Smashing device for infusion hose

An infusion hose and crushing device technology, which is applied in the field of infusion hose crushing devices and infusion hose processing equipment, can solve the problems of infusion hose management lag, etc., achieve simple, practical and convenient equipment, improve usability, and ensure easy maintenance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

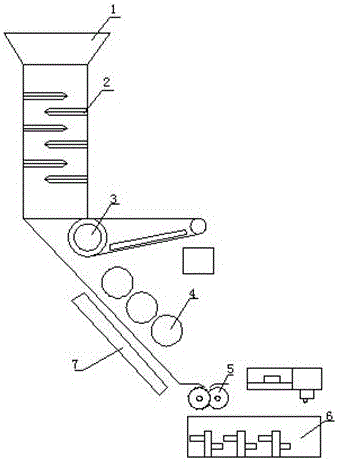

[0039] Such as figure 1 As shown, the crushing device of the infusion hose of the present invention discloses a crushing device of the infusion hose, which includes a feeding zone, a shearing zone, a magnetic separation zone, a flattening zone, and a crushing zone arranged in sequence from top to bottom , and a collection area; a sterilization mechanism 8 is provided above the collection area.

[0040] The feeding area is provided with a hopper 1, the output port of the hopper 1 is rectangular, and the cross-sectional area ratio of the inlet and outlet of the hopper 1 is 2-5. The design of the hopper 1 can facilitate the transportation and accumulation of the infusion hose, and facilitate the timely feeding of the shearing mechanism 2 .

[0041] The shearing zone includes a vertically arranged shearing channel and multiple sets of shearing mechanisms 2 arranged in the shearing channel, and multiple sets of shearing mechanisms 2 are alternately arranged on both sides of the s...

Embodiment 2

[0048] The crushing system of the transfusion hose of the present invention comprises a hopper 1, a shearing mechanism 2, a magnetic separation mechanism 3, a flattening mechanism 4, a crushing mechanism 5, a collection chamber 6, a controller, a sterilization mechanism 8, and a driving mechanism;

[0049] A vertical shearing channel is connected below the hopper 1; more than two sets of shearing mechanisms 2 are arranged alternately on both sides of the shearing channel, and the shearing mechanisms 2 are arranged obliquely downward; the shearing mechanism 2 includes a shearing mechanism 2 includes a serrated fixed blade and a serrated movable blade. The fixed blade and the movable blade cooperate to form a shearing force; the shearing mechanism 2 is hinged in the shearing channel and can rotate downward around the hinge, and a A spring for resetting the shearing mechanism 2;

[0050] The magnetic separation mechanism 3 is below the shear channel, and the magnetic separation m...

Embodiment 3

[0059] Based on embodiment 1 or 2, the ceramic layer of 10-15mm is arranged on the surface of its ceramic roller, and this ceramic layer is made up of the material of parts by weight: 60 parts of silicon carbide, 5 parts of silica sol, 0.6 part of hydroxymethyl cellulose, 4.1 Parts of sodium lignosulfonate, 2 parts of paraffin, 20 parts of mullite powder, 13 parts of quartz sand, 13 parts of clay powder, 3 parts of sillimanite, 7 parts of zirconium dioxide, 12 parts of ceramic powder, 13 parts of titanium carbide, 4 parts 1 part of purple sand mud, 6 parts of boron nitride, 0.4 part of manganese dioxide, 0.6 part of bamboo charcoal carbon fiber; the sterilizing mechanism 8 is sterilized by disinfectant, and the disinfectant is composed of the following materials by weight: 45 parts of octanoic acid, 12 parts of nonanoic acid , 43 parts of alcohol, 3 parts of iodine solution, 6 parts of sodium hypochlorite, 1 part of cesium hydroxide, 4 parts of capric acid, 4 parts of benzoic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com