Patents

Literature

267results about How to "Improve processing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

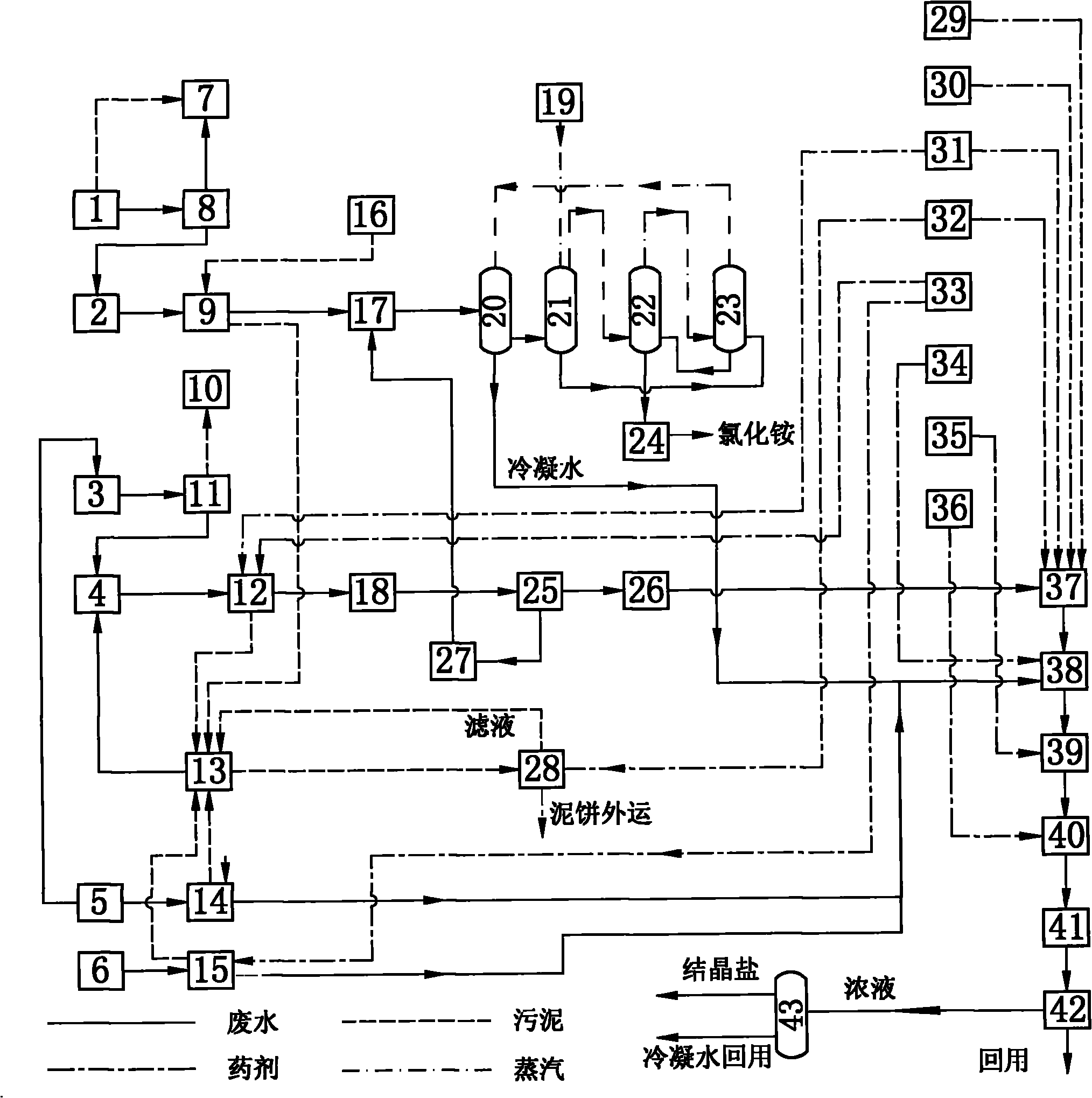

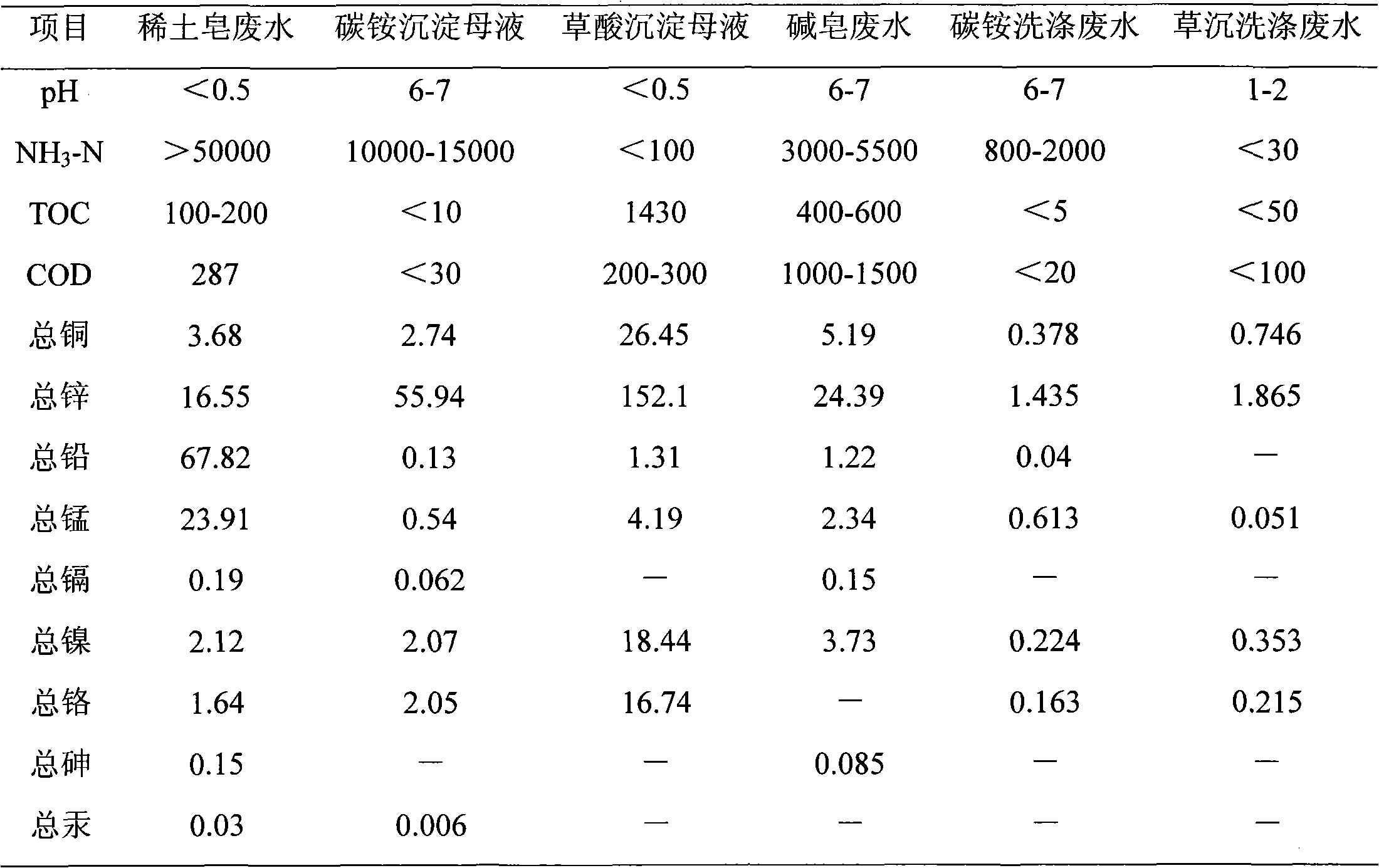

Resource recovery and zero discharge process for treating rare-earth wet-method smelting wastewater

InactiveCN102079601ASimple processingImprove processing effectFatty/oily/floating substances removal devicesGeneral water supply conservationTriple effectChemistry

The invention discloses a resource recovery and zero discharge process for treating rare-earth wet-method smelting wastewater, which comprises the following steps: (1) carrying out segregated collection on wastewater; (2) pretreatment: recovering kerosene and P507 from wastewater by floatation oil removal, and precipitating by adding alkali to remove heavy metals and oxalate radicals; (3) recovering NH4Cl in high-concentration ammonia nitrogen wastewater by triple-effect evaporation, concentration and crystallization; (4) denitrifying medium / low-concentration ammonia nitrogen wastewater by ammonia stripping / absorption; (5) carrying out reverse osmosis desalination advanced treatment on the wastewater; and (6) recovering CaCl2 by evaporating, concentrating and crystallizing the reverse osmosis concentrated water. The invention can produce certain economic benefits by recovering kerosene, P507 and industrial-grade NH4Cl products in the wastewater, and the wastewater can achieve the water quality standard for reuse water, thereby realizing zero discharge of wastewater in rare-earth wet-method smelting enterprises.

Owner:广州中科院地球化学研究科技开发有限公司

Paint for automobile exhaust purification in tunnel and underground car park

The invention discloses a coating used for purifying automobile tail gas in tunnels and underground parking lots, which consists of 20-40 parts of silicon acrylic emulsion, 10-30 parts of photocatalytic titanium dioxide nano powder, 5-15 parts by weight negative ion powder, 5-10 parts of ultra-fine diatomite, 10-20 parts of water, 5-15 parts of ordinary titanium dioxide, 4-8 parts of heavy calcium carbonate, 5-10 parts of light calcium carbonate, 1-2 4 parts of propylene glycol, 0.2-0.4 parts of leveling agent, 0.3-0.8 parts of thickener, 0.2-0.4 parts of defoamer, 0.8-1.5 parts of dispersant and 0.3-0.4 parts of wetting agent. The coating of the present invention has added high-efficiency adsorptive diatomite, which can enhance the adsorption of harmful gases and enhance the treatment effect; the adhesion between the coating made of nanoparticles and the substrate is improved; the nano photocatalytic coating of the present invention has The photocatalytic efficiency is high, and it has the effect of releasing negative ions, and can effectively purify the air; the nano photocatalytic coating of the present invention is very convenient for construction, and the thickness of the coating can also be adjusted according to the viscosity of the coating.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

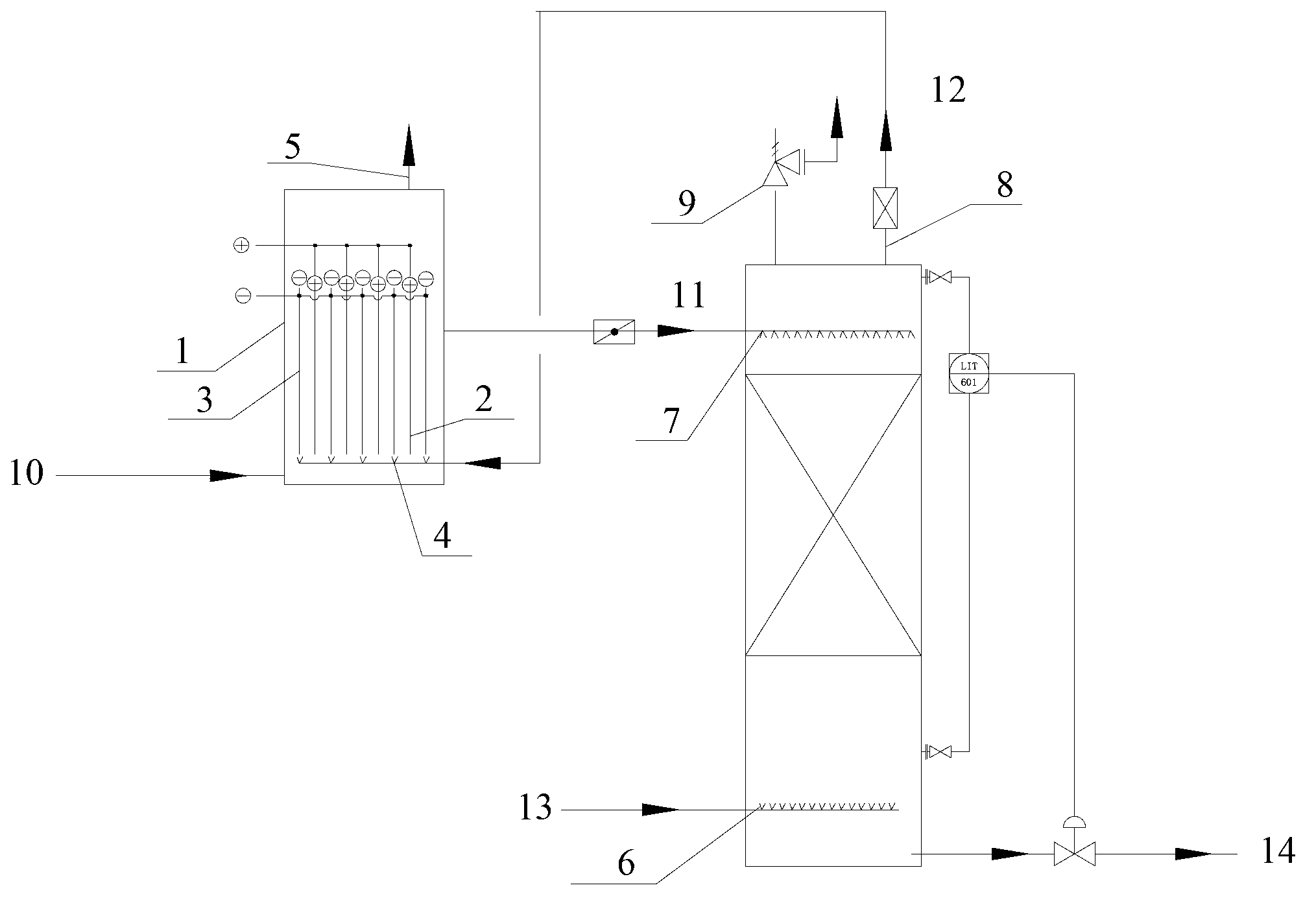

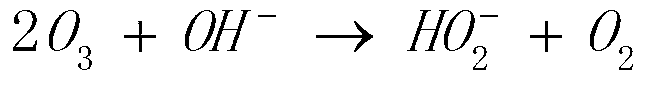

Method and device for enhanced ozone oxidation wastewater treatment of ozone tail gas

ActiveCN103304018AImprove processing effectEasy to handleWater/sewage treatment by oxidationExhaust gasChemistry

The invention relates to a method and a device for enhanced ozone oxidation wastewater treatment of ozone tail gas. According to the method, ozone and oxygen in ozone oxidation reaction tail gas are subjected to electrocatalytic reduction to obtain hydrogen peroxide; the hydrogen peroxide catalyzes the ozone to generate hydroxyl radicals; and organic matters in wastewater are mineralized and decomposed. The device comprises a pre-electrolysis unit and an ozone oxidation unit, wherein a tail gas outlet of the ozone oxidation unit is connected to the pre-electrolysis unit. According to the method and the device, oxygen and ozone resources in the tail gas are fully utilized; destroying treatment is not needed; and an ozone oxidation treatment effect is enhanced.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL SCI & TECH

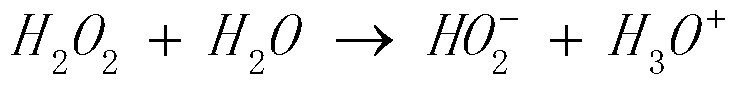

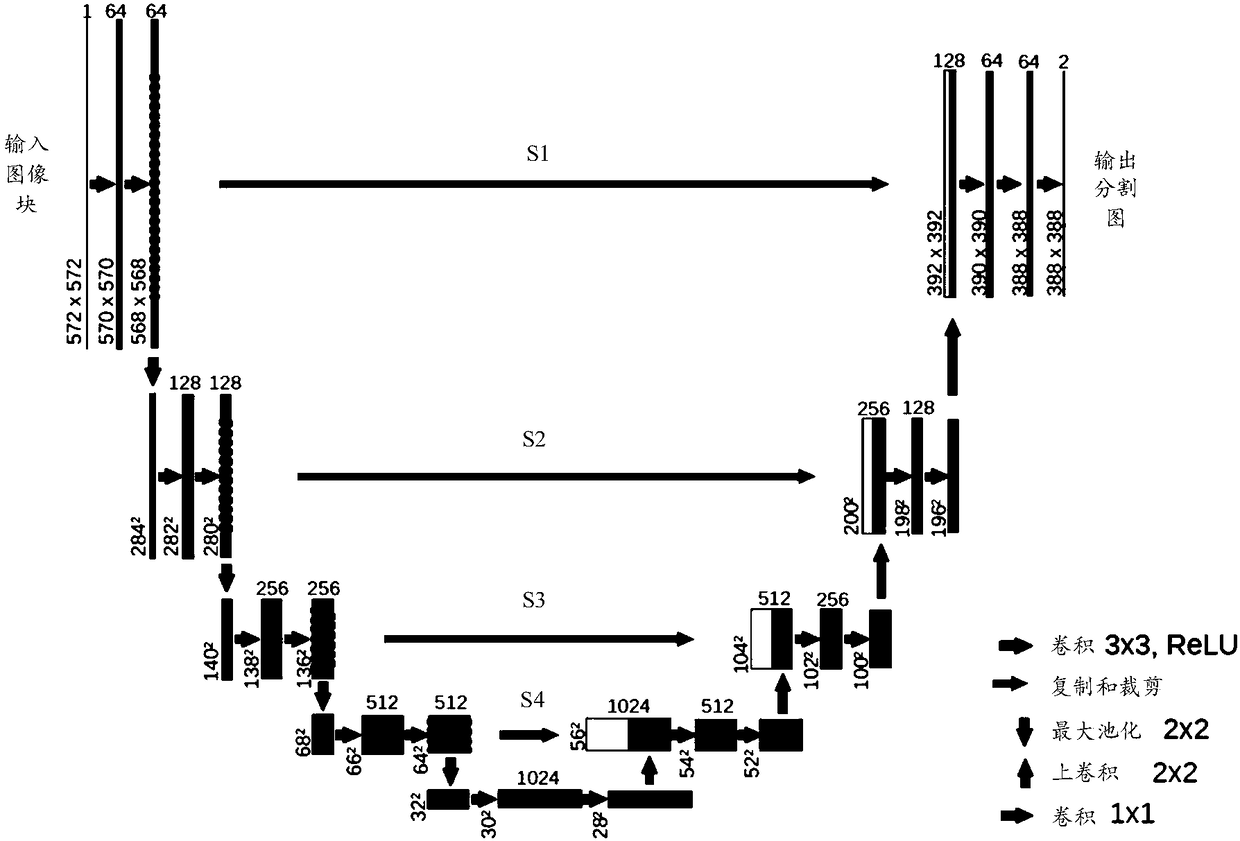

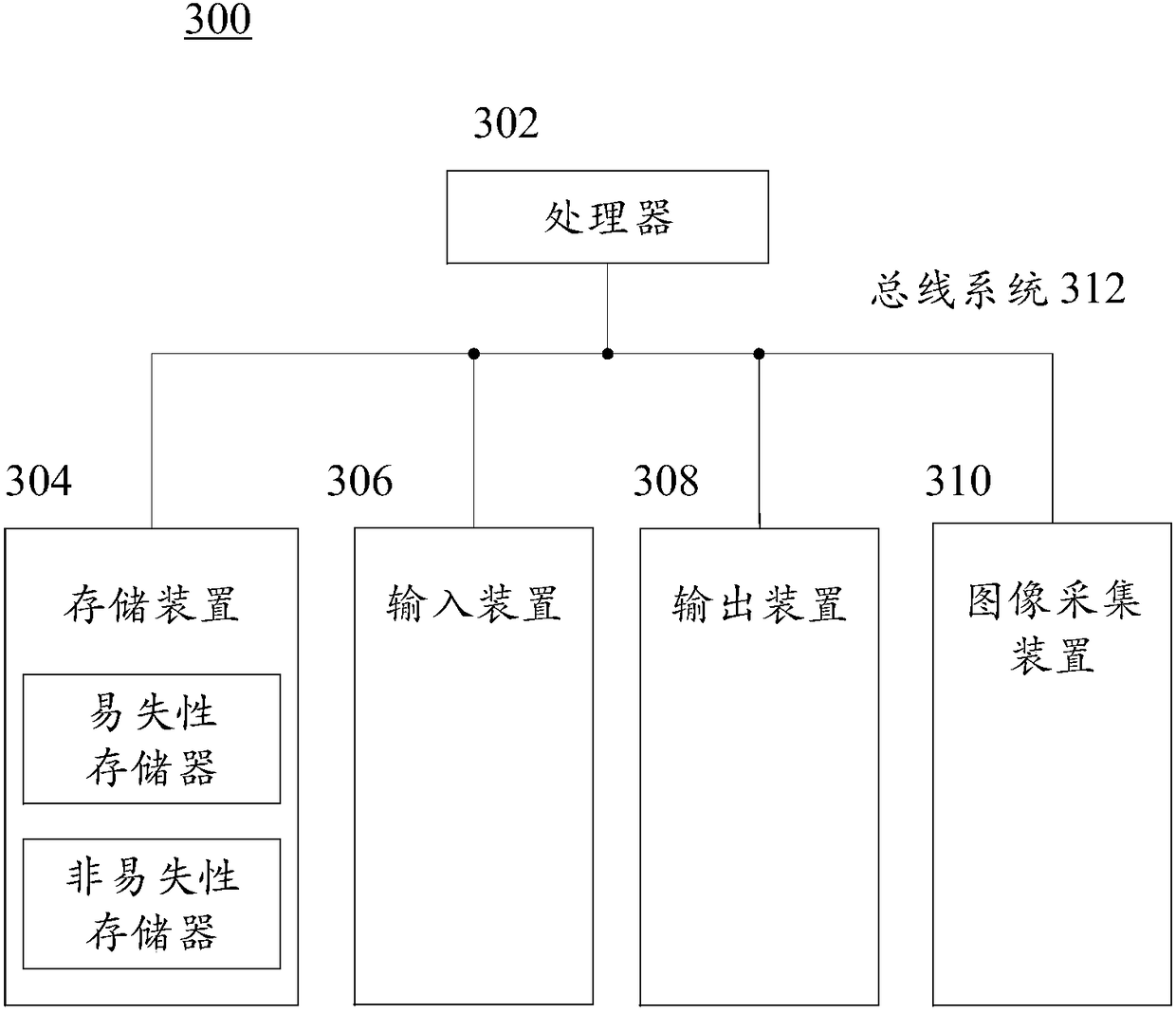

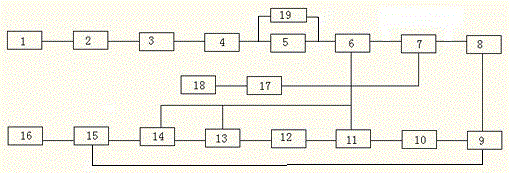

Semantic segmentation method, semantic segmentation device, semantic segmentation system and storage medium

ActiveCN108876792AImprove processing effectAccurate Semantic Segmentation ResultsImage enhancementImage analysisConvolutionDeconvolution

The embodiment of the invention provides a semantic segmentation method, a semantic segmentation device, a semantic segmentation system and a storage medium. The method comprises the steps of: obtaining an image to be processed; and inputting the image to be processed into a U-shaped network, so that a semantic segmentation result of the image to be processed output by the U-shaped network is obtained, wherein the contraction path of the U-shaped network comprises n convolutional modules, which are connected in sequence; output features of the ith convolutional module in the n convolutional modules are combined with output features of at least one convolutional module after the ith convolutional module; the combined features are in jump connection with the output end of a deconvolution layer in the contraction path of the U-shaped network and corresponding to the ith convolutional module, wherein n is an integer, which is greater than 1; and i is greater than or equal to 1 and less than n. According to the semantic segmentation method, the semantic segmentation device, the semantic segmentation system and the storage medium in the embodiment of the invention, because of adoption ofshallow features and deep features, the U-shaped network can be well improved in a fusion manner; and thus, a relatively accurate semantic segmentation result can be obtained.

