Tea rolling device with multi stations

A rolling device and multi-station technology, applied in the field of tea rolling devices, can solve the problems of high labor intensity, low production efficiency, poor weight accuracy of tea leaves, etc., and achieve the effects of reducing labor intensity, improving production efficiency, and having a simple and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

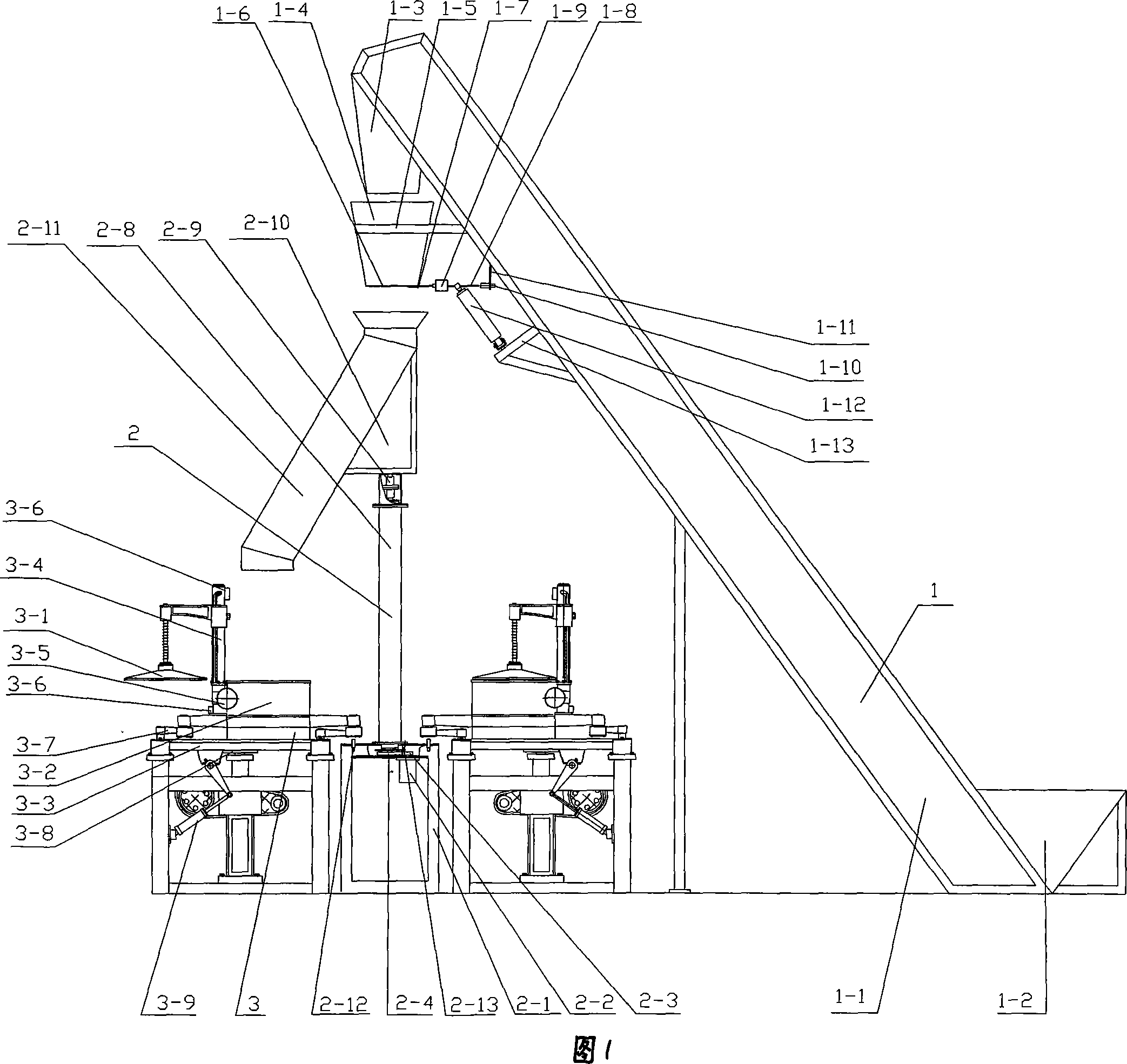

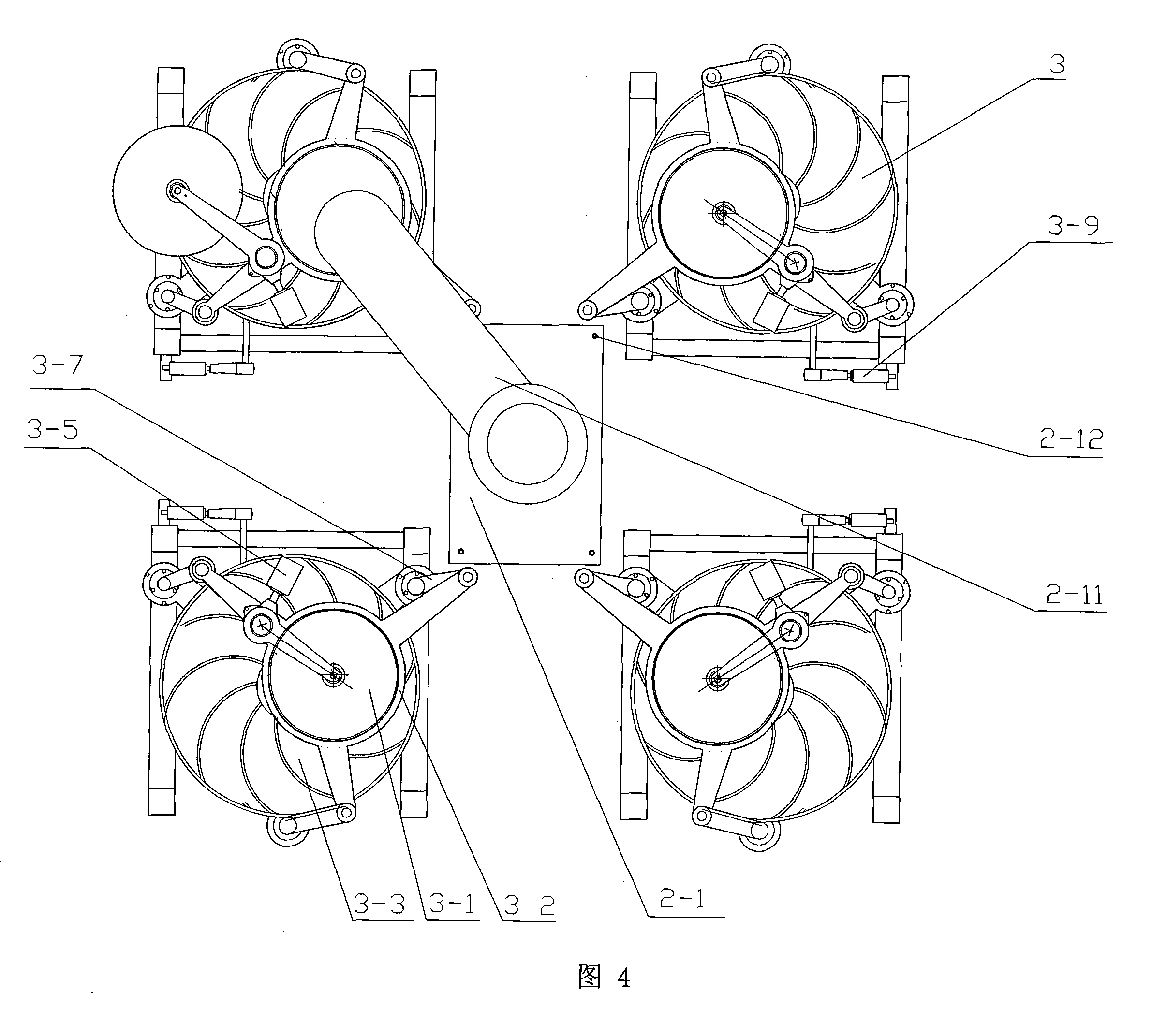

[0020] Embodiment 1: Referring to Figures 1 to 4, a multi-station tea rolling device, including a rolling machine 3, is characterized in that: a transmission weighing mechanism 1 and a rotary feeding mechanism 2 are added beside the rolling machine 3, and the The discharge end of the conveying weighing mechanism 1 cooperates with the feed end of the rotary feeding mechanism 2 , and the discharge end of the rotary feeding mechanism 2 cooperates with the feed end of the kneading machine 3 .

