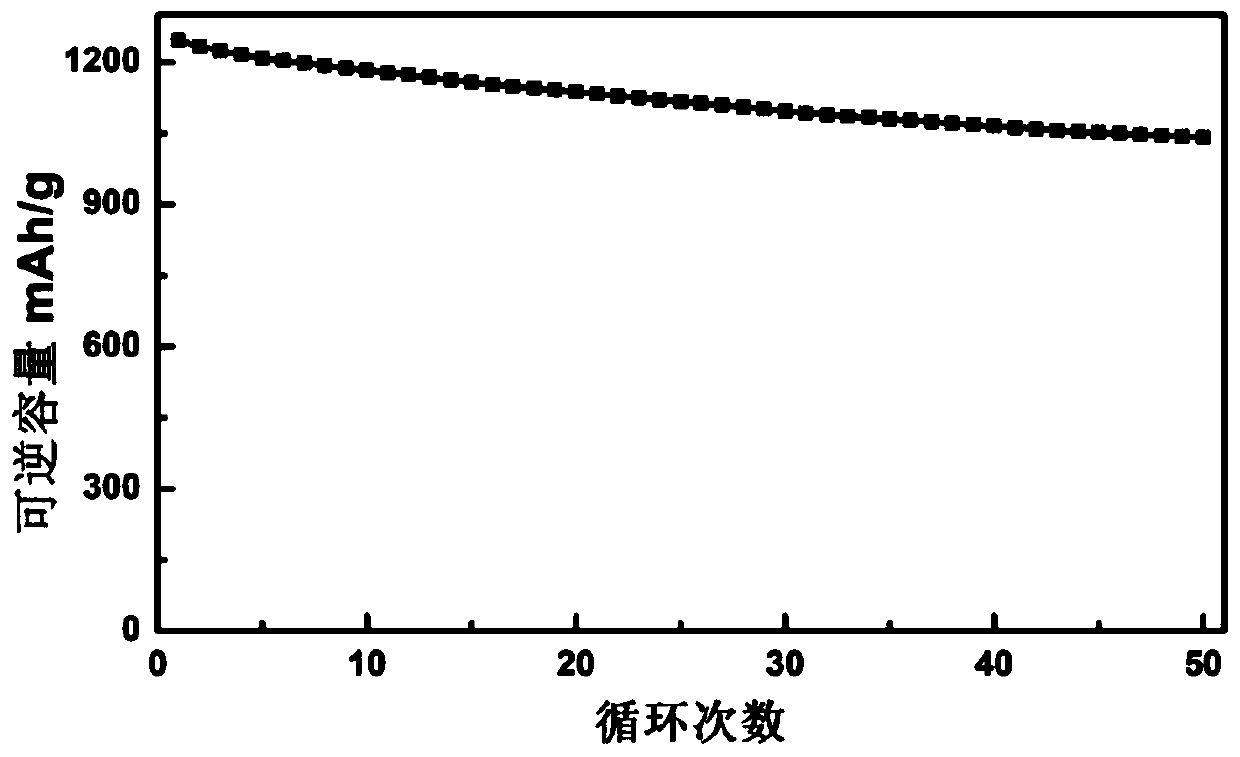

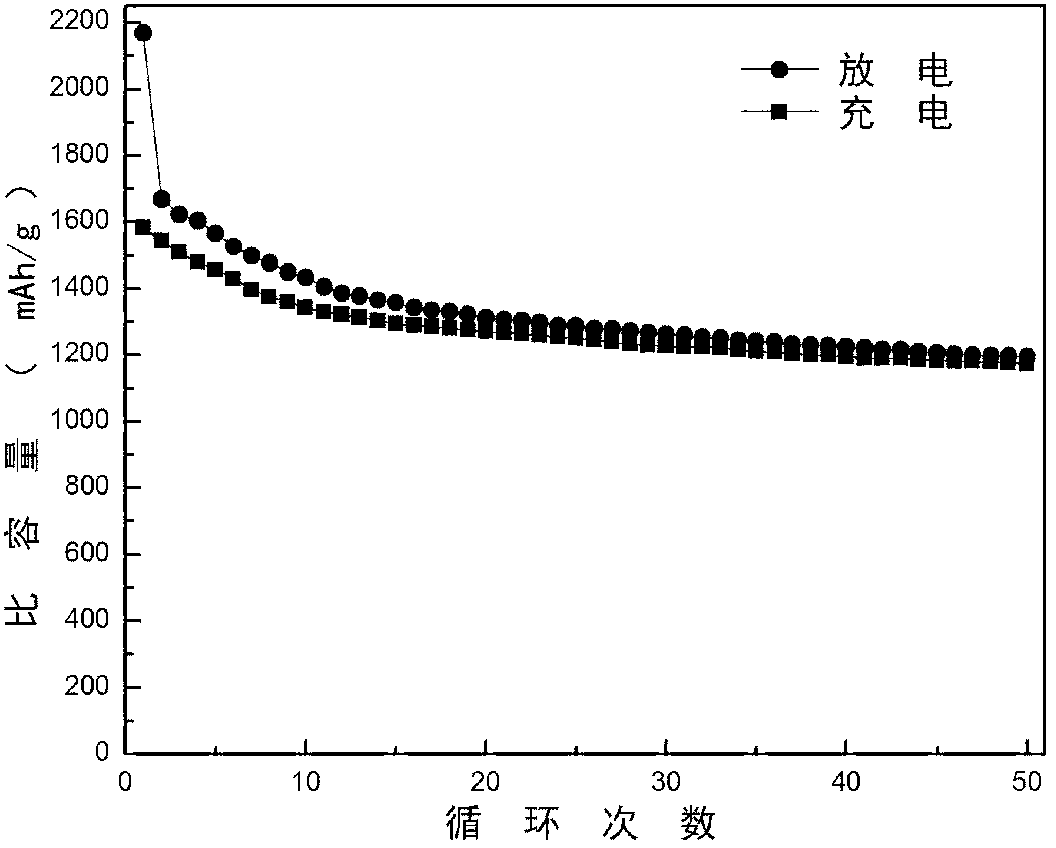

The invention discloses a lithium battery silicon-carbon nanotube composite cathode material as well as a preparation method and application of the lithium battery silicon-carbon nanotube composite cathode material. The preparation method of the lithium battery silicon-carbon nanotube composite cathode material comprises the following steps of: mixing and uniformly stirring an organic carbon source and nanometer silicon based on the mass ratio of (0.4-9): 1, adding a catalyst to obtain mixed slurry, drying by a closed circulation spray dryer to obtain a precursor, insulating the precursor for 1-5 hours at the temperature of 300-700 DEG C to obtain a sample, feeding the sample in a tube furnace, increasing the temperature to 500-900 DEG C under the mixed gas of gaseous organic carbon source and N2 and Ar2, and naturally cooling to obtain the lithium battery silicon-carbon nanotube composite cathode material. The lithium battery silicon-carbon nanotube composite cathode material has excellent electrochemical properties, high first charge-discharge efficiency up to more than 2000mAh / g, reversible specific capacity of about 1100mAh / g after cycle of 50 weeks, and good specific capacity and cycle performance, and the problems of low first efficiency, large irreversible capacity loss and poor conductivity of silicon when being used to prepare a lithium ion battery cathode are successfully solved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

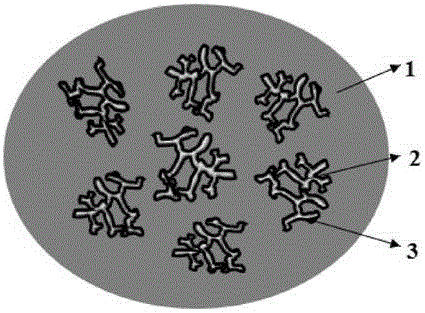

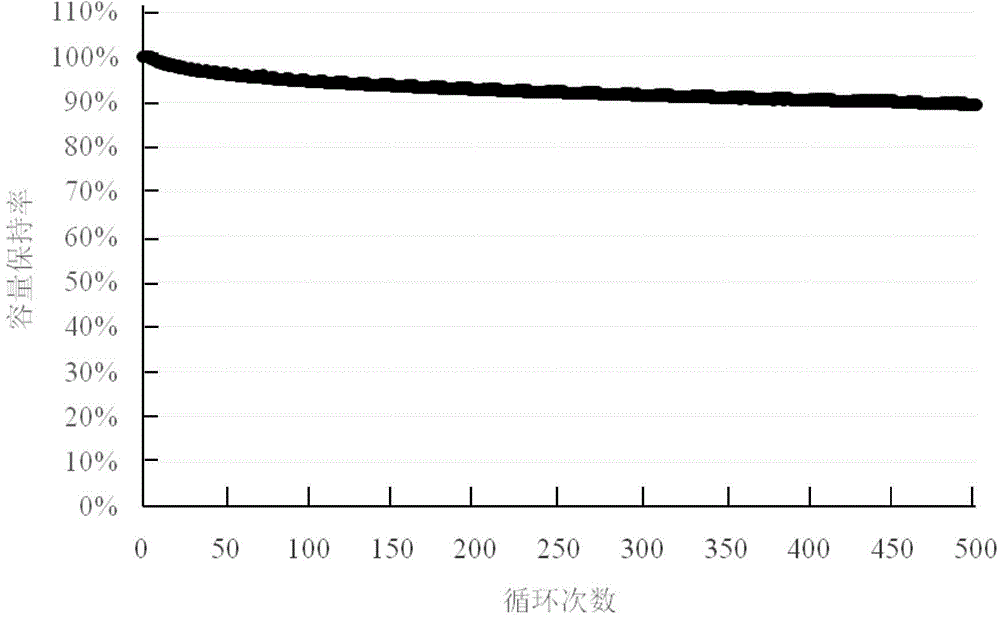

Silicon-based composite and preparation method thereof and lithium ion battery with silicon-based composite

ActiveCN106159229AThe process is simple and easy to controlEasy to processMaterial nanotechnologyCell electrodesCarbon layerSilicon oxide

The invention relates to a silicon-based composite and a preparation method thereof and a lithium ion battery with the silicon-based composite. The silicon-based composite comprises a carbon matrix and carbon-coating dendritic nanometer silicon evenly distributed in the carbon matrix; the carbon-coating dendritic nanometer silicon includes dendritic nanometer silicon and a carbon coating layer coating the surface of the dendritic nanometer silicon. The preparation method includes: restoring silicon oxide through metal to prepare the dendritic nanometer silicon, coating a conductive carbon layer in situ in the silicon surface through a homogeneous coating technology, and dispersing the carbon-coating dendritic nanometer silicon in the carbon matrix through a fusion technology. The preparation method is simple in technology and good in processability, the obtained silicon-based composite, serving as a anode material to produce batteries, has the advantages of high specific capacity, long cycle life and high electrical conductivity; first reversible capacity is above 1480mAh / g, first coulomb efficiency is above 87.1%, and 450 times of circulation capacity retention is above 91.1%.

Owner:BTR NEW MATERIAL GRP CO LTD

Lithium ion battery negative electrode active material, preparation method thereof, negative electrode and lithium ion battery comprising negative electrode

InactiveCN107293701AIncrease capacityReduce capacityCell electrodesSecondary cellsCarbon layerSilicon alloy

The invention proposes a lithium ion battery negative electrode active material, a preparation method thereof, a negative electrode and a lithium ion battery comprising the negative electrode. The negative electrode active material is of a core-shell structure, wherein the core comprises lithium silicon alloy particles, and the shell is a carbon layer. In the negative electrode active material employing the core-shell structure of which the core is the lithium silicon alloy particles and the shell is the carbon layer, the volume expansion effect of silicon used as the negative electrode can be effectively reduced; and when the negative electrode is applied to the battery, relatively high capacity of the obtained battery can be maintained, and meanwhile, the battery also has good cycle property.

Owner:BYD CO LTD

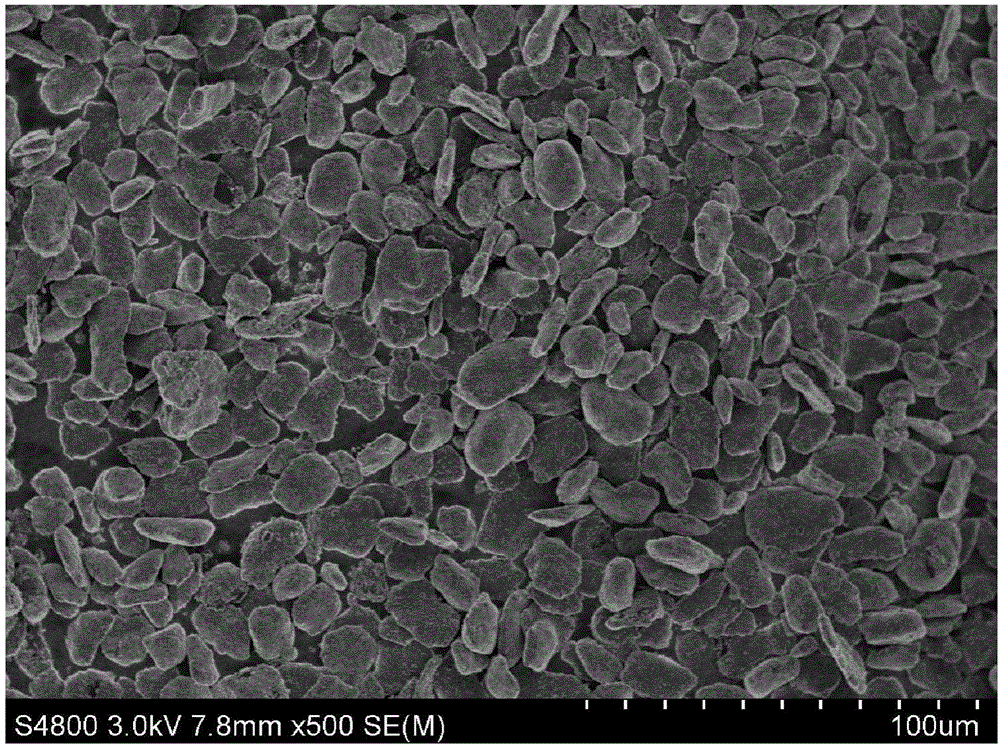

Preparation method of porous long-circulation silicon carbon negative electrode material

InactiveCN107623113AAlleviate the volume expansion effectImprove conductivityCell electrodesLi-accumulatorsCarbon sourceLiquid phase

