Patents

Literature

310results about How to "Little pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano antibacterial powdered paint and its micro-suspension one-step preparation therefor

InactiveCN1844270ALittle pollutionEasy reunionAntifouling/underwater paintsPaints with biocidesUltrasonic dispersionOrganic polymer

The invention relates to a manufacturing domain of nanopowder composite, especially to a nano antibacterial powder coating and one-step manufacturing method of microsuspension. The nano antibacterial powder coating consists of water, mixture monomer, pigment, surface processing agent, nanometre-sized inorganic antiseptic particle and auxiliary agent. The method comprises dispersing components such as water and suspending disperser by ultra-audio wave, then performing dispersion by high-shear emulsifier to prepare the predispersion; afterwards, adding the other components into polymerization kettle according to priority, after agitation and heating, adding the said predispersion at one time, reacting at a constant temperature, then cooling, discharge, centrifugally dewatering and drying to obtain the product. The invention solves the problems that the nanoparticles are easy to aggregate inside the organic polymer existed in present technology and the manufacturing engineering of the traditional powder coating is difficult, and has advantages that the process flow is short, the equipment investment is low, and can save working hours and energy resource, is of no dust pollution, the prepared powder coating particles is of regular shape, and has better levelling property in application.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

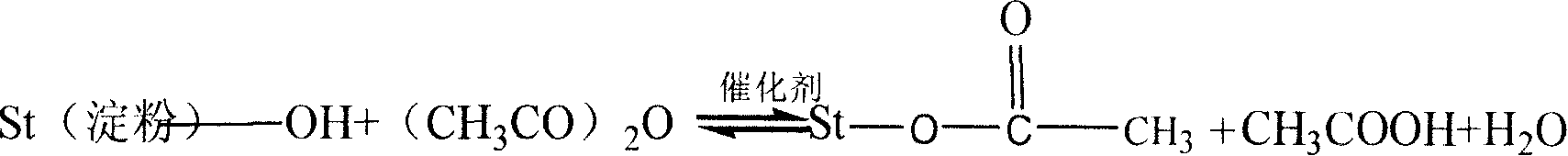

Membrane material for producing coated material and preparation technique thereof

InactiveCN101200393ALow priceLittle pollutionFertiliser formsFertilizer mixturesEthylic acidPerylene derivatives

The invention relates to a fertilizer production, substantially an acetic ester starch film material for manufacturing envelope controlled releasing fertilizer and the preparation technology. The film material takes the starch as the major material, and the property of the starch is changed by adopting a series of chemical processes, thereby the performance of the necessary film material of the envelope controlled releasing fertilizer can be realized, and the film material for preparing envelope controlled releasing fertilizer can be obtained. The invention takes the starch derivative which can be biodegraded fully as the film material to prepare the envelope controlled releasing fertilizer; the process of the invention for manufacturing the raw material of the film material and the film material fetching are simple, the equipment invention is less; the manufacture can be small-scale production implemented in laboratory or a mass production in factory.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

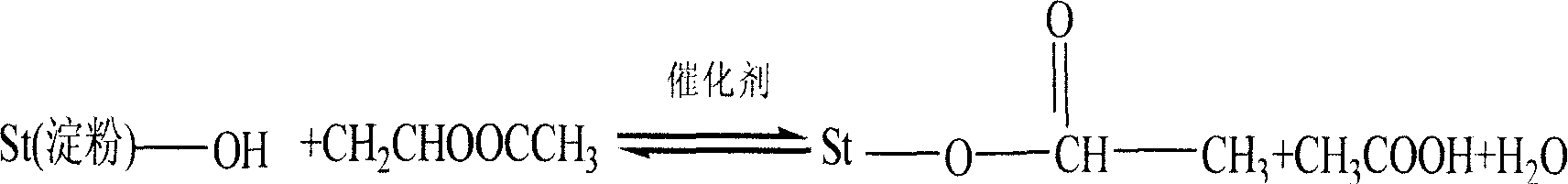

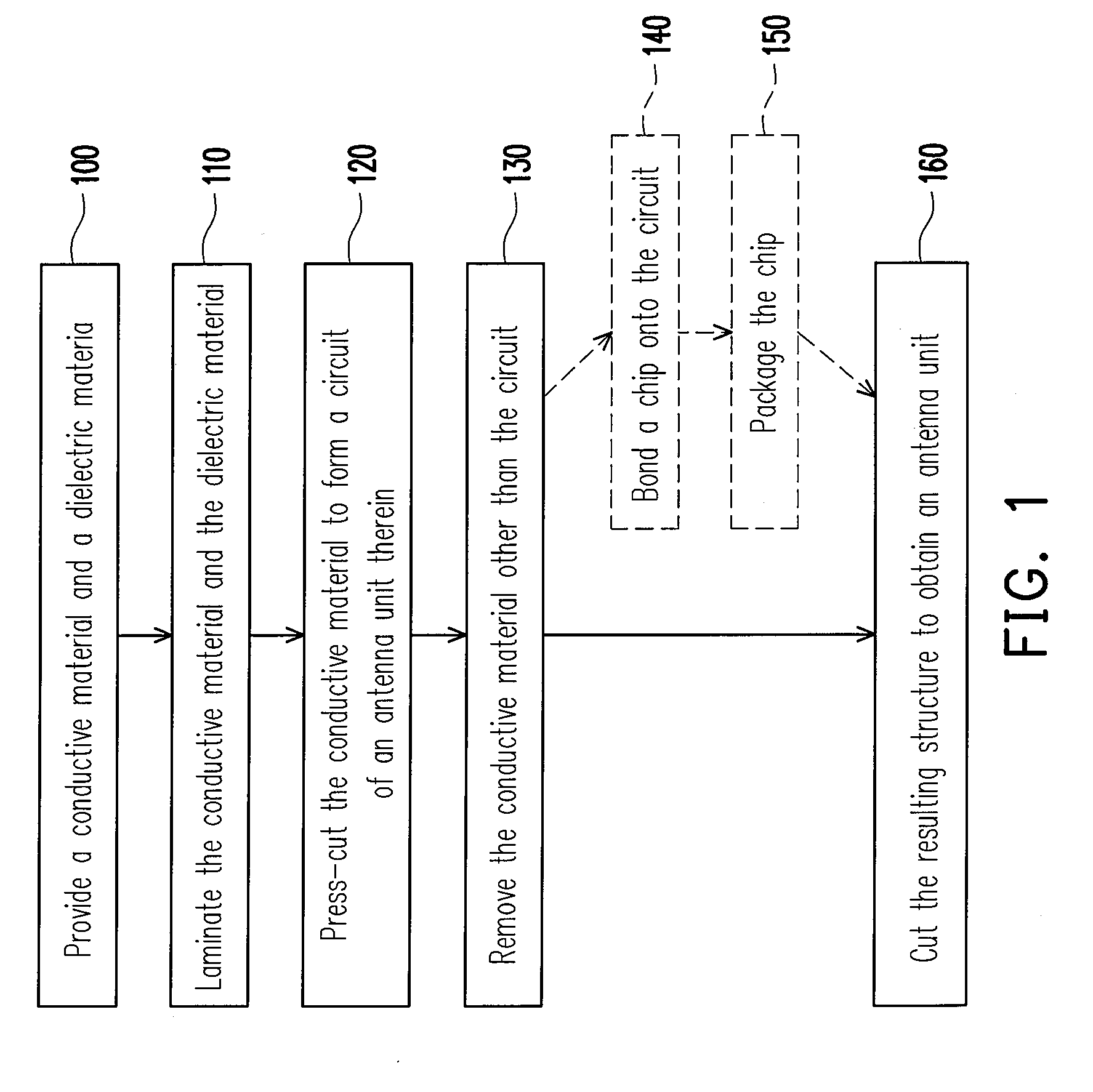

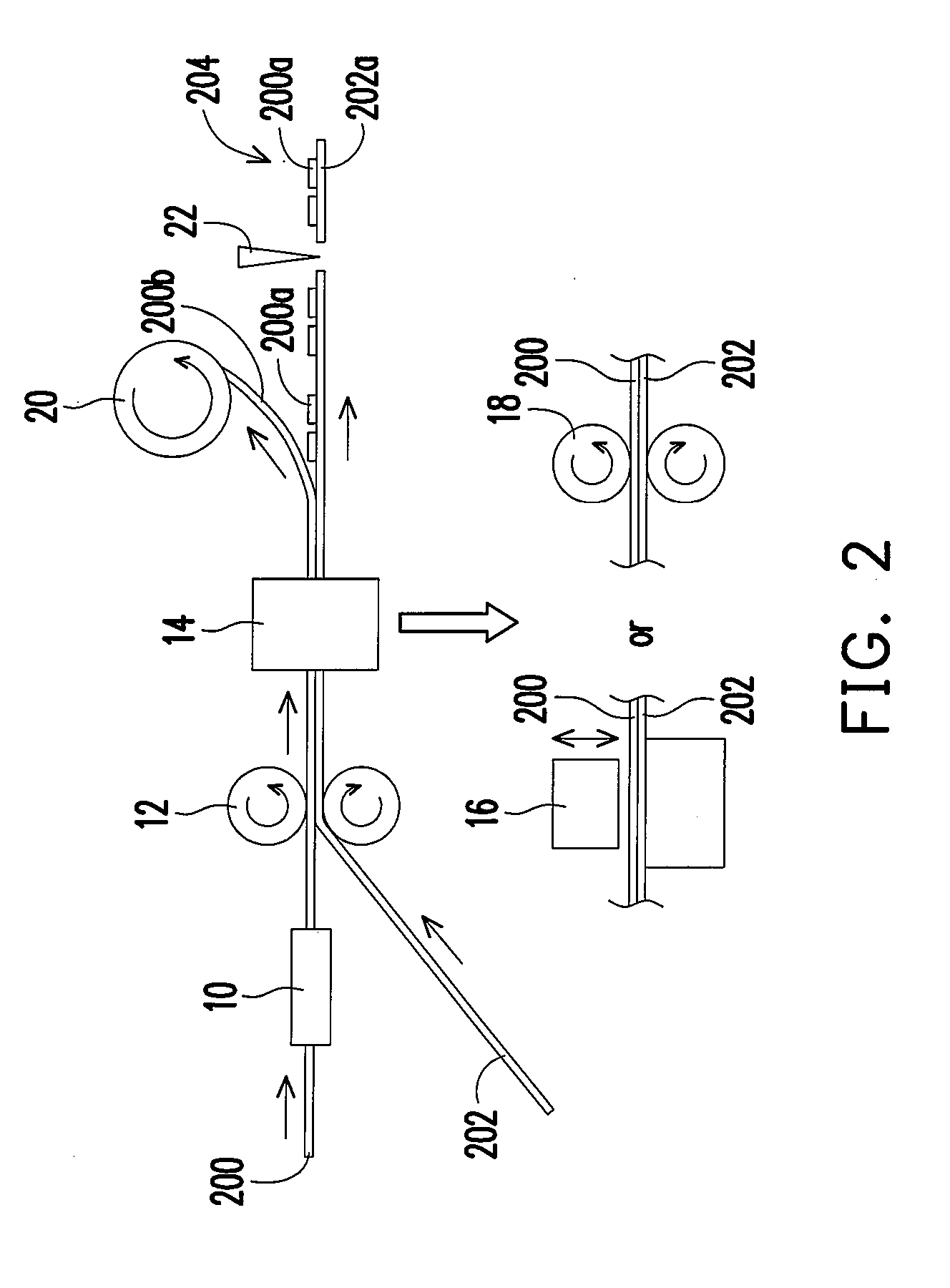

Method for fabricating antenna units

InactiveUS20080047130A1Improve efficiencyLittle pollutionPrinted circuit manufacturePrinted inductor incorporationConductive materialsComposite structure

A method of fabricating antenna units is described, including providing a conductive material and a dielectric material, laminating the conductive material and the dielectric material, press-cutting the conductive material to form therein circuits of a plurality of antenna units, removing the conductive material other than the circuits to form a composite structure, and cutting the composite structure to obtain the antenna units. Before each antenna unit is obtained through cutting, a chip may be bonded onto the circuit thereof and then packaged so that an RFID tag is obtained after the cutting. The method allows the manufacturer to conduct a fabricating process in high efficiency, low cost and little pollution in a continuous manner, and also allows each antenna to have a full receiving performance due to the precision of the process.

