Patents

Literature

40results about How to "Realize cycle job" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

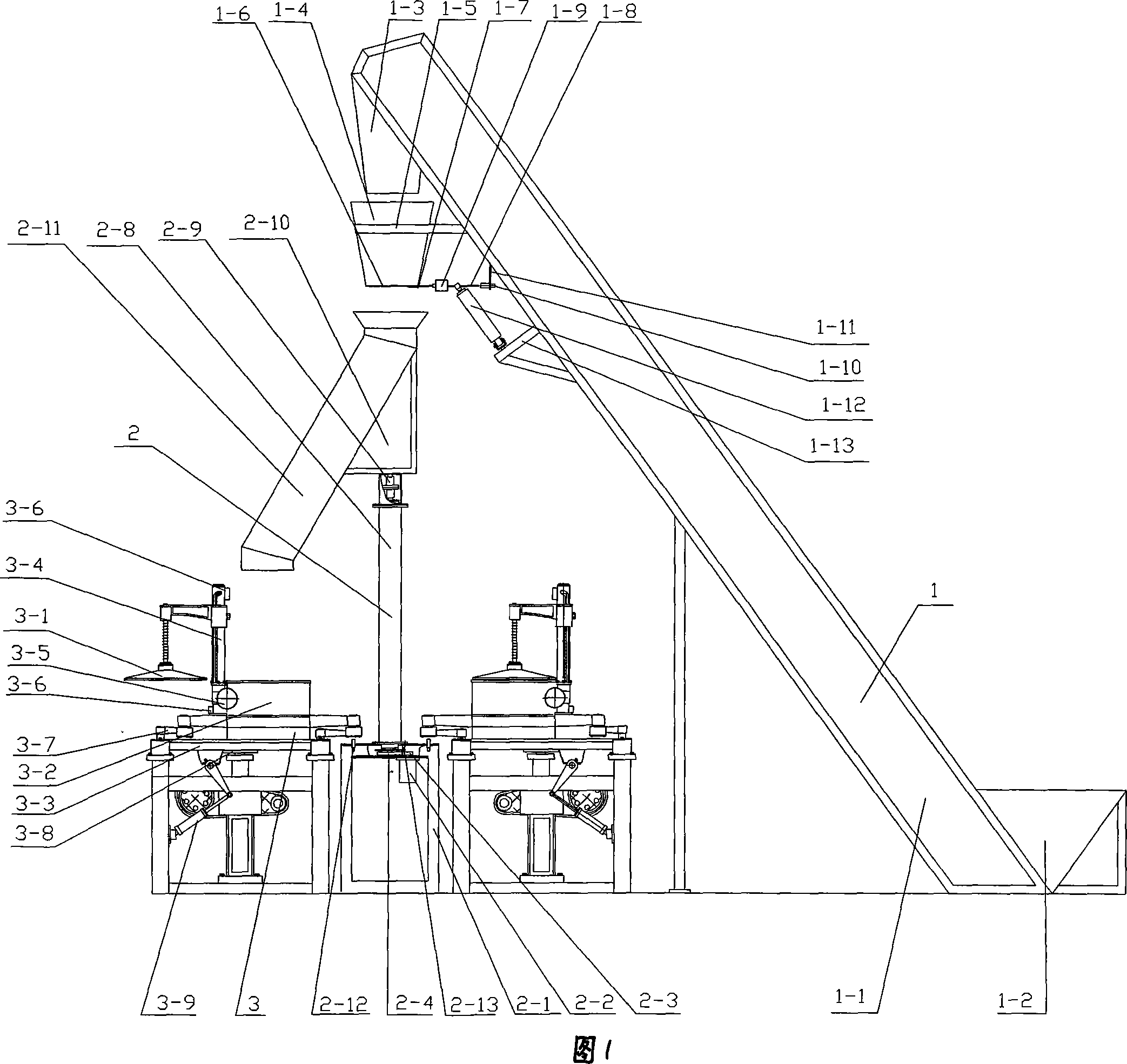

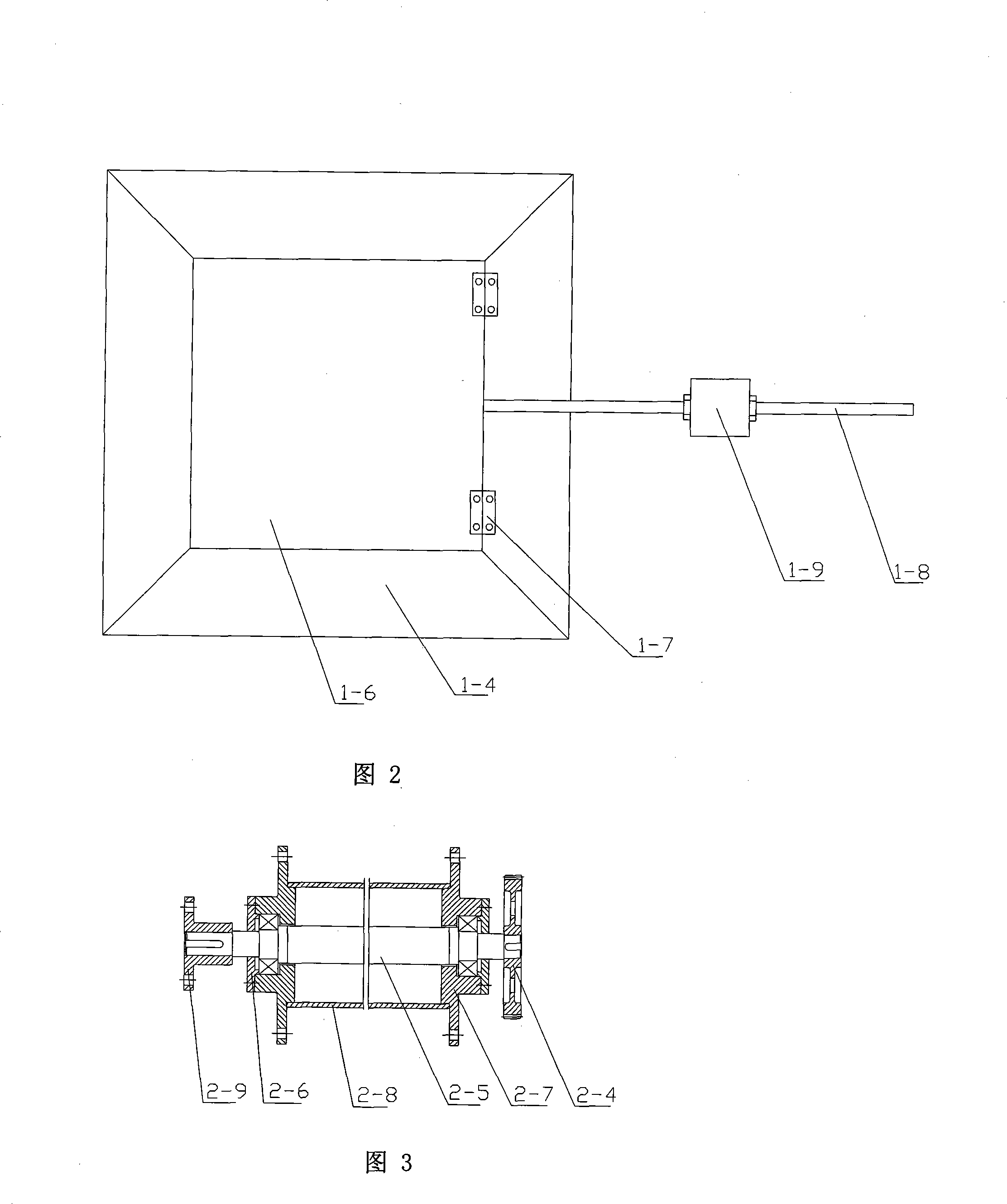

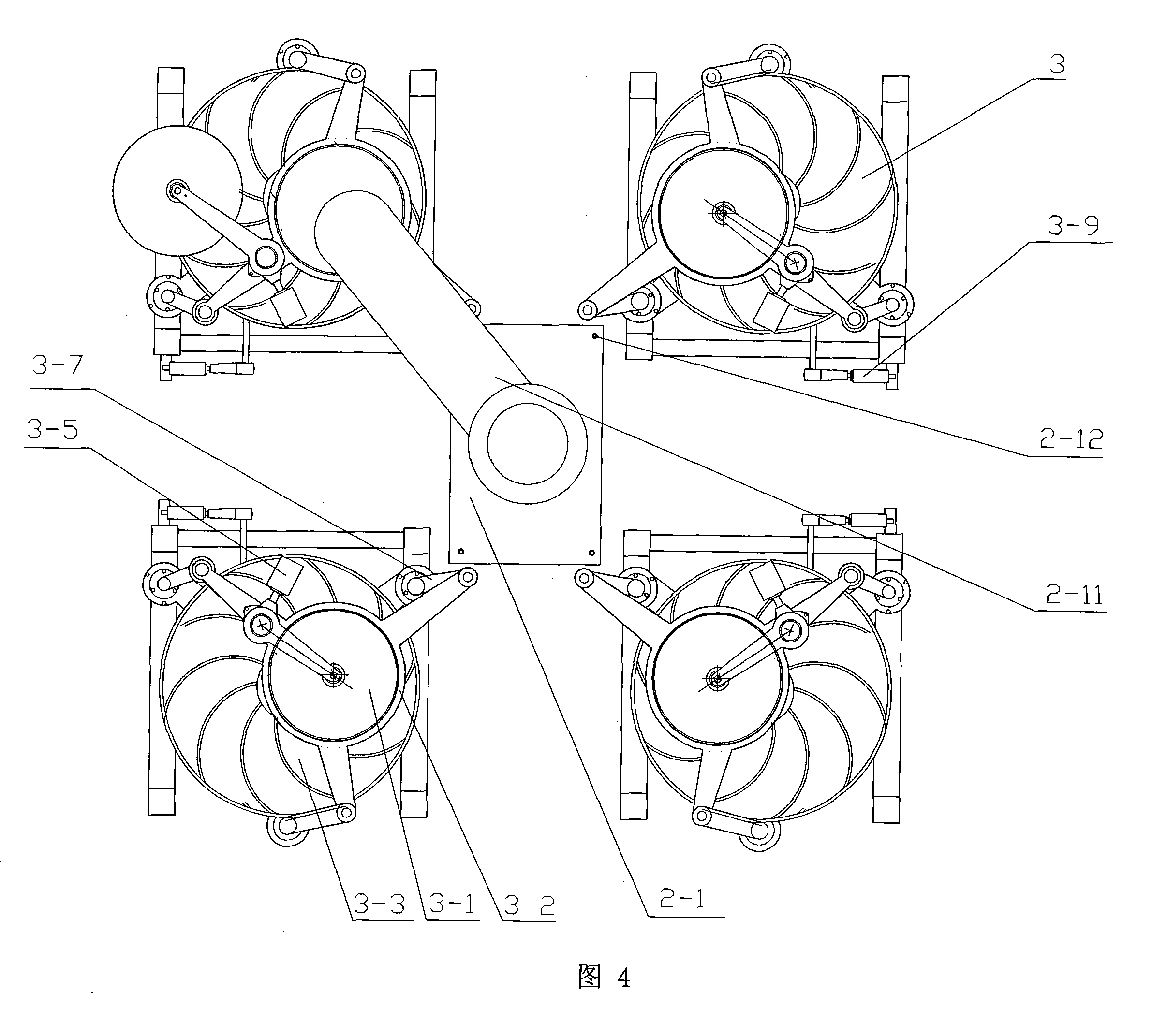

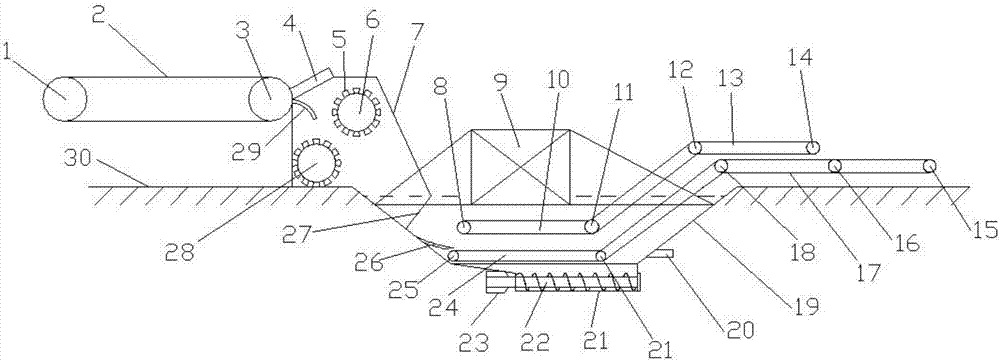

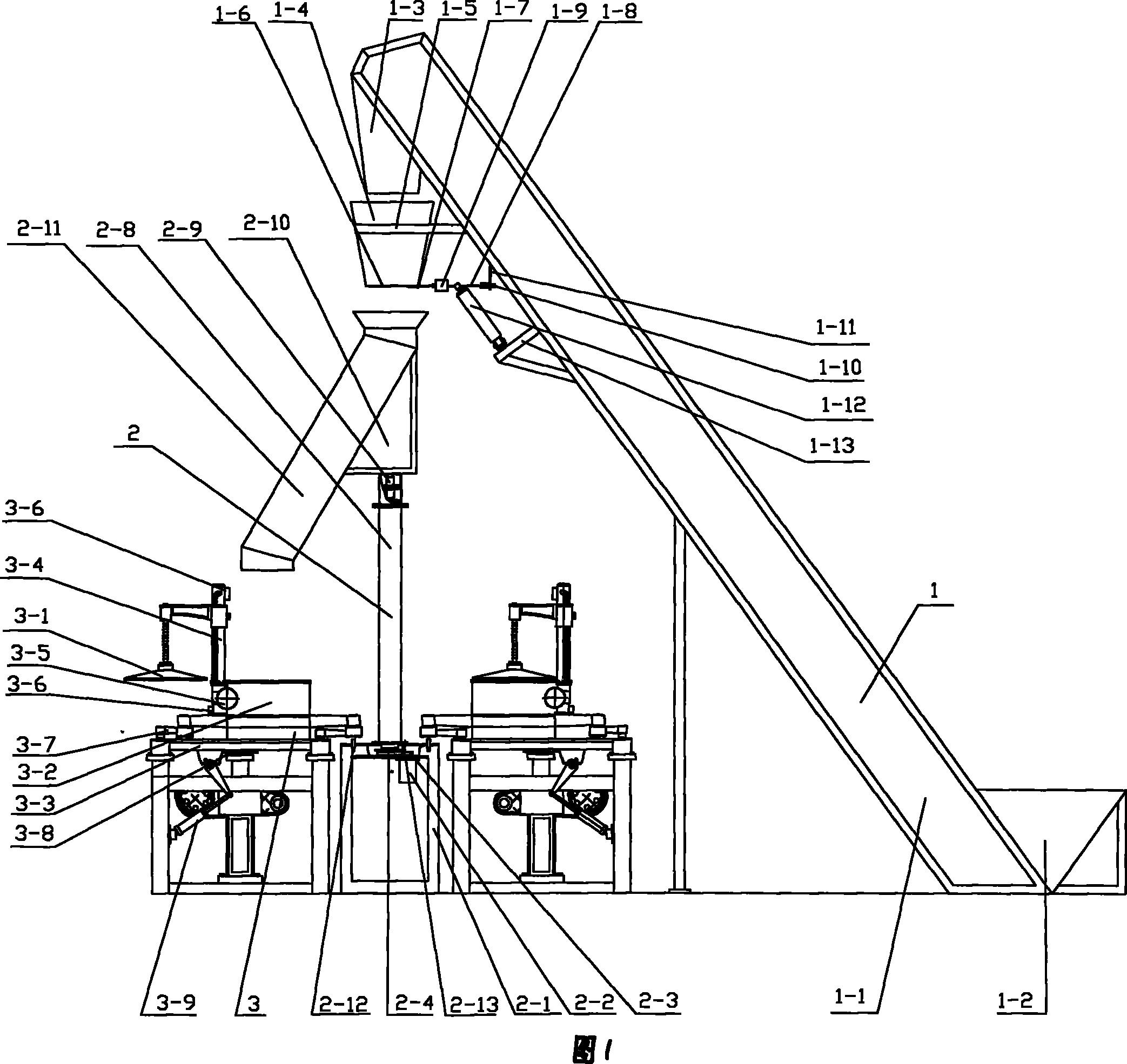

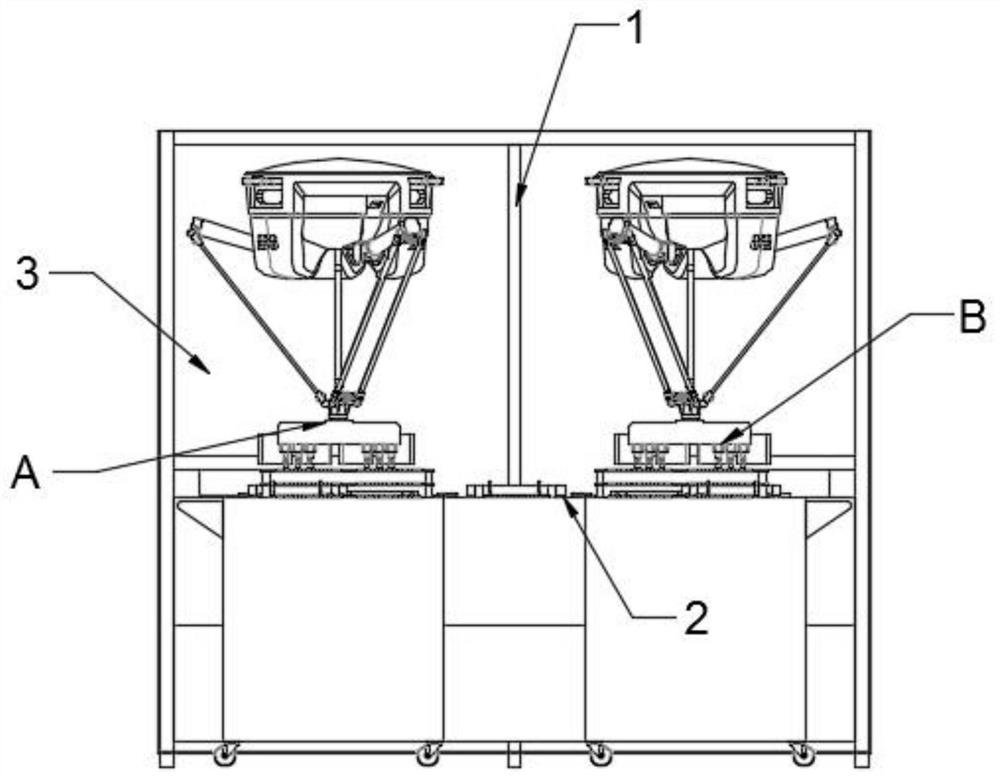

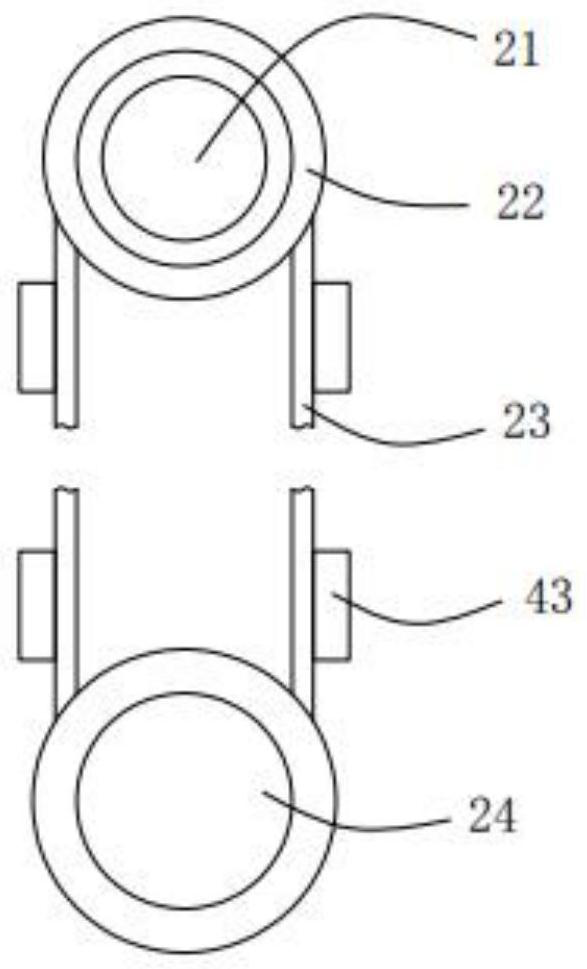

Tea rolling device with multi stations

InactiveCN101223923ASimple structureIncrease productivityPre-extraction tea treatmentAutomatic controlMechanical engineering

