Patents

Literature

88 results about "Vapor–liquid equilibrium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In thermodynamics and chemical engineering, the vapor–liquid equilibrium (VLE) describes the distribution of a chemical species between the vapor phase and a liquid phase. The concentration of a vapor in contact with its liquid, especially at equilibrium, is often expressed in terms of vapor pressure, which will be a partial pressure (a part of the total gas pressure) if any other gas(es) are present with the vapor. The equilibrium vapor pressure of a liquid is in general strongly dependent on temperature. At vapor–liquid equilibrium, a liquid with individual components in certain concentrations will have an equilibrium vapor in which the concentrations or partial pressures of the vapor components have certain values depending on all of the liquid component concentrations and the temperature. The converse is also true: if a vapor with components at certain concentrations or partial pressures is in vapor–liquid equilibrium with its liquid, then the component concentrations in the liquid will be determined dependent on the vapor concentrations and on the temperature. The equilibrium concentration of each component in the liquid phase is often different from its concentration (or vapor pressure) in the vapor phase, but there is a relationship. The VLE concentration data can be determined experimentally, approximated with the help of theories such as Raoult's law, Dalton's law, and Henry's law.

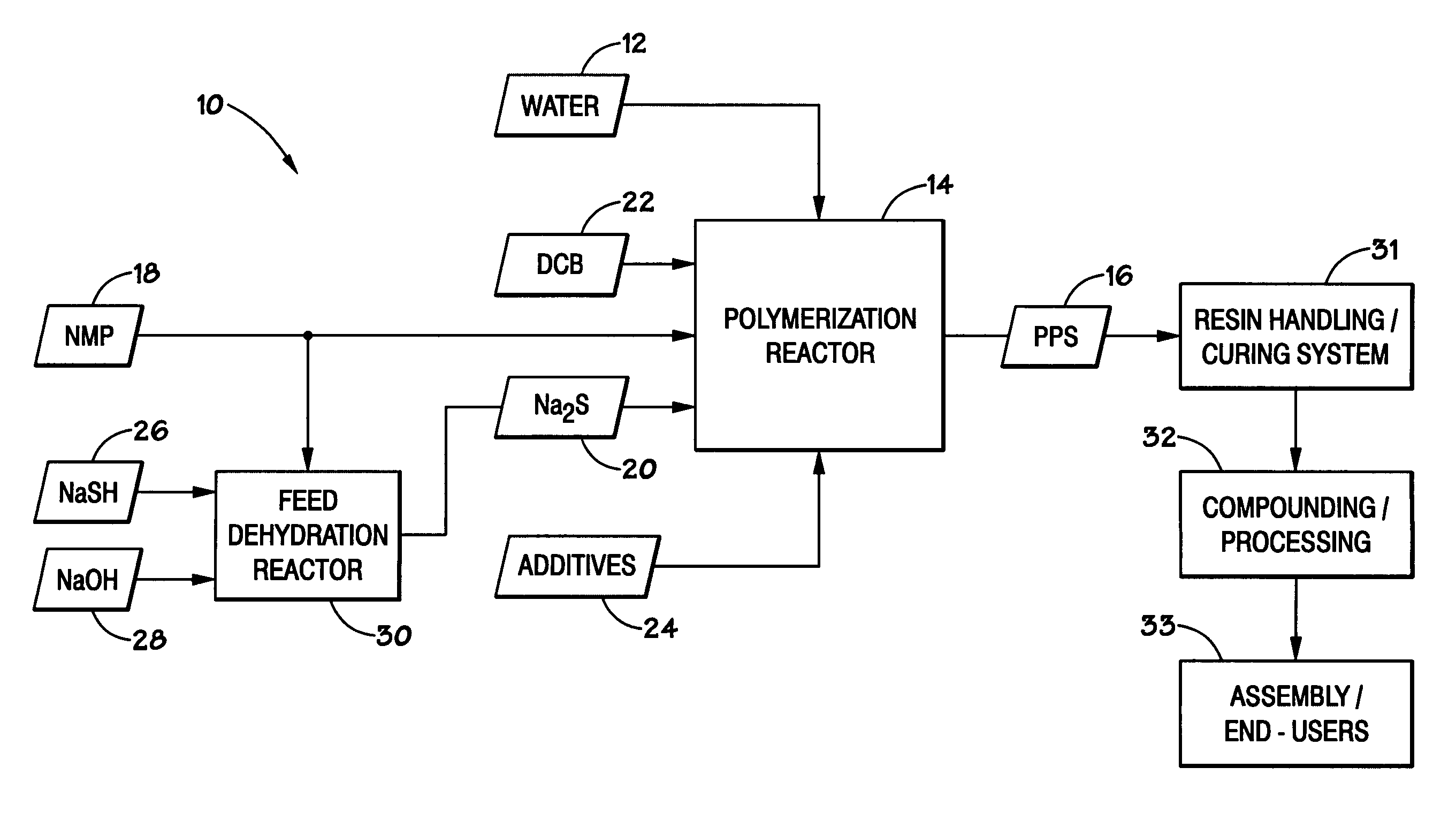

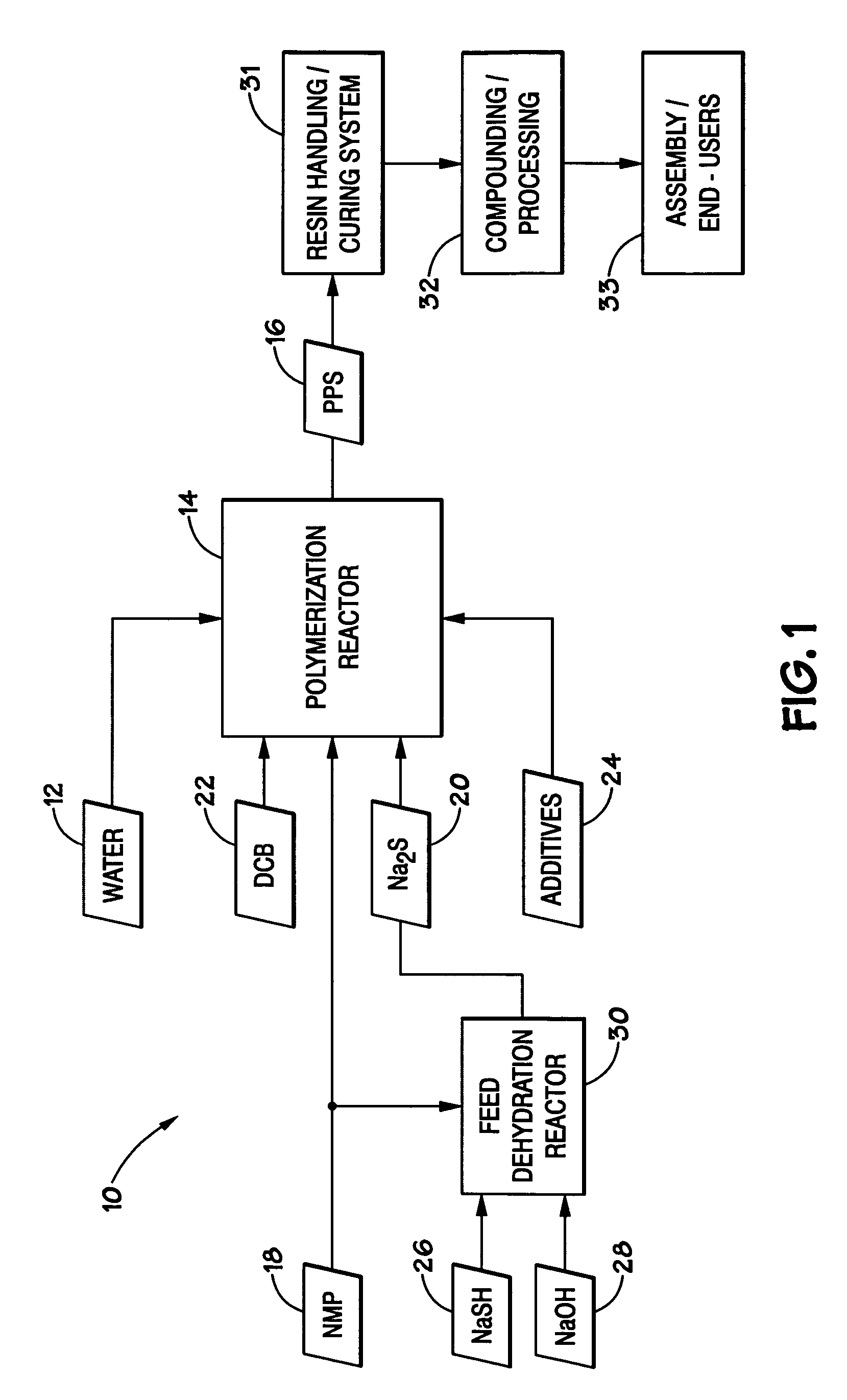

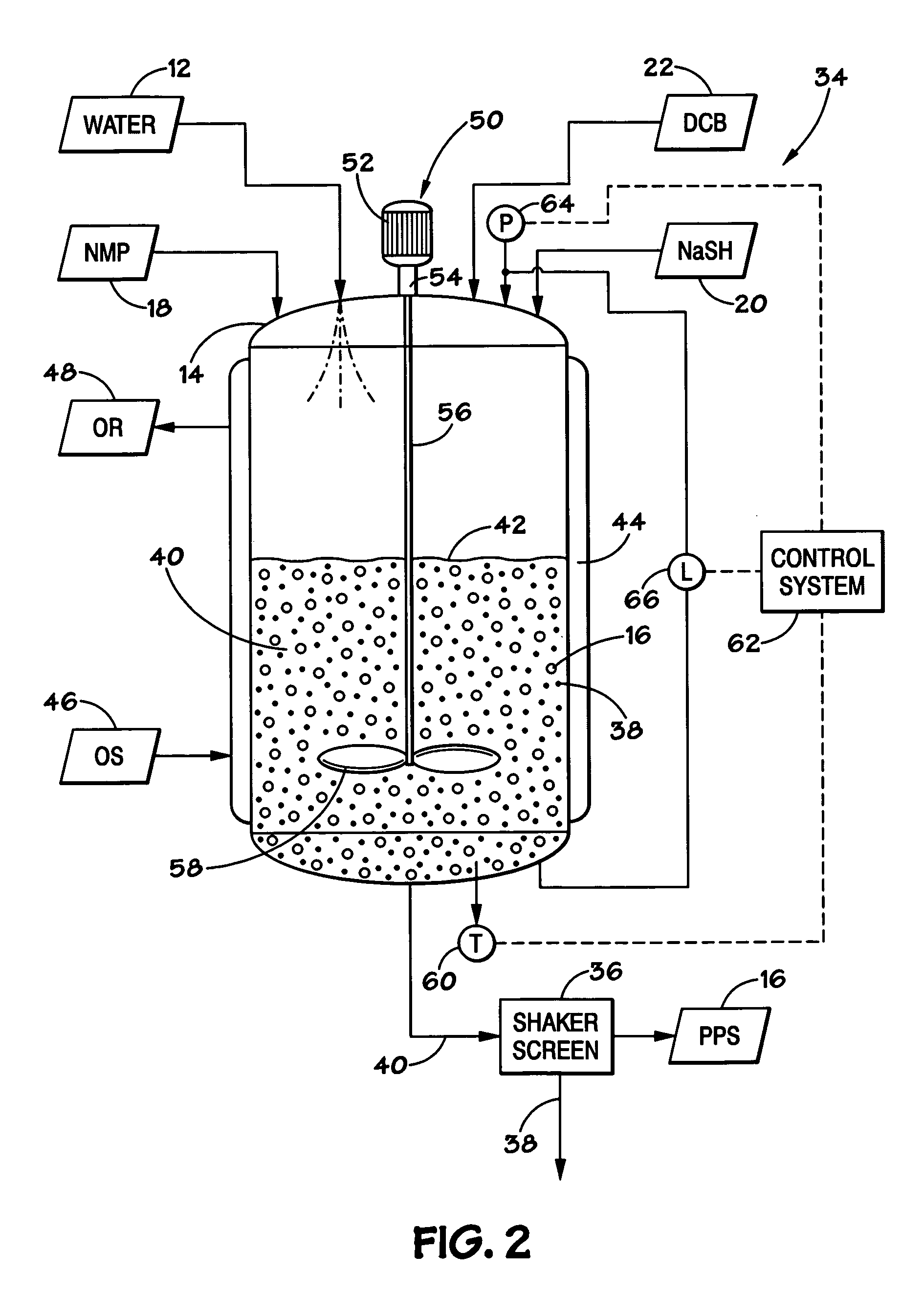

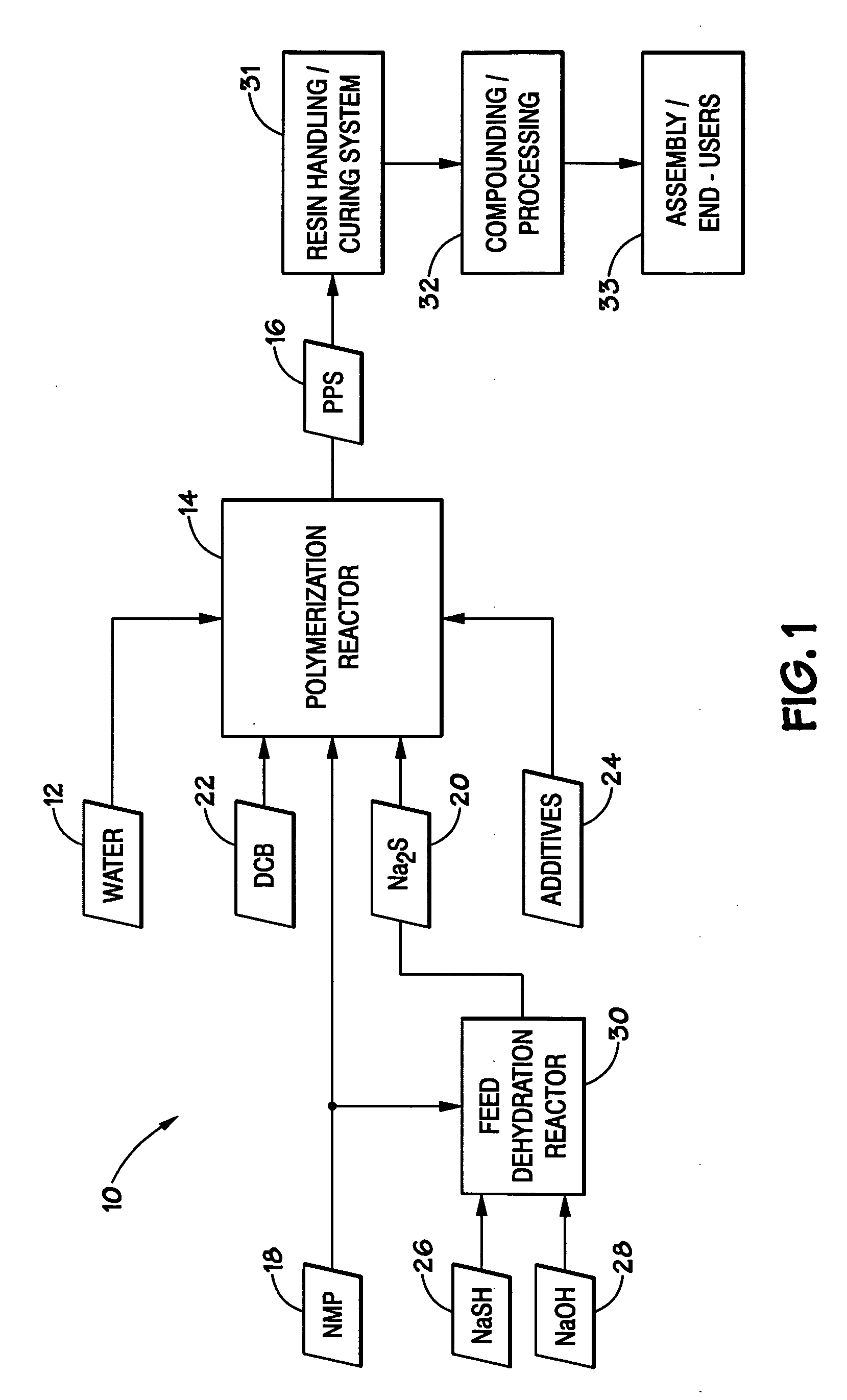

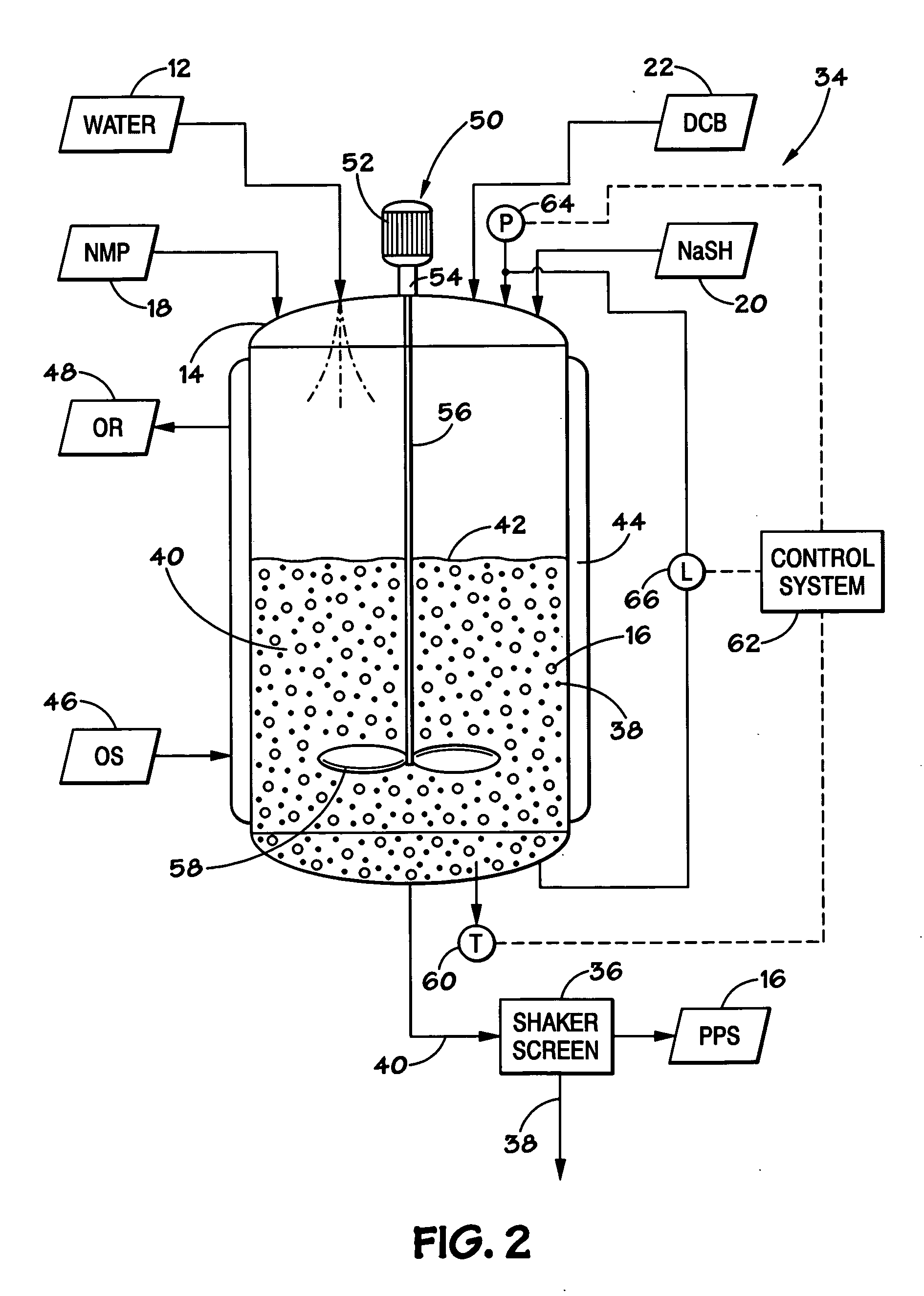

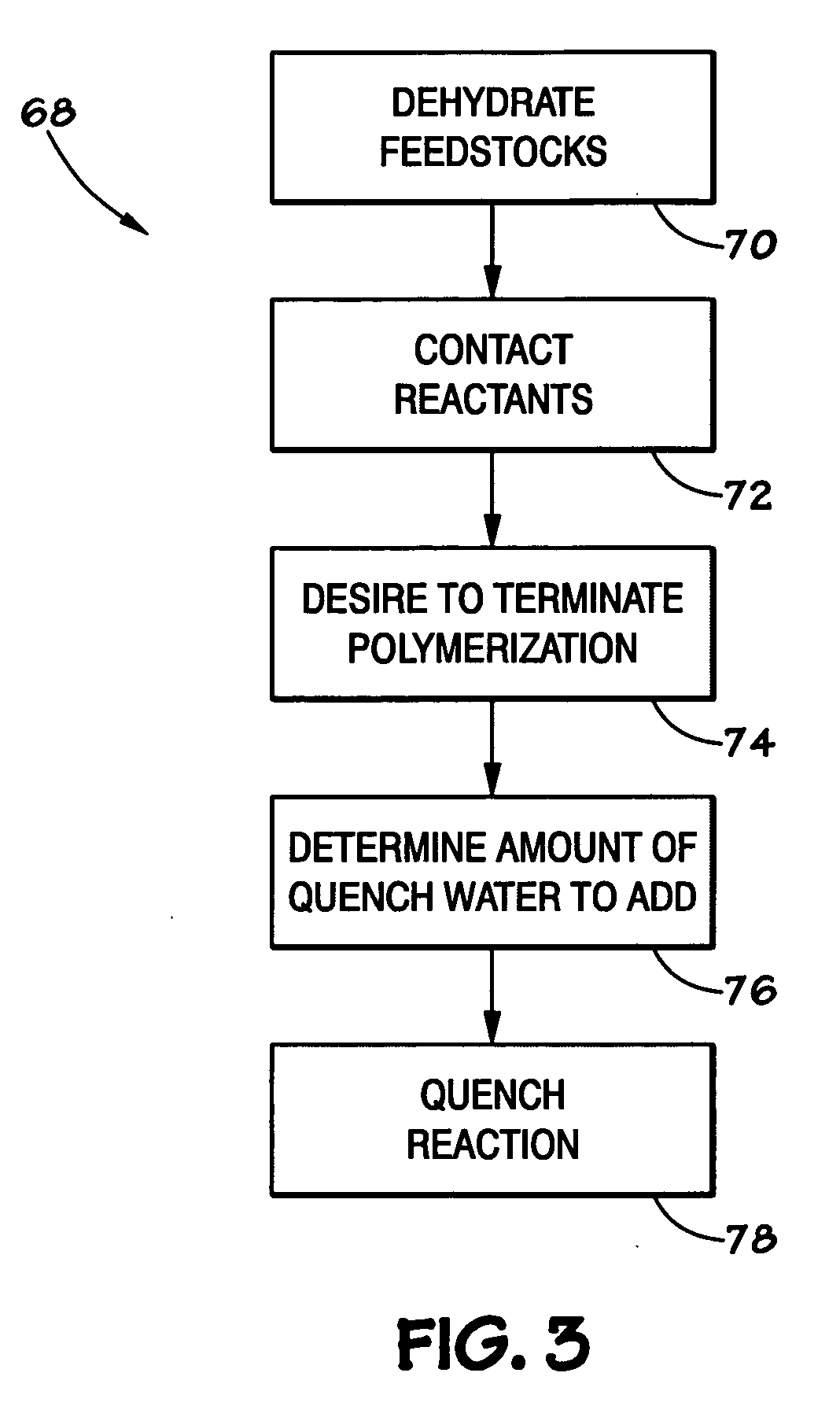

Inferred water analysis in polyphenylene sulfide production

A method for producing polyphenylene sulfide (PPS) polymer, including polymerizing reactants in a reaction mixture in a vessel to form PPS polymer in the vessel, measuring values of operating variables of the vessel and / or PPS process, and determining the amount of quench fluid to add to the vessel based on the values of the operating variables. The technique may rely on the vapor liquid equilibrium (VLE) of the mixture to calculate the concentration of water existing in the reactor prior to quench, and accounts for the effectiveness of the upstream dehydration process and in the amount of water produced during the polymerization. The technique is a striking improvement over the trial-and-error estimation of the amount of quench water based on human operating experience, and avoids direct measurements of the existing water concentration in the reactor. The result is improved control of PPS particle size and other properties.