Owner:赣州市瑞富特科技有限公司

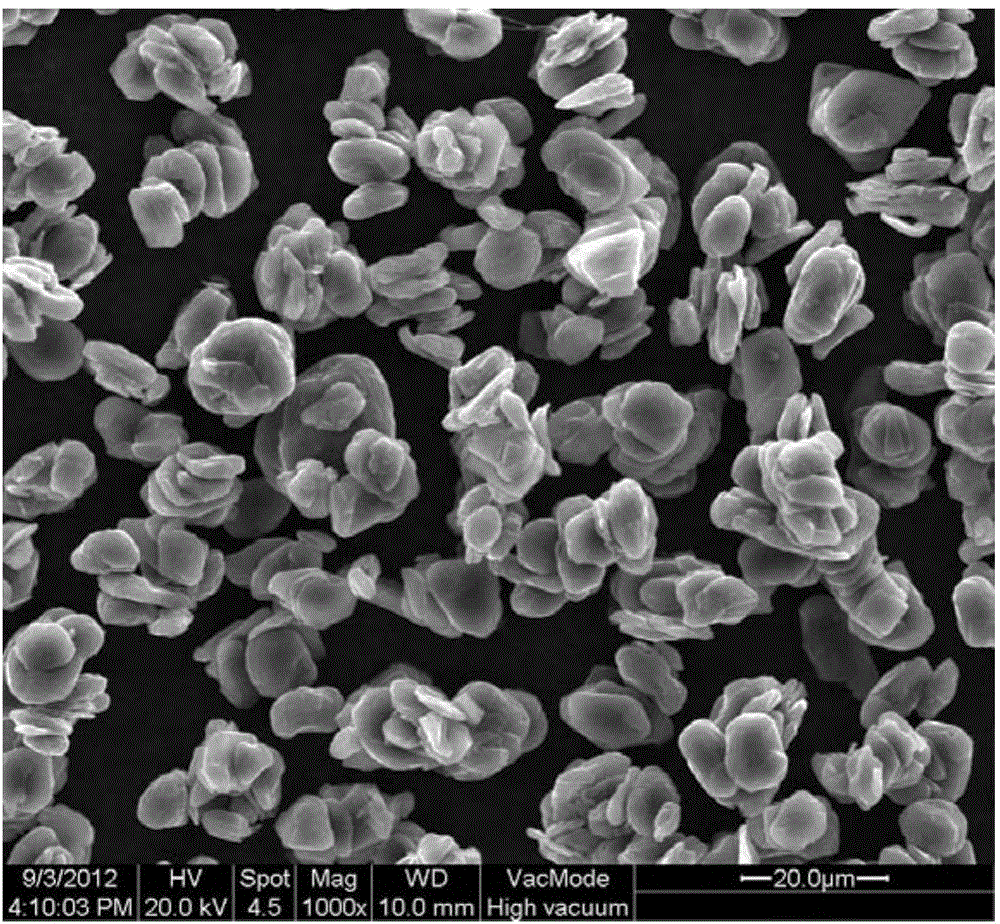

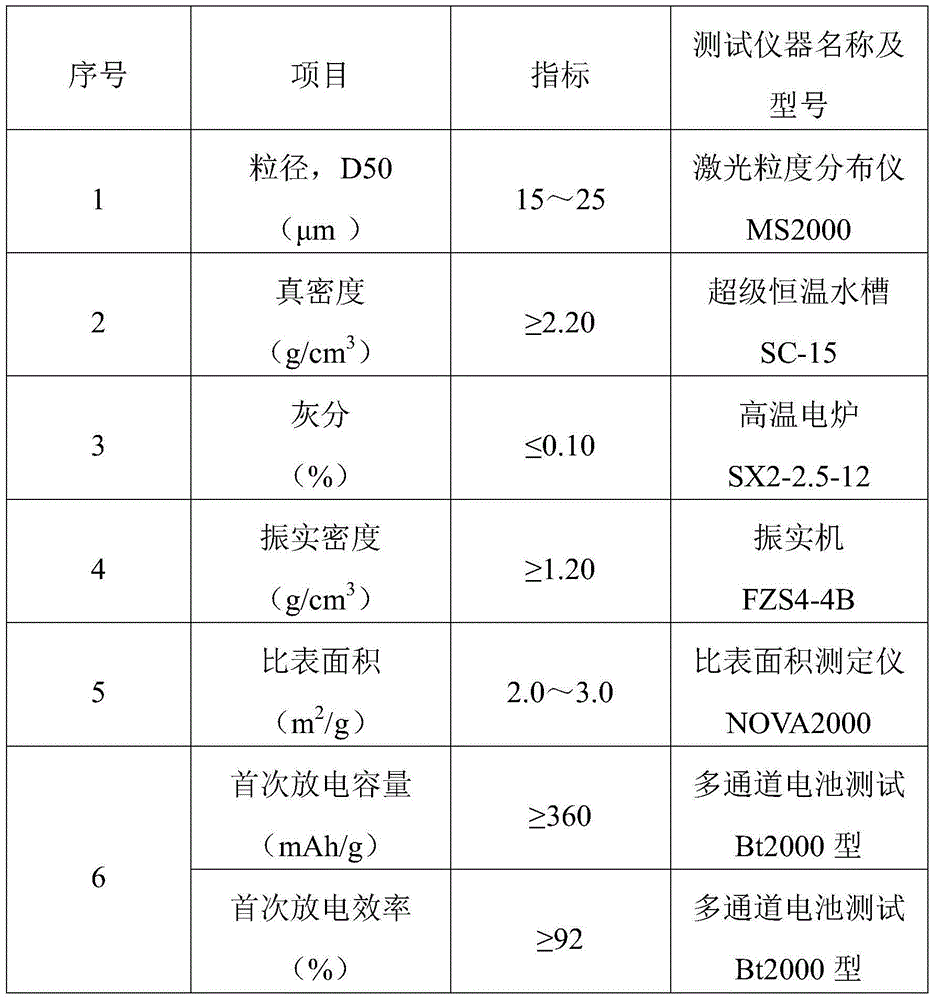

Lithium ion battery graphite anode material and preparation method thereof

ActiveCN105731427AAlleviate the volume expansion effectWide variety of sourcesCell electrodesAdhesiveCarbonization

The invention discloses a lithium ion battery graphite anode material and a preparation method thereof. The preparation method includes the steps of: 1) heating and kneading a mixture of natural graphite and an adhesive; 2) performing hot isostatic pressing moulding at 500-1000 DEG C under 50-100 MPa; 3) performing carbonization; 4) performing graphitization; and 5) crushing and classifying a product. The lithium ion battery graphite anode material has high tap density, large discharge capacity and good cycle performance, is reduced in internal pores of graphite particles, reduces expansion and is improved in cycle performance.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

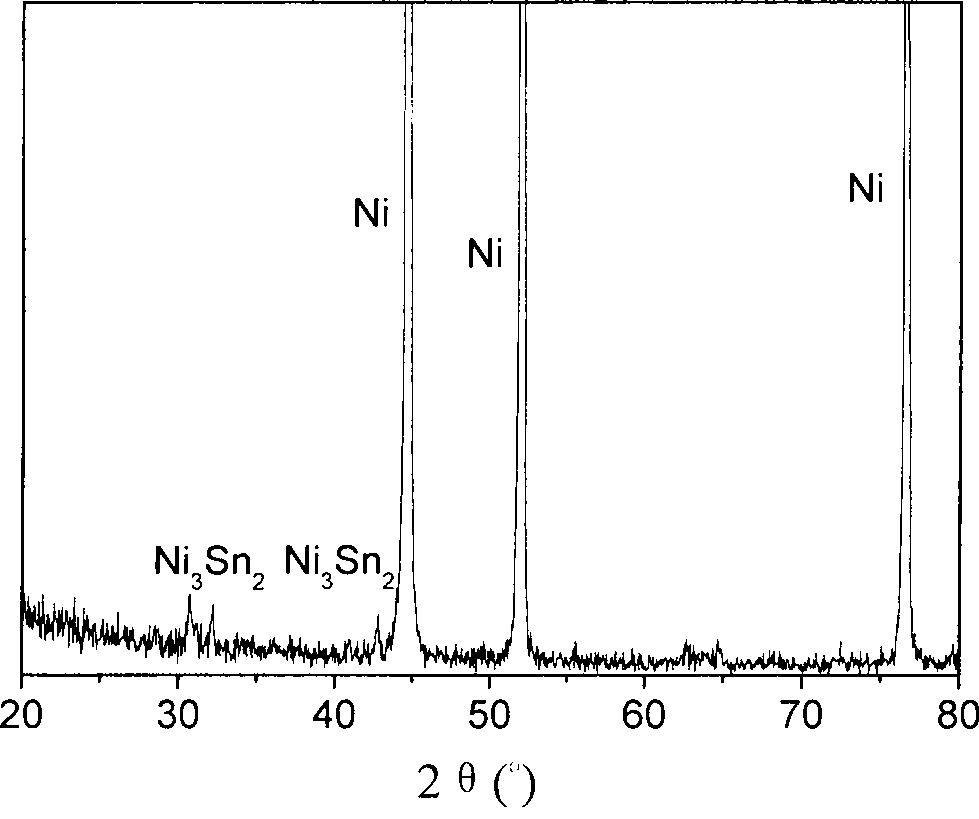

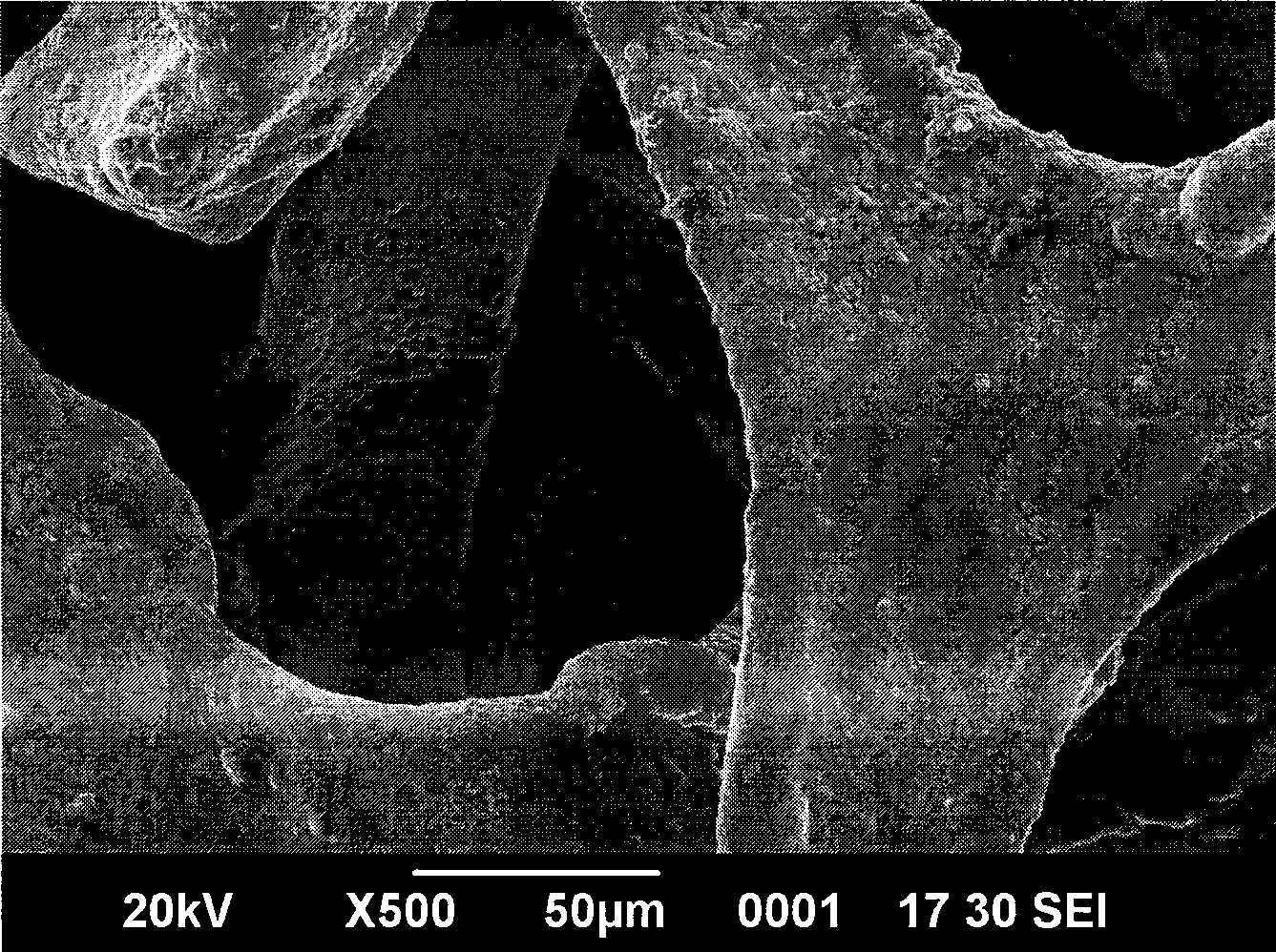

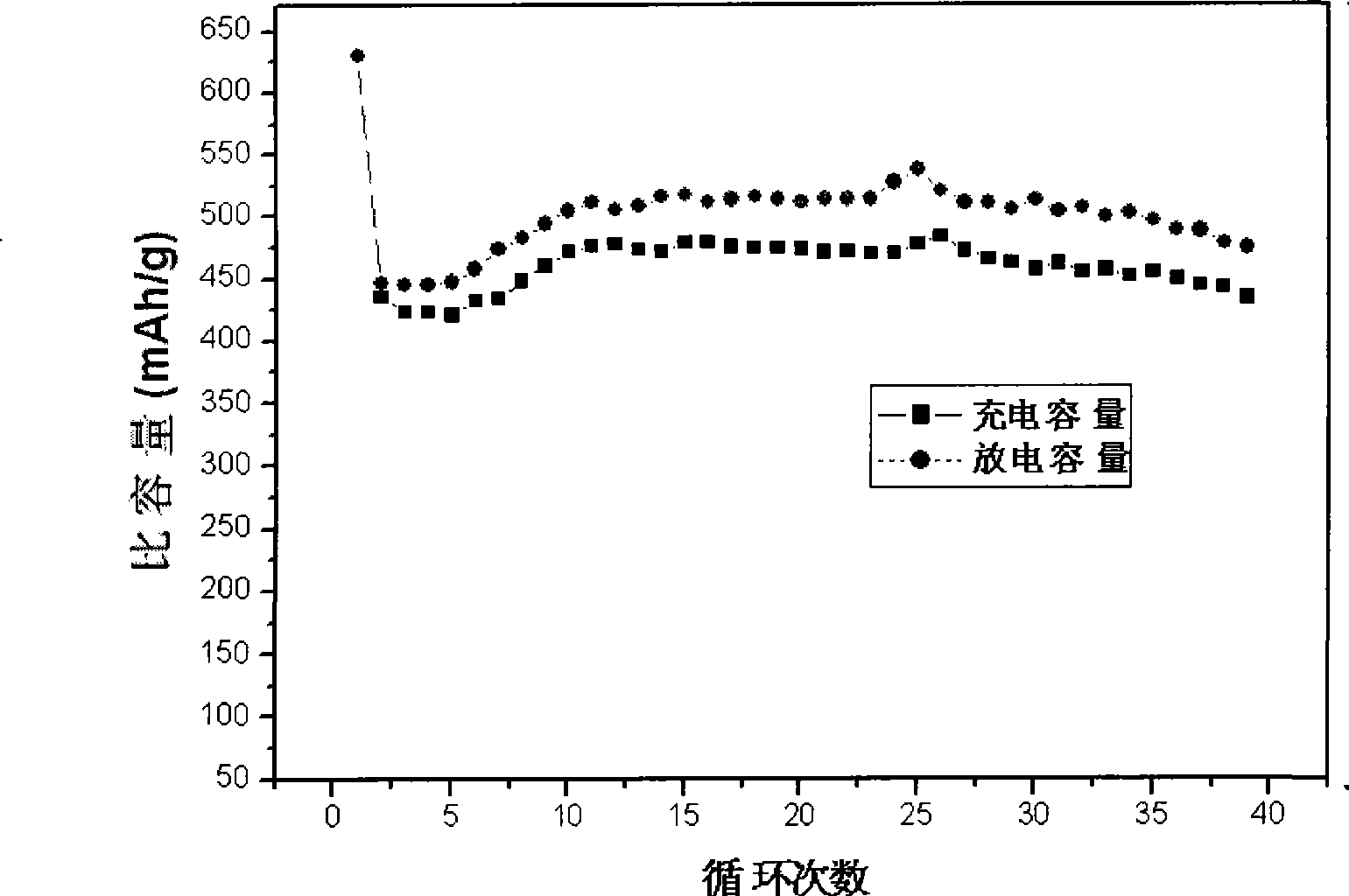

Method for preparing nickeltin thin film electrode for lithium ion battery through electrochemical deposition

InactiveCN101447567AThe preparation process is easy to controlSimple processElectrode manufacturing processesCyclic processThin film electrode

The invention relates to a method for producing lithium ion battery nickeltin thin-film electrode through electrochemical deposition. The method is characterized in that porous foamed nickel is adopts as the matrix, a nickeltin thin-film is obtained from the foamed nickel matrix through electrochemical deposition, and the lithium ion battery nickeltin thin-film electrode taking the foamed nickel as the matrix is produced. The method is simple, convenient and feasible, the cost is low, the nickeltin thin-film electrodes are distributed on the foamed nickel matrix, the expansion of the electrodes in the charging and discharging cyclic process can be eased, therefore, the cycle performance of the battery is improved, and the invention has potential application prospect on the application aspect of the electrode material of the lithium ion battery.

