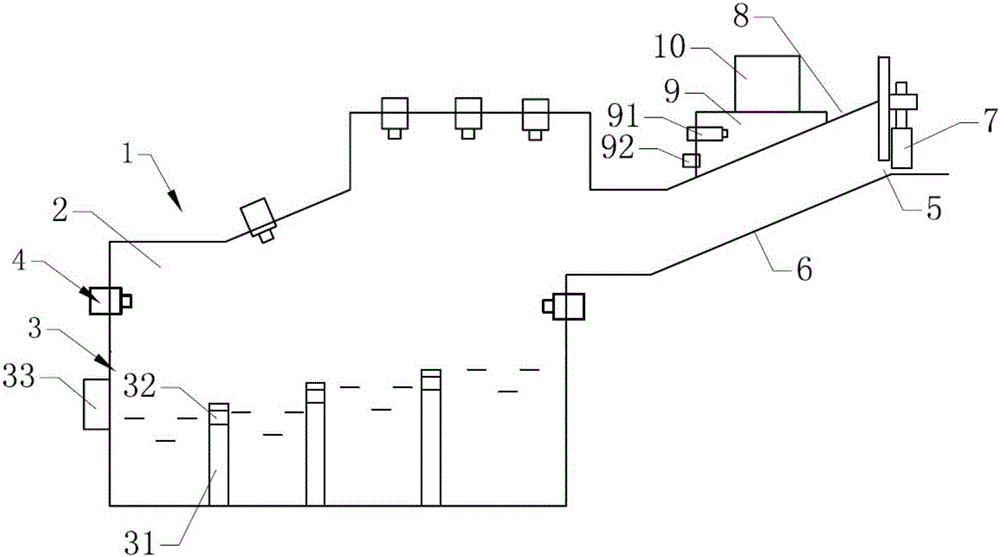

Melting furnace for byproduct industrial salt treatment and treatment method

A technology for by-product industry and melting furnace, which is applied to the melting furnace for by-product industrial salt treatment and the processing field, can solve the problems of poor effect of by-product industrial salt, and achieve the effect of ensuring quality and improving treatment effect.

- Summary

- Abstract

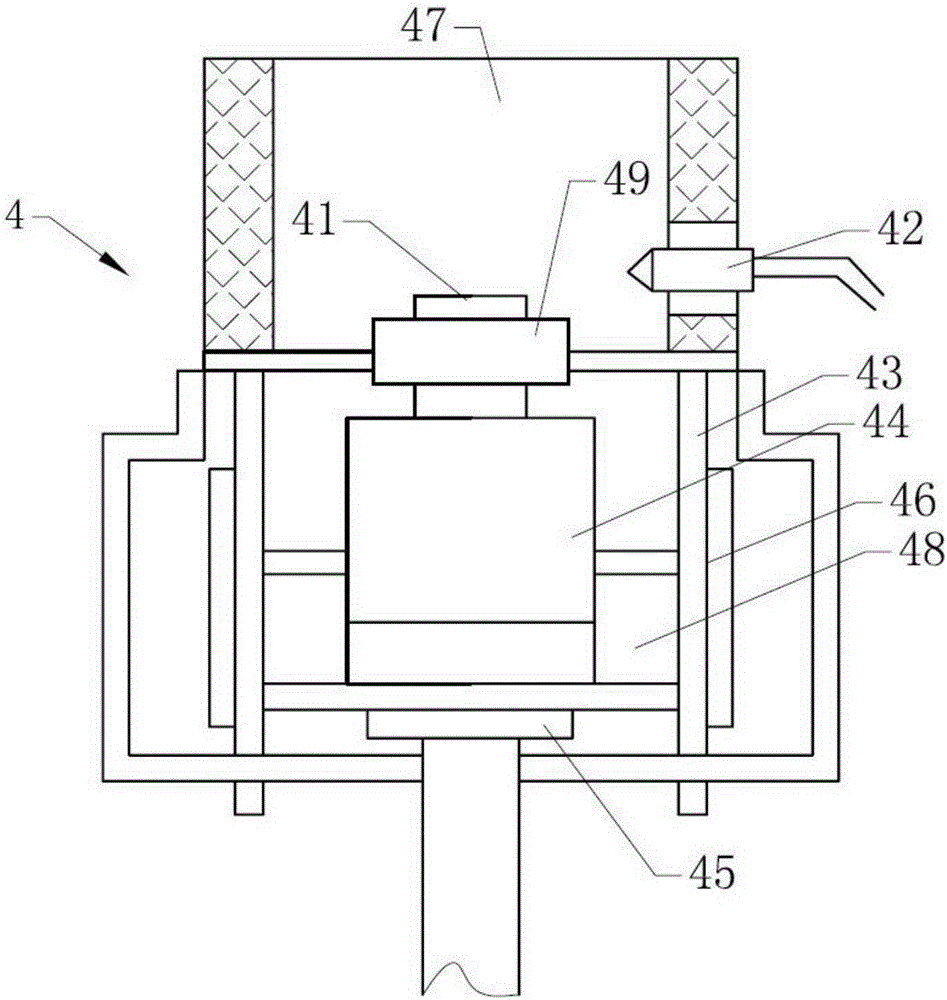

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The processing method of by-product industrial salt of the present invention comprises the steps:

[0042] (1) Rinse the by-product industrial salt with deionized water and dry it, and be pulverized into particles with a particle diameter of 2mm,

[0043] (2) Use the feeding port to send the granular by-product industrial salt into the feeding channel, and at the same time, use the restraint of the gate on the feeding port to make the granular by-product industrial salt form a waterfall flow on the surface of the feeding channel, and control The thickness of the by-product industrial salt flow material is 0.9cm. The auxiliary heating chamber above the feed channel is used to preliminarily heat the by-product industrial salt. The heating temperature of the auxiliary heating chamber is 700°C. Part of the organic matter is decomposed, and the decomposed products The gas is fully burned inside, and the gas is discharged through the exhaust port;

[0044] (3) The by-product...

Embodiment 2

[0050] The processing method of by-product industrial salt of the present invention comprises the steps:

[0051] (1) Rinse the by-product industrial salt with deionized water and dry it, and be pulverized into particles with a particle diameter of 3mm,

[0052] (2) Use the feeding port to send the granular by-product industrial salt into the feeding channel, and at the same time, use the restraint of the gate on the feeding port to make the granular by-product industrial salt form a waterfall flow on the surface of the feeding channel, and control The thickness of the by-product industrial salt stream is 0.8cm. The auxiliary heating chamber above the feeding channel is used to preliminarily heat the by-product industrial salt. The heating temperature of the auxiliary heating chamber is 900°C. Part of the organic matter is decomposed, and the decomposed products are heated in the auxiliary heating chamber. The cavity is fully burned, and the gas is discharged through the exhau...

Embodiment 3

[0059] The processing method of by-product industrial salt of the present invention comprises the steps:

[0060] (1) Rinse the by-product industrial salt with deionized water and dry it, and be pulverized into particles with a particle diameter of 2.5mm,

[0061] (2) Use the feeding port to send the granular by-product industrial salt into the feeding channel, and at the same time, use the restraint of the gate on the feeding port to make the granular by-product industrial salt form a waterfall flow on the surface of the feeding channel, and control The thickness of the by-product industrial salt stream is 0.8cm. The auxiliary heating chamber above the feeding channel is used to preliminarily heat the by-product industrial salt. The heating temperature of the auxiliary heating chamber is 800°C. The cavity is fully burned, and the gas is discharged through the exhaust port;

[0062] (3) The by-product industrial salt flows into the melting chamber, and the furnace wall of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com