Owner:SOLVAY SA

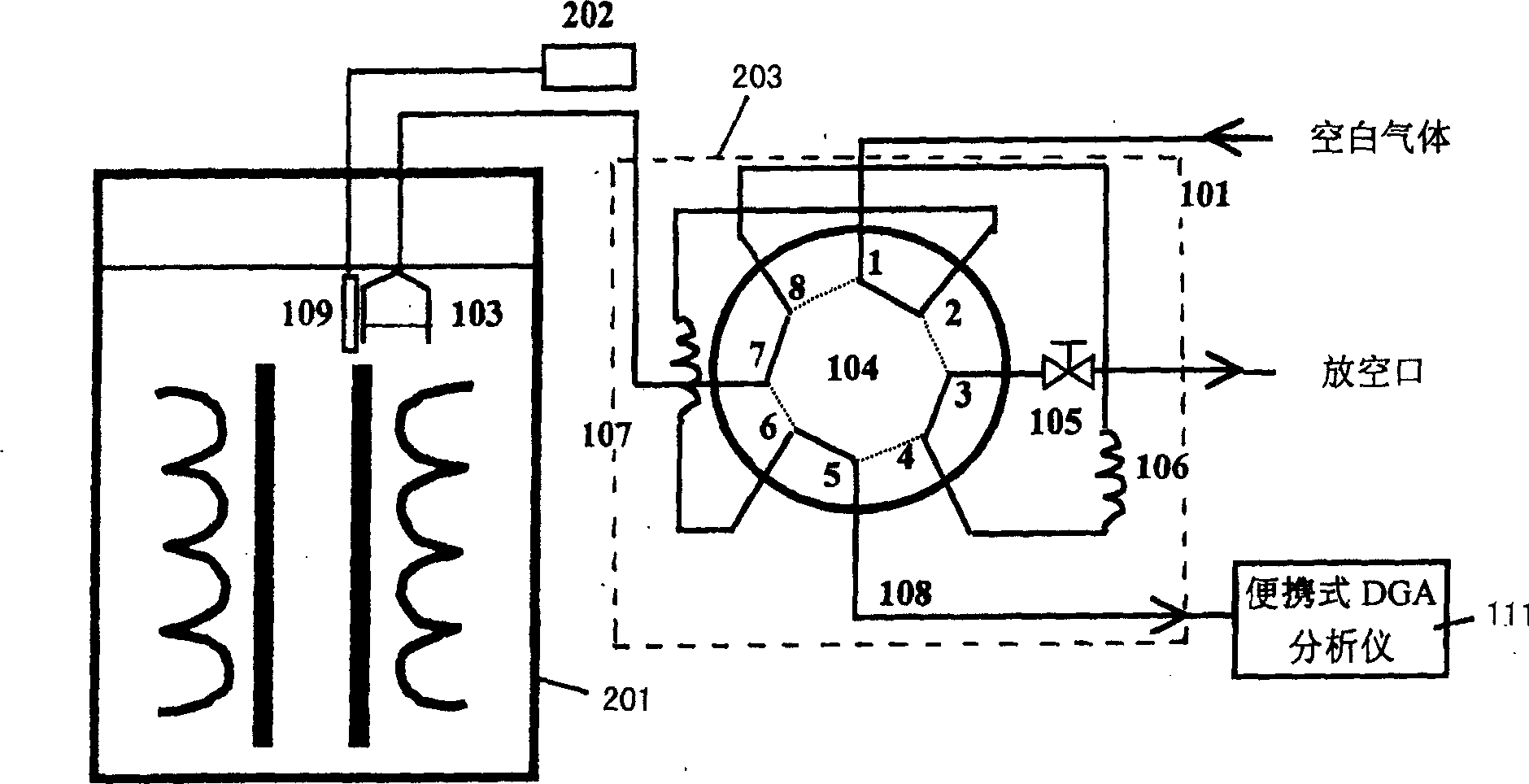

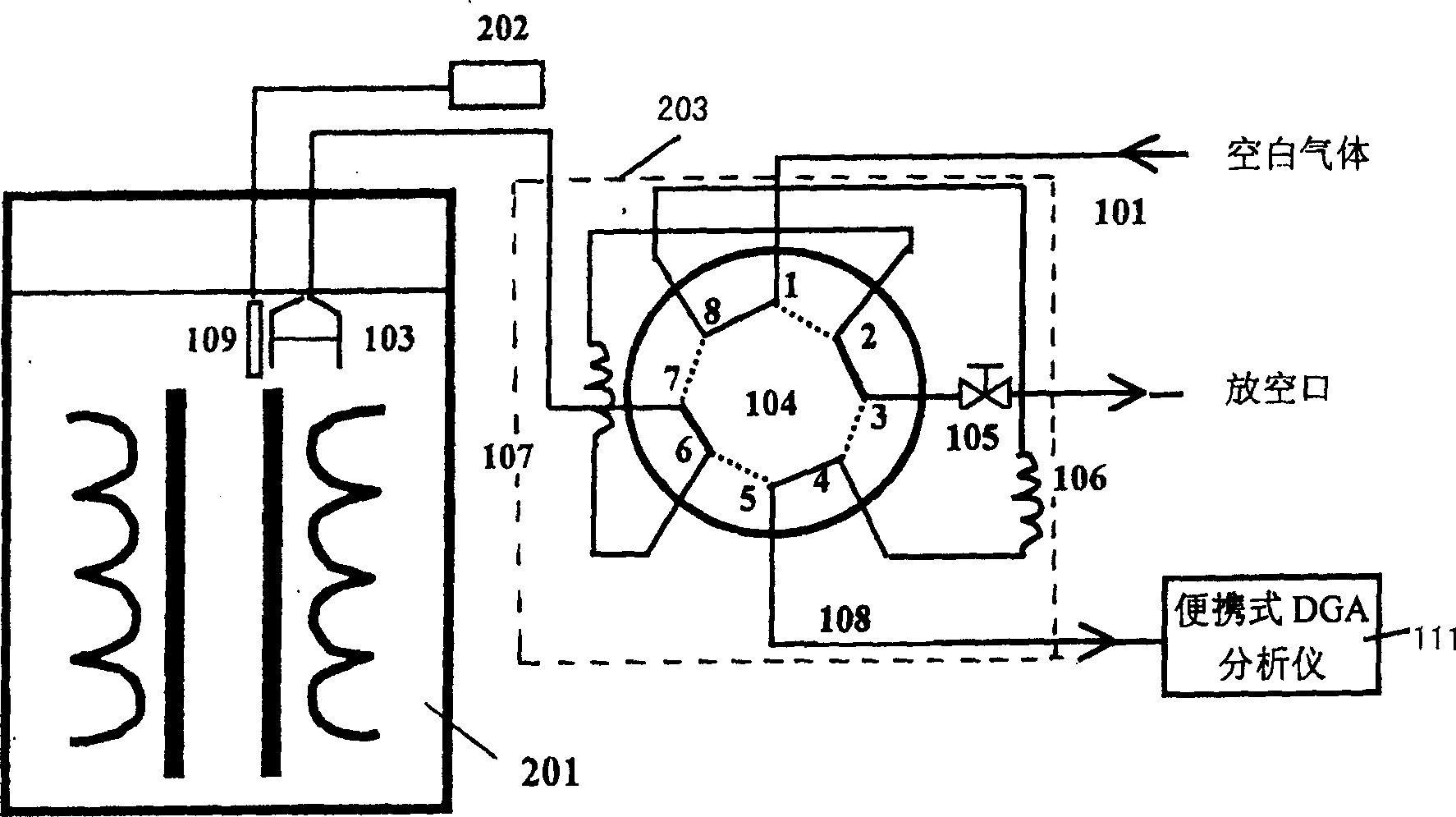

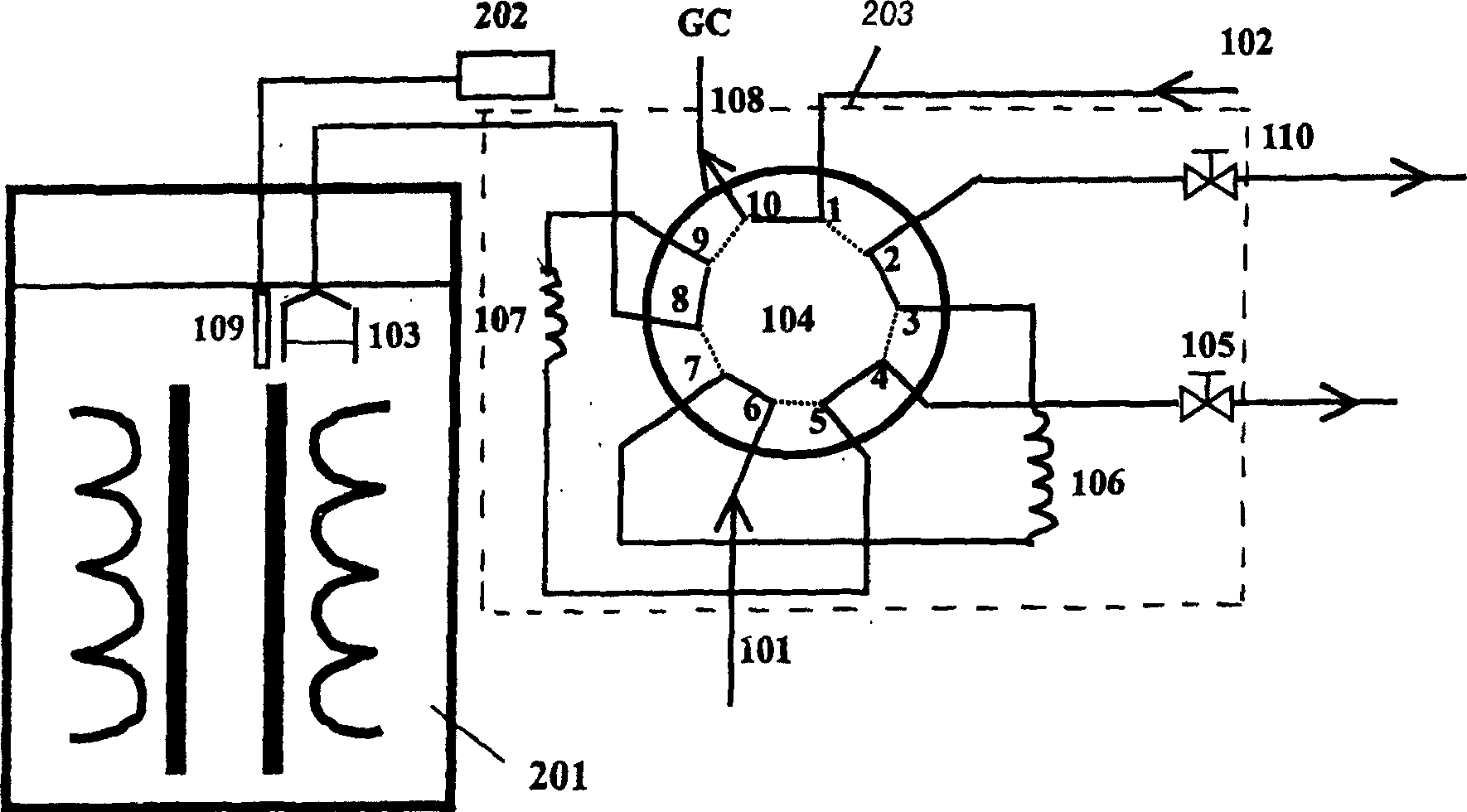

Dissolved gas sampling apparatus and method used in transformer oil gas-chromatography on-line analysis

ActiveCN1721835AGuaranteed volumeGuaranteed repeatabilityWithdrawing sample devicesPreparing sample for investigationGas liquid chromatographicProduct gas

The invention relates to a sampling device and method of gas chromatographic online analysis transformer dissolved gas, which comprises sampling probe, temperature sensor, multi-ported valve, sample quantitative pipe, marginal gas quantitative pipe, cutoff valve and marginal gas regulating system. The method directly inserts sampling probe into transformer oil and presses marginal gas into sampling probe by switching of multi-ported valve; the transformer oil is circulated by oil pump so that the dissolved gas of transformer oil can spill into marginal gas and then it achieves gas-liquid equilibrium in probe.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

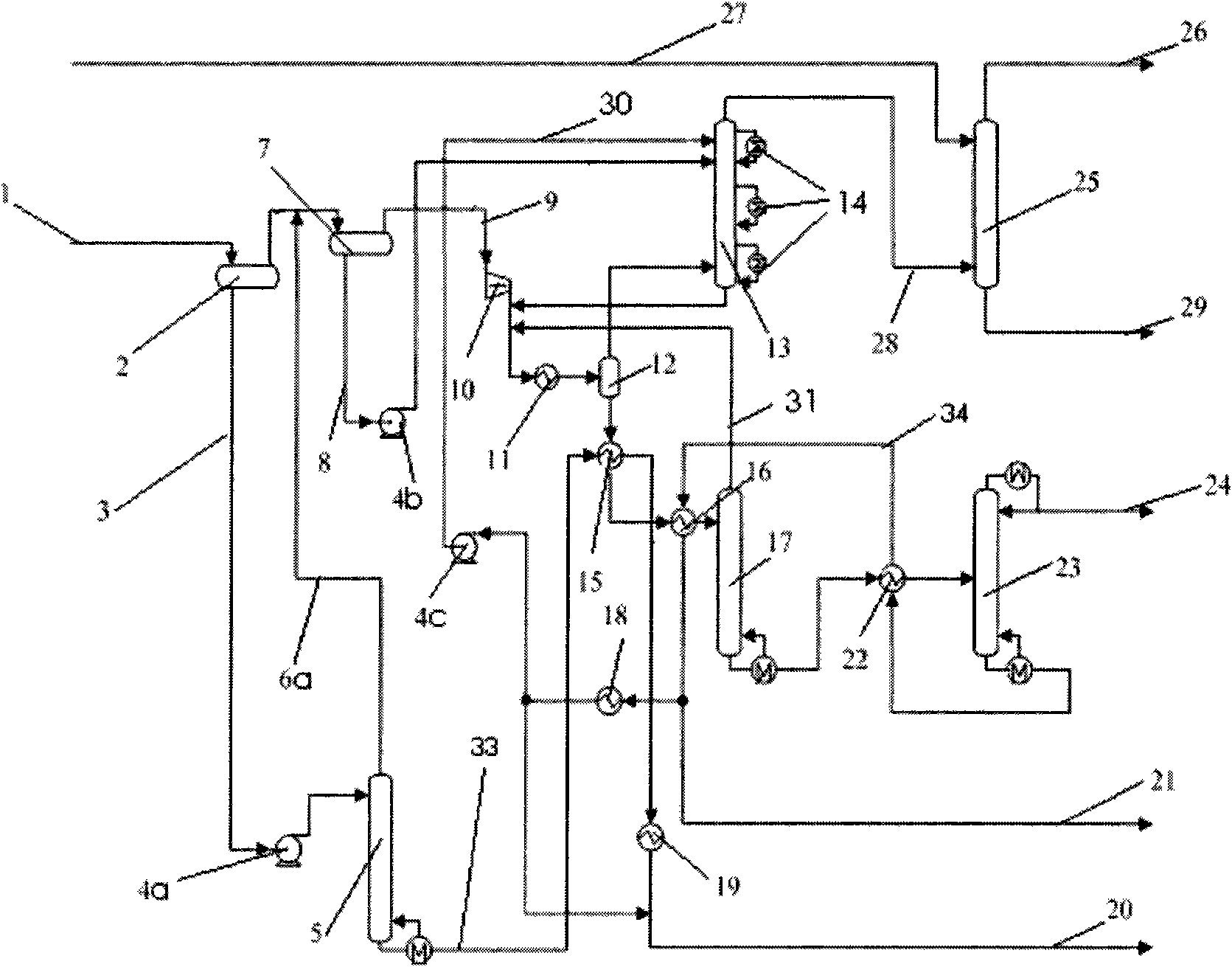

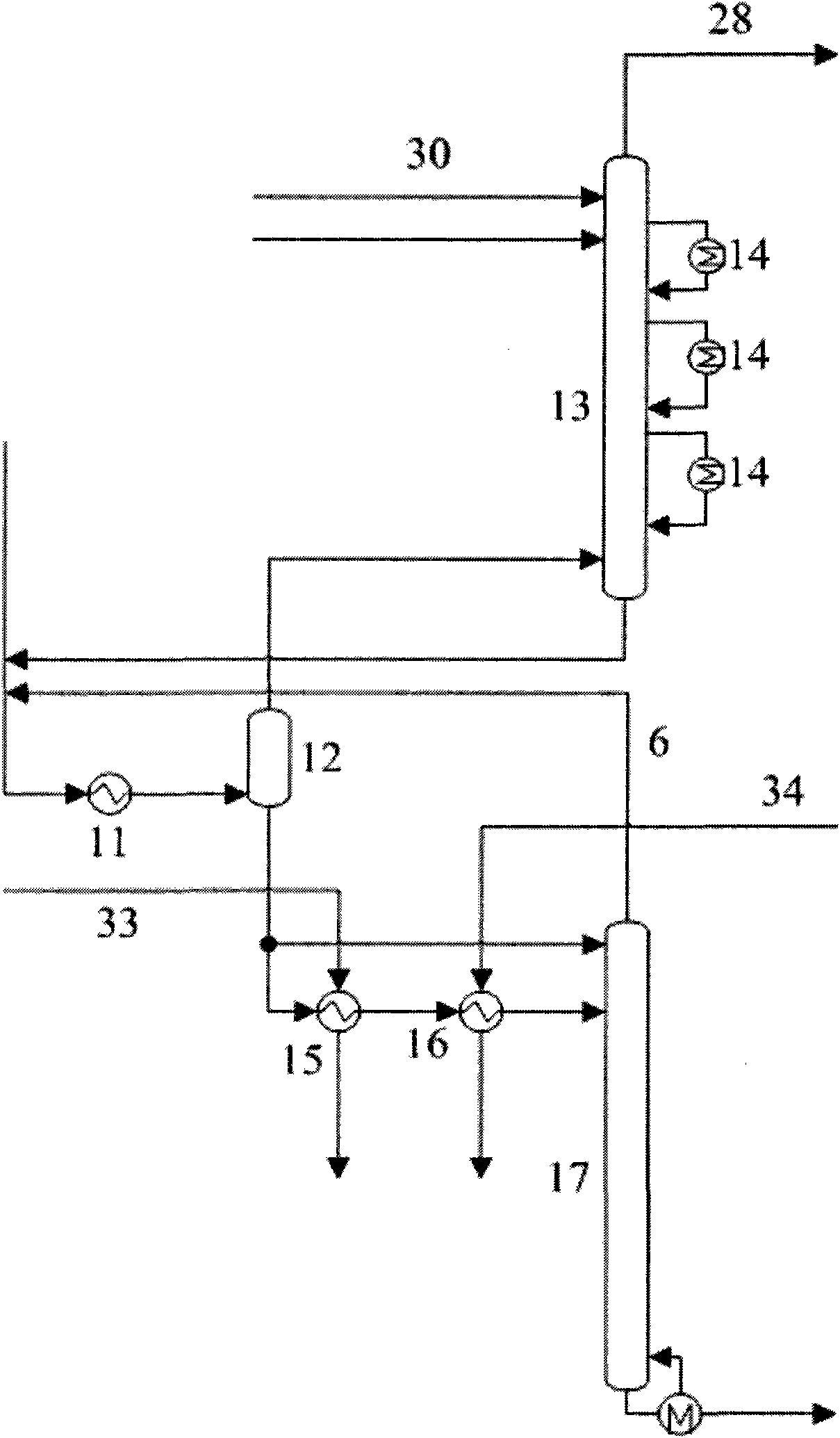

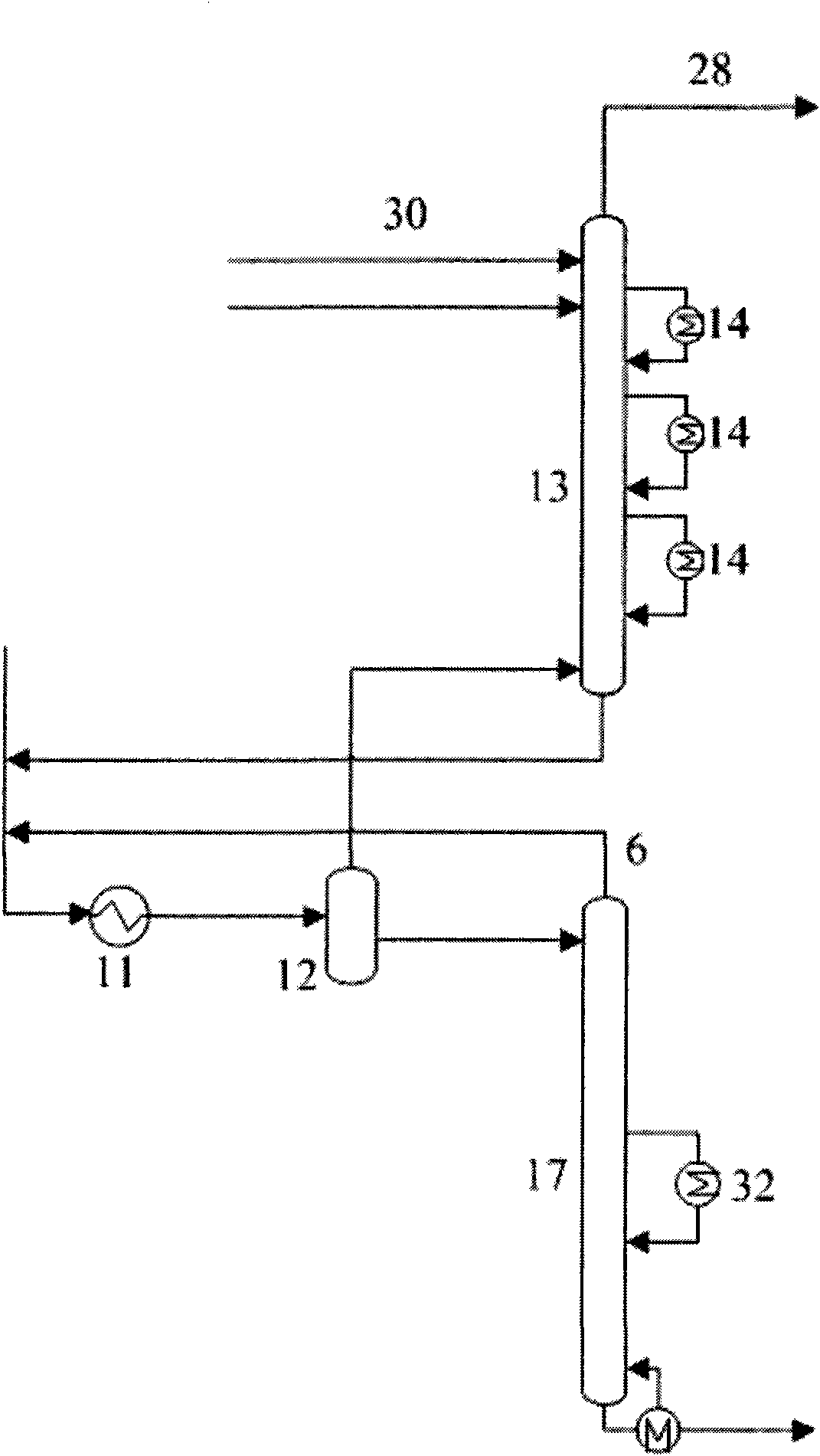

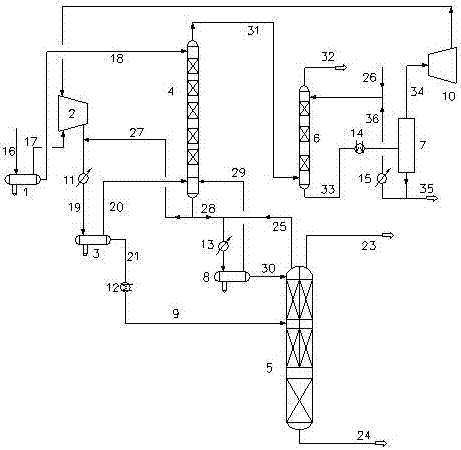

Method for saving energy and producing more propylene in absorption-stabilization system by catalytic cracking

ActiveCN101659876AReduce olefin contentTo achieve the goal of producing more propyleneOrganic chemistryCatalytic crackingGasolineEngineering

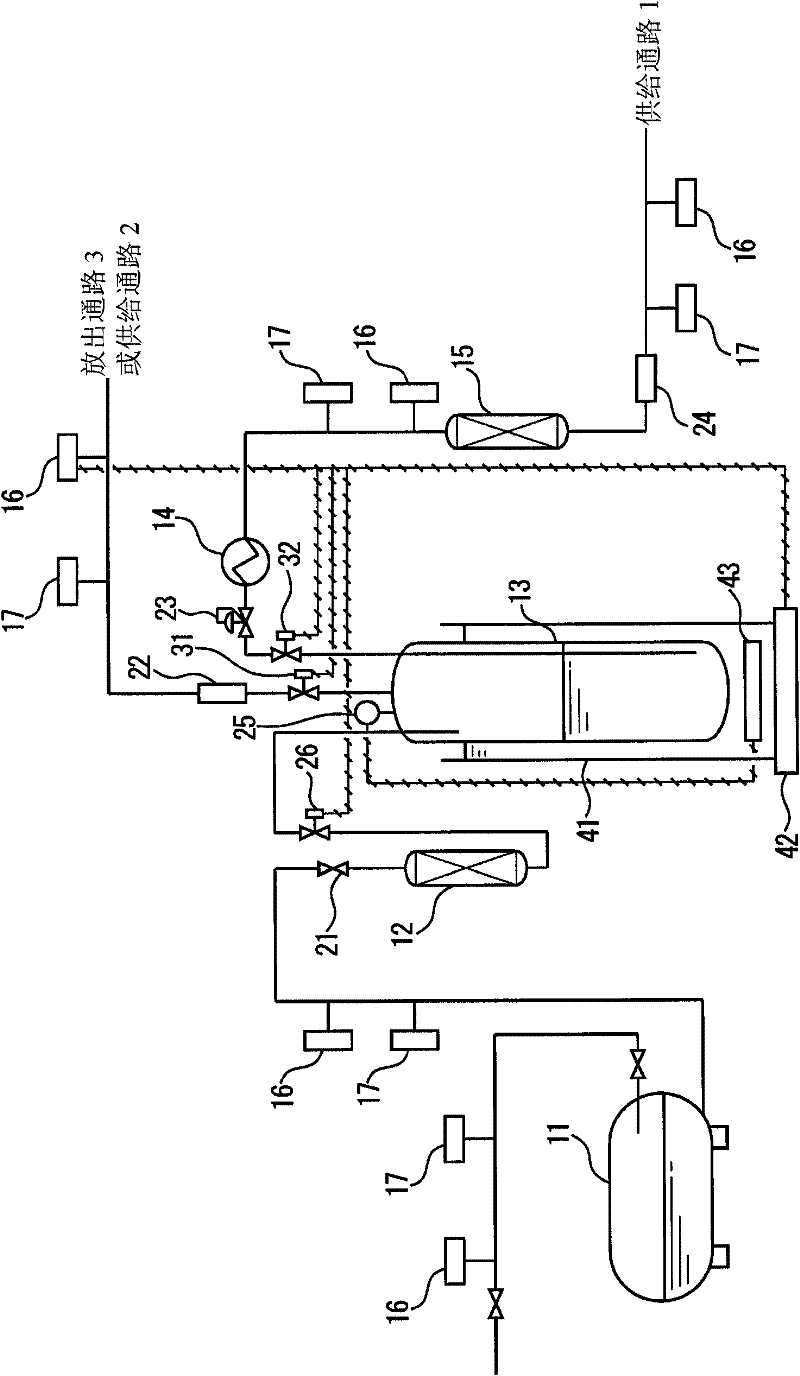

The invention relates to a method for saving energy and producing more propylene in an absorption-stabilization system by catalytic cracking. A liquid phase of a vapor-liquid equilibrium tank exchanges heat with stable gasoline on the bottom of a desorber T305 through a heat exchanger E301, exchanges heat with stable gasoline on the bottom of a stabilization tower T304 through a heat exchanger E302, and then enters a desorber T302; deethanized gasoline on the bottom of the desorber T302 exchanges heat with the stable gasoline on the bottom of a stabilization tower T304 through a heat exchanger E305, and then enters the stabilization tower T304; the stable gasoline on the bottom of the stabilization tower T304 is cooled by the heat exchanger E305 and the heat exchanger E302, a part of the stable gasoline enters a reaction-regeneration system for recycling, the rest stable gasoline is cooled by a heat exchanger E303, and a part of the rest stable gasoline enters an absorption tower T301; and the stable gasoline on the bottom of the desorber T305 is subjected to two-stage cooling of the heat exchanger E301 and a heat exchanger E304, serves as a stable gasoline product and is discharged from the device. The thermal load is reduced by 15.8 to 17.7 percent; and the alkene content in the stable gasoline product is reduced by 34.3 percent.

Owner:PETROCHINA CO LTD

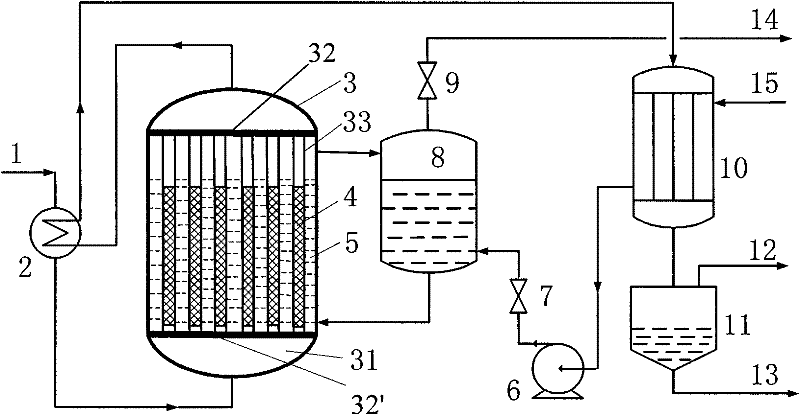

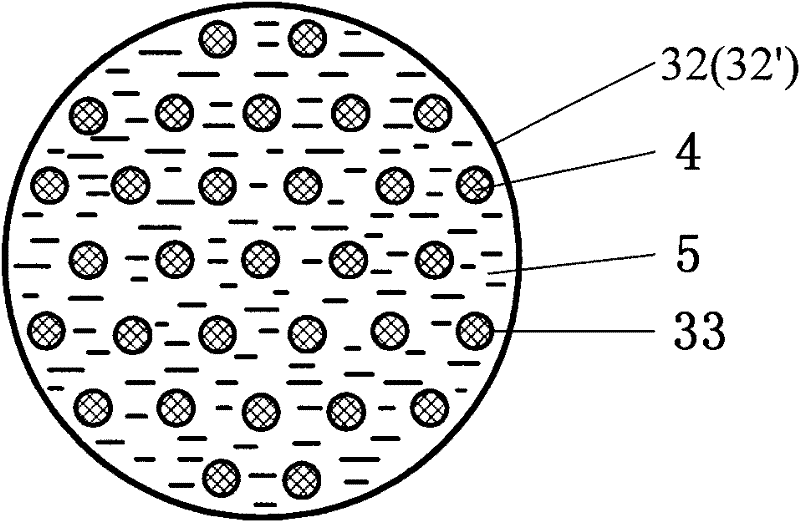

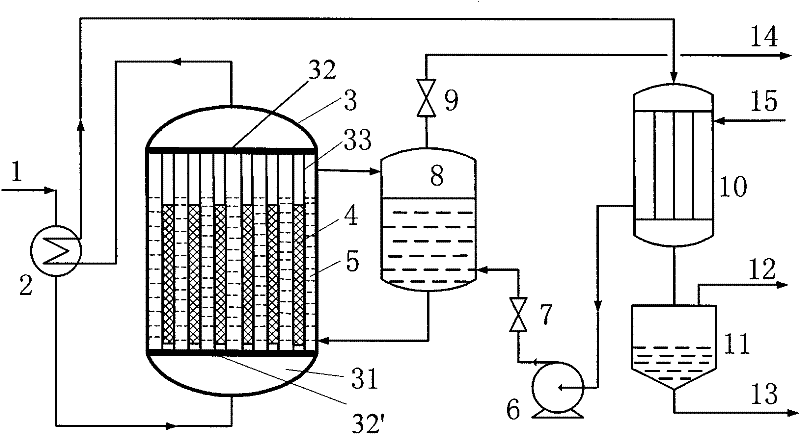

Complete methanation reaction device for synthesis gas

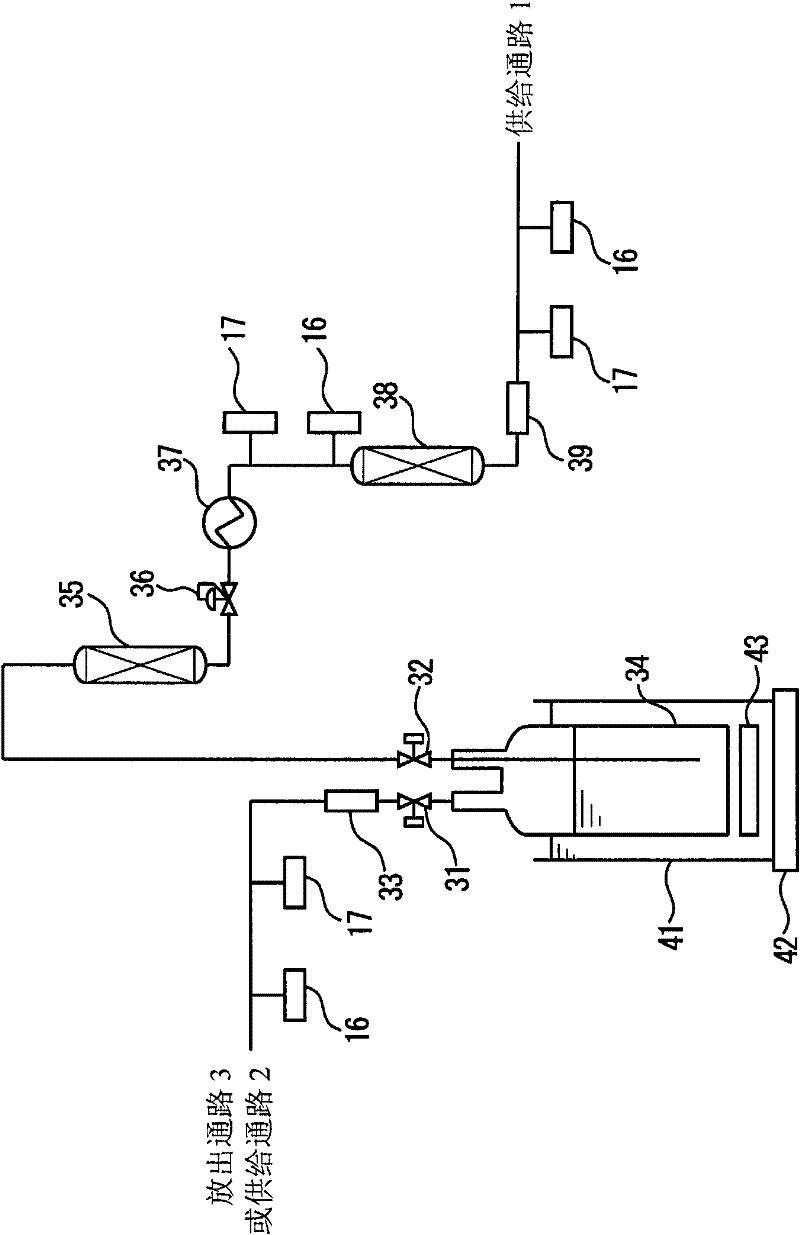

ActiveCN102234213AIncrease production capacityImprove efficiencyHydrocarbon from carbon oxidesChemical industryLiquid productMethanation