Owner:ADVANCED CONNECTEK INC

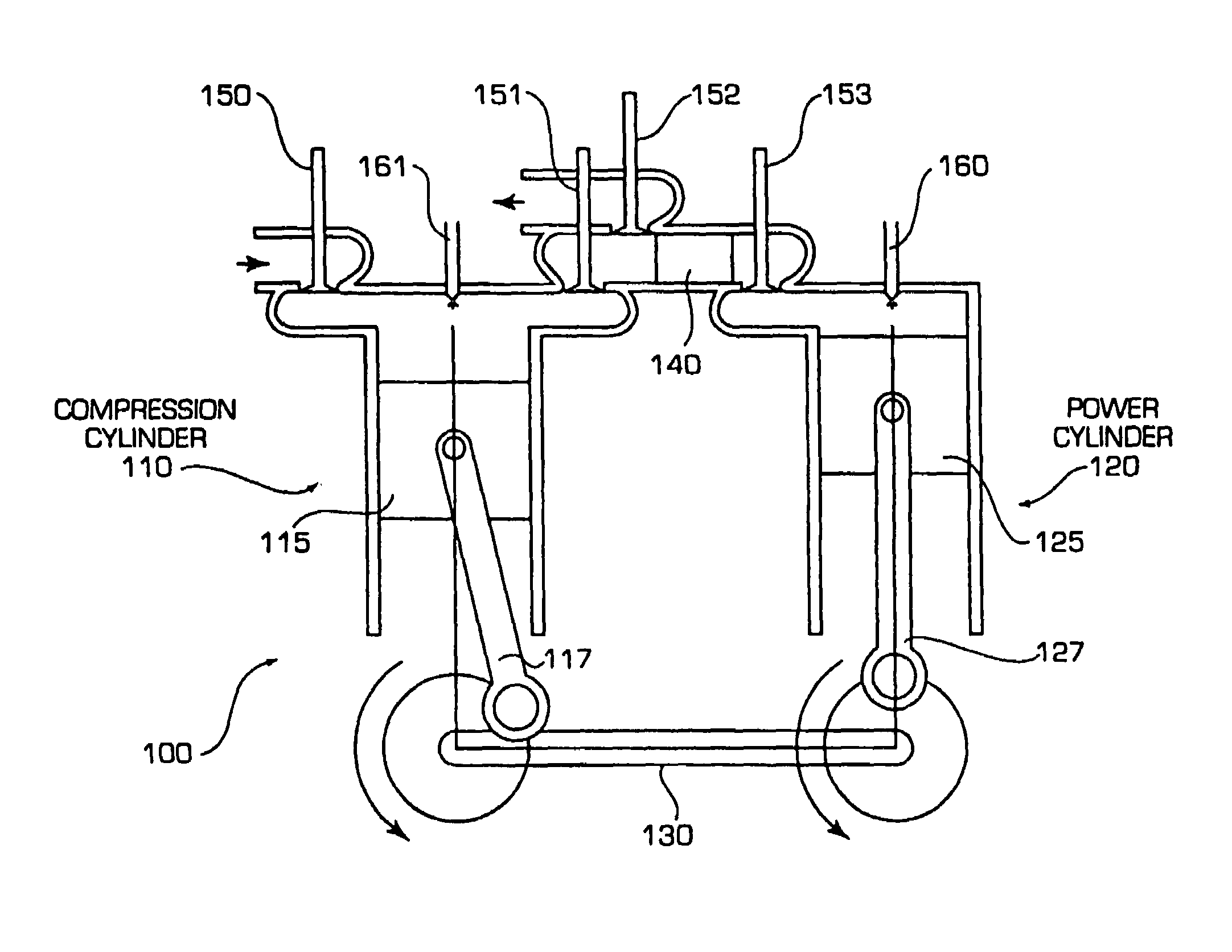

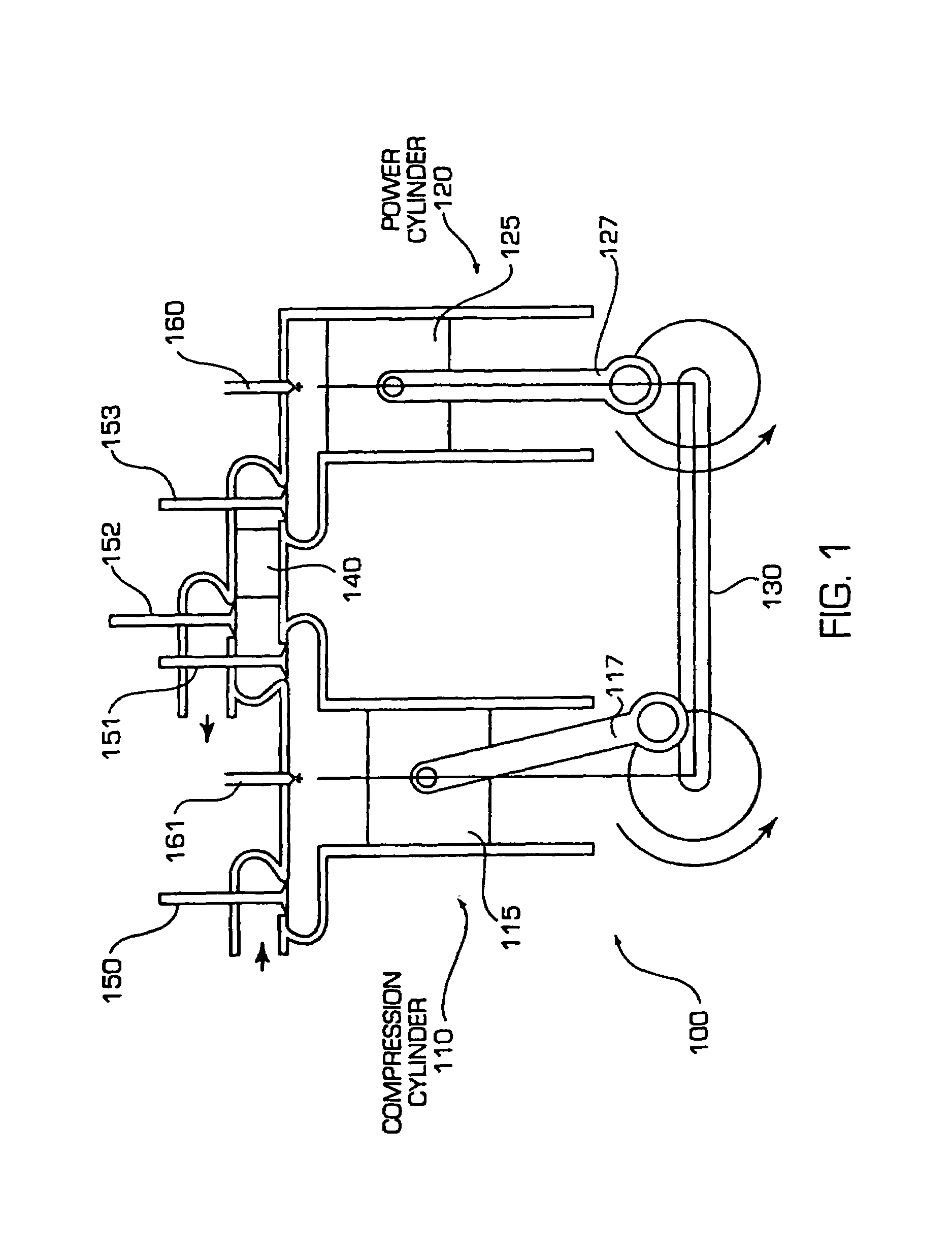

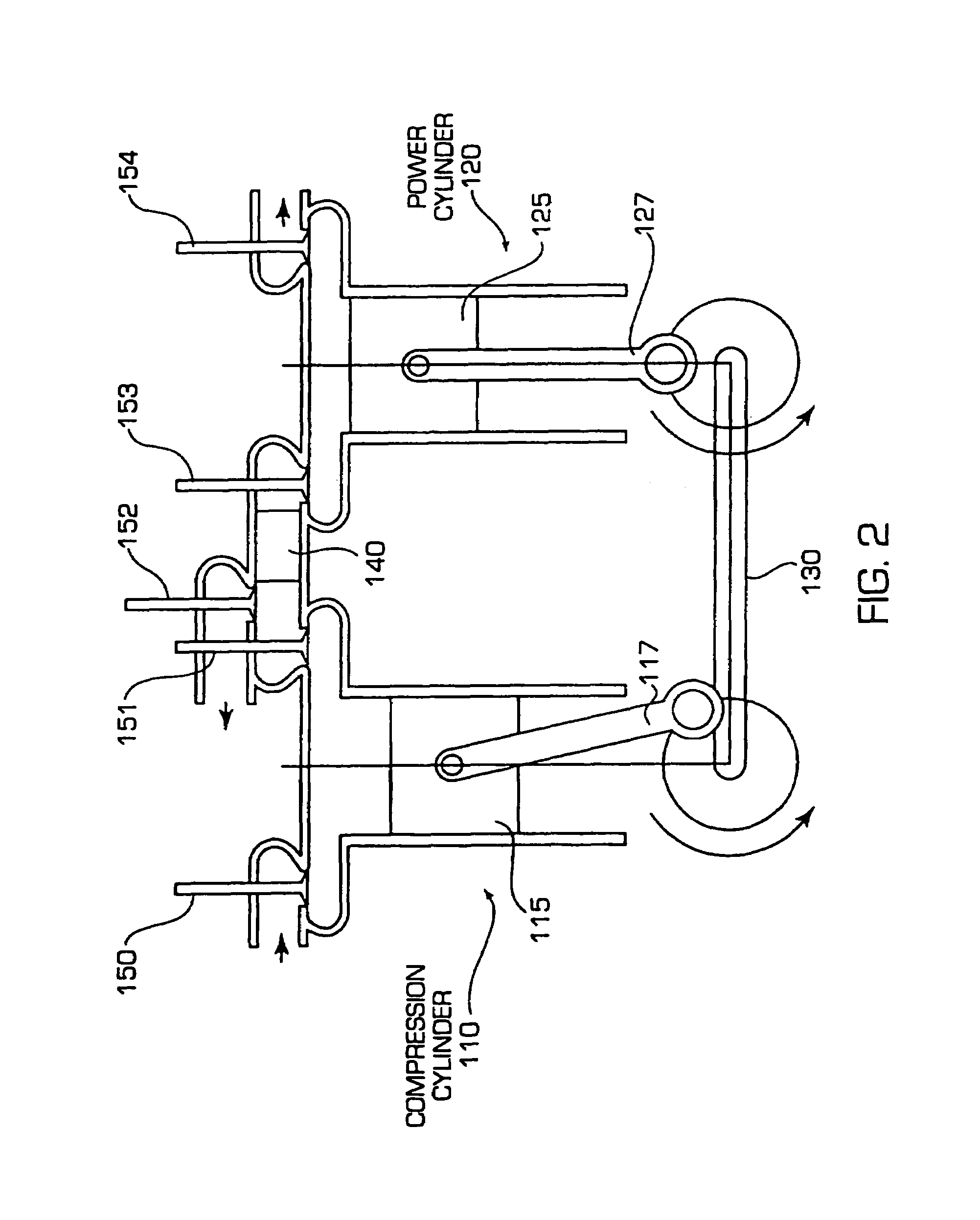

Internal combustion engine with regenerator, hot air ignition, and naturally aspirated engine control

InactiveUS7219630B2Reduce the temperatureReduce heat lossValve arrangementsNon-fuel substance addition to fuelNaturally aspirated engineInternal combustion engine

Owner:PATTON RICHARD

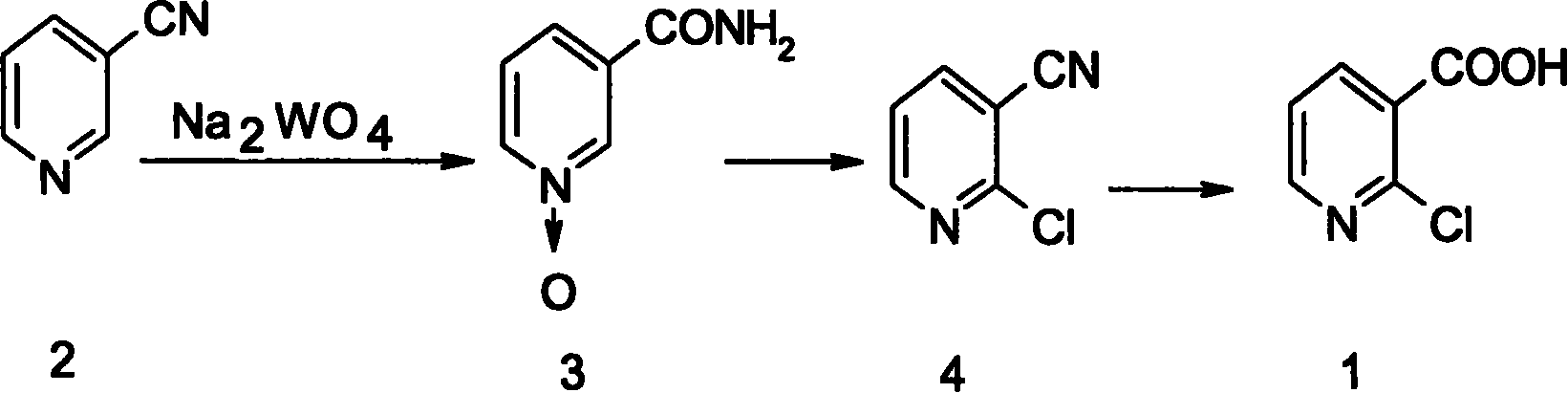

Preparation method of 2-chloronicotinic acid

InactiveCN101117332ANot easy to decomposeLittle pollutionOrganic chemistryHalohydrocarbonPositive pressure

The invention discloses a preparation process for 2-Chloronicotinic acid. In the prior art, the disadvantage is that the overdosed catalyzer is used and has a bad effect, the oxidation yields are very low; during the chlorination reaction, POCl3 can make chloro-substitutions on a plurality of positions of nicolinamide- N- oxido, which leads to that the chloro-substitution products on 2-position have low yields. In the invention, with the existence of acetyl pyruvic molybdenum, the 3-Pyridinecarbonitrile takes water as the solvent and is dripped in 20 to 30 percent of H2O2, and then is made a heat preservation to realize a full oxidation reaction; under the anhydrous reaction and with the positive pressure protection of nitrogen, the acquired nicolinamide- N- oxido is cooled between minus 10 and 10 DEG C to be diluted by the halohydrocarbon solvent, and then is dripped in the organic base, and is reacted with the chlorination reagent under the action of phenyl dichlorophosphate; the strong alkaline solution is used to make a dehydration reaction with the acquired 2-chloro-3-cyanopyridine. The invention takes the acetyl pyruvic molybdenum as the catalyzer and oxidizer, has high oxidation yields; adopts the organic base as the acid-binding agent, makes chloro-substitutions between the chlorination reagent and the nicolinamide- N- oxido, and has above 85 percent of chloro-substitution yields.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