Owner:HEFEI UNIV OF TECH

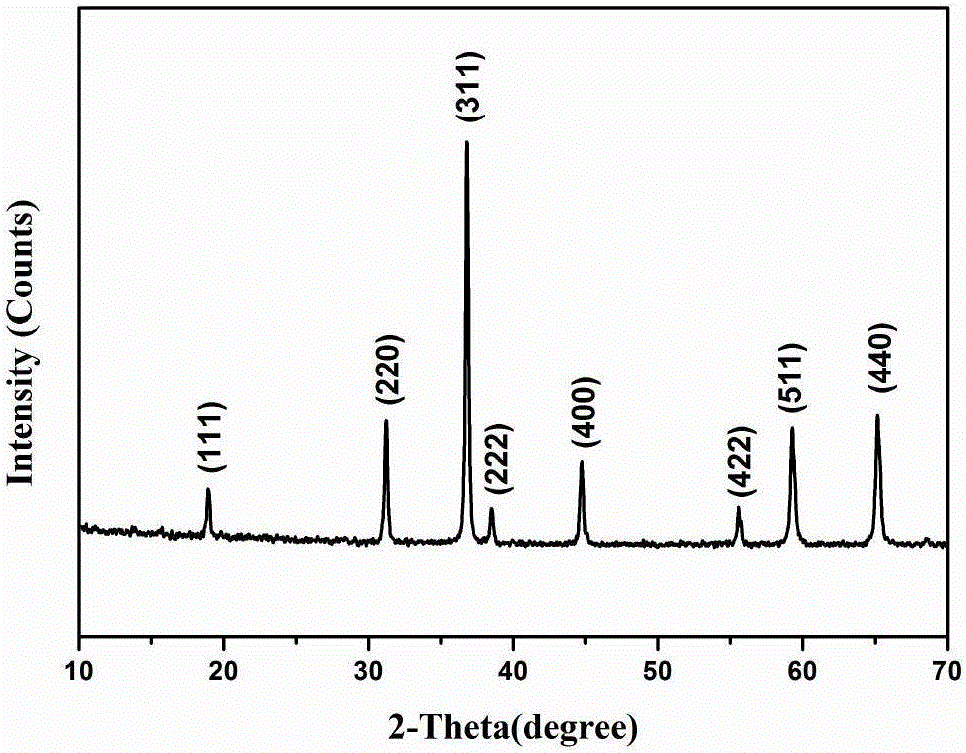

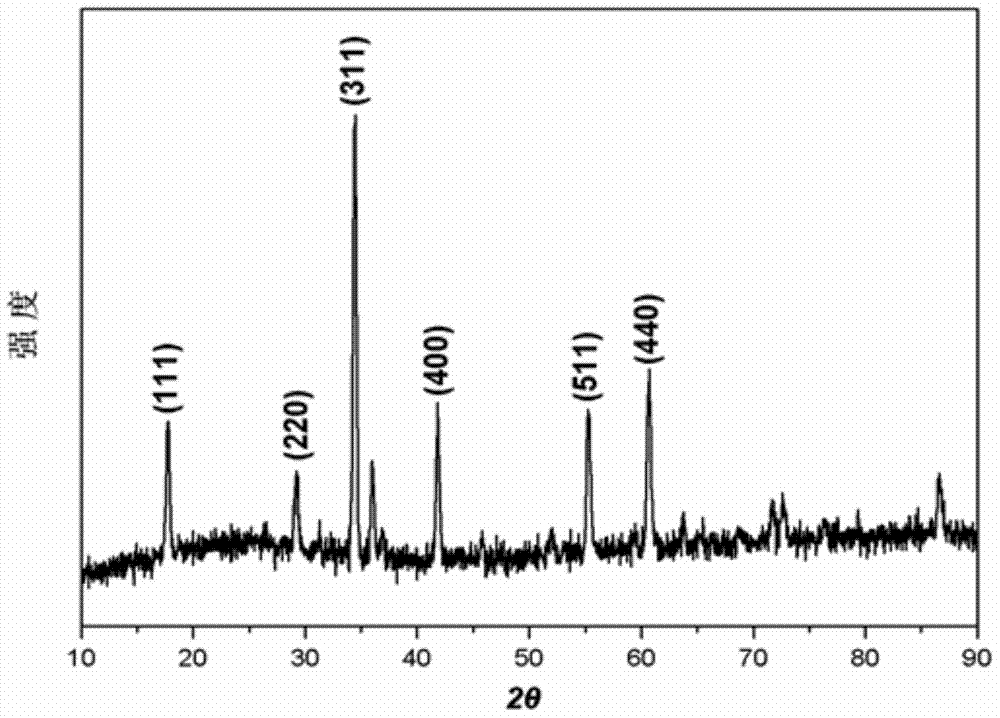

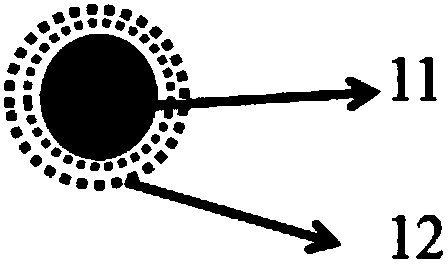

Preparation method of lithium ion battery anode material using biomass as carbon source and with C@Co3O4 core-shell structure

ActiveCN105826538AImprove cycle stabilityImproved magnification performanceCell electrodesSecondary cellsElectrochemistryHeat treated

Provided is a preparation method of a lithium ion battery anode material using biomass as a carbon source and with a C@Co3O4 core-shell structure .Edible fungus is utilized as biomass carbon, a carbon sphere precursor having surface activity is obtained through hydrothermal carbonization of concentrated sulfuric acid and then is heated and stirred in a solution containing cobalt salt to make the cobalt salt adsorbed on the surface, and then the lithium ion battery anode material with the C@Co3O4 core-shell structure is obtained through heat treatment .The electrical conductivity of the material is not only improved, the volume expansion effect of Co3O4 in the charging and discharging process is also relieved, and a Co3O4 structure is stabilized, so that the cycling stability and rate performance of a lithium ion battery are improved somewhat, and the lithium ion battery anode material having excellent electrochemical properties is obtained .

Owner:SHAANXI UNIV OF SCI & TECH

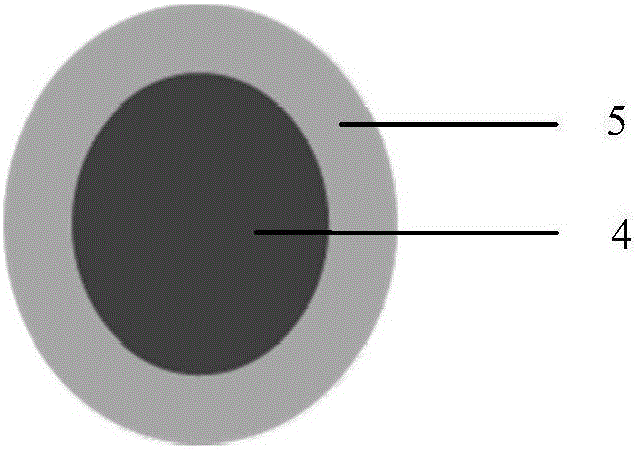

Single-layer/double-layer coated silicon oxide composite anode material and preparation method thereof

ActiveCN107959012AImprove cycle stabilityAlleviate the volume expansion effectCell electrodesCarbon layerSilicon oxide

The invention provides a single-layer / double-layer coated silicon oxide composite anode material and a preparation method thereof. The single-layer coated silicon oxide composite anode material is a two-layer composite material which has a core-shell structure, an inner core is a silica precursor, an outer layer is a lithium titanate layer, and the silica precursor is a material which is formed byuniformly dispersing and distributing silicon on silica. The double-layer coated silicon oxide composite anode material is a three-layer composite material which has a core-shell structure, an innercore is a silica precursor, a middle layer is a lithium titanate layer, and the outermost layer is a carbon layer which coats the outer surface of the lithium titanate layer. The double-layer coated silicon oxide composite anode material has the three-layer structure, the inner core is the silica precursor, the middle layer is the lithium titanate layer, the outermost layer is the carbon layer, the volume effect of silicon oxide can be buffered well, and thus, the double-layer coated silicon oxide composite anode material has high specific capacity and excellent cycle performance.

