Complete methanation reaction device for synthesis gas

A complete methanation and reaction device technology, which is applied in the field of synthesis gas complete methanation reaction device, can solve the problems of complex process and small production capacity, and achieve the effects of simplifying the process, improving heat transfer rate and increasing the operating range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

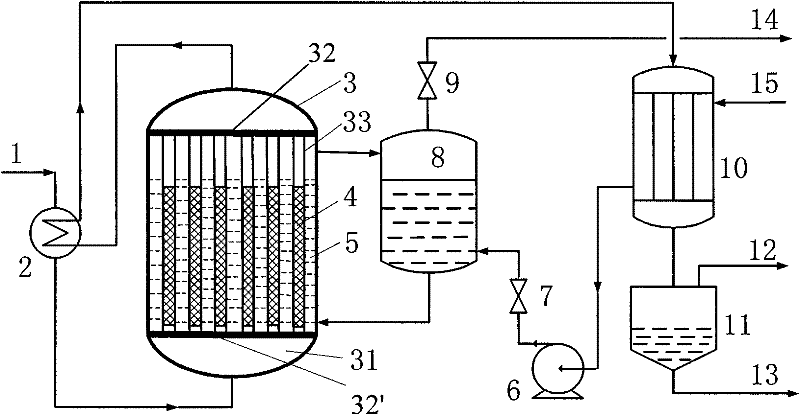

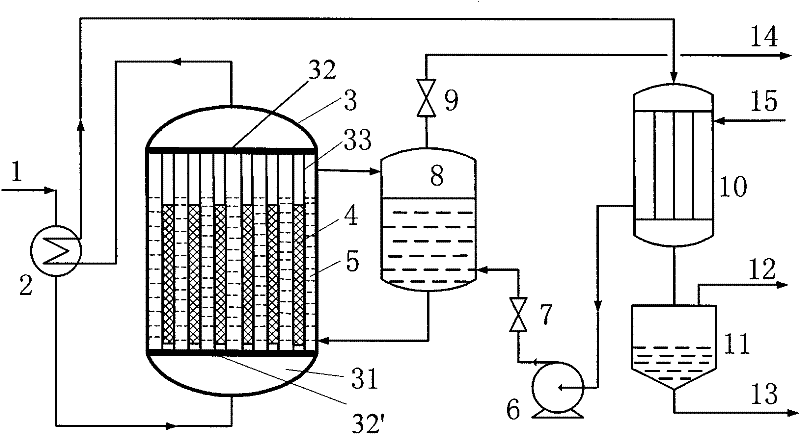

[0031] figure 1 It is the structural schematic diagram of the synthesis gas complete methanation reaction device of the present embodiment, by figure 1 It can be seen that the complete methanation reaction device for synthesis gas provided by the present invention includes: a shell-and-tube reactor, a heat exchanger 2, a steam drum 8, a feed water pump 6, a condenser 10 and a gas-liquid Separator 11;

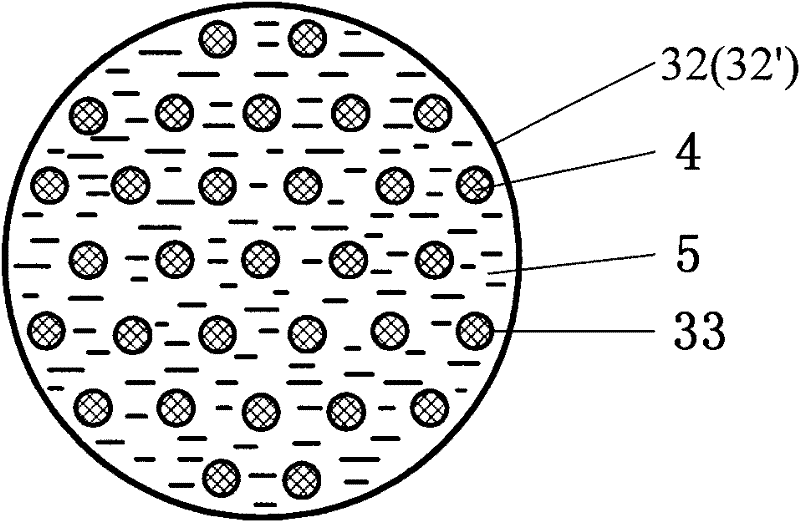

[0032] The shell-and-tube reactor is divided into an upper chamber 3, a middle chamber and a bottom chamber 31 by a reactor cavity, which are respectively fixed on the upper and bottom walls of the inner cavity of the reactor cavity. The lower horizontal gas distribution plate 32' and the upper horizontal gas distribution plate 32 of the three parts are composed of a tube array composed of tubes; the lower horizontal gas distribution plate 32' and the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com