Solar high-temperature thermochemical coupling phase-change reactor

A solar thermal and reactor technology, which is applied to solar thermal collectors, solar thermal energy, solar thermal collectors in specific environments, etc. Heat transfer performance, effect of improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

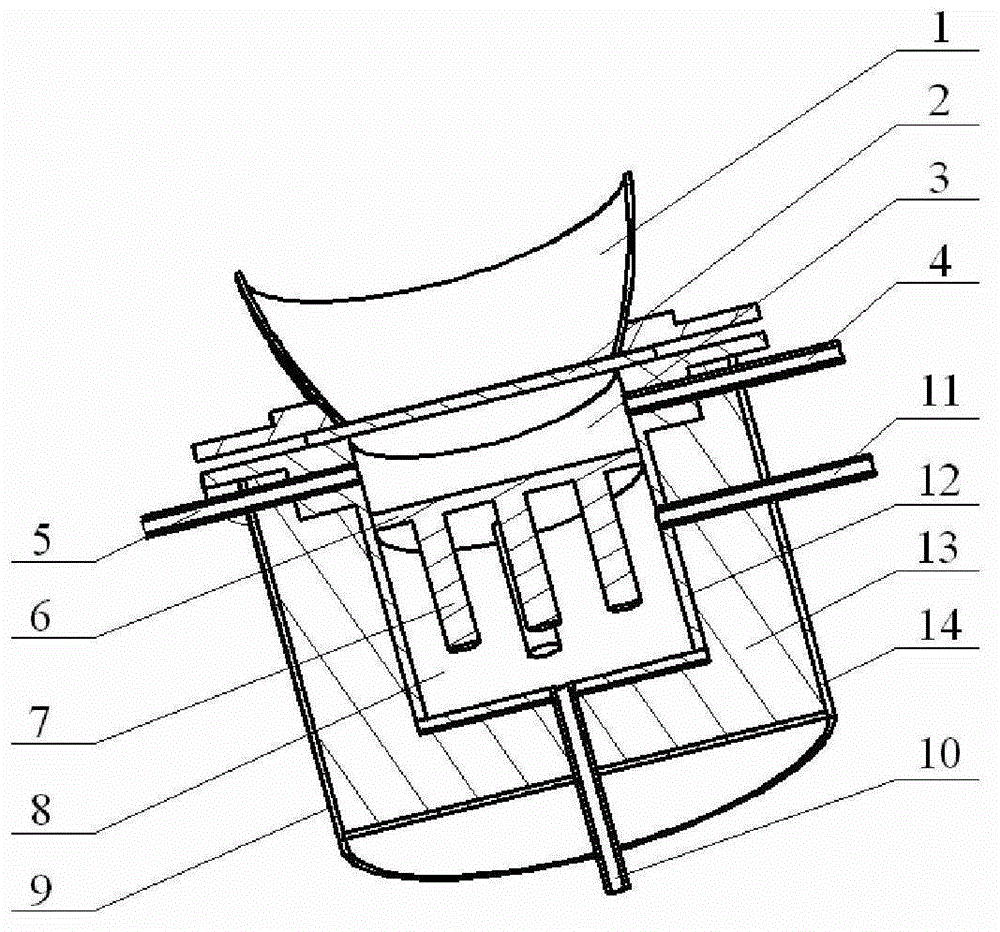

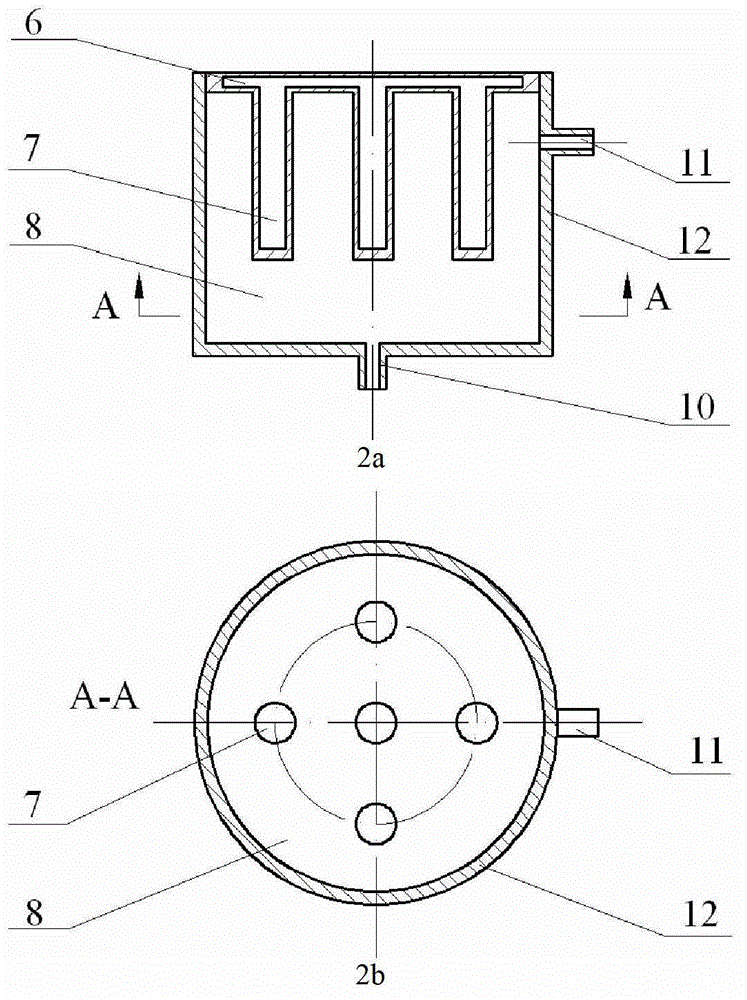

[0029] Solar high temperature thermochemical coupled phase change reactor (structural schematic diagram as figure 1 , figure 2 shown), consists of CPC secondary concentrator 1, quartz glass window 2, heat plate 6, heat pipe 7 and cylinder 9; reactor cylinder 9 has an inner wall 12, an insulation layer 13, and an outer wall 14 from inside to outside. One side of the quartz glass window 2 is preceded by a flange-connected CPC concentrator 1, and the other side forms a heat-absorbing chamber 3 with the heat-absorbing side of the heat plate 6 and the inner wall 12 of the cylinder 9, which is located in the heat-absorbing chamber The cylinder side on the 3 is provided with an axisymmetric cooling medium inlet 4 and cooling medium outlet 5; the heat pipe 7 is welded on the reaction side of the hot plate 6, and the working chamber inside the hot plate 6 and the working chamber inside the heat pipe 7 are connected as A whole, coupled as a "special-shaped heat pipe", the material of ...

Embodiment 2

[0032]On the basis of Example 1, the quartz glass window 2 is cooled by the cooling medium argon gas passed into the heat-absorbing chamber 3; the ratio of the height of the axial cylinder of the heat-absorbing chamber 3 to the height of the axial cylinder of the entire reactor is 1 / 20 The material of the hot plate 6 