Owner:ETRUST POWER ETP GRP LTD

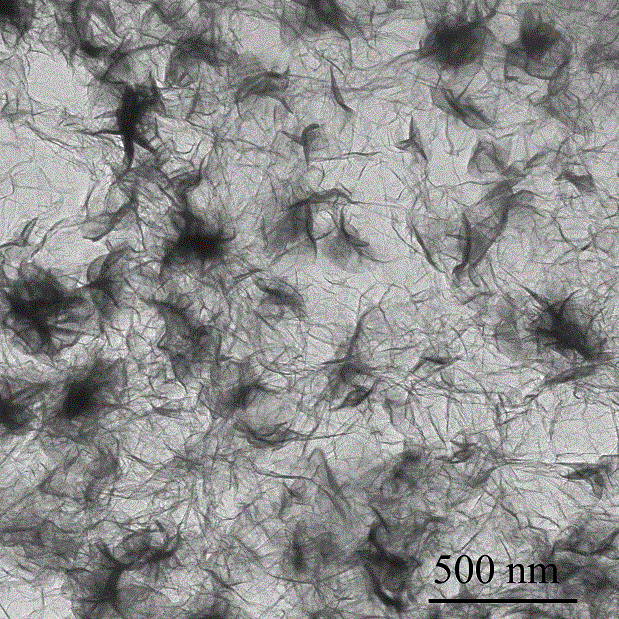

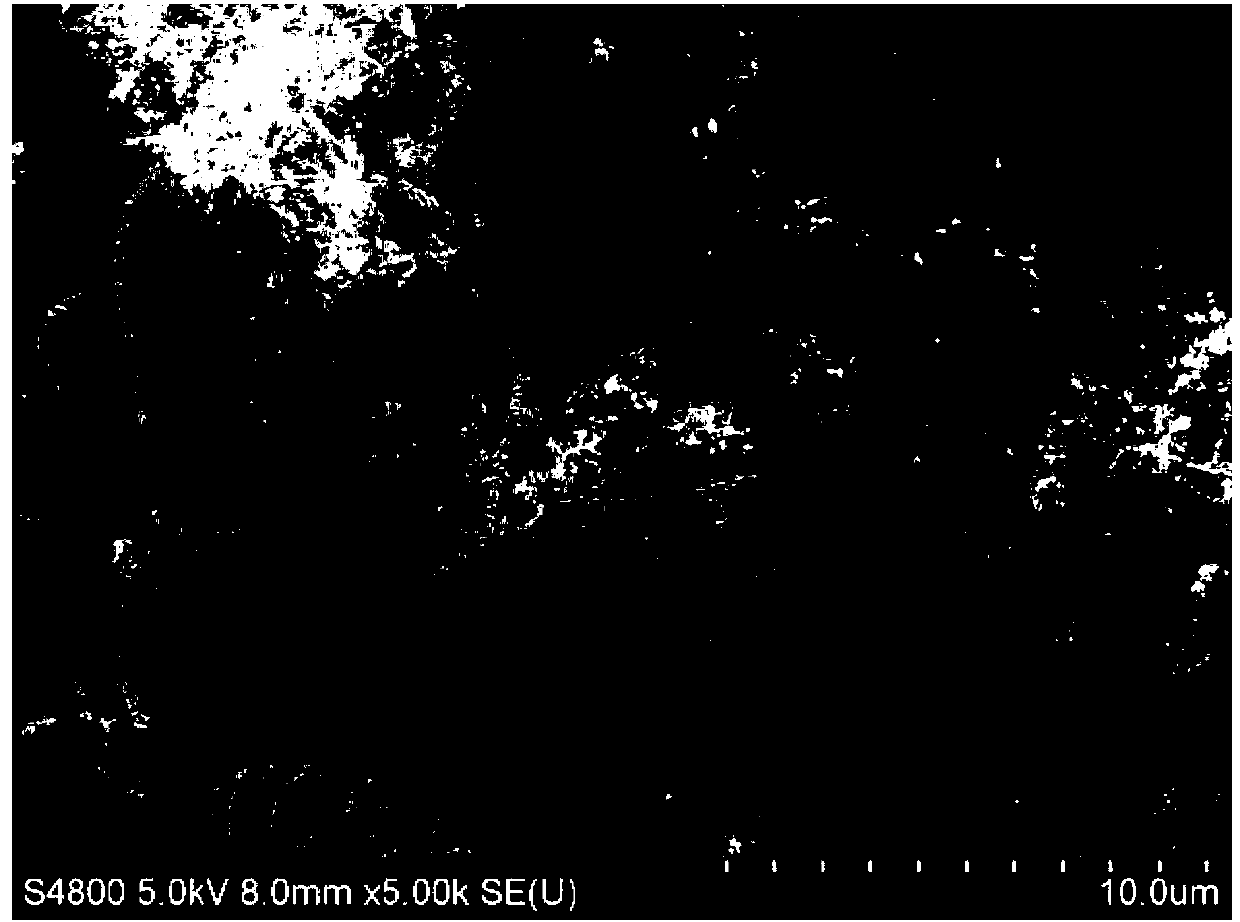

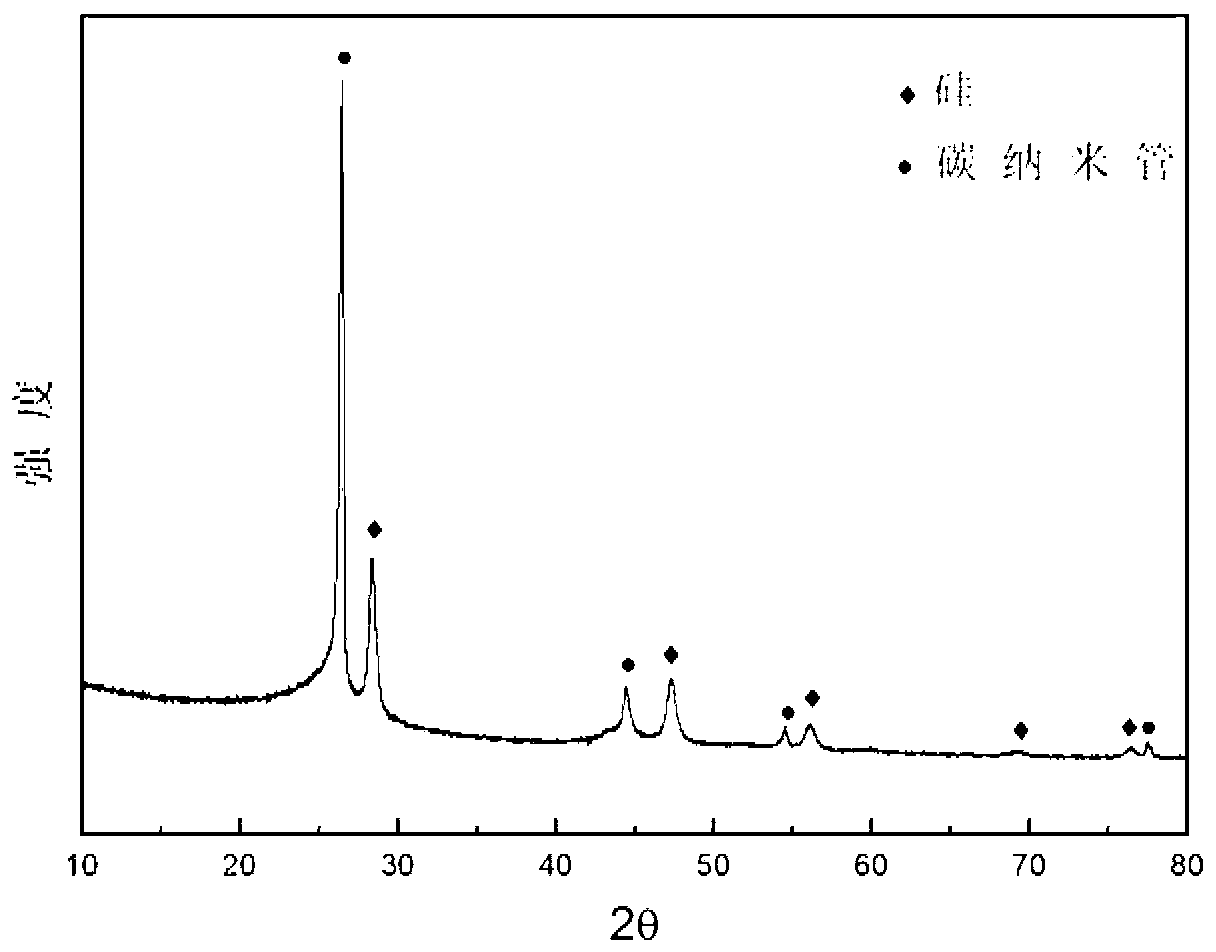

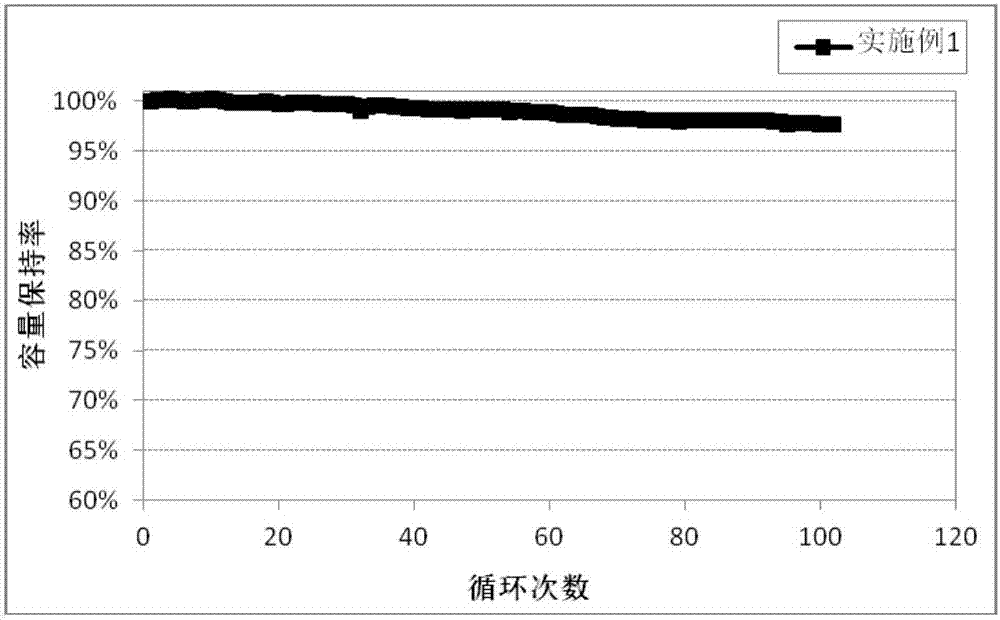

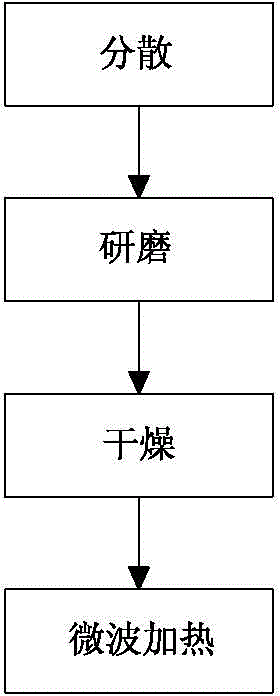

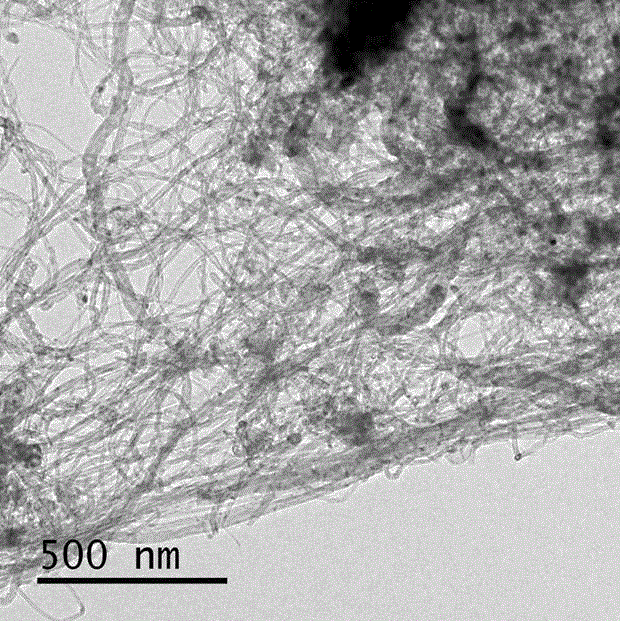

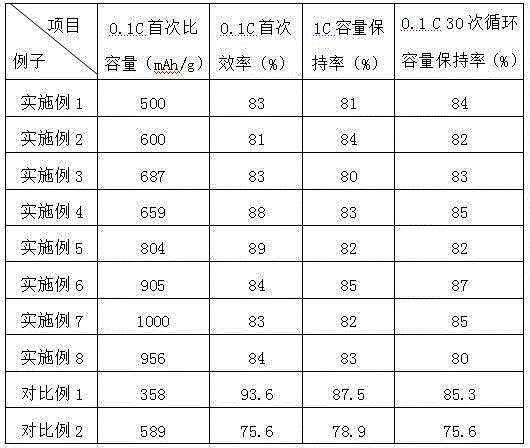

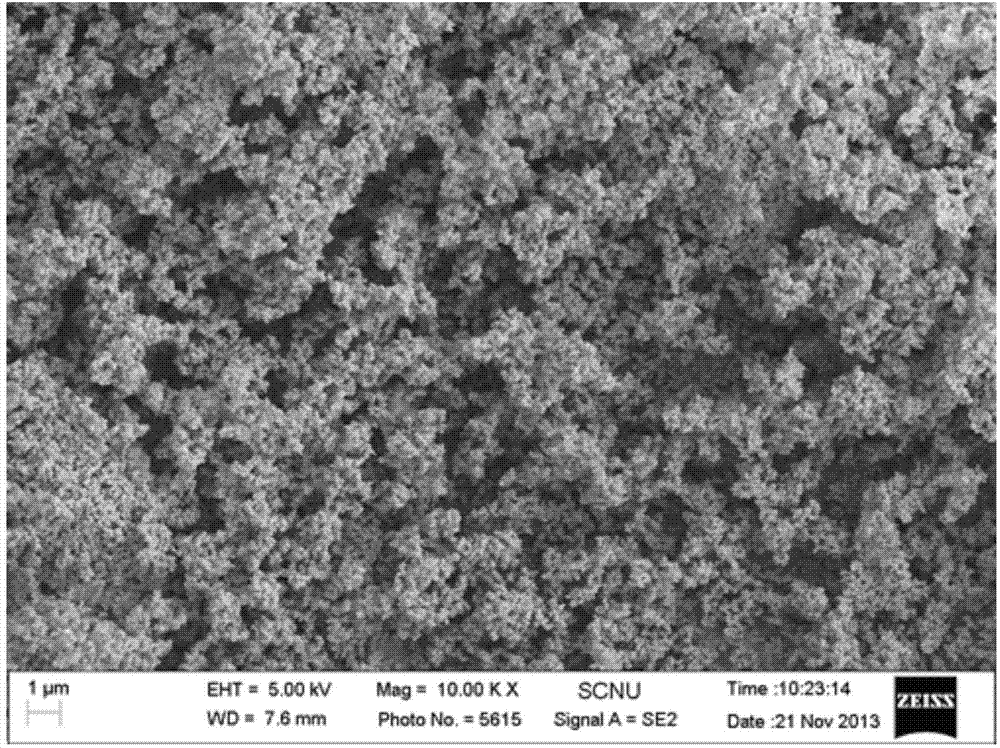

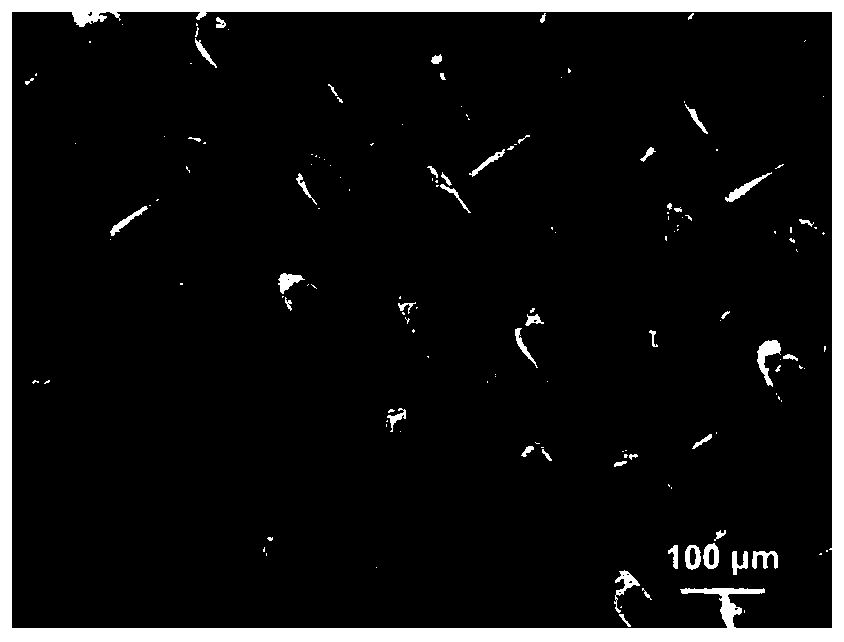

Method for preparing composite cathode material of silicon-carbon nanotube of lithium ion battery

ActiveCN104617261AAlleviate the volume expansion effectImprove conductivityNegative electrodesNanotechnologyDischarge efficiencyCarbon nanotube

The invention discloses a method for preparing a composite cathode material of a silicon-carbon nanotube of a lithium ion battery. According to the method, firstly, the surface of nano silicon is coated with a carbon source, carbon nanotubes are generated in microwave treatment, and furthermore the surface of silicon is also coated with an introduced catalyst, so that the carbon nanotubes which are coated with the carbon source and are generated through catalytic cracking are very uniformly distributed on the surface of nano silicon, the problems that in the prior art the nano silicon is high in volume expansion effect, low in first charge / discharge efficiency and poor in circulation stability are solved, and both the conductivity and the mechanical property of the composite cathode material prepared by using the method disclosed by the invention are greatly improved and the circulation property, the multiplying power charge and discharge performance and the initial charge-discharge efficiency of the composite cathode material as a lithium lion battery cathode material are all greatly improved when being compared with those of a silicon-carbon nanotube cathode material which is mixed in a mechanical ball-milling manner as silicon and carbon nanotubes are compounded in an in-situ manner in the method disclosed by the invention. In addition, the method disclosed by the invention is simple in process, and the energy consumption is greatly reduced due to the adoption of a simple and efficient microwave chemical method.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

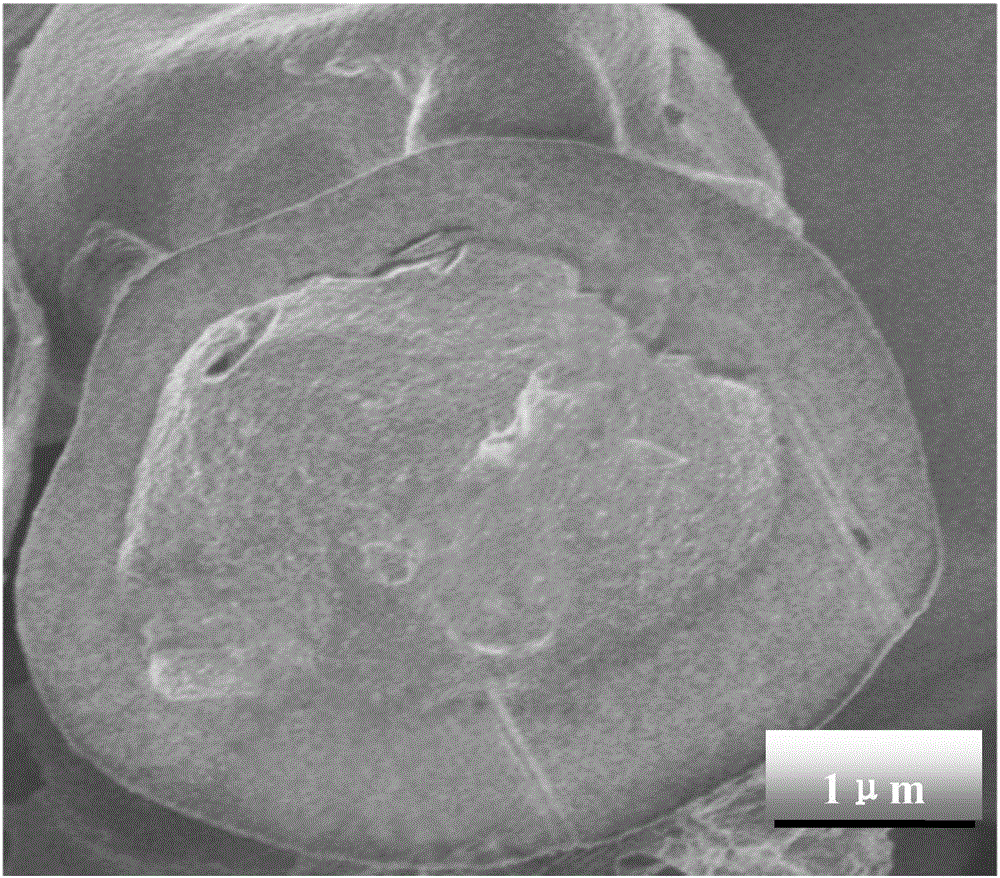

Lithium ion battery negative nanometer material SnO2/MCMB (Mesophase Carbon Micro Beads) shell, and preparation method and application thereof

InactiveCN103236518AImprove the first charge and discharge efficiencyHigh specific capacityCell electrodesSecondary cellsReaction temperatureCharge discharge

The invention discloses a lithium ion battery negative nanometer material SnO2 / MCMB (Mesophase Carbon Micro Beads) shell, and a preparation method and application of the shell. The SnO2 / MCMB shell is prepared by reacting reactants in a mixed solution of deionized water and absolute ethyl alcohol at the volume ratio of 1:1 for 24-48 hours at 160-200 DEG C. By controlling the ratio, the reaction temperature and the reaction time of the reaction solvents, the structure, the size and the feature of the product are improved, the material performance is improved, and the first charge-discharge efficiency, the specific capacity and the cycle performance of the SnO2 / MCMB shell are improved. A shell structure is adopted, the cycle stability of carbon and an effect of alleviating volume expansion of tin-based oxide with rod-shaped nanometer SnO2 are effectively combined, and the problems that tin-based oxide is low in first efficiency, large in irreversible capacity loss and poor in conductivity performance when tin-based oxide is used for preparing a lithium ion battery negative material are solved. The preparation method is simple in preparation technology and low in cost, and can be applied to industrial production.

