Patents

Literature

46results about How to "Reduce Maillard reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production technique for chicken powder with great freshness flavor

ActiveCN103689522AIncrease umamiImprove sensory qualityFood ingredientsFood preparationMonosodium glutamateAdditive ingredient

The invention discloses a production technique for chicken powder with a great freshness flavor, and belongs to the technical field of processing food seasoning. The chicken powder comprises the following materials according to mass: 30kg of fresh chicken skeletons, 30kg of fresh chicken, 7kg of maltodextrin, 2.5kg of disodium nucleotide, 0.1kg of sodium citrate, 7kg of trehalose, 10kg of edible salt, 10kg of monosodium glutamate, 2kg of lentinula edodes, 1kg of radix puerariae, and 0.4kg of pepper; the production technique comprises the steps: pretreating active ingredients, and carrying out high-temperature high-pressure sealed cooking, fine treatment, enzymolysis for flavor, mixing, spray drying, filling and capping. According to the production technique, the processes are simple, the energy consumption can be reduced, the loss of flavor components can be effectively reduced and sufficient release of flavor substances is promoted, the chicken powder is rich in chicken flavor, harmonious in saline taste, delicate flavor and perfume, luminous in color, good in rehydration property, smooth in mouthfeeling, free from sand grains, and milkily white in soup feeling.