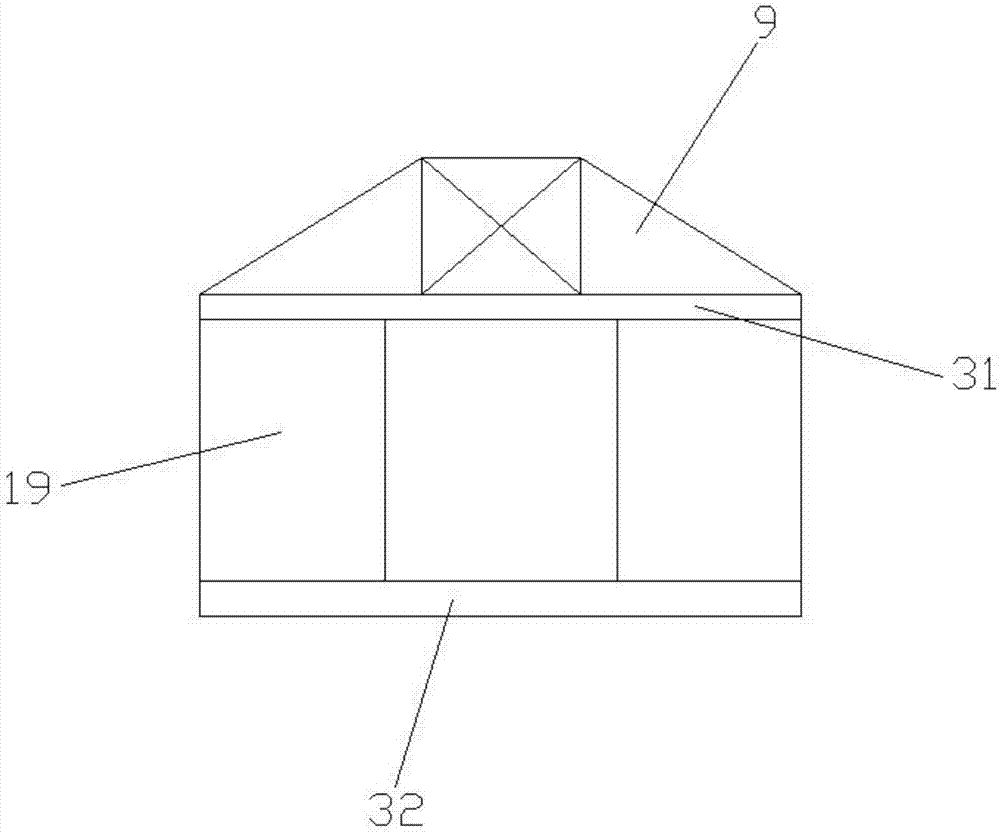

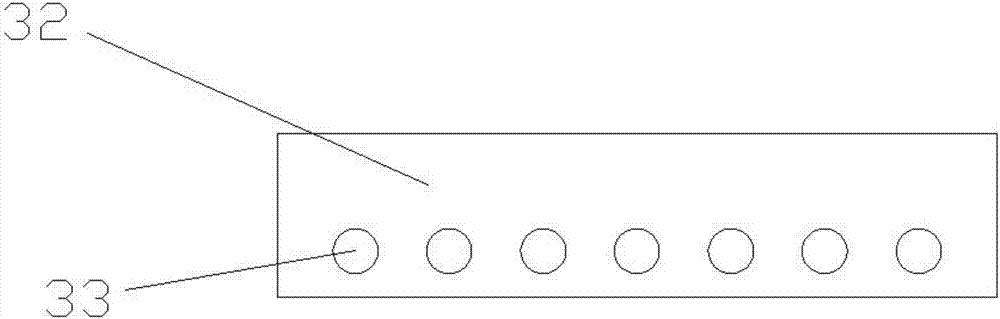

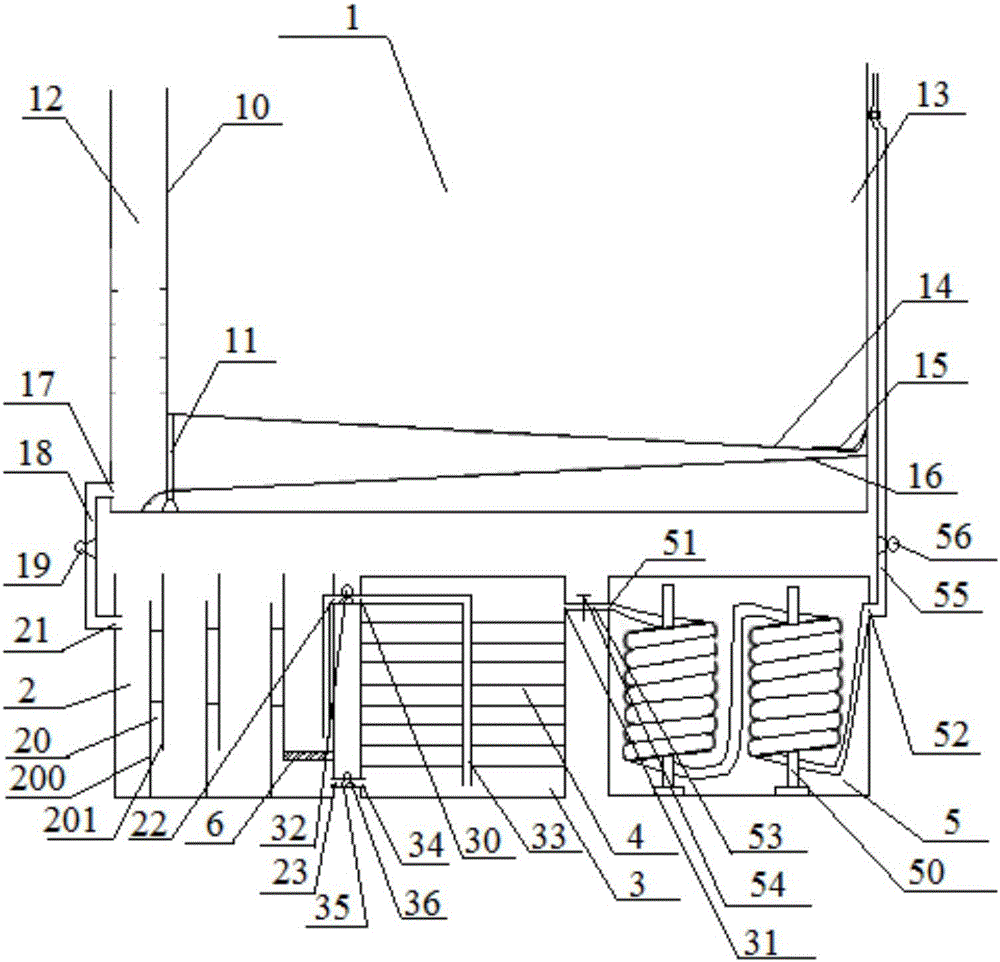

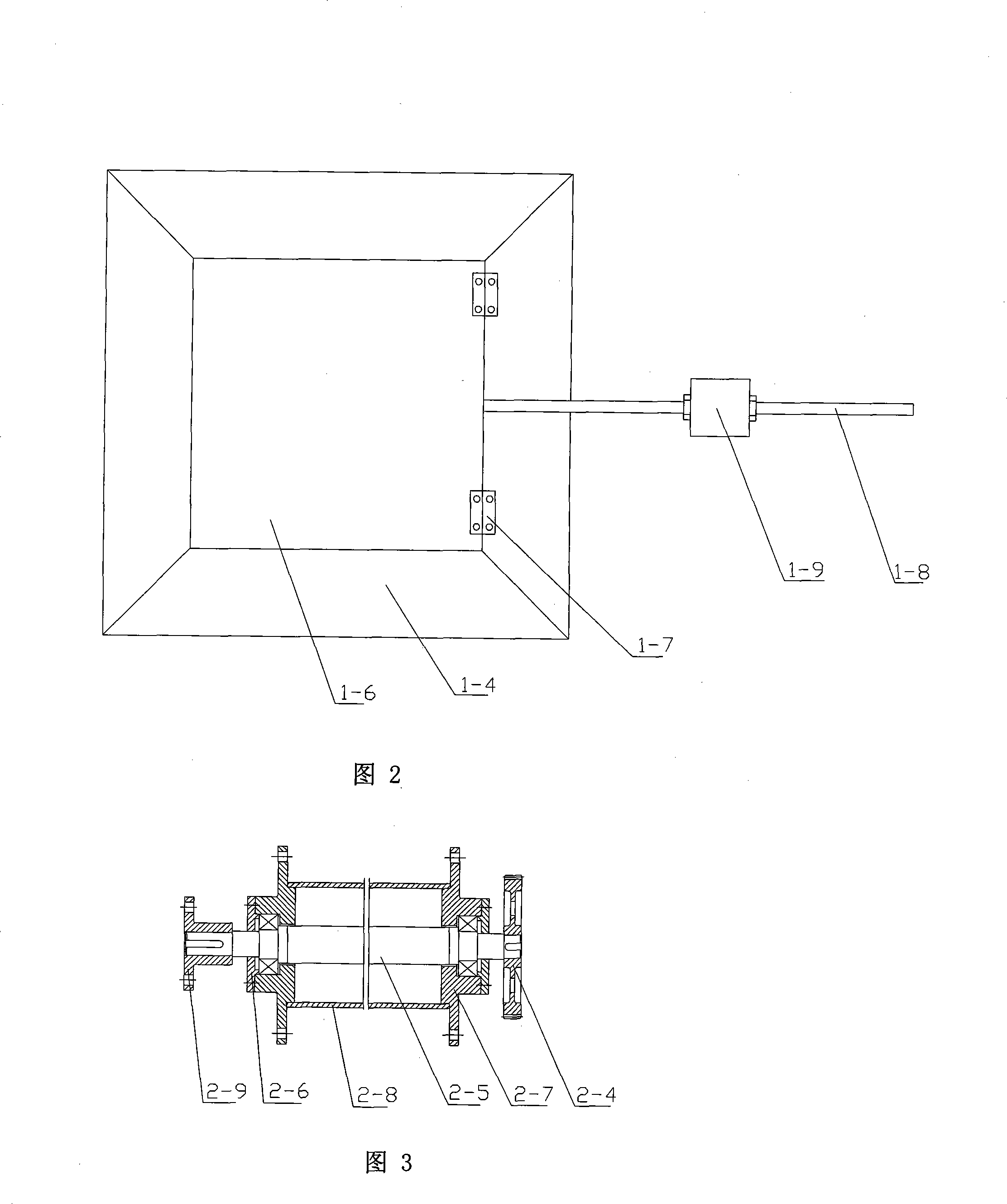

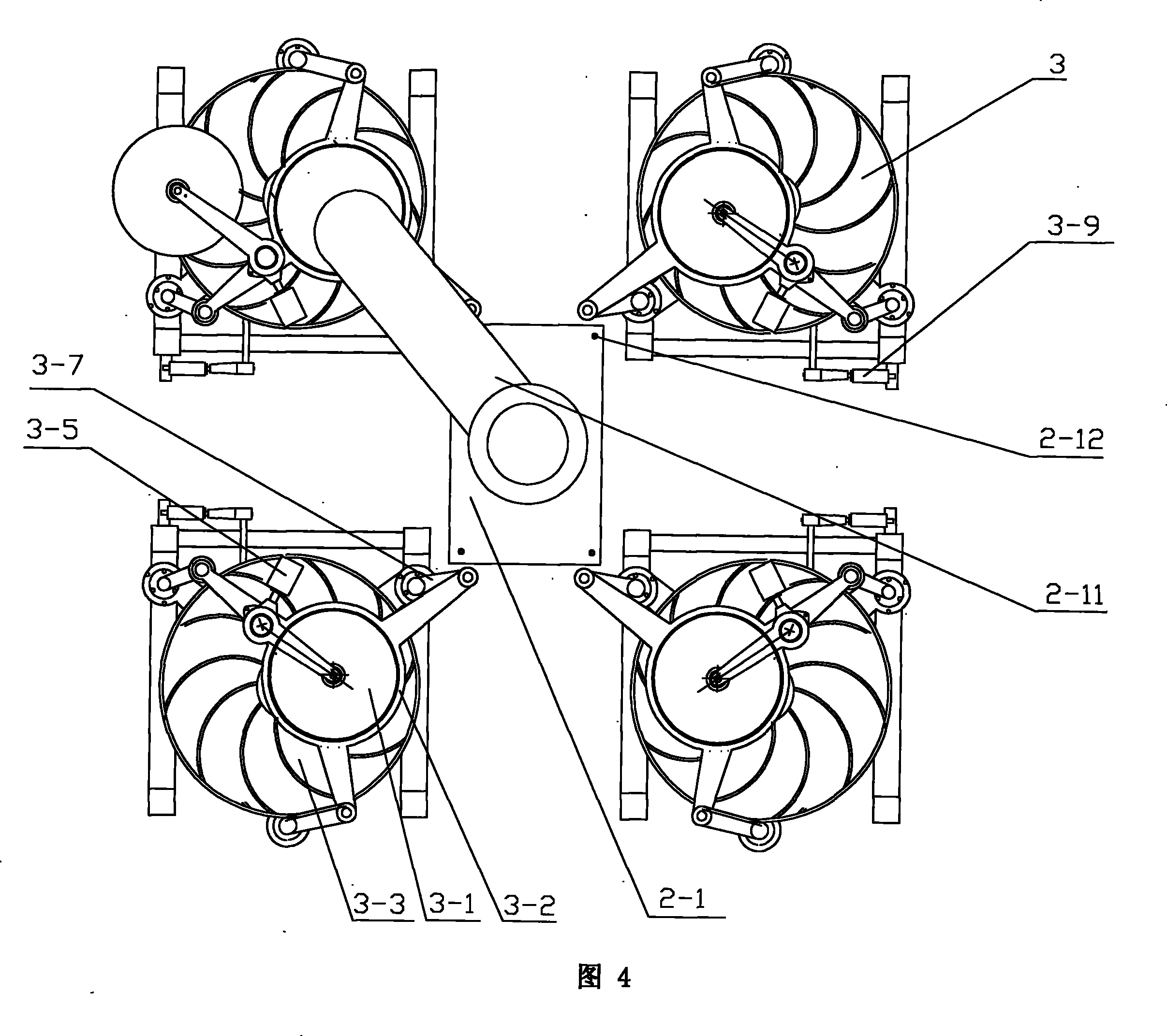

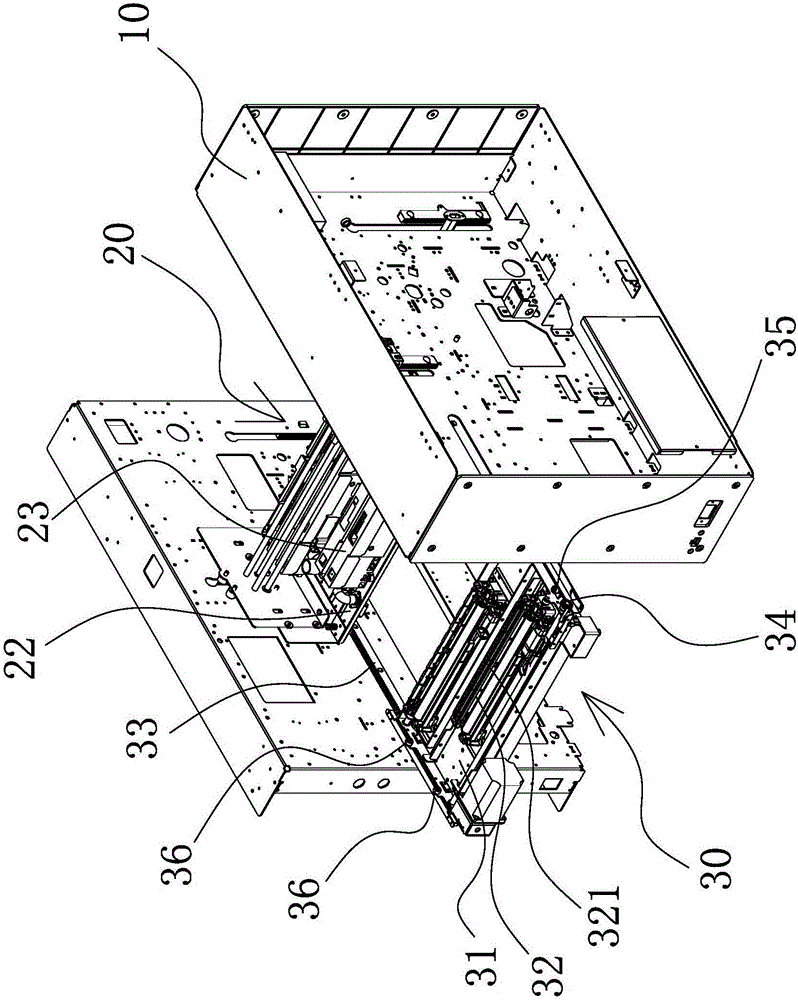

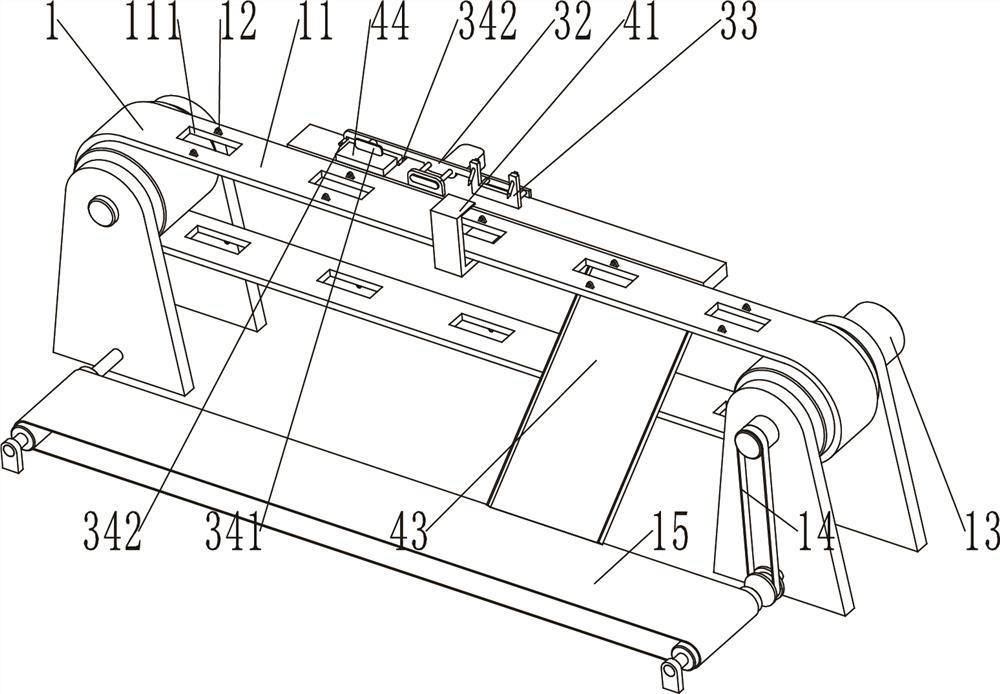

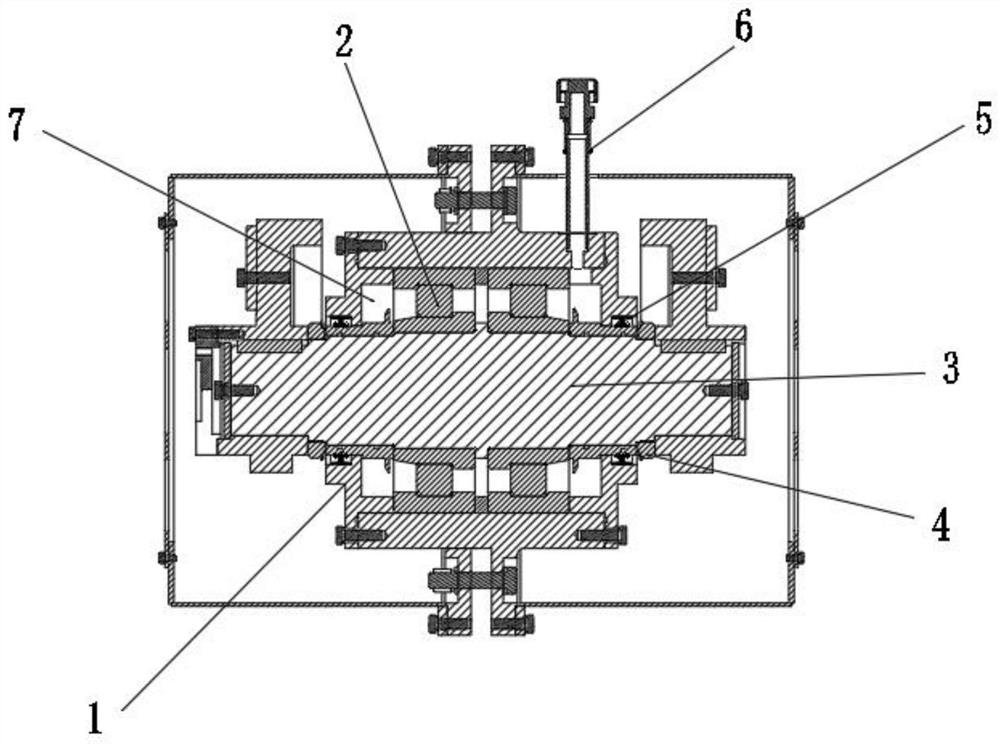

The invention relates to a multi-station tea leaves rolling device which comprises a rolling machine (3). The device is characterized in that a transmission weighing mechanism (1) and a rotary material-feeding mechanism (2) are additionally arranged near the rolling machine (3); the material outlet end of the transmission weighing mechanism (1) is matched with the material inlet end of the material-feeding mechanism (2); the outlet end of the material-feeding mechanism (2) is matched with the inlet end of the rolling machine (3). The multi-station tea leaves rolling device of the invention has simple and reasonable structure, can automatically, continuously, effectively and exactly carry out weighing, feeding and rolling, can realize circular operation of a plurality of rolling machines at will and meet rolling requirement for different scales, achieves continuous and automatic control of rolling tea procedure, thereby greatly improving the production efficiency of tea rolling and relieving labor intensity; besides, the invention has little equipment investment and convenient production.