Owner:SOUTH CHINA NORMAL UNIVERSITY

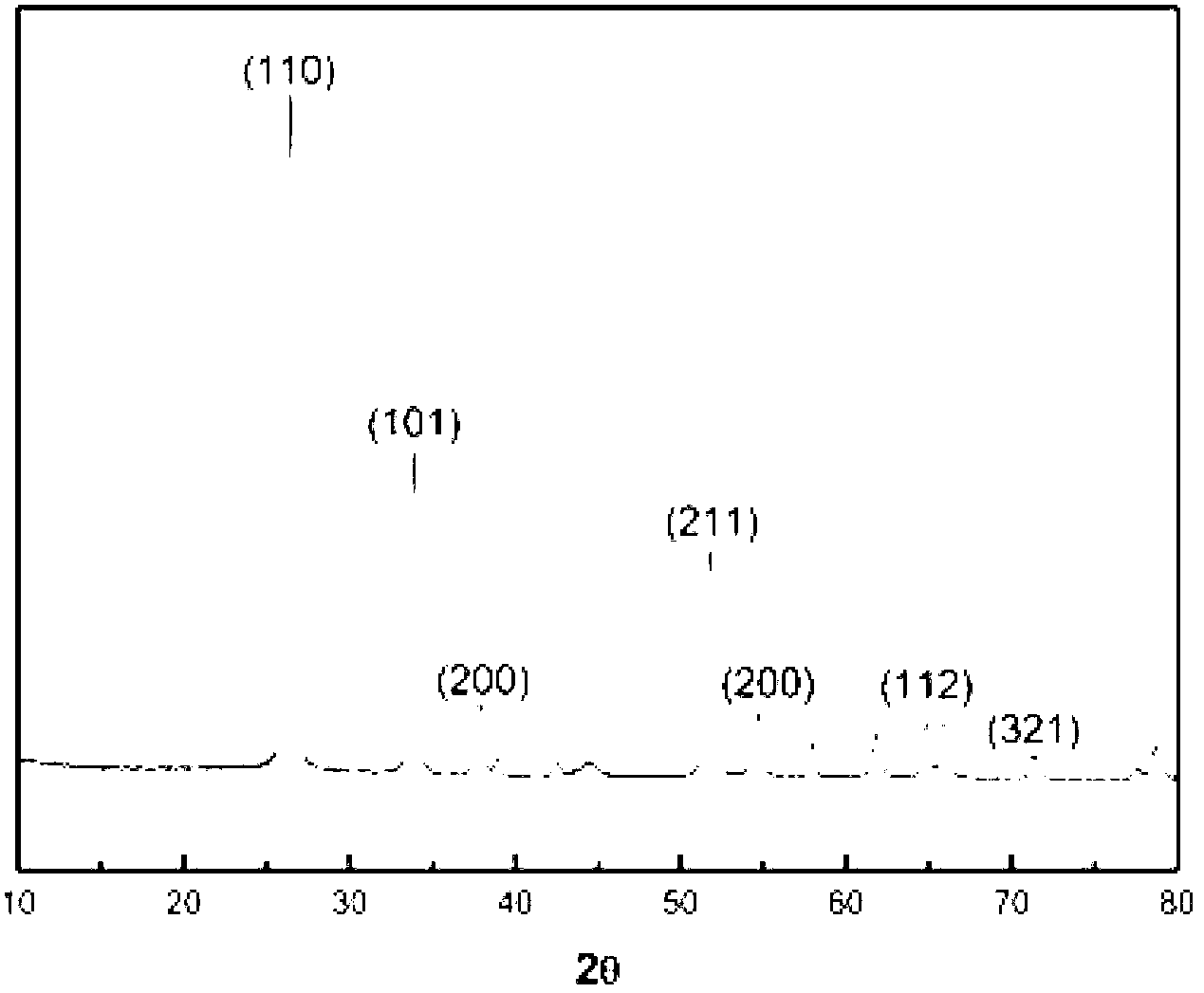

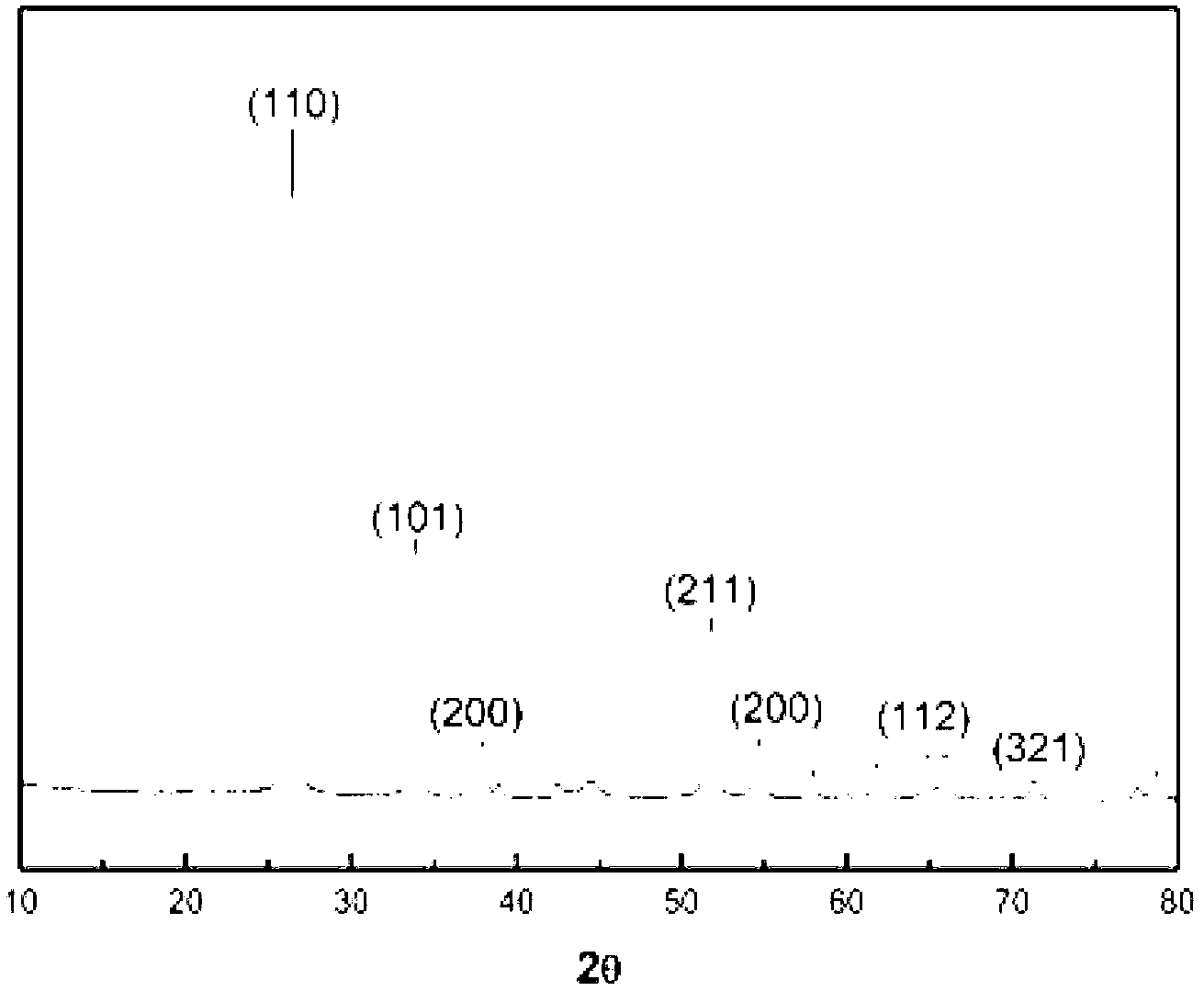

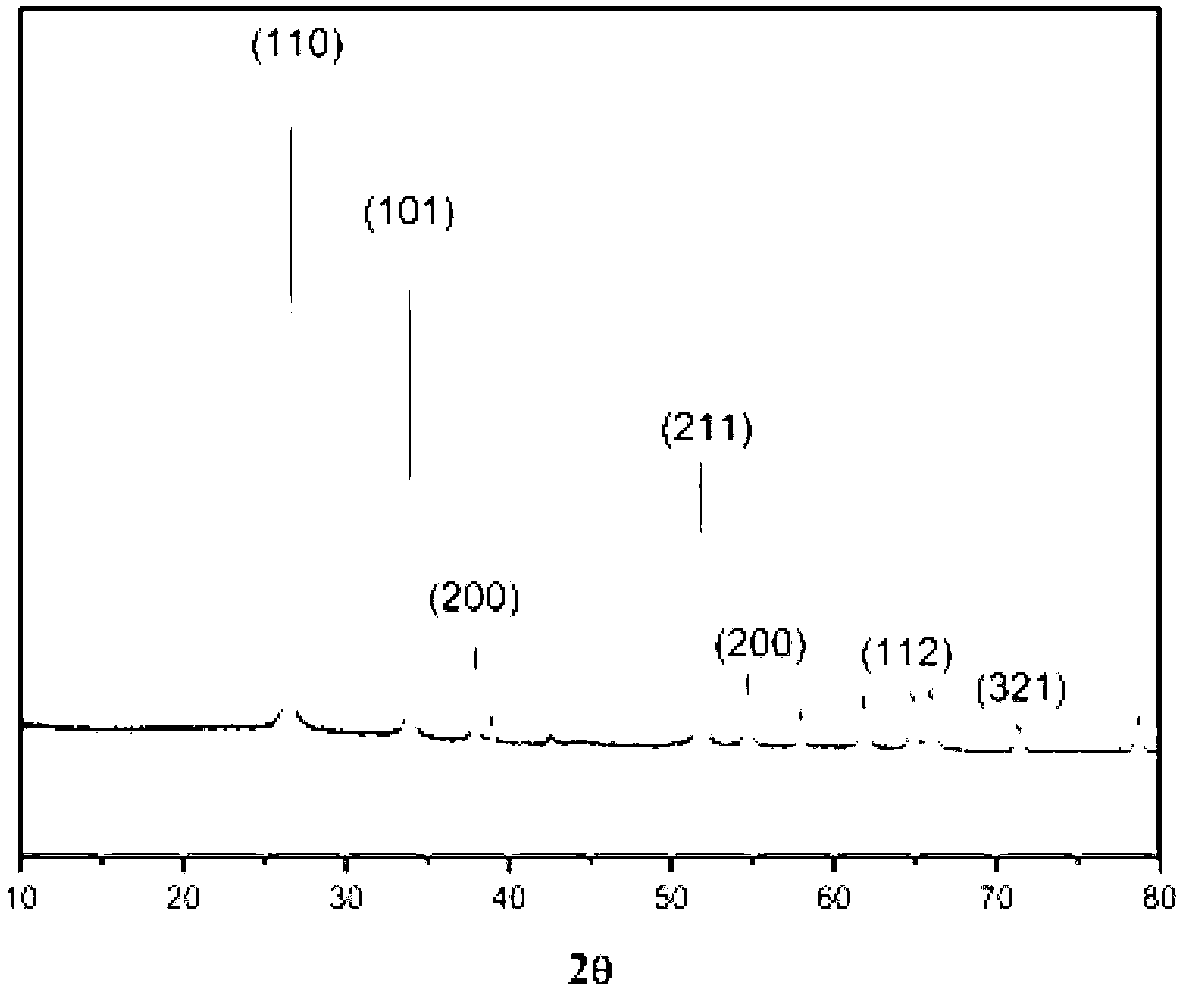

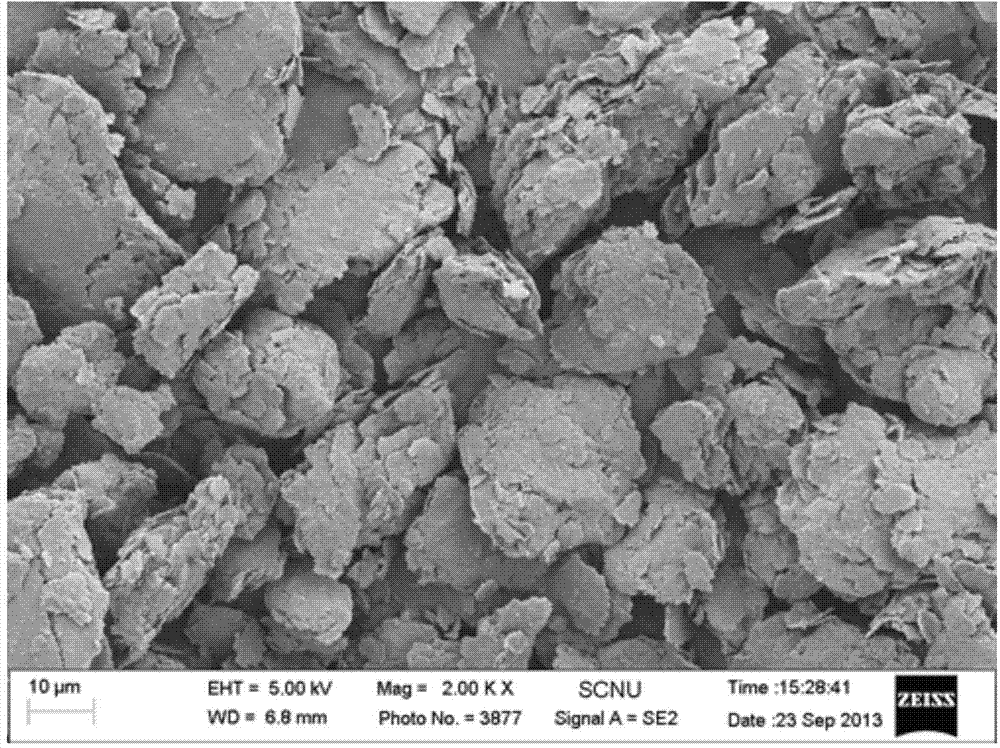

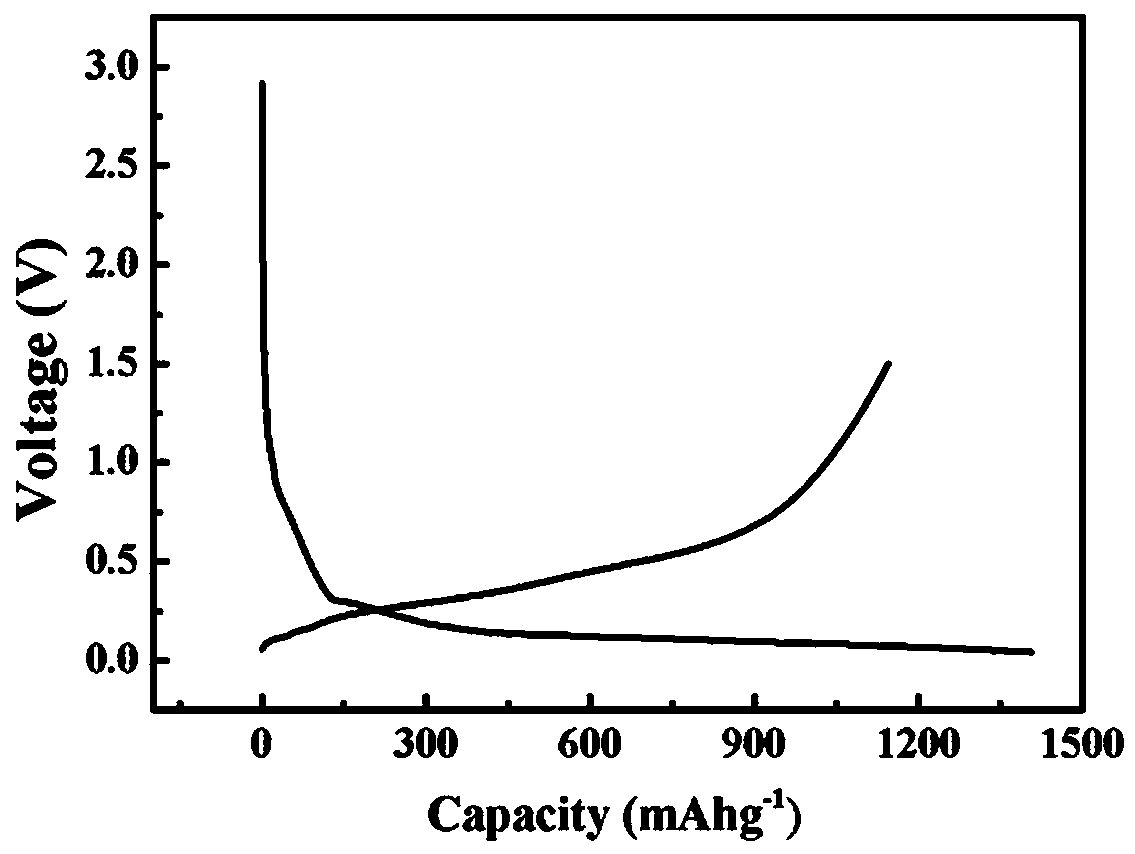

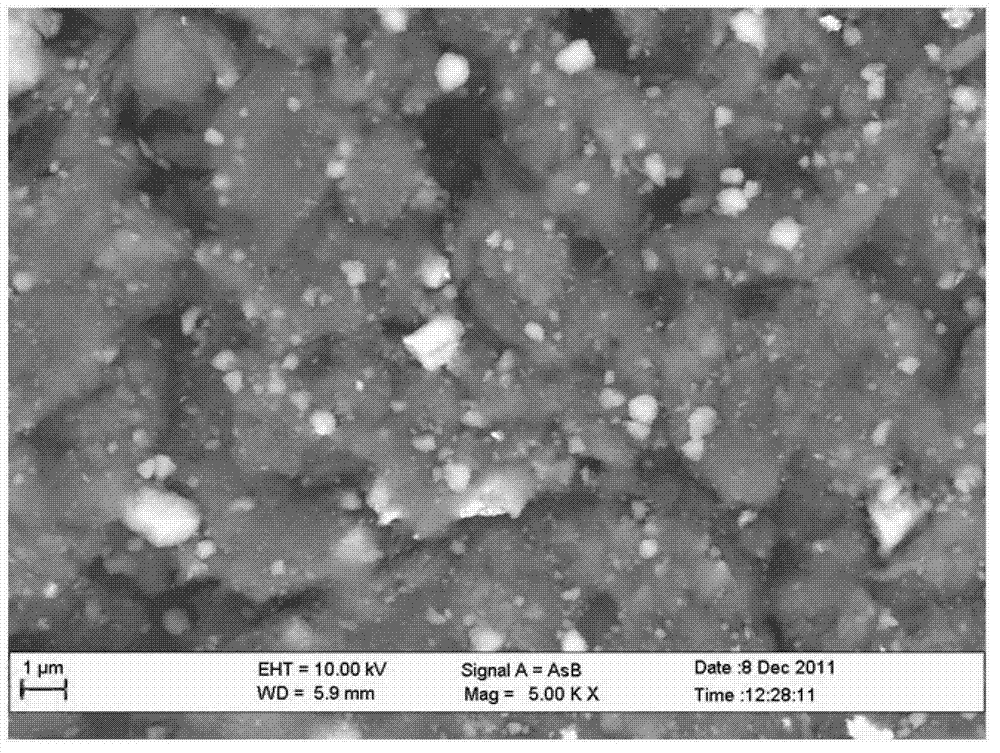

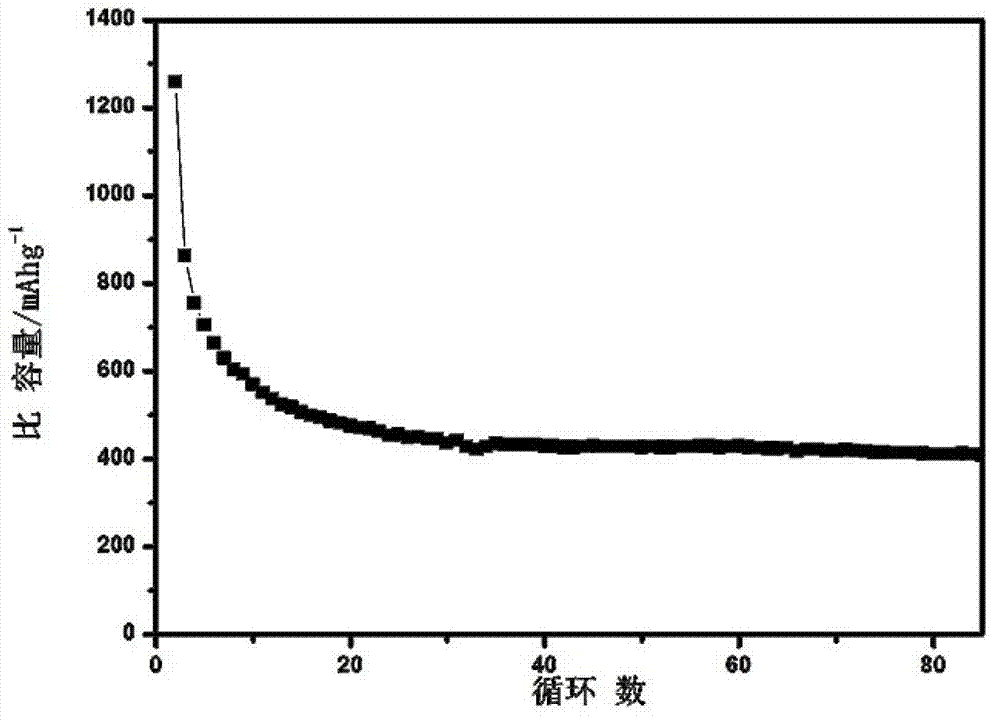

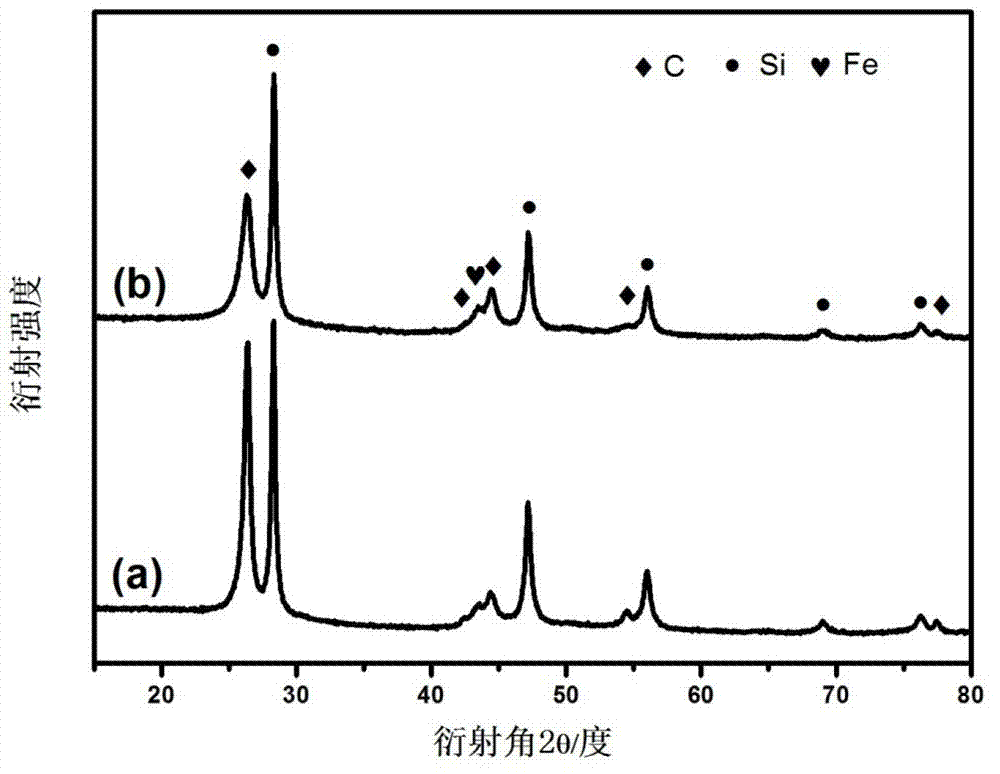

Co2SnO4/C nano-composite negative electrode material for lithium ion battery, preparation and application of Co2SnO4/C nano-composite negative electrode material

ActiveCN103972497ASmall particle sizeAlleviate the volume expansion effectCell electrodesSecondary cellsLithium electrodeAmorphous carbon

The invention discloses a Co2SnO4 / C nano-composite negative electrode material for a lithium ion battery, preparation and application of the Co2SnO4 / C nano-composite negative electrode material. The method comprises the steps of dissolving tin salt and cobalt salt into a dispersing agent to obtain dispersion liquid; dropwise adding sodium hydroxide solutions into the dispersion liquid under the stirring condition; reacting, filtering or centrifuging and drying in vacuum to obtain powder; spreading the powder under the inert gas environment, raising the temperature to 900 DEG C, and then reacting to obtain a reaction product; mechanically milling the reaction product and graphite in a period of time and carrying out nano-milling again; finally, centrifuging the obtained solution to obtain a precipitate; washing and drying to obtain the Co2SnO4 / C