The invention relates to a complete methanation reaction device for synthesis gas. The device consists of a tube-shell reactor, a heat exchanger, a steam pocket, a make-up water pump, a condenser and a gas-liquid separator, wherein a catalyst is filled in a tube of the reactor; the shell pass is superheated water for removing heat; heat released in methanation reaction is absorbed through the phase change of high-pressure superheated water in the shell pass of the reactor and taken out of the device; the generated steam enters the steam pocket, is subjected to gas-liquid balance and can directly form superheated steam to be supplied to the outside; the temperature of a catalyst bed in the tube of the reactor is regulated and controlled by controlling the balance pressure of the superheated steam; reaction product exit gas exchanges heat with raw material gas and is continuously condensed; and a gaseous product and a liquid product are separated by the gas-liquid separator. The device can realize the continuous and stable operation of the complete methanation reaction of the synthesis gas, can effectively improve heat transfer efficiency and control the temperature of the reaction bed in a phase change heat transfer mode at a high temperature and under high pressure, expands the operation range of the complete methanation reaction of the synthesis gas, and can effectively recycle the heat released in the reaction.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

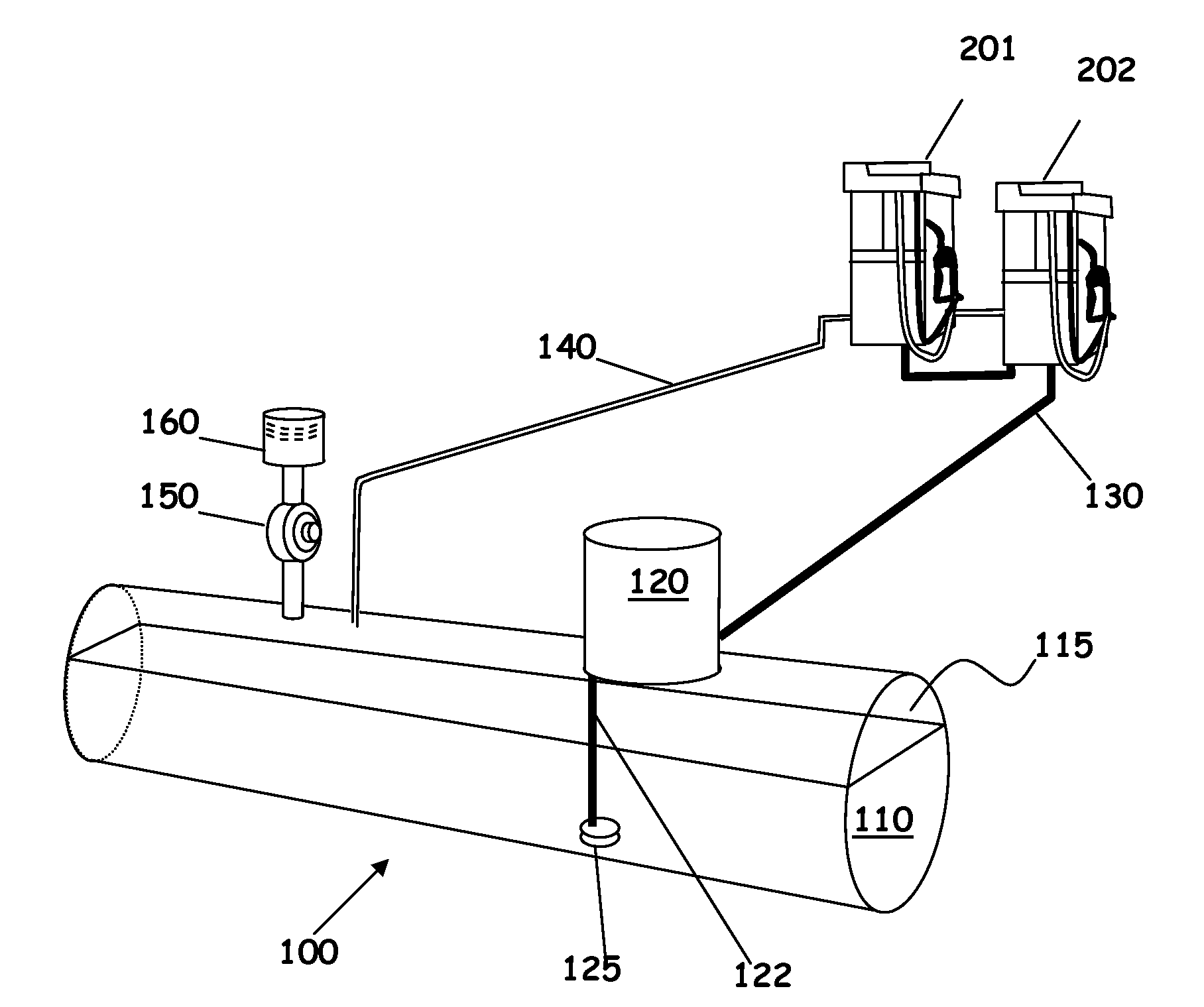

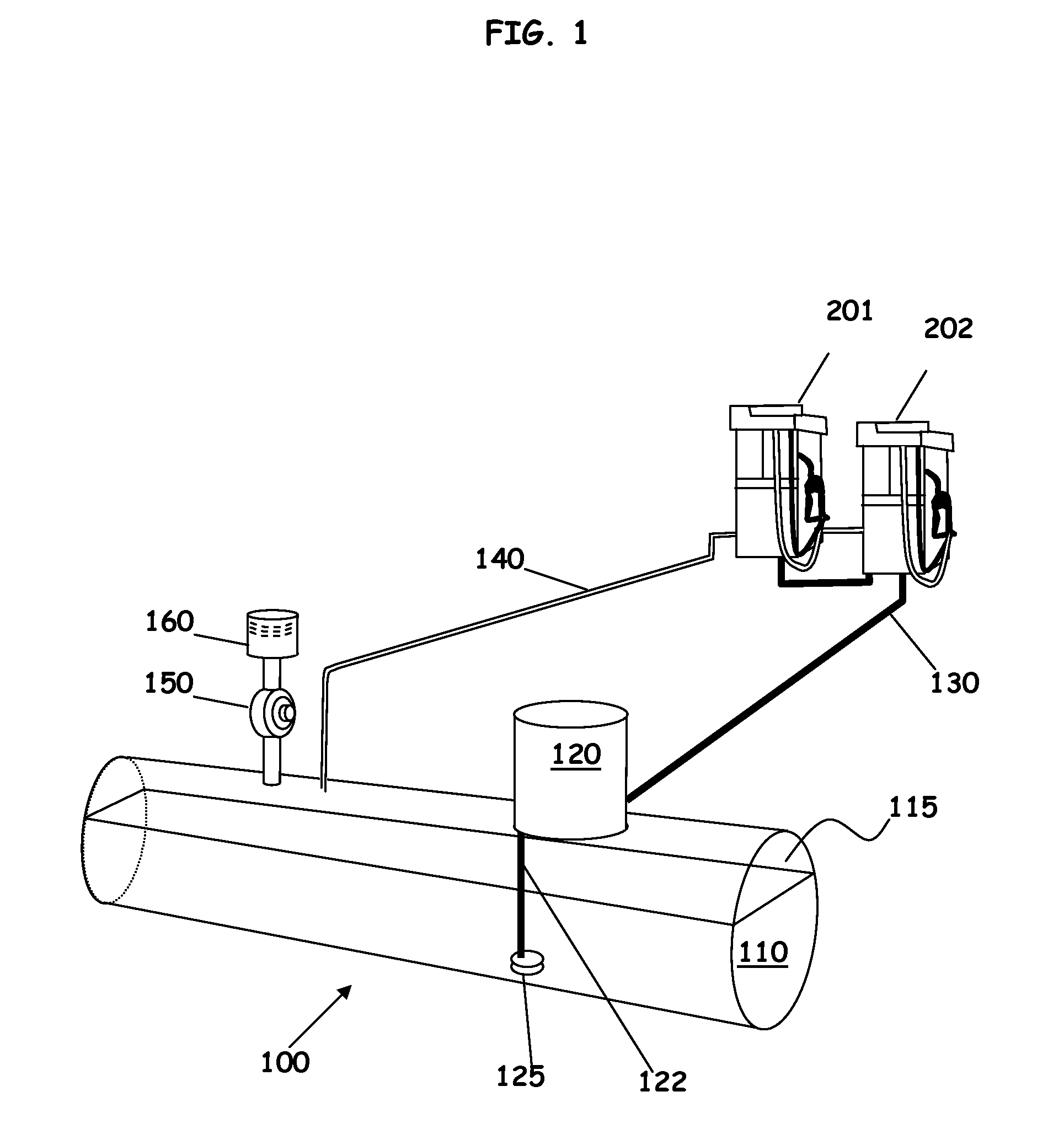

Control of vapor emissions from gasoline stations

ActiveUS20090056827A1Enhance vapor-liquid equilibriumMinimize emission levelGas treatmentIsotope separationActivated carbonSorbent

The present invention relates to a vapor recovery system for gas station that is capable of controlling vapor emission to less than 0.38 lbs / 1000 gallons fuel dispensed. The system may include at least one canister containing adsorbents such as activated carbon, zeolite, activated alumina, silica, and other adsorbents for passive removal of hydrocarbon vapors in venting air. Additionally, the system may include a means to enhance vapor-liquid equilibrium in the ullage of the fuel tank and accordingly minimize vapor emission level.

Owner:INGEVITY SOUTH CAROLINA

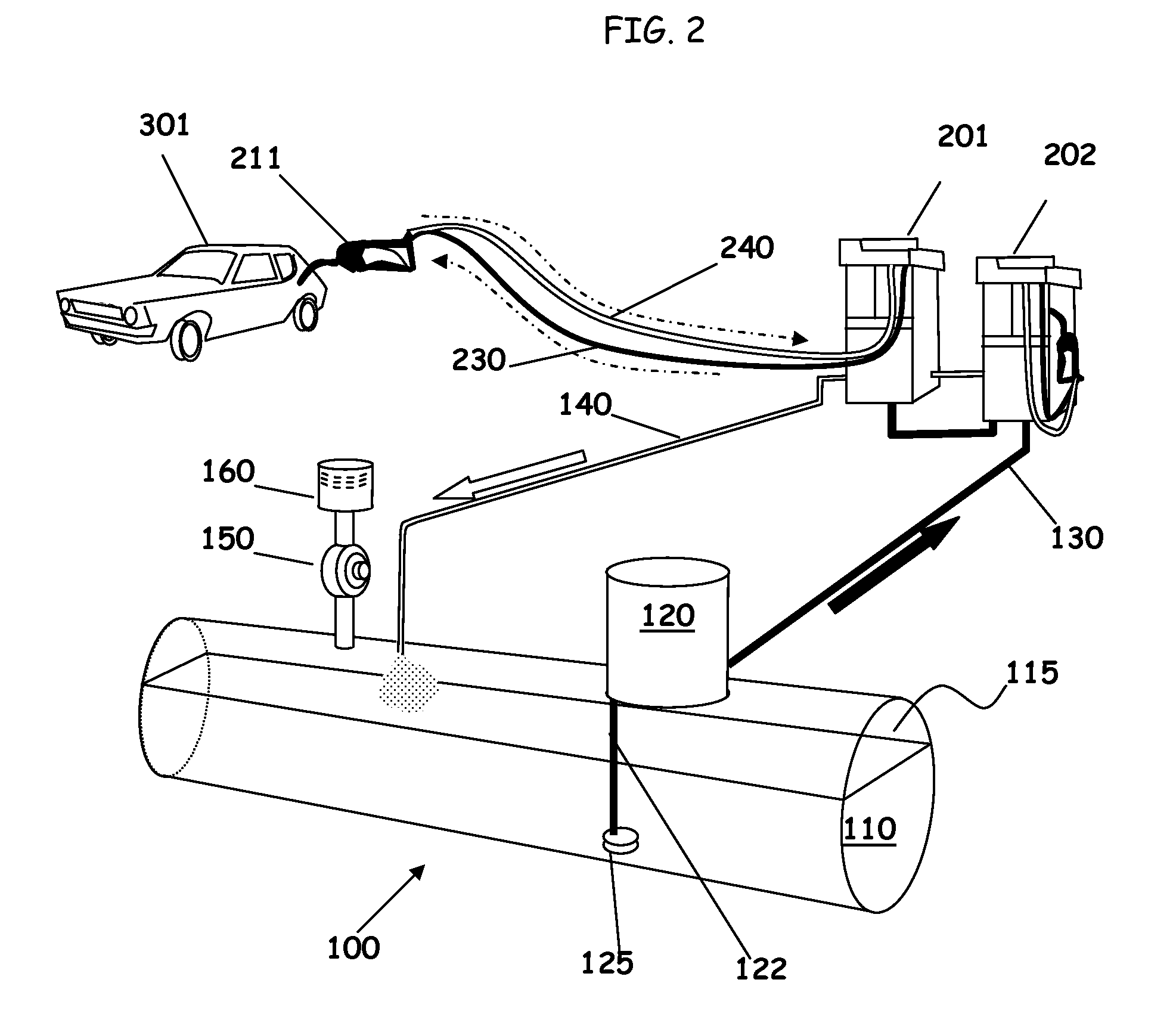

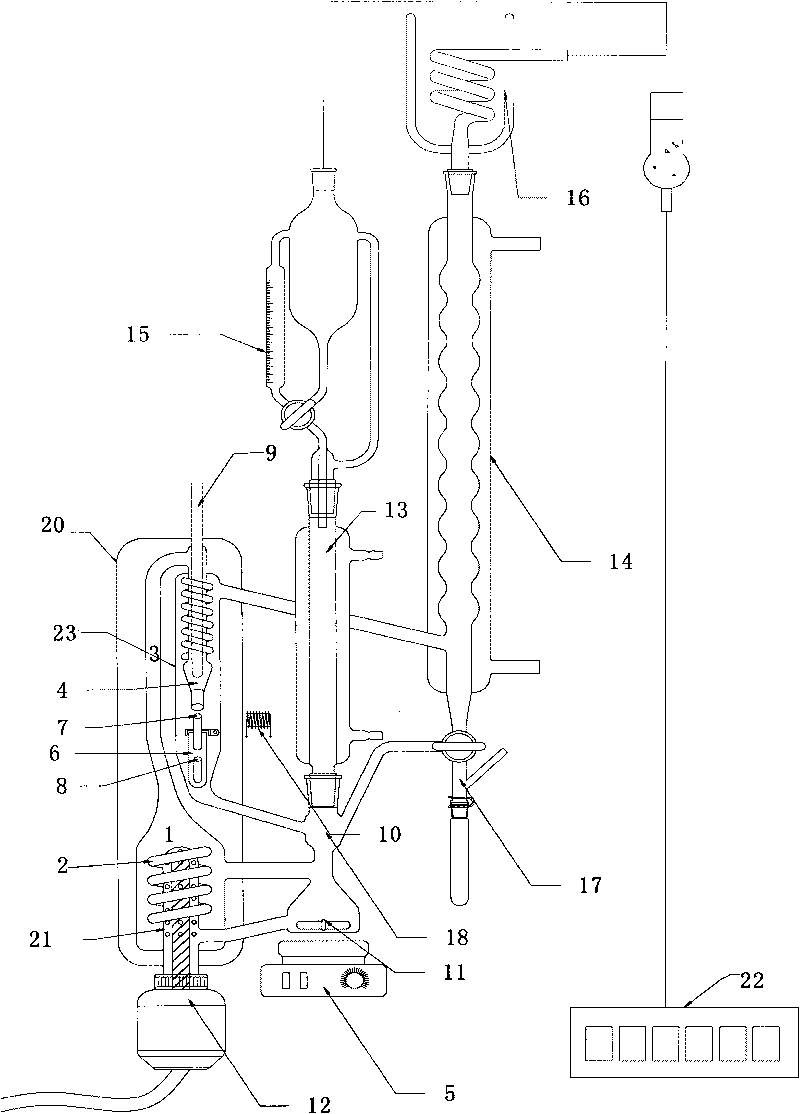

Gas-liquid-liquid equilibrium data measurement device

InactiveCN101726507AFully contactedAccurate measurementLaboratory glasswaresInvestigating phase/state changeMeasurement deviceThree-phase

The invention discloses a gas-liquid-liquid equilibrium data measurement device. An equilibrium still comprises three circulation loop structures for accelerating the circular mixing of fluid. The liquid phase in a hating still is homogenized by an ultrasonic homogenizer for improving the mass transfer rate and rapidly achieving the equilibrium. The separation is performed through stirring and heating. A liquid-liquid split phase tube is arranged in a gas-liquid separation chamber, so the liquid-liquid split phase experiment condition is the same as the gas-liquid equilibrium condition. The still is used for performing gas-liquid-liquid equilibrium measurement; gas-liquid-liquid three phase samples accurately representing gas-liquid-liquid equilibrium components can be obtained, time consumption is low, the equilibrium components and equilibrium temperature are accurately measured, and the experimental operation is simple and convenient.