Owner:MEGVII BEIJINGTECH CO LTD

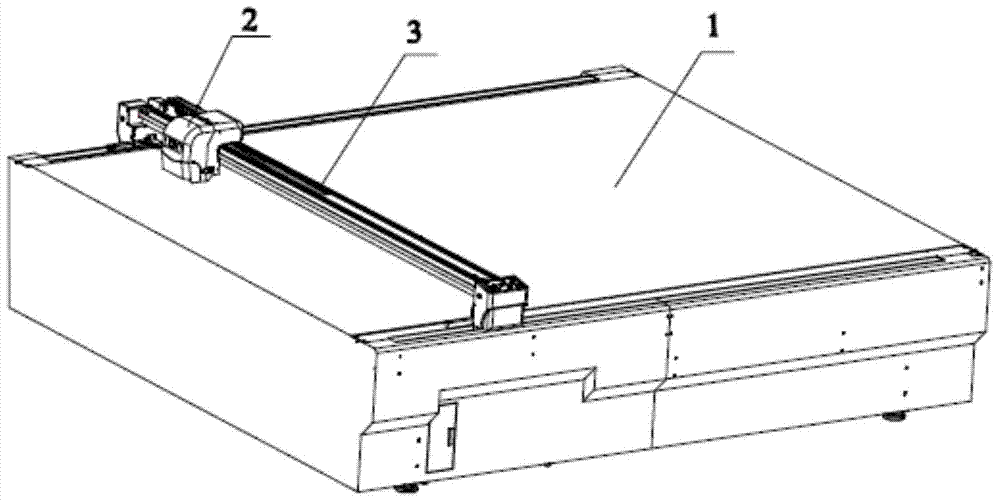

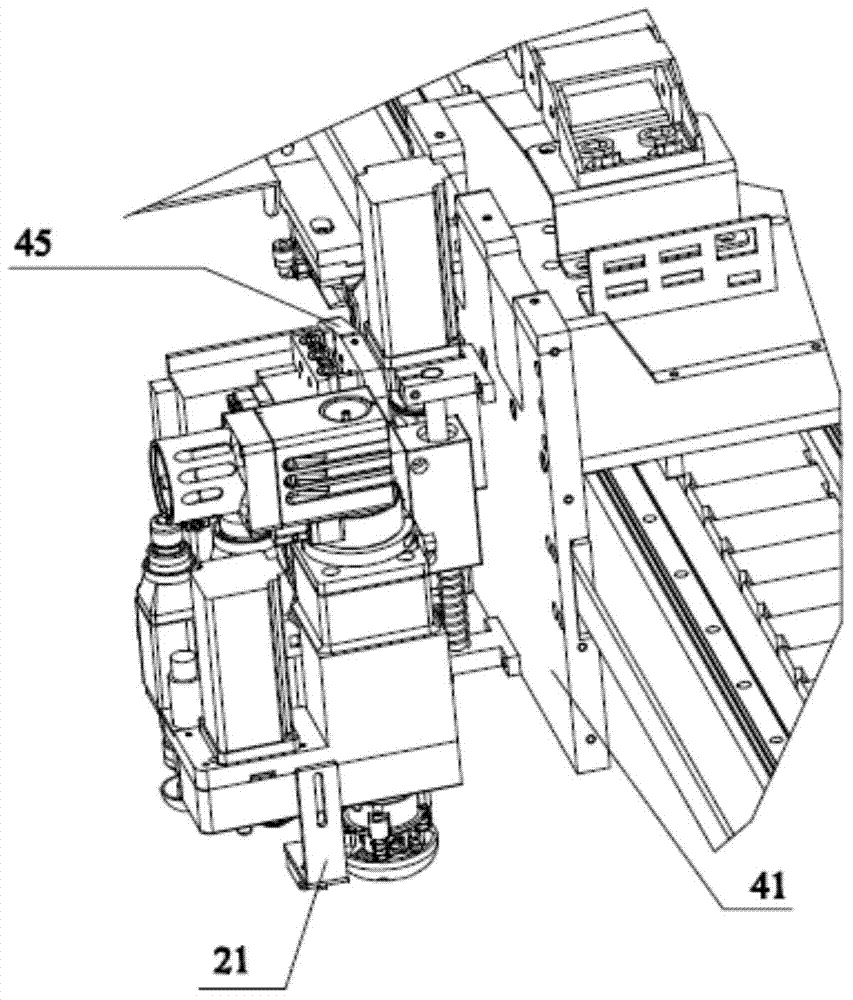

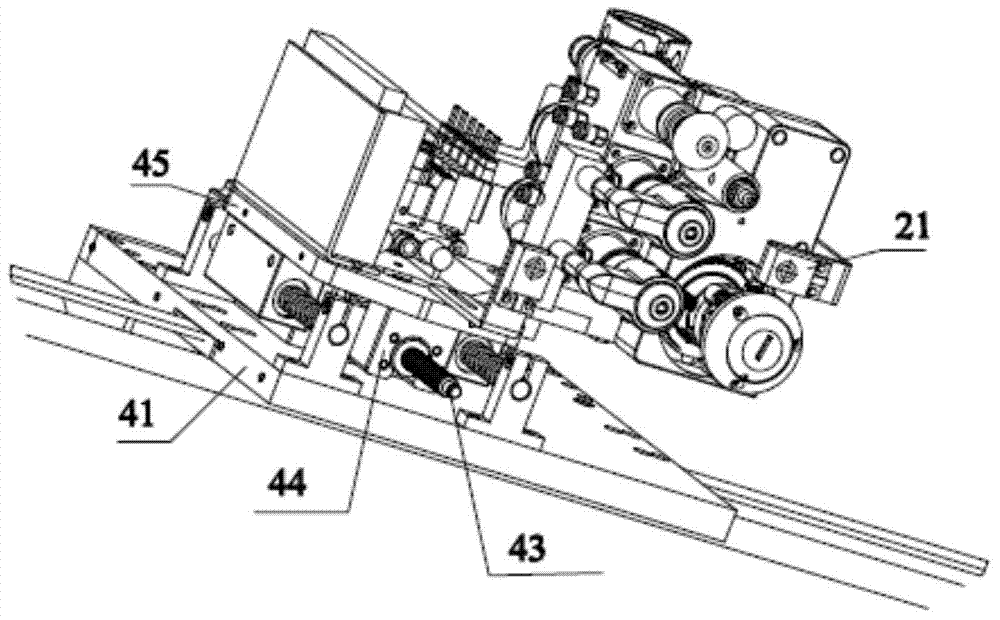

Automatic shearing machine and machine head control method of automatic shearing machine

ActiveCN104328643AImprove processing effectGuaranteed complete processingSevering textilesNumerical controlDistance sensorsControl theory

The invention relates to the technical field of automatic shearing, and discloses an automatic shearing machine and a machine head control method of the automatic shearing machine. A distance sensor is arranged on a machine head, the distance sensor is used for obtaining the distance between the located position of the machine head and a sensing surface vertically under the located position of the machine head, the automatic shearing machine is provided with a controller and a vertical moving mechanism, the controller is connected with the distance sensor, the controller is used for comparing the distance obtained by the distance sensor with the preset distance, if the distance obtained by the distance sensor is different from the preset distance, control signals are generated, and the vertical moving mechanism is controlled to regulate the vertical position of the machine head until the distance obtained by the distance sensor equals to the preset sensor. The distance between the machine head and a shearing table top is obtained through the distance sensor, and the vertical moving mechanism can regulate the vertical position of the machine head, so that the machine head can move along with the shearing table top, the processing effect is improved, the processing completeness can be ensured, and the contact damage between the processing device arranged on the machine head and the shearing table top can also be avoided.

Owner:长园和鹰科技(河南)有限公司

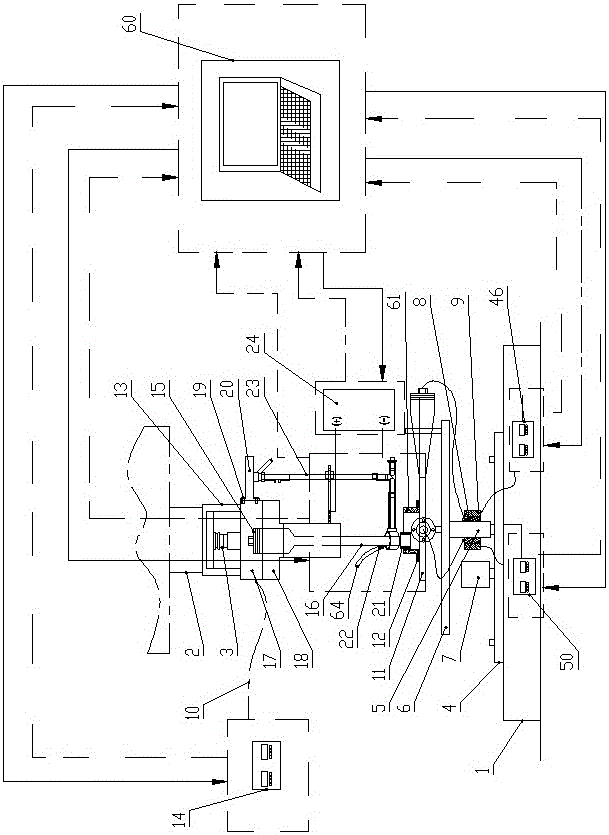

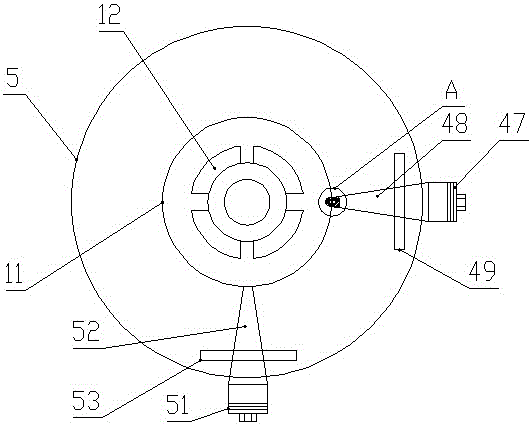

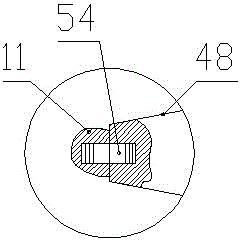

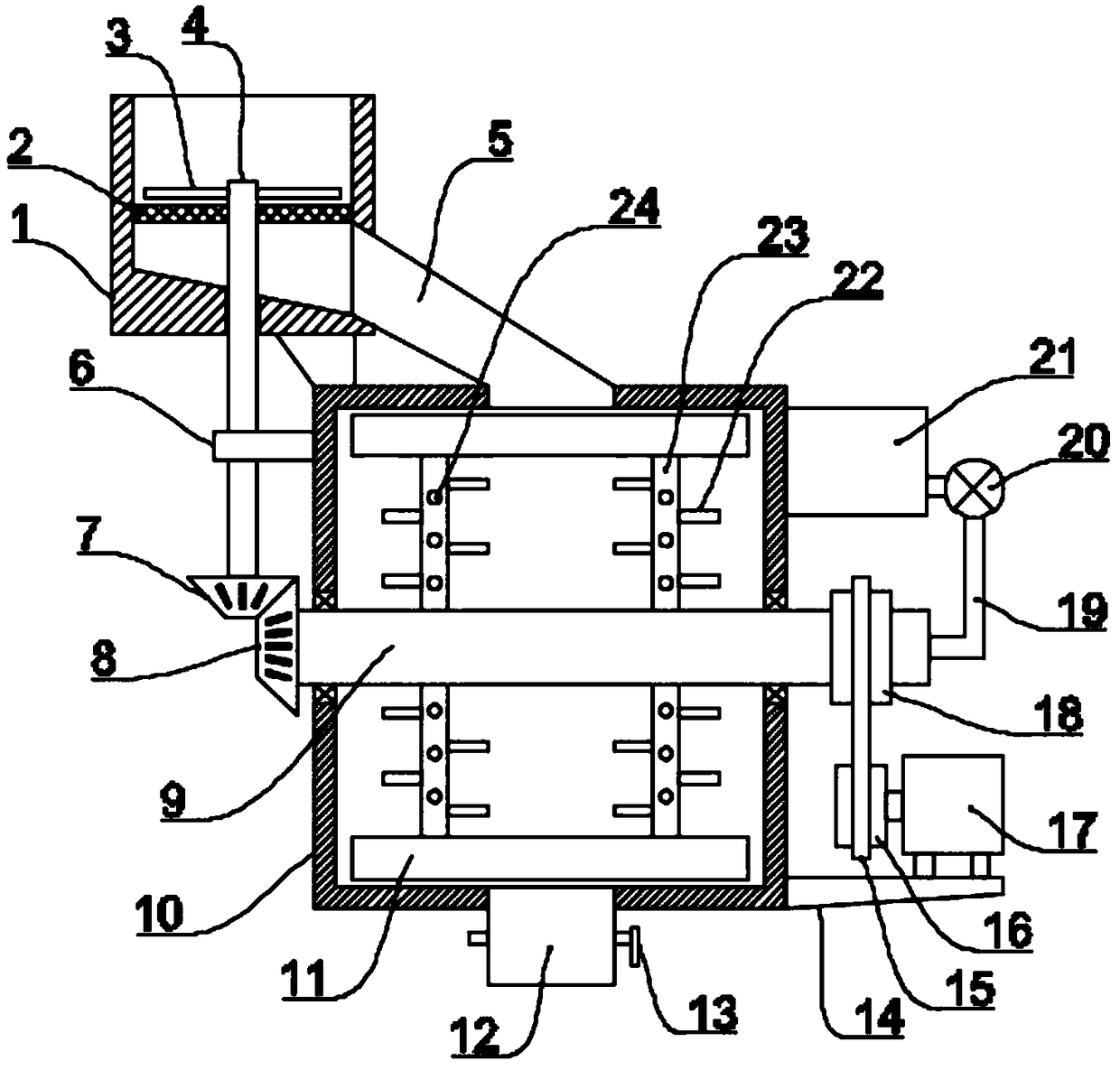

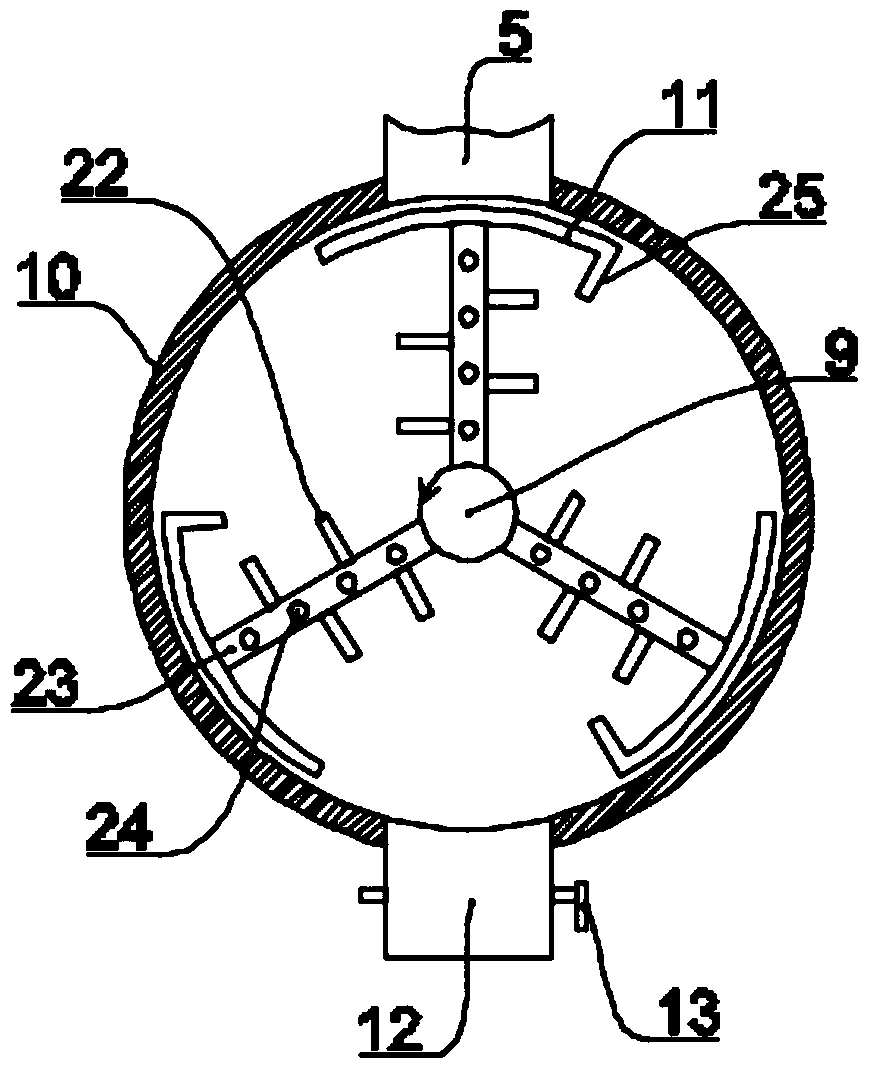

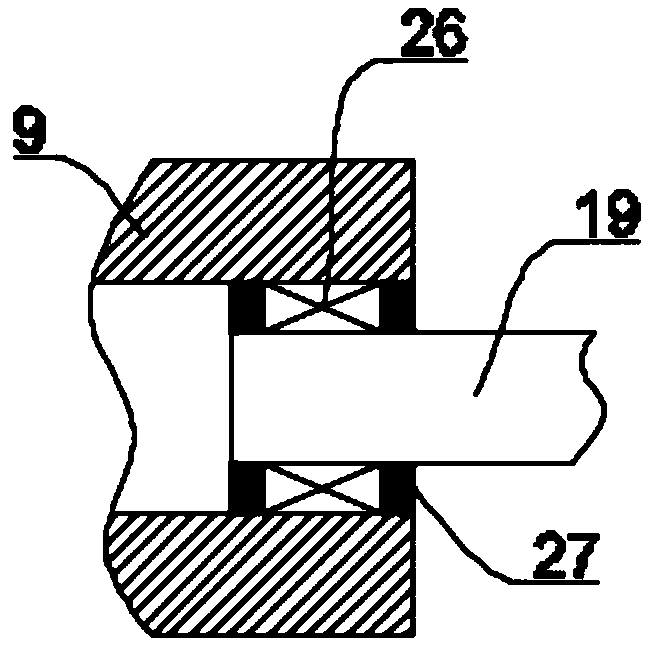

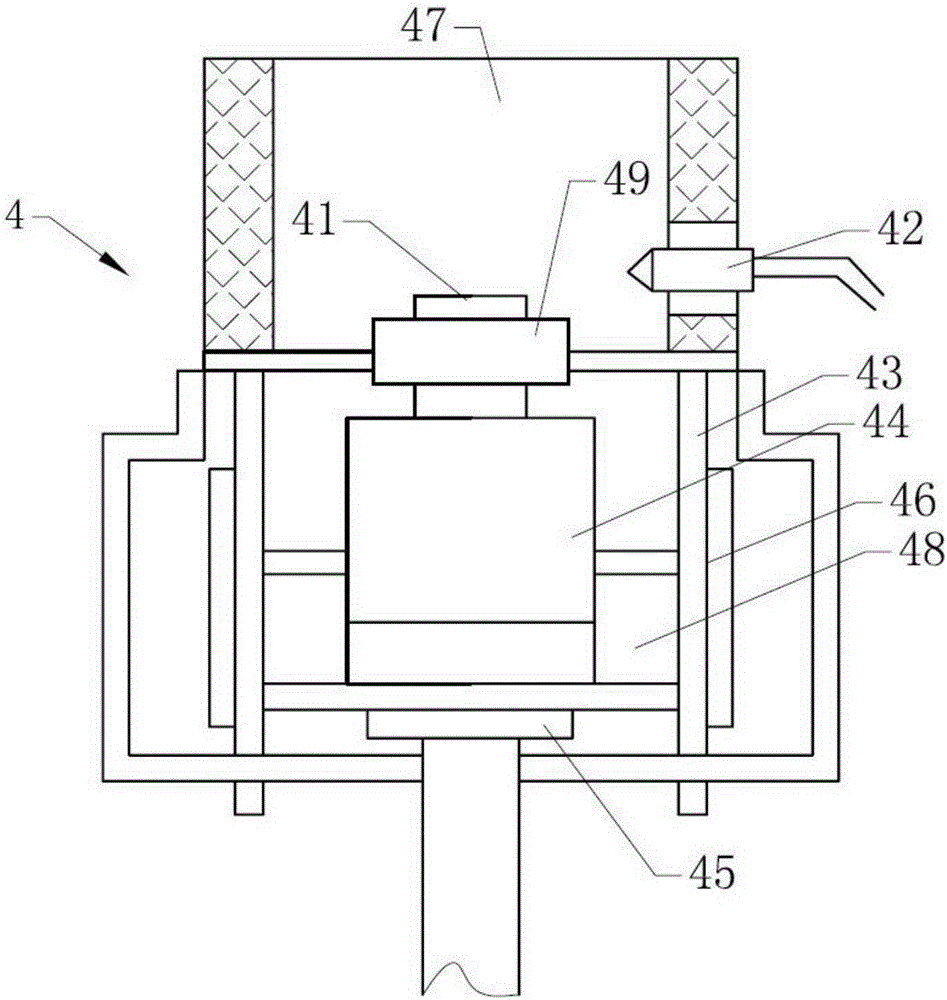

Controllable multi-dimensional ultrasonic ELID composite internal grinding test device