Owner:GUANGDONG JIALONG FOOD

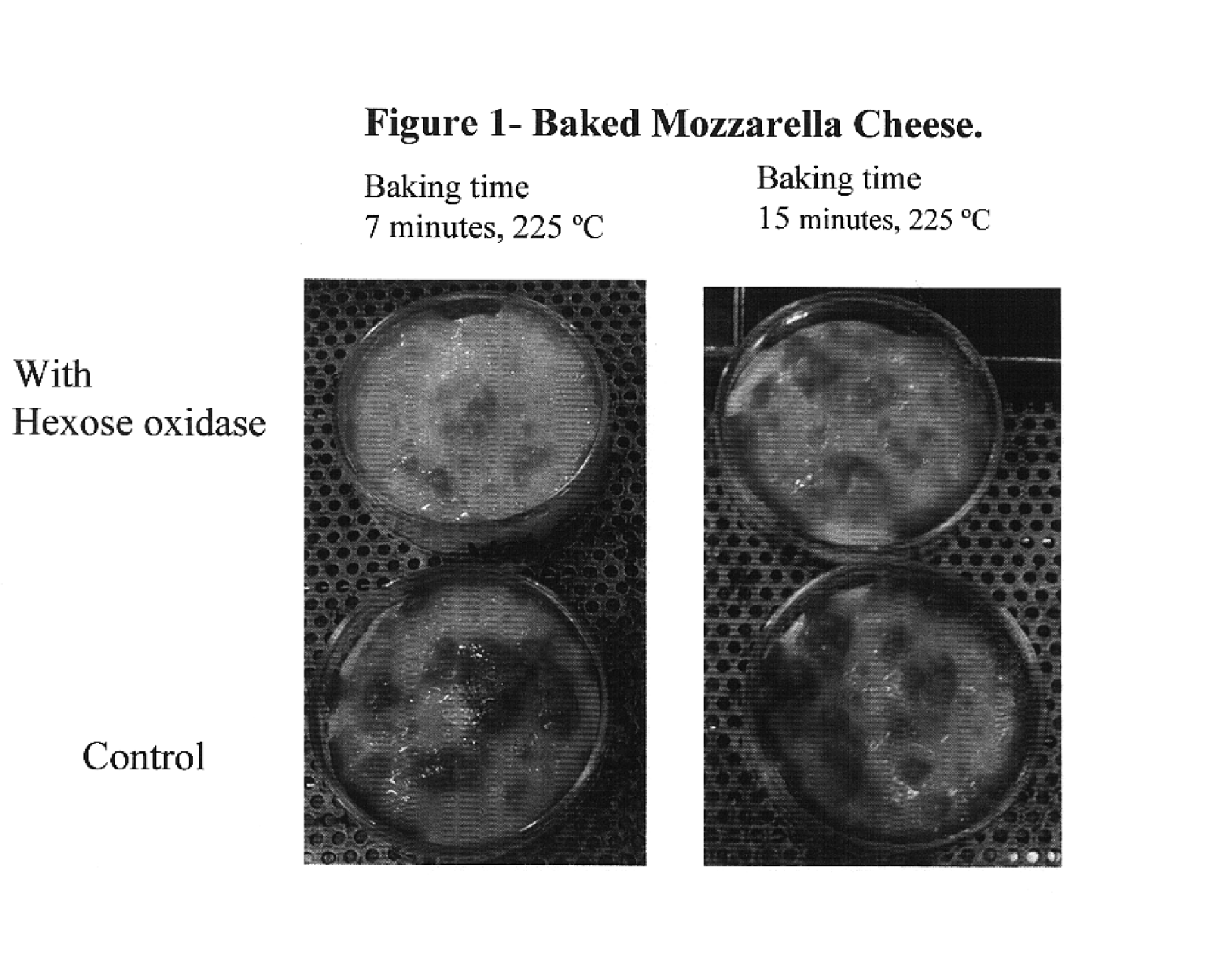

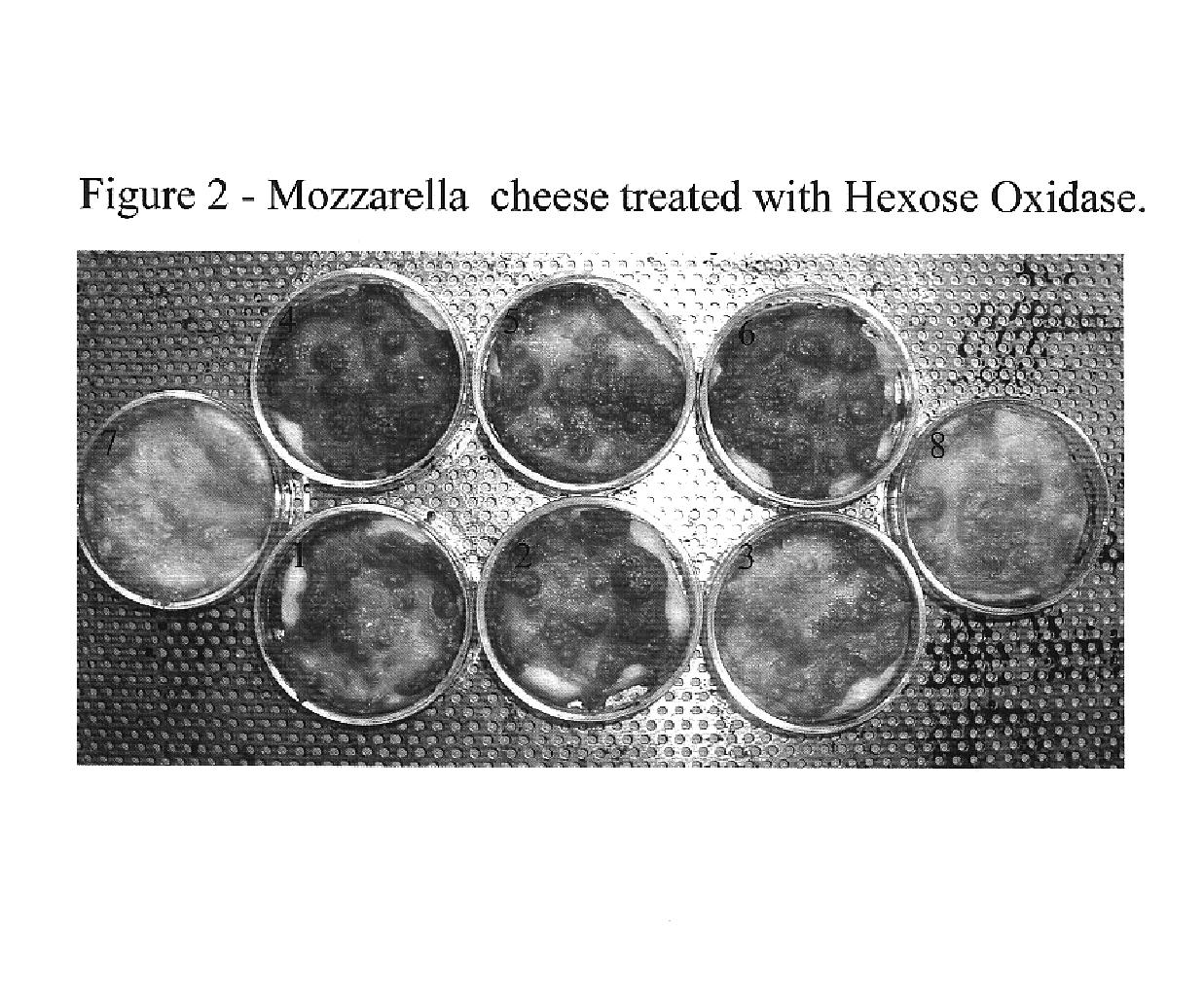

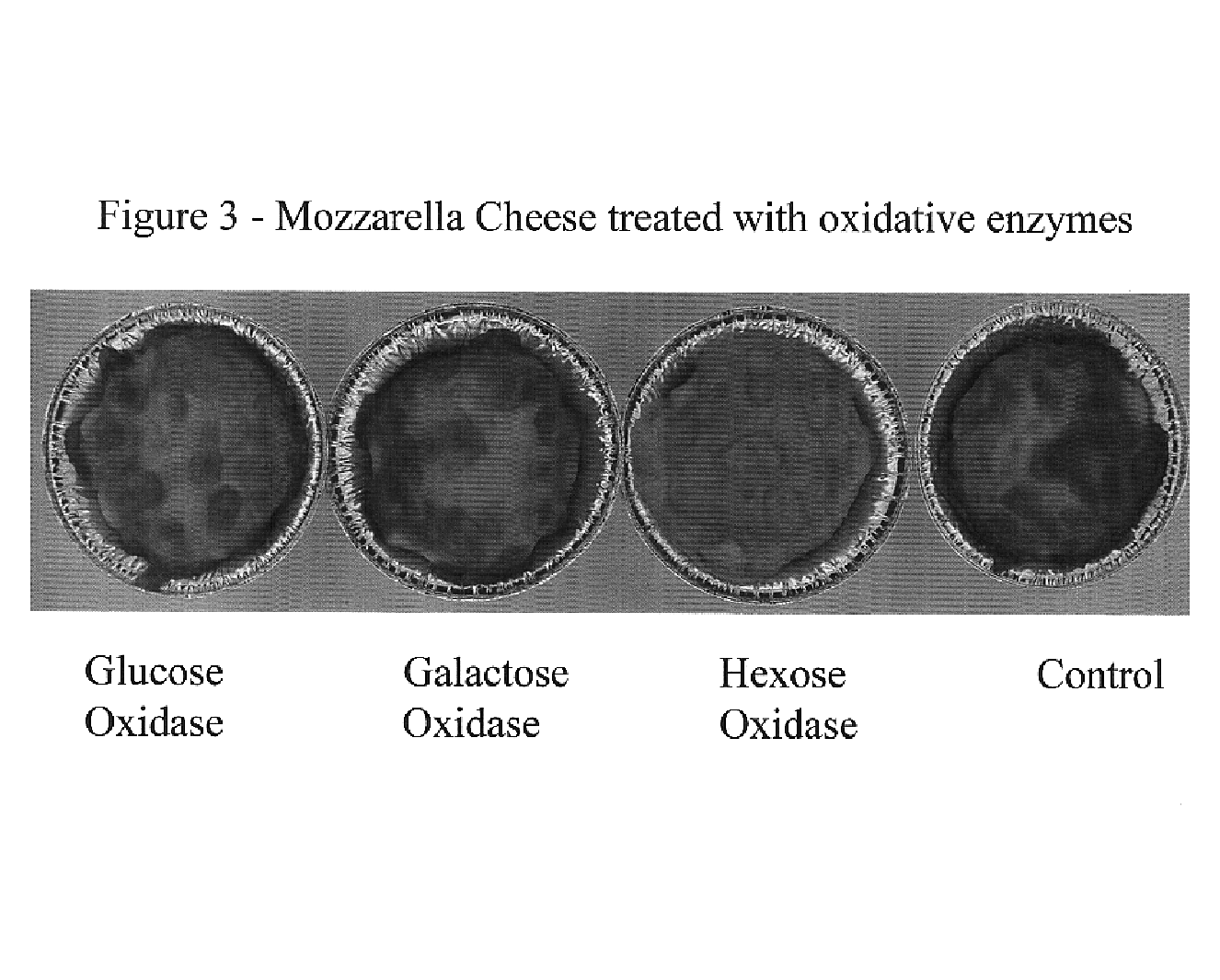

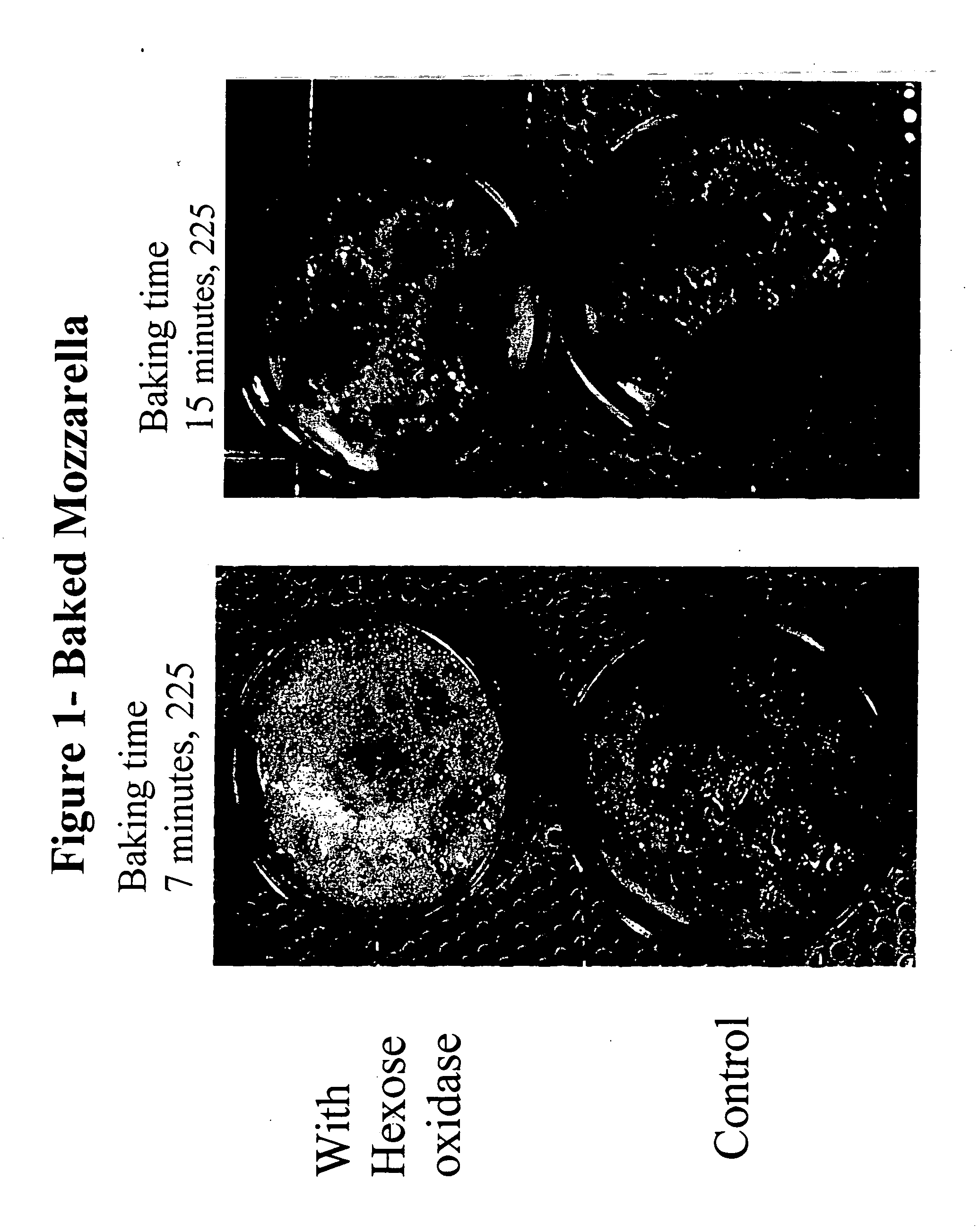

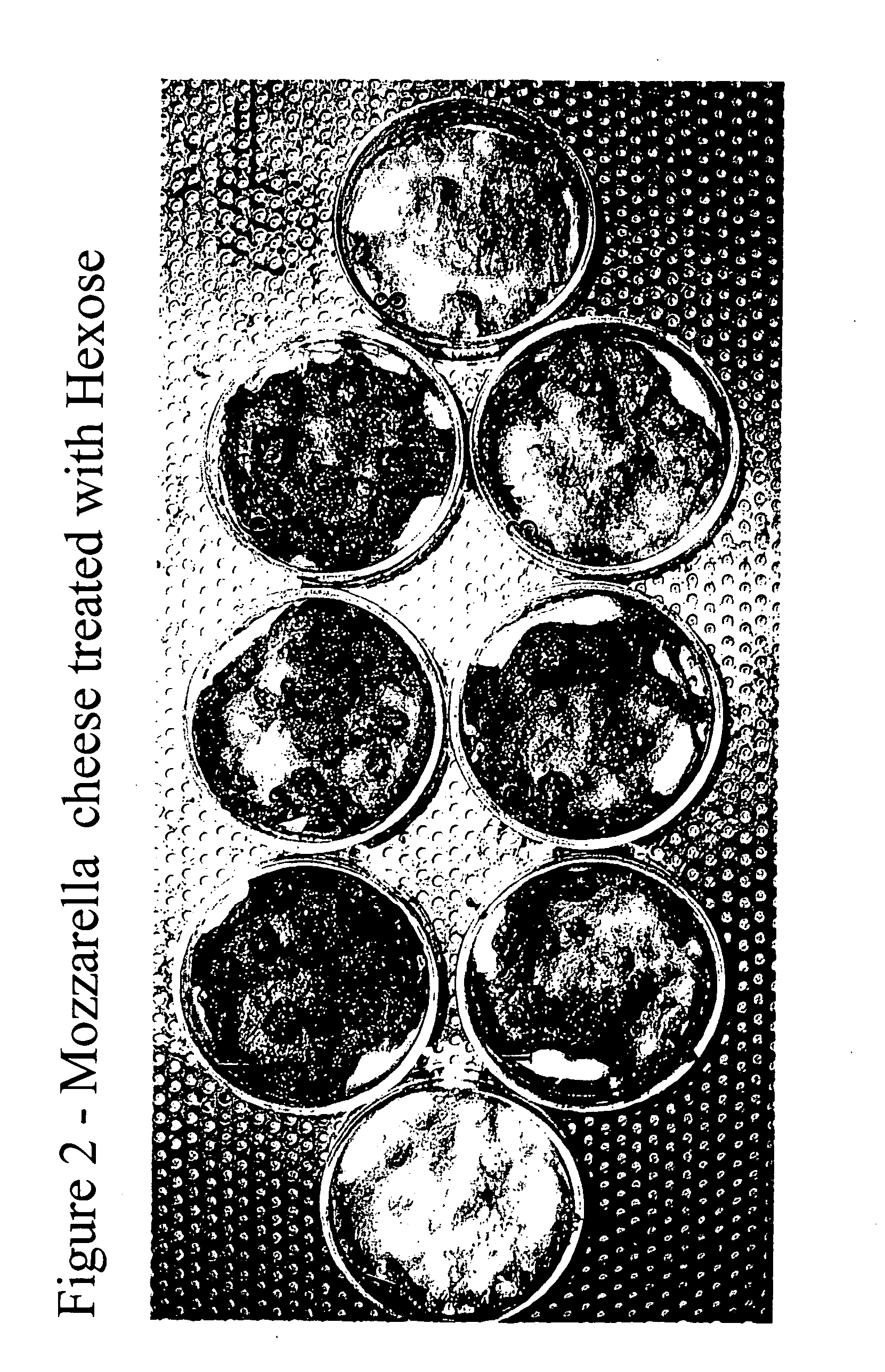

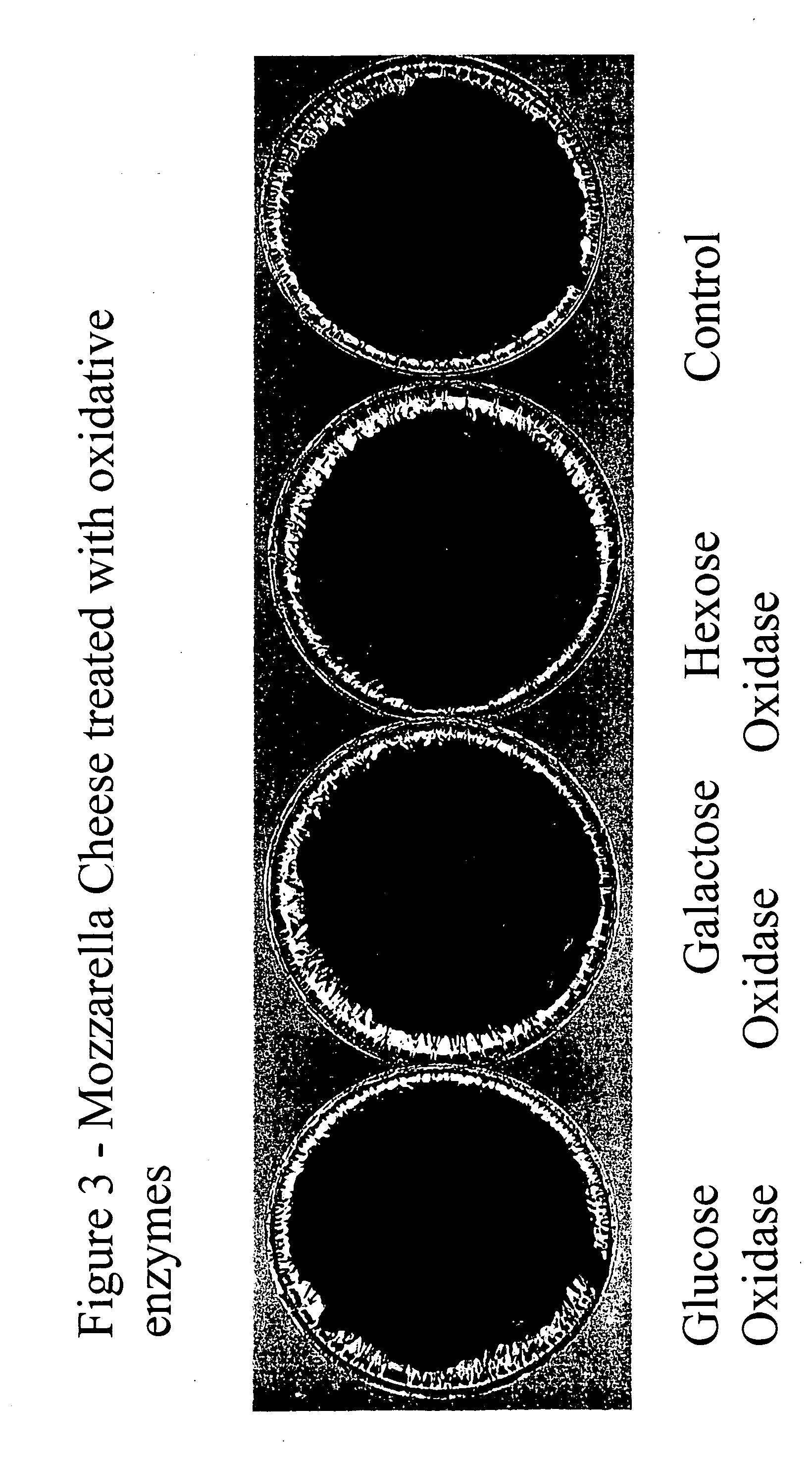

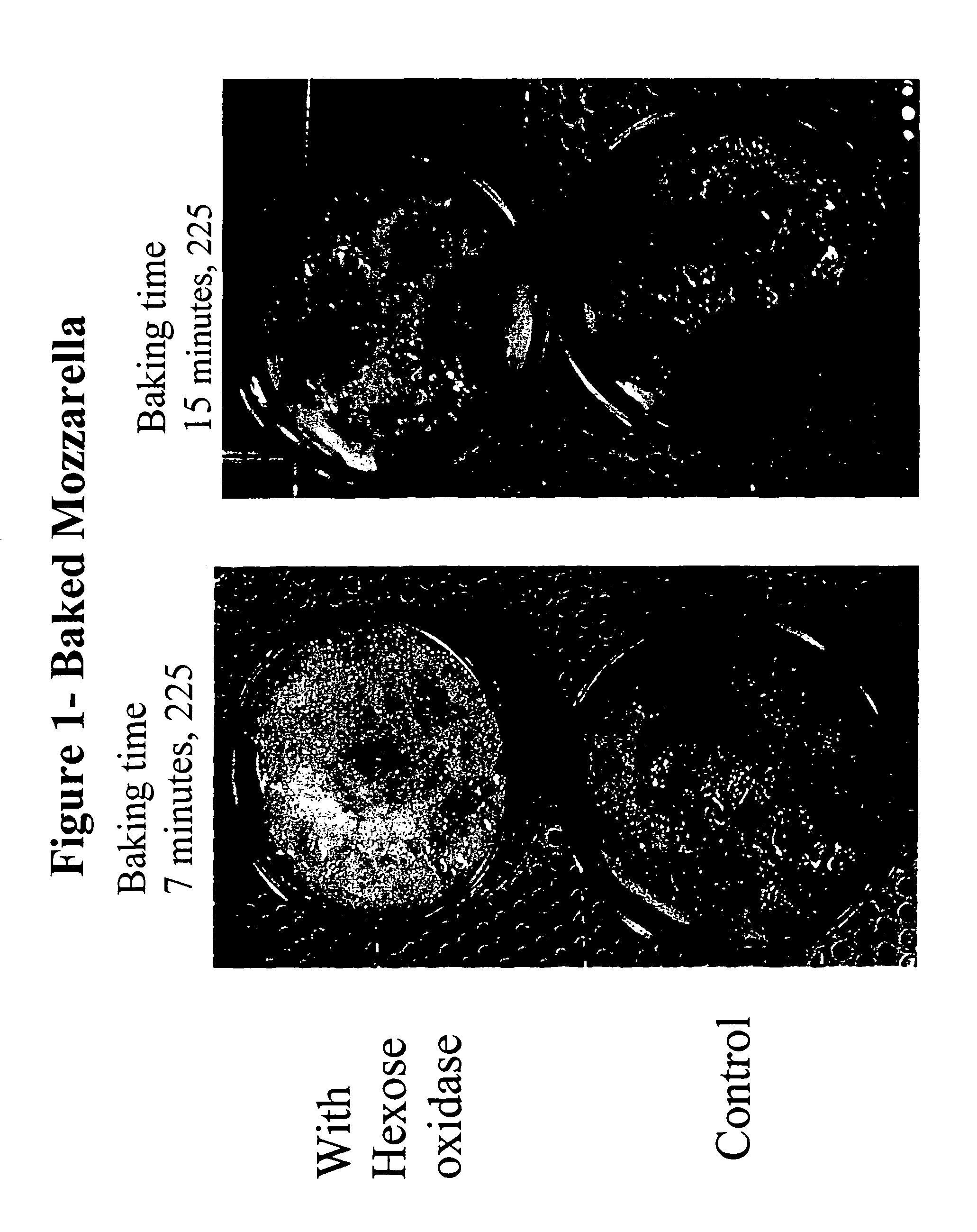

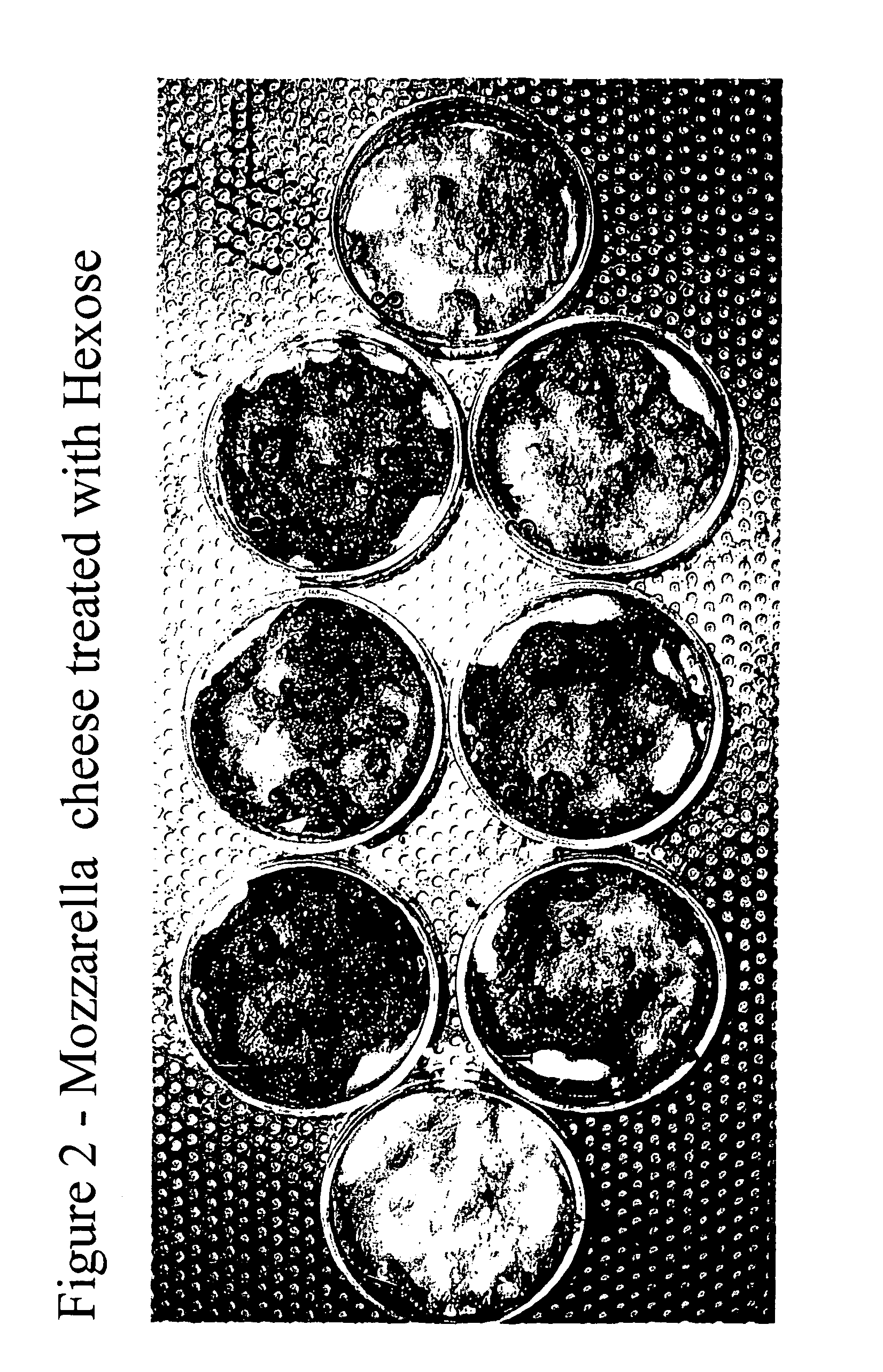

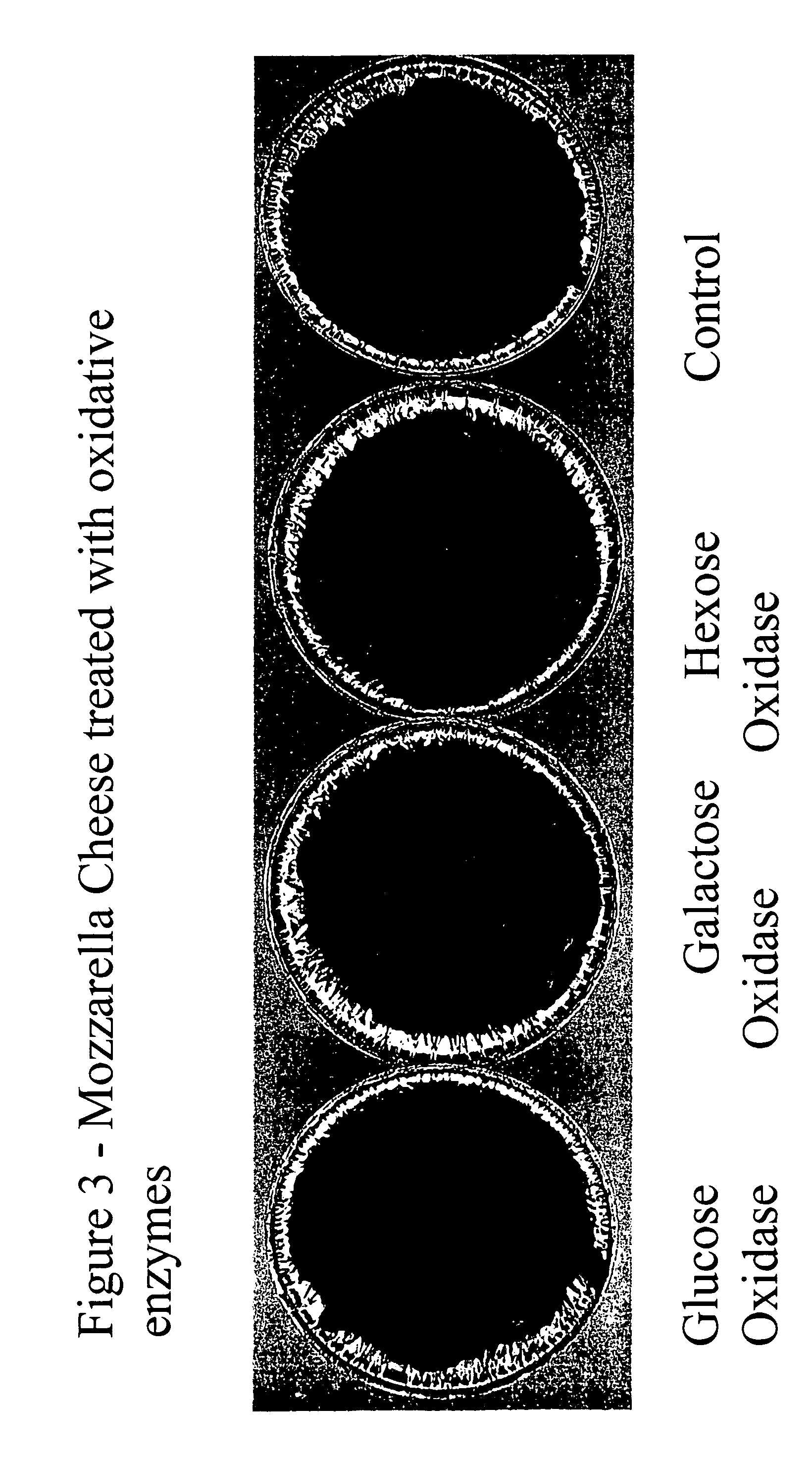

Method of reducing or preventing Maillard reactions in potato with hexose oxidase

InactiveUS6872412B2Avoid the Maillard reactionEliminating the reducing sugarMilk preparationTea extractionMaillard reactionOxidative enzyme

There is provided a process for the prevention and / or reduction of Maillard reaction in a foodstuff containing (i) a protein, a peptide or an amino acid and (ii) a reducing sugar, the process comprising contacting the foodstuff with an enzyme capable of oxidising a reducing group of the sugar.

Owner:DUPONT NUTRITION BIOSCIENCES APS

Preparation method of dried beancurd stick and dried beancurd stick prepared thereby

InactiveCN101971887AIncrease productionHigh dissolution rateCheese manufactureFood sciencePropionateMildew

The invention relates to a preparation method of dried beancurd stick and dried beancurd stick prepared thereby. The preparation method comprises the following steps: 1) grinding peeled soybean into soybean milk; 2) carrying out homogenization treatment on the soybean milk and preparing the homogenized soybean milk; 3) adding a mildew preventive and a film-forming agent in the homogenized soybean and carrying out heating and milk boiling treatment; and 4) heating, uncovering bamboo and forming. The method adopts a water grinder for grinding and high-pressure homogenization, and improves the dissolution rate of protein, thus improving the yield of the dried beancurd stick; film-forming agent Curdlan is added in the homogenized soybean milk so as to accelerate the film forming speed; and mildew preventive calcium propionate is added to effectively restrain the growth of the mould, and prolong the shelf life of the dried beancurd stick. The invention has the advantages of low cost, simple and easy technique and larger application and promotion values.

Owner:健盛食品股份有限公司

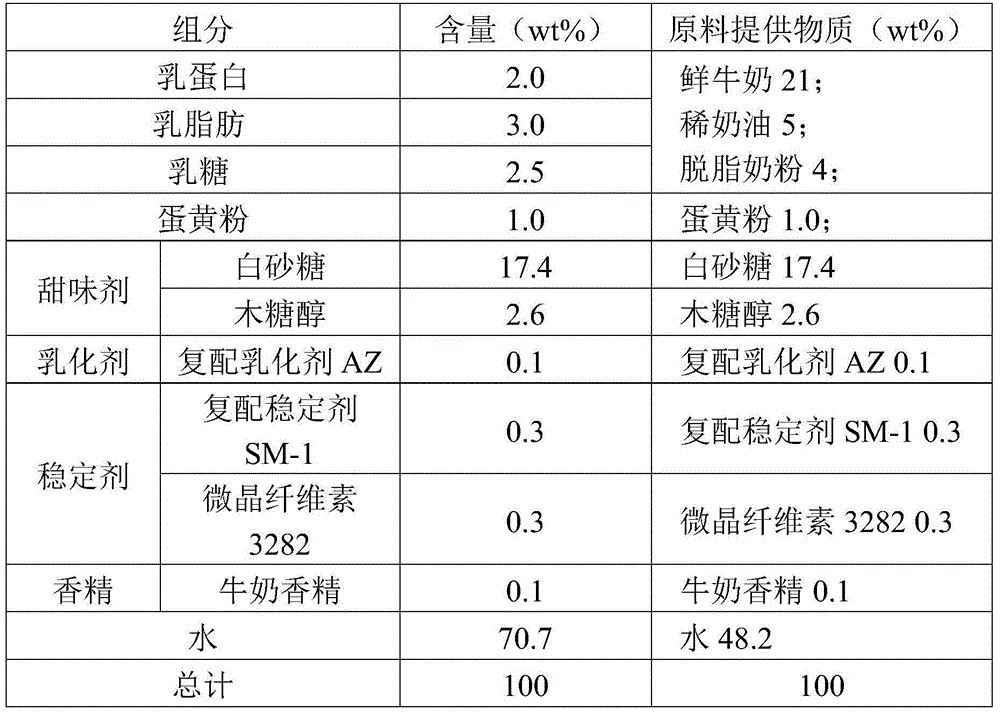

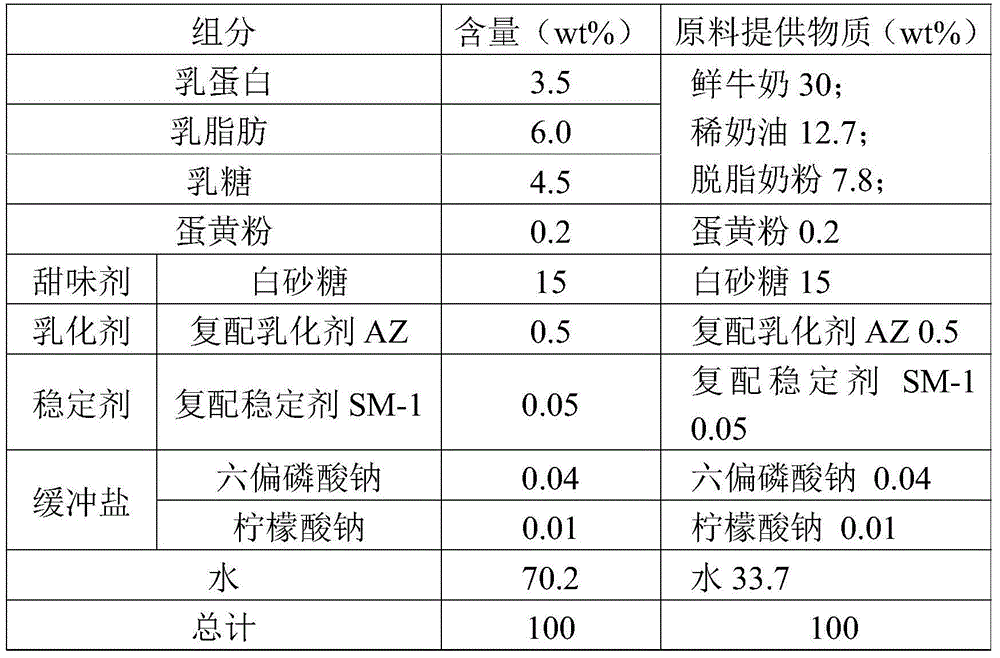

Ice cream milk paste and preparation method and soft ice cream thereof