Owner:SUN YAT SEN UNIV

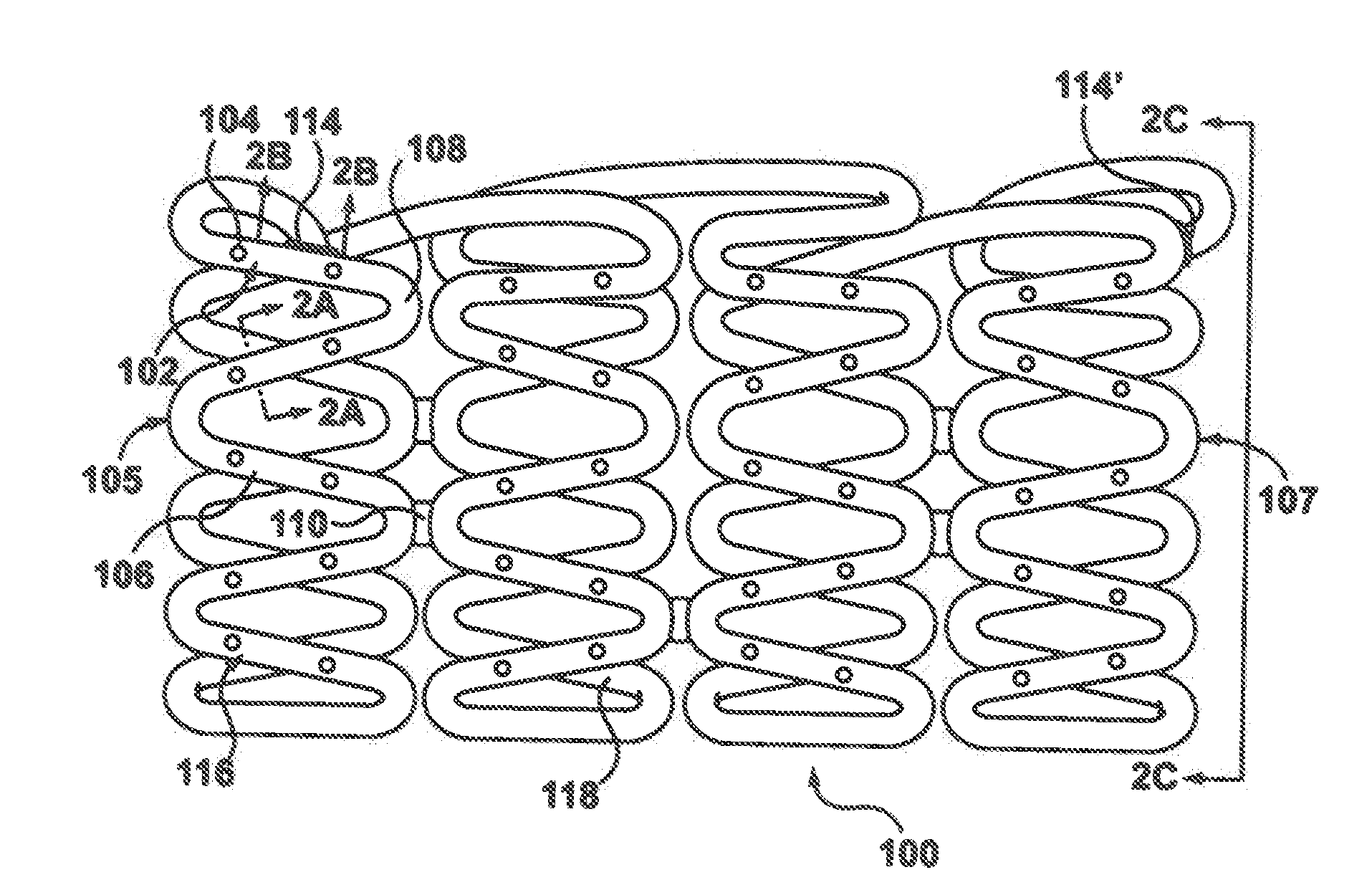

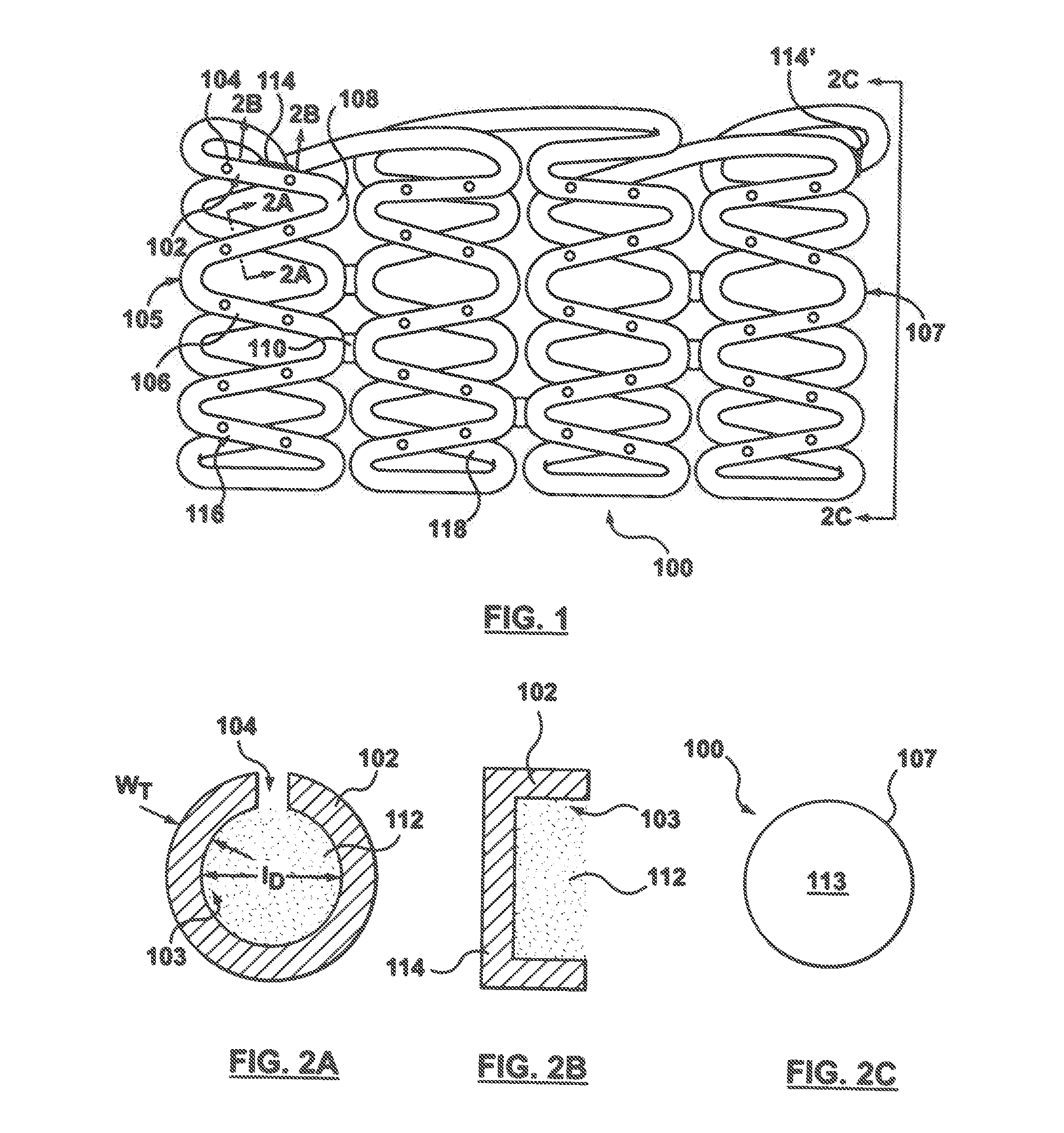

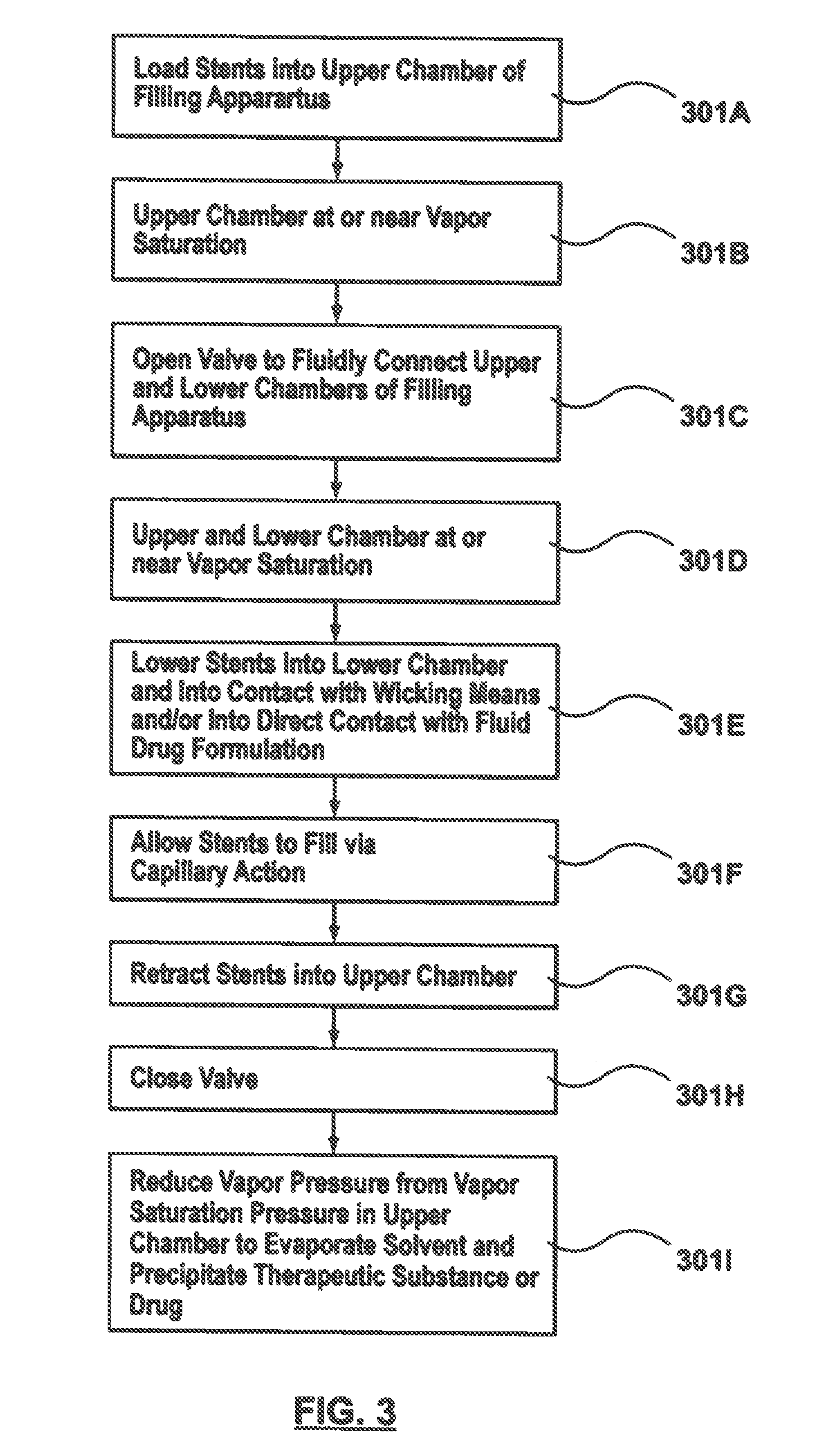

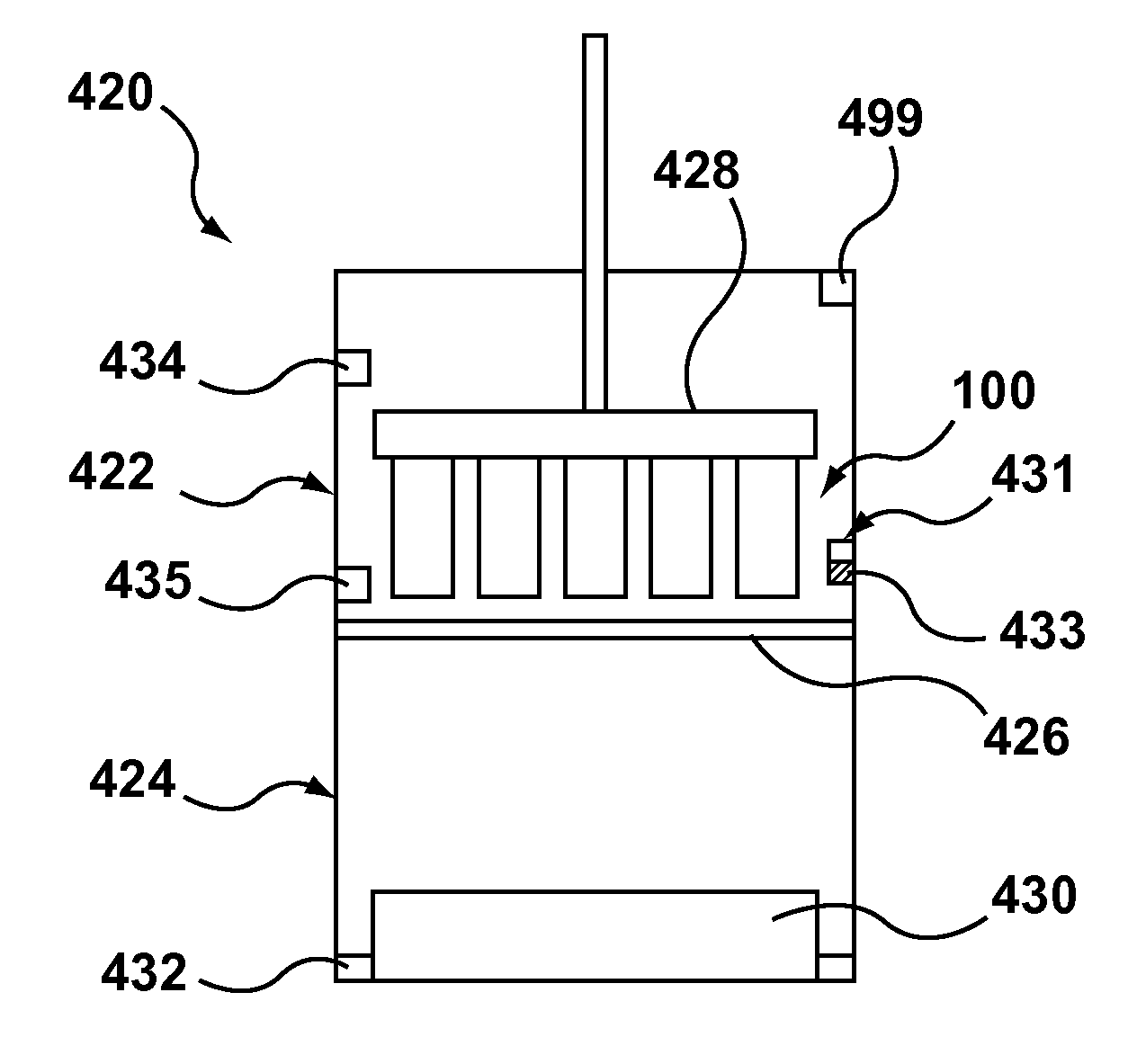

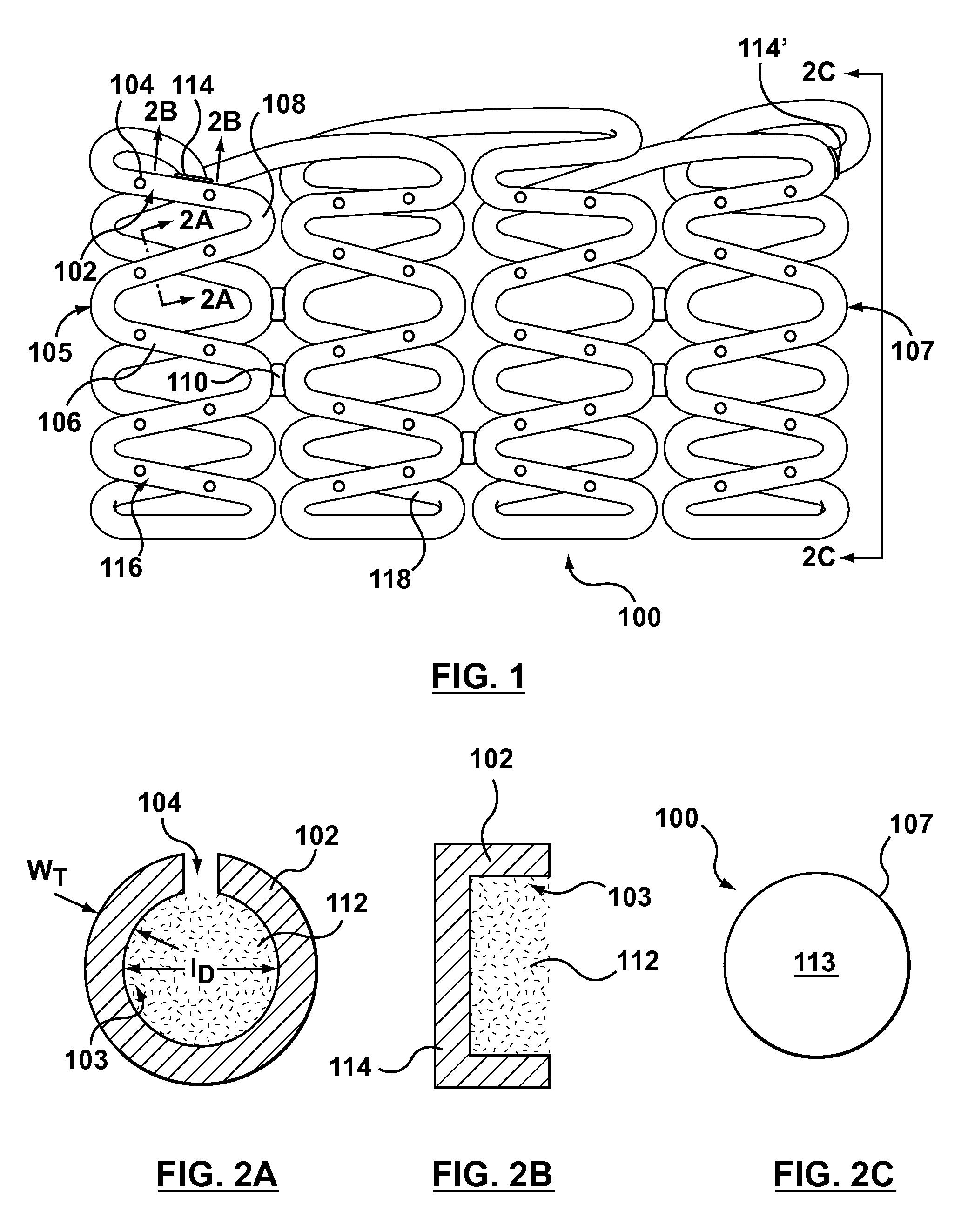

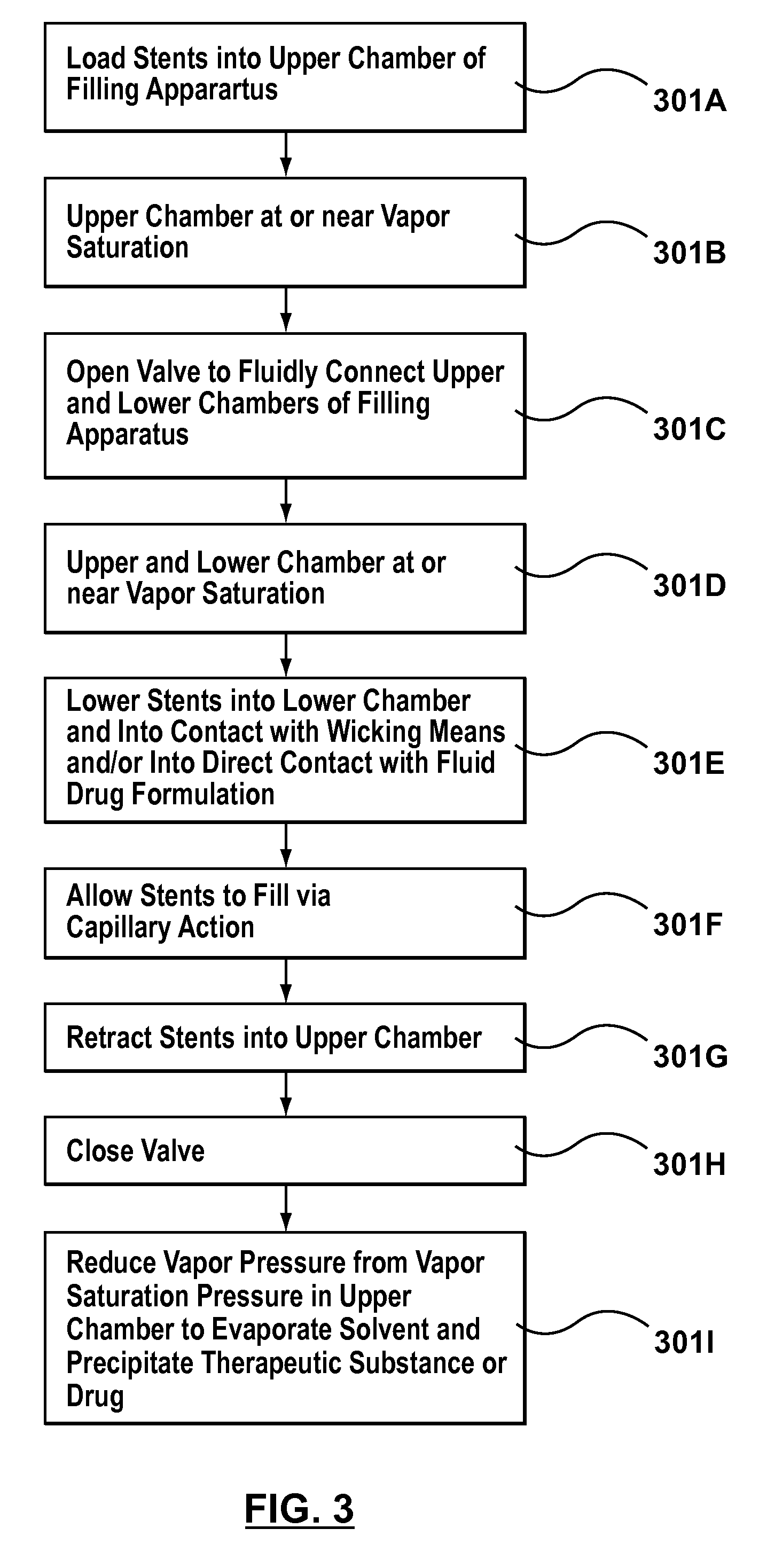

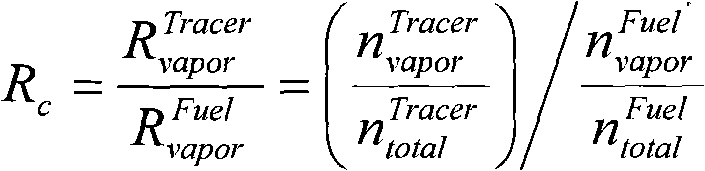

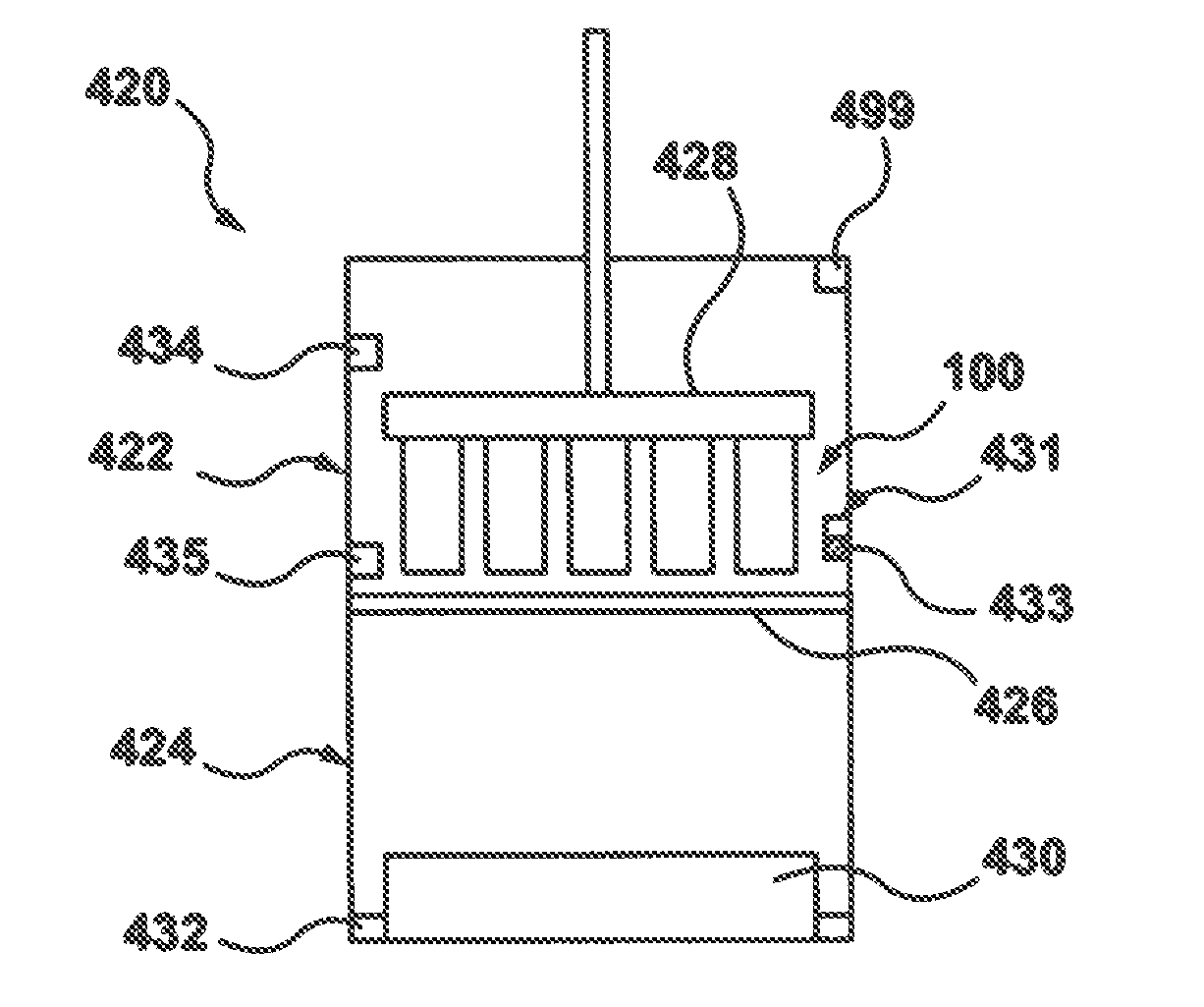

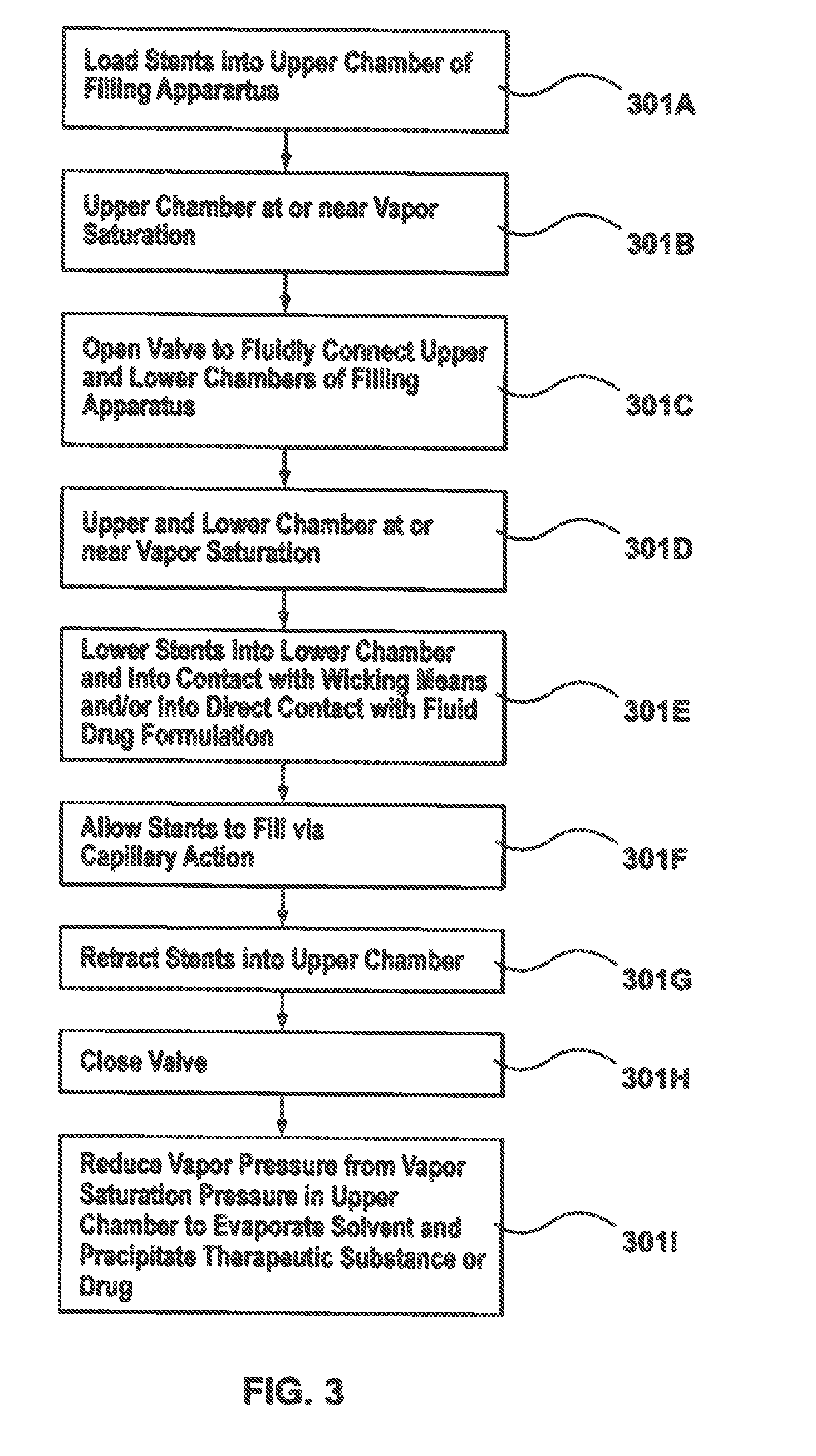

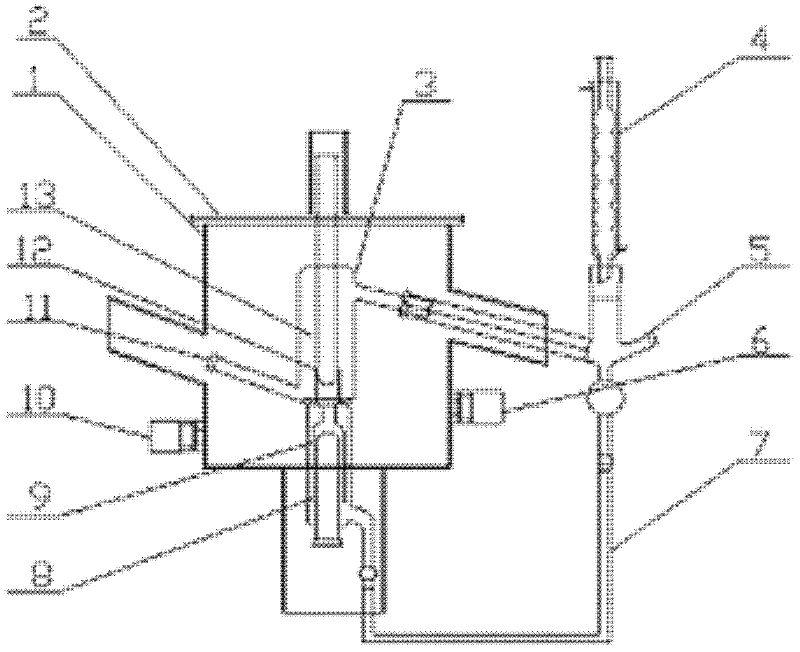

Apparatus and methods for filling a drug eluting medical device via capillary action

Methods and apparatus are disclosed for filling a therapeutic substance or drug within a hollow wire that forms a stent. The stent is placed within a chamber housing a fluid drug formulation. During filling, the chamber is maintained at or near the vapor-liquid equilibrium of the solvent of the fluid drug formulation. To fill the stent, a portion of the stent is placed into contact with the fluid drug formulation until a lumenal space defined by the hollow wire is filled with the fluid drug formulation via capillary action. After filling is complete, the stent is retracted such that the stent is no longer in contact with the fluid drug formulation. The solvent vapor pressure within the chamber is reduced to evaporate a solvent of the fluid drug formulation. A wicking means may control transfer of the fluid drug formulation into the stent.

Owner:MEDTRONIC VASCULAR INC

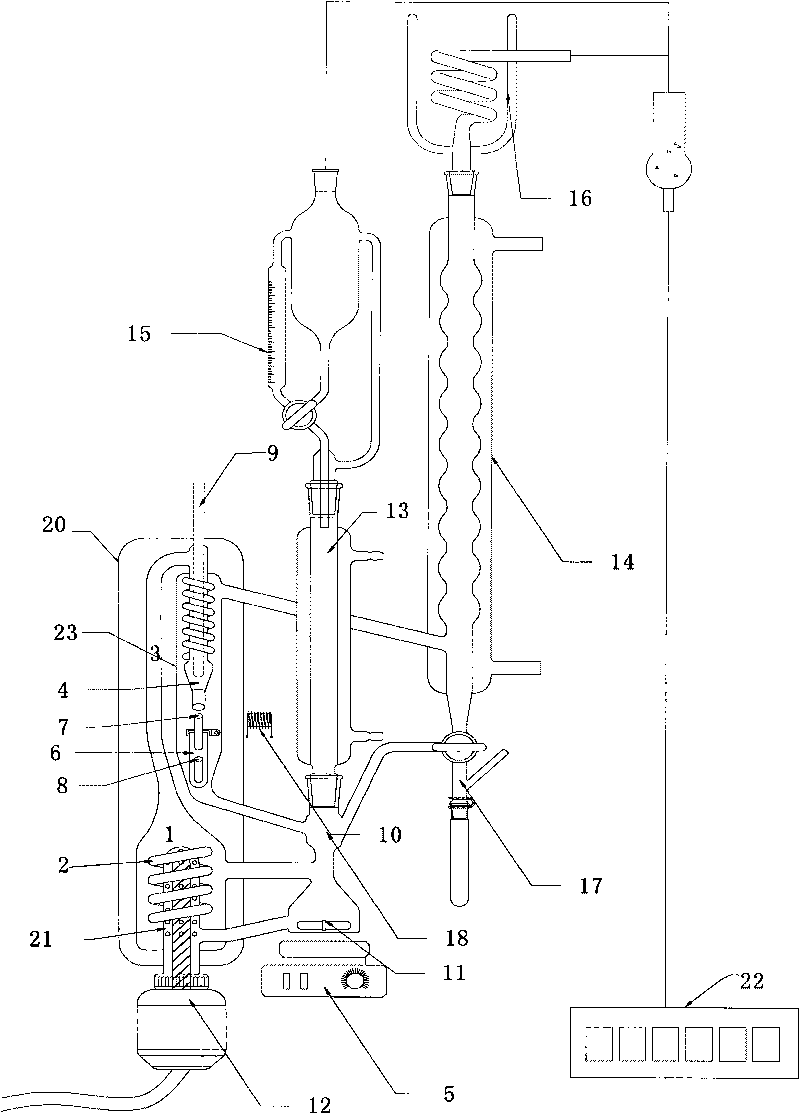

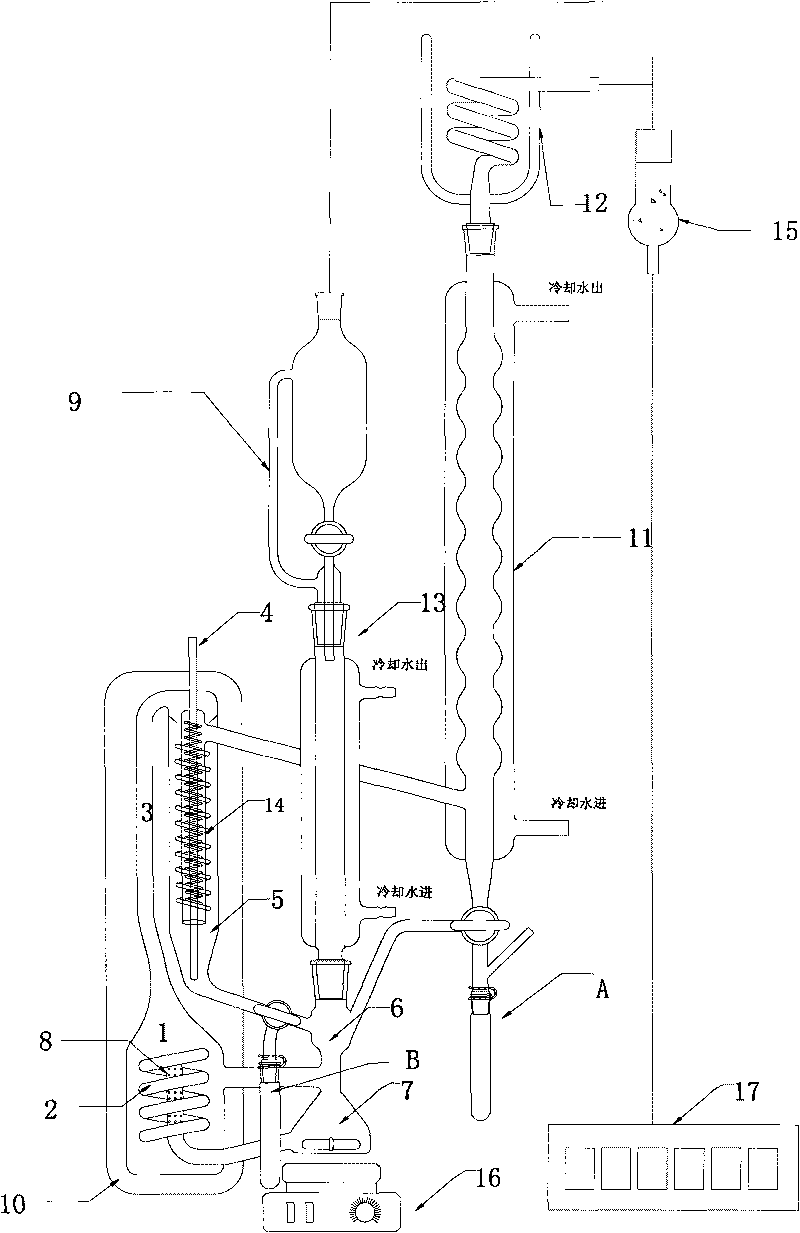

Isobaric gas-liquid equilibrium measuring device

InactiveCN101726508AAchieve the effect of a centrifugal pumpWell mixedLaboratory glasswaresInvestigating phase/state changeGas phaseMechanics

The invention relates to an isobaric gas-liquid equilibrium measuring device, belongs to the field of thermodynamic data measurement, and consists of a gas-liquid equilibrium kettle and a pressure controller. When the device measures the gas-liquid equilibrium data, the liquid phase in the gas-liquid equilibrium kettle continuously circulates in three circulation loops and the gas phase is completely mixed and contacted with the liquid phase to fast achieve the equilibrium, so the isobaric gas-liquid equilibrium measuring device can ensure that the gas phase and the liquid phase samples can accurately represent the composition of the gas phase and the liquid phase during the gas-liquid equilibrium, and has the advantages of short measuring time, simple and convenient operation and accurate measuring result.

Owner:SUN YAT SEN UNIV

Gas-liquid two-phase working substance coupled vibrations type thermo-acoustic engine

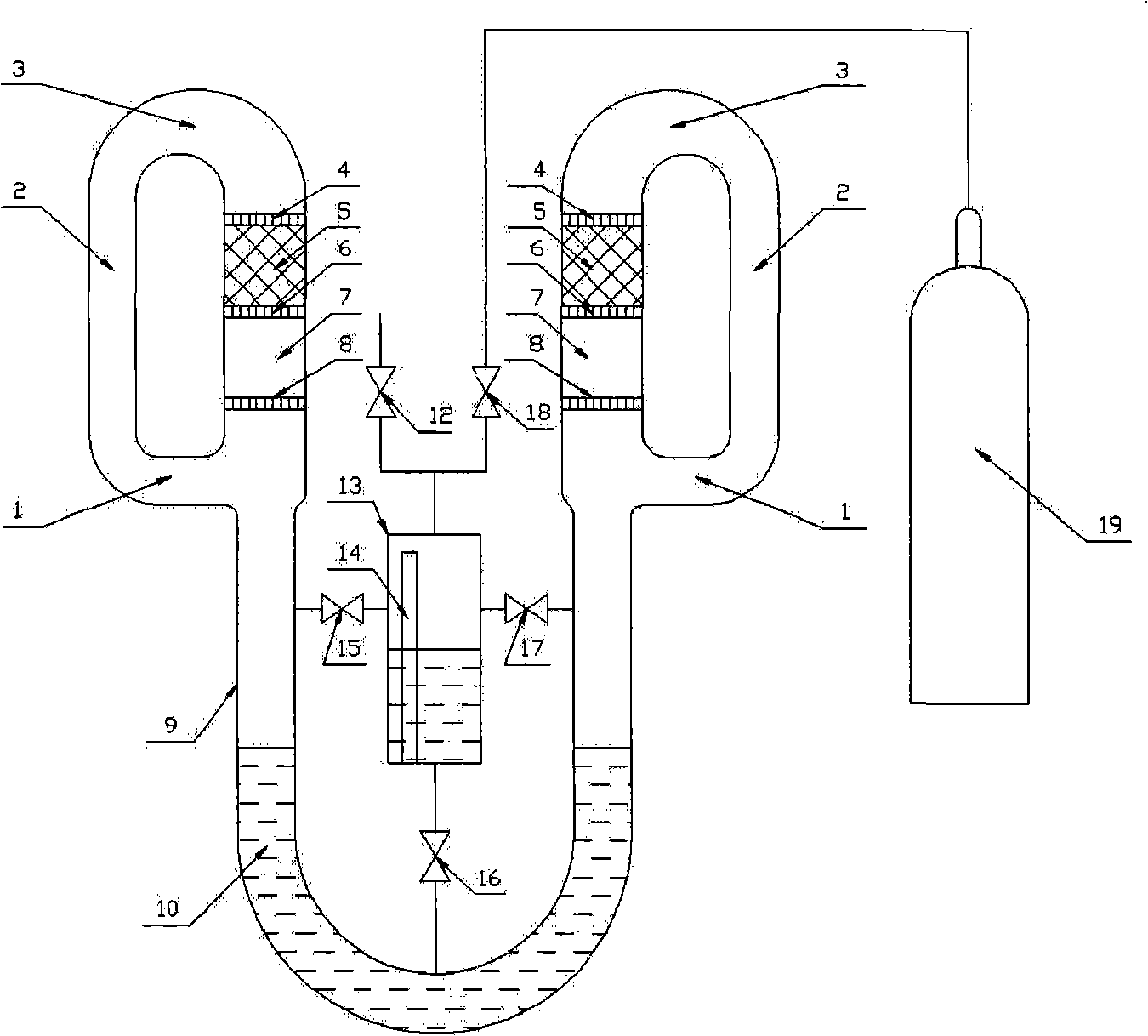

InactiveCN101260871AImprove conductivityEasy to adjustMachines/enginesMechanical power devicesCapacitanceExhaust valve

The invention discloses a gas-liquid two-phase working substance coupled vibration type thermoacoustic engine, which comprises a loop traveling wave thermoacoustic core, a U-shaped resonant pipe, a liquid piston, a resonant cavity and an acoustic impedance regulator which are connected with each other in turn, wherein, the loop traveling wave thermoacoustic core comprises a feedback pipe, a phonoreceptive pipe, an acoustic capacitance pipe, a first water cooler, a heat regenerator, a heater, a thermal buffer tube and a second water cooler which are connected with each other in turn; and the liquid piston consists of a liquid column which is formed by arrangement of room-temperature ionic liquid inside the U-shaped resonant pipe; the acoustic impedance regulator comprises a gas-liquid surge tank, a fluid level gauge, an exhaust valve, an inflation valve, a steel cylinder, a first gas-phase balancing valve, a second gas-phase balancing valve and a liquid-phase balancing valve. The gas-liquid two-phase working substance coupled vibration type thermoacoustic engine introduces the room-temperature ionic liquid provided with 'zero' vapor pressure characteristic into the prior thermoacoustic engine to form a gas-liquid two-phase working substance coupled vibrating system, realizes acoustic oscillation and thermoacoustic conversion of the reinforced thermoacoustic engine through the acoustic impedance regulator, improves the acoustic power output capacity, and realizes operation below 10 hertz under the condition of relatively small physical dimension.

