Patents

Literature

369results about How to "Improve flattening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

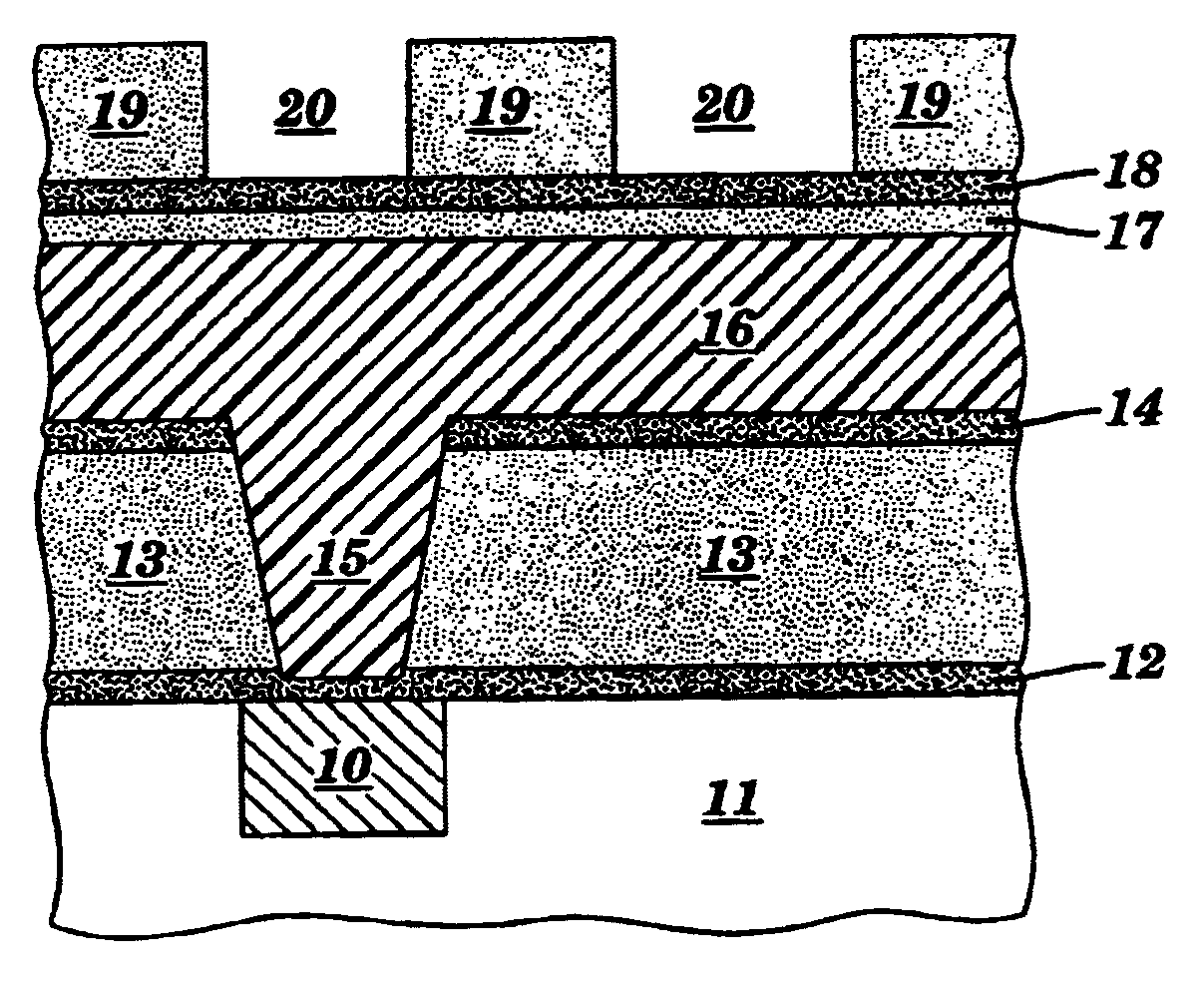

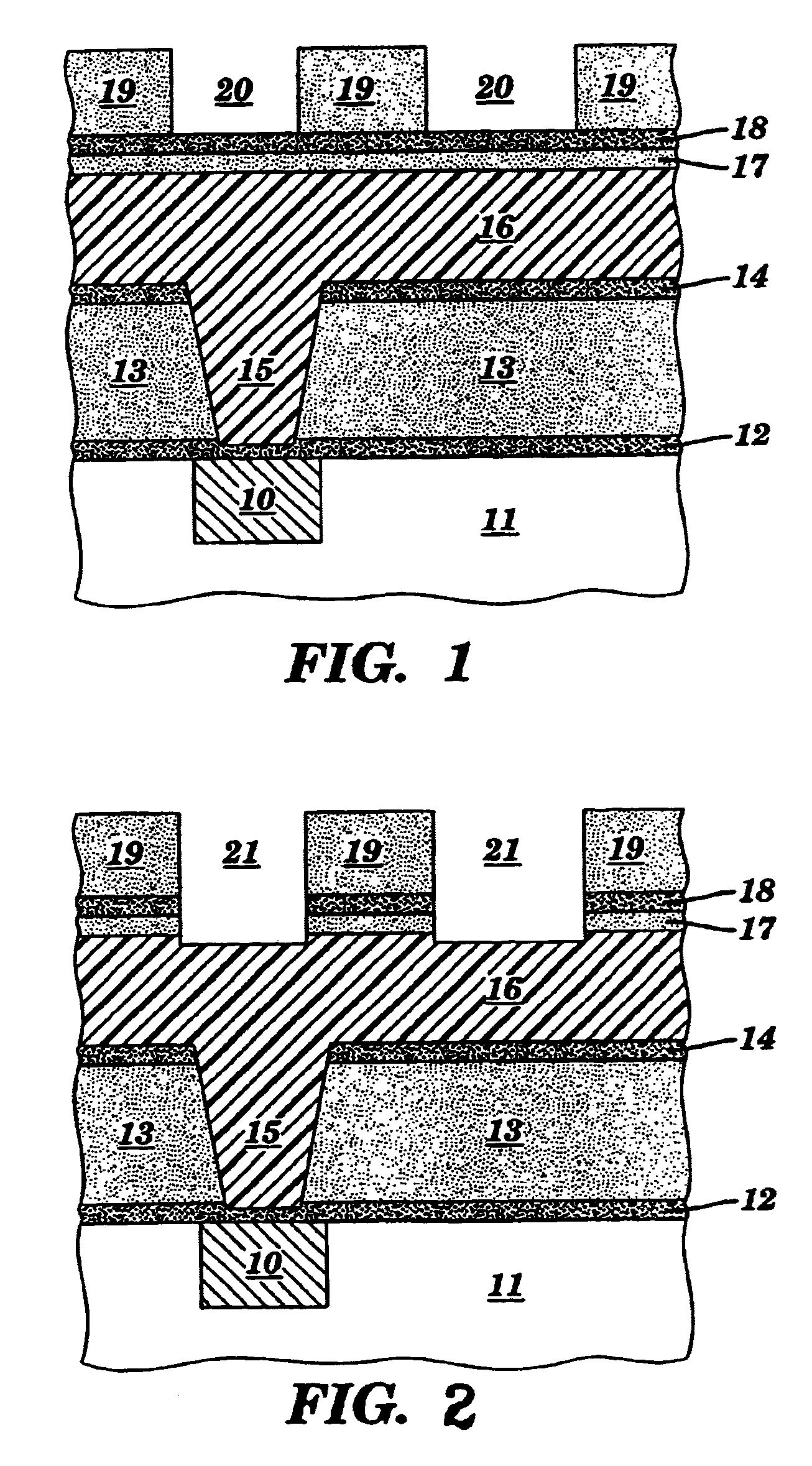

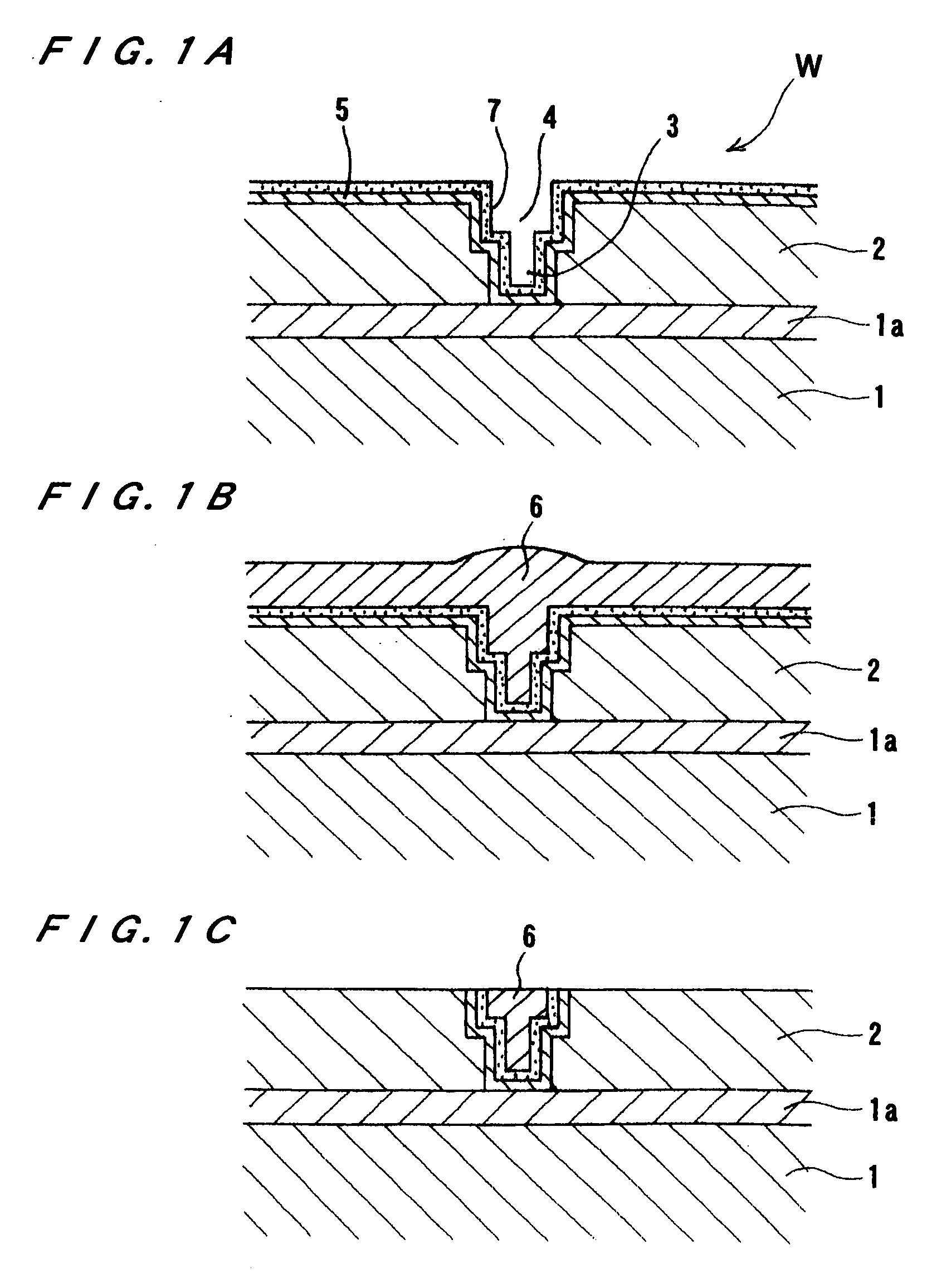

Method for forming damascene structure utilizing planarizing material coupled with diffusion barrier material

ActiveUS7030031B2Improve flattening effectImprove manufacturabilitySemiconductor/solid-state device manufacturingCable/conductor manufactureDiffusion barrierPhotoresist

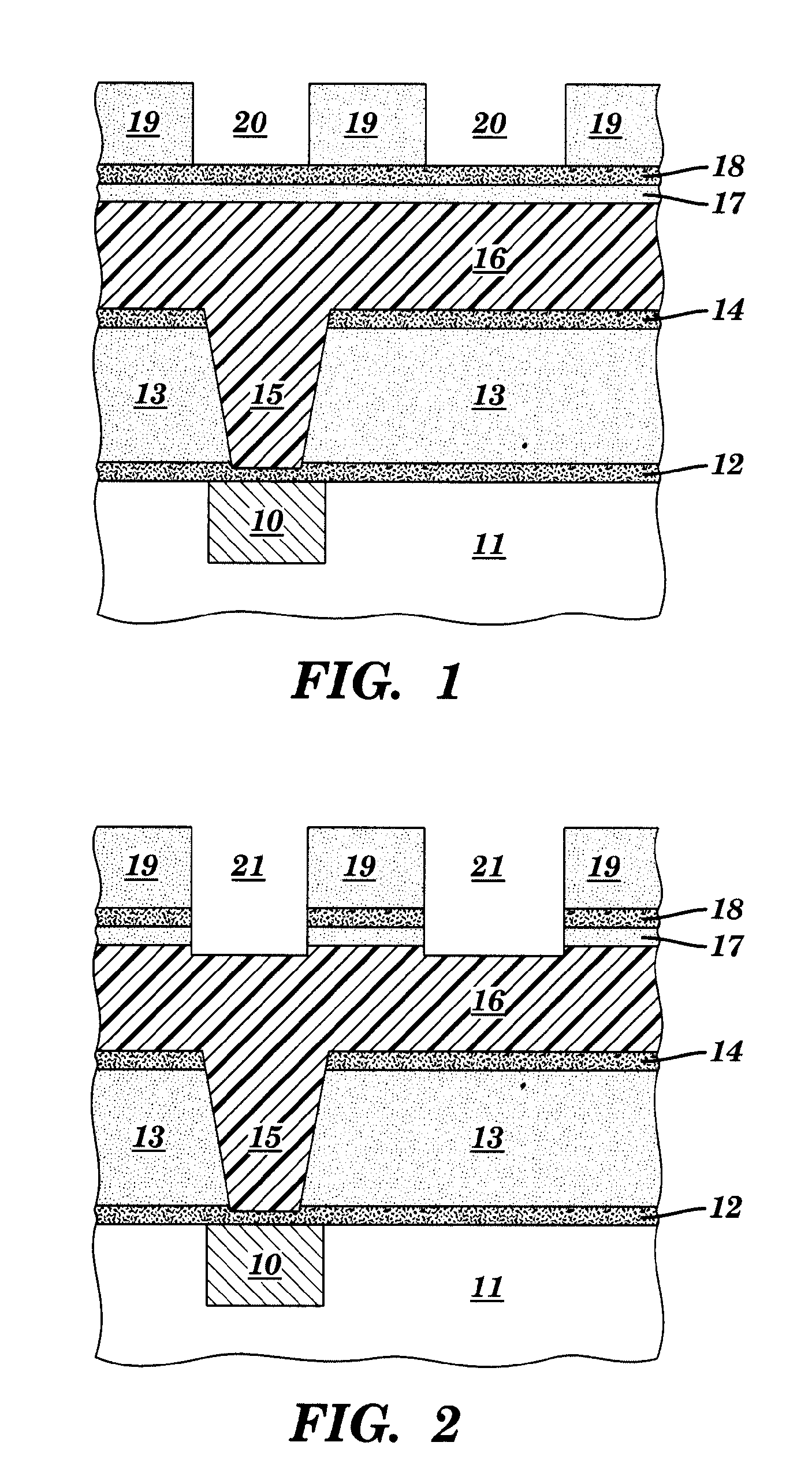

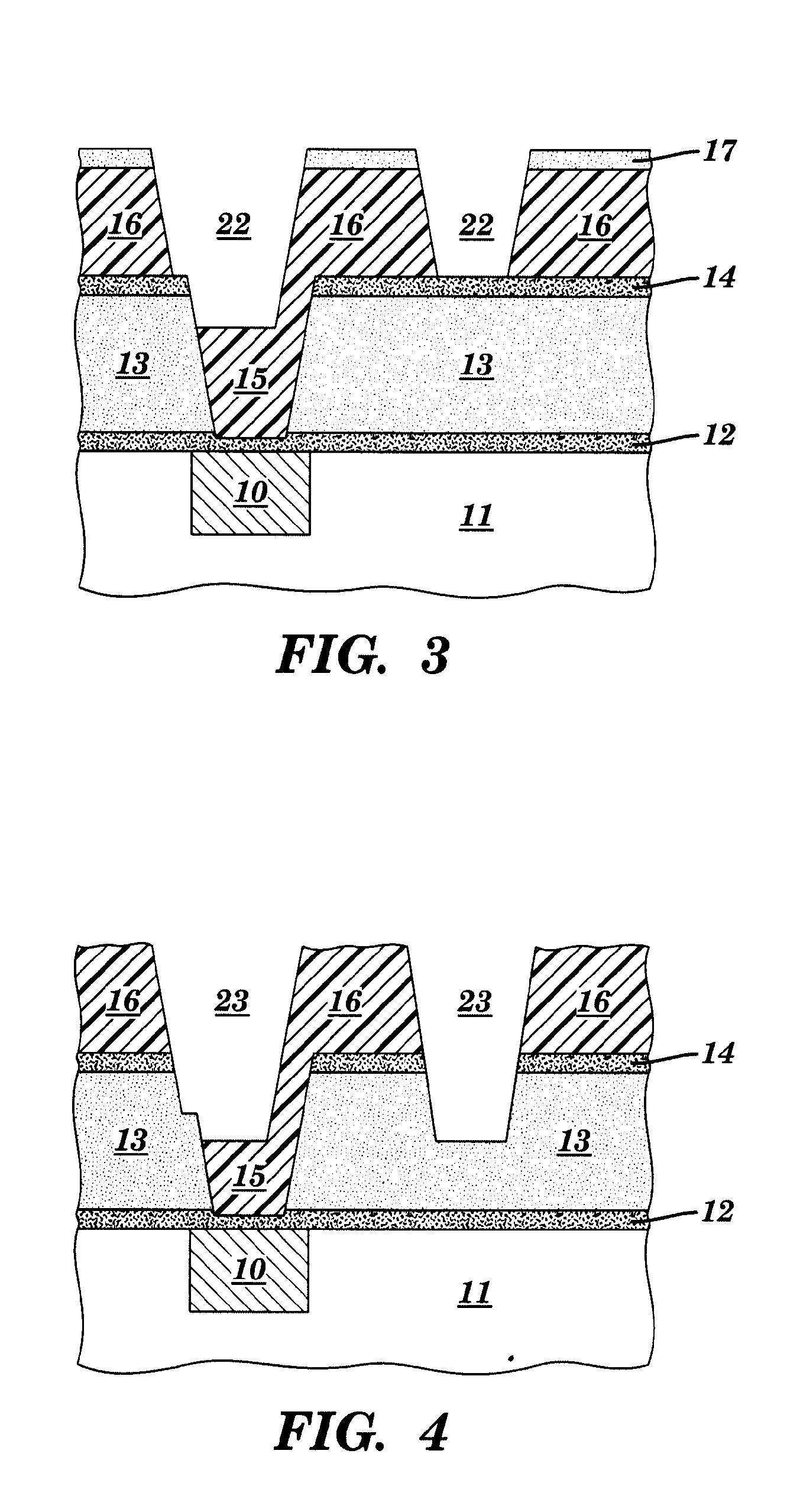

This invention relates to the manufacture of dual damascene interconnect structures in integrated circuit devices. Specifically, a method is disclosed for forming a single or dual damascene structure in a low-k dielectric thin film utilizing a planarizing material and a diffusion barrier material. In a preferred dual damascene embodiment of this method, the vias are formed first in the dielectric material, then the planarizing material is deposited in the vias and on the dielectric material, and the barrier material is deposited on the planarizing material. The trenches are then formed lithographically in the imaging material, etched through the barrier material into the planarizing material, and the trench pattern is transferred to the dielectric material. During and following the course of these etch steps, the imaging, barrier and planarizing materials are removed. The resultant dual damascene structure may then be metallized. With this method, the problem of photoresist poisoning by the interlevel dielectric material is alleviated.