The invention discloses an ice cream milk paste and a preparation method and a soft ice cream thereof. The ice cream milk paste comprises the following active ingredients in percentage by weight: 3-6% of milk fat, 2-3.5% of lactoprotein, 2.5-4.5% of lactose, 0.2-1.0% of yolk powder, 5-20% of sweetening agent, 0.05-0.5% of an emulsifying agent, and 0.05-0.6% of a stabilizer and water; the method comprises the following steps: (1) evenly mixing the yolk powder, sweetening agent and water, heating to 60-80DEG C, and then evenly mixing together with the emulsifying agent and the stabilizer to obtain a liquor A; (2) cooling to 30-63DEG C, then evenly mixing together with milk fat raw material, the lactoprotein raw material, the lactose raw material and water to obtain a liquor B, and controlling pH to be 6.5-6.8; and (3) performing scraper type ultrahigh-temperature instantaneous sterilization and sterile homogenization and cooling. The prepared ice cream milk paste is off-white color or faintly yellow, fine in mouth feeling, standout in flavor, and good in stability, and pipe blocking or pipe coking cannot be caused during preparation.

Owner:BRIGHT DAIRY & FOOD CO LTD

Modified germinated brown rice extrusion puffed food and processing method thereof

InactiveCN104187434AReduce lossesPromote swellingFood ingredientsFood shapingMonoglycerideAdditive ingredient

The invention discloses a modified germinated brown rice extrusion puffed food and a processing method thereof and relates to the technical field of food processing. The food comprises the following components by weight parts: 50-90 parts of corn flour, 10-50 parts of modified germinated brown rice flour, 0-10 parts of corn starch, 0-10 parts of seasoner, 0-2 parts of calcium carbonate, 0-2 parts of monoglyceride, 0-2 parts of soya bean lecithin and 0-2 parts of edible colloid. By utilizing the processing method, continuous and efficient features of extrusion puffing are kept, the taste of germinated brown rice processed food is improved, and the problem of retention of functional ingredients in the processing of the germinated brown rice extrusion puffed food is solved.

Owner:NANJING UNIV OF FINANCE & ECONOMICS

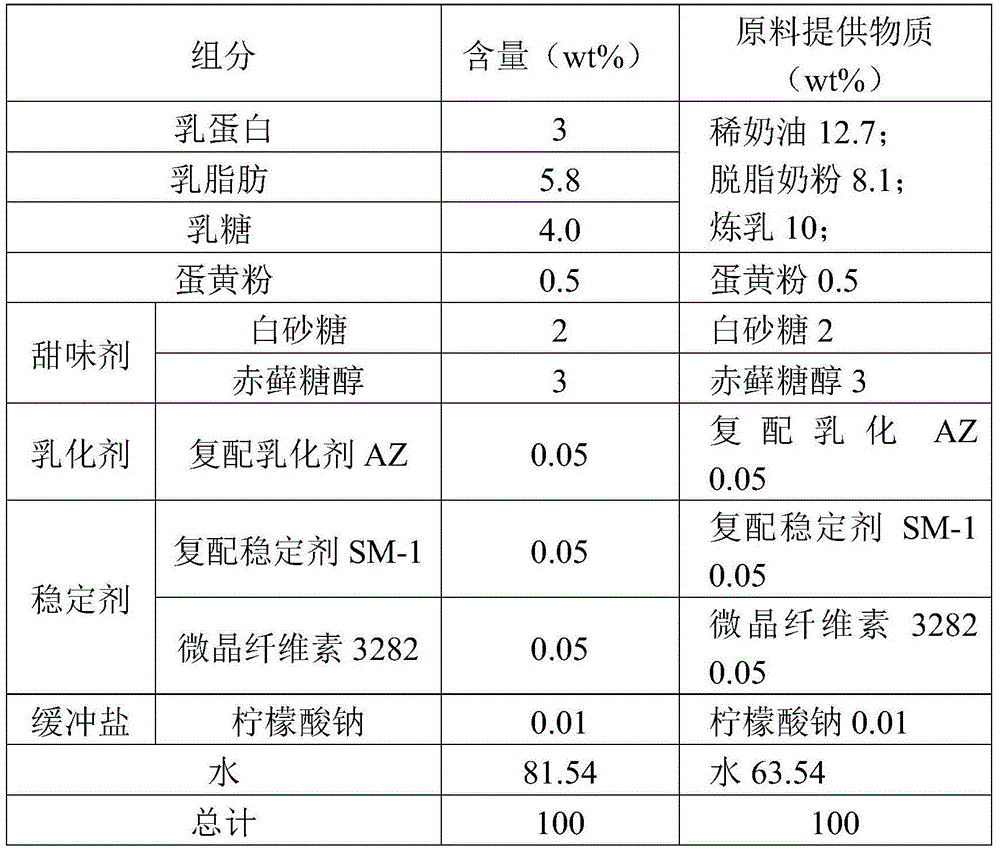

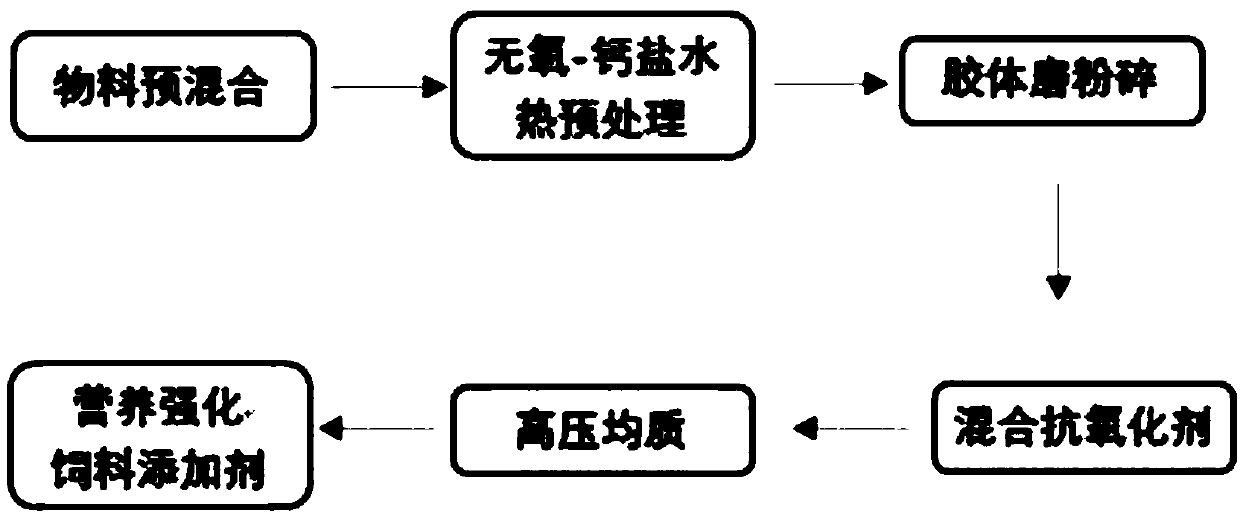

Nutrient strengthened feed additive as well as preparation technology and application thereof

