Heat transfer device without phase transition and manufacturing method thereof

A technology without phase change and manufacturing method, which is applied in the direction of indirect heat exchangers, lighting and heating equipment, etc., to achieve the effect of inhibiting phase change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0047] According to one embodiment, the fluid is selected as a suitable working medium. A fluid can be a gas or a liquid.

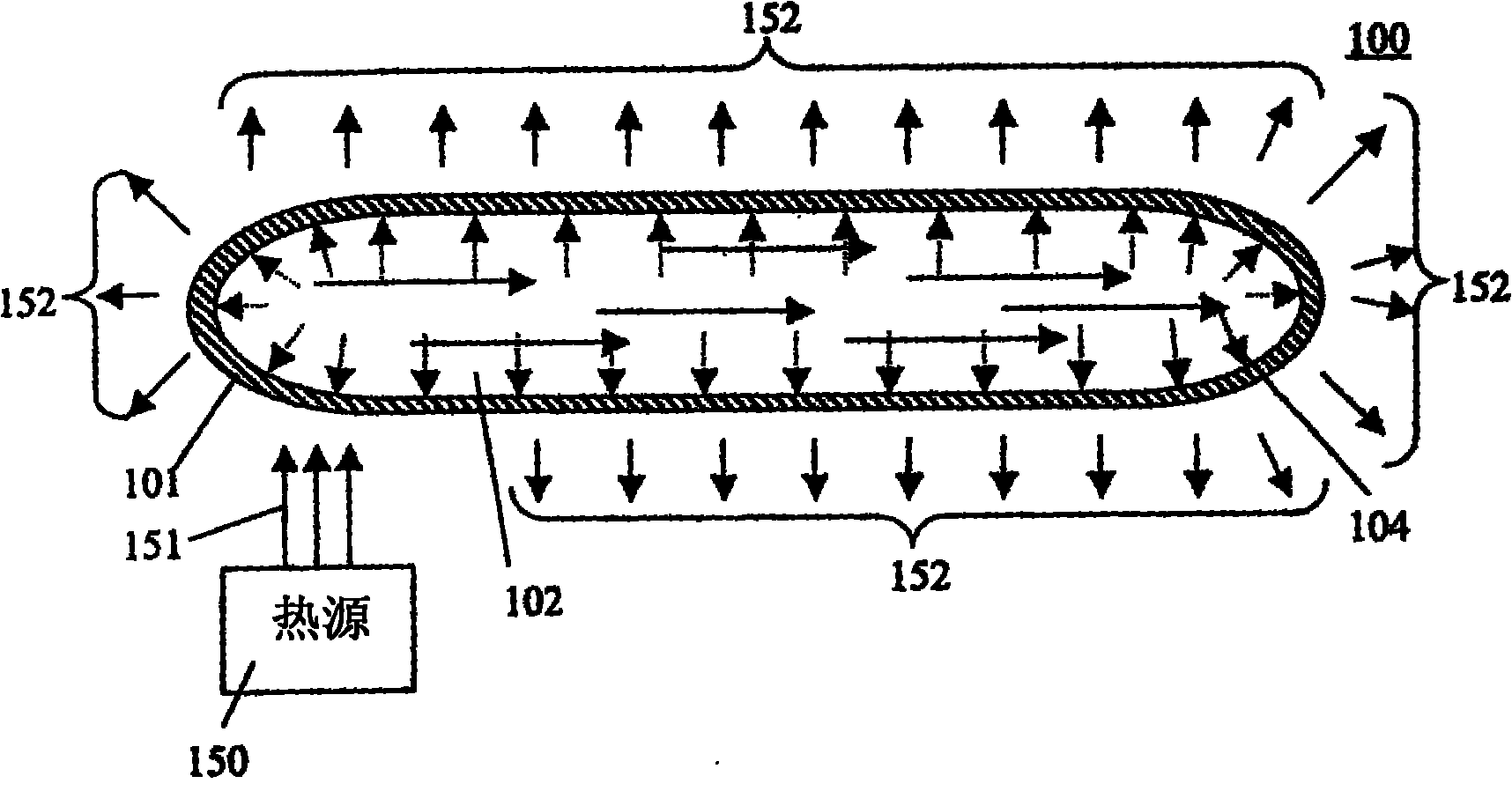

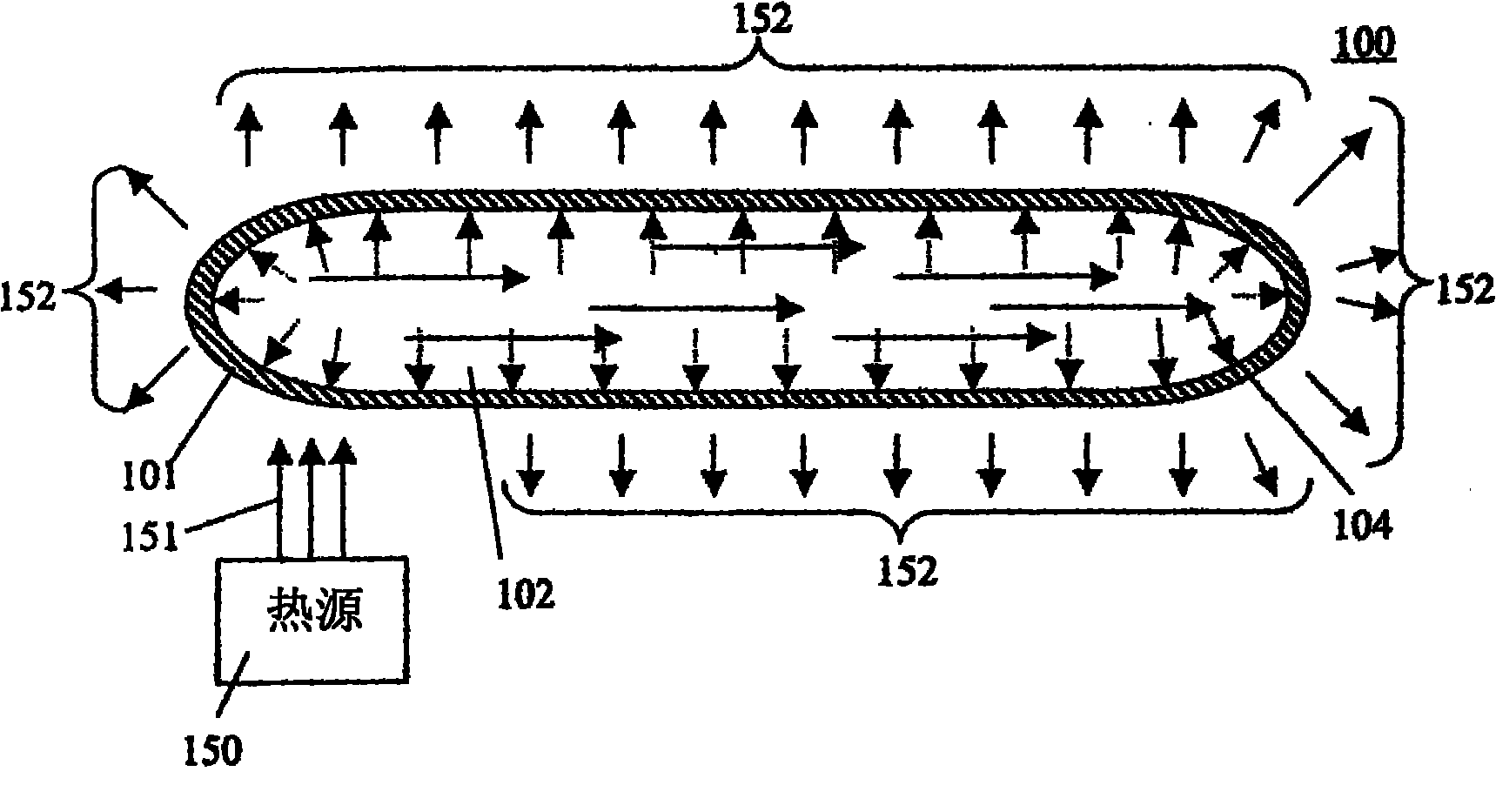

[0048] by figure 1 For example, the heat emitted by the heat source 150 can conduct heat transfer at all temperatures.

[0049] According to one embodiment, a liquid such as water can be used as the working medium 102 to transfer heat from one side of the heat transfer device 100 to the other side. When one side of the heat transfer device 100 receives external heat, the liquid in the cavity body 102 is heated and begins to expand. Molecules in the liquid are heated and begin to transfer the heat received to the attached cooler molecules. Therefore, the liquid in the hollow body 101 gradually and evenly increases the pressure. When the temperature of the liquid reaches the working state or working temperature, the working pressure of the liquid is substantially equal to the pressure used when the working medium 102 is filled into the hollow body 101 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com