Owner:CHONGQING ACAD OF AGRI SCI

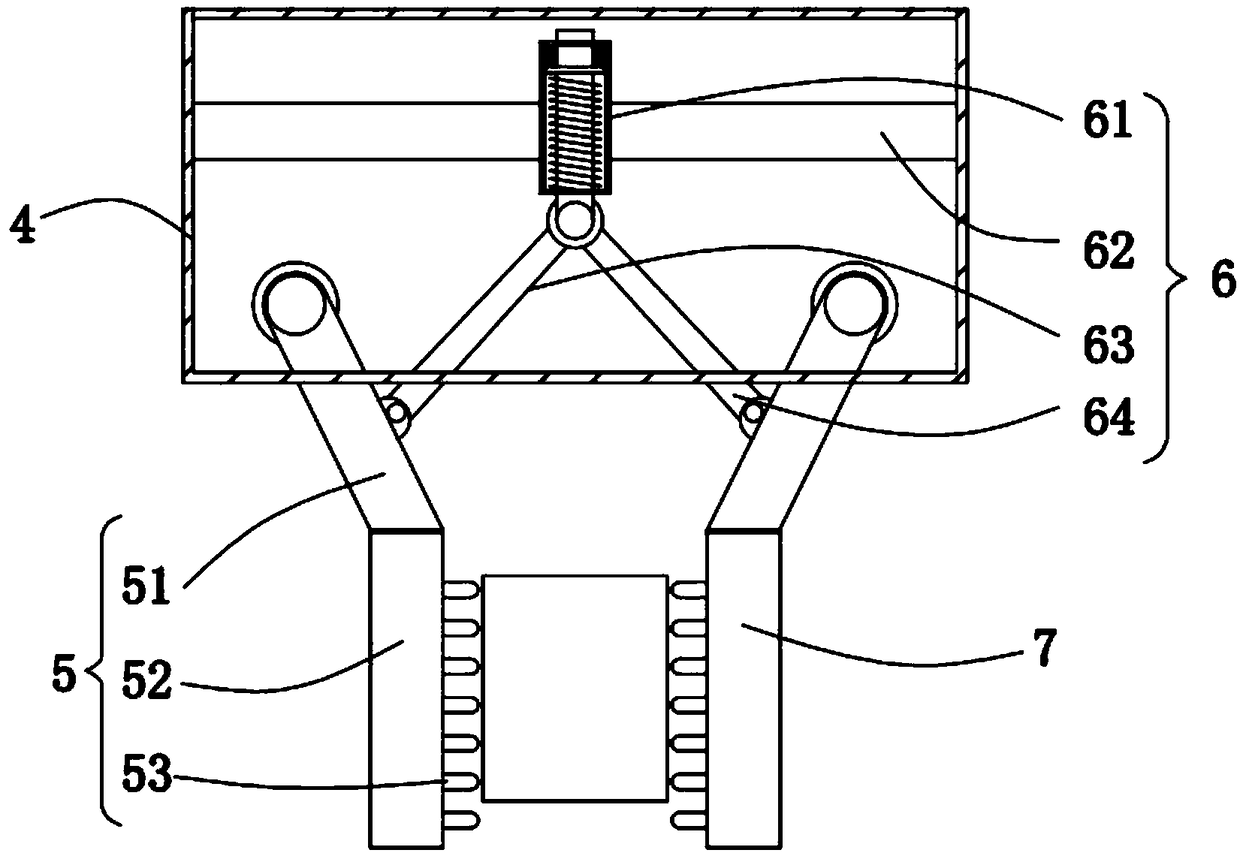

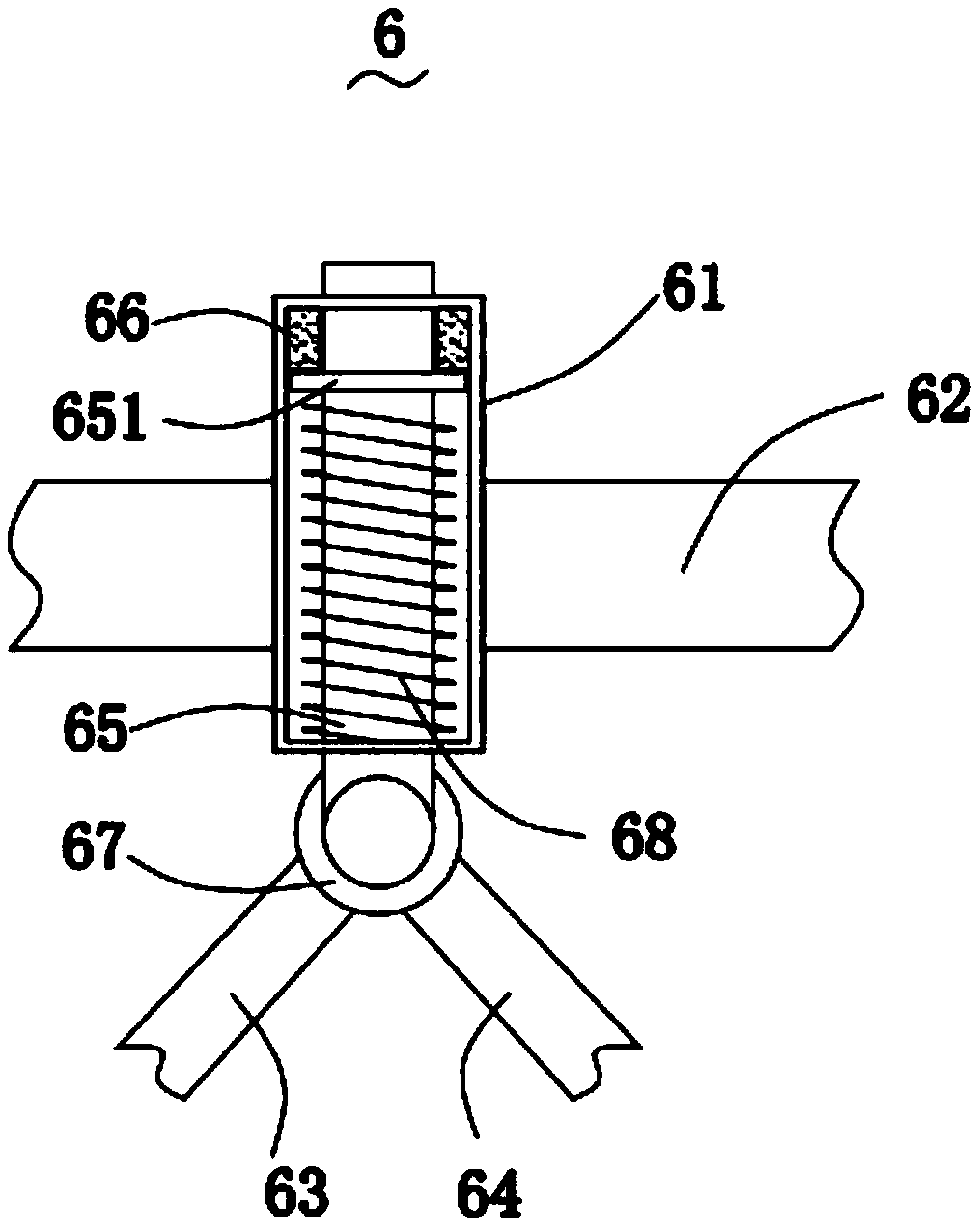

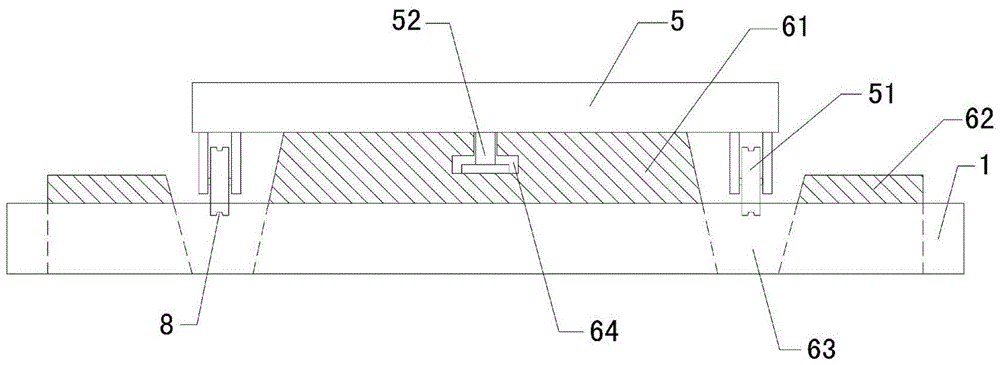

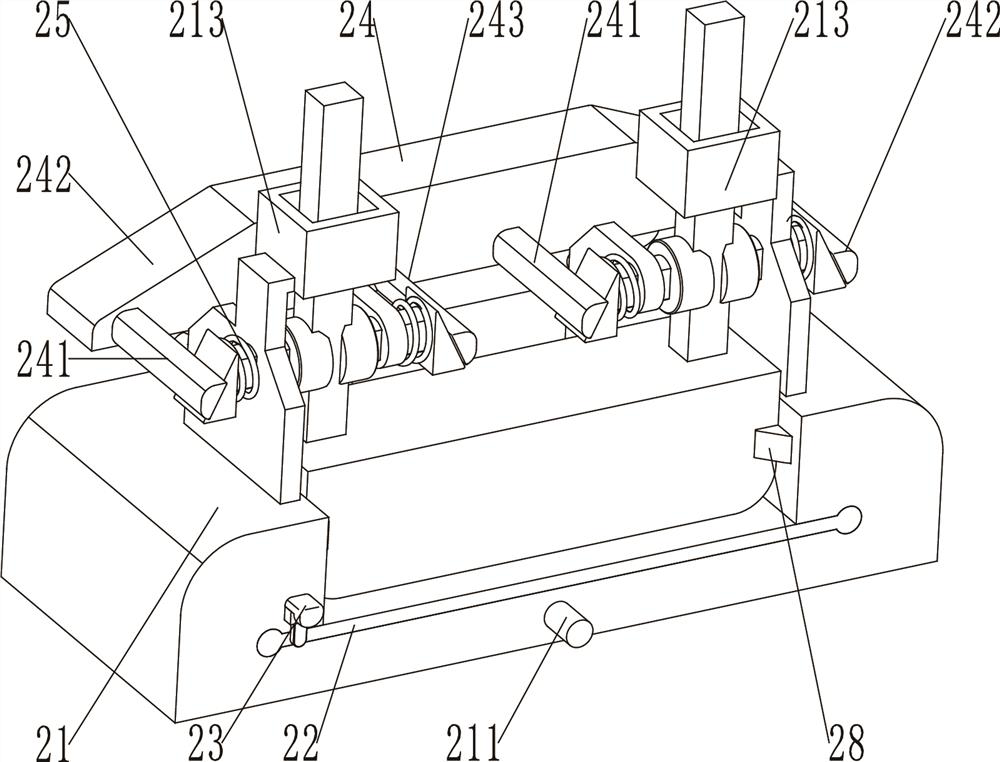

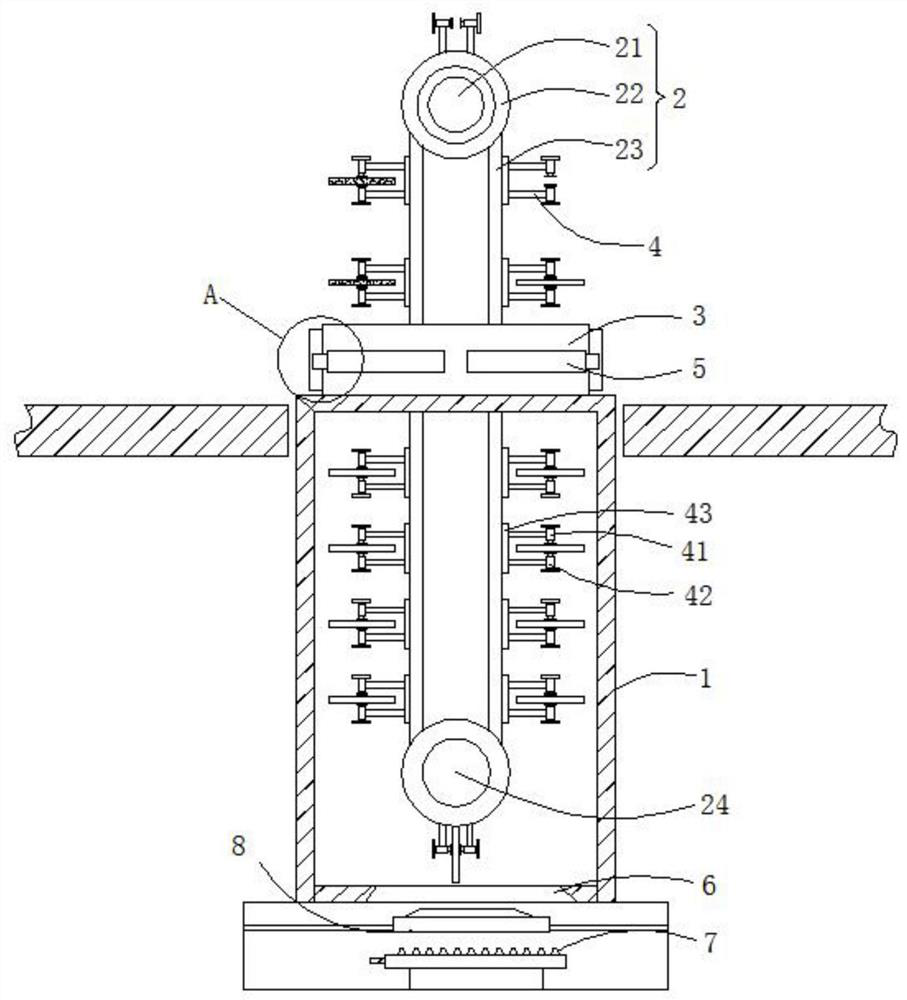

Mechanically-controlled-type automatic discharging manipulator

PendingCN108942993AImprove work performanceExtended service lifeGripping headsArmsEngineeringManipulator

The invention relates to the field of manipulators, in particular to a safety auxiliary device used for a non-motor vehicle. The invention discloses a mechanically-controlled-type automatic discharging manipulator which comprises a base, a pneumatic mechanism, a movable rod, a box body, a first clamping mechanism, an opening and closing mechanism, a pressing-type switch, an adjusting and controlling mechanism, a machining mould, a power box and a conveyer belt. According to the mechanically-controlled-type automatic discharging manipulator, the clamping manipulator is pushed by the pneumatic mechanism; the pressing-type switch can move along the bottom surface of the movable rod; when the clamping mechanism moves to two sides of a workpiece, a first pressing block presses down the switch,so that the clamping mechanism can clamp the workpiece, and automatic clamping is realized; when the switch is electrified, a second pressing block is flush with the first pressing block, so that theclamping mechanism can maintain a clamping state when a pneumatic rod is at a retrieving state; when the workpiece moves to the top of the conveyer belt, the pressing-type switch is reset and powered-off, so that the opening and closing mechanism drives the clamping mechanism to open; the workpiece falls on the conveyer belt, so that discharging and conveying are realized; and besides, the adjusting and controlling mechanism moves upwards to be reset, so that circular work is realized.

Owner:ANHUI UNIV OF SCI & TECH

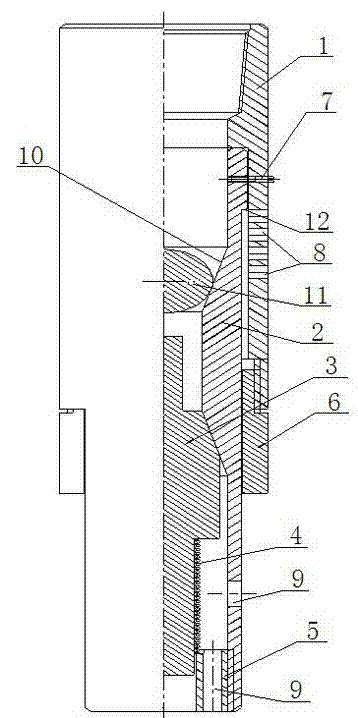

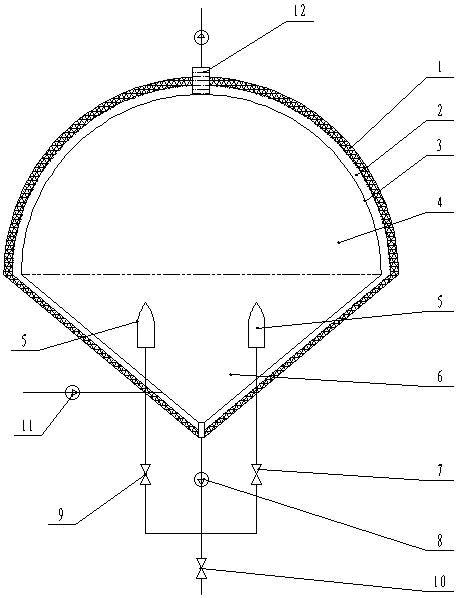

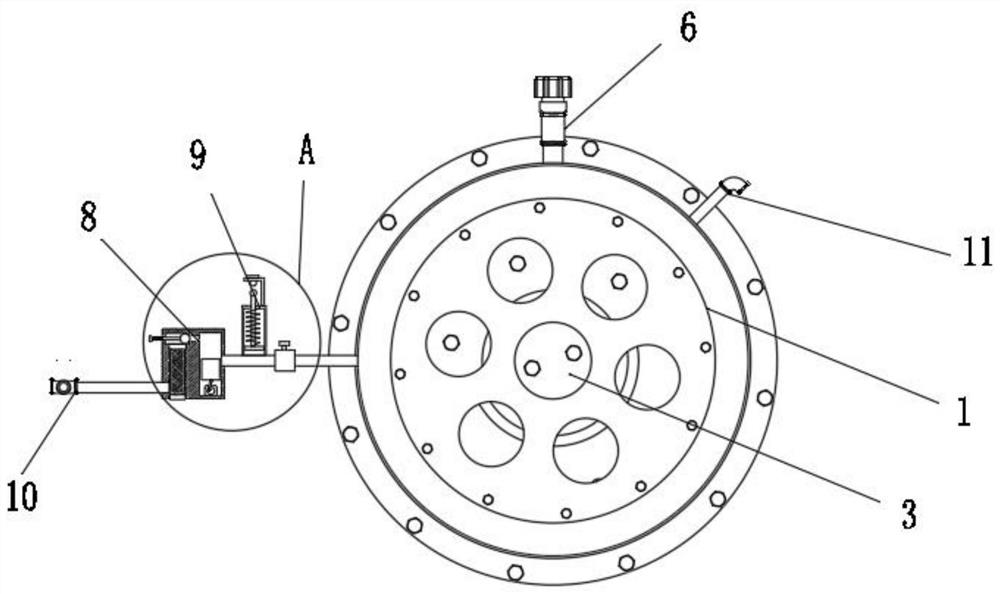

Downhole constant pressure valve for oil tube

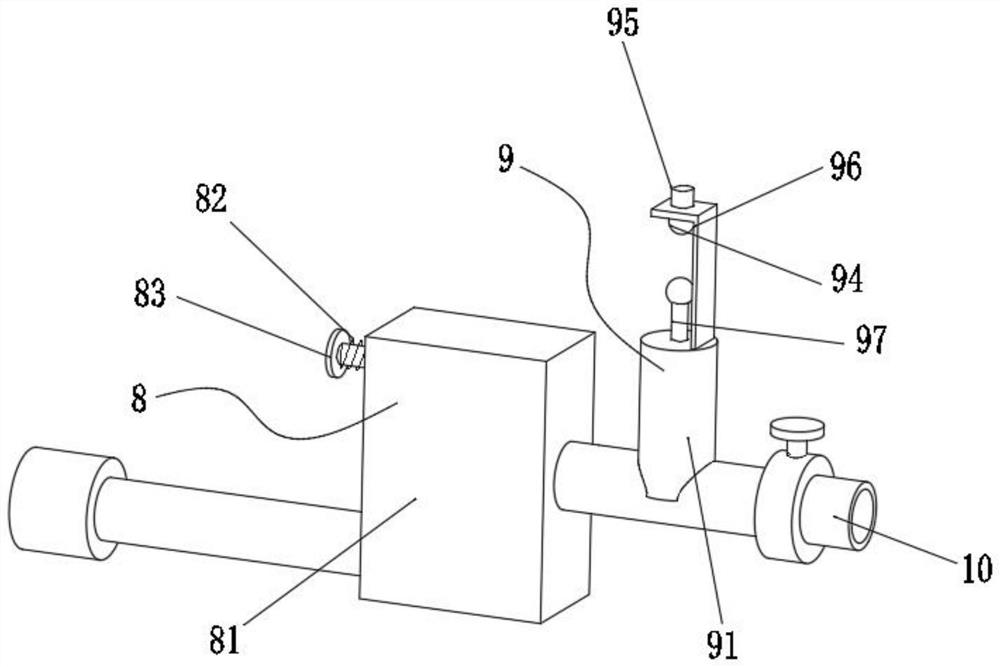

ActiveCN102808596AWon't leakRealize cycle jobFlushingWell/borehole valve arrangementsPetroleum engineeringDrilling fluid

The invention discloses a downhole constant pressure valve for an oil tube. The downhole constant pressure valve for the oil tube comprises a valve body and a spool. The spool is disposed in the valve body. A gap between the spool and the middle of the valve body is sealed by a spring. The spring is located on a spring holder connected to the lower portion of the valve body. The upper portion of the valve body is connected with a bonnet through a shear pin. The lower portion of the valve body is provided with a water hole for drilling fluid circulation. The upper portion of the bonnet is connected with the oil tube, an anti-fall cap holding the valve body from falling is connected to the lower portion of the bonnet, and a gas production mesh sealed by the valve body which does not fall yet is arranged in the middle of the bonnet. The downhole constant pressure valve in the mechanical structure is capable of effectively and temporarily plug a running oil string when inside the running oil string, so that leakage of borehole pressure from the oil string is guaranteed, cycle operation can be achieved effectively when the oil string runs down and after the oil string is in position, gas production can be achieved effectively after a Christmas tree is installed, and dependence on environmental factors such as temperature is not needed. The downhole constant pressure valve for the oil tube has the advantages of reasonable design, simple structure, low cost, high reliability, high stability, convenience in operation, high safety, high practicality and the like, and construction progress is quickened effectively.

Owner:CHINA PETROLEUM & CHEM CORP +1

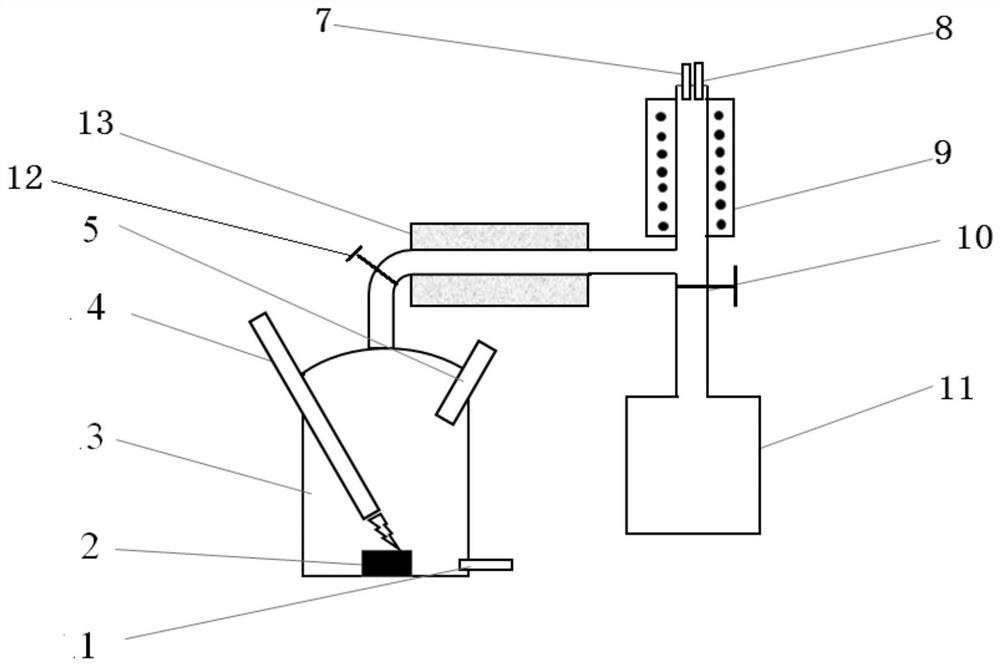

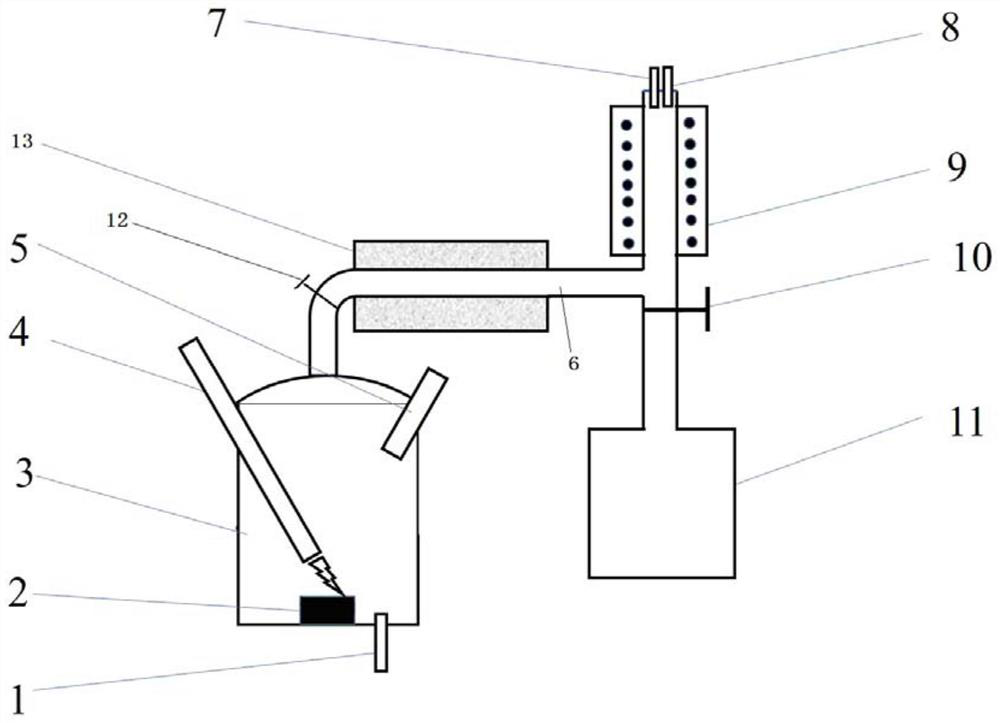

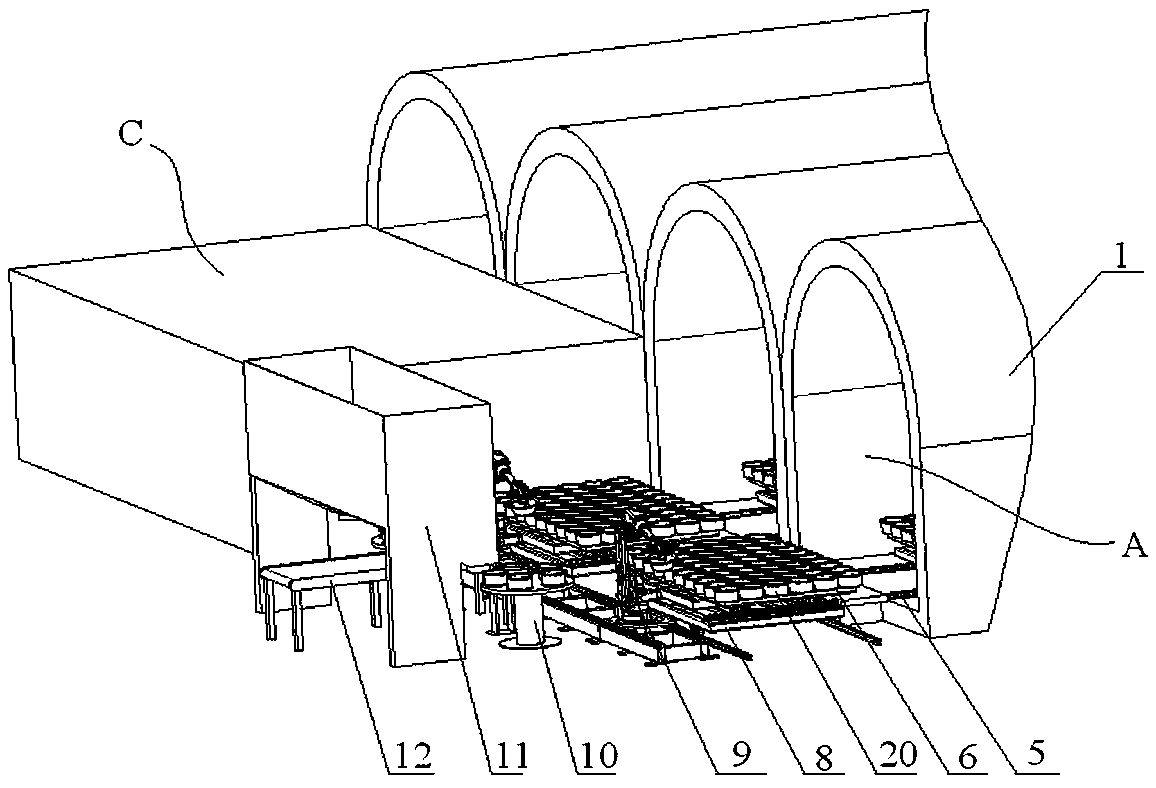

Continuous preparation system and preparation method of single-walled carbon nanotube

The invention belongs to the technical field of new materials, and relates to a single-walled carbon nanotube continuous preparation system and a process method, the device is formed by connecting a high temperature reaction chamber and a cooling unit in series, and vacuum, gas circuit, control, cooling and feeding systems and the like are used for assistance. According to the preparation method,a metal catalyst serving as a counter electrode is evaporated to form tiny catalyst particles by utilizing high temperature generated by direct-current arc flame, the tiny catalyst particles are rapidly combined with a high-temperature cracked organic carbon source to catalyze to generate single-walled carbon nanotubes, the single-walled carbon nanotubes are cooled and then enter a gas-solid separator, the obtained single-walled carbon nanotubes are enriched and separated by utilizing a magnetic field, and finally, the gas-solid separator is subjected to back-blowing by adopting inert gas to obtain a final product. According to the method, the catalyst can exist in the form of ultrafine particles in a high-temperature growth state, strict regulation and control on the purity, the pipe diameter structure and the like of the single-walled carbon nanotube are truly realized, and the high-quality single-walled carbon nanotube is continuously prepared. The device and the process are high inproduction efficiency and have important industrialization value.