Owner:GLOBALFOUNDRIES US INC

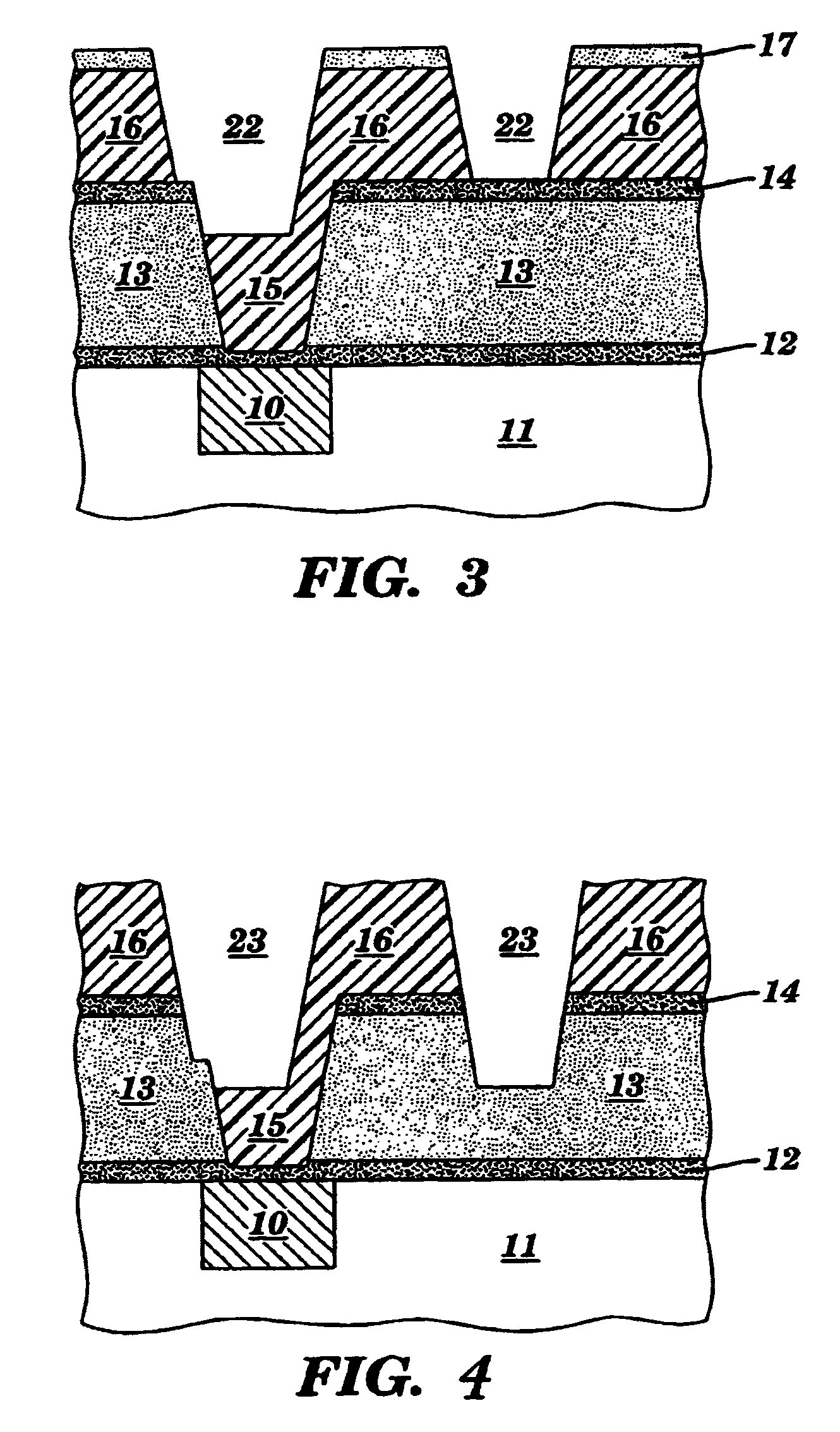

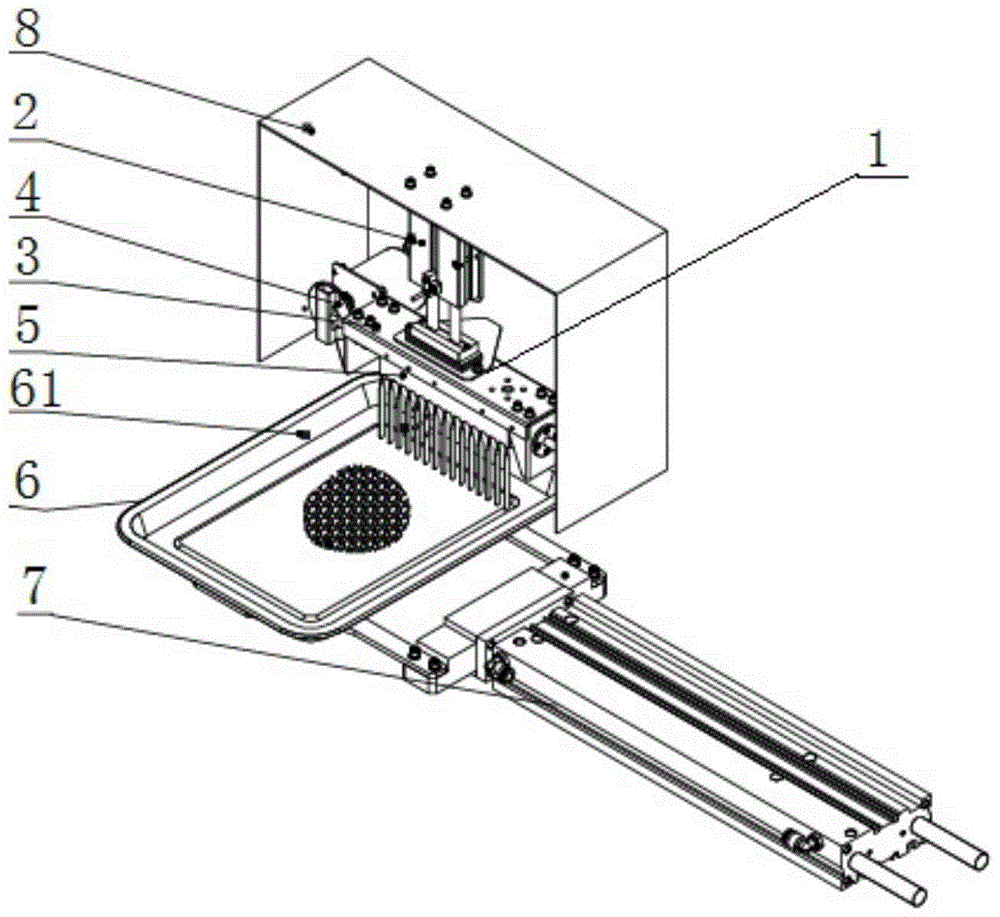

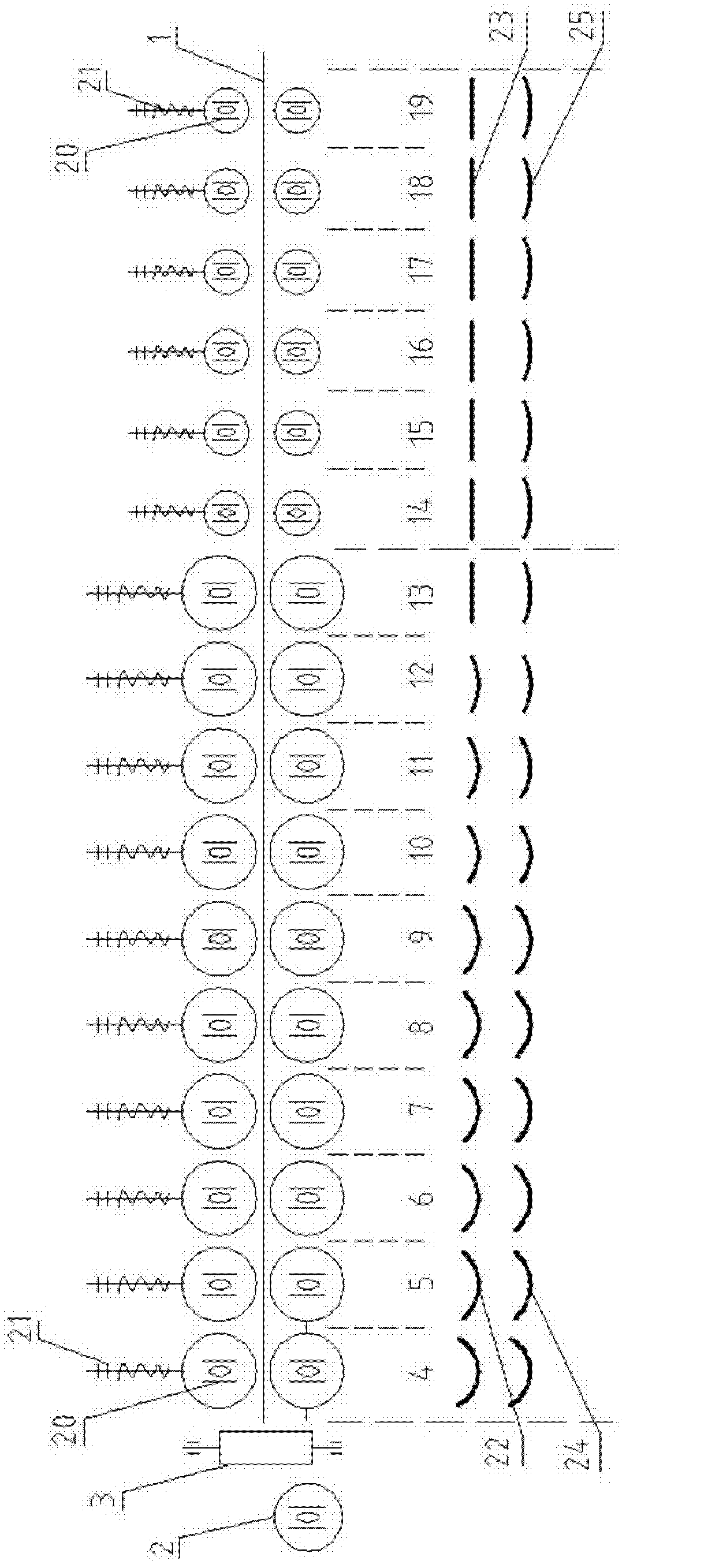

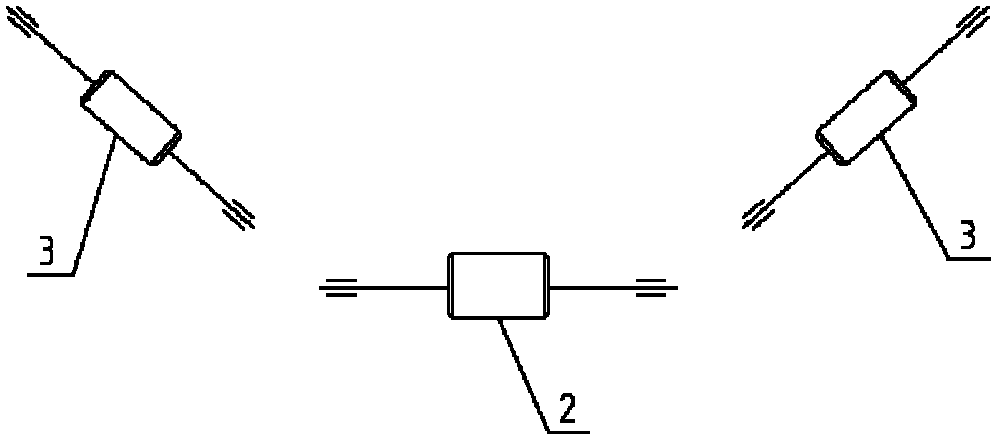

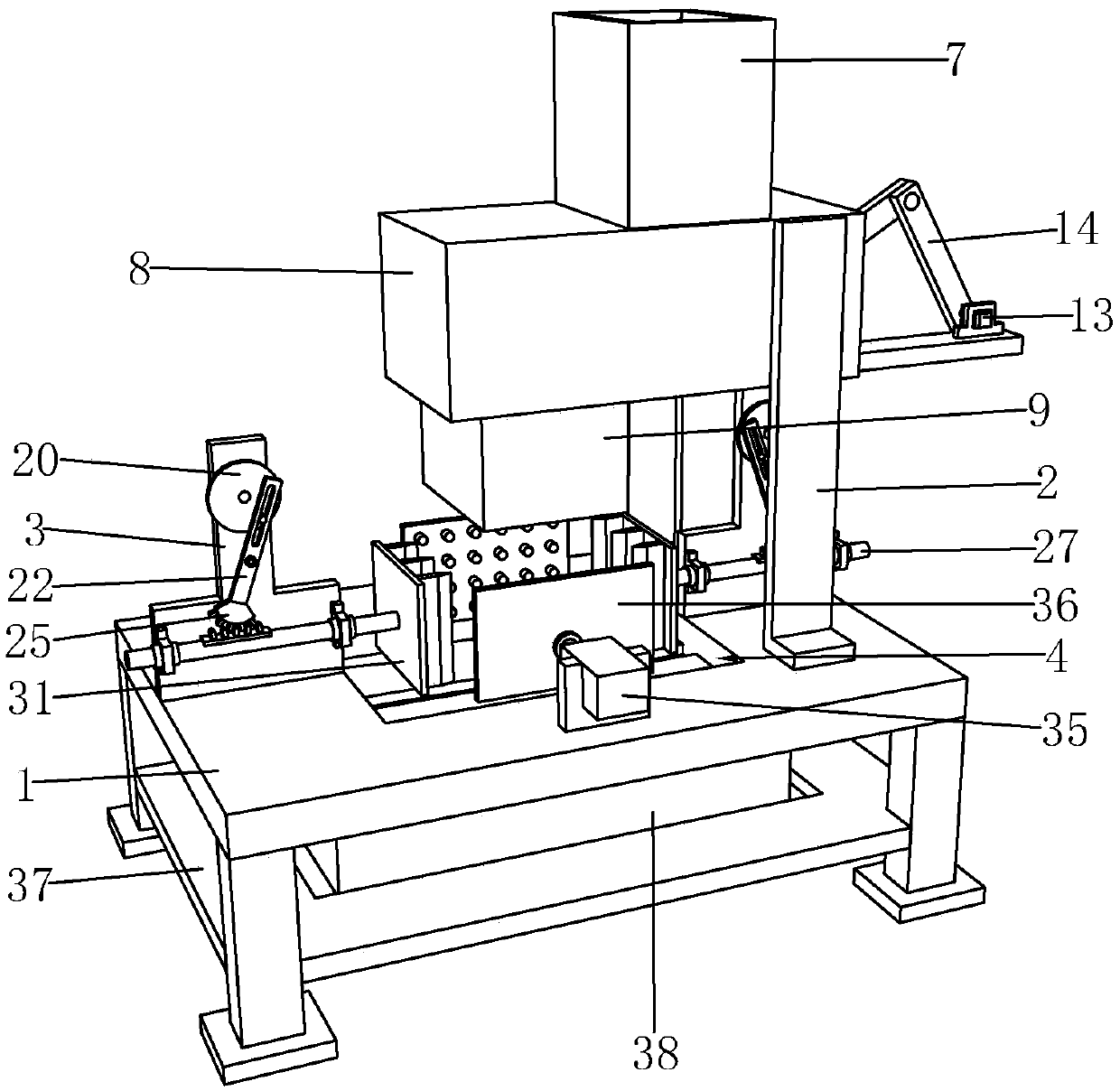

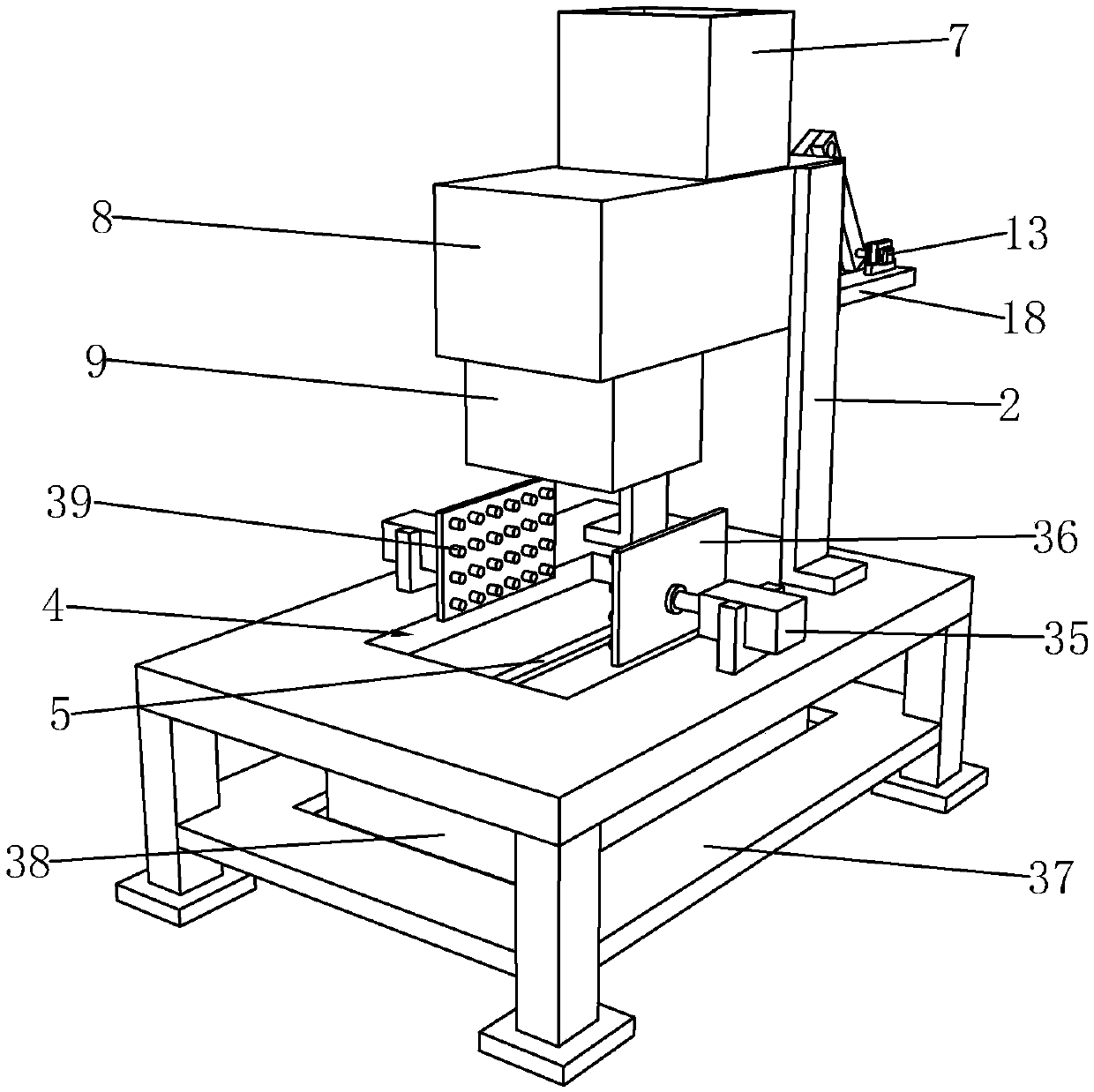

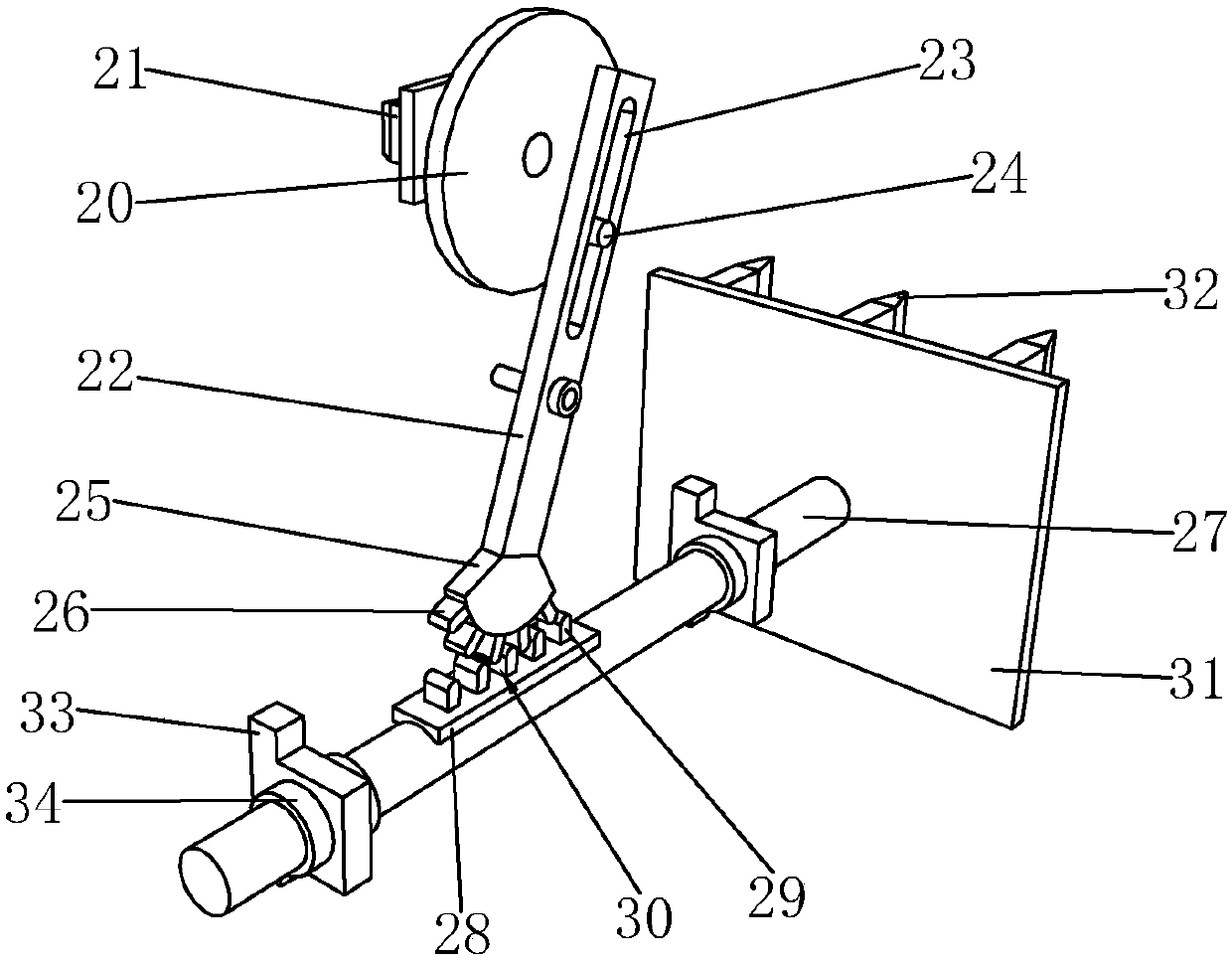

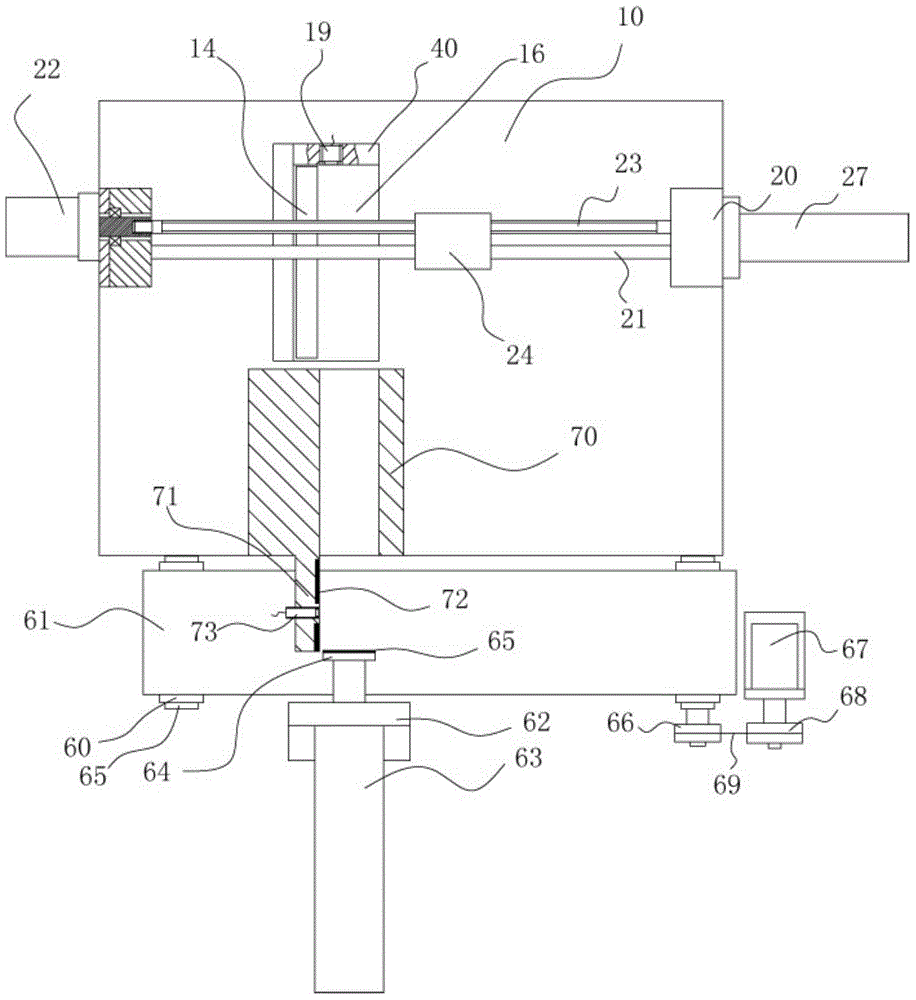

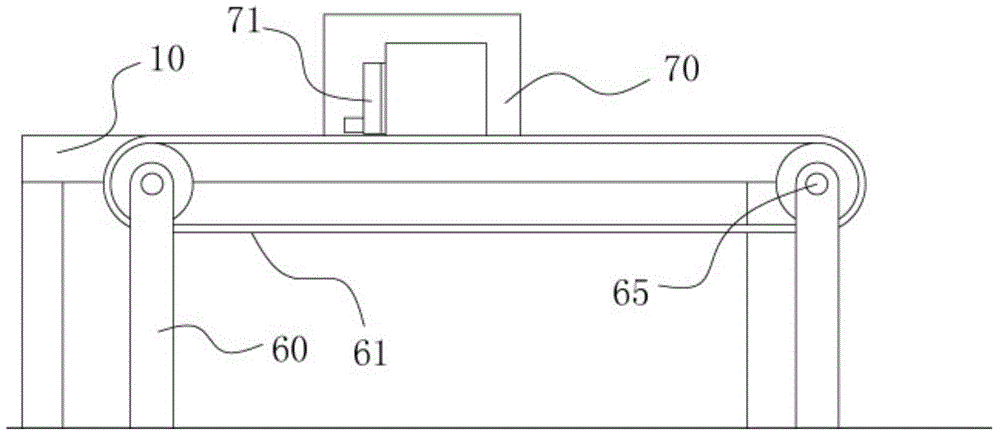

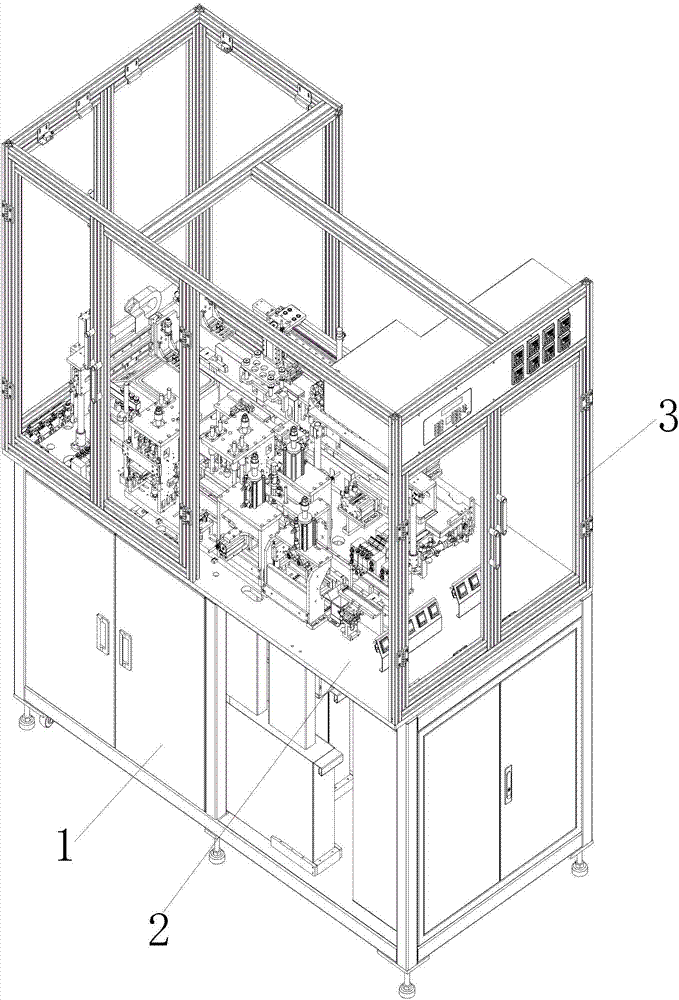

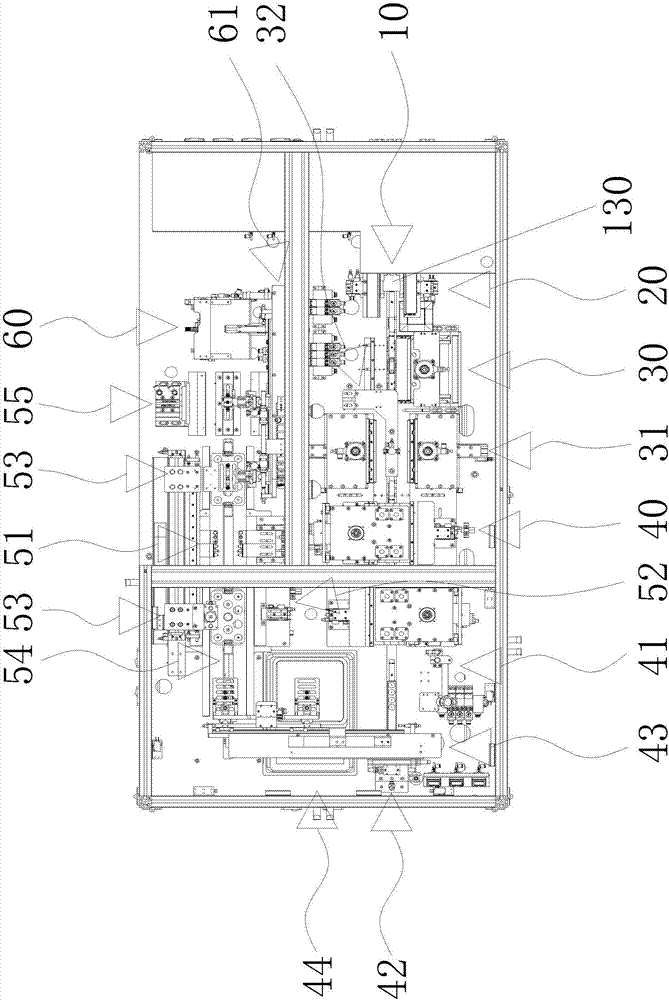

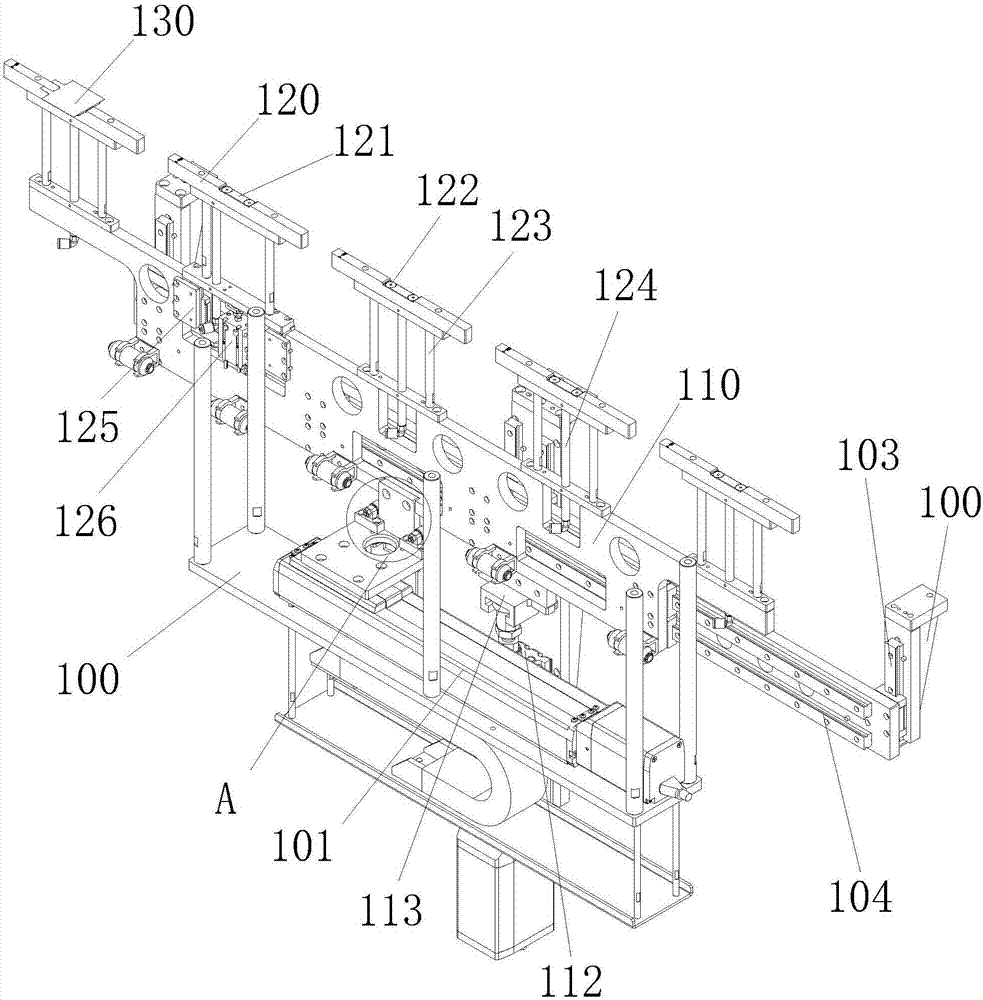

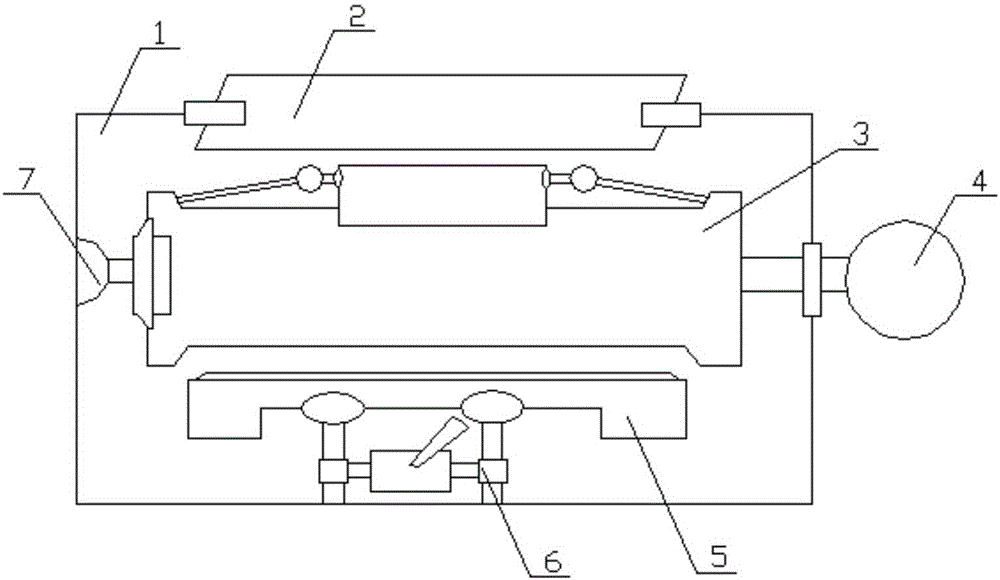

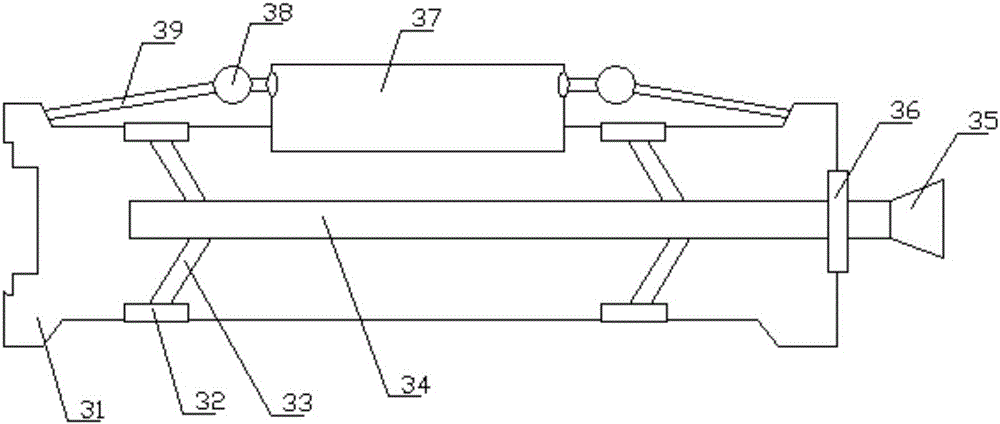

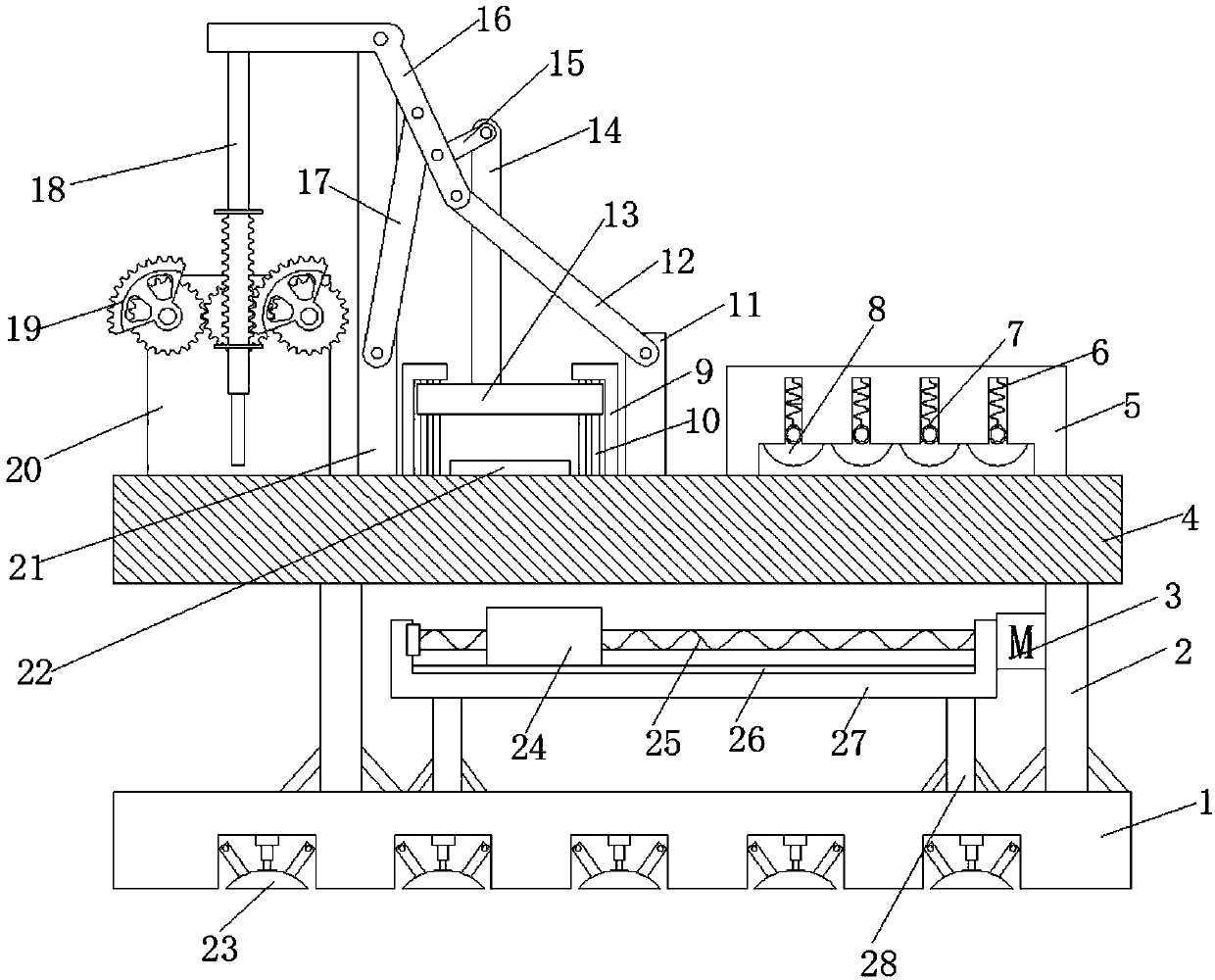

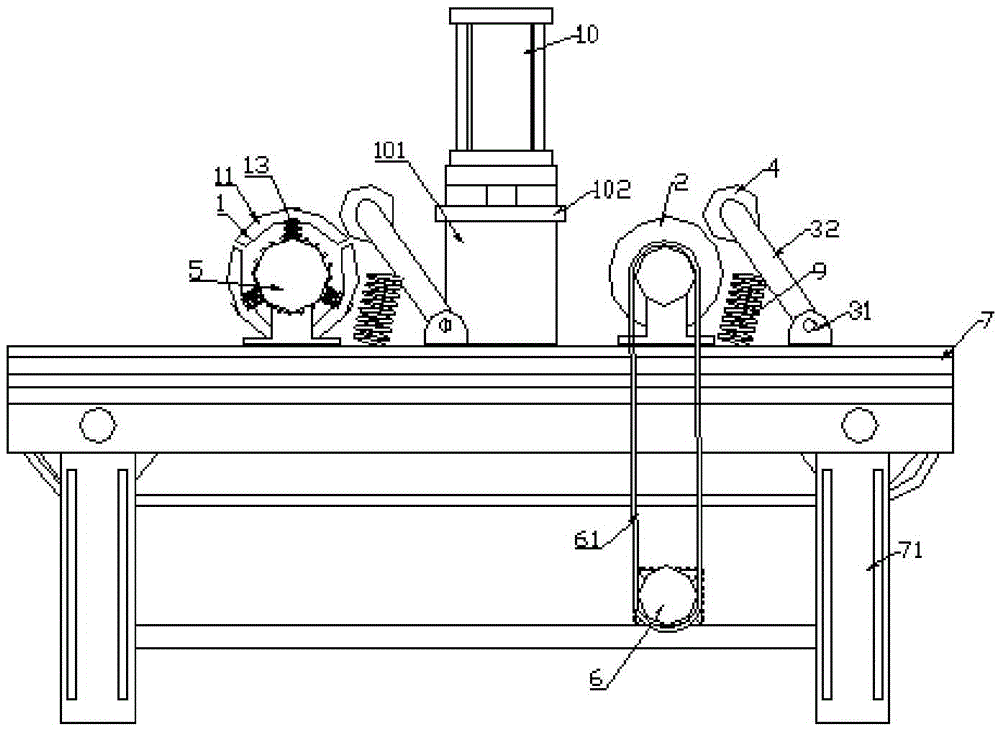

Flattening device and flattening method thereof

ActiveCN105236164AImprove flattening effectImprove the leveling effectLoading/unloadingEngineeringAutomation

The invention relates to the technical field of coal detection equipment, in particular to a flattening device and a flattening method thereof. The flattening device comprises a moving mechanism and a sample placing mechanism below the moving mechanism. The moving mechanism comprises a horizontal driving mechanism, a connection fixing base and a flattening assembly. The flattening assembly comprises a guide rod and a strike-off piece which is fixed below the guide rod and is parallel with the guide rod. The guide rod horizontally penetrates through the connection fixing base. The horizontal driving mechanism is arranged at one end of the guide rod and used for driving the flattening assembly to move in the length direction of the guide rod. The moving mechanism and the sample placing mechanism move vertically and relatively in the direction perpendicular to the sample placing mechanism, and move horizontally and relatively in the direction perpendicular to the guide rod. The flattening device adopts the automatic flattening manner, so that the manual flattening manner is omitted, the degree of automation is high, the applicable flattened sample range is wide, and the flattening efficiency and effect are improved.

Owner:长沙开元仪器有限公司

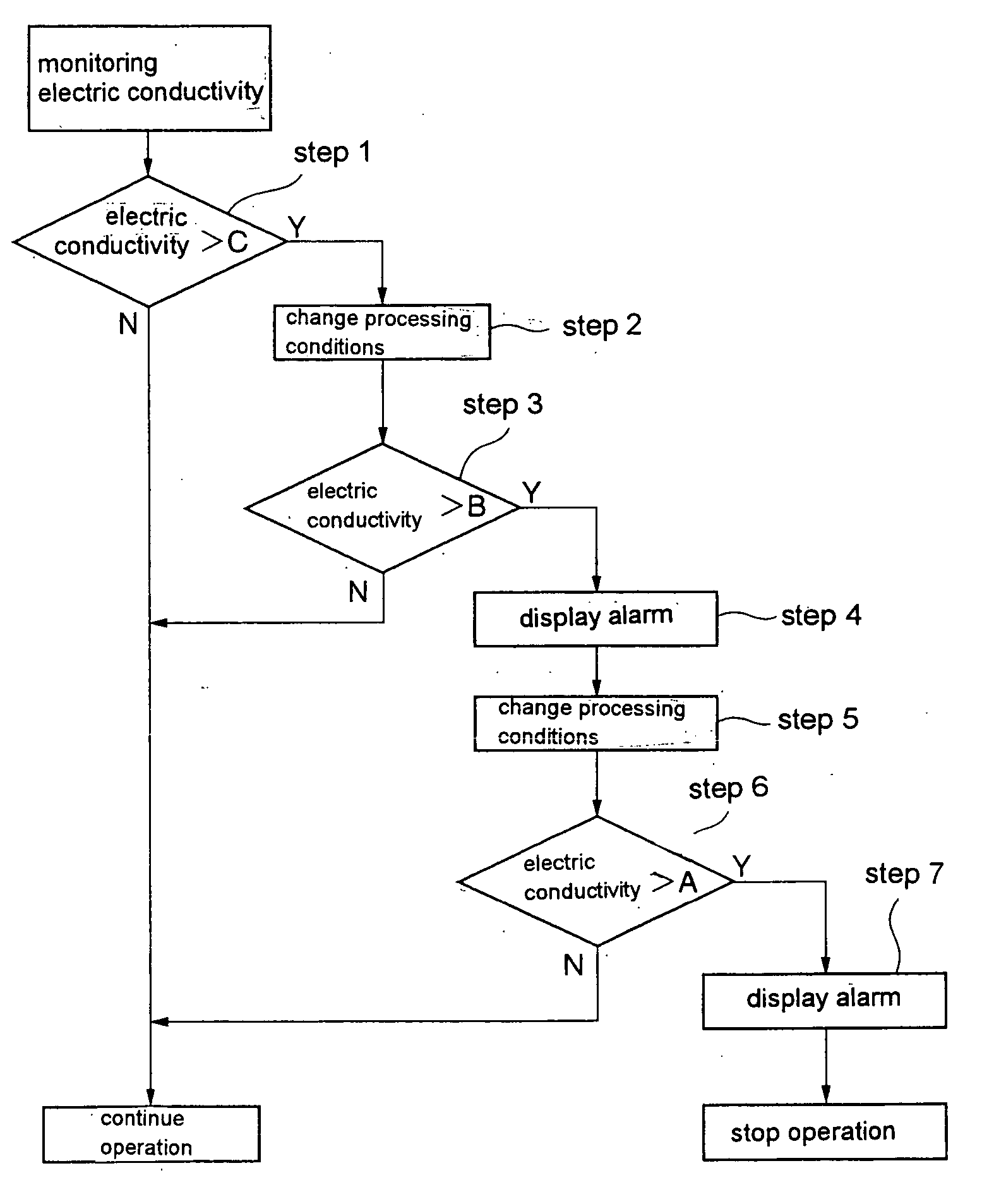

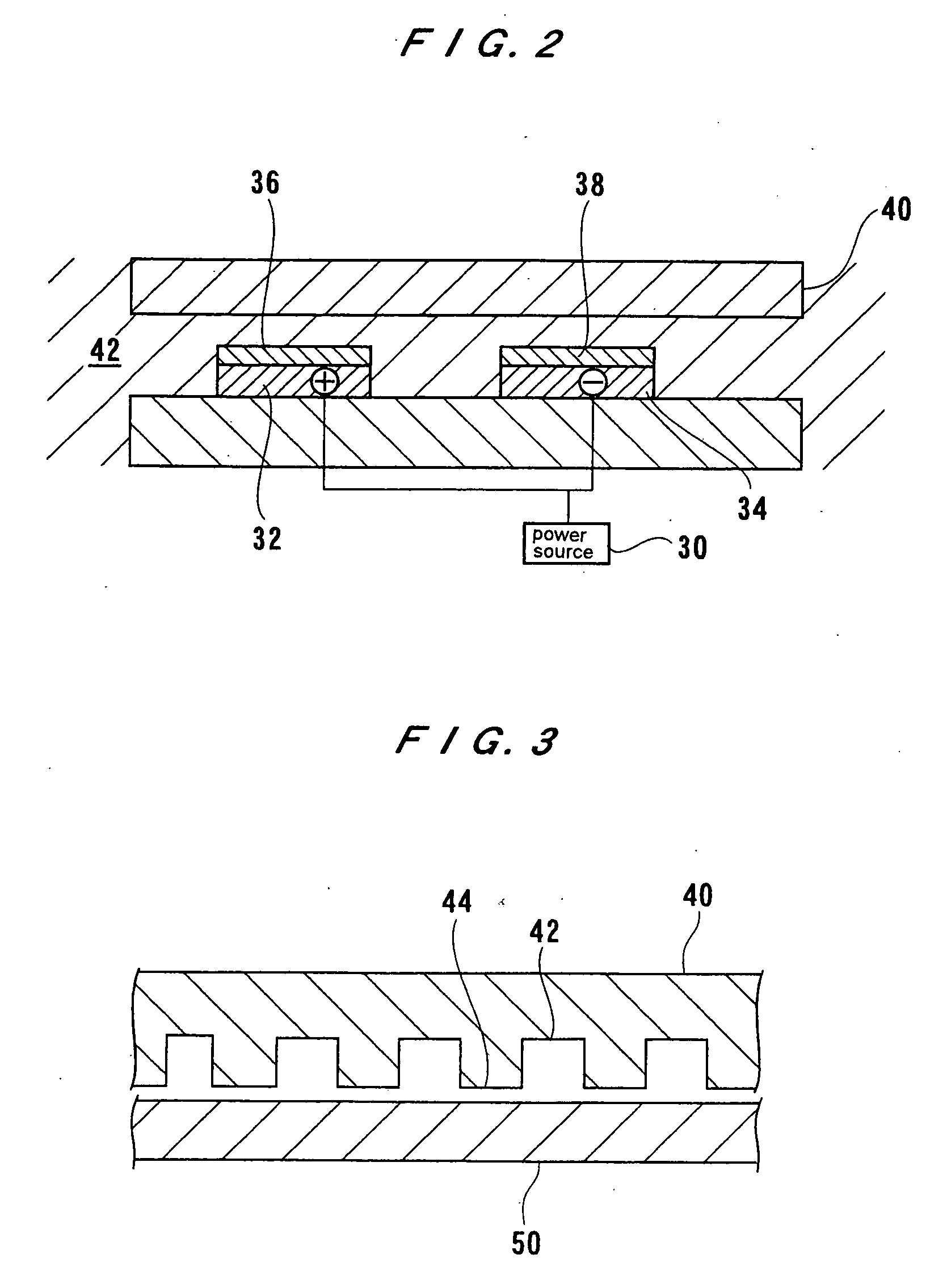

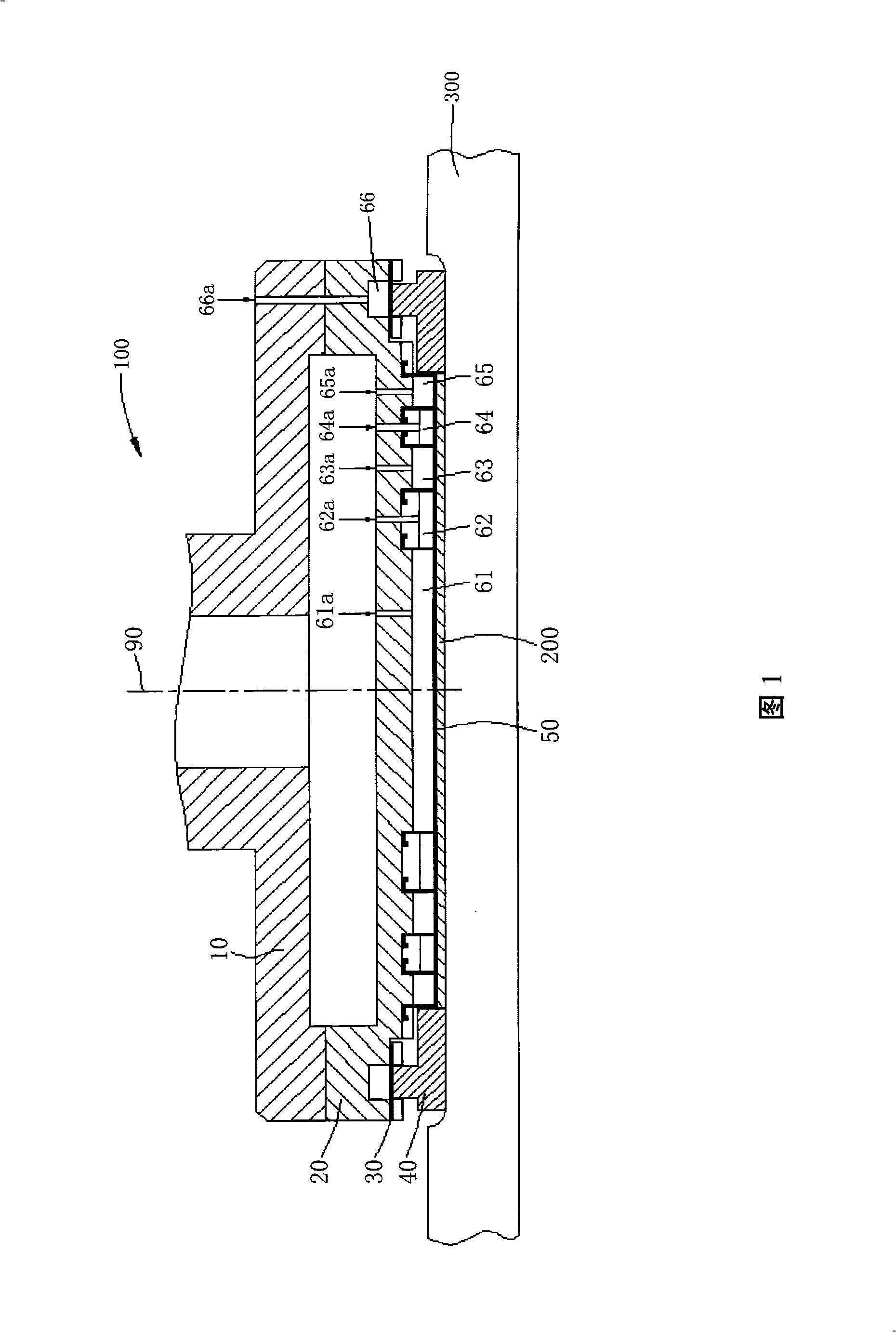

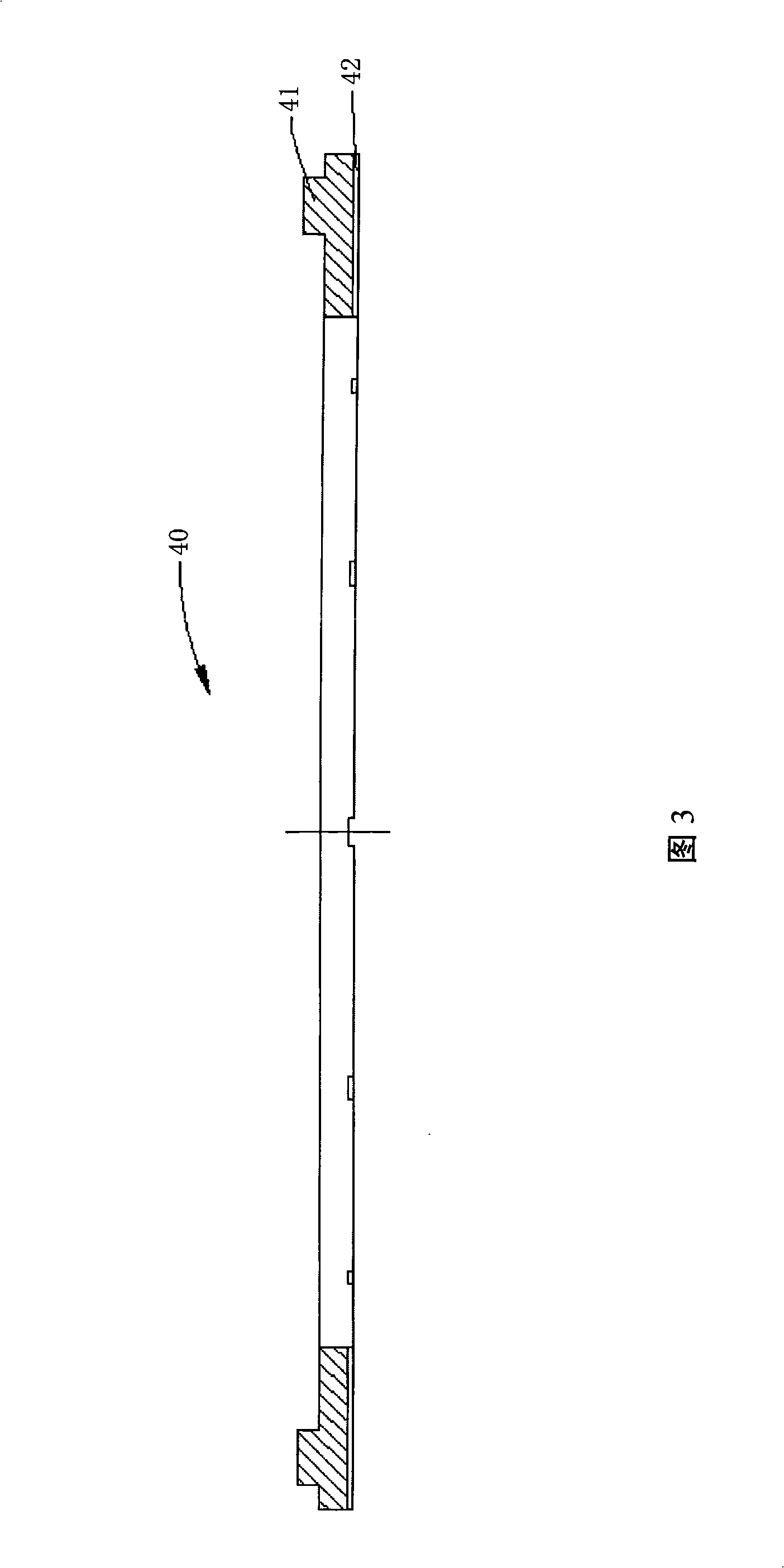

Electrochemical machining device and electrochemical machining method

InactiveUS20060144711A1Suppress change in electric conductivityImprove flattening effectCellsMachining electric circuitsElectricityElectrolysis

A object of this invention is to provide an electrolytic processing method and apparatus that can suppress a change in the electric conductivity of a fluid due to contaminants, such as processing products produced in electrolytic processing, so that the fluid can maintain good flattening properties. The electrolytic processing apparatus of this invention includes: a processing electrode (42) that can come into contact with a workpiece (W); a feeding electrode (44) for feeding electricity to the workpiece (W); a holder (22) for holding the workpiece (W); a power source (26) for applying a voltage between the processing electrode (42) and the feeding electrode (44); a fluid supply section (50) for supplying a fluid between the workpiece (W) and at least one of the processing electrode (42) and the feeding electrode (44); a sensor (80) for measuring the electric conductivity of the fluid; and a control section (84) for changing the processing conditions based on the electric conductivity measured by the sensor (80).

