Lithium ion battery silicon oxygen anode material and preparation method thereof, and lithium ion battery

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of general rate performance of composite negative electrode materials, difficult to meet high rate charge and discharge, and inability to completely remove lithium ions, etc. Excellent cycle performance, low volume expansion effect, high rate performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In a second aspect, the present invention provides a method for preparing a silicon-oxygen negative electrode material for a lithium-ion battery, comprising the following steps:

[0036] (1) Perform high-speed ball milling of graphite and elemental dopants under an inert atmosphere to obtain a mixture;

[0037] (2) Add silicon oxide to the above mixture and continue ball milling to obtain a mixture of silicon oxide and element-doped graphite;

[0038] (3) Mix the mixture of silicon oxide and element-doped graphite, organic carbon, and organic solvent, dry and granulate under an inert atmosphere to obtain a negative electrode material precursor;

[0039] (4) The anode material precursor obtained in step (3) is heated up to 500-1200° C. for calcination under an inert atmosphere, kept warm, and cooled to obtain the anode material for lithium ion batteries.

[0040] Wherein, the mass ratio of the graphite and the element dopant is (10-100):1, for example, it can be 10:1, 2...

Embodiment 1

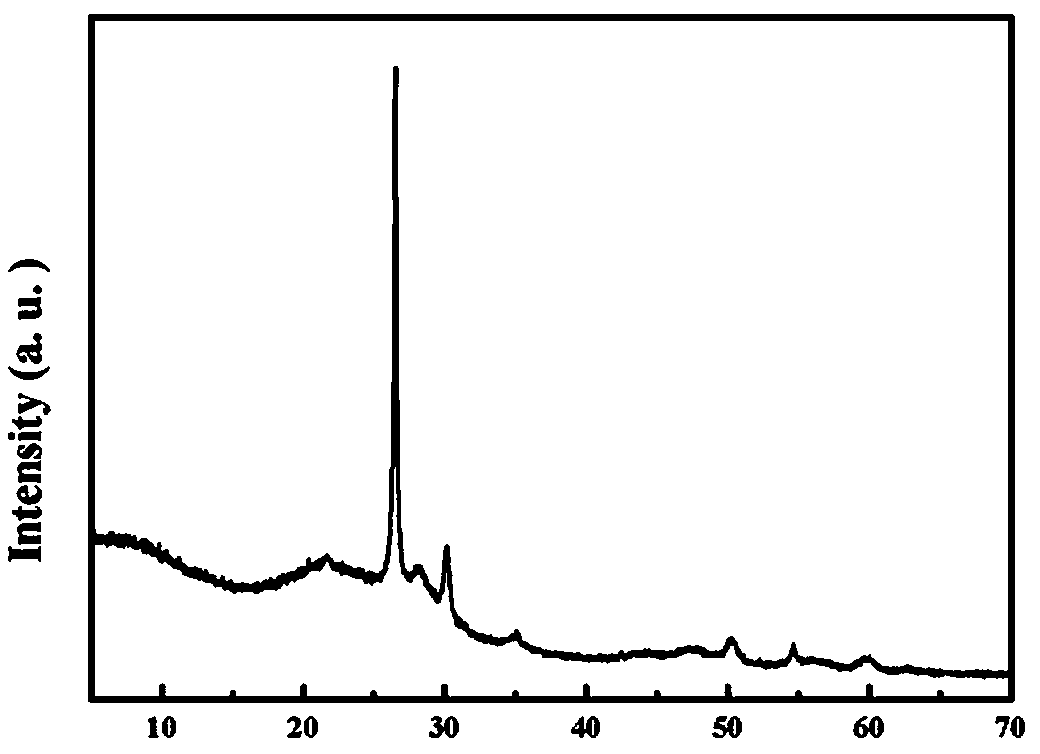

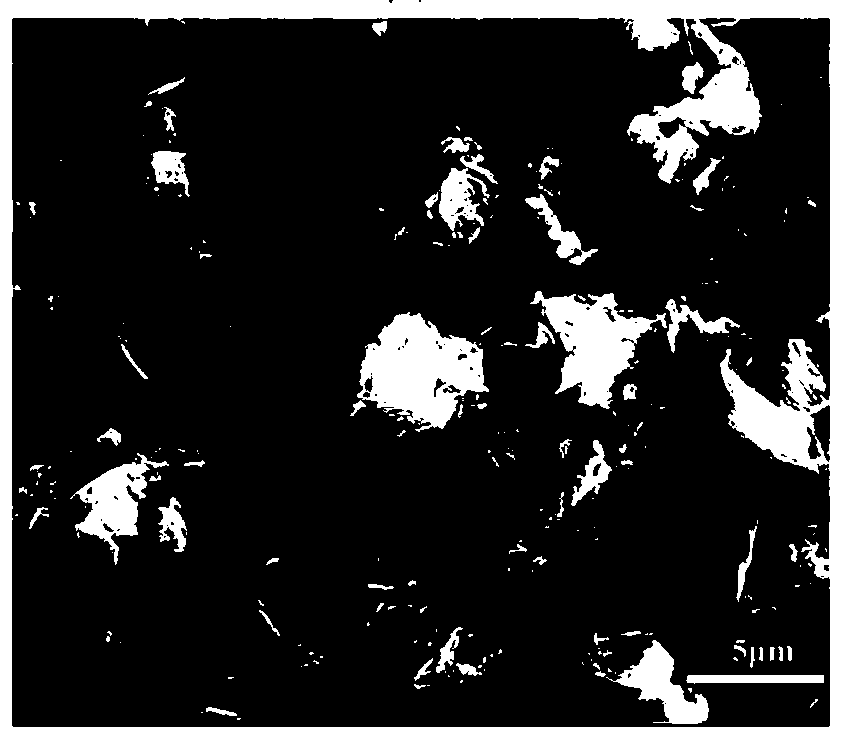

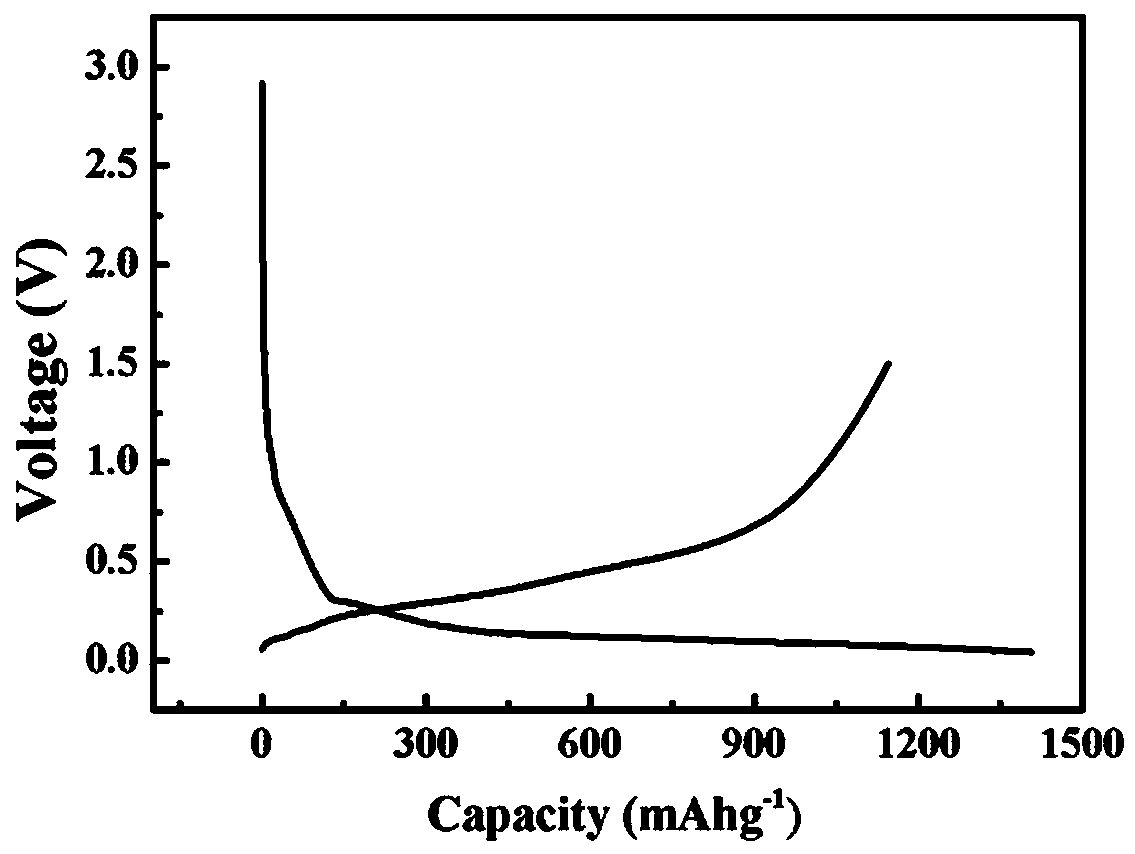

[0055] A silicon-oxygen negative electrode material for a lithium ion battery, the preparation method of which comprises the steps of:

[0056] (1) 100 parts of graphite and 10 parts of carbon disulfide were subjected to high-speed ball milling under an inert atmosphere for 5 hours at a speed of 600 r / min to obtain a mixture;