Owner:JIANGXI COPPER TECHNOLOGY RESEARCH INSTITUTE CO LTD

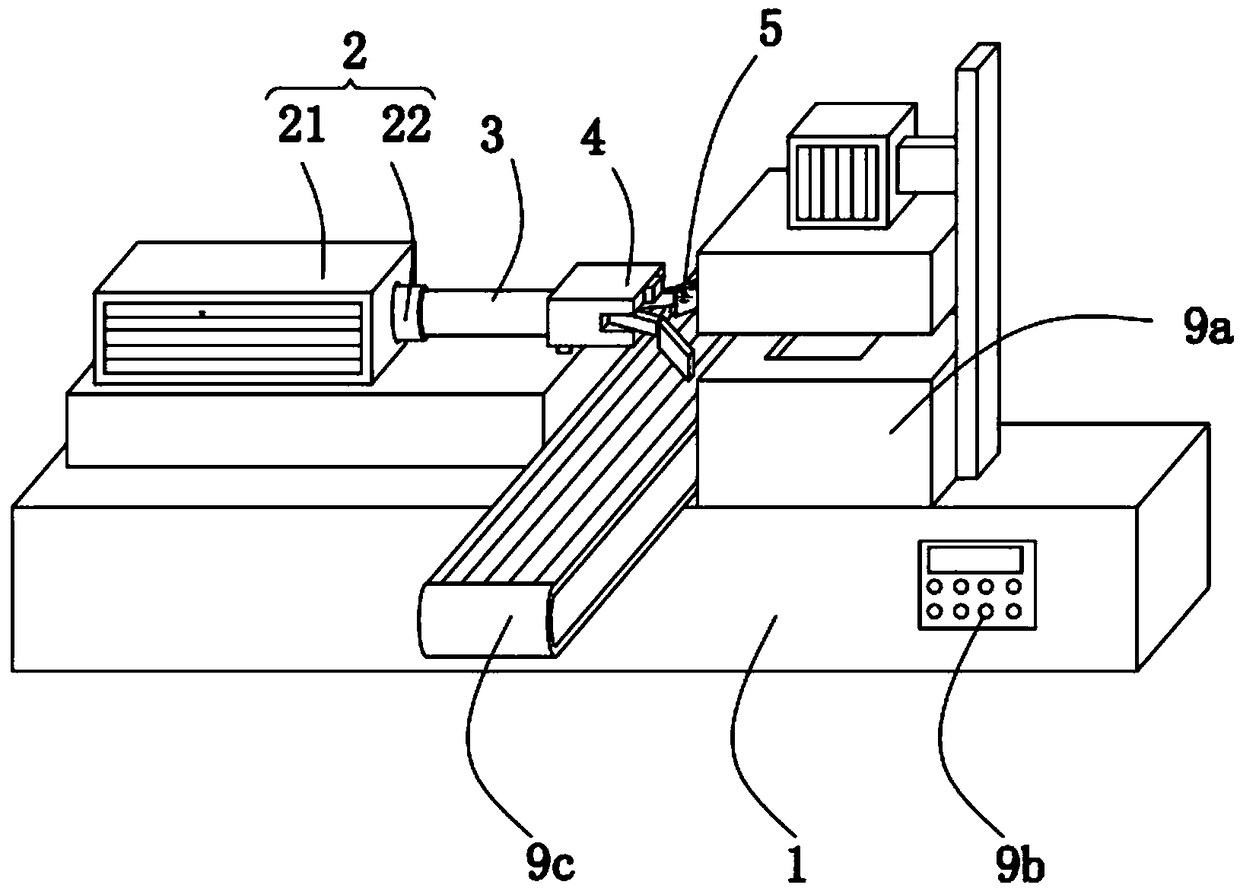

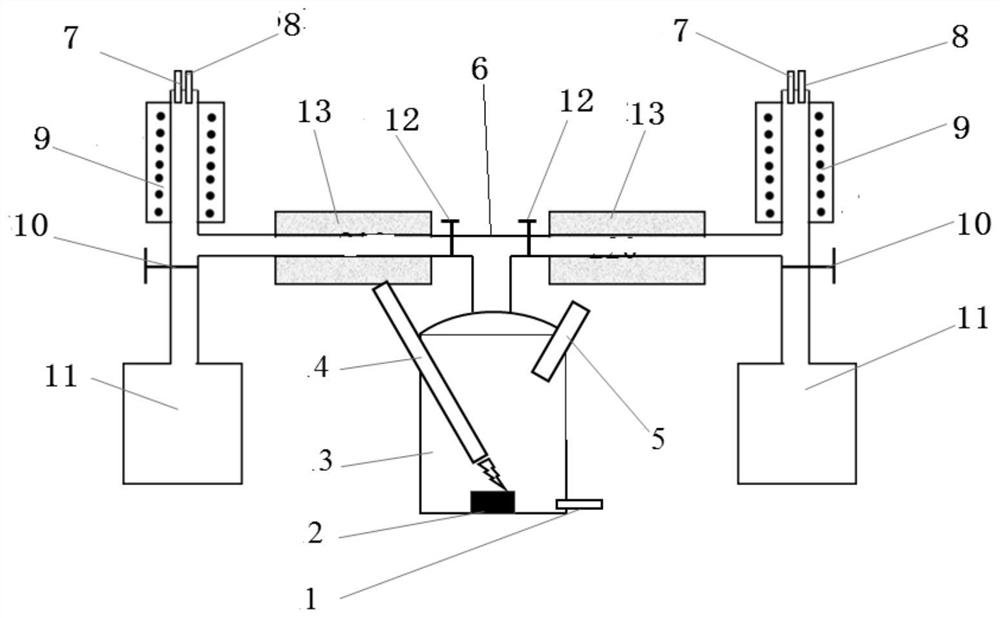

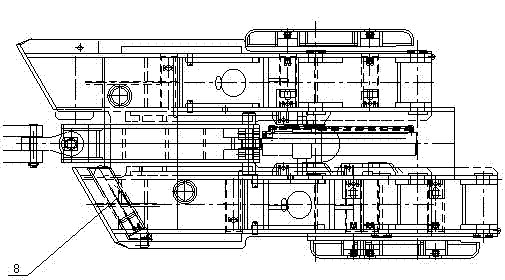

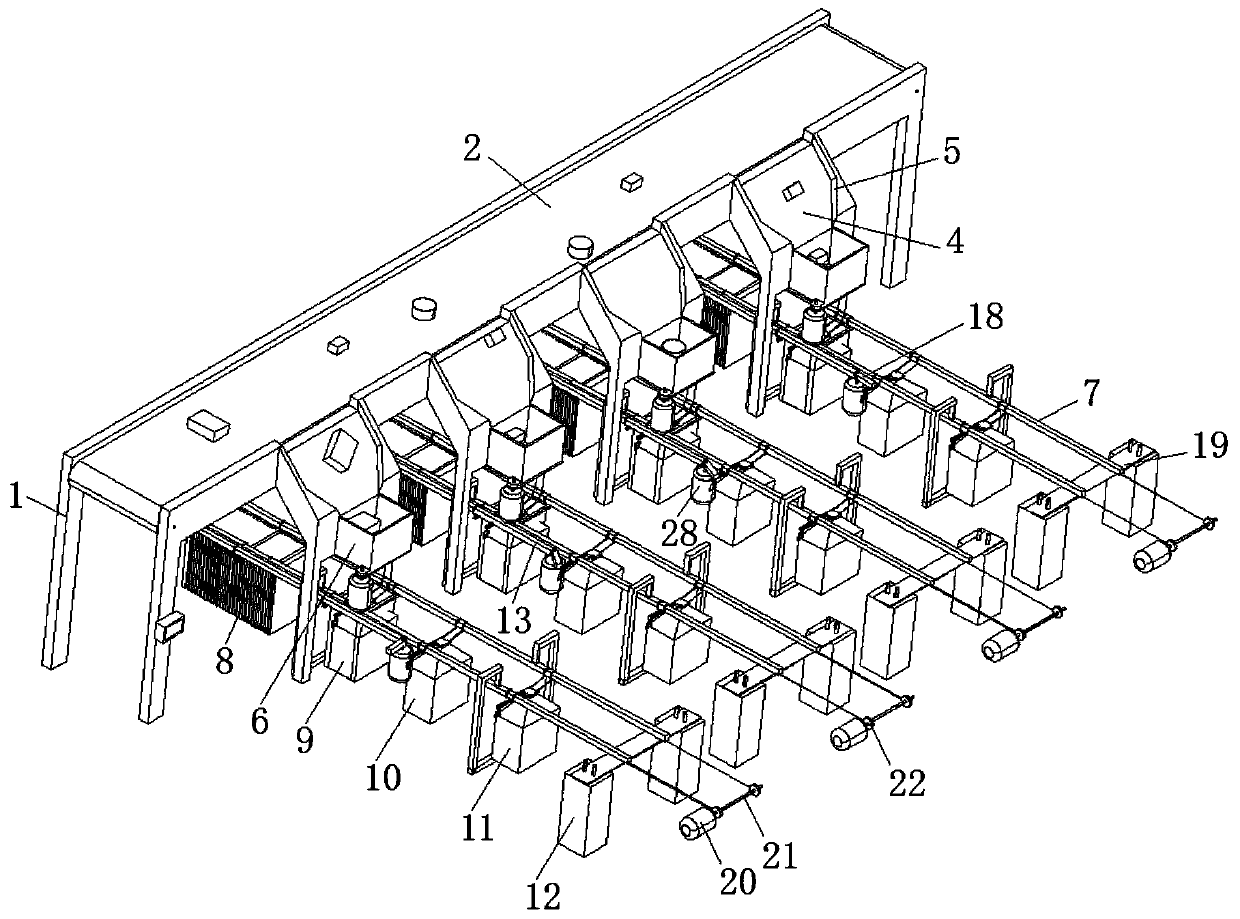

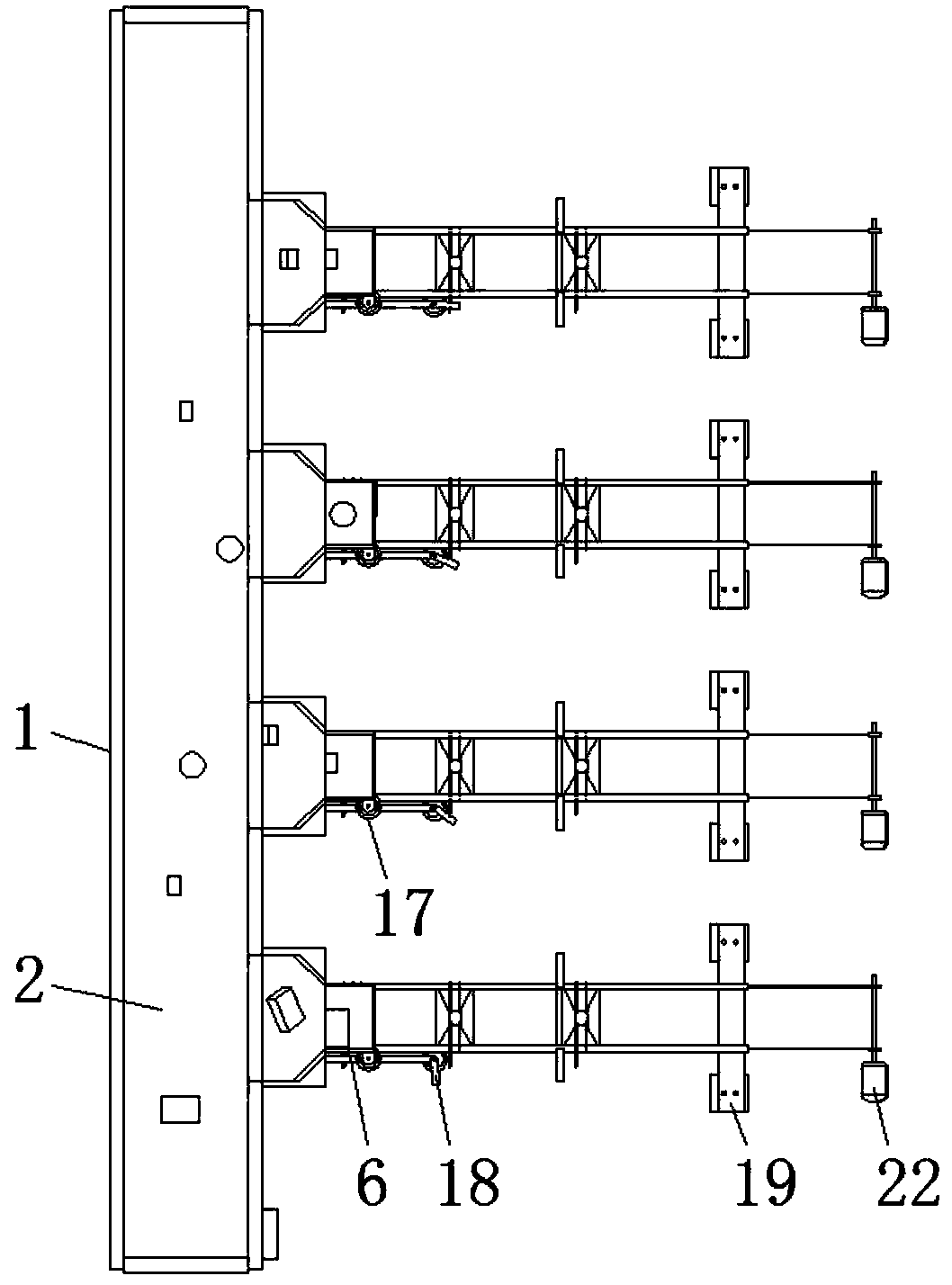

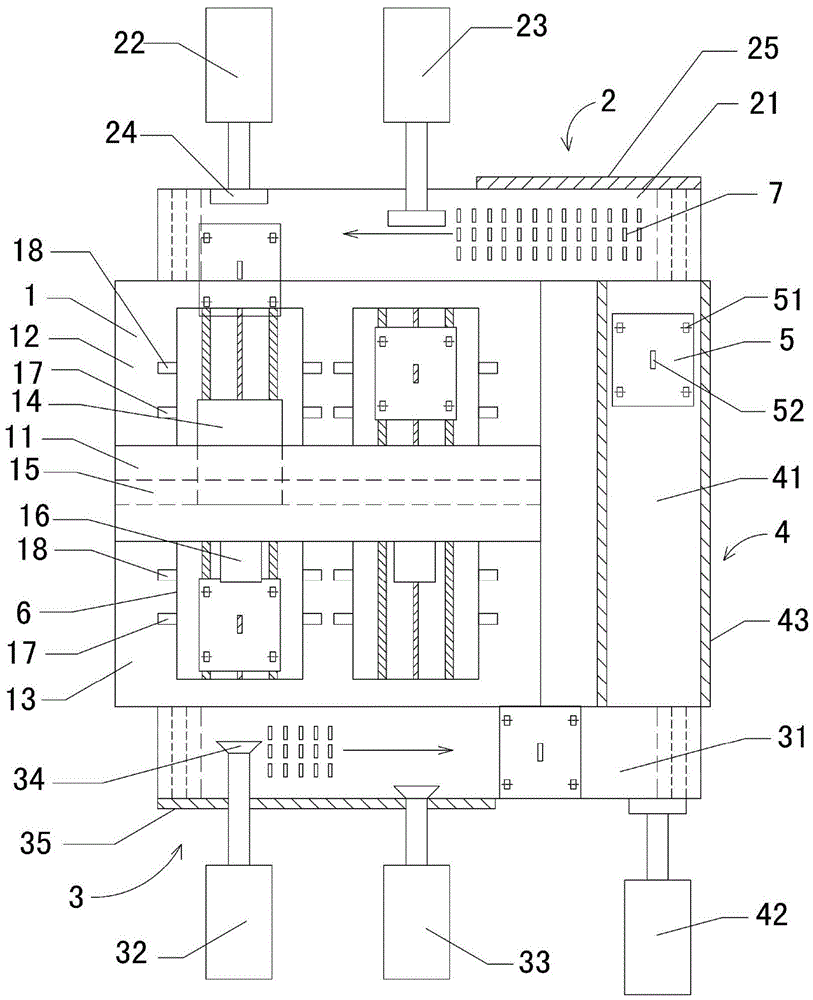

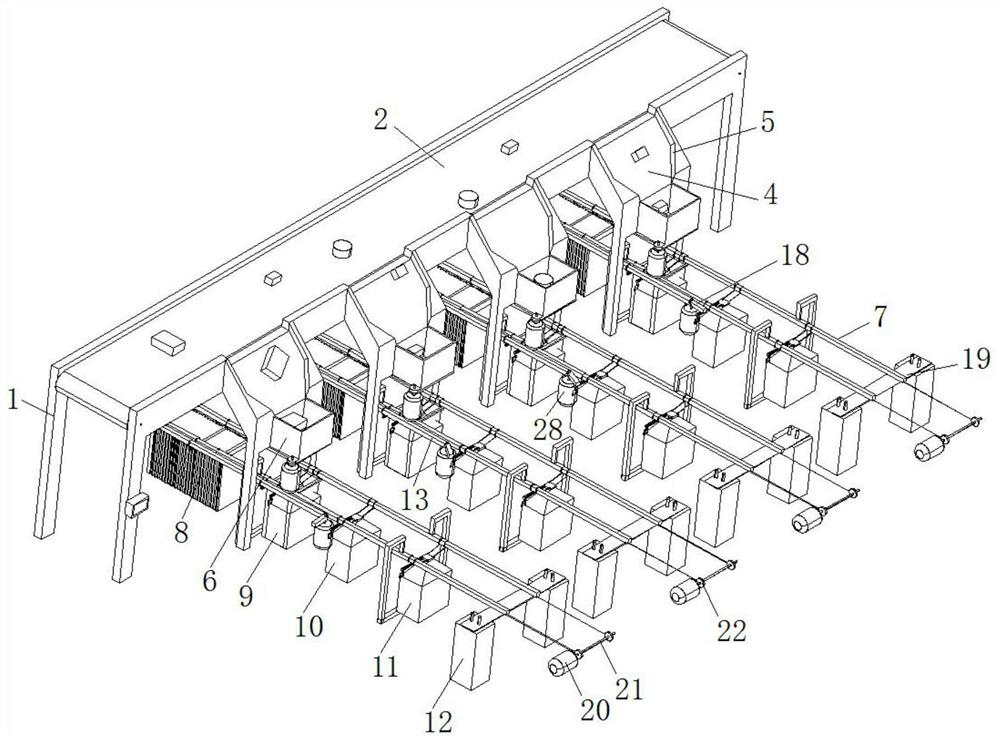

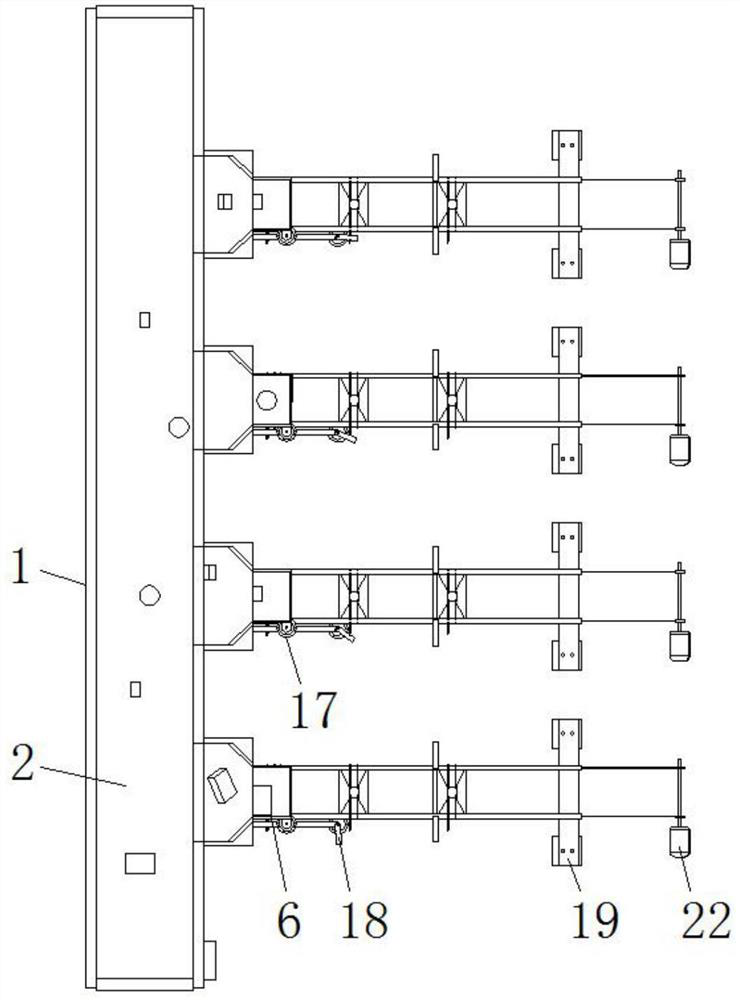

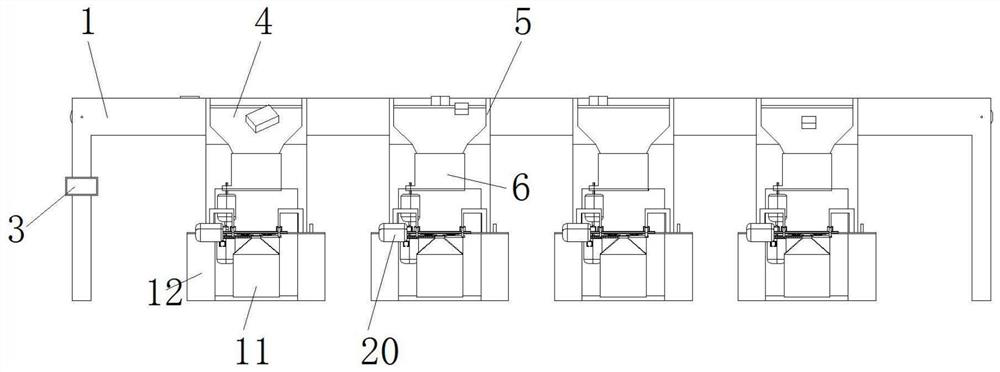

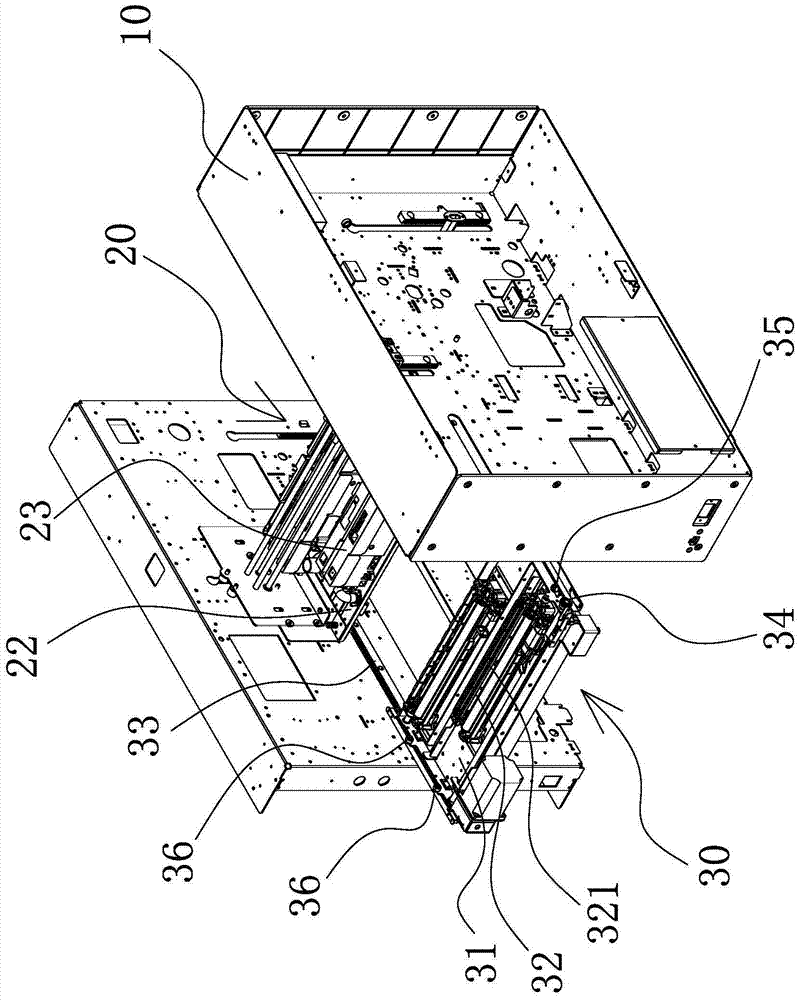

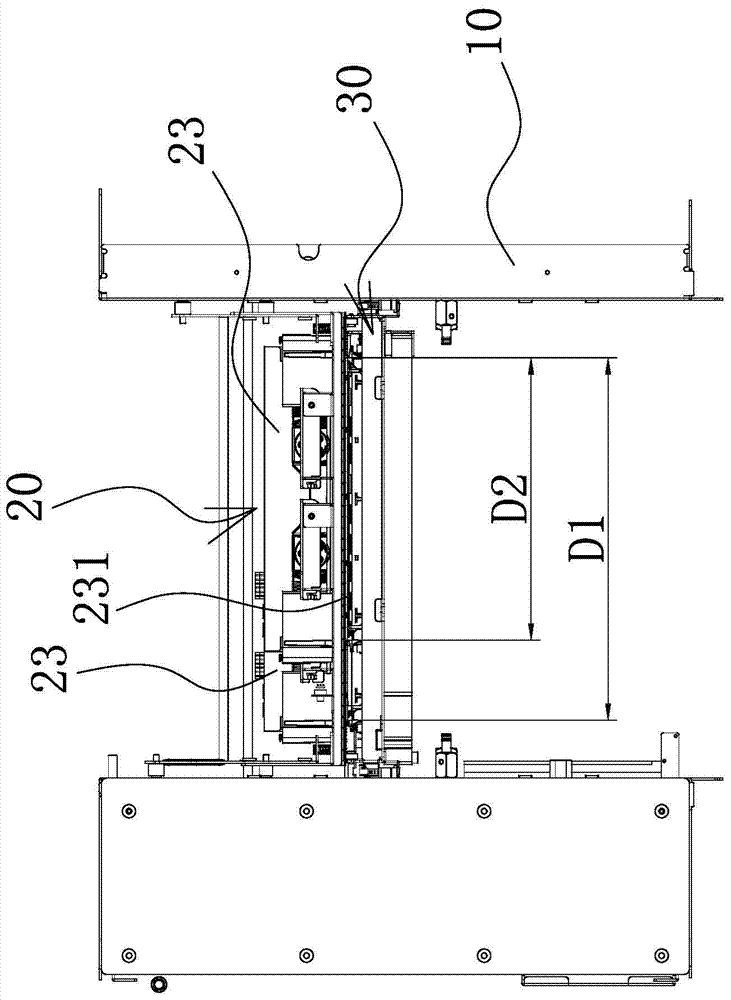

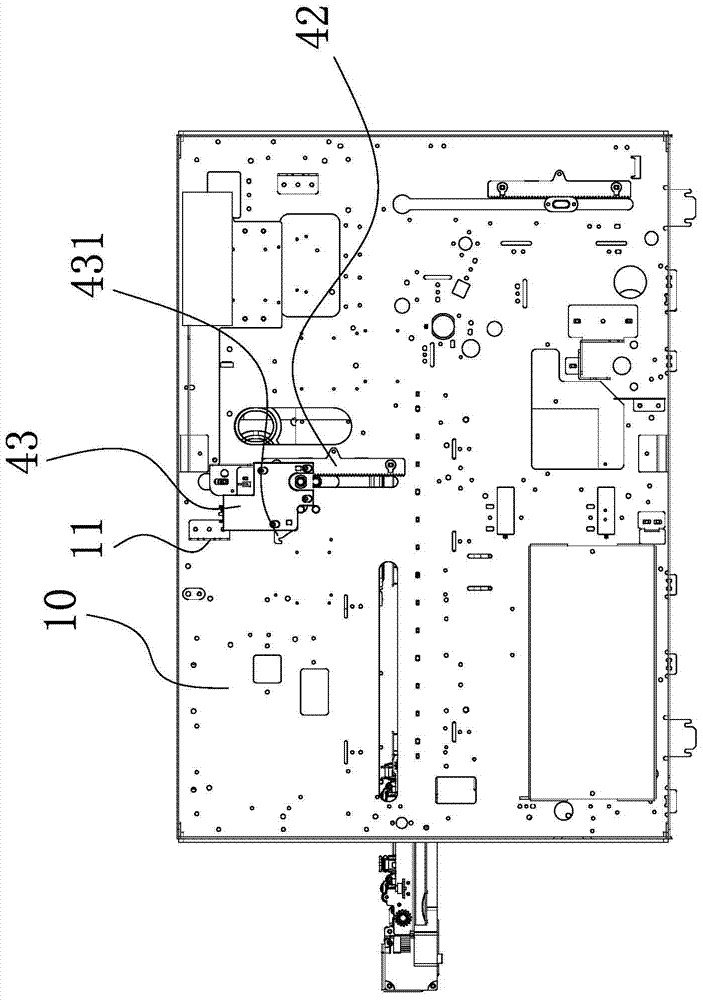

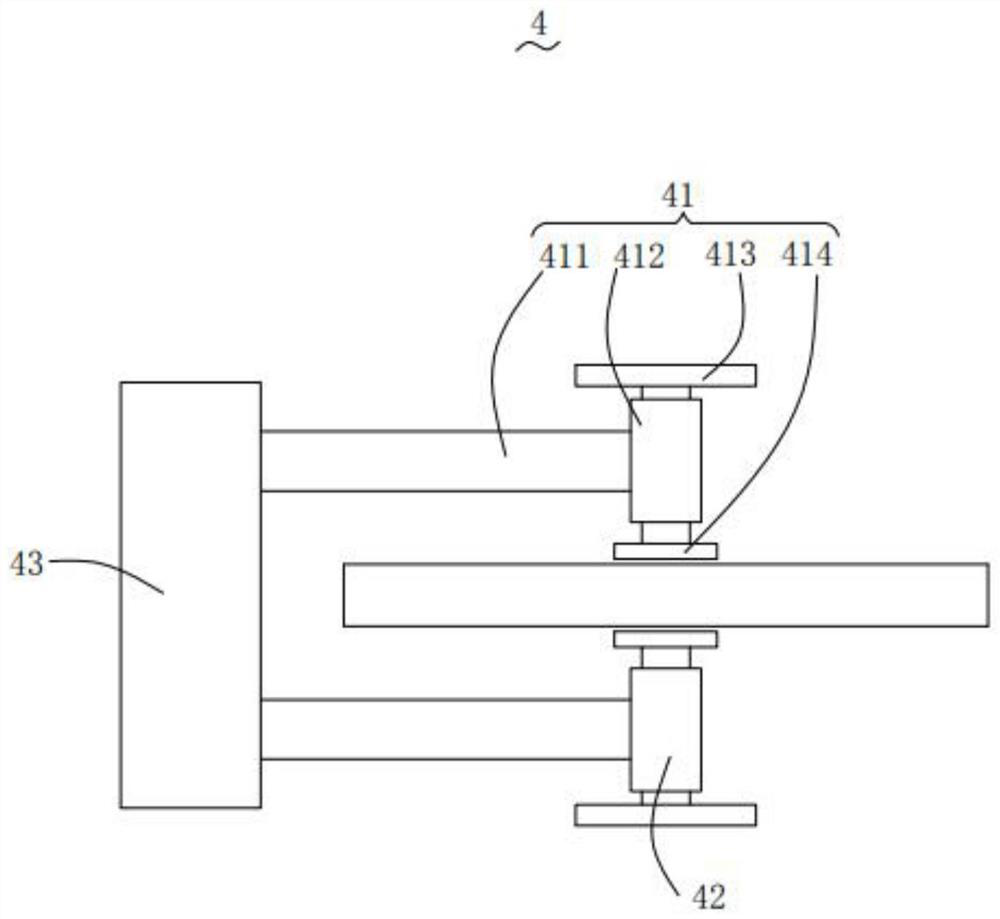

Novel CNC processing machine

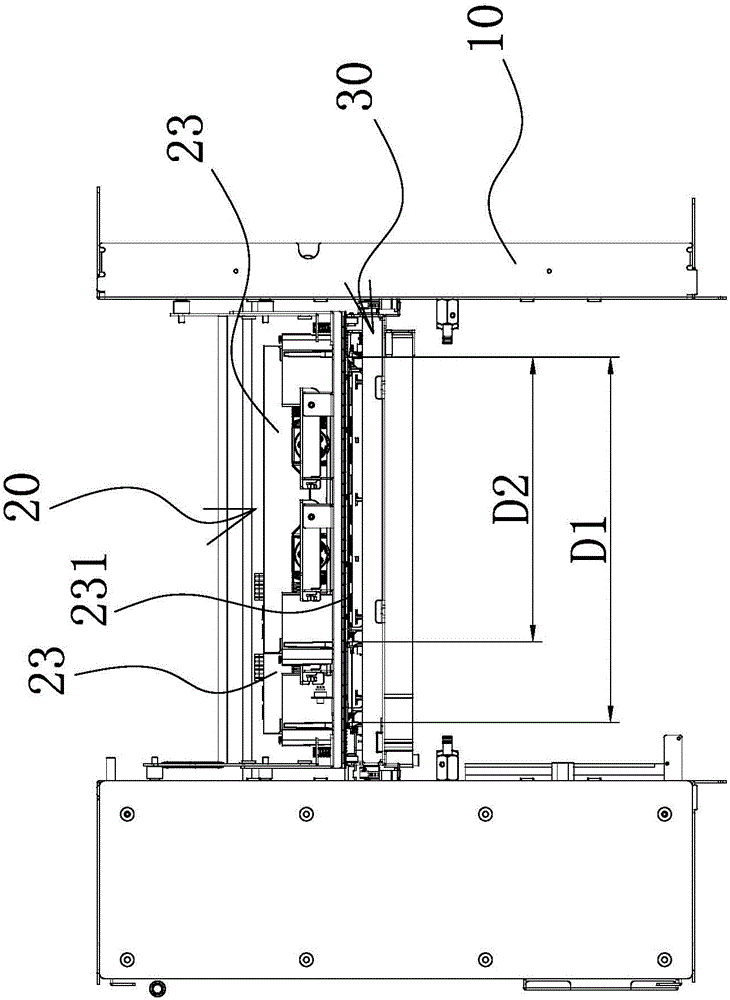

ActiveCN104191247ARealize cycle jobIncrease productivityOther manufacturing equipments/toolsMetal working apparatusEngineeringMachining process

The invention relates to a novel CNC processing machine which can effectively complete an automatic feeding and discharging process. A plurality of workpiece machining processes can be carried out at the same time. The novel CNC processing machine comprises a workbench, a material conveying mechanism, a discharging mechanism, a circulating feeding mechanism and a moving table. The material conveying mechanism comprises a material conveying belt, a first material conveying oil cylinder and a second material conveying oil cylinder. The first material conveying oil cylinder and the second material conveying oil cylinder are used for pushing the moving table from the material conveying belt to a guiding track base and are used for pushing the moving table from one side of a feeding zone of the guiding track base to one side of a discharging zone. The discharging mechanism comprises a discharging conveying belt, a first discharging oil cylinder and a second discharging oil cylinder. The output ends of the first discharging oil cylinder and the second discharging oil cylinder are provided with sucking discs. The first discharging oil cylinder and the second discharging oil cylinder are used for sucking the moving table from the guiding track base to the discharging conveying belt. The discharging conveying belt is in transmission connection with a discharging speed reducing motor. The circulating feeding mechanism comprises a sliding way and a material pushing oil cylinder. Two sliding ends of the circulating feeding mechanism are communicated with a discharging end of the discharging conveying belt and a feeding end of the material conveying belt respectively.

Owner:山东火炬科技服务有限公司

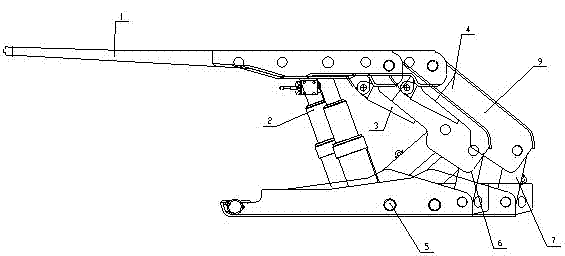

Rhombic hydraulic support for pseudo-inclined down mining working surface of steep coal seam

ActiveCN102373937ASatisfy the improvement requirements of comprehensive mechanized coal mining methodSolve a series of mining related problemsMine roof supportsStress conditionsEngineering

The invention relates to a rhombic hydraulic support for a pseudo-inclined down mining working surface of steep coal seam. The rhombic hydraulic support is adaptable to the characteristic of a coal mining process technique in a pseudo-inclined down arrangement manner, and is in close combination with the matching characteristic of a coal mining method and equipment through researching the movement discipline of wall rocks in a comprehensive mining process mining field and the stress condition of a comprehensive mining support under the control discipline. The rhombic hydraulic support is characterized in that: a traditional four-connecting-rod stable mechanism is divided into two parts, and at the same time, the top beam and base are designed into a rhombic-like structure, thus stable beam end distance and person walking space are formed. The rhombic hydraulic support has the characteristics that: through the development of the rhombic hydraulic support for the steep coal seam, the current mining situation of the steep coal seam is changed, the coal resources are effectively and reasonable utilized, the blank in the important supporting field of comprehensive mechanical mining of the steep coal seam is filled, a premise condition is created for achieving automatic machine tracking and other unmanned automatic working surfaces of the steep coal seam, therefore, the rhombic hydraulic support has broad application prospects.

Owner:TIANDI SCI & TECH CO LTD

Construction garbage crushing, sorting and recycling treatment device