ActiveCN107927327AImprove digestion and absorption rateImprove digestibilityAnimal feeding stuffAccessory food factorsFood additiveAntioxidant

The invention relates to a nutrient strengthened feed additive as well as a preparation technology and application thereof. The preparation technology mainly comprises the following steps of (1) pretreating materials: uniformly mixing nutrient-enriched plant biomass to be treated, with a 0.1-1% ferrum-free calcium chloride aqueous solution; (2) pretreating the nutrient-enriched plant biomass through an oxygen-free calcium salt hydrothermal method so as to obtain solid hydrothermal plant biomass; (3) mixing the solid hydrothermal plant biomass with nutrient-enriched microorganism thalli to obtain a mixture, pouring the mixture in a colloid mill, and performing treatment so as to obtain colloid mill treatment fluid; (4) adding an antioxidant to the colloid mill treatment fluid; and (5) homogenizing and emulsifying the oxidation resistant-colloid mill treatment fluid with a high pressure homogenizer. The nutrient strengthened feed additive prepared by the preparation technology disclosedby the invention forcefully protects nutrient components in plant seeds, has the advantages of being high in digestibility, good in absorptivity, high in nutrient conversion rate and high in deposition rate, can notably increase the content of specific nutrients in livestock and poultry products, and can be used as a feed additive for livestock and poultry, aquaculture animals and companion animals.

Owner:SHANTOU UNIV

Method for producing natto soy

The invention discloses a method for producing bean soy sauce, comprising that mixing bean soup and soya bean in the bean production as 20-50:50-80 weight ratio to ferment for 4-12 months at normal temperature to obtain soy sauce resource, then adding bean soup or salt water whose Baum degree is 16Be-25Be at 30-80% weight ratio into said soy sauce resource to be laid for 24-48h at room temperature, compressing into the final product. The inventive soy sauce comprises a kinase which can restrain color change and Merad reaction, while the bean has high nutrient value and special taste.

Owner:张溪水

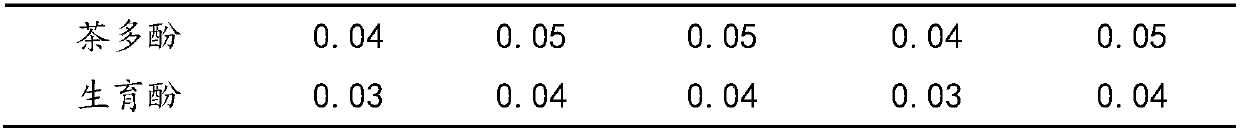

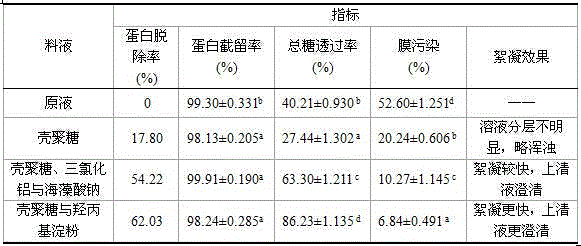

Method for preparing soybean whey oligosaccharide through coupling of heating, flocculating, air floating and ultra-filtering

InactiveCN104530143AReduce Maillard reactionIncrease contentSugar derivativesOligosaccharidesCouplingUltrafiltration

The invention relates to a method for extracting a soybean whey oligosaccharide from soybean whey. The method concretely includes the steps that heating, flocculating, air floating and intermittent flow-crossing ultra-filtering are coupled; a segmented treatment mode is adopted in a ground-breaking mode at a pretreatment stage, and ingeniously combined with air floating separation; composite flocculants with specific components and a specific proportion are selected. The high-quality soybean oligosaccharide product low in maillard browning reaction occurrence rate is provided, the extraction ratio of the soybean whey oligosaccharide can reach 85% and is much higher than that at a common level in the field, the effect that all steps and parameters supplement each other and act in a coordinated mode is achieved, the cost is lowered, and the method is high in operability.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Method

ActiveUS20050202121A1More browningAvoid the Maillard reactionMilk preparationFruit and vegetables preservationBiotechnologyMaillard reaction

There is provided a process for the prevention and / or reduction of Maillard reaction in a foodstuff containing (i) a protein, a peptide or an amino acid and (ii) a reducing sugar, the process comprising contacting the foodstuff with an enzyme capable of oxidising a reducing group of the sugar.

Owner:DUPONT NUTRITION BIOSCIENCES APS

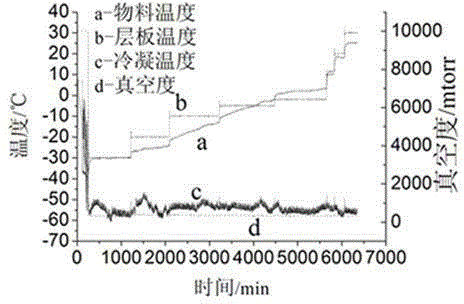

Processing method for rapidly curing rhizoma polygonati zen food

InactiveCN107156826AGreat tasteShorten the timeFood thermal treatmentFood dryingMaillard reactionHigh pressure

The invention relates to a processing method for rapidly curing rhizoma polygonati zen food. The processing method includes steps of selecting perennial rhizoma polygonati, removing tassel and mud, and cleaning rhizoma polygonati; removing pityriasis simplex, mould and necrosis parts of rhizoma polygonati; removing rhizoma polygonati bark; cooking under high temperature and high pressure; removing moisture at the surface at low temperature; vacuum-drying; filling nitrogen at low temperature and drying in the absence of oxygen; vacuum-packaging; high-temperature sterilizing; packaging the finished product. The processing method has the following advantages that 1, the water content of the prepared rhizoma polygonati is within 25-30%, thus the rhizoma polygonati is soft and delicious and can be eaten as food; 2, the Maillard reaction is greatly reduced, the loss of nutrient components is reduced, and the nutrition utilization rate is improved; time is saved and efficiency is improved; the processing cycle is about 2 days, and the process is not influenced by weather; thus the production cycle is improved by 5-8 times; 3, the energy source cost is saved. The rhizoma polygonati moisture can be separated out once through a vacuum drying technology, thereby exempting the repeat steaming and shinning process and reducing the cost. The food is not added with manual additive and meets the concept of zen food and modern health-preserving consumption concept.

Owner:黄山五溪源中药材科技有限公司

Method for preparing abalone active glycopeptide by subcritical fluid extraction and enzyme membrane coupling reaction and reaction system

InactiveCN108977487AReduce lossesShort reaction timeBioreactor/fermenter combinationsBiological substance pretreatmentsHydrolysateEnzyme membrane

The invention relates to the field of preparation of glycopeptides, and discloses a method for preparing an abalone active glycopeptide and a reaction system. The method for preparing the abalone active glycopeptide comprises the following steps: (1) subcritical fluid extraction: heating a mixture of abalone viscera and water to 130 to 150 DEG C for 0.1 to 5 hours for performing subcritical fluidextraction to obtain an extraction liquid; (2) deodorization and degreasing: deodorizing and degreasing the extraction liquid by activated adsorption carbon to obtain an impurity removal liquid; (3) enzyme membrane coupling reaction: subjecting the impurity removal liquid to an enzymatic hydrolysis reaction, continuously filtering an enzymatic hydrolysate with an ultrafiltration membrane having amolecular weight cut off of 5-20 kDa in the enzymatic hydrolysis reaction process to obtain a dialysate and a retentate, and the retentate returning to the enzymatic hydrolysis reaction step; (4) desalting treatment. The abalone active glycopeptide can be prepared by the method provided by the invention, the reaction time can be shortened, the obtained glycopeptide is light yellow or brown, the quality is good, the enzyme amount can be reduced, the enzyme recycling rate can be improved, the energy consumption can be reduced, and the production cost can be reduced.

Owner:XIAMEN DAOZHIYUAN BIOTECH

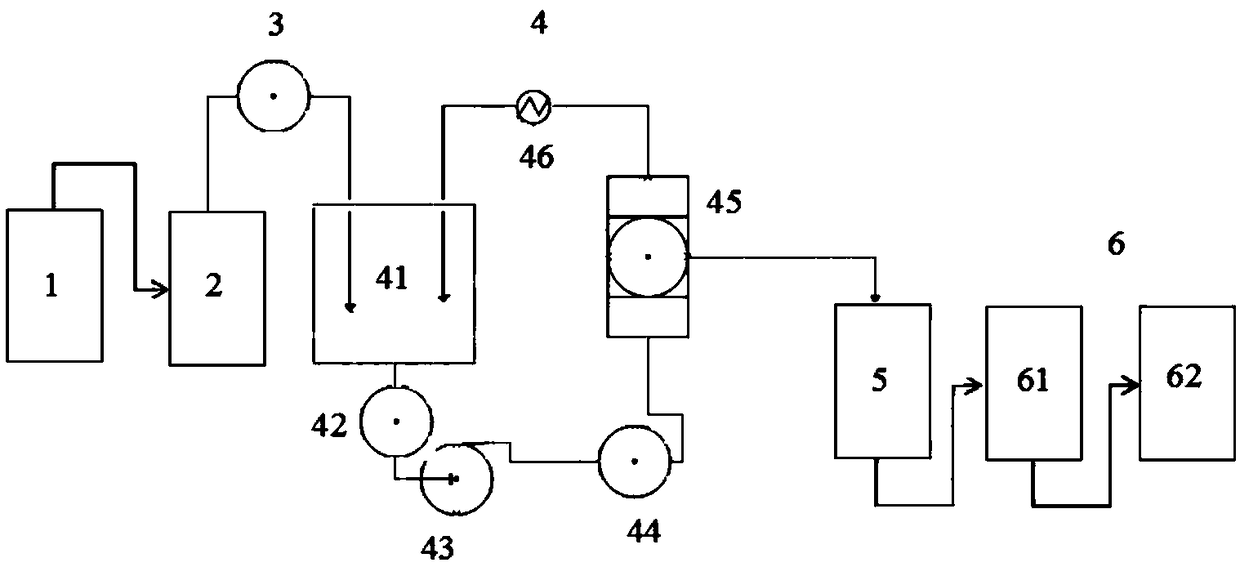

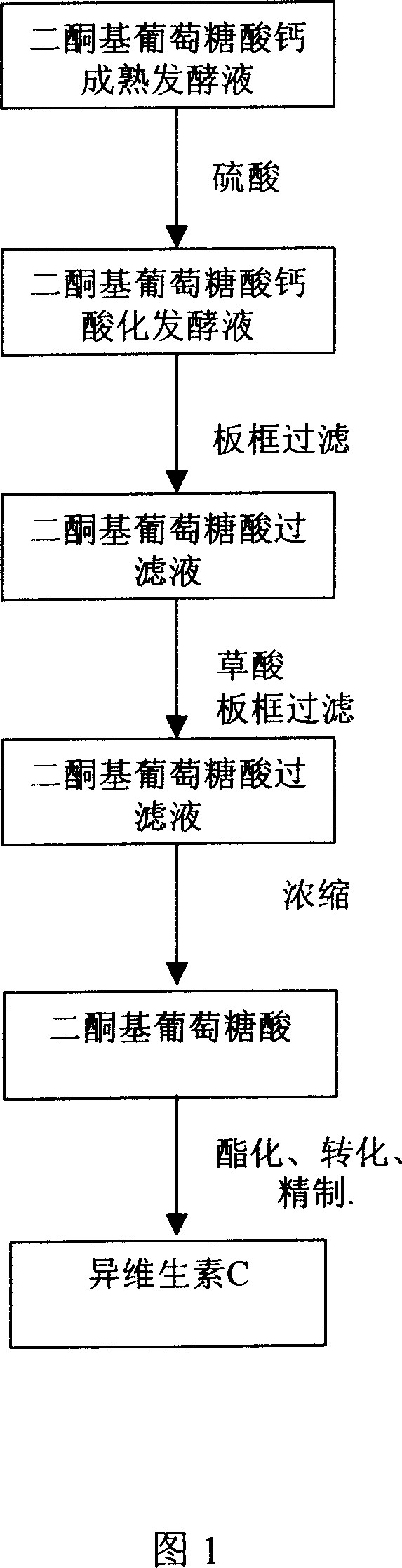

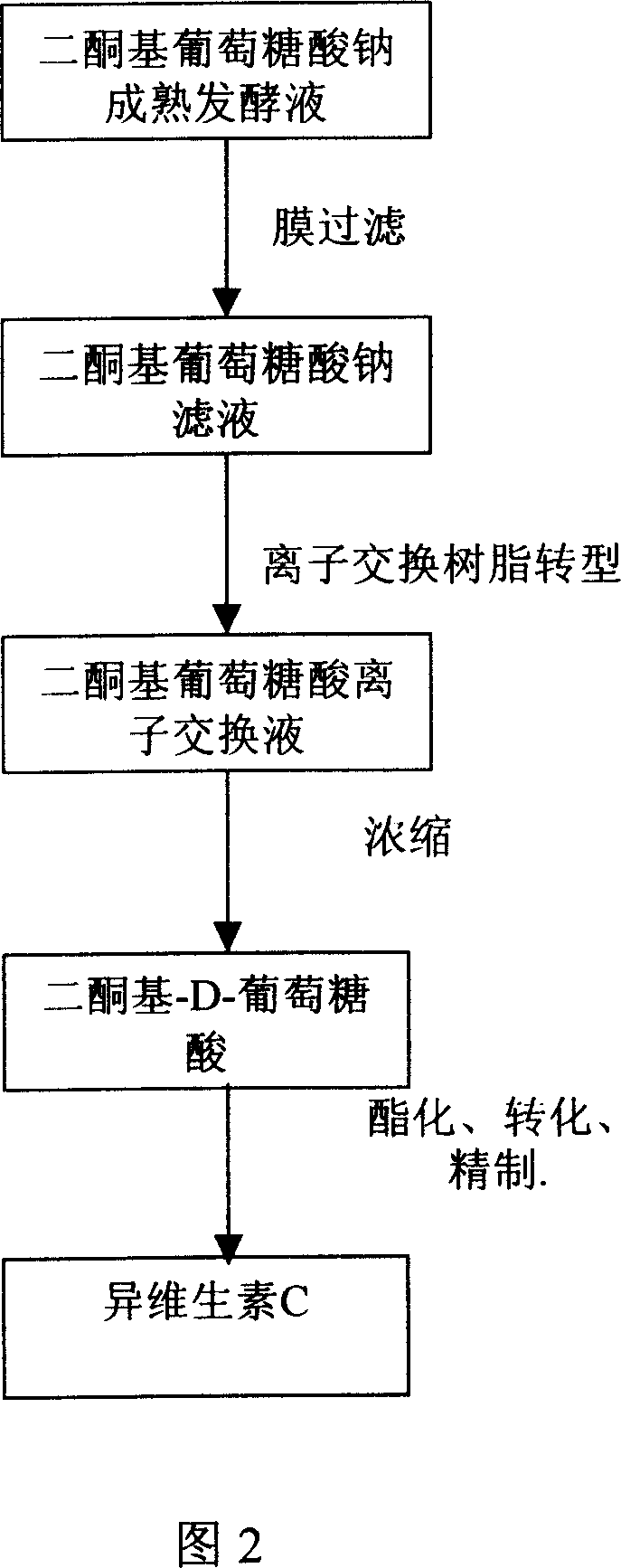

Process for producing isovitamine C by membrane-resin method

A process for preparing isovitamin C by membrane-resin method includes such steps as membrane filtering of the fermented liquid of sodium diketogluconate, ion exchange and concentrating by ion exchange resin, esterifying, converting and refining.

