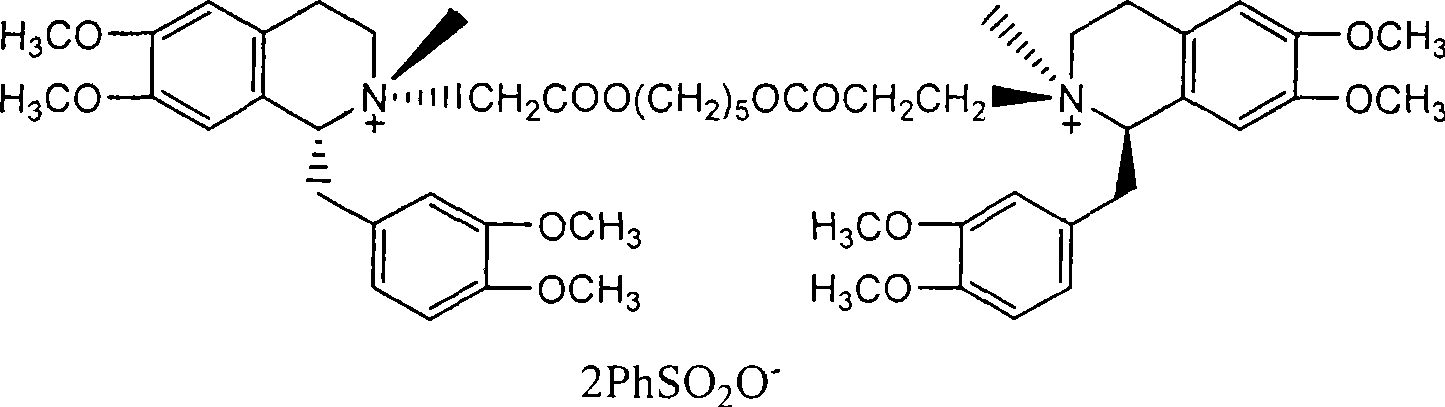

Method for separating and purifying cisatracurium besylate by preparative liquid chromatography

A kind of technology of atracurium besylate and atracurium besylate, applied in the field of medicinal chemistry, can solve problems such as no indication of industrialized production, manual operation, low yield, etc., achieve automatic operation, organic solvent The effect of less and higher yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Equipment: Varian SD-1preparative HPLC

[0031] Chromatographic column: spherical silica gel, 16um, 250mm×110mmID

[0032] Mobile phase: A dichloromethane; B methanol = 100:10, adjust the pH value to 3-4 with benzenesulfonic acid

[0033] Duty ratio: 150

[0034]Column pressure: 300psi

[0035] Column temperature: 5-10°C

[0036] Flow rate: 300ml / min

[0037] Detection wavelength: 280nm

[0038] Injection volume: 10g / injection

[0039] After dissolving the crude product of atracurium besylate obtained by synthesis with a mobile phase, load it on a chromatographic column, then elution and separation with a mobile phase, collect in sections to obtain a cisatracurium solution, wash with 10% saline, and organic The layers were concentrated and dried under reduced pressure, the concentrated solution was dissolved in water, adjusted to pH=4.0 with benzenesulfonic acid, and freeze-dried to obtain an off-white or off-white solid—atracurium cis-benzenesulfonate, with a pro...

Embodiment 2

[0041] The stationary phase was adjusted to 10 micron spherical silica gel, the mobile phase was adjusted to dichloromethane:methanol=100:20, and the load ratio was 100. Others were the same as in Example 1. The yield of the final product was 80%, and the purity was greater than 96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com