The invention discloses a construction waste crushing, sorting and reusing treatment device, which comprises a water tank, the water tank is filled with water, the water tank is in a V-shaped structure, the left and right sides of the water tank are provided with embankments, and the left side of the water tank is provided on the embankment. There is a crushing mechanism, the crushing mechanism includes a casing, and the casing is a folded cylindrical structure; the casing is installed on the top embankment on the left side of the water tank; the right side of the top of the casing is provided with a left-sloping feed port. The invention provides a construction waste crushing, sorting and reusing treatment device. The invention utilizes different types of particles with different densities after crushing to be sorted in water; the structure design is ingenious and novel; the invention can quickly and efficiently sort out suspended particles The present invention adopts water separation, and there is almost no dust in the separation process, which is beneficial to environmental protection; the sludge generated after the separation of the present invention is convenient for cleaning and realizes the recycling operation.

Owner:童红妃

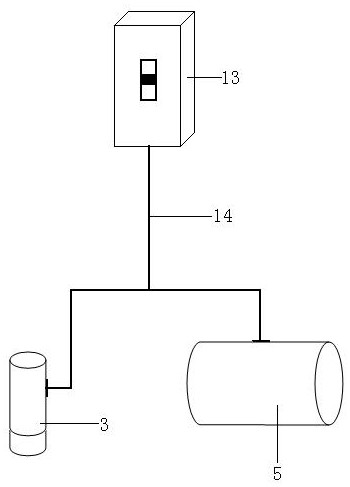

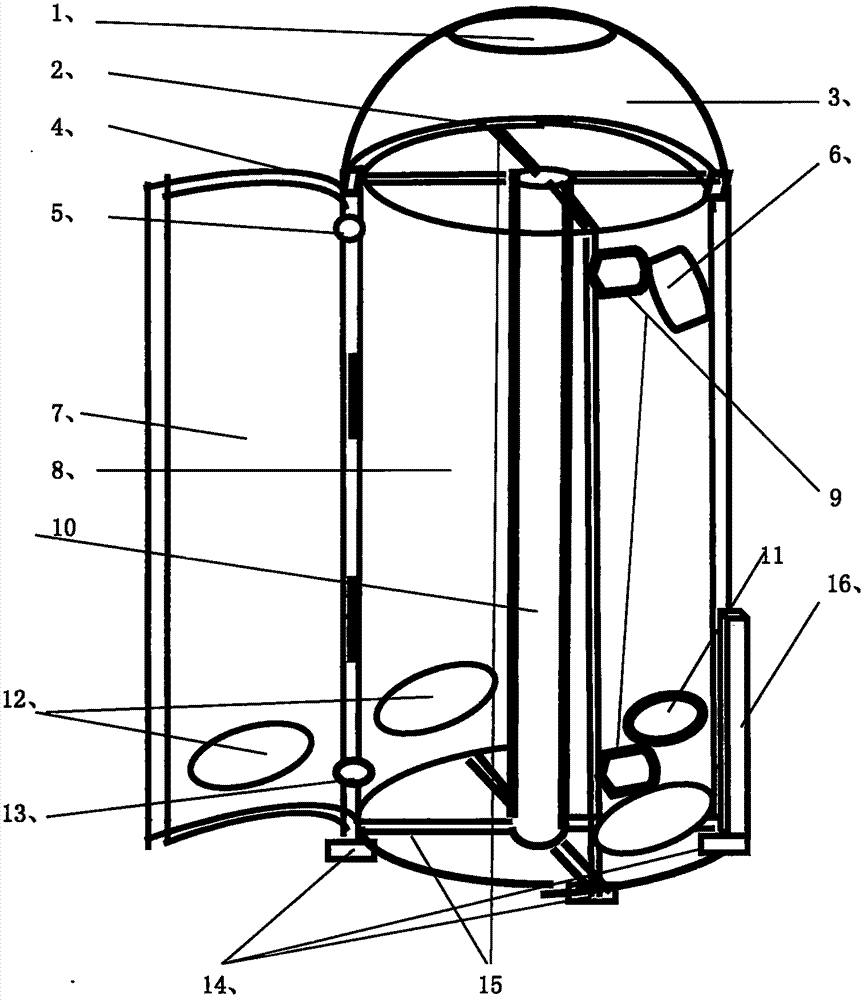

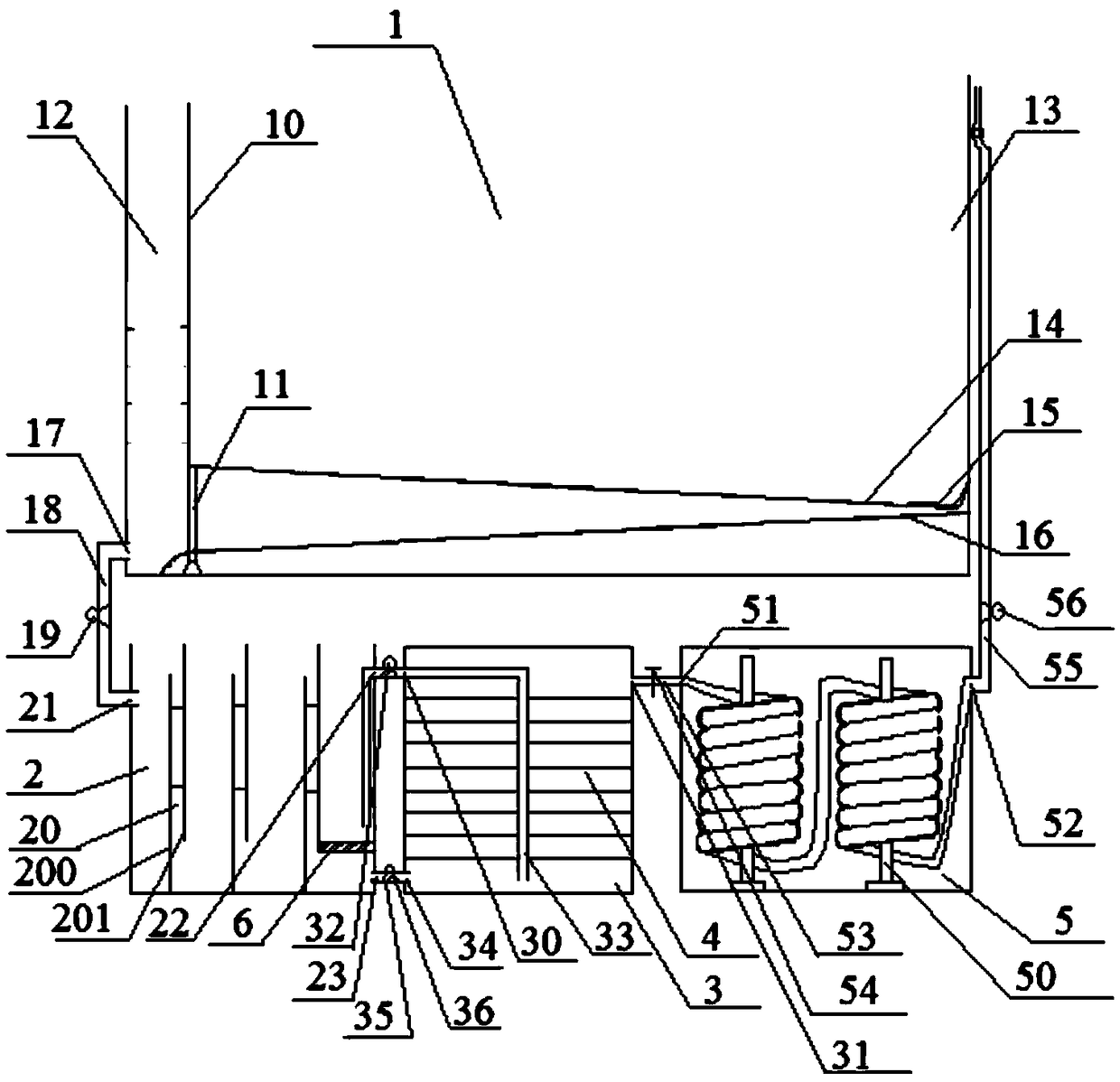

Turtle culture device capable of easily removing excrement

ActiveCN106259144AEffective absorptionAvoid problems that are not conducive to the growth of turtlesWater/sewage treatment by irradiationWaste water treatment from animal husbandryFecesMaterial resources

The invention discloses a turtle culture device capable of easily removing excrement. The device comprises a culture pond, a precipitation tank, a filter tank and a sterilizing pool; the culture pond comprises a first baffle, a second baffle, a third baffle and a waste outlet, the sedimentation tank comprises multiple overflow plates, a waste inlet and a precipitation liquid outlet, the filter tank comprises a first filter assembly, a precipitation liquid inlet and a clear liquid outlet, and the sterilizing pool comprises ultraviolet sterilizing lamps, a clear liquid inlet and a sterilizing liquid outlet; the waste outlet is communicated with the waste inlet through a first pipeline, the precipitation liquid outlet is communicated with the precipitation liquid inlet through a second pipeline, the clear liquid outlet is communicated with the clear liquid inlet through a third pipeline, and the sterilizing liquid outlet is communicated with the culture pond through a fourth pipeline. The turtle culture device has the advantages that the excrement are easy to remove, manpower and material resources are reduced, circulating operation can be achieved, and the problem that due to the fact that great changes are caused to a living environment of turtles by overall cleaning and water changing, the living environment is not beneficial for turtle growth is avoided.

Owner:天津鼎拓恒远知识产权服务有限公司

Shearing sending system

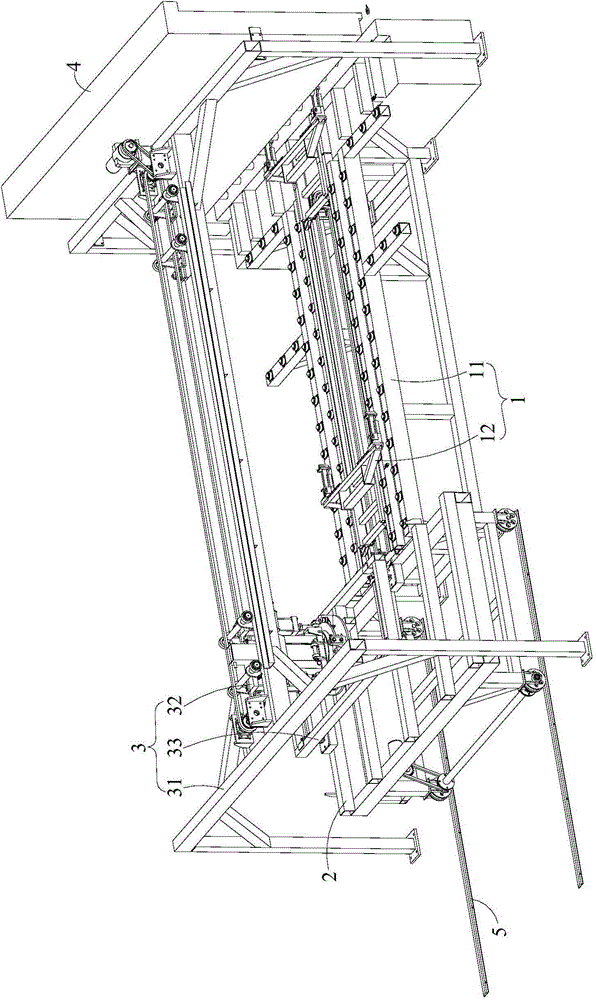

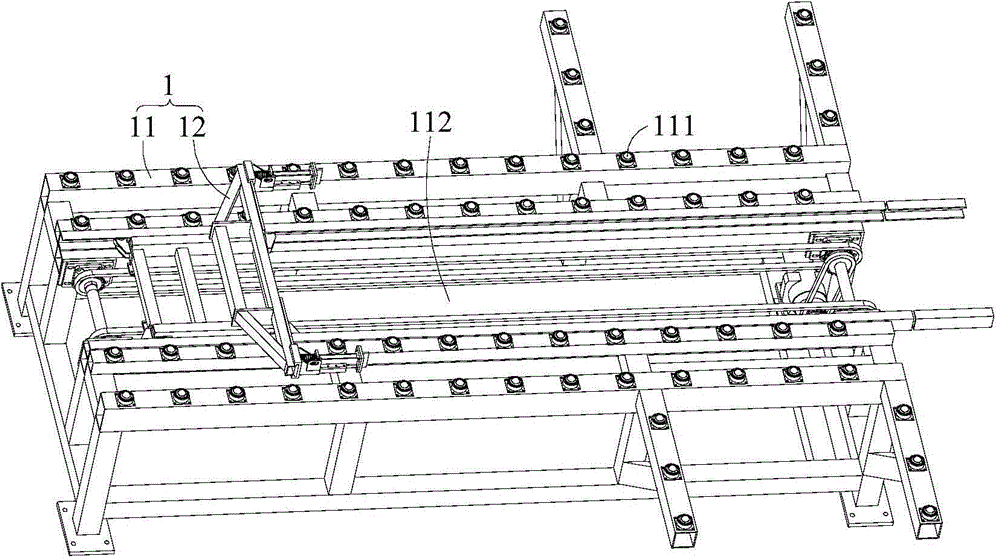

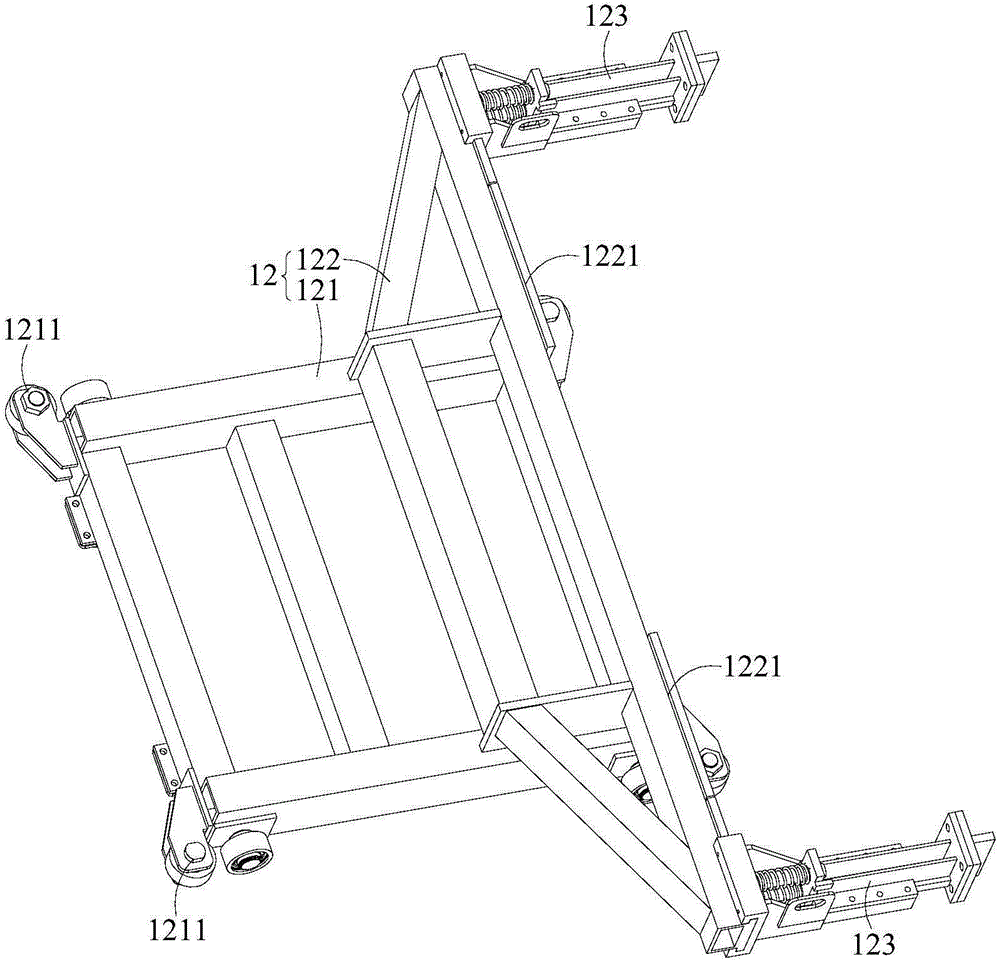

ActiveCN104555284AHigh degree of automationReduce labor intensityConveyorsAutomatic controlControl system

The invention discloses a shearing sending system. The system comprises a pushing unit, a storage frame, a feeding unit and an automatic control system. The pushing unit is used for pushing plates to a plate shearer, and the storage frame is used for storing plates. The feeding unit comprises a rail frame, a sliding trolley and a suction unit. The rail frame is erected above the pushing unit, the sliding trolley is arranged on the rail frame movably, and the suction unit is arranged below the sliding trolley and capable of being driven by the sliding trolley to transport the storage frame to a delivery frame. The automatic control system is used for controlling the pushing unit, the storage frame, the sliding trolley and the suction unit synchronously. By means of the system, automatic pushing and circulation operations are achieved during sending of plates to the plate shearer, the shearing sending and whole plate shearing process automatic degree is improved, the work efficiency is improved, and the worker labor intensity is reduced greatly.