Owner:凯能高科技工程(上海)有限公司

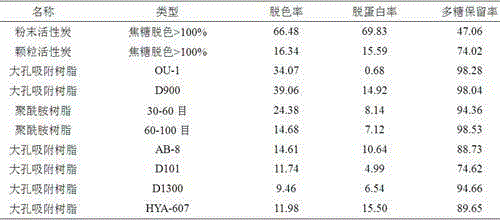

Decolorizing method for Huping jujube polysaccharide solution

InactiveCN105199008AHigh purityHigh decolorization rate and polysaccharide retention rateActive carbonPolyamide

The invention discloses a decolorizing method for a Huping jujube polysaccharide solution. The decolorizing method concretely includes the steps that 1, peel and pit removing is performed on Huping jujubes, paste making is performed after the Huping jujubes are cut into slices, and a vacuum freeze drying technology is adopted for drying treatment to obtain Huping jujube powder; 2, a certain amount of jujube powder is weighed, and through the steps of extracting, concentrating, alcohol precipitation, alcohol washing and others, crude polysaccharides is obtained; 3, crude polysaccharides are redissolved in distilled water, three decolorizing agents including macroporous adsorption resin, active carbon and polyamide resin are added for decolorizing, and D900 type macroporous adsorption resin is sieved out to serve an ideal decolorizing agent; 4, crude polysaccharides are redissolved in a buffering solution, and through D900 type macroporous adsorption resin, decolorizing, concentrating and drying are performed to obtain Huping jujube polysaccharides, wherein the PH value of the buffering solution is 11-12. By the adoption of the decolorizing method, the Huping jujube crude polysaccharide solution is convenient and easy to decolorize, no harmful chemical substances are introduced, one-off decolorizing rate can reach 80-90%, the retention rate of polysaccharides can reach 80-90%, and deproteinization rate can also reach 30-40%. Resin can be recycled in a renewable mode, the requirements for the cost and equipment are low, and industrialized production of Huping jujube polysaccharides is facilitated.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

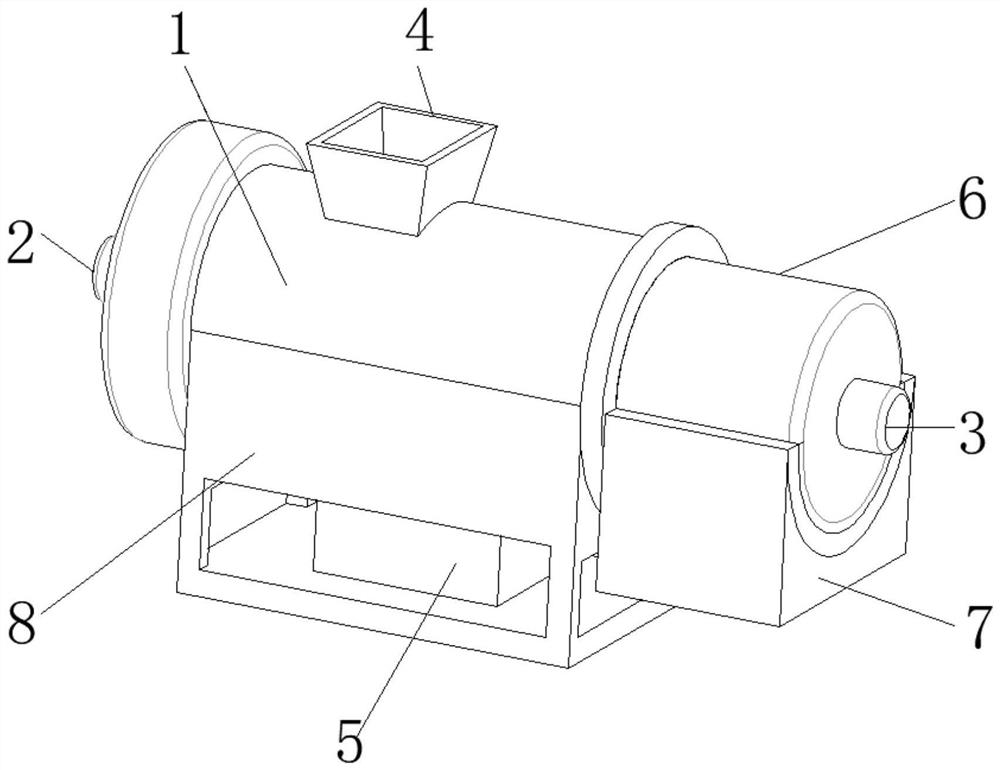

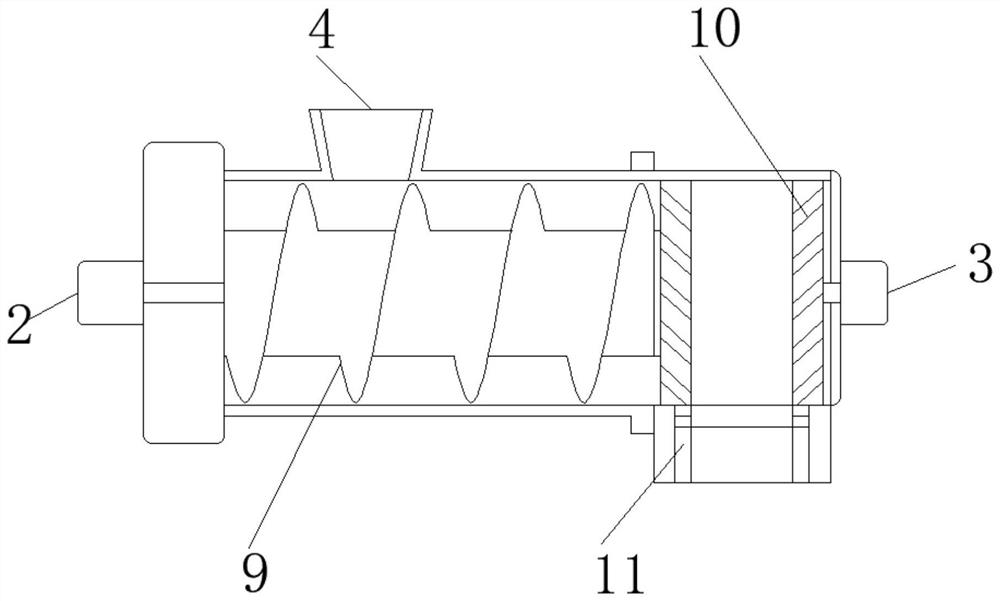

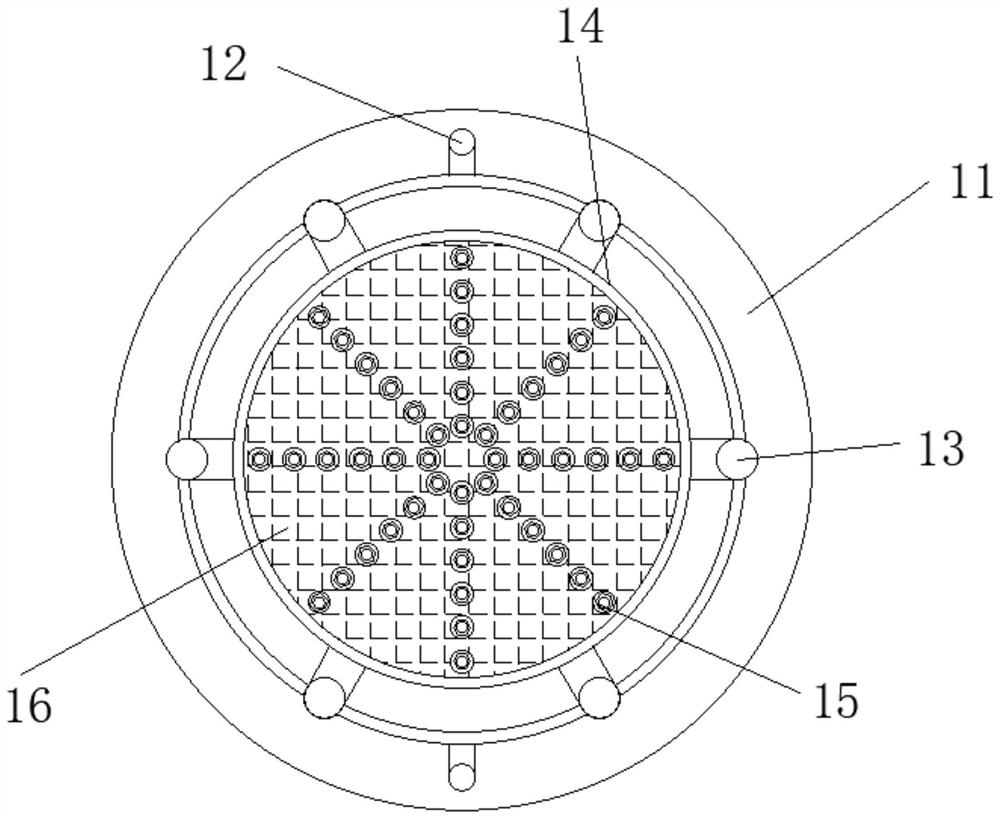

Feed processing device

InactiveCN112673824AStir fully and evenlyAvoid crackingFeeding-stuffLighting and heating apparatusMaillard reactionCoupling

The invention provides a feed processing device, and relates to the field of feed processing. The feed processing device comprises a conveying pipe, a motor a, a motor b, a feeding hopper, a water tank, an extrusion pipe, a pressing mechanism and a supporting frame, a feeding groove is formed in the outer wall of the top end of the conveying pipe, the inner wall of the feeding groove is welded to the feeding hopper, the motor a is arranged on the outer wall of one end of the conveying pipe, an output shaft of the motor a is connected with a spiral auger a through a coupling, the outer wall of the bottom end of the conveying pipe is fixedly connected with the supporting frame through screws, the outer wall of one side of the supporting frame is movably connected with the water tank, and the extrusion pipe is welded to the conveying pipe. According to the feed processing device, cracks on the surfaces of particles caused by different humidity during straw pressing are prevented, feed can be rapidly cooled during extrusion forming, the Maillard reaction during feed pressing is slowed down, the formed feed is flatter and smoother and is not prone to being excessively wet or fragmentary, and meanwhile spraying of straw powder is reduced.

Owner:汪琴

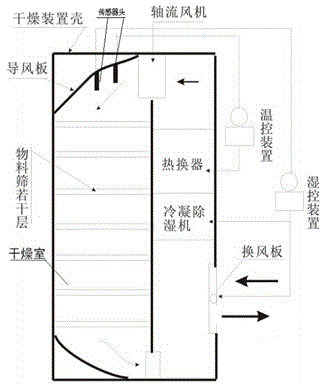

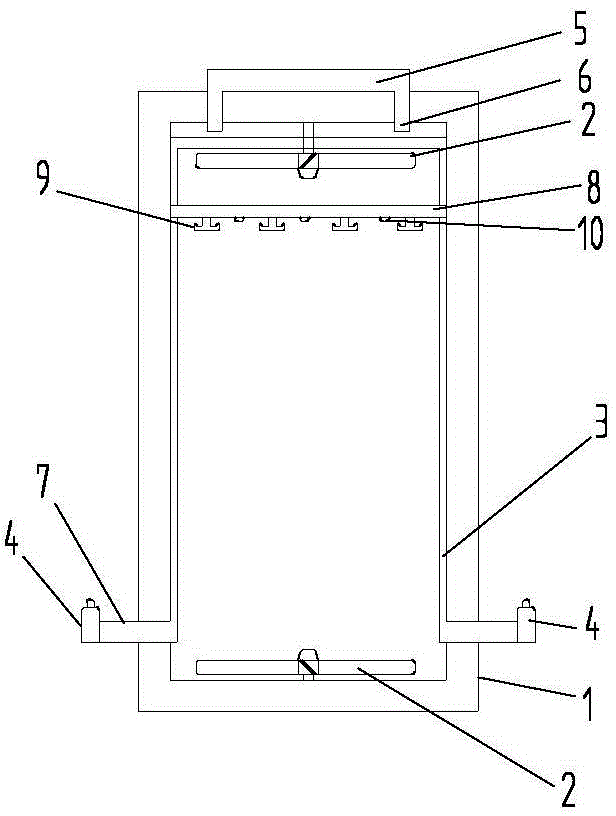

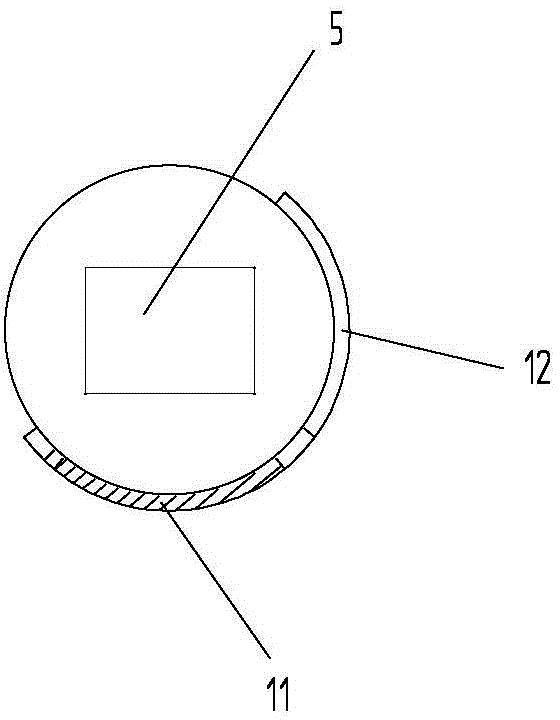

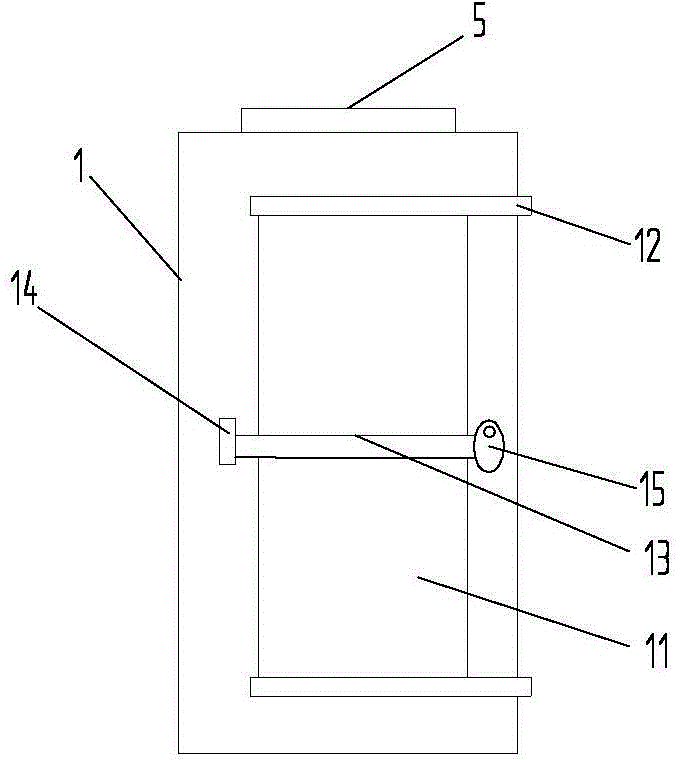

Low-temperature drying processing technology of longan pulp

InactiveCN104473083ARich flavorChange color quicklyFood preservationFood preparationMaillard reactionAdditive ingredient

The invention discloses a low-temperature drying processing technology of longan pulp. A specific drying device is adopted and dries the longan pulp under the drying conditions of low temperature smaller than 40 DEG C, an axial flow fanwind speed of 8-20 m per second and the relative air humidity smaller than 50%; and the drying device comprises a casing, a drying chamber, an air deflector, an axial flow fan, a temperature control device, a humidity control device, a heat exchanger, a condensationdehumidifier and an air exchange plate. According to the technology, high-speed dry air flow and a material are sufficiently contacted, fresh and wet longan pulp can be rapidly dried without overhigh temperature, a Maillard reaction in the drying process is reduced, color change of a product is little, original flavor and nutritional ingredients are preserved, and a high-quality dried longan pulp product with shallow color and heavy flavor is obtained.