Owner:EBARA CORP

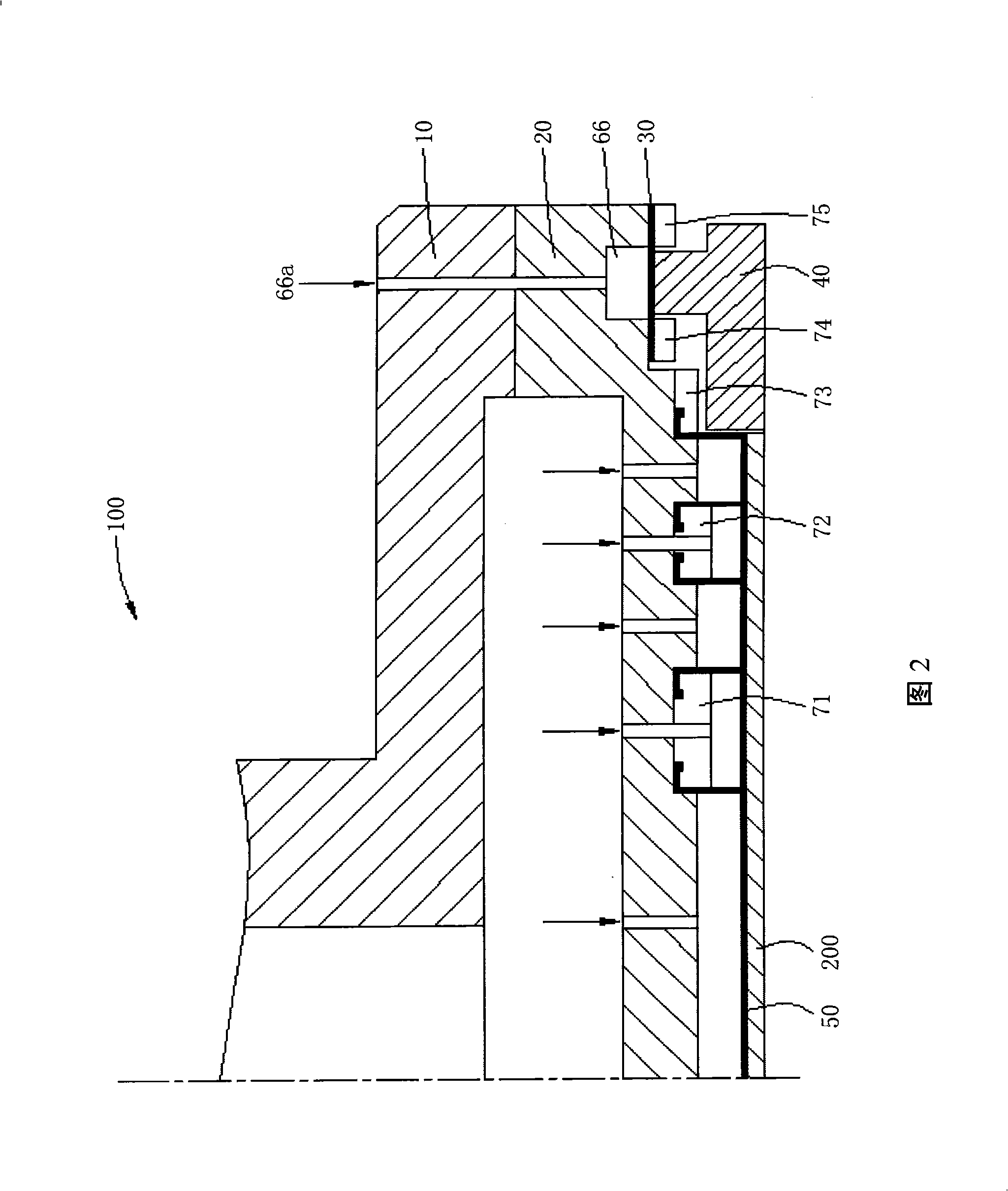

Polishing head for chemico-mechanical polishing

InactiveCN101342679AImprove flattening effectPolishing machinesSemiconductor/solid-state device manufacturingRetaining ringEngineering

The present invention discloses a polishing head used for chemical mechanical polishing. The polishing head comprises a pedestal with an annular groove at the underside edge area, a retaining ring membrane which is fixed under the pedestal and forms a retaining ring chamber with the annular groove, a retaining ring which is floated under the retaining ring chamber by the retaining chamber membrane which is provided with a bag area which is arranged just under the pedestal and is used for containing a wafer, and a multiple-chamber membrane which is provided with a circular plane and is assembled with a plurality of concentric annular ribs. The circular plan, the concentric annular ribs and the lower surface of the pedestal form a plurality of mutually independent concentric annular chambers. During the polishing process, the polishing head can apply different lower pressures on different areas at the back of the wafer by the concentric annular chambers, so as to obtain good uniformity.

Owner:TSINGHUA UNIV

Method for forming damascene structure utilizing planarizing material coupled with compressive diffusion barrier material

ActiveUS20050079701A1Improve flattening effectImprove manufacturabilitySemiconductor/solid-state device manufacturingDiffusion barrierPhotoresist

This invention relates to the manufacture of dual damascene interconnect structures in integrated circuit devices. Specifically, a method is disclosed for forming a single or dual damascene structure in a low-k dielectric thin film utilizing a planarizing material and a compressive diffusion barrier material. The barrier material preferably has a compressive stress of greater than 300 MPa. In a preferred dual damascene embodiment of this method, the vias are formed first in the dielectric material, then the planarizing material is deposited in the vias and on the dielectric material, and the barrier material is deposited on the planarizing material. The trenches are then formed lithographically in the imaging material, etched through the barrier material into the planarizing material, and the trench pattern is transferred to the dielectric material. During and following the course of these etch steps, the imaging, barrier and planarizing materials are removed. The resultant dual damascene structure may then be metallized. With this method, the problem of photoresist poisoning by the interlevel dielectric material is alleviated.

