Methods for edulcoration and desalinization of 1,3-methyl glycol fermentation liquor

A technology of propylene glycol and fermented liquid, which is applied in the field 1, can solve the problems of high salt content in feed liquid, small production capacity, high production cost, etc., and achieve the effects of good treatment effect, low loss rate, and small environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

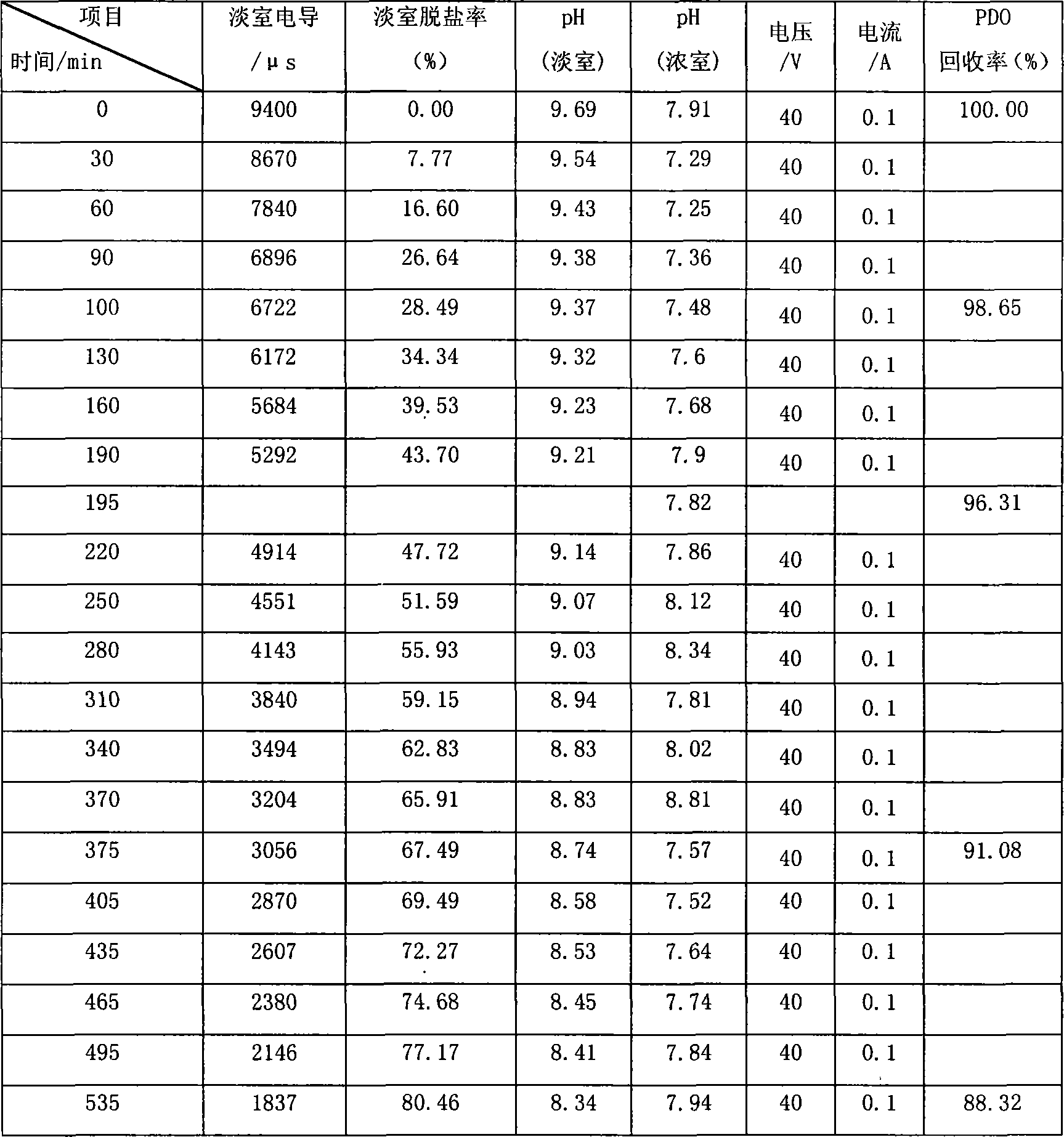

Examples

Embodiment Construction

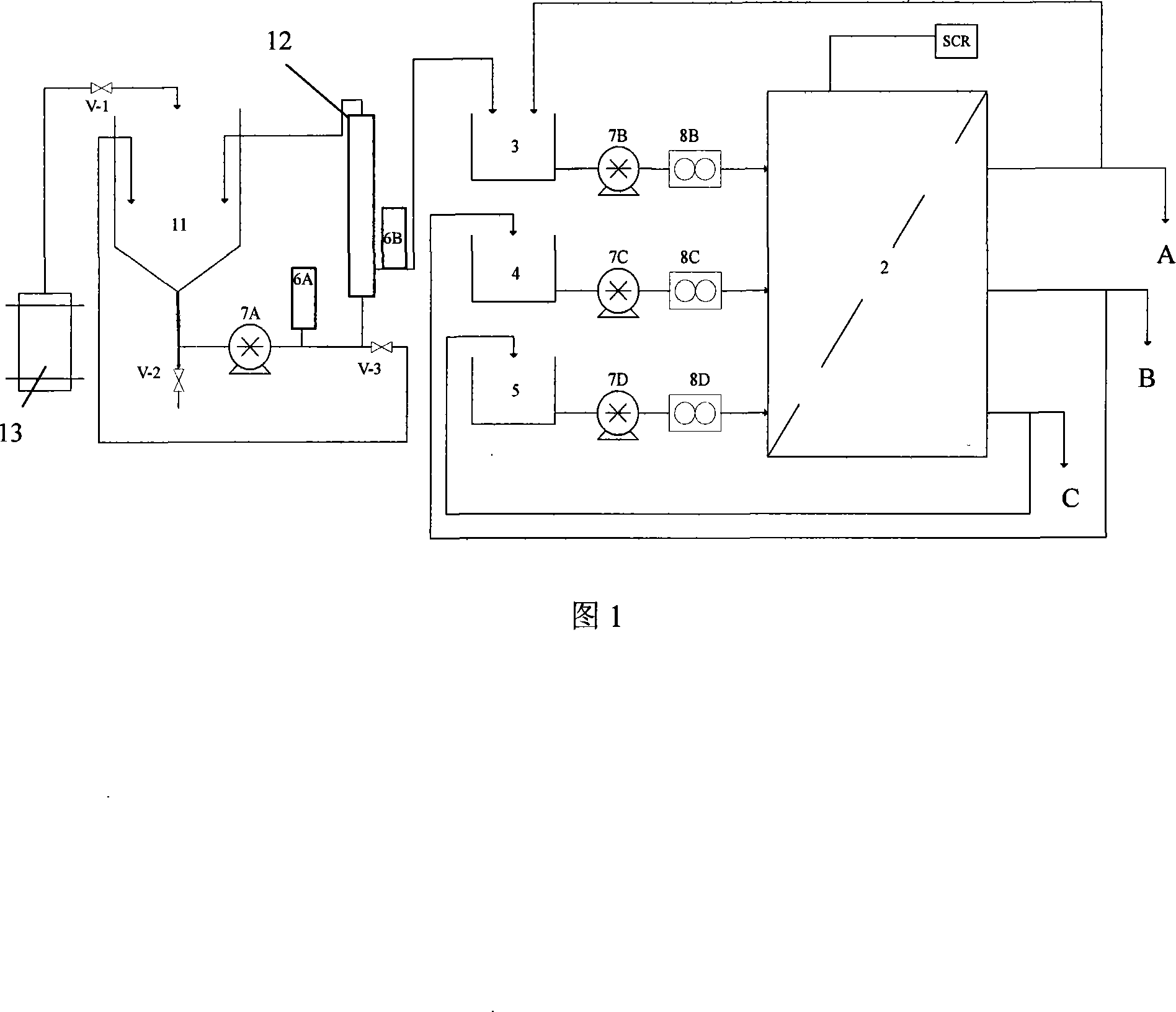

[0019] The following embodiments will further illustrate the present invention in conjunction with accompanying drawing 1 .

[0020] 1. Impurity removal by ceramic membrane:

[0021] 1) Check that the switches and valves of the ceramic membrane equipment are in the normal switching state, and connect the power supply; 2) Add the fermentation liquid pretreated by the filter bag into the material tank of the ceramic membrane equipment (according to the needs of the experiment, the fermentation liquid can be continuously replenished), and turn on Power supply, adjust the appropriate operating pressure, and start to filter; 3) regularly detect the temperature, pressure, filtration rate (calculate membrane flux), filtrate and filter residue in the concentration of 1,3-propanediol; 4) collect the filtrate, when the filtration ends, the membrane When the flux drops significantly, add water to elute the 1,3-propanediol contained in the filter residue in the material barrel, and the am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com