Patents

Literature

375 results about "Phase change heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phase change heat transfer is a broad field that finds applications in almost all of the engineering disciplines. Boiling and condensation are two of the most important phase change processes as they are generally associated with high heat transfer rates.

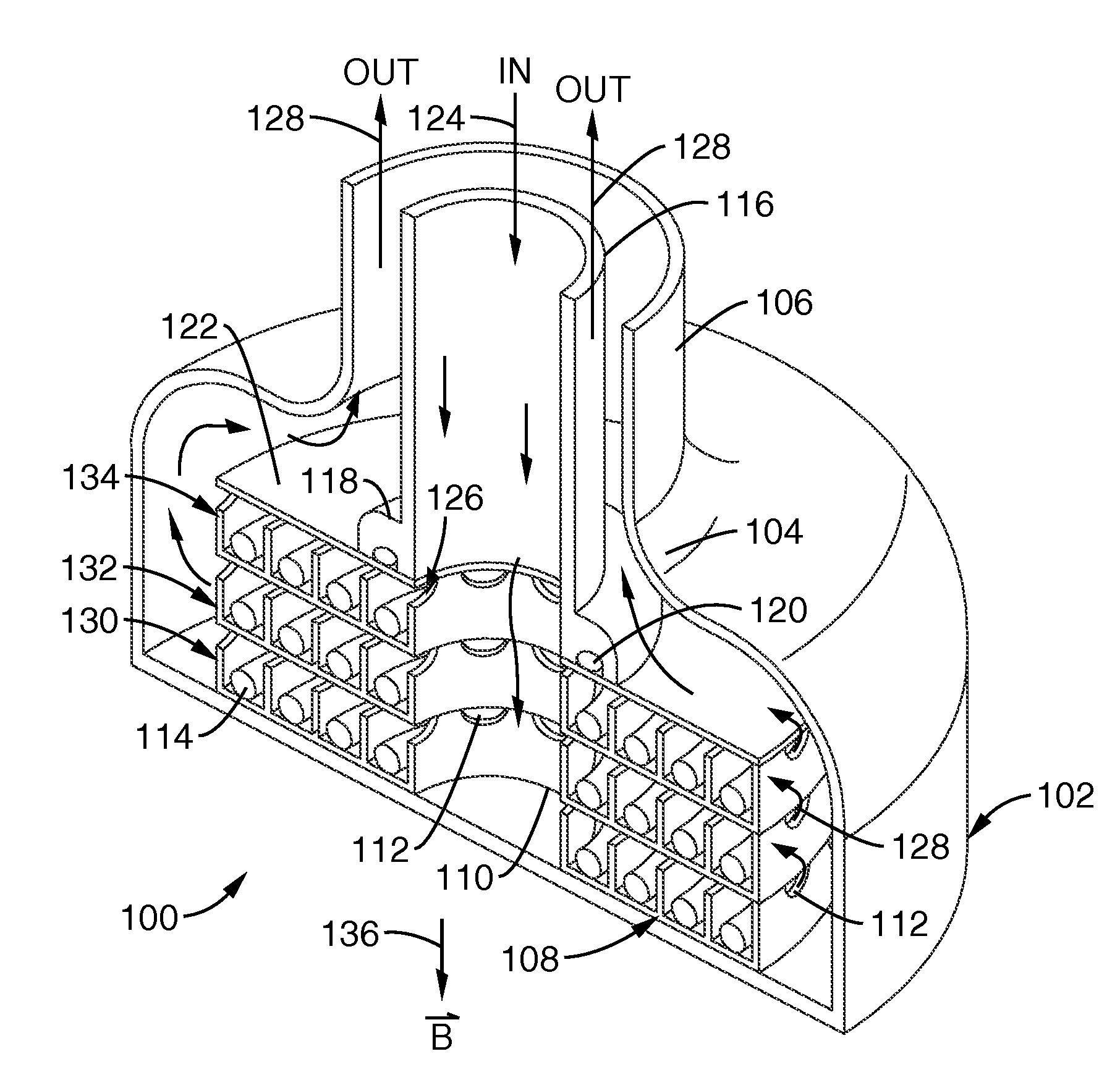

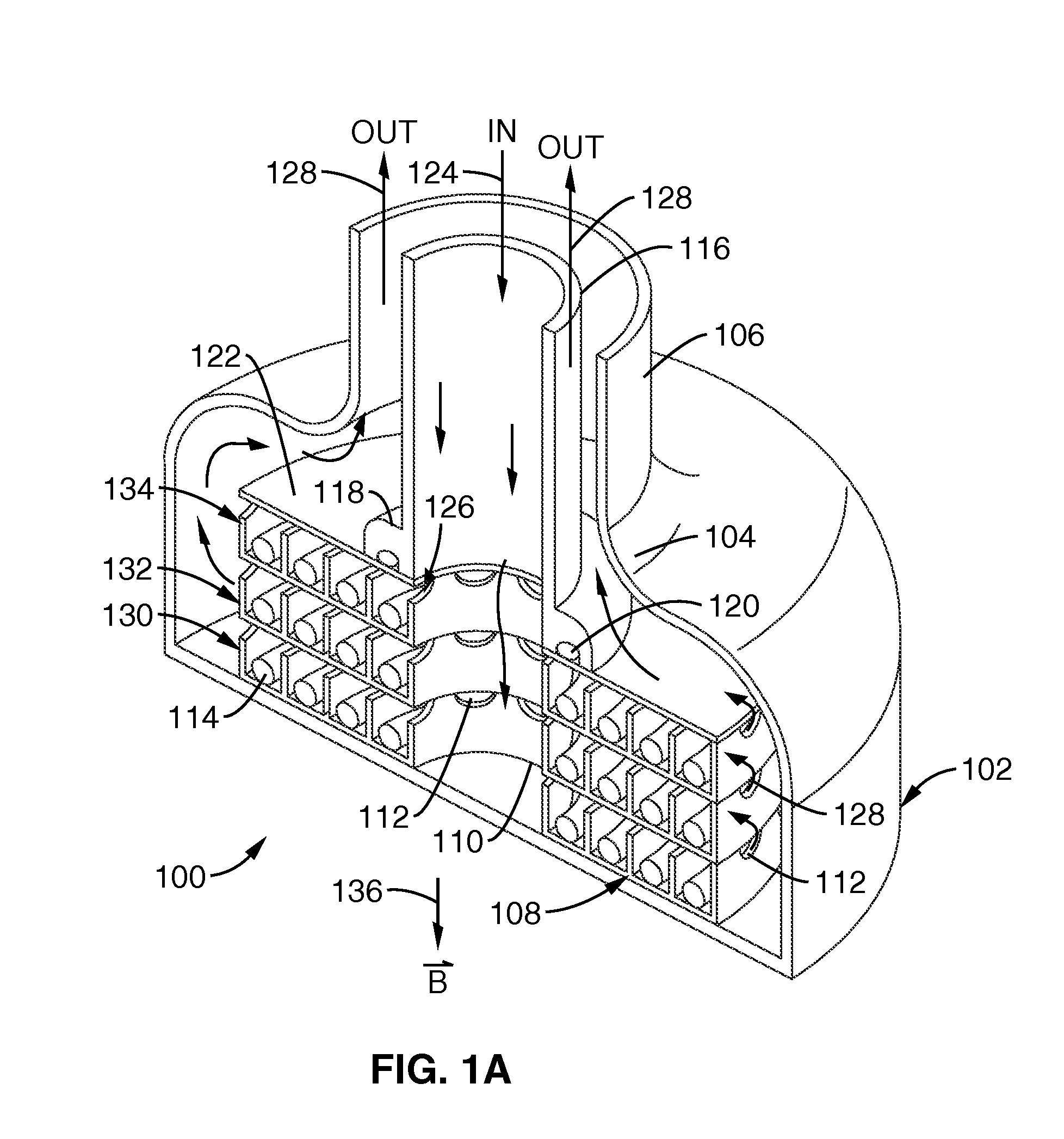

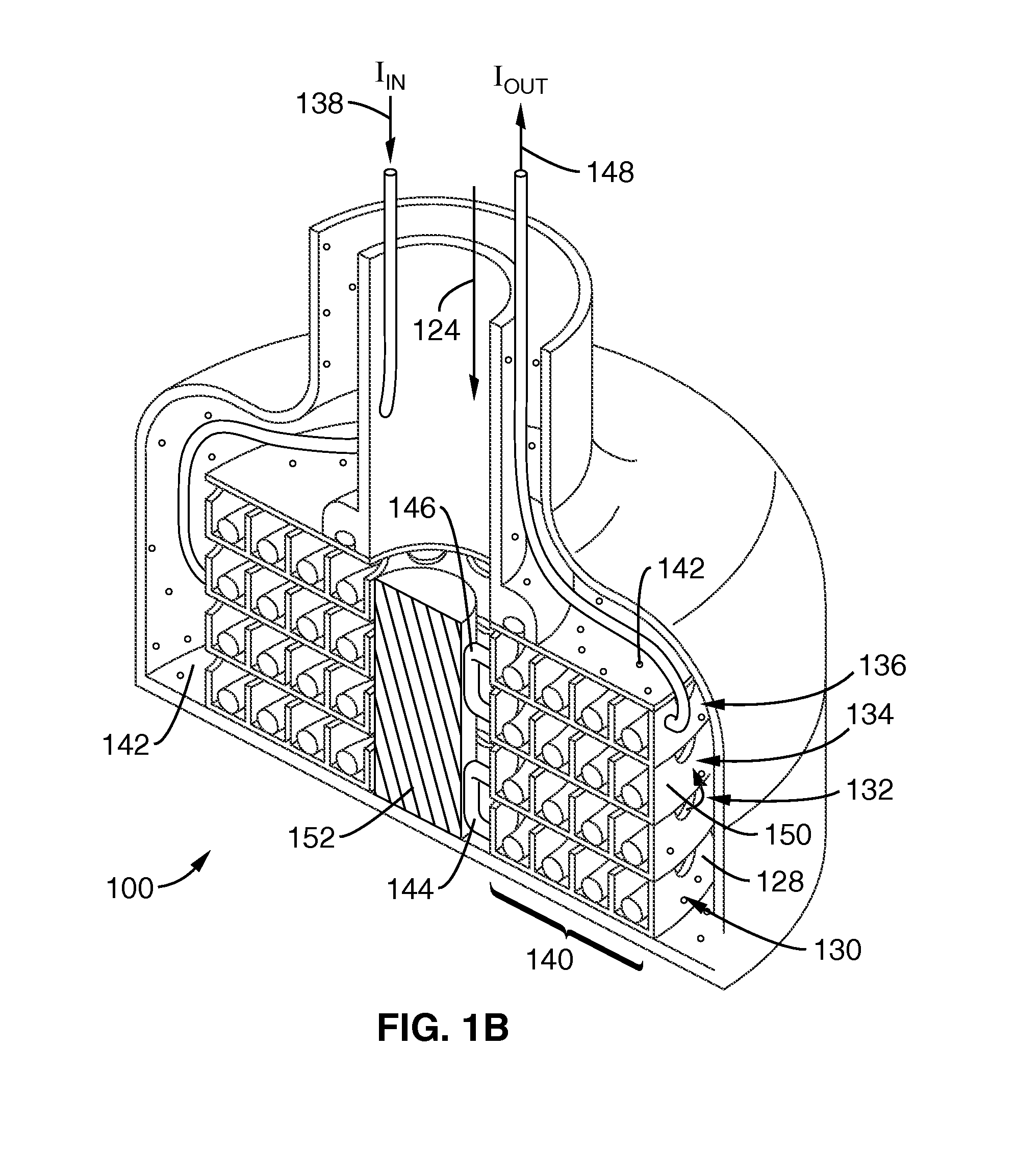

Apparatus and method for transcranial and nerve magnetic stimulation

InactiveUS20090108969A1Avoid lostElectromagnets without armaturesTransformers/inductances coolingNeuronal stimulationLitz wire

An electromagnet coil comprising Litz wire windings and power leads without break or interruption is cooled by a perfluorinated liquid by sensible and phase change heat transfer in a closed system. The electromagnet coil may be housed in a pentagonal or hexagonal pressure vessel to allow high packing densities in an array or helmet configuration. The helmet is then lowered over a human cranium for transcranial electromagnetic stimulation. The Litz wire windings reduce the power and voltages required for operation, yet allow production of over 2 T of accurately directed magnetic pulses for direct nerve or neuron stimulation. The perfluorinated liquid maintains the temperature of the helmet to less than 35-40° C., ensuring a comfortable temperature device for a human test subject. A utility cable connects the helmet to an external cooling unit and an external power supply.