Owner:范德和 +1

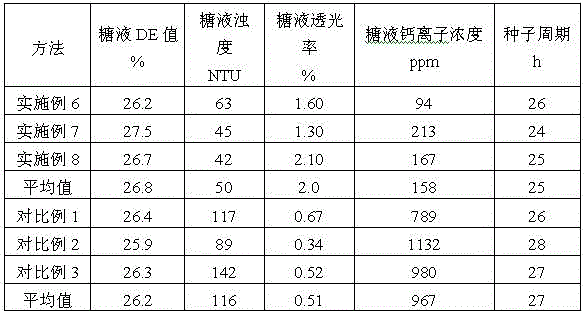

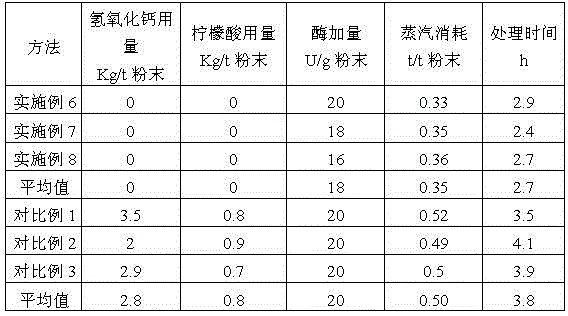

Processing method for starchiness materials and application of processing method in citric acid preparing industry

InactiveCN105567749AGood flocculation effectReduce dosageMicroorganism based processesFermentationAmylaseSide effect

The invention discloses a processing method for starchiness materials. According to the processing method, citric-acid waste water is utilized as a raw material. The processing method comprises the steps of material smashing, pulp mixing, once enzyme supplementation, once spraying, flashing and solid-liquid separation; and the enzyme is selected from acid-resisting alpha- thermostable amylase. The processing method is suitable for low-pH liquefying conditions. According to the processing method, the operation is greatly simplified, the energy consumption and producing cost are reduced, the ideal protein flocculating and purifying effect is guaranteed, and the side effects caused to following fermentation and purification are reduced. When the processing method is applied to the critic acid preparing industry, the seed growing speed is obviously increased, the seed cultivating period is shortened, the fermentation index is further improved, the fermentation period is shortened, and the converting rate is improved. Thus, the processing method has important industrial application value.

Owner:JIANGSU GUOXIN UNION ENERGY CO LTD +1

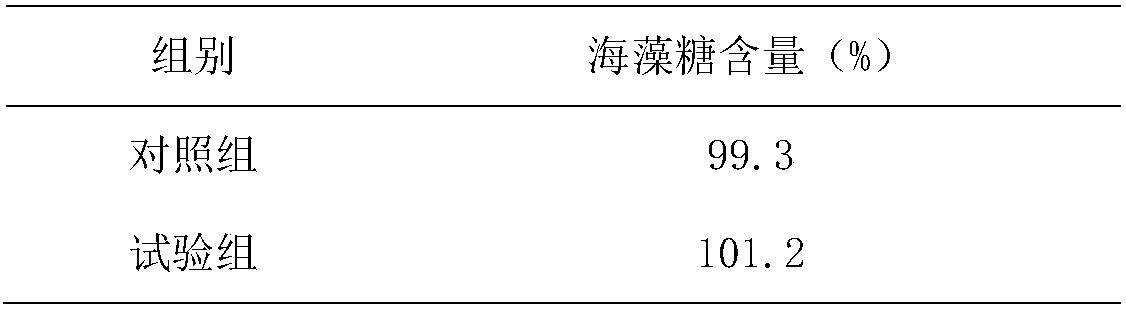

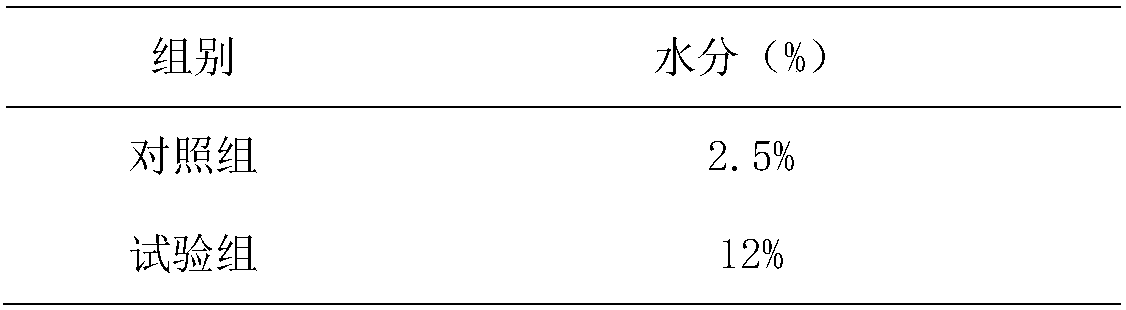

Preparation method of high-content trehalose

ActiveCN108130350ALow costImprove bulkSugar derivativesTransferasesChromatographic separationMaillard reaction

The invention discloses a preparation method of high-content trehalose. The preparation method of the high-content trehalose sequentially comprises the following steps: (1), preparing starch milk; (2), liquefying; (3), performing double enzymolysis; (4), filtering to remove protein; (5), decolorizing; (6), desalting; (7), performing nanofiltration and chromatographic separation purification; (8),performing concentration crystallization; and (9), separating and drying to obtain a finished product. The preparation method has the advantages as follows: the prepared product has the trehalose content being higher than 99.7%, and is high in functionality; compared with an ordinary trehalose product, the using amount of the high-content trehalose for achieving the same effect can be reduced by 2-5%; for baking, the high-content trehalose can increase the bulkiness of a baked product, and for a cosmetic, the high-content trehalose can improve the moisture retention of the cosmetic; occurrenceof a maillard reaction can be effectively reduced; the product provided by the invention is high in yield, so that the output of an enterprise can be increased and industrial production is facilitated; the product provided by the invention is relatively uniform in granularity and has a smaller granule size than the ordinary trehalose, is high in dissolution speed and convenient to use.

Owner:TONGLIAO MEIHUA BIOLOGICAL SCI TECH CO LTD

Instant milk cubilose and preparation method thereof

PendingCN111466441ASolve the problem of prone Maillard reactionKeep the flavorMilk preparationMilk preservationBiotechnologyEngineering

The invention relates to instant milk cubilose and a preparation method thereof. The method comprises the following steps of performing sterilization treatment on a cubilose raw material, and placingthe cubilose raw material in a sterile heat preservation cabinet for heat preservation; soaking the cubilose raw material subjected to heat preservation so as to obtain soaked cubilose; sequentially carrying out filtration, osmotic concentration, degreasing standardization treatment, secondary homogenization and centrifugation on milk to obtain sterilized milk; and heating the sterilized milk to 50 DEG C, carrying out stirring and hydrating for 20 minutes, continuously heating the milk to 60 DEG C, adding a stabilizer, the soaked cubilose and sugar, and carrying out sterilizing treatment to obtain the instant milk cubilose. By using the method provided by the invention, the instant milk cubilose which retains the color and taste of the milk and has the relatively long shelf life can be obtained.

Owner:大洲新燕(厦门)生物科技有限公司

Method for producing natto soy

The invention discloses a method for producing bean soy sauce, comprising that mixing bean soup and soya bean in the bean production as 20-50:50-80 weight ratio to ferment for 4-12 months at normal temperature to obtain soy sauce resource, then adding bean soup or salt water whose Baum degree is 16Be-25Be at 30-80% weight ratio into said soy sauce resource to be laid for 24-48h at room temperature, compressing into the final product. The inventive soy sauce comprises a kinase which can restrain color change and Merad reaction, while the bean has high nutrient value and special taste.

Owner:张溪水

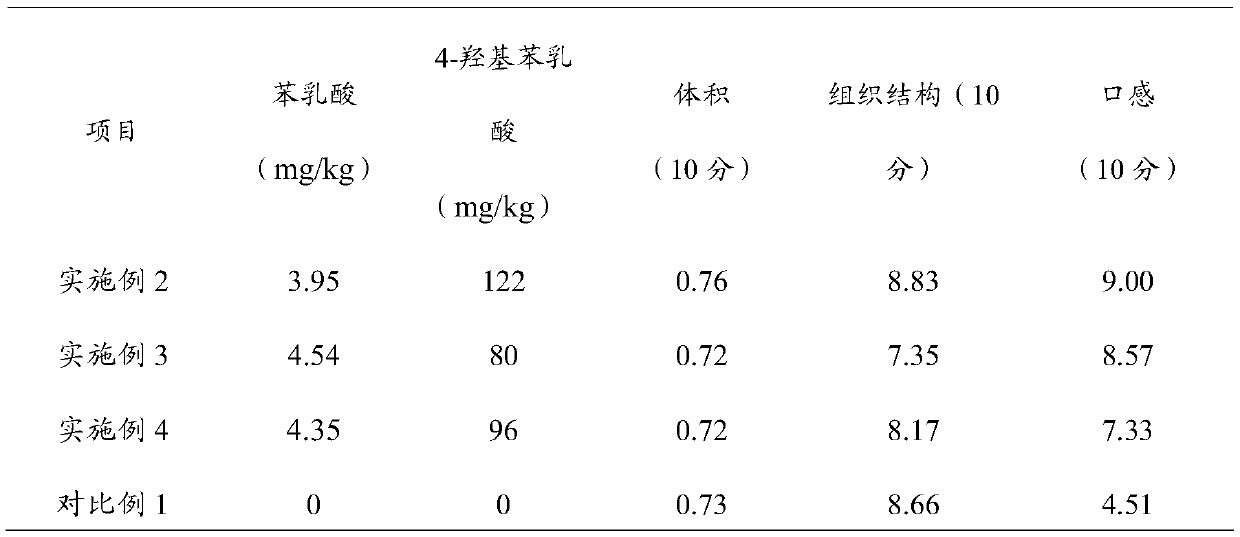

Fermentation lactic acid bacteria light bread and making method thereof

PendingCN110754495ASolve the problem that the lactic acid bacteria cannot be fully fermentedSolve the problem of sufficient fermentationDough treatmentPre-baking dough treatmentBiotechnologyLactic acid bacterium

The invention discloses fermentation lactic acid bacteria light bread. The fermentation lactic acid bacteria light bread comprises components of flour, characteristic lactic acid bacteria fermentationliquid and the like, wherein the lactic acid bacteria fermentation liquid is prepared by fermentation of compound lactic acid bacteria strains, milk powder, glucose and the like. The milk powder andpart of glucose powder in the components for the bread are separately made into a lactic acid bacteria culture medium, and the compounding lactic acid bacteria strain is fermented in advance, so thatthe problem that in the normal bread making process, lactic acid bacteria are added, and the lactic acid bacteria are sufficiently fermented, can be solved. The invention further discloses a making method of the fermentation lactic acid bacteria light bread. According to a dough technology of the bread, improvement is performed, and multi-step dough fermentation processes are adopted, so that thelactic acid bacteria bread is subjected to multi-step fermentation treatment in the dough fermentation process, and the lactic acid bacteria can propagate in the stage. The lactic acid bacteria and the main dough are mixed, and secondary fermentation is performed, so that massive metabolism products being unique in flavor can be obtained. The fermentation time of the lactic acid bacteria is prolonged, and besides, the ageing of starch can be effectively delayed.

Owner:FUJIAN DALI FOOD TECH CO LTD

Method for producing fuel ethanol based on high-quality DDGS product

ActiveCN109971616AWeaken the solid phase Maillard reactionReduce Maillard reactionBioreactor/fermenter combinationsBiological substance pretreatmentsOperating temperatureBiomass

The invention belongs to the technical field of biomass energy production, and discloses a method for producing fuel ethanol based on a high-quality DDGS product. A mash preparation unit and a rectification unit are used, a second rectification tower waste mash of the rectification unit is delivered to a waste mash treatment unit, solid substances in the waste mash are recycled, and the DDGS product is produced; secondary rectification tower top steam is heated and pressurized through a compressor, the steam-liquid equilibrium temperature of the obtained pressurized reflux steam of the secondary rectification tower is higher than the operating temperature of a crude tower kettle, and the pressurized reflux steam is sent to a reboiler of a crude tower as a heating medium; the secondary rectification tower top steam is heated and pressurized through the compressor to obtain secondary rectification tower pressurized adsorption steam which is superheated steam, preheating operation is notrequired, and the superheated steam is directly delivered to an adsorber A or an adsorber B of an adsorption unit for adsorption dehydration operation to obtain a fuel ethanol product. By the technical scheme, the industrial problems of high heating temperature of solid-containing materials such as fermented mash and waste mash, easiness in scarring of equipment such as the reboiler and a tray, unstable production, influence on DDGS product quality and the like in an existing main fuel ethanol production process are solved.

Owner:TIANJIN UNIV

Opposite turbulence smoke oven

InactiveCN104304354AReduce pollutionFast heatingMeat/fish preservationBaking ovenEngineeringHeat sink

The invention discloses an opposite turbulence smoke oven which comprises an oven body, fans, heat radiating fins and throttling valves, wherein the oven body is cylindrical; a smoke generator is arranged at the upper part of the oven body; a smoke inlet pipe extending in the oven body is arranged below the smoke generator; steam pipelines are respectively arranged on two sides of the oven body; the throttling valves are respectively arranged on the steam pipelines; the heat radiating fins are arranged on the periphery and the upper part of the inner wall of the oven body; the heat radiating fins are connected with the steam pipelines; the fans are respectively arranged at the upper part and the lower part in the oven body and are centrally symmetric; cross beams are respectively arranged below the fans; a track is arranged below each cross beam; a temperature and open fire sensor is arranged between the tracks and is connected with each throttling valve through a wire; an oven door is arranged in front of the oven body; oven door tracks are respectively arranged at the upper part and the lower part of the oven door; a crank arm is arranged at the middle of the oven door; one side of the crank arm is fixed on the oven body through a hinge; a locking device is arranged on the other side of the crank arm. The opposite turbulence smoke oven disclosed by the invention has the beneficial effects of simple process, no open fire for baking and higher safety.