Owner:ZHEJIANG UNIV

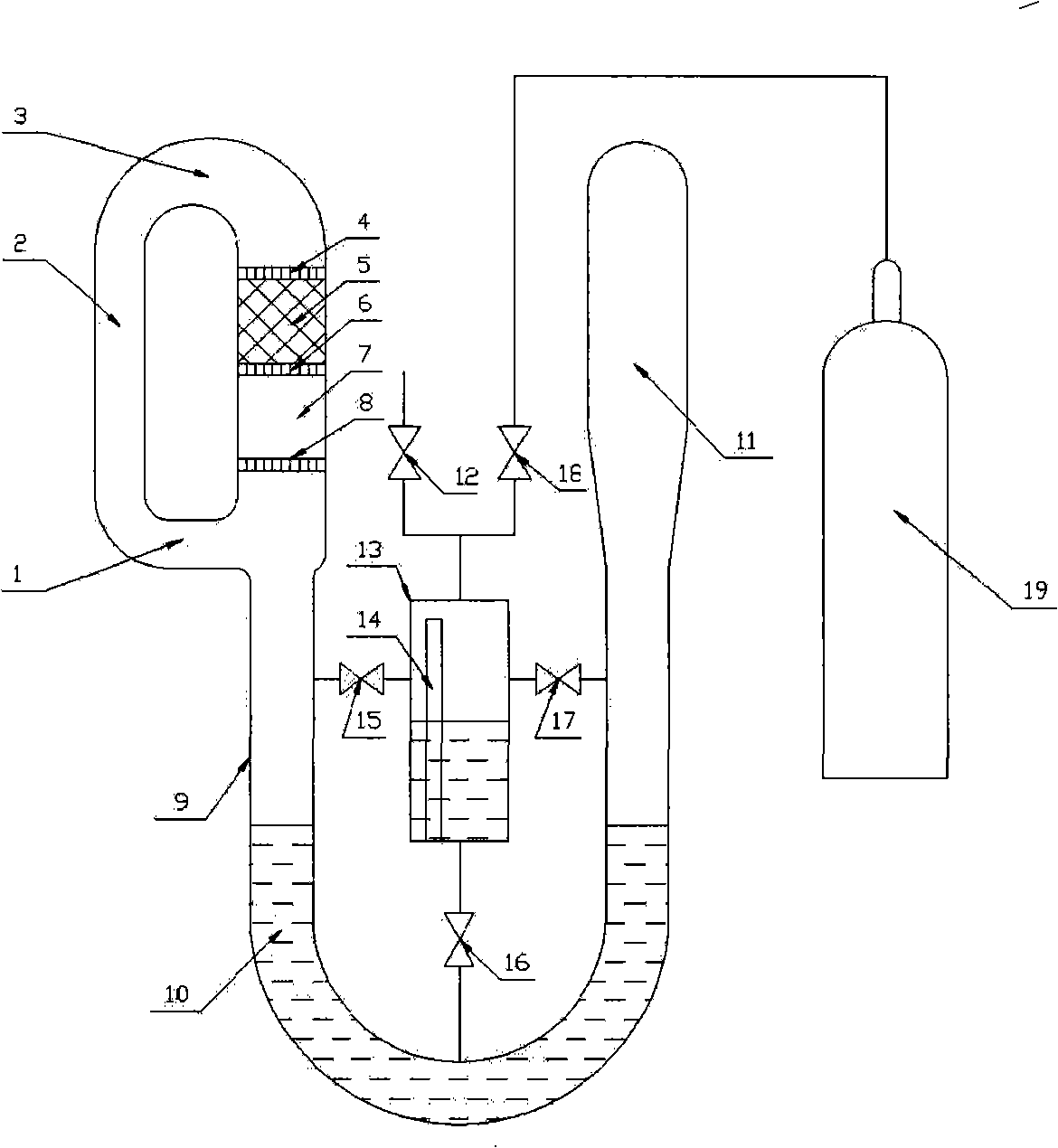

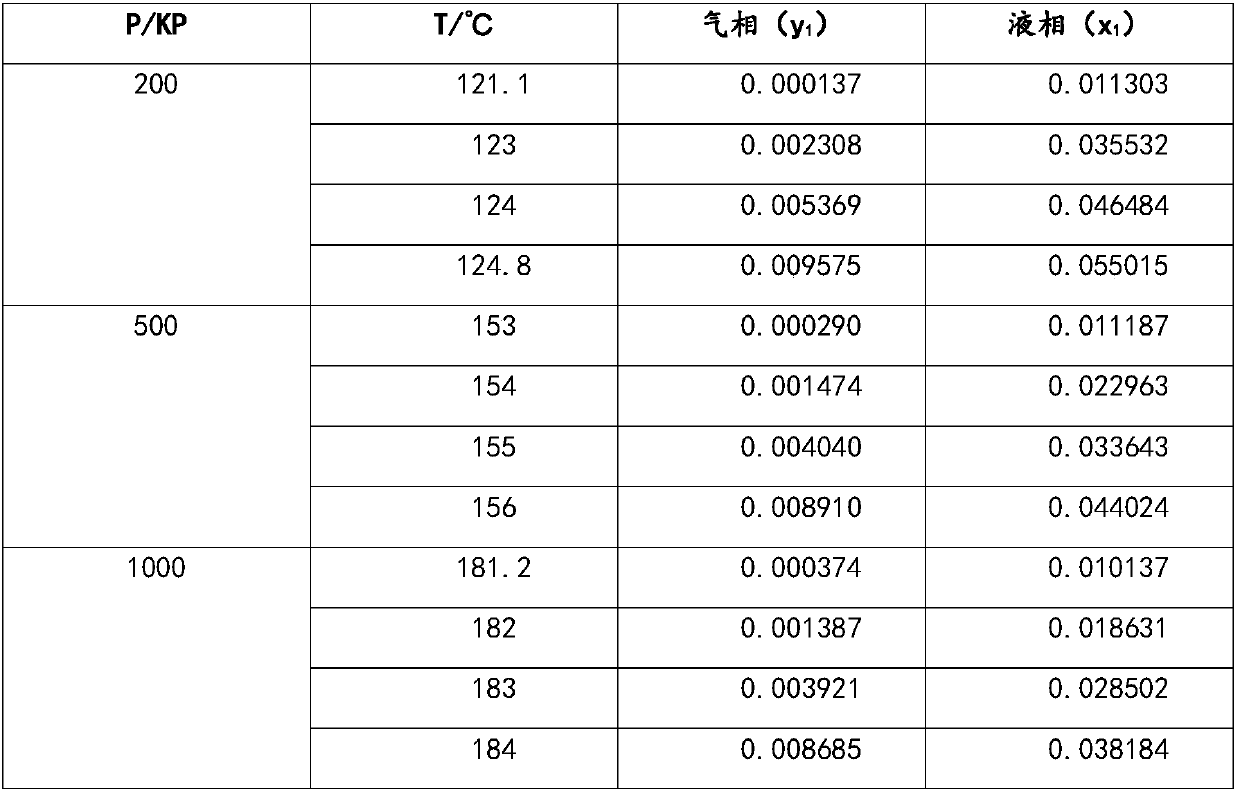

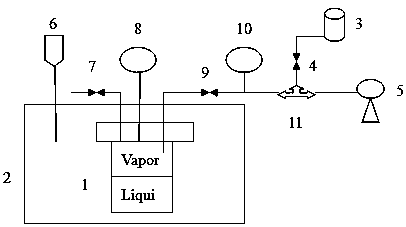

High-temperature high-pressure gas-liquid balance testing device and method

The invention provides a high-temperature high-pressure gas-liquid balance testing device and method, and relates to the technical field of phase balance testing. The high-temperature high-pressure gas-liquid balance testing device comprises a balance kettle, a condenser and a buffering tank, a gas phase outlet is formed in the top of the balance kettle and is communicated with an inlet of the condenser, an outlet of the condenser is communicated with the buffering tank, a liquid phase outlet is formed in the bottom of the balance kettle, a gas phase inlet is formed in the top of the balance kettle, a liquid phase sampling pipe is arranged between the liquid phase outlet and the liquid phase inlet and is provided with a liquid phase sampling opening, a gas phase inlet is formed in the bottom of the balance kettle, and a gas phase sampling pipe is arranged between the gas phase inlet and the inlet of the condenser and is provided with a gas phase sampling opening. The high-temperature-high-pressure gas-liquid balance testing device and method solve the technical problem that an existing gas-liquid phase balance testing device cannot satisfy measurement of gas-liquid balance data athigh temperature and high pressure and have the advantages that gas-liquid dual circulation is adopted, the gas-liquid phase balance data can be measured within a wide temperature and pressure range,and the data accuracy is guaranteed.

Owner:SINOPEC ENG GRP CO LTD

Inferred water analysis in polyphenylene sulfide production

A method for producing polyphenylene sulfide (PPS) polymer, including polymerizing reactants in a reaction mixture in a vessel to form PPS polymer in the vessel, measuring values of operating variables of the vessel and / or PPS process, and determining the amount of quench fluid to add to the vessel based on the values of the operating variables. The technique may rely on the vapor liquid equilibrium (VLE) of the mixture to calculate the concentration of water existing in the reactor prior to quench, and accounts for the effectiveness of the upstream dehydration process and in the amount of water produced during the polymerization. The technique is a striking improvement over the trial-and-error estimation of the amount of quench water based on human operating experience, and avoids direct measurements of the existing water concentration in the reactor. The result is improved control of PPS particle size and other properties.

Owner:SOLVAY SA

Apparatus and methods for filling a drug eluting medical device via capillary action

Methods and apparatus are disclosed for filling a therapeutic substance or drug within a hollow wire that forms a stent. The stent is placed within a chamber housing a fluid drug formulation. During filling, the chamber is maintained at or near the vapor-liquid equilibrium of the solvent of the fluid drug formulation. To fill the stent, a portion of the stent is placed into contact with the fluid drug formulation until a lumenal space defined by the hollow wire is filled with the fluid drug formulation via capillary action. After filling is complete, the stent is retracted such that the stent is no longer in contact with the fluid drug formulation. The solvent vapor pressure within the chamber is reduced to evaporate a solvent of the fluid drug formulation. A wicking means may control transfer of the fluid drug formulation into the stent.

Owner:MEDTRONIC VASCULAR INC

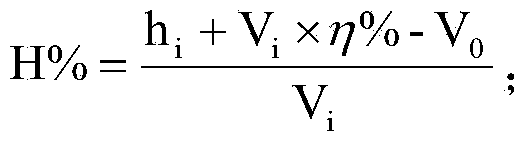

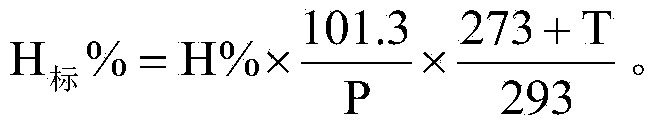

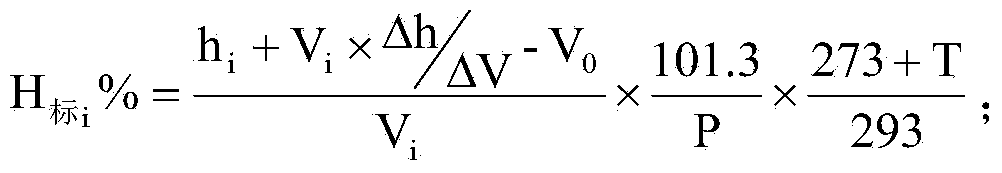

Test method for detecting air content of oil of transformer newly put into operation by oscillation method

Owner:STATE GRID CORP OF CHINA +1

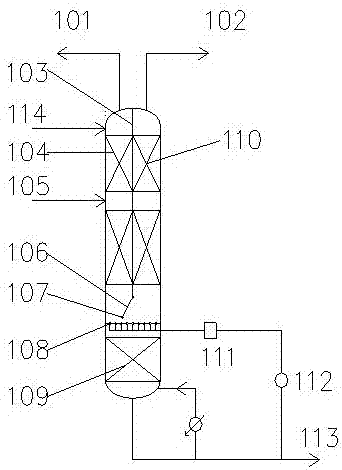

Absorption-stabilization technology and system for refining

ActiveCN107298988AReduce the amount of gas phaseReduce loadGaseous mixture working upGas compressorDesorption

The invention provides an absorption-stabilization technology and system for refining. The absorption-stabilization system comprises a gas-liquid balance tank, a rich gas compressor, a rich gas balance tank, an absorption tower, a desorption-stabilization dividing wall tower, a re-absorption tower, a regeneration tank, a desorption gas balance tank and a vacuum pump. The invention further provides the absorption-stabilization technology utilizing the absorption-stabilization system. By adopting the absorption-stabilization technology and system, provided by the invention, the concentration of liquefied gas in dry gas is greatly reduced; and meanwhile, the yield of catalytic gasoline and the liquefied gas can be improved and the energy consumption of the system is greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

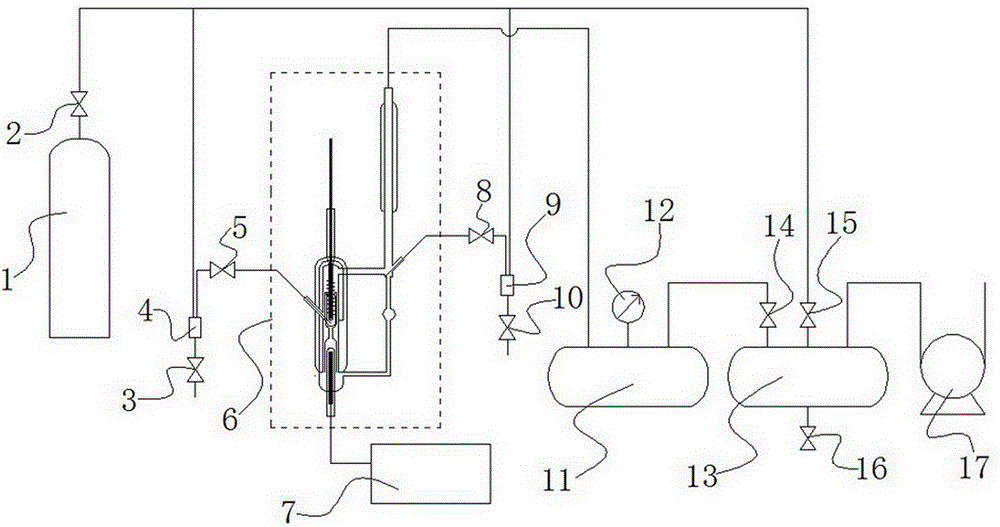

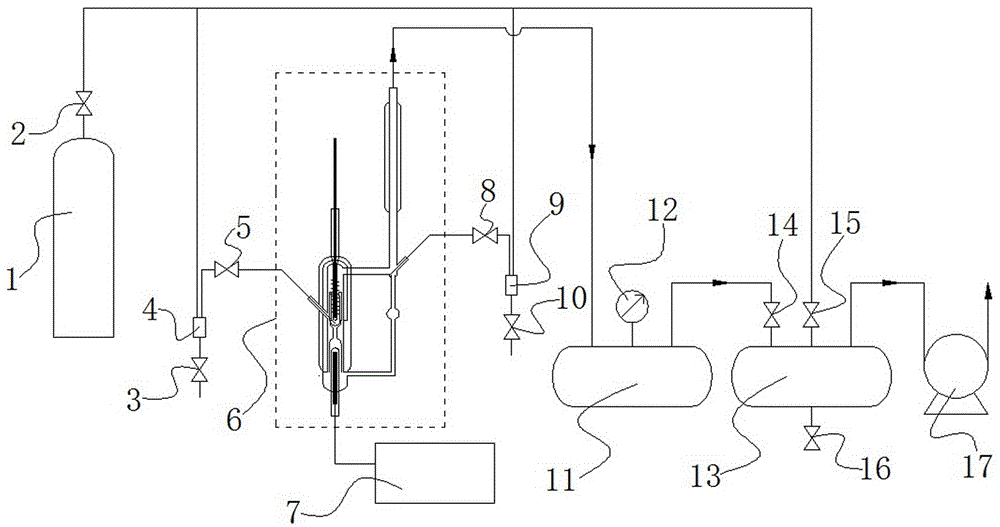

Decompression gas-liquid balance measuring system

ActiveCN106442897AAvoid the disadvantages of difficult samplingFacilitate automation improvementMaterial analysisElectricityBuffer tank

A decompression gas-liquid balance measuring system is composed of a gas cylinder, a liquid phase sampling tank, a gas phase sampling tank, an adjustable power supply, a decompression and pressure stabilizing tank, a decompression buffer tank, a rotary-vane vacuum pump and a gas-liquid balance device, wherein the gas-liquid balance device is composed of a gas-liquid balance kettle, a precision mercurial thermometer, an electric heating rod and a glass condensation pipe. The decompression gas-liquid balance measuring system can perform smooth sampling under the high vacuum degree, and therefore the defect that sampling of a manual needle cylinder is difficult is overcome.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

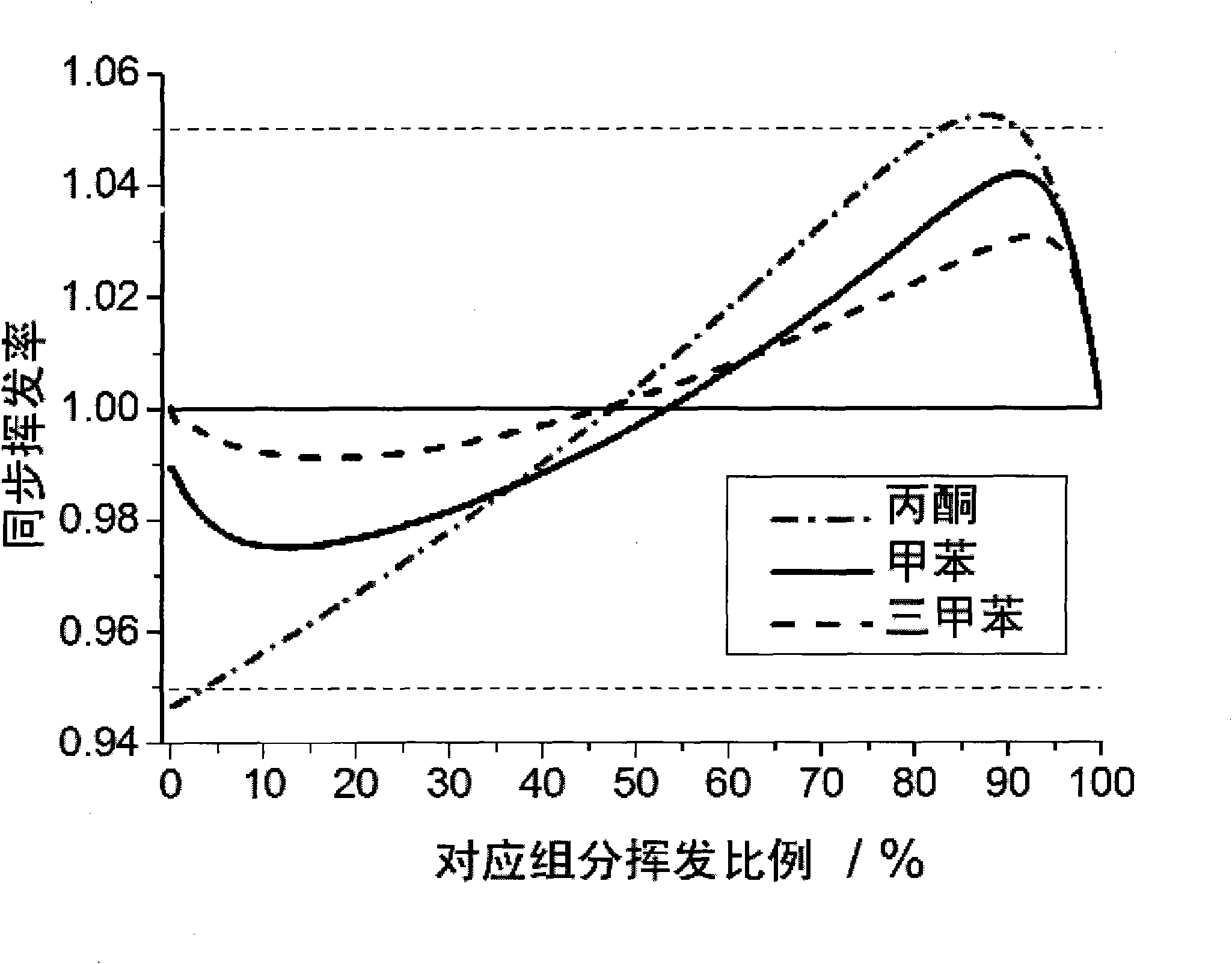

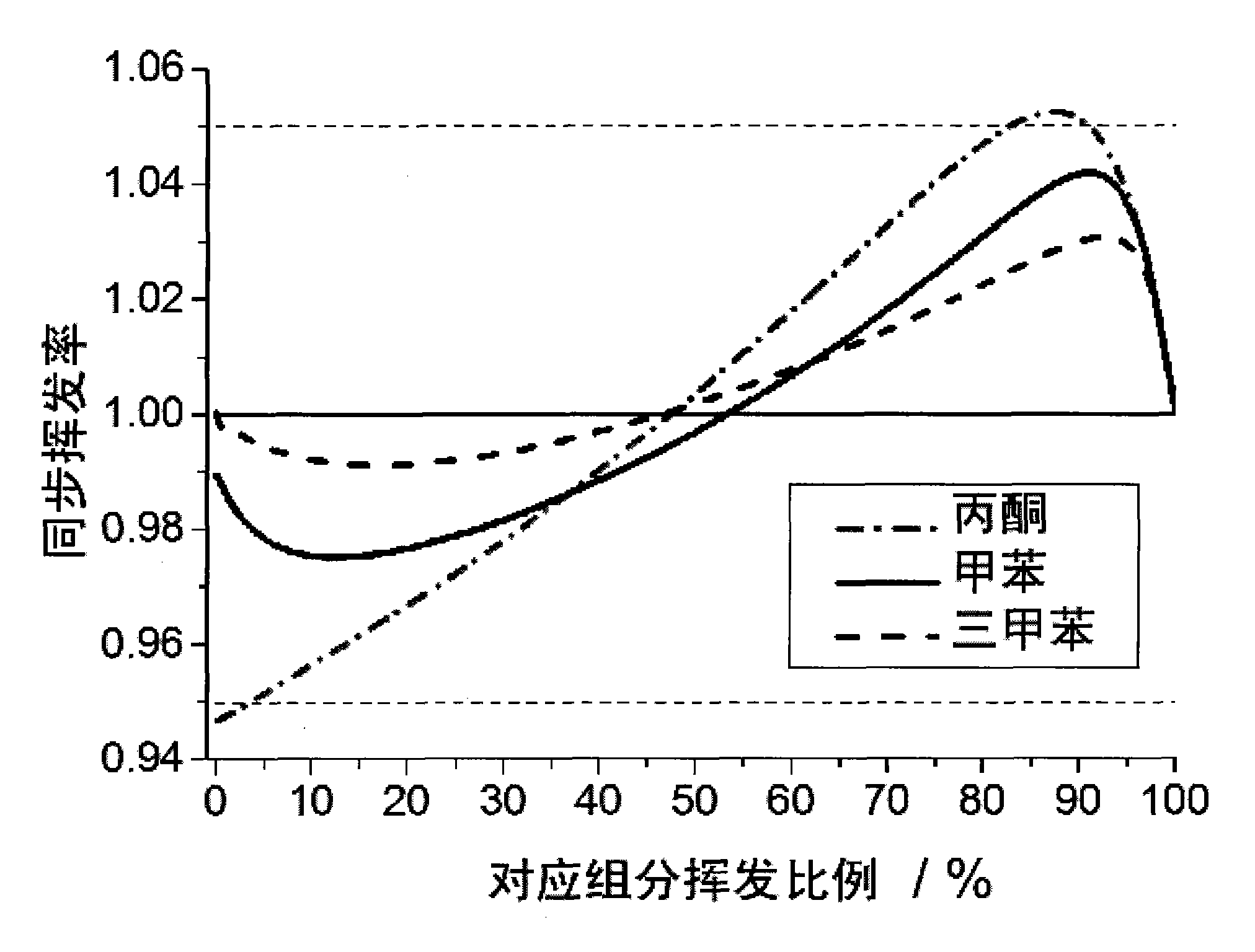

Method for optimizing experimental fuel proportioning based on thermogravimetric analysis and gas-liquid dual-phase calculation

InactiveCN101769823AThe test method is simple and reliableImprove calculation accuracyWeighing by removing componentEngine testingAlkaneAdditive ingredient

The invention relates to a method for optimizing experimental fuel proportioning based on thermogravimetric analysis and gas-liquid dual-phase calculation. Thermogravimetric analysis is performed to get an actual fuel volatilization characteristic curve; three types of saturated alkanes capable of characterizing all groups of fuels are mixed into an initial testing fuel to get a volatilization characteristic curve; according to the difference between the two volatilization characteristic curves, a testing fuel with adjusted usage of saturated alkanes is prepared; after repeated adjustment tests, a sample fuel is obtained; a gas-liquid equation of equilibrium and a universal chemical activity coefficient are used to calculate gas and liquid phases which are evaporated, and alkanes with adjusted synchronous volatilization are added; according to the difference between the volatilization characteristic curves of the new sample fuel and the actual fuel, proportions in the three groups are adjusted finely; after a plurality of repeated fine adjustment of the proportions of two types of alkanes in the three groups, a target fuel is obtained. Under the precondition of ensuring good synchronous volatilization rates of tracers and corresponding ingredients, a multi-ingredient fuel which has similar actual fuel volatilization characteristics is obtained.

Owner:TSINGHUA UNIV

Apparatus and methods for filling a drug eluting medical device via capillary action

Methods and apparatus are disclosed for filling a therapeutic substance or drug within a hollow wire that forms a stent. The stent is placed within a chamber housing a fluid drug formulation. During filling, the chamber is maintained at or near the vapor-liquid equilibrium of the solvent of the fluid drug formulation. To fill the stent, a portion of the stent is placed into contact with the fluid drug formulation until a lumenal space defined by the hollow wire is filled with the fluid drug formulation via capillary action. After filling is complete, the stent is retracted such that the stent is no longer in contact with the fluid drug formulation. The solvent vapor pressure within the chamber is reduced to evaporate a solvent of the fluid drug formulation. A wicking means may control transfer of the fluid drug formulation into the stent.