nano-composite negative electrode material for the lithium ion battery. According to the Co2SnO4 / C nano-composite negative electrode material for the lithium ion battery, by adopting a form of doping the material and amorphous carbon, the material has the advantages of high charging / discharging efficiency for the first time, high specific capacity and high cycling stability.

Owner:SOUTH CHINA NORMAL UNIVERSITY

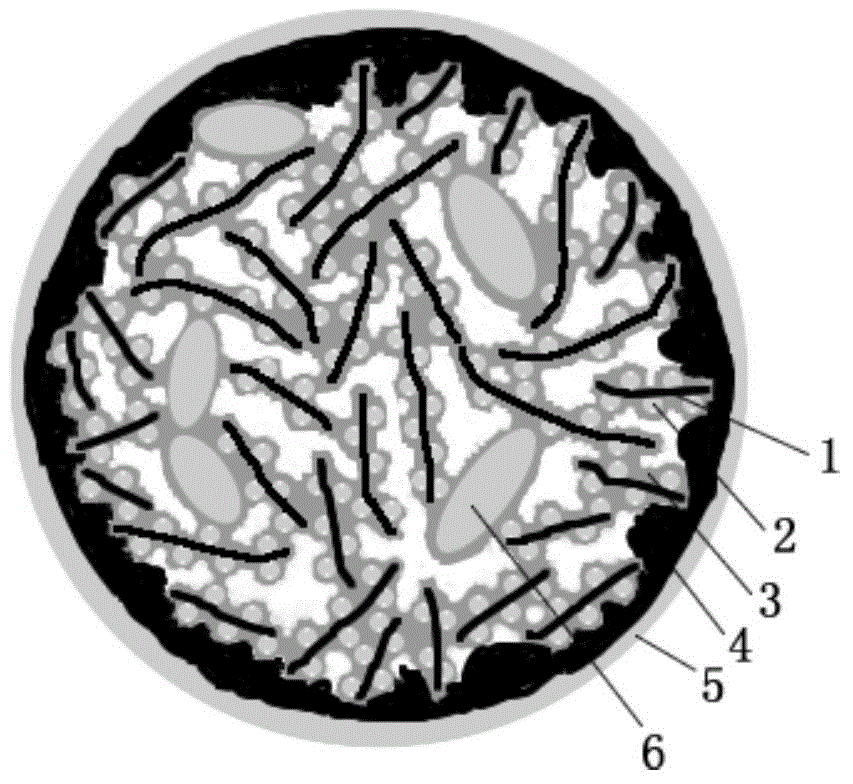

Lithium-ion battery silicon-carbon composite anode material and preparation method thereof

ActiveCN105006554AAlleviate the volume expansion effectReduce swelling effectCell electrodesSecondary cellsCarbon compositesNano silicon

The invention belongs to the field of lithium-ion battery anode materials, and provides a lithium-ion battery silicon-carbon composite anode material and a preparation method thereof. The lithium-ion battery silicon-carbon composite anode material comprises a core-shell structure and is characterized in that a core comprises nano silicon / graphene sheets and soft carbon, and the core is the nano silicon / graphene sheets and soft carbon composite particles which are obtained by performing heat treatment on a soft carbon precursor and the nano silicon / graphene sheets, the soft carbon is attached to the surfaces of the nano silicon / graphene sheets, and free spaces are formed among the nanometer silicon / graphene sheets; the shell is composed of a second carbon material and nano carbon which are coated on the surface of the core sequentially.

