Method for preparing desulfurizing agent by carrying out thermal activation on red mud and active carbon

A technology of activated carbon and thermal activation, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of large desulfurization agent consumption, high equipment operating costs, poor desulfurization effect, etc., to reduce desulfurization agent consumption , Realize the effective utilization of resources and the effect of simple and easy-to-obtain red mud source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Red mud and activated carbon are mixed at a mass ratio of 1:20, activated in a muffle furnace at 900°C for 15 minutes, and cooled to obtain a new type of desulfurizer, which is used in wet flue gas desulfurization.

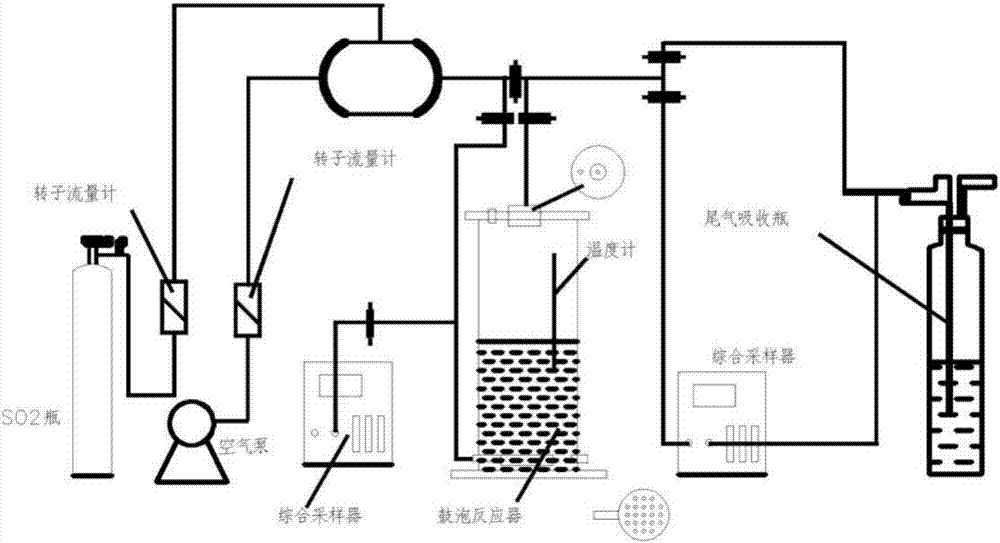

[0025] The desulfurization test device adopts a laboratory bubbling absorption tower (see attached figure 2 ), weigh 400g of activated red mud to make desulfurization slurry by solid-to-liquid ratio (S / L) 1:5 and add it to the absorption tower, the SO concentration is 1500ppm 2 It enters the absorption tower from the bottom of the tower and reacts with the desulfurization slurry. The test conditions are: temperature 25°C, gas flow rate 2L / min, and run for 100min. The desulfurization effect obtained by this method can reach 90.9%.

Embodiment 2

[0027] Red mud and activated carbon are mixed at a mass ratio of 1:10, activated in a muffle furnace at 1000°C for 15 minutes, and a new desulfurizer is obtained after cooling, which is used for wet flue gas desulfurization.

[0028] The desulfurization test device adopts a laboratory bubbling absorption tower (see attached figure 2 ), weigh 400g of activated red mud to make desulfurization slurry by solid-to-liquid ratio (S / L) 1:5 and add it to the absorption tower, the SO concentration is 1500ppm 2 It enters the absorption tower from the bottom of the tower and reacts with the desulfurization slurry. The test conditions are: temperature 25°C, gas flow rate 2L / min, and run for 100min. The desulfurization effect obtained by this method can reach 88.8%.

Embodiment 3

[0030] Red mud and activated carbon are mixed at a mass ratio of 1:30, activated in a muffle furnace at 800°C for 20 minutes, and cooled to obtain a new type of desulfurizer, which is used in wet flue gas desulfurization.

[0031] The desulfurization test device adopts a laboratory bubbling absorption tower, weighs 400g of activated red mud to make a desulfurization slurry at a solid-to-liquid ratio (S / L) of 1:5, and adds it to the absorption tower with a concentration of 1500ppm SO 2 It enters the absorption tower from the bottom of the tower and reacts with the desulfurization slurry. The test conditions are: temperature 25°C, gas flow rate 2L / min, and run for 100min. The desulfurization effect obtained by this method can reach 89.3%.

[0032] The desulfurization agent prepared according to the present invention is made into a desulfurization slurry at a solid-to-liquid ratio (S / L) of 1:5 and added to the absorption tower to carry out a wet desulfurization reaction at room ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com