Multifunctional anti-collision wall construction trolley and anti-collision wall construction method thereof

A technology for construction trolleys and anti-collision walls, which is applied to bridge parts, erection/assembly of bridges, bridges, etc., can solve the problems of restricting the use of trolleys, poor pouring quality, time-consuming and labor-intensive problems, and achieve low efficiency and splicing The effect of less frequency and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

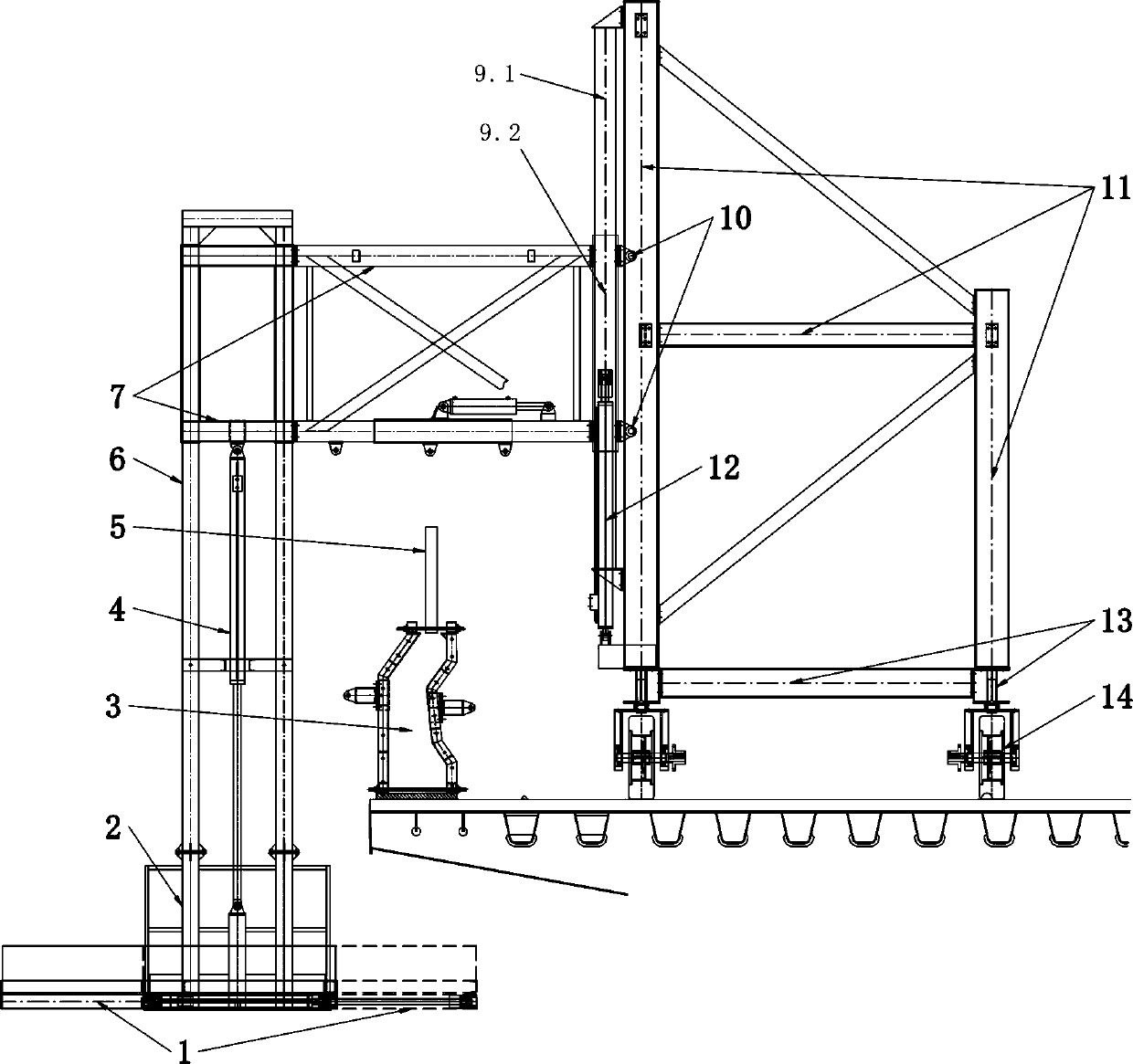

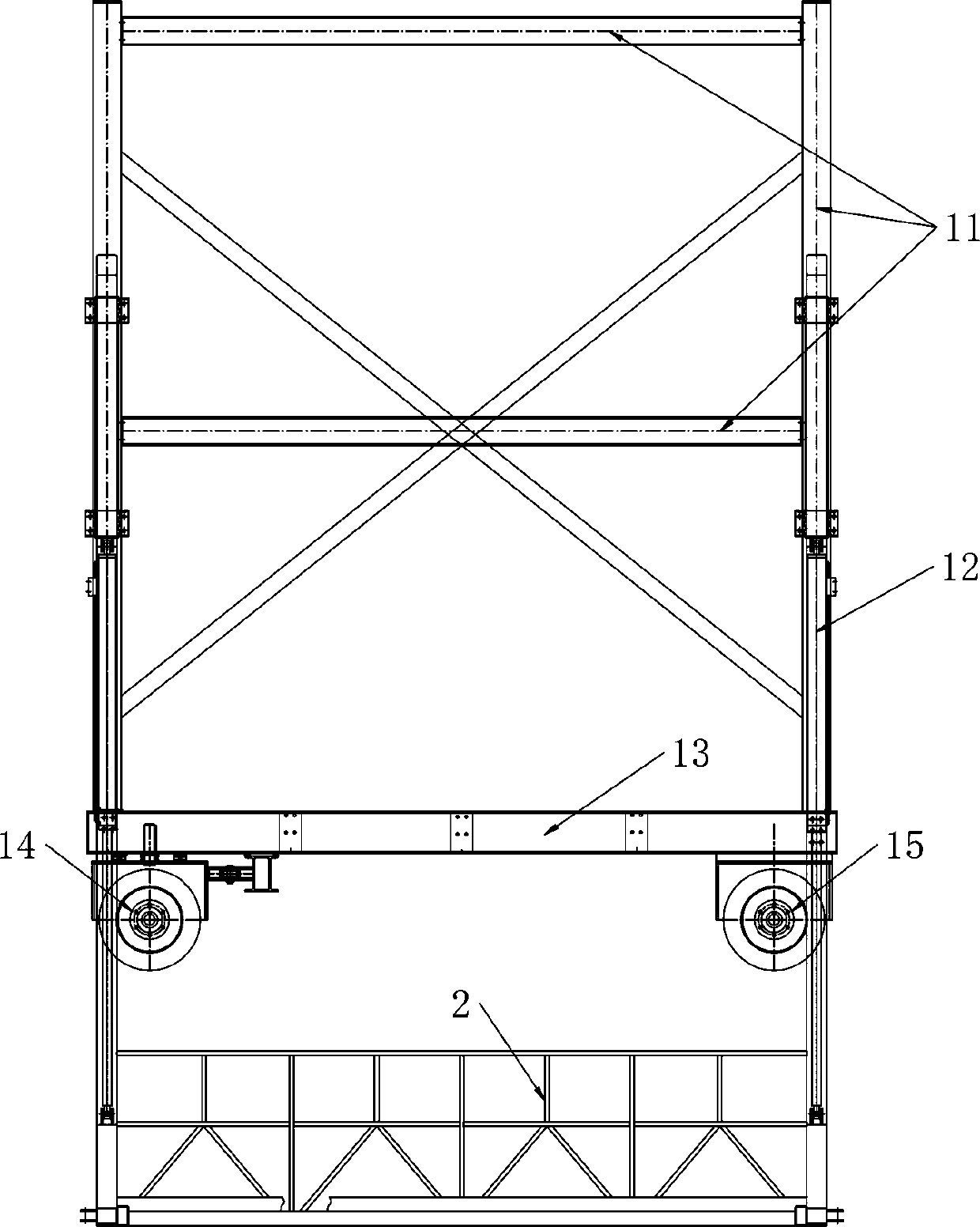

[0041] Embodiment one: if Figure 1-Figure 4 As shown, the present invention provides a multifunctional anti-collision wall construction trolley, comprising a bearing platform 13 and a main truss 11 installed on the upper end of the bearing platform, a hanger 7 is installed on the outside of the main truss 11, and a hanger 7 is installed on the outside of the hanger The lower part of the frame 7 is provided with a formwork hoisting mechanism for hoisting the formwork of the anti-collision wall, and can drive the formwork of the anti-collision wall to move outward or inward;

[0042] The outside of the main truss 11 is provided with a hanger lifting device that drives the hanger 7 to move up and down;

[0043] A traveling mechanism is installed at the lower end of the carrying platform, and a counterweight is installed at the upper end.

[0044] In this embodiment, a gondola platform 2 capable of lifting is also included, and the gondola platform 2 is installed on the outside ...