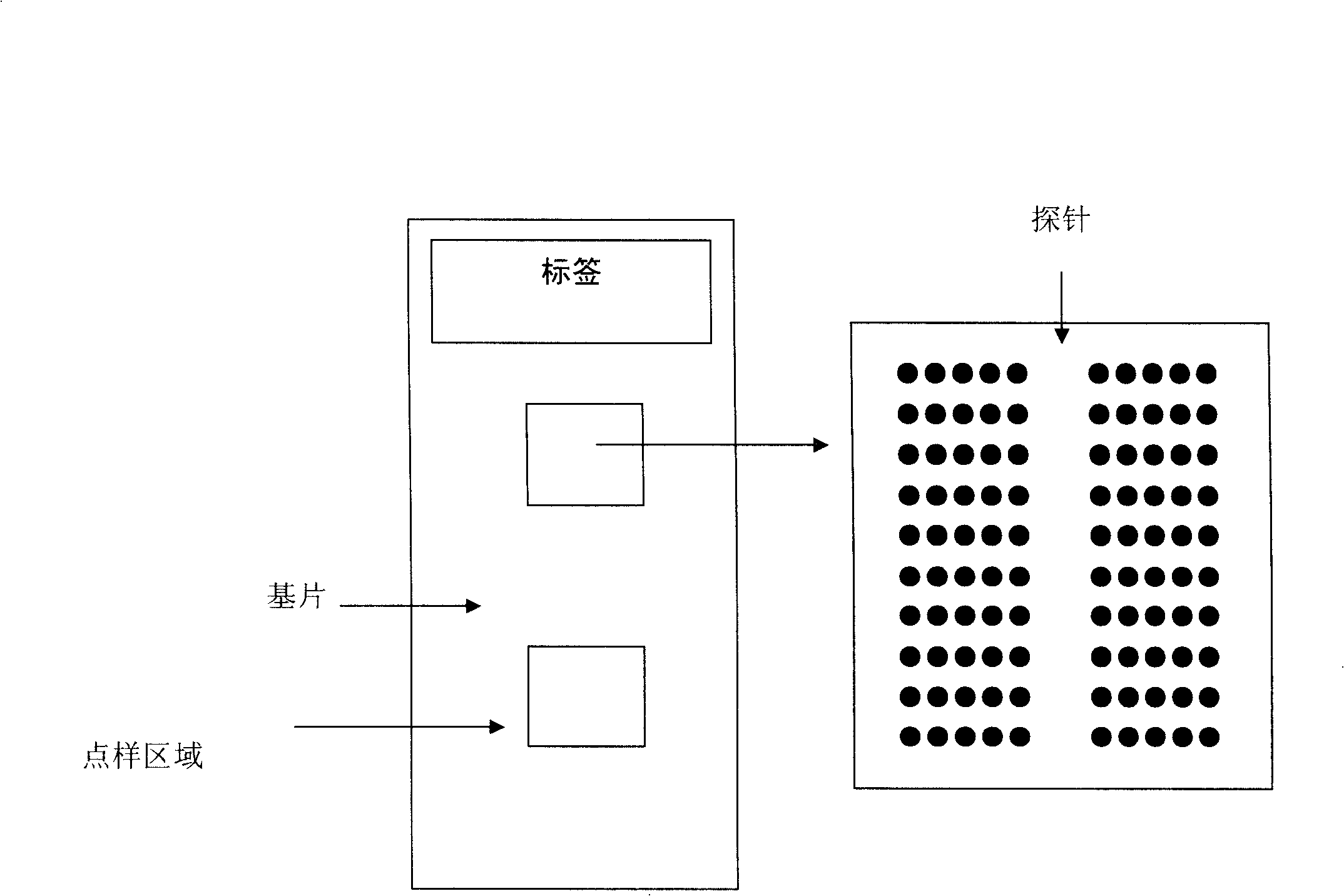

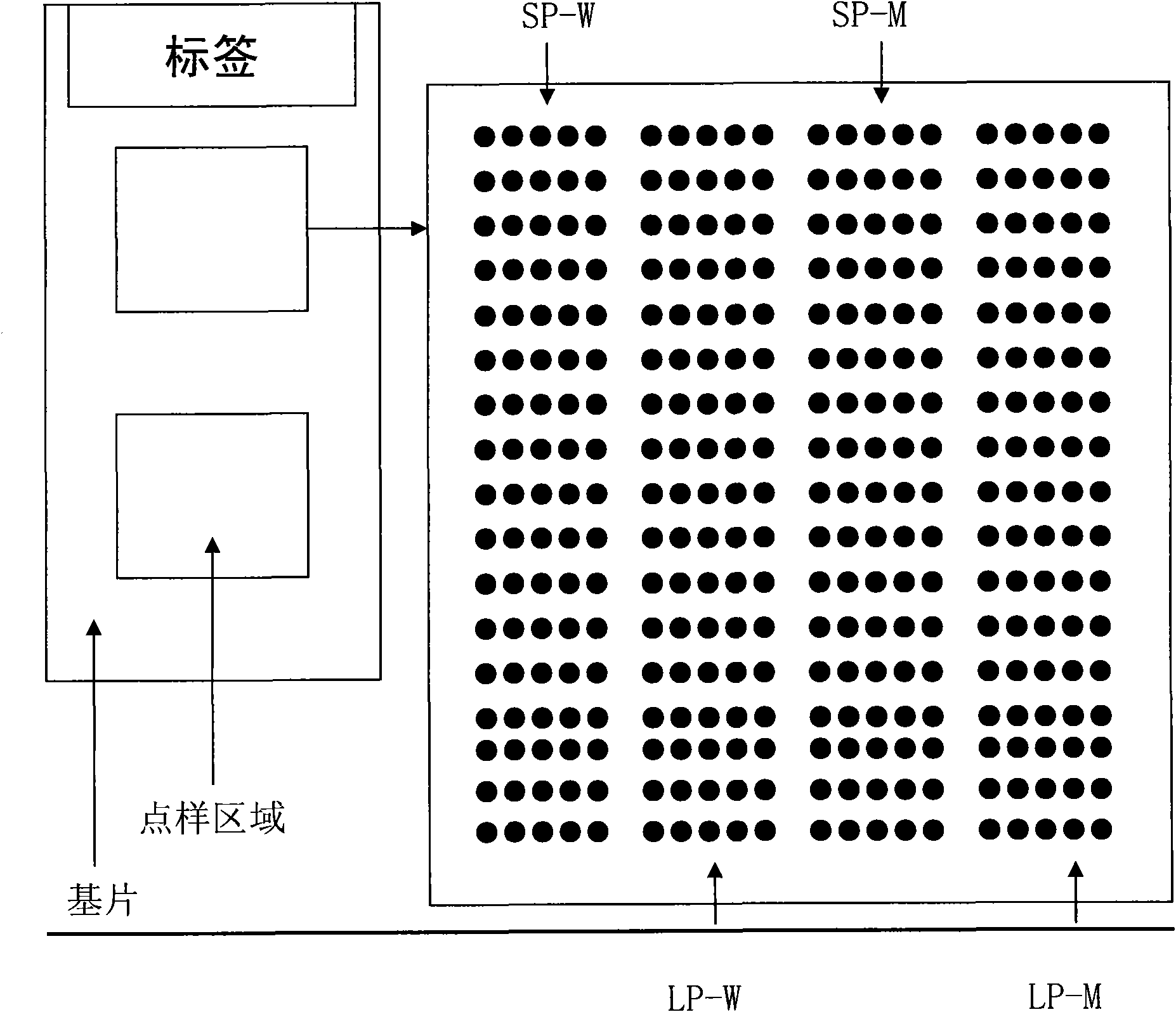

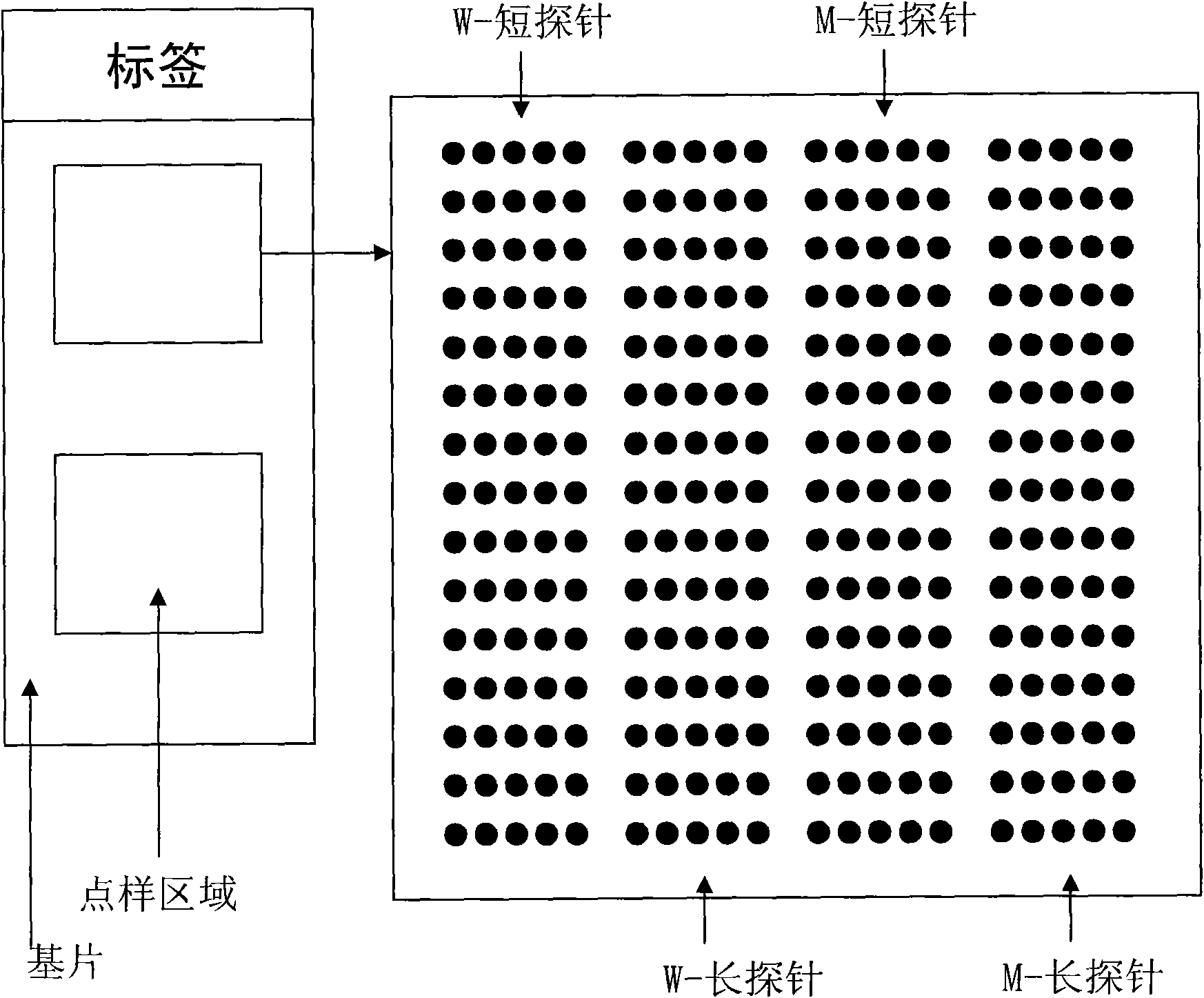

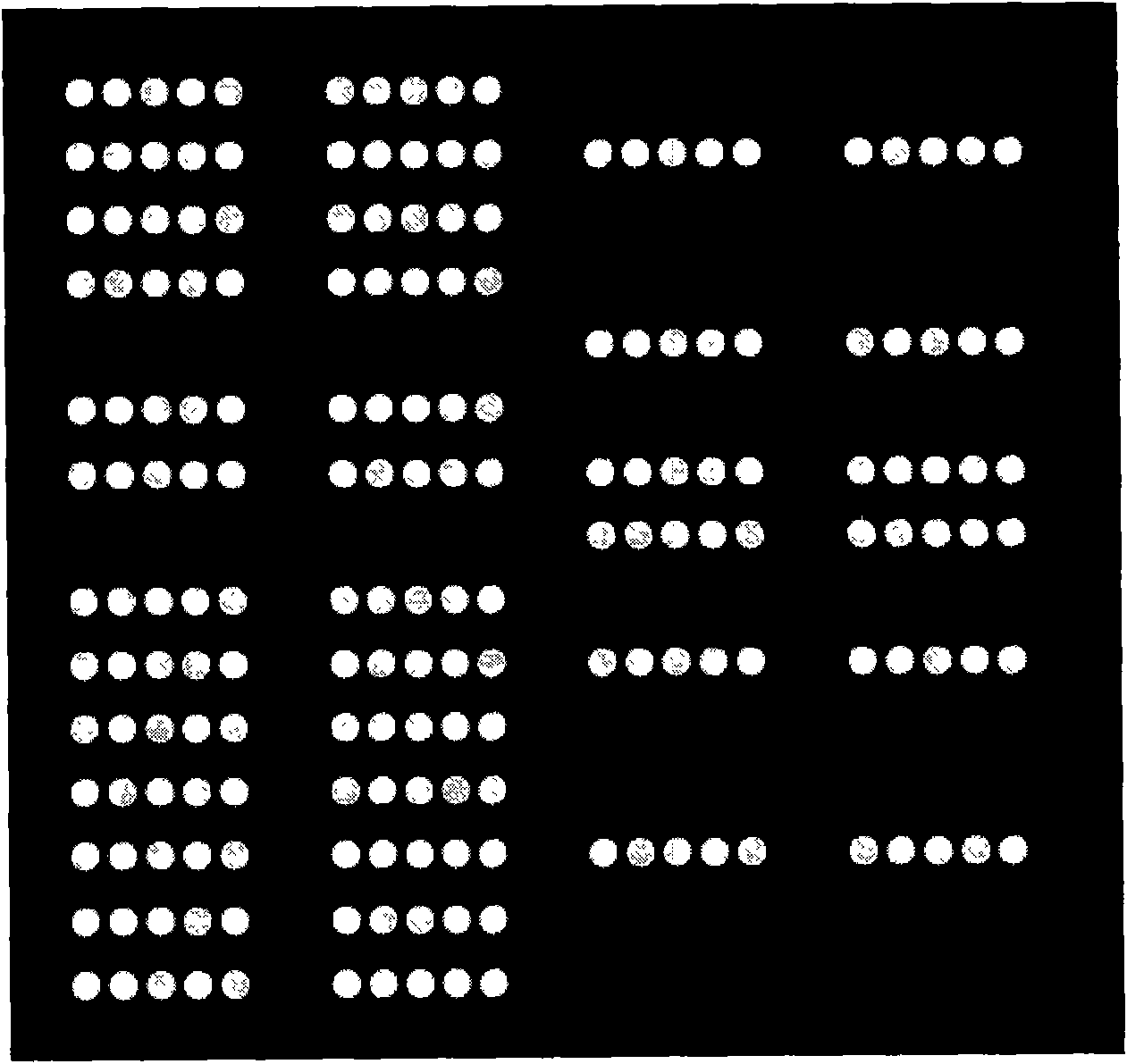

Gene chip for detection of hyperpiesis individual medicine correlated gene mutation and uses thereof

InactiveCN101343658AAccurate detectionSensitive detectionMicrobiological testing/measurementGNB3CYP2C9*3

The invention relates to a gene chip used for detecting gene mutation relating to a high blood pressure personalized medicine. The gene chip for detecting the gene mutation relating to high blood pressure personalized medicine comprises a solid phase support, a gene probe (an oligonueleotide probe) fixed in the solid phase support sequentially and a PCR primer used for amplifying the mutated gene fragment in the sample; the gene probe (the oligonueleotide probe) and the PCR primer are designed aiming at one or two points of the gene mutation in ACE (I / D) and CYP3A5*3 and / or two or more points as follows: CYP2C9*3, CYP2C9*13, AGTR1(A1166C), CYP2D6*10, ADRB1(C1165G), TSC(C1784T), ADRB3(T727C), SCNN1G_rs5729, SCNN1G_rs5723, ENOSA_rs1799983 and GNB3(C825T). The invention provides the gene chip and applications thereof for conveniently, quickly and systematically detecting the gene mutation relating to high blood pressure personalized medicine so as to determine drug reactions.

Owner:湖南宏灏基因生物科技有限公司

Method for quickly extracting herbaceous fibers in factory fermentation mode by using full-function strains

InactiveCN102559541ALittle pollutionShort degumming cycleBacteriaMicroorganism based processesFiberBiological activation

The invention discloses a method for quickly extracting herbaceous fibers in a factory fermentation mode by using function strains. The method comprises the steps of pre-treating a herbaceous fiber raw material, inoculating activated strain liquid to the herbaceous fiber raw material for factory fermentation, post-treating the fermented material and the like. The method specifically comprises the following steps of: rolling or cutting the herbaceous fiber raw material, and performing activation and amplification treatment on Dickeya dadantii strains to obtain strain suspension; diluting the strain suspension, and then performing soaking inoculation and soaking fermentation or wetting fermentation on the herbaceous fiber raw material till fibers are dispersed; and performing post-treatment such as hot water inactivation, washing and the like on the fermented product till the herbaceous fibers meeting the subsequent processing requirements are obtained. The method has the advantages of short degumming period, low production cost, stable product quality, low environmental pollution and the like.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

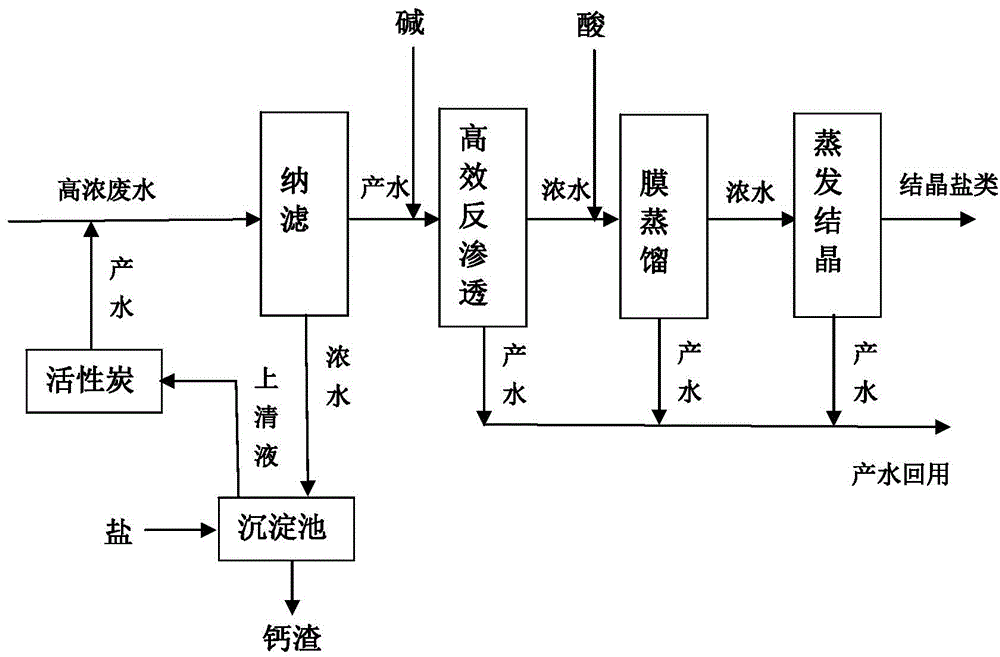

High-concentration wastewater zero-discharging method

ActiveCN105198143ARealize in-depth treatment and even zero discharge problemsEfficient reverse osmosis treatmentEnergy based wastewater treatmentMultistage water/sewage treatmentHigh concentrationReverse osmosis

The invention relates to the field of industrial wastewater treatment, in particular to a high-concentration wastewater zero-discharging method. Accoridng to the method, a 'nanofiltration + efficient reverse osmosis + membrane distillation + evaporative crystallization' method is adopted to treat high-concentration wastewater. Firstly, nanofiltration is adopted to remove hardness, multivalent ions and parts of organic matter in the high-concentration wastewater so as to obtain nanofiltration producing water and nanofiltration concentrated water, then an efficient reverse osmosis technology is adopted to conduct deep concentration treatment on the nanofiltration producing water, deep concentration treatment is conducted on the obtained efficient reverse osmosis concentrated water through membrane distillation to obtain membrane-distillation concentrated water, further evaporative crystallization treatment is performed to enable salt solids in the membrane-distillation concentrated water to crystallize out, and centralized drying disposal is performed, wherein salt is added into the nanofiltration concentrated water to perform precipitation treatment so as to obtain calcium residues, supernate obtained after precipitation is subjected to activated carbon adsorption and then is mixed with the high-concentration wastewater, and the mixed liquid is fed into a nanofiltration unit for circular treatment. By means of the high-concentration wastewater zero-discharging method, water resources are recycled to the most degree while the problem of high-concentration wastewater discharging is solved, and zero discharging of high-concentration wastewater is basically achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

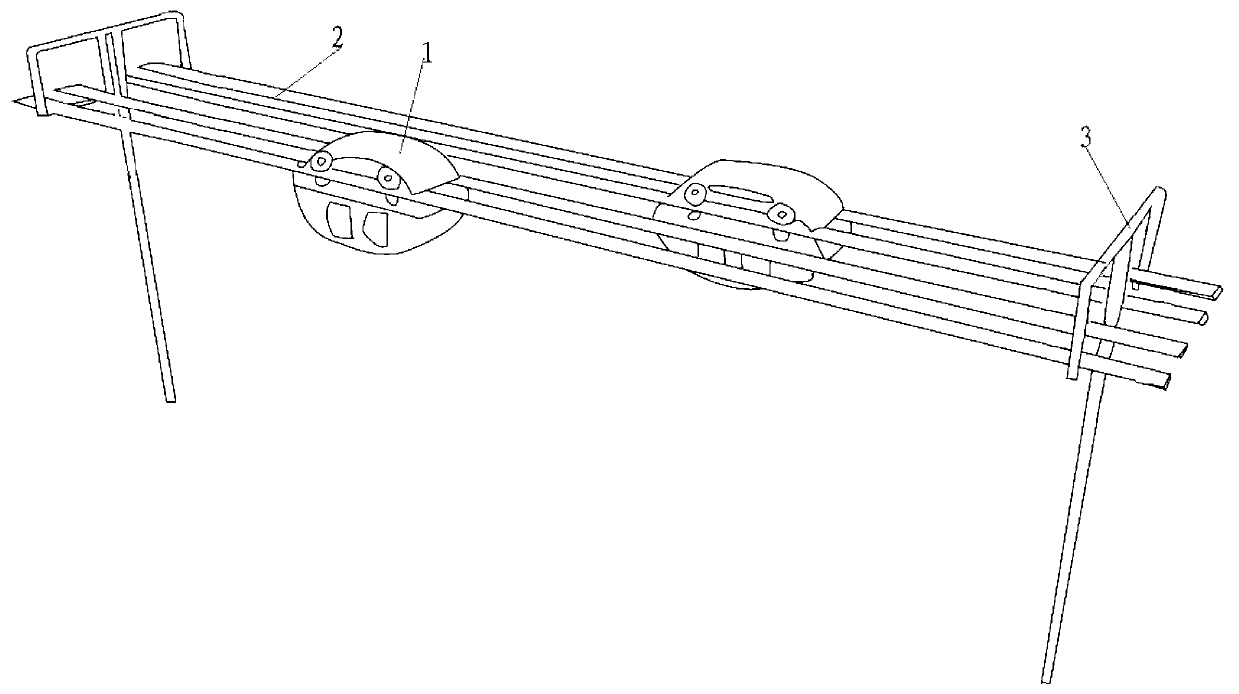

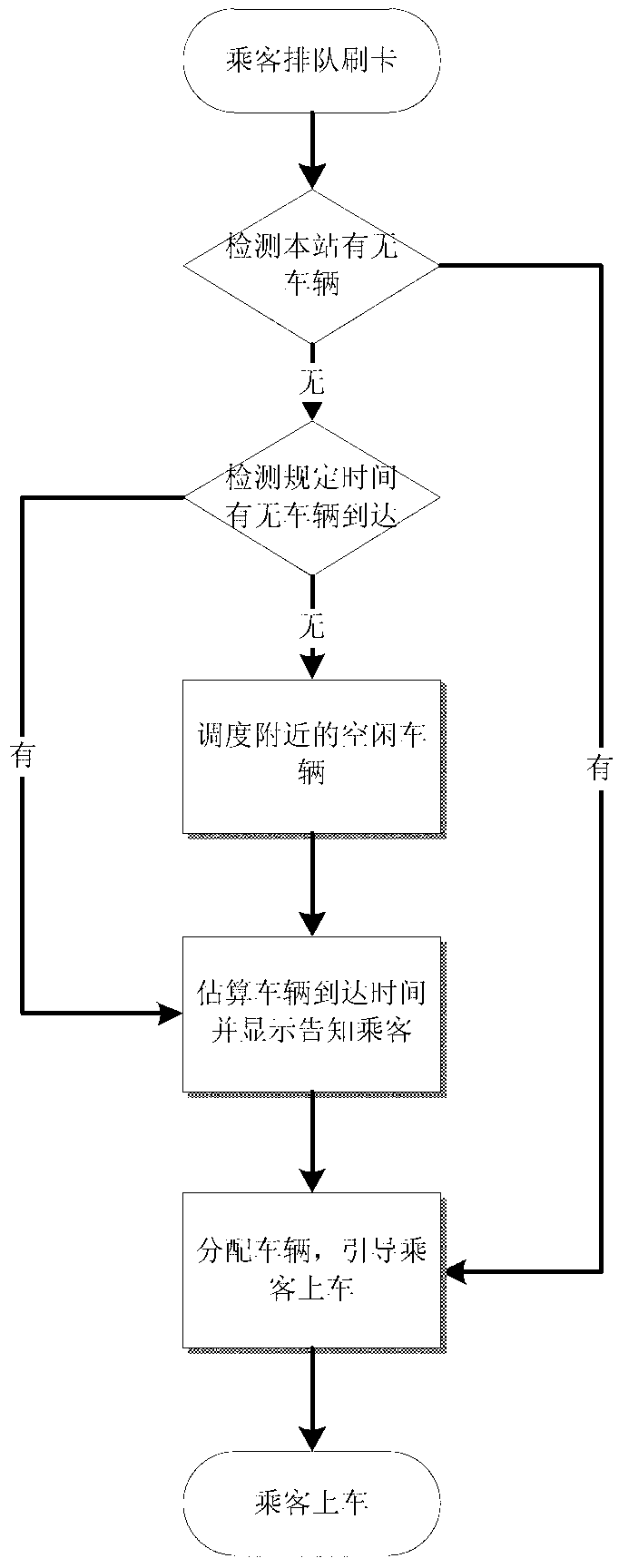

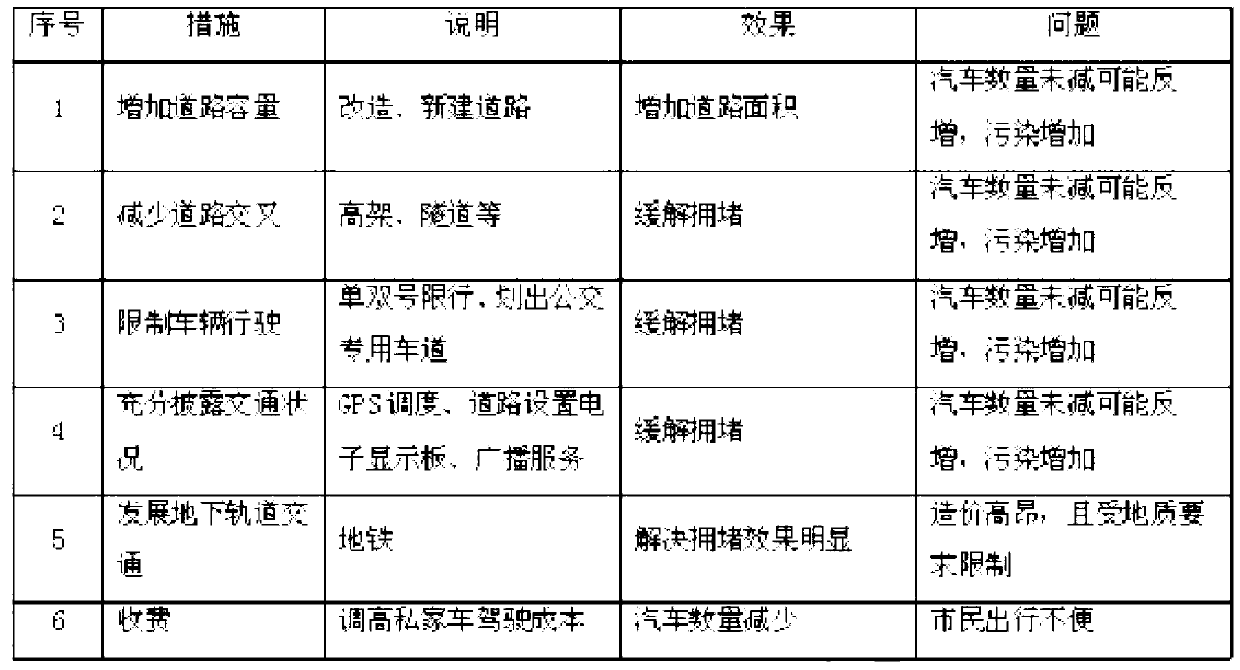

Overhead miniature rail automatic public traffic system

InactiveCN103273924ASmall footprintDriving speedRailway transportElevated railway with suspended vehicleEngineeringControl system

The invention relates to a brand new public traffic system, in particular to an overhead miniature rail automatic public traffic system. The overhead miniature rail automatic public traffic system comprises automatic driving vehicles, overhead rails and a central control system, wherein the automatic driving vehicles are controlled by the central control system to run on the overhead rails, and the automatic driving vehicles are of miniature hanging type structures and hung on the overhead rails for running. Compared with the prior art, the overhead miniature rail automatic public traffic system has the advantages that the running mode similar to a point-to-point nonstop mode of taxies is directly adopted, a full-automatic running mode is adopted, therefore, the overhead miniature rail automatic public traffic system is small in occupied space, high in running speed, light in environment pollution, low in construction cost compared with metros and overhead roads, rapid, comfortable, safe, suitable for traffic requirements of various big cities and capable of completely relieving traffic pressure of the whole cities. In addition, the overhead miniature rail automatic public traffic system will become a technical revolution of public traffic systems.

