Composite material and preparation method thereof

A composite material and material package technology, applied in the field of composite materials and their preparation, can solve problems such as poor mixing and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] On the other hand, the embodiment of the present invention also provides a method for preparing a composite material, comprising the following steps:

[0028] S01: Provide carbon-based active material cores;

[0029] S02: preparing the alloyed active material layer on the surface of the carbon active material core;

[0030] S03: Prepare the shell layer on the surface of the alloyed active material layer.

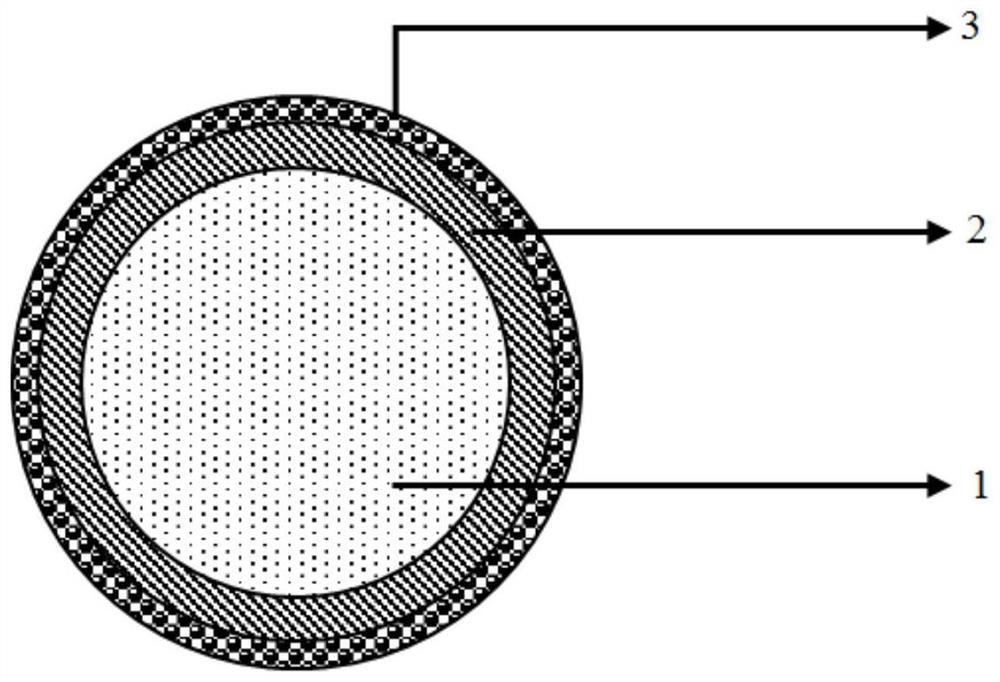

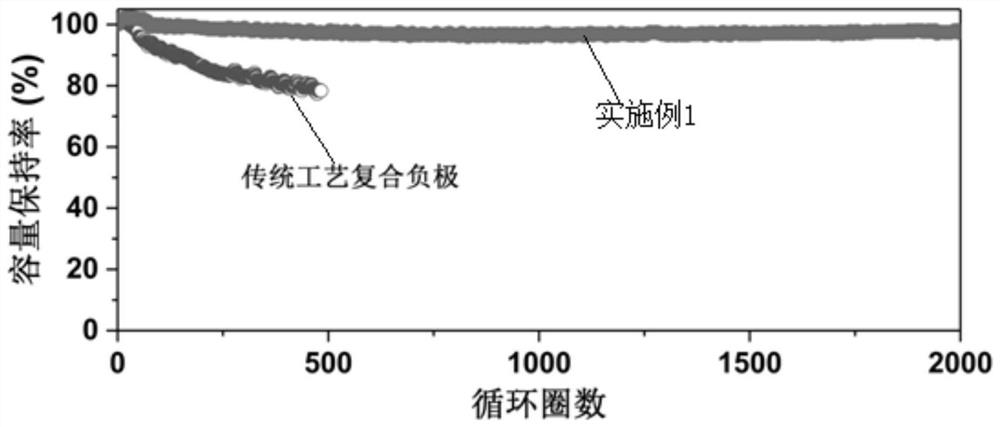

[0031] The preparation method of the composite material provided by the embodiment of the present invention is prepared into a composite material composed of three layers, that is, a carbon-based active material core located at the core, an alloyed active material layer located in the middle, and an outer shell layer located on the outer surface. The composite material with unique structure can be used as negative electrode active material; the composite material obtained by this preparation method can not only achieve highly uniform dispersion of different active ma...

Embodiment 1

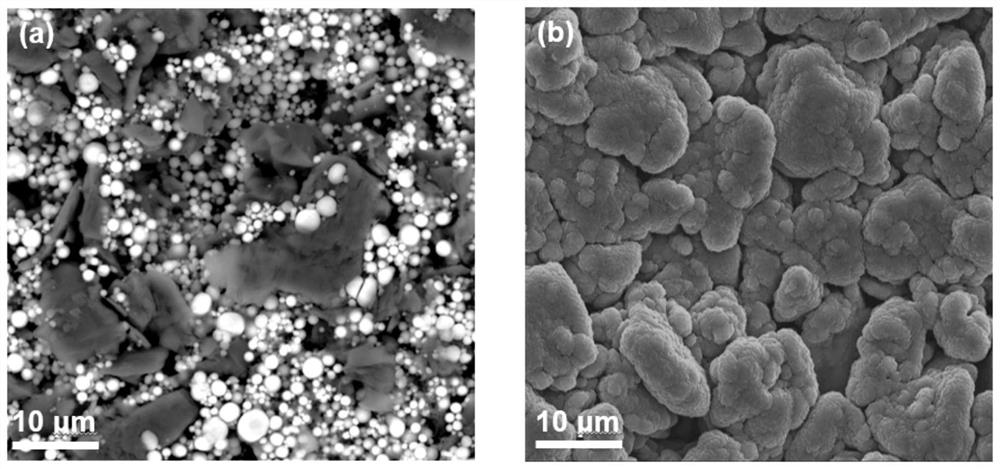

[0040] This embodiment provides a composite material: natural graphite is used as the carbon active material core, aluminum is used as the alloyed active material layer, and carbon material is used as the outer shell layer, wherein the D50 of natural graphite is 12 μm, and the alloyed active material layer is The thickness is 1 μm, the thickness of the shell layer is 100nm, and the mass percentage of aluminum is 40%; the composite material is used as the negative electrode active material to prepare the negative electrode, and the specific preparation process is as follows:

[0041] (1) Using natural graphite particles as the base material and pure aluminum as the sputtering target material, magnetron sputtering technology is used to deposit aluminum active materials on the surface of graphite particles to obtain an alloyed active material layer, and the thickness of the controlled film layer is about 3 μm .

[0042] (2) Using sucrose solution as a precursor, adopting high-tem...

Embodiment 2-7

[0048] The difference between embodiment 2-7 and embodiment 1 is that different carbon active substances are used, and the others are the same. The carbon active substances used are respectively: artificial graphite, soft carbon, hard carbon, MCMB, coke, graphene , the half-cell electrochemical performance test was carried out on the negative electrodes of Examples 2-7 under the condition of 0.2C rate, and compared with Example 1, the test results are shown in Table 1 below.

[0049] Table 1

[0050]

[0051] It can be seen from Table 1 that the anodes prepared with different carbon active materials all have good cycle stability and capacity retention, and the anode prepared by MCMB has the highest capacity retention.

[0052] Anodes based on alloyed active material layers with different thicknesses

[0053] The difference between Examples 8-16 and Example 1 is that the thickness of the aluminum active material layer is different as the alloyed active material layer, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com