Owner:LOS ALAMOS NATIONAL SECURITY

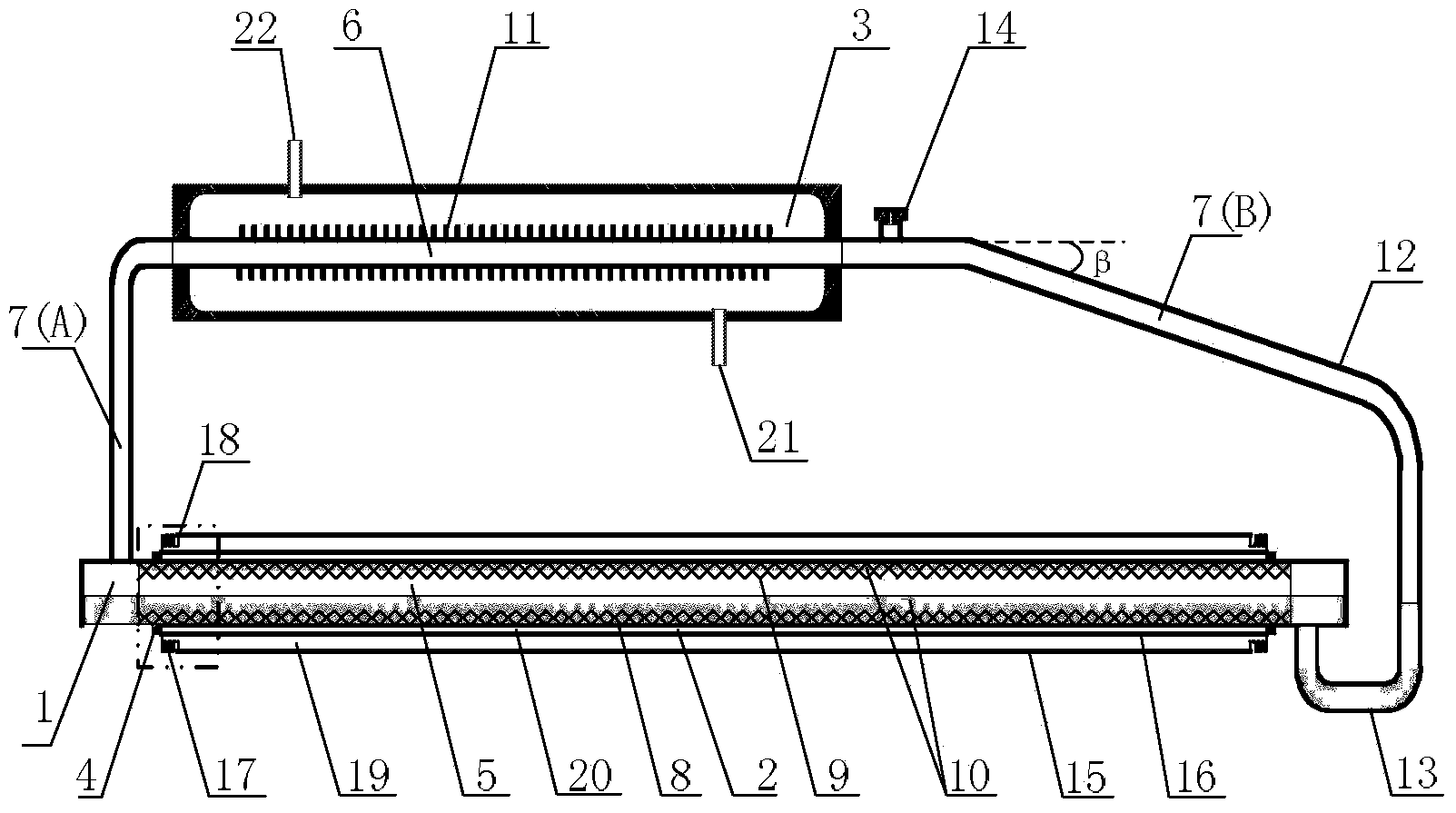

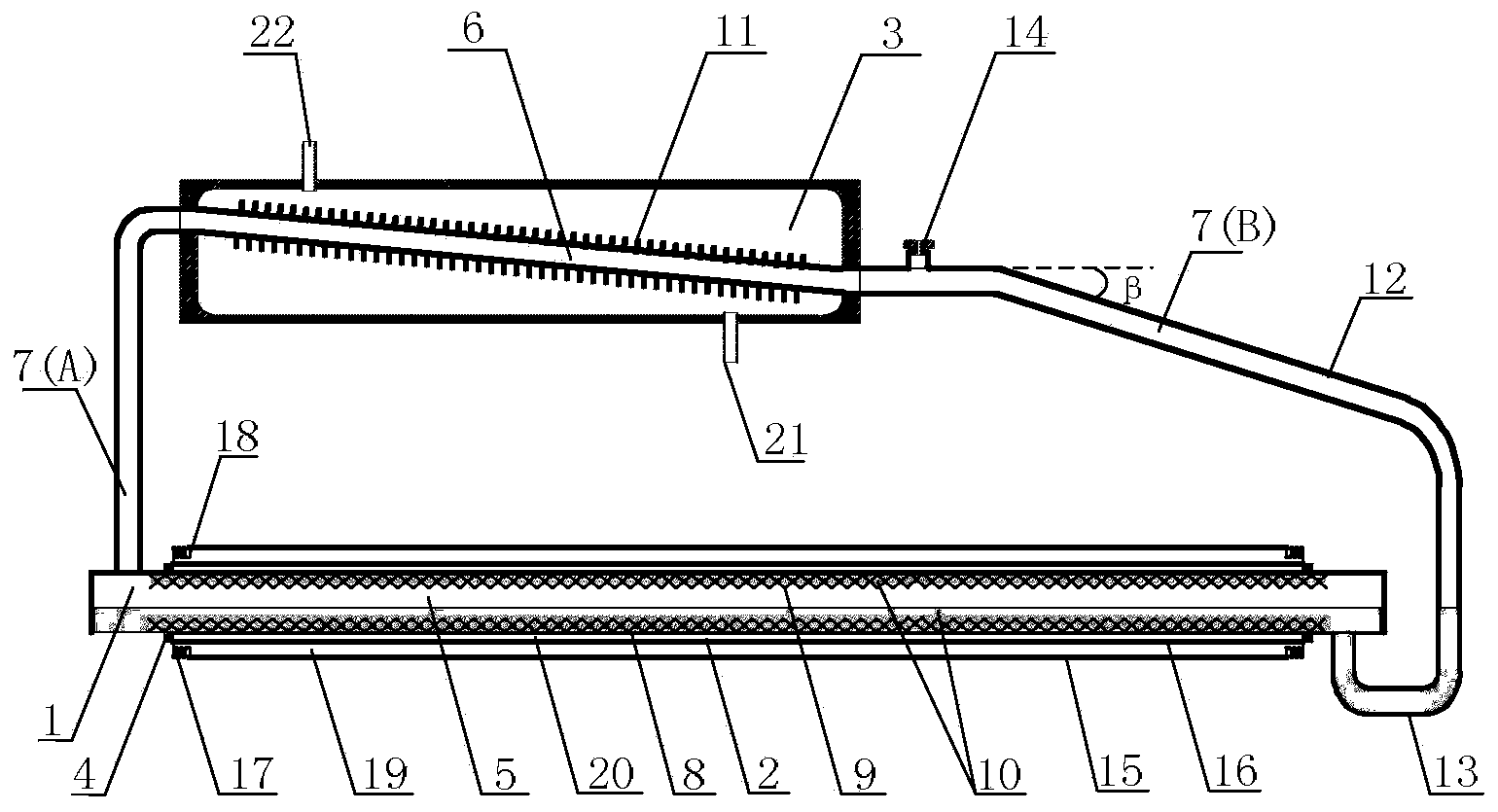

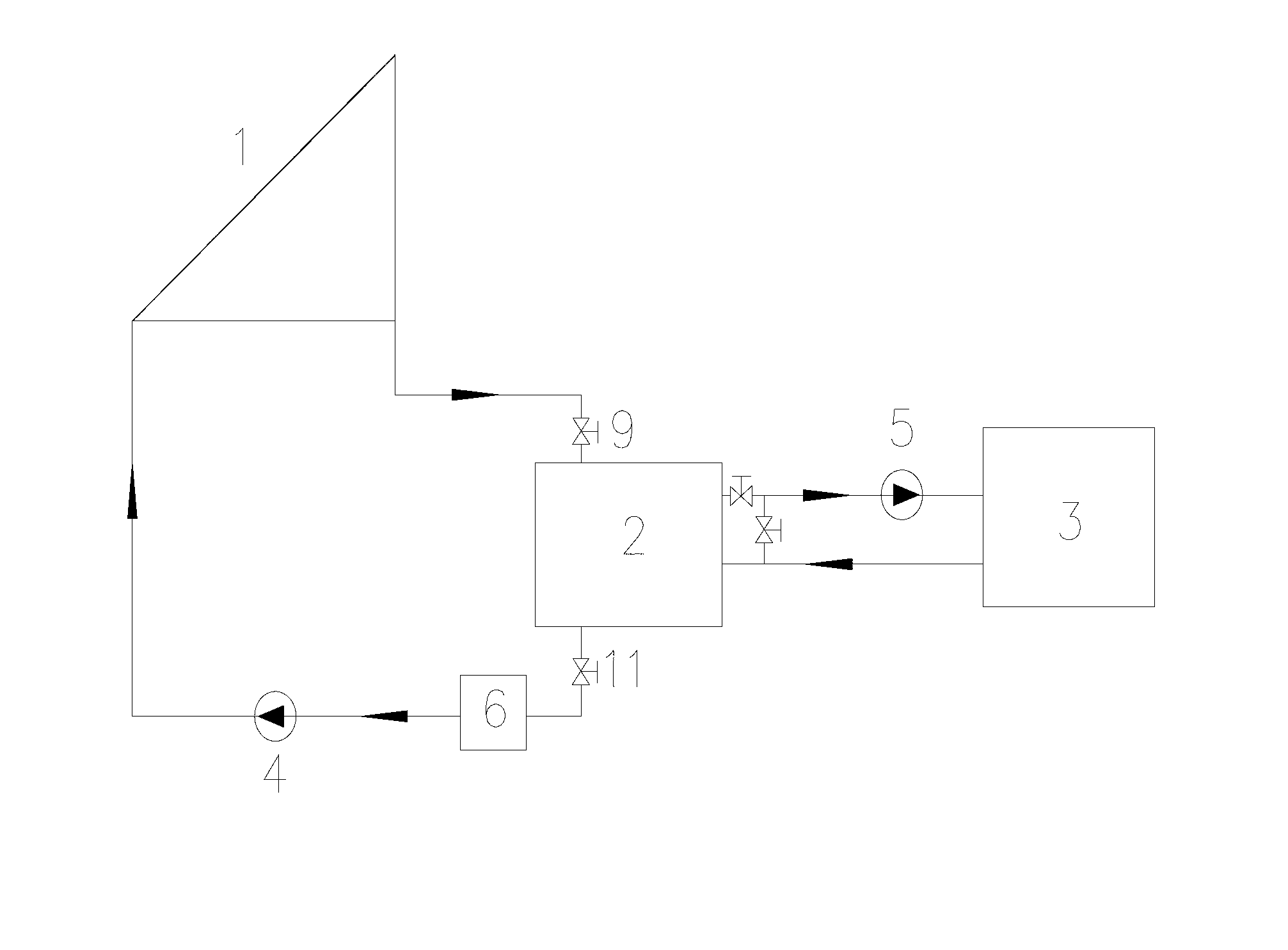

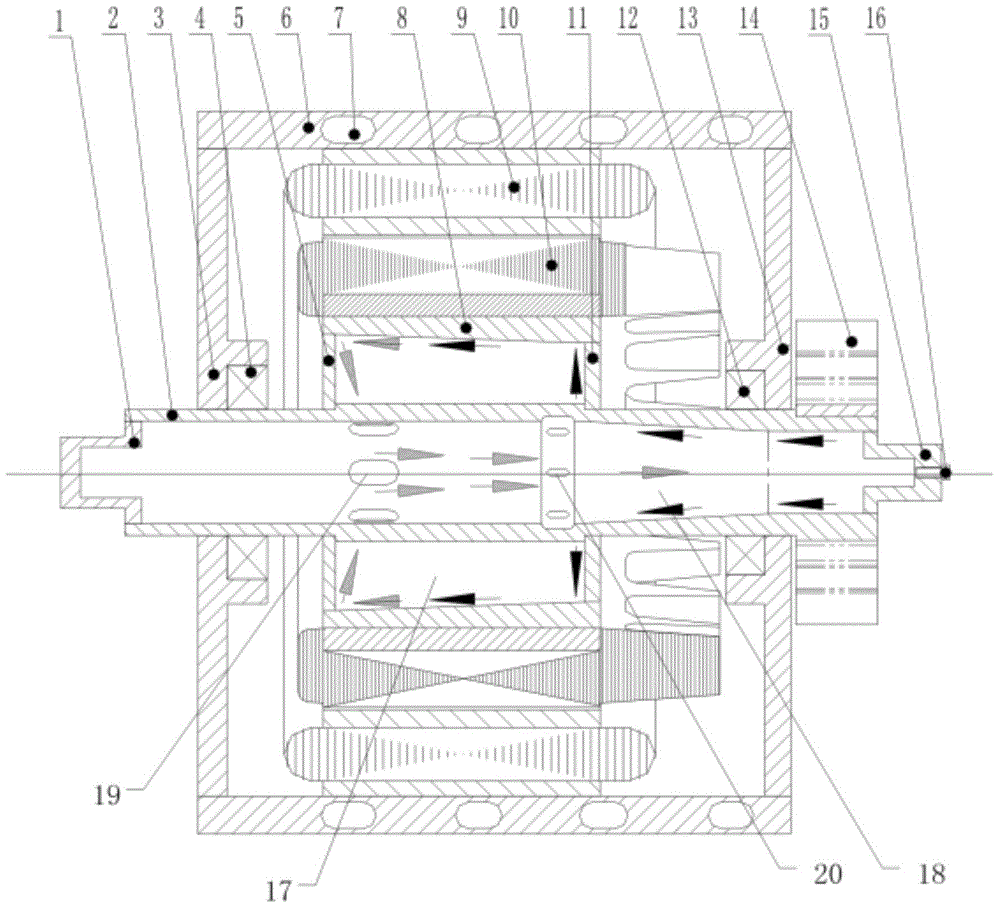

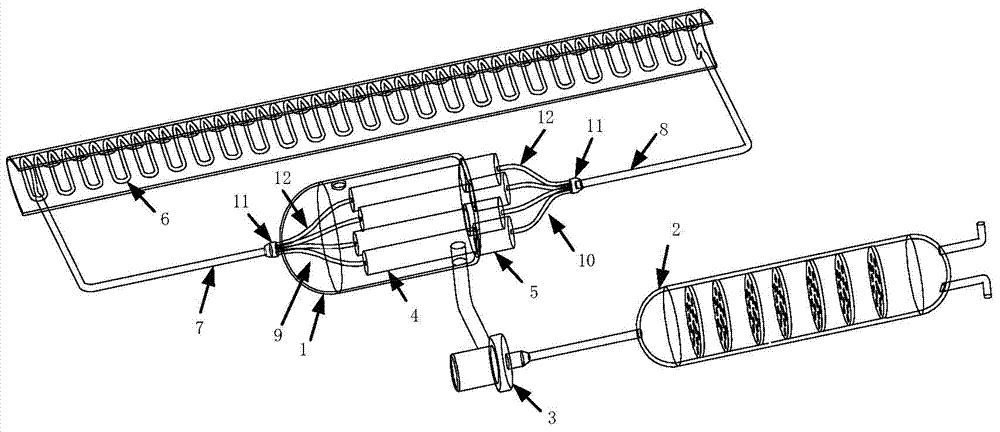

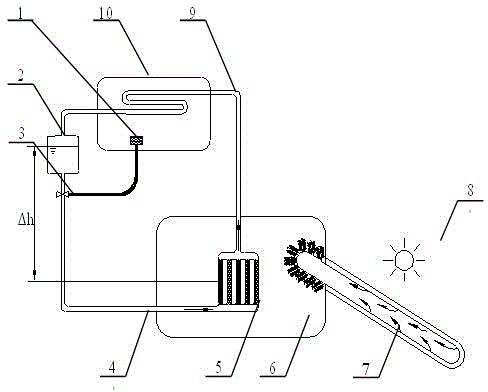

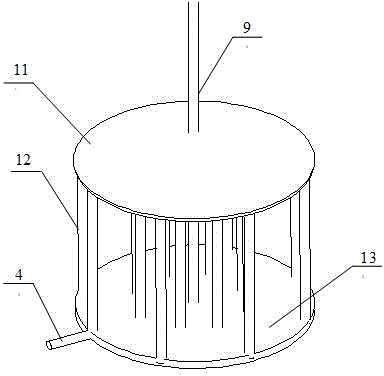

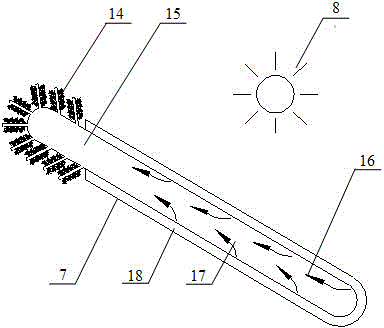

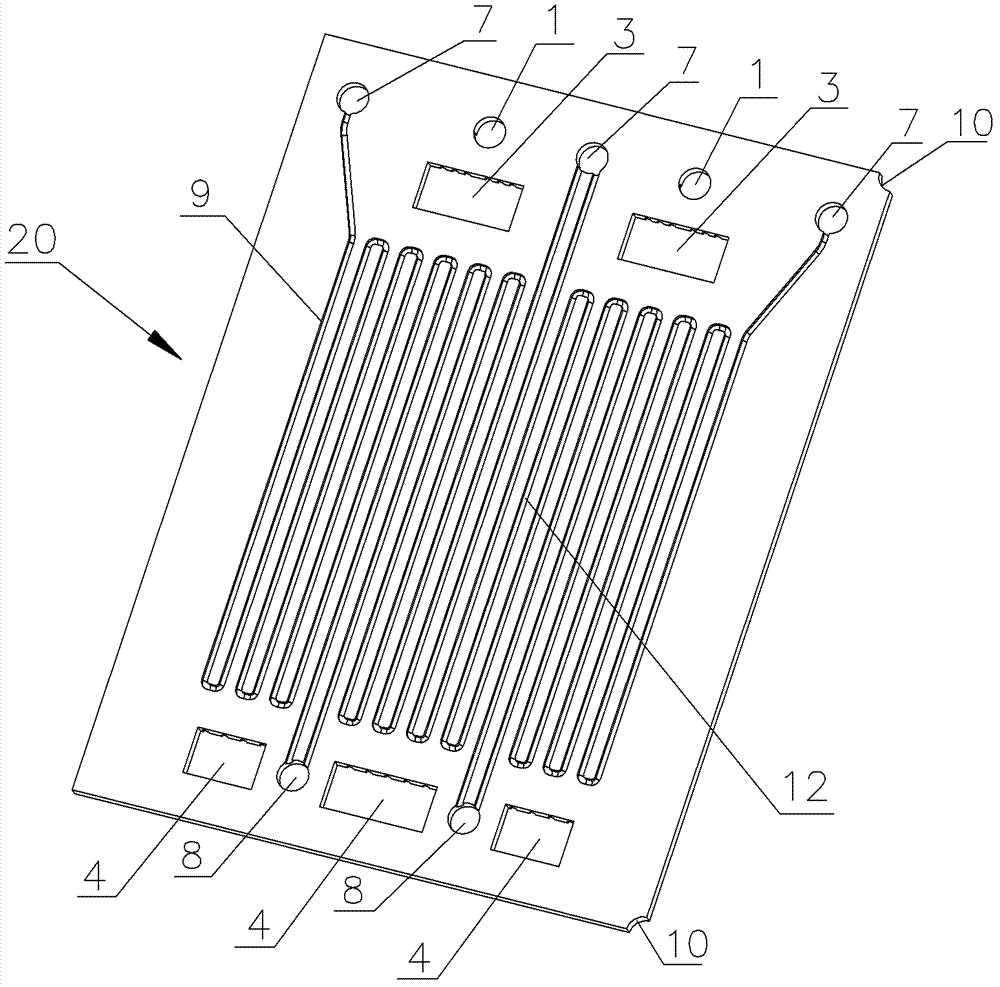

Solar medium-high-temperature loop heat pipe steam generator

ActiveCN104279770ALow costImprove reliabilitySolar heating energySteam generation heating methodsMicro-loop heat pipeEvaporation

The invention relates to a solar medium-high-temperature loop heat pipe steam generator which is composed of a loop heat pipe (1), a straight-through all-glass vacuum pipe (2), a steam pocket (3) and a sealing ring (4). The loop heat pipe (1) is a closed loop formed by an evaporation section (5), a condensation section (6), a first heat insulation section (7(A)) and a second heat insulation section (7(B)), the first heat insulation section (7(A)) is a steam ascending pipe, the second heat insulation section (7(B)) is formed by a condensing liquid descending pipe (12) and a U-shaped liquid storage pipe (13), the straight-through all-glass vacuum pipe (2) and the evaporation section (5) are placed coaxially to form an annular non-vacuum space (20), two ends of the annular non-vacuum space (20) are sealed by adopting sealing rings (4), and the steam pocket (3) is in sealed connection with the condensation section (6) of the loop heat pipe (1). The solar medium-high-temperature loop heat pipe steam generator is suitable for groove-type solar DSG technology, high-efficiency phase change of the heat pipe is utilized for heat transfer to heat water in the steam generator so as to directly generate high-temperature steam, system cost is lowered, and system running reliability is improved.

Owner:NANJING UNIV OF TECH

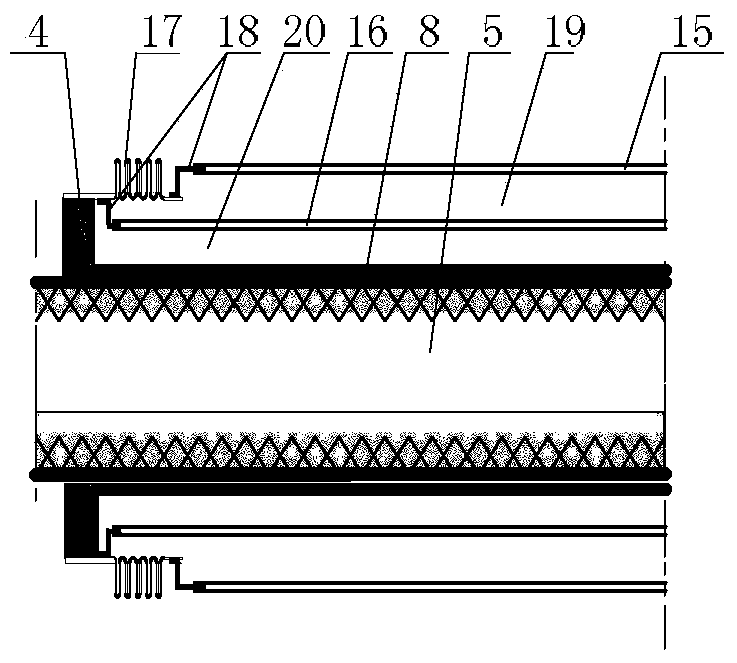

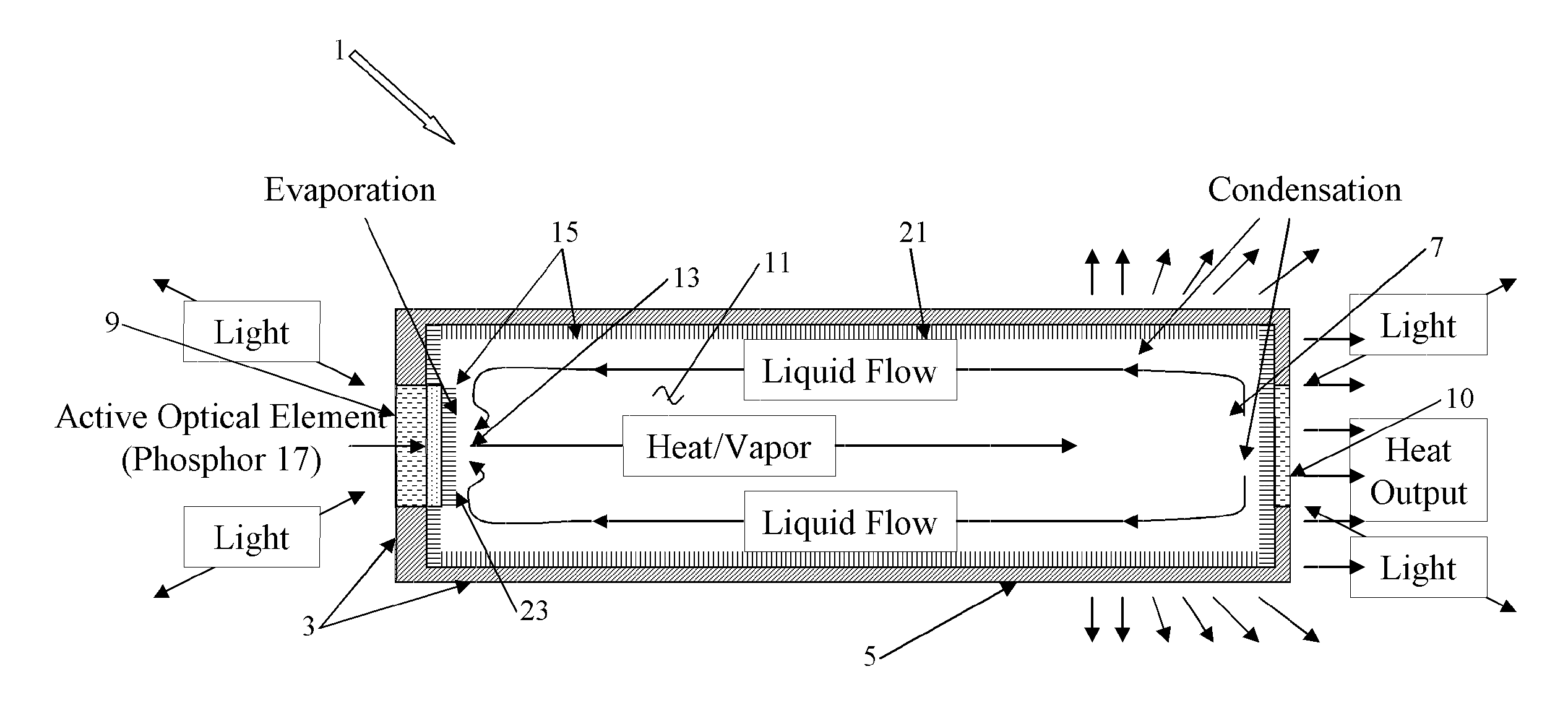

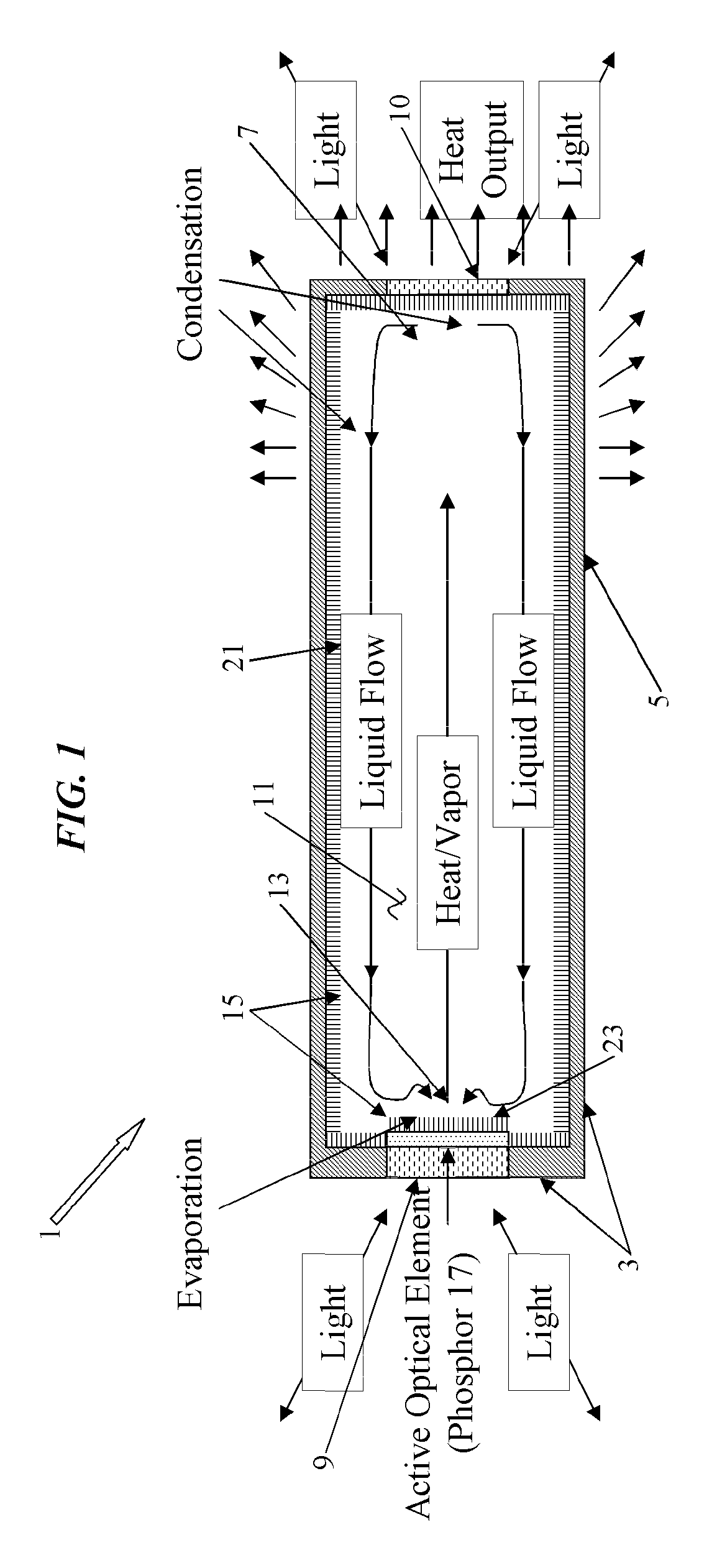

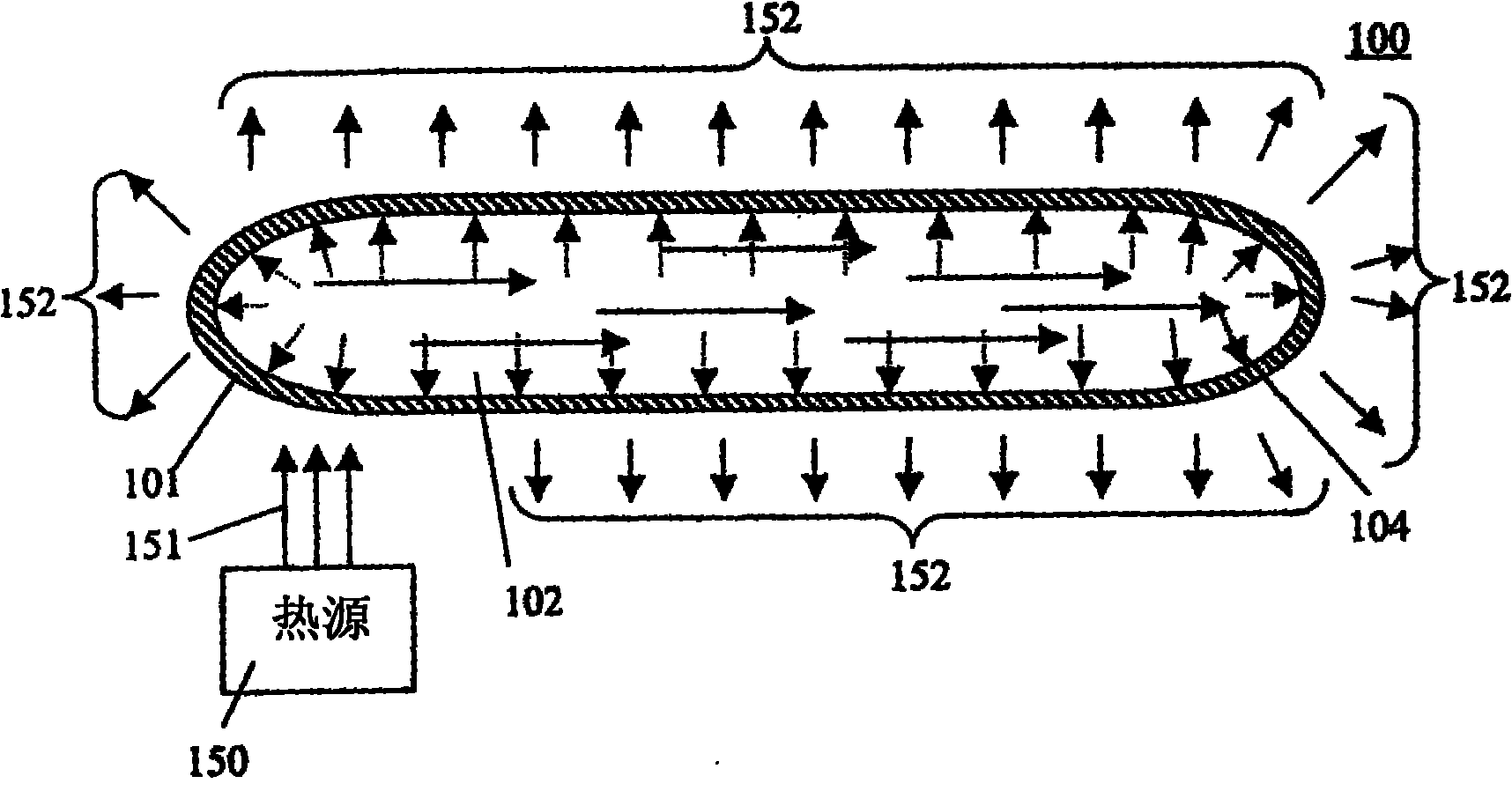

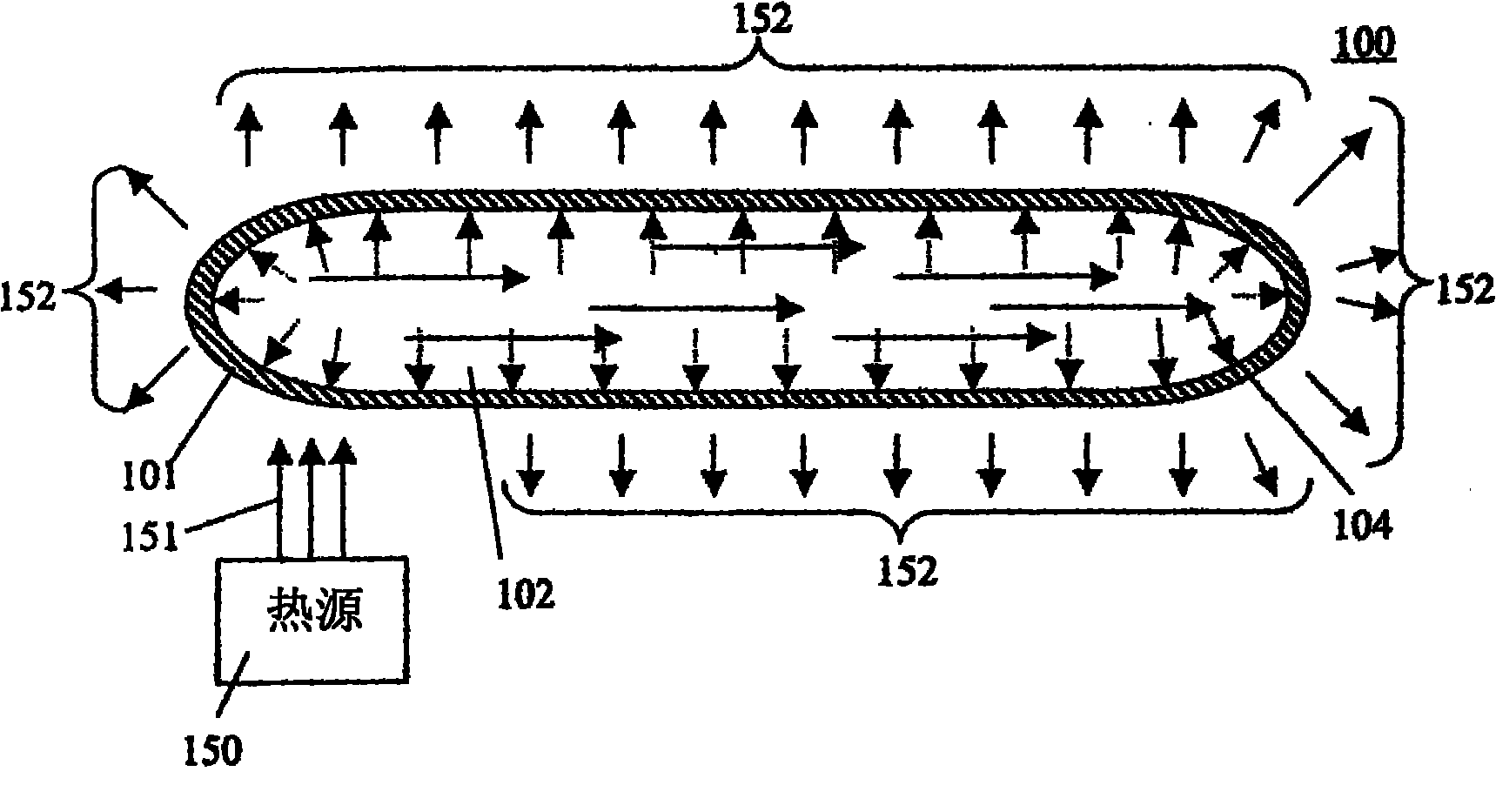

Phosphor incorporated in a thermal conductivity and phase transition heat transfer mechanism

ActiveUS20130049040A1Reduce thermal degradationPlanar light sourcesPoint-like light sourceWorking fluidPhotoluminescence

A thermal conductivity and phase transition heat transfer mechanism has an opto-luminescent phosphor contained within the vapor chamber of the mechanism. The housing includes a section that is thermally conductive and a member that is at least partially optically transmissive, to allow emission of light produced by excitation of the phosphor. A working fluid also is contained within the chamber. The pressure within the chamber configures the working fluid to absorb heat during operation of the lighting device, to vaporize at a relatively hot location at or near at least a portion of the opto-luminescent phosphor as the working fluid absorbs heat, to transfer heat to and condense at a relatively cold location, and to return as a liquid to the relatively hot location. Also, the working fluid is in direct contact with or contains at least a portion of the opto-luminescent phosphor.