Owner:MEDTRONIC VASCULAR INC

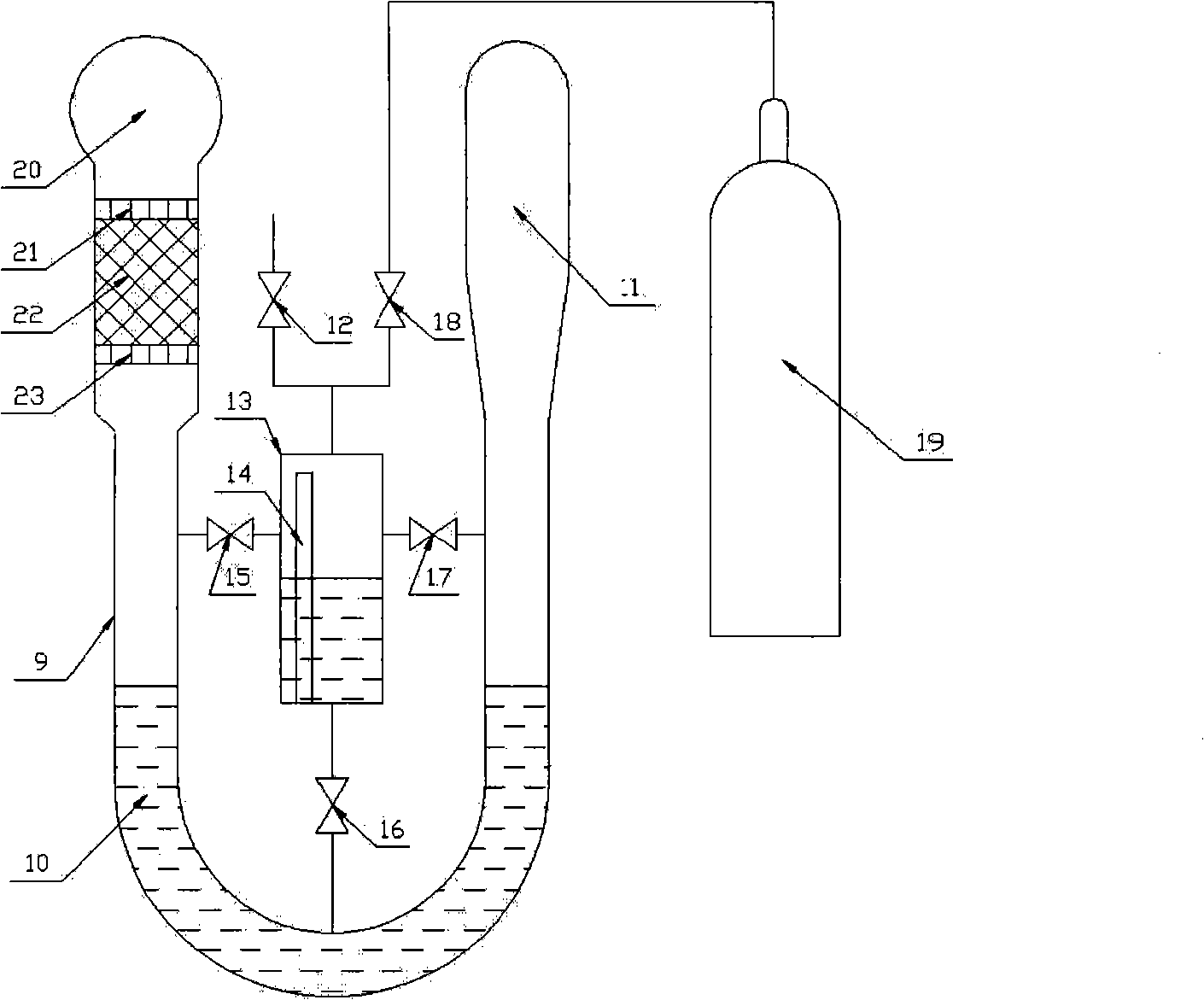

Microwave field vapor-liquid equilibrium measuring device and determination method

InactiveCN102519782ARealize energy savingHeating fastComponent separationPreparing sample for investigationVapor liquidMicrowave cavity

The invention relates to a microwave field vapor-liquid equilibrium measuring device and a determination method. A vapor-liquid equilibrium kettle (3) is arranged in a microwave cavity main body (1); temperature measurement points of a vapor-liquid interface infrared thermodetector (6) are arranged on an upper surface of a mixture liquid; temperature measurement points of a liquid phase main body infrared thermodetector (10) are arranged on a middle part of a liquid phase main body upper segment (9); a microwave generator (14) is connected with a rectangular waveguide (15) through a microwave circulator water load (16); the rectangular waveguide (15) is connected with an interface of the microwave cavity main body (1); the microwave generator (14) effects microwave energy on an interface of the liquid phase main body upper segment (9) of the vapor-liquid equilibrium kettle and a vapor main body (13); and the liquid is heated, vaporized and condensed by a condenser (4) and returns to a liquid phase main body lower segment (8) through a back flow (7); after equilibrium, samples are taken respectively from a liquid phase sample tap (11) and a vapor sample tap (5) and analyzed. Microwave does not heat the vapor-liquid equilibrium kettle body made of a borosilicate glass material but directly effects on vapor phase main body and the liquid phase main body, so as to realize characteristics of energy saving, rapidness and efficient heating.

Owner:TIANJIN UNIV

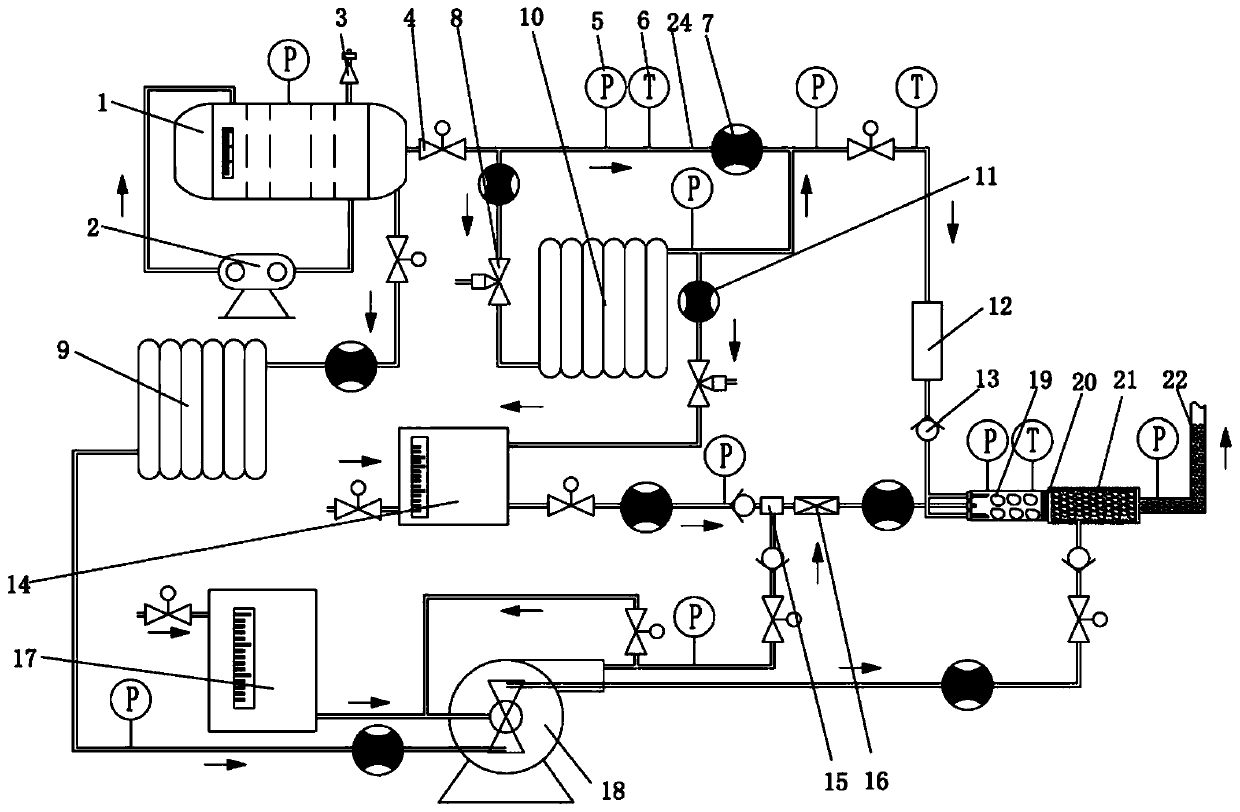

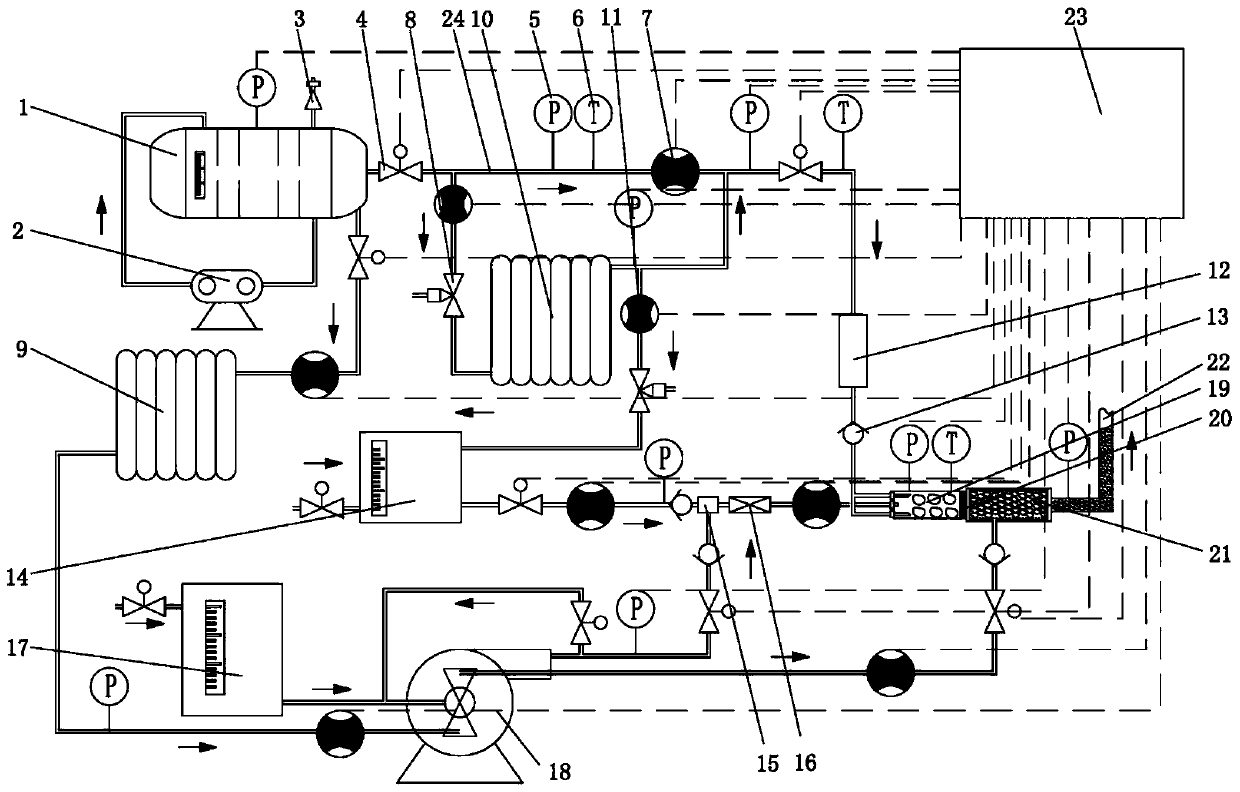

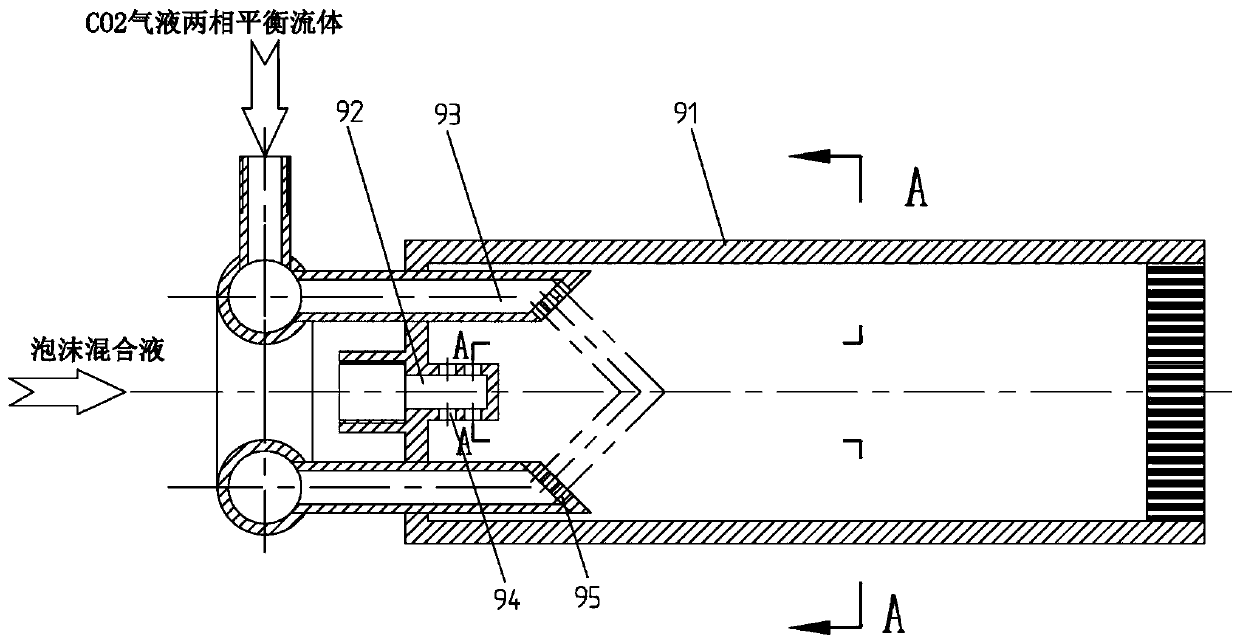

Positive pressure foam fire extinguishing system based on two-phase flow drive and foam generation method

Owner:XIAN UNIV OF SCI & TECH +1

Method and device for measuring solubility of refrigerant and refrigerating machine oil

The invention relates to a method and a device for measuring solubility of refrigerant and refrigerating machine oil. According to the method and the device, the problems of pressure resistance and seal are easily solved in the measuring process, and the equipment is easy to manufacture. When the gas phase composition is not analyzed in the gas-liquid equilibrium calculation process, the gas phase composition can be calculated by P-T-x, so that the problems such as difficulty and measurement inaccuracy brought by lots of analysis work of solubility data which is directly measured by liquid-phase sampling analysis and sampling deviated from the equilibrium are solved.

Owner:WUHAN UN LUBRICANT TECH

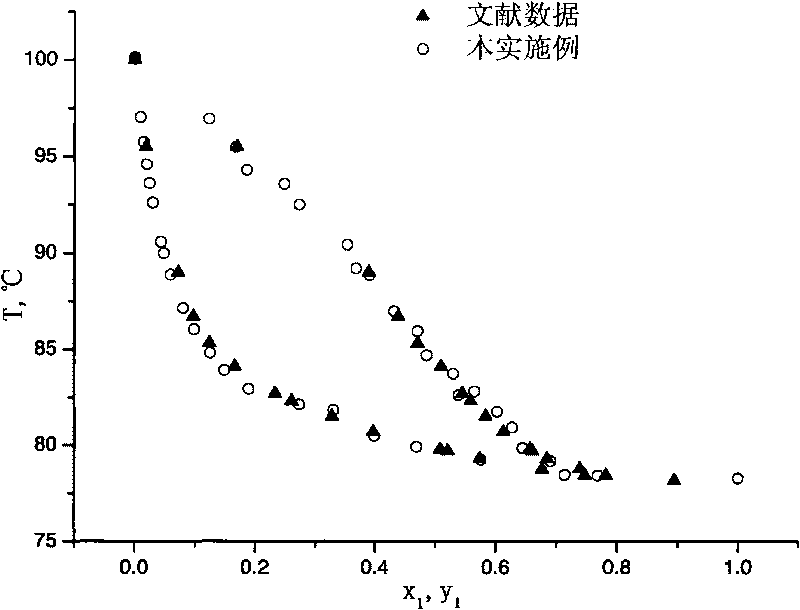

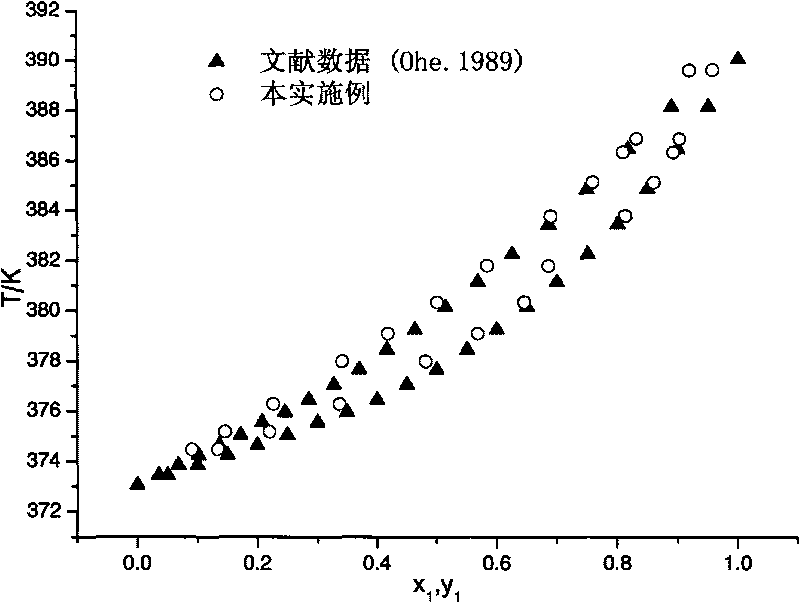

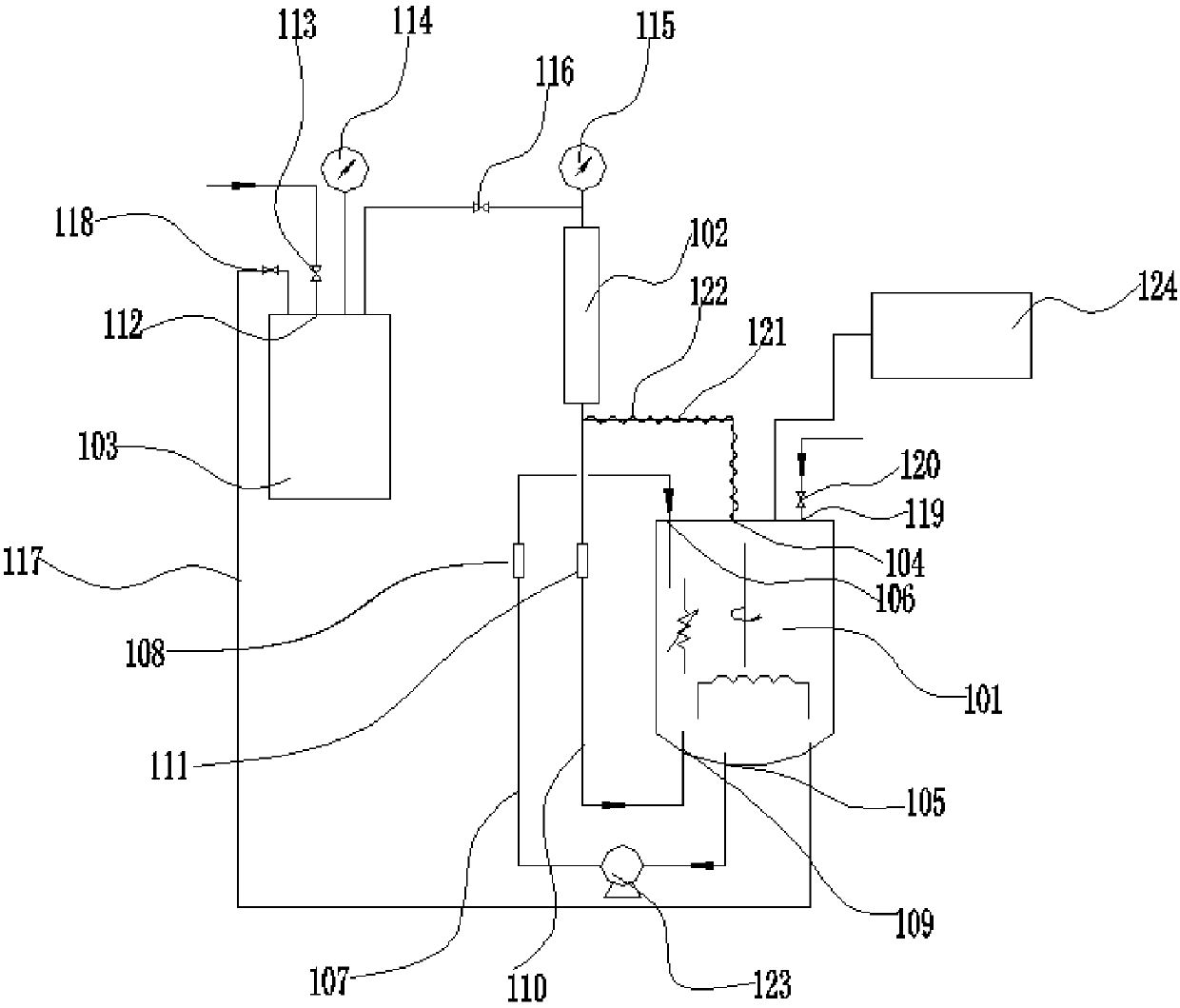

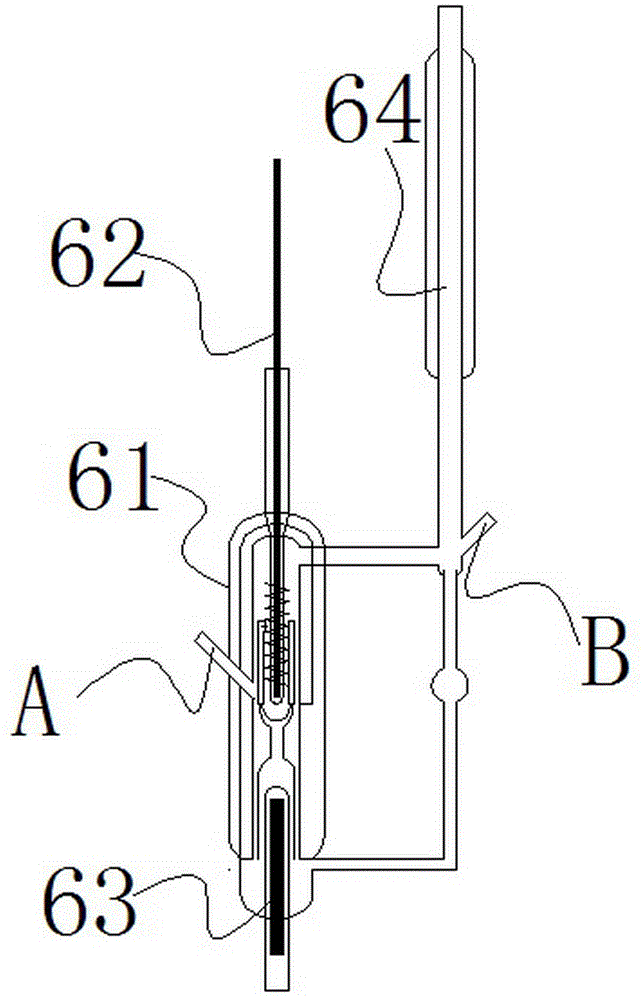

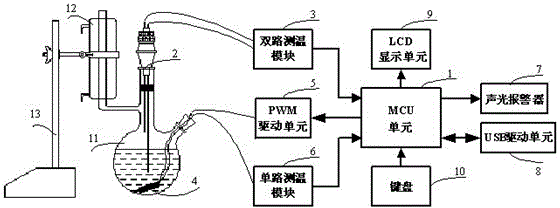

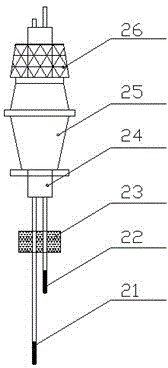

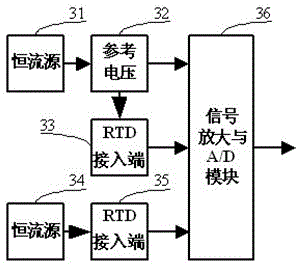

Automatic experiment and analysis device for gas-liquid equilibrium phase diagram of binary liquid solution

ActiveCN103604826APrecise temperature controlRealize synchronized measurementsInvestigating phase/state changeTemperature controlData acquisition

The invention discloses an automatic experiment and analysis device for a gas-liquid equilibrium phase diagram of a binary liquid solution. The automatic experiment and analysis device comprises a fixed bracket, a flask, a heating device, a fractionating device, a temperature measurement device, a micro control unit and a PWM (pulse width modulation) driving unit, wherein a heating stick assembly is adopted as the heating device; one end of the heating stick assembly extends into the flask, and the other end of the heating stick assembly is connected with the micro control unit through the PWM driving unit; the temperature measurement device comprises a double-path RTD (resistance temperature detector) assembly and a double-path temperature measurement module; one end of the double-path RTD assembly extends into the flask, and the other end of the double-path RTD assembly is connected with the micro control unit through the double-path temperature measurement module; an RTD sensor in the double-path RTD assembly extends into the binary liquid solution, and another RTD sensor is positioned above the binary liquid solution. The automatic experiment and analysis device for the gas-liquid equilibrium phase diagram, which is disclosed by the invention, can automatically measure and control the temperature and judge a gas-liquid equilibrium state accurately and sequentially and also finish experiment operations such as data acquisition, data analysis and data displaying; therefore, the precision of temperature control is improved, and the operation is easy.

Owner:CHUZHOU SEEK ELECTRONICS

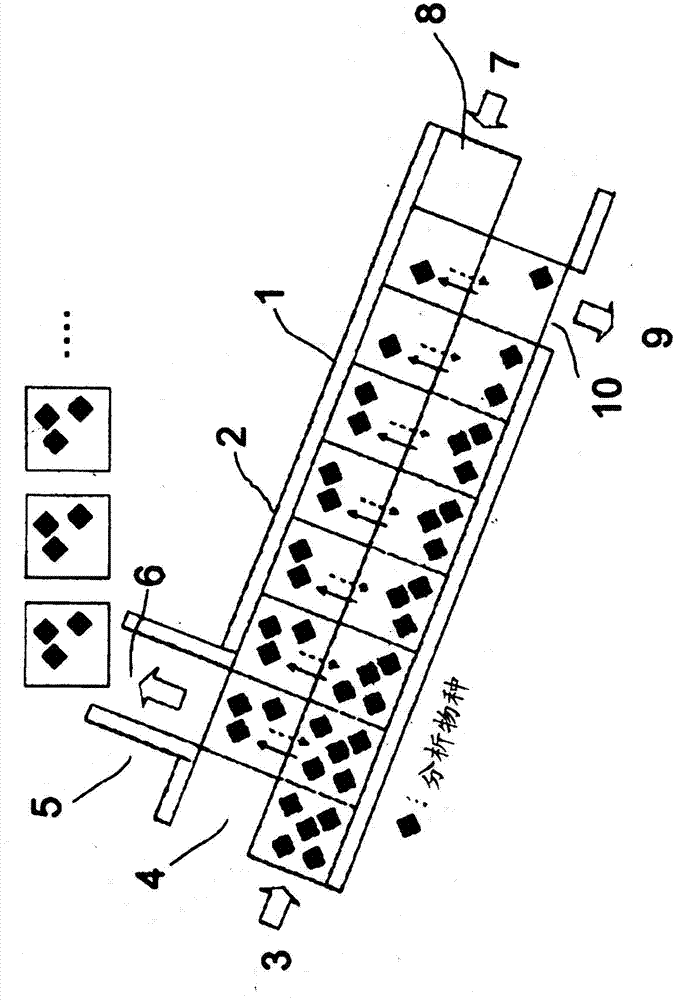

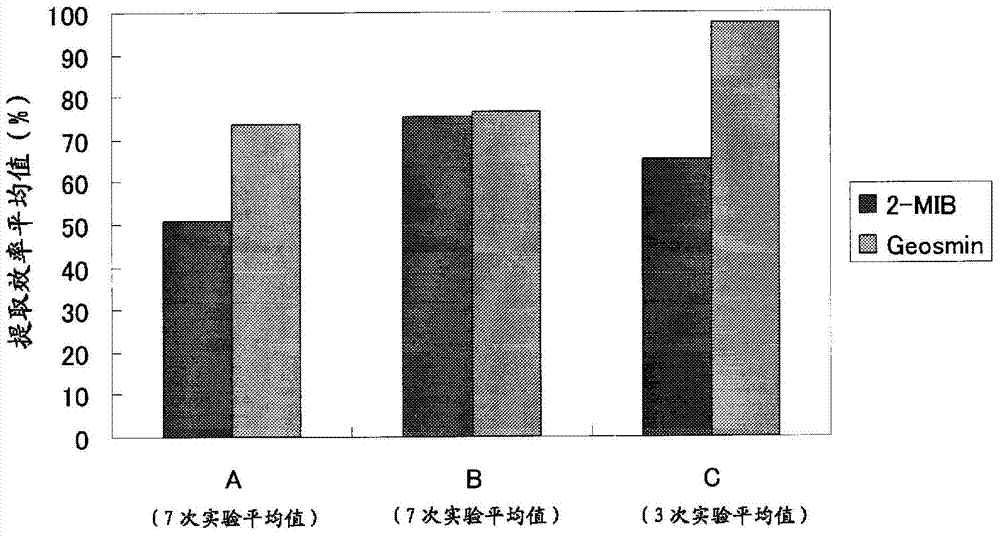

Vapor-liquid contact extraction method and device

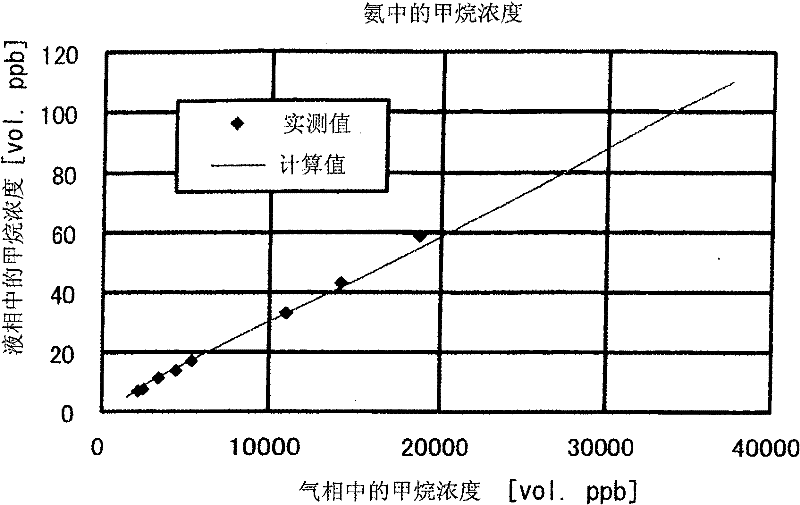

ActiveCN103946683AAdequate and rapid contactMake sure to analyze the speciesComponent separationWithdrawing sample devicesSolubilityVapor liquid

The present invention provides a method and device for quickly extracting analytical species present in a liquid phase when using vapor-liquid contact extraction for analyzing species having "a large partition coefficient in the vapor-liquid equilibrium," "a high water solubility," or "a low olfactory threshold; " and further provides a method and device for introducing the analytical species as a sample in GC or the like without user assistance over prolonged and continuous periods of time. This method and device perform vapor-liquid contact of a sample liquid and purge gas using a vapor-liquid contact extraction unit for continuously introducing the sample liquid from above and the purge gas from below, and extract the analytical species from the test sample liquid. The purge gas is prevented from flowing out from a liquid reservoir provided to a discharge pipe connected to a bottom part of the vapor-liquid contact extraction unit while the liquid sample is discharged via the reservoir.