Owner:SHANDONG HUACHANG FOOD TECH

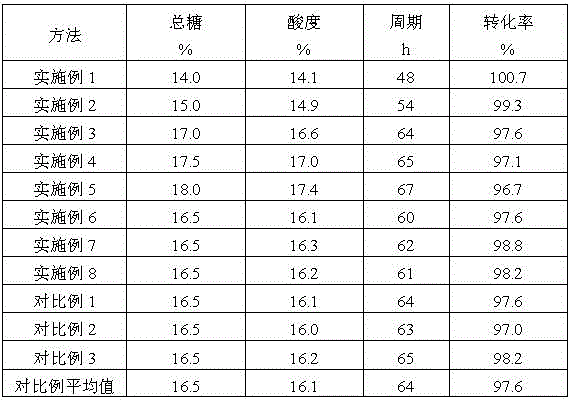

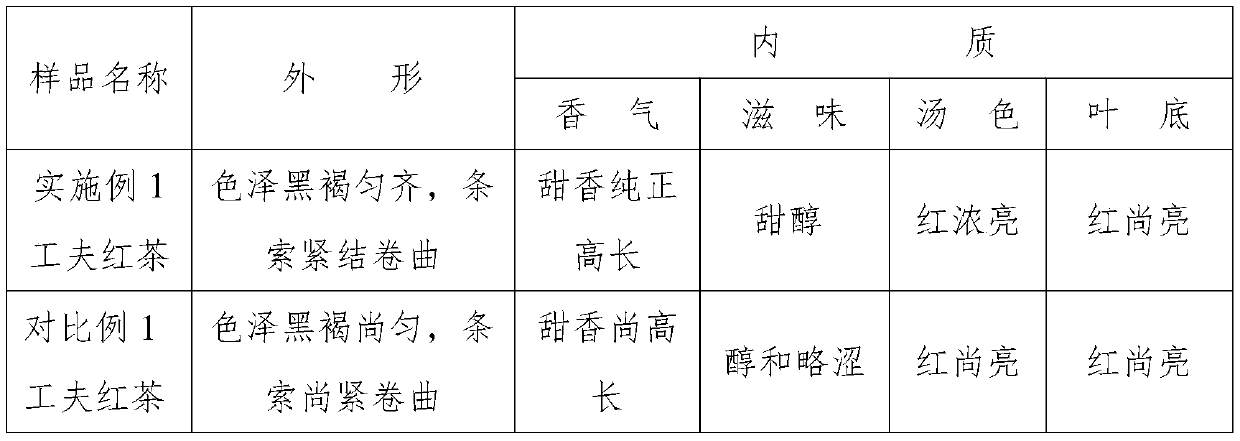

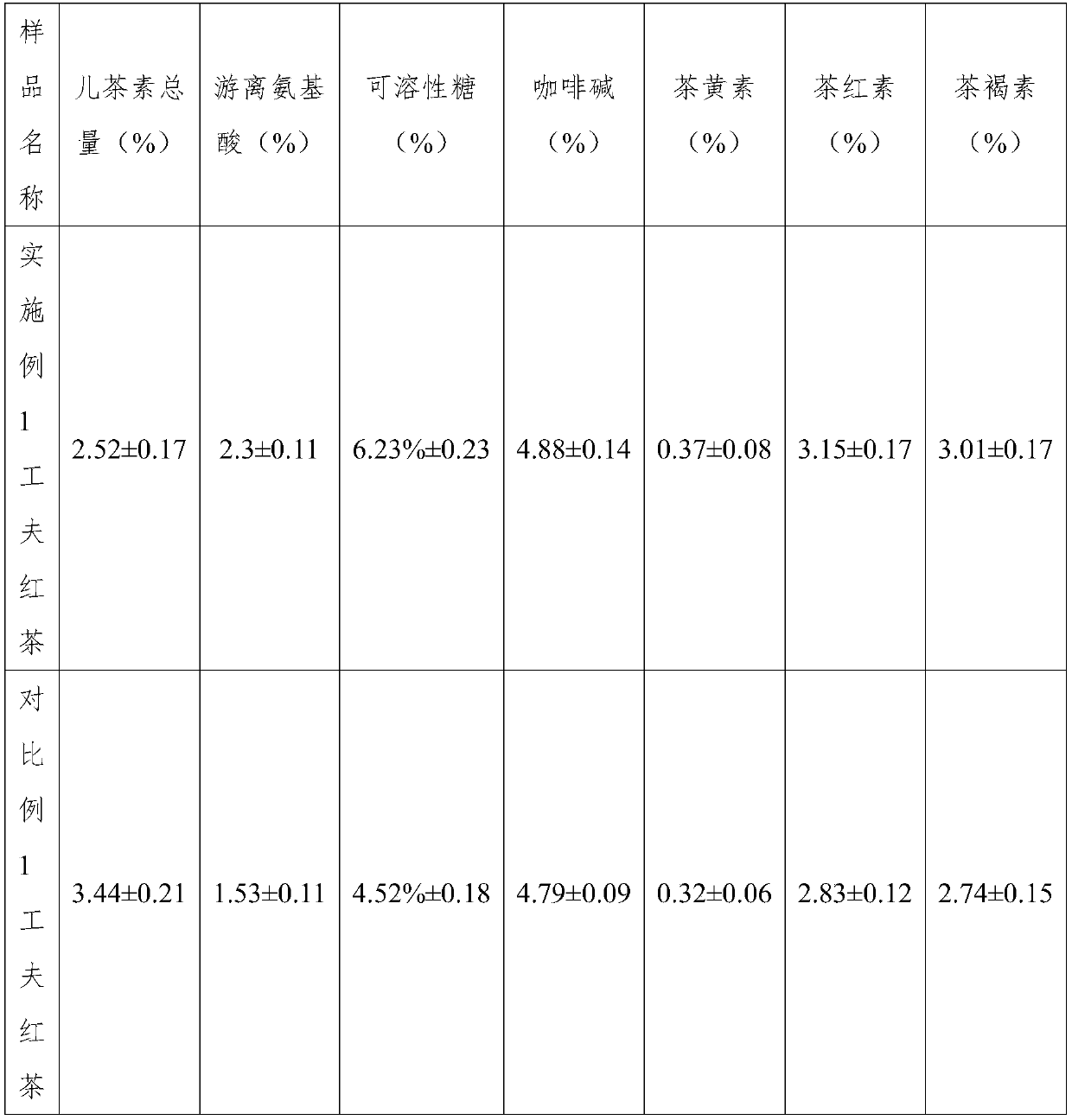

Processing method of congou black tea

ActiveCN111513149AIncrease the sweetness of the tastePromote conversionPre-extraction tea treatmentTea catechinSugar

The invention relates to a processing method of congou black tea. The method comprises the following steps: (1) temperature-controlled withering: carrying out low-temperature treatment and high-temperature treatment on fresh tea leaves into two stages at 15-30 DEG C to obtain withered leaves with a water content reduced to 55-59%; 2) low-temperature rolling: gradually performing pressurizing rolling and reduced-pressure rolling according to a light-heavy-light principle at 16-18 DEG C; 3) variable-temperature fermentation: putting the tea leaves into a fermentation machine, and performing high-temperature fermentation and then low-temperature fermentation under a condition that the humidity is 90% or and the temperature is 25-45 DEG C; 4) high-temperature short baking: reducing the water content of the tea leaves to 10-15%; 5) after-ripening alcoholization: performing high-low temperature alternate treatment at a temperature from -4 to 30 DEG C, and 6) low-temperature long-time baking:baking the tea leaves at 75 to 80 DEG C. According to the method, the taste sweetness of the congou black tea can be improved by reducing astringent substances such as catechinic acid and effectivelyretaining sweet substances such as soluble sugar and amino acid in the tea leaves.

Owner:湖南省茶叶研究所

Method

ActiveUS8163317B2More browningAvoid the Maillard reactionMilk preparationFruit and vegetables preservationMaillard reactionEnzyme

Owner:DUPONT NUTRITION BIOSCIENCES APS

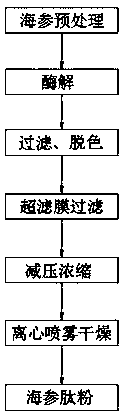

Method for decolorizing sea cucumber peptide powder by membrane filtration technology

InactiveCN109628540AReduce Maillard reactionTo achieve the purpose of decolorizationPeptide preparation methodsFermentationMaillard reactionUltrafiltration

The invention belongs to the technical field of physical engineering, in particular to a method for decolorizing sea cucumber peptide powder by a membrane filtration technology. The method includes the following steps of sea cucumber pretreatment, enzymolysis, filtration, decolorization, ultrafiltration membrane filtration, decompression concentration, spray drying and the like. By enzymolysis, filtration, decolorization, ultrafiltration membrane filtration and the other steps, the maillard reaction in the production process of the sea cucumber peptide powder can be effectively reduced, some pigment molecules are intercepted, and thus the purpose of decolorizing sea cucumber peptide powder is achieved.

Owner:WEIHAI YUWANG GRP MARINE BIOLOGICAL ENGCO

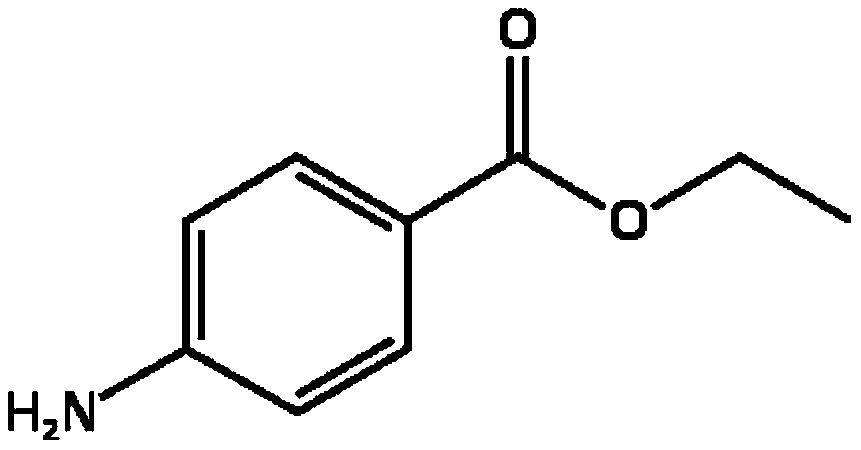

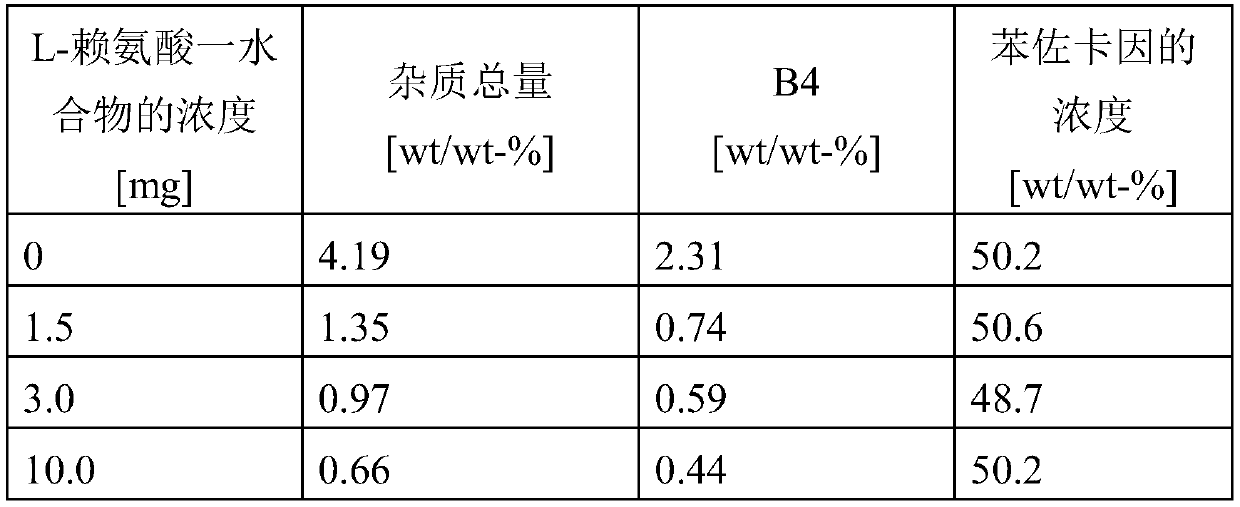

Pharmaceutical composition comprising benzocaine with enhanced stability

InactiveCN109833303AReduce Maillard reactionOrganic active ingredientsSenses disorderMaillard reactionActive agent

The invention provides a pharmaceutical composition comprising benzocaine with enhanced stability. Disclosed is a pharmaceutical formulation comprising benzocaine, a pharmaceutically acceptable salt or derivative thereof as a pharmaceutically active agent comprising at least one nucleophilic amino group, a reducing sugar, an excipient, and an amino acid as a stabilizing agent with at least one free amino group, wherein the stabilizing agent reacts with the reducing sugar in order to at least substantially reduce the Maillard reaction between the at least one nucleophilic amino group of the pharmaceutically active agent with the reducing sugar.

Owner:MEDICE ARZNEIMITTEL PUTTER

Method for controlling Maillard reaction of honey

PendingCN113693220ALower protein contentReduce contentFood preservationFiltration circuitsBiotechnologyMaillard reaction

The invention discloses a method for controlling a Maillard reaction of honey. The method comprises the following steps of: collecting fresh honey, heating the honey, and carrying out ultrasonic filtration to remove particulate matters and suspended matters in the honey to obtain original honey for later use; placing the original honey into an ultrafiltration device, pressurizing, carrying out primary ultrafiltration membrane filtration, and filling filtrate obtained after filtering into a next-stage ultrafiltration device to carry out secondary ultrafiltration membrane filtration so as to obtain filtrate; placing the filtrate in a sealed tank body, keeping the tank body in a low-temperature environment for a period of time, when the filtrate flows slowly, placing the whole tank body between an N pole and an S pole in a magnetic sterilization container, keeping rotating, starting up the magnetic sterilization container, and performing magnetic sterilization on the filtrate by using a magnetic force; and taking out the sterilized filtrate, and placing the filtrate at the room temperature until the filtrate is recovered into the flowing state. According to the method disclosed by the invention, the Maillard reaction in the honey is greatly reduced by reducing the protein in the honey, and meanwhile, the original flavor is kept.

Owner:广西蜜博士蜂业有限责任公司

A kind of fuel ethanol production method based on high-quality ddgs product

ActiveCN109971616BWeaken the solid phase Maillard reactionReduce Maillard reactionBioreactor/fermenter combinationsBiological substance pretreatmentsReboilerProcess engineering

The invention belongs to the technical field of biomass energy production, and discloses a fuel ethanol production method based on high-quality DDGS products. unit, the solid phase is recovered, and DDGS products are produced; the top steam of the second refining tower is heated and pressurized by the compressor, and the vapor-liquid equilibrium temperature of the obtained pressurized reflux steam of the second refining tower is higher than the operating temperature of the crude tower tower kettle, and is used as a heating element. The medium is sent to the reboiler of the coarse tower; the top steam of the second purification tower is heated and pressurized by the compressor, and the pressurized adsorption steam of the second purification tower is superheated steam, which does not need preheating operation, and is directly sent to the adsorber A or adsorption unit of the adsorption unit. Device B performs adsorption dehydration operation to obtain fuel ethanol product. This technical solution solves the problems faced by the current mainstream production process of fuel ethanol, such as fermentation mash, waste mash and other solid-containing materials with high heating temperature, reboilers and trays and other equipment are prone to scarring, production is unstable, and affects the quality of DDGS products and other industries. problem.