ActiveCN105666254AImprove processing effectRealize multi-dimensional controllabilityGrinding machine componentsMachine toolUltrasonic vibration

The invention discloses a controllable multi-dimensional ultrasonic ELID composite internal grinding test device. The device comprises a worktable and a machine tool main shaft; the lower end of the machine tool main shaft is coaxially connected with a shank; a Z-direction ultrasonic vibration system is arranged at the lower part of the shank; an ELID online finishing device is arranged on the right side of the Z-direction ultrasonic vibration system; a fixed plate is horizontally arranged on the upper surface of the worktable; a rotating shaft is arranged at the middle part of the fixed plate; the lower end of the rotating shaft is rotationally connected with the fixed plate; the upper end of the rotating shaft is fixedly connected with a turntable parallel to the fixed plate; the fixed plate is provided with a motor positioned on one side of the rotating shaft; the turntable is provided with an X-direction ultrasonic vibration system and a Y-direction ultrasonic vibration system; a circular tray is arranged above the turntable; a circular chuck is arranged in the center of the circular tray; and a computer control system is arranged on the right side of the worktable. The device is convenient for adjustment, reliable in performance, economical and practical, is suitable for ultraprecise machining of hard and brittle materials, and can realize compounding of multi-dimensional ultrasonic vibration and ELID grinding technology.

Owner:KEYIZHAN INTELLIGENT EQUIP CO LTD +1

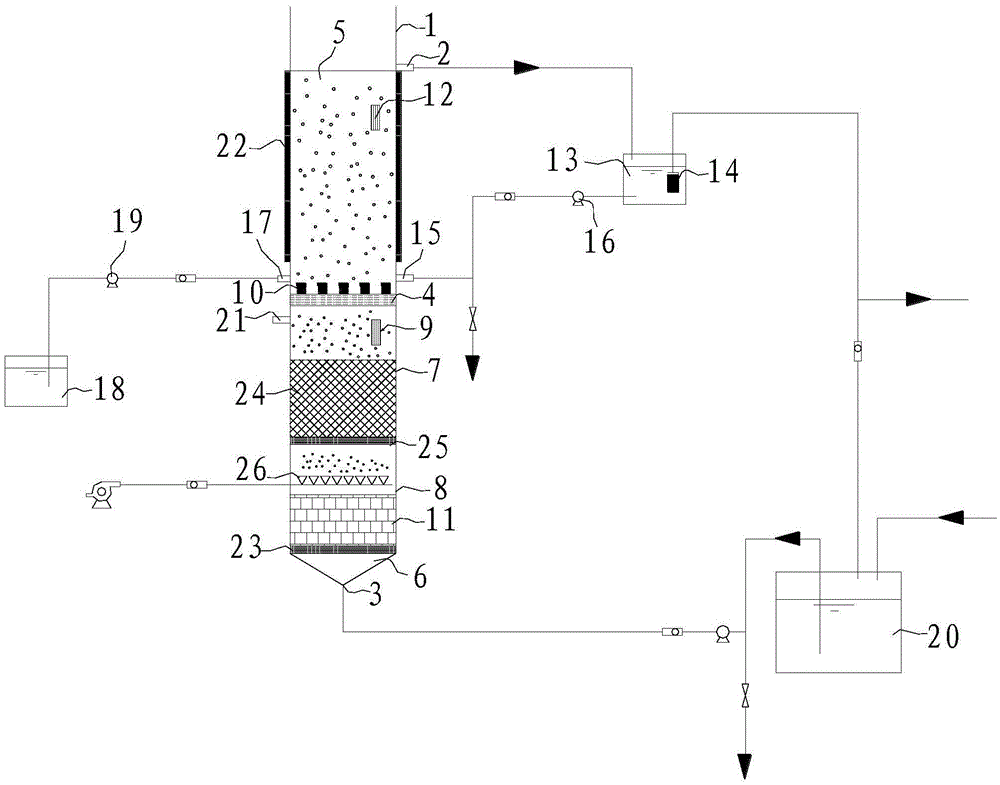

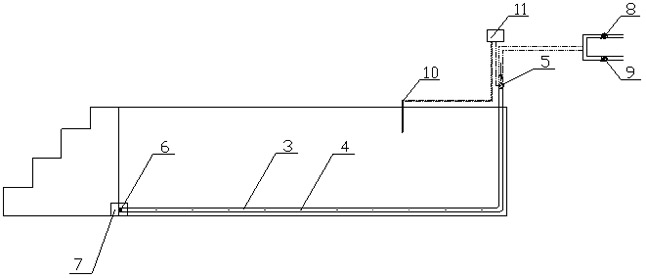

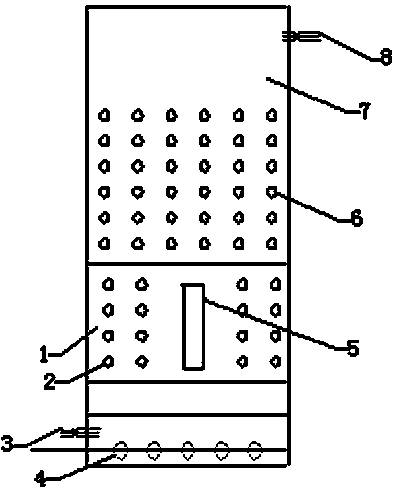

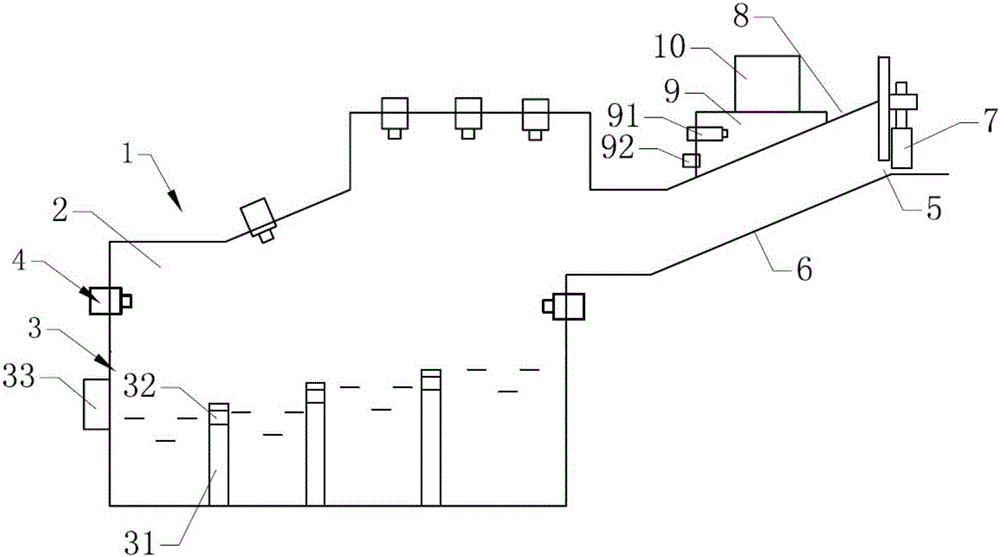

Microalgal culture based biogas liquid treatment device and method

ActiveCN105621789APromote growthImprove processing effectBioreactor/fermenter combinationsBiological substance pretreatmentsBiogasPre treatment

The invention discloses a microalgal culture based biogas liquid treatment device and method. The biogas liquid treatment device comprises a tank body, wherein a water outlet is formed in the top of the tank body; a water inlet is formed in the bottom of the tank body; an interlayer is arranged in the tank body and used for dividing the tank body into an upper microalgal culture chamber and a lower pretreatment chamber; a plurality of channels used for conveying materials into the microalgal culture chamber are formed in the interlayer; a filter device is arranged in each channel; the pretreatment chamber is divided into an upper aerobic reaction region and a lower facultative reaction region; solid fillers are arranged in each of the facultative reaction region and the aerobic reaction region; and an aeration device is further arranged at the lower part of the solid fillers in the aerobic reaction region. The biogas liquid treatment device has a good biogas liquid treatment effect and can achieve the purpose of treating high-concentration ammonia-nitrogen wastewater.

Owner:YANGTZE DELTA REGION INST OF TSINGHUA UNIV ZHEJIANG

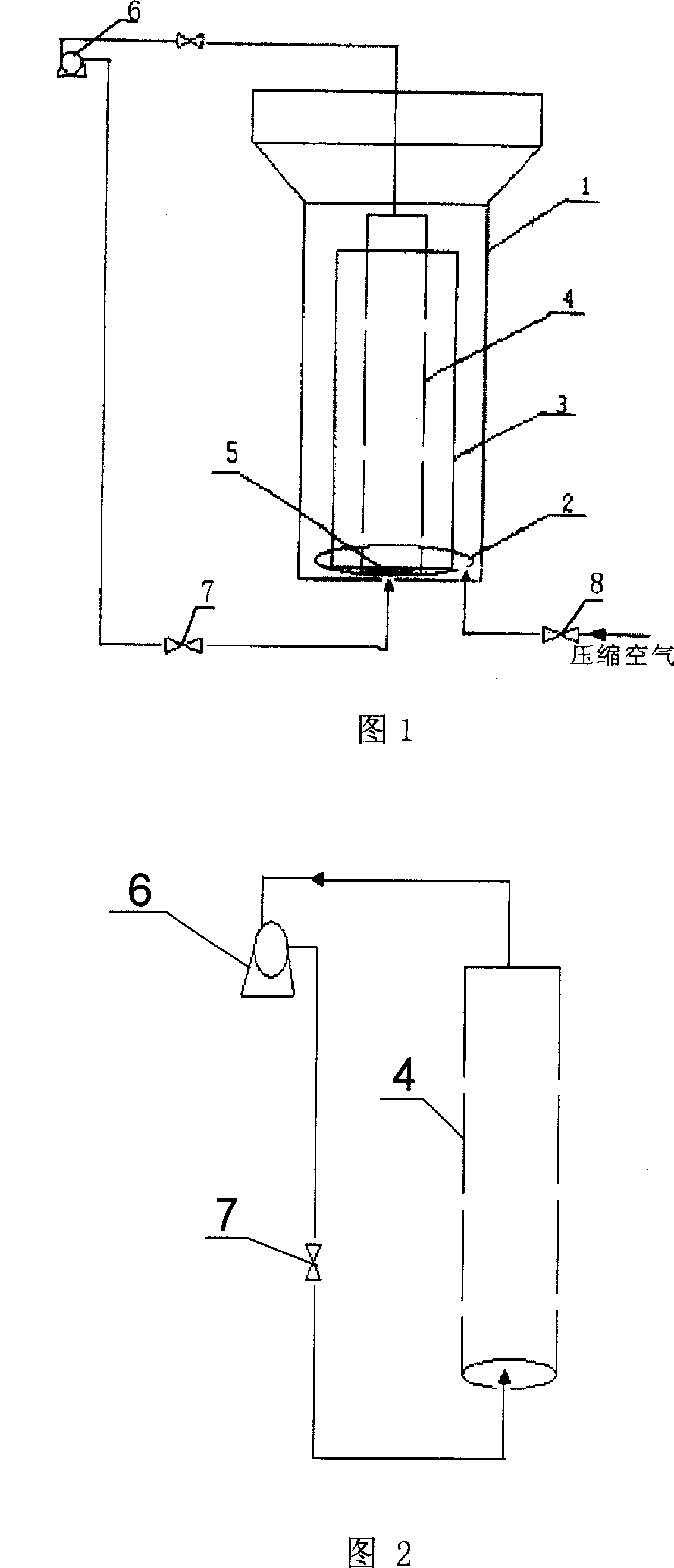

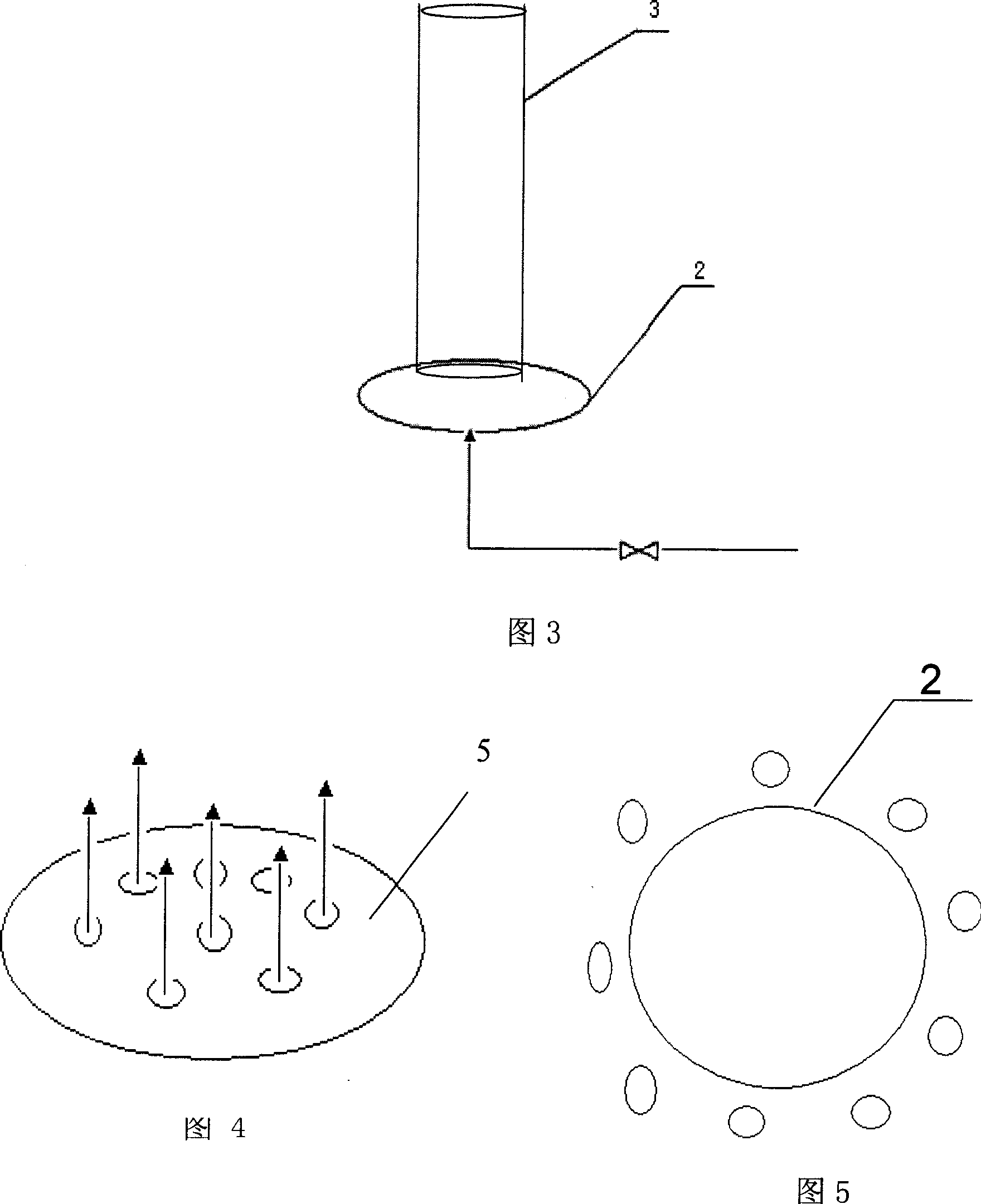

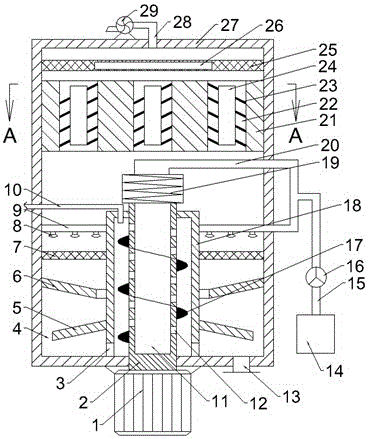

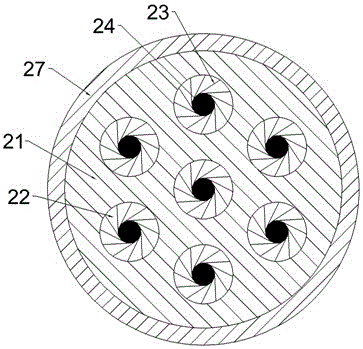

Anaerobic and aerobic coupled pneumatic lift type circulation biochemical reactor, and method for treating wastewater of chemical fiber

InactiveCN101003406AImprove processing effectEasy to makeTreatment with aerobic and anaerobic processesAnaerobic treatmentTreatment effect

This invention discloses an anaerobic / aerobic coupling airlift loop bioreactor and method for treating chemical fiber wastewater. In the column of the bioreactor there are an outer flow-guiding cylinder and an inner flow-guiding cylinder. The outer flow-guiding cylinder surrounds the inner flow-guiding cylinder. An outer gas distributor and an inner gas distributor are fixed at the bottom of the column. The bottom of the outer flow-guiding cylinder is sheathed with the outer gas distributor. The inner gas distributor is fixed at the inner bottom of the inner flow-guiding cylinder. The method utilizes the bioreactor for biochemical treatment of chemical fiber wastewater. Compressed air is introduced into the bioreactor so that the liquid in the flow-guiding cylinders moves upward, therefore large circulation is formed between the two flow-guiding cylinders, and anaerobic treatment and aerobic treatment are coupled. Wastewater treated can satisfy discharge standards. The method has such advantages as easy operation, convenient management, good anaerobic / aerobic effect, and good biochemical treatment effect, and is suitable for industrial application.