Owner:GLOBALFOUNDRIES US INC

Bamboo block thermal shaping method and device

ActiveCN102632532AImprove flattening effectRealize continuous productionWood working apparatusEngineeringMachining

The invention discloses a bamboo block thermal shaping method and device. The bamboo block thermal shaping method provided by the invention is a machining method for implementing the shaping of the walls of the bamboos and comprises the following steps of: extruding and unfolding bamboo blocks by utilizing multiple grades of bunching gradient profile rollers by means of certain thermoplasticity of the walls of the bamboos which are boiled and are softened at high temperature under the allowed condition of horizontal allowed stress of the bamboo materials, and cooling and shaping. The device provided by the invention mainly comprises a horizontal support roller and lateral guide rollers, wherein the horizontal support roller which is used for conveying arc bamboo blocks is installed below the foremost end of a rack platform; the lateral guide rollers are installed at two sides at the front end of the rack platform; the rack platform is also sequentially provided with a first grade profile roller, other multiple-grade profile rollers and multiple-grade cooling and shaping rollers; and the profiles of the upper roller and the lower roller of each grade profile roller are matched with a flower-type unfolding pattern of the shaping for the bamboo materials. The device provided by the invention is simple in structure, and is convenient to use, and the integrity and horizontal intensity of the walls of the bamboos after being shaped are ensured, thus the arc bamboo blocks are unfolded into bamboo sheets with good integrity under the pressure of rolling.

Owner:HUNAN ACAD OF FORESTRY

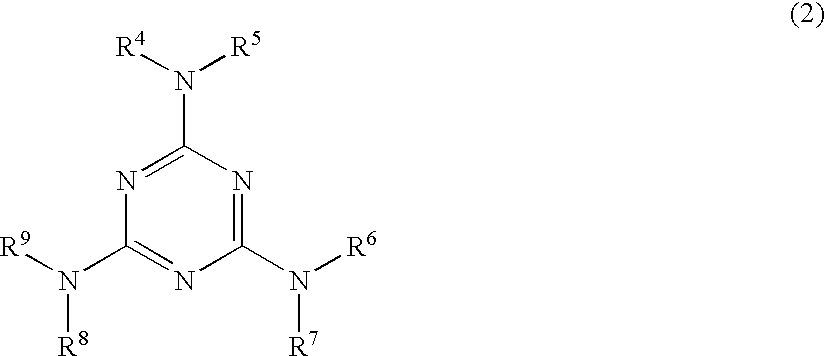

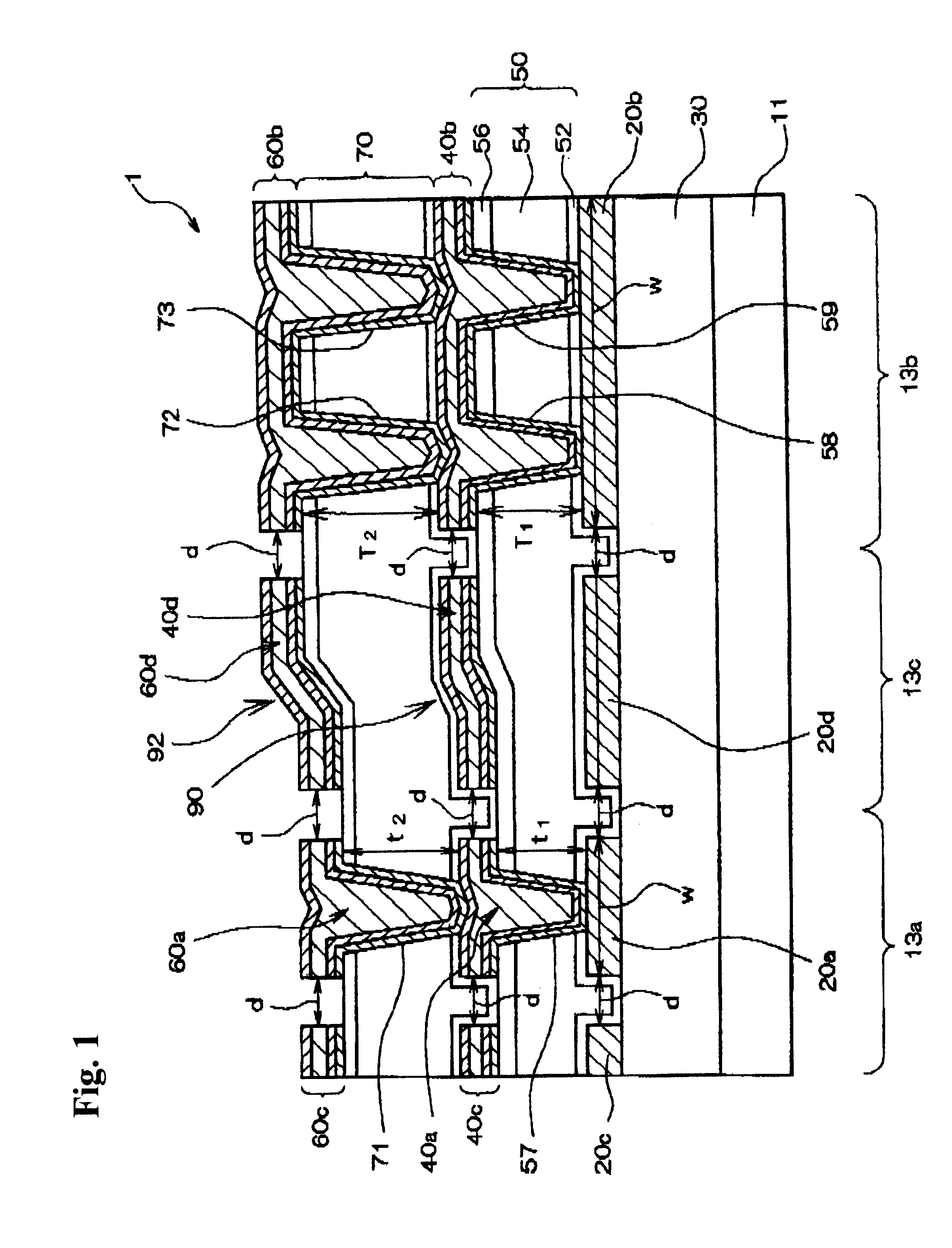

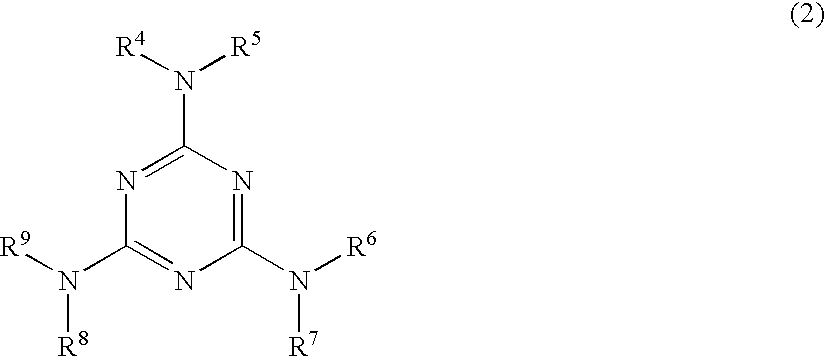

Radiation-sensitive composition, insulating film and organic EL display element

InactiveUS6797450B2Improve flattening effectHigh transparencySolid-state devicesSemiconductor/solid-state device manufacturingHigh resistanceResist

According to the present invention, there are provided an insulating film for an organic EL element, which has sufficiently low water permeability and a good sectional form and whose reactivity with a basic material and an electrode made from a metal having a low work function is suppressed, an insulating film for an organic EL element, which enables the formation of a through hole or U-shaped cavity therein and has excellent flattening performance, high transparency and high resistance to a resist stripper, and a radiation sensitive resin composition for forming the insulating film.An organic EL display element having this insulating film is free from an emission failure and has sufficiently long luminance half-life period and excellent reliability.The above composition comprises an alkali-soluble resin which may have an epoxy group and a 1,2-quinonediazide compound.

Owner:JSR CORPORATIOON

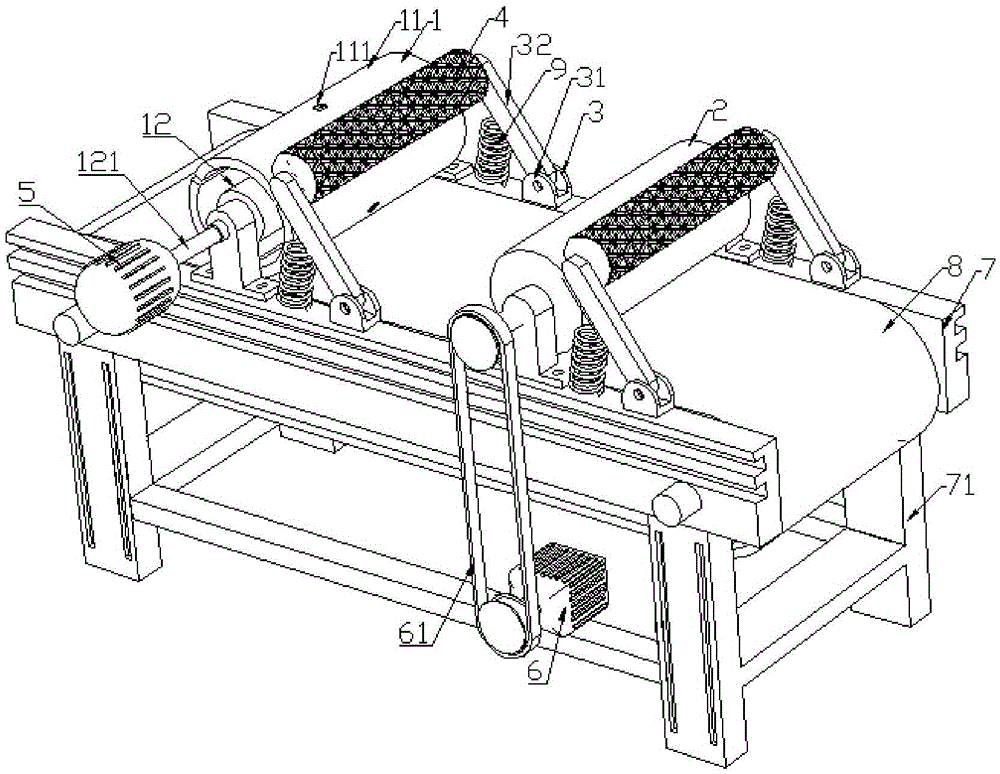

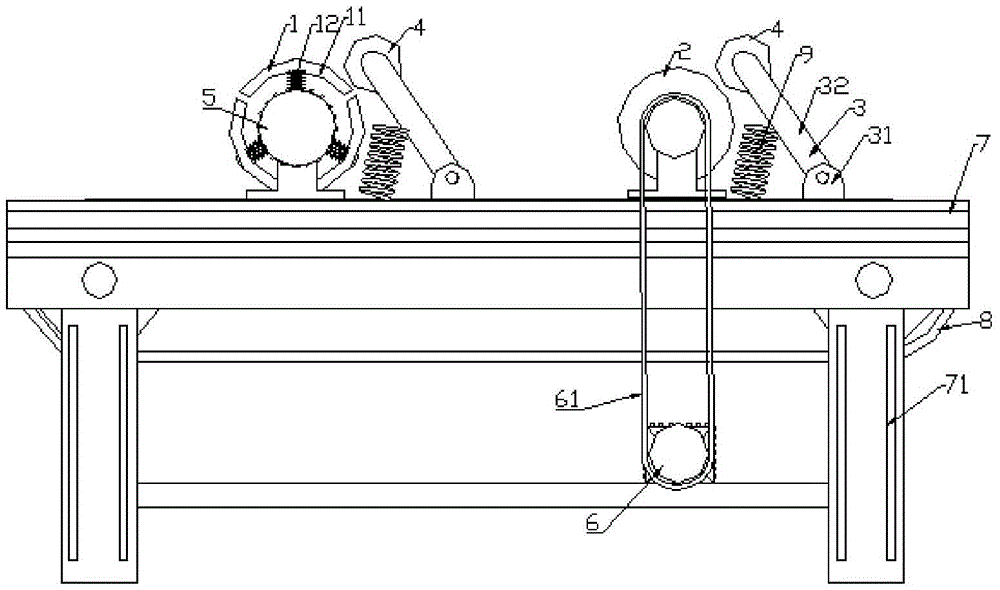

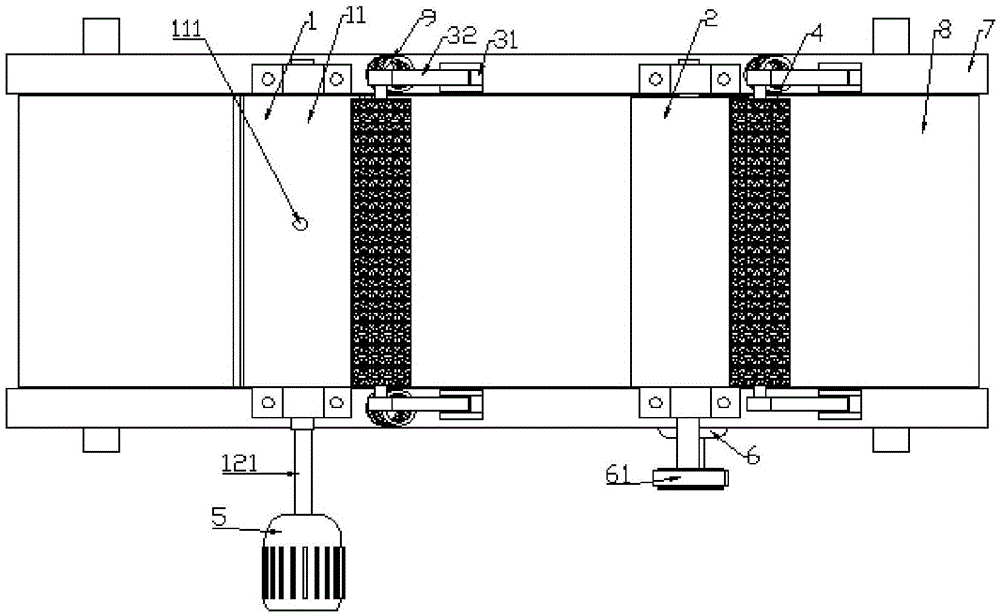

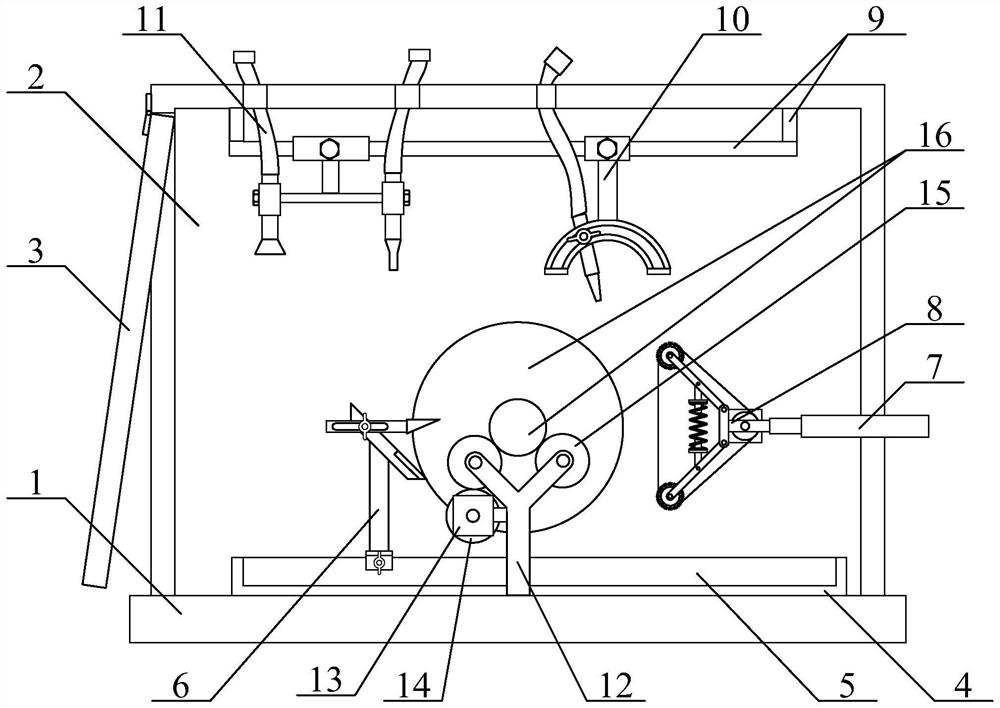

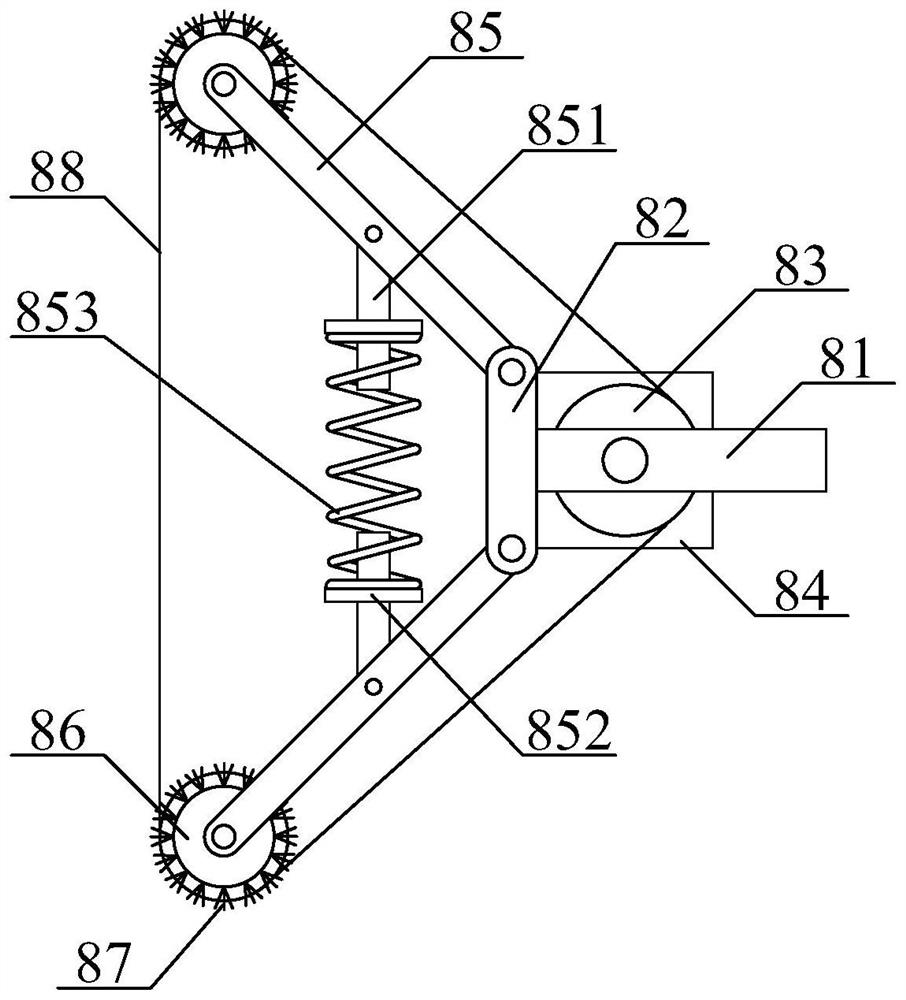

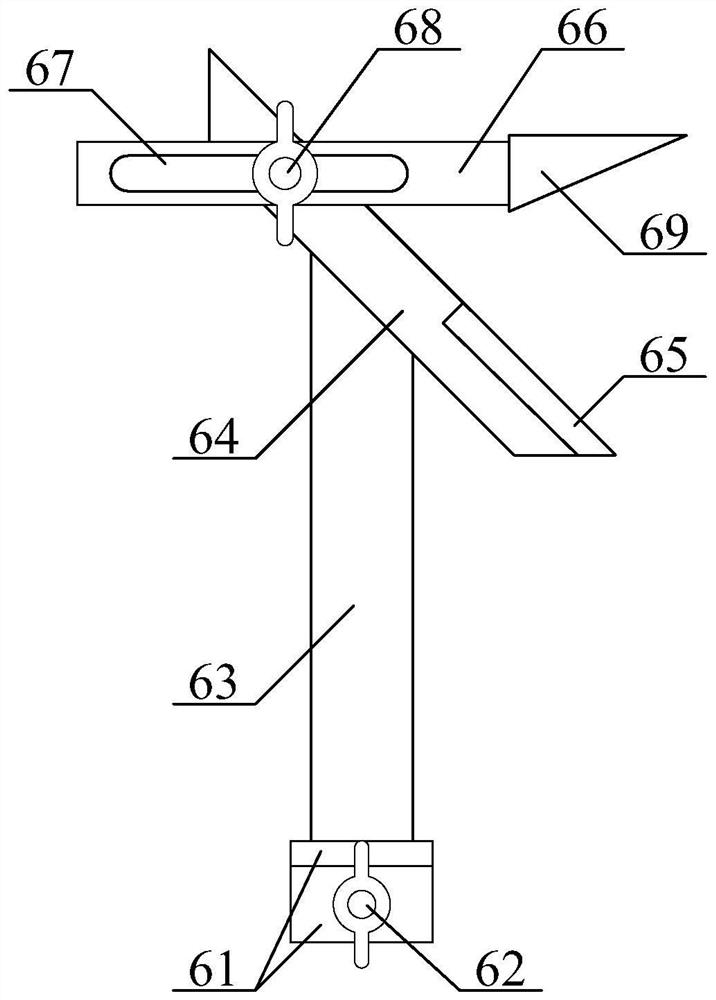

Paper currency flattening and arranging device

InactiveCN105354918AHigh speedGood flattening effectCoin/currency accepting devicesMicrocomputerMicrocontroller

The invention discloses a paper currency flattening and arranging device. The paper currency flattening and arranging device comprises a single-chip microcomputer as well as a first-stage flattening mechanism and a second-stage flattening mechanism which are controlled by the single-chip microcomputer; the first-stage flattening mechanism is clamped onto a base and is detachably connected with the second-stage flattening mechanism; the first-stage flattening mechanism comprises two supporting plates, an upper-and-down movement shaft and a first rolling shaft which are fixed between the two supporting plates and are parallel to each other, and a first money feeding opening provided with a sensor, wherein the first money feeding opening is located above the upper-and-down movement shaft and the first rolling shaft; the second-stage flattening mechanism comprises a second money feeding opening, a money discharging opening and the base; a recessed cavity is formed in the base; and a second rolling shaft and a third rolling shaft which are parallel to each other are arranged in the recessed cavity. According to the paper currency flattening and arranging device provided by the invention, friction can be provided for paper currencies through relative movement between the shafts, and therefore, dog-eared and wrinkled paper currencies can be flattened, and a plurality of folded paper currencies can be also flattened. The paper currency flattening and arranging device has the advantages of high speed, excellent flattening and pressing effects and high processing efficiency, and can assist in saving a lot of time for subsequent counting and classification.