Owner:ABL IP HLDG

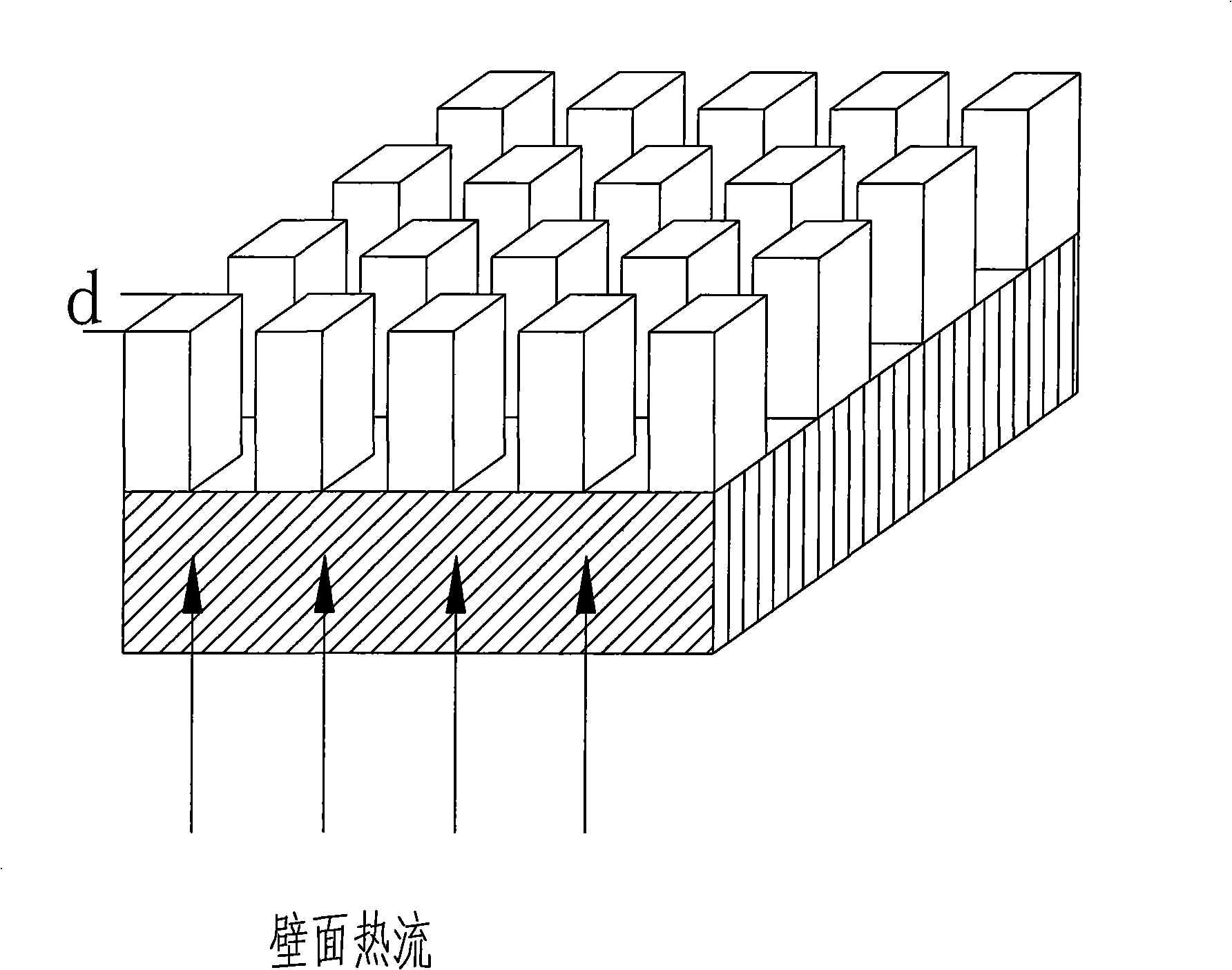

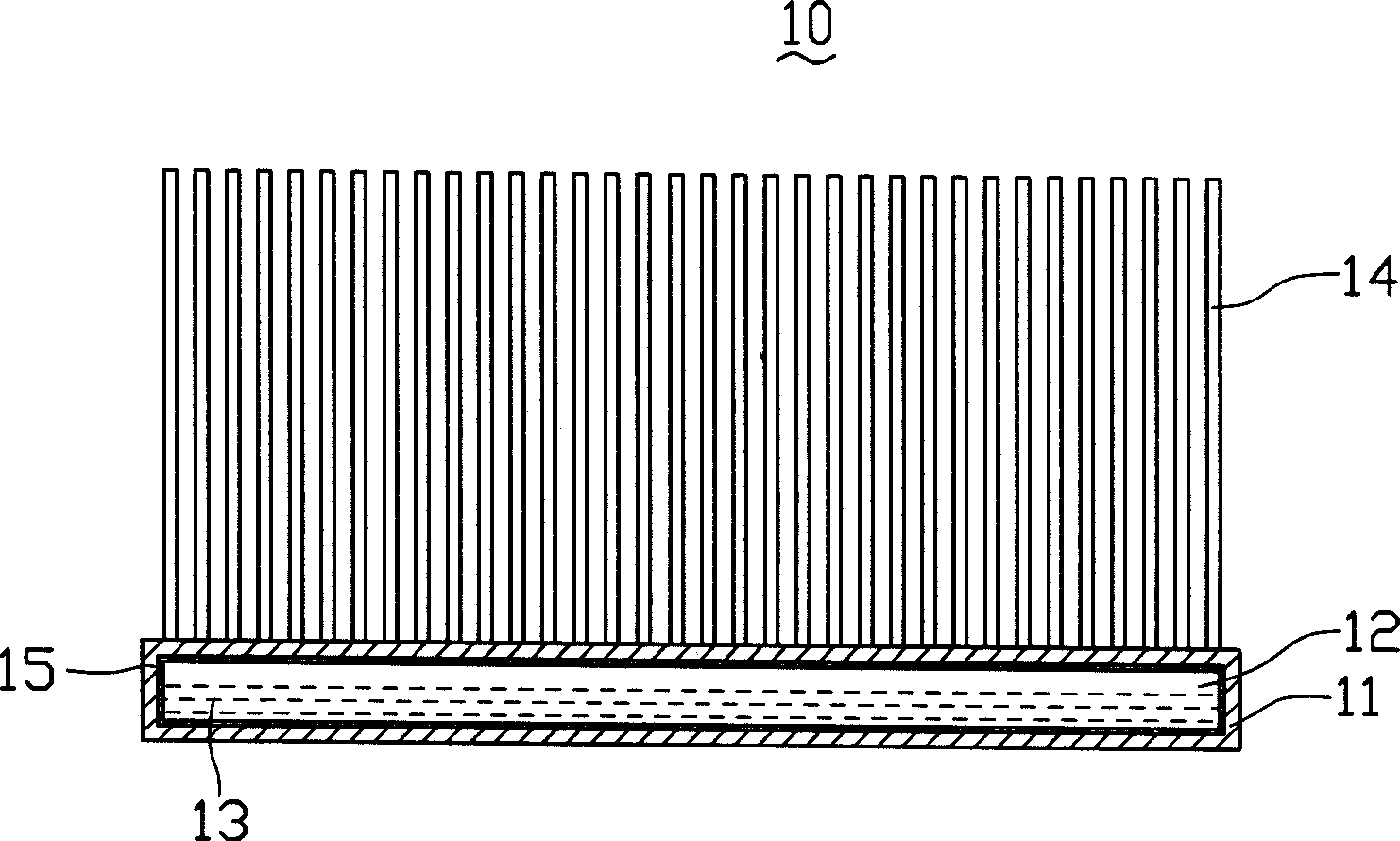

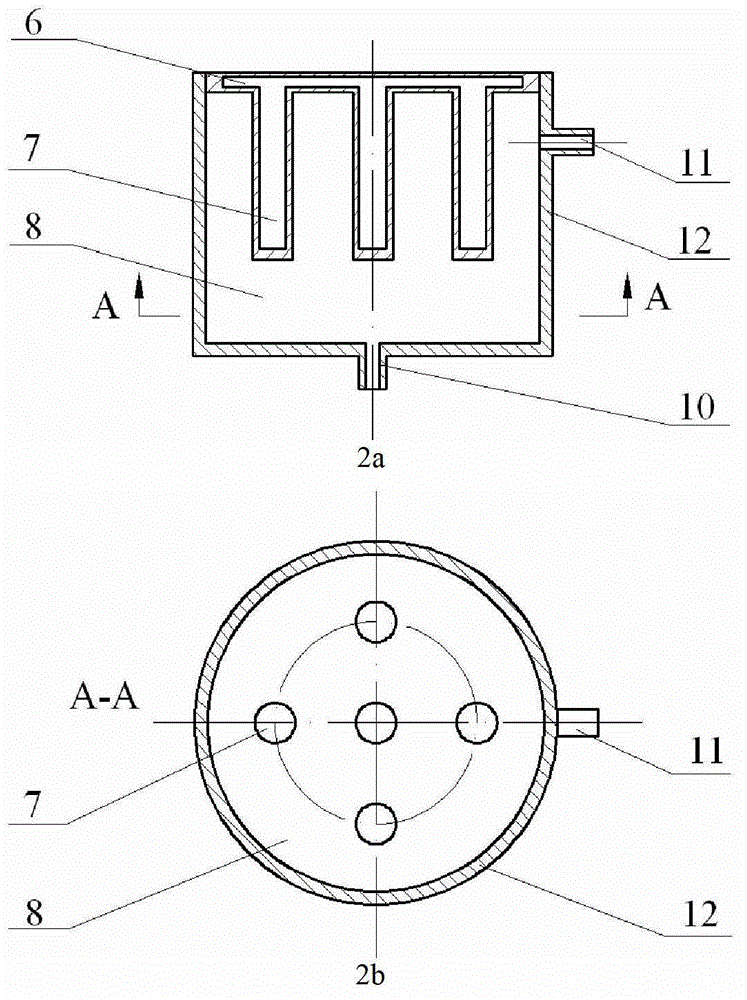

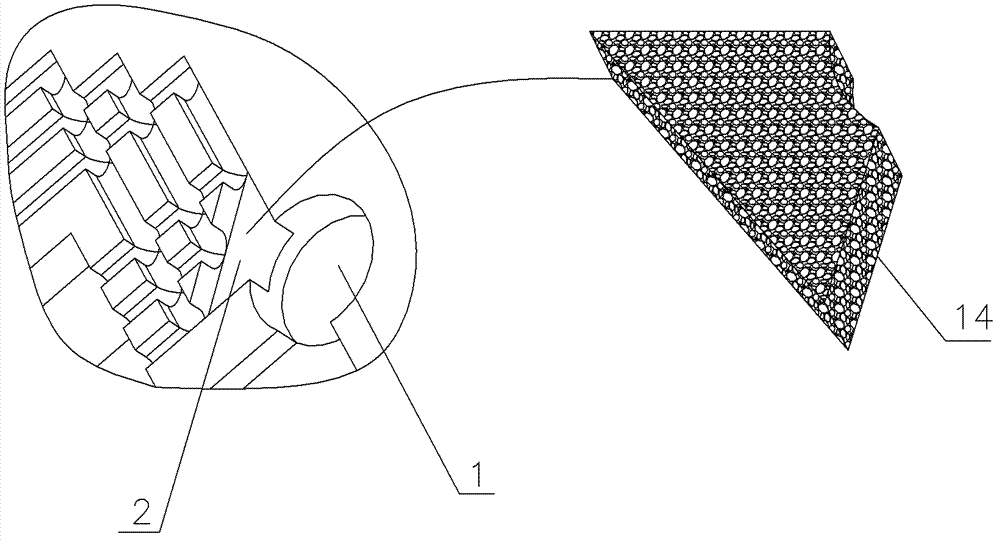

Boiling heat transfer device of electronic component

InactiveCN101541159AGood effectAvoid shockSemiconductor/solid-state device detailsSolid-state devicesElectronic componentBoiling heat transfer

The invention relates to the research field of boiling phase change heat transfer, in particular to a boiling heat transfer device of an electronic component. The boiling heat transfer device comprises a cooling plate fixed to the surface of the electronic component, a metal foam layer is sintered or welded on the upper surface of the cooling plate, the metal foam layer is provided with square column type microstructures with the width of 50 micron to 200 micron, and the interval between the square column type microstructures is 50 micron to 200 micron.

Owner:XI AN JIAOTONG UNIV

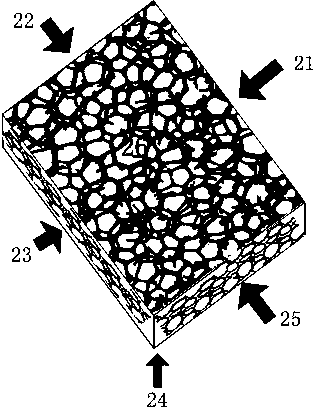

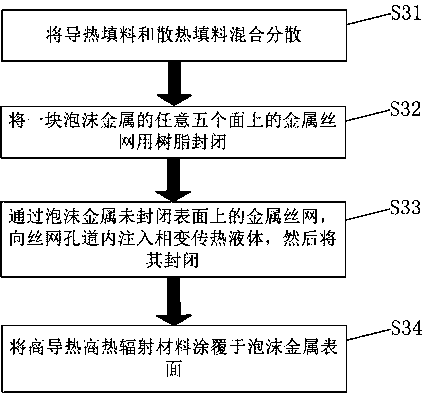

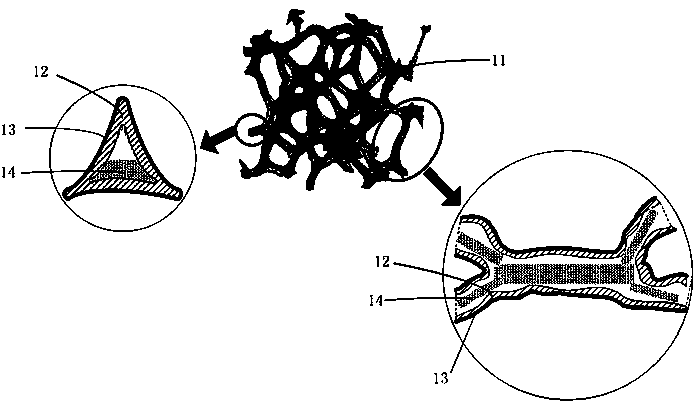

Three-dimensional network porous heat-conducting heat radiation device and preparation method thereof

PendingCN107936777AImprove thermal conductivitySmall specific surface areaSemiconductor/solid-state device detailsSolid-state devicesHeat conductingElectron

The invention relates to a three-dimensional network porous heat-conducting heat radiation device and a preparation method thereof. The three-dimensional network porous heat-conducting heat radiationdevice comprises foam metal, high-heat-conduction high-heat-radiation material and a phase-changing heat transferring material, wherein the heat transferring performance is improved by virtue of the phase-changing heat transferring material filling pores inside a foam metal skeleton wire net, the heat radiation performance is improved by virtue of the high-heat-conduction high-heat-radiation material smeared on the surface of the foam metal skeleton, and the three-dimensional network porous heat-conducting heat radiation device is suitable for the electron industry and solves the heat radiation problem of heating elements and devices.

Owner:WUZHOU HGP ADVANCED MATERIALS TECH CORP

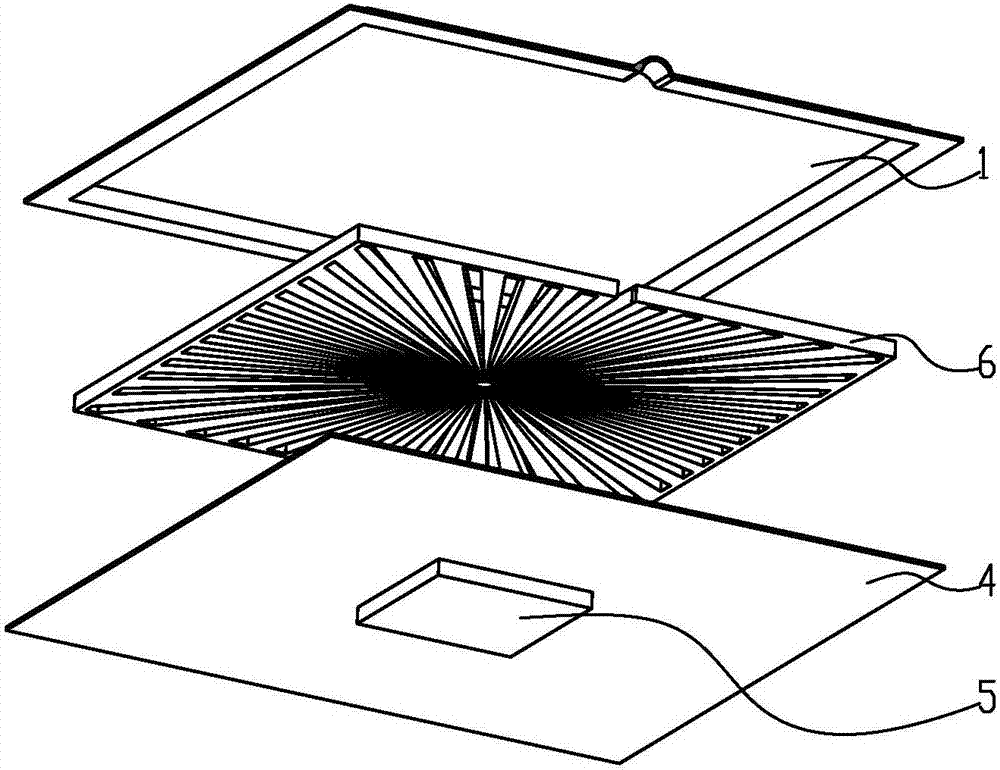

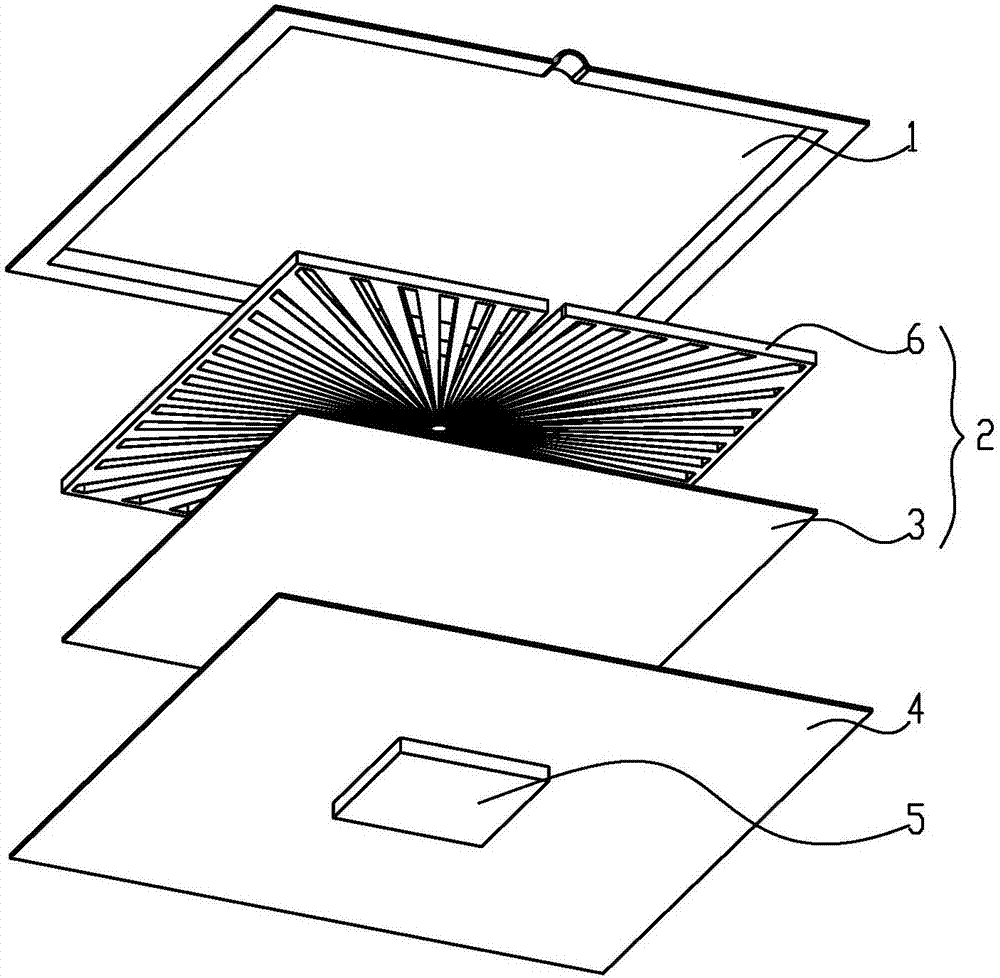

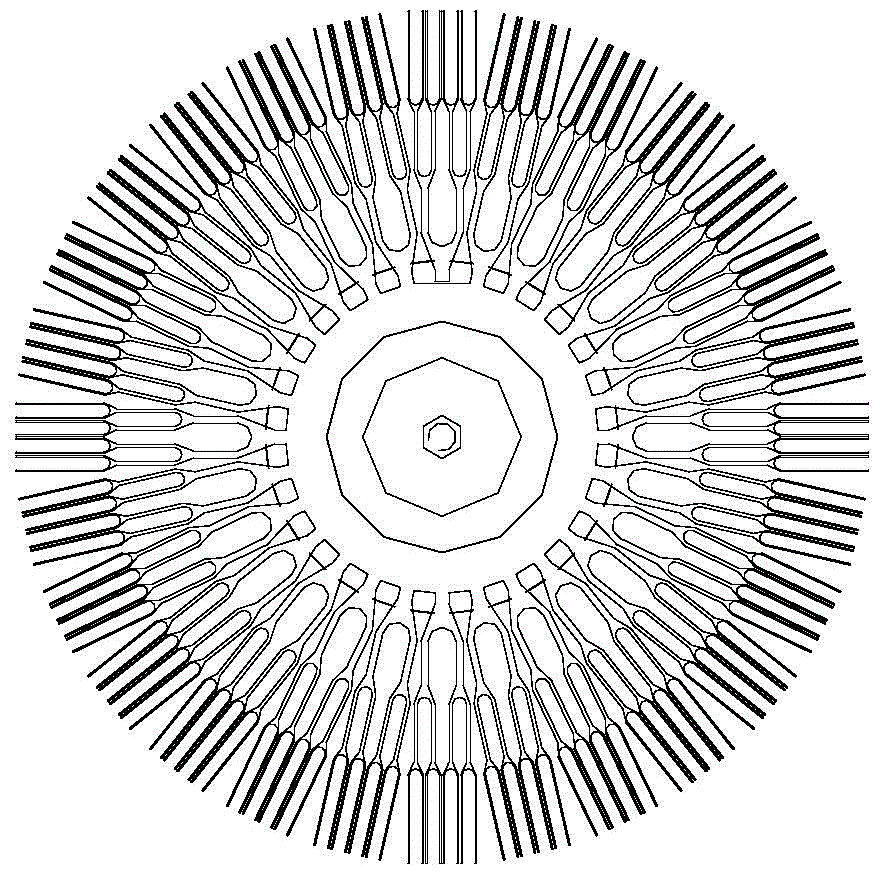

Ultrathin heat homogenizing plate structure

PendingCN107401941ASolve the cooling problemIndirect heat exchangersEngineeringVolumetric Mass Density

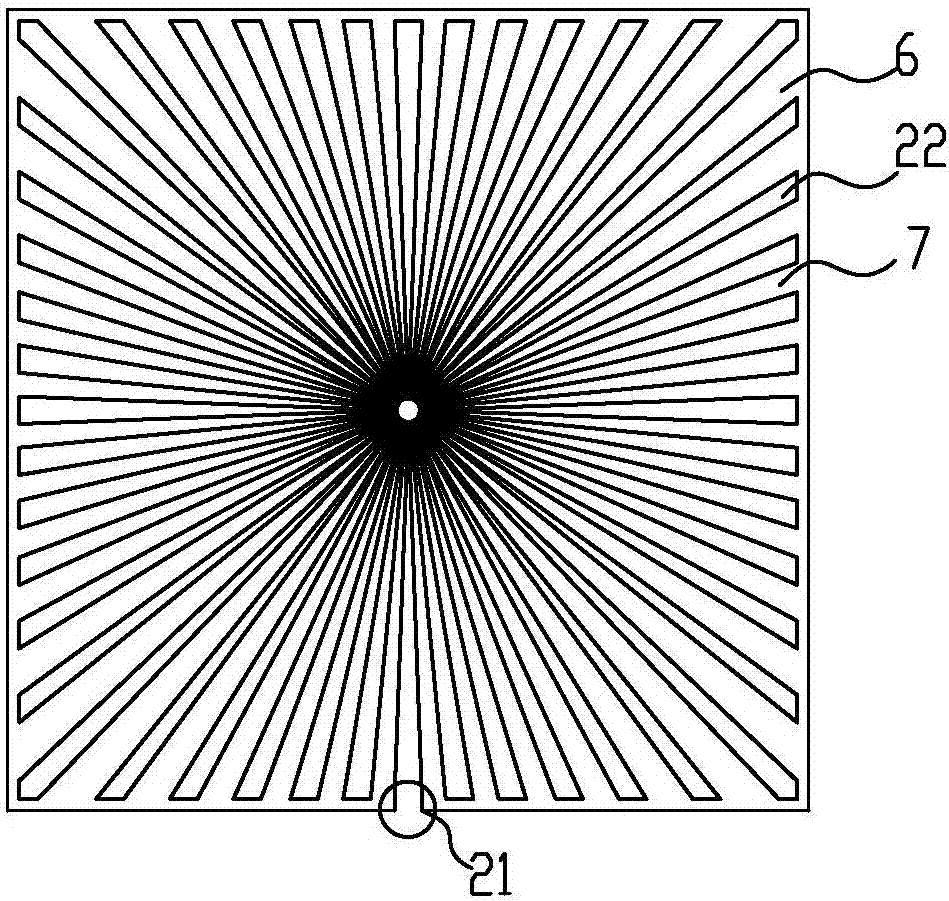

The invention relates to an ultrathin heat homogenizing plate structure. The ultrathin heat homogenizing plate structure comprises an upper shell plate, at least one layer of liquid suction core and a lower shell plate which are sequentially arranged. The lower surface of the upper shell plate is fixedly connected with the upper surface of the uppermost layer of the liquid suction core, and the bottom face of the bottommost layer of the liquid suction core is fixedly connected with the upper surface of the lower shell plate. By using the center of a heat source located on the lower shell plate or the upper shell plate as a center, a plurality of channels which are diffused outwards from the centers and are gradually widened are formed in one layer of the liquid suction core in a ring array mode. The effect of arranging the channels which are diffused outwards and are gradually widened by using the center of the heat source as the center is to provide diffusion paths of working medium steam. A working medium is diffused in all directions along the channels after being evaporated, the purpose of arranging the center of the heat source to be the diffused channel center lies in that the evaporated working medium carries heat of the heat source to be diffused to a whole heat homogenizing plate, the condensed working medium can flow back to the heat source position to be recycled continuously under the capillary force action of the liquid suction cores, and the ultrathin heat homogenizing plate can effectively solve the heat radiating problem of high heating flux electronic components in a narrow space through the principle of phase change heat transfer.