Owner:TIANJIN UNIV

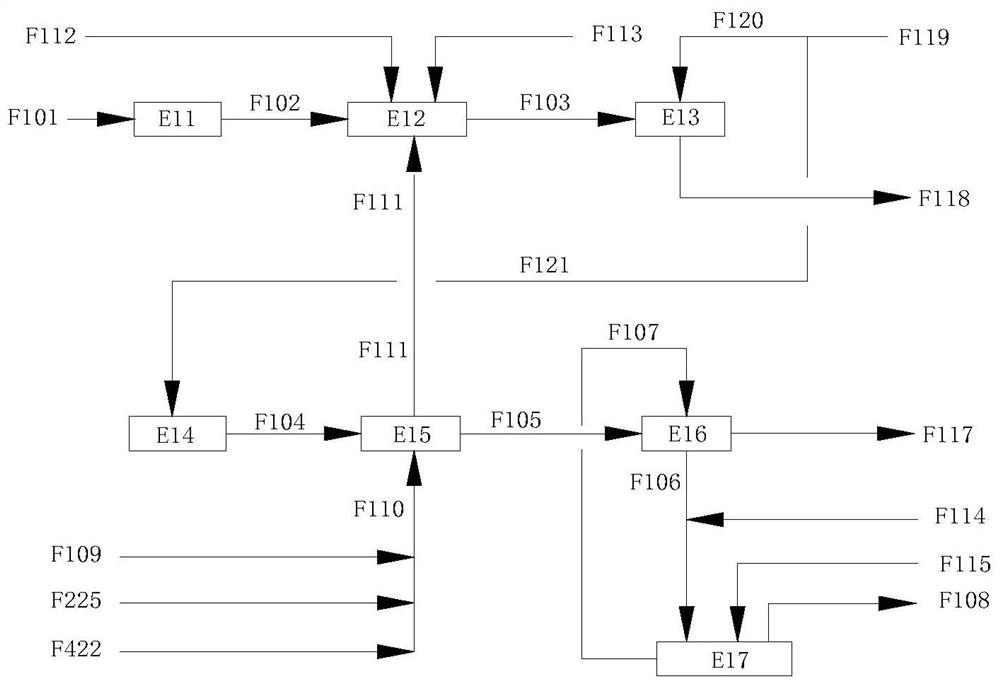

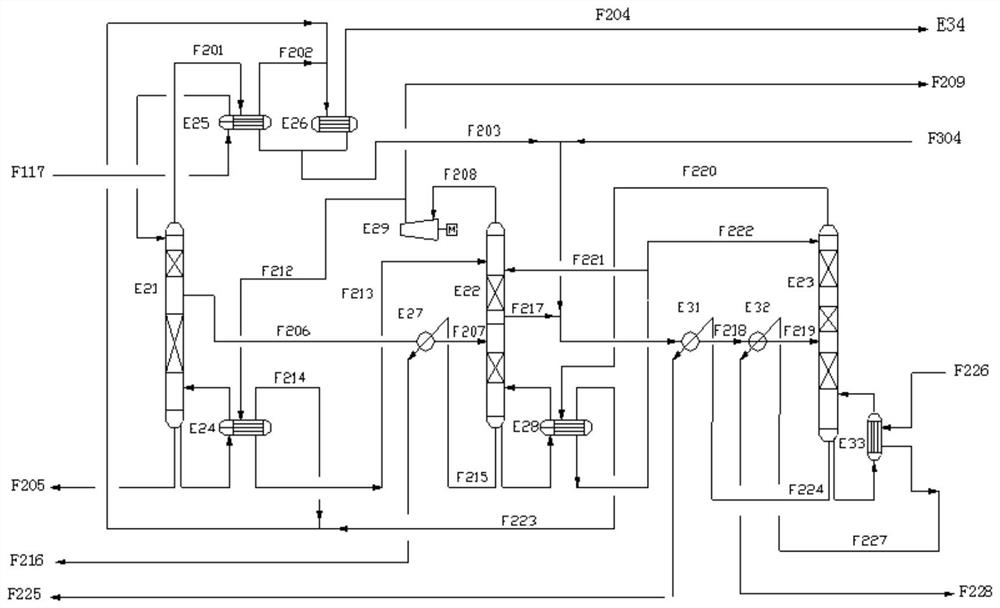

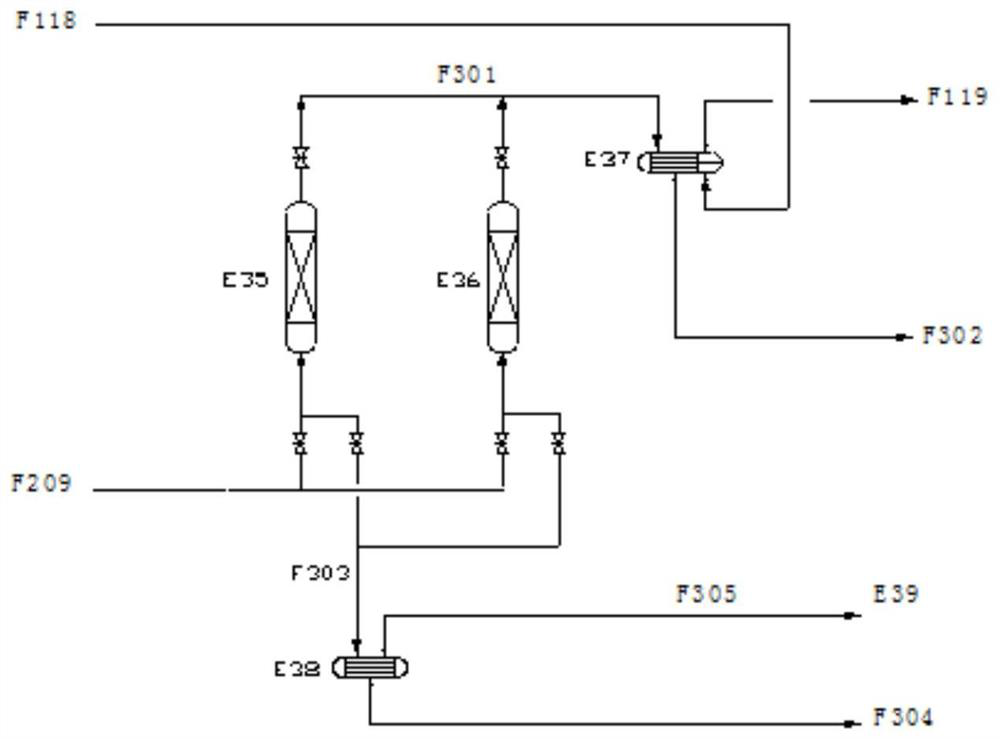

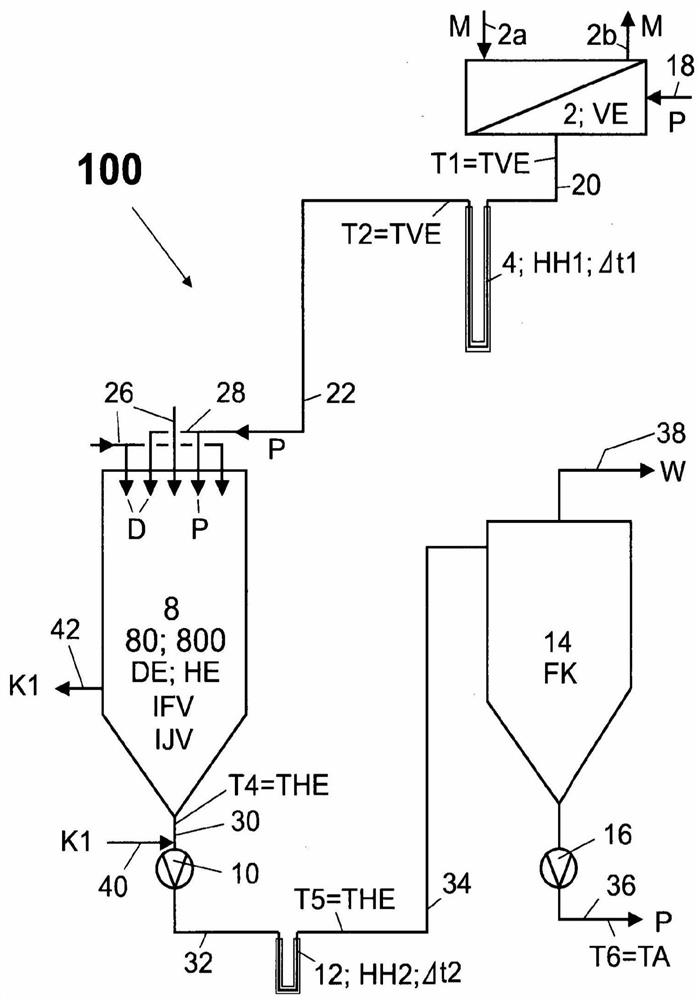

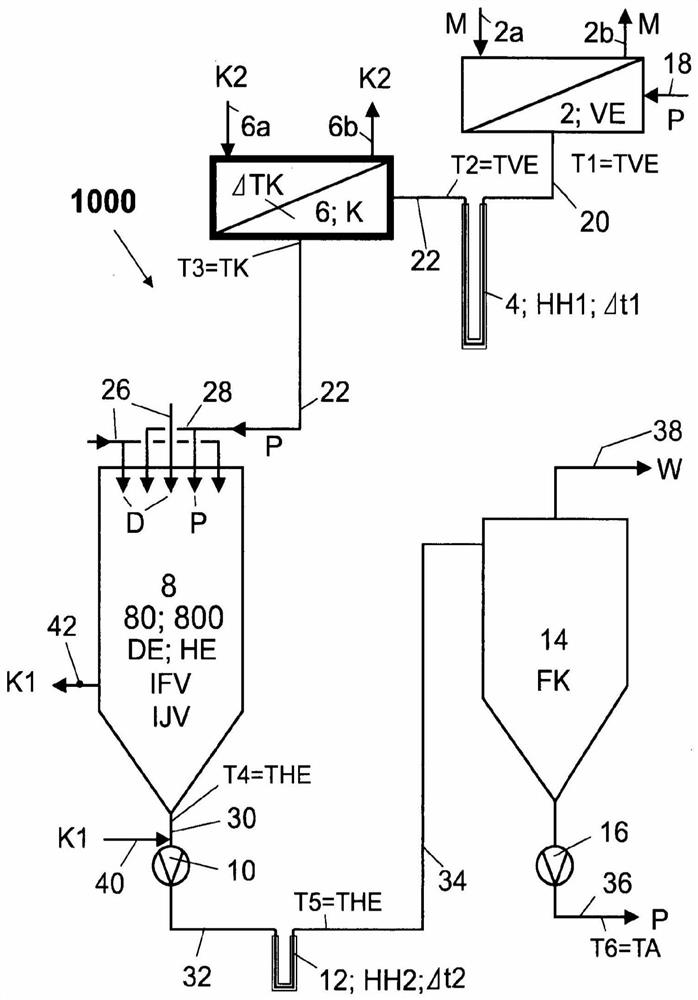

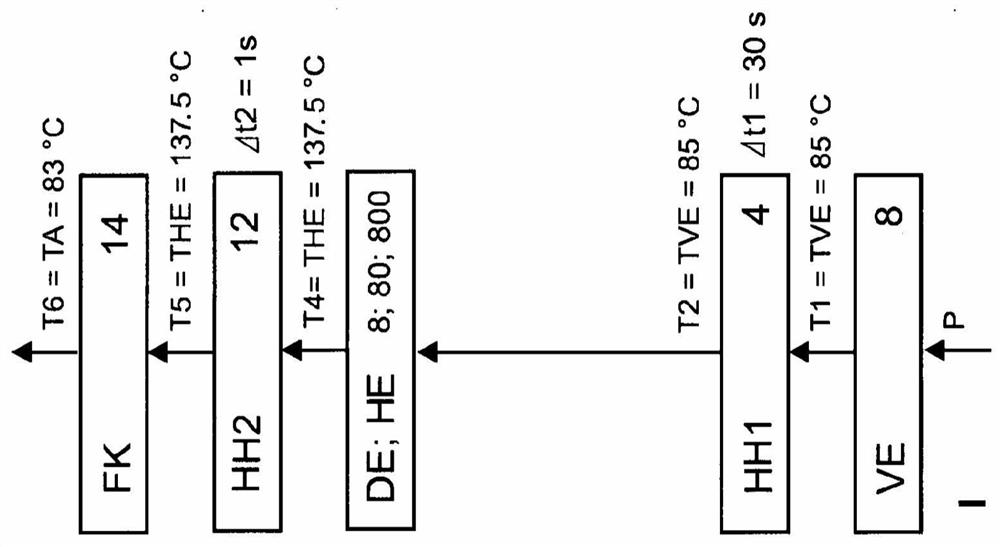

Method and apparatus for directly heating protein-rich dairy product by introducing water vapor into said dairy product

The invention relates to a method and an apparatus 1000 for directly heating DE a protein-rich dairy product P by introducing water vapor D into the dairy product P, where the directly heated DE is configured in the form of an immersion or injection IFV or UV. The aim of the invention is to implement a method of said type and a device for carrying out said method, the method and apparatus achieve a significant extension of use time during the process or in the apparatus and here ensure that a higher undenatured whey protein content is achieved in the treated protein-rich dairy product compared to the prior art. According to the method technology, the aim is achieved in that, prior to direct heating (DE), a cooling step by co-flow heat exchange is carried out from the preheating temperature (TVE) to the cooling temperature (TK) in the range ([Delta] TKlt; (5 to 15) K), indirectly cooling (K) the preheated and insulated dairy product (P); controlling the direct heating from a cooling temperature (TK) to a high heating temperature (THE) with a direct heating adjustment parameter known per se; and cooling the dairy product (P) from the high heating temperature (THE) to the forcibly necessary output temperature (TA) by rapid cooling (K) after the measure of the feature (d).

Owner:GEA TDS

Making technology of yellow wine loaded in oak buckets

InactiveCN110229736AReduce browningReduce Maillard reactionAlcoholic beverage preparationFlavorUltrafiltration

The invention discloses a making technology of yellow wine loaded in oak buckets. The making technology comprises the following production steps of step I, taking a yellow wine base produced by usingpolished glutinous rice as a raw material for standby application, adding a coagulant aid to the yellow wine base, performing stirring at the same time to obtain a solution, then placing the solutionin environment of minus 5 DEG C, performing freezing for 22-26h, and then taking out the frozen solution; step II, firstly performing fine filtration on the yellow wine base taken out in the step I, then performing ultrafiltration, then putting the yellow wine base after ultrafiltration in oak buckets, and performing ageing for the time being 90-120d; step III, taking out the aged yellow wine in the step II, performing blending, and performing inspection; step IV, filtering the yellow wine obtained in the step III through a yellow wine filter; and step V, stably storing the filtered yellow wine, and instantaneously heating the wine to 82-90 DEG C through a special sterilizing system for sterilization. According to the making technology disclosed by the invention, after the yellow wine is aged through the oak buckets, peculiar flavor is formed, the color of a wine body can maintain pale golden, and vinosity is mellow, comfortable, smooth and harmonious.

Owner:广东明珠珍珠红酒业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com