Owner:GUANGDONG UNIV OF TECH

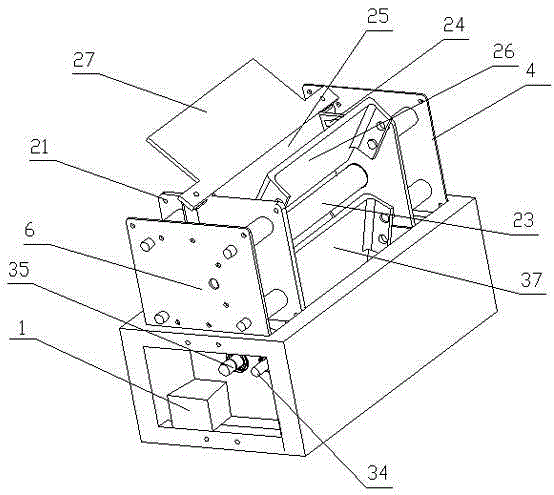

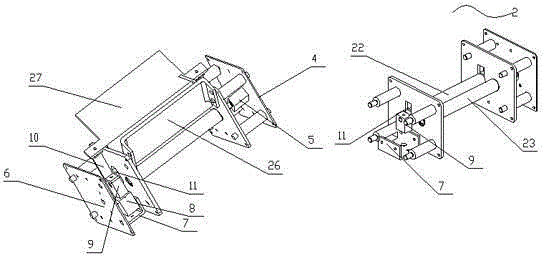

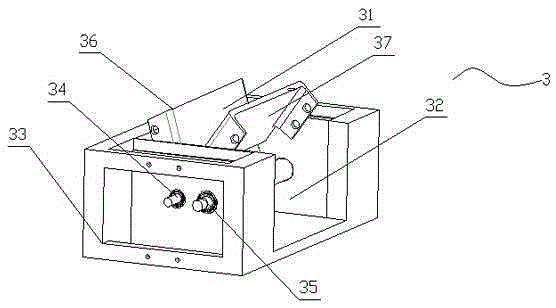

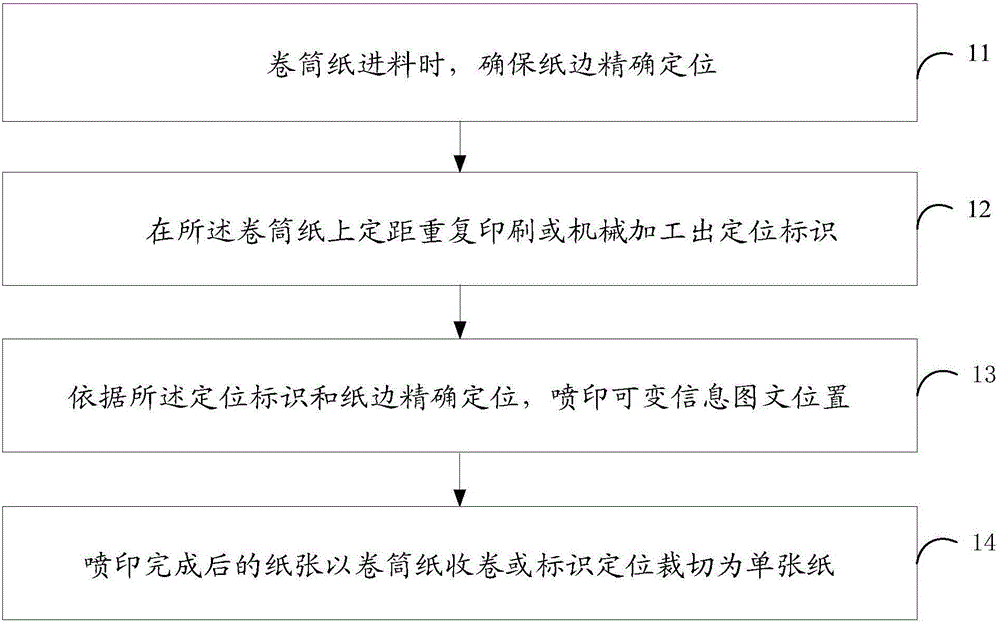

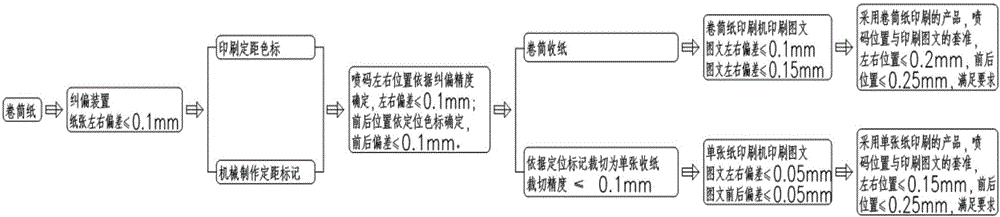

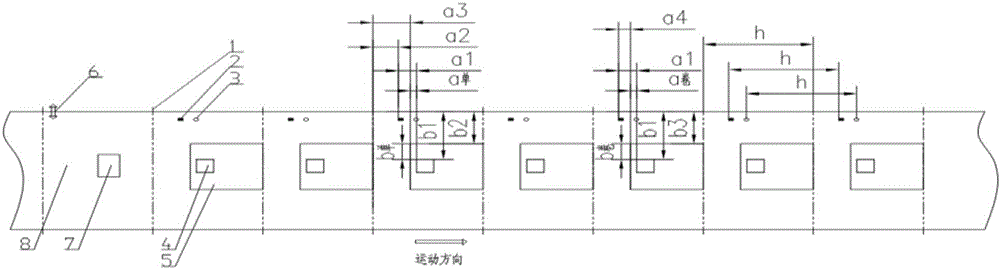

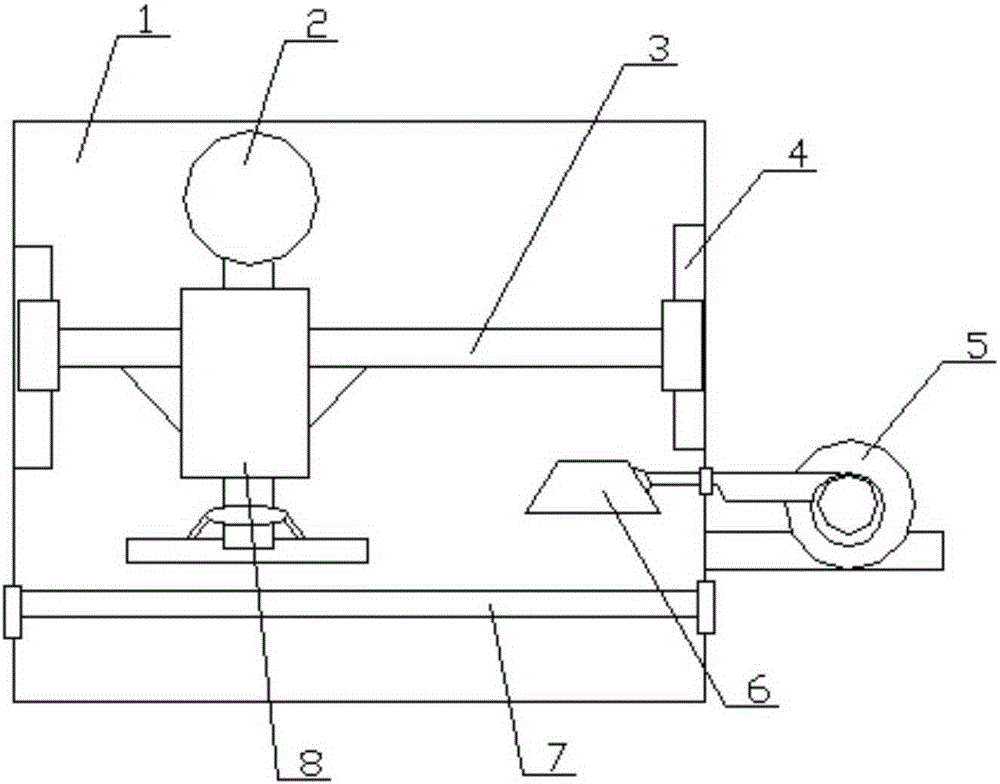

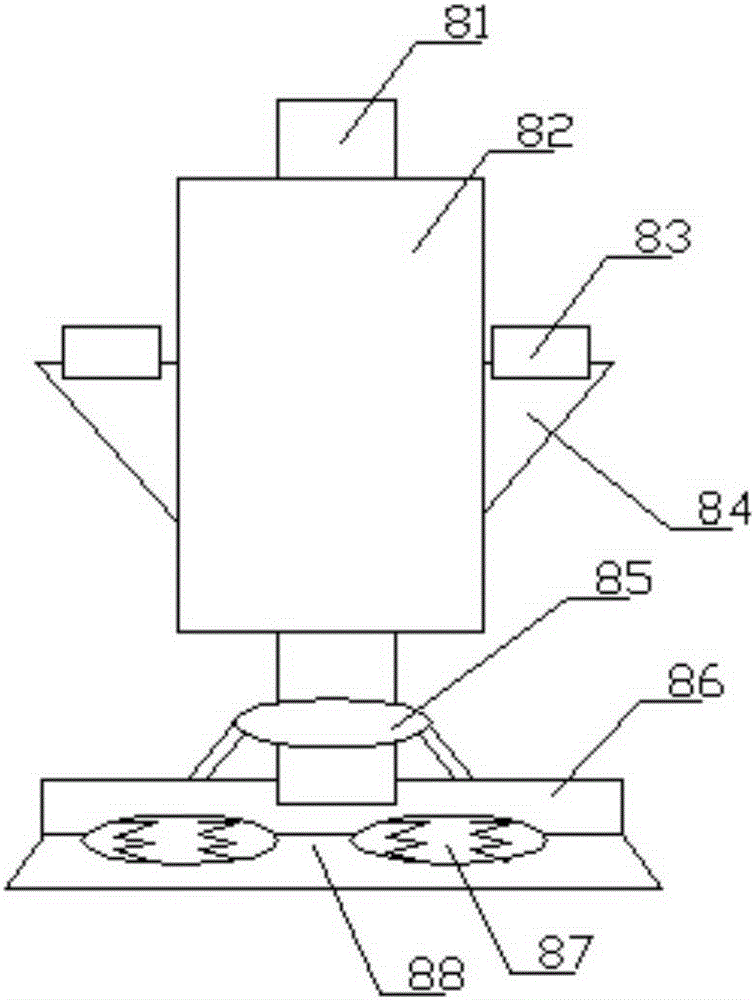

Method and system for printing variable graphic and text information on printed product

InactiveCN105774280ASolve registration problemsSolve pollutionDuplicating/marking methodsOther printing apparatusGraphicsRolling paper

The invention discloses a method and a system for printing variable graphic and text information on a printed product. The method comprises the steps of guaranteeing the accurate positioning of paper margins when roll paper is fed; repeatedly printing or machining positioning marks on the roll paper at a certain distance; printing the position of the variable graphic and text information according to the positioning marks and the accurate positioning of the paper margins; after printing, rolling the roll paper or cutting the paper into single sheets by positioning according to the marks. According to the technical scheme of the embodiment, the process of spraying a code first and then printing is adopted, so that the problem of registration of the printed product and the printed variable graphic and text information is preferably solved, additionally, the problems that the paper is flattened so as to increase the printing quality and an inkjet head is polluted by dust on the printed product are solved, the matching problem of the speed of a printing machine and the printing speed is solved, and the matching problem of printing gloss oil and printing ink is solved.

Owner:XINXIANG XINJI RUIBO PRINTING MACHINERY CO LTD

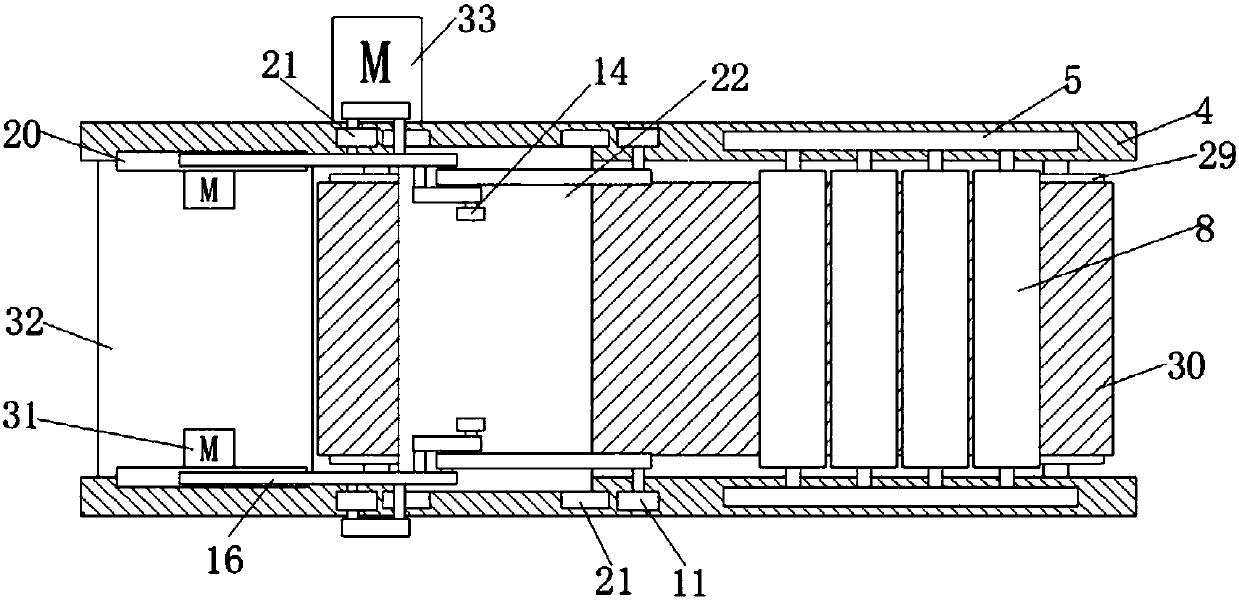

Cloth flat pressing equipment

The invention relates to the technical field of mechanical equipment, in particular to cloth flat pressing equipment. The cloth flat pressing equipment comprises a host machine body and also comprises an operation table, an ascending and descending rail, a cross beam, a second flat pressing component, a first driving component, a second driving component and a first flat pressing component, wherein the second flat pressing component comprises a guide tube body, a main transmission shaft, a side edge sliding wing, a slide seat, an installing disc, a rotating connecting seat, a press disc and an inner regulating element. The cloth flat pressing equipment has the advantages that the operation is convenient; the regulation is convenient; the flat pressing effect is good; the flat pressing efficiency is high.

Owner:苏州盛泽科技创业园发展有限公司

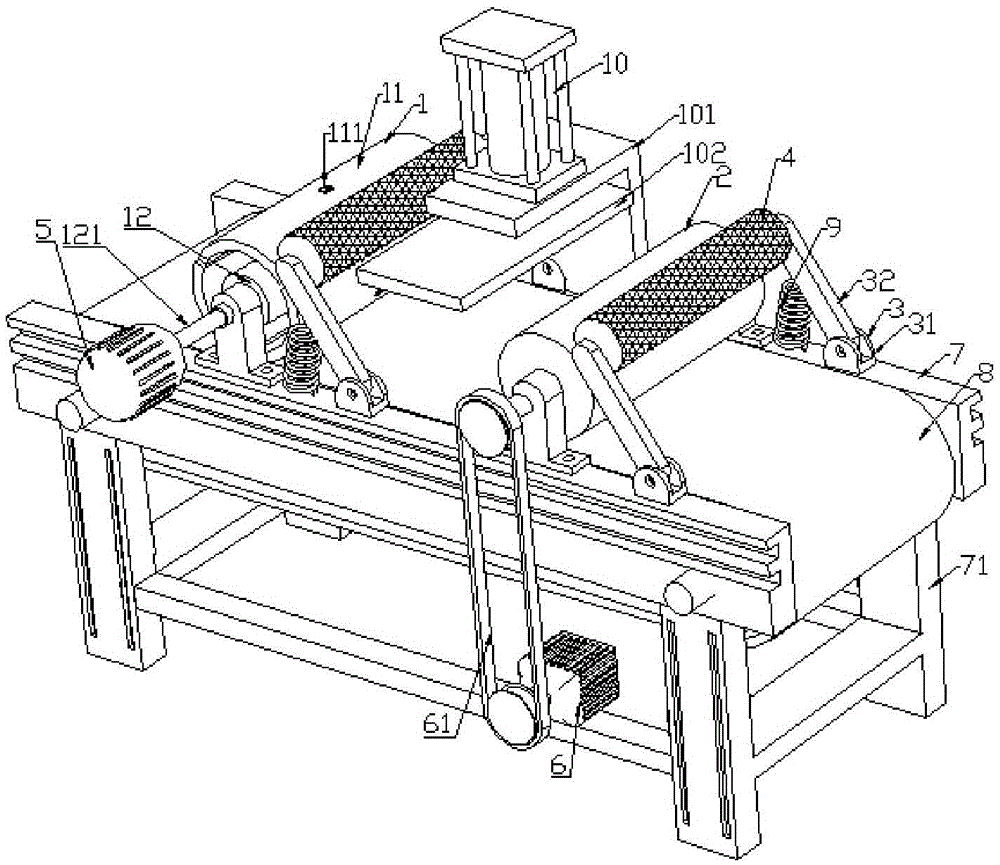

Flattening mechanism for textiles

InactiveCN105479791AClean up in timeImprove flattening effectCleaning using toolsRotary pressFiberAnnular array

The invention provides a flattening mechanism for textiles. The flattening mechanism comprises a conveying belt, and a pre-pressing roller and a flattening roller are sequentially arranged above the conveying belt; the pre-pressing roller comprises an inner roller and outer roller blades, the inner roller is cylindrical, the outer roller blades are arranged along the central axis of the inner roller in a ring array mode, the outer edge lines of the outer roller blades form an arc surface, a screw hole a is formed in the inner roller, screw holes b corresponding to the screw hole a are formed in the outer roller blades respectively, and the inner roller and the outer roller blades are fixedly connected through screws penetrating through the screw hole a and the screw holes b; a cleaning mechanism is arranged above the conveying belt and comprises a brush roller, and the brush roller makes contact with the pre-pressing roller and the flattening roller. According to the invention, the cleaning mechanism is arranged so that cotton fibers and the like can be cleared any time; the pre-pressing roller is adjustable in diameter so as to be capable of being used for flattening raw cotton material of different thicknesses; the raw cotton material is pressed twice, so that the flattening effect is good.

Owner:TIANJIN JIAXUAN TEXTILE

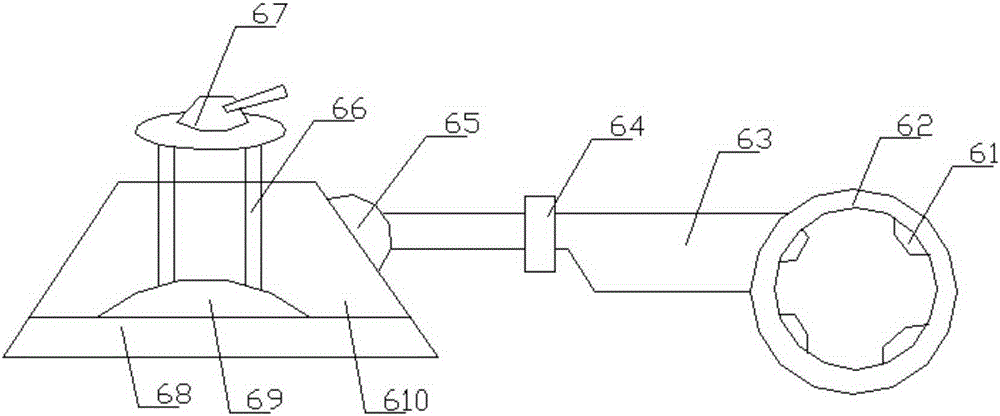

Flattening device for waste carton recycling

InactiveCN109530393AEasy to recycleQuick Unified CollectionSolid waste disposalMetal working apparatusPunchingCarton

The invention discloses a flattening device for waste carton recycling. The device comprises a worktable, a supporting frame, a fixed support and a containing groove are arranged on the worktable, a rotating disc and a driving motor are arranged on the fixed support, the driving motor is connected with the rotating disc, the fixed support is movably connected with a swing rod, a strip limiting groove is formed in the swing rod, a fixed pin is eccentrically arranged on the rotating disc, the fixed pin is located in the strip limiting groove, a fan-shaped fixed plate is arranged at one end of the swing rod, convex teeth are circumferentially distributed on the periphery of the fan-shaped fixed plate, a punching rod is in sliding connection to the fixed support, a fixed strip is arranged on the punching rod, positioning teeth are arranged on the fixed strip, a positioning groove is formed between two adjacent positioning teeth, and the positioning grooves and the convex teeth are in corresponding. The device is novel in structure, automatic and efficient, the labor intensity and the manual cost are reduced, rapid flattening molding is achieved, the flattening effect is good, and recycling of waste cartons can be facilitated.

Owner:嵊州市东浦天地彩印包装有限公司

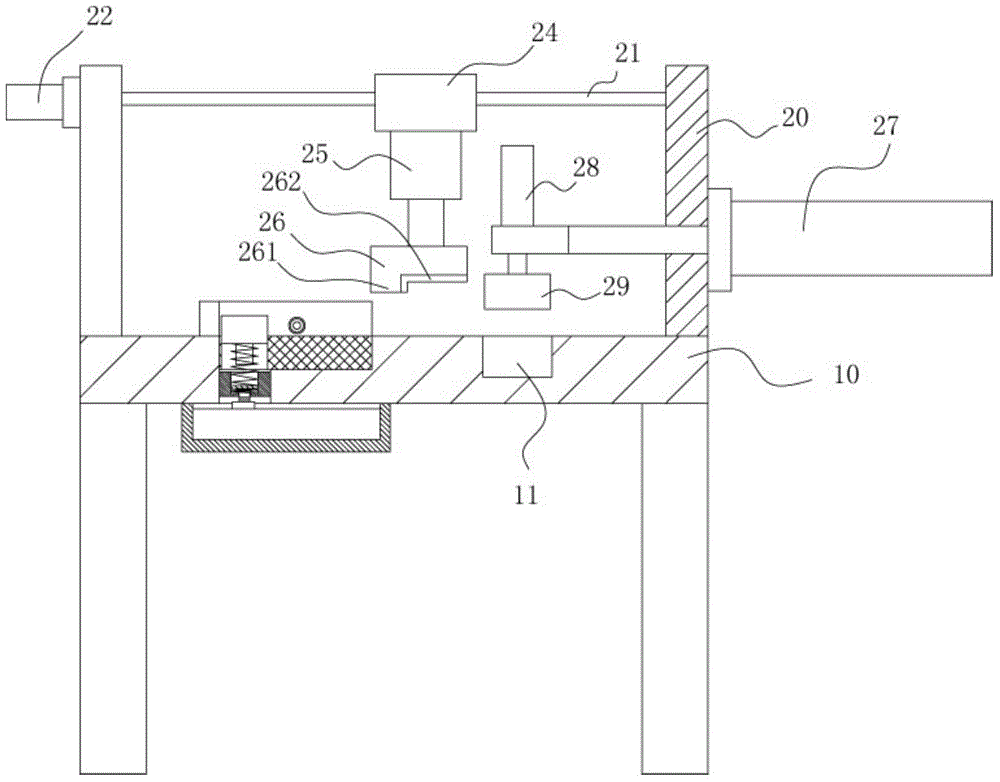

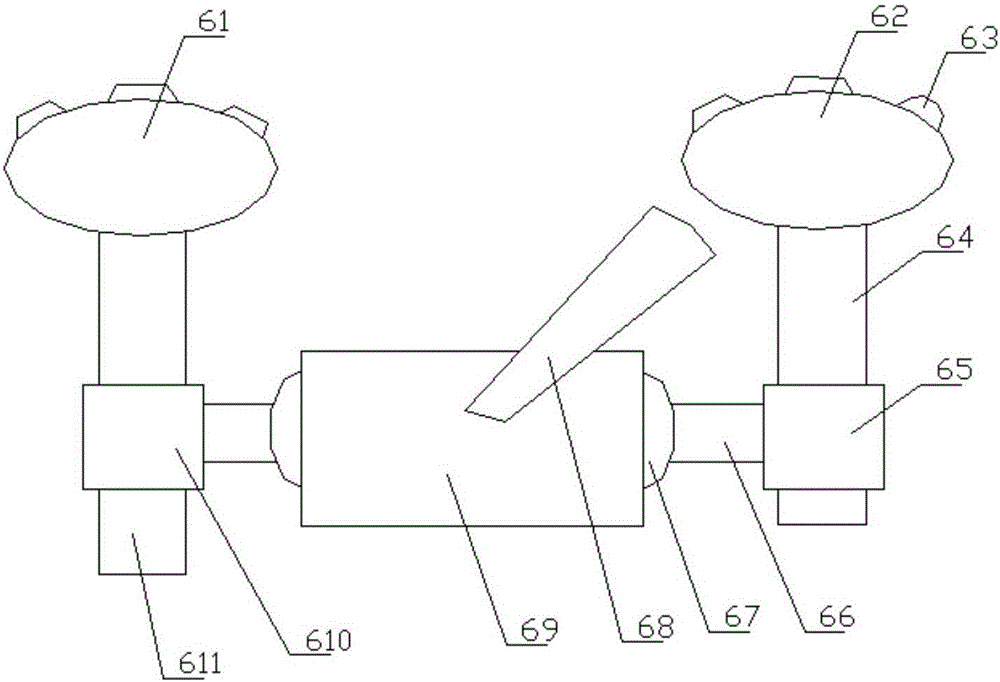

Metal plate conveying and flattening mechanism for electronic accessories

ActiveCN104889278APrecise feedingImprove flattening effectMetal-working feeding devicesPositioning devicesEngineeringDrive motor

The invention discloses a metal plate conveying and flattening mechanism for electronic accessories. The metal plate conveying and flattening mechanism comprises a framework and a conveying frame, the conveying frame is arranged on the front side wall of the framework, a groove and a pressing groove are formed in a top plate of the framework, the pressing groove is formed in the right side of the groove, supporting plates are fixed at the left end and the right end of the top plate of the framework, two ends of a limit rod are fixed onto the two supporting plates, a driving motor is fixed onto one supporting plate, an output shaft of the driving motor extends into an inserting hole in the supporting plate and hinged into the inserting hole through a bearing, a spline is arranged at one end of an adjusting screw, extends into the inserting hole and is inserted into a spine hole in the output shaft of the driving motor, the other end of the adjusting screw is hinged onto the other supporting plate, a movable block is screwed in the adjusting screw and inserted into the limit rod, and a pushing cylinder is fixed at the bottom of the movable block. The electronic accessories can be automatically conveyed and fed by a metal plate, a compression block is controlled to press down the electronic accessories, and the metal plate conveying and flattening mechanism is precise in feeding, fine in flattening effect and high in automation degree.