Owner:SOUTH CHINA UNIV OF TECH +1

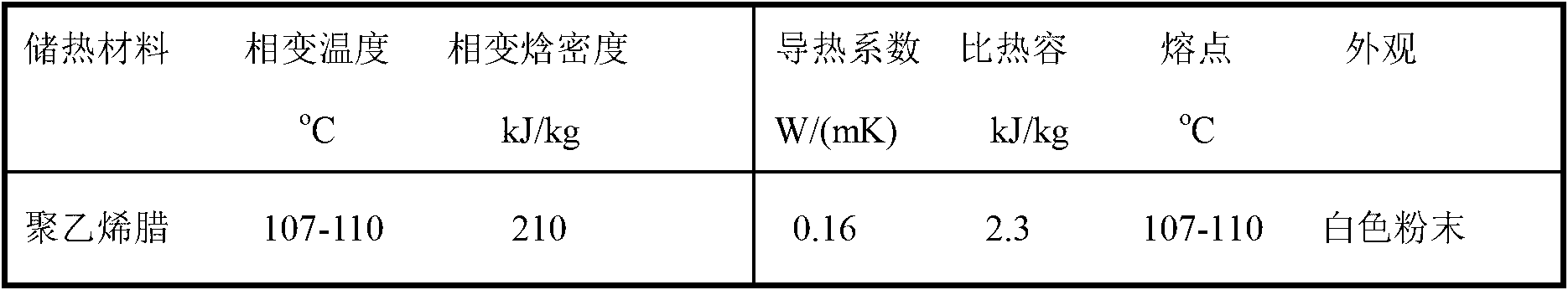

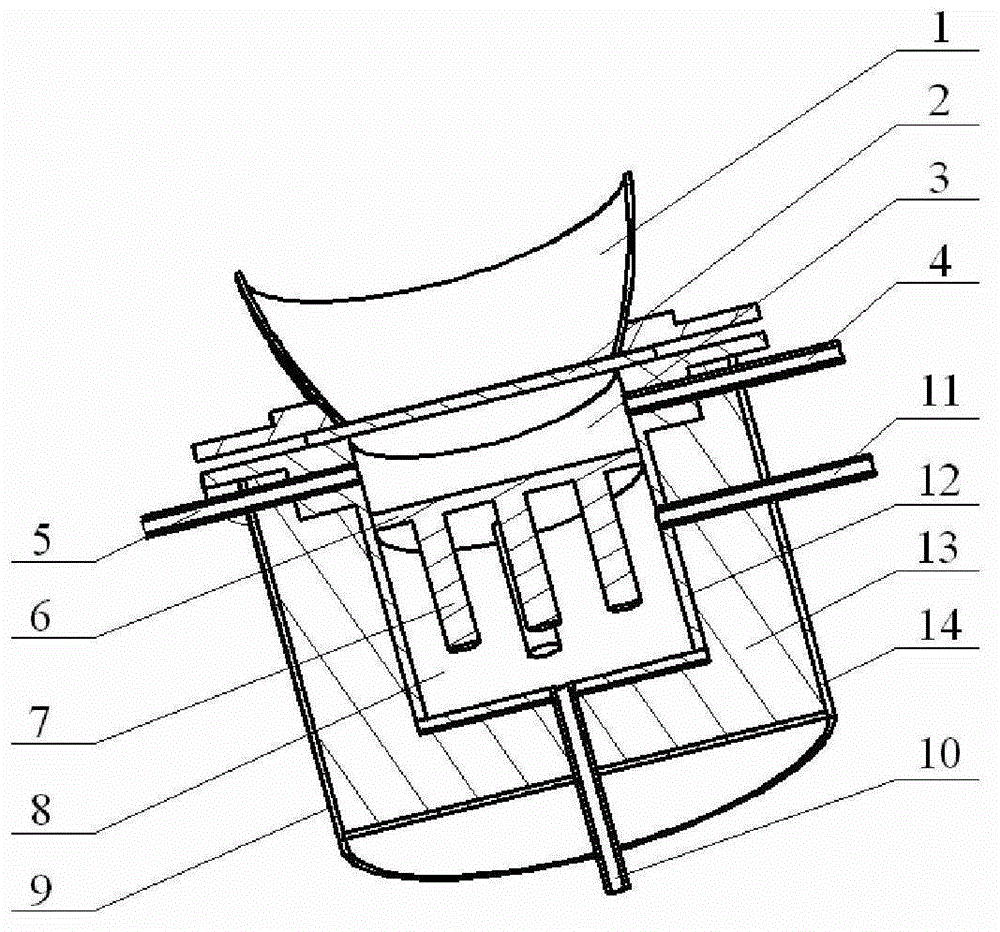

Phase-change heat transfer type intermediate temperature heat reservoir as well as manufacturing and application thereof

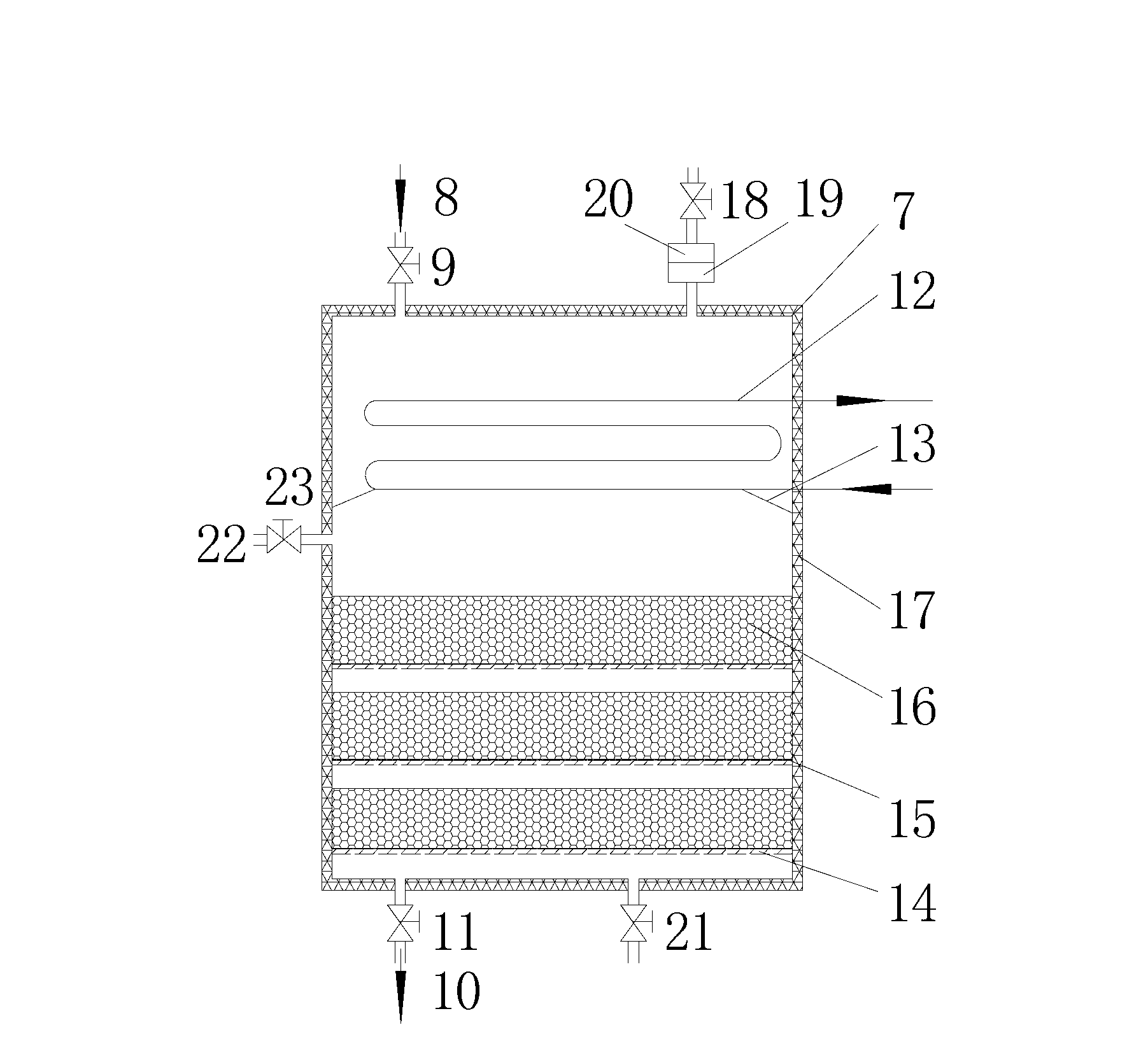

InactiveCN103017368AImprove heat transfer effectImprove heat transfer coefficientSolar heat devicesHeat storage plantsHeat conductingWater vapor

The invention discloses a phase-change heat transfer type intermediate temperature heat reservoir and an intermediate temperature solar air-conditioning system formed by the phase-change heat transfer type intermediate temperature heat reservoir. The phase-change heat transfer type intermediate temperature heat reservoir is a closed pressure container and comprises a box body, a plurality of ring frames, screens, heat accumulation layers and heat exchanging tubes, wherein the plurality of ring frames are respectively and horizontally fixed on the inner wall at the lower part of the box body, a plurality of screens are respectively arranged on each ring frame, the heat accumulation layers are respectively paved on each sieve screen, each heat accumulation layer is formed by mixing a composite phase-change heat accumulation material and grains of sand, the heat exchanging tubes are arranged in an inner cavity in the upper part of the box body, a tube cavity of each heat exchanging tube is isolated from the inside of the box body and is communicated with the outside of the box body, wherein a heat conducting device flows in the tube cavity, the intermediate temperature heat accumulation device takes water and water vapor as phase-change heat transfer working mediums, and the phase-change heat transfer mediums are directly evaporated or condensed on the surface of the granular composite phase-change heat accumulation material to realize phase-change heat exchange. The phase-change heat transfer type intermediate temperature heat reservoir and the intermediate temperature solar air-conditioning system have the advantages of excellent heat exchange capability, high solar utilization ratio, simple structure, easy manufacture and long service life.

Owner:SHANGHAI JIAO TONG UNIV +1

Heat radiator

InactiveCN1878451AImprove thermal efficiencyReduce the temperatureDigital data processing detailsSemiconductor/solid-state device detailsWorking fluidHeat transmission

The invention relates to a heat emitter, which comprises: a base and several heat emission fins extending from one surface of base. Wherein, said base contains one sealing hollow chamber filled with working fluid; the working fluid is added with nanometer thermal conducive material particles; when the heat emitter works, the heat of heating electric element is transmitted to the base; the internal working fluid will be heated and vaporized, to adsorb the phase-change heat into gas; when the gas reaches one side of heat emission fin, it is cooled to be condensed into liquid to release heat; and the heat emission fin will transmit the heat to environment, to reduce the temperature heating electric element. Since the heat emission base uses phase-change heat transmission, and the working fluid is added with high-conductivity nanometer thermal conductive material particles, the heat emission efficiency is improved significantly.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

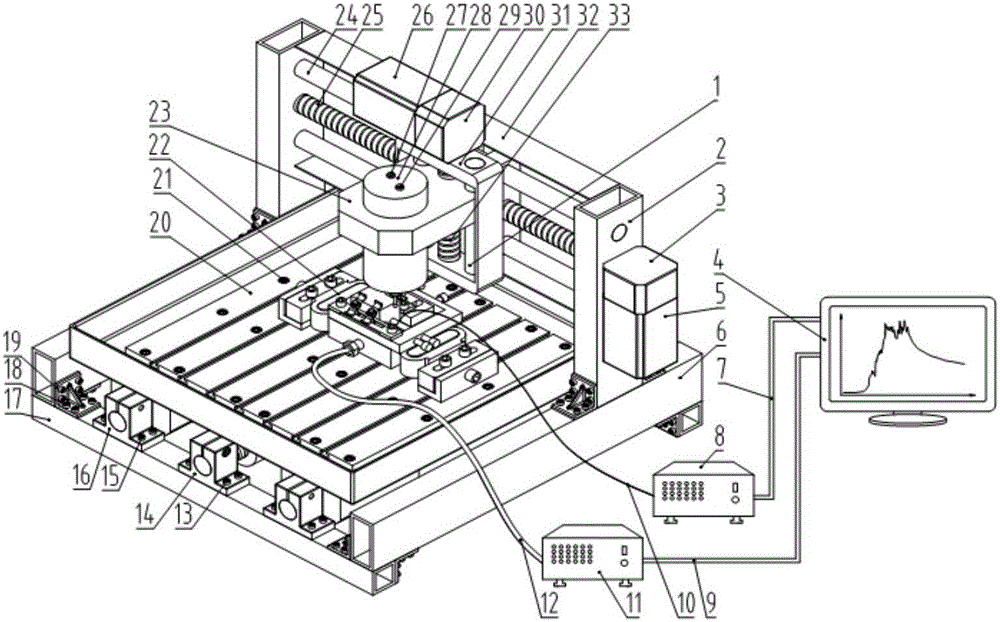

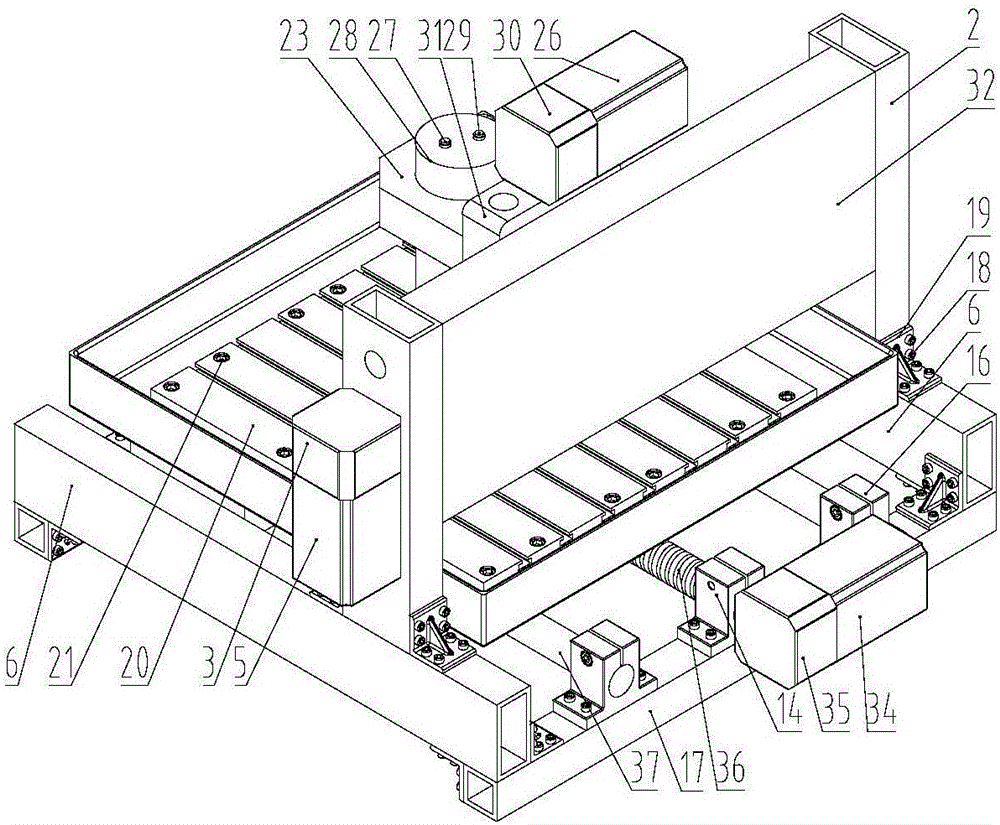

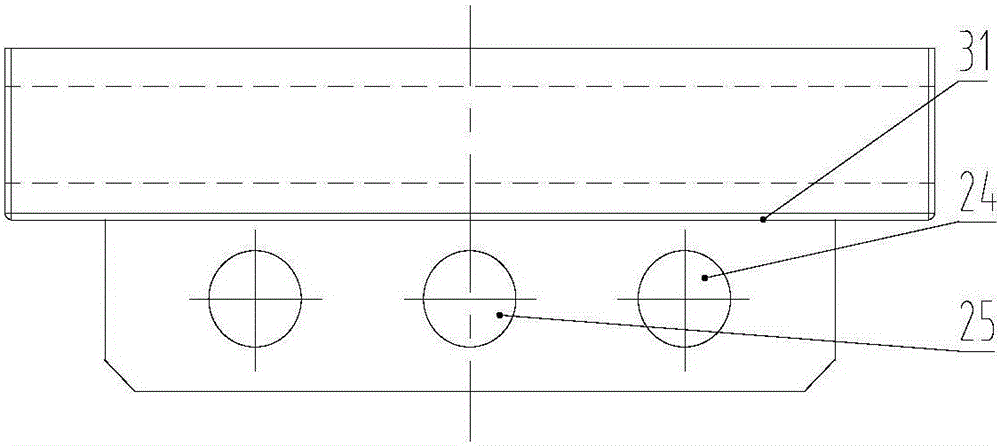

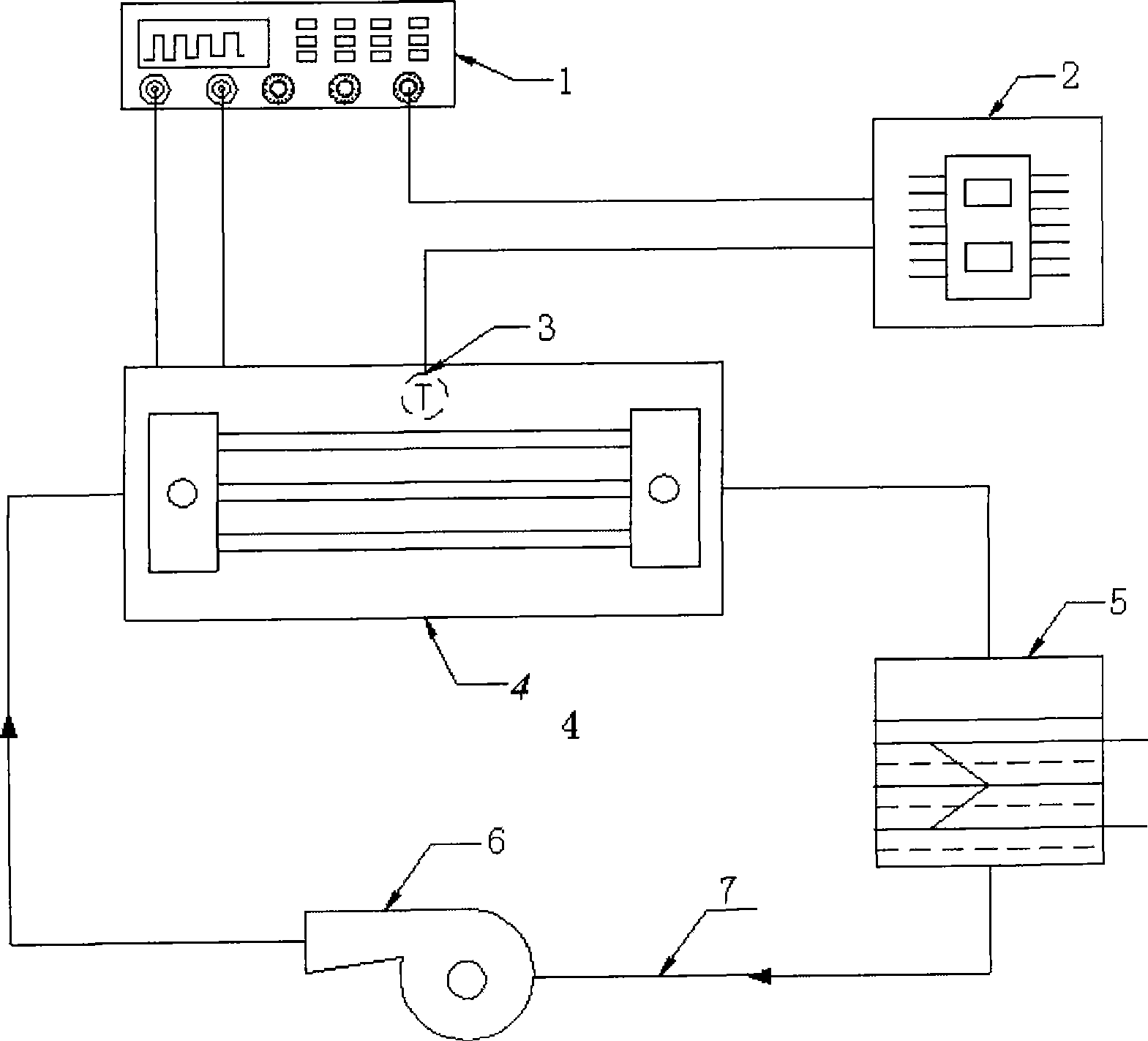

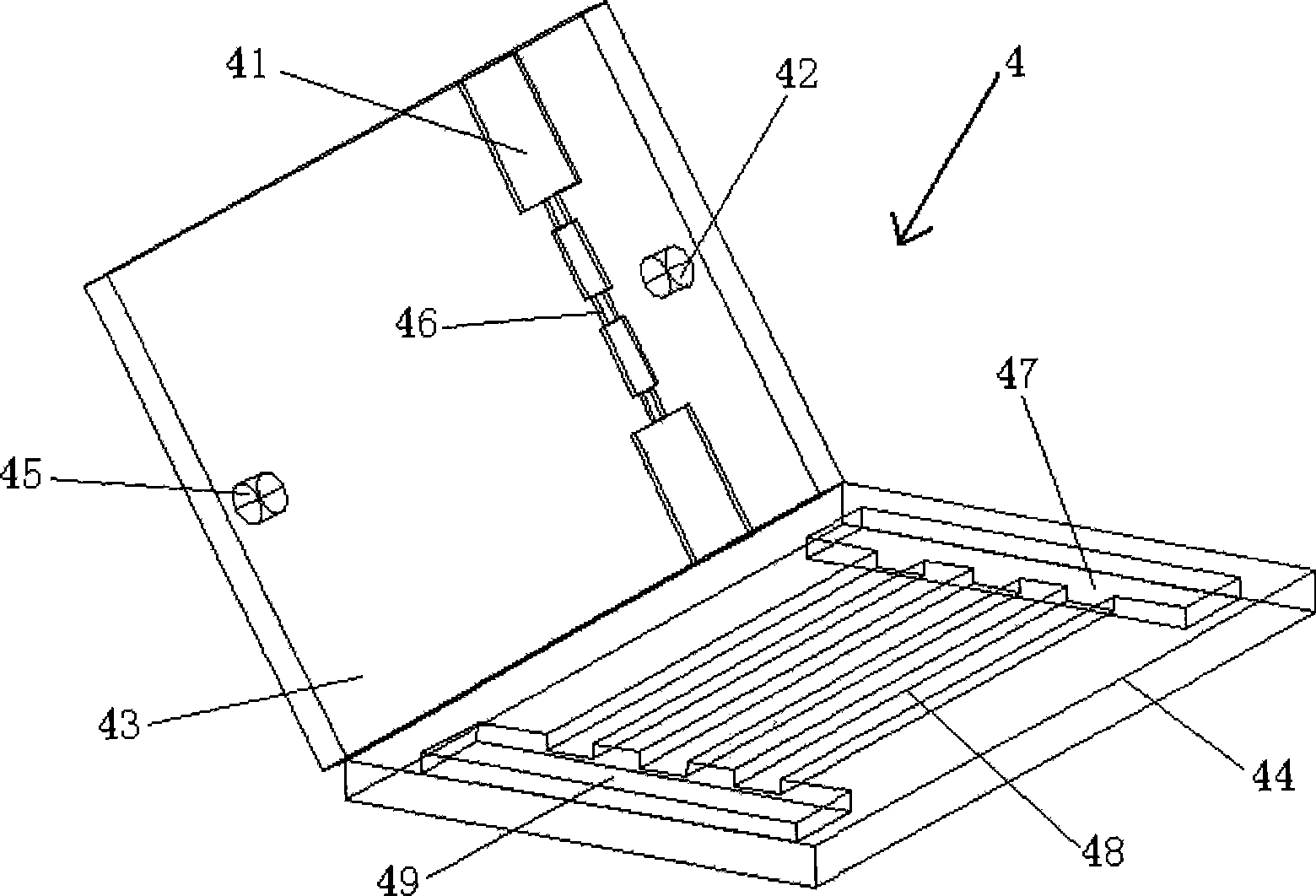

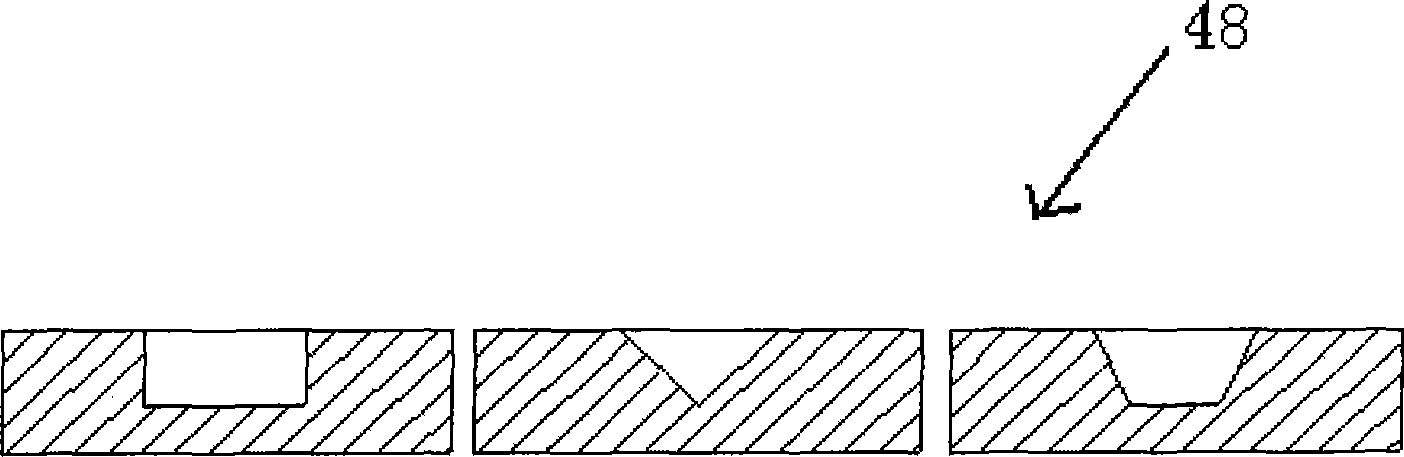

Orthopedic surgery grinding experimental device with cooling and electrostatic atomization film formation functions