and the heat pipe 7 is tungsten, the working medium in the working chamber is silver, and the liquid-absorbing core is a metal powder sintered liquid-absorbent core; the shape of the heat plate 6 is spherical; the shape of the heat pipe 7 is a cylinder, and there are 6 pieces , the arrangement on the reaction side of the hot plate 7 is a circular distribution; the ratio of the axial height of the hot plate 6 to the axial height of the heat pipe 7 is 1 / 10; all walls constituting the reaction chamber 8 in the reactor are coated with metal base ceramic coating; the height-to-diameter ratio of the cylinder part on the reaction chamber 8 is 3:1, and the chemical reactio...

Embodiment 3

[0034] On the basis of Example 1, the quartz glass window 2 is cooled by the cooling medium helium gas that passes into the heat-absorbing chamber 3; the ratio of the height of the axial cylinder of the heat-absorbing chamber 3 to the height of the axial cylinder of the entire reactor is not less than 1 / 10; the material of the hot plate 6 and the heat pipe 7 is niobium, the working fluid in the working chamber is lithium, and the liquid-absorbing core is a groove liquid-absorbent core; the shape of the heat plate 6 is an ellipsoid; the shape of the heat pipe 7 is a cylinder with 4 Roots, arranged in a square on the reaction side of the hot plate 6; the ratio of the axial height of the hot plate 6 to the axial height of the heat pipe 7 is not less than 1 / 3; all walls forming the reaction chamber 8 in the reactor are coated with Silicide coating; the height-to-diameter ratio of the cylinder part on the reaction chamber 8 is 80:1, and the chemical reaction involved in it is the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com