Metal plate conveying and flattening mechanism for electronic accessories

A technology for accessories and sheet metal, applied in the field of sheet metal conveying and flattening mechanism for electronic accessories, can solve the problems of easy crushing of hands, small size of sheet metal parts, hidden safety hazards, etc., and achieves good flattening effect and high degree of automation , Feeding accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

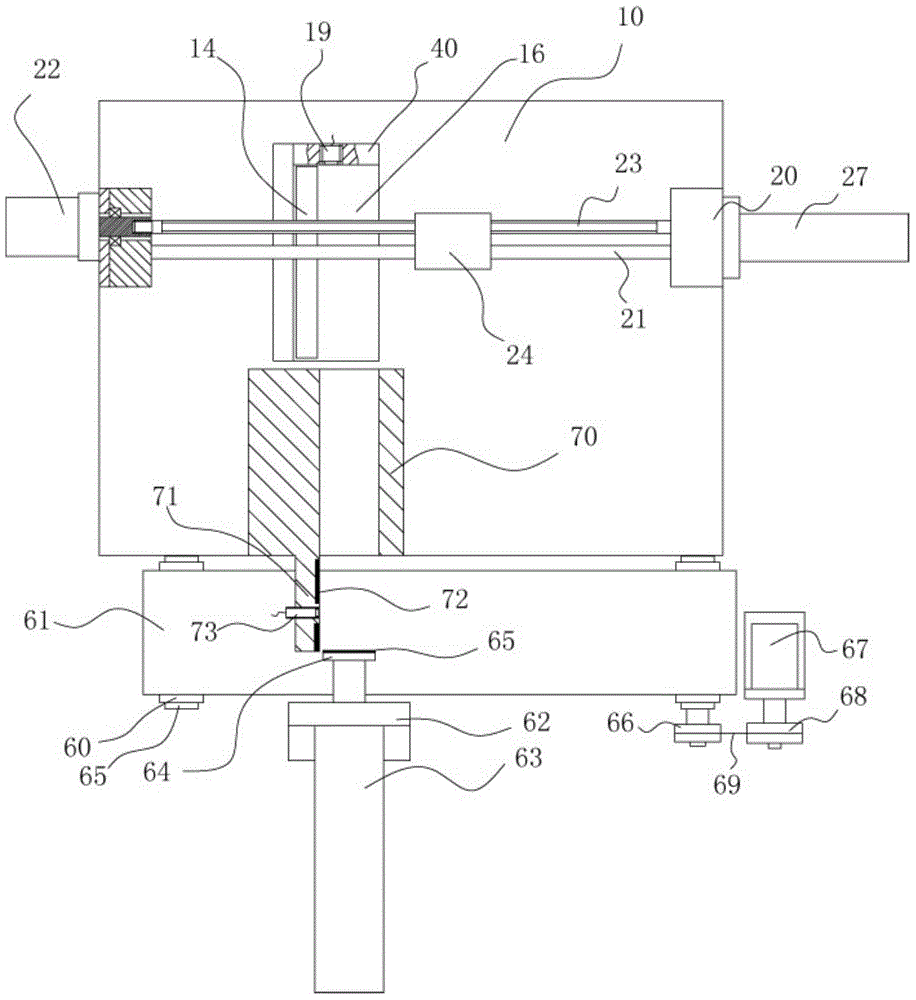

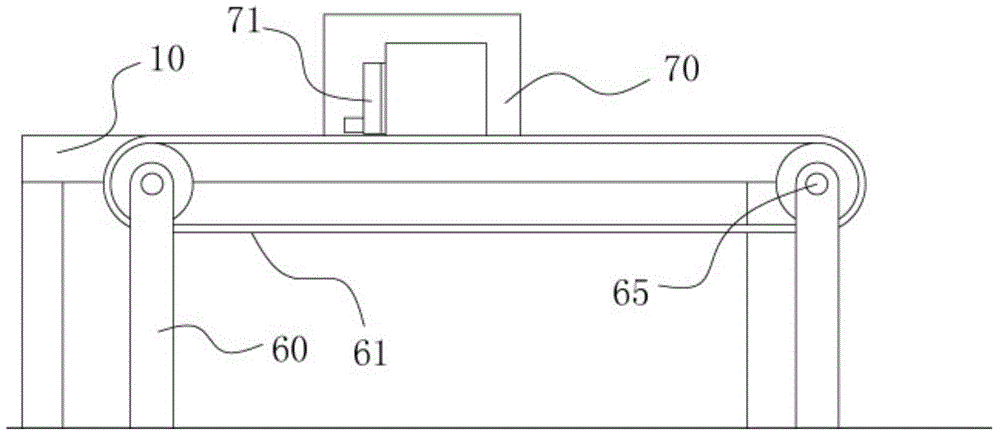

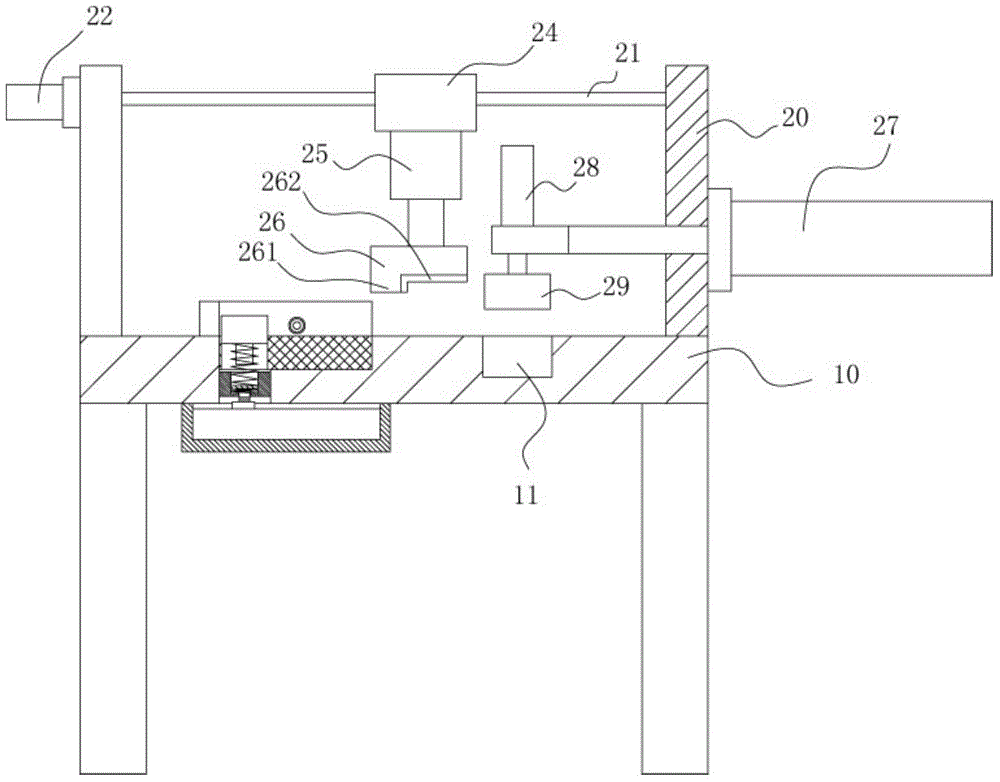

[0018] Example: see Figures 1 to 4 As shown, a sheet metal conveying and flattening mechanism for electronic accessories includes a frame 10 and a conveying frame 60. Binder groove 11, binder groove 11 is on the right side of groove 15, and the left and right ends of the top plate of frame 10 is fixed with support plate 20, and the two ends of stop bar 21 are fixed on two support plates 20, and drive motor 22 is fixed on one of the supporting plates 20, and the output shaft of the drive motor 22 extends into the socket provided in the supporting plate 20 and is hinged in the socket through a bearing. One end of the adjusting screw 23 has a spline portion, and the spline portion Stretch in this socket and insert in the spline hole that the output shaft of drive motor 22 has, the other end of adjustment screw rod 23 is hinged on another support plate 20, and moving block 24 is screwed in adjustment screw rod 23 and Insert sleeve in the limit rod 21, the bottom of the moving bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com