The invention discloses an orthopedic surgery grinding experimental device with the cooling and electrostatic atomization film formation functions. The orthopedic surgery grinding experimental device comprises linear three-axis platform, an electric spindle and a workpiece fixing device. The linear three-axis platform can move front and back, left and right, and up and down. The linear three-axis platform comprises an X-axis structure capable of moving left and right, a Y-axis structure capable of moving front and back, and a Z-axis structure capable of moving up and down. The workpiece fixing device is fixed to the Y-axis structure. The electric spindle is fixed to the Z-axis structure and installed at the upper end of the workpiece fixing device. A grinding head is installed at the lower end of the electric spindle, a grinding cooling device is arranged in a grinding head handle or around the grinding head, and an electrostatic atomization film formation device is arranged around the grinding head. The high-speed grinding surgery experimental device can be suitable for drop irrigation type cooling, pouring type cooling, aerial fog type cooling, nano-fluid aerial fog type cooling and grinding region temperature drop modes for phase-change heat transfer type grinding heads, hydrophilic type grinding heads, electrostatic atomization inner-cooling grinding tools and the like.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

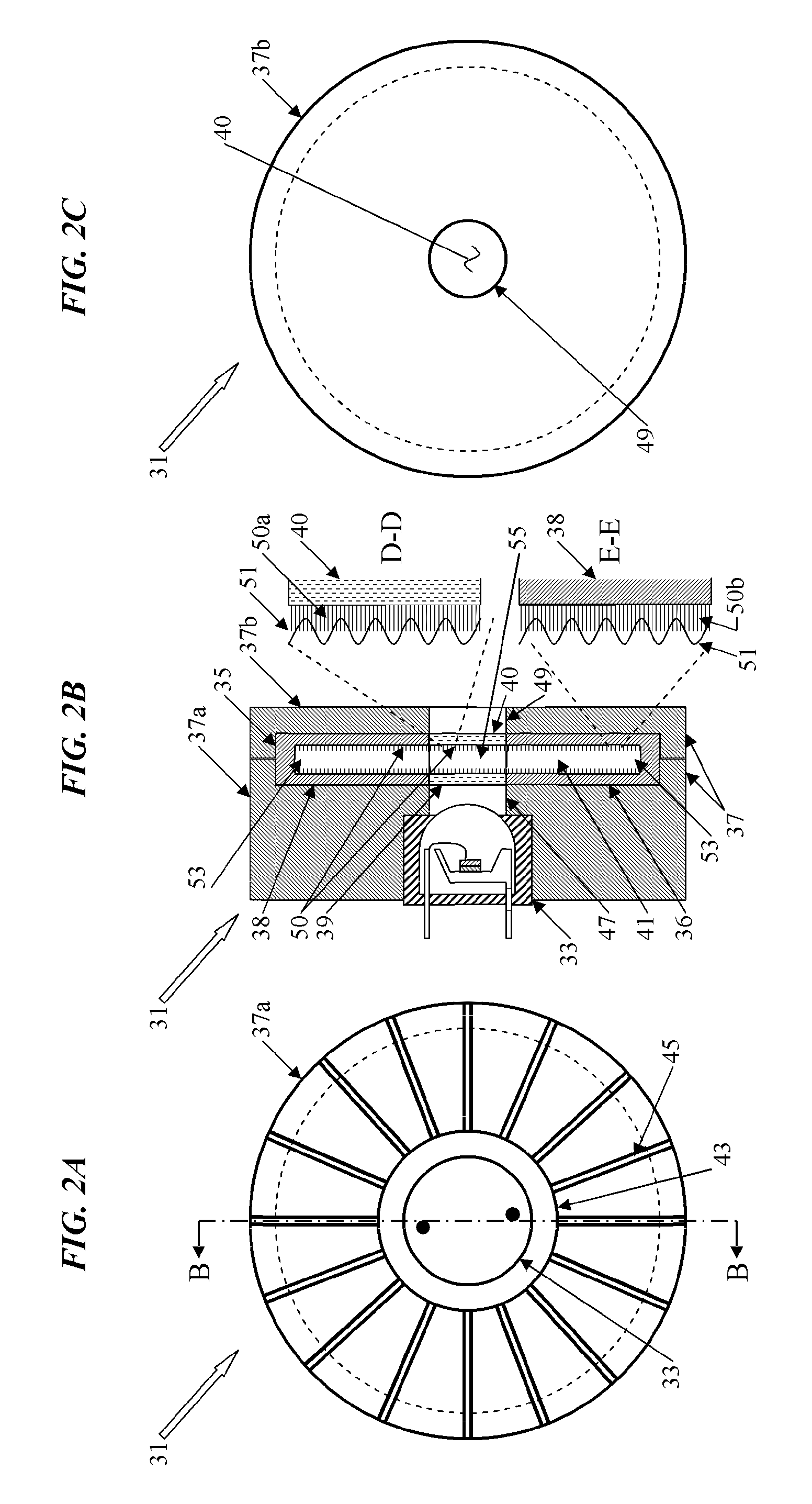

Motor with rotor cooled

InactiveCN104578504AReduce weightReduce bearing burdenMagnetic circuit rotating partsCooling/ventillation arrangementMotor shaftPhase change heat transfer

Owner:TIANJIN SANTROLL ELECTRIC AUTOMOBILE TECH CO LTD

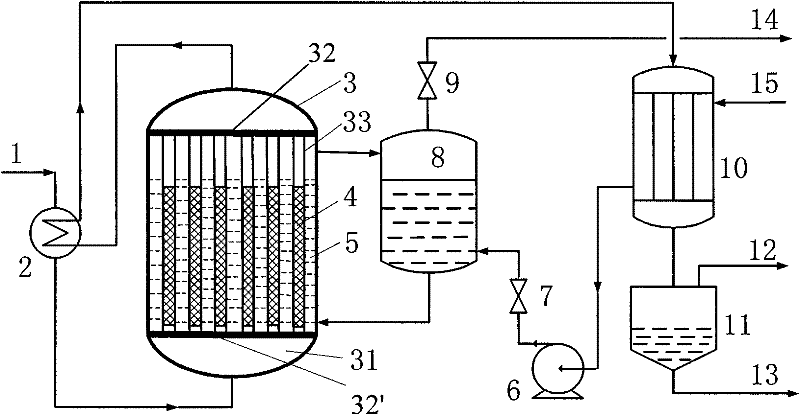

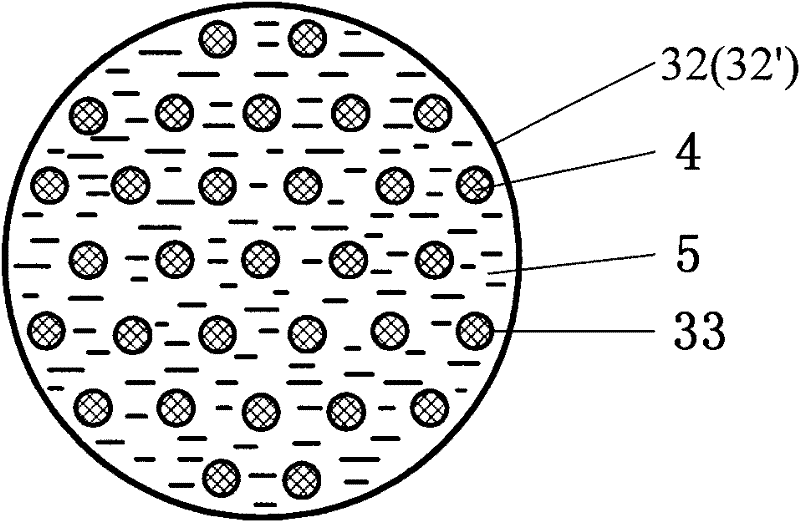

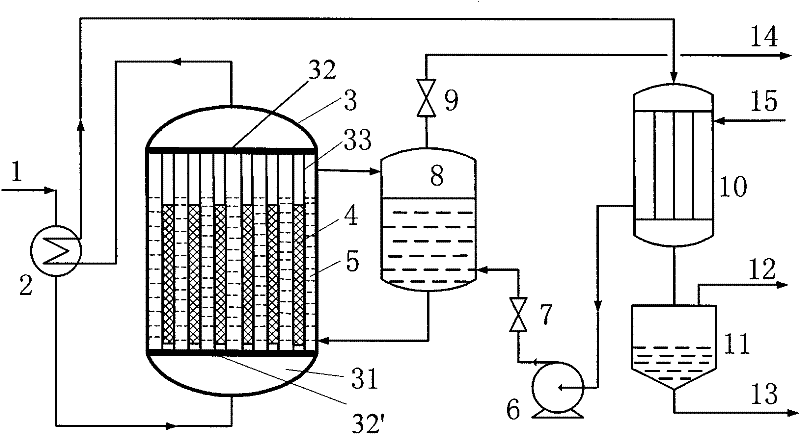

Complete methanation reaction device for synthesis gas

ActiveCN102234213AIncrease production capacityImprove efficiencyHydrocarbon from carbon oxidesChemical industryLiquid productMethanation

The invention relates to a complete methanation reaction device for synthesis gas. The device consists of a tube-shell reactor, a heat exchanger, a steam pocket, a make-up water pump, a condenser and a gas-liquid separator, wherein a catalyst is filled in a tube of the reactor; the shell pass is superheated water for removing heat; heat released in methanation reaction is absorbed through the phase change of high-pressure superheated water in the shell pass of the reactor and taken out of the device; the generated steam enters the steam pocket, is subjected to gas-liquid balance and can directly form superheated steam to be supplied to the outside; the temperature of a catalyst bed in the tube of the reactor is regulated and controlled by controlling the balance pressure of the superheated steam; reaction product exit gas exchanges heat with raw material gas and is continuously condensed; and a gaseous product and a liquid product are separated by the gas-liquid separator. The device can realize the continuous and stable operation of the complete methanation reaction of the synthesis gas, can effectively improve heat transfer efficiency and control the temperature of the reaction bed in a phase change heat transfer mode at a high temperature and under high pressure, expands the operation range of the complete methanation reaction of the synthesis gas, and can effectively recycle the heat released in the reaction.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

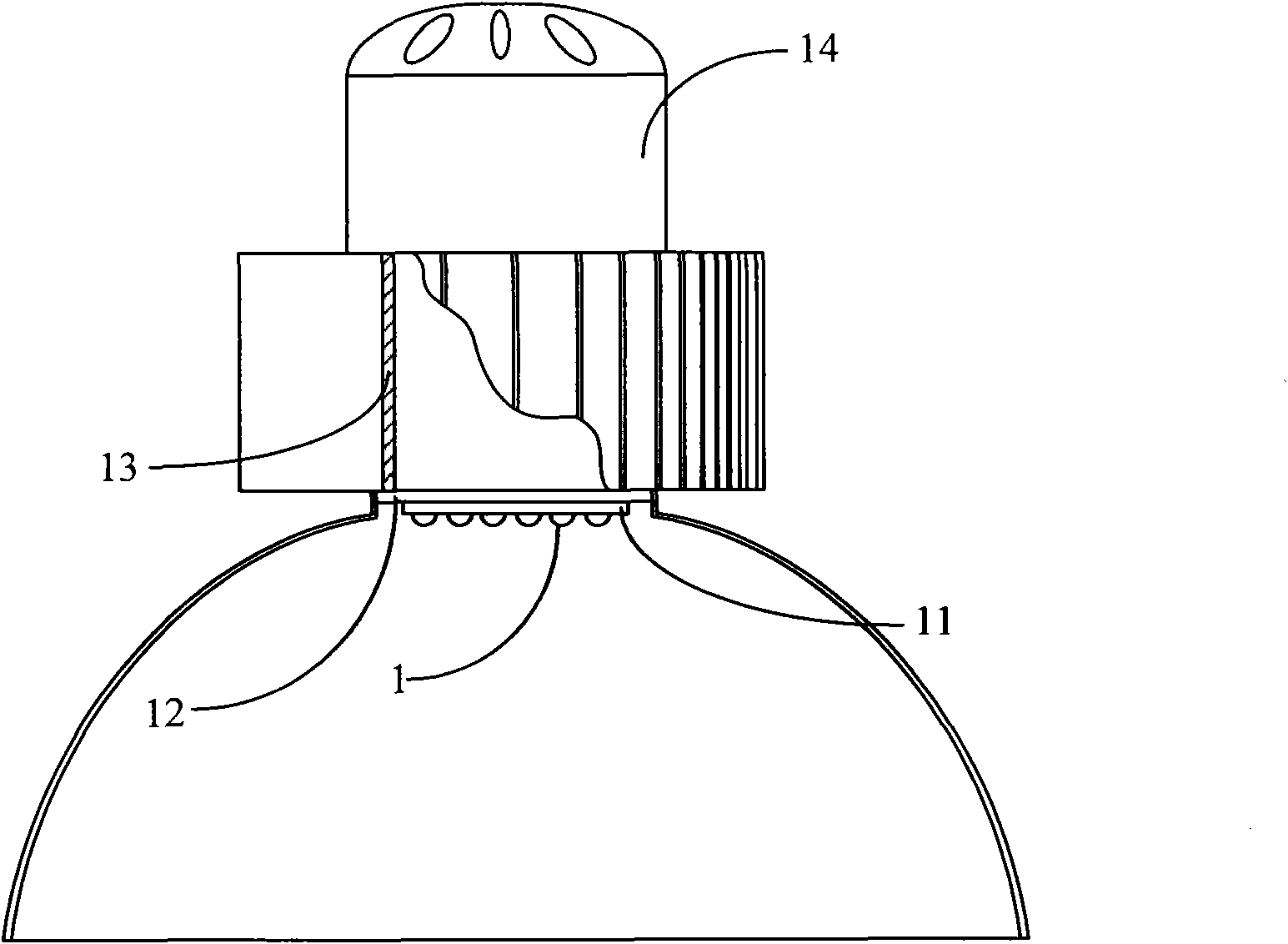

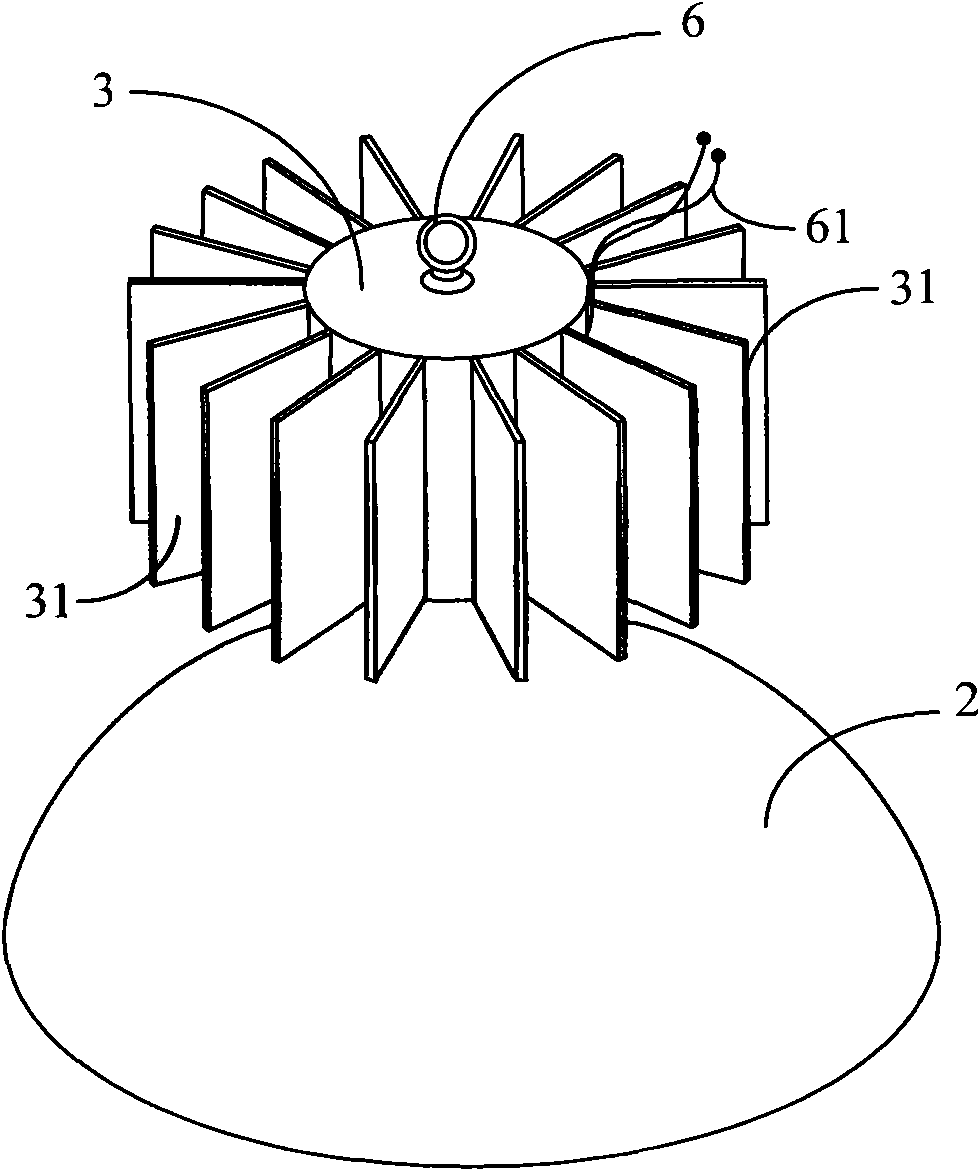

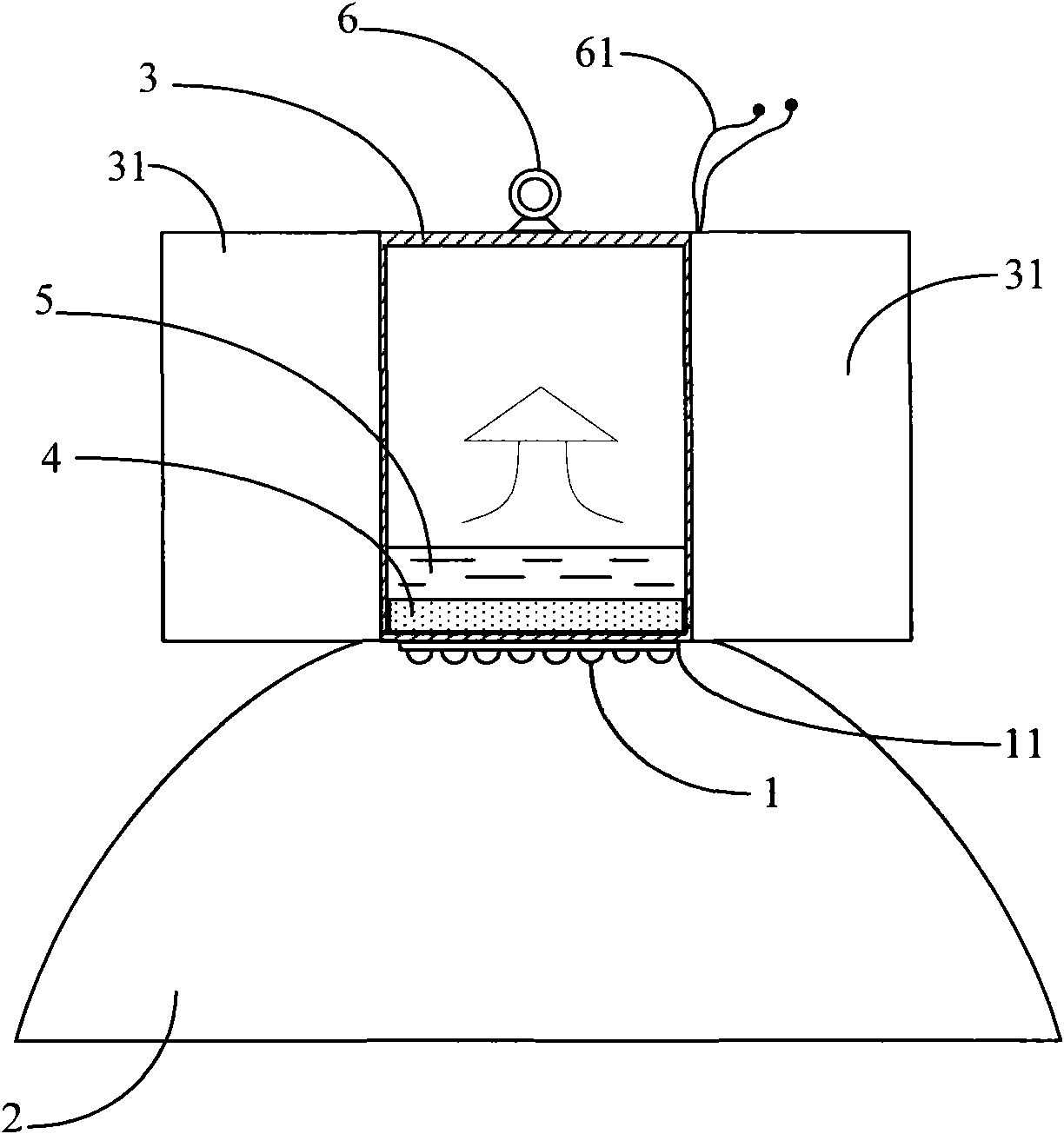

Semiconductor light source mining lamp

InactiveCN102109128ALower junction temperatureImprove heat transfer efficiencyLighting applicationsPoint-like light sourceJunction temperatureAluminum substrate

The invention discloses a semiconductor light source mining lamp. The lamp comprises a radiating device and an aluminum substrate, wherein the surface of the aluminum substrate is provided with light emitting diode (LED) chips; the radiating device comprises a phase change heat transfer cylinder which forms a sealed cavity; the sealed cavity is filled with liquid working medium which is subjected to phase change when heated; the outer wall of the phase change heat transfer cylinder is provided with radiating fins; and the phase change heat transfer cylinder is arranged on the surface of the aluminum substrate and is away from the LED chips. In the lamp, a technical means of phase change heat transfer is adopted; and a phase change process of the liquid working medium is utilized to quickly, uninterruptedly and circularly transfer heat, and the heat produced by the LED chips is quickly transferred to a shell of the phase change heat transfer cylinder and the radiating fins, so that the junction temperature of the LED chips can be effectively reduced.

Owner:DALIAN GOLDEN THERMALWAY TECH

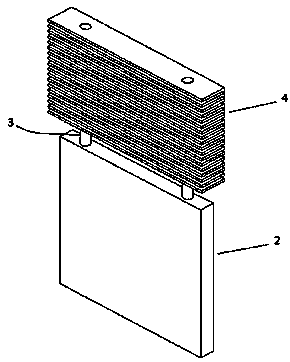

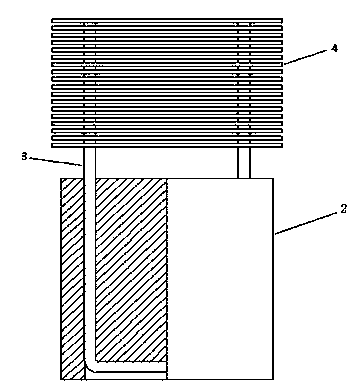

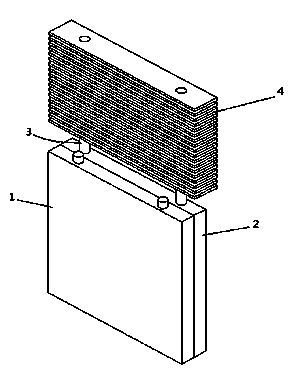

Efficient heat radiation device for lithium ion power battery

InactiveCN103825067AMeet the requirements of actual driving conditionsImprove cooling efficiencySecondary cellsWorking fluidElectrical battery

The invention discloses an efficient heat radiation device for a lithium ion power battery. The device comprises a thermal-arrest panel which can tightly fit with the battery, a U-shaped heat pipe filled with a working fluid and a radiating fin group. A bent part in the middle of the U-shaped heat pipe is embedded in the thermal-arrest panel, and overhanging parts at two ends of the U-shaped heat pipe extend out of the thermal-arrest panel. The radiating fin group is tightly secured to the overhanging parts of the U-shaped heat pipe through holes. By the device, efficient heat radiation of the lithium ion battery can be realized, and temperature uniformity between single batteries of a battery pack is raised. Thus, usability of the battery pack is raised, the thermorunaway risk is reduced, and service life of the battery pack is prolonged. A phase-change heat-transfer element heat pipe with high heat transfer coefficient is adopted. The phase-change heat-transfer element heat pip has good heat storage and heat radiation properties and has high operation reliability. Meanwhile, the device provided by the invention has advantages of simple structure and low cost, and is energy-saving and environmentally friendly.