Owner:韩斐迪

Lignin-bound biochar coated urea and preparation method thereof

InactiveCN104628482ASimple structureHigh porosityUrea compound fertilisersLayered/coated fertilisersCoated ureaAgricultural biomass

The invention relates to lignin-bound biochar coated urea and a preparation method thereof and belongs to the technical field of utilization of agricultural biomass. A binder used in the lignin-bound biochar coated urea comprises acid-precipitated lignin, a pyroligneous liquid and water in different weight ratios. The preparation method comprises the following steps of dissolving acid-precipitated lignin in a pyroligneous liquid or a pyroligneous liquid and water to obtain the binder; and granulating, spraying and drying to obtain the lignin-bound biochar coated urea finished product. The binder is novel in components and environment-friendly; the preparation method is reasonable and simple, the preparation process is simple and feasible, low in production cost; and the urea has the advantages of high fertilizer utilization rate, long fertilizer effect time, light environmental pollution and good antibacterial effect, and the soil structure is improved.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Culture medium, fruiting bag and high-yield culture technique of Pleurotus nebrodensis

ActiveCN102584398AImprove conversion utilizationProtect quality and safetyHorticultureFertilizer mixturesPleurotus nebrodensisGypsum

The invention discloses a culture medium, a fruiting bag and a high-yield culture technique of Pleurotus nebrodensis. The culture medium of the Pleurotus nebrodensis is prepared by mixing main materials and auxiliary materials, wherein the main materials consist of cotton bark, wheat bran and nutritive grains, and the auxiliary materials consist of gypsum, farm-oriented monopotassium phosphate and lime. The weight of the culture medium in each fruiting bag is 200-285g. According to the invention, by a reasonable adjustment of components and a proportion of the culture medium, the conversion utilization rate of the culture medium is improved remarkably, the technical problem that the culture medium with rich nutrients is likely to bepolluted is well solved, and a common prejudice that the culture medium with rich nutrients is likely to be polluted is overcome.

Owner:李传华

Nano composite powder coatings and dispersion polymerization preparation method thereof

The present invention relates to the field of nano-powder composite material preparation, in particular to a composite nano-powder coating and a preparation method adopting dispersion polymerization thereof. The ingredients used to prepare the nano-powder coating include water, alcohol, monomer mixture, inorganic nano-particles, pigment filler and assistant. Surface treatment is first carried out on the nano-particles and the pigment filler, which are then added into the monomer mixture and dispersed by ultrasonic so that mixed solution is produced. Then, the mixed solution is added into alcohol-water mixed solution containing dispersion stabilizer and dispersed by ultrasonic, and after six hours of temperature reaction, the product undergoes centrifugation and vacuum drying so that the final product is prepared. The present invention resolves the defects of the prior art, including large powder particle diameter, uneasy scumbling and uneven coating, and avoids the problems of the complexity of the traditional preparation technique and the easy agglomeration of nano-particles in organic polymers. The preparation method adopting dispersion polymerization has the advantages of short process flow, little investment, energy saving, no powder pollution, etc.; the prepared powder coating is characterized by neat particle shape, small particle diameter and easy scumbling and has functions such as antibacterial function and ultraviolet-resisting function; the powder coating in use has good leveling property.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

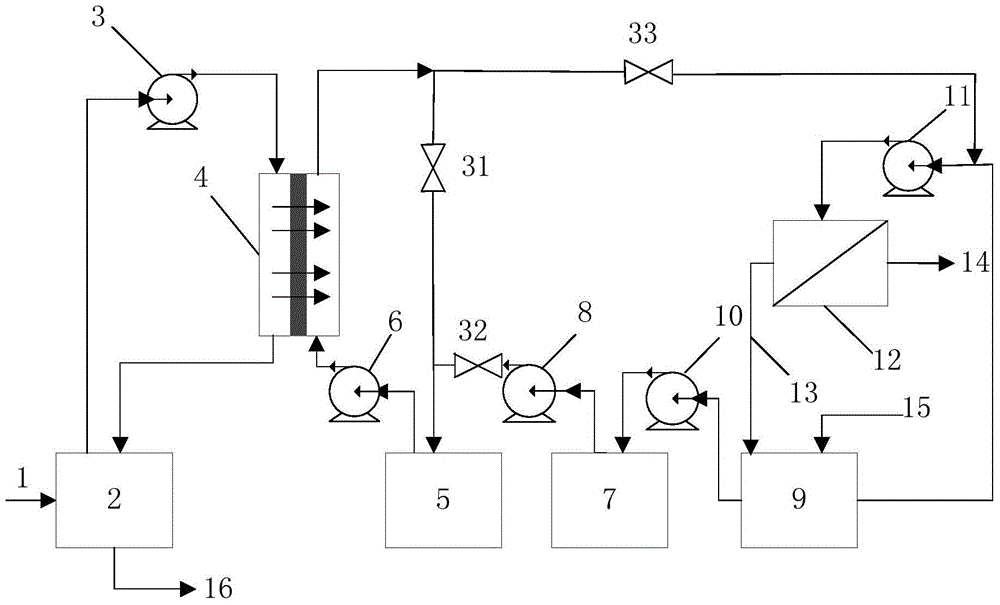

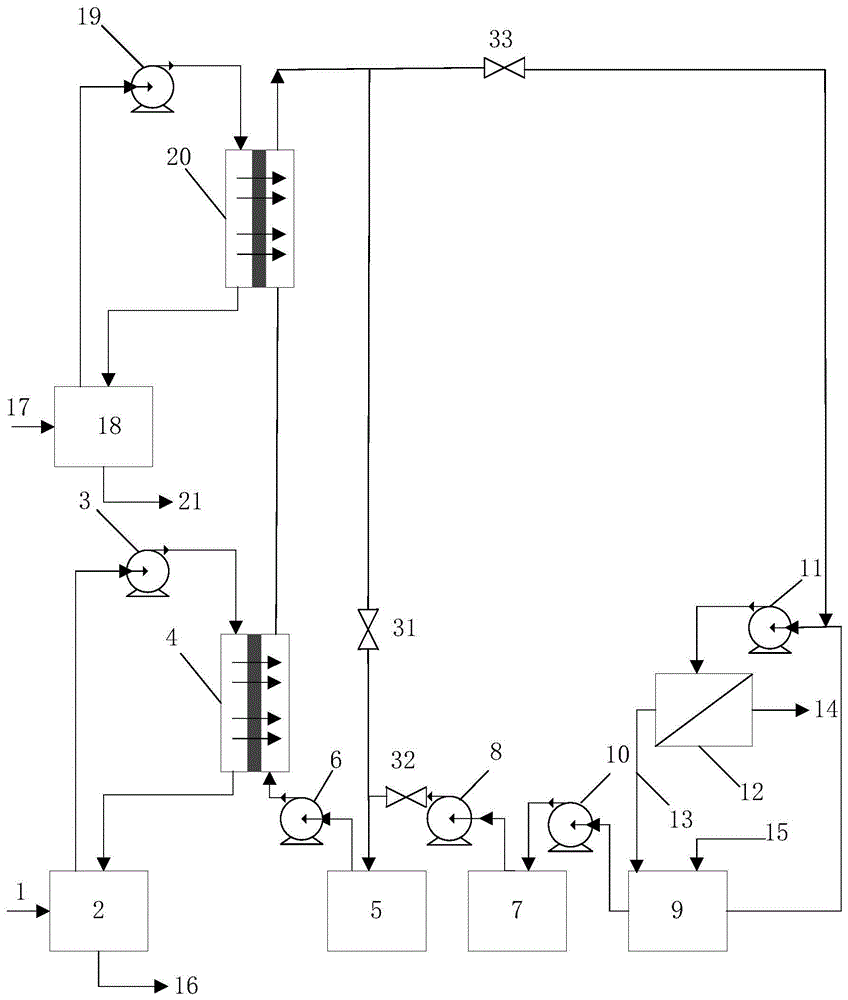

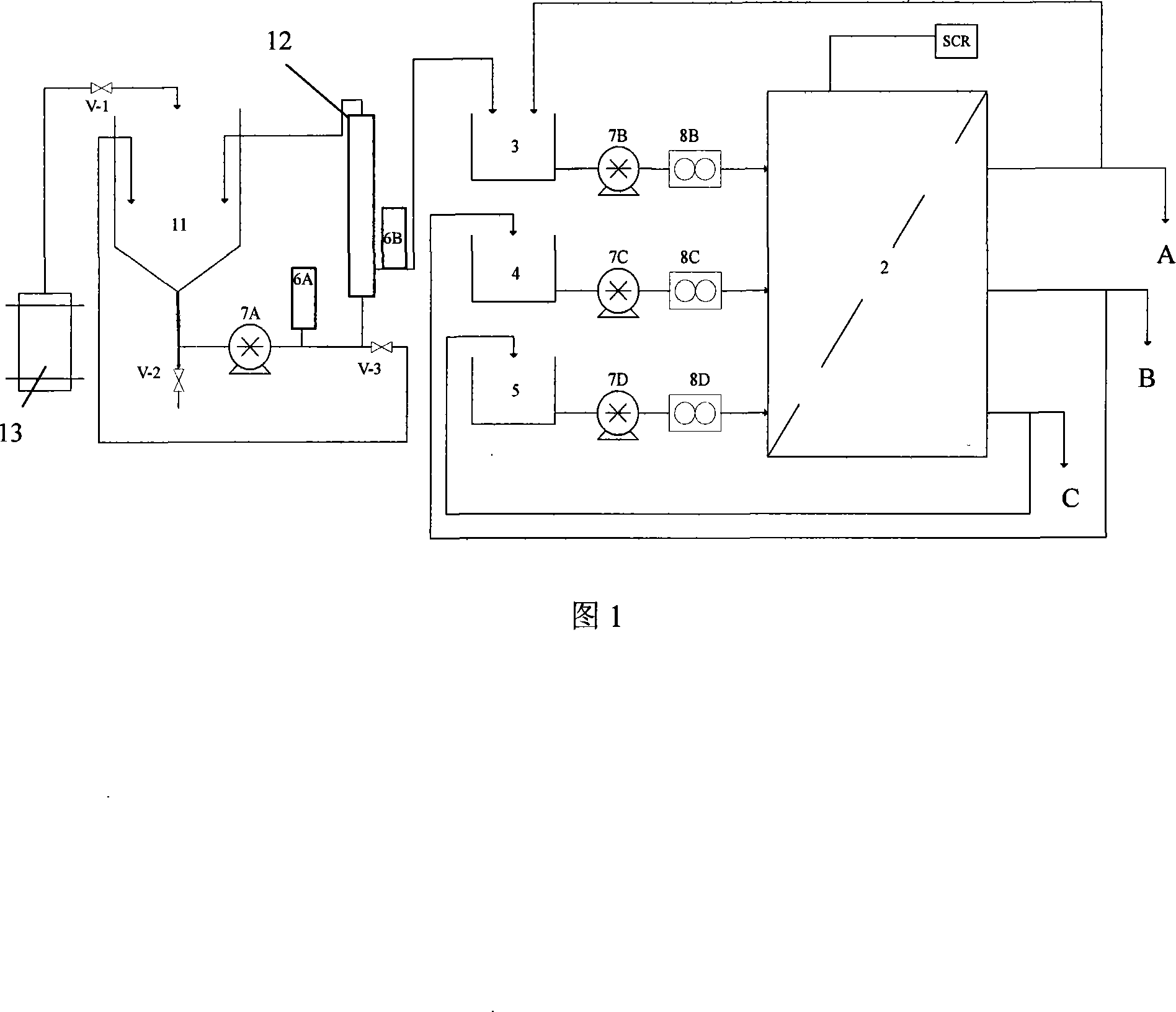

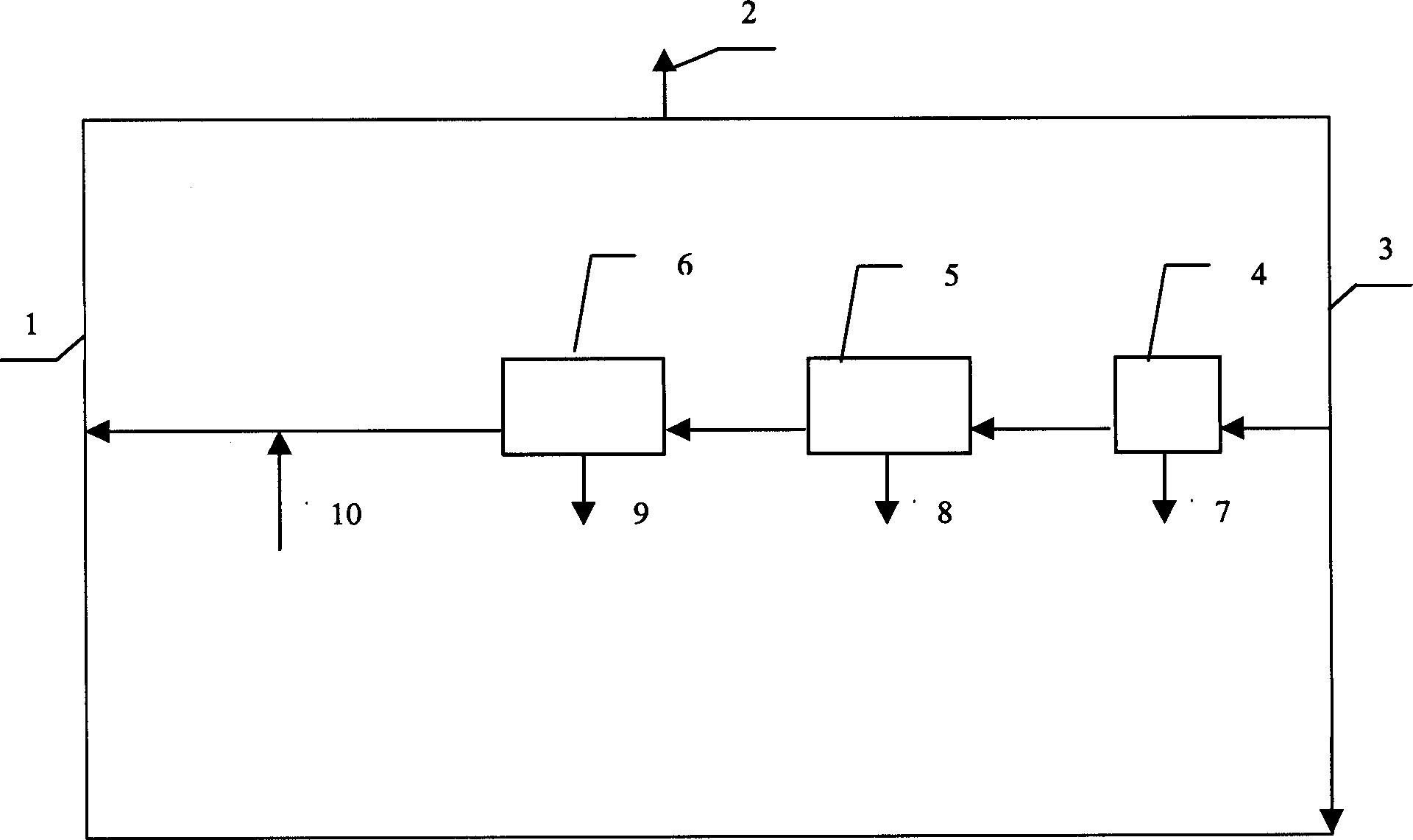

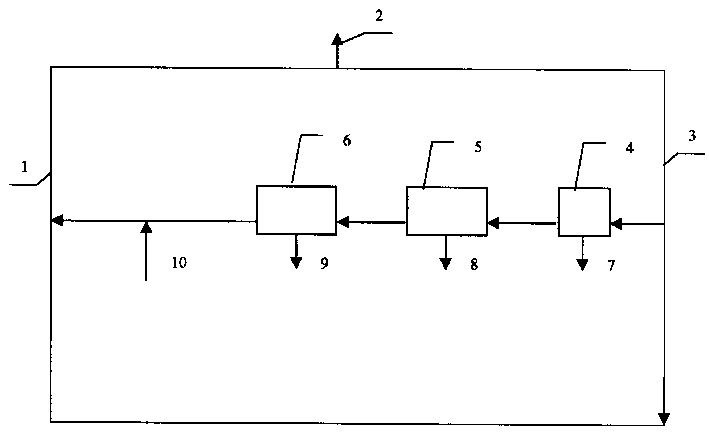

Forward osmosis coupled membrane distillation wastewater treatment apparatus and method thereof

ActiveCN104591457AEfficient use ofSimple methodWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentWater resourcesWastewater

The invention provides a forward osmosis coupled membrane distillation wastewater treatment apparatus and a method thereof. The apparatus includes a first stage forward osmosis unit or a second stage forward osmosis unit and a membrane distillation unit. The above forward osmosis unit is composed of a forward osmosis raw water pool, a forward osmosis raw water pump, a forward osmosis membrane module, a forward osmosis driving liquid pool and a forward osmosis driving liquid pump; the membrane distillation unit is composed of a membrane distillation thick water raw water pool, a membrane distillation thick water pump, membrane distillation, a membrane distillation water heating pool, a membrane distillation thick water raw water pump, a membrane distillation water feeding pump and a membrane distillation assembly; and the forward osmosis unit is connected with the membrane distillation unit through a pipeline and a valve. The method comprises the following steps: high salinity wastewater treated by the membrane distillation unit is used as a forward osmosis driving liquid, membrane distillation thick water is diluted through continuous concentration of forward osmosis feeding liquid side raw water, the diluted membrane distillation thick water returns to the membrane distillation unit and is continuously treated, and above steps are cycled. The apparatus and the method effectively solve the treatment problem of the membrane distillation thick water, and maximally recover the water resource in the wastewater.

