A kind of fuel ethanol production method based on high-quality ddgs product

A technology of fuel ethanol and DDGS, which is applied in the fields of biochemical equipment and methods, biofuels, liquid production bioreactors, etc., can solve the problems of uneconomical latent heat, influence, loss of nutrients, etc., and achieve the effect of good industrial application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

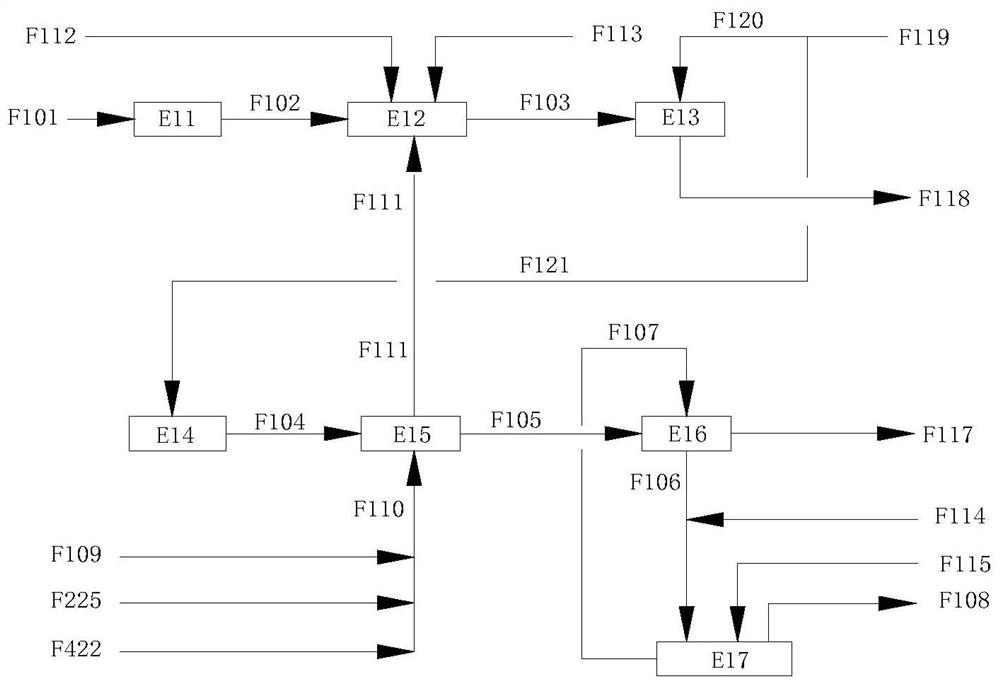

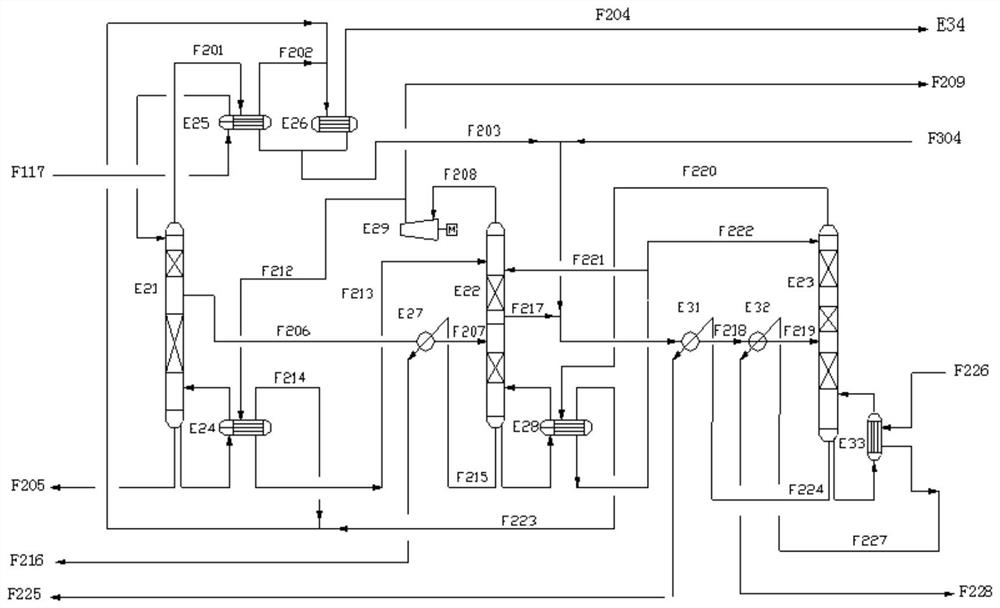

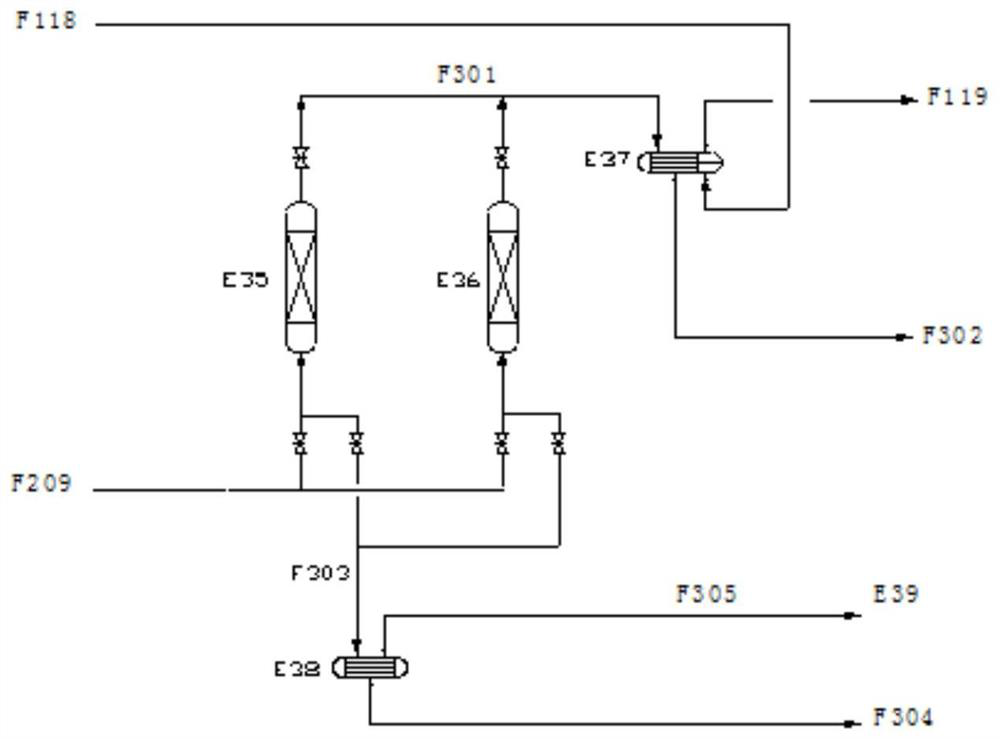

[0127] Using wheat as raw material to produce fuel ethanol products and DDGS products, the production process mainly includes mash preparation unit, rectification unit, adsorption dehydration unit and waste mash treatment unit. For the operation process, see figure 1 - Flow chart of mash preparation unit, figure 2 - Rectification unit flow chart, image 3 -Flow chart of adsorption dehydration unit, Figure 4 - Flow chart of spent mash treatment unit, and figure 1 , figure 2 , image 3 and Figure 4 The marking numbers and names of the equipment involved in . The production implementation is described as follows:

[0128] 1. Mash preparation unit

[0129] Prepare slurries. The wheat raw material F101 is sent to the pulverizer E11 for pulverization, the pulverized material F102 is sent to the mixer E12, and the preheated mixing water F111, the liquefaction enzyme F112 and the nutrient salt ammonia water F113 are added at the same time, and the powder slurry F103 is obt...

Embodiment 2