Owner:江苏盐城龙湖文化产业发展有限公司

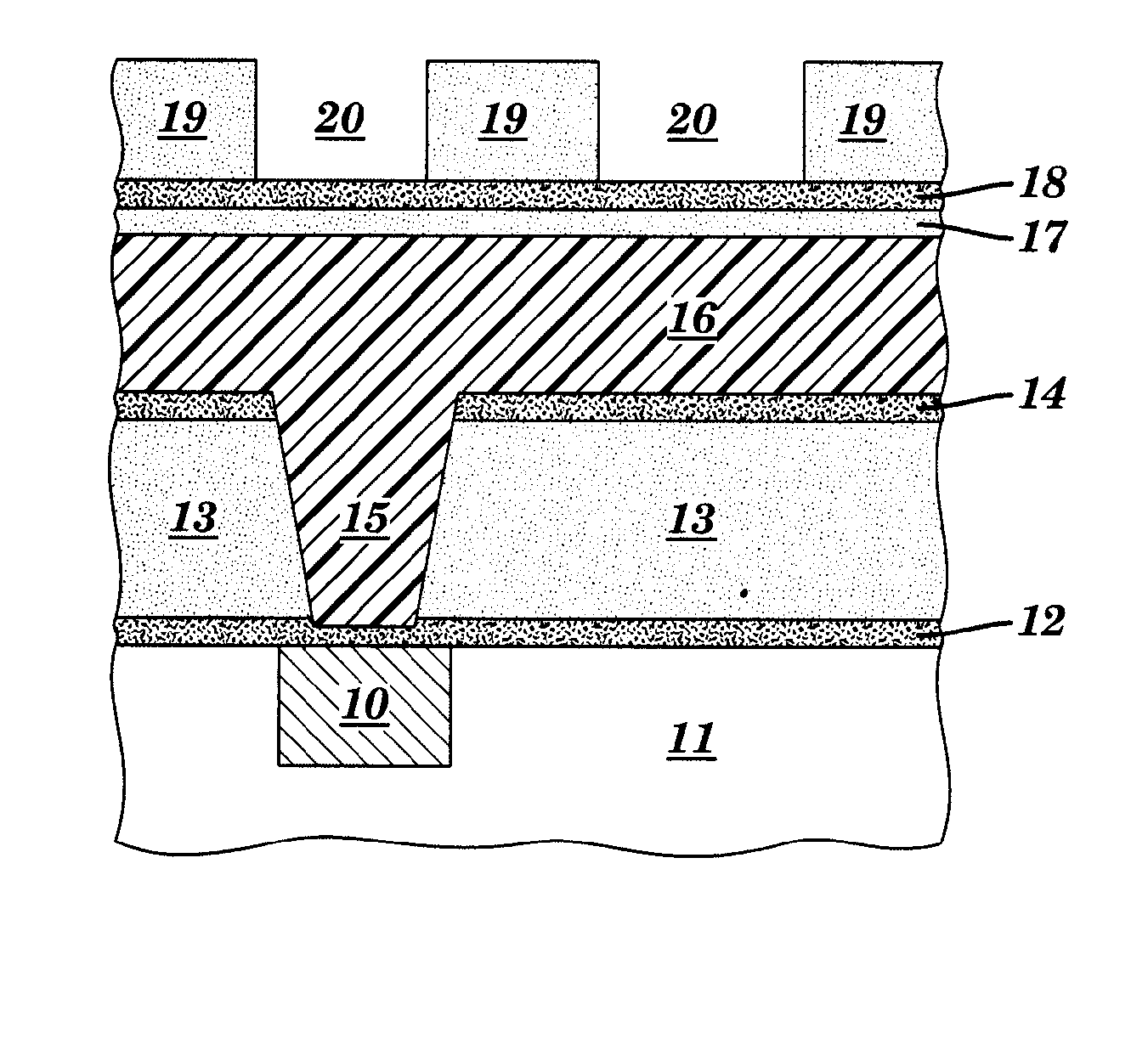

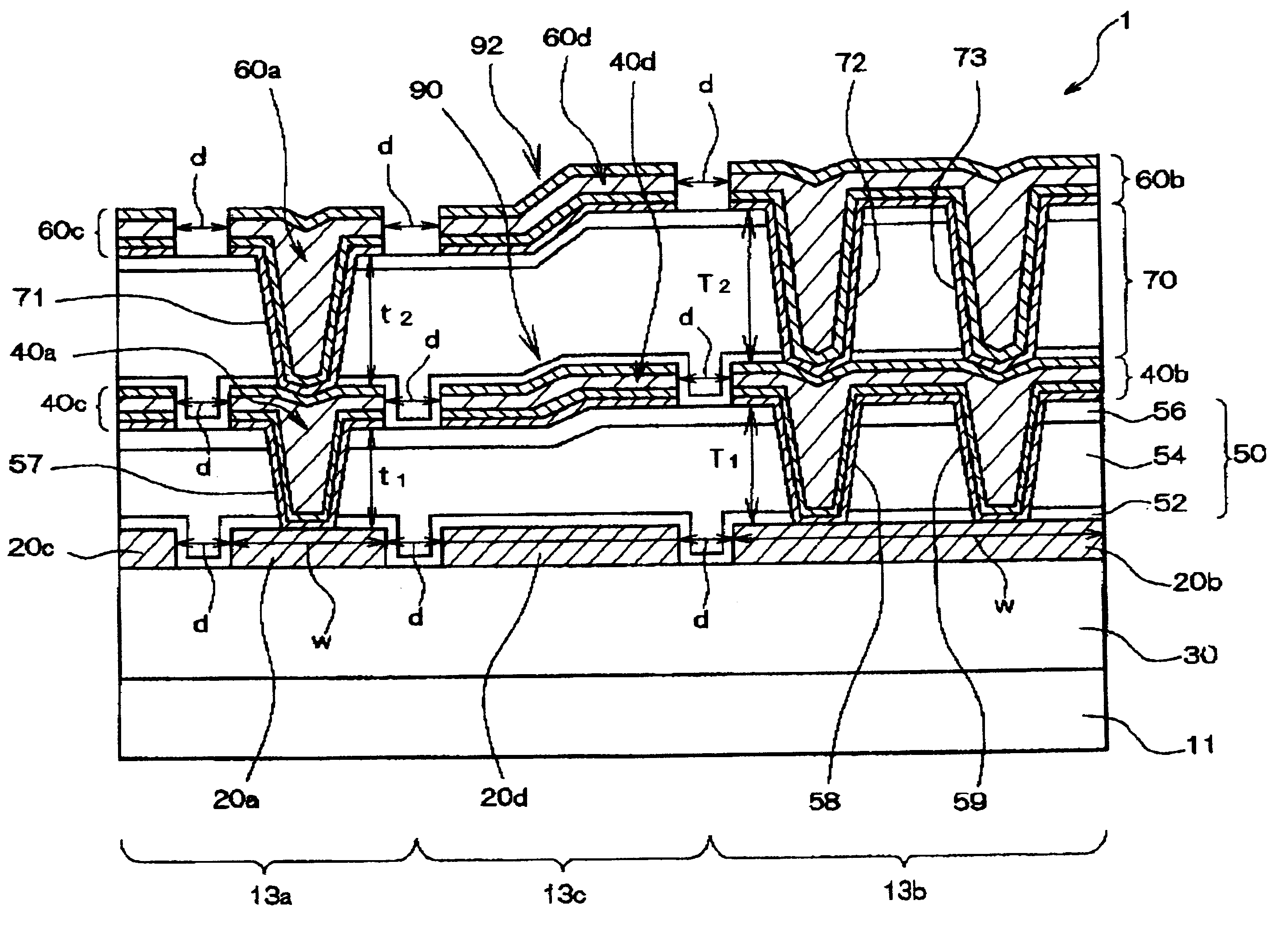

Semiconductor device and method for making pattern data

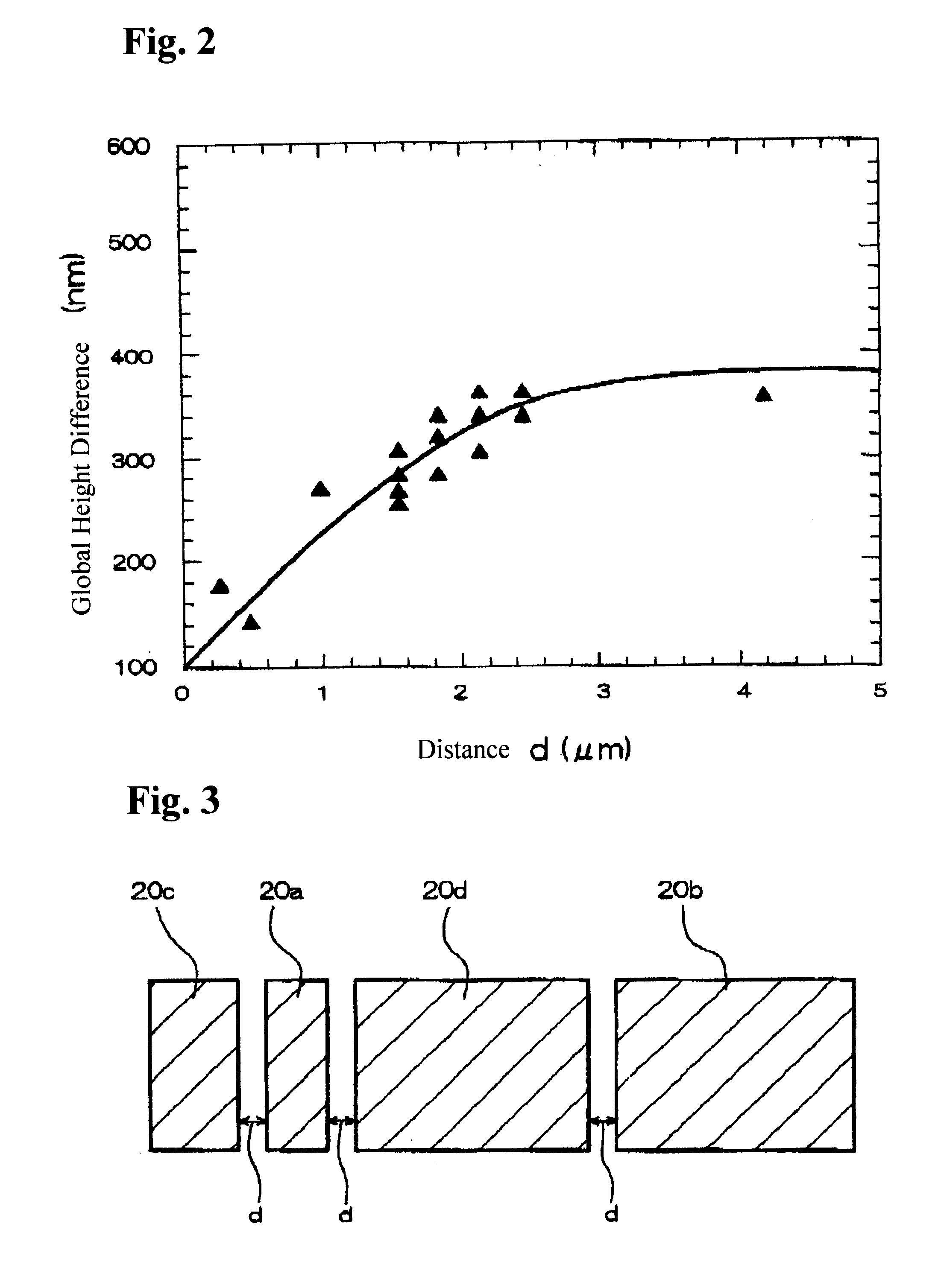

InactiveUS6287948B1Small height differenceOvercome lack of focusTransistorSemiconductor/solid-state device detailsSilanesEngineering

A semiconductor device has a first region, a second region and a border region between the first region and the second region. The semiconductor device has an interlayer dielectric layer, covering at least the first region and the second region. A first wiring layer is located in the first region and defines a relatively small pattern. A second wiring layer is located in the second region and defines a relatively large pattern that is wider than the small pattern. A first dummy pattern is formed in the first region and a second dummy pattern is formed in the border region. The interlayer dielectric layer includes a planarization silicon oxide film. The planarization silicon oxide film is one of a silicon oxide film formed by a polycondensation reaction between a silicon compound and hydrogen peroxide, an organic SOG (Spin On Glass) film an inorganic SOG film and a silicon oxide film formed by reacting an organic silane with ozone or water. The interlayer dielectric layer located over the first wiring layer is thinner than the interlayer dielectric layer located over the second wiring layer such that a global height difference occurs in the border region between the first region and the second region.

Owner:ADVANCED INTERCONNECT SYST LTD

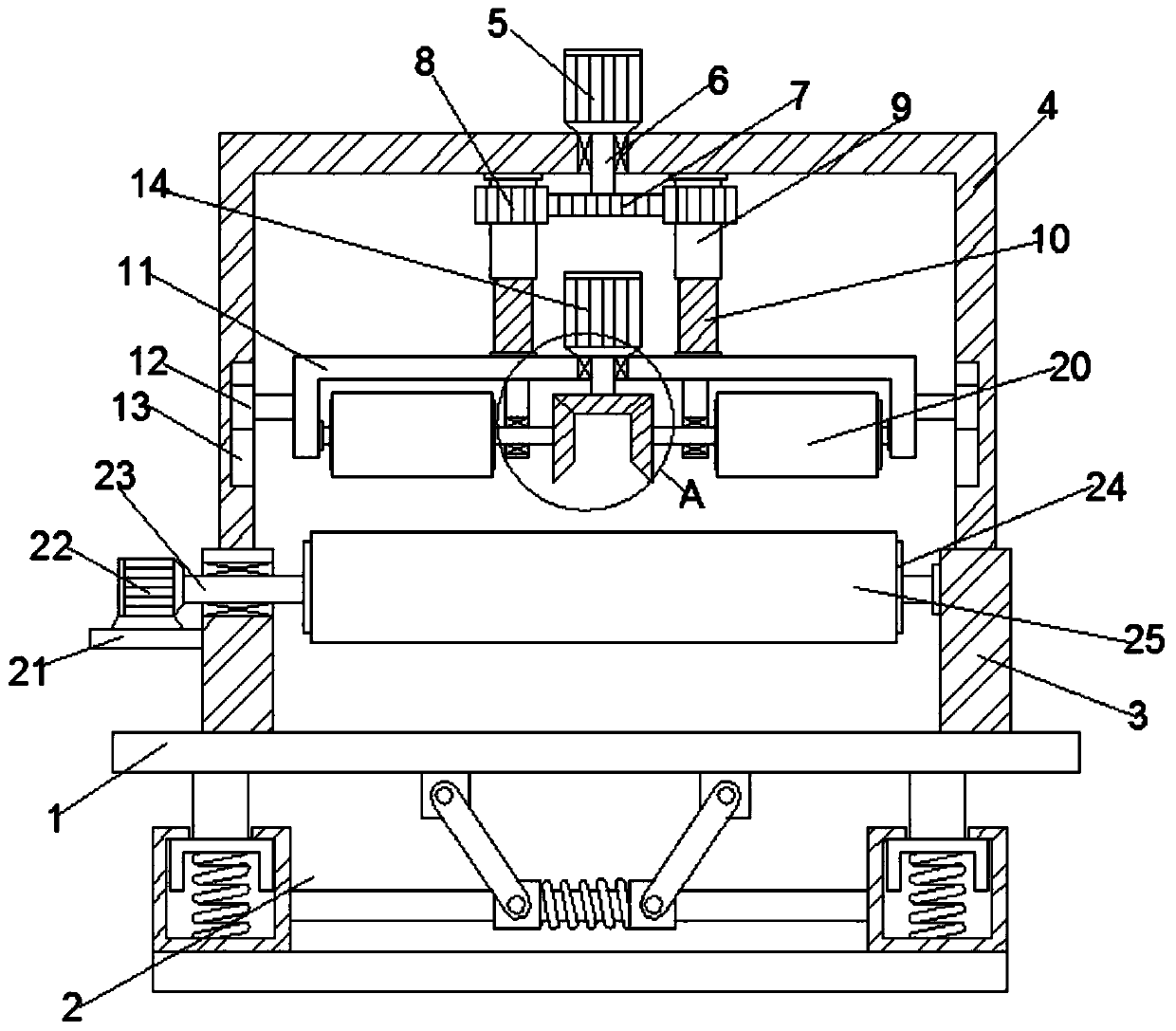

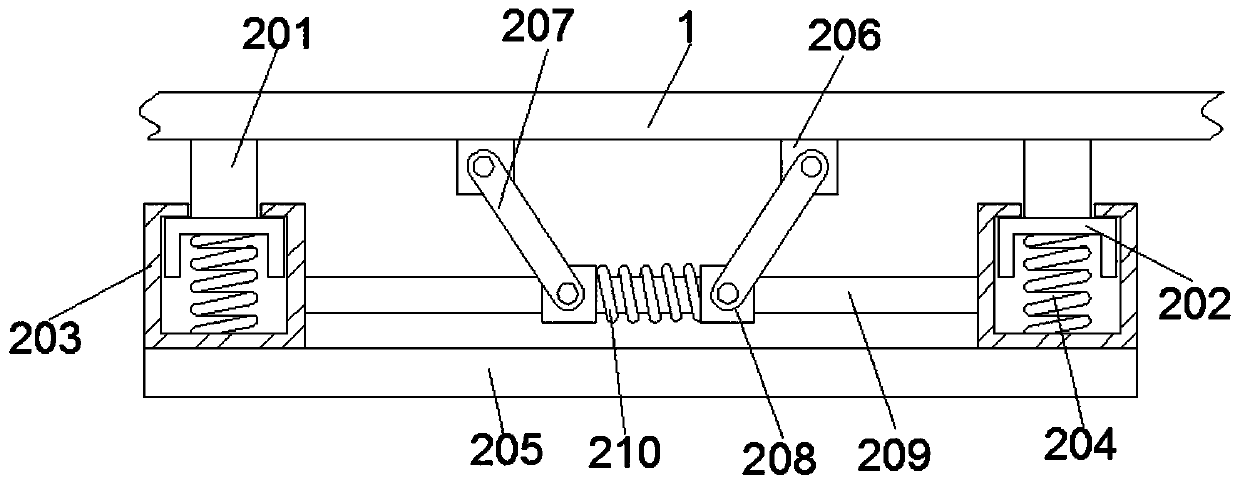

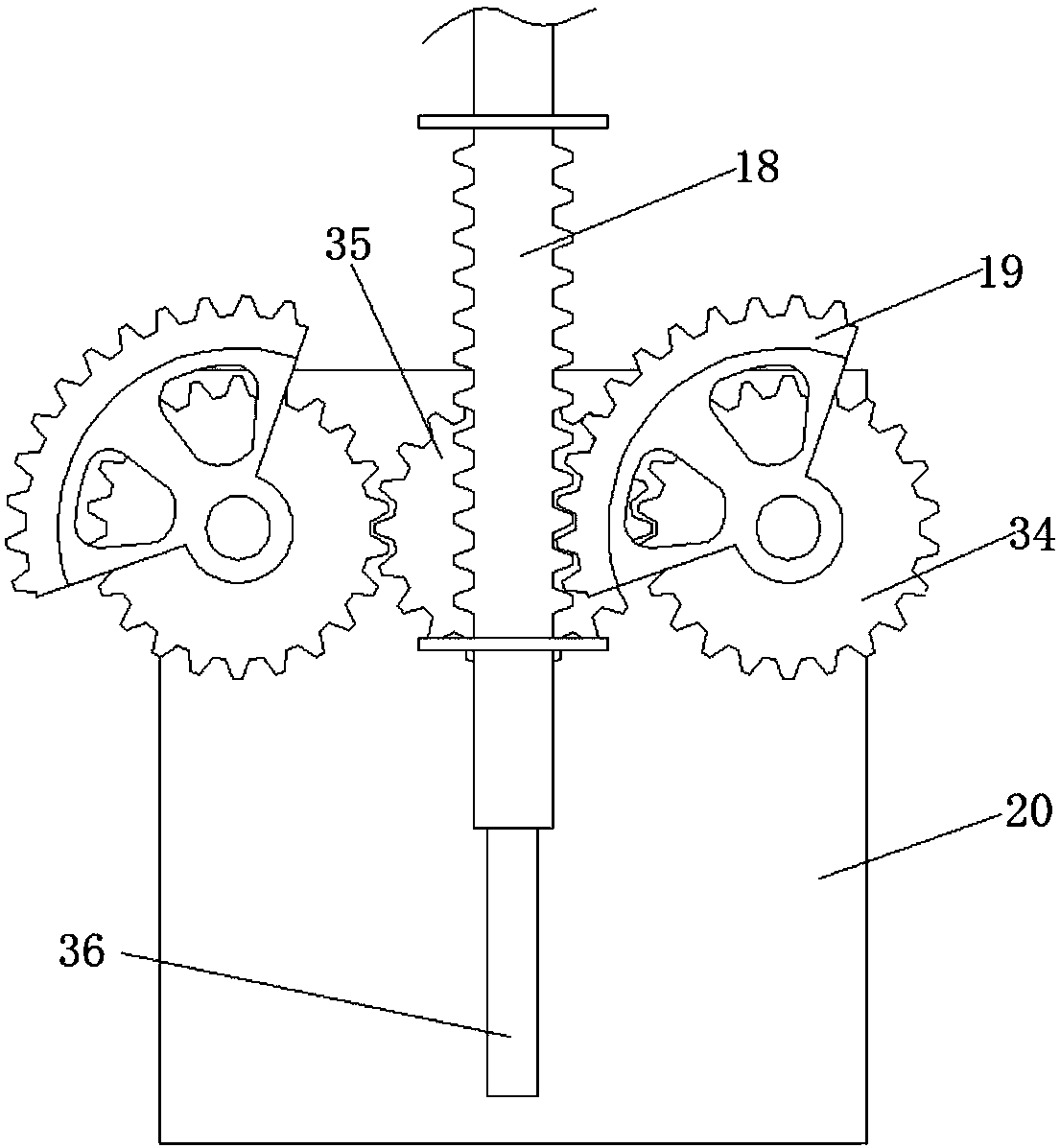

Dual-roller flattening machine with supporting structure

InactiveCN110239149AImprove work efficiencyMeet thickness requirementsMechanical working/deformationGear wheelFixed frame

The invention relates to the technical field of flattening machines, in particular to a dual-roller flattening machine with a supporting structure. The machine comprises a base, a supporting mechanism is arranged on the bottom of the base, fixed plates are symmetrically mounted on the two sides of the top of the base, a fixed frame is arranged between the tops of the fixed plates, a first driving motor is arranged in the middle of the top wall of the fixed frame, the output end of the first driving motor is provided with a first rotating shaft, and the first rotating shaft penetrates through the middle of the top wall of the fixed frame to be connected with a first gear. According to the dual-roller flattening machine with the supporting structure, the flattening thickness of the flattening machine is adjusted, thickness needs of different products can be met, under cooperation of a pressing roller and a conveying belt, the products can be flattened, the flattening treatment effect is better, two sets of products are flattened, the work efficiency of the flattening machine is improved, meanwhile, through the effect of a first damping spring and a second damping spring, damage of vibration to equipment is reduced, and the service life of the equipment is prolonged.

Owner:安徽文博纸品印刷有限公司

Automatic-expansion patch and using method thereof

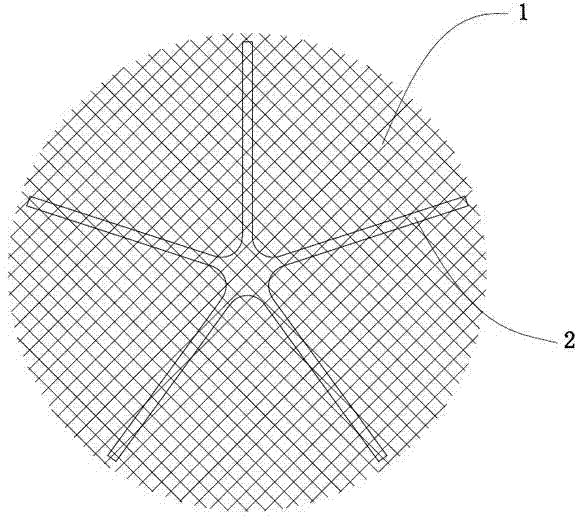

ActiveCN104510544ADoes not affect collapseImprove flattening effectProsthesisEngineeringOperation time

The invention relates to an automatic-expansion patch and a using method of the automatic-expansion patch. The automatic-expansion patch overcomes the defect that an existing patch is soft on the whole and can be conveniently contracted, but the patch cannot be conveniently expanded to be flat so as to cover a weak area or a defect area. A net sheet is combined with an automatic-expansion reinforcing support, and the support is arranged in a radiating mode relative to the center of the patch; meshes of the net sheet cover the surface of the support. Due to the fact that the net sheet is combined with the automatic-expansion reinforcing support, before the patch is used, the support is soft, and contraction of the patch cannot be affected. After the patch is put into a human body, the support expands automatically or through the external force, the support is arranged in the radiating mode, and therefore the support can support the whole patch, portions without expanding cannot be reserved on the patch, the expansion effect is good, the operation that a machine stretches into the interior to conduct manual intervention is not required, expansion of the patch is accomplished at one time, and the operation time is short.