Owner:TSINGHUA UNIV

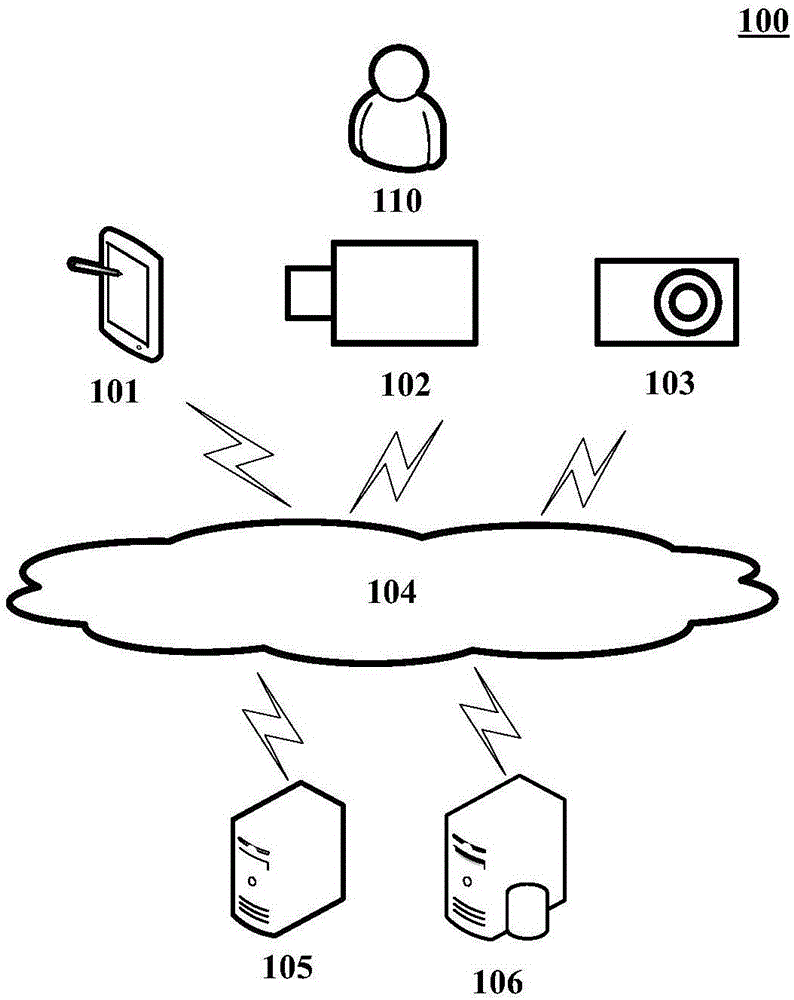

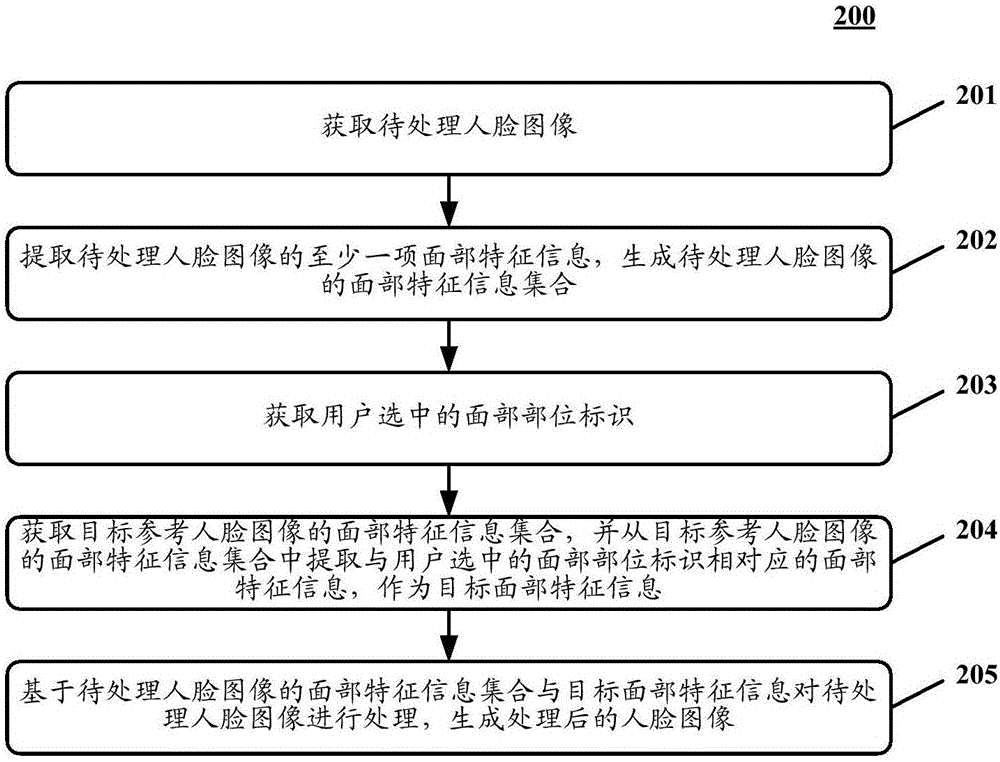

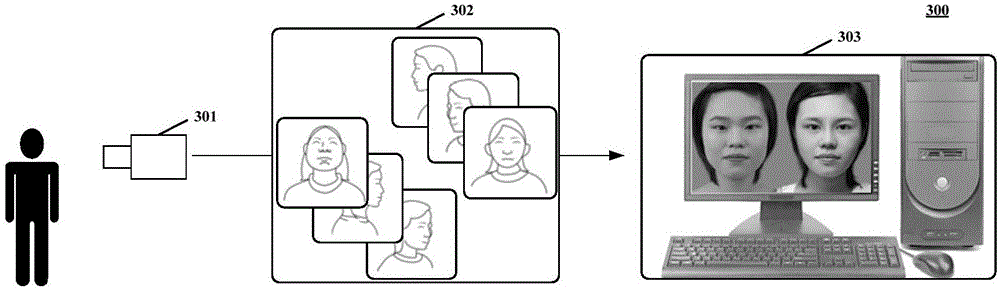

Method and device for processing face images

ActiveCN106682632AImprove processing effectEasy to handleCharacter and pattern recognitionFacial characteristicImaging processing

The invention discloses a method and device for processing face images. According to one embodiment. The method comprises the steps that face images to be processed are obtained; at least one item of face feature information of the face images to be processed is extracted to generate a face feature information set of the face images to be processed; face part identifiers selected by users are obtained; a face feature information set of target reference face images is obtained, and the face feature information corresponding to the face part identifiers selected by the users are extracted from the face feature information set of the target reference face images to serve as target face feature information; the face images to be processed are processed based on the face feature information set of the face images to be processed and the target face feature information to generate face images obtained after processing. A face image processing effect is improved by adopting the method.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

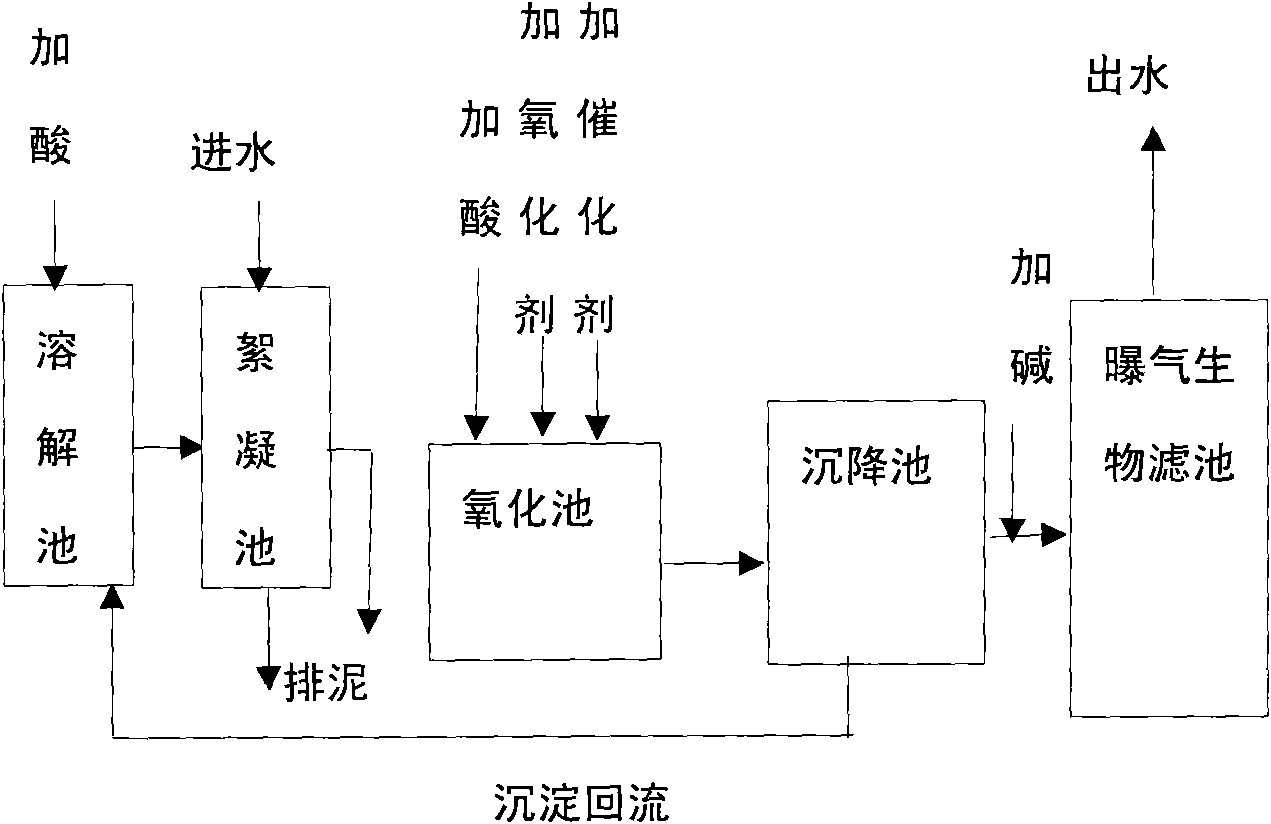

Method for treating wastewater by combining catalytic oxidation with biological aerated filter

ActiveCN102040308AImprove processing effectReduce acid and alkali consumptionMultistage water/sewage treatmentWater/sewage treatment by neutralisationChemistrySediment flow

The invention relates to a method for treating wastewater by combining catalytic oxidation with a biological aerated filter, which sequentially comprises the following steps of: 1) adding all or part of the wastewater to be treated into a flocculating tank, performing flocculation sedimentation, and adding into an oxidation tank; 2) adding acid into the oxidation tank to regulate the pH value of the wastewater to be 0 to 6, adding an oxidant and a catalyst and performing catalytic oxidation reaction; and 3) adding the oxidized wastewater into a settling tank for settling, discharging supernatant, adding alkali to regulate the pH value to be 6 to 9, adding into the biological aerated filter for treating, and discharging; and making settled acidic sediments flow back to a dissolving tank, adding the acid to regulate the pH value until the sediments are completely dissolved, adding solution into the flocculating tank and performing flocculation sedimentation reaction on the solution and all or part of the wastewater to be treated. Compared with the prior art, the method reduces the consumption of the acid and the alkali and treatment cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for improving saline-alkali soil by flat laying deep ploughing application of desulfurized gypsum

InactiveCN106171104AImprove processing effectEasy to handleOther chemical processesOrganic fertilisersGypsumAlkali soil

The invention discloses a method for improving saline-alkali soil by flat laying deep ploughing application of desulfurized gypsum. The method for improving saline-alkali soil by flat laying deep ploughing application of the desulfurized gypsum comprises a step S1 of performing matching of an improved material; a step S2 of treating saline-alkali soil surface layer soil; a step S3 of flatly laying the improved material on the saline-alkali soil where surface layer soil is removed; a step S4 of performing deep ploughing treatment; a step S5 of mixing the surface layer soil and the improved material; and a step S6 of performing irrigation. According to the method, different treatment modes are adopted for soils of different depths, the deep layer soil with a relatively low salinization degree is treated through a small amount of improved material, the surface layer soil with a high salinization degree is treated through a large amount of improved material, treatment of separating the different soils is achieved, and the saline-alkali soil treatment effect is improved.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

System and method for treating sewage

InactiveCN105884145AImprove processing effectReduce the amount of acid and alkaliWater/sewage treatment by centrifugal separationTreatment involving filtrationSewage treatmentSewage

The invention provides a system and a method for treating sewage. The system comprises a thick grid, a water collecting tank, a fine grid, a rotational flow sand settling tank, a regulating tank, an emergency tank, a coagulation sedimentation tank, gas flotation equipment, an intermediate water tank, ultra-filtration equipment, a concentrated water regulating tank, a multistage coagulation sediment, an A2O biochemical tank, an inclined-tube sedimentation tank, a fiber turntable filter tank, a sludge concentrated water tank, a sludge dewatering room, a disinfection tank and a water recycling tank. The system and the method have the advantages that diversified processes for treating the sewage are combined with one another to form the complete system for treating the sewage, accordingly, different stages of sewage can be assuredly effectively treated, and treatment effects can be improved; outlet water treated by the aid of the system is high in quality, requirements of national emission indexes can be met, the outlet water can be applied to life again, and accordingly water resources can be reused.

Owner:SICHUAN GERUISI ENVIRONMENT TECH CO LTD

Method for aerobic quick composting of urban domestic sludge as well as device and using method thereof

InactiveCN102060585ASimple methodImprove processing effectBio-organic fraction processingOrganic fertiliser preparationCompostTreatment effect

The invention relates to a method for aerobic quick composting of urban domestic sludge as well as a device and a using method thereof. In the invention, an air duct is installed at the bottom of a fermentation tank, and the temperature of the fermentation tank is controlled by using a draught fan, therefore, a composting treatment effect is enhanced, the compost environment is improved, the quality of a compost product is improved; and the method for aerobic quick composting of the urban domestic sludge has important meaning for promoting organic solid wastes to realize recycling of cultivated lands.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI +1

Molding and aging technology of 7A04 superhard aluminum alloy section bar

The invention discloses a molding and aging technology of a 7A04 superhard aluminum alloy section bar. The molding and aging technology comprises the following steps of selecting a specific aluminum material, heating a mold, heating a casting bar, heating an ingot-receiving cylinder, putting the casting bar and the mold into an extruder, carrying out extrusion, carrying out residual thickness extrusion, carrying out cooling, stretching and straightening crops and tailing so that a finished product is obtained, and carrying out framing, aging and air cooling. The molding and aging technology has molding stability, realizes extrusion molding and has good processing effects.

Owner:ZHEJIANG RUIJIN COPPER ALUMINUM SECTION BAR

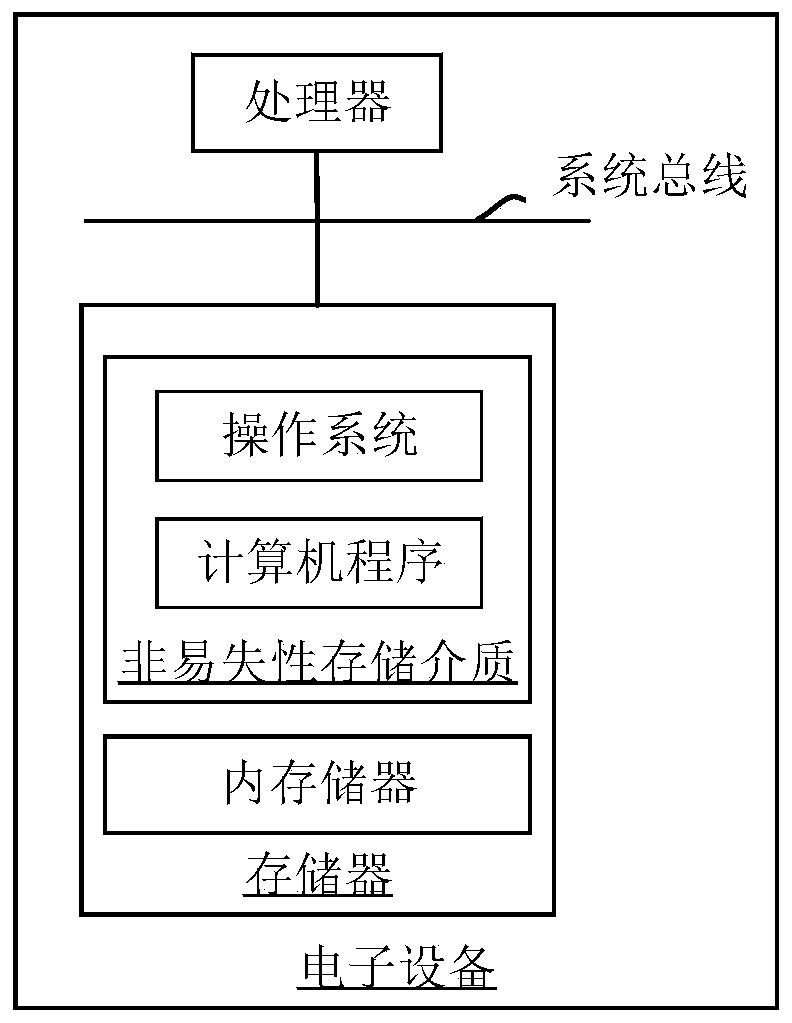

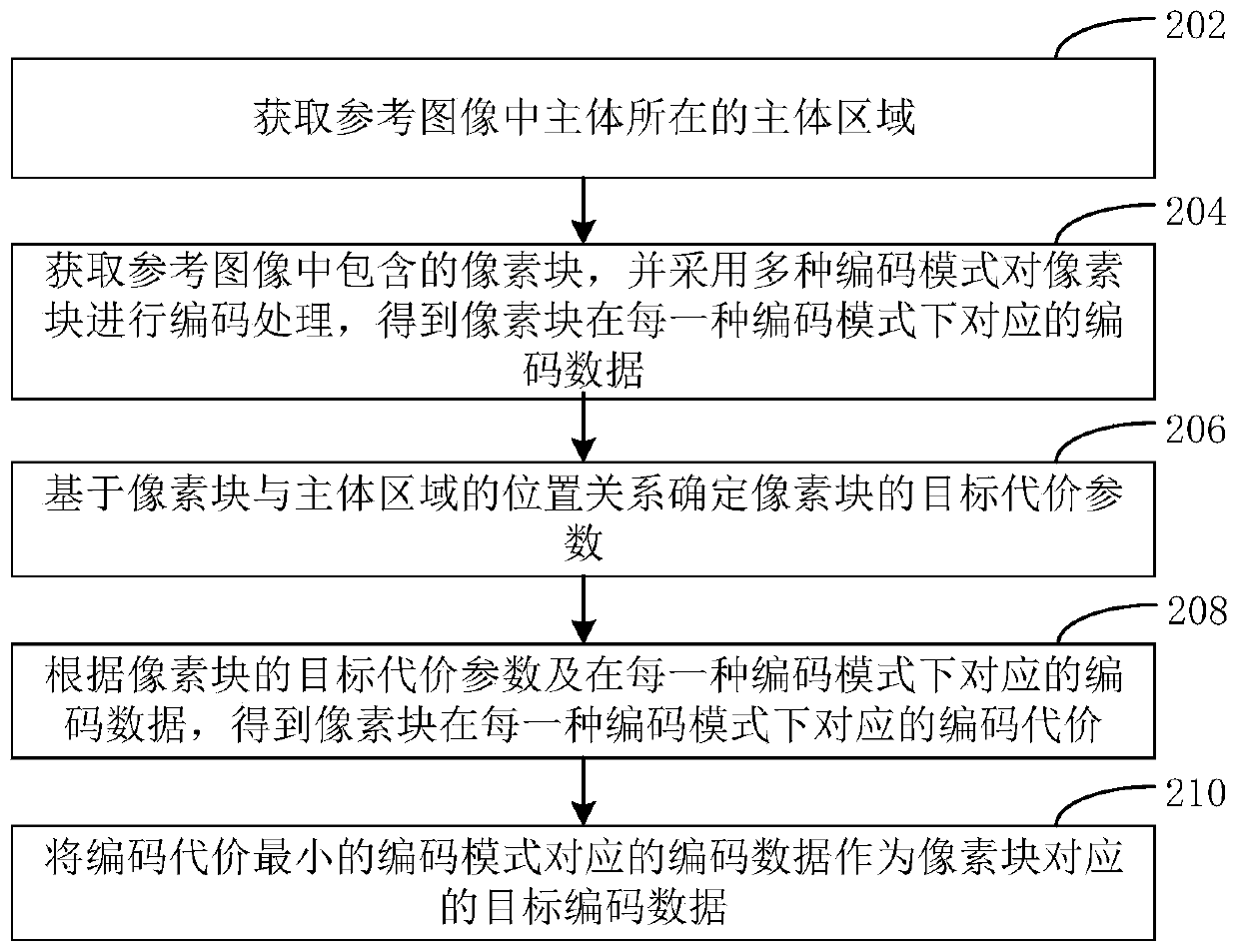

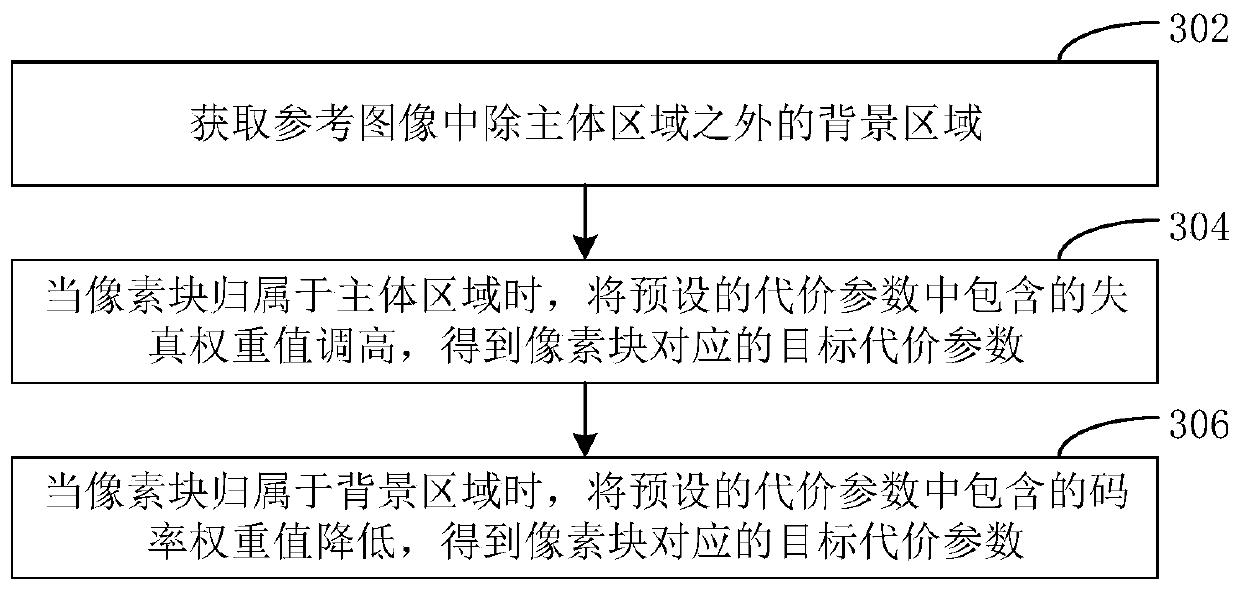

Image coding method and device, electronic equipment and computer readable storage medium