Owner:中集车辆(江门市)有限公司

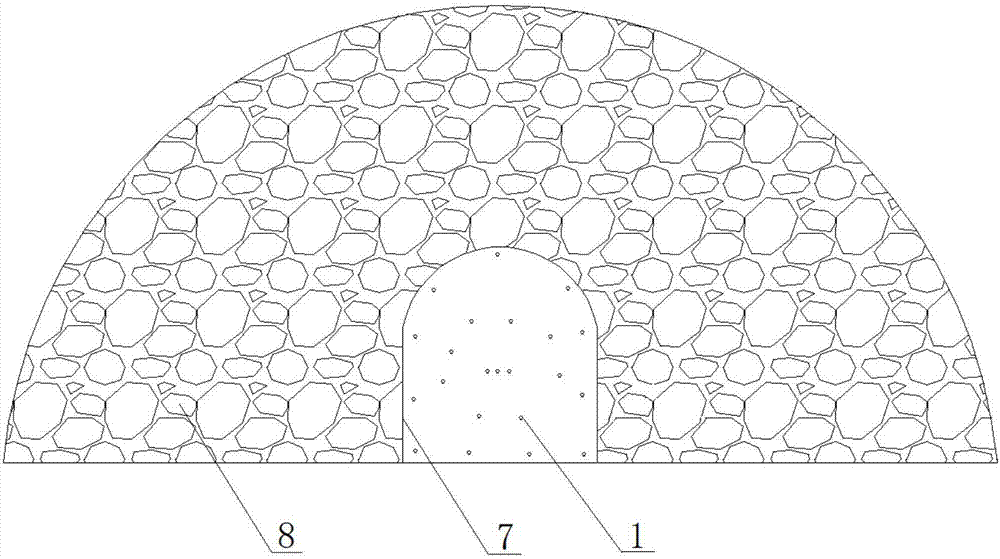

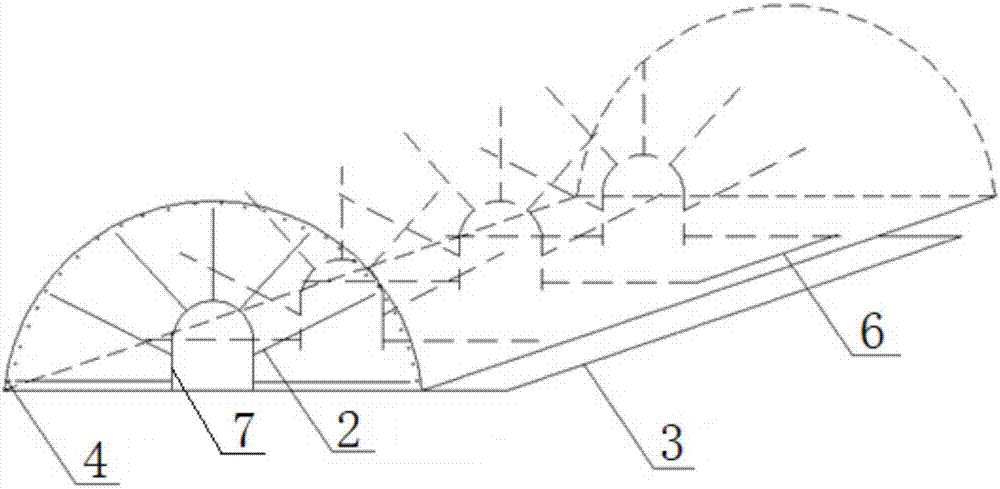

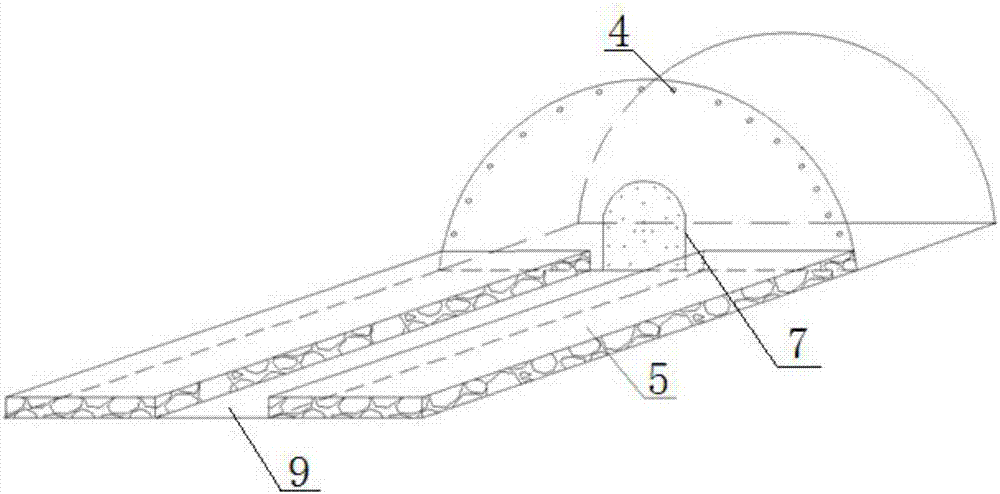

Large-section tunnel circular blasting and tunnelling method

InactiveCN107462118APrevent landslidesRealize cycle jobBlastingGeomorphologyUltimate tensile strength

The invention discloses a large-section tunnel circular blasting and tunnelling method. The large-section tunnel circular blasting and tunnelling method comprises the following steps that a segment of guiding tunnel is tunnelled in the middle of the bottom end of the tunnel face of a large-section tunnel in the extension direction of the large-section tunnel; guiding holes are punched in a plurality of cross sections of the guiding tunnel according to a certain depth in the radial direction, and the guiding holes are distributed in a fan shape along the guiding tunnel; a plurality of large-section perimeter holes are punched in edges of fan-shaped outlines formed by the distribution of the multiple guiding holes in the axial direction of the guiding tunnel; after the guiding holes and the large-section perimeter holes are detonated, a segment of the large-section tunnel is formed, a passage is shovelled out in the middle of the large-section tunnel, and the waste stones detonated and caved are shovelled to the two sides of the passage to be used for paving steps; and the segmented and circular construction is performed until the tunnelling work of the whole large-section tunnel is accomplished. By means of the large-section tunnel circular blasting and tunnelling method, the circular operation of large-section tunnel blasting and tunnelling is achieved, the tunnelling efficiency is improved, the vibration of blasting is greatly reduced, the safety of the tunnel construction is improved, the requirements for the drilling equipment are lowered, the working strength of the staff is lowered, and the drilling work efficiency is improved.

Owner:WUHAN UNIV OF TECH

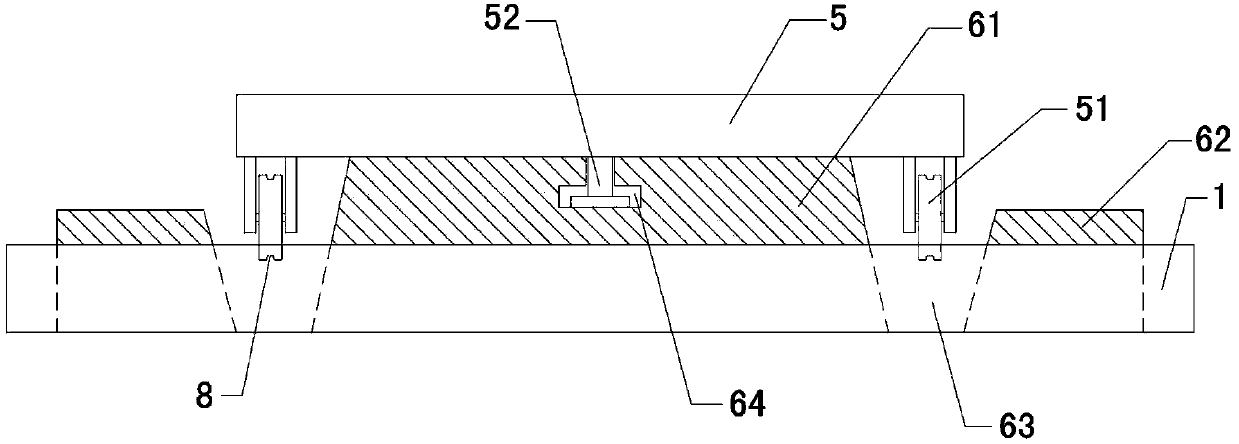

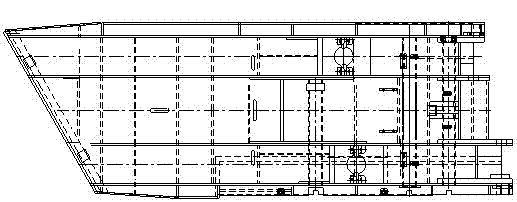

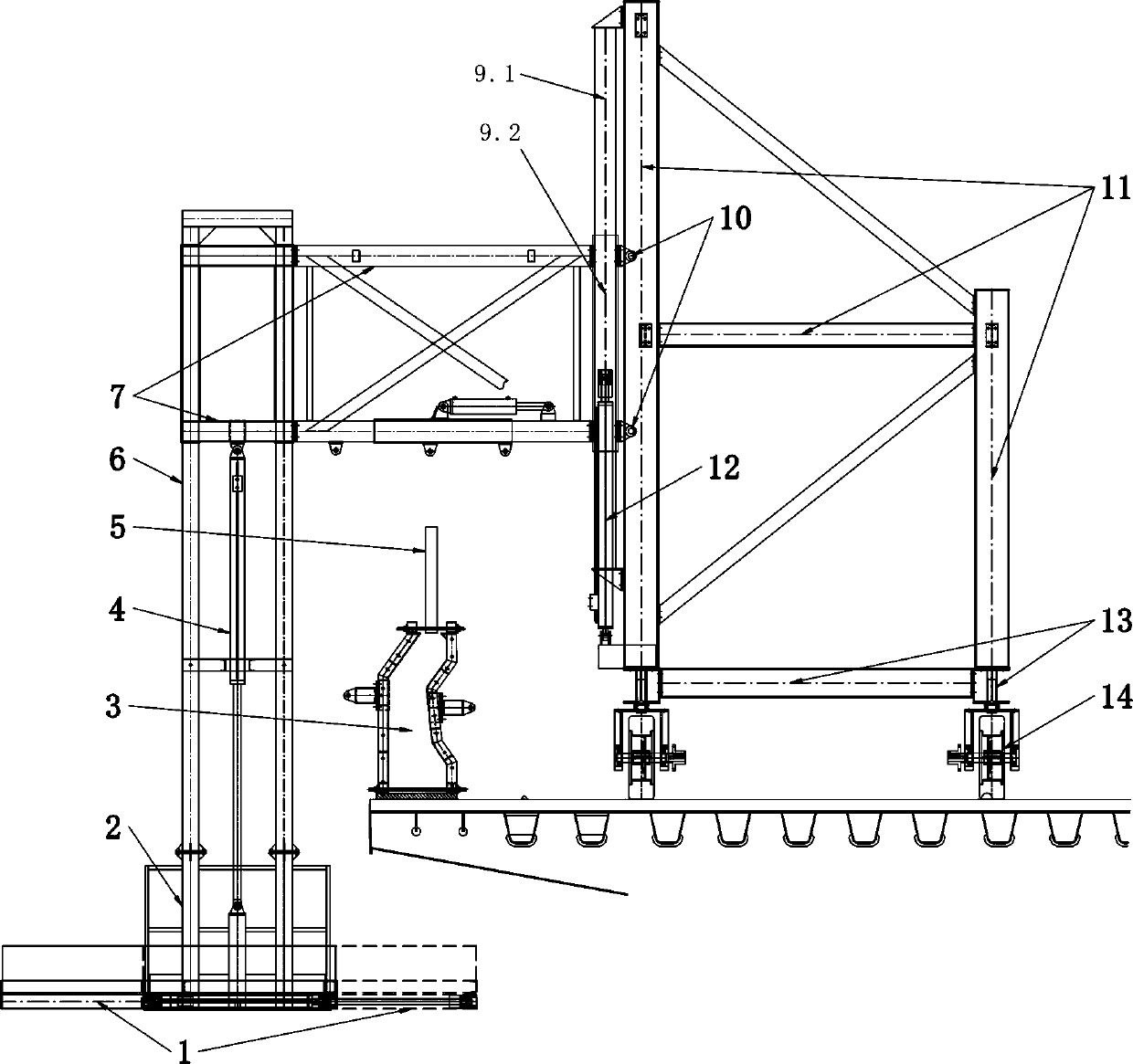

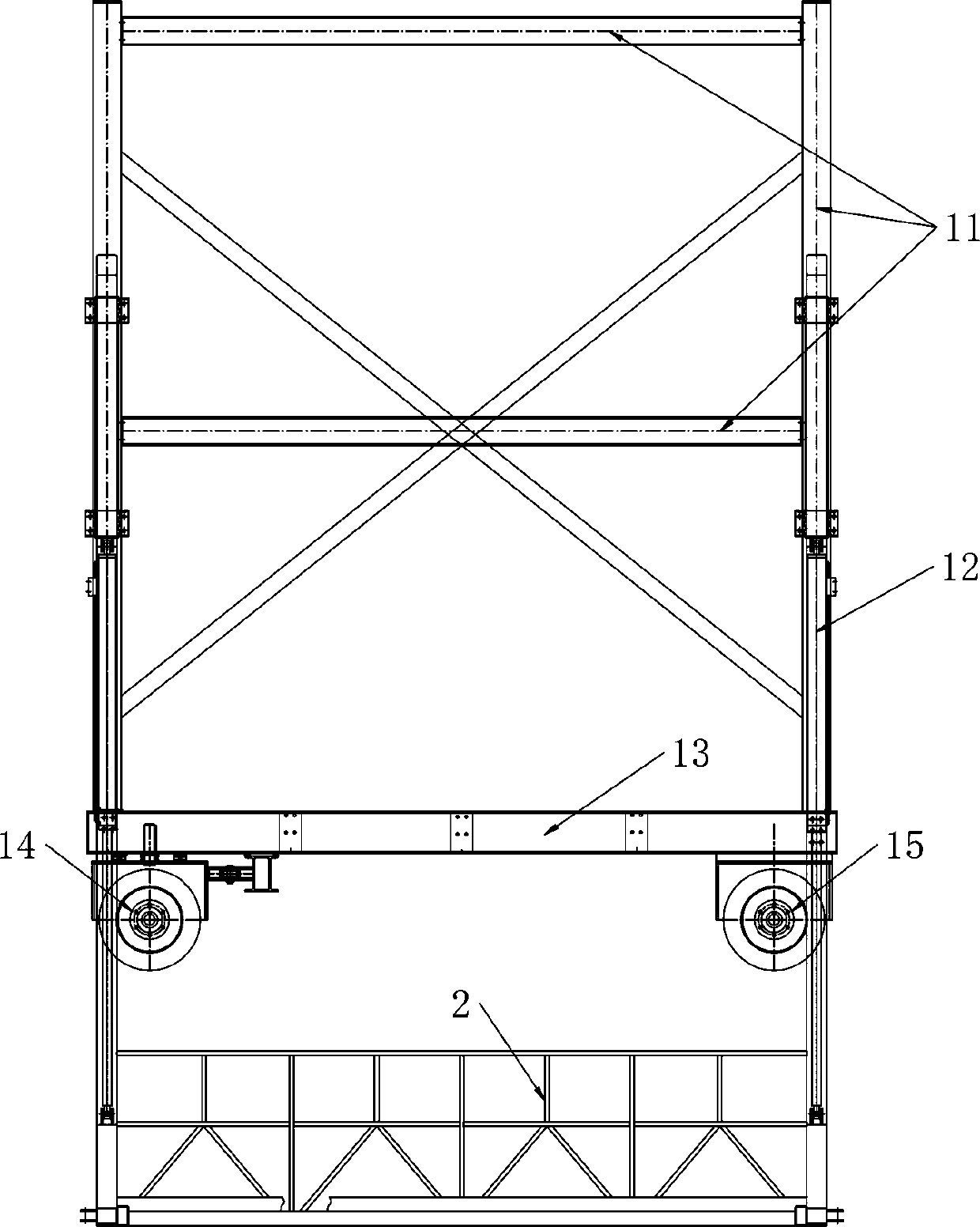

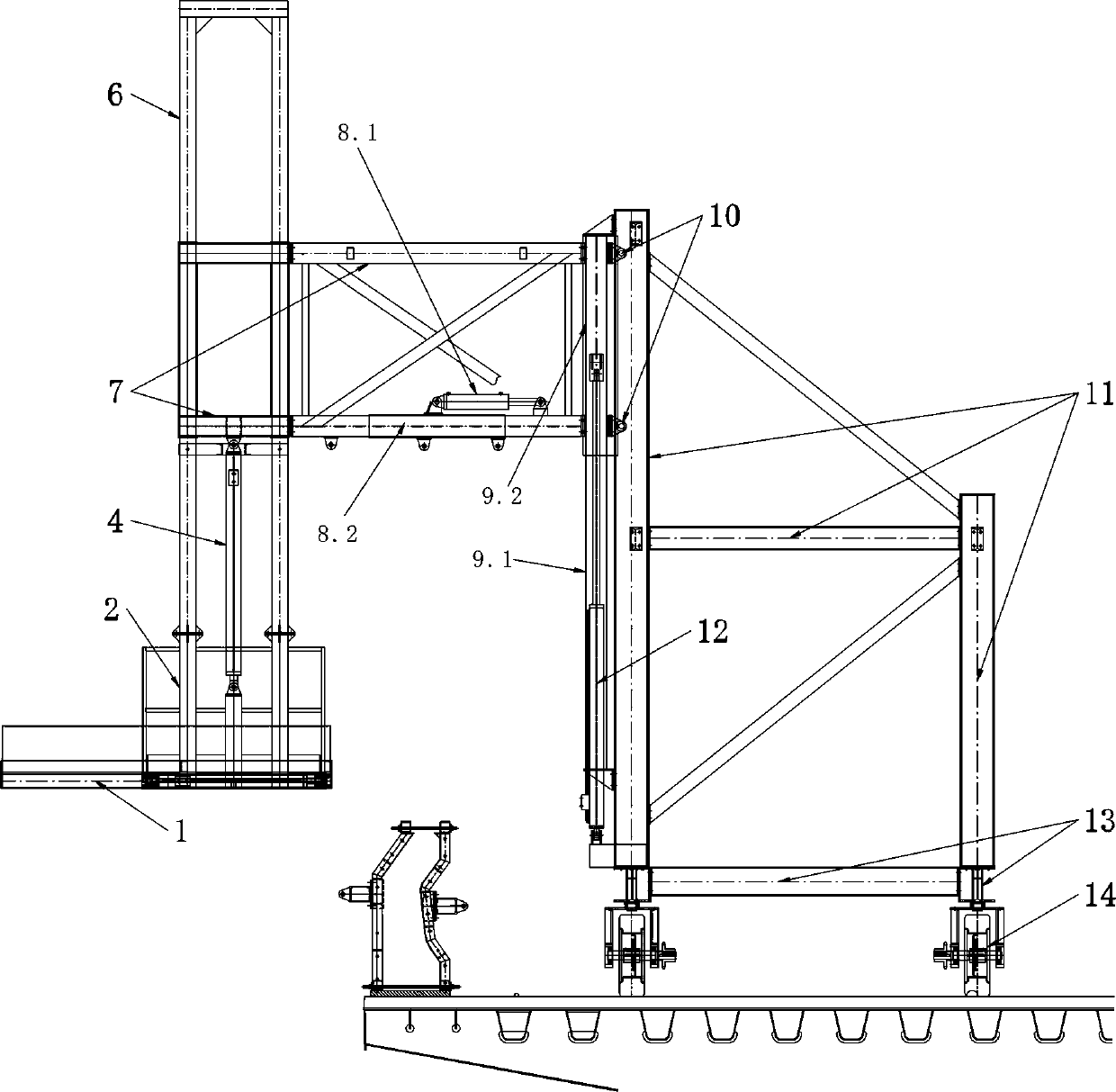

Multifunctional anti-collision wall construction trolley and anti-collision wall construction method thereof

PendingCN110983951AReasonable designSimple structureBridge structural detailsBridge erection/assemblyArchitectural engineeringHanging basket

The invention discloses a multifunctional anti-collision wall construction trolley and an anti-collision wall construction method thereof. The trolley comprises a bearing platform and a main truss installed at the upper end of the bearing platform, a lifting cantilever hanging bracket is installed on the outer side of the main truss, and a formwork hoisting mechanism which is used for hoisting ananti-collision wall formwork and can drive the anti-collision wall formwork to move towards the outer side or the inner side is arranged below the hanging bracket. A lifting and horizontally telescopic hanging basket is arranged on the outer side of the cantilever hanging bracket. A walking mechanism is installed at the lower end of the bearing platform, and balancing weights are installed at theupper end of the bearing platform. The trolley is reasonable in design, simple in structure, convenient to use and easy to implement, the trolley can hoist grouped formworks to move in multiple directions, cyclic construction can be achieved, the defects of traditional single formwork assembling and pouring are overcome, and the trolley can enable the construction efficiency to be higher.

Owner:DUJIANGYAN XIANDAI MACHINERY MFG

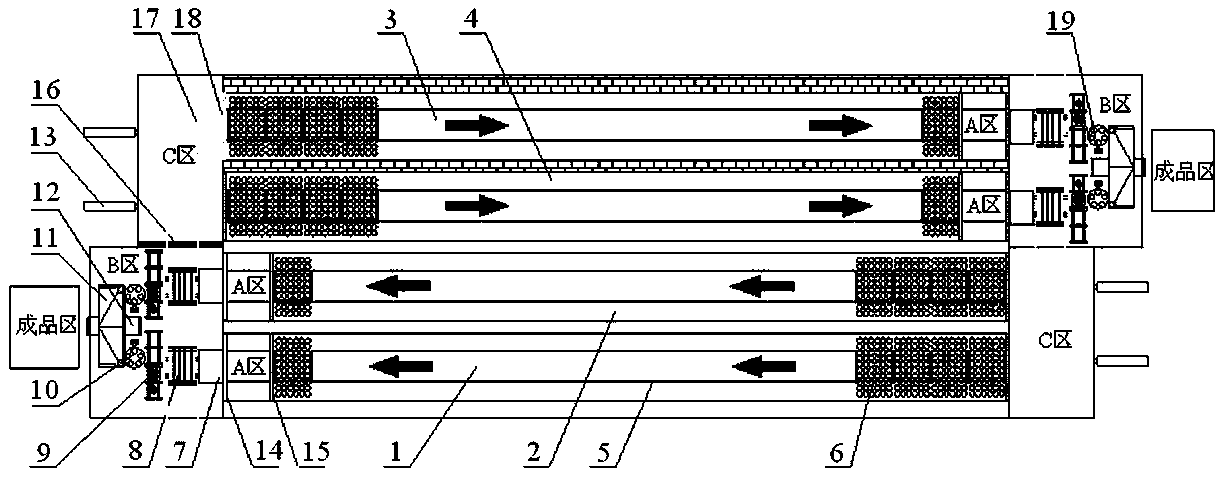

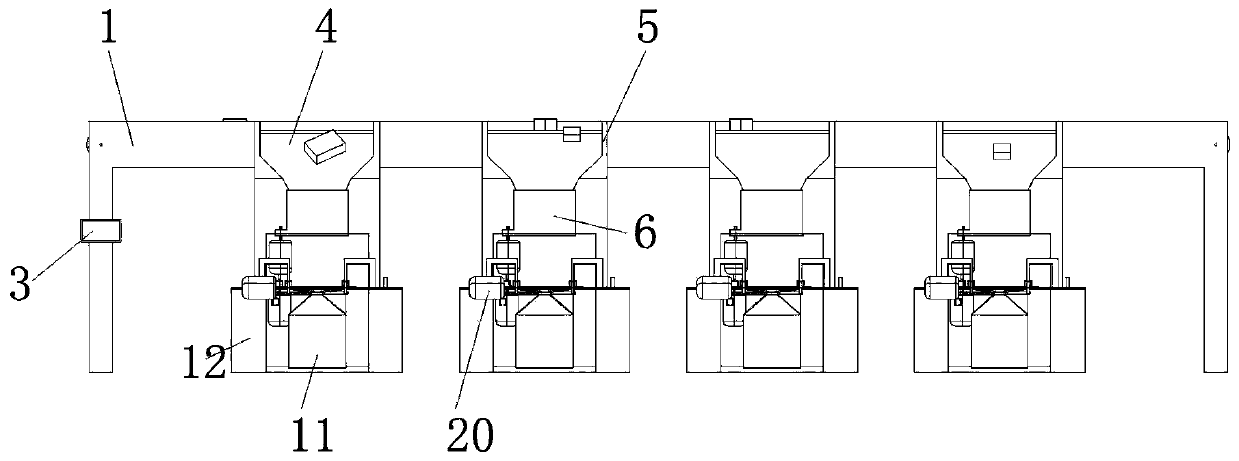

Intelligent production cycle assembly line for cyanuric acid

PendingCN108299321ARealize remote controlRealize cycle jobOrganic chemistryHydraulic cylinderProcess engineering

The invention discloses an intelligent production cycle assembly line for cyanuric acid. The intelligent production cycle assembly line comprises at least two kilns which are arranged side by side; each kiln is internally provided with a kiln guide rail and a driving device; trolleys positioned in the two kilns walk along the opposite directions; a feed buffer area is arranged at one end of each kiln, and a hydraulic cylinder is arranged in each feed buffer area; a material transfer area is arranged at the other end of each kiln, and a material transfer device is arranged in each material transfer area; a finished product area is arranged at the outer side of each material transfer area, and a finished product conveying belt is arranged between each material transfer area and the corresponding finished product area; a ferry vehicle guide rail is arranged between each kiln and the corresponding material transfer area and in the feed buffer area of another kiln, and is provided with a ferry vehicle; the material transfer areas are separately provided with a traction apparatus for pulling the trolleys onto the ferry vehicles; a control device is also arranged outside the kilns. The intelligent production cycle assembly line for the cyanuric acid can realize the automatic and continuous production of the cyanuric acid, and enables a material to be evenly fed and evenly heated in the kilns, so that the product quality and the production efficiency are further improved.