Embodiment 2

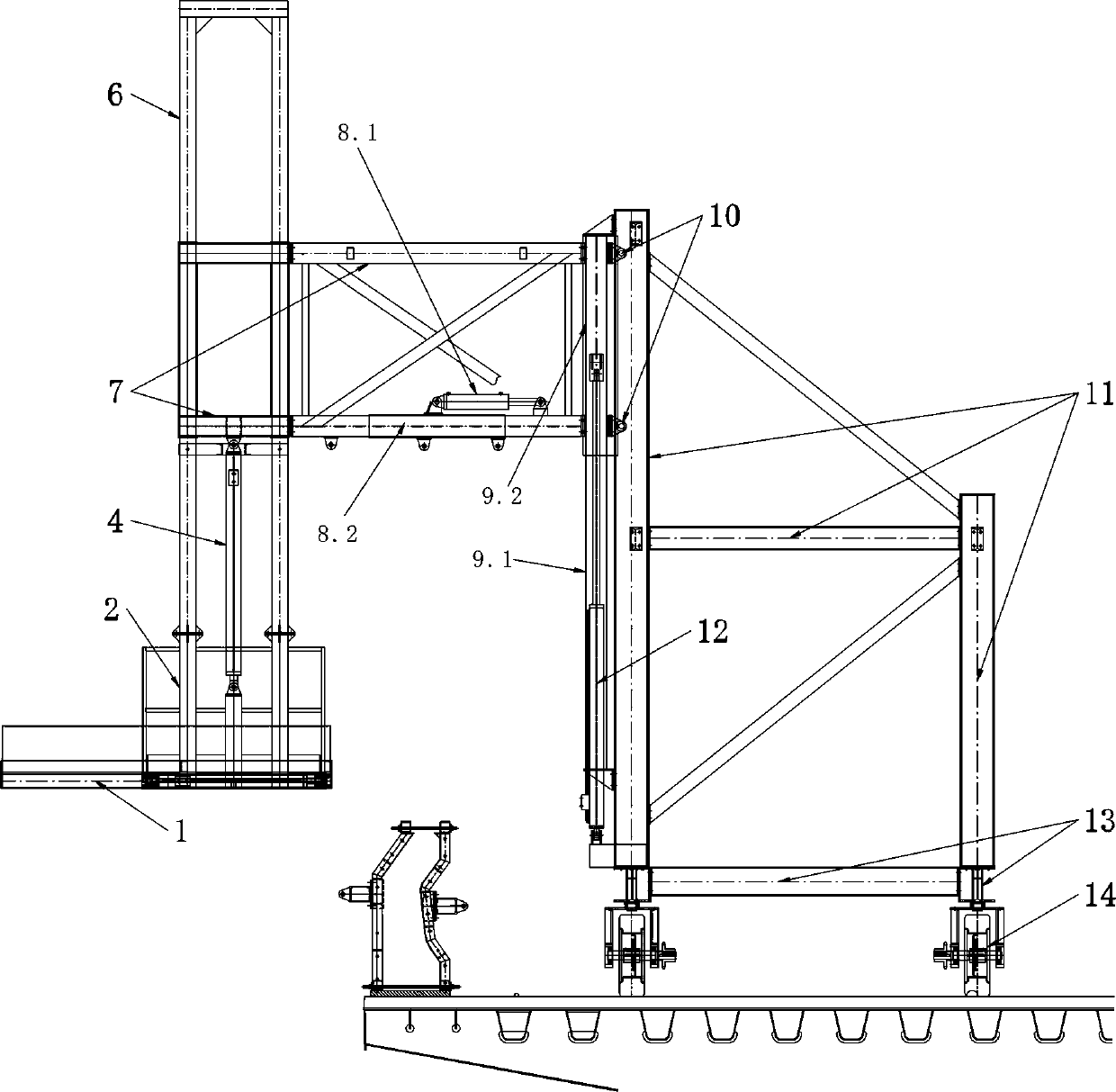

[0065] Such as Figure 5 As shown, a multifunctional anti-collision wall construction trolley includes a bearing platform 13 and a main truss 11 installed on the upper end of the bearing platform. A hanger 7 is installed on the outside of the main truss 11, and a hanger 7 is installed below the hanger 7. A formwork hoisting mechanism that is used to hoist the formwork of the anti-collision wall and can drive the formwork of the anti-collision wall to move outward or inward;

[0066] The outside of the main truss 11 is provided with a hanger lifting device that drives the hanger 7 to move up and down;

[0067] A traveling mechanism is installed at the lower end of the carrying platform, and a counterweight is installed at the upper end.

[0068] In this embodiment, the hanger lifting device includes a hanger guide rod 9.1, a bushing 9.2 and a hanger lifting cylinder 12,

[0069] The guide rod 9.1 is fixedly installed on the outside of the truss and runs through the casing 9.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com