Owner:SHIMADZU SEISAKUSHO CO LTD +1

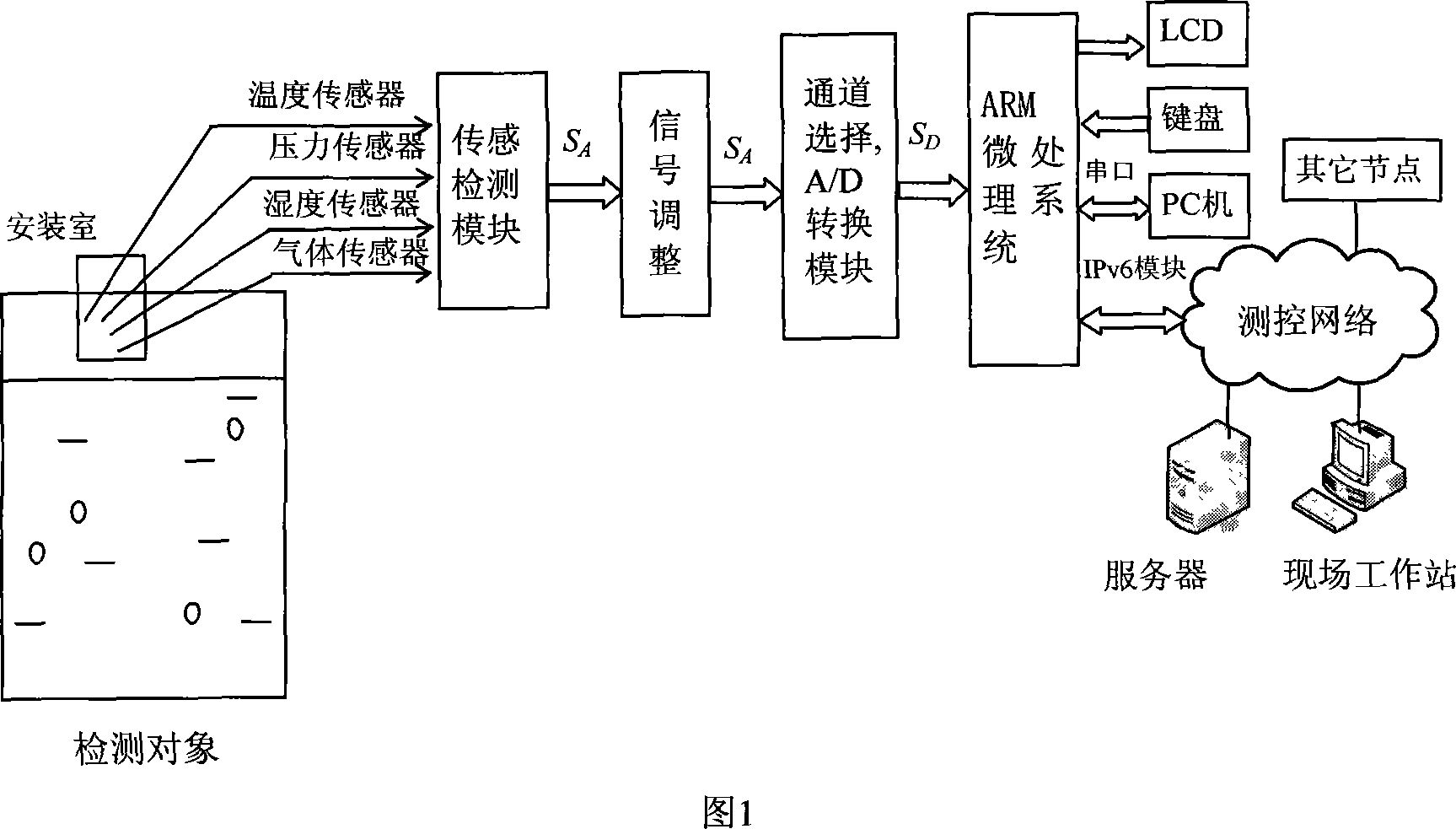

Online detecting method and device for high precision liquid ethanol concentration

InactiveCN101051052AAccurate temperatureAccurate pressureMaterial analysis by electric/magnetic meansSpecial data processing applicationsCommunication interfaceAlcohol

A method for on-line detecting concentration of high precision liquid state alcohol (LSA) includes using gas transducer to make detection on concentration of gas state alcohol (GSA) and obtaining concentration of GSA quickly and accurately by utilizing multi-scale multidimensional interpolation decoupling means to eliminate out influence on gas transducer from non-measured object for detected signal, calculating concentration of LSA based on gas-liquid balance mechanism and realizing distributed on-line monitor on concentration of LSA in industrial process by utilizing IPv6 communication interface. The device used for realizing said method is also disclosed.

Owner:SOUTH CHINA UNIV OF TECH

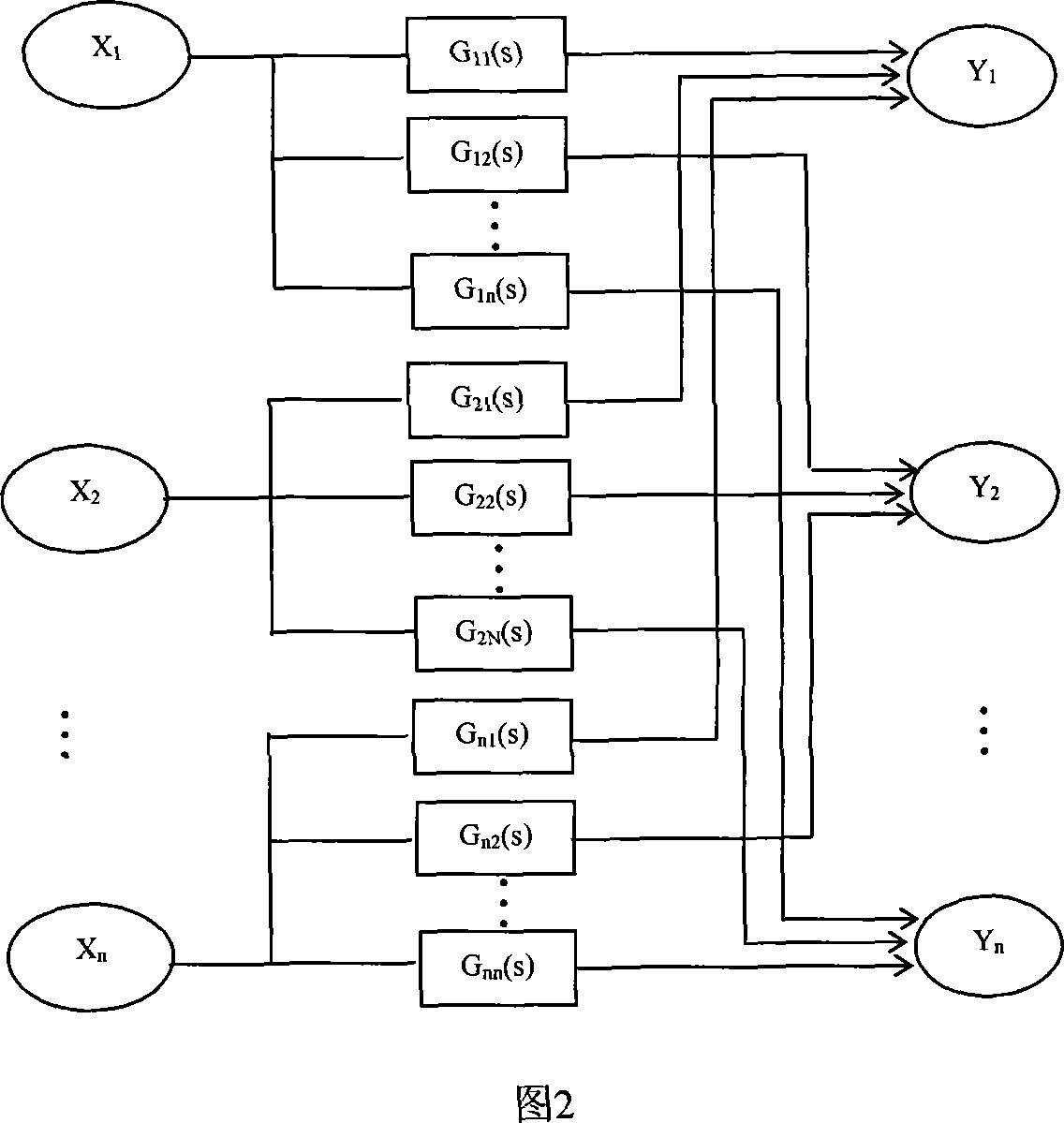

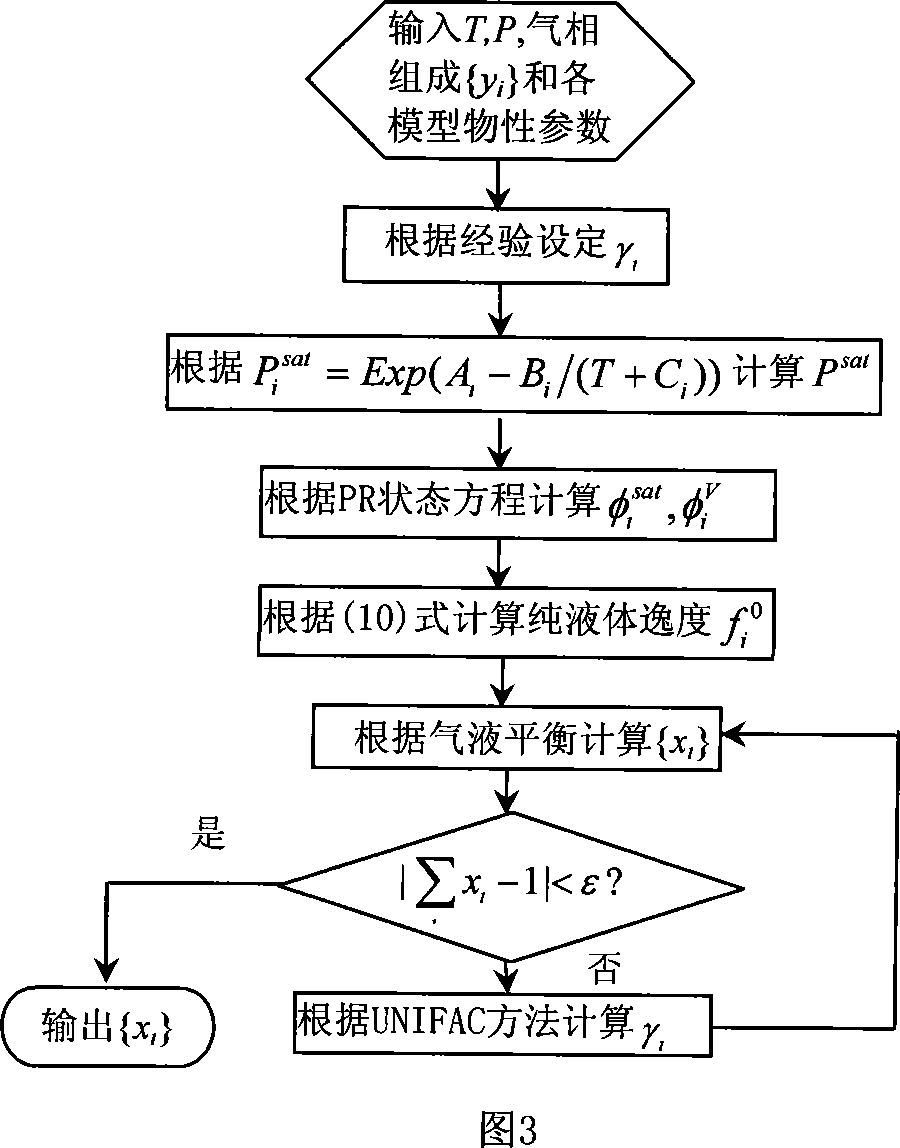

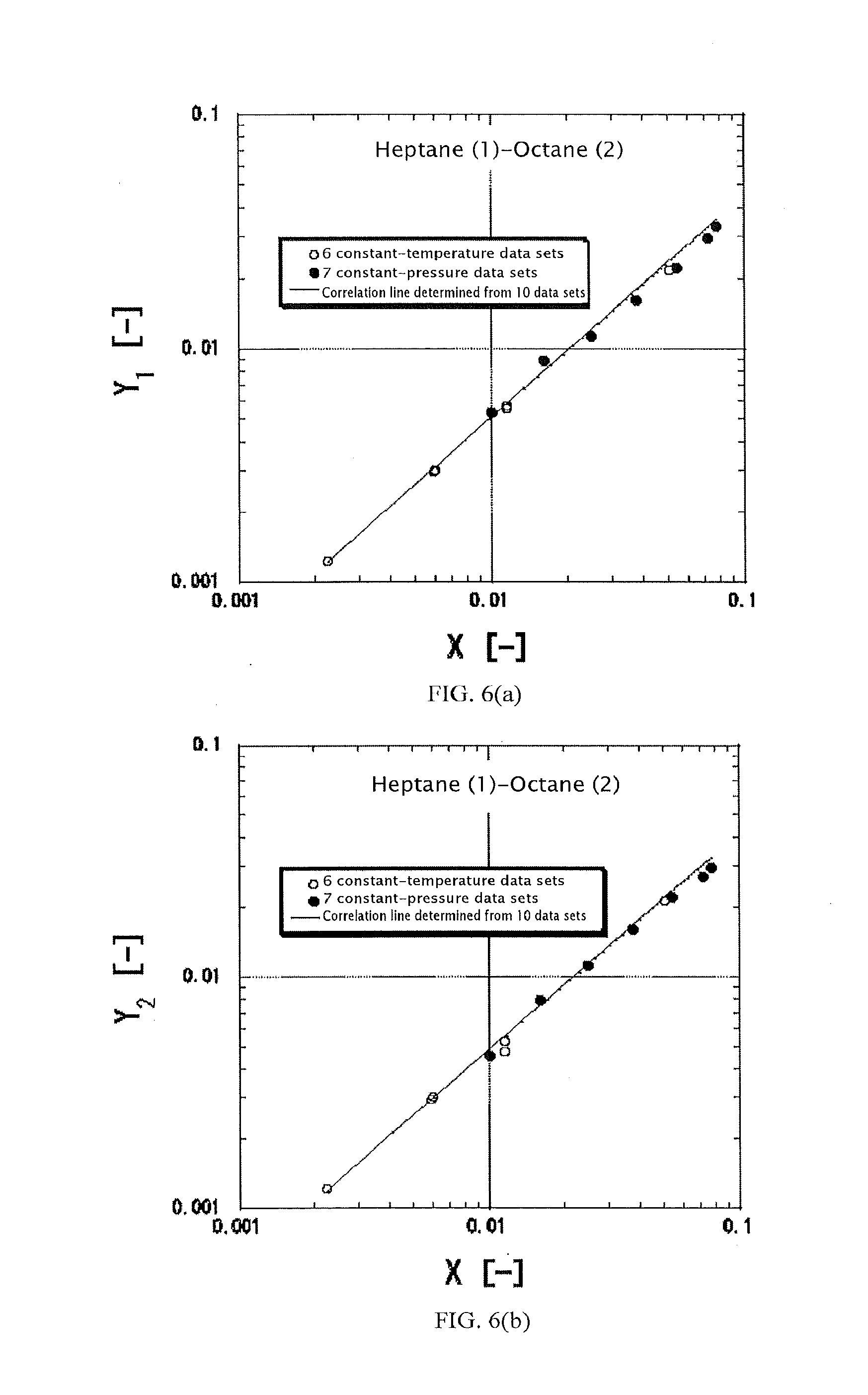

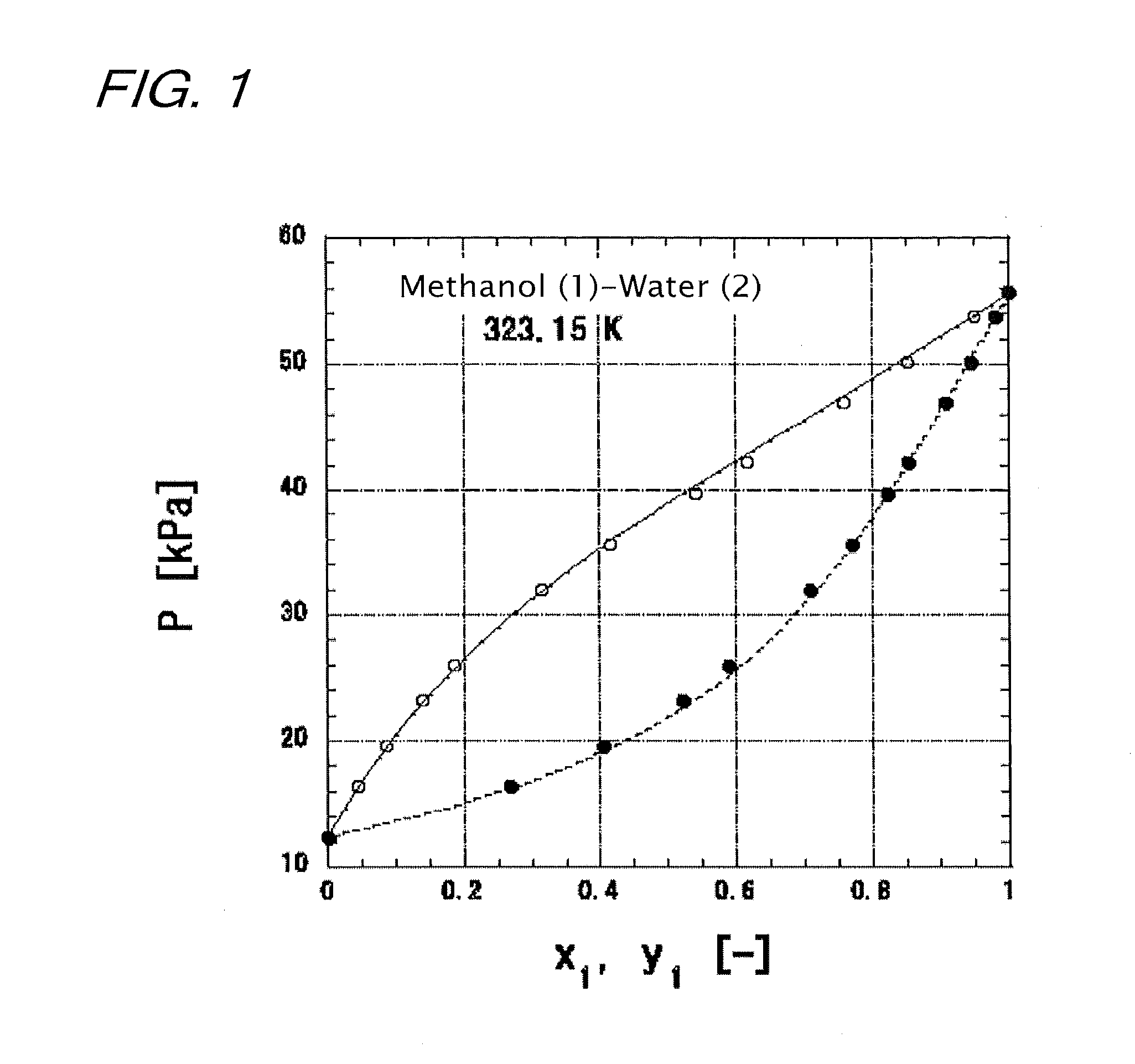

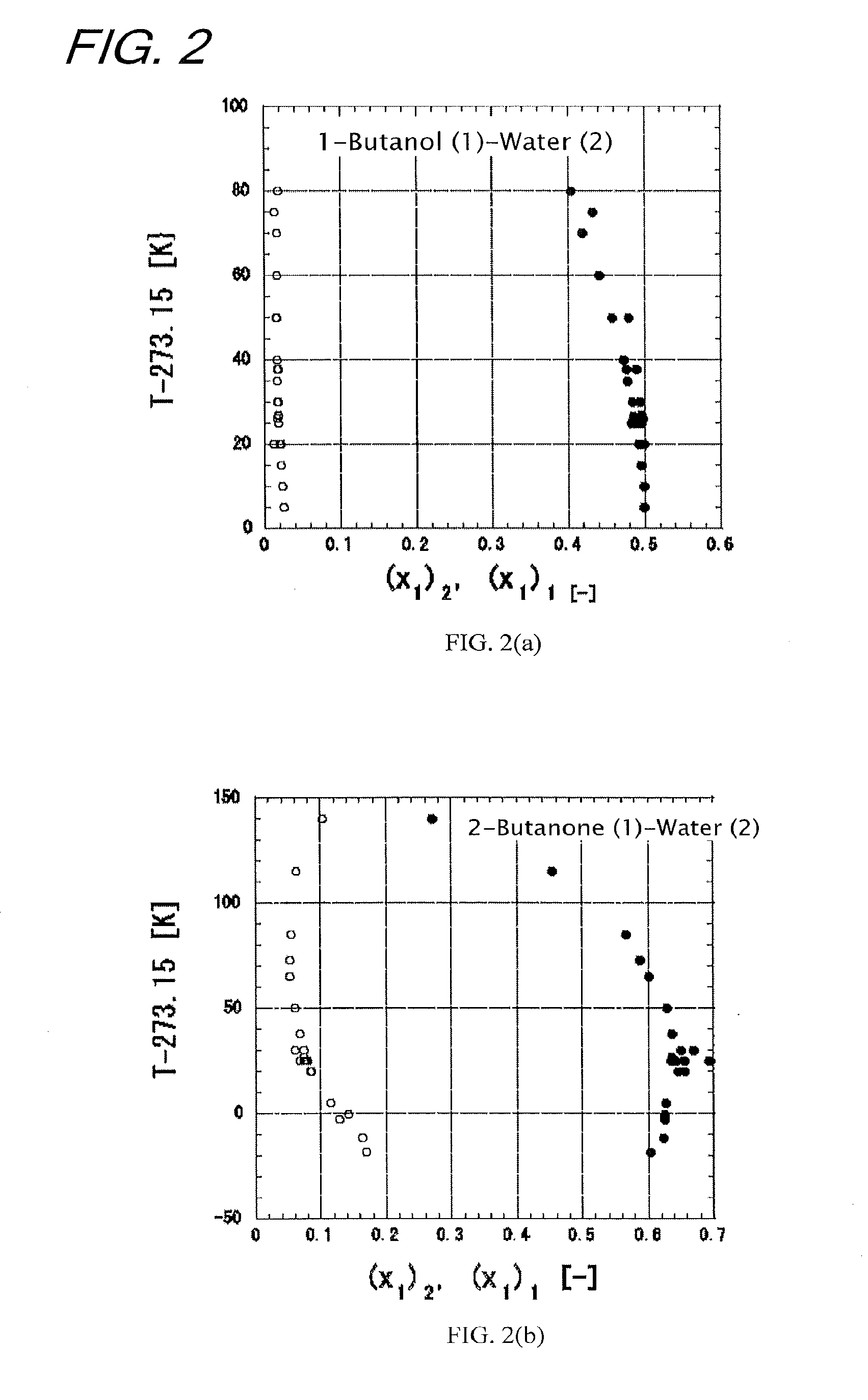

Highly accurate correlating method for phase equilibrium data, and phase equilibrium calculation method

ActiveUS20140288905A1Highly accurate correlationOperated inexpensivelySolvent extractionDistillation regulation/controlDistillationPredictive methods

A method for precisely predicting phase equilibrium from existing phase equilibrium data on the basis of a wide range of phase equilibrium data including binary vapor-liquid equilibrium data; a method or apparatus for designing or controlling a component separator or a refiner using the prediction method; and a program for designing this design or control apparatus. Binary phase equilibrium measurement data is used to calculate an index of proximity ratio to critical points and infinite dilution pressure gradients. The obtained index is correlated with the infinite dilution pressure gradients to newly calculate infinite dilution activity coefficients from the respective index to infinite dilution pressure gradients correlations. The obtained infinite dilution activity coefficients values are used to predict phase equilibrium. Thus, the obtained values are used to design or control a component separator or a refiner, such as a distillation column.