Owner:CHINA PETROLEUM & CHEM CORP +1

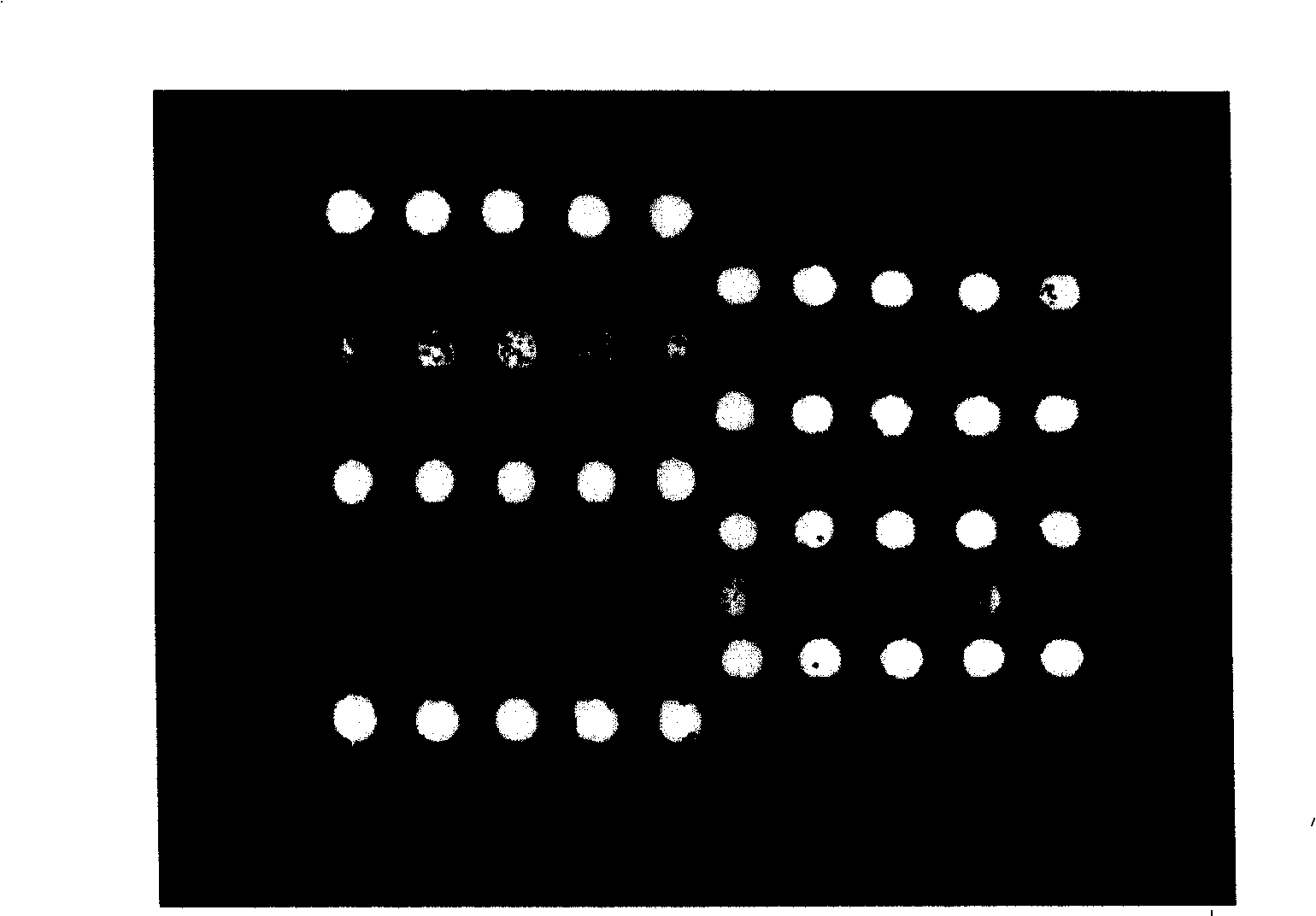

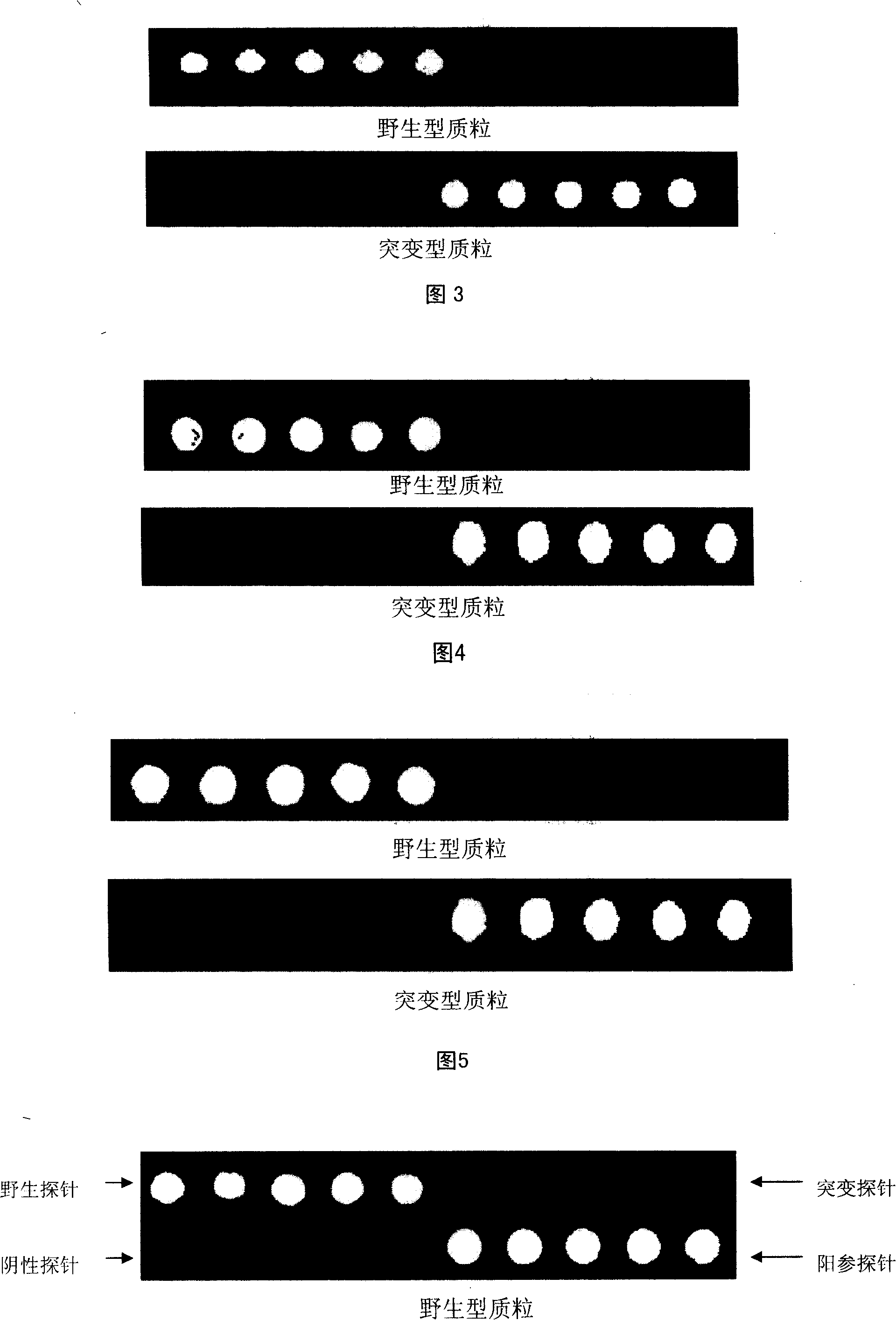

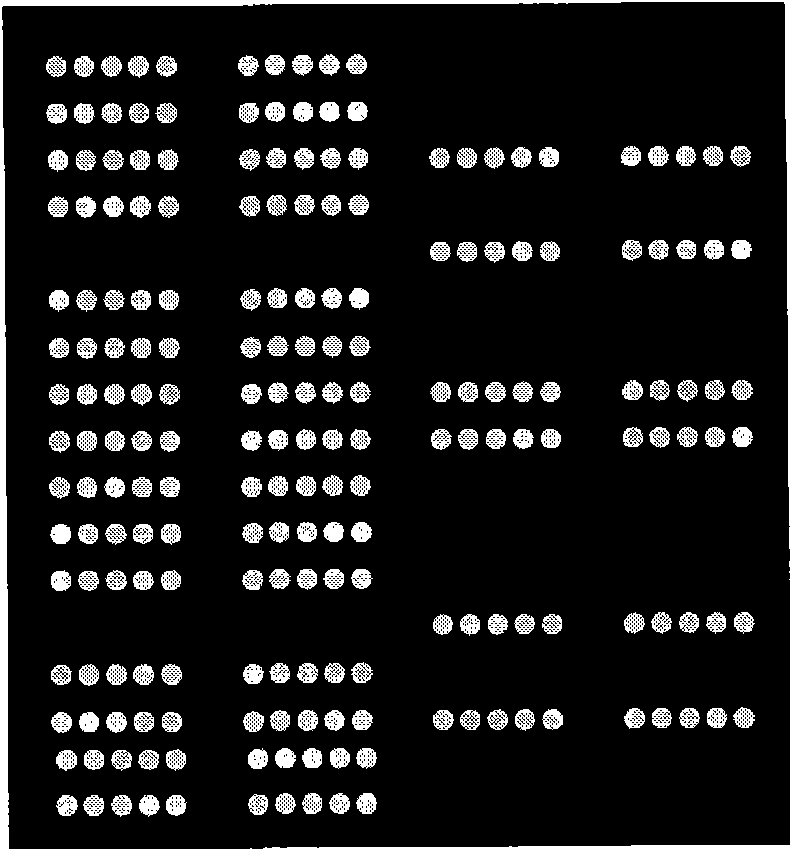

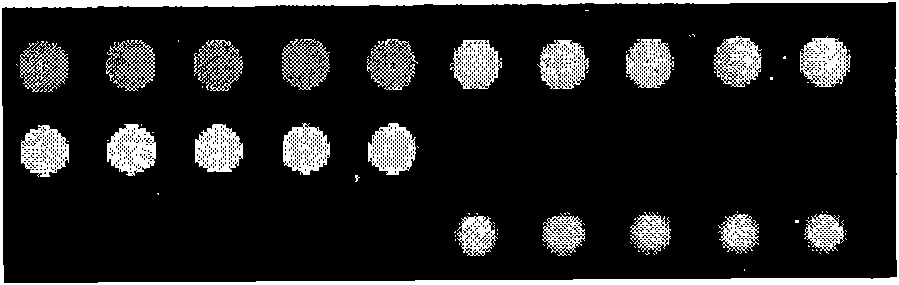

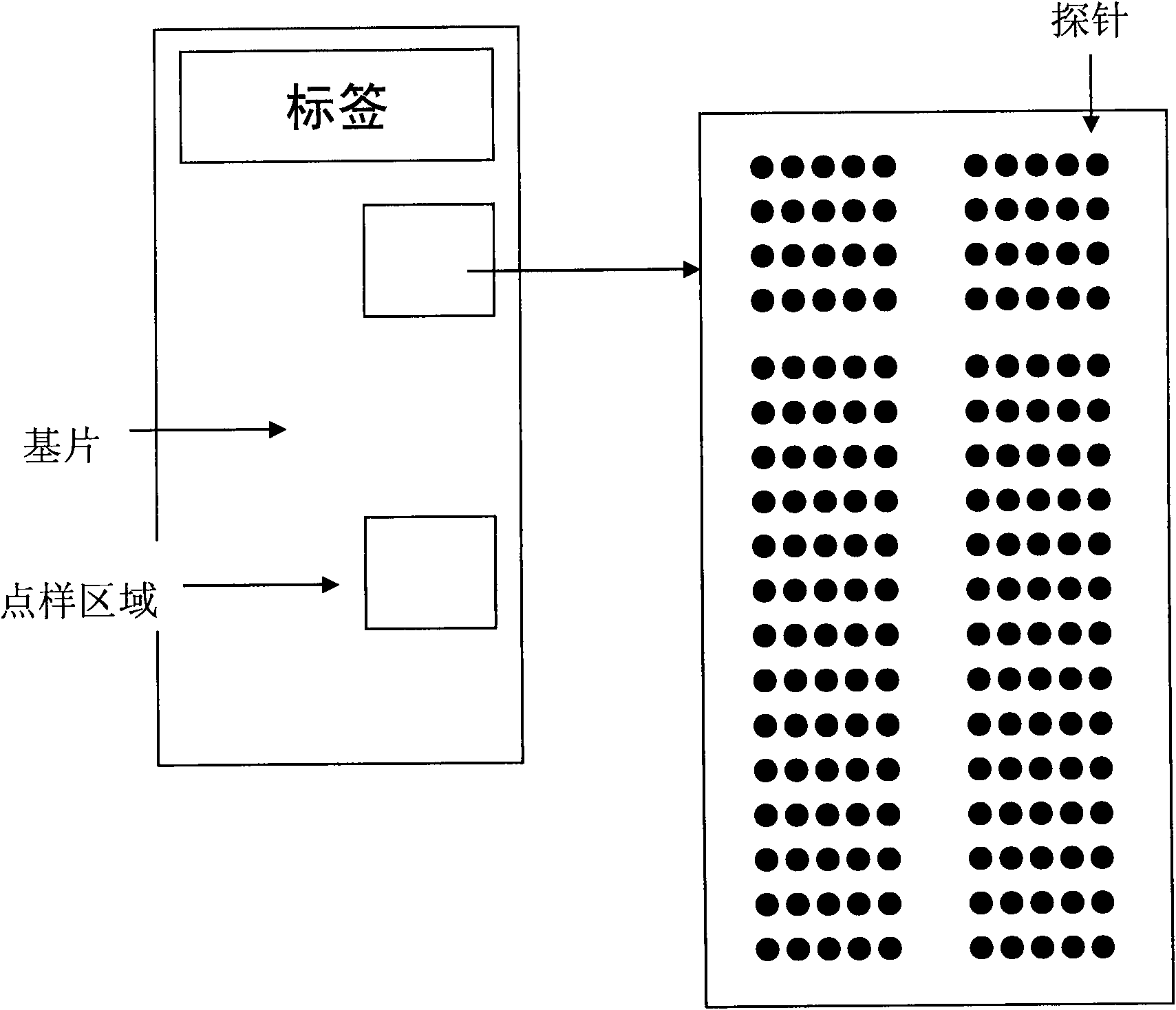

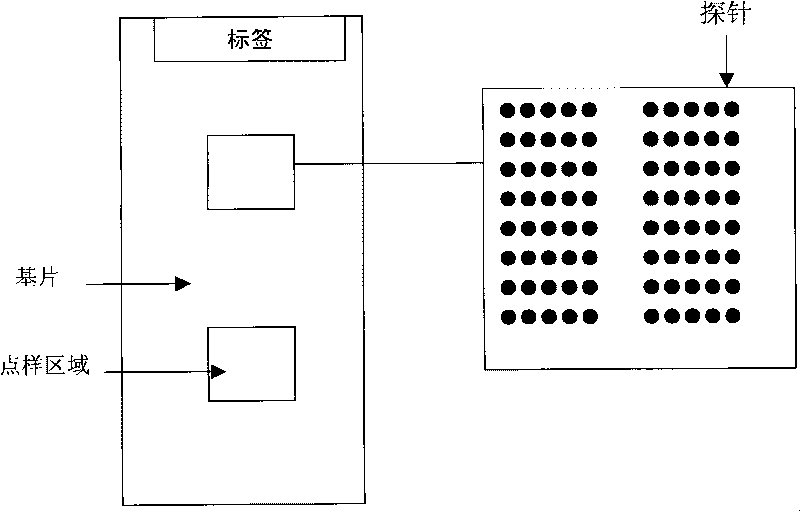

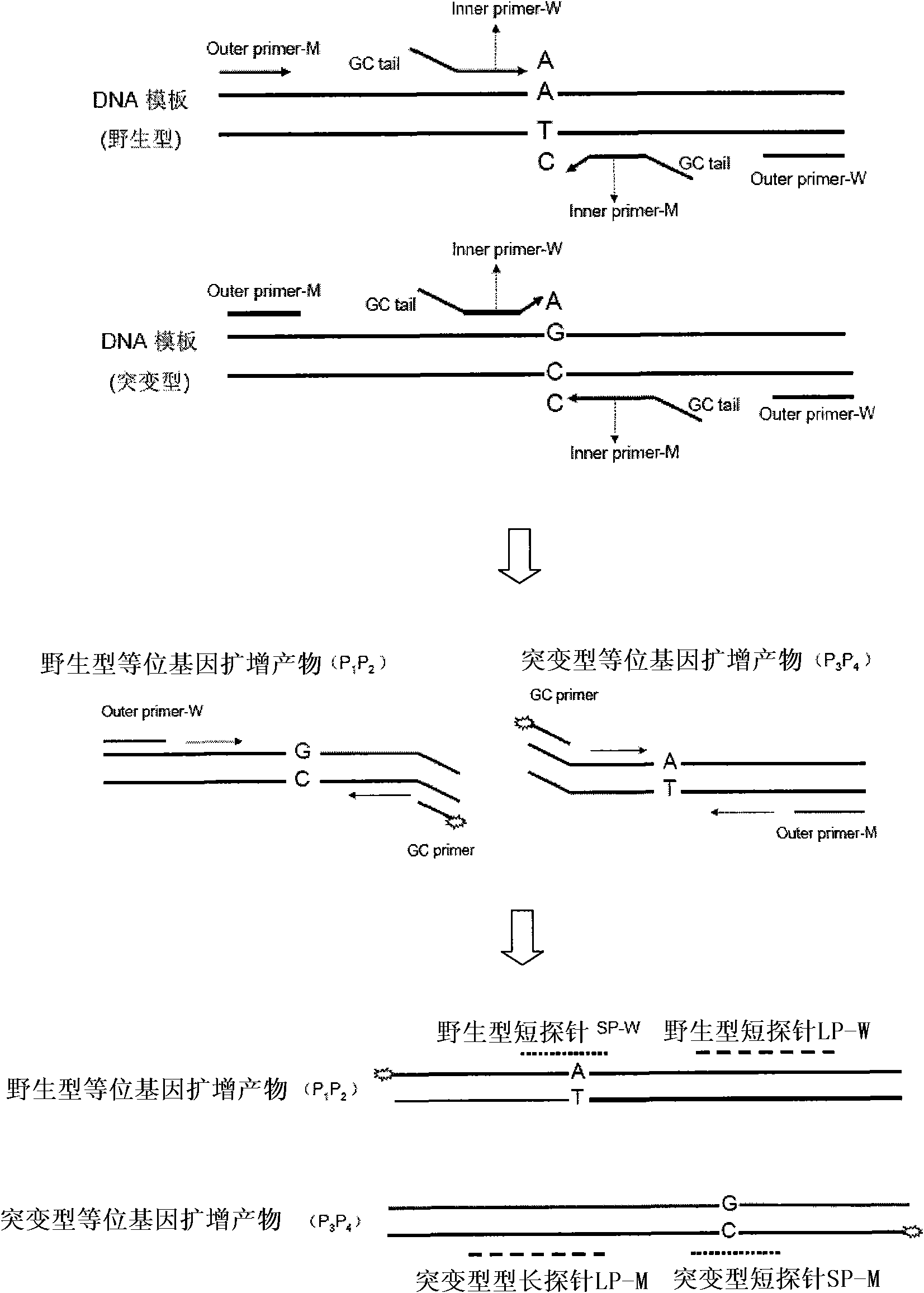

Double-probe gene mutation detecting method based on allele special amplification as well as special chip and kit thereof

