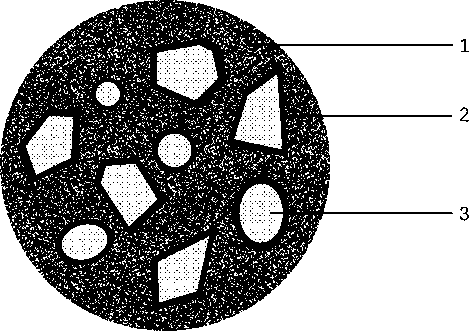

Lithium ion battery pre-lithiated silicon-carbon multilayer composite negative electrode material and preparation method thereof

A technology of pre-lithiated silicon carbon and lithium-ion batteries, which is applied in the field of electrochemistry, can solve the problems of high preparation cost, electrode pulverization and falling off, and electrolyte consumption, and achieve good mechanical properties, stable cycle performance, and isolation of electrolyte Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

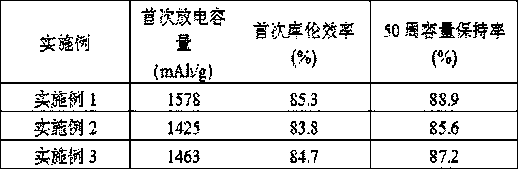

Embodiment 1

[0042] A method for preparing a lithium-ion battery pre-lithiated silicon-carbon multilayer composite negative electrode material, comprising the following specific steps:

[0043] (1) Put the silica particles in a high-energy ball mill for ball milling. The speed of the ball mill is set at 500 rpm, the mass ratio of balls to particles is set at 100:1, and the milling time is 24 h.

[0044] (2) Place the ball-milled silicon oxide particles in a fusion machine, add lithium-containing ionic liquid LiMIM-TFSI, the mass ratio of silicon oxide particles to lithium-containing ionic liquid is 20:1, and the fusion time is 3 h .

[0045] (3) Put the mixed silicon oxide particles in a high-temperature tube furnace for sintering, pass in argon gas for protection, and raise the temperature to 600 °C for 2 h to make the silicon oxide particles and lithium-containing ionic liquid A sufficient reaction is carried out, and then the temperature is automatically lowered to obtain pre-lithiated...

Embodiment 2

[0050] A method for preparing a lithium-ion battery pre-lithiated silicon-carbon multilayer composite negative electrode material, comprising the following specific steps:

[0051] (1) Put the silicon oxide particles in a jet mill for pulverization.

[0052] (2) Put the pulverized silicon oxide in a fusion machine, add LiBMIM-TFSI, the mass ratio of silicon oxide particles to LiBMIM-TFSI is 20:1, the speed of the fusion machine is 800 rpm, and the fusion time is 5 h.

[0053] (3) The SiO particles fused with LiBMIM-TFSI were placed in a high-temperature tube furnace for sintering, protected by nitrogen gas, and the temperature was raised to 800 °C for 2 h, so that the SiO particles and lithium-containing The ionic liquid undergoes a sufficient reaction, and then the temperature is automatically lowered to obtain pre-lithiated silicon oxide particles.

[0054] (4) Ultrasonic disperse pre-lithiated silicon oxide in an aqueous solution of nickel citrate, wherein the mass ratio o...

Embodiment 3

[0058] A method for preparing a lithium-ion battery pre-lithiated silicon-carbon multilayer composite negative electrode material, comprising the following specific steps:

[0059] (1) Place silicon oxide particles in a mechanical mill for pulverization.

[0060] (2) Put the pulverized silicon oxide particles in a fusion machine, add lithium-containing ionic liquid LiEMIM-PF6, wherein the mass ratio of silicon oxide particles to lithium-containing ionic liquid is 30:1, and the speed of the fusion machine is 1000 rpm, the fusion time is 3h.

[0061] (3) Put the mixed silicon oxide particles in a high-temperature tube furnace for sintering, pass in argon gas for protection, raise the temperature to 500 °C for 2 h, and make the silicon oxide particles and lithium-containing ionic liquid A sufficient reaction is carried out, and then the temperature is automatically lowered to obtain pre-lithiated silicon oxide particles.

[0062](4) Ultrasonically disperse the pre-lithiated sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com