Owner:贾忠

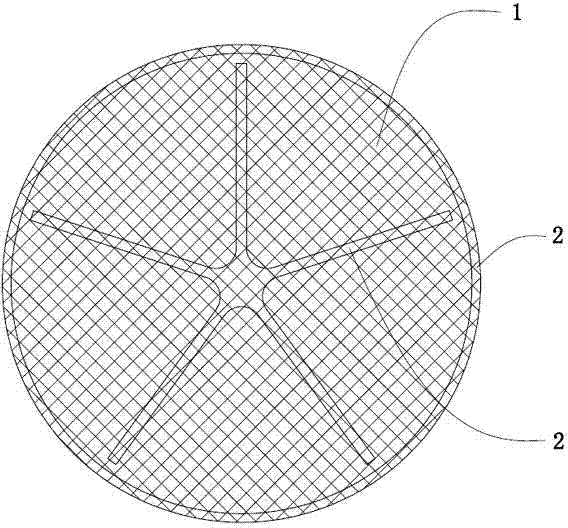

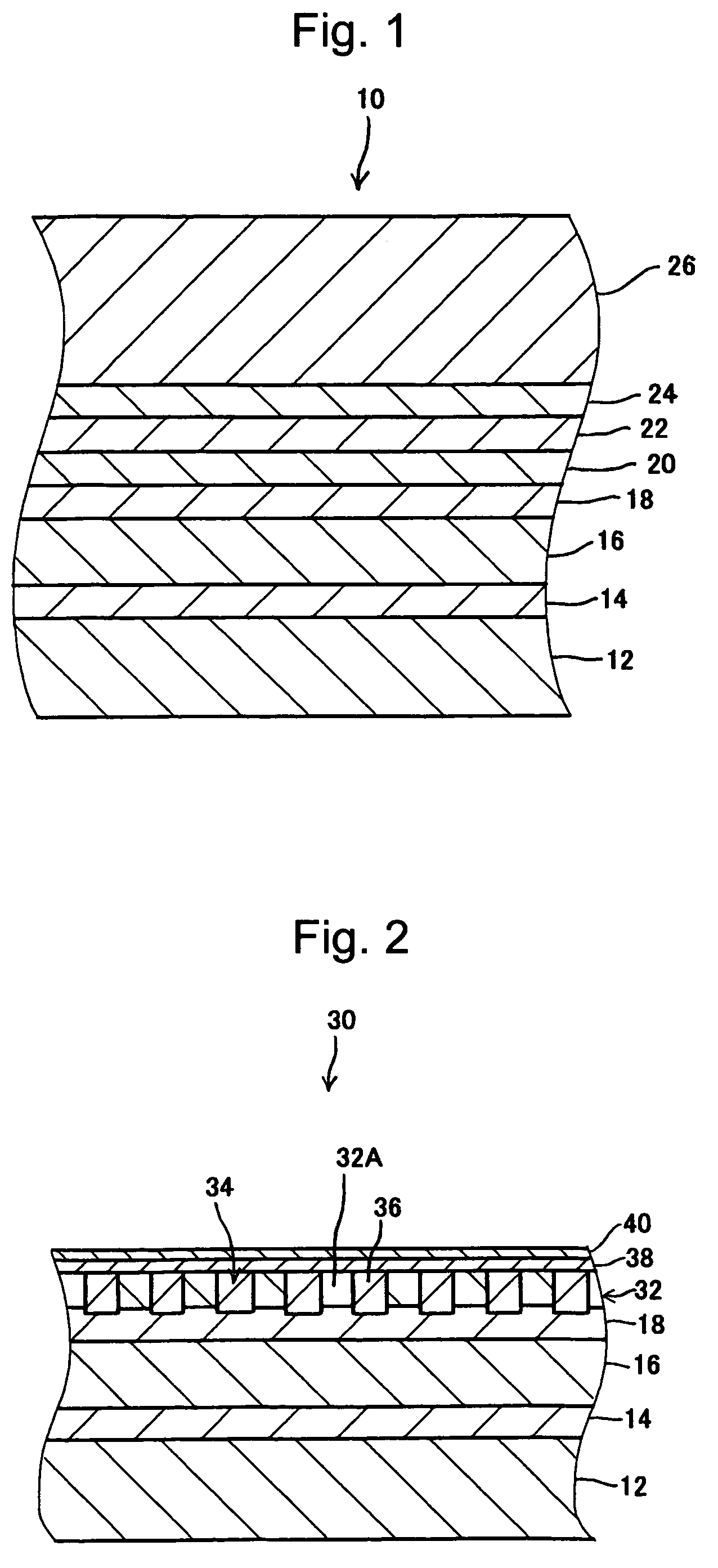

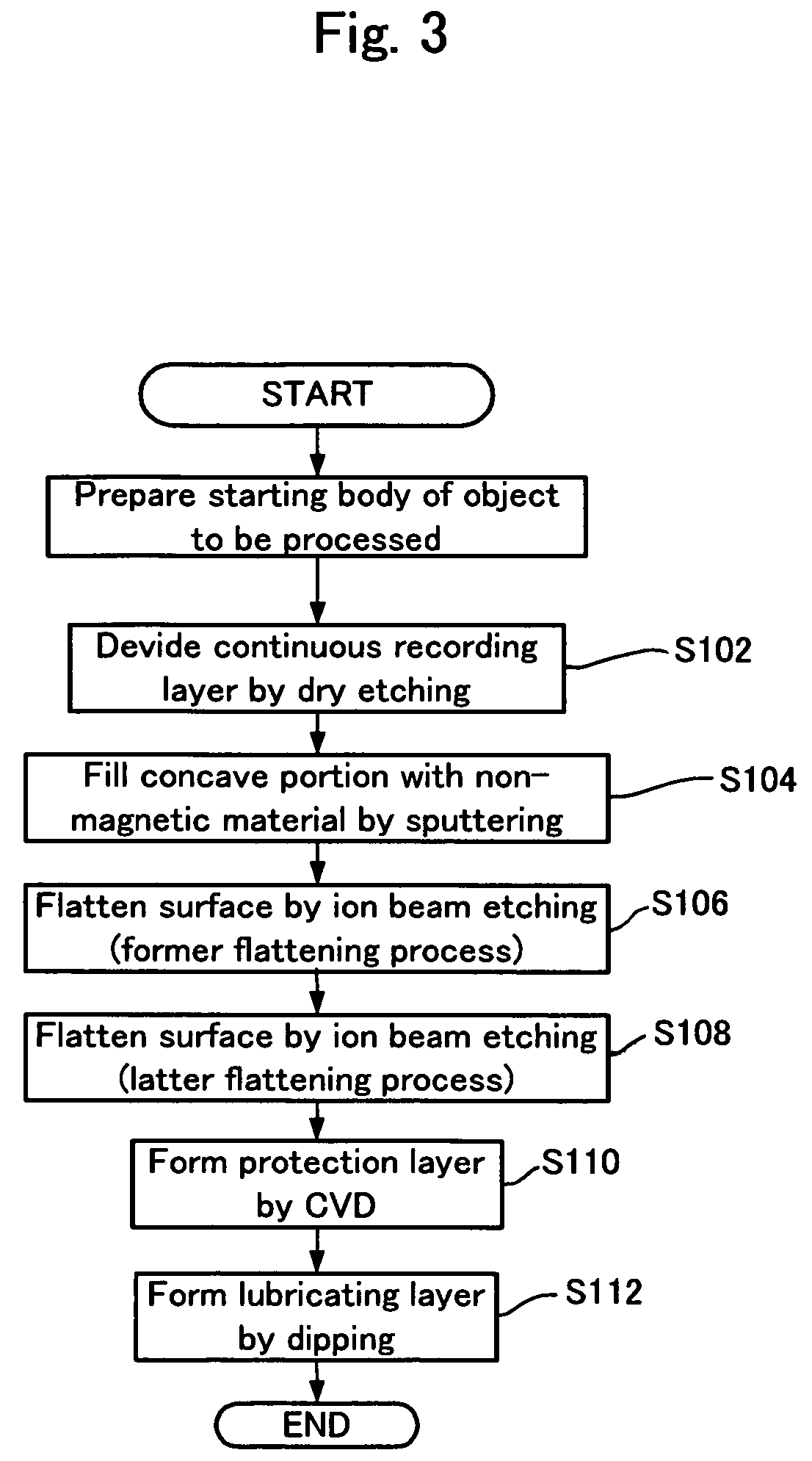

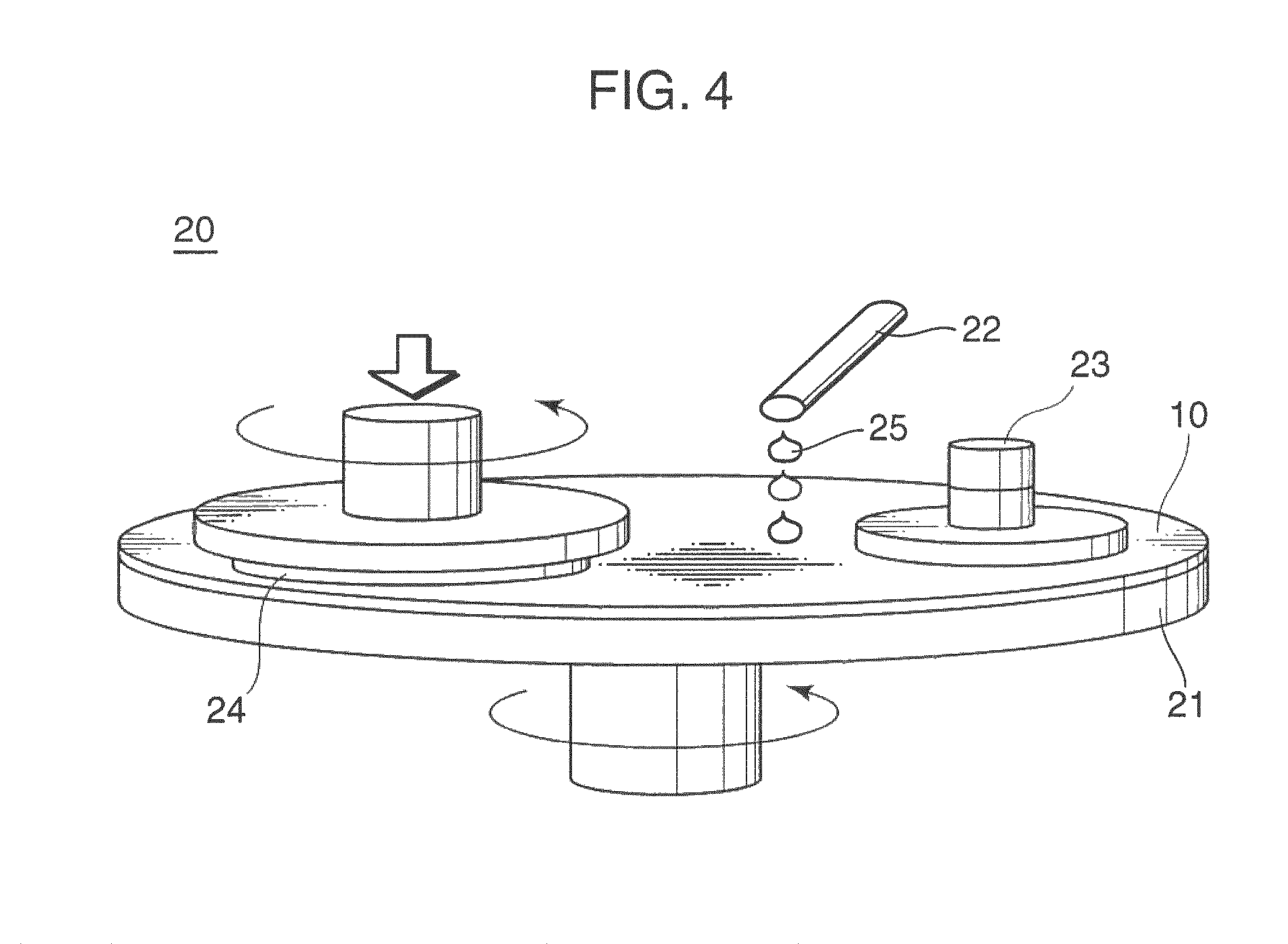

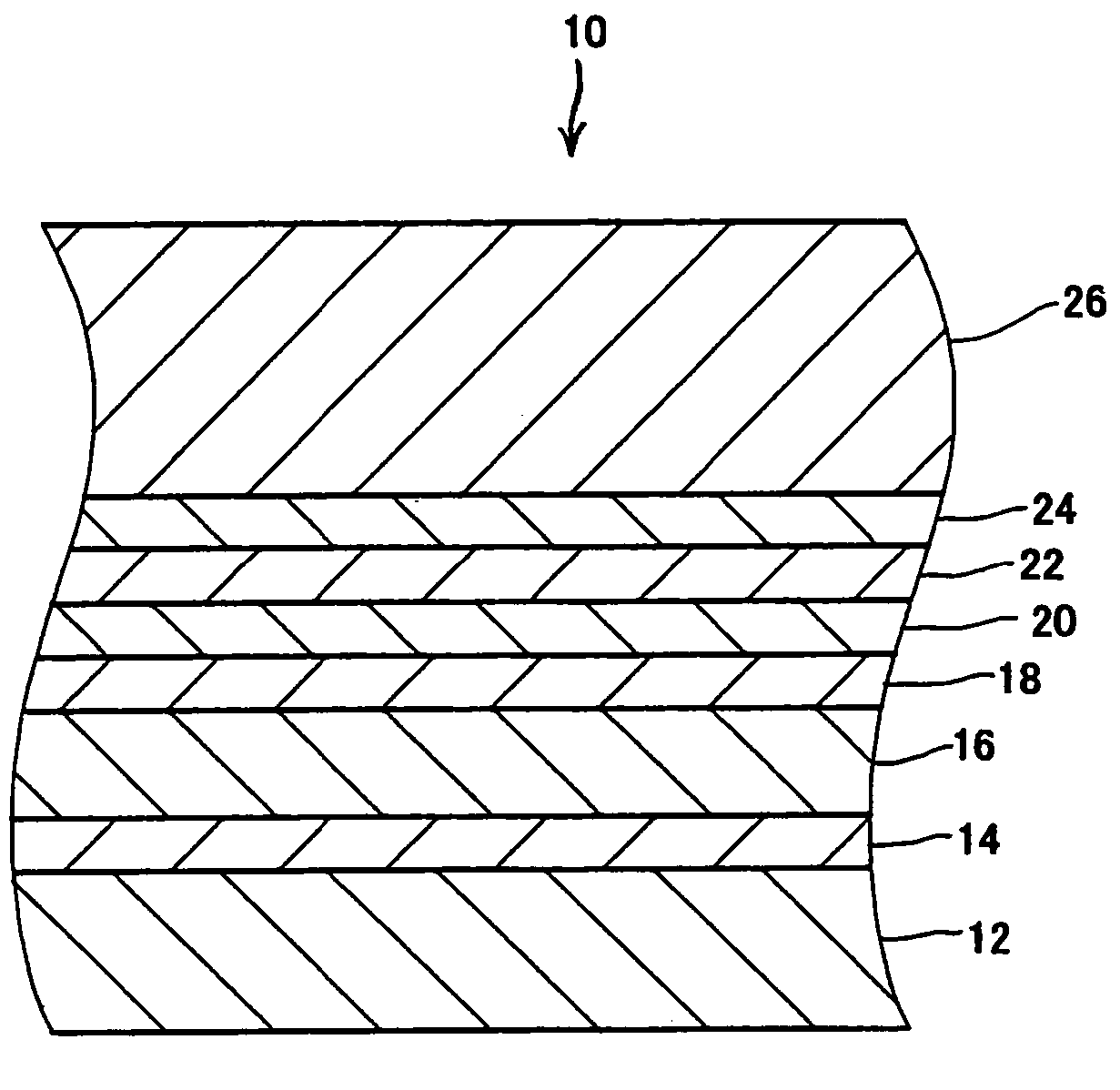

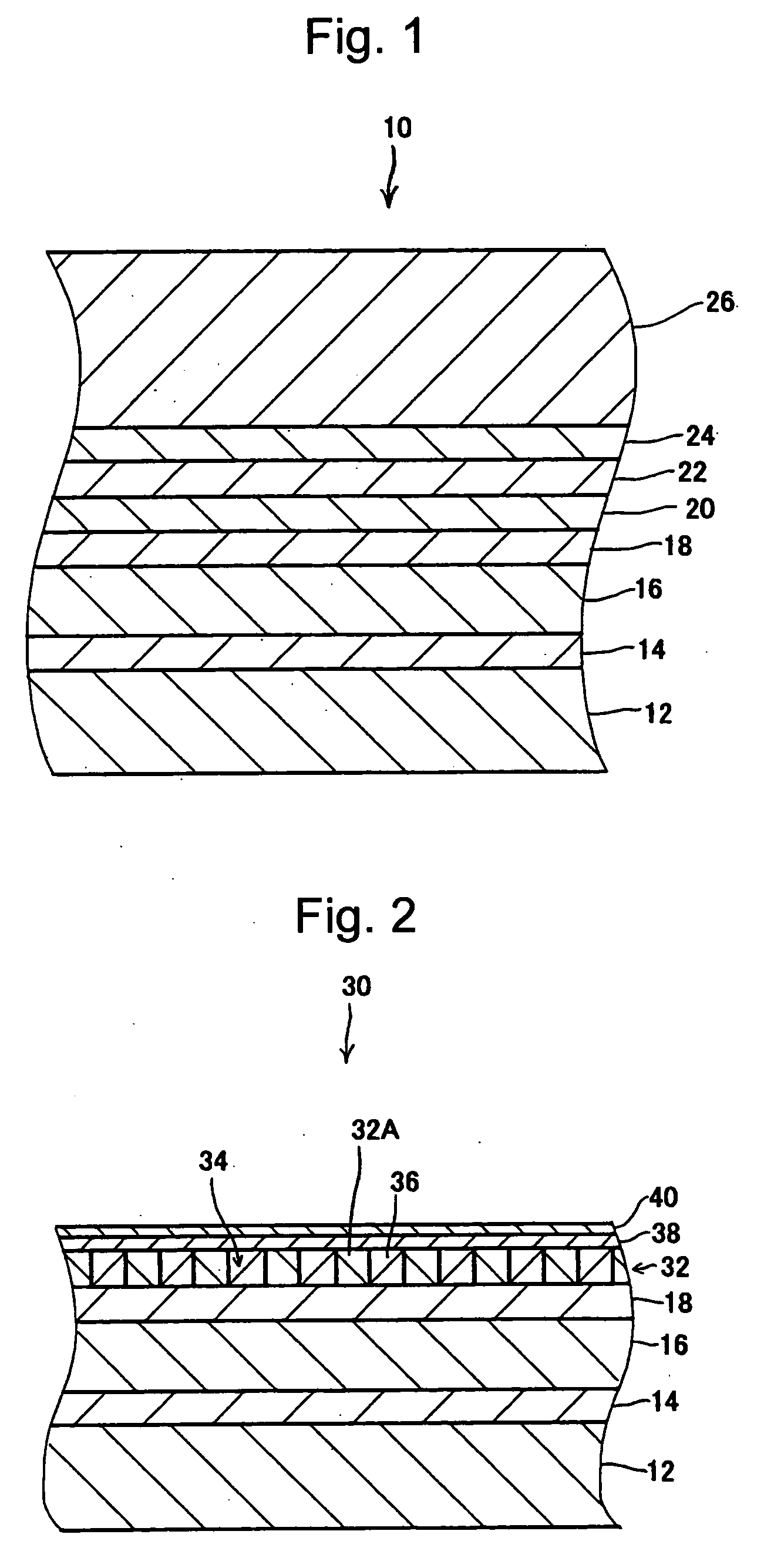

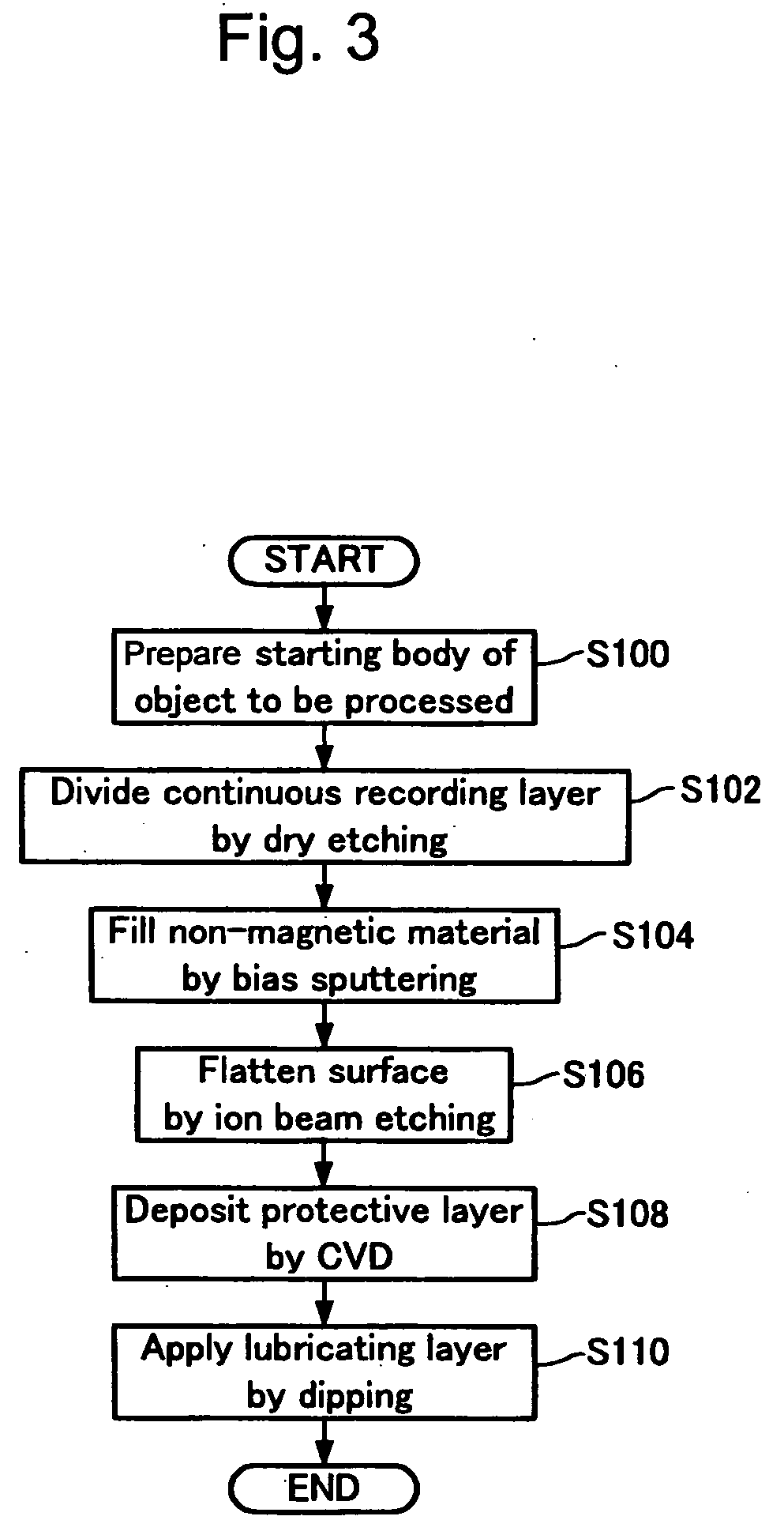

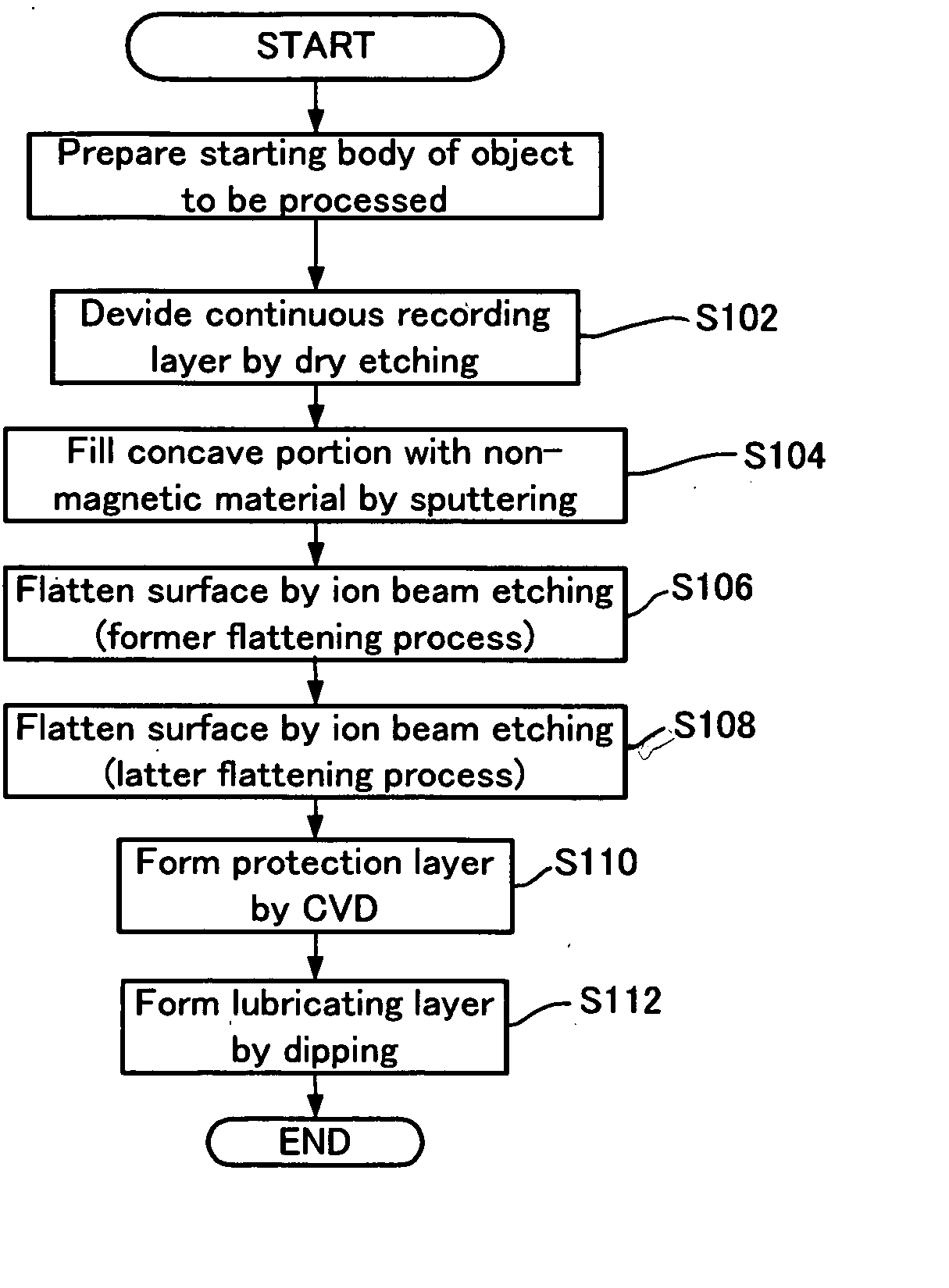

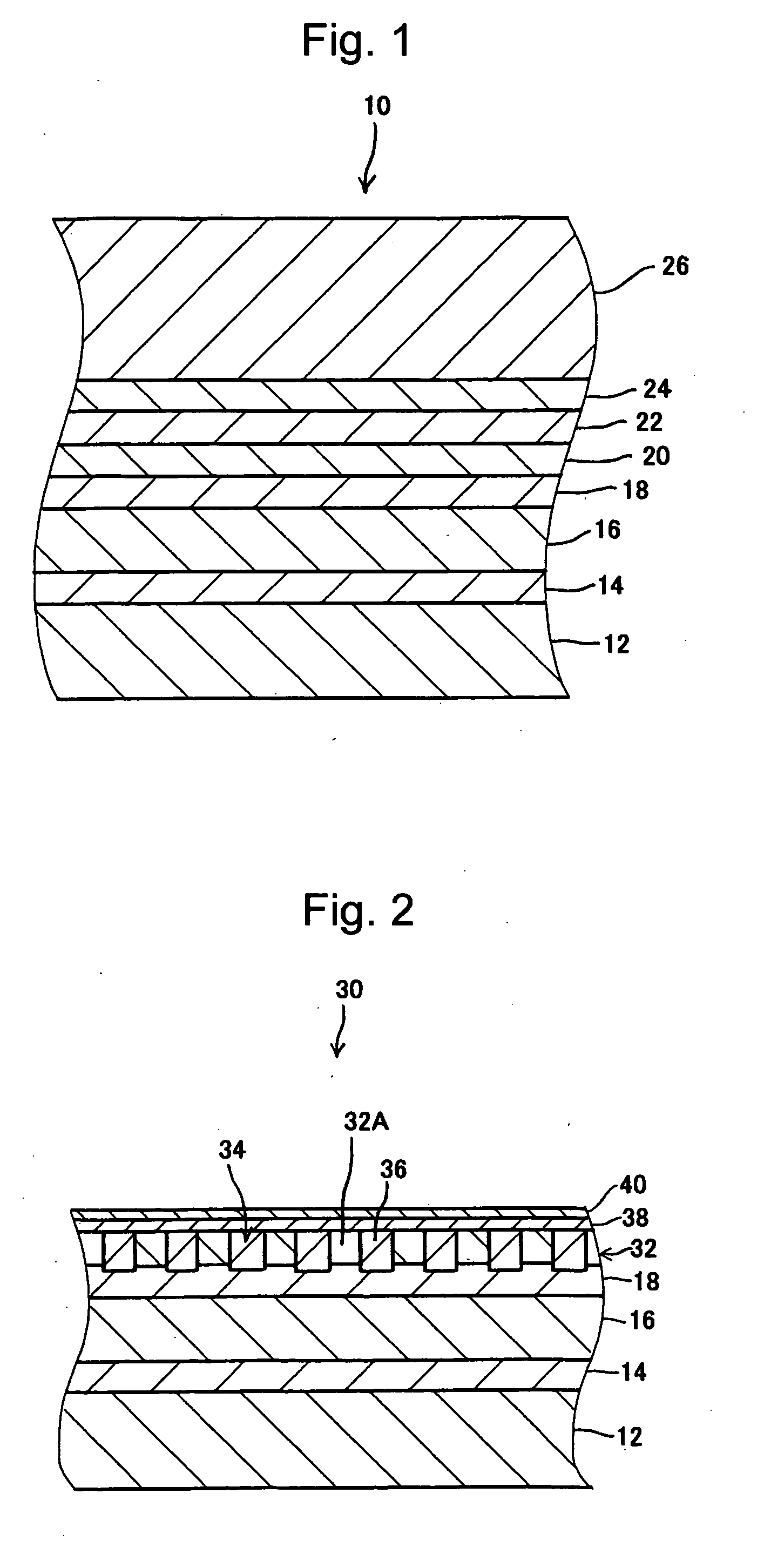

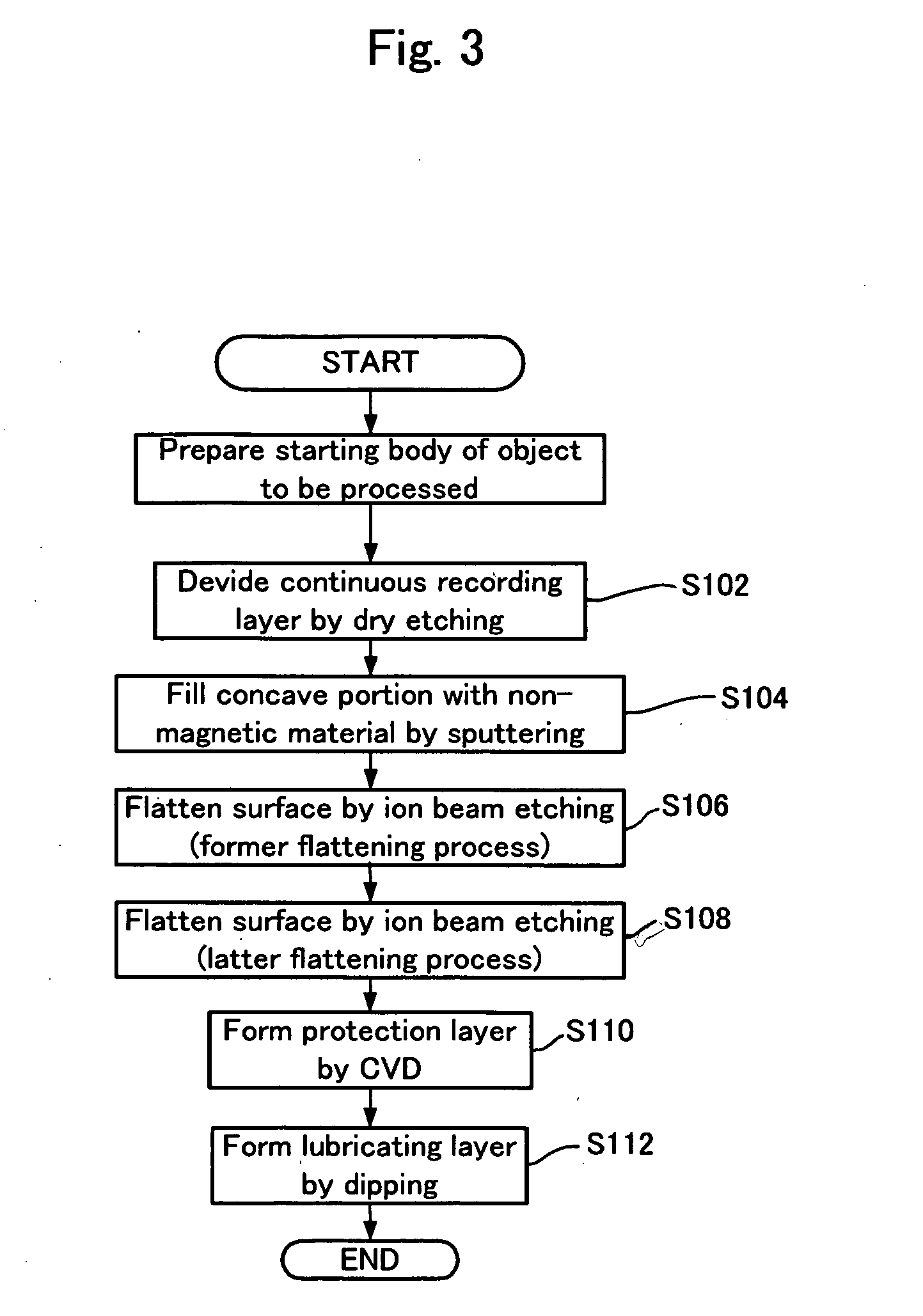

Method for manufacturing a magnetic recording medium

InactiveUS7273563B2Maintain stable propertiesGood recording and reproduction characteristicDecorative surface effectsConductive/insulating/magnetic material on magnetic film applicationEngineeringRecording layer

A method for manufacturing a magnetic recording medium is provided, which can efficiently manufacture a magnetic recording medium that includes a recording layer formed in a concavo-convex pattern and has good recording and reproduction characteristics. The method includes: a non-magnetic material filling step of depositing a non-magnetic material over a recording layer formed in a predetermined concavo-convex pattern over a substrate so as to fill a concave portion of the concavo-convex pattern with the non-magnetic material; and a flattening step of removing the excess part of the non-magnetic material above the recording layer by dry etching so as to flatten the surfaces of the non-magnetic material and the recording layer. The flattening step includes a former flattening step and a latter flattening step for finishing.

Owner:TDK CORPARATION

Flanging machine

PendingCN107984733AStrong adsorptionFast deliveryFinal product manufactureElectrolyte accumulators manufactureEngineeringFlanging

The invention discloses a flanging machine. The flanging machine comprises a rack and a base arranged on the rack, wherein a trimming carrying and conveying mechanism, an alignment mechanism, a trimming mechanism and a flanging mechanism are arranged on the base; the trimming carrying and conveying mechanism is used for conveying a battery; the alignment mechanism is positioned on the two sides ofthe trimming carrying and conveying mechanism and is used for seeking the central line of the battery; the trimming mechanism is used for cutting a redundant laminating film; the flanging mechanism is used for bending the residual laminating film; an overturning mechanism used for overturning the battery is arranged in the position, following the flanging mechanism, on the base; a roll folding and carrying mechanism used for carrying the battery, a prepressing locating mechanism which is positioned on the two sides of the roll folding and carrying mechanism and is used for prepressing the laminating film and locating the battery, and a roll folding mechanism used for folding the laminating film through rolling are arranged in the position, following the overturning mechanism, on the base;and a hot pressing shaping mechanism used for leveling the laminating film is arranged in the position, following the roll folding mechanism, on the base. According to the flanging mechanism, trimming, flanging, code scanning, weighing, shaping and overturning can be automatically carried out on the battery, the automation degree is high, product specifications are uniform, the battery is not damaged, manpower is greatly saved, and quality is improved.