Owner:河北明睿智能科技有限公司

Tea rolling device with multi stations

InactiveCN101223923BKnead weight reductionKnead weight increasePre-extraction tea treatmentAutomatic controlEngineering

The invention relates to a multi-station tea leaves rolling device which comprises a rolling machine (3). The device is characterized in that a transmission weighing mechanism (1) and a rotary material-feeding mechanism (2) are additionally arranged near the rolling machine (3); the material outlet end of the transmission weighing mechanism (1) is matched with the material inlet end of the material-feeding mechanism (2); the outlet end of the material-feeding mechanism (2) is matched with the inlet end of the rolling machine (3). The multi-station tea leaves rolling device of the invention has simple and reasonable structure, can automatically, continuously, effectively and exactly carry out weighing, feeding and rolling, can realize circular operation of a plurality of rolling machines at will and meet rolling requirement for different scales, achieves continuous and automatic control of rolling tea procedure, thereby greatly improving the production efficiency of tea rolling and relieving labor intensity; besides, the invention has little equipment investment and convenient production.

Owner:CHONGQING ACAD OF AGRI SCI

Ink jet system of printing equipment

ActiveCN105128530ASmooth movementEasy to controlPrintingElectrical and Electronics engineeringNozzle

The invention provides an ink jet system of printing equipment, and belongs to the technical field of printing machinery. The ink jet system of the printing equipment comprises a frame, an ink jet mechanism and a nozzle cleaning mechanism, wherein the ink jet mechanism comprises a conveying channel horizontally arranged and used for conveying a printing medium, a working flat plate movably mounted above the conveying channel, and at least one nozzle detachably inserted on the working flat plate; the working flat plate can be displaced in the vertical direction to be near or far from the conveying channel; an ink outlet for jetting ink to the printing medium is formed in the lower end surface of the nozzle; the ink jet direction of the ink outlet is perpendicular to the conveying direction of the conveying channel; and the nozzle cleaning mechanism is arranged below the working flat plate, and is used for cleaning ink in the nozzle. The ink jet system of the printing equipment has the advantages of reasonable design and reliable work.

Owner:宁波荣大创想智造科技有限公司

Automatic bagging and packaging device based on logistics sorting system

ActiveCN110803309ARealize cycle jobImprove efficiencySolid materialLogistics managementAgricultural engineering

The invention discloses an automatic bagging and packaging device based on a logistics sorting system. The automatic bagging and packaging device comprises a frame, wherein a conveying belt is arranged on the inner side of the frame through a conveying roller; a main controller is fixedly arranged on the outer side of the frame; an opening structure is arranged on the side of the top of the frame;an obliquely arranged slideway is fixedly arranged at the openings on the side of the top of the frame; baffles are fixedly arranged on two sides of the slideway; a prepackage box is fixedly arrangedat the bottom of the slideway; and a slide bar I is fixedly arranged below the frame. According to the automatic bagging and packaging device based on the logistics sorting system, the traditional manual packaging is replaced by a mechanical mode, the manual processing pressure is relieved, the human resources are released, the expense of manual cost is saved, and the production income is increased; and after the bag is transported away, the preparatory bag can move to the position right below the prepackage box under the pulling of the rope, so that the circulation operation is realized, theefficiency is extremely high, the development trend of modern intelligent logistics is met, and the application prospect is wide.

Owner:NORTHEASTERN UNIV

cnc processing machine

ActiveCN104191247BRealize cycle jobIncrease productivityOther manufacturing equipments/toolsMetal working apparatusMobile stationMachining

The invention relates to an automatic loading and unloading process which can effectively complete the process of processing multiple workpieces at the same time. It includes a workbench, a feeding mechanism, a discharging mechanism, a circular feeding mechanism and a mobile table. The feeding mechanism includes a feeding conveyor belt, a first feeding cylinder and a second feeding cylinder. The first feeding cylinder and the second feeding cylinder are used to automatically move the mobile platform The feeding conveyor belt is pushed to the guide rail seat, and is also used to push the mobile table from the side of the feeding area of the guide rail seat to the side of the discharging area; the discharging mechanism includes the discharging conveyor belt, the first discharging oil cylinder and the second discharging Oil cylinder, the output ends of the first discharge cylinder and the second discharge cylinder are provided with suction cups, the first discharge cylinder and the second discharge cylinder are used to attract the mobile platform from the guide rail seat to the discharge conveyor belt, and the discharge conveyor belt uploads A discharge reduction motor is dynamically connected; the circular feeding mechanism includes a slideway and a pusher cylinder, and the two ends of the slide are respectively connected with the discharge end of the discharge conveyor belt and the feed end of the feed conveyor belt.

Owner:山东火炬科技服务有限公司

High-pressure spray type dewatering device for urban sludge

InactiveCN110357391ADehydration fastIncrease the heating areaSludge treatment by de-watering/drying/thickeningSprayerTower

The invention discloses a high-pressure spray type dewatering device for urban sludge. The high-pressure spray type dewatering device for urban sludge comprises a drying tower; a sludge treatment cabin is arranged in the drying tower and is connected with a sludge inputting mechanism and a sludge outputting mechanism; the drying tower is provided with a heating layer that surrounds the sludge treatment cabin; the sludge treatment cabin is composed of an upper spray heating chamber and a lower sludge returning and gathering chamber; the spray heating chamber is in a semispherical shape; the sludge returning and gathering chamber is in the shape of a cone with its upper part being a major-diameter end; and a sludge sprayer is arranged in the sludge treatment cabin and connected with a sludgecirculation system. The high-pressure spray type dewatering device of the invention can change viscous sludge into mist shape sludge, thereby increasing a heating area and strengthening a heat exchange rate; so sludge dewatering is accelerated, and a dewatering rate is improved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

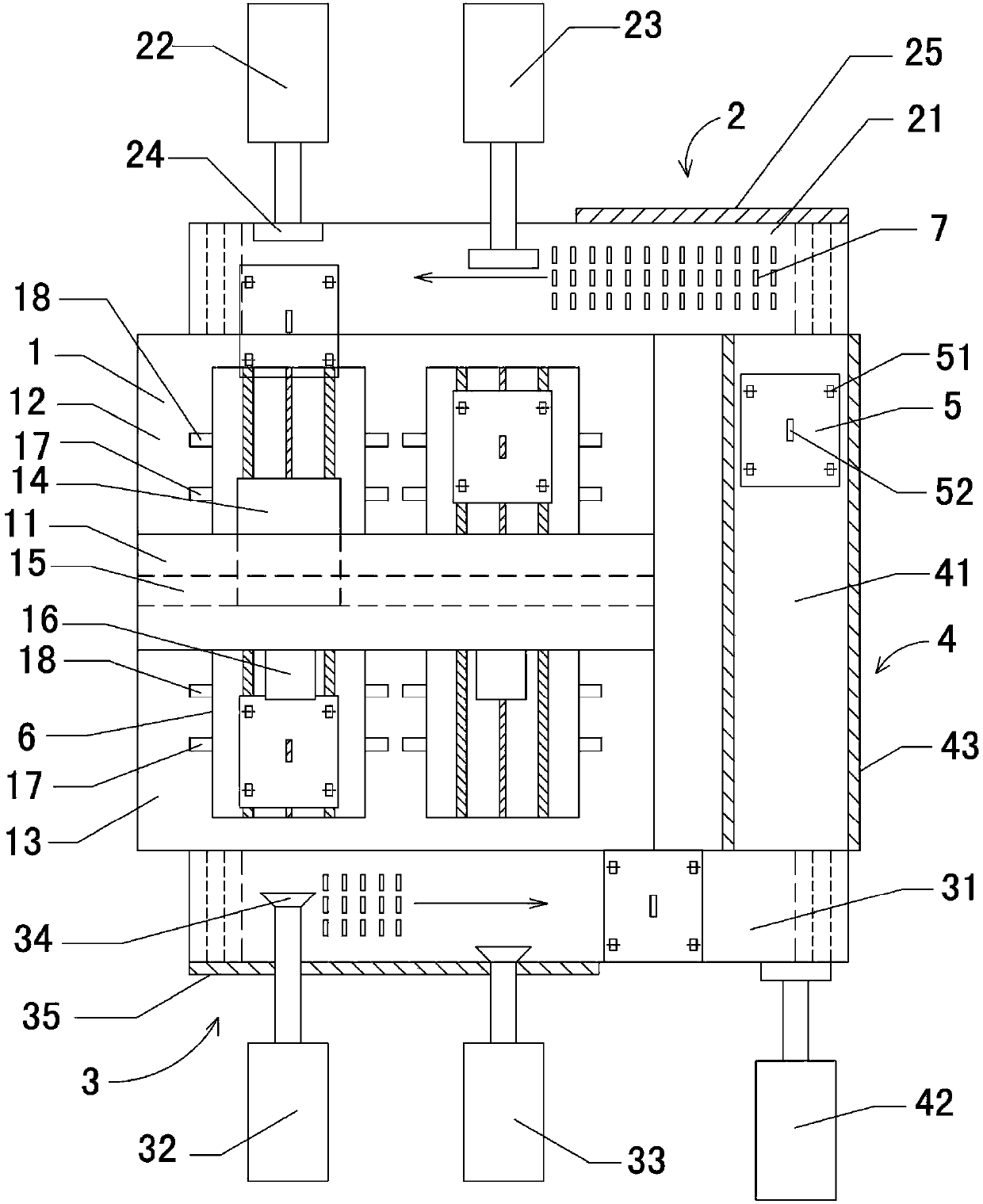

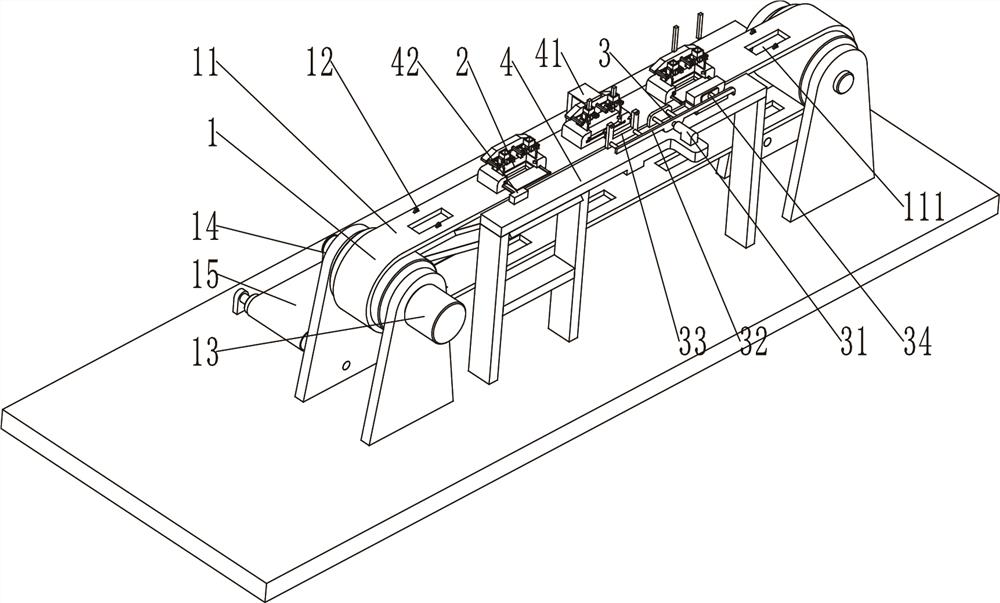

Continuous welding equipment for resonator

ActiveCN114589436ARealize cycle jobLock failureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAssembly line

The continuous welding equipment comprises a circulating assembly line and an automatic clamping device, the circulating assembly line comprises a circulating belt, a plurality of discharging holes are formed in the circulating belt, rotating protruding blocks are arranged on the circulating belt and located on the two sides of the discharging holes, and the automatic clamping device comprises a base. A rotating shaft is arranged on the base, the bottom face of the automatic clamping device is in press contact with the belt face of the circulating assembly line, and the automatic clamping device is rotationally arranged on the rotating protruding block through the rotating shaft. The invention provides an automatic circulating resonator welding device which can realize automatic positioning and clamping of resonator parts, welding operation of the resonator parts after clamping, automatic falling after welding, and no mutual touch in the falling process, so that the quality problem of pin bending caused by mutual touch is reduced, and the production efficiency is improved. The overall production efficiency is improved, and the equipment investment cost is reduced.

Owner:金华市创捷电子有限公司

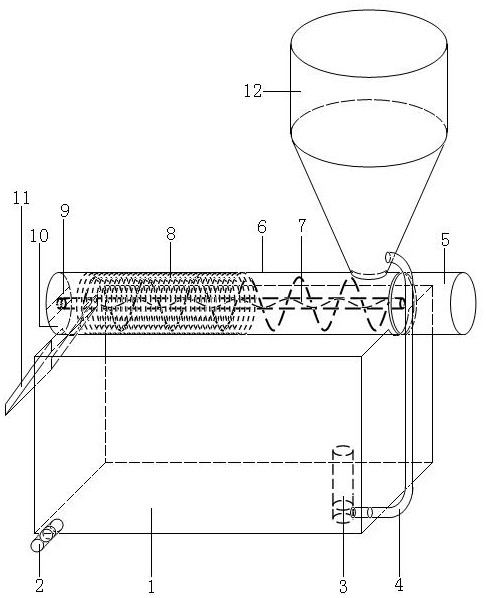

Rapid wheat cleaning facility

InactiveCN112916081AUniform humidityUniform dry humidityGrain millingAgricultural scienceAgricultural engineering

The invention discloses a rapid wheat cleaning facility and belongs to the field of wheat processing facilities. A hollow cylindrical cleaning barrel is longitudinally and horizontally mounted above a water tank, a conical stock bin is mounted above the right side of the cleaning barrel, a cylindrical gear motor is mounted at the top end of the right side of the cleaning barrel, a spiral propeller is mounted in the cleaning barrel, a cylindrical blow-off pipe is arranged on the left side of the cleaning barrel, and a cylindrical water pump is mounted in the water tank and connected with the bottom of the stock bin through a C-shaped water pipe. After entering the stock bin, wheat flows into the cleaning barrel together with clean water pumped by the water pump, the wheat is quickly overturned up and down by the spiral propeller and pushed leftwards after entering the cleaning barrel, the wheat is washed while being stirred by the propeller and then pushed into the blow-off pipe, muddy water is discharged from small holes of the blow-off pipe, and wheat is pushed into a chute on the left side of the blow-off pipe, falls into a conveying belt of the drying room and then enters the drying room to be dried.

Owner:湖北旺发粮油有限公司

Automatic bag sorting and packaging device based on logistics sorting system

ActiveCN110803309BRealize cycle jobImprove efficiencySolid materialLogistics managementAgricultural engineering

The invention discloses an automatic bag sorting and packaging device based on a logistics sorting system, which includes a frame, a conveyor belt is installed on the inside of the frame through conveying rollers, and a main controller is fixedly installed on the outside of the frame. The side of the top of the frame is an open structure, and the opening on the side of the top of the frame is fixedly equipped with an inclined slideway, the two sides of the slideway are fixedly installed with baffle plates, and the bottom of the slideway is fixedly installed with The box is pre-packed, and a slide bar 1 is fixedly installed under the rack. The automatic bag sorting and packaging device based on the logistics sorting system uses a mechanical method to replace the traditional manual packaging, relieves the pressure of manual processing, releases human resources, saves labor costs, and increases production revenue. And after the bags to be packed are transported away, the pre-packaged bags will move to the position directly below the pre-packed boxes under the pull of the rope, so as to realize cycle operation with high efficiency, in line with the development trend of modern smart logistics, and has a wide range of applications prospect.

Owner:NORTHEASTERN UNIV LIAONING

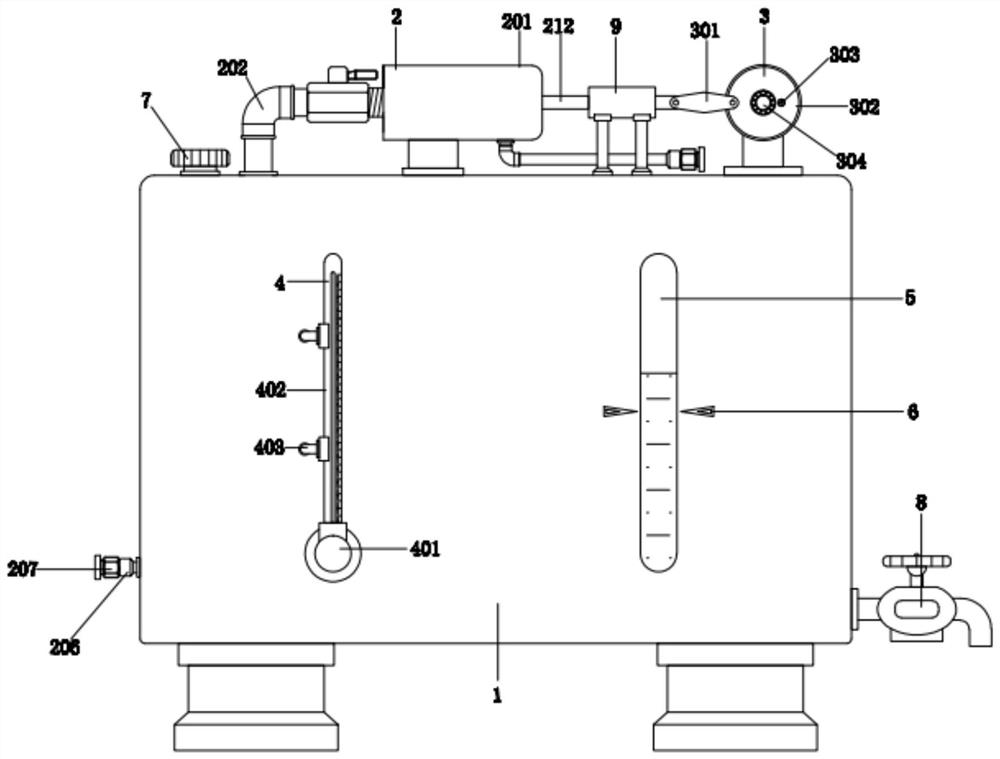

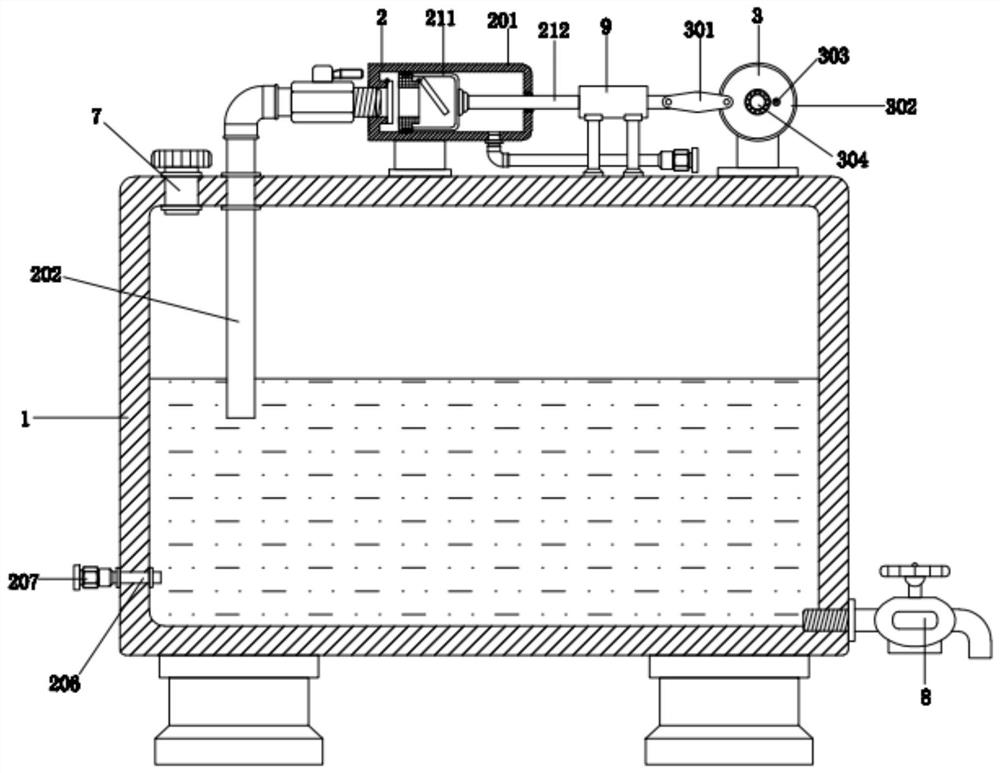

Injection molding water circulation energy-saving equipment

The invention discloses injection molding water circulation energy-saving equipment. The equipment comprises a water storage tank, a water circulation mechanism is arranged above the water storage tank, a water injection port is fixedly connected to the left side of the upper surface of the water storage tank, and a valve is arranged at the bottom end of the right surface of the water storage tank. According to the injection molding water circulation energy-saving equipment, the water storage tank is matched with the water circulation mechanism, and a pull rod is intermittently pulled left andright at the moment, so that the bottom end of a first bent pipe generates suction force to suck in cold water in the water storage tank, the cold water is discharged from a first connector to enteran injection molding device to circulate in an internal water circulation pipeline and flows back into the water storage tank through a second connector and a short pipe, and then the cold water circulation operation is achieved; and electric energy does not need to be used for providing kinetic energy for cold water circulation in the period, so that the energy saving performance of the injectionmolding water circulation equipment is improved, the enterprise electricity consumption can be reduced, and the application and popularization are facilitated.

Owner:绍兴市华获智能装备有限公司

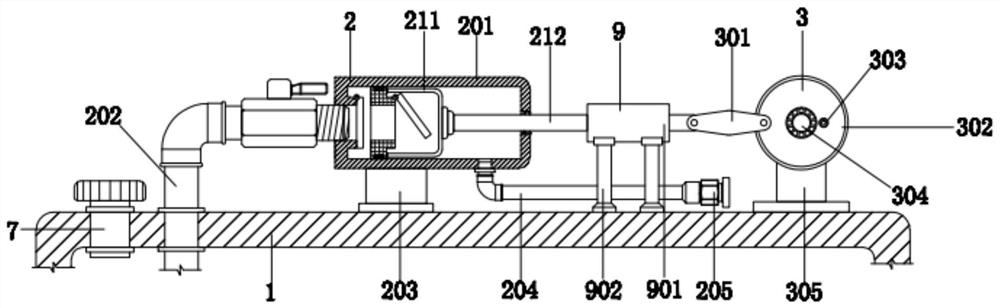

A pipe pile production feeding system

A pipe pile production feed system is characterized in that a feed hole of a mixer at the top of a mixing station is connected with a conveyor belt, a distribution cart is disposed on a second level below the discharge hole of the mixer, two to ten distribution hoppers and the distribution cart are mounted on guide rails and can be driven to reciprocate on the guide rails by a reciprocating traction device, the distribution hoppers are disposed on a third level below the position of the distribution cart, each distribution hopper is correspondingly connected with one feed hopper on the fourth level, each feed hopper is fixedly mounted above a corresponding light rail, a flatcar driven to move through a light rail traction device is disposed on the light rails, and a limit device used for limiting a pipe pile lower mould is disposed on the flatcar. The system has the advantages that idle time of each concrete pipe pile device is shortened greatly, utilization rate of equipment is increased, and the yield of concrete pipe piles per unit time is more doubled as high as the yield of the original equipment.