Owner:王凤鸣

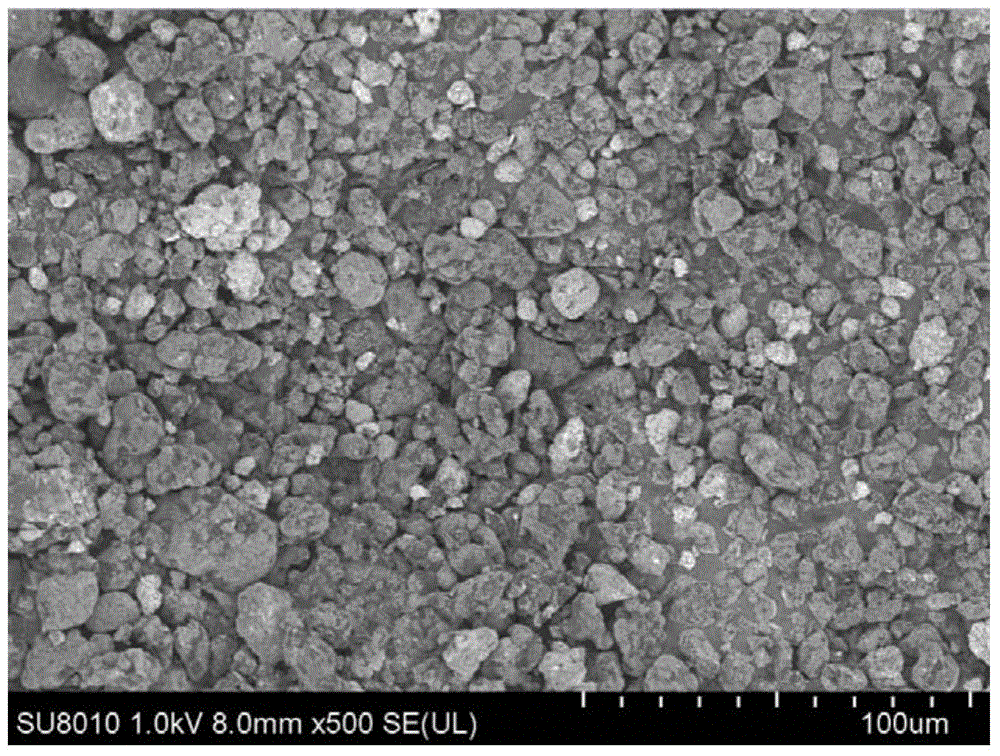

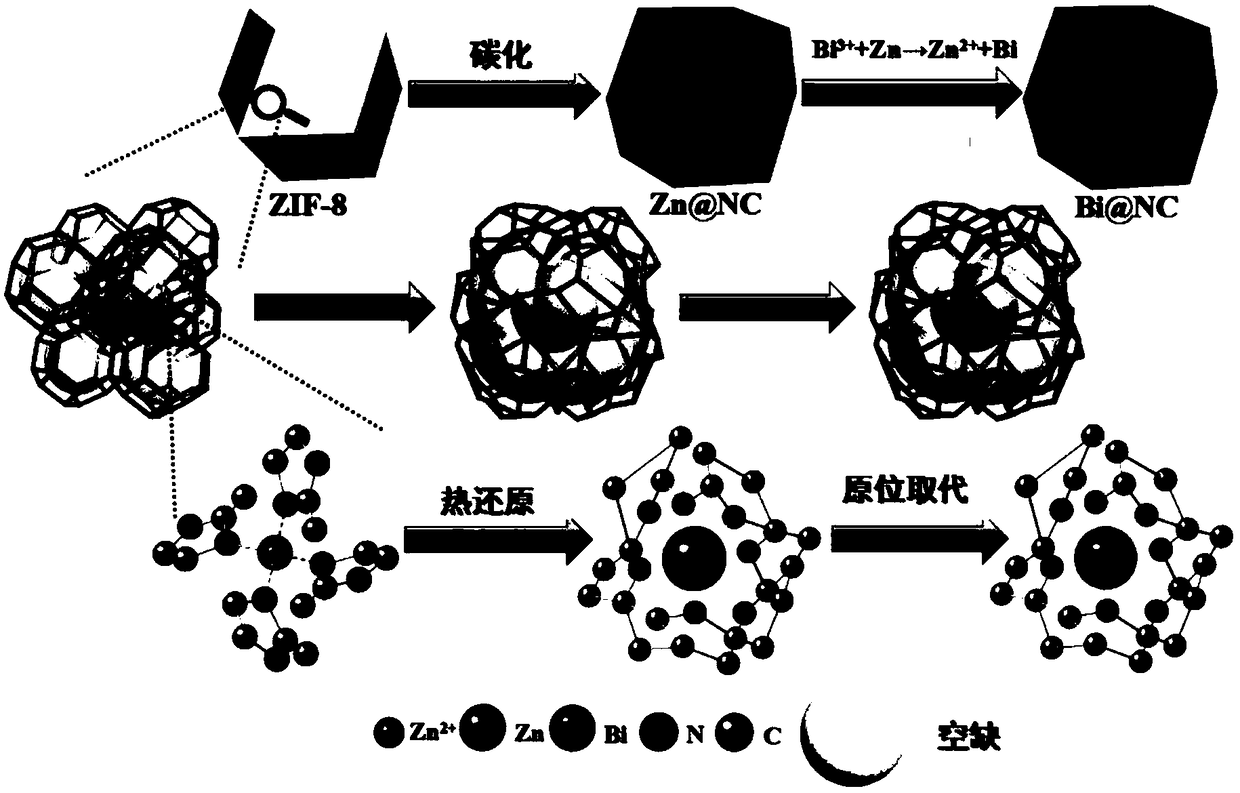

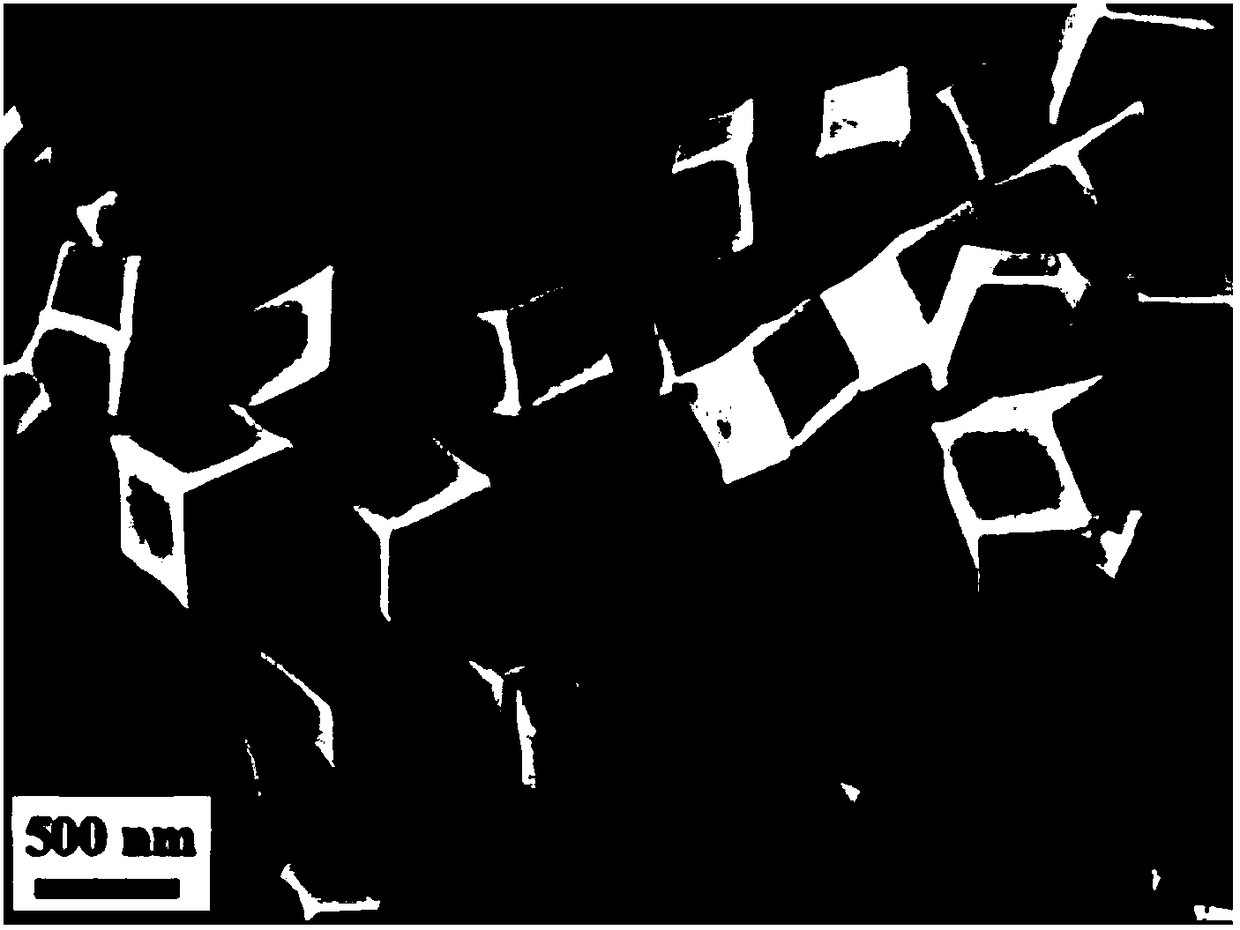

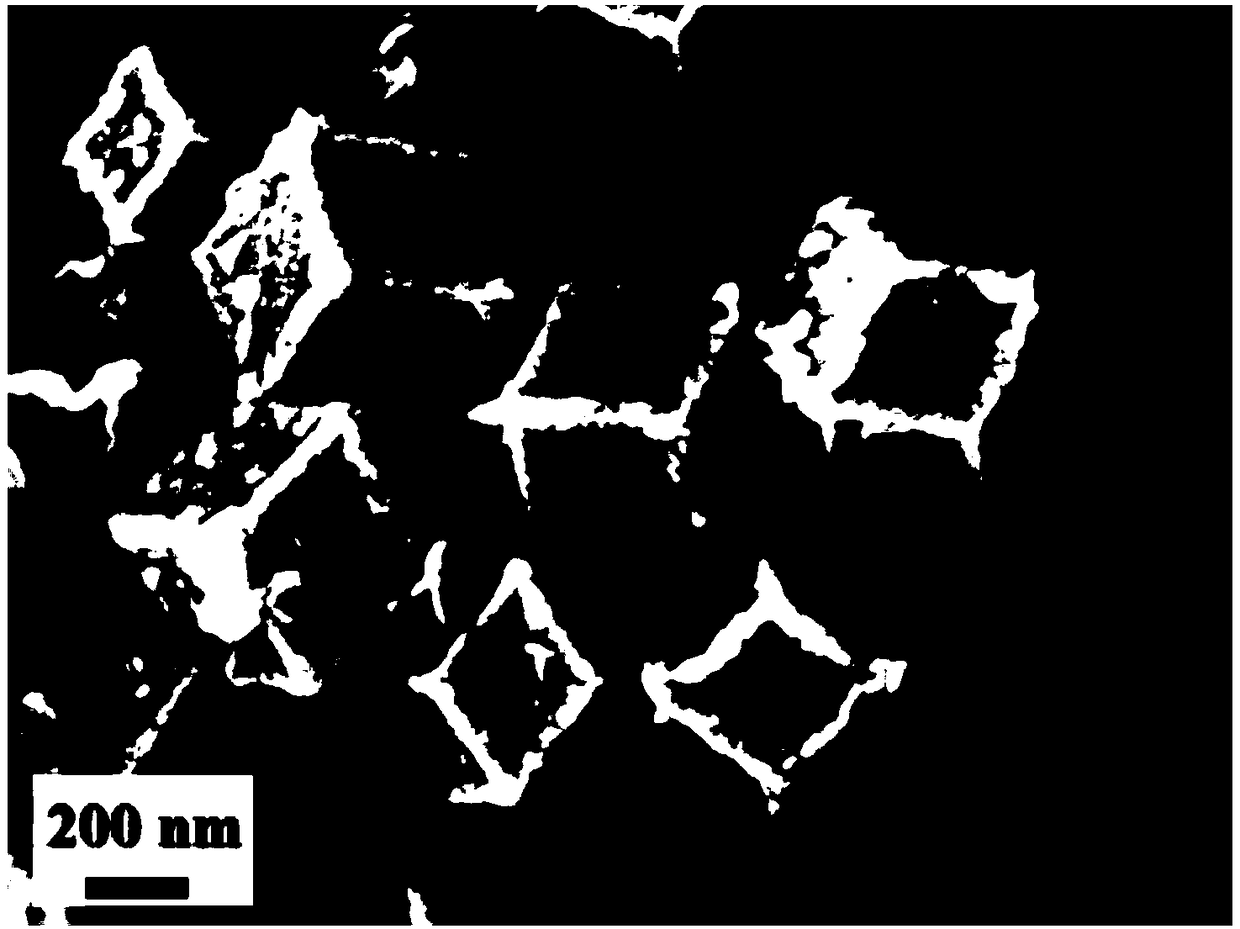

Nanoparticle-compounded ZIF-8 negative electrode material of high specific capacity bismuth as well as preparation method and application of nanoparticle-compounded ZIF-8 negative electrode material

InactiveCN108832110AThe synthesis method is simpleMild conditionsMaterial nanotechnologyCell electrodesInternal resistanceCarbonization

The invention belongs to the field of lithium ion batteries, and discloses a nanoparticle-compounded ZIF-8 negative electrode material of high specific capacity bismuth as well as a preparation methodand application of the nanoparticle-compounded ZIF-8 negative electrode material. The environment in a methanol solution is utilized to enable zinc ions (Zn<2+>) in zinc nitrate hexahydrate to cooperate with a 2-methylimidazole ligand to form a ZIF-8 precursor, after the precursor is subjected to high-temperature carbonization treatment in an inert gas shielding atmosphere of nitrogen gas, Zn<2+>is reduced by pyrolytic carbon in the ZIF-8 to zinc elementary substance (Zn) to form Zn@NC, finally, Bi replaces Zn in situ through simple replacement reaction (Bi<3+> plus Zn arrow Bi plus Zn<2+>)so as to obtain Bi@NC finally. The obtained Bi@NC greatly improves the conductivity of Bi, is conducive to reduction of internal resistance and transmission of electrons, and improves the performanceof reaction kinetics; meanwhile, the volume expansion of Bi@NC in the charging and discharging processes is eased, and the reversible specific capacity and cyclic stability of Bi@NC are improved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

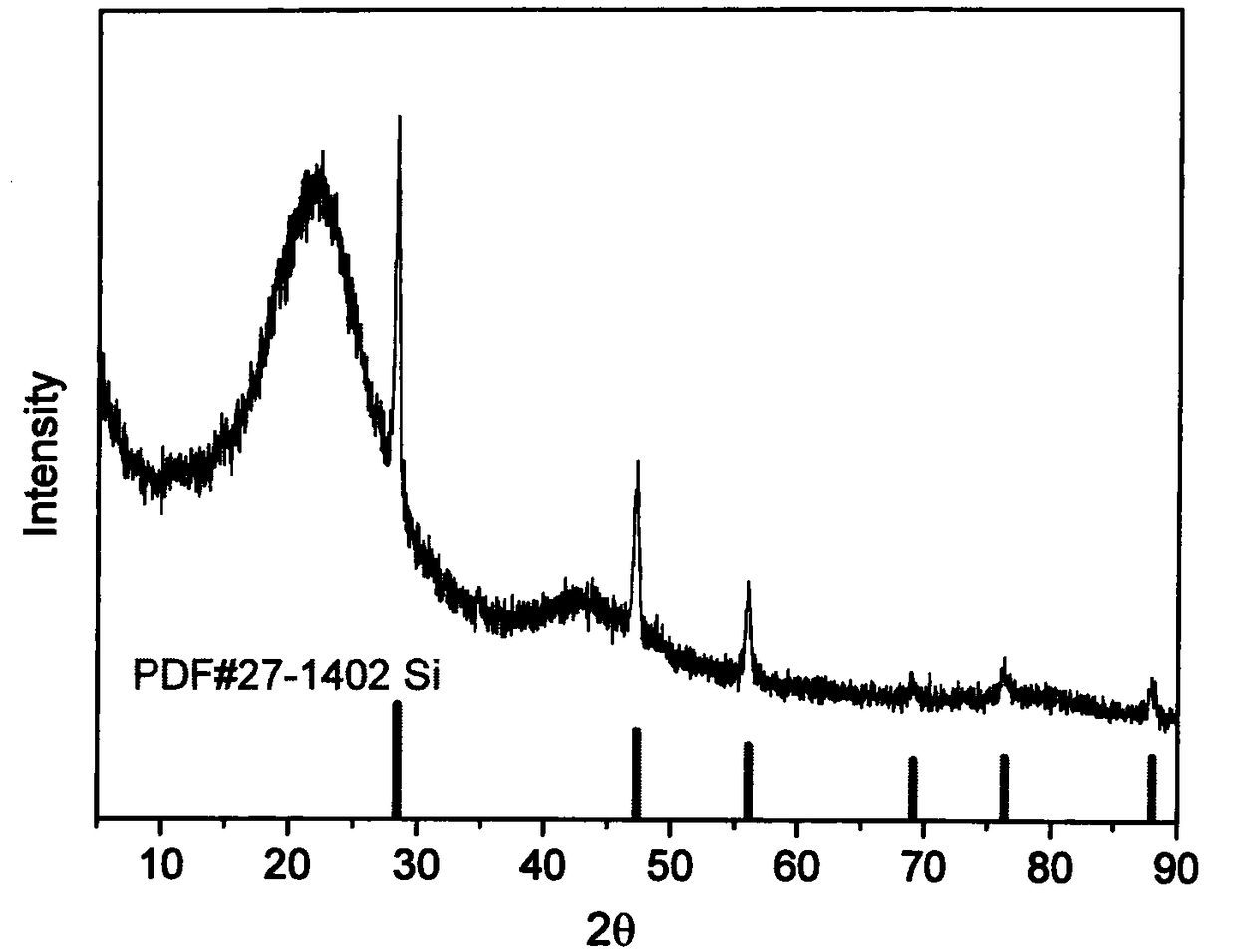

Lithium ion battery silicon oxide composite negative electrode material and preparation method thereof

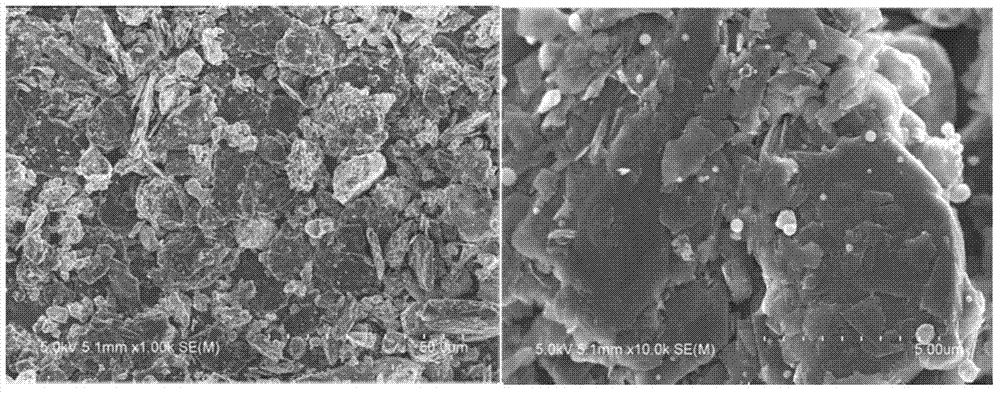

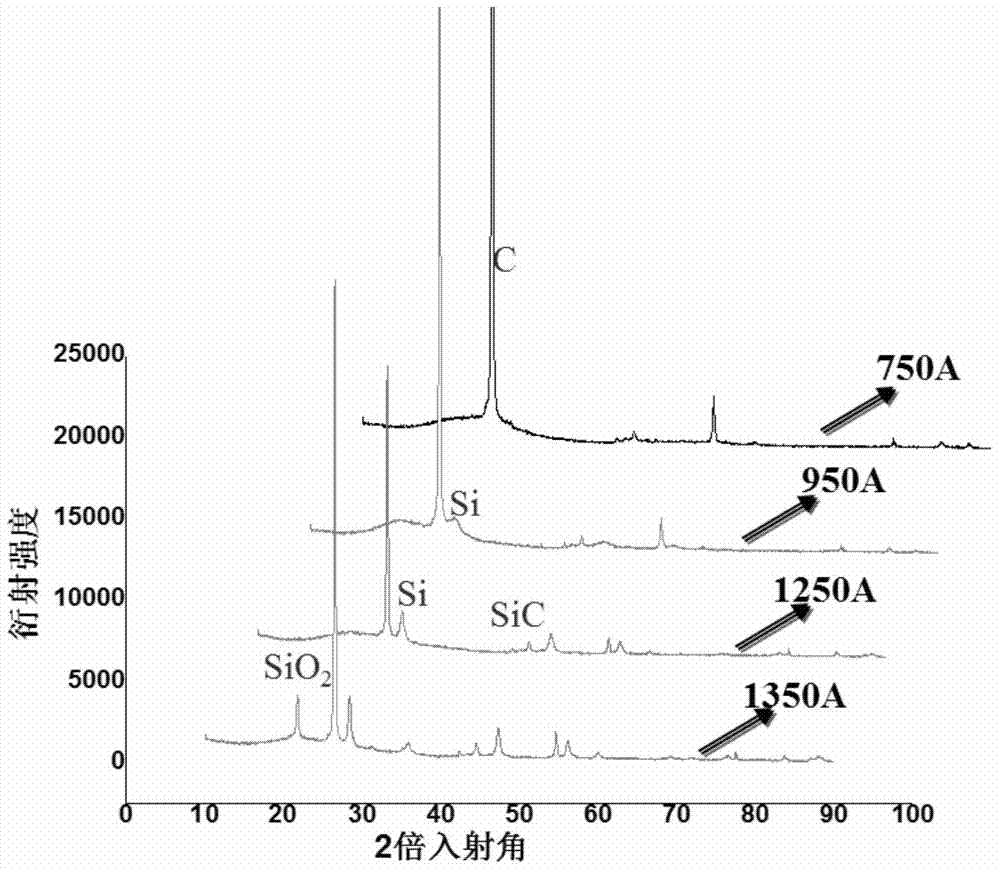

InactiveCN104852020AReduce formation rateImprove electrochemical cycle stabilityCell electrodesSilica nanoparticlesCarbon coating