Owner:SOUTH CHINA UNIV OF TECH

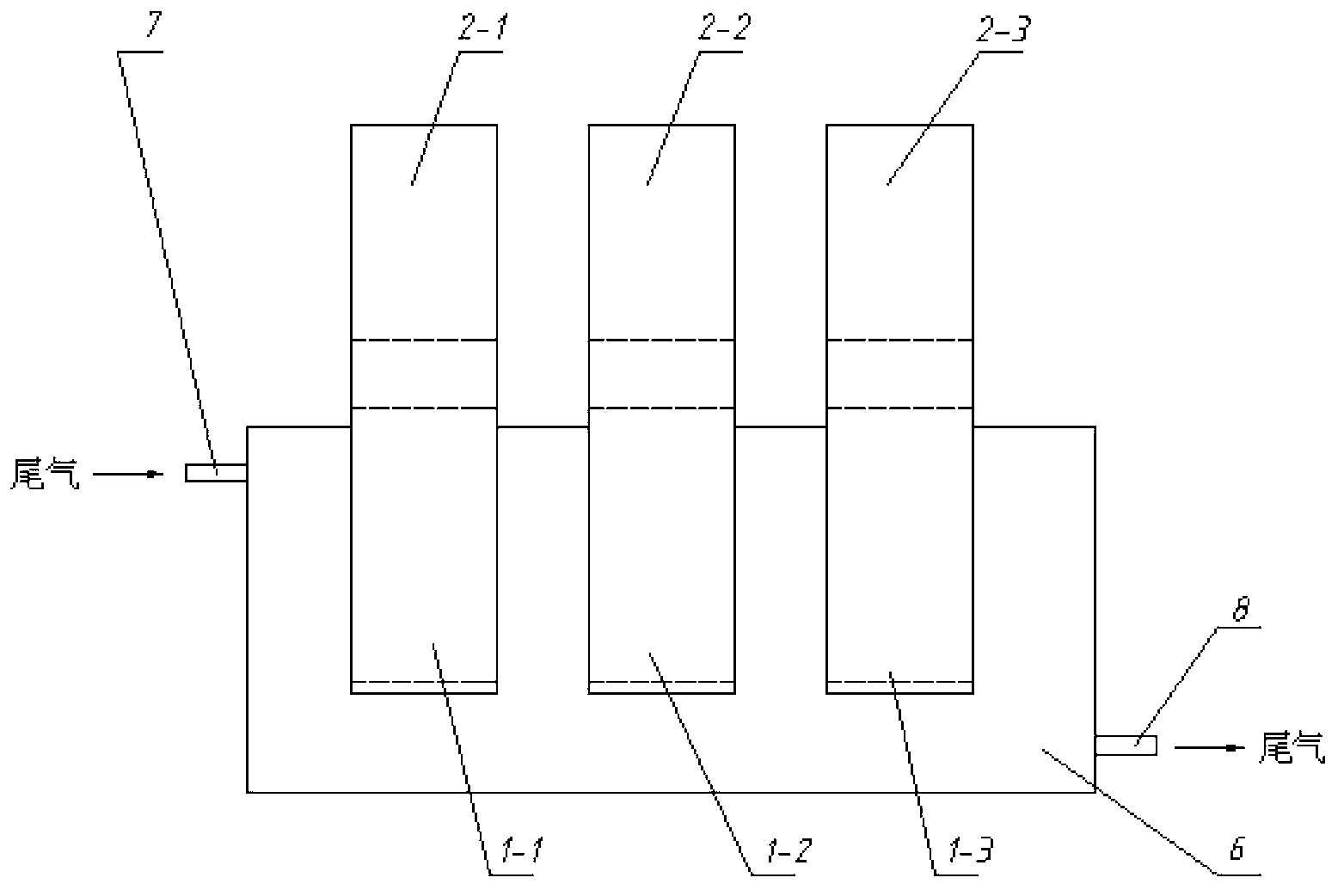

Ice preventing and removing system for aircraft wing

The invention discloses an ice preventing and removing system for an aircraft wing. The system comprises a waste gas treatment device, an air pump, a shell, an evaporator, a condenser, an air line and a liquid line, wherein engine waste gas treated by the waste gas treatment device is introduced into the shell to heat the evaporator, working media are vaporized after being heated in the evaporator and then led out through the air line, and then the working media are cooled into liquid in the condenser located on the skin and give out heat, and finally flow back to the evaporator through the liquid line to finish the whole circulation. According to the system, the vapor-liquid two-phase flow phase change heat transfer design concept is adopted, vapor-liquid phase conversion of the working media is utilized to transmit heat, and then the purpose of preventing and removing ice on the aircraft wing is achieved; engine waste gas of an airplane is utilized as the heat source to increase the comprehensive utilization rate of airplane energy.

Owner:BEIHANG UNIV

Solar high-temperature thermochemical coupling phase-change reactor

ActiveCN102744027AImprove heat transfer performanceImprove reaction efficiencySolar heating energySolar heat devicesChemical reactionEngineering

The invention relates to a solar high-temperature thermochemical coupling phase-change reactor. The solar high-temperature thermochemical coupling phase-change reactor comprises a CPC (Card Programmed Calculator) secondary optical collector, a quartz glass window, a heat plate, a heat pipe and a cylinder body, wherein a main body is coupled by the heat plate and the heat pipe, the heat plate is positioned at a photothermal conversion side, the heat pipe extending out of the heat plate is positioned at a reaction side, and the heat plate and the heat pipe are communicated into an integer; a heat absorption cavity is formed by the quartz glass window, the heat plate positioned at a heat absorption side and the inner wall of the cylinder body; and a reaction cavity is formed by the heat plate positioned at the reaction side, the heat pipe and the cylinder body. Sunlight is converged and then shines on the heat absorption side of the heat plate, optical energy is converted into heat energy, the heat energy is transferred to an internal working medium through the heat absorption side of the heat plate, the internal working medium transfers heat to the heat plate positioned at the reaction side and the wall surface of the heat pipe through phase-change heat transfer, and a reactant absorbs the heat emitted from the wall surface for chemical reaction. The solar high-temperature thermochemical coupling phase-change reactor can be used for intermediate-high temperature thermal chemical reaction, i.e. the pyrolysis or the reduction of metallic oxides, and the like, prevents the sintering or the damage caused by local overheating of the surface of the heat absorption side, reduces the temperature gradient of the reaction cavity and increase the efficiency and the stability.

Owner:NANJING UNIV OF TECH

Movable heat storage and discharge device based on pulsating heat pipes and heat storage and discharge method thereof

PendingCN106767082AGuaranteed uptimeSimple structureHeat storage plantsEnhanced heat transferCooling chamber

The invention provides a movable heat storage and discharge device based on pulsating heat pipes and a heat storage and discharge method thereof. The heat storage and discharge device comprises a shell, a heating chamber, a phase-change material chamber, a cooling chamber and the pulsating heat pipes, wherein the heating chamber, the phase-change material chamber, the cooling chamber and the pulsating heat pipe are all arranged in the shell; the heating chamber, the phase-change material chamber and the cooling chamber are separated by stainless steel partitions; at least one group of pulsating heat pipes pass through the partitions and are arranged in the shell; the parts, which are arranged in the heating chamber and the cooling chamber, of the pulsating heat pipes include straight pipe sections and elbows, and the parts, which are arranged in the phase-change material chamber, of the pulsating heat pipes are straight pipe sections; the parts, which are arranged in the heating chamber, of the pulsating heat pipes are evaporating sections, the parts, which are arranged in the phase-change material chamber, of the pulsating heat pipes are insulation sections, and the parts, which are arranged in the cooling chamber, of the pulsating heat pipes are condensation sections; and fluid inlets and outlets are formed in one end of the cooling chamber and the heating chamber. Phase-change heat transfer of working media in the pulsating heat pipes and phase-change heat storage of phase-change materials are used, so that waste heat is absorbed, stored, transferred and released, thereby effectively recycling the waste heat.

Owner:SHANGHAI MARITIME UNIVERSITY

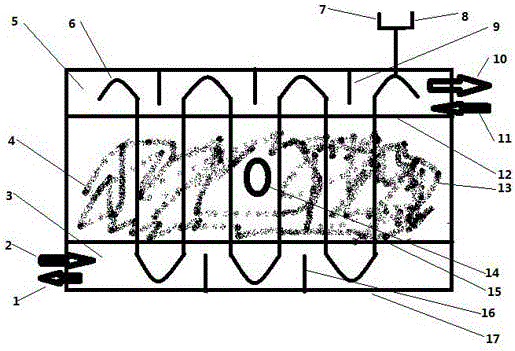

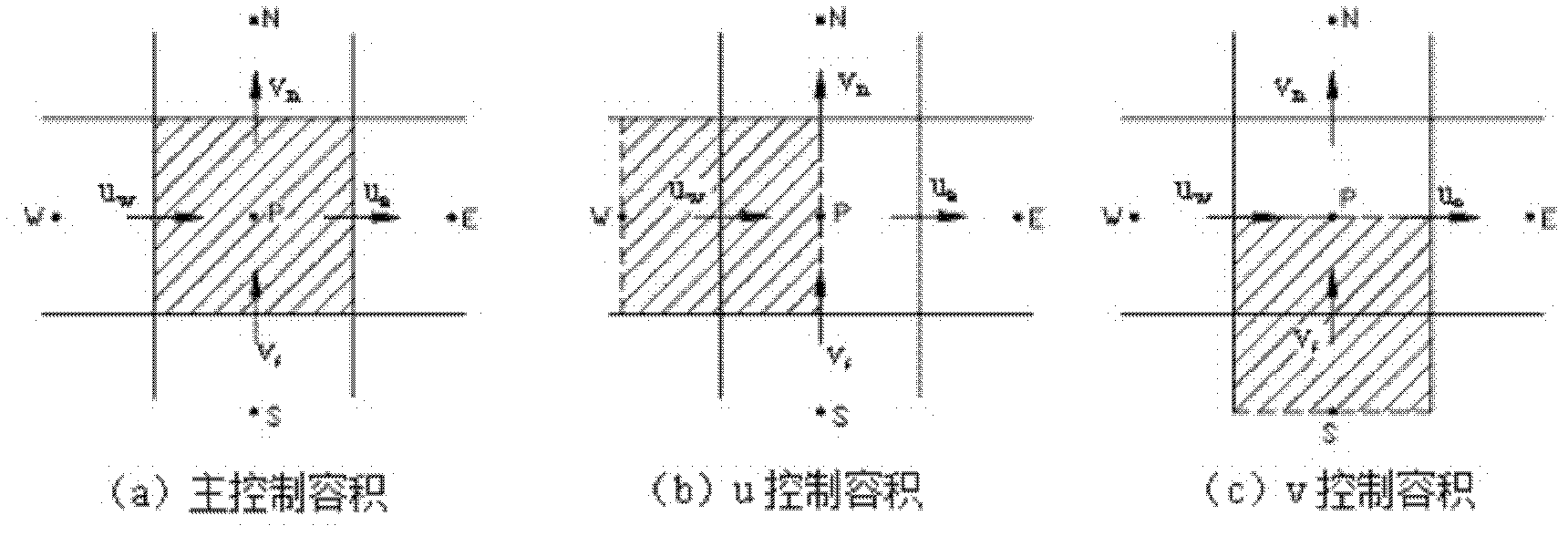

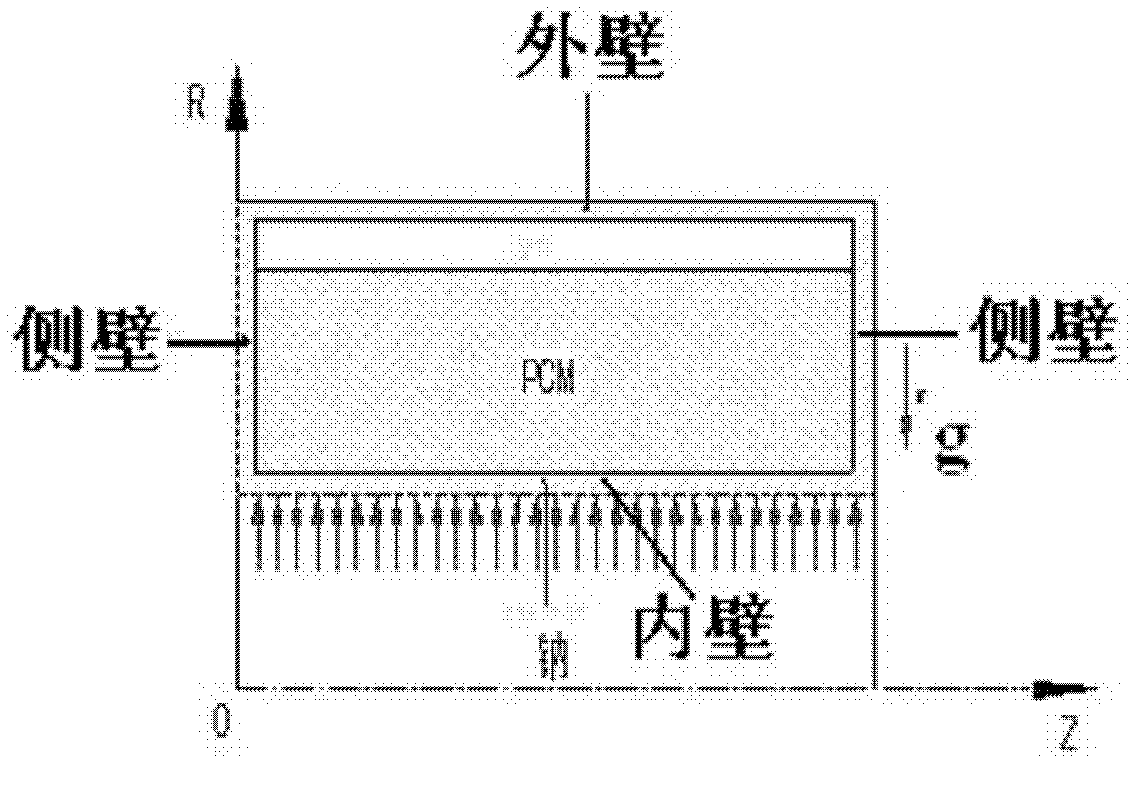

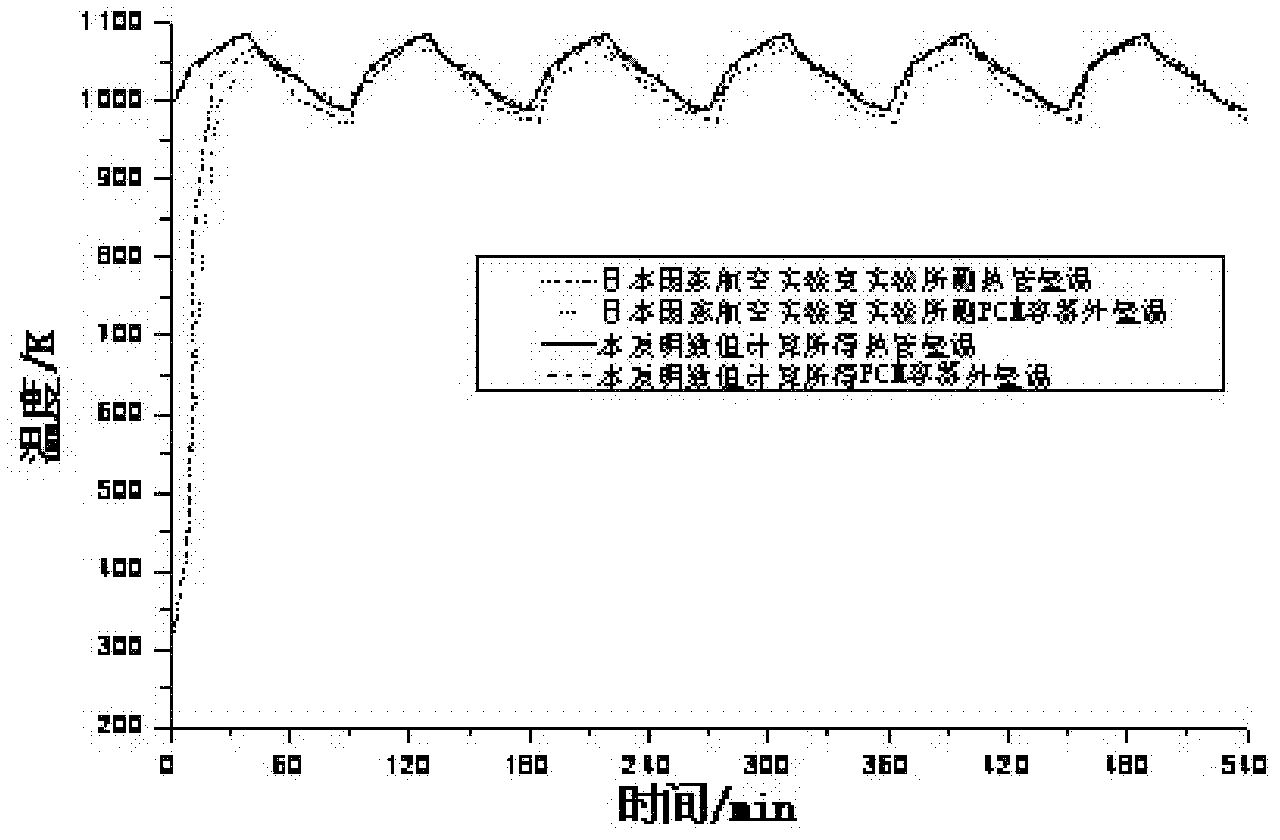

Numerical simulation method for solid/liquid phase change in high-temperature heat storage container in gravity condition

The invention provides a numerical simulation method for solid / liquid phase change in a high-temperature heat storage container in a gravity condition. Numerical calculation is carried out for the complicated problem of phase change heat transfer while natural convection, cavitation and radiation conditions are simultaneously considered, technicians can acquire change of melting rate of solid / liquid phase change materials in the high-temperature heat storage container in a field and distribution of a flow field, a temperature field and liquid phase by the aid of a computer, and accordingly important references for optimizing the design of heat storage containers, suppressing cavitation, improving heat storage efficiency and reducing 'hot spots' and 'hot release'. By the aid of the numerical simulation method, the complicated problem of melting / solidification inside the high-temperature heat storage container in the gravity condition is simply and efficiently solved by the aid of a calculation program based on an enthalpy method, a finite control volume method and SIMPLE algorithm, and the numerical simulation method has important practical values.

Owner:江苏中国科学院能源动力研究中心 +1

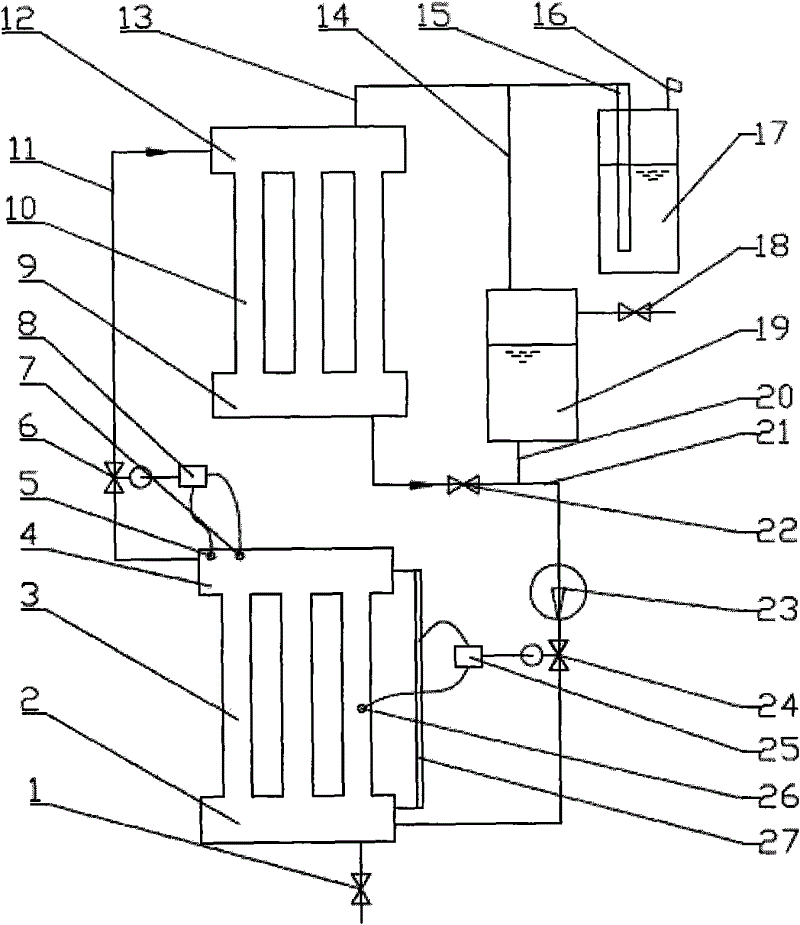

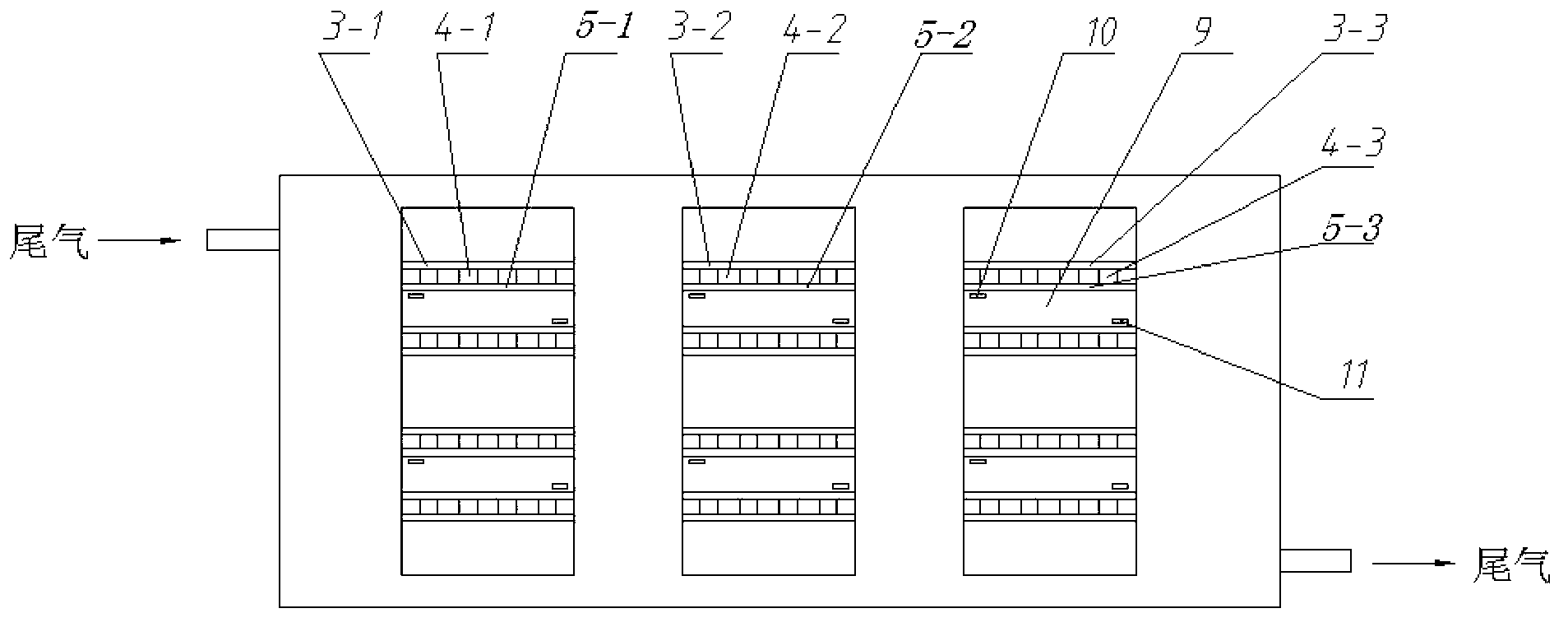

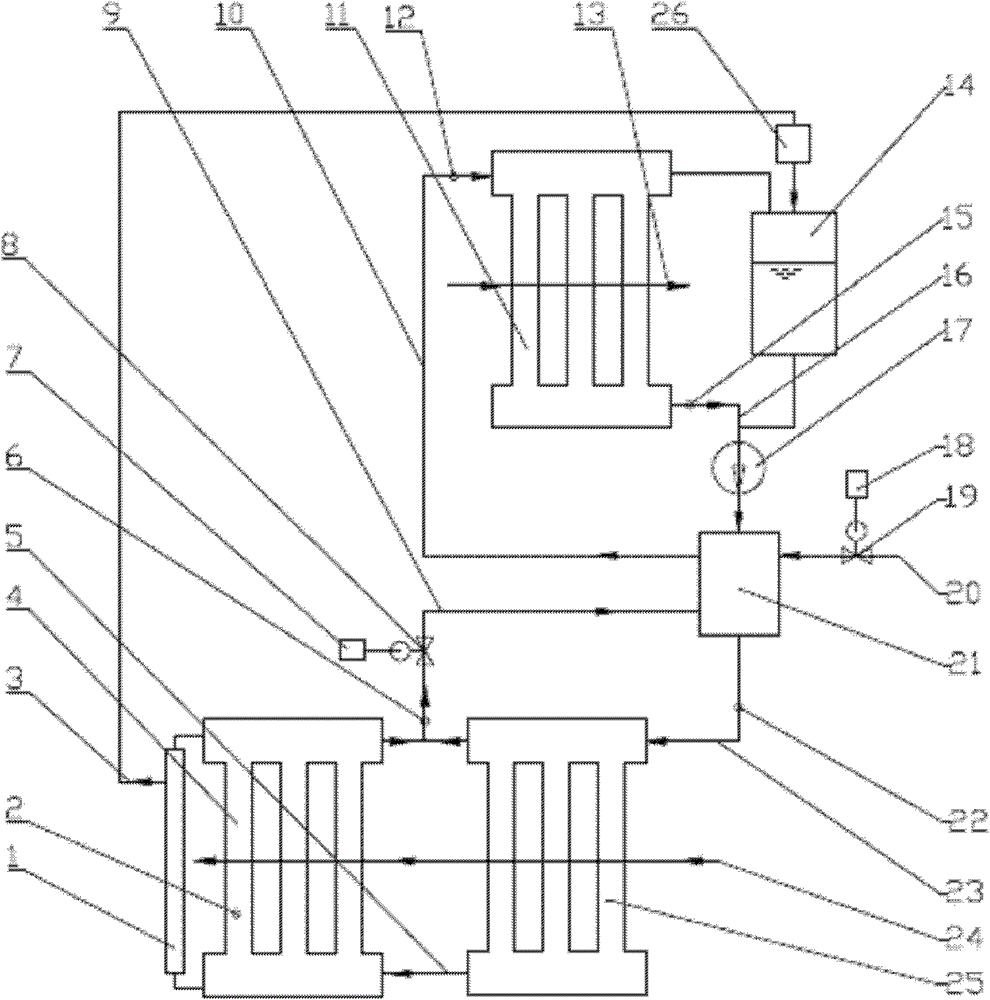

Sub-control phase change heat transfer system and sub-control phase change heat transfer method

InactiveCN102620583AImprove reliabilityHigh precisionIndirect heat exchangersHeat exchange apparatusEngineeringPhase change heat transfer

The invention relates to a sub-control phase change heat transfer system. The sub-control phase change heat transfer system comprises a heat absorption device and a heat release device which are mutually communicated through a vapor pipe (11) and a condensed fluid pipe (21) so as to form a sub-control phase change heat transfer loop. The sub-control phase change heat transfer system is characterized by comprising an airflow regulating valve (6), an airflow regulating valve controller (8), a liquid flow regulating valve (24) and liquid flow regulating valve controller (25), wherein the airflow regulating valve (6) is arranged in the pipeline of the vapor pipe (11) and the opening of the airflow regulating valve (6) is controllable; and the liquid flow regulating valve (24) is arranged in the pipeline of the condensed fluid pipe (21) and the opening of the liquid flow regulating valve (24) is controllable. The invention also provides a sub-control heat transfer method. In the method, the phase change heat transfer parameters of the heat absorption device and the heat release device are respectively independently controlled.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