Owner:宁波蛟川构件有限公司

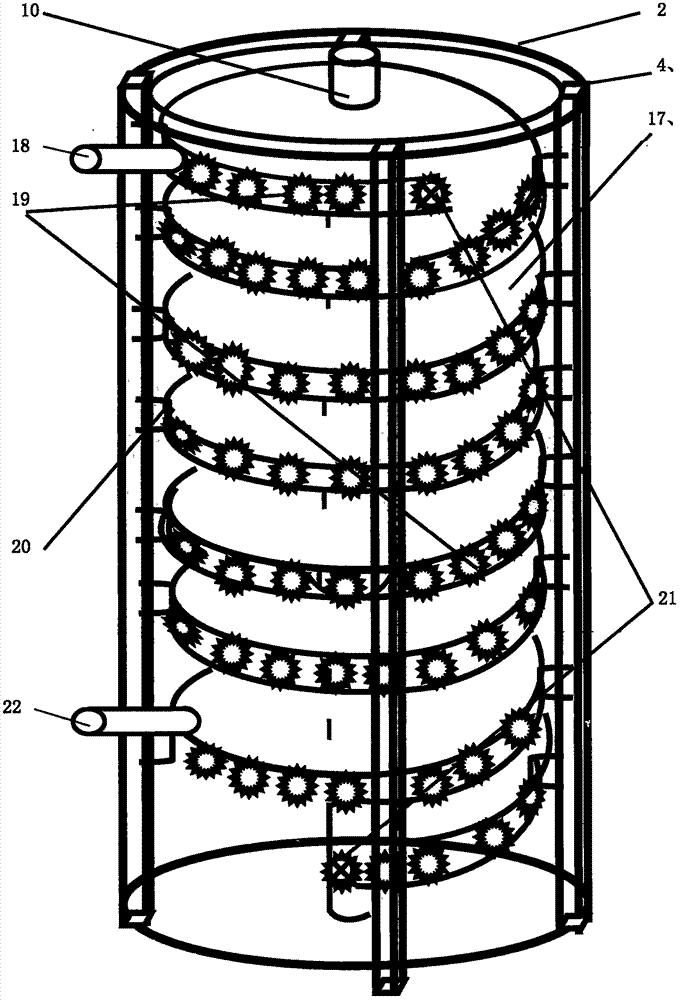

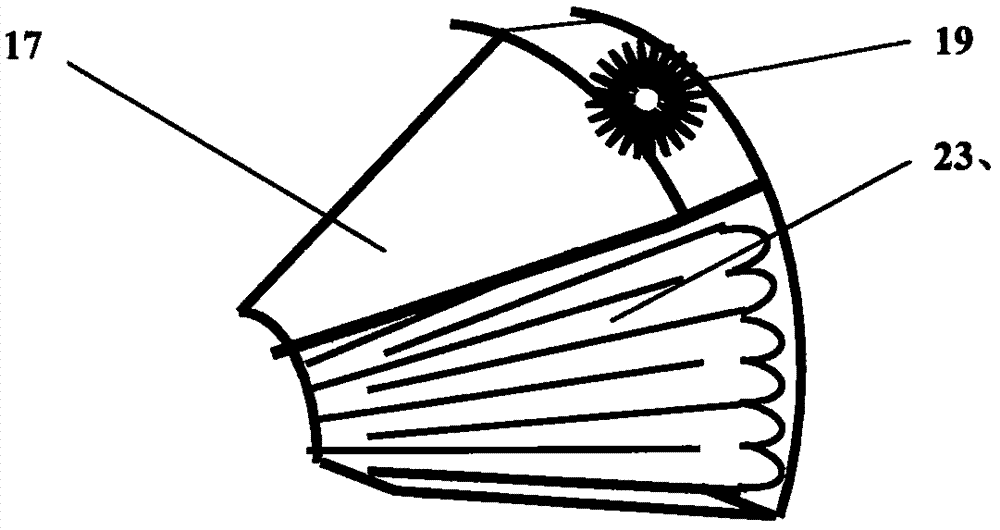

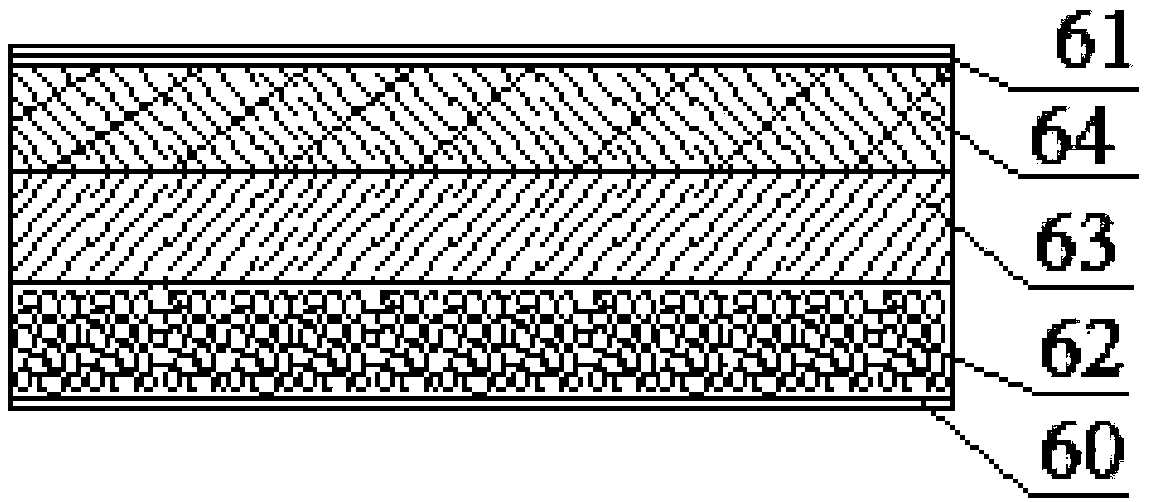

A spiral disc belt type low temperature dryer device

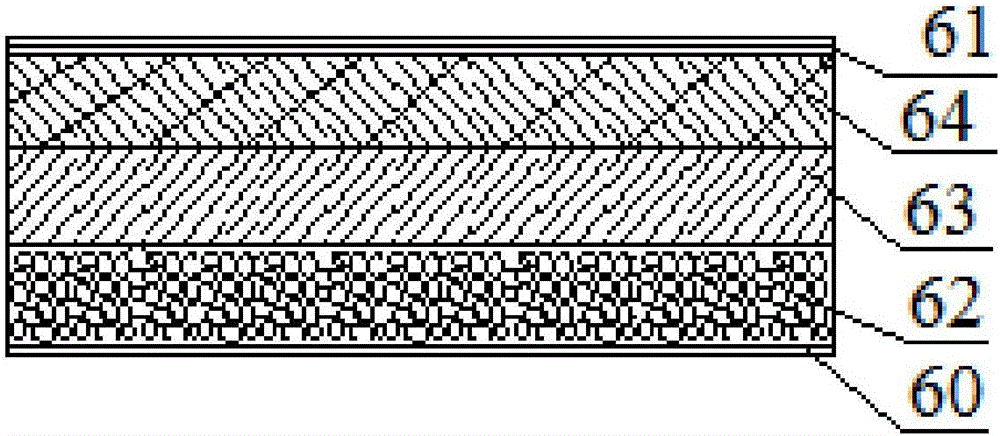

InactiveCN105716387BNot subject to wear and tearImprove dry product qualityDrying solid materialsDrying machines with local agitationCentral cylinderHeating system

The invention discloses a helical coil belt-type low-temperature drier device being suitable for drying heat sensitive materials of which the moisture contents are 60 percent or higher. The helical coil belt-type low-temperature drier device mainly comprises ten systems such as a heat-insulating outer barrel and ventilation system, a helical heating coil system, a helical drying coil belt system, a heating coil and drying coil fitting system, a heating coil circulatory heating system, a drying coil belt movement power and control system, a feeding and material bearing system, a material receiving system, and a complete machine operation control system, wherein a cylindrical heat-insulating outer barrel comprises an up-down ventilation system; a fixed helical heating coil, which surrounds a central cylinder and is fixed on four upright posts in the wall of the outer barrel via an arch-shaped connection plate, is arranged in the heat-insulating outer barrel; 60 DEG C water flows in the helical heating coil in a circulatory manner for heating; a helical sector-shaped drying coil belt, of which the head is connected with the end, is attached on the helical heating coil; power traction holes in the outer end of the drying coil belt are occluded with driving wheels and transmission wheels on outer facades of the heating coil via pressing pinch plates; and under the driving of a driving motor, and interaction of stretching ball bearings in the drying coil belt, the drying coil belt performs helically circulatory and reciprocating movement along the surface of the heating coil, so that the materials attached on the drying coil belt can be dried continuously at a low temperature.

Owner:张柱

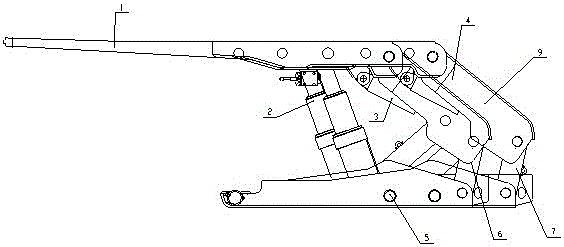

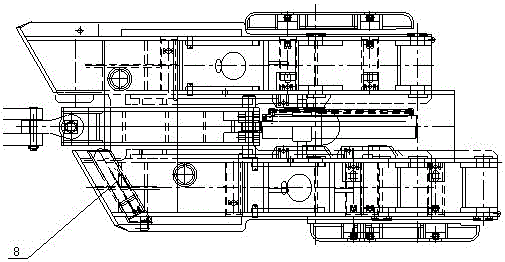

Rhombus-shaped hydraulic support in steeply inclined coal seam dipping pseudo-inclined mining face

ActiveCN102373937BSatisfy the improvement requirements of comprehensive mechanized coal mining methodSolve a series of mining related problemsMine roof supportsPedestrianFour-bar linkage

The invention relates to a rhombus-shaped hydraulic support in a steeply inclined coal seam mining face, which adapts to the coal mining process characteristics of the inclined pseudo-inclined arrangement, splits the traditional four-bar linkage into two parts, and simultaneously designs the top beam and the base as Diamond-shaped structure, through adjustment devices such as balance adjustment oil cylinders hinged on the top beam and cover beam to realize the adjustment of the support state, to ensure a stable beam end distance to prevent the roof from falling, to maintain the smooth flow of the pedestrian passage in front of the hydraulic support, and to form a stable beam end distance and pedestrian space.

Owner:TIANDI SCI & TECH CO LTD

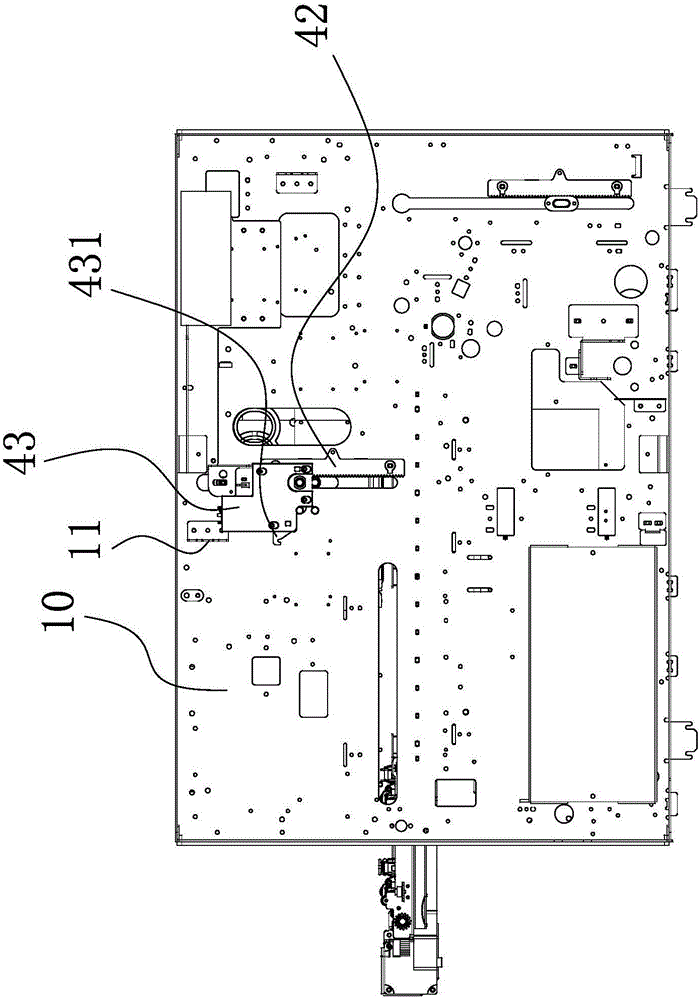

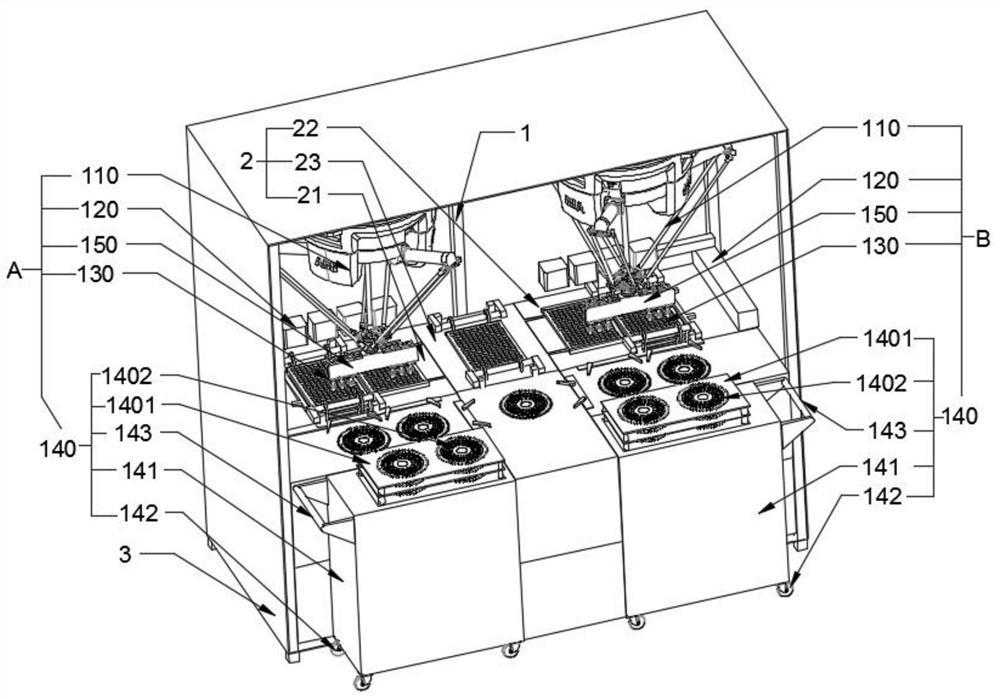

Automatic stacking device for grinding tools

PendingCN112720090AIncrease productivityLabor savingLapping machinesOther manufacturing equipments/toolsMachineKnife blades

The invention provides an automatic stacking device for grinding tools. The automatic stacking device comprises a rack, a workbench fixed to the rack, a protection plate fixed to the outer wall of the rack, a pre-grinding stacking system and a post-grinding stacking system. The workbench is divided into a first machining area, a second machining area and a temporary storage area in the transverse direction, and the first machining area and the second machining area are symmetrically arranged relative to the temporary storage area. The pre-grinding stacking system and the post-grinding stacking system are arranged in the first machining area and the second machining area correspondingly. According to the automatic stacking device, blades can be automatically transferred and stacked into a blade clamp disc from a blade disc through a machine, and therefore labor is saved, the production cost is reduced, and the production efficiency is improved.

Owner:天津泰美科科技有限公司

Inkjet system for printing equipment

The invention provides an ink jet system of printing equipment, and belongs to the technical field of printing machinery. The ink jet system of the printing equipment comprises a frame, an ink jet mechanism and a nozzle cleaning mechanism, wherein the ink jet mechanism comprises a conveying channel horizontally arranged and used for conveying a printing medium, a working flat plate movably mounted above the conveying channel, and at least one nozzle detachably inserted on the working flat plate; the working flat plate can be displaced in the vertical direction to be near or far from the conveying channel; an ink outlet for jetting ink to the printing medium is formed in the lower end surface of the nozzle; the ink jet direction of the ink outlet is perpendicular to the conveying direction of the conveying channel; and the nozzle cleaning mechanism is arranged below the working flat plate, and is used for cleaning ink in the nozzle. The ink jet system of the printing equipment has the advantages of reasonable design and reliable work.

Owner:宁波荣大创想智造科技有限公司

Circular vibrating screen lubricated by thin oil

The invention belongs to the technical field of vibration exciters, and particularly relates to a circular vibrating screen lubricated by thin oil. The circular vibrating screen comprises a mounting body, a bearing, a main shaft, a lip-shaped sealing ring, an exhaust pipe, a lubricating inner cavity, a pressurizing assembly, a releasing assembly, an oil discharging pipe and an oil inlet pipe, wherein the bearing is installed in the mounting body in a matched mode, the main shaft is installed in the mounting body, the main shaft penetrates through the interior of the bearing, and the lubricating inner cavity is formed between the mounting body and the main shaft. The thin oil is added through the oil inlet pipe in the using process and has the obvious advantages, a plurality of lubricating points which are widely distributed can be lubricated in time, meanwhile, friction heat generated by friction is taken away, and metal abrasive particles and other mechanical impurities on the friction surface are taken away and washed away along with flowing and circulation of oil, so that the purposes of good lubrication, friction reduction, abrasion reduction, consumption reduction of quick-wear parts, power consumption reduction and prolonging of the service life of equipment are achieved.

Owner:洛阳元耐机械有限公司

Turtle breeding device that is easy to remove dirt

ActiveCN106259144BEffective absorptionAvoid problems that are not conducive to the growth of turtlesWater/sewage treatment by irradiationWaste water treatment from animal husbandryFecesFishery

The invention discloses a turtle breeding device which is easy to remove feces, comprising: a breeding tank including a first baffle, a second baffle, a third baffle and a waste outlet; a sedimentation tank including a plurality of overflow plates , a waste material inlet and a sedimentation liquid outlet; a filter tank, which includes a first filter assembly, a sedimentation liquid inlet, and a clear liquid outlet; a sterilizing pool, which includes an ultraviolet germicidal lamp, a clear liquid inlet, and a sterilizing liquid outlet; the waste material outlet passes through the first The pipeline is communicated with the waste material inlet; the sedimentation liquid outlet is communicated with the sedimentation liquid inlet through the second pipeline; the clear liquid outlet is communicated with the clear liquid inlet through the third pipeline; the sterilizing liquid outlet is communicated through the fourth The pipeline communicates with the culture pond. The invention has the beneficial effects of being easy to remove feces, reducing manpower and material resources, and being able to circulate, and avoiding large changes in the living environment of turtles due to overall cleaning and changing water, which is not conducive to the growth of turtles.

Owner:天津鼎拓恒远知识产权服务有限公司

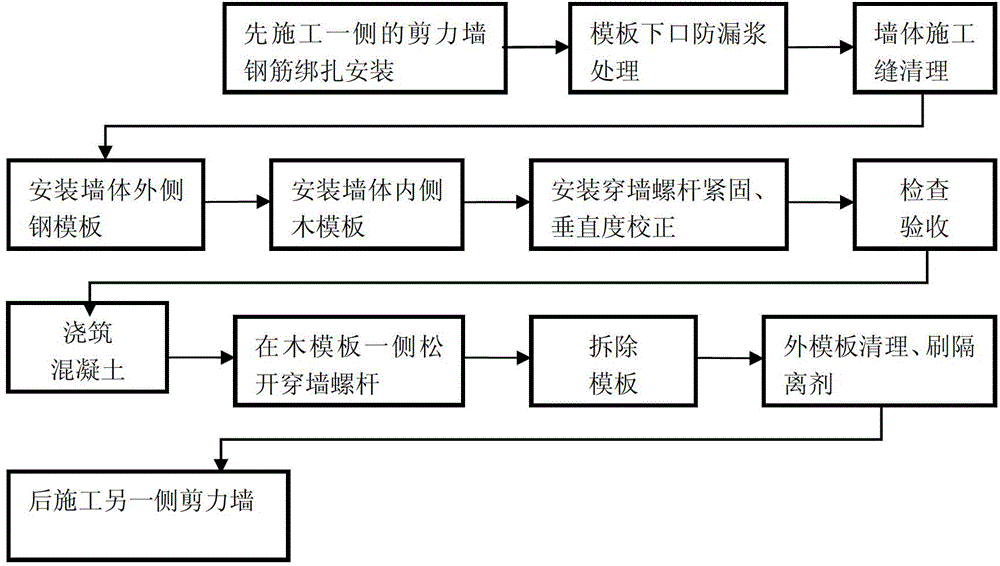

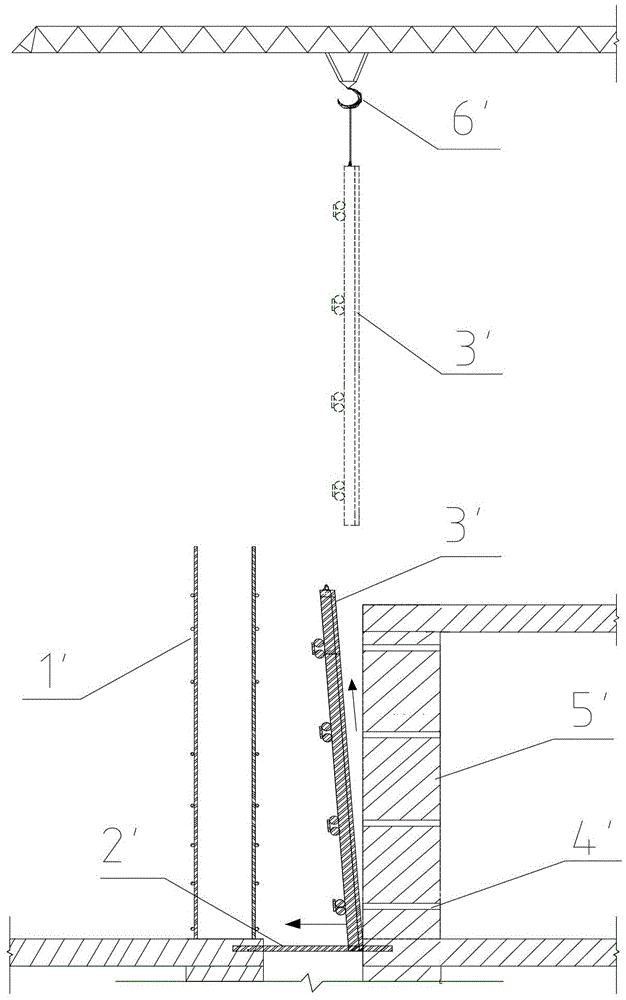

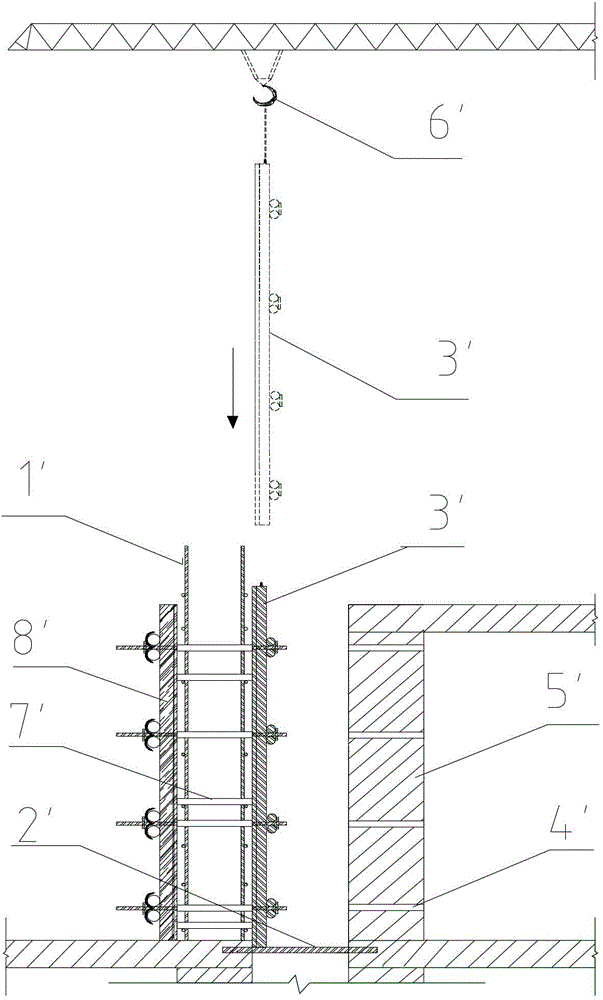

Construction method of double shear wall formworks at deformation joint of high-rise building

ActiveCN102979304BQuality improvementReduce consumptionForms/shuttering/falseworksBuilding material handlingSlurryTower crane

The invention relates to a construction method of double shear wall formworks at a deformation joint of a high-rise building, in particular to a construction method of double shear wall formworks at a deformation joint of a high-rise building. The construction method comprises the following steps: firstly constructing a shear wall at one side of the deformation joint; binding reinforcing steel bars; carrying out slurry leakage-proof treatment on a lower opening of the formwork; arranging an outside steel formwork of a wall body and an inside wooden formwork of the wall body; installing a wall penetrating screw, tightening the wall penetrating screw and rectifying the verticality of the wall penetrating screw; pouring concrete; removing the formworks; and finally constructing the shear wall at the other side of the deformation joint. With the adoption of the construction method provided by the invention, the phenomena of formwork shifting and slurry leaking cannot easily occur, the quality of pouring the concrete can be effectively controlled, the construction cost is effectively saved, and the problem that cracks and damage can be caused to a building in swinging is solved. With the adoption of the construction method provided by the invention, after the construction of the shear wall at one side of the deformation joint is completed, the outside steel formwork can be immediately hung to the shear wall to be constructed at the other side of the deformation joint by a tower crane, and the steel formworks are used in an alternating and circulating manner to form a line production operation, so that the working time is effectively shortened.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

A carburizing furnace for metal workpieces

ActiveCN109487201BRealize cycle jobEasy to install and disassembleSolid state diffusion coatingEngineeringCarburizing

Owner:嘉善龙焱热处理厂(普通合伙)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com