[0057] (2) Add silicon oxide (SiOx, x=1) to the mixture obtained in step (1) and continue ball milling for 10 h at a rotation speed of 500r / min to obtain a mixture of silicon oxide and element-doped graphite;

[0058] (3) mixing the mixture of silicon oxide and element-doped graphite, pitch, and tetrahydrofuran, and spray-drying in an inert atmosphere to obtain a negative electrode material precursor;

[0059] (4) Heat the negative electrode material precursor obtained in step (3) to 800°C for 3 hours in an inert atmosphere, keep it warm for at least 0.5 hours, cool to room temperature, crush and sieve to obtain the silicon-oxygen negative electrode mat...

Embodiment 2

[0063] A silicon-oxygen negative electrode material for a lithium ion battery, the preparation method of which comprises the steps of:

[0064] (1) Perform high-speed ball milling on graphite for 5 hours under a hydrogen atmosphere, the internal pressure is 1bar-5bar, and the rotation speed is 600r / min to obtain a mixture;

[0065] (2) Add silicon oxide (SiOx, x=1) to the mixture obtained in step (1) and continue ball milling for 10 h at a rotation speed of 500r / min to obtain a mixture of silicon oxide and element-doped graphite;

[0066] (3) mixing the mixture of silicon oxide and element-doped graphite, pitch, and tetrahydrofuran, and spray-drying in an inert atmosphere to obtain a negative electrode material precursor;

[0067] (4) Heat up the negative electrode material precursor obtained in step (3) to 1200°C for 1 hour in an inert atmosphere, keep it warm for at least 0.5 hours, cool to room temperature, crush and sieve to obtain the silicon-oxygen negative electrode mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com