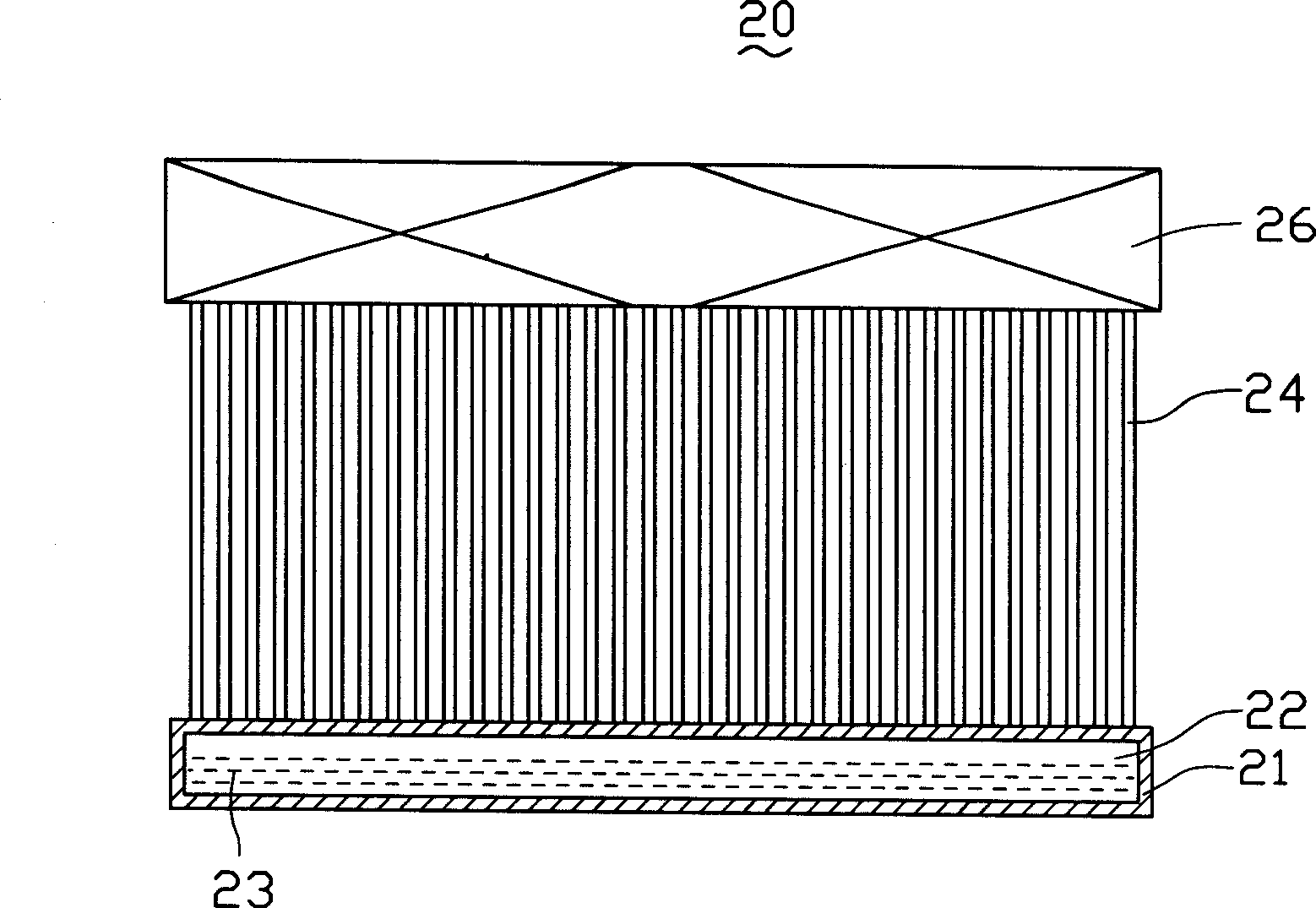

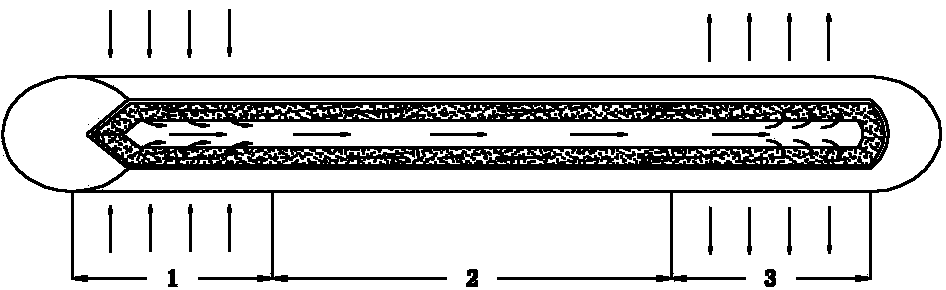

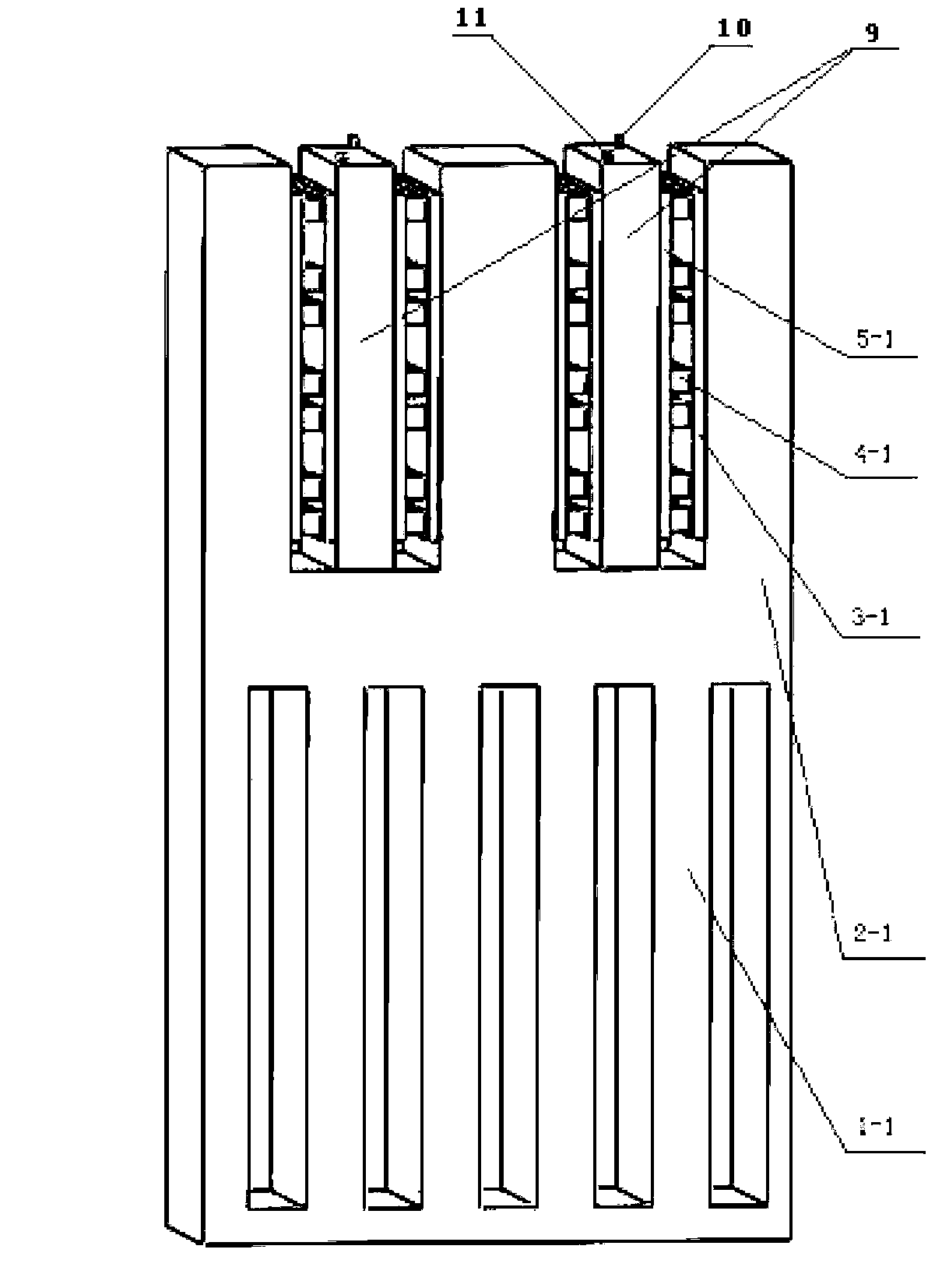

Heat management method for proton exchange membrane fuel cell based on array heat pipe phase change heat transfer

InactiveCN103715441AGuaranteed stabilityEnsure safetyFuel cell auxillariesThermodynamicsHeat management

The invention relates to a heat management method for a proton exchange membrane fuel cell based on array heat pipe phase change heat transfer. The heat management method for the proton exchange membrane fuel cell is characterized by comprising the following step of tightly inlaying array micro-channel heat pipes, which are connected in parallel, onto a fuel cell plate, wherein the pipe diameter of each heat pipe is 0.3cm-0.5cm. The proton exchange membrane fuel cell heat management method provided by the invention has the advantages that the fire-new heat pipe manner is adopted to carry out heat management, a cell is internally radiated through the heat pipes, and the problems that the local overheating is processed and the like are solved; the total temperature drop of the heat pipes is the sum of temperature drop of all parts of a steam flowing channel, an evaporation section and a condensation section, the volume of a wick of each heat pipe is very small, the temperature drop of vapor stream is not large, and the thermodynamic property is good.

Owner:JILIN JIANZHU UNIVERSITY

Ultra-supercritical strengthening fluid heat-transferring method and heat-transferring medium

InactiveCN101284984AImprove heat transfer performanceAchieve heat transferHeat-exchange elementsBulk chemical productionEnhanced heat transferWorking temperature

The invention discloses a supercritical multiphase enhanced heat transfer method and a heat transfer medium. The method is to add an auxiliary phase change heat transfer material to a basic heat transfer medium, so as to ensure that: when no phase change heat transfer is carried out in the working temperature range of the basic heat transfer medium, the auxiliary phase change heat transfer material carries out phase change heat transfer; when the basic heat transfer medium carries out phase change heat transfer, the auxiliary phase change heat transfer material carries out phase change heat transfer at the phase change temperature lower than a basic phase change heat transfer medium. The method and the medium can realize the integral thermal control and thermal management on heat transfer.

Owner:李建民

Lunar vehicle temperature control system

ActiveCN104803011AGuaranteed heating effectGuaranteed normal transmissionCosmonautic environmental control arrangementLiquid storage tankEngineering

The invention discloses a lunar vehicle temperature control system. The lunar vehicle temperature control system comprises a self-circulation fluid circuit, a phase-changing material energy storage device and a solar driving evaporation condensation self-reflux heat exchanging device, wherein the self-circulation fluid circuit comprises a liquid storage tank, a liquid pipeline, a porous core evaporator, a gas pipeline and a capillary pipe temperature control flow valve which is connected to the liquid pipeline; the phase-changing material energy storage device comprises an energy storage box and a phase-changing material which is arranged in the energy storage box, and the porous core evaporator is arranged in the energy storage box; the solar driving evaporation condensation self-reflux heat exchanging device comprises a vacuum pipe and a phase-changing heat conduction medium in the vacuum pipe, the vacuum pipe comprises a heat absorption evaporation area and a heat release condensation area, the heat release condensation area is arranged in the phase-changing material of the energy storage box, and a tree-shaped branch rib structure is arranged in the heat release condensation area. By adopting the temperature control system, the heat balance of a lunar vehicle body is maintained, the high-efficiency transmission of the heat can be realized without power supply, the heat supply safety and long-term running stability of the lunar vehicle can be greatly improved at moonlit night, and a reliable temperature control effect can be provided for the lunar vehicle.

Owner:SOUTHEAST UNIV

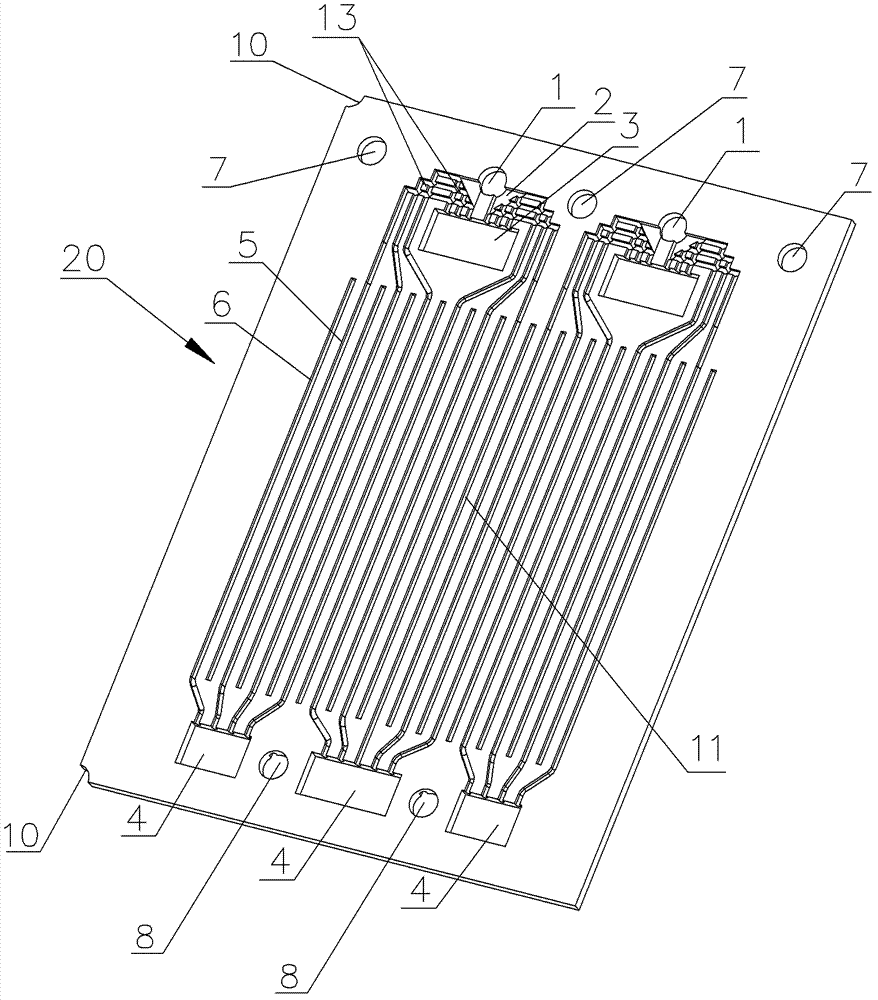

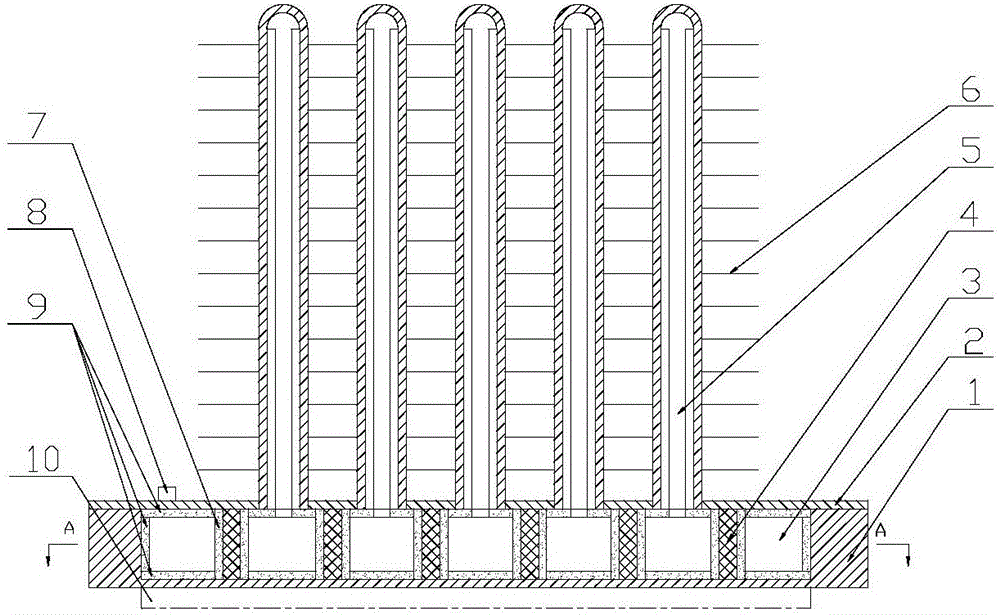

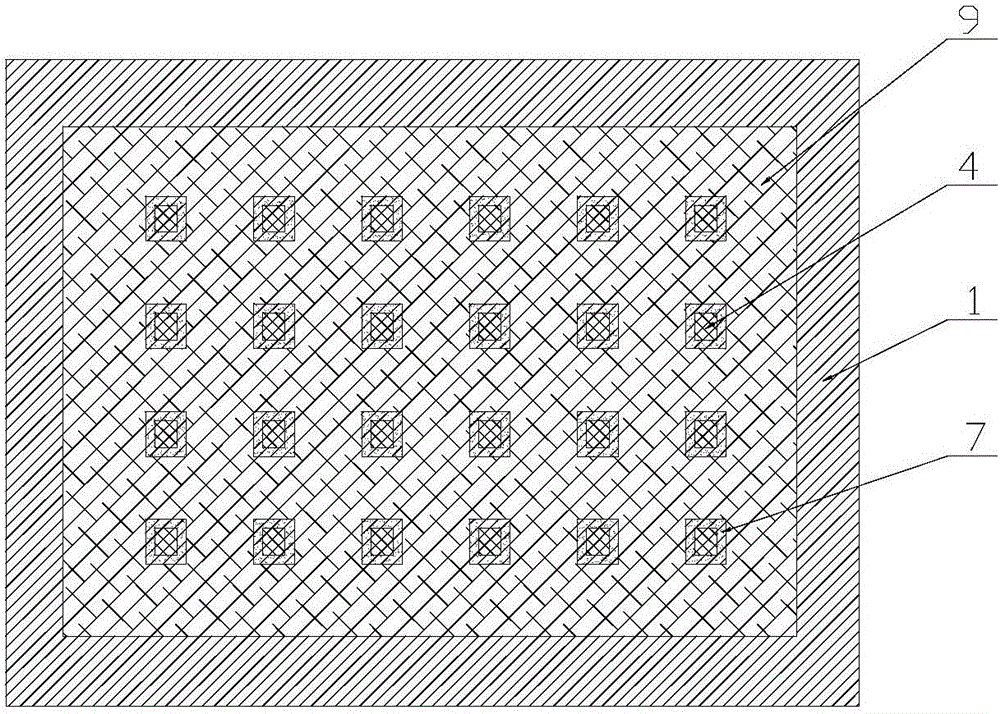

Proton exchange membrane fuel cell based on phase-change heat transfer and bipolar plate thereof

ActiveCN103247807AReduce volumeLow costFinal product manufactureSolid electrolyte fuel cellsEngineeringProton exchange membrane fuel cell

The invention discloses a proton exchange membrane fuel cell based on phase-change heat transfer and a bipolar plate thereof. The bipolar plate of the fuel cell comprises a planar plate, wherein a cathode flow field with a groove structure is arranged on one side surface of the planar plate, an air inlet and a water inlet are arranged on one end of the cathode flow field, an air outlet is arranged on the other end, a water inlet diffusion area is arranged between the water inlet and the cathode flow field, and the water inlet diffusion area is composed of porous substances or polymers embedded in the groove; and an anode flow field with a groove structure is arranged on the other side surface of the planar plate. The bipolar plate has advantages of no cooling channel, small volume and low cost, and adoption of phase-change heat transfer enables heat radiation efficiency to be greatly raised. The proton exchange membrane fuel cell assembled by the bipolar plate does not need a humidifier, a cooling medium storage case, a cooling medium pump and a cooling medium heat exchanger, thereby greatly reducing volume, weight and cost of the system, and reducing a control difficulty.

Owner:WUHAN TROOWIN POWER SYST TECH

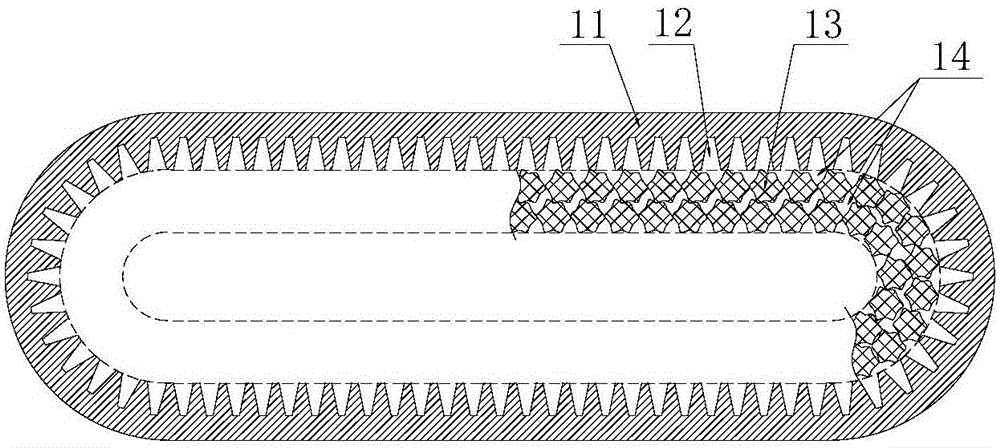

Composite wick type special-shaped heat pipe radiator

InactiveCN106643246AIncrease temperatureFast fullIndirect heat exchangersCooling/ventilation/heating modificationsEvaporationMetal fibers

The invention discloses a composite wick type special-shaped heat pipe radiator. The composite wick type special-shaped heat pipe radiator comprises a base plate, special-shaped heat pipes and radiating fins arranged on the outer sides of the heat pipes. Evaporation cavities are formed in the base plate. Each heat pipe comprises a heat pipe body with the special-shaped section. Grooves are formed in the inner wall of each heat pipe body, and protrusions are formed between the adjacent grooves. A fluffy-shaped fin fiber layer I is laid on the inner wall of each heat pipe body. Each fluffy-shaped fin fiber layer I is made of metal fibers, wherein the surface of each fluffy-shaped fin fiber layer I is provided with irregular protrusions and / or pits and each fluffy-shaped fin fiber layer I is of a fluffy-shaped fin structure. Inner spaces of the heat pipes communicate with the corresponding evaporation cavities, and the inner spaces of the heat pipes and the evaporation cavities form an airtight phase-change heat transfer cavity together. According to the composite wick type special-shaped heat pipe radiator, the fluffy-shaped fin fiber layers are sintered inside the evaporation cavities, the effect that each evaporation cavity is quickly filled with a backflow working medium can be guaranteed, the working media in the evaporation cavities can be evenly distributed, the section shape of each heat pipe is made special, wind resistance caused when airflow passes through the radiating fins and a special-shaped heat pipe bundle of the radiator can be effectively reduced, and the radiating efficiency is improved.

Owner:CRRC DALIAN INST CO LTD

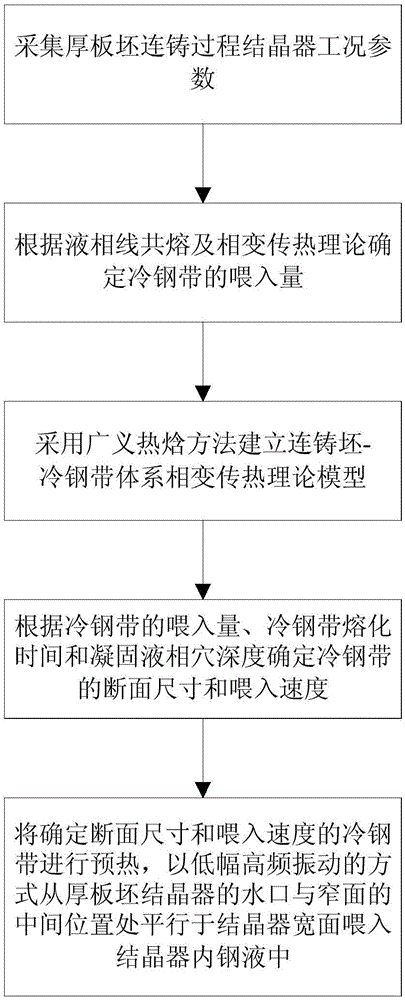

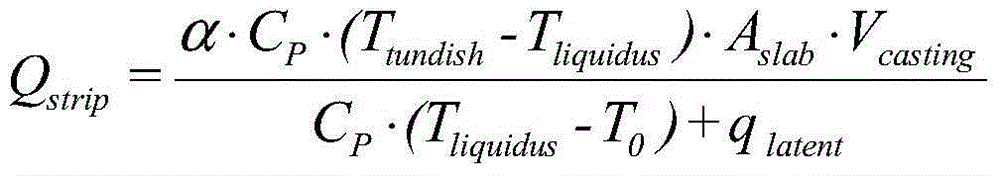

Method for determining steel belt feeding process parameter of crystallizer in thick slab continuous casting process

ActiveCN105033216AReduce macro segregationIncrease equiaxed crystal ratioLiquid coreCongruent melting

The invention relates to a method for determining the steel belt feeding process parameter of a crystallizer in the thick slab continuous casting process. The method comprises the steps the work condition parameter of the crystallizer in the thick slab continuous casting process is collected, and the feeding quantity of a cold steel belt is determined through the work condition parameter of the crystallizer in the thick slab continuous casting process based on the liquidus congruent melting and phase change heat transfer theory; a continuous casting slab-cold steel belt system phase change heat transfer theoretical model is built through a generalized enthalpy method, namely, a relation model among the melting time and feeding thickness of the cold steel belt, the superheat degree of casting molten steel and the initial temperature of the cold steel belt; the section size and feeding speed of the cold steel belt are determined through the continuous casting slab-cold steel belt system phase change heat transfer theoretical model according to the feeding quantity and melting time of the cold steel belt and the depth of a solidified liquid core; and the cold steel belt with the determined section size and feeding speed is preheated and fed into molten steel in the crystallizer through the position between a water opening and a narrow face of the thick slab crystallizer parallel to the wide face of the crystallizer in a low-amplitude high-vibration manner.