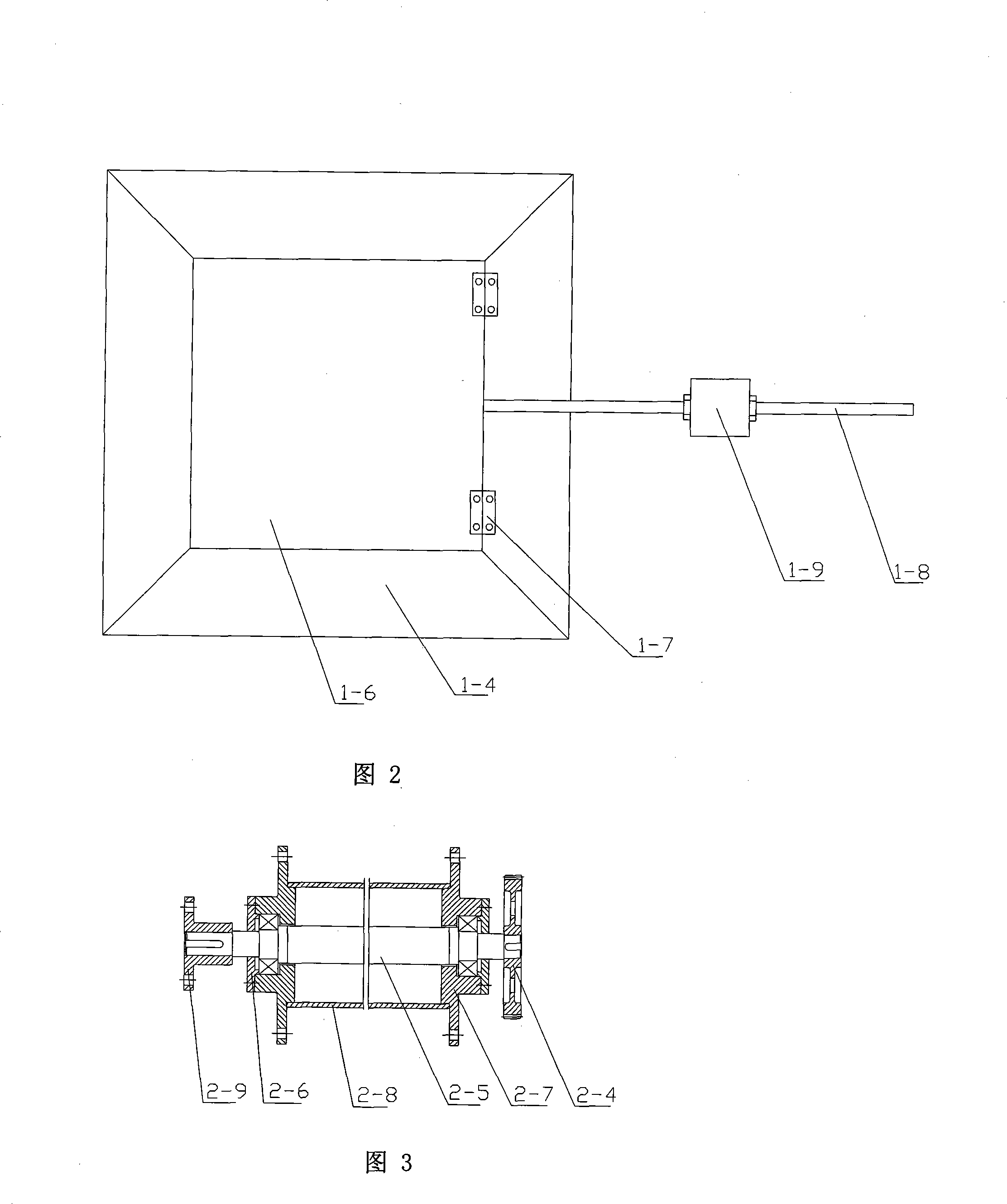

[0021] The conveying weighing mechanism 1 includes a hoist 1-1, a feed hopper 1-2, a lower hopper 1-3, a charging box 1-4, a bottom plate 1-6, a connecting rod 1-8, and a counterweight 1-9 , a weighing sensor 1-10 and an air pump 1-12; wherein, the feed hopper 1-2 is connected to the feeding place at the lower end of the elevator 1-1, and the lower hopper 1-3 is connected to the The lower part of the discharge port at the upper end of the elevator 1-1; the charging box 1-4 is positioned by ...

Embodiment 2

[0025] Embodiment 2: Referring to Fig. 5, a multi-station tea rolling device, in this embodiment, except that the kneading barrel positioning sensor 2-12 is fixedly connected to the outstretched pole on the stand of the kneading machine 3 , and correspond to the outer end of the crank 3-7 on the side of the frame 2-1 of the kneading machine 3 at the outermost position of its operation, other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com