Owner:TOKYO METROPOLITAN PUBLIC UNIV CORP

Method for supplying refined liquefied gas

Owner:NIPPON SANSO CORP

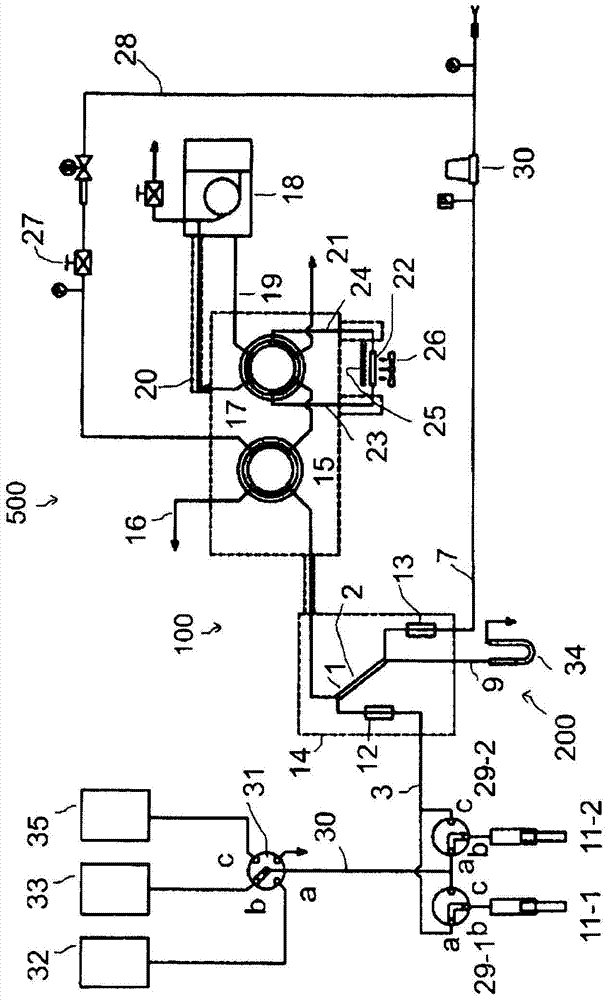

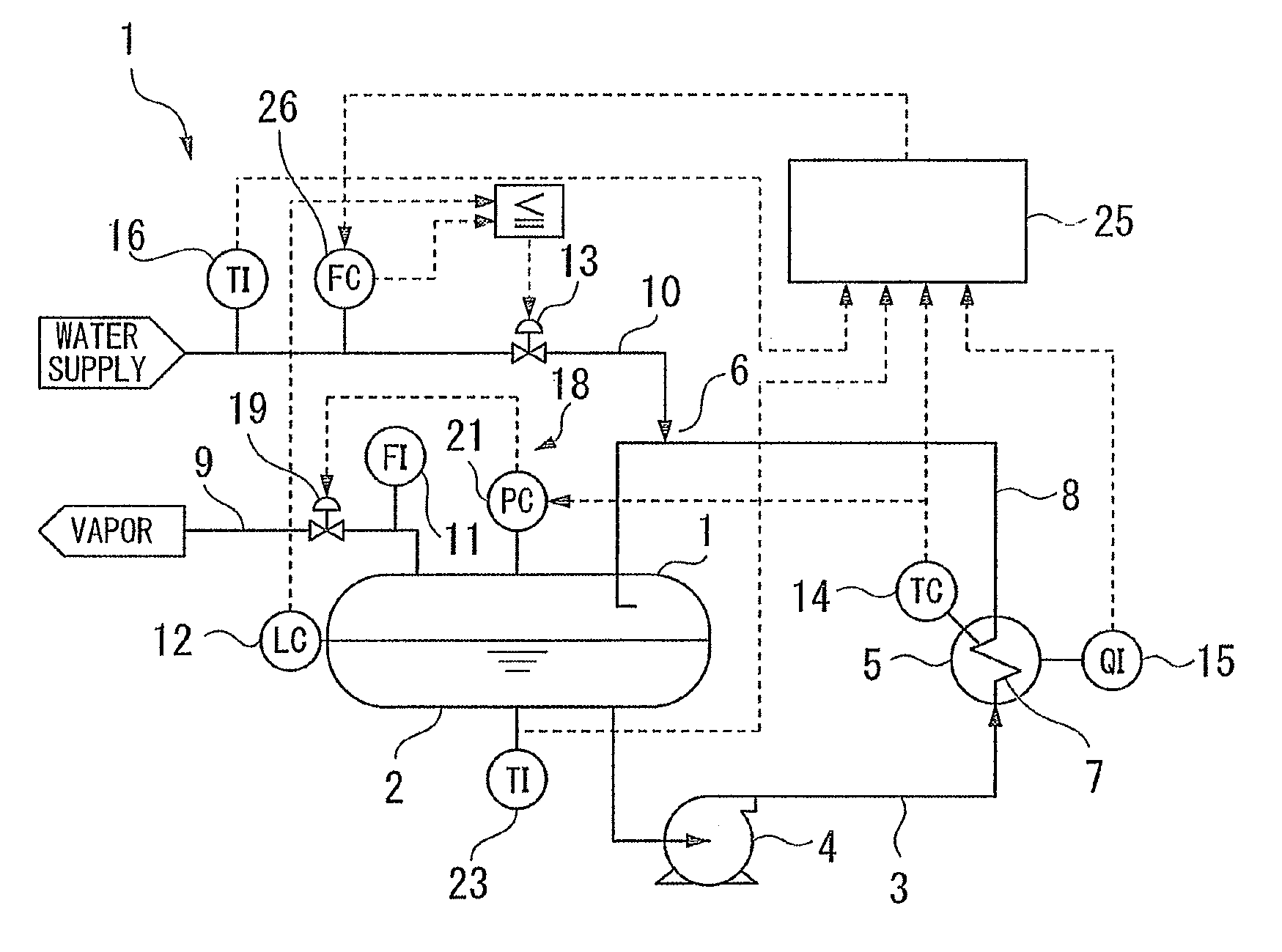

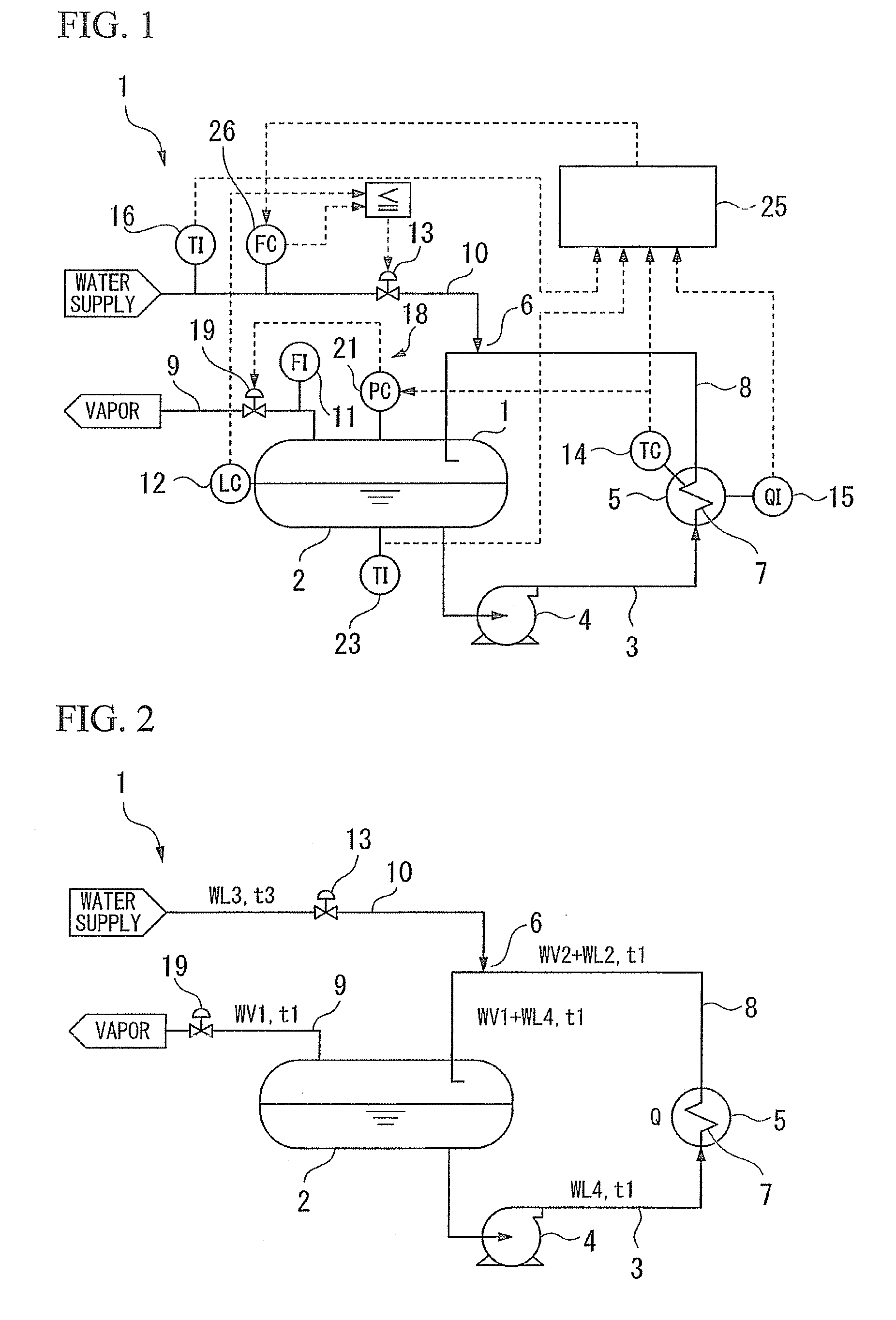

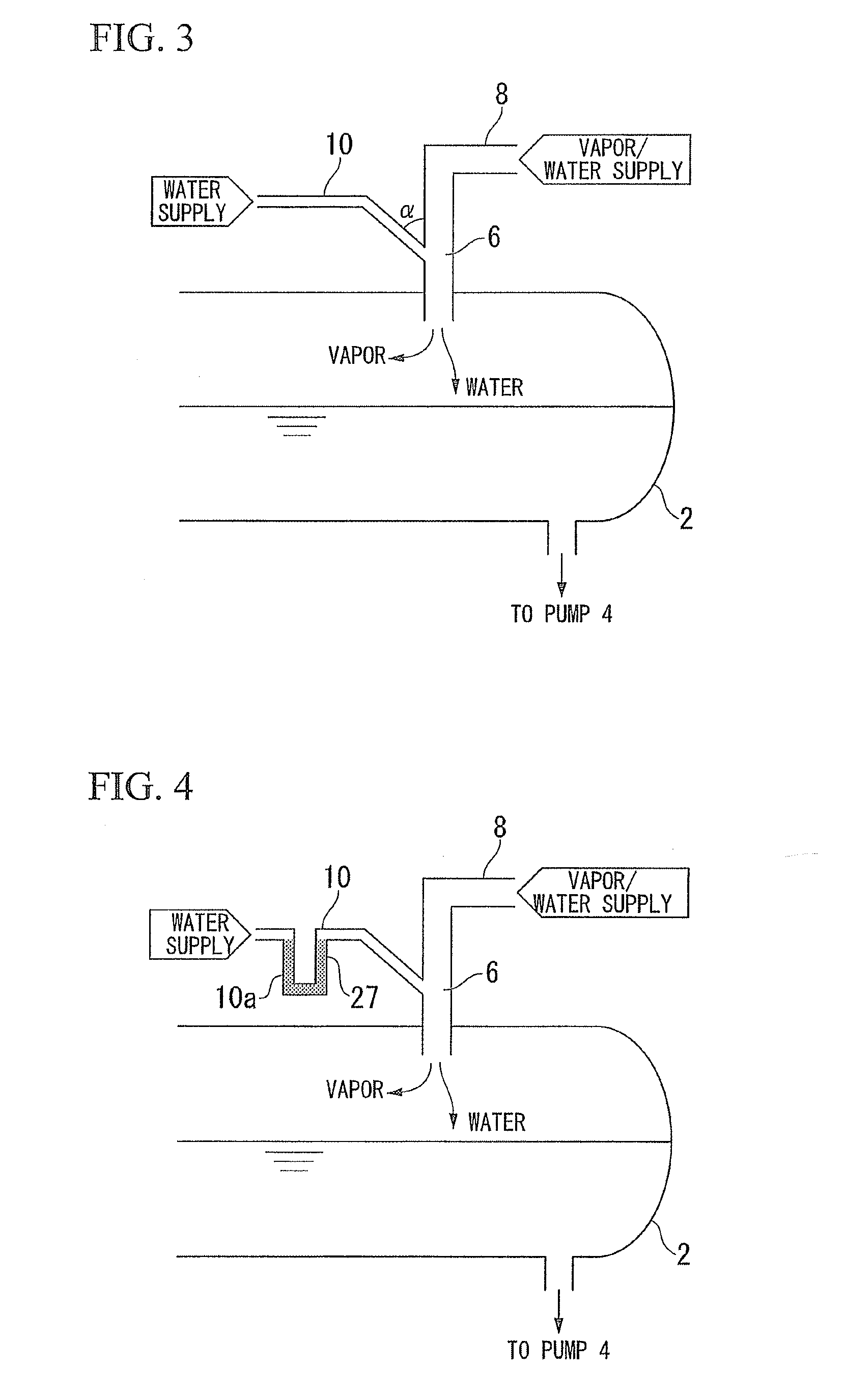

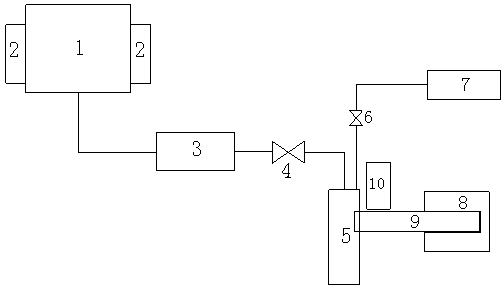

Temperature control system

InactiveUS20140157813A1Maintain temperatureAvoid equipmentDomestic cooling apparatusSteam/vapor condensersTemperature controlControl system

A temperature control system of the invention recovers reaction heat in a reactor in which an exothermal reaction occurs, to control the temperature in the reactor. The temperature control system includes: a refrigerant drum in which vapor and a liquid refrigerant are stored in a vapor-liquid equilibrium state; a heat removing section arranged in the reactor to evaporate a part of the liquid refrigerant supplied from the refrigerant drum by the reaction heat; a Return line that returns mixed phase fluid of vapor and the liquid refrigerant generated in the heat removing section to the refrigerant drum; a Vapor outlet line that supplies vapor in the refrigerant drum to outside of the system; and a Replenishing line that supplies makeup water in an amount matched with an amount of vapor discharged to the outside of the system, to the Return line.

Owner:JAPAN PETROLEUM EXPLORATION CO LTD +5

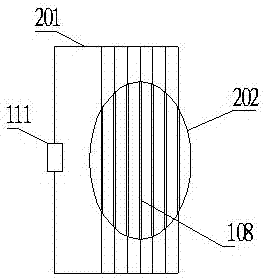

Working medium filling system for independent parallel multichannel flat heat pipe, and filling method thereof

InactiveCN108955328AConsistent qualityHigh degree of automationSteam/vapor condensersIndirect heat exchangersVapor liquidHigh volume manufacturing

The invention discloses a working medium filling system for an independent parallel multichannel flat heat pipe, and a filling method thereof. The filling system comprises a working medium tank, a quantitative system, a constant temperature common chamber, a flat heat pipe, a variable temperature system, a vacuum system and a sealing system; and control valves are arranged between the quantitativesystem and the constant temperature common chamber as well as between the constant temperature common chamber and the vacuum system. During filling, non-condensable gas in a pipeline system and the flat heat pipe is pumped out firstly, and then high temperature and high pressure working medium vapor is filled into the flat heat pipe through the quantitative system; when temperature and pressure vapor-liquid equilibrium is achieved, working media in the parallel multichannel flat heat pipe are in the vapor-liquid phase coexisting state; at the moment, one end of the parallel multichannel flatheat pipe is sealed through the sealing system, so that the independent parallel multichannel flat heat pipe is made. The working medium filling system has the advantages of stable overall performance, the high filling quality and automation degree, and the simple technology, and is suitable for mass production, and the mass consistency of the working media in each flat heat pipe channel can be controlled accurately.

Owner:李卫东

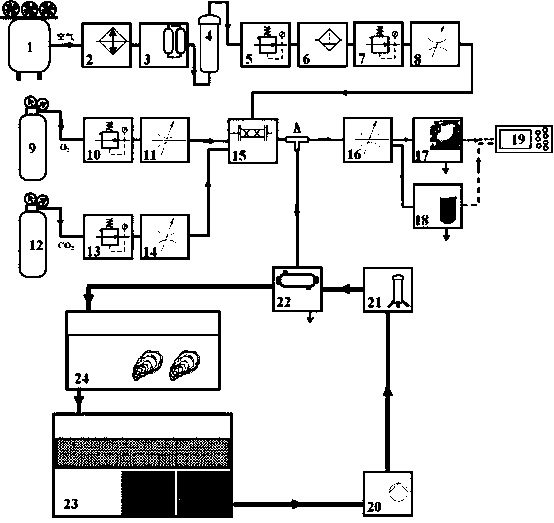

Device and method for precise control on dissolved oxygen and pH value in medium/small-size aquaculture water

PendingCN110451626AIncrease oxygen concentrationIncrease oxygen flowWaste water treatment from animal husbandryPisciculture and aquariaEngineeringAir compressor

The invention relates to a device and a method for precise control on dissolved oxygen and pH values in medium / small-size aquaculture water. The device comprises a gas mixer, an air compressor, an oxygen steel cylinder and a carbon dioxide steel cylinder, wherein the air compressor, the oxygen steel cylinder and the carbon dioxide steel cylinder are respectively connected with the input end of thegas mixer; the output end of the gas mixer is connected with a first end of a three-way tube; a second end of the three-way tube is connected with a first input end of a degassing membrane; a third end of the three-way tube is connected with an oxygen sensor and a carbon dioxide sensor; data of the oxygen sensor and the carbon dioxide sensor are transmitted to a recorder and are displayed; and the output end of the degassing membrane communicates with an aquaculture vat. Through reading of the oxygen sensor and the carbon dioxide sensor, different gas flows can be precisely adjusted, furthermore, air, oxygen and carbon dioxide can be sufficiently mixed in a static mixer, and after the mixed gas and seawater meet gas-liquid balance in the degassing membrane, seawater with stable and controllable dissolved oxygen and pH values is obtained from the output end of the degassing membrane for aquaculture or related scientific research experiment.

Owner:QUANZHOU NORMAL UNIV

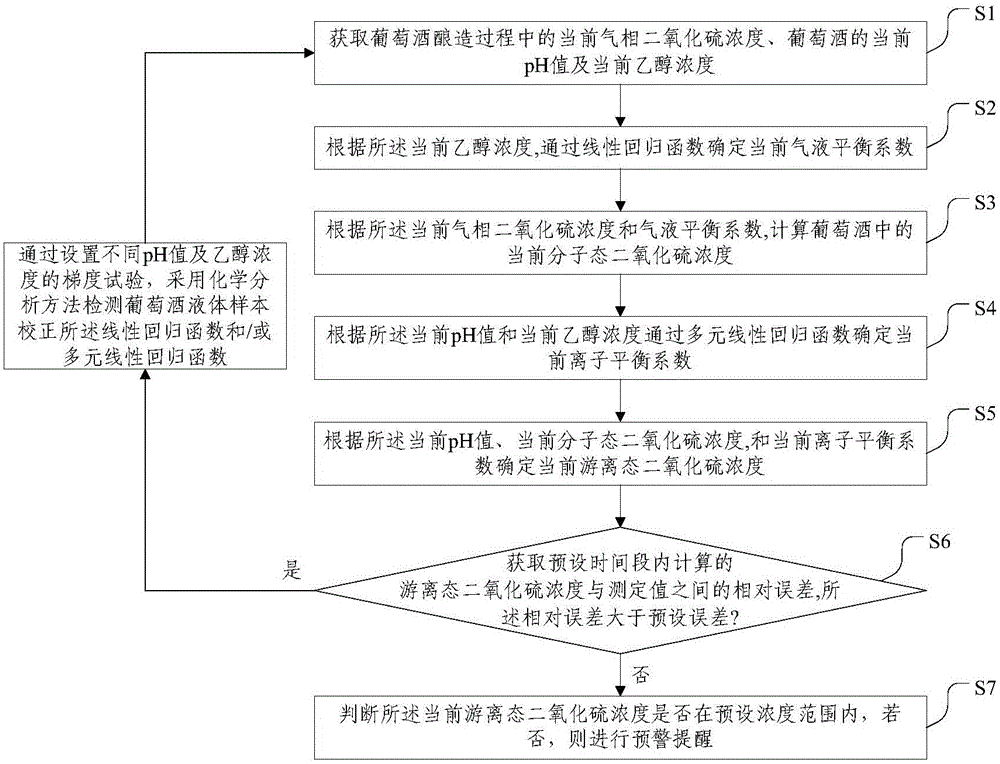

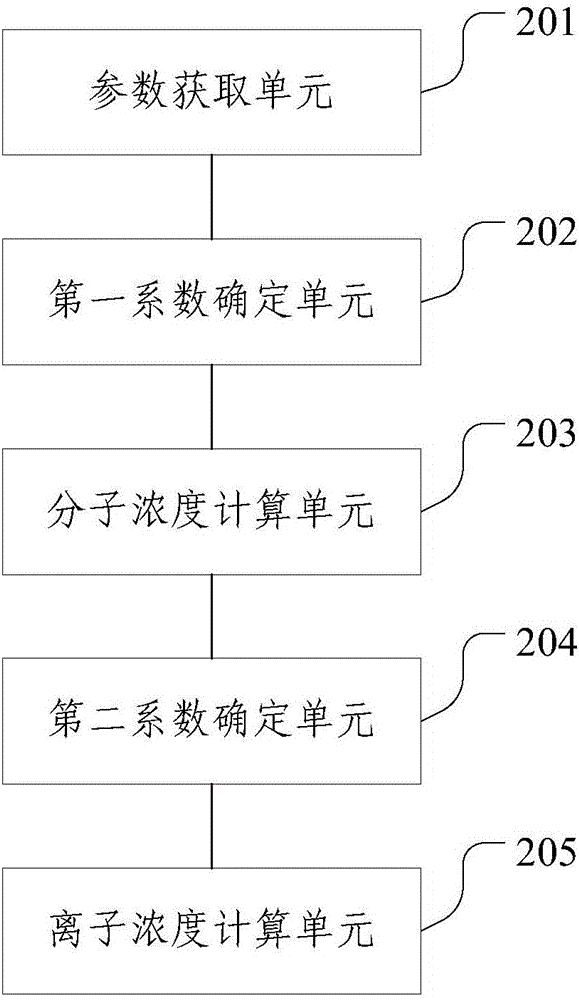

Online monitoring method and device for sulfur dioxide in wine making process

ActiveCN106124714ADirect and efficient quality monitoringAccurate Quality MonitoringTesting beveragesLinear regression functionQuality control

The invention discloses an online monitoring method and device for sulfur dioxide in wine making process and relates to the technical field of food monitoring. Based on the gas-liquid phase equilibrium and dissociation equilibrium principle in the wine making process, multiple factors influencing equilibrium are fully considered, after data in the wine making process is acquired, a gas-liquid equilibrium coefficient and an ionic equilibrium coefficient of a current wine equilibrium system are calculated through a linear regression function, the concentration of molecular-state sulfur dioxide in the wine is calculated according to a gas-liquid phase molecular-state sulfur dioxide equilibrium relationship, and then the concentration of free-state sulfur dioxide is calculated according to a dissociation equilibrium relationship between the molecular-state sulfur dioxide and free-state sulfur dioxide in liquid. By means of online monitoring method and device, the concentration of the free-state sulfur dioxide in the wine can be quickly, nondestructively and intelligently detected, convenience and real-time performance are achieved, and direct, efficient and accurate wine quality monitoring and quality control and raw material saving in the making process can be achieved easily.

Owner:CHINA AGRI UNIV

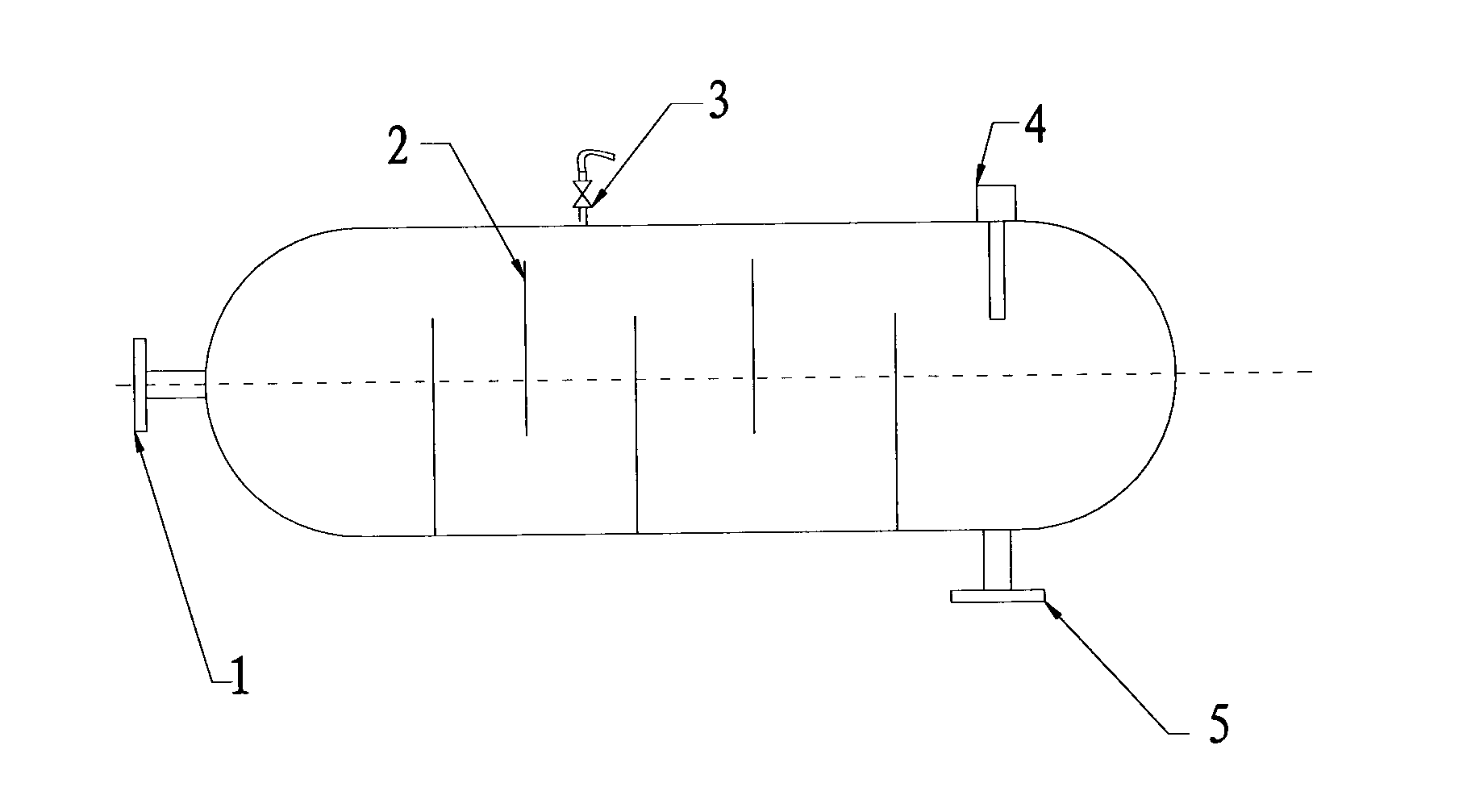

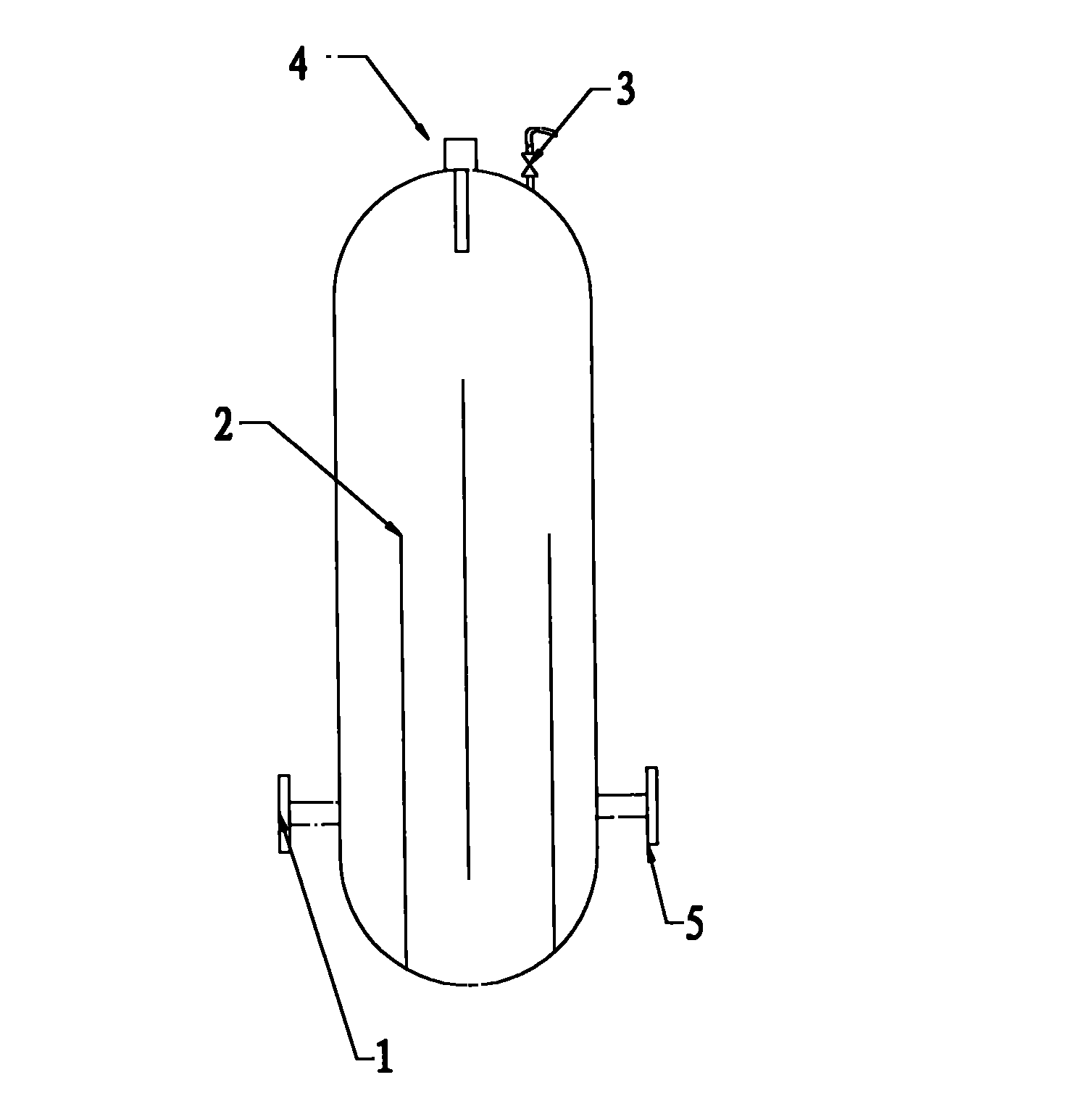

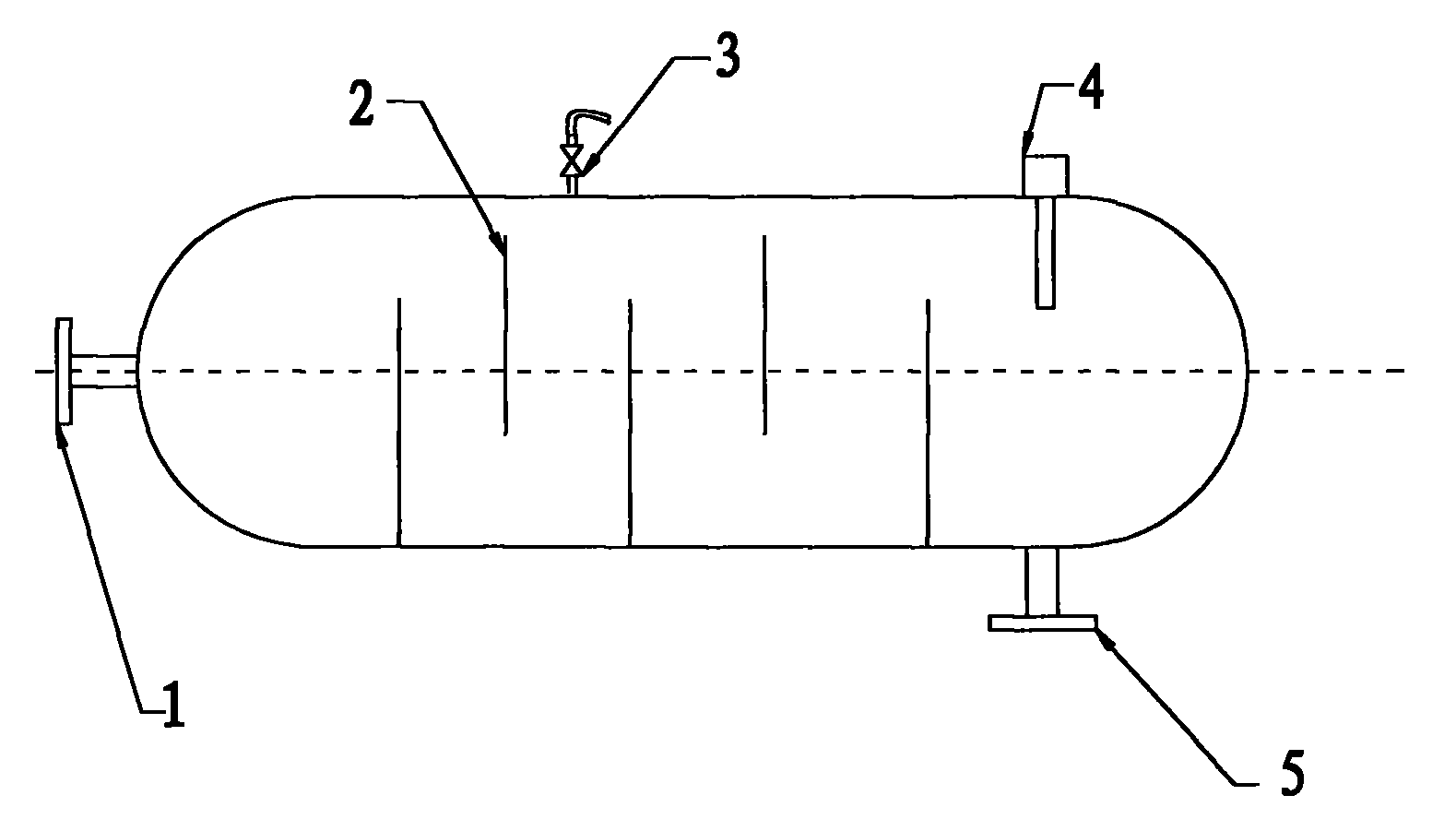

Gas-liquid equilibrium dissolved air vessel

InactiveCN102583616APrecise control of liquid levelGuarantee the effect of dissolved airWater/sewage treatment by degassingWater/sewage treatment by flotationControl systemEngineering

The invention discloses a gas-liquid equilibrium dissolved air vessel comprising a vessel body and a control system and being characterized in that the vessel body is internally provided with a plurality of rectification baffles; the top of the vessel body is provided with a liquid level sensor; an electromagnetic valve is arranged at an air outlet at the top of the vessel body; and the electromagnetic valve and the liquid level sensor are respectively connected with the control system through a signal. The gas-liquid equilibrium dissolved air vessel provided by the invention can be used for precisely controlling the liquid level to achieve the function of a gas-liquid equilibrium vessel, the dissolved air effect is ensured, and complex manual operation is omitted.

Owner:WUXI GONGYUAN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com