ActiveCN101619352AEasy to detectAvoid the hassle of markingMicrobiological testing/measurementGenotypeOligonucleotide

The invention relates to a method for identifying gene mutation types in the field of gene analysis as well as a special chip and a kit thereof. The gene mutation detecting method comprises the following steps: taking a genome to be detected from a human tissue as a template, carrying out multiple allele special PCR amplification by a primer group that is designed aiming at special mutant sites and DNA polymerase without 3'-5' end exonclease activity, then hybridizing the obtained PCR product and an oligonucleotide probe (allele special probe) on the gene chip, and confirming mutation types of all gene sites according to the hybridizing result. The allele special probe is designed aiming at special gene types of gene mutant sites to be detected. The invention can detect gene mutations in comprehensive, systemic and high-flux ways and has light environmental pollution as well as simple and rapid operation compared with PCR-RFLP and a sequencing method.

Owner:CENT SOUTH UNIV

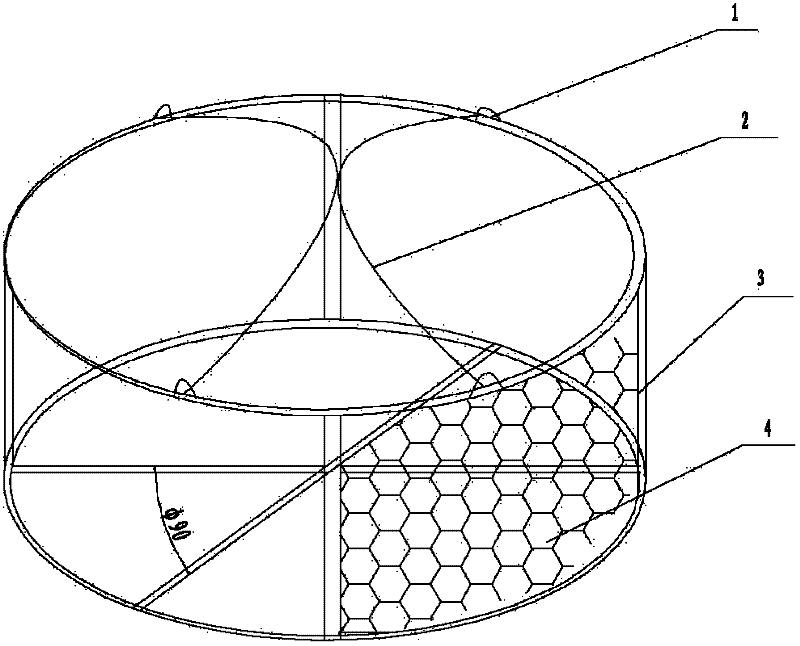

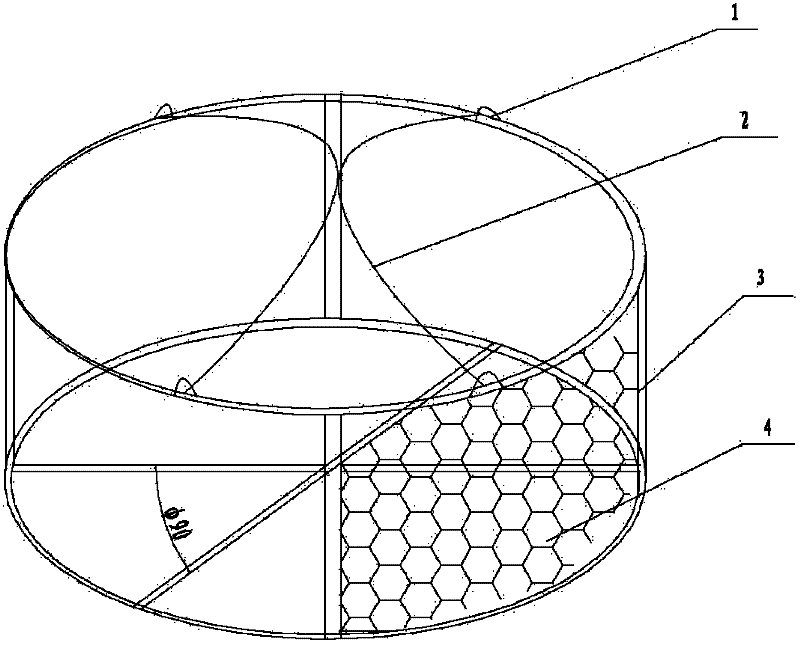

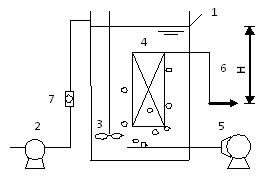

Dynamic membrane automatic water flow-out solid-liquid separation method applicable to domestic sewage treatment

ActiveCN102616986ACompact structureReduce energy consumptionMultistage water/sewage treatmentActivated sludgeWater flow

The invention provides a dynamic membrane automatic water flow-out solid-liquid separation method applicable to domestic sewage treatment. The method includes: adding powder particles with fine water permeable performance into activated sludge to form biological intensified powder mixed liquid to structurally improve the activated sludge; combining with the dynamic membrane separation technique to greatly improve the filtering capacity and water permeability of dynamic membrane filter cakes; performing solid-liquid separation of discharged water by allowing a dynamic membrane component to be driven by a water head having lower fixed gravity action and formed by liquid level waterhead between the upper liquid level of the immersed dynamic membrane component in a reaction device and a wateroutlet, stably controlling the unit area membrane filter flux of the dynamic membrane component to be more than 20-60L / m2h and the continuous operating time to be longer than 120h without action of external power; and allowing the dynamic membrane to completely shed with the air backwashing time being 1min-2min and the air inlet pressure being 9.8-49kPa. The dynamic membrane component does not need to be chemically cleaned regularly, and control and operation of the method can be automatically controlled in the whole process. The dynamic membrane solid-liquid separation technique can realize automatic water flowing out under differential pressure of low-liquid-level waterhead, energy consumption is greatly reduced, operation process is simplified, and discharged water is high in quality.

Owner:TONGJI UNIV

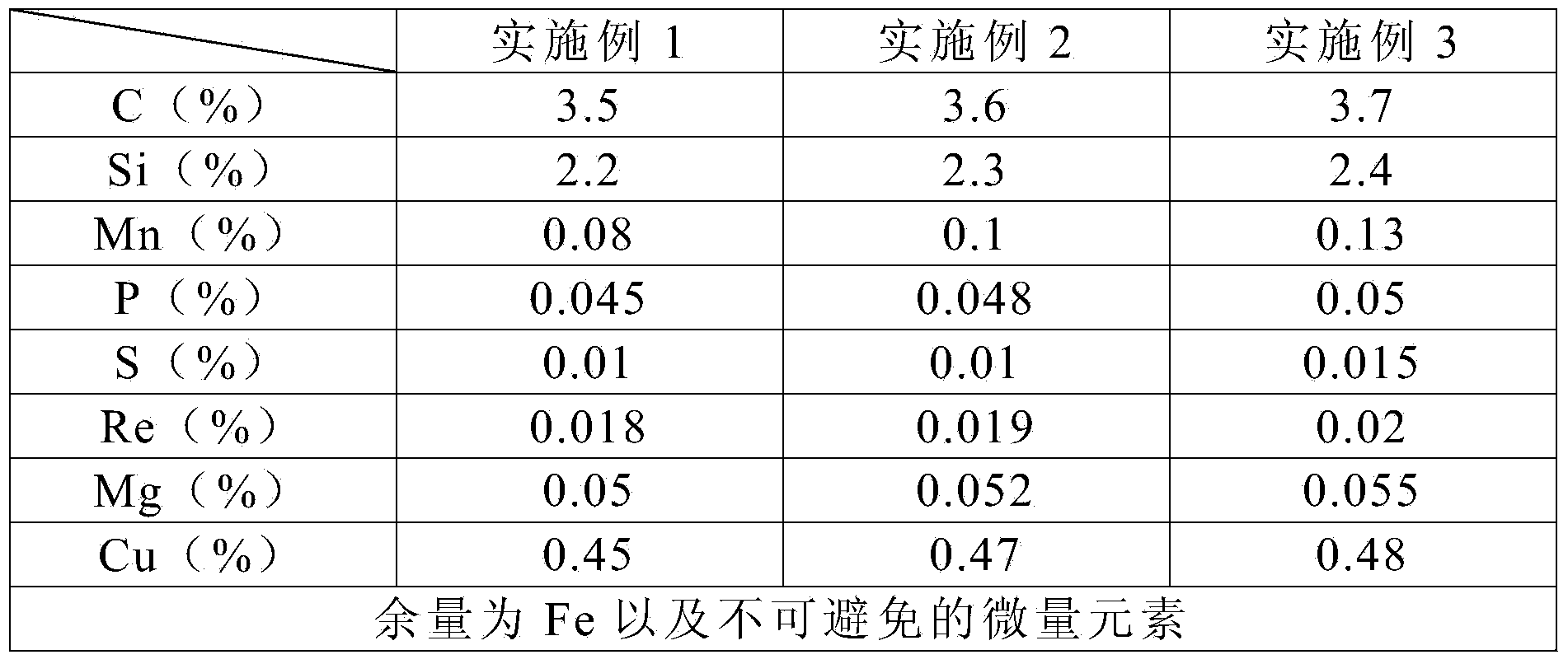

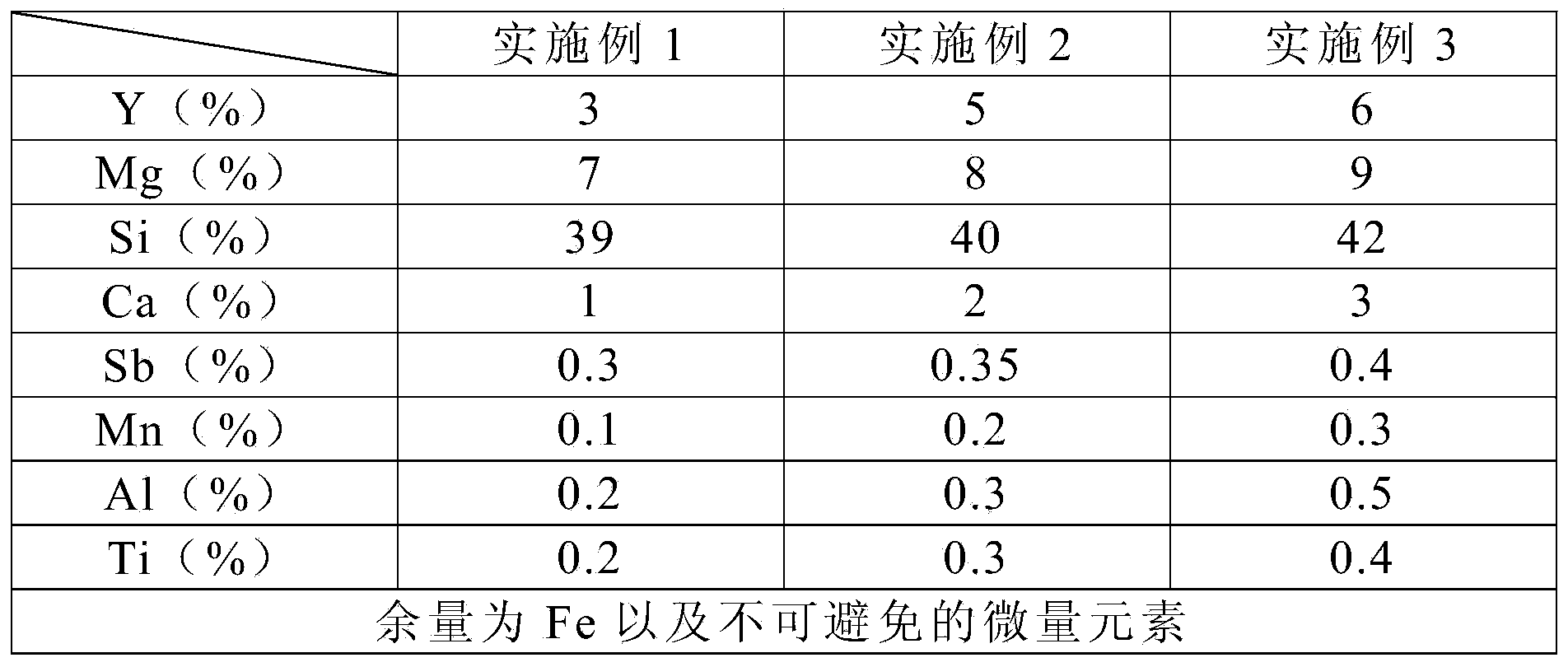

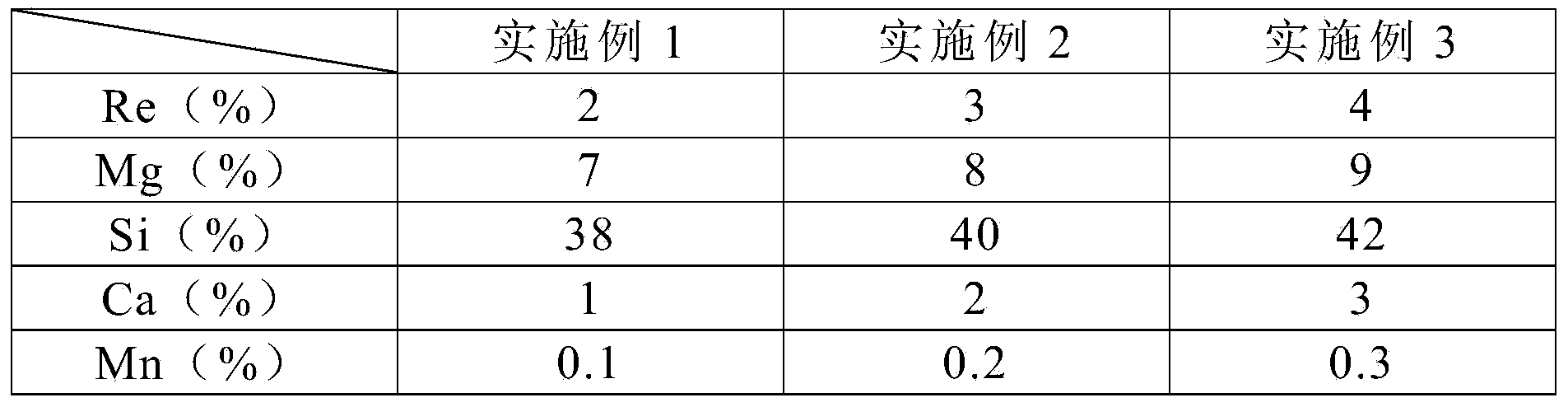

Novel as-cast 500-7 nodular cast iron

InactiveCN103484753AShorten the production cycleReduce coal consumptionTrace element compositionDuctile iron

The invention relates to a novel as-cast 500-7 nodular cast iron which comprises the following components in percentage by mass: 3.5-3.7% of C, 2.2-2.4% of Si, 0.1-0.2% of Mn, 0.045-0.05% of P, 0.01-0.015% of S, 0.018-0.02% of Re, 0.05-0.055% of Mg, 0.45-0.48% of Cu, and the balance of Fe and inevitable microelements. The elements come from coke, limestone, new pig iron, returning iron, electrolytic copper, steel scrap and iron alloy. The preparation method comprises the following steps: weighing the raw materials according to the percentage by mass of the novel as-cast 500-7 nodular cast iron, smelting, spheroidizing and inoculating three times to obtain the novel as-cast 500-7 nodular cast iron. The novel as-cast 500-7 nodular cast iron has the advantages of short production cycle, low pollution, low cost and high strength, and can obtain a ferrite / pearlite mixed matrix under as-cast conditions.