The invention discloses a preparation method of a lithium ion battery silicon oxide composite negative electrode material, the method includes the following steps: (1) weighting a certain amount of silicon oxide SiOx, organic carbon and a graphite oxide precursor raw material for ball milling for 0.5-24 h to fully mix the precursor raw material; and (2) calcining the mixed precursor raw material in a protective atmosphere at 600-1400 DEG C for 0.5-12 h, and performing post-processing to obtain the silicon oxide composite negative electrode material. Through silicon oxide disproportionation, silica nanoparticles are distributed evenly in silicon dioxide, by organic carbon splitting decomposition, carbon coating is obtained, the probability of the formation of a SEI (solid electrolyte interphase) film in the material charge and discharge process can be reduced, the material electrochemical cycle stability can be improved, and by addition of graphite, good conductivity and ratio stability performance can be provided for the material. The production process is simple, raw material is cheap and easy to obtain, equipment is general, and mass production is easy.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Preparation method of zinc oxide/nitrogen-doped carbon composite material capable of being used for lithium ion battery negative electrode

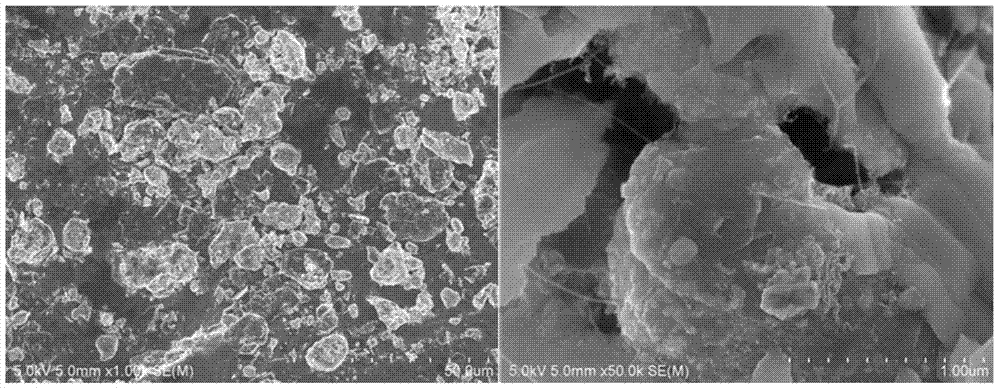

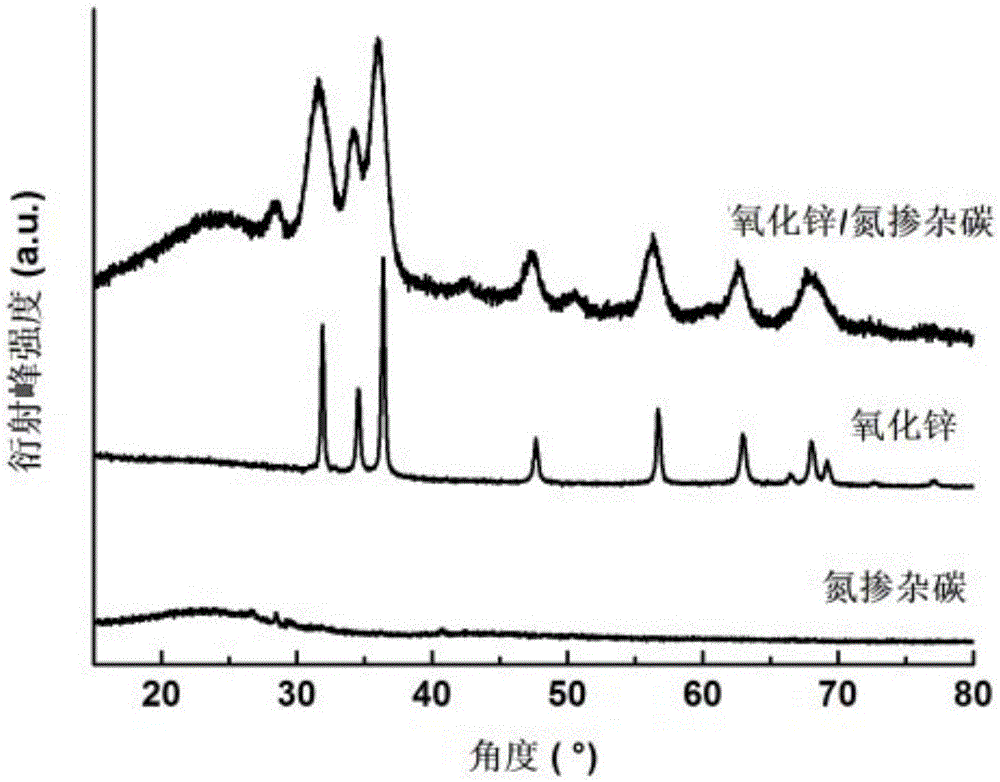

ActiveCN105591090AImprove conductivityImprove electrochemical performanceCell electrodesSecondary cellsCarbon compositesPolypyrrole

The invention provides a preparation method of a zinc oxide / nitrogen-doped carbon composite material capable of being used for a lithium ion battery negative cathode. The method is applied to low-temperature polymerization reaction to prepare polypyrrole, then polypyrrole is prepared into nitrogen-doped carbon, and then the zinc oxide / nitrogen-doped carbon composite material is prepared through a sol-gel method. Compared with other carbon materials, nitrogen elements in nitrogen-doped carbon can change distribution of electron cloud around carbon atoms, agglomeration of the carbon atoms is effectively prevented, and compared with other common carbon materials, the nitrogen-doped carbon composite material has more excellent electrical conductivity and chemical stability.

Owner:SYNERGY INNOVATION INST OF GDUT HEYUAN

Composite metal lithium negative electrode with filler and preparation method thereof

ActiveCN110931712ANegative electrode with high mechanical strengthGrowth inhibitionNegative electrodesSecondary cellsMetallic lithiumBattery cell

The invention discloses a composite metal lithium negative electrode with filler and a preparation method thereof, and belongs to the technical field of secondary batteries. The composite metal lithium negative electrode comprises metal lithium, a framework material and a filler, wherein the filler is filled in a pore structure of the framework material; the pore structure of the framework material is filled with or not filled with the filler; and the metal lithium is combined with the framework material in a pressing mode such as rolling. According to the composite metal lithium negative electrode provided by the invention, the filler can regulate and control the deposition behavior of metal lithium in the macroporous structure of the framework material, inhibit the growth of lithium dendrites in the macroporous structure of the framework material, slow down the volume expansion effect and effectively improve the cycle performance of a battery.

Owner:TSINGHUA UNIV

Multi-element alloy compound anode material, preparation method and lithium ion battery containing compound anode material

ActiveCN107634212AHigh magnificationImprove cycle performanceMaterial nanotechnologyCell electrodesCarbon layerPotential market

The invention relates to a porous multi-element alloy compound anode material, a preparation method and a lithium ion battery containing the compound anode material. The multi-element alloy compound anode material provided by the invention comprises modified nanometer active materials, graphene chips dispersed between the modified nanometer active materials and amorphous conductive carbon layers wrapped on the modified nanometer active materials and the graphene chips. The lithium ion battery prepared from the compound material provided by the invention has excellent circulating and rate capabilities, lower volume expansion effect and potential market application prospect. The preparation technology according to the invention is simple, controllable and suitable for industrial production.

Owner:BTR NEW MATERIAL GRP CO LTD

Preparation method of Co3O4/nitrogen doped graphene composite electrode material

InactiveCN105489399AEasy to operateStable structureHybrid capacitor electrodesHybrid/EDL manufactureFiltrationNitrogen doped graphene

The invention provides a preparation method of Co3O4 / nitrogen doped graphene composite electrode material. The preparation method comprises the following steps that step 1. nitrogen doped graphene is prepared; step 2. a soluble alkaline solution is prepared; step 3. polyacrylamide (PAM), heptahydrated cobalt sulfate and nitrogen doped graphene prepared in the step 1 are ultrasonic-dispersed in deionized water so that mixed liquid A is obtained; step 4. the soluble alkaline solution prepared in the step 2 is dropped in the mixed liquid A to react, and pH=8.5-10 is obtained through adjustment so that mixed liquid B is obtained; and step 5. the mixed liquid B is transferred to a microwave reactor to perform heating reaction, and suction filtration, washing and drying are performed on the product after the end of reactor so that the Co3O4 / nitrogen doped graphene composite electrode material is obtained finally. The prepared composite material is stable in structure, and the method has advantages that the method is simple and environment-friendly, the reaction conditions are moderate, reaction is easy to control, cost is low and the technology and the process are simple and convenient.

Owner:JIANGSU UNIV

Preparation method of zinc oxide quantum dot negative electrode material coated with multilevel structure carbon

ActiveCN104201361AGuaranteed uniformityGuarantee sufficiencyCell electrodesSecondary cellsCharge dischargeCarboxylic acid

The invention discloses a preparation method of a zinc oxide quantum dot negative electrode material coated with multilevel structure carbon. The method comprises the following steps: firstly, a phenyl / pyridyl carboxylic acid compound and zinc salt are weighed at a mole ratio, and a coordination polymer of zinc and carboxylic acid is prepared by utilizing a hydrothermal / solvothermal method under the conditions that the pH value is 5-11, the temperature ranges from 80 DEG C to 180 DEG C, and the reaction time is 5-36h; secondly, the prepared polymer is calcined for 30min-120min at 400 DEG C to 800 DEG C in an inert atmosphere, so that the zinc oxide quantum dot (2-100nm) negative electrode material coated with multilevel structure carbon is prepared. The zinc oxide material prepared by the method has the following advantages: (1) the precursor purity is high, and the zinc oxide negative electrode material with high purity and high performance can be obtained after calcination; (2) a multilevel carbon structure array can play a role of'fixing frame' for zinc oxide, reduce the volume effect in a charge-discharge cycle process, improve the structure stability of zinc oxide, and further improve the electronic conductivity of zinc oxide, so as to improve the battery cycle performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Lithium ion battery silicon oxygen anode material and preparation method thereof, and lithium ion battery

InactiveCN110391406AImprove the first Coulombic efficiencyExtended service lifeCell electrodesSecondary cellsHigh rateSilicon oxygen

The invention discloses a lithium ion battery silicon oxygen anode material and a preparation method thereof, and a lithium ion battery. The lithium ion battery silicon oxygen anode material is a core-shell structure, the core-shell structure is composed of an inner core and a coating layer, the inner core is a mixture of silicon oxide and element doped graphite, and the coating layer is organic pyrolytic carbon, wherein, the element is at least one of H, S, P, Cu, Fe and Ni. The anode material is high in first coulombic efficiency and long in service life, and has the high rate performance.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

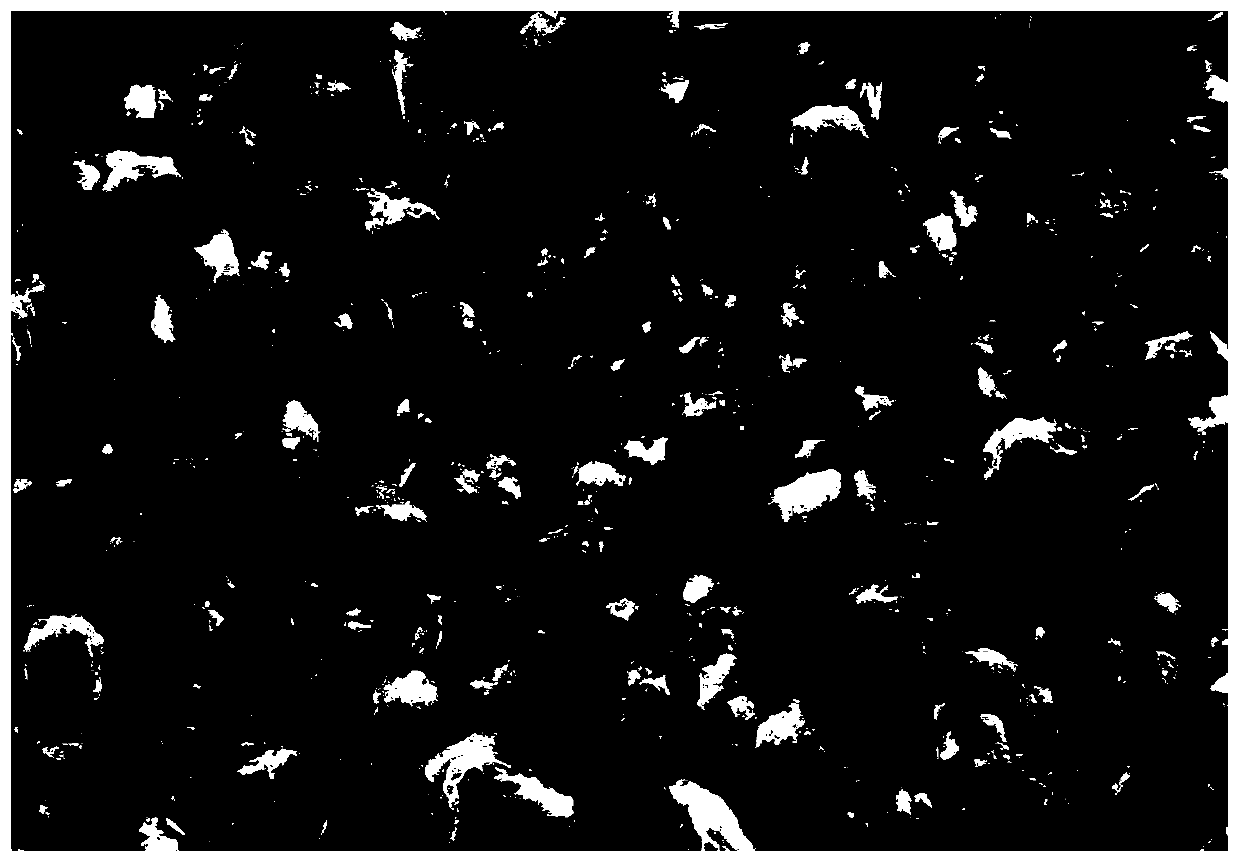

Preparation method for silicon carbon composite material for lithium ion battery negative electrode

ActiveCN102832376AEvenly distributedImprove cycle performanceCell electrodesCarbon compositesHigh energy

The invention discloses a preparation method for a silicon carbon composite material for a lithium ion battery negative electrode. The method comprises the following steps: primary ball milling: a step of adding a grinding aid into elementary silicon for ball milling; and secondary ball milling: a step of mixing silicon powder obtained after primary ball milling with carbon powder and adding a grinding aid for ball milling again. The mass content of the carbon powder is 20 to 80%. A discharge gas medium employed in the dielectric barrier discharge plasma assisted high-energy ball milling method is inert gas. According to the invention, silicon in the composite material prepared in the invention can be finely and uniformly distributed on a carbon matrix, effective refining of silicon can be carried out on the basis that the integrity of graphite sheets is ensured, reversible capacity of a battery is improved, the problems of volume expansion and poor conductivity of a silicon-based electrode are alleviated, and comprehensive performance of the lithium ion battery is improved.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com