ActiveCN110267041AImprove processing effectEasy to handleDigital video signal modificationDistortionWeight value

The invention relates to an image coding method and device, electronic equipment and a computer readable storage medium. The method comprises the steps of obtaining a main body area where a main body is located in a reference image; obtaining pixel blocks contained in the reference image, and carrying out coding processing on the pixel blocks by adopting a plurality of coding modes to obtain coding data corresponding to the pixel blocks in each coding mode; determining a target cost parameter of the pixel block based on the position relation between the pixel block and the main body area; obtaining the corresponding coding cost of the pixel block in each coding mode according to the target cost parameter of the pixel block and the corresponding coding data in each coding mode; and taking the coded data corresponding to the coding mode with the minimum coding cost as the target coded data corresponding to the pixel block. In this way, the distortion weight value or the code rate weight value of the pixel block can be dynamically adjusted, so that image details in or out of the main body area are reserved directly, and the image coding processing effect can be improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

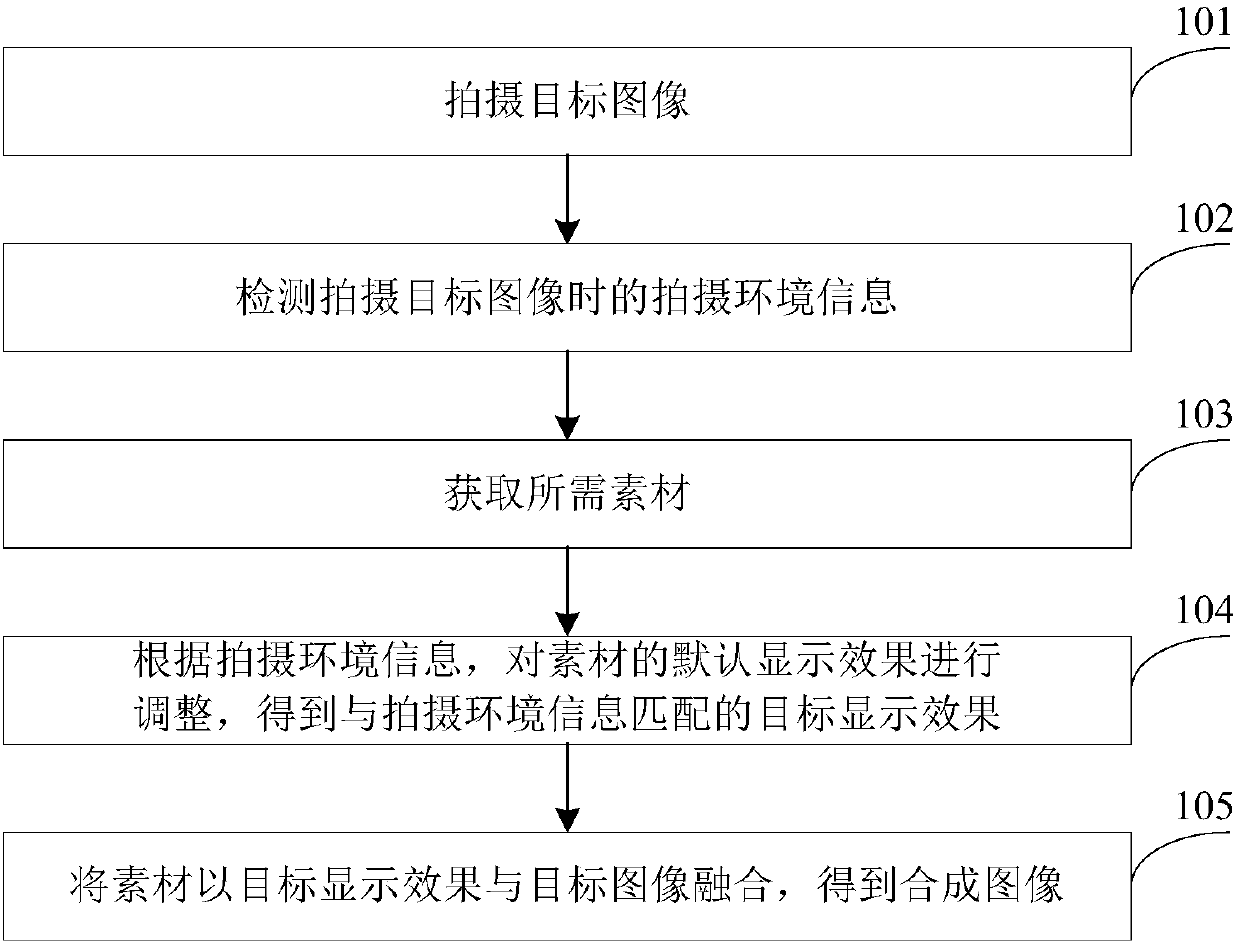

Image processing method and device, electronic equipment, and medium

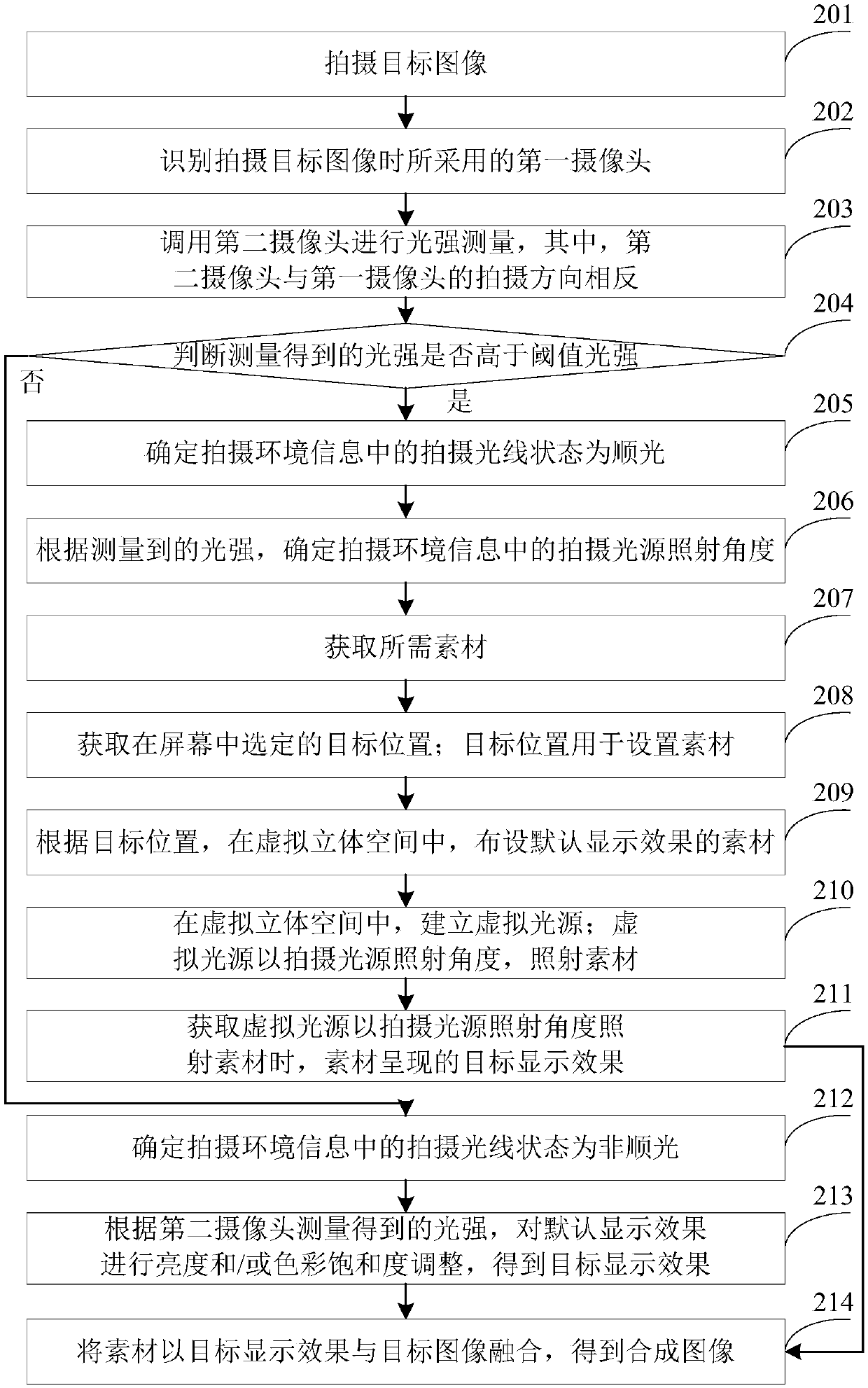

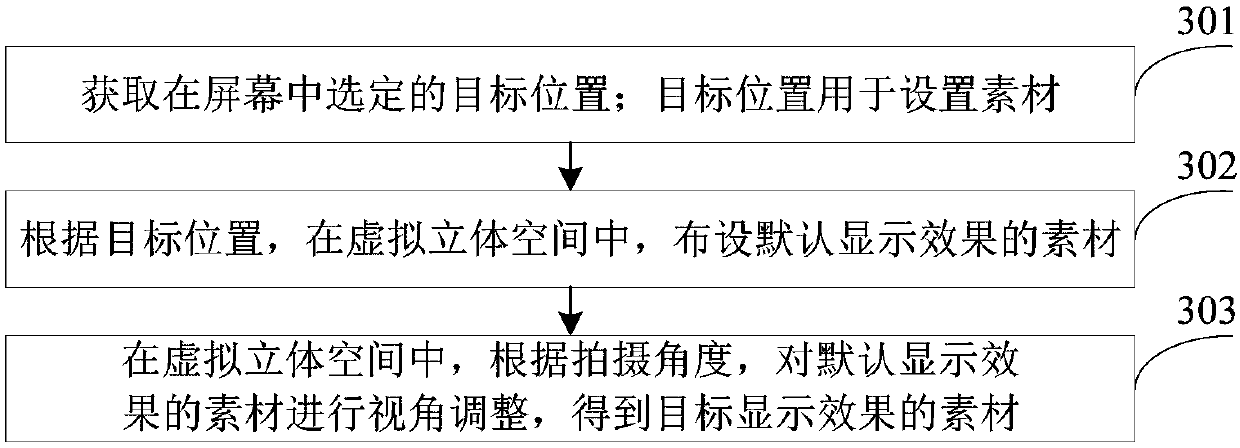

ActiveCN107566751AImprove processing effectImprove shooting experienceImage enhancementTelevision system detailsComputer graphics (images)Automatic tuning

The invention provides an image processing method, an image processing device, electronic equipment and a medium. The method comprises the steps of shooting a target image; detecting information of ashooting environment when the target image is shot; acquiring required materials; adjusting the default display effect of the materials according to the shooting environment information to acquire a target display effect matched with the shooting environment information; integrating the materials with the target display effect with the target image to acquire a composite image. According to the method, the display effect of the materials can be automatically adjusted according to the information of the shooting environment where a shot object is located, so that the display effect of the materials is matched with the shooting environment, the processing effect of the image is enhanced, and the shooting experience of a user is improved.

Owner:北京乐蜜科技有限责任公司

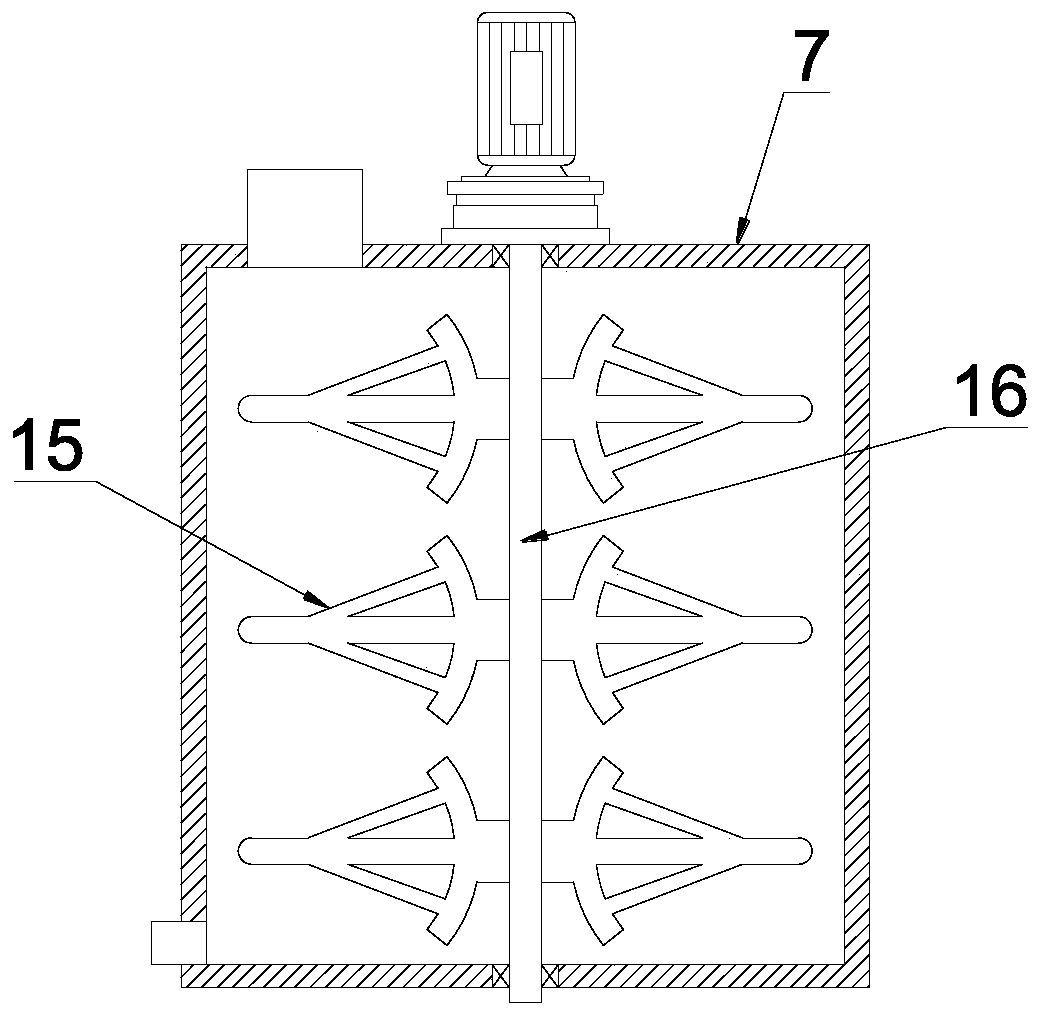

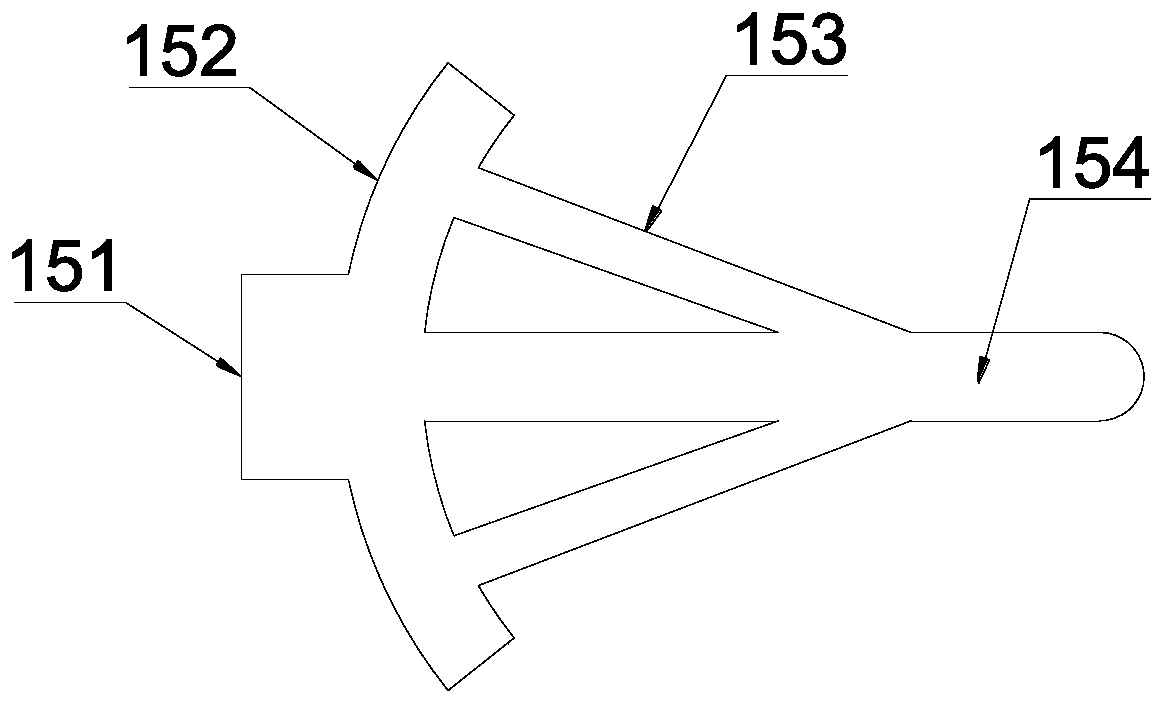

Linkage pre-treatment remediation device for contaminated soil

InactiveCN109013690AImprove processing effectImprove repair effectContaminated soil reclamationGrain treatmentsContaminated soilsPre treatment

The invention discloses a linkage pre-treatment remediation device for contaminated soil. The linkage pre-treatment remediation device for contaminated soil comprises a remediation box. A guide pipe is connected to the top of the remediation box, and the other end of the guide pipe is connected to the bottom of the side face of a pre-treatment box. A vertical shaft is mounted in the middle of thepre-treatment box. A crushing knife is mounted on in the pre-treatment box and is located on the vertical shaft. A screen is mounted under the crushing knife. A rotary cylinder is arranged in the middle of the remediation box. A plurality of stirring mechanisms are mounted on the portion, located in the remediation box, of the rotary cylinder. A second bevel gear is mounted at the left end of therotary cylinder. A first bevel gear engaged with the second bevel gear is mounted at the lower end of the vertical shaft. The right end of the rotary cylinder is connected with a liquor pipe. A pressure pump is mounted on the liquor pipe. The other end of the liquor pipe is connected to the bottom of the side face of a liquor box. The linkage pre-treatment remediation device for contaminated soilis reasonable in structural design; soil can be pretreated, and intermittent feeding and discharging for processing can be achieved, the liquor adding and mixing effect is good, and the soil remediation quality is improved.