Owner:宁波康发铸造有限公司

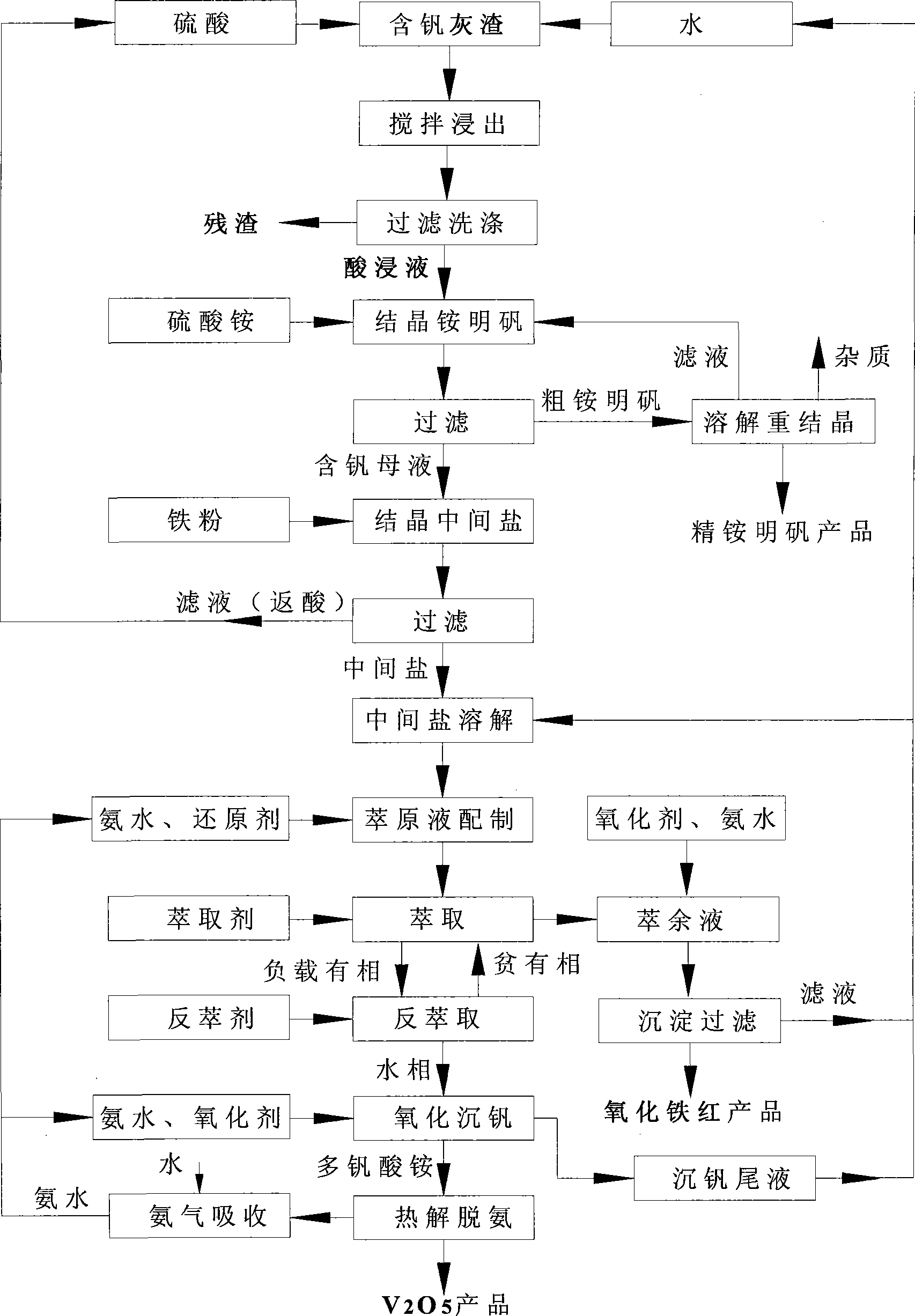

Vanadium pentoxide extraction method by direct acid dipping of stone coal ash containing vanadium

InactiveCN101381103ASimple processImprove the operating environmentVanadium oxidesSlagResource utilization

The invention provides a method for extracting vanadic oxide from vanadiferous stone coal ash slag through direct acid leaching. The method comprises the following steps: an acid leaching solution obtained by the vanadiferous stone coal ash slag through direct acid leaching is added with ammonium sulphate to prepare tschermigite as a byproduct; a vanadiferous mother solution is added with an iron simple substance and is heated, evaporated, condensed and crystallized to form an intermediate salt crystal in order that vanadium is fully enriched in intermediate salt; the intermediate salt is dissolved to prepare an extractive stock solution; the extractive stock solution is subjected to extraction, back extraction, oxidation and vanadium precipitation to prepare ammonium ployvanadate; and the ammonium ployvanadate is subjected to pyrolysis and deamination to prepare a V2O5 product with purity of over 98 percent. The process is wholly operated in a liquid phase and has no pollution by exhaust gas; waste liquid is basically returned to a system for reclaiming and utilization; the discharged waste liquid is little and is easy to treat; the total reclaiming rate of vanadium can reach over 75 percent; simultaneously, aluminum resource in the ash slag can be reclaimed to form the tschermigite as the byproduct; and the yield of the byproduct can reach dozens to hundreds of times of the yield of the V2O5 product. The process has the advantages of good operating condition, high mechanization and automation degree, high resource utilization rate, low comprehensive cost, good benefit and light pollution.

Owner:ZHEJIANG UNIV +1

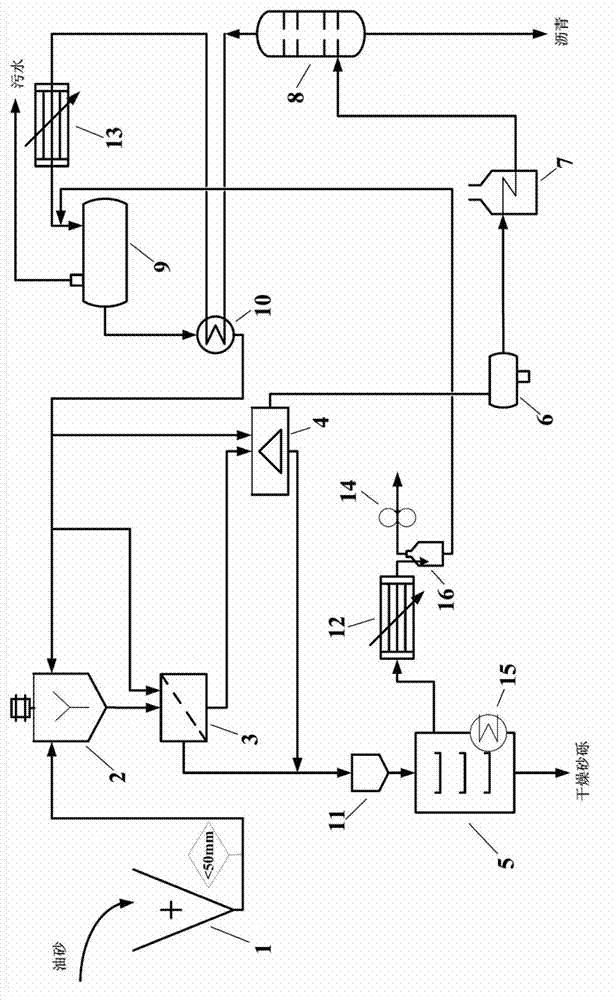

Method and device for extracting asphalt from oil sand through solvent extraction

InactiveCN102925191ASolve sticking problemsRetain the original natureLiquid hydrocarbon mixture productionSolventSolvent extraction

The invention relates to a method and a device for extracting asphalt from oil sand through solvent extraction. The method comprises steps as follows: step 1, crushing and sieving asphalt-containing oil sand, mixing sieved oil sand with solvent at a temperature of 30 to 90 DEG C, and agitating, then extracting a solvent, so as to obtain mixed size; step 2, sieving the mixed size at the second time to remove rough sand, so as to obtain fine sand size; and step 3, centrifugally separating the fine sand size to obtain fine sand, separating the rest asphalt solution to obtain the asphalt, and removing the solvent. The invention also provides the device for extracting the asphalt from the oil sand through the solvent extraction. According to the method for extracting the asphalt from the oil sand provided by the invention, the method of extracting the solvent is carried out to extract the asphalt in the oil sand, and all processes in the method are physical processes, so little pollution is generated, and original nature of the asphalt can be kept; and the method is one of the most efficient technologies for applying the oil sand as a road building material.

Owner:北京润达油气工程股份有限公司

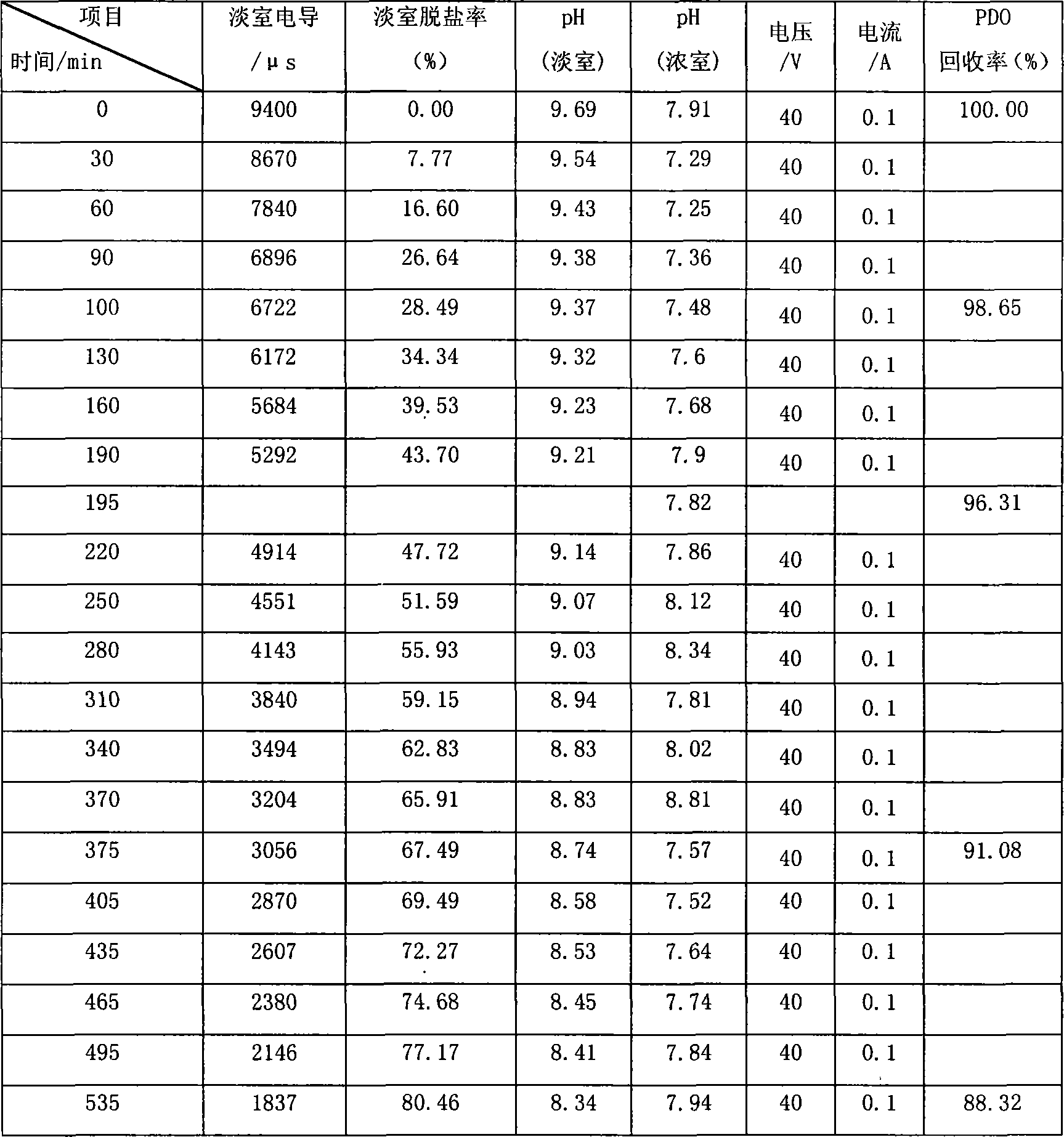

Methods for edulcoration and desalinization of 1,3-methyl glycol fermentation liquor

ActiveCN101117306ASolve the problem of membrane foulingSolve technical problems such as flow channel blockageHydroxy compound separation/purificationLoss rateDistillation

An impurity removing and desalting method for 1, 3-propanediol zymotic fluid relates to a 1, 3-propanediol zymotic fluid, which provides the An impurity removing and desalting method for 1, 3-propanediol zymotic fluid. Micro filtering impurity removing is that the 1, 3-propanediol zymotic fluid with germ is preprocessed by a filtering bag and enters a ceramics film device micro for micro filtering impurity removing. The germ body and protein macromolecular matter are removed from zymotic fluid to get the zymotic filter fluid of the 1, 3-propanediol. The salt removing by electrodialysis is that zymotic filter fluid containing the 1, 3-propanediol is put into an electrodialysis device to remove salt and completes when filtrate conductance is reduced to 2000 us. Therefore, the electrodialysis operation is stopped. The filter fluid enters the following technics for condensation and purification. The invention has a bigger film flux, a good treating effect and light ion exchanging film pollution. The salt removing by electrodialysis has low energy consumption and good treating effect. The conductance of material liquid can be completely reduced to 2000 us to satisfy techincs demand of following concentration and distillation. The loss rate of the 1, 3-propanediol is low with little environment pollution.

Owner:SUNTAR MEMBRANE ENVIRONMENT TECH +1

Process for treating cyclic cooling water

InactiveCN1448342AImprove reuse rateLittle pollutionWater/sewage treatment bu osmosis/dialysisLoose filtering material filtersFiberEnvironmental engineering

The present invention relates to the circular cooling water treating method and belongs to the field of industrial water saving technology. Available circular cooling water deep treating method has poor economical performance. The present invention is that to available circular cooling water system with relatively low concentration multiple fiber filtering and low pressure reverse osmose treating apparatus following the side filtering line is increased, 0.2-2 % of circular water is led out for coarse filtering and fiber filtering treatment, and filtered water is reverse osmose treated, the osmosed liquid is returned to the cooling water system, and the exhausted concentrated liquid accounting for 15-25 % of treated water amount is exhausted and treated. The present invention may be used in circular cooling water system with low concentration multiple.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for regeration of citrus internode stem and genetic transformation

InactiveCN1833488AImprove disinfection effectNo chimerismPlant phenotype modificationHorticulture methodsBudBiology

A regeneration and genetic transformation method for citrus includes immersing seeds in the solution of alcohol or mercuric chloride for disinfection, flushing with aseptic water, culturing in culture medium to obtain aseptic seedling, inducing the bud of check material, culturing in culture medium MS, adding growth regulator, transforming explant, using Agrobacterium to dipdys the intersegemental stem of said aseptic seedling, inducing resistant bud, adventitious bud grafting, and secondary grafting in greenhouse.

Owner:邓子牛 +2

Gene chip used for detecting related gene mutations of malignancy individual medications and application thereof

InactiveCN101619350AAccurate detectionSensitive detectionMicrobiological testing/measurementMalignancyWilms' tumor

The invention relates to a gene analysis detecting product, in particular to a gene detecting chip and a reagent matched with the same, more particular to a gene detecting chip and a matched reagent used for detecting a series of gene mutations that are closely related to the reactiveness of medicines for treating malignancy as well as the application thereof. The gene chip can detect known gene mutations closely related to individual difference of anti-tumor medicine reaction in comprehensive, systemic and high-flux ways by selecting appropriate mutant sites and designing appropriate primers and probes and can work out corresponding adjusting schemes aiming at different medicines.

Owner:湖南宏灏基因生物科技有限公司

Method for separating and purifying cisatracurium besylate by preparative liquid chromatography

InactiveCN101475530AHigh purityHigh yieldIon-exchange process apparatusOrganic chemistryChromatographic separationSilica gel

The invention discloses a method for separating and purifying cis-benzene sulfonic acid atracurium through preparative liquid chromatography, which is to use a mobile phase to dissolve benzene sulfonic acid atracurium, load the benzene sulfonic acid atracurium on a preparative liquid-phase chromatographic silica gel column, perform normal-phase or opposite-phase liquid-phase chromatographic separation under the elution of the mobile phase, and reclaim the cis-benzene sulfonic acid atracuriums, wherein immobile-phase silica gel is modified bonded silica gel, and the particle diameter of the immobile-phase silica gel is between 1 and 200 micrometers; the load ratio of the immobile-phase silica gel to atracurium is not more than 1,000; and the pressure of the silica gel column is between 250 and 400 psi. The cis-benzene sulfonic acid atracurium obtained by the method has high purity, high yield and low cost; the amount of an organic solvent used is low; the pollution is light; and the maneuverability is strong. The treatment time of the method is shortened by approximately 10 times compared with the prior art, and simultaneously the method can feed samples continuously, realize automatic operation and the like.

Owner:SHANGHAI PHARMA DONGYING JIANGSU PHARMA CO LTD

Styrene block copolymer reacting and extruding polymerization

A styrene block copolymer reacting extruding polymerizing method is carried out by: delivering styrene monomer, initiating agent, styrene / conjugated diene mixed monomer into screw extruder for polymerization, or delivering styrene monomer, mono-functional organic alkali metal or alkali earth metal initiating agent, styrene / conjugated diene mixed monomer, and coupler into screw extruder for polymerization, and obtaining styrene block copolymer. Its advantages include low cost and consumption, short production period, high output efficiency and no environmental pollution.