[0156] Using rice and cassava mixed raw materials to produce fuel ethanol products and DDGS products, the production process mainly includes mash preparation unit, rectification unit, adsorption dehydration unit and waste mash treatment unit. For the operation process, see figure 1 - Flow chart of mash preparation unit, figure 2 - Rectification unit flow chart, image 3 -Flow chart of adsorption dehydration unit, Figure 4 - Flow chart of spent mash treatment unit, and figure 1 , figure 2 , image 3 and Figure 4 The marking numbers and names of the equipment involved in . The production implementation is described as follows:

[0157] 1. Mash preparation unit

[0158] Prepare slurries. The mixed raw material F101 of rice and cassava is sent to the pulverizer E11 to be pulverized, the pulverized material F102 is sent to the mixer E12, and the preheated mixing water F111, the liquefaction enzyme F112 and the nutrient salt ammonia water F113 are added at the same time,...

Embodiment 3

[0186] Using corn as raw material to produce fuel ethanol products and DDGS products, the production process mainly includes mash preparation unit, rectification unit, adsorption dehydration unit and waste mash treatment unit. figure 1 - Flow chart of mash preparation unit, figure 2 - Rectification unit flow chart, image 3 -Flow chart of adsorption dehydration unit, Figure 4 - Flow chart of spent mash treatment unit, and figure 1 , figure 2 , image 3 and Figure 4 The marking numbers and names of the equipment involved in . The production implementation is described as follows:

[0187] 1. Mash preparation unit

[0188] Prepare slurries. The corn raw material F101 is sent to the pulverizer E11 for pulverization, the pulverized material F102 is sent to the mixer E12, and the preheated mixing water F111, the liquefaction enzyme F112 and the nutrient salt ammonia water F113 are added at the same time, and the slurry F103 is obtained and sent to the mixing tank E13, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com