Owner:甘灿琼

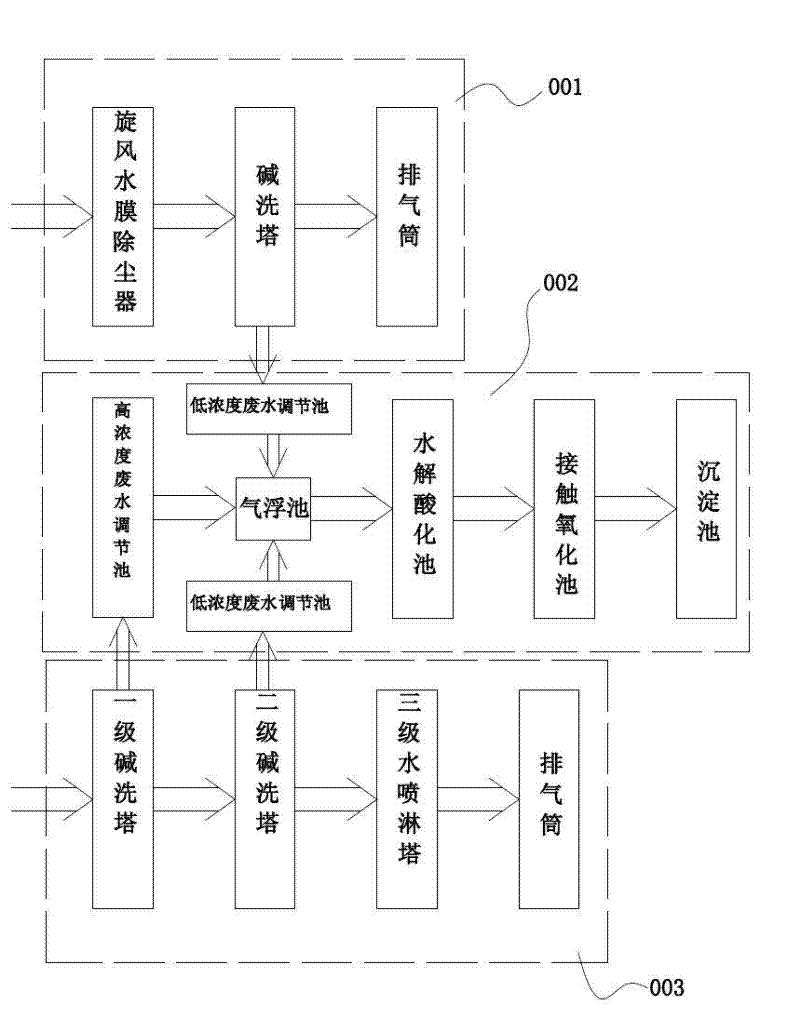

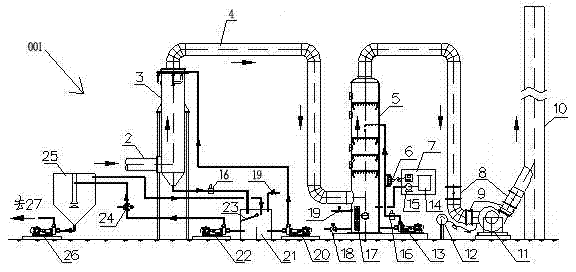

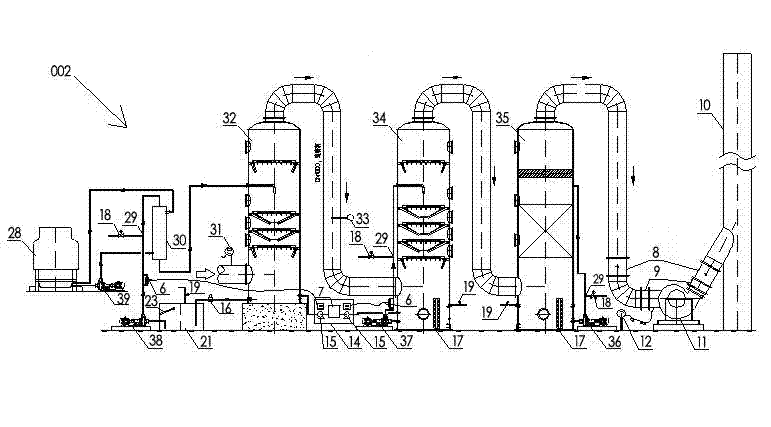

Device for treating waste gas used on production line of scouring pad

ActiveCN102309915AImprove processing effectGood governanceUsing liquid separation agentMultistage water/sewage treatmentTreatment effectSolution treatment

The invention relates to a device for treating waste gas used on a production line of a souring pad to treat the waste gas step by step, which solves the problem that the present waste gas treating device is not suitable for treating the waste gas from the production of the scouring pad. The device comprises a glue-spraying waste gas treatment system which treats the waste gas generated in a glue-spraying process, an oven waste gas treatment system which treats the waste gas generated in an oven process and a waste gas absorption solution treatment system which treats the absorption solution generated from the above two systems, the glue-spraying waste gas treatment system and the oven waste gas treatment system are respectively corresponding to a glue-spraying process and an oven processduring the production of the scouring pad, waste gas generated by the two processes is treated by the two systems respectively, so that the treatment effect can be enhanced, the waste gas absorption solution generated in the process of treatment can be treated by the waste gas absorption solution treatment system, so that the treatment effect is good, the treated waste gas meets the national discharge standard.

Owner:浙江省环境工程有限公司

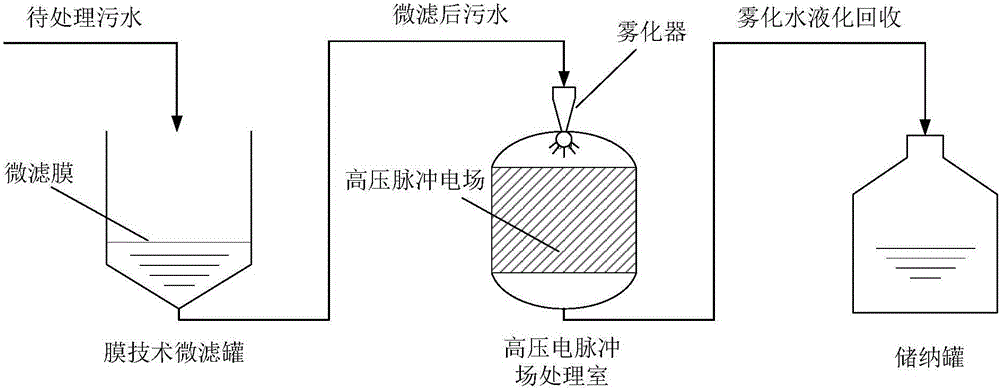

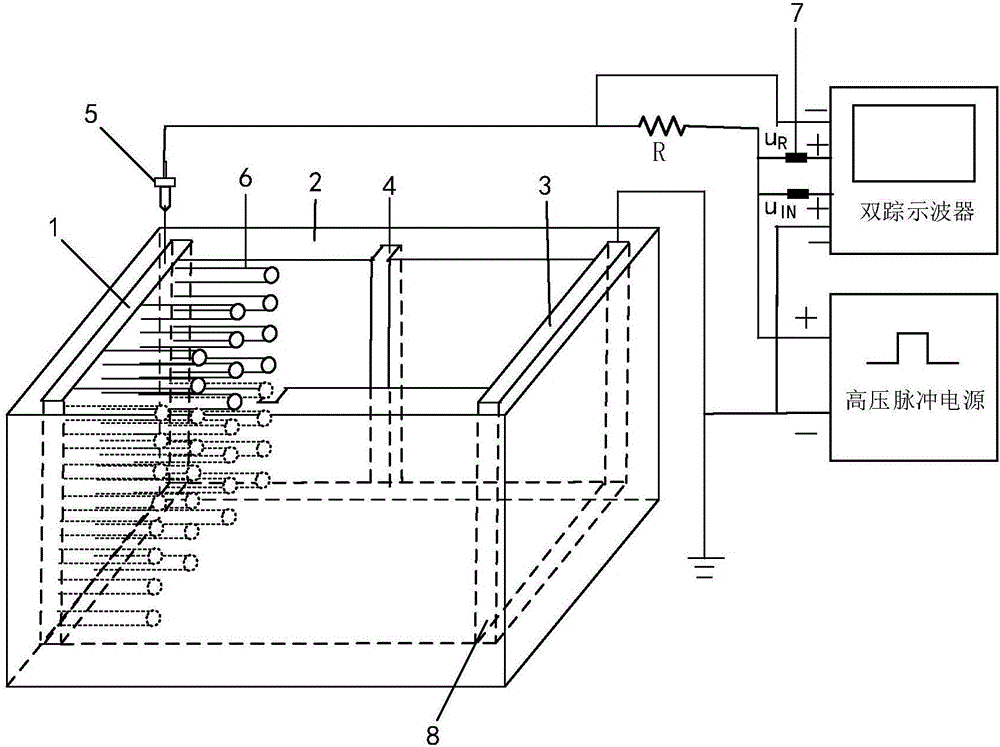

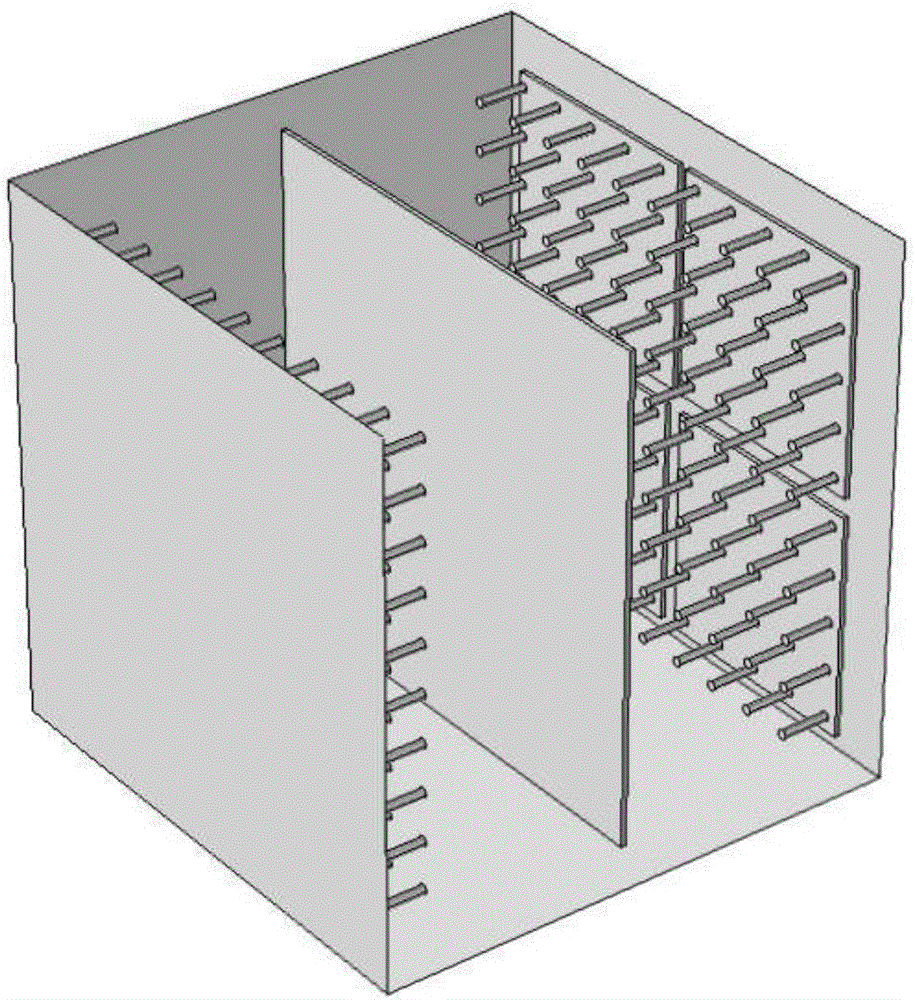

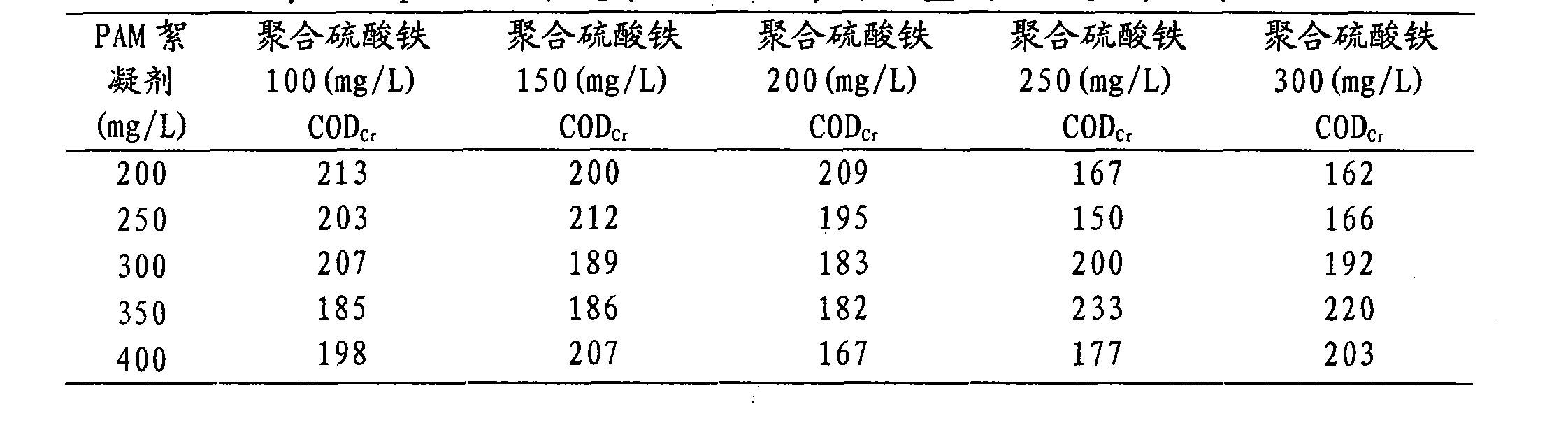

Industrial sewage treatment technique and system based on high-voltage nanosecond pulsed electric field technology

InactiveCN105948372AImprove the speed and effect of sewage treatmentImprove processing effectMultistage water/sewage treatmentWater/sewage treatment by sorptionLight sourceSewage treatment

The invention discloses an industrial sewage treatment technique based on high-voltage nanosecond pulsed electric field technology. The technique comprises the following steps: 1. preliminary treatment: carrying out preliminary treatment on sewage to be treated by using microfiltration membrane technology in combination with coagulation and adsorption processes to remove suspended particles, fibers and bacteria in the sewage; and 2. high-voltage pulsed field treatment: atomizing the sewage subjected to microfiltration so that the water fog is positioned among multiple needle-board special-shaped electrodes, and applying high-voltage pulses among the electrodes to generate a high-voltage pulsed electric field so as to degrade organic substances in the water fog, thereby implementing sewage purification. The technical scheme does not need any additional oxidant; the reaction system does not need high temperature, high pressure, additional light source or any other auxiliary technical means; and thus, the technique is novel water treatment technology which integrates shock waves, optical, electric and chemical oxidation, and has the advantages of high efficiency and no secondary pollution. The invention also discloses a treatment system based on the method.

Owner:SHIJIAZHUANG TIEDAO UNIV

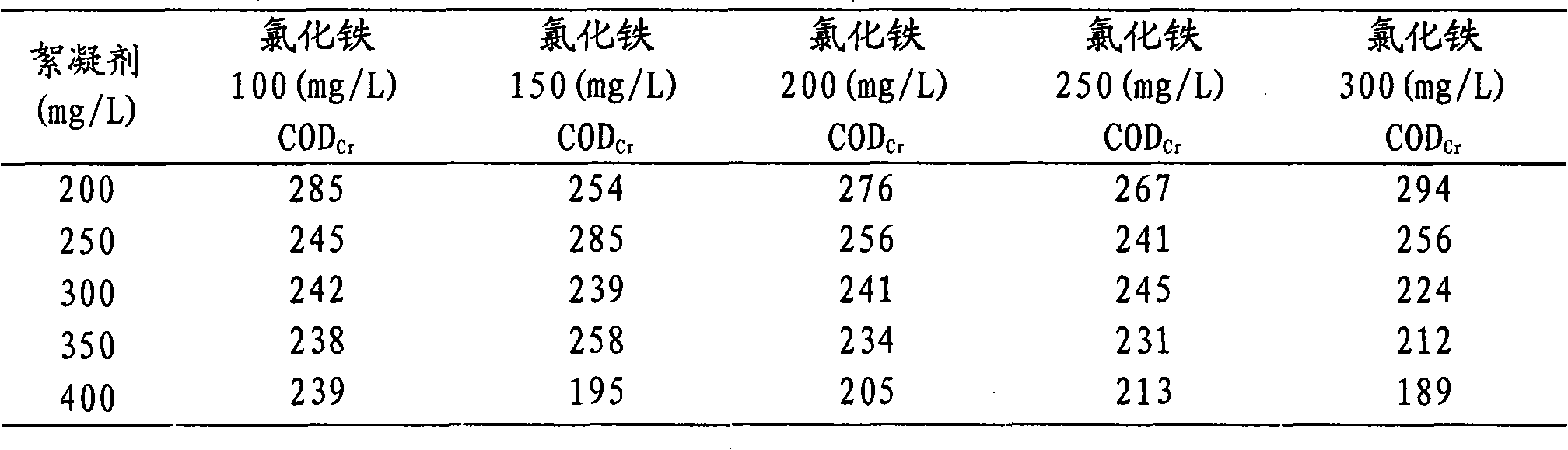

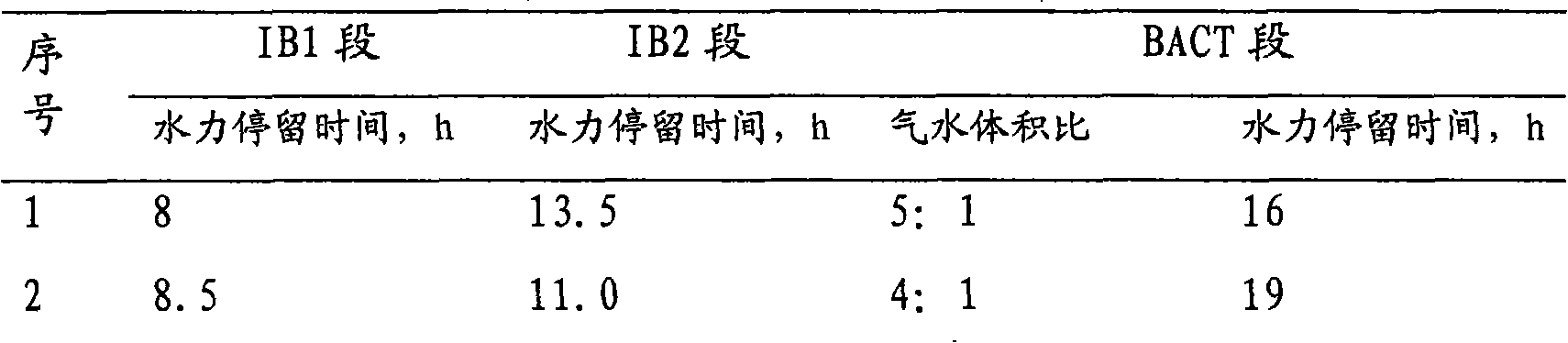

Discharge and standard reaching treatment method for thick oil sewage of oilfields

ActiveCN102030442AReduce petroleum and CODCr contentImprove processing effectTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentChemistrySewage treatment

The invention relates to a method and a process for treating thick oil sewage. The thick oil sewage is treated by adopting the process flows of air flotation pretreatment, biochemical treatment of immobile biology-bio-augmentation and compositive technology (IB-BACT), ozone treatment, bioactive carbon treatment and water discharge, the chemical oxygen demand (CODCr) of the discharged water not only can reach the level 1 discharge standard limit (the CODCr does not exceed 100mg / L) of national sewage comprehensive discharge standards (GB8978-1996), but also can reach the standard limit (the CODCr does not exceed 50mg / L) of local sewage discharge standards (DB21 / 1627-2008) of Liaoning province.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

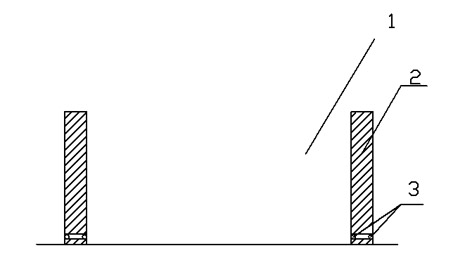

Desulfuration device based on spiral gas-liquid mixing and rotational flow gas-liquid separating principle

ActiveCN105688634AImprove processing effectAvoid lime rainCombination devicesGas treatmentWater pipeSpiral blade

A desulfuration device based on the spiral gas-liquid mixing and rotational flow gas-liquid separating principle comprises a shell. A rotating shaft is arranged at the bottom of the shell. The bottom end of the rotating shaft is connected with a motor below the shell. A hollow inner cavity is formed in the rotating shaft. A rotating water pipe connector is arranged at the top end of the rotating shaft and communicated with a first liquid inlet pipe. A plurality of first through holes communicated with the outside of the rotating shaft are formed in the hollow inner cavity. Spiral blades are arranged on the rotating shaft and sleeved with a sleeve. The top end of the sleeve is closed and provided with an air inlet pipe. The bottom end of the sleeve is fixedly connected with the bottom in the shell. The desulfuration device has the advantages that waste gas is driven by the spiral blades to be sufficiently mixed with a lime solution, and the processing effect of waste gas is effectively improved; under the effect of diversion blades, the lime solution contained in waste gas is separated from waste gas, and the 'lime rain' phenomenon is avoided.

