Method for decolorizing sea cucumber peptide powder by membrane filtration technology

A technology of sea cucumber peptide powder and membrane filtration, applied in the field of physical engineering, can solve problems such as affecting product quality, and achieve the effect of reducing Maillard reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

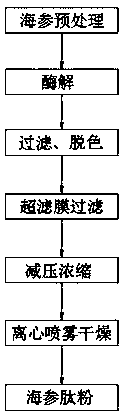

[0020] see figure 1 A method for decolorizing sea cucumber peptide powder using membrane filtration technology, comprising the steps of:

[0021] S1. Sea cucumber pretreatment: cut 1 kg of fresh sea cucumber with scissors to remove internal organs, chop the sea cucumber skin and grind it into a slurry;

[0022] S2. Enzymolysis: add 0.4% alkaline protease, 0.5% neutral protease; 0.2% flavor enzyme by weight of solids in the extract, and enzymolyze at 50°C-55°C for 4 hours;

[0023] S3. Filtration and decolorization: use diatomaceous earth and activated carbon to decolorize the raw materials;

[0024] S4, ultrafiltration membrane filtration: Utilize ultrafiltration membrane to decolorize and filter;

[0025] S5. Concentration under reduced pressure: use a double-effect concentrator to concentrate the enzymatic solution to a solid content of 30%-40%;

[0026] S6. Spray drying: control the inlet temperature at 160°C-190°C, the outlet air temperature at 90°C-100°C, and the feed ...

Embodiment 2

[0028] see figure 1 A method for decolorizing sea cucumber peptide powder using membrane filtration technology, comprising the steps of:

[0029] S1. Sea cucumber pretreatment: cut 1 kg of fresh sea cucumber with scissors to remove internal organs, chop the sea cucumber skin and grind it into a slurry;

[0030] S2. Enzymolysis: add 0.4% alkaline protease, 0.5% neutral protease; 0.2% flavor enzyme by weight of solids in the extract, and enzymolyze at 50°C-55°C for 4 hours;

[0031] S3. Filtration and decolorization: use diatomaceous earth and activated carbon to decolorize the raw materials;

[0032] S4, ultrafiltration membrane filtration: Utilize ultrafiltration membrane to decolorize and filter;

[0033] S5. Concentration under reduced pressure: use a double-effect concentrator to concentrate the enzymatic solution to a solid content of 30%;

[0034] S6. Spray drying: control the temperature of the feed inlet to 160°C, the temperature of the outlet air to 90°C, and the fe...

Embodiment 3

[0036] see figure 1 A method for decolorizing sea cucumber peptide powder using membrane filtration technology, comprising the steps of:

[0037] S1. Sea cucumber pretreatment: cut 1 kg of fresh sea cucumber with scissors to remove internal organs, chop the sea cucumber skin and grind it into a slurry;

[0038] S2. Enzymolysis: add 0.4% alkaline protease, 0.5% neutral protease; 0.2% flavor enzyme by weight of solids in the extract, and enzymolyze at 50°C-55°C for 4 hours;

[0039] S3. Filtration and decolorization: use diatomaceous earth and activated carbon to decolorize the raw materials;

[0040] S4, ultrafiltration membrane filtration: Utilize ultrafiltration membrane to decolorize and filter;

[0041] S5. Concentration under reduced pressure: use a double-effect concentrator to concentrate the enzymatic solution to a solid content of 40%;

[0042] S6. Spray drying: control the temperature of the feed inlet to 190°C, the temperature of the outlet air to 100°C, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com