Owner:EAST CHINA UNIV OF SCI & TECH

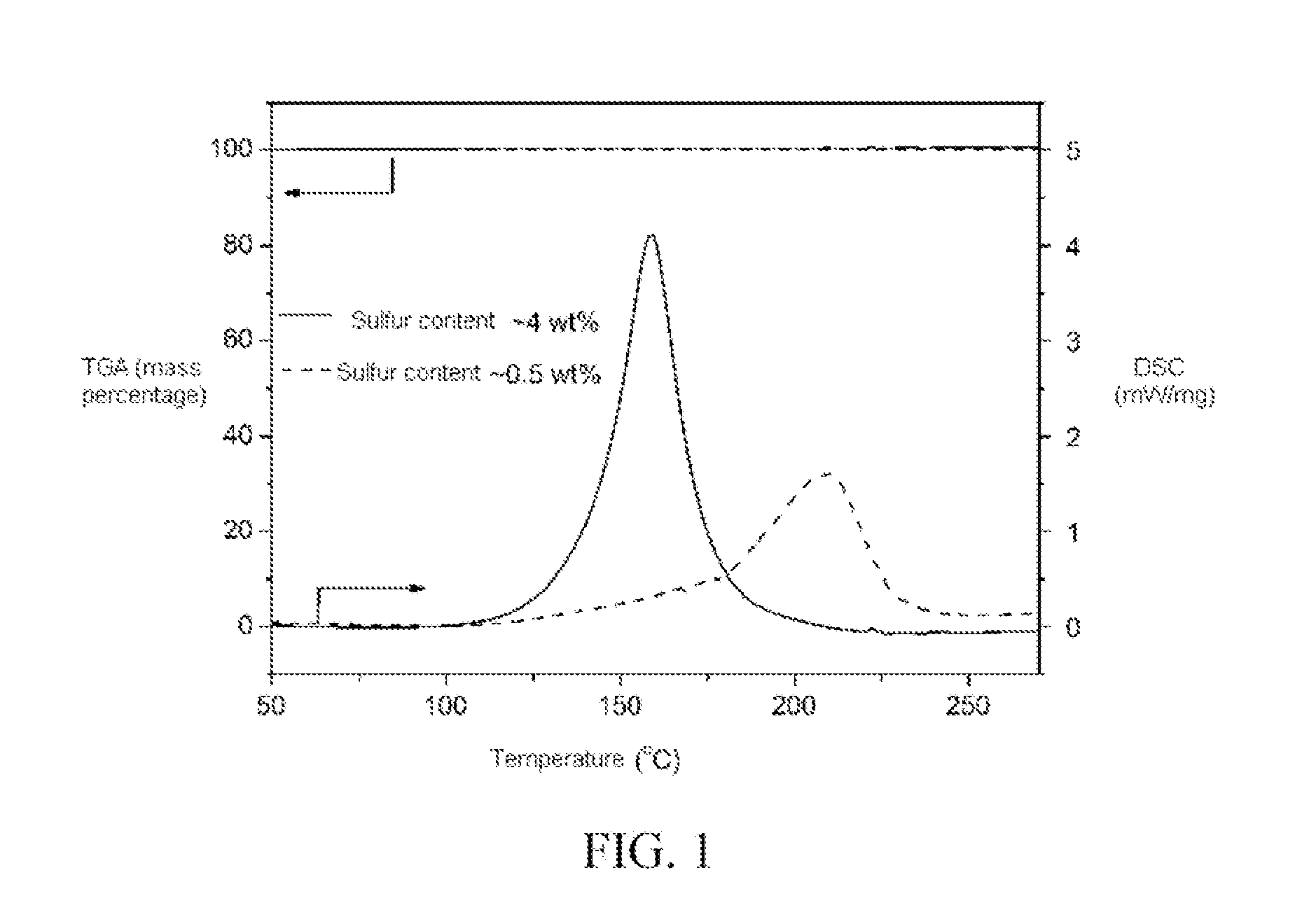

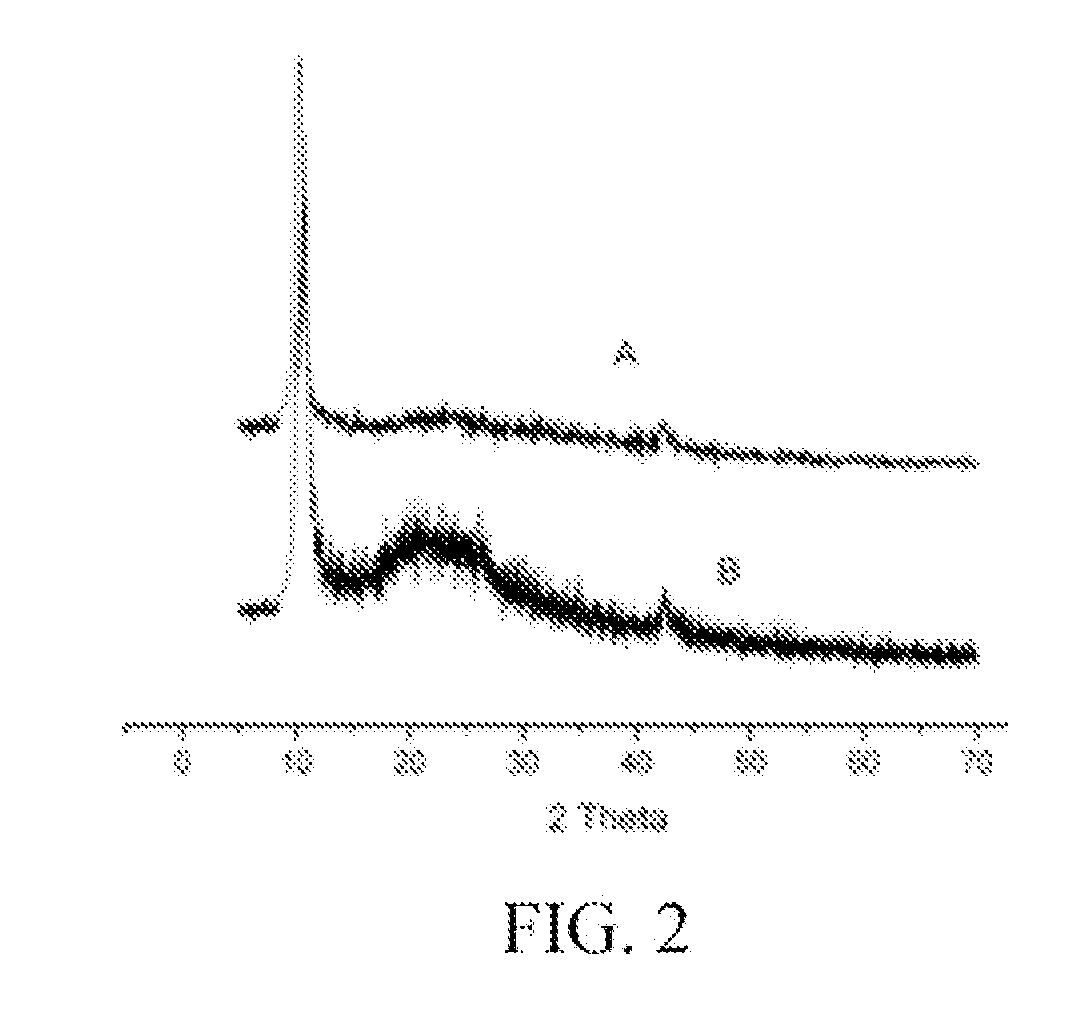

Method for low-temperature preparation of graphene and of graphene-based composite material

ActiveUS20150175426A1Wide applicationEmission reductionMaterial nanotechnologyGrapheneSupercapacitorSensor materials

Provided is a method for room-pressure and low-temperature preparation of graphene, comprising: heat treating a compound of graphite oxide and sulfuric acid in either room pressure or negative pressure at a temperature between 50 and 400° C., thus converting graphite oxide into graphene. Also provided is a method for low-temperature preparation of a graphene composite material. The acquired graphene and graphene composite material are applicable in optical materials, electrically-conductive materials, sensor materials, catalytic materials, battery materials, and supercapacitor materials.

Owner:WUHAN UNIV

Method for culturing maggot by utilizing manure slurry

The invention belongs to the technical field of animal manure comprehensive utilization and culture, and relates to a method for culturing maggot by utilizing livestock and poultry manure slurry. The method comprises the following steps: collecting animal manure in a temporary animal manure lagoon; fermenting effective microorganism (EM) strain, or enzymatic microorganism, or mixed strains of the EM strain and the enzymatic microorganism to ensure that the manure slurry is liquefied to form liquefied manure slurry; putting putrescent food in an outdoor fly concentrated position; putting collected seed maggot on a net chain above a fly cage to collect fly eggs and maggot; and maintaining the temperature of diluted manure slurry in a maggot culture pond, introducing oxygen to ensure that the maggot is cultured for 3 to 4 days and developed into imagochrysalis, and capturing by utilizing a net bag. The culture process has the advantaages of simple process, high animal manure utilization, safe and reliable equipment, high maggot culture benefit, large comprehensive utilization value, high quality of maggot and light environmental pollution, and can be used for large-scale industrial culture.

Owner:QINGDAO ZHONGREN PHARMA

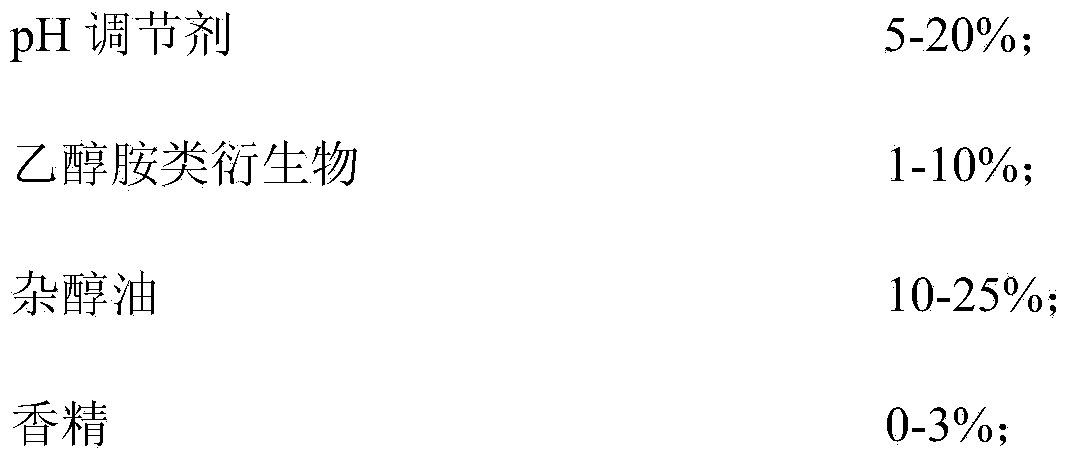

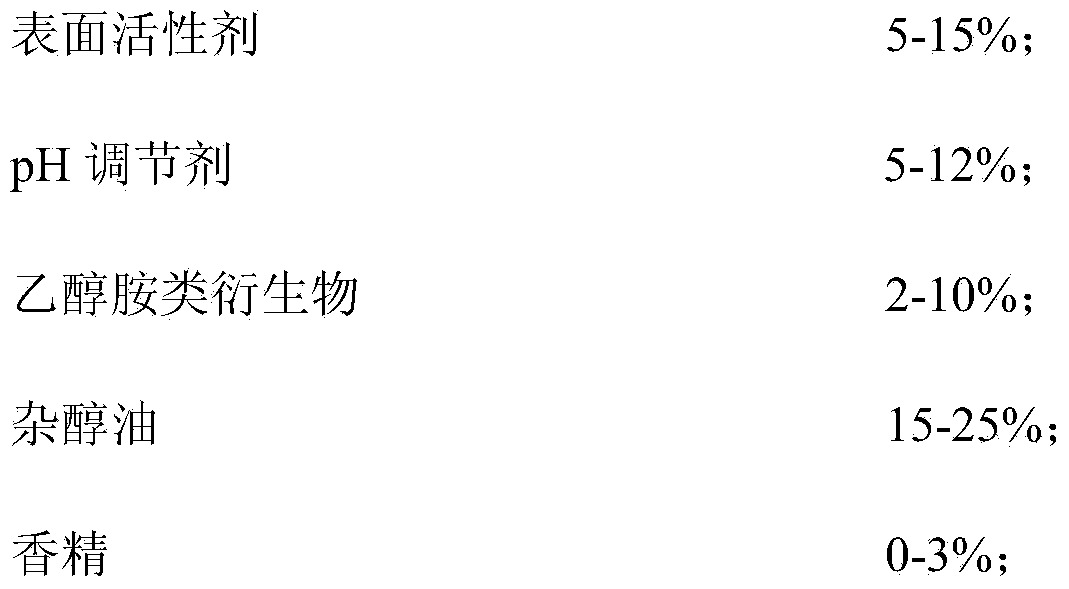

Cleaning agent for removing heavy dirt and greasy dirt

InactiveCN103710161AIncreased source of alkalinityLow viscosityNon-ionic surface-active compoundsOrganic detergent compounding agentsFiberCleansing Agents

The invention discloses a cleaning agent for removing heavy dirt and greasy dirt. The cleaning agent comprises the following components in percentage by weight: 5%-30% of a surfactant, 5%-20% of a pH (Potential of Hydrogen) modifier, 1%-10% of ethanol amine derivatives, 10%-25% of fusel oil, 0-3% of essence and the balance of water, wherein the surfactant is selected from one or two of negative ion surfactants and nonionic surfactants; the fusel oil is a side product generated in a process for fermentation production of edible alcohol by using starch as a raw material. The cleaning agent disclosed by the invention can be used for effectively percolating into the heavy dirt and greasy dirt which are deposited on the surface of a hard material in a room temperature and a lower temperature; furthermore, with the adoption of the cleaning agent, the greasy dirt and the dirt can be prevented from being re-deposited. The cleaning agent does not pollute fibers, such as cotton, hemp and chemical fibers, and metal wires which are used for scrubbing, so that the fibers and the metal wires for scrubbing are easy to rinse and clean by the water.

Owner:SHANGHAI JIAO TONG UNIV

Gene detection chip of OATP1B1 major gene mutation

ActiveCN101717816AAccurate detectionSensitive detectionNucleotide librariesMicrobiological testing/measurementHigh pressureMedicine use

The invention relates to a gene detection chip, in particular to a gene detection chip used for detecting common major gene mutation of organic anion transferred polypeptide 1B1 (OATP1B1 in short), which is closely related to reactiveness of medicines used for curing high blood pressure, malignant tumor, 2 type diabetes mellitus, hypercholesterolemia. Through selecting 8 mutational sites and designing out corresponding probes, the invention realizes the detection on the mutational sites and is capable of providing information of the mutation sites, thereby providing foundation for medication guiding.

Owner:CENT SOUTH UNIV

Method for detecting related gene mutations of diabetes drug treatment as well as special chip and kit thereof

ActiveCN101619351ALittle pollutionEasy to operateMicrobiological testing/measurementDiabrezideDrug treatment

The invention discloses a method for detecting related gene mutations of diabetes drug treatment as well as a special chip and a kit thereof. The method comprises the following steps: taking a genome to be detected from a human tissue as a template, carrying out multiple PCR amplification by a primer group that is designed aiming at special mutant sites and DNA polymerase without 3'-5' end exonclease activity, then hybridizing the obtained PCR product and an allele specific probe on the gene chip, and confirming mutation types of related genes of diabetes drug treatment according to the hybridizing result. The invention can detect known gene mutations closely related to the individual difference of anti-tumor medicine reaction in comprehensive, systemic and high-flux ways and greatly improve the accuracy and the specificity of chip detection.

Owner:CENT SOUTH UNIV

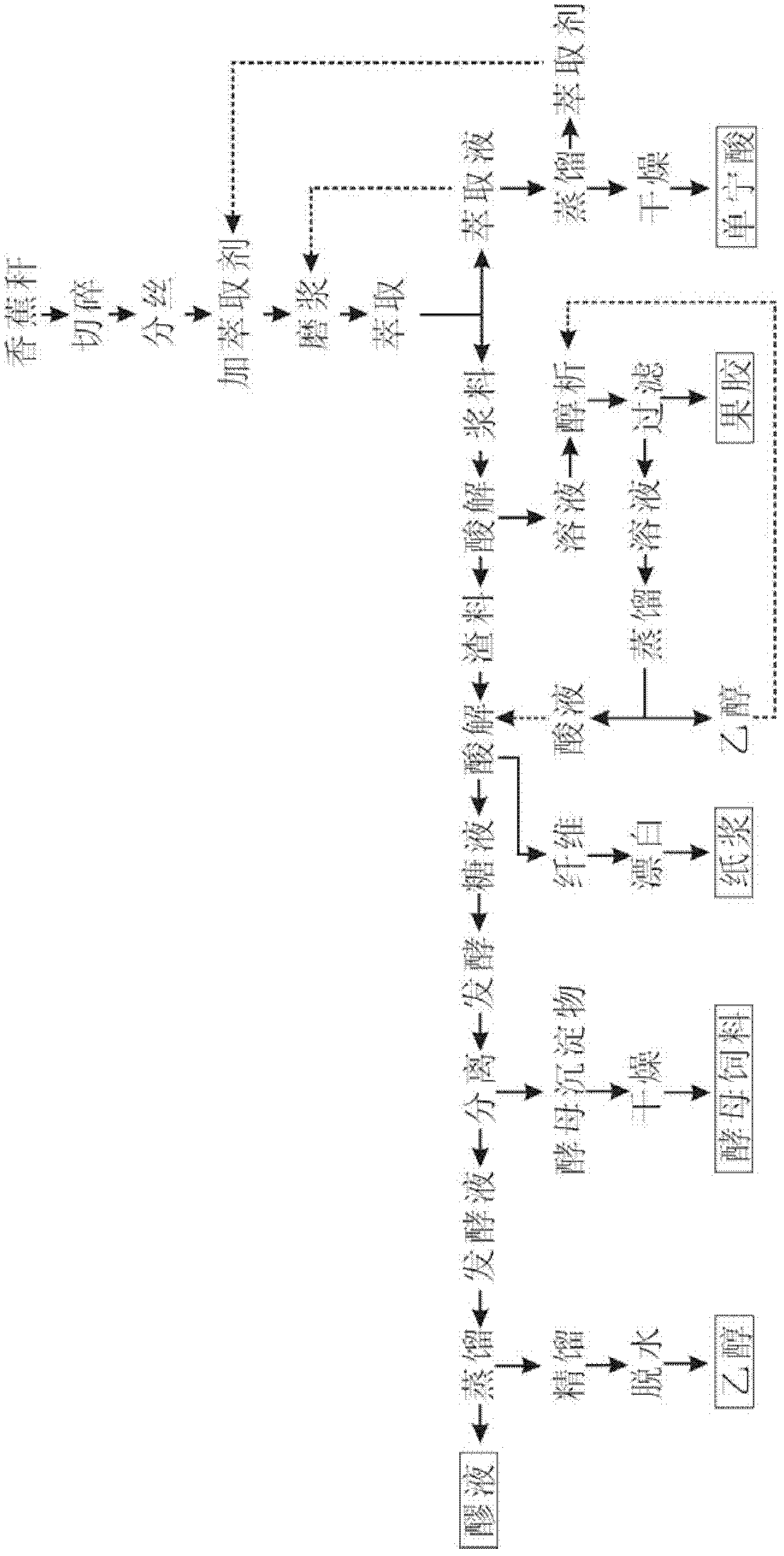

Method and technology for high-value comprehensive utilization of banana stems and leaves

ActiveCN103320476AHigh purityShorten fermentation timeEsterified saccharide compoundsNatural cellulose pulp/paperCelluloseFiber

The invention provides a comprehensive utilization method of banana stem and leaf resources. The method adopts banana stems and leaves as raw materials to successively produce tannic acid, pectin, paper pulp fibers, fuel ethanol, and yeast fodder. The method comprises the steps of: adopting banana stems and leaves as the raw materials, crushing the banana stems and leaves into a slurry form by beating via an extractant, and extracting tannin via an extracting liquid while pulping; subjecting the rest banana stem and leave slurry to acidolysis, and extracting pectin of the banana stems and leaves by stewing the banana stem and leave slurry at a normal pressure; and subjecting the remaining slurry to acidolysis, and degrading polysaccharide, starch and the other degradable substances into soluble degraded sugars by stewing at a high temperature and a high pressure, wherein the degraded sugars and reducing sugar of the banana stems and leaves constitute a soluble substance aqueous solution, so that a separation of cellulose from degradable substances is realized. The method provided by the invention can share the comprehensive utilization cost of banana stems and leaves, and can greatly increase the utilization efficiency of banana stem and leaf resources.

Owner:HAINAN BEIOU BIOENERGY DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com