Owner:上海汇舸环保科技有限公司

A remediation method for soil polluted by chlorobenzenes

InactiveCN104607456AImprove processing effectImprove oxidation performanceContaminated soil reclamationWater contentHydroxycitric acid

A remediation method for soil polluted by chlorobenzenes is disclosed. The method includes following steps of: 1) smashing the polluted soil, and adjusting the water content; and 2) spraying the soil with a sodium persulfate solution, spraying a Fe (II) citric acid chelate solution under the existence of sodium persulfate, and reacting to remove the chlorobenzene pollutants in the soil. By a manner of activating the sodium persulfate by the Fe (II) citric acid chelate, the chlorobenzene pollutants in the soil are removed by utilization of a strong oxidizing property of the sodium persulfate. The sodium persulfate is added into the soil through a spraying manner, and a chelating agent is sprayed under the existence of the sodium persulfate to activate the sodium persulfate, thus increasing the oxidizing and removing rate of the chlorobenzene pollutants by an oxidant. The method is advantageous in that: the method is simple in operation and good in removing effects, a remediation process has no influence on physical and chemical properties of the soil, and the method is free of secondary pollution.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Photoelectric composite biological treatment method and reactor for photoelectric composite biological treatment method

InactiveCN104030531AImprove processing effectGood energy saving effectWater/sewage treatmentMultistage water/sewage treatmentEnzymeTreatment effect

The invention relates to a reactor for a photoelectric composite biological treatment method. The reactor comprises a container, wherein a micro-electrolysis treatment zone is arranged in the container, an iron-carbon filler with a TiO2 coating is arranged in the micro-electrolysis treatment zone, a photocatalytic reaction zone is arranged inside the micro-electrolysis treatment zone, an aeration device is arranged at the lower part of the micro-electrolysis treatment zone, a biological treatment zone is arranged at the upper part of the micro-electrolysis treatment zone, a suspended filler supported with a biological enzyme is arranged in the biological treatment zone, a water inlet or water outlet is formed at the upper end of the container and a water outlet or water inlet is formed at the lower end of the container. The invention also provides the photoelectric composite biological treatment method of wastewater. According to the photoelectric composite biological treatment method of wastewater disclosed by the invention, by the synergic effect of the micro-electrolysis and biological method, the problems of existing water treatment technology are solved, the treatment effect of wastewater is improved, the treatment efficiency is improved, energy conservation is achieved and the treatment cost is reduced.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

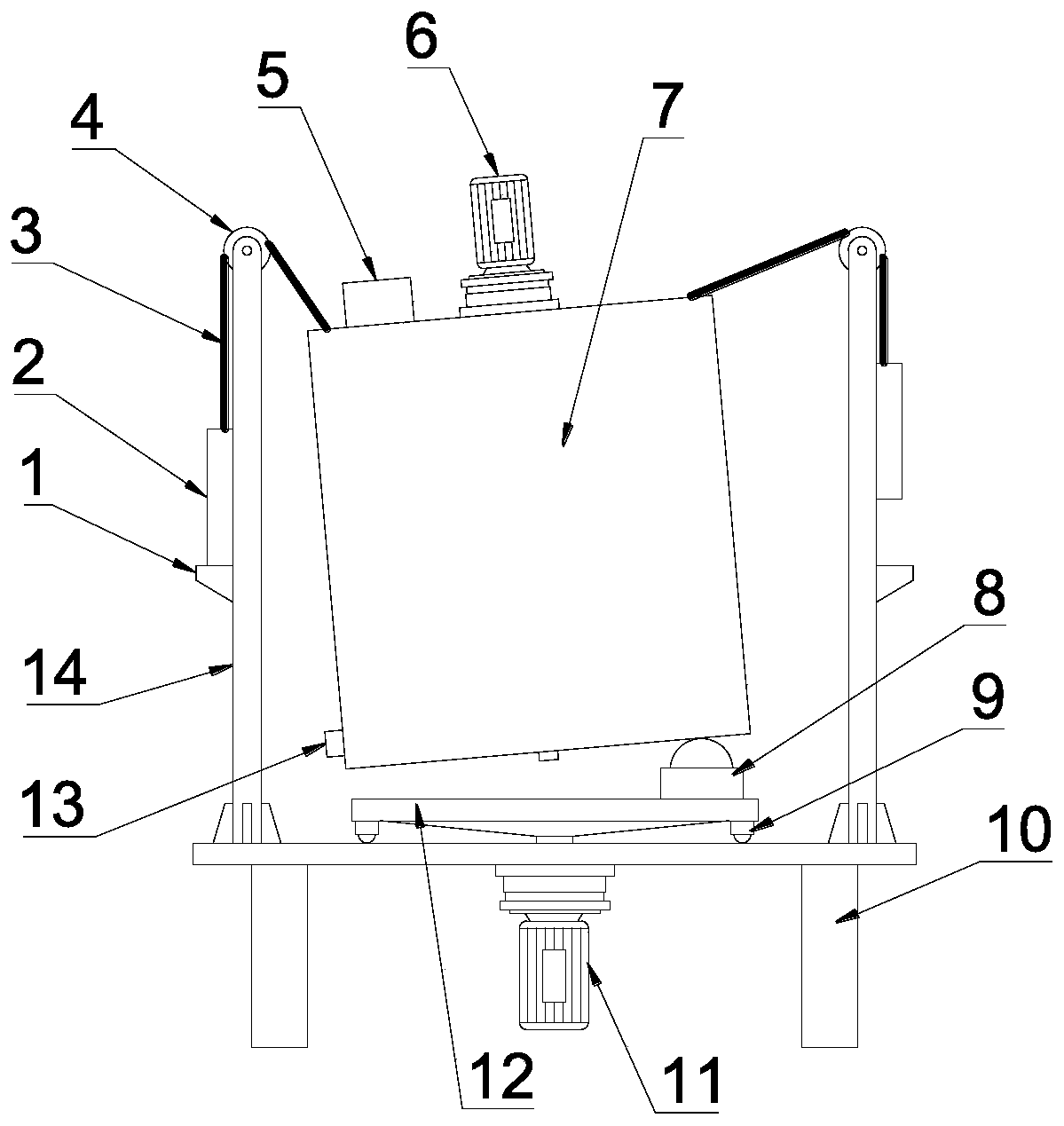

Cement blending device for hydraulic engineering construction

InactiveCN109849181AImprove stabilityImprove processing effectCement mixing apparatusEnvironmentally friendlyWire rope

The invention discloses a cement blending device for hydraulic engineering construction. The device comprises a blending box, a rack and stand columns; a stirring shaft is arranged in the middle of the blending box, the top of the blending box is provided with a first driving mechanism used for driving the stirring shaft to rotate, multiple stirring assemblies are arranged at the position, on thestirring shaft, of the inner side of the blending box, the rack is arranged below the blending box, a rotating disc is arranged on the upper side of the rack, the rotating disc is driven by a second driving mechanism on the lower side of the rack to rotate, a first universal ball assembly used for enabling the blending box to incline is arranged on the outer ring of the upper side of the rotatingdisc, the stand columns are arranged on the outer ring of the top of the rack in the circumferential direction, guide wheels are arranged on the upper ends of the stand columns, a steel wire rope is wound on the guide wheels, one end of the steel wire rope is connected to the outer ring of the top of the blending box, and the other end of the steel wire rope is connected with the tops of weights on the outer sides of the stand columns. The cement stirring blending effect and efficiency can be improved, the device saves energy and is environmentally friendly, and the higher popularization and practicability value is achieved.

Owner:尹瑜

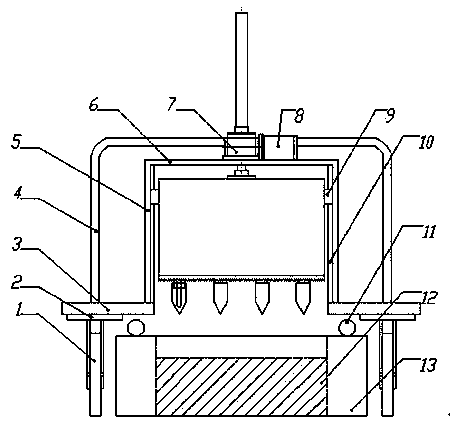

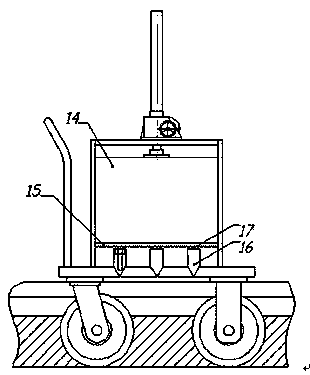

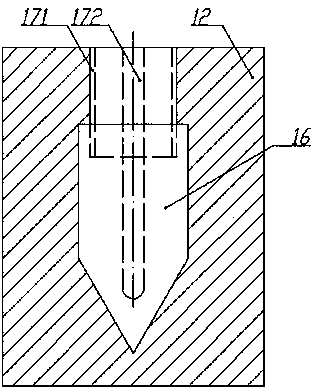

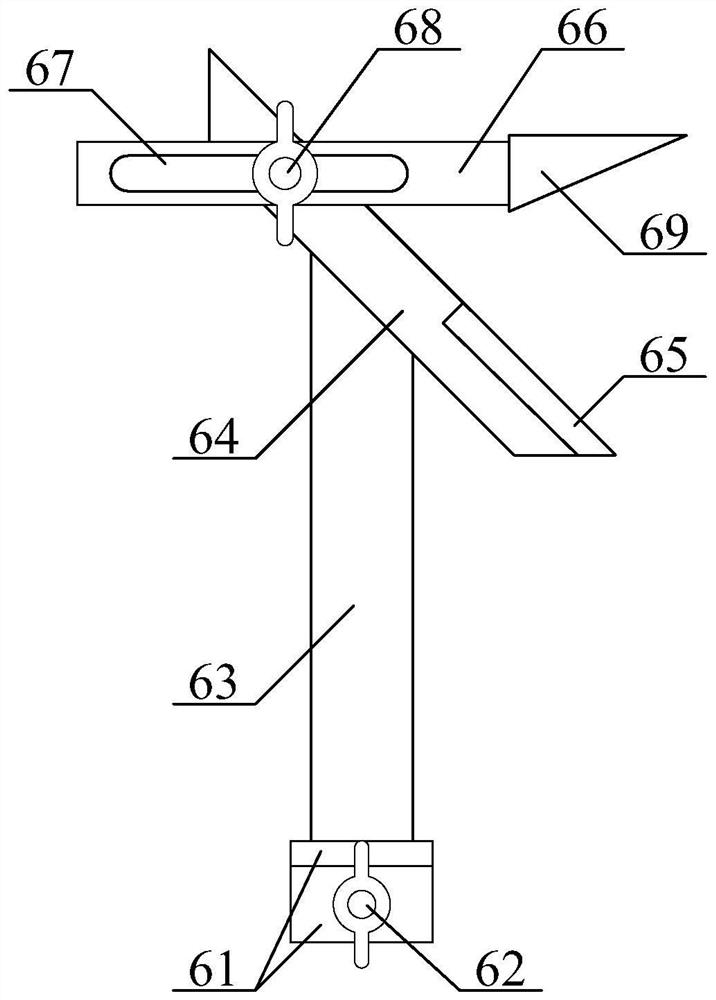

Lifting type microwave soil treatment device

ActiveCN103814882AImprove processing effectGuaranteed uniformityInsect catchers and killersRadiationBiologySoil science

The invention discloses a lifting type microwave soil treatment device which comprises a microwave generating and irradiating device, a lifting device and a trolley body. A magnetron, a transformer, coaxial tubes and the like form the microwave generating and irradiating device. The microwave generating and irradiating device generates microwaves and irradiates the microwaves into soil. The lifting device enables the microwave generating and irradiating device to ascend and descend. In the operation process, the coaxial tubes are inserted into the soil by the lifting device to act on the soil. The microwave generating and irradiating device is lifted by the lifting device when the lifting type microwave soil treatment device is not in operation. The lifting type microwave soil treatment device is easy and convenient to operate, and capable of being used for treatment of soil in a greenhouse and soil in a cultivation trough in the greenhouse; after treatment, the lifting type microwave soil treatment device plays a role in conducting sterilization, deinsectization, soil-borne disease prevention and the like on the soil.

Owner:JIANGSU UNIV

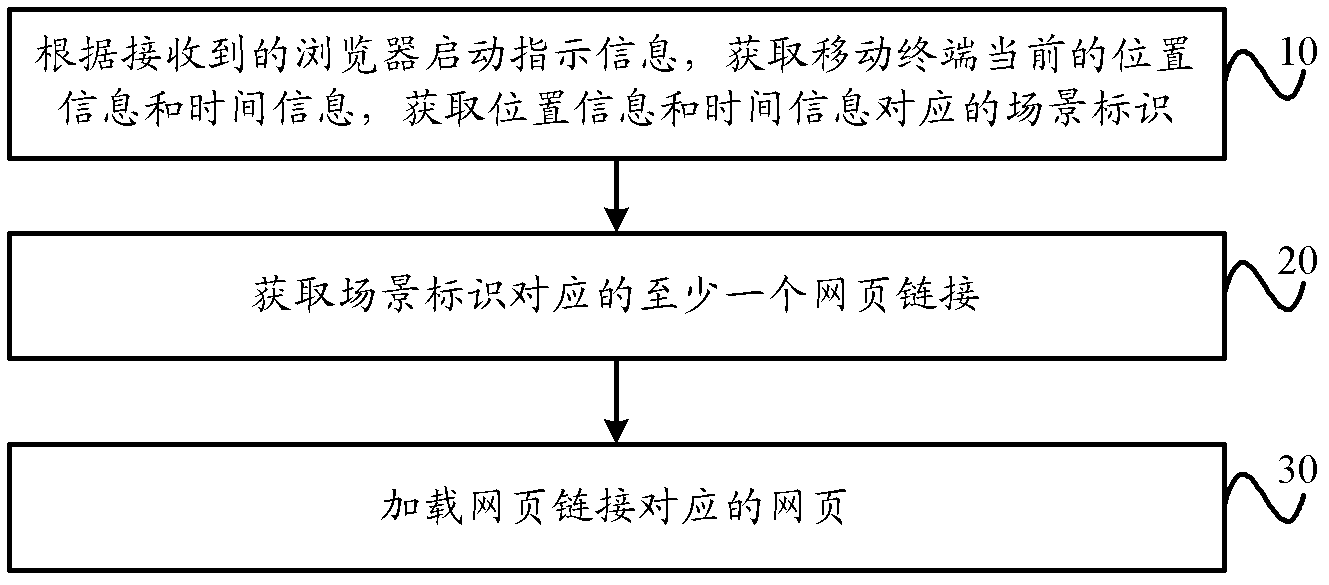

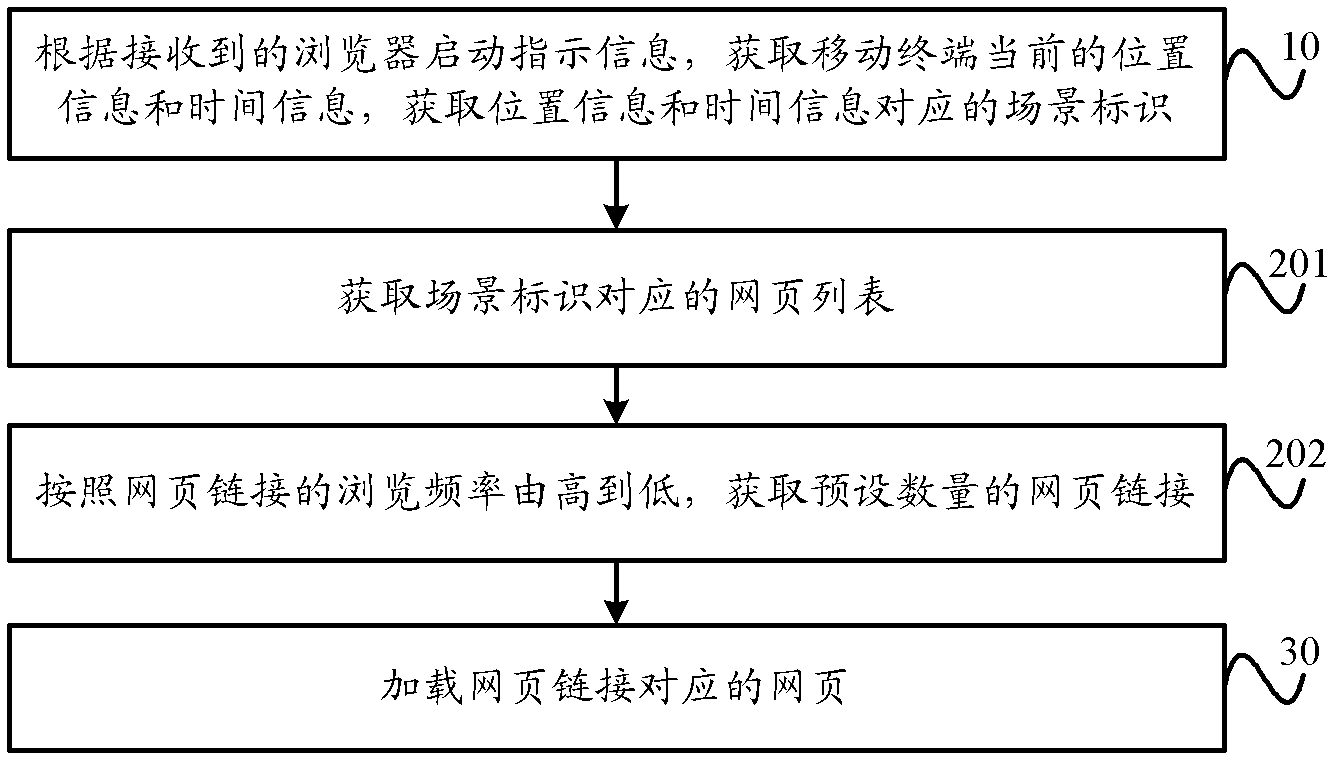

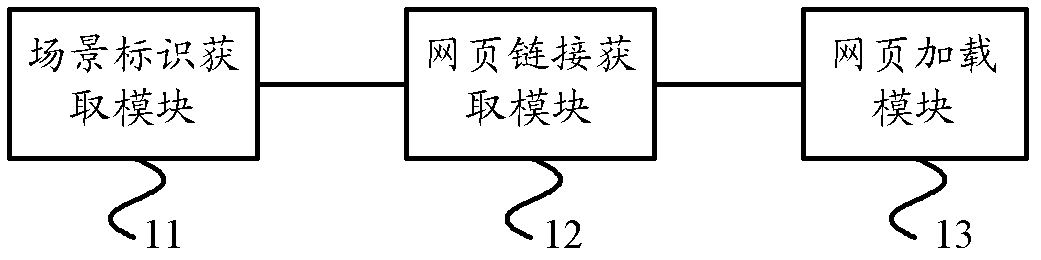

Web page processing method and device for mobile terminal

InactiveCN102542065AAvoid time and effortImprove processing effectSpecial data processing applicationsTime informationWeb page

The invention provides a web page processing method and device for a mobile terminal. The web page processing method for the mobile terminal comprises the steps of obtaining current position information and time information of the mobile terminal and a scene mark corresponding to the position information and the time information according to received browser start indication information; obtaining at least one web page link corresponding to the scene mark; and loading a web page corresponding to the web page link. The web page processing method and device for the mobile terminal, which are provided by the invention, have the advantages that web page links corresponding to scenes can be obtained according to different scenes where a user is located, and web pages corresponding to the web page links can be automatically loaded. Not only can the web pages be automatically loaded, but the web pages presenting for the user aim at browsing habits and needs of the user at different scenes, so the time and the energy of the user, which are spent on remembering or seeking web addresses, are avoided, and the web page processing effect of the mobile terminal is improved.

Owner:BEIJING BENY WAVE SCI & TECH

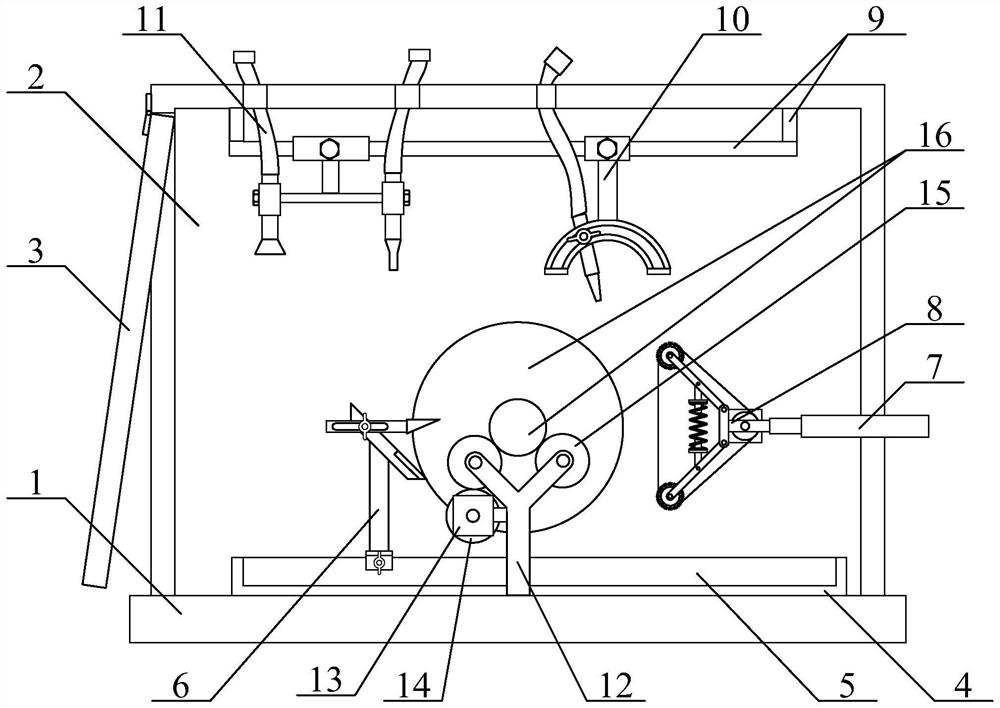

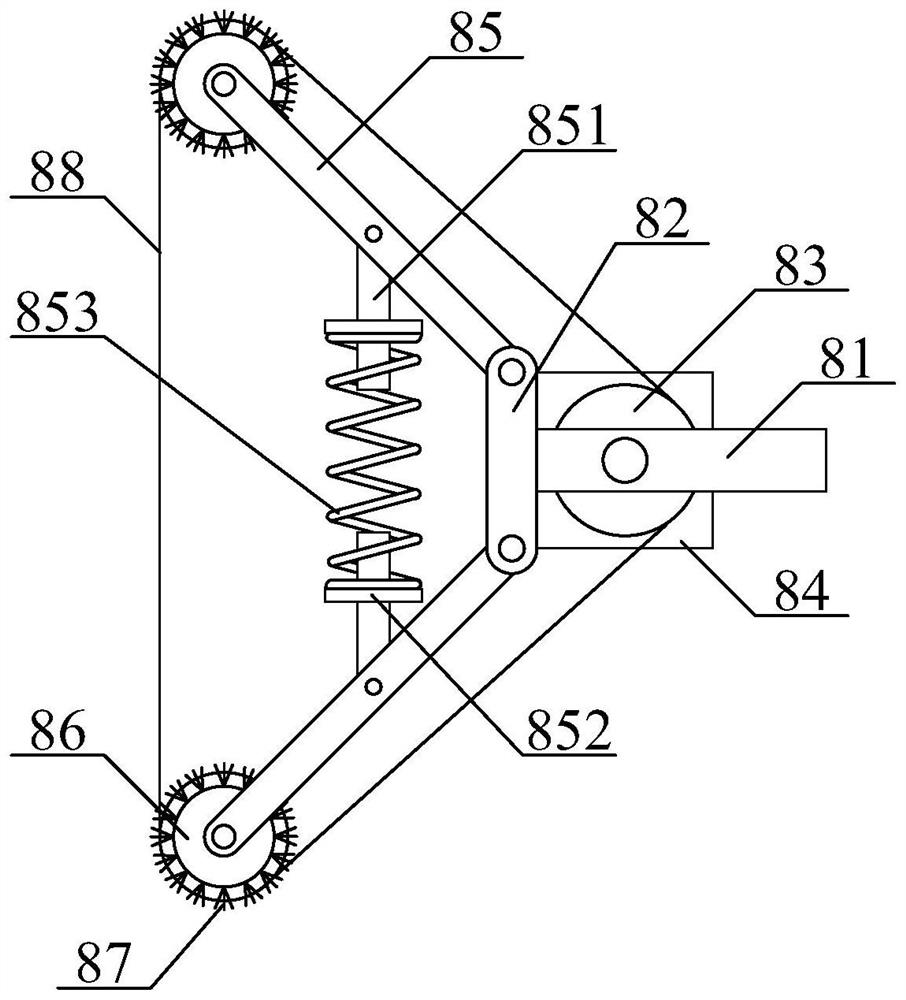

Tungsten carbide spraying equipment with both grinding and surface defect repair functions

ActiveCN111962003AImprove processing effectImprove flattening effectMolten spray coatingGrinding drivesGrindingDrive motor

The invention provides tungsten carbide spraying equipment with both grinding and surface defect repair functions. The equipment comprises a base, a shell, a protective cover, a collecting frame, a collecting groove, a roller shaping frame structure, a cylinder, an arc surface polishing frame structure, a guide rail, an adjustable spraying fun fixing frame structure, a machining cleaning frame structure, a Y-shaped frame, a drive motor, a driving wheel, a driven wheel and a to-be-machined roller. The shell is in bolt connection with the upper portion of the base. The protective cover is in hinged connection with the left side inside the shell. The collecting frame is in bolt connection with the middle of the upper portion of the base. The equipment has the beneficial effects that by arranging the roller, a polishing motor, a rotating roller, a brush and a polishing belt, the surface of the to-be-machined roller is polished and ground conveniently, the polishing motor drives the rollerto rotate, the surface of the to-be-machined roller is ground through the grinding belt, and meanwhile unmolten tungsten carbide powder remaining at the corners of the front and back ends of the to-be-machined roller is cleaned thoroughly through the brush.

