Production process tail gas cleaning treatment device

A tail gas cleaning and treatment device technology, applied in the direction of climate sustainability, climate change adaptation, separation methods, etc., can solve the problems of affecting the reaction, increasing equipment energy consumption, etc., to reduce impurities, reduce resources, and improve absorption Effects of Processing Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

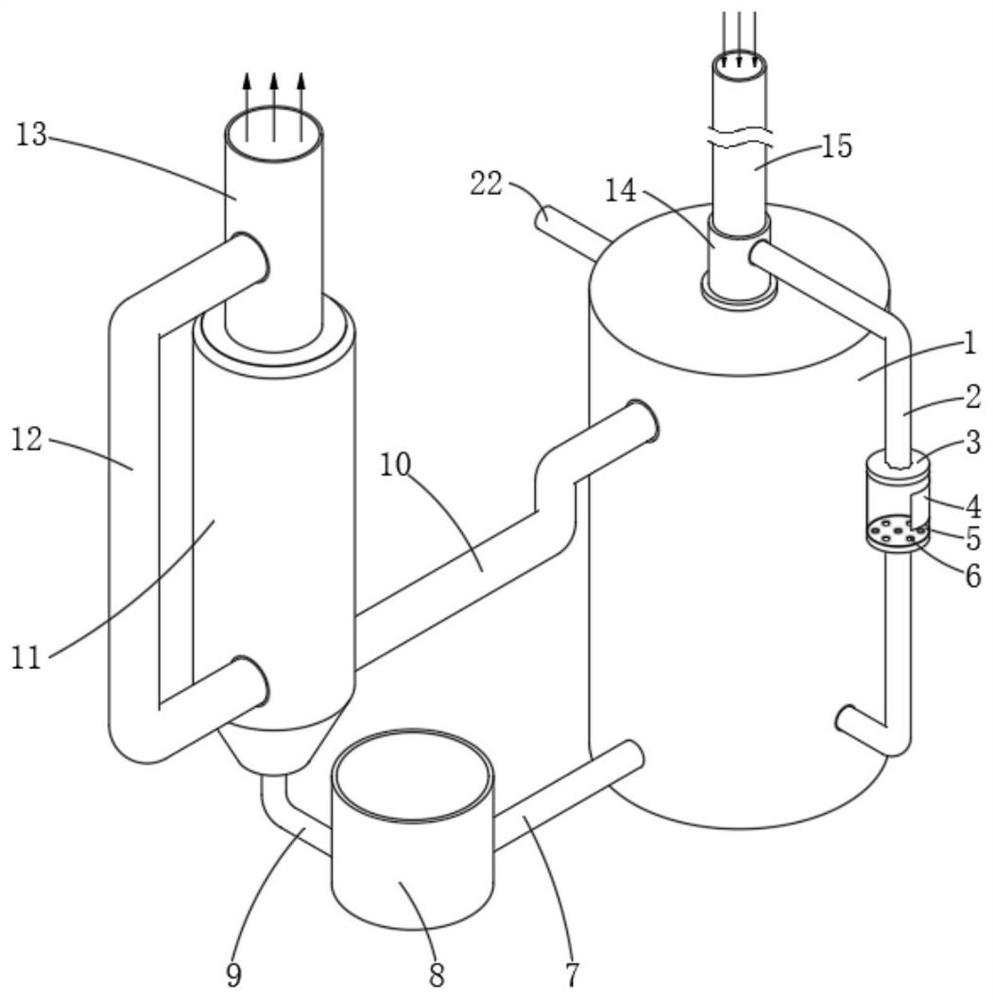

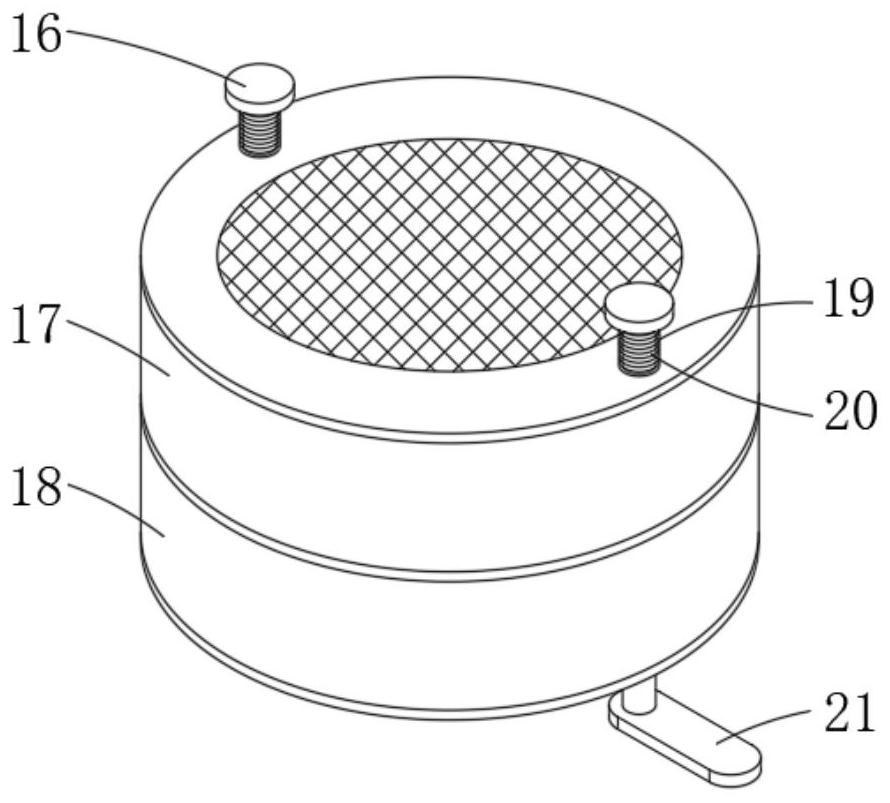

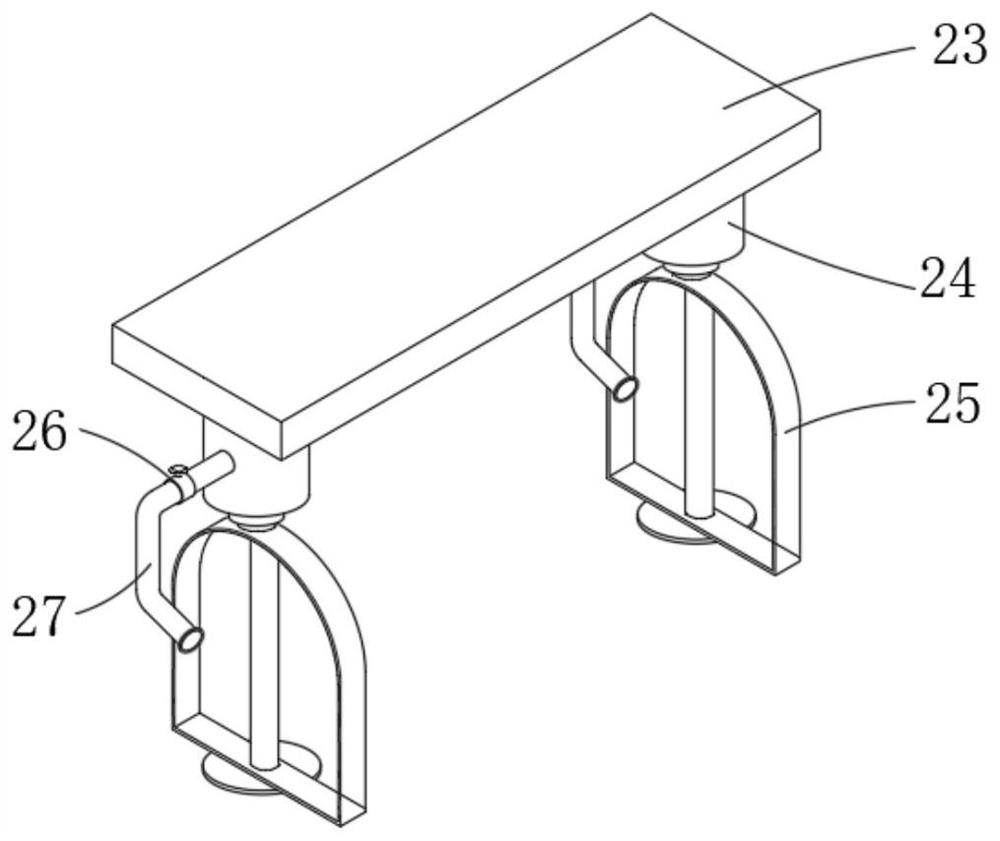

[0025] see Figures 1 to 3 , In the embodiment of the present invention, a production process tail gas cleaning treatment device includes a purification box 1, an air intake mechanism, a spray mechanism, a backwash mechanism, a reflux preheating mechanism, a discharge box 11, a dehumidification adsorption mechanism, and a reflux dehumidification mechanism. and absorbent discharge mechanism.

[0026] The inner bottom end of the purification box 1 is installed with a plurality of evenly distributed electric heating wires, so that the neutralization and absorption liquid can be heated, and the effect of exhaust gas treatment is improved. The treated air intake mechanism, the air i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com