Owner:SUZHOU SUNMICRO AUTOMATION TECH CO LTD

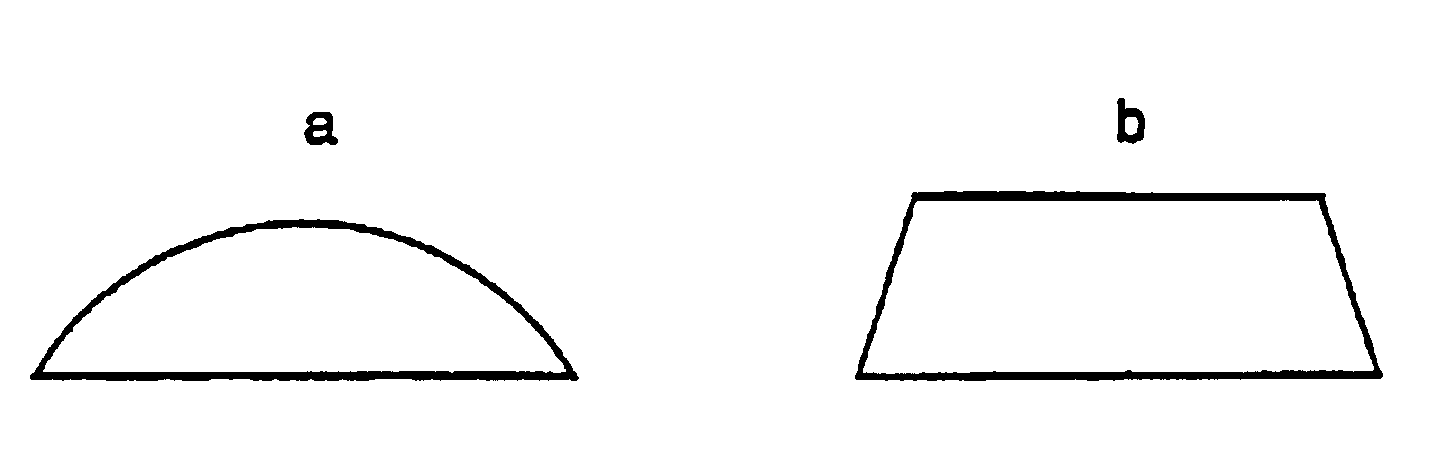

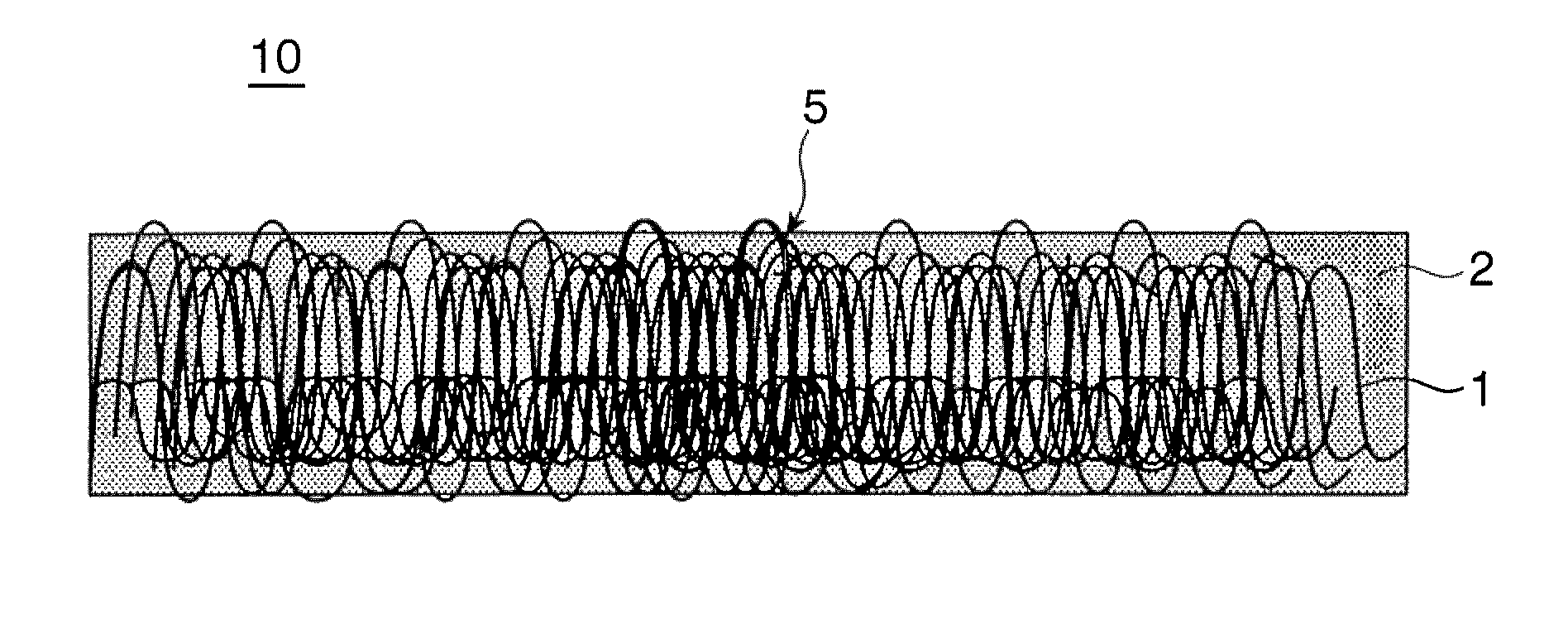

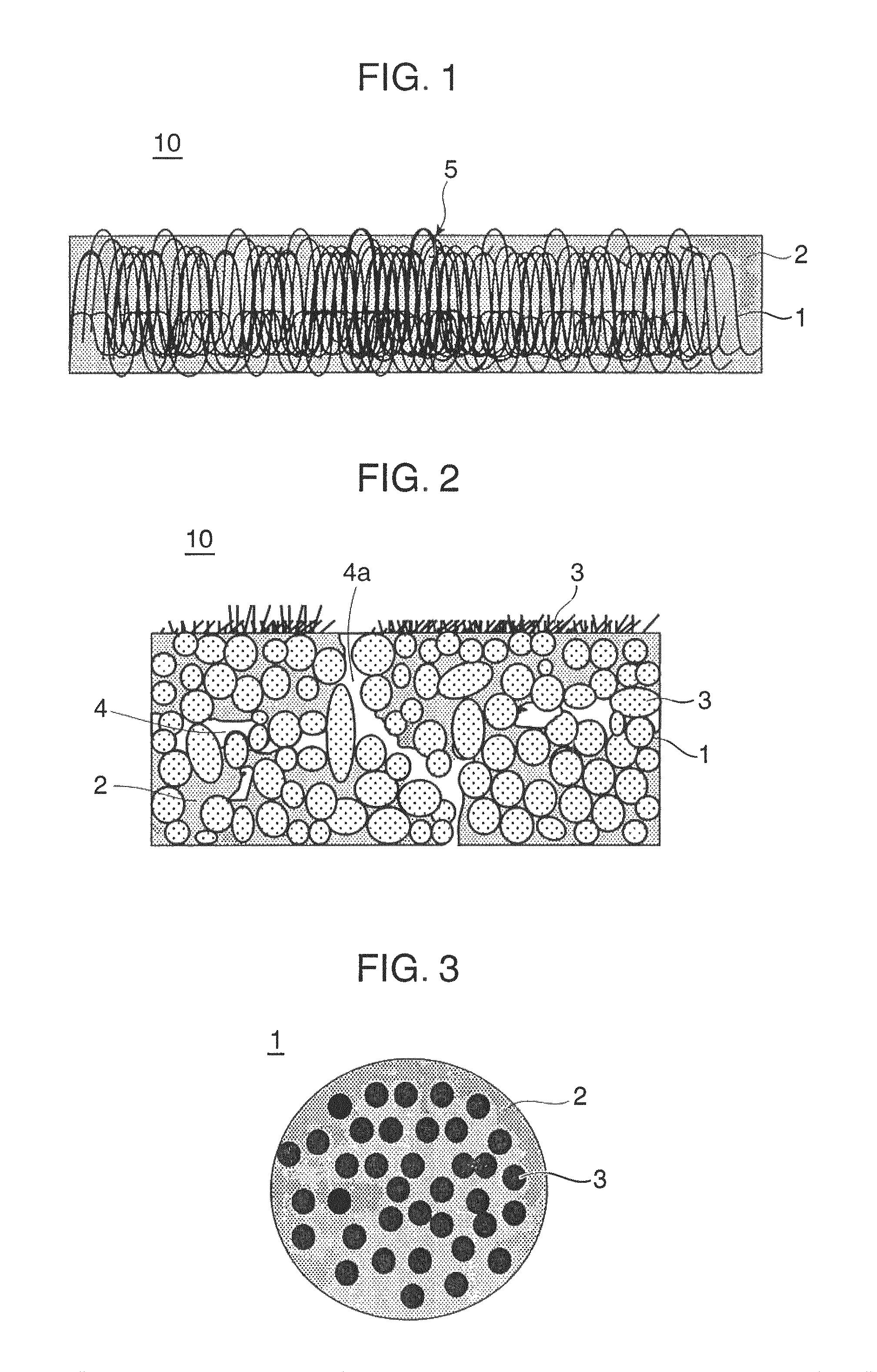

Polishing pad, and method for manufacturing polishing pad

ActiveUS8647179B2Scratch resistantImprove flattening effectRevolution surface grinding machinesAbrasion apparatusElastomerSquare Millimeter

Owner:KURARAY CO LTD

Method for manufacturing magnetic recording medium

InactiveUS20050186357A1Efficient preparationImprove accuracyDecorative surface effectsConductive/insulating/magnetic material on magnetic film applicationMetallurgyRecording layer

A method for manufacturing a magnetic recording medium is provided, by which a magnetic recording medium having a recording layer formed in a concavo-convex pattern, a sufficiently flat surface, and high recording and reproducing precision is efficiently manufactured. In a non-magnetic material filling step, a non-magnetic material is deposited over a recording layer formed in a predetermined concavo-convex pattern over a substrate to fill concave portions of the concavo-convex pattern with the non-magnetic material. In a flattening step, an excess part of the non-magnetic material above the recording layer is removed by dry etching, to flatten surfaces of the recording layer and the non-magnetic material. Processing conditions are set so as to substantially equalize an etching rate of the non-magnetic material with an etching rate of the recording layer with respect to the dry etching in the flattening step.

Owner:TDK CORPARATION

Flattening machinery

Owner:JIASHAN SHENGSHIDE FUR GARMENT

Method for manufacturing a magnetic recording medium

InactiveUS20050175791A1Maintain stable propertiesEasy to recordDecorative surface effectsConductive/insulating/magnetic material on magnetic film applicationEngineeringNon magnetic

A method for manufacturing a magnetic recording medium is provided, which can efficiently manufacture a magnetic recording medium that includes a recording layer formed in a concavo-convex pattern and has good recording and reproduction characteristics. The method includes: a non-magnetic material filling step of depositing a non-magnetic material over a recording layer formed in a predetermined concavo-convex pattern over a substrate so as to fill a concave portion of the concavo-convex pattern with the non-magnetic material; and a flattening step of removing the excess part of the non-magnetic material above the recording layer by dry etching so as to flatten the surfaces of the non-magnetic material and the recording layer. The flattening step includes a former flattening step and a latter flattening step for finishing.

Owner:TDK CORPARATION

Radiation-sensitive composition, insulating film and organic el display element

InactiveUS20030054284A1Improve flattening effectHigh transparencyElectroluminescent light sourcesSolid-state devicesResistHigh resistance

According to the present invention, there are provided an insulating film for an organic EL element, which has sufficiently low water permeability and a good sectional form and whose reactivity with a basic material and an electrode made from a metal having a low work function is suppressed, an insulating film for an organic EL element, which enables the formation of a through hole or U-shaped cavity therein and has excellent flattening performance, high transparency and high resistance to a resist stripper, and a radiation sensitive resin composition for forming the insulating film. An organic EL display element having this insulating film is free from an emission failure and has sufficiently long luminance half-life period and excellent reliability. The above composition comprises an alkali-soluble resin which may have an epoxy group and a 1,2-quinonediazide compound.

Owner:JSR CORPORATIOON

Leveling device for manufacturing printed circuit board

ActiveCN107708309AEasy to flattenImprove flattening effectPrinted circuit manufacturePrinted circuit boardConveyor belt

The invention discloses a leveling device for manufacturing a printed circuit board. The leveling device comprises a base. Four first support rods are symmetrically arranged on the base. The two firstsupport rods with corresponding positions are connected together with a fixing plate thereon. A fixing plate is fixedly connected between the two fixing plates. Two driving rollers are commonly connected rotatably between two fixing plates. Two driving rollers are commonly provided with a conveyor belt thereon. A PCB in process is arranged on the conveyor belt. Each of the fixing plate is fixedlyconnected with a first mounting plate and a second mounting plate on the upper surface. Each first mounting plate is rotatably connected with a first connecting rod and a rotating rod thereon. Each second mounting plate is rotatably connected with a second connecting rod thereon. The leveling device in the invention has the advantages of ingenious structure, convenient use, stable overall device,multiple flattening modes, good flattening effect, few occurrence of warping phenomenon, reduction of many hidden troubles in subsequent steps and unnecessary scrapping, reduction of production cost,and high promotion value.

Owner:乐凯特科技铜陵有限公司

Smashing device for infusion hose

ActiveCN106216365AConducive to screeningEasy to replaceSolid waste disposalMagnetic separationMedical equipmentEngineering

The invention relates to treatment equipment for an infusion hose, in particular to a smashing device for the infusion hose, and belongs to the field of medical equipment. The smashing device comprises a material entering region, a shearing region, a magnetic separation region, a pressing region, a smashing region and a collection region which are arranged in sequence from top to bottom, wherein a sterilization mechanism is arranged above the collection region. As the existing infusion instrument is of a plastic structure, part of which is provided with metal, by the use of the above mentioned structure, the shearing region is firstly used for shearing the infusion hose into proper sections, and then the section with the metal is subjected to magnetic separation to screen out a metal needle head; then the rest of the plastic sections are pressed by the pressing region; after being pressed, the plastic sections are compacted so as to facilitate smashing of plastic; and after the plastic sections pass through the smashing region, the smashing of the plastic hose, recycling of resources, energy conservation and consumption reduction are realized. The smashing device for the infusion hose is simple in structure and convenient to use, and can smash the infusion hose into particles, prevent the infusion hose from being recycled and avoid transmission of viruses or germs on the infusion hose; and the medical safe environment is improved.

Owner:成都创慧科达科技有限公司

Polishing liquid for CMP process and polishing method

InactiveCN1784770AImprove the finishExcellent abrasivenessSemiconductor/solid-state device manufacturingLiquid-crystal displaySilicon oxide

The invention discloses a grinding liquid for a CMP method, which is characterized in that it contains grinding materials, aqueous solvents and additives, and contains at least 15% by weight of grinding material particles with a particle diameter of 20-80nm based on the weight of the grinding liquid; The grinding method of grinding is suitable for the flattening process of the surface of the device wafer on which at least the silicon oxide film is formed, and can effectively and stably exhibit superior grinding characteristics such as flattening characteristics, low defect characteristics and high cleaning characteristics, the most suitable It is the planarization process of the surface of semiconductor devices including interlayer insulating film or element separation film, magnetic head and substrate for liquid crystal display in the semiconductor industry.

Owner:SANYO CHEM IND LTD +1

Flatting machine with rolling brushes

InactiveCN105648692AWide range of applicationsSave human effortTextile shapingEngineeringCOTTON WOOL

The invention provides a flatting machine with rolling brushes. The flatting machine comprises a conveyor belt, wherein a pre-pressing roller and a flatting roller are arranged above the conveyor belt in sequence; the pre-pressing roller comprises an inner roller and an outer roller blade; the inner roller is of a cylindrical body; the outer roller blade is annularly arranged along the central axis of the inner roller; an arch-shaped surface is formed by an outer edge line of the outer roller blade; a threaded hole a is formed in the inner roller; a threaded hole b corresponding to the threaded hole a is formed in the outer roller blade; the inner roller and the outer roller blade are fixedly connected through a threaded rod penetrating through the threaded hole a and the threaded hole b; the conveyor belt is also provided with a cleaning mechanism; the cleaning mechanism comprises the rolling brushes; the rolling brushes are in contact with the pre-pressing roller and the flatting roller; the conveyor belt is also provided with a pressing plate; the pressing plate is fixedly connected with an air cylinder. According to the flatting machine with the rolling brushes, provided by the invention, the defect of the prior art is solved; due to the arrangement of the cleaning mechanism, sundries of cotton wool and the like can be cleaned at any time; the diameter of rollers is adjustable, so that the flatting machine is suitable for flatting cotton raw materials of different thicknesses, and through secondary grinding, the flatting effect is good.

Owner:TIANJIN JIAXUAN TEXTILE

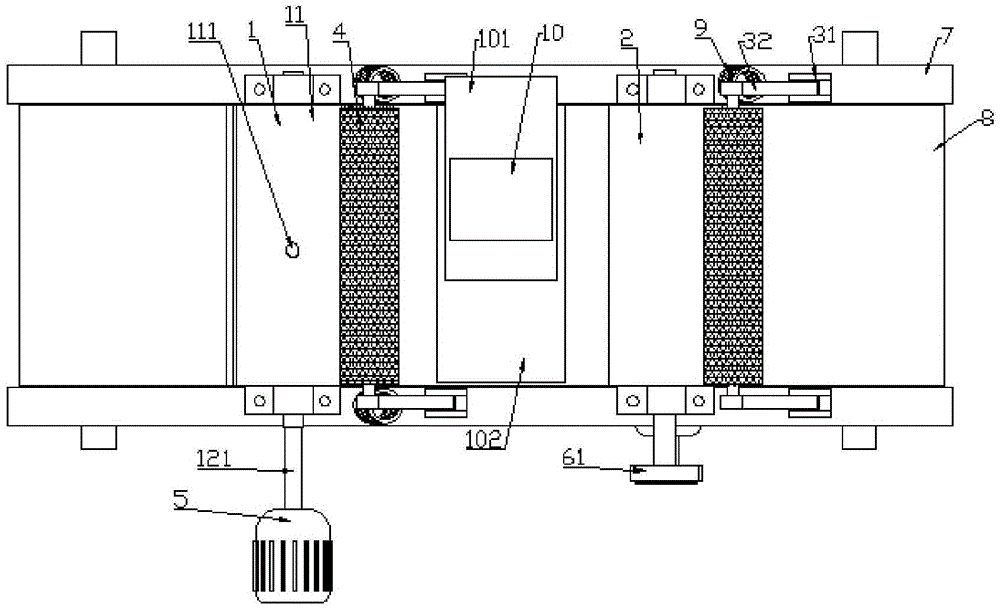

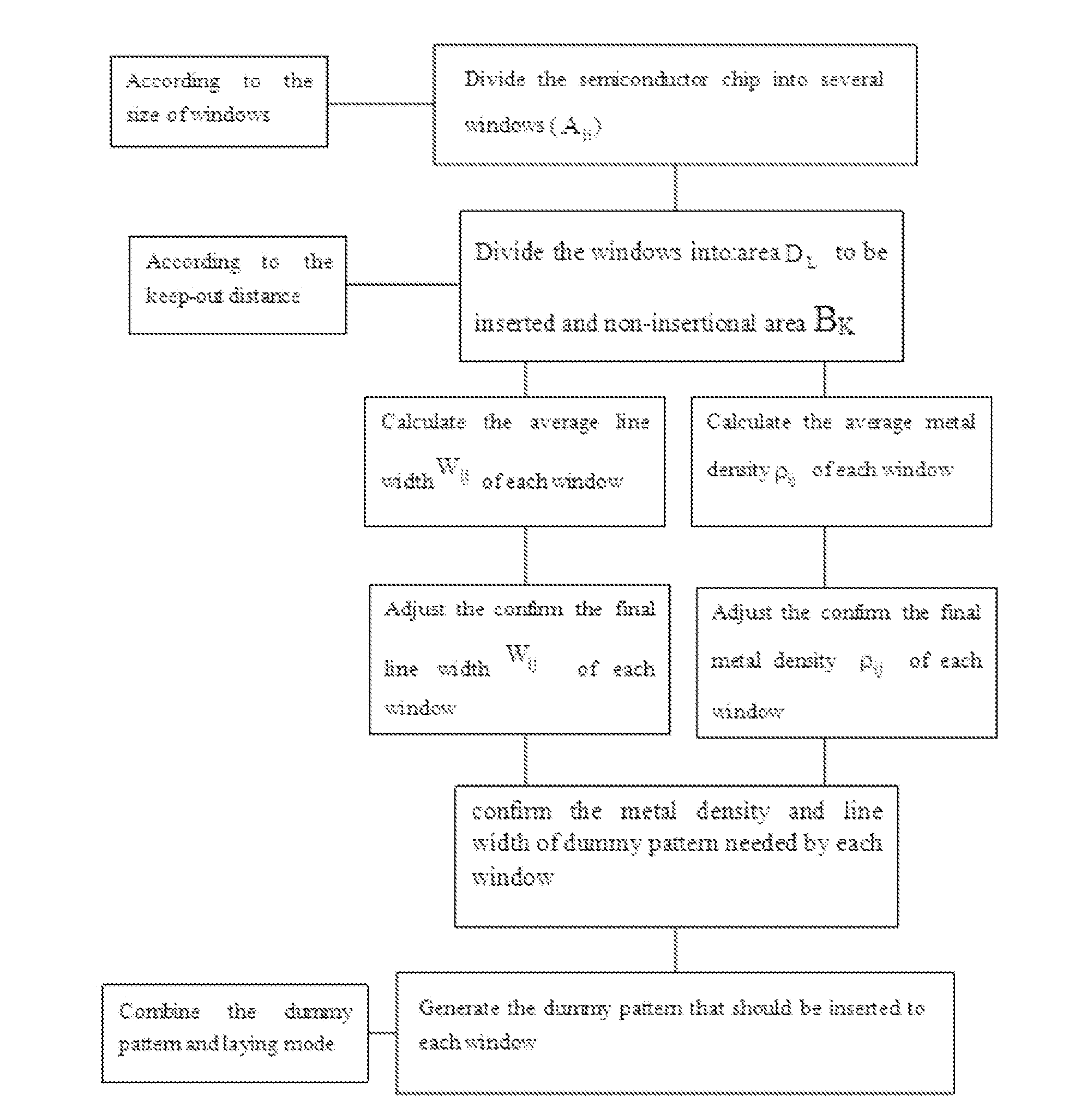

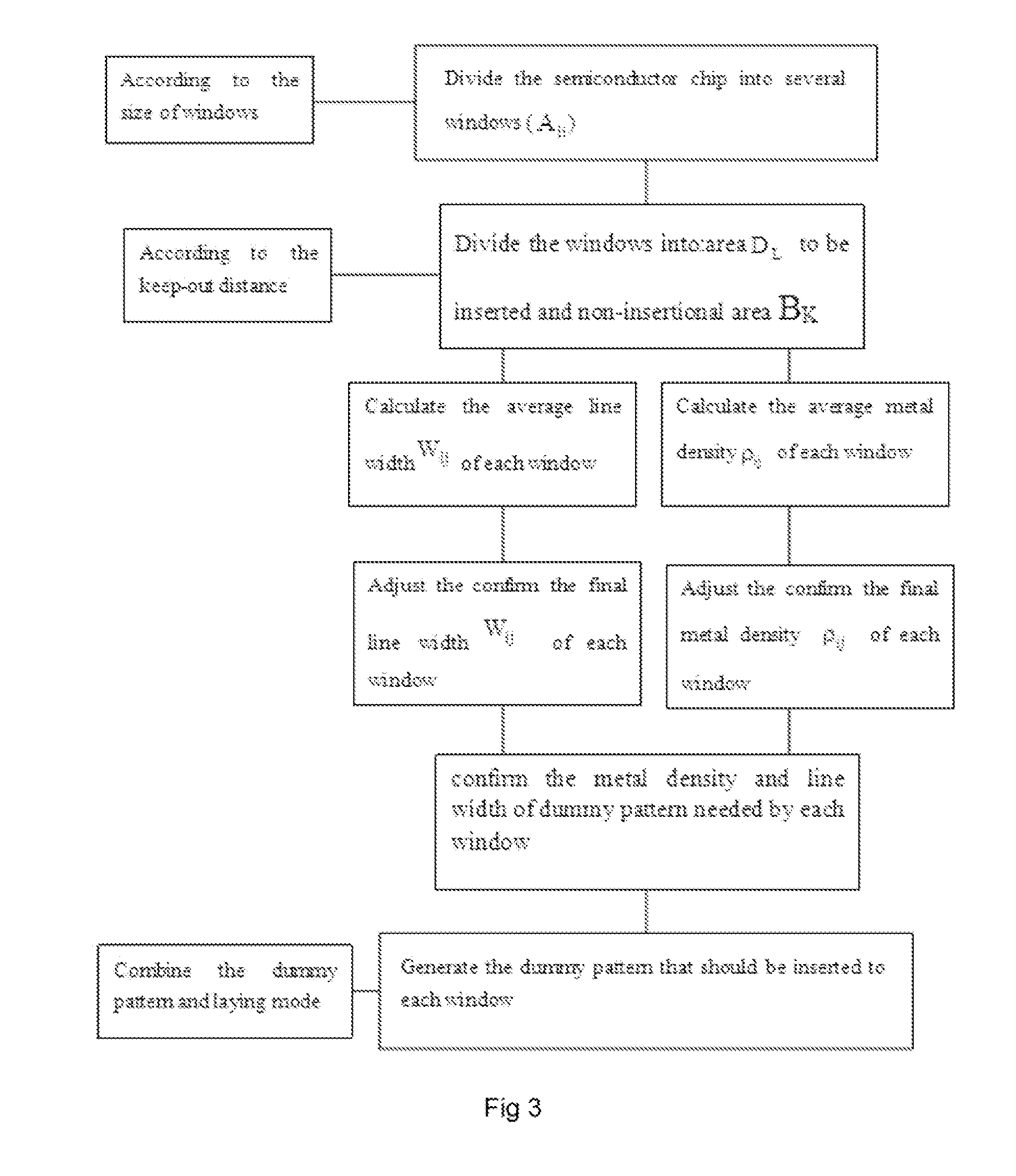

Algorithm of cu interconnect dummy inserting

ActiveUS20130227502A1Reasonable densityReasonable widthCAD circuit designTotal factory controlCopper platingSemiconductor chip

The present invention disclosed an algorithm of Cu interconnect dummy inserting, including: divide the surface of semiconductor chip into several square windows with an area of A, each of which is non-overlap; perform a logic operation on each square window; and divide the window into two parts: ① the area to-be-inserted; ② the non-inserting area; determine the metal density of the dummy pattern that should be inserted to each square window and the line width; determine the dummy pattern that should be inserted to the windows according to the metal density, line width, the pre-set dummy pattern and the layouting rules. The beneficial effects of the present invention is: avoided the shortcomings of fill density maximization in the rule-based filling method by using reasonable metal density and line width. And with a combination of the influence of line width and density to the copper plating process and chemical mechanical polishing morphology in model-based filling method, it can achieve a better planarization effect.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

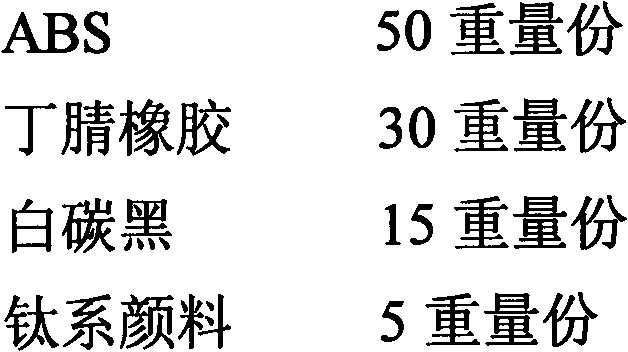

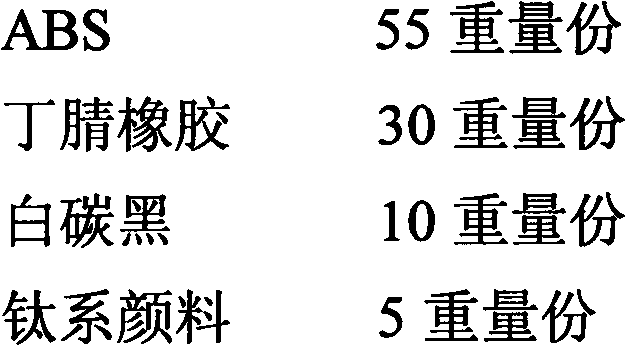

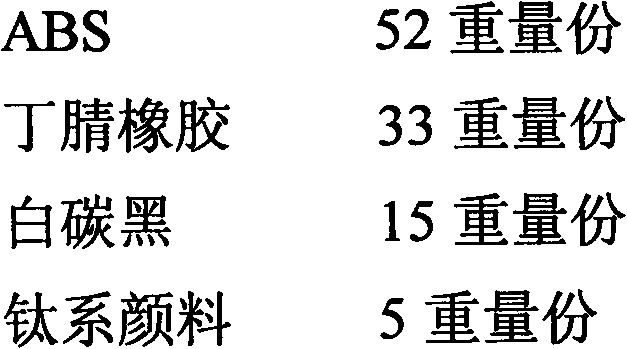

Antistatic ABS (Acrylonitrile Butadiene Styrene) laminated board

InactiveCN102582188ALow costMarket price stabilitySynthetic resin layered productsAntistatic MaterialsElectric properties

The invention discloses an antistatic ABS (Acrylonitrile Butadiene Styrene) laminated board which comprises a static dissipative layer and an electroconductive layer, wherein the static dissipative layer comprises the following components in percentage by weight: 50-55% of ABS, 30-35% of antistatic material, 6-15% of filler and 1-5% of pigments, and the electroconductive layer comprises the following components in percentage by weight: 50-55% of ABS, 30-35% of electroconductive black, 10-15% of filler. The antistatic ABS laminated board has prolonged antistatic effect which can exist with the board product. The antistatic ABS laminated board has the advantages of stable electric property, high heat resistance, good flattening performance and good antistatic performance.

Owner:YIYUAN ELECTRONICS TECH

Tungsten carbide spraying equipment with both grinding and surface defect repair functions

ActiveCN111962003AImprove processing effectImprove flattening effectMolten spray coatingGrinding drivesGrindingDrive motor

The invention provides tungsten carbide spraying equipment with both grinding and surface defect repair functions. The equipment comprises a base, a shell, a protective cover, a collecting frame, a collecting groove, a roller shaping frame structure, a cylinder, an arc surface polishing frame structure, a guide rail, an adjustable spraying fun fixing frame structure, a machining cleaning frame structure, a Y-shaped frame, a drive motor, a driving wheel, a driven wheel and a to-be-machined roller. The shell is in bolt connection with the upper portion of the base. The protective cover is in hinged connection with the left side inside the shell. The collecting frame is in bolt connection with the middle of the upper portion of the base. The equipment has the beneficial effects that by arranging the roller, a polishing motor, a rotating roller, a brush and a polishing belt, the surface of the to-be-machined roller is polished and ground conveniently, the polishing motor drives the rollerto rotate, the surface of the to-be-machined roller is ground through the grinding belt, and meanwhile unmolten tungsten carbide powder remaining at the corners of the front and back ends of the to-be-machined roller is cleaned thoroughly through the brush.

Owner:合力(天津)能源科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com