Owner:合力(天津)能源科技股份有限公司

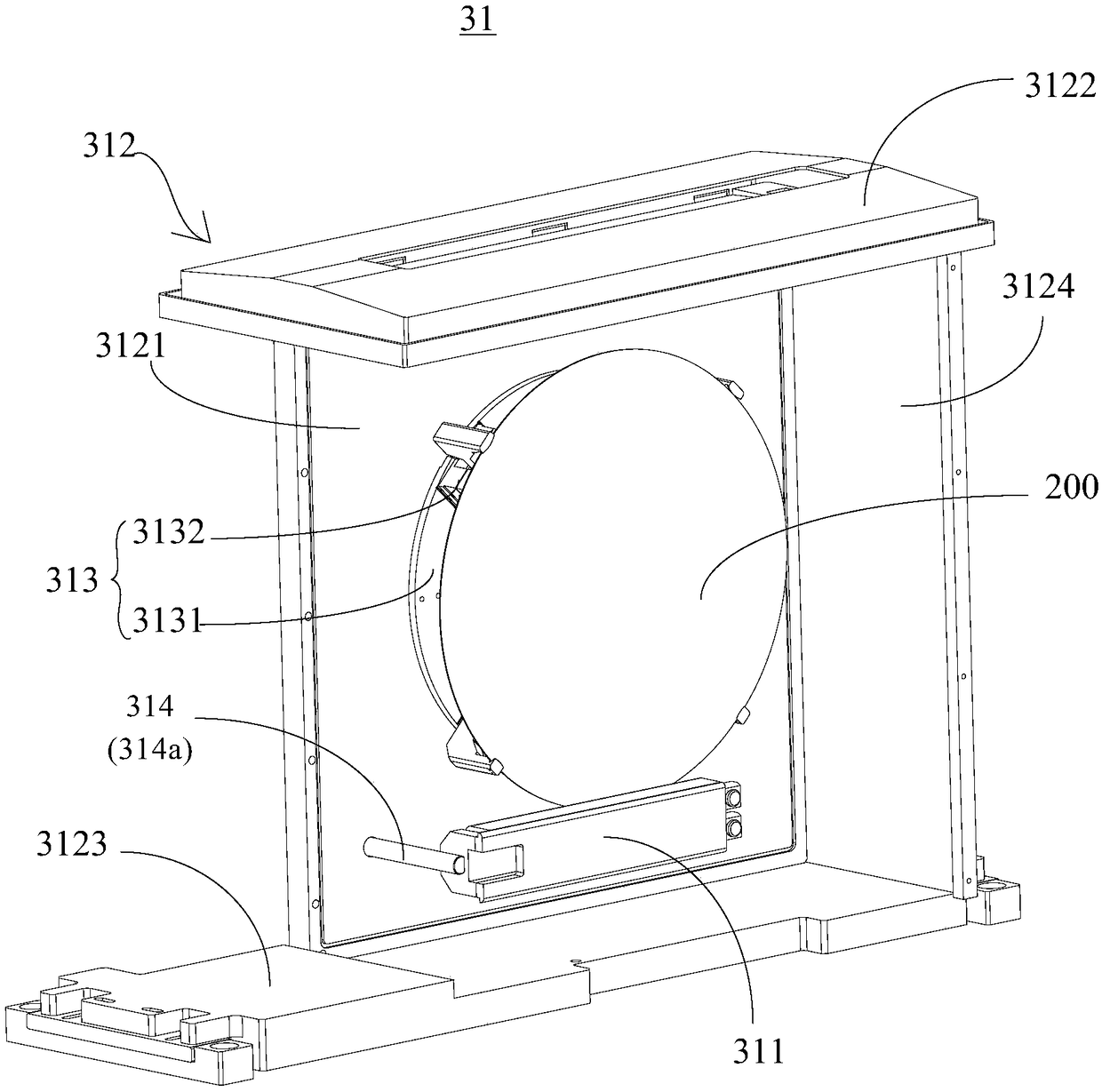

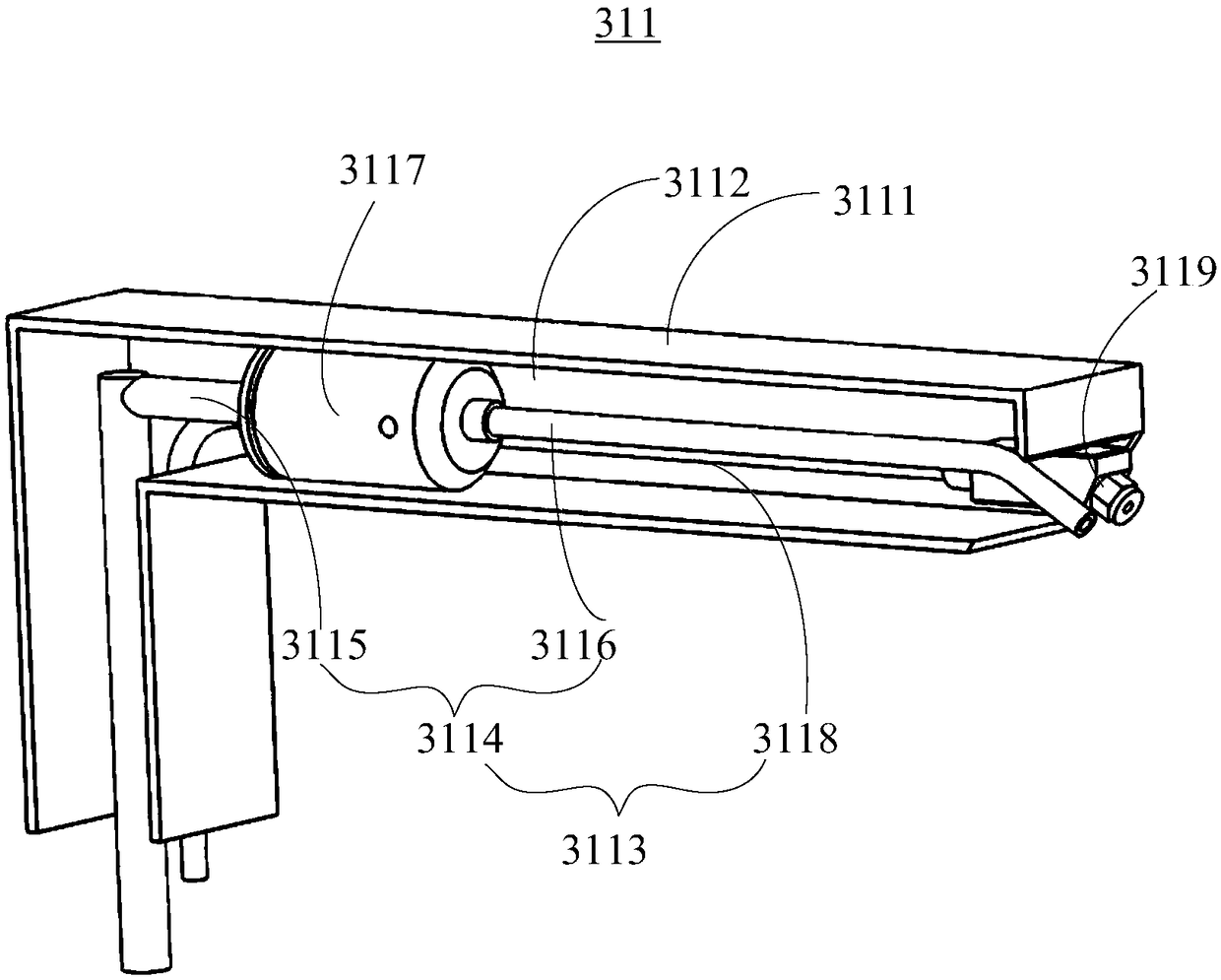

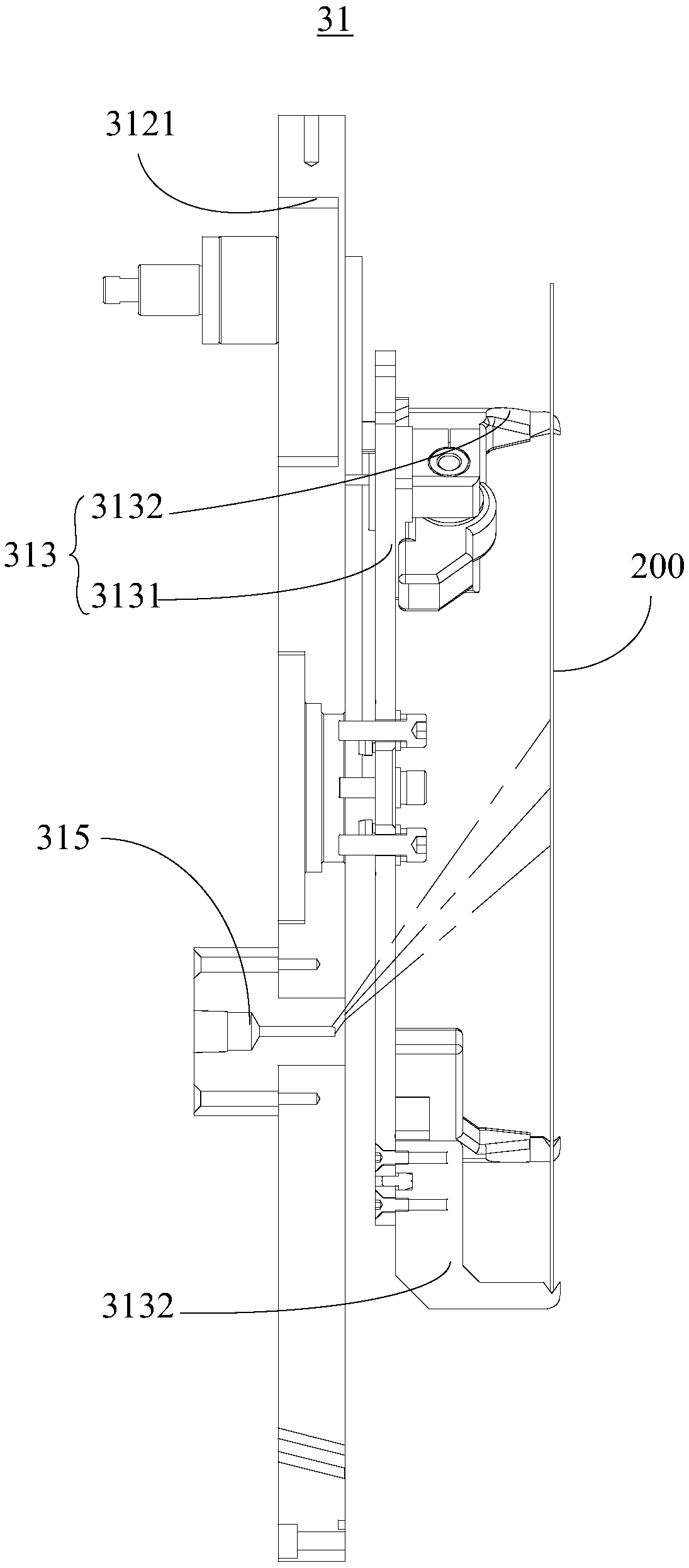

Wafer processing device and method and chemical mechanical polishing system

PendingCN109048644AReduce the possibility of damageImprove processing effectSemiconductor/solid-state device manufacturingLapping machinesChemical-mechanical planarizationEngineering

The invention discloses a wafer processing device and method and a chemical mechanical polishing system. The wafer processing device comprises a driving assembly and a processing assembly, the drivingassembly drives a wafer to rotate, and the processing assembly swings around the axis perpendicular to the surface of the wafer so as to inject a fluid to the surface of the wafer. When the processing device is used for processing the wafer, the wafer can be prevented from being damaged, and the processing effect is good.

Owner:TSINGHUA UNIV +1

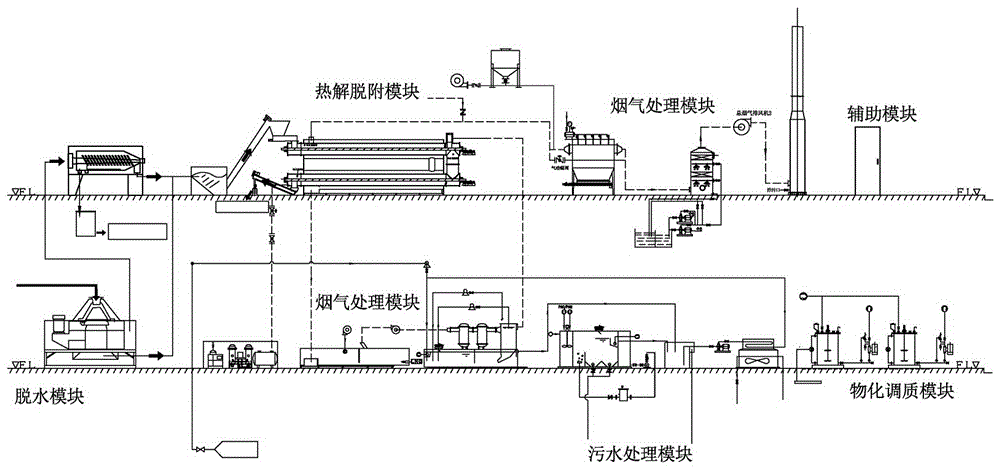

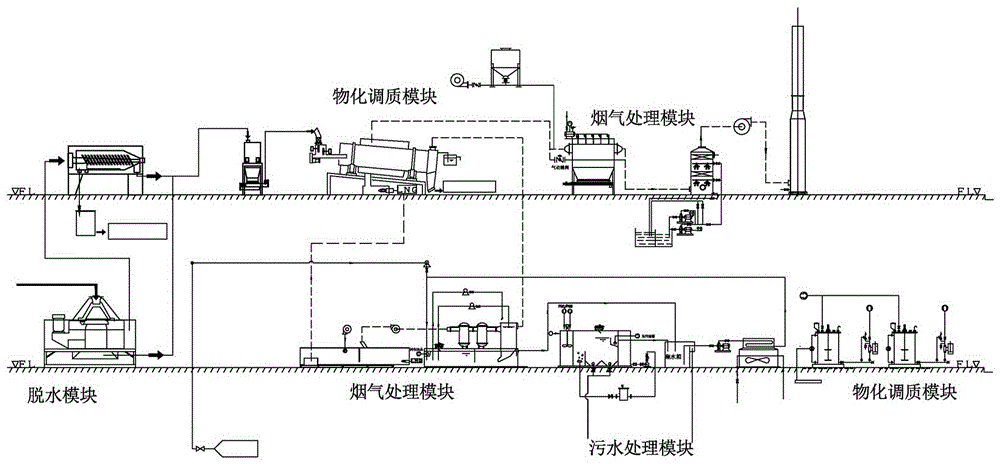

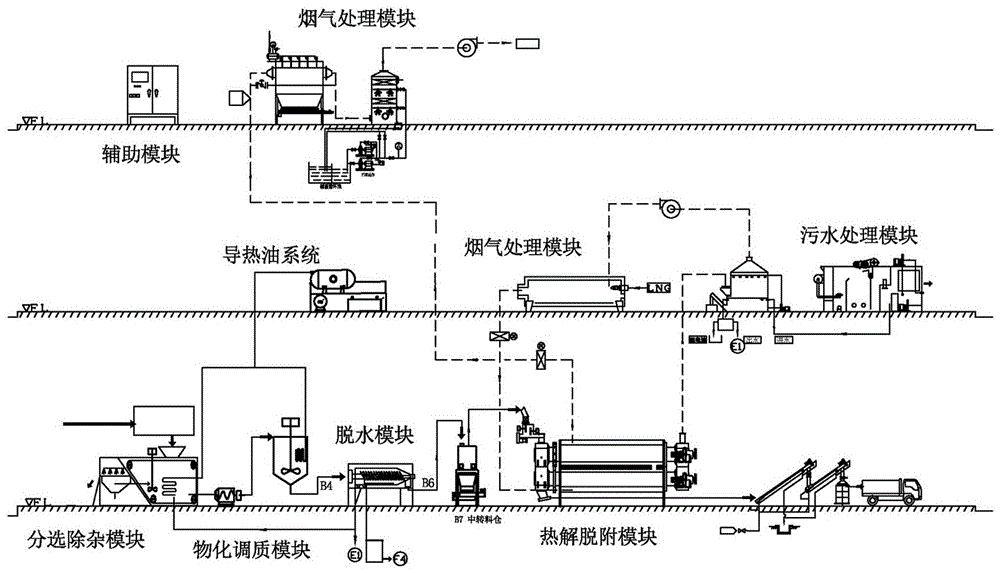

Method for constructing sludge treatment system based on sludge component

InactiveCN106746416AImprove processing effectSave equipment and site investmentWaste water treatment from quariesCombination devicesWater contentChemistry

The invention relates to the field of oily sludge treatment and specifically relates to a method for constructing a sludge treatment system based on a sludge component. The method is suitable for the treatment of the sludge with the oil content from 5% to 50% and the water content from 0% to 85%. The method comprises the following steps: 1) dividing modules: dividing 9 modules according to a treatment process required by the sludge treatment under the above conditions, namely, a sorting impurity removing module, a materialization tempering module, a dewatering module, a drying / desiccation module, a pyrolysis desorption module, a pyrolysis carbonizing module, a flue gas treatment module, a wastewater treatment module and an auxiliary module; 2) sludge variety determining: determining the sludge variety according to the oil content or resource of the sludge; 3) selecting the modules: selecting the modules required by the treatment process according to the sludge variety; and 4) constructing a system: constructing and assembling a device according to the selected modules.

Owner:ZHE JIANG ECO ENVIRONMENTAL TECH CO LTD

Melting furnace for byproduct industrial salt treatment and treatment method

ActiveCN106608649AImprove processing effectGuaranteed qualityHeat treatmentsAlkali metal halide purificationTreatment effectNozzle

Belonging to the technical field of byproduct industrial salt treatment, the invention relates to a melting furnace for byproduct industrial salt treatment and a treatment method. The melting furnace includes a furnace cavity body formed by a plurality of surrounding furnace wall surfaces, the furnace cavity body has an upper part defined as a heating cavity and a lower part defined as a smelting cavity, the furnace wall of the heating cavity is equipped with several flame nozzles, and the smelting cavity is internally equipped with at least two weirs higher than the bottom surface of the smelting cavity. The invention also discloses a method of treating byproduct industrial salt with the melting furnace. The melting furnace and treatment method provided by the invention greatly improve the treatment effect of the byproduct industrial salt and ensure the quality of a final product.

Owner:SHANDONG WEIFANG RAINBOW CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com