Owner:NORTHEASTERN UNIV

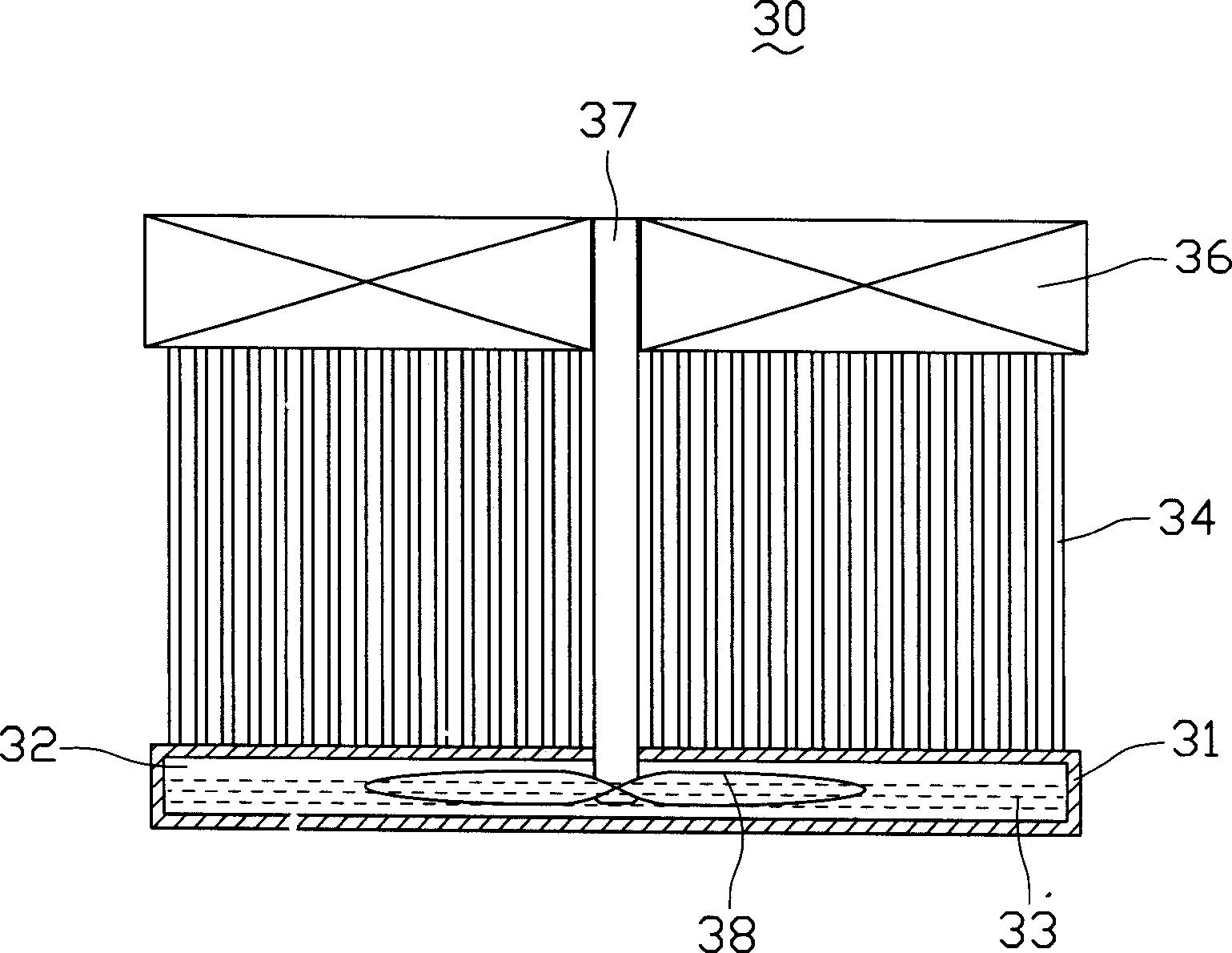

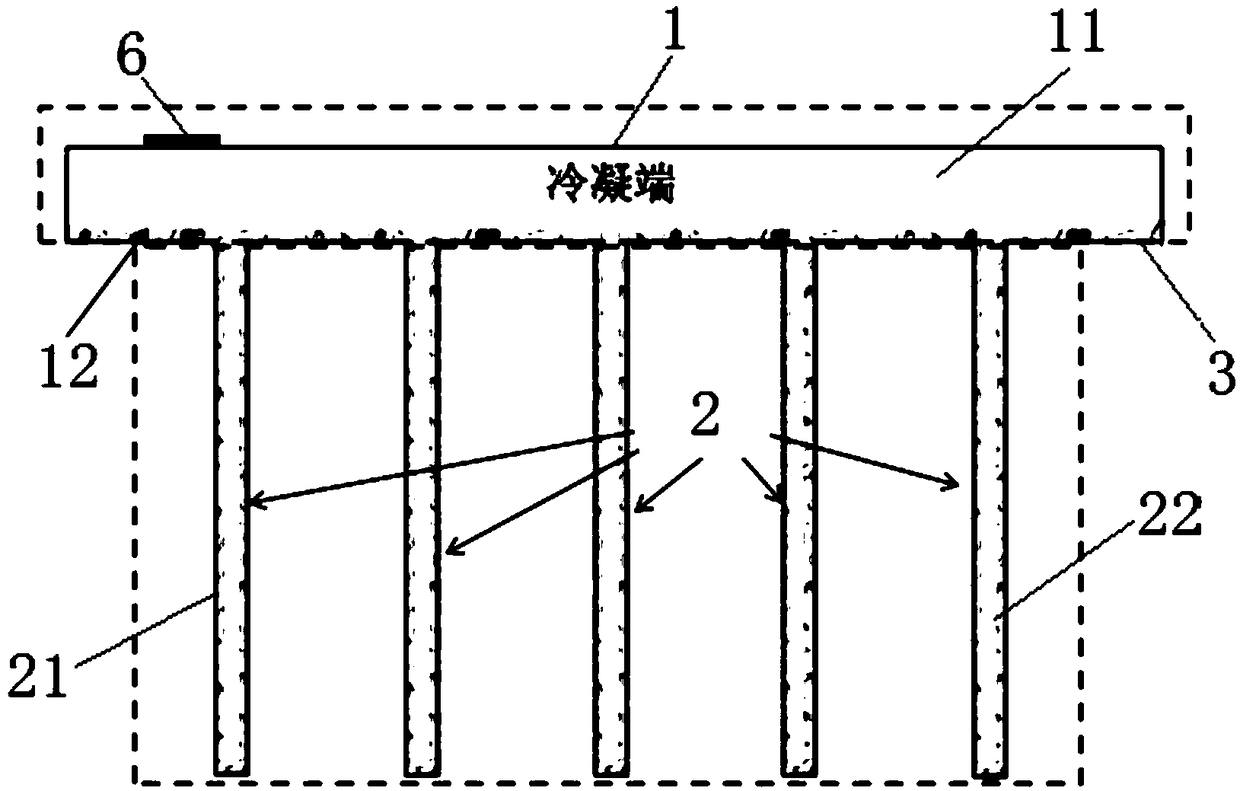

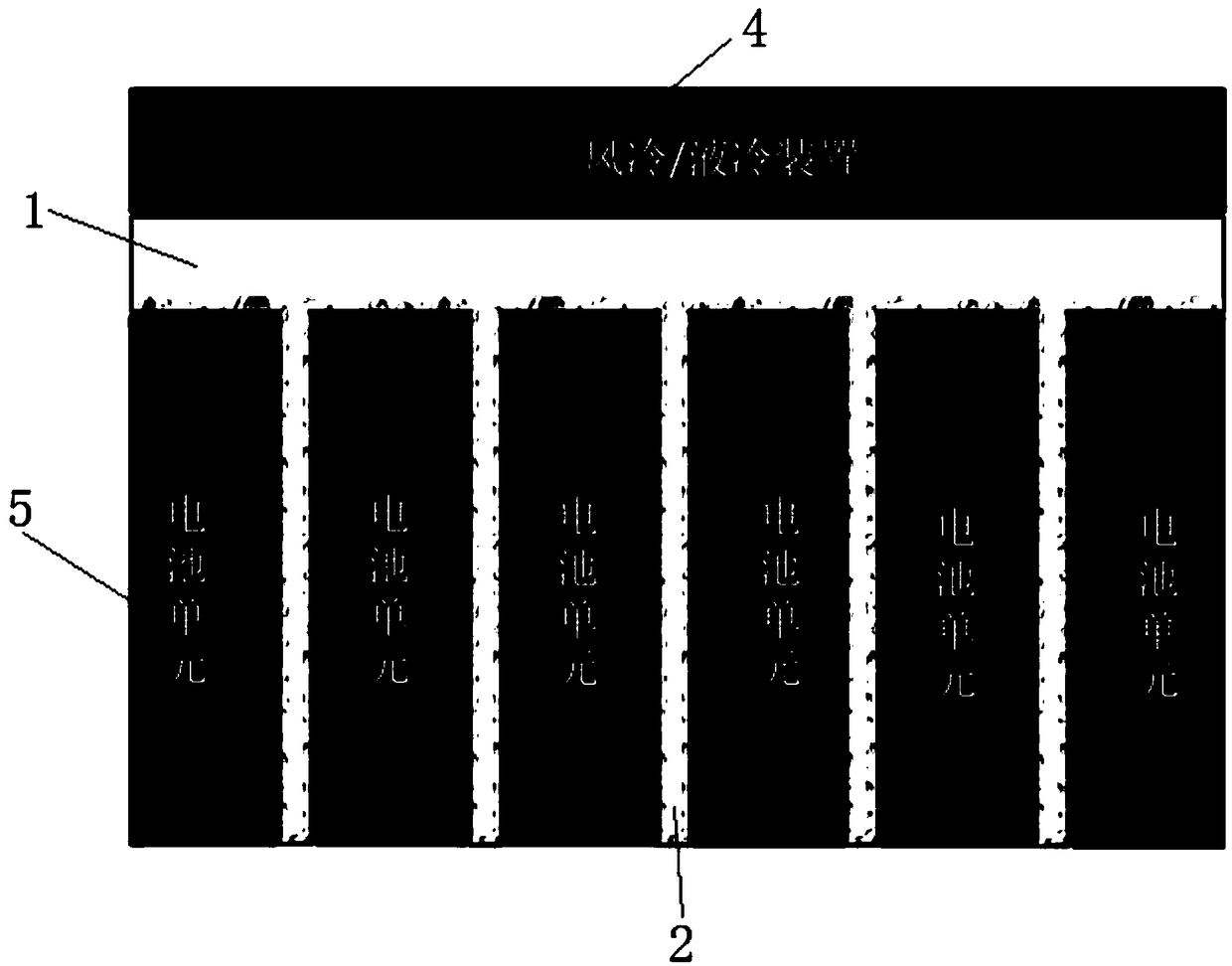

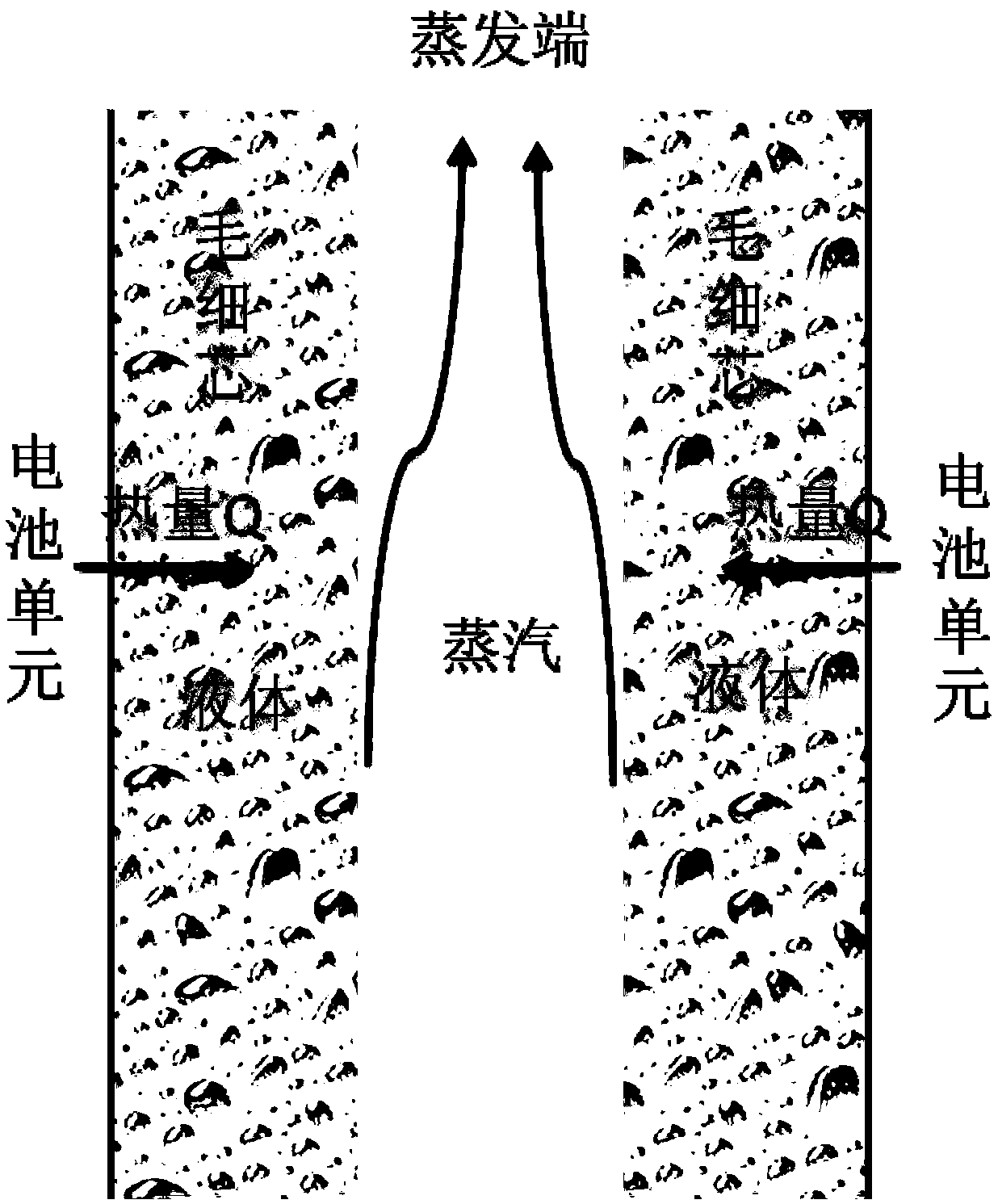

A battery two-phase heat dissipation device based on the heat pipe principle and a heat dissipation method thereof

The invention relates to a battery two-phase heat dissipation device based on the heat pipe principle and a heat dissipation method thereof. The device comprises a condensing end and a plurality of evaporating ends arranged at the bottom of the condensing end. The condensing end comprises a condensing chamber and a first capillary core arranged at the bottom of the inner side of the condensing chamber. Each evaporating end includes an evaporation chamber communicating with the condensing chamber and a second capillary core arranged on the inner wall of the evaporating chamber. The top of the condensing chamber is provided with a heat dissipation mechanism. As can be seen from the above technical proposal, the invention adopts the principle of heat pipe, utilizes the phase change heat transfer of the working medium, converts the heat of the battery unit into the phase change latent heat of a working medium charged in the device, and makes the phase change latent heat be rapidly led outalong the evaporatiing ends into the condensing end, and carries out heat exchange with an external heat dissipation device at the condensing end, thereby realizing the effective heat dissipation of asingle battery unit.

Owner:CHINA ELECTRONICS TECH GROUP CORP NO 16 INST

Semiconductor temperature difference power generation system

InactiveCN103078560ASmall temperature differenceImprove energy utilizationInternal combustion piston enginesExhaust apparatusThermoelectric materialsAbsorption capacity

The invention discloses a semiconductor temperature difference power generation system, which comprises phase-change heat transfer structures and temperature difference power generation modules; each phase-change heat transfer structure is composed of an evaporating section and a condensing section, and working medium with high heat absorption capacity and less useful energy loss within a temperature range, which is chosen according to the optimal working temperature of thermoelectric material, is filled in the pipeline of the evaporating section; the phase-change heat transfer structures comprise a high-temperature phase-change heat transfer structure, a medium-temperature phase-change heat transfer structure and a low-temperature phase-change heat transfer structure; the thermoelectric materials with different optimal working temperatures, which correspond to the evaporating sections, are also chosen by the temperature difference power generation modules; thermoelectric material hot ends cling to the surfaces of the condensing sections, and thermoelectric material cold ends cling to the wall surfaces of cooling passages. The invention broadens the useable range of the phase-change heat transfer structures in the whole process of heat transfer, reduces the temperature difference between a heat source and a generator, and increases the energy utilization rate of the system, and the semiconductor temperature difference power generation system is mainly used for supplying electric energy to an automobile power system.

Owner:TIANJIN UNIV

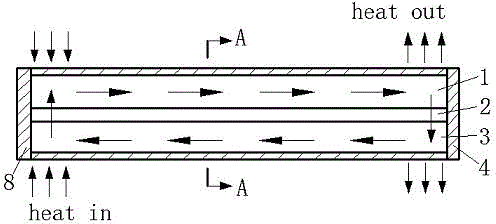

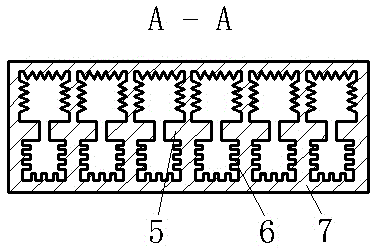

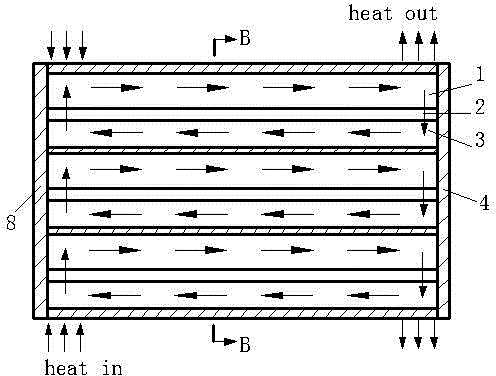

Plate type heat pipe with separation channels

ActiveCN104457359AImprove heat transfer performanceReduced frictional shearIndirect heat exchangersHeat resistanceFriction & shear

The invention relates to a plate type heat pipe with separation channels. According to the plate type heat pipe, one or more sets of separation channels are arranged in a plate type base body, one set of separation channels is composed of at least one evaporation channel and at least one condensation channel, the evaporation channels and the condensation channels are separated by reinforcing ribs, and capillary narrow clearances are formed in the reinforcing ribs. Working media with the phase-change heat transfer function are poured into the channels, and efficient heat transfer of the heat pipe is achieved. According to the plate type heat pipe, interface friction shear force of a vapor phase and a liquid phase in the work process of the heat pipe can be greatly reduced, and the novel plate type heat pipe has the obvious advantages of being low in heat resistance, high in heat exchange capacity, high in heat exchange efficiency, large in inclination range and the like, and is light, simple in structure, high in loading capacity, simple in manufacturing process, efficient, practical and low in cost.

Owner:长沙馨麓能源科技有限公司

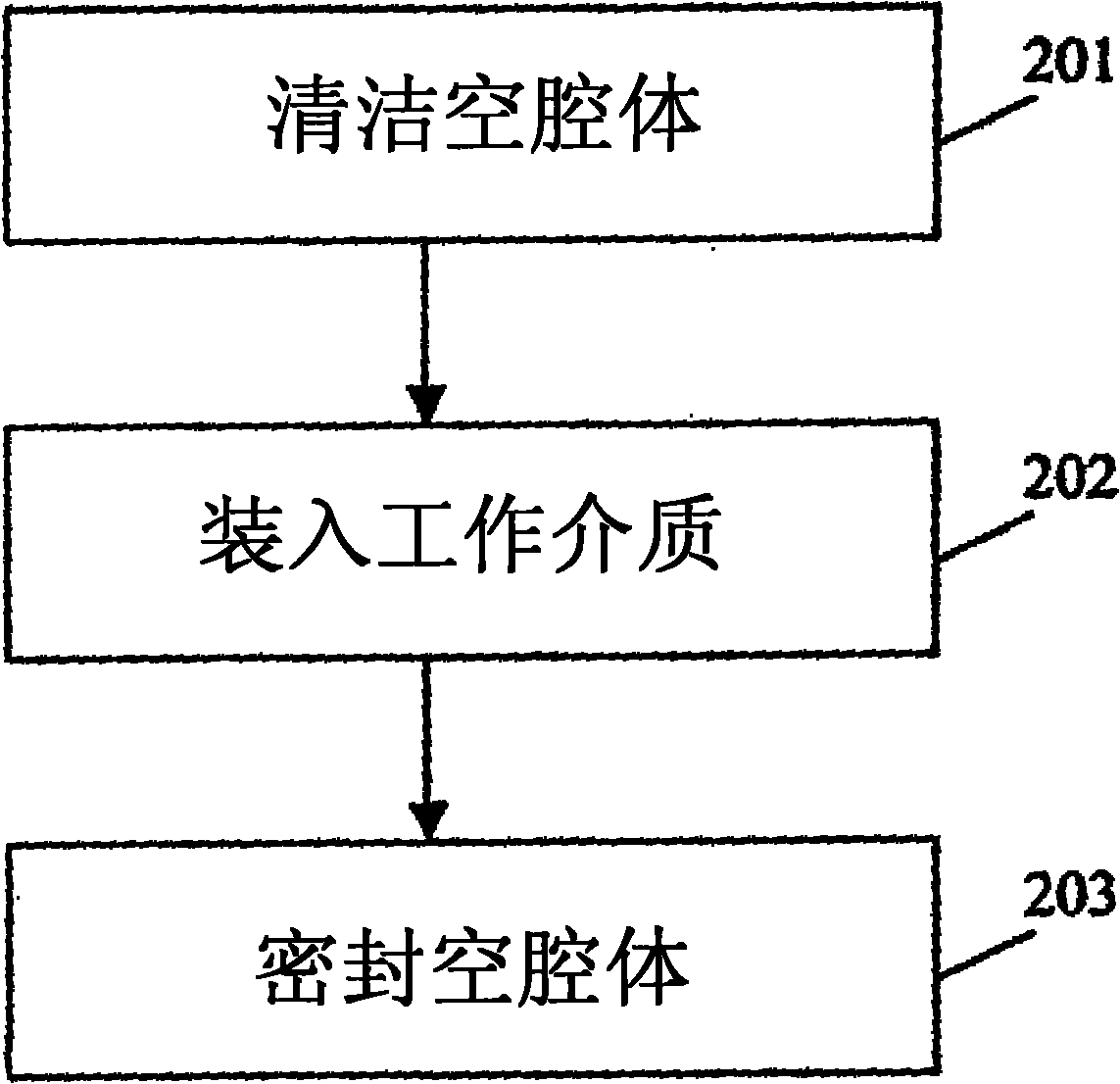

Heat transfer device without phase transition and manufacturing method thereof

InactiveCN102042775ATo achieve the effect of heat transferChange pressureIndirect heat exchangersEngineeringHeat transfer coefficient

The present invention provides a heat transfer device without phase transition and a manufacturing method thereof. The heat transfer device transfers heat without phase transition circularly, namely performs heat transfer without phase transition. Therefore, the heat transfer device which operates under a required working condition is provided. The heat transfer device is provided with a sealed member which limits a chamber body, and working medium which is accommodated in the chamber body, wherein the working medium is filled in the chamber body based on a temperature and a pressure under the required working condition. The invention also provides a manufacturing method thereof.

Owner:HAI O ENERGY M

Graded heat exchange distributed control phase-change heat transfer system and heat transfer method

InactiveCN103063067AHigh speedSufficient safety marginIndirect heat exchangersVapor liquidLiquid storage tank

The invention relates to a distributed control phase-change heat transfer system based on graded heat exchange and a heat transfer method. The system comprises a cold source heat exchanger, a heat source heat exchanger, a vapor-liquid heat exchanger and a liquid storage tank. An upper collecting tank of the cold source heat exchanger is communicated with the vapor-liquid heat exchanger through a vapor outlet pipe of the vapor-liquid heat exchanger. A lower collecting tank of the cold source heat exchanger and a lower portion liquid side of the liquid storage tank are respectively communicated with the vapor-liquid heat exchanger through condensation fluid pipes. An upper portion vapor side of the liquid storage tank is communicated with the upper collecting tank of the cold source heat exchanger. The heat source heat exchanger comprises a low-temperature heat source heat exchanger and a high-temperature heat source heat exchanger which are arranged in series. Vapor side communication pipes on the low-temperature heat source heat exchanger and the high-temperature heat source heat exchanger are combined into a vapor pipe to be communicated with a vapor side vapor inlet of the vapor-liquid heat exchanger. A liquid side outlet of the vapor-liquid heat exchanger is communicated with an upper collecting tank of the high-temperature heat source heat exchanger through a liquid outlet pipe of the vapor-liquid heat exchanger. The liquid side outlet of the vapor-liquid heat exchanger passes through the high-temperature heat source heat exchanger and the low-temperature heat source heat exchanger, and then is communicated with an upper portion liquid side of the liquid storage tank through an overflow pipe. The distributed control phase-change heat transfer system is better in effect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Seed gas bubble micro heat exchanger and seed gas bubble micro heat exchanger system

InactiveCN101447467AEliminate randomnessNon-repeatable eliminationSemiconductor/solid-state device detailsSolid-state devicesElectricityVoltage generator

The invention discloses a seed gas bubble micro heat exchanger system. The system comprises an IC chip to be cooled, a heat exchanger body for cooling the IC chip, a control circuit, a liquid supply circuit which is used for supplying liquid to a micro heat exchanger and is communicated to two ends of the heat exchanger body, an impulse voltage generator which is electrically connected with the heat exchanger body and used for supplying an exciting voltage signal to the heat exchanger body, and a final cold trap radiator which is connected with the liquid supply circuit and is used for releasing heat absorbed by the liquid supply circuit to the atmospheric environment, and the control circuit is electrically connected with the impulse voltage generator. The seed gas bubble micro heat exchanger system can trigger phase change heat transfer in micro-channels as quickly as possible, which thoroughly solves a difficult problem that high boiling starting point temperature, ensures that a micro heat transfer system is not over heated when being started, avoids burning down the chip to be cooled and greatly prolongs the service life of the chip to be cooled.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com